Buderus Logano GB125 BE Installation And Maintenance Instructions Manual

Installation and

Maintenance Instructions

Oil condensing boiler

CAUTION!

Observe the safety instructions of this installation

and maintenance manual before placing the boiler

in operation.

DANGER!

If installation, adjustment, modification, operation or

maintenance of the heating system is carried out by

an unqualified person, this may result in danger to

life and limb or property damage.

The directions of this installation and maintenance

manual must be followed precisely.

If you require assistance or further information, contact a qualified installer or an appropriate service

provider.

CAUTION!

The operating manual is a component of the technical documentation and must be handed over to the

operator of the heating system.

Discuss the instruction in this manual with the owner or operator of the heating system to ensure that

they are familiar with all information required for

operation of the heating system.

Logano GB125 BE US/CA

6 720 649 307 - 2011/07 US/CA

For contractors

Please read carefully prior

to installation and servicing.

Contents

Contents

1 Safety instructions and explanation of

symbols 3

1.1 Safety instructions 3

1.2 Explanation of symbols 4

2 Product description 5

2.1 Intended use 5

2.2 Standards, regulations and code compliance 5

2.3 Notes on installation and operation 5

2.4 Product description 6

2.5 Boiler water quality 7

2.6 Tools, Materials and Accessories 7

2.7 Scope of delivery 7

2.8 Dimensions and specifications 8

2.9 Conditions for operation 9

2.9.1 General operating conditions 9

2.9.2 Conditions for the boiler room and the

environment 10

2.9.3 Fuel conditions 10

2.9.4 Power supply conditions 10

2.9.5 Conditions for hydraulic system and water

quality 10

2.10 Disposal 11

3 Moving the boiler 12

3.1 Reducing the boiler weight for handling

purposes 12

3.2 Lifting and carrying the boiler 13

3.3 Moving the boiler with hand truck 13

4 Placing the boiler 14

4.1 Wall clearances 14

4.2 Reversing the burner door 15

4.3 Mounting the adjustable feet

(included with B-kit) 16

4.4 Positioning and leveling the boiler 16

5 Installing the boiler 17

5.1 Flue pipe installation 17

5.2 Test ports 18

5.3 Installation options 20

5.4 Making the water connections 22

5.4.1 Installing B-kit 22

5.4.2 Mounting the drain valve

(included with B-kit) 23

5.4.3 Installation of system components 23

5.5 Filling the heating system and checking

for leaks 24

5.6 Connecting the fuel supply 25

5.7 Bleed off condensate 25

5.8 Electrical supply connections 27

5.8.1 Installing the control panel 27

5.8.2 Installing the temperature sensor assembly 28

5.8.3 Power connection and connections of

additional components 29

5.8.4 Installing cable strain relief 30

5.9 Installing the back boiler cover 30

6 Starting up the heating system 31

6.1 Bringing the system up to operating

pressure 31

6.2 Testing safety valve 32

6.3 Checking position of heat exchanger baffles 32

6.4 Preparing the heating system for operation 32

6.5 Starting up the control panel and the burner 33

6.6 Taking measurements 33

6.7 Checking the manual reset high limit (STB) 34

6.8 Installing the burner hood 34

6.9 Commissioning log 35

7 Shutting down the heating system 36

7.1 Normal shut-down 36

7.2 Shutting down the heating system in an

emergency 36

7.2.1 Action in an emergency 36

8 Heating system inspection 37

8.1 Why is regular maintenance important? 37

8.2 Preparing the boiler for inspection 37

8.3 Cleaning the boiler 38

8.3.1 Cleaning the boiler with cleaning brushes 38

8.3.2 Wet cleaning (chemical cleaning) 39

8.4 Cleaning the heat exchanger system 40

8.5 Cleaning the neutralizing system and trap 42

8.6 Checking the air supply hose 44

8.7 Check heating system operating pressure 44

8.8 Test safety valve 45

8.9 Concentric supply air and flue gas routing 45

8.10 Air supply system 45

8.11 Inspection and maintenance reports 46

9 Troubleshooting 49

10 Examples of installations 50

11 Spare parts 53

12 Wiring diagrams 61

Index 62

2

Logano GB125 BE US/CA - Subject to technical modifications.

Safety instructions and explanation of symbols

1 Safety instructions and explanation of symbols

1

1.1 Safety instructions

If you smell flue gas

B Switch off the boiler (Æ page 36).

B Open windows and doors.

B Inform an authorized heating contractor.

Risk of poisoning. An insufficient supply of air can

result in dangerous escape of flue gas.

B Never close off or reduce the size of air intake and

outlet openings.

B The boiler must not be operated until the obstruction

has been removed.

B Ensure that no mechanical air-extraction equipment

draws air from the boiler room, e.g. kitchen vent hood,

clothes dryer, central vacuum system, etc.

B Inform the system user in writing of an existing problem

and associated dangers.

Danger from escaping flue gases

B Make sure that the vent pipes and gaskets are not

damaged.

B Use silicone as sealing compound.

B Never operate this boiler with a barometric or a

thermally-controlled vent damper.

B Connect only one boiler to each venting system or

chimney flue.

B The venting system piping must not feed into another

air extraction duct.

B Do not route the venting system piping through or

inside another duct used for exhaust air or other flue

gases.

B To prevent the combustion gases from reaching the

boiler room, the siphon must always be filled with

water.

Danger from electrical shock

B Before opening the boiler:

Disconnect the heating system from the electrical

power supply by means of the emergency shutoff

switch or the heating system circuit breaker on the

main fuse panel.

B It is not sufficient just to switch off the control panel.

B Take measures to ensure that the heating system

cannot be switched on again unintentionally.

Installation

B Correct and proper installation and adjustment of the

burner and the control panel are the fundamental

requirements for safe and economical operation of the

boiler.

B The boiler may only be installed or maintained by an

approved heating contractor.

B Do not modify any parts that carry flue gases.

B Only qualified electricians are permitted to carry out

electrical work. Follow applicable code.

B The hot water tank may only be used for heating

domestic hot water.

B Never shut off safety valves!

Water may escape from the safety valve when it is

being heated.

Danger due to failing to consider your own safety in

an emergency such as a fire

B Never put yourself at risk of fatal injury. Your own safety

must always take the highest priority.

Dangers posed by explosive and combustible

materials

B Do not use or store easily-combustible materials

(paper, lace curtains, clothing, thinners, paints, etc.)

near the boiler.

B Maintain a clearance of 16 inches (40.6 cm) from the

boiler.

Combustion air

B Keep the supply of combustion air free of corrosive

substances (e.g. halogenated hydrocarbons that

contain chlorine or fluorine compounds). This will help

prevent corrosion.

Logano GB125 BE US/CA - Subject to technical modifications.

3

1

Safety instructions and explanation of symbols

Inspection/maintenance

Heating systems must be maintained regularly.

This way, they maintain a high level of efficiency and low

fuel consumption.

You will achieve a high level of operational safety.

And you will obtain the cleanest possible combustion.

B Recommendation for customers: take out a

maintenance and inspection contract with an approved

heating contractor covering annual inspection and

condition-based maintenance.

B Maintenance and repairs may only be carried out by an

approved heating contractor.

B Have any faults corrected immediately in order to

prevent damage to the system.

B Use only genuine spare parts. Damage caused by the

use of parts not supplied by Buderus is not covered by

the Buderus warranty.

Instructing the customer

B Explain to the customer how the boiler works and how

to operate it.

B Inform the customer that he/she must not carry out any

alterations or repairs.

1.2 Explanation of symbols

Warnings are indicated by a warning

triangle and a gray background.

Signal words are used to indicate the seriousness of the

ensuing risk if measures for minimizing damage are not

taken.

• Caution indicates that minor damage to property may

occur.

• Warning means that minor injury or severe property

damage may occur.

• Danger means that severe injury may occur. Very

serious cases may result in death.

Notesare identified in the text by this symbol.

They are separated by horizontal lines above

and below the text.

Notes contain important additional information.

Notes do not contain any warnings or information about

hazards or risks.

Cross-references to particular places in the document or

to other documents are marked with an arrow Æ.

4

Logano GB125 BE US/CA - Subject to technical modifications.

2 Product description

Product description

2

This installation and maintenance manual contains

important information for the safe and correct installation,

initial start-up and maintenance of this boiler.

The Logano GB125 BE oil-fired condensing boiler is

generally referred to below simply as the boiler.

These installation and maintenance instructions are

designed for specialists, who – through their vocational

training and experience –are knowledgeable in handling

heating systems and DHW installations.

This boiler must only be installed with one of the Buderus

supplied concentric supply air and flue gas routing

systems.

• Concentric air supply and flue pipe exiting through

external wall

• Concentric supply air and flue gas routing via roof

• Concentric supply air/flue gas routing through a flue

inside a duct

This boiler produces significant amounts of acidic flue gas

condensate while in operation. Condensate may cause

damage to sewer pipes and septic systems, and disposal

may be subject to local regulations. In the absence of

such regulations Buderus recommends a condensate

neutralization kit.

The boiler must draw all combustion air from the outside.

2.3 Notes on installation and operation

When installing and operating the heating system

observe the following:

• The local building codes regarding the installation

• The local building codes regarding combustion air

supply and venting systems, and the chimney

connection

• Regulations governing power connection to the power

supply

• The regulations and standards relating to the safety

systems for the water heating system

Other important information

• Only operate the boiler with the combined combustion

air/flue venting system specifically designed and

approved for it.

• Follow the local code when connecting the

condensate outlet to the public sewer system.

2.1 Intended use

The boiler is designed for the central heating and indirect

heating of domestic hot water (e.g. in a hot water tank), for

instance in single family homes or multi-family buildings.

2.2 Standards, regulations and code

compliance

It is the installer's responsibility to ensure the

installation and operation of this heating

system meets all applicable federal, state,

and local codes.

The boiler must be installed by a qualified

installer and in accordance with all

requirements of NFPA-31, "Installation of OilBurning Equipment". Installation must

comply with all local and national legal

requirements and the regulations of all

institutions having legislative authority with

regard to the installation of oil-fired boilers.

