Page 1

Applications Manual for

Buderus GB142 Wall Hung Heaters

BTC 435001101 A | 05.2009

Page 2

Page 3

1

Introduction

1

2

stnenopmoC niaM fo noitpircseD

2 sgnitteS pmuP dna dlofinaM depip-erP

2 sknaT tceridnI sureduB rof gniziS pmuP

4 rellortnoC 01CB

4 rellortnoC mooR 01CR

4 snoitpO gnitaeH ecapS

4 noitarepO gnitaeH WHD

3

noitarepO fo noitpircseD

5 snoitcennoC dna snoisnemiD

6 gnitaeH ecapS

6 gnitaeH retaW toH citsemoD

4

7 senilediuG gnitneV

8 gnitneV latnoziroH

9 gnitneV lacitreV

61 gnipiP etasnednoC

5

snoitacilppA gniriW dna gnipiP

71 slobmyS lacirtcelE / lacinahceM

81 teser roodni dna enoz WHD htiw 241BG

02 enoz gnitaeh ffo/no dna enoz WHD htiw 241BG

GB142 with DHW zone, Comfort Zone and zone valves 22

GB142 with DHW zone, Indoor reset, Buderus Pumping Station and

zone valves

24

GB142 with DHW zone, single temperature of radiant. No Mixing Valve

required

26

GB142 with DHW zone, motorize mixing valve zone, thermostatic

mixing valves zone and high temperature zone.

28

GB142 with DHW zone, and high temperature on/off zones 30

GB142 with DHW zones, constant circulation w/ Comfort zone control 32

GB142 with DHW zone & the Buderus Quick Fit Modular Piping

systems

34

63 s’241BG elpitluM htiw gnipiP 241BG raeN

Multiple GB142 Units with DWH zone piping diagrams 40

14 sedoC rorrE 01CR

Table of Contents

Page 4

Page 5

Page 1

This GB142 Applications Manual is intended to present some of the most common applications

of the wall-hung Buderus GB142 heater for use in hot water space heating applications.

Applications are shown with both piping and corresponding electrical schematics. Auxiliary

equipment depicted does not necessarily represent any one particular manufacturer or specific

model number. There are a wide variety of techniques, practices and piping strategies possible

with hydronic heating systems and it is the responsibility of the installing contractor to determine

the most suitable arrangement for his application.

In an effort to simplify piping and electrical diagrams, only Diagrams 1P and 1E depict the

complete details with respect to piping and wiring of an indirect hot water tank. This part is left

off all subsequent drawings for clarity purposes.

Basic information regarding vent installation, clearances, condensate piping and termination

locations are included as well.

Although this manual covers many common applications for our equipment, system possibilities

are virtually endless. Should you encounter an application that is not covered in this manual or

have any questions regarding any of its content, we encourage you to contact your local sales rep

or us directly at Bosch Thermotechnology Corp.

1 INTRODUCTION 2 DESCRIPTION OF MAIN COMPONENTS

Page 6

Page 2

P

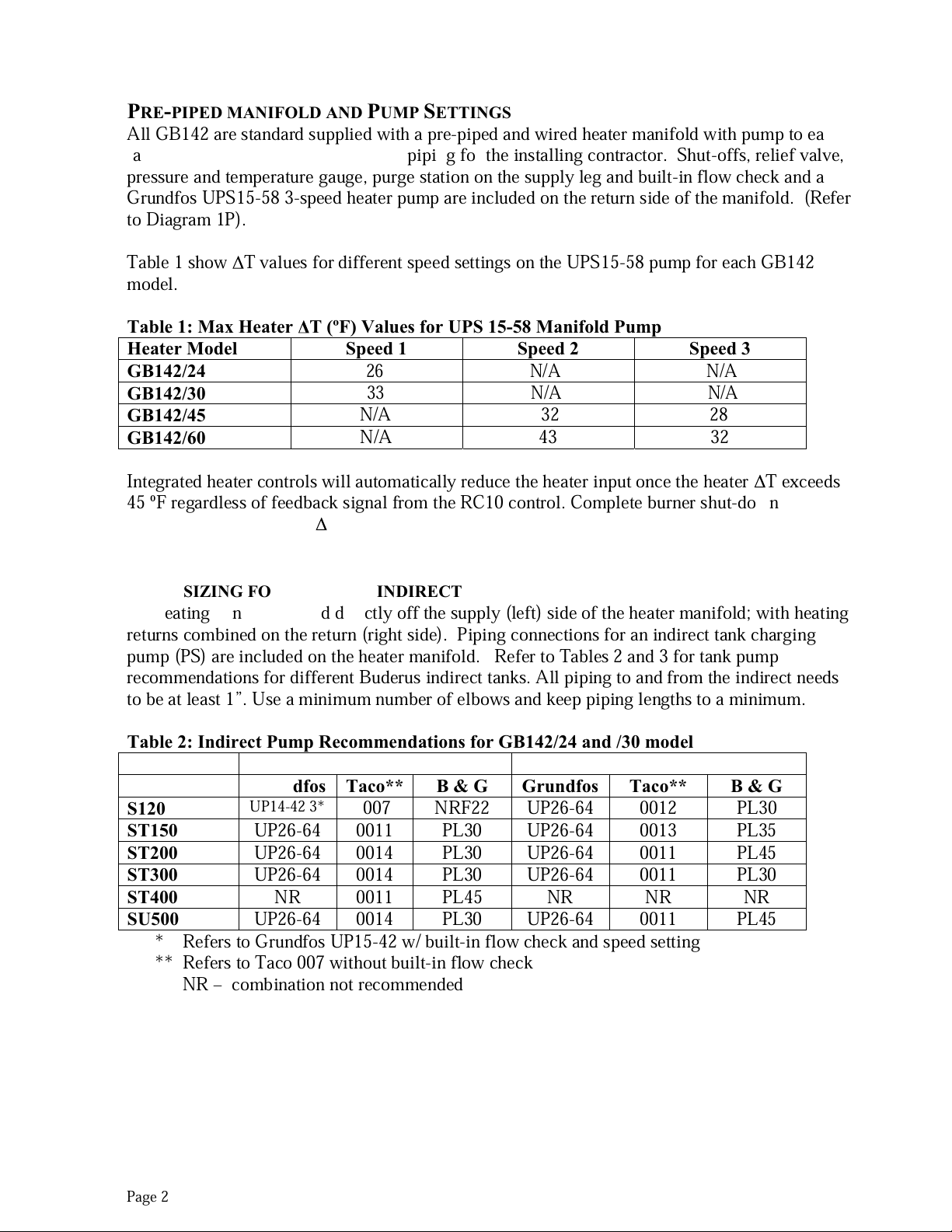

RE-PIPED MANIFOLD AND PUMP SETTINGS

All GB142 are standard supplied with a pre-piped and wired heater manifold with pump to easily

facilitate required primary/secondary piping for the installing contractor. Shut-offs, relief valve,

pressure and temperature gauge, purge station on the supply leg and built-in flow check and a

Grundfos UPS15-58 3-speed heater pump are included on the return side of the manifold. (Refer

to Diagram 1P).

Table 1 show T values for different speed settings on the UPS15-58 pump for each GB142

model.

Table 1: Max Heater

T (ºF) Values for UPS 15-58 Manifold Pump

Heater Model Speed 1 Speed 2 Speed 3

GB142/24

26 N/A N/A

GB142/30

33 N/A N/A

GB142/45

N/A 32 28

GB142/60

N/A 43 32

Integrated heater controls will automatically reduce the heater input once the heater T exceeds

45 ºF regardless of feedback signal from the RC10 control. Complete burner shut-down will

always take place before

T exceeds 99 ºF. The maximum flow rates are as follows:

GB142/24 or /30: 11 GPM, model /45: 15 GPM, model /60: 20 GPM.

P

UMP SIZING FOR BUDERUS INDIRECT TANKS

All heating zones are piped directly off the supply (left) side of the heater manifold; with heating

returns combined on the return (right side). Piping connections for an indirect tank charging

pump (PS) are included on the heater manifold. Refer to Tables 2 and 3 for tank pump

recommendations for different Buderus indirect tanks. All piping to and from the indirect needs

to be at least 1”. Use a minimum number of elbows and keep piping lengths to a minimum.

Table 2: Indirect Pump Recommendations for GB142/24 and /30 models.

03/241BG42/241BG

Tank Model Grundfos Taco** B & G Grundfos Taco** B & G

S120

UP14-42 3*

007 NRF22 UP26-64 0012 PL30

ST150

UP26-64 0011 PL30 UP26-64 0013 PL35

ST200

UP26-64 0014 PL30 UP26-64 0011 PL45

ST300

UP26-64 0014 PL30 UP26-64 0011 PL30

ST400

NR 0011 PL45 NR NR NR

SU500

UP26-64 0014 PL30 UP26-64 0011 PL45

* Refers to Grundfos UP15-42 w/ built-in flow check and speed setting

** Refers to Taco 007 without built-in flow check

NR – combination not recommended

Page 7

Page 3

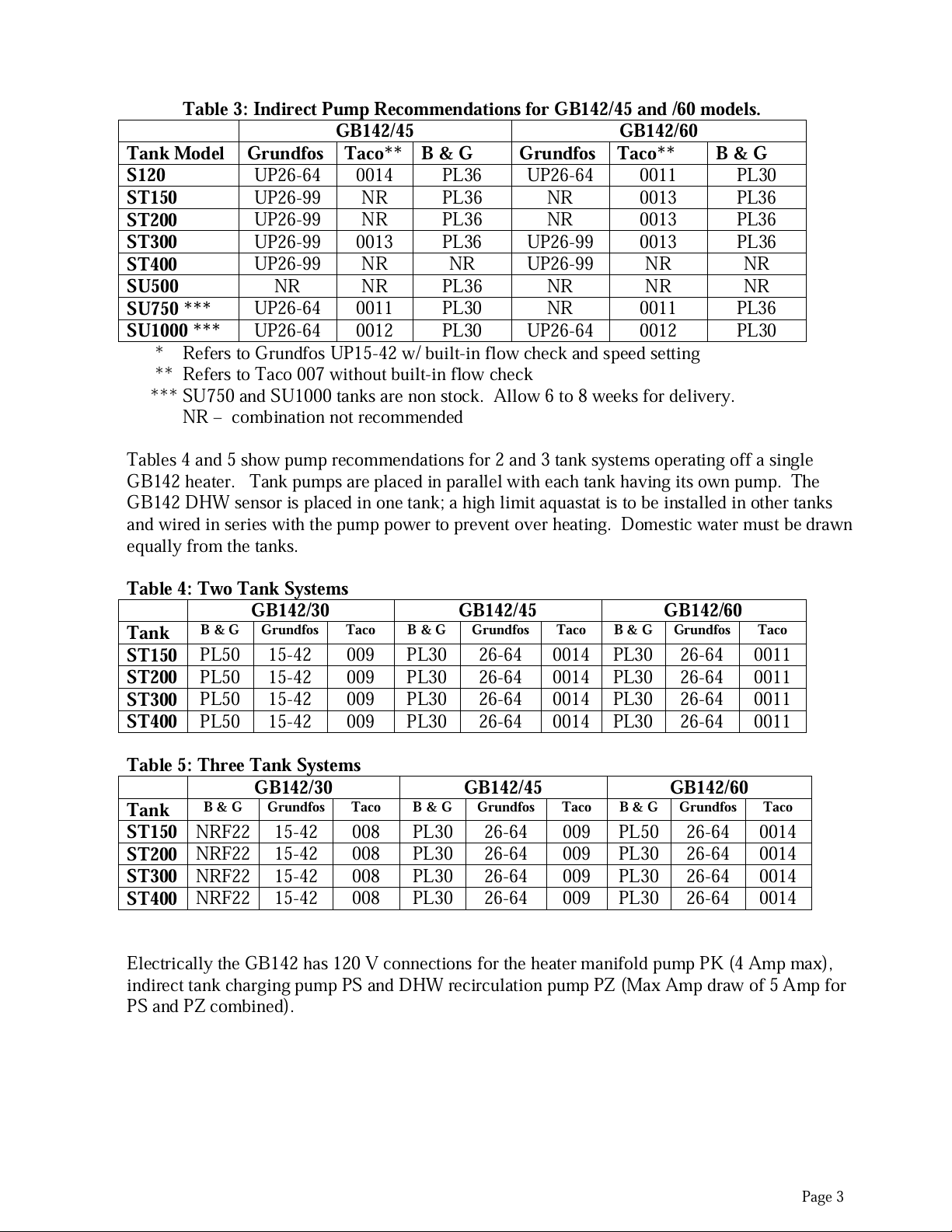

Table 3: Indirect Pump Recommendations for GB142/45 and /60 models.

06/241BG54/241BG

Tank Model Grundfos Taco** B & G Grundfos Taco** B & G

S120

UP26-64 0014 PL36 UP26-64 0011 PL30

ST150

UP26-99 NR PL36 NR 0013 PL36

ST200

UP26-99 NR PL36 NR 0013 PL36

ST300

UP26-99 0013 PL36 UP26-99 0013 PL36

ST400

UP26-99 NR NR UP26-99 NR NR

SU500

NR NR PL36 NR NR NR

SU750 ***

UP26-64 0011 PL30

NR 0011 PL36

SU1000 ***

UP26-64 0012 PL30 UP26-64 0012 PL30

* Refers to Grundfos UP15-42 w/ built-in flow check and speed setting

** Refers to Taco 007 without built-in flow check

*** SU750 and SU1000 tanks are non stock. Allow 6 to 8 weeks for delivery.

NR – combination not recommended

Tables 4 and 5 show pump recommendations for 2 and 3 tank systems operating off a single

GB142 heater. Tank pumps are placed in parallel with each tank having its own pump. The

GB142 DHW sensor is placed in one tank; a high limit aquastat is to be installed in other tanks

and wired in series with the pump power to prevent over heating. Domestic water must be drawn

equally from the tanks.