For Canada, the guidelines of the CSA/CGA

B139 Installation Code apply.

Logano GB125 BE US/CA - Subject to technical modifications.

5

2

Product description

2.4 Product description

This boiler is an oil-fired condensing boiler with

modulating control of boiler water temperature.

The boiler consists of:

• Control panel

• Boiler casing

• Boiler block with thermal insulation

• Burner

• Heat exchanger system

The control panel monitors and controls all electrical

boiler components.

The boiler casing prevents heat loss and reduces noise.

The boiler block transfers the heat generated by the

burner to the boiler water. The insulation prevents energy

loss.

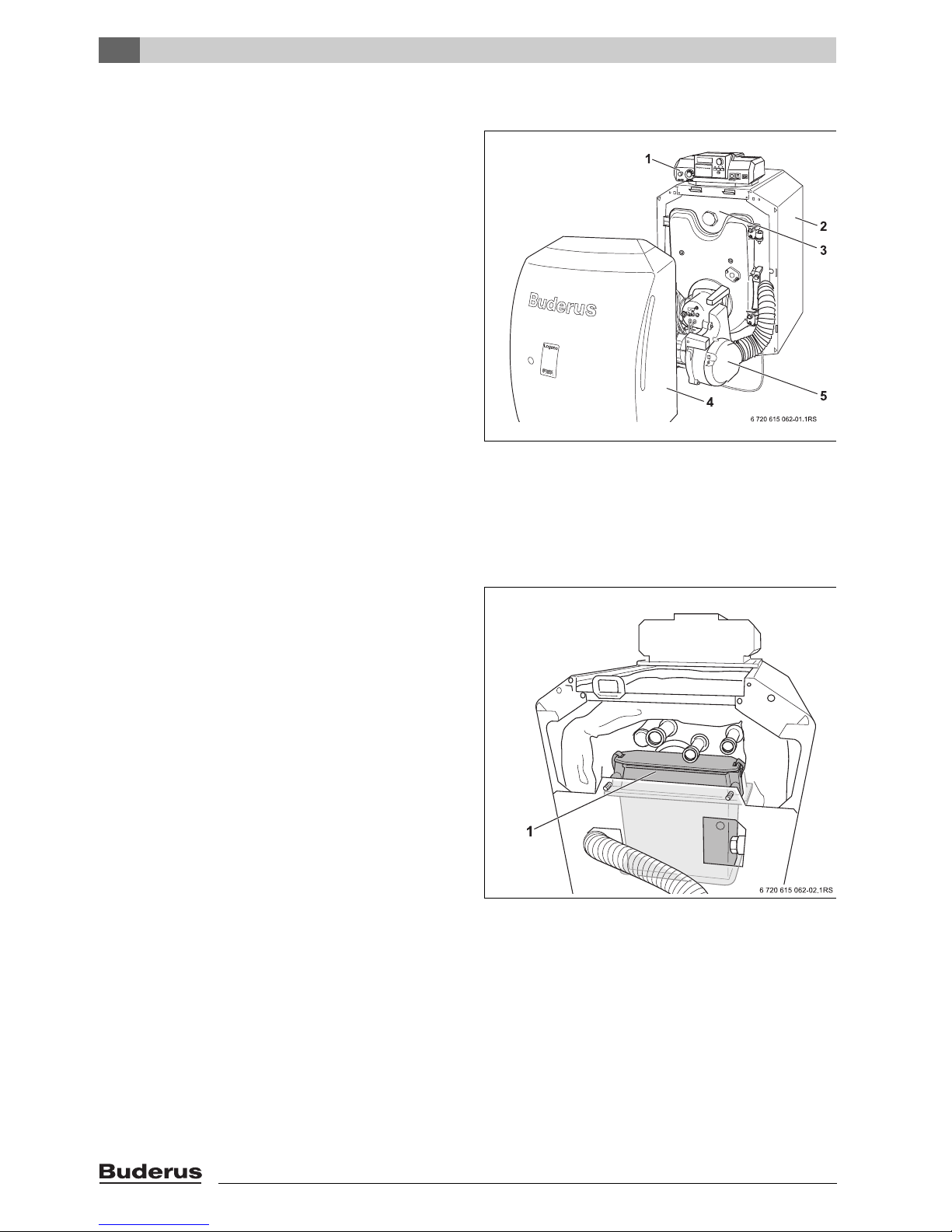

Fig. 1 Boiler with burner

1 Control panel

2 Boiler casing

3 Boiler block with thermal insulation

4 Burner hood

5 Burner

6

Fig. 2 Rear view with heat exchanger (thermal

insulation not shown)

1 Heat exchanger system

Logano GB125 BE US/CA - Subject to technical modifications.

Product description

2

2.5 Boiler water quality

Poor water quality can damage heating systems due to

scale formation and corrosion. (Tab. 8, page 10).

CAUTION: Risk of system damage due to

unsuitable boiler water!

B When using oxygen-permeable pipes, e.

g. for radiant floor heating systems, you

must separate the system using heat

exchangers. Unsuitable heating system

water promotes sludge formation and

corrosion. This can result in heat

exchanger malfunction and damage.

2.6 Tools, Materials and Accessories

For the installation and maintenance of the boiler, you

need standard tools used for central heating and DHW

systems, plus metric wrenches and metric Allen

wrenches.

The following may also prove useful:

• Hand truck with securing strap or Buderus boiler cart

• Wood battens

• Cleaning brushes and/or chemical cleaning agent for

wet cleaning

2.7 Scope of delivery

B After delivery, check all packaging for perfect

condition.

B Check the delivery for completeness.

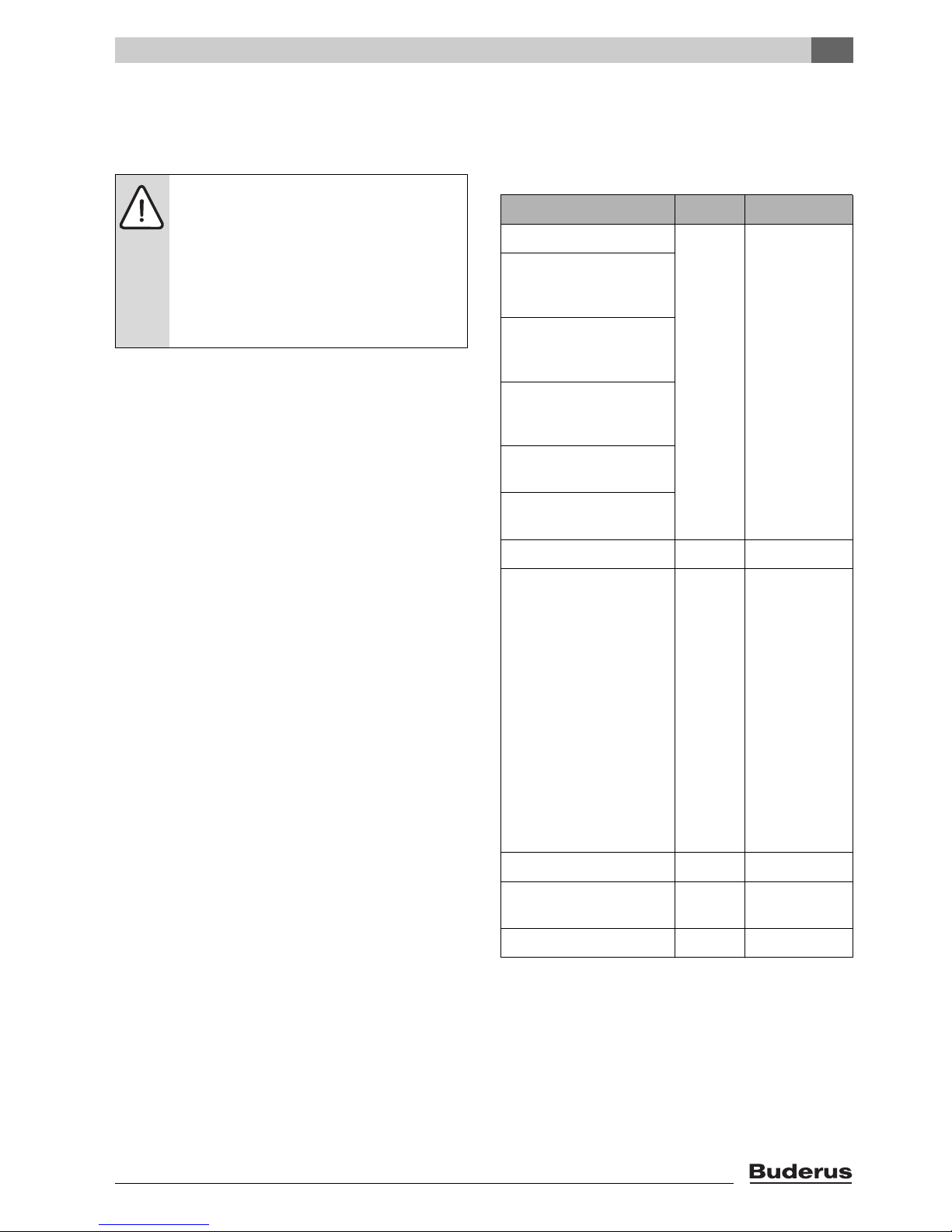

Component Qty Packaging

Boiler block 1 1 pallet

Boiler casing, factoryinstalled on the boiler

block

Burner hood, factoryinstalled on the boiler

block

Heat exchanger system,

factory-installed on the

boiler block

Oil burner with factoryinstalled burner door

Air supply hose, factoryinstalled

Siphon 1 1 bag

B-kit components:

1 1 foil

• Conversion nipple

(1¼ " NPT)

• 30 psi safety valve

• Drain valve (¾ ")

• Pressure/temperature

gauge

• Double nipple

(1¼ " NPT × R1¼ )

• 90°-elbow (1¼ ” NPT)

• 90°-elbow (¾ " NPT)

• Screw set (for burner

mounting)

• Adjustable feet

1)

package

1)

Logano GB125 BE US/CA - Subject to technical modifications.