Table 4: Two Tank Systems

GB142/30 GB142/45 GB142/60

Tank

B & G Grundfos Taco B & G Grundfos Taco B & G Grundfos Taco

ST150

PL50 15-42 009 PL30 26-64 0014 PL30 26-64 0011

ST200

PL50 15-42 009 PL30 26-64 0014 PL30 26-64 0011

ST300

PL50 15-42 009 PL30 26-64 0014 PL30 26-64 0011

ST400

PL50 15-42 009 PL30 26-64 0014 PL30 26-64 0011

Table 5: Three Tank Systems

GB142/30 GB142/45 GB142/60

Tank

B & G Grundfos Taco B & G Grundfos Taco B & G Grundfos Taco

ST150

NRF22 15-42 008 PL30 26-64 009 PL50 26-64 0014

ST200

NRF22 15-42 008 PL30 26-64 009 PL30 26-64 0014

ST300

NRF22 15-42 008 PL30 26-64 009 PL30 26-64 0014

ST400

NRF22 15-42 008 PL30 26-64 009 PL30 26-64 0014

Electrically the GB142 has 120 V connections for the heater manifold pump PK (4 Amp max),

indirect tank charging pump PS and DHW recirculation pump PZ (Max Amp draw of 5 Amp for

PS and PZ combined).

Page 8

Page 4

The low voltage side is equipped with the following terminals:

1) RC terminals (orange color) for an indoor room sensor for firing and modulating the

burner. (RC10 control standard supplied with GB142).

2) FA optional outdoor sensor terminals (blue color) connections (requires RC34 controller;

available Fall 2005).

3) WA T-T terminals (light green color) connections for optional conventional thermostat.

4) FW DHW tank sensor terminals (light gray color) for sensing tank water temperature.

(Tank sensor standard supplied with GB142).

5) EV terminals (red color) for connecting of an optional safety such as LWCO, manual

reset high limit or any other type of external limit circuit.

BC10 C

ONTROLLER

A BC10 control panel is installed in every GB142 which includes a diagnostic display, status

indicator lights, dials for DHW and maximum heater temperature as well as programming and

diagnostic access buttons. A detailed description of all diagnostic and status codes is provided

with the GB142 Installation and Service Manual.

RC10 R

OOM CONTROLLER

A RC10 room controller is provided with every GB142 to provide indoor reset and pin point

precision control back to the BC10. The RC10 must be installed in a reference location for

indoor feedback to the GB142. The RC10 will control the modulation and heater water

temperature based on maintaining desired indoor comfort levels. The RC10 is typically placed

in the main living area for optimum comfort and accurate temperature control. Give careful

consideration to the placement of the RC10 sensor.

The use of the RC10 indoor room controller is shown in a number of diagrams to achieve

maximum comfort and efficiency from the product. Suggested timings of the post purge for the

boiler pump (PK) are shown on each wiring diagram.

Note:

Never

connect a RC10 control and a thermostat or end switch at the same time.

S

PACE HEATING OPERATION:

The PK boiler pump operates and the burner fires on a call for heat from the T-T terminal or

from the RC10 controller. Use only T-T connections or RC terminals,

but do NOT use both at

the same installation

. Once the call for heat is satisfied, the PK pump continues to operate

through an adjustable programmable post-purge cycle before shutting down. The PK pump can

also set to operate continuously for up to 24 hours after the last call for heat.

DHW H

EATING OPERATION:

A call for heat from the FW (DHW) sensor brings the control into DHW priority, shutting off the

PK pump, firing the boiler to maximum temperature and operating the PS pump. Internal logic

includes an anticipative DHW heating cycle with automatically adjusting post purge feature and

reduces burner modulation rate.

Page 9

Page 5

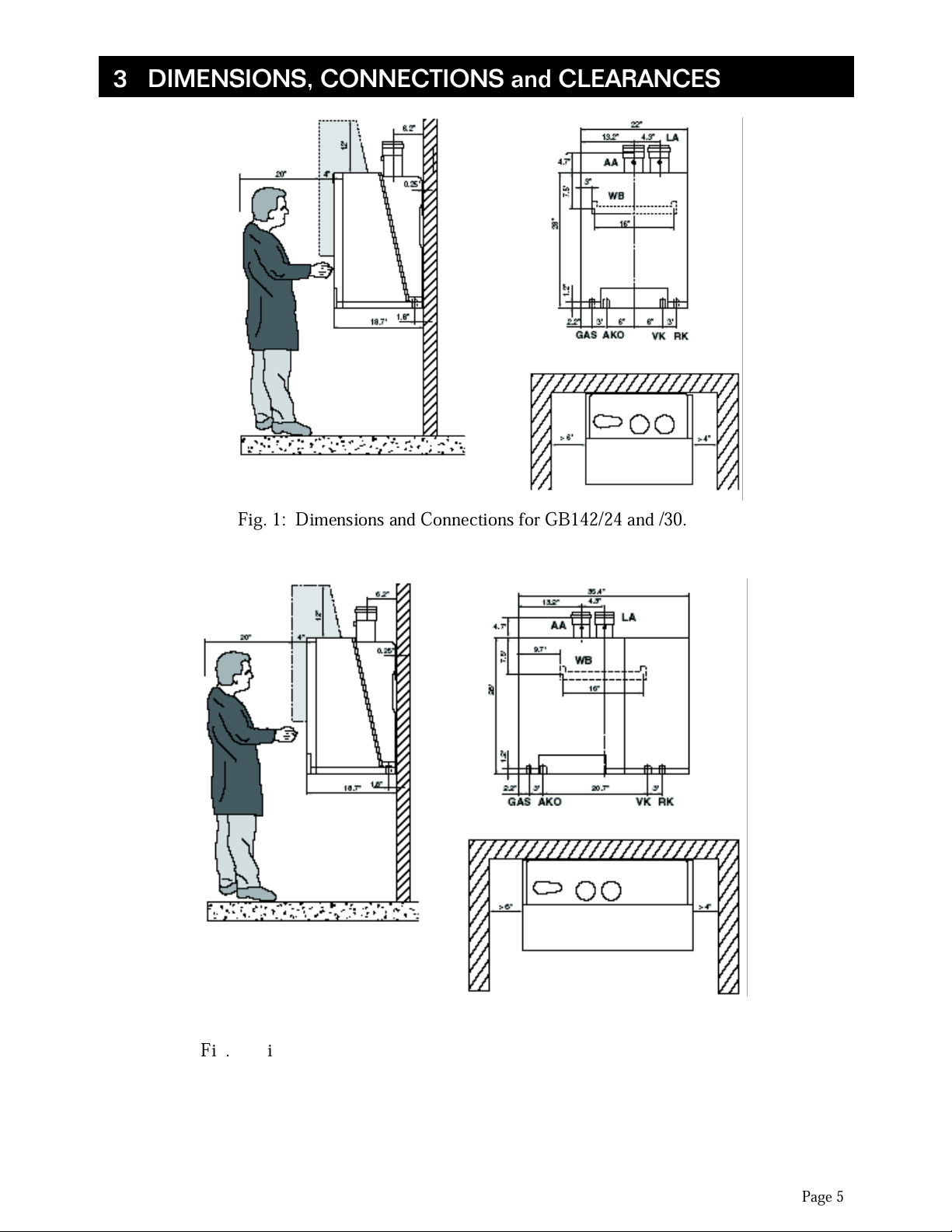

3 DIMENSIONS, CONNECTIONS AND CLEARANCES 3 DIMENSIONS, CONNECTIONS and CLEARANCES

Fig. 1: Dimensions and Connections for GB142/24 and /30.

Fig. 2: Dimensions and Connections for GB142/45 and /60.

Page 10

Page 6

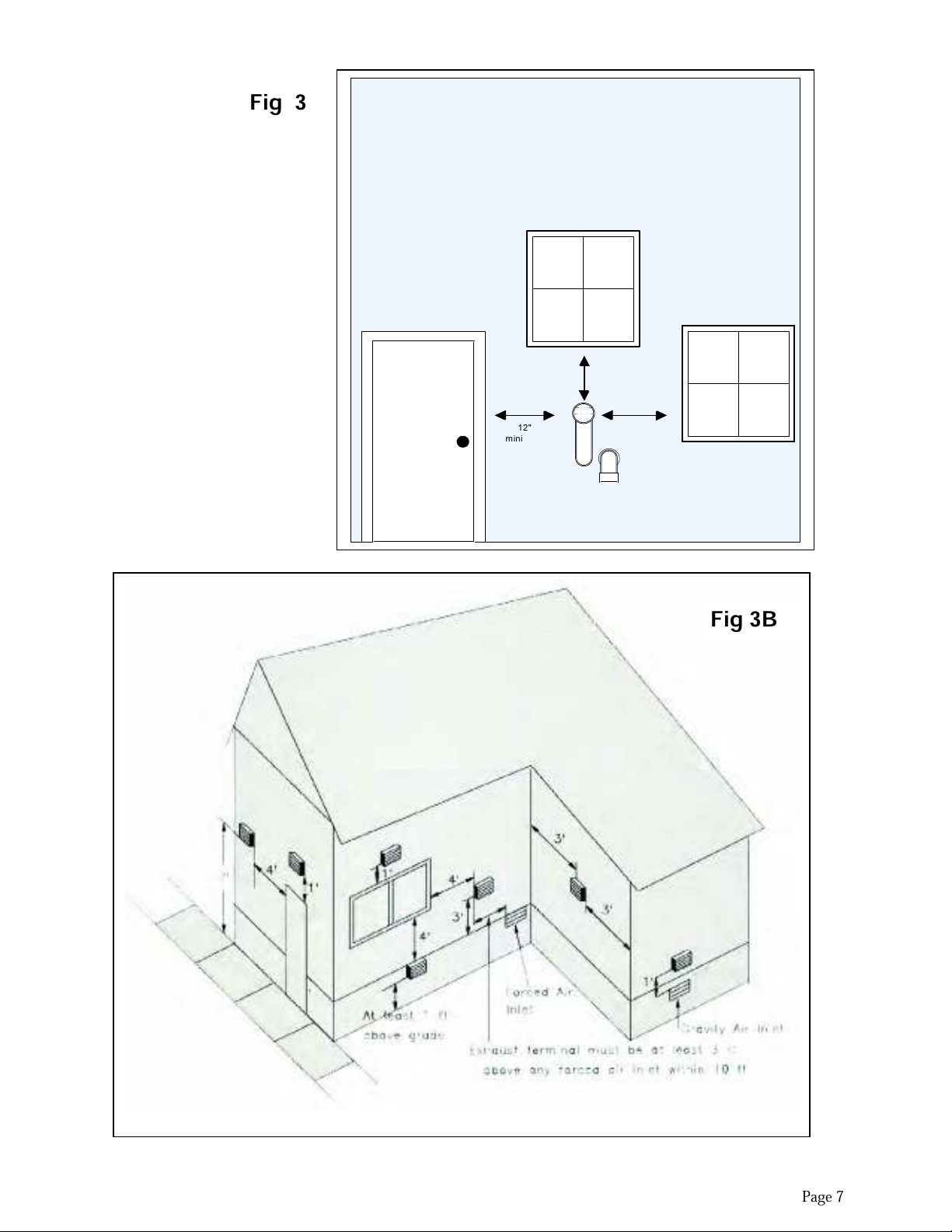

V

ENTING GUIDELINES

The GB142 is suitable for side-wall as well as vertical venting using field supplied 3” PVC or

CPVC pipe in compliance with ANSI, ASTM D1785 (schedule 40 PVC), F441, D2665 (PVC-

DWV), or ABS-DWV Schedule 40. Cement and primer must comply with ASTM D2564. For

Canada, use CSA or ULC certified PVC or CPVC pipe, fittings and cement.

Foam core PVC

pipe can not be used.

Note:

Installation must comply with local requirements/codes, National Fuel Gas Code, ANSI

Z223.1 (USA installations) CSA B149.1 or B149.2 (Canadian installations). In Canada, venting

must comply with ULC-S636.

Note:

Installing contractor must install condensate tee (supplied by Buderus) immediately after

the first 90 degree flue elbow. Condensate must be drained into a condensate pump or

appropriate drain.