Control panel 1 1 box

Tigerloop oil filter and

11 box

de-aerator

Technical documentation 1 bag

Tab. 1 Scope of delivery

1) Under the burner hood

7

2

Product description

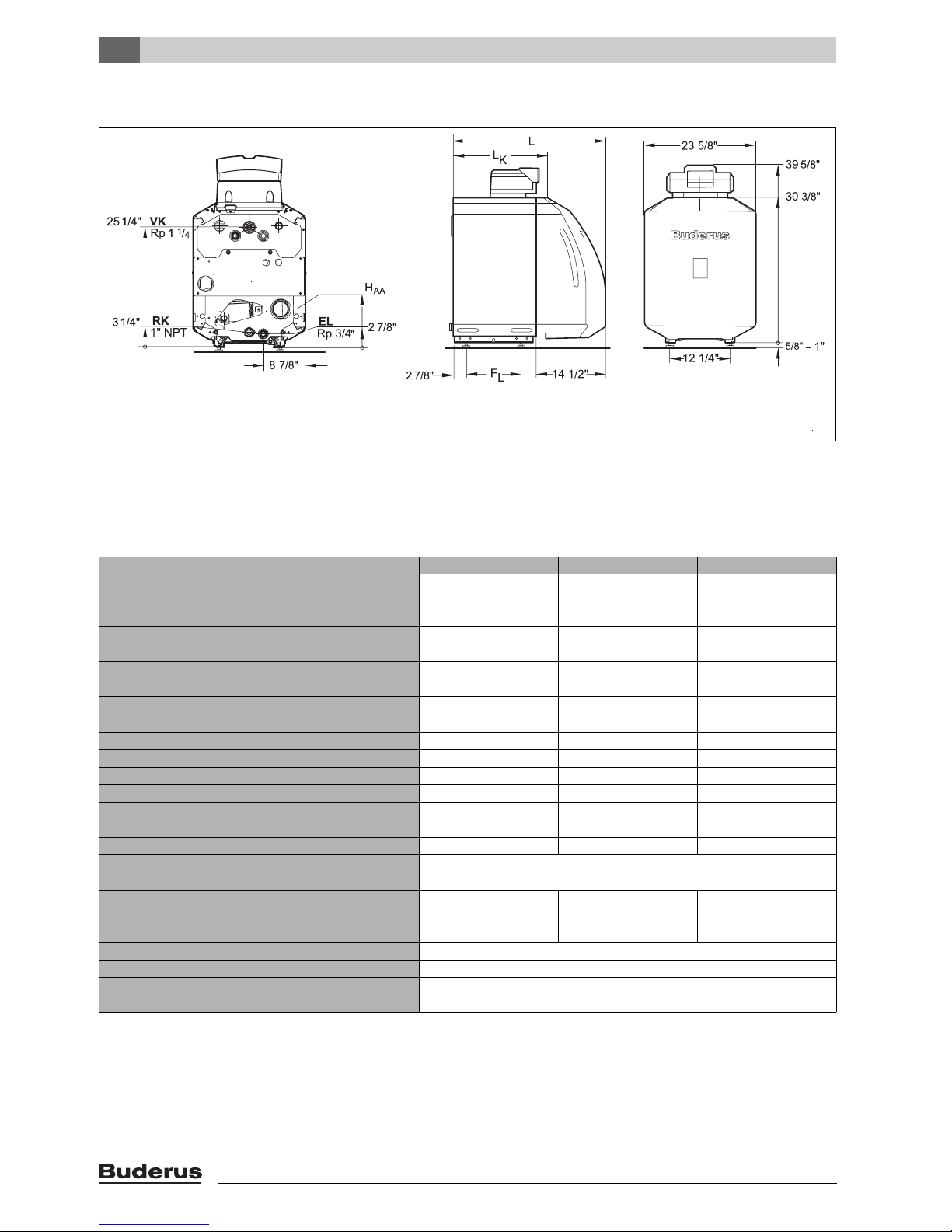

2.8 Dimensions and specifications

Fig. 3 Connections and dimensions (measurements in inches)

VK = Boiler supply

RK = Boiler return

EL = Boiler drain (connection for drain valve)

6 720 649 309-01.1ITL

Dimensions and connections:

Boiler type Unit GB125/22 BE GB125/30 BE GB125/35 BE

Boiler sections 344

Rated heat output (gross output)

131/86 °F

Rated heat output (net IBR rating)

131/86 °F

Rated heat output/heating capacity

(gross output)176/140 °F

Rated heat output

(net IBR rating)176/140 °F

Rated thermal input/burner input MBtu/hr 81 108 131

AFUE % 91.2 91.1 91.0

Flue gas temperature 176/140 °F °F (°C) 176 (80) 176 (80) 192 (89)

Boiler water content gal (l) 8.7 (35.6) 11.8 (44.9) 11.8 (44.9)

Gas volume of combustion chamber and heat

exchanger

Oil consumption/oil firing rate gph (l/h) 0.60 (2.3) 0.75 (2.9) 0.95 (3.6)

Flue gas resistance in. W.C.

Heat exchanger water pressure drop

(DeltaT = 18 °F)

Maximum supply temperature

Maximum operating pressure psi (bar) 44 (3)

Maximum time constant of thermostat and

manual reset high limit (STB)

1)

MBtu/hr 76 102 124

MBtu/hr 67 90 109

MBtu/hr 75 100 121

MBtu/hr 65 87 105

cu. ft.

(l)

(Pa)

ft. of

head

(mbar)

°F (°C) 212 (100)

s 40

1.5 (42.9) 2.0 (57.9) 2.0 (57.9)

0.08" - 0.14" W.C. (20 - 35)

1.8' (54) 2.0' (60) 2.7' (81)

Tab. 2 Technical specifications

1) Safety limit (manual reset high limit, STB)

Maximum permitted supply temperature = manual reset high limit (STB) – 32 °F

Example: manual reset high limit (STB) = 212 °F, maximum possible supply temperature = 212 - 32 = 180 °F

The safety limit must comply with the requirements applicable in your country.

8

Logano GB125 BE US/CA - Subject to technical modifications.

Product description

Boiler type Unit GB125/22 BE GB125/30 BE GB125/35 BE

Boiler overall length (L) Inches 37 1/2" 42 3/8" 42 3/8"

Boiler block length (LK) Inches 25 3/4" 30 1/2" 30 1/2"

Combustion chamber length Inches 16" 20 1/2" 20 1/2"

Combustion chamber length Inches 10 5/8"

Burner door thickness Inches 2 1/3"

Distance between boiler feet (FL) Inches 16 1/8" 20 7/8" 20 7/8"

Net weight

1)

lbs 423 503 503

Tab. 3 Dimensions, weight and other data for boilers with burners

1) Weight incl. packaging material approx. 6-8 % more.

2.9 Conditions for operation

Maintaining the specified operating conditions will enable

the boiler to provide a high level of reliability and long

service life. Some details relate only to operation with

Logamatic control panels from Buderus.

CAUTION: Risk of system damage if

operating conditions are not maintained.

Extreme divergence from the stated

conditions may cause irreversible damage to

individual components of the boiler.

B The information on the rating plate is

definitive.

2

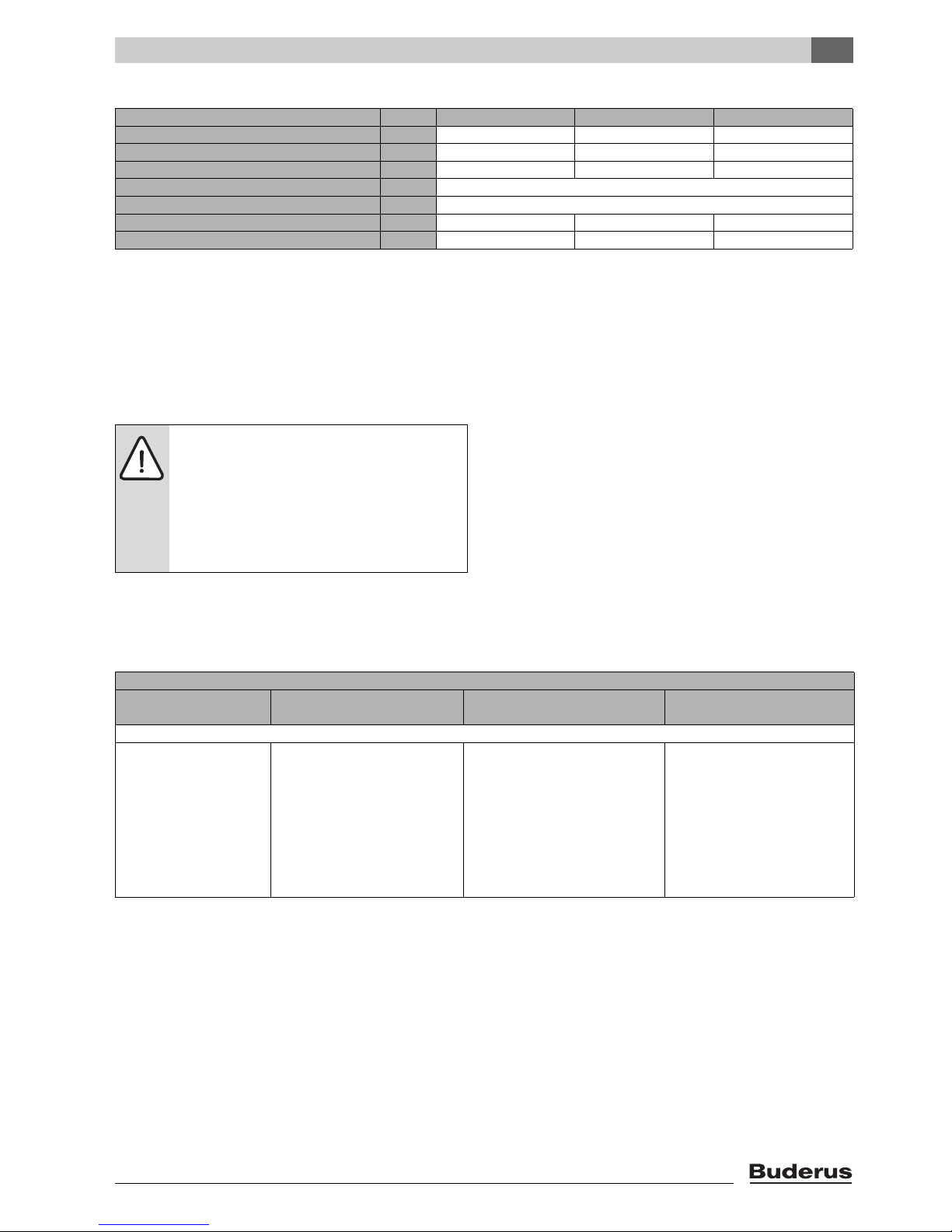

2.9.1 General operating conditions

Operating conditions

Min. boiler water tempera-

ture

In combination with Logamatic control panel for variable low-temperature operating modes, such as Logamatic 2107.