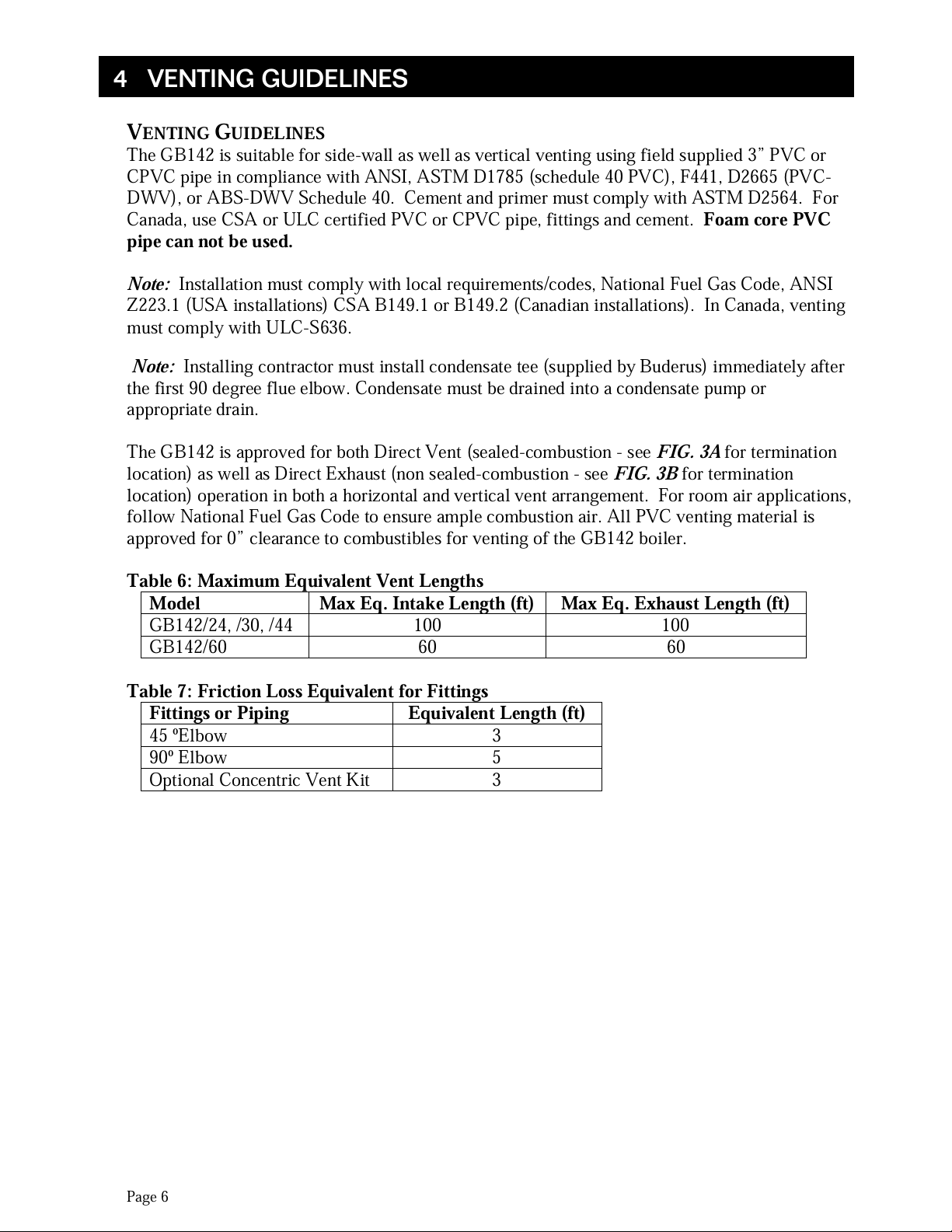

The GB142 is approved for both Direct Vent (sealed-combustion - see

FIG. 3A

for termination

location) as well as Direct Exhaust (non sealed-combustion - see

FIG. 3B

for termination

location) operation in both a horizontal and vertical vent arrangement. For room air applications,

follow National Fuel Gas Code to ensure ample combustion air. All PVC venting material is

approved for 0” clearance to combustibles for venting of the GB142 boiler.

Table 6: Maximum Equivalent Vent Lengths

Model Max Eq. Intake Length (ft) Max Eq. Exhaust Length (ft)

00100144/,03/,42/241BG

060606/241BG

Table 7: Friction Loss Equivalent for Fittings

Fittings or Piping Equivalent Length (ft)

3woblEº54

5woblEº09

Optional Concentric Vent Kit 3

4 VENTING GUIDELINES

Page 11

Page 7

Fig 3B

12"

minim um

12"

minim um

12"

minim um

Fig. 3A

Page 12

Page 8

D

IRECT VENT/SEALED COMBUSTION & DIRECT VENT/NON-SEALED

COMBUSTION TERMINATION GUIDELINES

WARNING: Follow these instructions when determining vent termination location to avoid

possibility of severe personal injury, death, substantial property damage or cross contamination

of combustion air. Gas vent extending through an exterior wall shall not terminate adjacent to the

wall or below building extensions such as eaves, parapets, balconies or decks. Failure to comply

could result in severe personal injury, death or substantial property damage. Locate the

concentric vent/air termination using the following guidelines.

The total length of piping for vent or combustion air should not exceed the limits in Table

6 for maximum output.

One must consider the immediate environment when locating the vent/air termination.

Gases will form a white plume in winter. Plume could obstruct window view.

Prevailing winds could freeze condensate and cause water/ice buildup on building,

plants or roof. Do not terminate vent in window well, stairwell, alcove, courtyard, or

other recessed areas.

Maintain Minimum Clearances below to prevent potential problems;

1. Vent must terminate at least 12 inches above grade, anticipated snow line or roof

surface (Canada 18” minimum).

2. Vent termination must be at least 7 feet above a public walkway.

3. Vent must be 3 feet above any forced air intake within 10 feet.

4. Vent must terminate at least 3 feet horizontally, from electric meters, gas meters,

regulators, relief valves, and other equipment, and in no case above or below, unless a

3 feet horizontal distance is maintained

5. Do not extend exposed vent pipe outside the building beyond recommended distance.

Condensate could freeze and block vent pipe.

6. Vent should terminate at least 3 feet away from adjacent walls, inside corners and

below roof overhang.

7. It is not recommended to terminate vent above any door or window, condensate can

freeze causing ice formations.

8. Do not use chimney as a raceway if another appliance or fireplace is vented into or

through chimney.

9. The exhaust vent must be pitched up toward the termination a minimum of ¼” in. per

foot. Condensate must flow back to the Boiler freely, without accumulating in the

vent.