No requirements. Operating

temperatures are safeguarded

by the Logamatic control

panel.

2)

Operating interruption

(complete boiler shutdown)

Automatically by Logamatic control

panel

Heating zone with

heating zone mixing valve

Not required but recommended with

low-temperature heating system design

130/113 °F.

Required with:

• Radiant floor heating system

• Systems with large water capacity:

> 115 gal/MBH

(1 MBH = 100,000 Btu/hr)

1)

Min. return temperature

No requirements

Tab. 4 General operating conditions

1) A heating zone with a mixing valve improves controllability and is specifically recommended for systems with several heating zones.

2) If the control panel does not influence the heating zones or a heating zone actuating component (e.g. Pumplogic), the burner ON mode must

reach an operating temperature of 122 °F within 10 min by restricting volume flow.

Logano GB125 BE US/CA - Subject to technical modifications.

9

2

Product description

2.9.2 Conditions for the boiler room and the environment

Operating conditions Notes – Requirement in greater detail

Temperature in the boiler room 40 to 104 °F

(5 to 40 °C)

Relative humidity max. 90 % No condensation or precipitation inside the boiler room

Dust/airborne particles − Excessive dust inside the boiler room must be avoided when the boiler is operat-

ing, e.g.:

• Dust from building work

Combustion air supplied from outside must not be excessively loaded with dust

or airborne seed; if necessary, air filters should be installed to prevent this:

• Air supply contaminated with dust from dirt roads and paths.

• Air supply contaminated with dust from production and processing facilities, e.g. quarries, mines, etc.

• Airborne particles from thistles and similar

Halogenated-hydrocarbon compounds

Small animals − Prevent small animals from entering the boiler room, particularly through the air inlet vents –

Fire safety − Maintain clearances between the boiler and flammable materials in accordance with local

Flooding − In case of an acute risk of flooding, disconnect the boiler in time from its fuel and power

− The combustion air must be free from halogen-hydrocarbon compounds.

• Identify the source of halogen-hydrocarbon compounds and seal it off. Where this is

impossible, route combustion air from areas that are not contaminated by halogenhydrocarbon compounds.

by installing screens.

regulations. A minimum clearance of 16” is required. Never store flammable materials or liquids in the vicinity of the boiler.

supply before water enters the room. Any general and burner components or control equipment that comes into contact with water must be replaced before starting up again.

Tab. 5 Boiler room and ambient conditions

2.9.3 Fuel conditions

Country All countries

Fuels #2 Fuel oil ASTM D396-05 Type 2

Approved for B5 Fuel Oil (5% biodiesel (B100) according ASTM D6751)

Remarks The burner may only be operated with the specified fuel. Clean and service once a year. Check that the entire

system functions properly at the same time. Immediately remedy faults.

Tab. 6 Country-specific fuels and remarks

2.9.4 Power supply conditions

Operating conditions Notes – Requirement in greater detail

Line voltage 110 – 120 V The outer casing/boiler must be grounded to protect people and in order to function correctly.

Circuit breaker 10 A

Frequency 60 Hz

Protection class − IP 40 (protected against contact by entry of foreign objects > 0.04 inches Ø (> 1 mm Ø ), no

waterproofing)

Tab. 7 Power supply

2.9.5 Conditions for hydraulic system and water quality

Operating conditions Notes – Requirement in greater detail

Operating pressure (above atmospheric)

Permissible test pressure 45 – 58 psi

Safety temperature limitation by TR

temperature controller

Safety temperature limitation by manual reset high limit (STB)

Water quality − The heating system may only be filled and topped up with water of domestic water qual-

15 – 44 psi

(1 to 3 bar)

(3 to 4 bar)

122 – 194 °F

(50 to 90 °C)

212 °F

(100 °C)

Maximum 30 psi with the supplied safety valve.

ity. We recommend a pH level of 8.2 – 9.5.

Tab. 8 Hydraulics and water quality

10

Logano GB125 BE US/CA - Subject to technical modifications.

2.10 Disposal

B Dispose of boiler packaging in an environmentally-

responsible manner.

B All heating system components that have to be

replaced should be disposed of in environmentallyresponsible manner at an authorized disposal site.

Product description

2

Logano GB125 BE US/CA - Subject to technical modifications.

11

3

Moving the boiler

3 Moving the boiler

This section details how to move the boiler safely.

CAUTION: Risk of system damage from

impact shocks!

Fragile components could be damaged.

B Follow the transport instructions on the

packaging.

Protect connectors against contamination if

the boiler is not immediately put into

operation.

Dispose of packaging in an environmentallyresponsible manner.