10. Multiple boiler vent terminations; See Venting application.

Page 13

Page 9

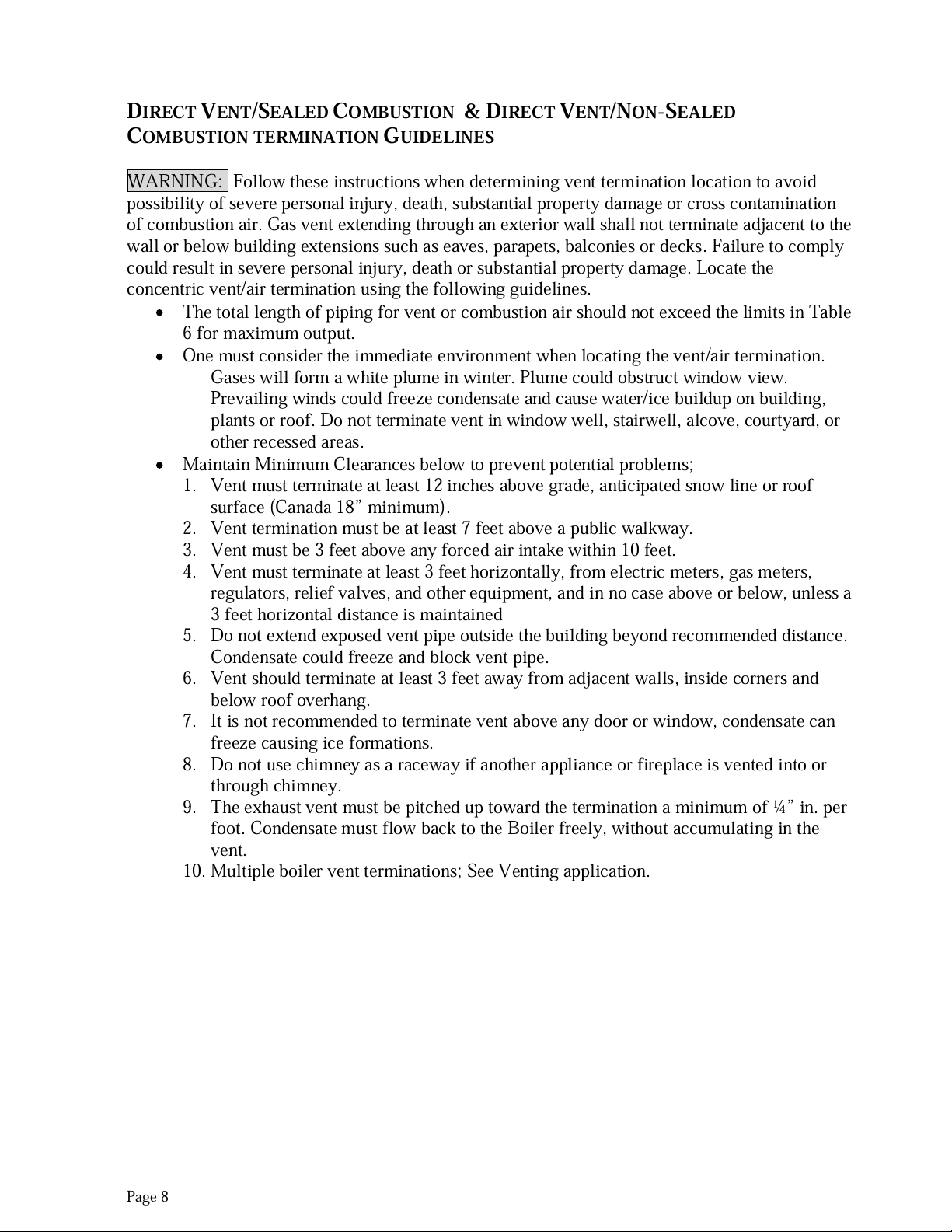

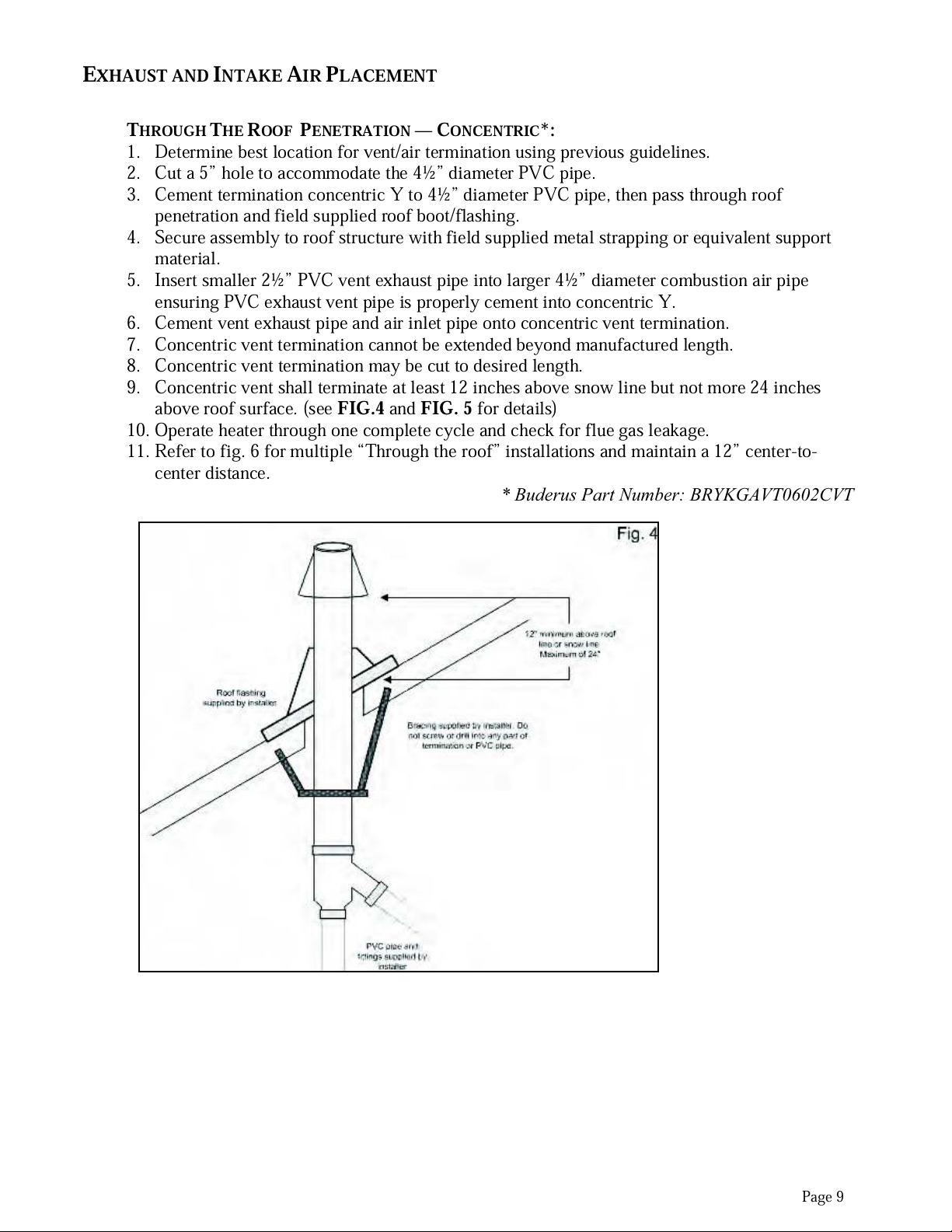

THROUGH THE ROOF PENETRATION — CONCENTRIC*:

1. Determine best location for vent/air termination using previous guidelines.

2. Cut a 5” hole to accommodate the 4½” diameter PVC pipe.

3. Cement termination concentric Y to 4½” diameter PVC pipe, then pass through roof

penetration and field supplied roof boot/flashing.

4. Secure assembly to roof structure with field supplied metal strapping or equivalent support

material.

5. Insert smaller 2½” PVC vent exhaust pipe into larger 4½” diameter combustion air pipe

ensuring PVC exhaust vent pipe is properly cement into concentric Y.

6. Cement vent exhaust pipe and air inlet pipe onto concentric vent termination.

7. Concentric vent termination cannot be extended beyond manufactured length.

8. Concentric vent termination may be cut to desired length.

9. Concentric vent shall terminate at least 12 inches above snow line but not more 24 inches

above roof surface. (see

FIG.4

and

FIG. 5

for details)

10. Operate heater through one complete cycle and check for flue gas leakage.

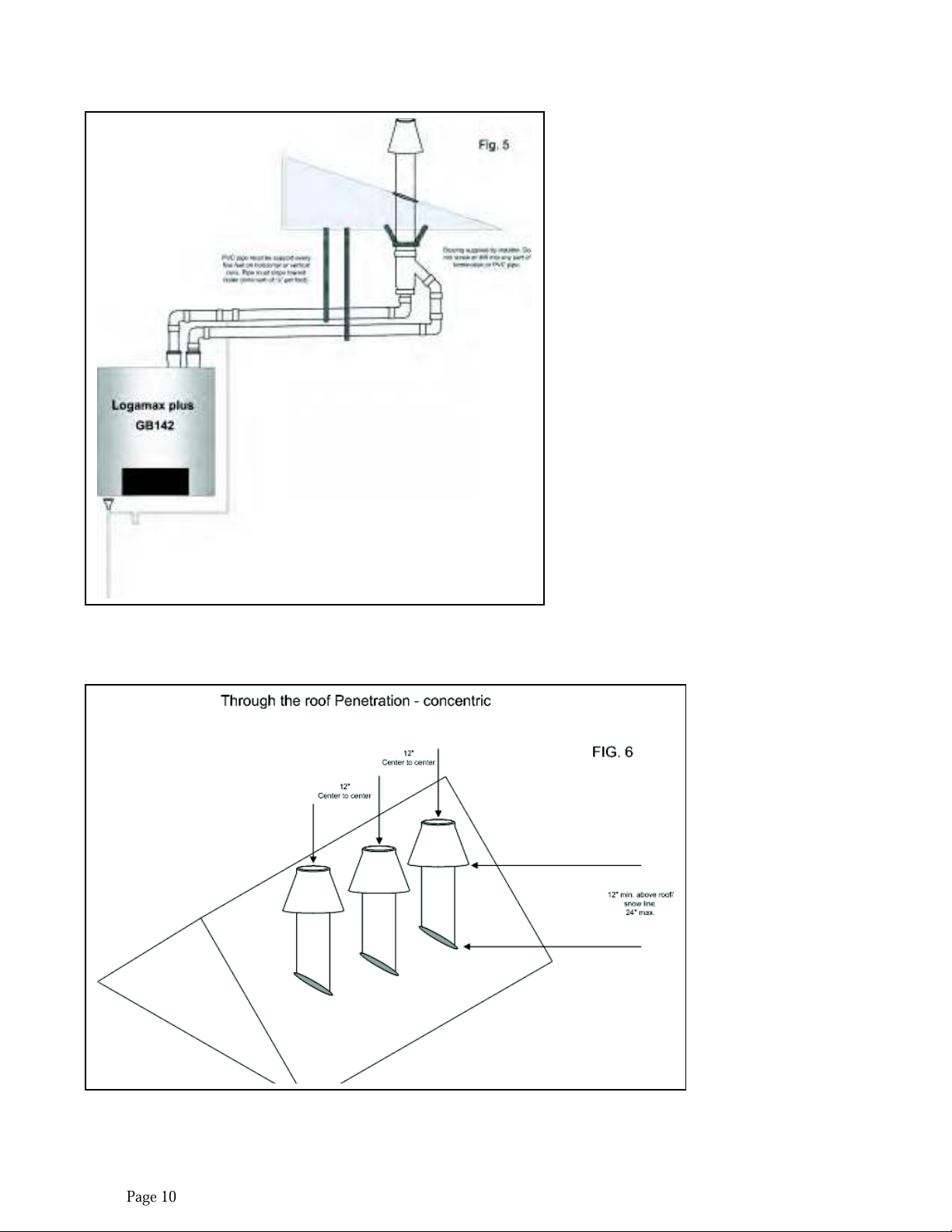

11. Refer to fig. 6 for multiple “Through the roof” installations and maintain a 12” center-to-

center distance.

* Buderus Part Number: BRYKGAVT0602CVT

E

XHAUST AND INTAKE AIR PLACEMENT

Page 14

Page 10

Page 15

Page 11

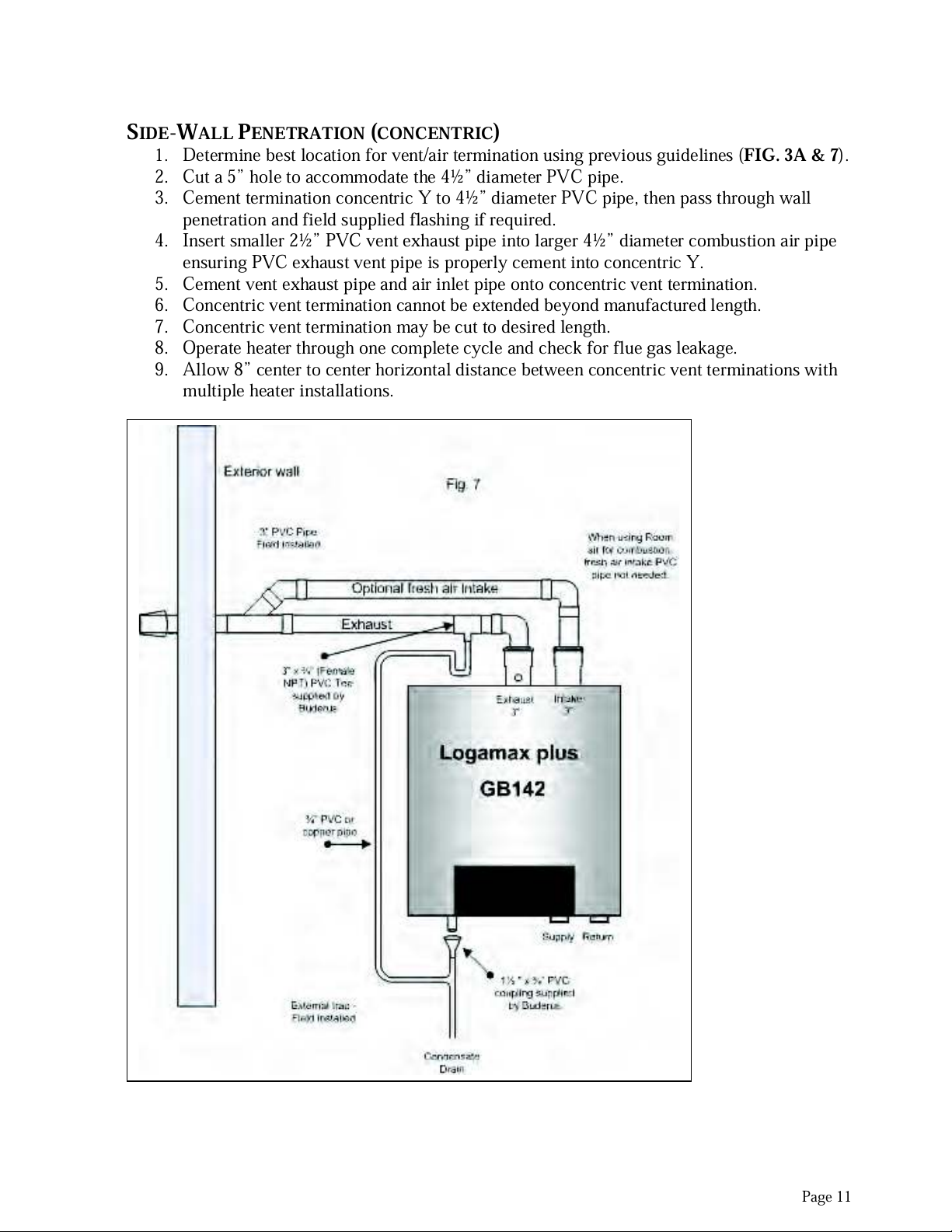

S

IDE-WALL PENETRATION (CONCENTRIC)

1. Determine best location for vent/air termination using previous guidelines (

FIG. 3A & 7

).