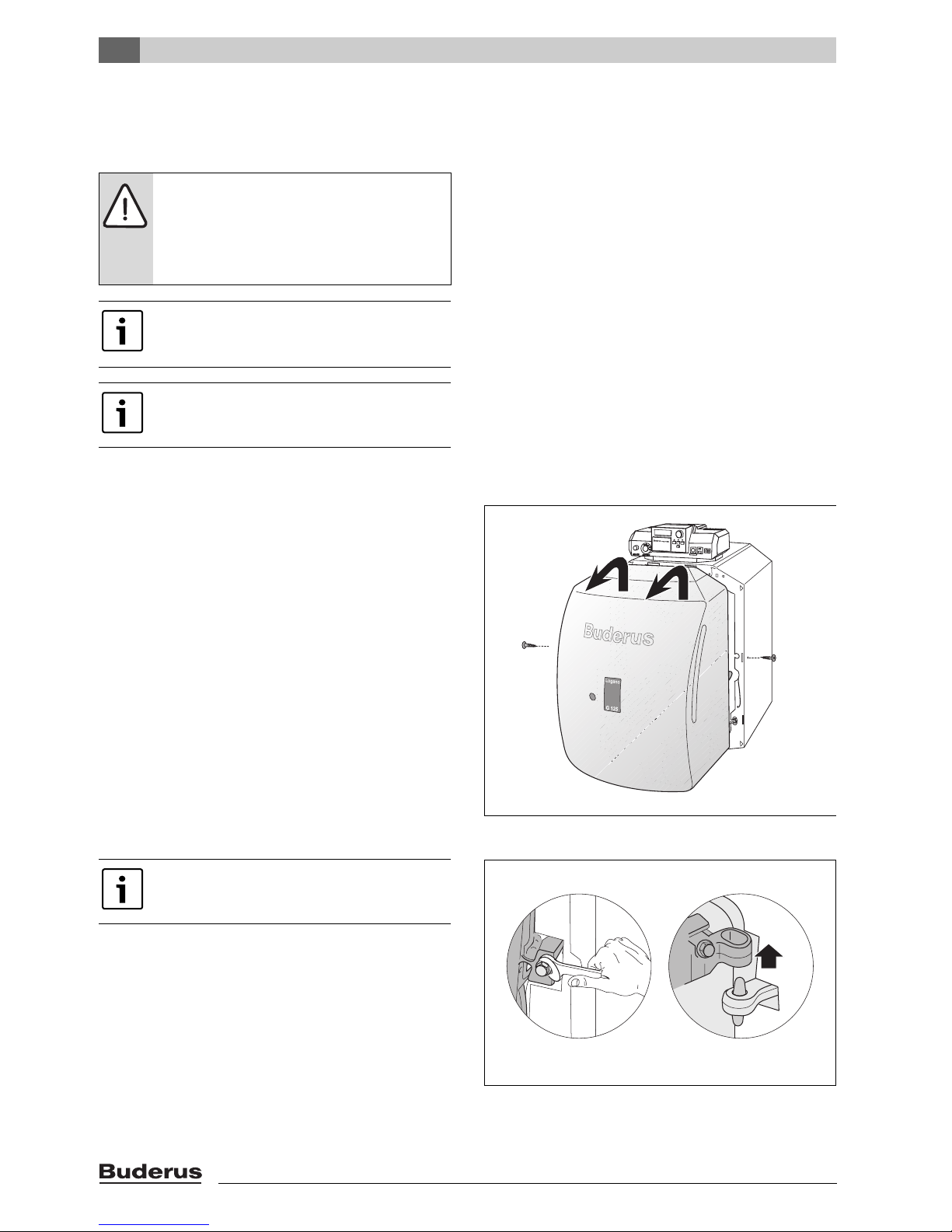

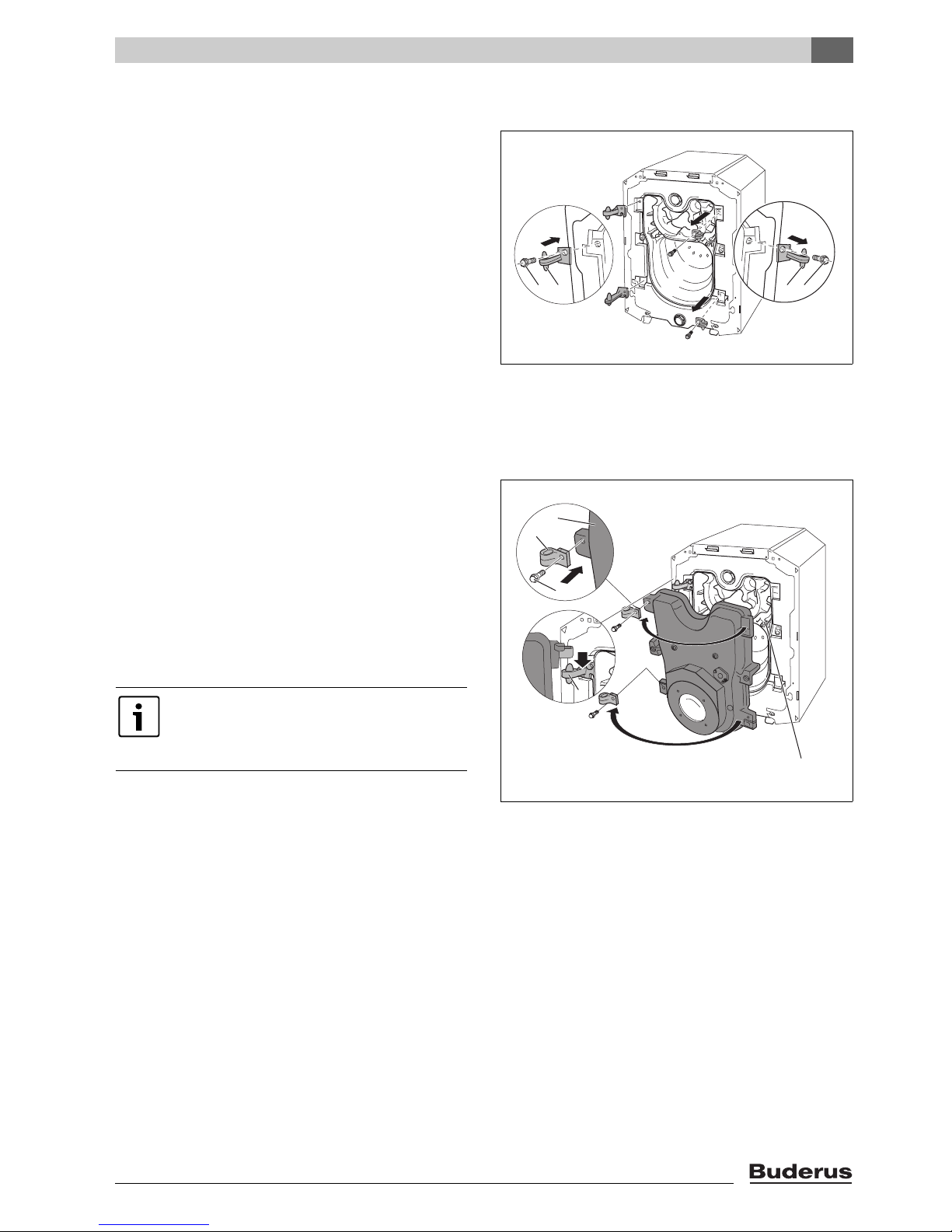

3.1 Reducing the boiler weight for handling purposes

If required, you can reduce the weight of the boiler by

removing the burner hood and door.

B Unscrew the burner hood screws.

B Lift burner hood slightly and pull forwards to remove.

B Before removing the burner door: unplug the burner

plug from the burner controller.

Prevent the burner door from falling over and

damaging the burner and burner tube.

B Unscrew two hex bolts at the sides.

B Open the boiler door.

B Lift the burner door off its hinges.

12

Fig. 4 Removing burner hood

7 747 019 141-04.1RS

Fig. 5 Removing the burner door

Logano GB125 BE US/CA - Subject to technical modifications.

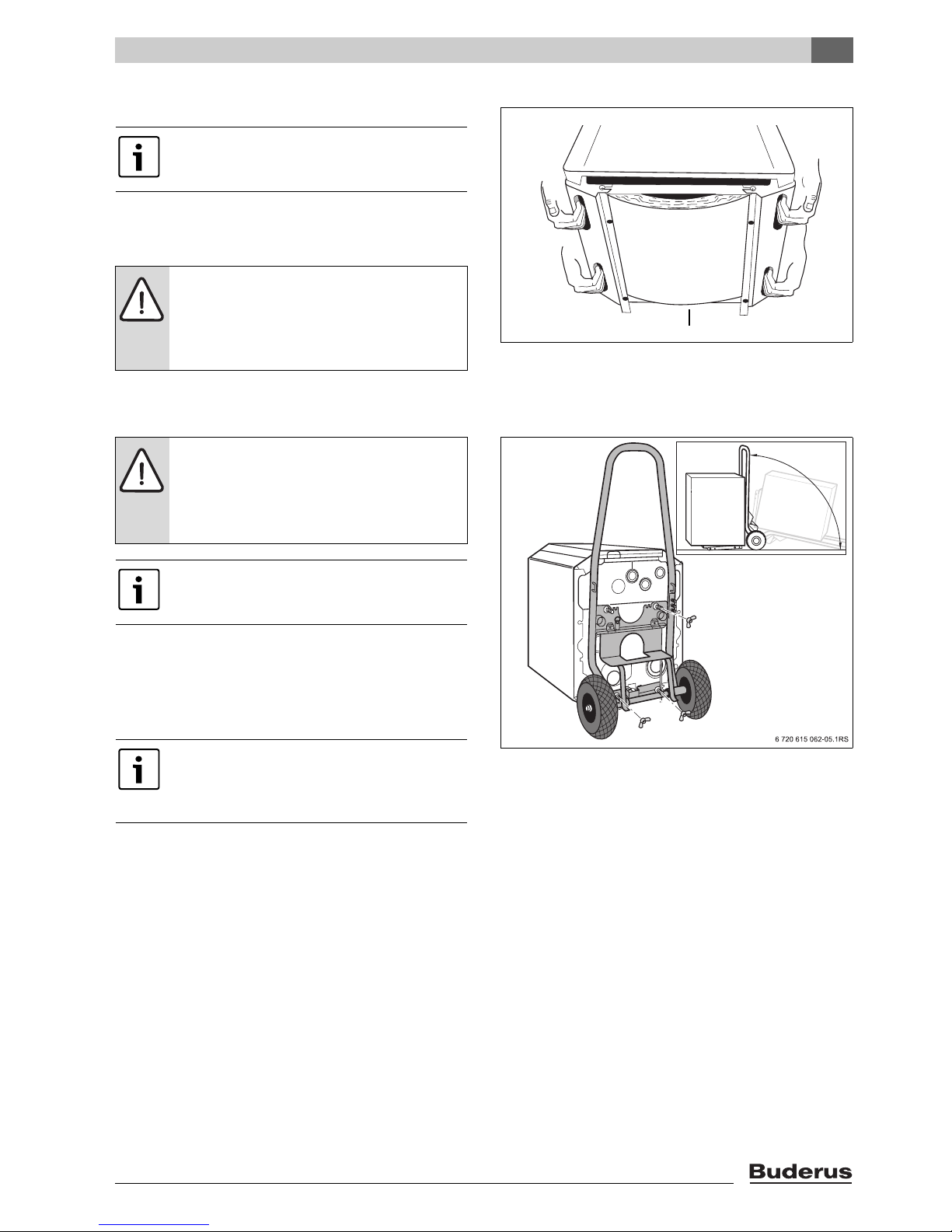

3.2 Lifting and carrying the boiler

The boiler is secured to the pallet by 2

screws for transportation purposes.

The boiler can be held and carried at the grip positions

shown (Fig. 6).

B Unscrew the transit screws.

WARNING: Risk of injury from carrying

heavy loads!

B Always lift and move the equipment with

the assistance of another person using the

grip positions shown.

3.3 Moving the boiler with hand truck

WARNING: Risk of injury if load is

inadequately secured during transportation!

B Use suitable means of transportation, e.g.

the Buderus boiler hand truck with strap.

B Secure the load against falling.

Moving the boiler

Fig. 6 Lifting and carrying the boiler

3

7 747 019 141-05.1RS

You can order the boiler hand truck from your

Buderus distributor.

Moving the boiler with hand truck (Fig. 7)

B Place the hand truck (e.g. boiler trolley or sack truck) at

the back of the boiler.

B Boiler, securing on the hand truck.

B Move the boiler to the installation location.

The boiler trolley can also be used to facilitate

work on the underneath of the boiler, e.g.

fitting the adjustable feet (Æ Chapter 4.3,

page 16).

Fig. 7 Moving the boiler with a boiler hand truck

Logano GB125 BE US/CA - Subject to technical modifications.

13

4

Placing the boiler

4 Placing the boiler

This section describes how to install and place the boiler

in the boiler room.

CAUTION: Risk of system damage due to

freezing!

B Install the heating system in a frost-free

room.

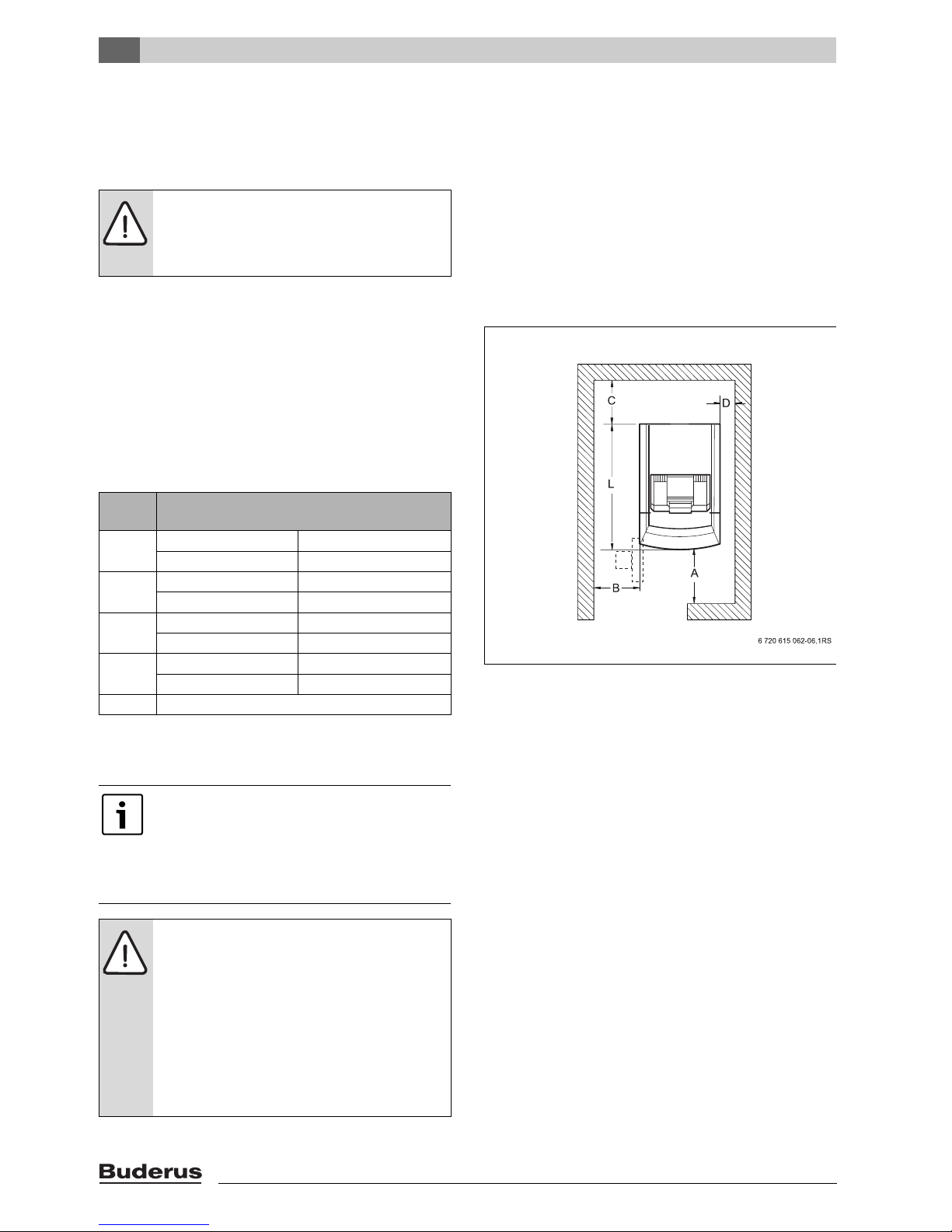

4.1 Wall clearances

Wherever possible, position the boiler with the

recommended wall clearances. Reducing the minimum

clearances makes the boiler more difficult to access.

The boiler base or foundation must be perfectly flat and

level.

The burner door is factory-installed with the hinges on the

right. The burner door can be converted to left-hand

closing.

Dimension

A Recommended 40"

Minimum 27"

B Recommended 27"

Minimum 16"

C Recommended 28"

Minimum 20"

D Recommended 16"

Minimum 6"

L Æ Chapter 2.8, page 8

Tab. 9 Recommended and minimum wall clearances

(dimensions in inches).

The boilers are designed for a side clearance

of 6".

Where applicable, allow extra wall

clearances for additional components such

as DHW tank pipe connections, flue silencer,

other flue components, etc.

WARNING: Risk of fire from flammable

materials or liquids!

B Clearances less than 6" must comply with

local and statutory codes.

B Make sure that there is a sufficient

clearance between combustible materials

and the chimney connection as specified

by NFPA 31 (distance of 18 ").

B The floor must comply with the

requirements of NFPA 31.

Wall clearance

Fig. 8 Wall clearances in the boiler room (boiler

positioned on the right-hand side)

14

Logano GB125 BE US/CA - Subject to technical modifications.

4.2 Reversing the burner door

The burner door is factory-installed with the hinges on the

right – the burner door opens to the right. You can change

the burner door hinges over to the left-hand side if

required to suit the installation site.

Requirement: the burner hood must have been removed

first (Æ Chapter 3.1, page 12).

B Removing the burner door (Æ Chapter 3.1, page 12).

B Unscrew the hex bolts [1] and remove the hinge pins

[2].

B Fix the hinge pins [2] on the left-hand side of the boiler

using the hex bolts.

B Unscrew the hex bolts [1] and remove the hinge barrels

[2].

B Fix the hinge barrels [2] on the left-hand side of the

burner door [3] using the hex bolts.

B Hang the burner door [3] by locating the hinge barrels

[2] on the hinge pins [4].

B Check that the heat exchanger baffles are placed

horizontally (Æ Chapter 6.3, page 32).

B Close the burner door [3] and secure with the two hex

bolts. Tighten the hex bolts evenly (approx. 90 lbs in) so

that the burner door seals properly.

If the burner door hinges have been changed

over to the left-hand side, the burner cable

must be disconnected from the burner before

opening the burner door.

Placing the boiler

12 21

7 747 019 141-08.1RS

Fig. 9 Reversing the burner door (boiler block

attachments)

1 Hex bolts

2 Hinges

3

2

1

4

7 747 019 141-09.1RS

4

5

Logano GB125 BE US/CA - Subject to technical modifications.

Fig. 10 Reversing the burner door (door attachments)

1 Hex bolts

2 Hinge barrels

3 Burner door

4 Hinges

5 Heat exchanger baffle plates

15

4

Placing the boiler

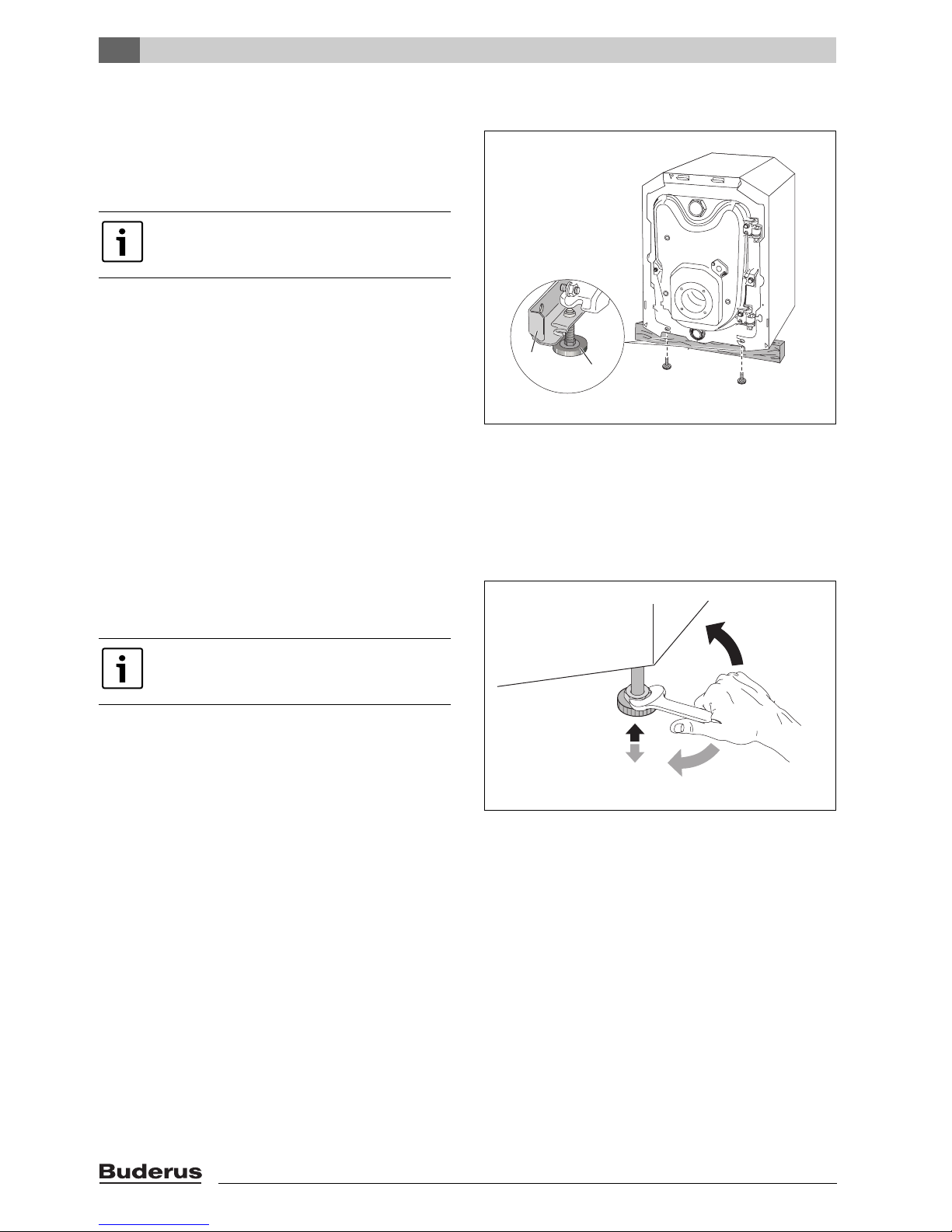

4.3 Mounting the adjustable feet (included with B-kit)

Level the boiler by turning the adjustable feet to prevent

air pockets becoming trapped inside the boiler.

Requirement: the burner hood or burner door panel must

have been removed first (Æ Chapter 3.1, page 12).

If the boiler is mounted on top of a horizontal

hot water tank the adjustable feet are not

used.

B Tilt the boiler with the aid of a hand truck or trolley (Æ

Chapter 3.3, page 13) or place a wooden batten

underneath to jack it up.

B Screw in adjustable feet [2] ¼ " – 1/8".

B Gently set the boiler down.

1

Fig. 11 Fitting the adjustable feet

(burner not shown)

1 Angle bracket

2 Adjustable feet

2

7 747 019 141-10.1RS

4.4 Positioning and leveling the boiler

B Position the boiler in its final location.

B Level the boiler by rotating the adjustable feet as

required and using a level.

Protect boiler connections from damage and

dirt if the boiler is not to be installed

immediately.

7 747 019 141-11.1RS

Fig. 12 Leveling the boiler

16

Logano GB125 BE US/CA - Subject to technical modifications.

5 Installing the boiler

Installing the boiler

5

This section details how to install your boiler correctly.