2. Cut a 5” hole to accommodate the 4½” diameter PVC pipe.

3. Cement termination concentric Y to 4½” diameter PVC pipe, then pass through wall

penetration and field supplied flashing if required.

4. Insert smaller 2½” PVC vent exhaust pipe into larger 4½” diameter combustion air pipe

ensuring PVC exhaust vent pipe is properly cement into concentric Y.

5. Cement vent exhaust pipe and air inlet pipe onto concentric vent termination.

6. Concentric vent termination cannot be extended beyond manufactured length.

7. Concentric vent termination may be cut to desired length.

8. Operate heater through one complete cycle and check for flue gas leakage.

9. Allow 8” center to center horizontal distance between concentric vent terminations with

multiple heater installations.

Page 16

Page 12

T

HROUGH THE ROOF PENETRATION (NON-CONCENTRIC)

1. Determine best location for vent/air termination using previous guidelines.

2. Air pipe penetration – Cut a hole for the air pipe. Size the air pipe hole as close as desired

to the air pipe outside diameter.

3. Vent pipe penetration – Cut a hole for the vent pipe. Size the vent pipe hole as close as

desired to the vent pipe outside diameter.

4. Space the air and vent holes to provide the minimum spacing (see

FIG. 8

).

5. Follow all local codes for isolation of vent pipe when passing through floors, ceilings and

roofs.

6. Install a field supplied roof penetration boot/flashing.

Minumum of

12" above roof

line/snow line

24"

minimum

Minimum 12"

Maximum 24"

Fig. 8

Page 17

Page 13

T

ERMINATION AND FITTING

1. Prepare the vent termination coupling and the air termination elbow by inserting the bird

screens provided with boiler into the three inch fittings.

2. The combustion air inlet shall terminate at least 12 inches above maximum snow line or

24 inches above roof surface which ever is greater.

3. The combustion air inlet pipe must terminate in a downward position using two 90 degree

elbows. The combustion air inlet pipe shall terminate at least two feet horizontally from

the center line of the exhaust vent, this is to prevent cross contamination of flue gases

into the combustion air stream.

4. The exhaust vent must terminate vertically upward with a coupling and bird screen. The

top of the coupling shall termination at least 12 inches above the bottom of the down-

turned 90° elbow, but no more than 24 inches.

M

ULTIPLE HEATER INSTALLATION

Terminate all exhaust vents at the same height and all combustion air inlets at the same height,

while maintaining the minimum 12” to a maximum of 24” height clearance from the exhaust to

the down turned 90 degree elbow and combustion air inlet. Exhaust vent termination edge shall

be at least 12” from the edge of the air inlet pipe of an adjacent heater. Exhaust vent terminations

may be place next to each other as practical, like wise air intake terminations may also be placed

next to each other. The combustion air inlet is part of the direct vent system and not classified as

a forced air inlet (see

FIG. 9A

and

9B

).

Minim um 24" from

center to center

12"

Minimum

Minim um 12"

Maximum 24"

Fig. 9A

Page 18

Page 14

S

IDE-WALL PENETRATION (NON-CONCENTRIC)

1. Determine best location for vent/air termination using previous guidelines.

2. Cut a 4” hole to accommodate the 3½” diameter PVC pipe. Through the wall penetration

may be sealed with a field provided flashing if required.

3. Insert bird screens provided with heater into both exhaust and combustion air (field

supplied) elbows.

4. Combustion air inlet elbow should always be positioned downward.

5. The exhaust outlet or elbow shall always be positioned pointing away from the building.

6. Combustion air inlet elbow must terminate at least 12” below exhaust elbow or outlet, but

not exceed 15” maximum separation.

7. Combustion air inlet must maintain at least 12” above grade and/or snow line.

8. Combustion air inlet may be extended vertically upward a maximum of 24” from the

building penetration (see

FIG. 10

).

9. Do not extend exposed exhaust vent pipe outside the building beyond recommendations.

10. Horizontal termination shall not extend beyond 18 inches from the building (based on

minimum 12 inch required separation between intake and exhaust). Exhaust vent vertical

rise shall not extend beyond 39” from building penetration to termination elbow.

Condensate could freeze and block vent pipe.

11. Operate heater through one complete cycle and check for flue gas leakage.

Page 19

Page 15

Multiple Heater installation

– Terminate all exhaust vents at the same height and all

combustion air inlets at the same height, while maintaining the minimum 12 inches vertical

height clearance from between exhaust and combustion air inlet. Exhaust vent termination edge

shall be at least 12 inches laterally from the edge of the air inlet pipe of an adjacent heater. The

combustion air inlet is part of the direct vent system and not classified as a forced air inlet.

Page 20

Page 16

C

ONDENSATE PIPING

Figure 7 shows a typical sealed combustion installation.

The furnished 3” x ¾” socket female vent condensate drain must be installed as close as

possible to the exhaust connection with the ¾” branch pointing down to drain condensate.

Install furnished 1-1/2” x ¾” coupling under GB142 condensate drain, install a ¾” PVC

tee and bring in upper vent drain with a trap into this tee.

Pour 1 qt. of water in exhaust pipe and make sure to fill the external trap and internal trap

of the GB142.

In case of vertical venting, install a short horizontal run to install the vent condensate

drain.

Page 21

Version 1.2 04/05 Page 17

5 DRAWINGS

Low Loss Header

5 DRAWINGS

Page 22

Page 18 Version 1.2 04/05

Page 23

Page 19

Page 24

Page 20 Version 1.2 04/05

Page 25

Page 21

Page 26

Page 22 Version 1.2 04/05

Page 27

Page 23

Page 28

Page 24 Version 1.2 04/05

Page 29

Page 25

Page 30

Page 26 Version 1.2 04/05

Page 31

Page 27

Page 32

Page 28 Version 1.2 04/05

Page 33

Page 29

Page 34

Version 1.2 04/05

Page 30

Page 35

Page 31

Page 36

Page 32 Version 1.2 04/05

Page 37

Page 33

Page 38

Page 34 Version 1.2 04/05

Page 39

Page 35

Page 40

Page 36 Version 1.2 04/05

"E"

"A"

Supply

"E"

"A"

"B"

"B"

Return

Page 41

Page 37

"E"

"A"

Supply

"E"

"B"

"C"

"B"

Return

"A"

"E"

"C"

Page 42

Page 38 Version 1.2 04/05

"E"

"A"

Supply

"E"

"B"

"C"

"B"

"A"

Return

"E"

"C"

"D"

"D"

"E"

Page 43

Version 1.2 04/05 Page 39

Page 44

Page 40 Version 1.2 04/05

Page 45

Page 41

Page 46

Page 42

Page 47

Page 48

Bosch Thermotechnology Corp., reserves the right to make changes without notice

due to continuing engineering and technological advances

Bosch Thermotechnology Corp.

50 Wentworth Avenue

Londonderry, NH 03053

Tel: 1-800-BUDERUS

Fax: 1-603-584-1681

www.buderus.net

Loading...

Loading...