This involves the following steps:

• Flue pipe installation

• Providing air supply for combustion

• Making the water connections

• Making the electrical connections

• Connecting the fuel supply

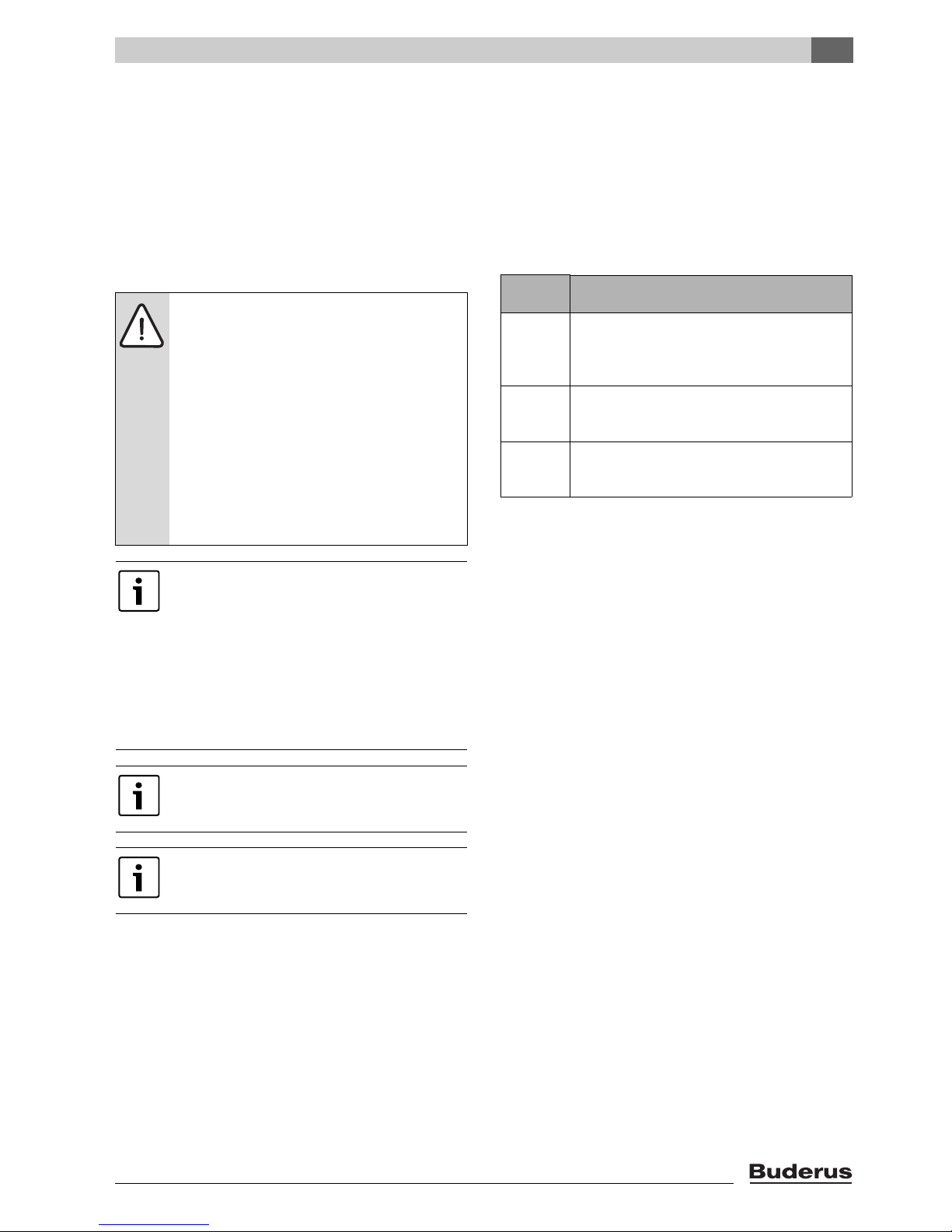

DANGER: Risk of fatal injury from toxic flue

gases!

B Never connect more than one boiler to a

flue system – regardless of whether the

flue is vertical or horizontal.

B Common venting systems can cause

damage to property and personal injury.

B Do not route the flue system through

another flue system that is in use, e.g. a

masonry chimney connected to a wood

stove.

B Follow the instructions of the flue pipe

manufacturer.

The boiler must be installed by a trained and

certified installer in accordance with all

requirements of NFPA-31, "Installation of OilBurning Equipment". Installation must

comply with all local and national codes

applicable to the installation of oil-fired

boilers.

5.1 Flue pipe installation

The overall burner air supply/boiler flue pipe system

conforms to the types of oil combustion equipment listed

in the table below.

Observe the national standards and regulations for

operating oil-fired appliances.

Installation type

HT-K

DO

GA-K

Tab. 10 Types of installation

Combustion air supply and flue system

I

or

II

or

III

or

Concentric supply air and flue pipe exiting

through external wall. Combustion air supply

and flue systems are part of the combustion

equipment.

Concentric supply air and flue gas routing

via roof. Combustion air supply and flue sys-

tems are part of the combustion equipment.

Concentric air/flue gas routing through a flue

inside a duct. The space around the vent

pipe is used for combustion air.

In Canada, the requirements of CSA/CGAB139 Installation Code apply.

The GB125 boiler is approved for zero (0")

clearance between its concentric vent pipe

and combustibles.

Because of the tight construction of modern

houses, this boiler must draw all air supply for

combustion from outside (RLU).

Logano GB125 BE US/CA - Subject to technical modifications.

17

5

Installing the boiler

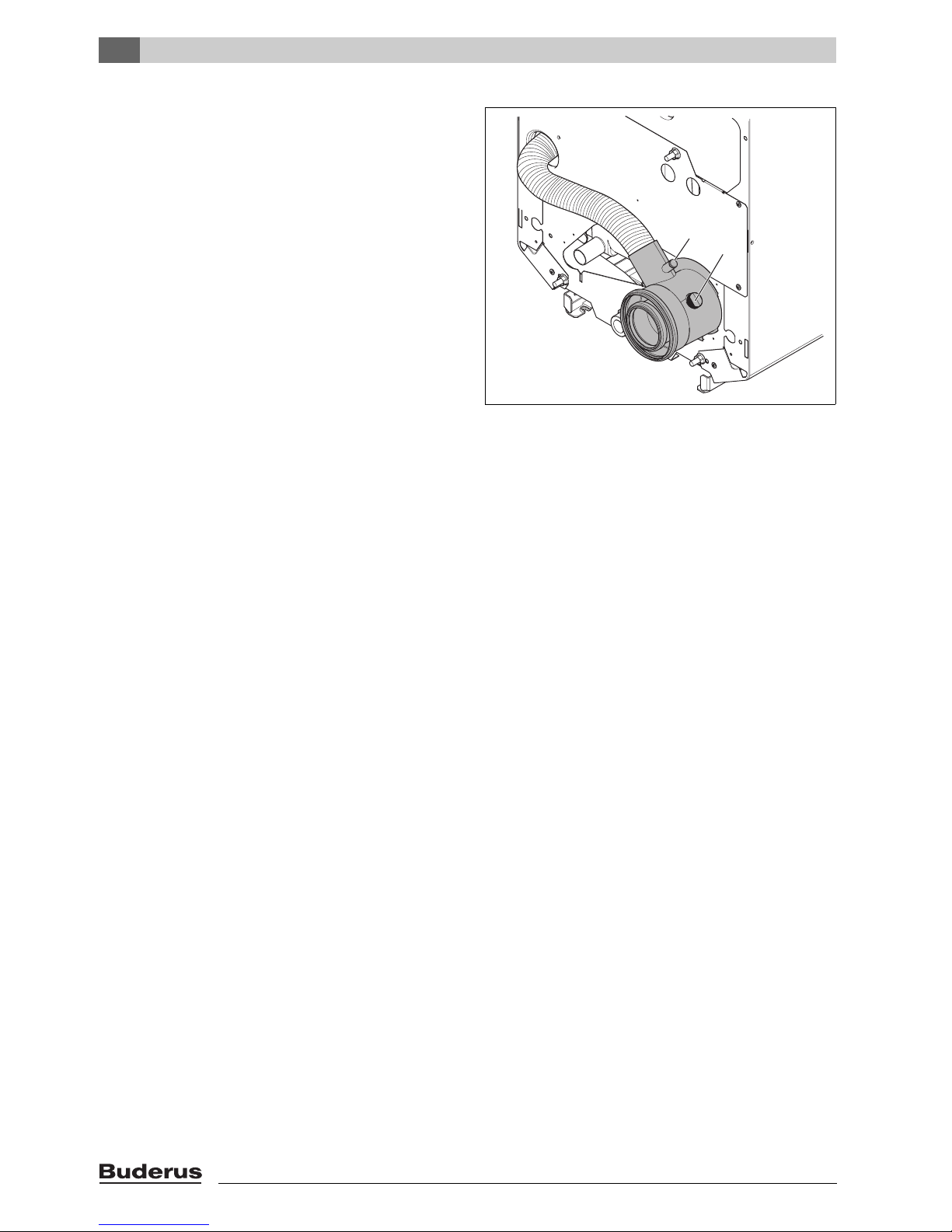

5.2 Test ports

Flue gas readings and combustion air temperature

readings are taken exclusively at the dedicated testing

ports.

Follow the directions in the instructions for the Logatop

BE oil burner.

1

2

6 720 649 309-03.1ITL

Fig. 13 Installing the flue/air connector (included with

the venting system)

1 Air intake test port

2 Flue gas test port

18

Logano GB125 BE US/CA - Subject to technical modifications.

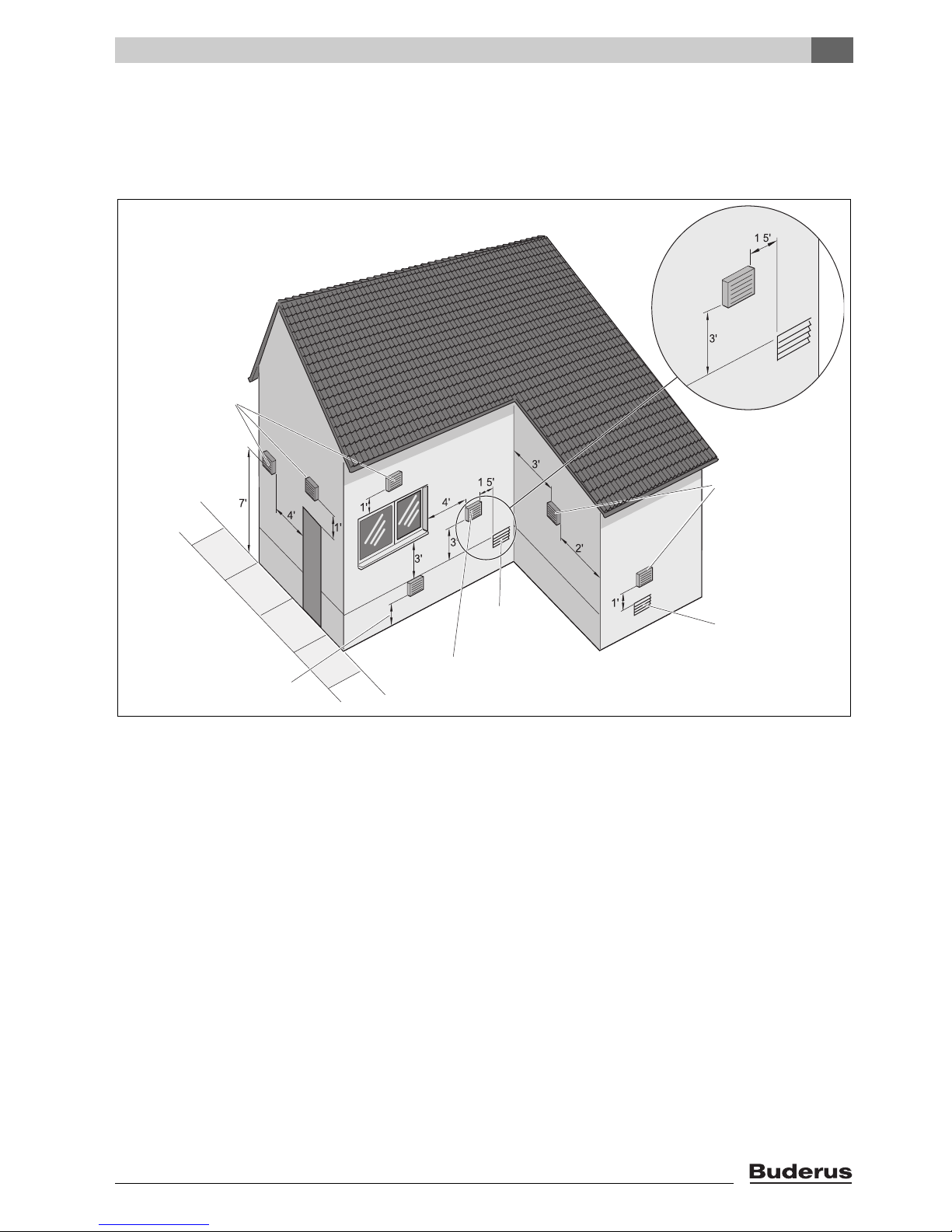

Choice of installation site for side-wall flue termination

Choosing the right location for the terminal is critical to

proper functioning of the appliance. As well as the

minimum clearances (Æ Fig. 14), the following rules must

be observed:

Concentric

wall terminations

on the house wall

Installing the boiler

.

5

at least 1 ft above grade

and snow line

Concentric wall terminations on the house wall

must be at least 3 ft above forced air inlets within 10 ft.

Fig. 14 Minimum clearances for side wall terminations

1. The termination should not face the prevailing wind

direction.

2. The termination must be installed in such a way that the

flue gases can disperse freely without re-entering the

building.

3. The termination must be at least 2 ft from adjacent

buildings and it must not be possible for the flue gas to

enter adjacent buildings.

4. Where the building adjoins public walkways, the

termination must be located at least 7 ft above ground.

Make sure that freezing condensate does not

constitute a hazard.

5. The termination must never be located below building

overhangs, roof eaves, porches, enclosed spaces or

lower parts of the building that could prevent

unrestricted outflow of the flue gases.

6. The termination must never be located within 3 ft of

inside corners of buildings and never less than 2 ft from

outside corners of buildings.

7. If there is a fan-assisted air intake vent within 10 ft, the

termination must be at least 3 ft above it.

.

Forced Air Inlet

Concentric

wall terminations

on the house wall

Gravity Air Inlet

8. The termination must be at least 4 ft below, 1 ft above

or 4 ft horizontally from doors, windows or air inlet

vents.

9. The termination must be at least 1 ft above ground and

snow line, and protected from falling and accumulating

snow, ice, leaves or debris.

10. The termination should be at least 3 ft from any type

of building opening, oil tank filling or venting apparatus,

and 6 ft from gas meters and similar equipment.

11. The position of the termination should be chosen so

that the last horizontal section of pipe slopes

downwards to the inside by ¼ " per ft. The flue terminal

itself must also be inclined at ¼ " per ft to the inside so

that any condensate drains inwards.

6 720 641 158-20.1TL

Logano GB125 BE US/CA - Subject to technical modifications.

19

5

Installing the boiler

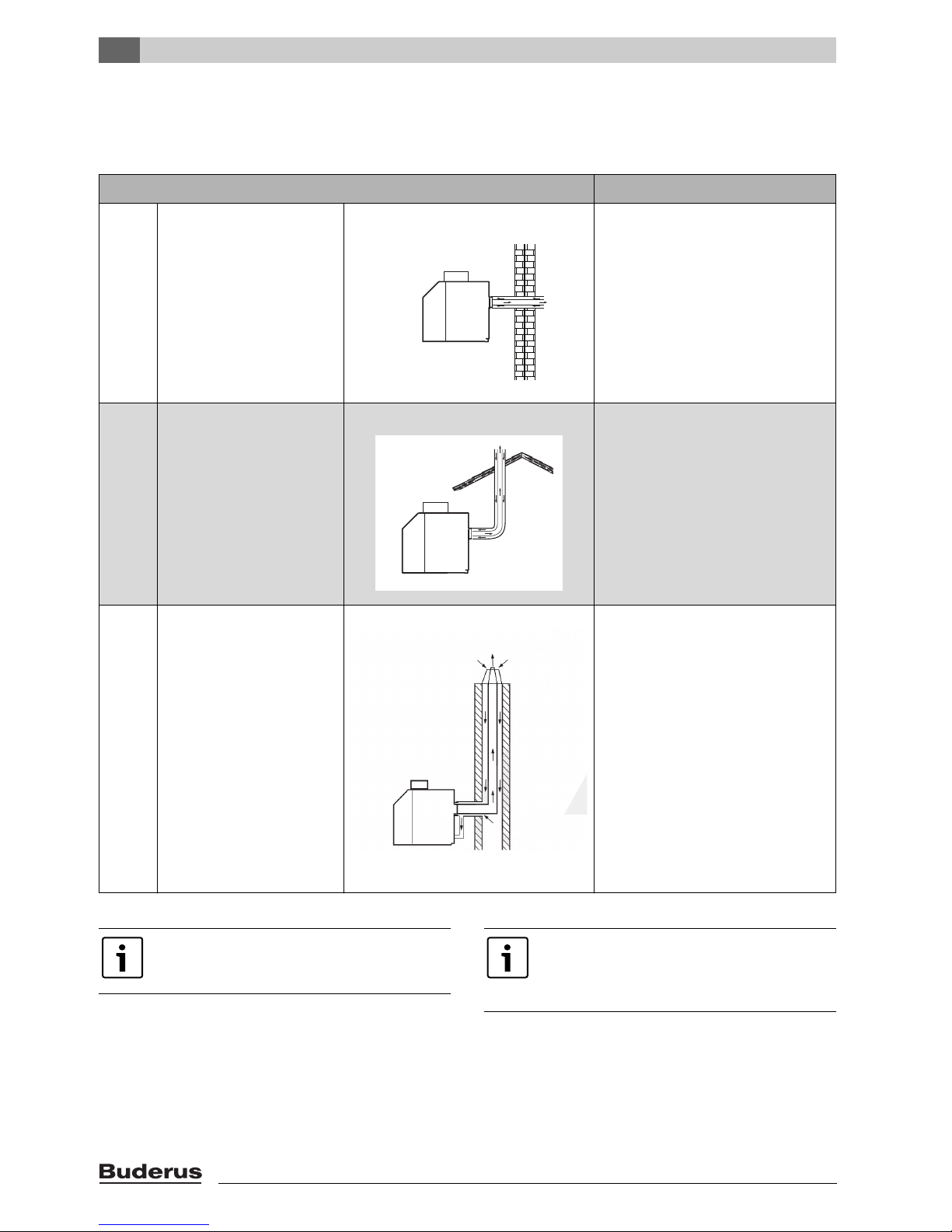

5.3 Installation options

The GB125 boiler is approved with the following flue gas

systems available from Buderus:

Types of installation Description

I

Concentric air supply and

or

flue pipe exiting through

HT-K

DO

external wall.

II

Concentric supply air and

or

flue gas routing via roof.

Horizontal direct vent concentric

combustion air and venting pipe

system.

Vertical concentric supply air and

flue gas routing.

III

Concentric air/flue gas

or

routing through a flue

GA-K

inside a duct.

Tab. 11 Installation options

To prevent reverse flow of flue gas into the air

intake even with wind influence, the included

wall terminations must be used.

Table 12, page 21 shows the maximum permissible vent

length for the different types of systems.

Flue pipe inside an existing masonry

chimney similar to a liner. Chimney

chase used as a raceway to bring in

combustion air. Concentric supply

air and flue gas routing from the

chimney to the boiler.

Installation type III or GA-K may not be

suitable for homes with a double flue chimney

where the second flue is used with a second

combustion appliance.

20

Logano GB125 BE US/CA - Subject to technical modifications.

Loading...

Loading...