MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Order this document by:

DSP56007/D

DSP56007

SYMPHONY AUDIO DSP FAMILY

24-BIT DIGITAL SIGNAL PROCESSORS

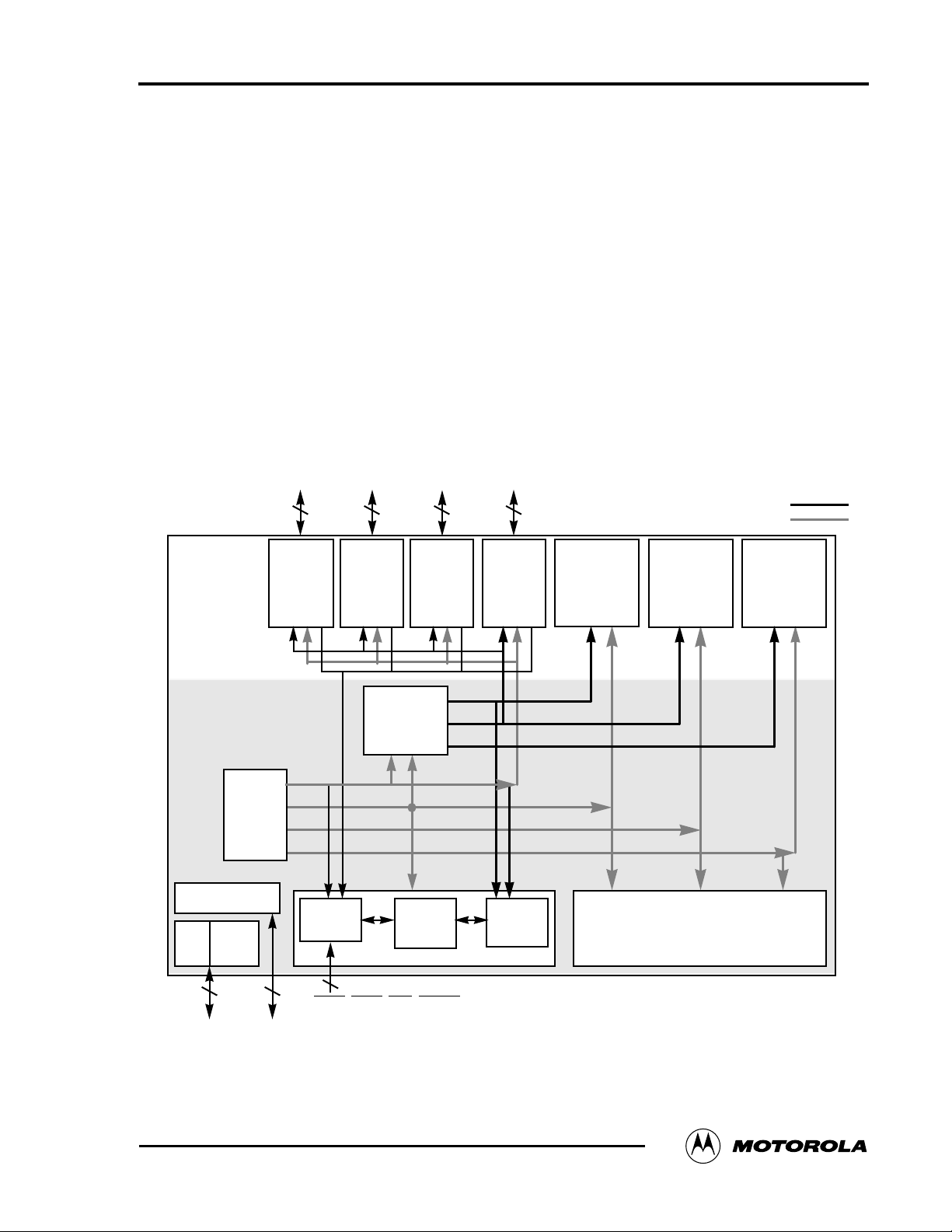

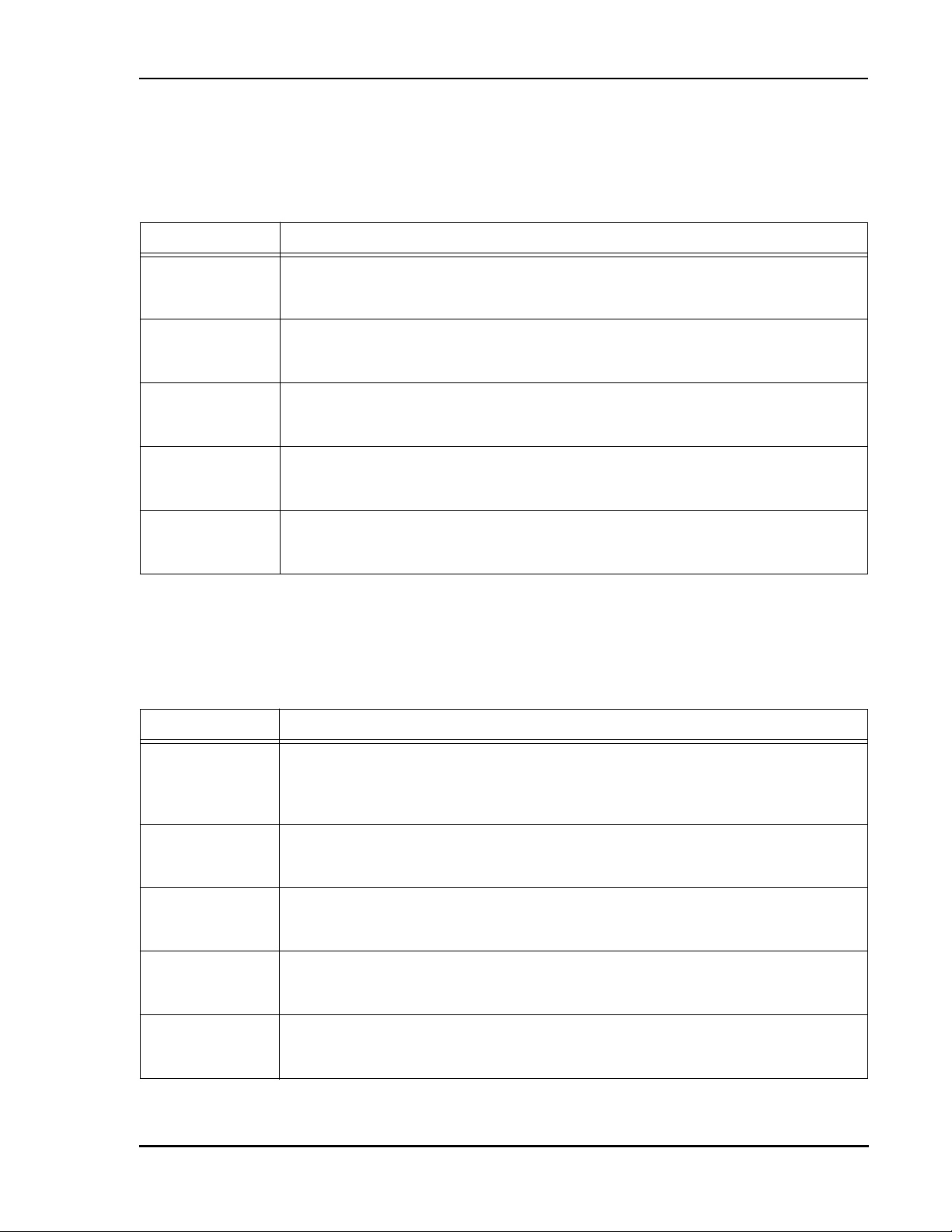

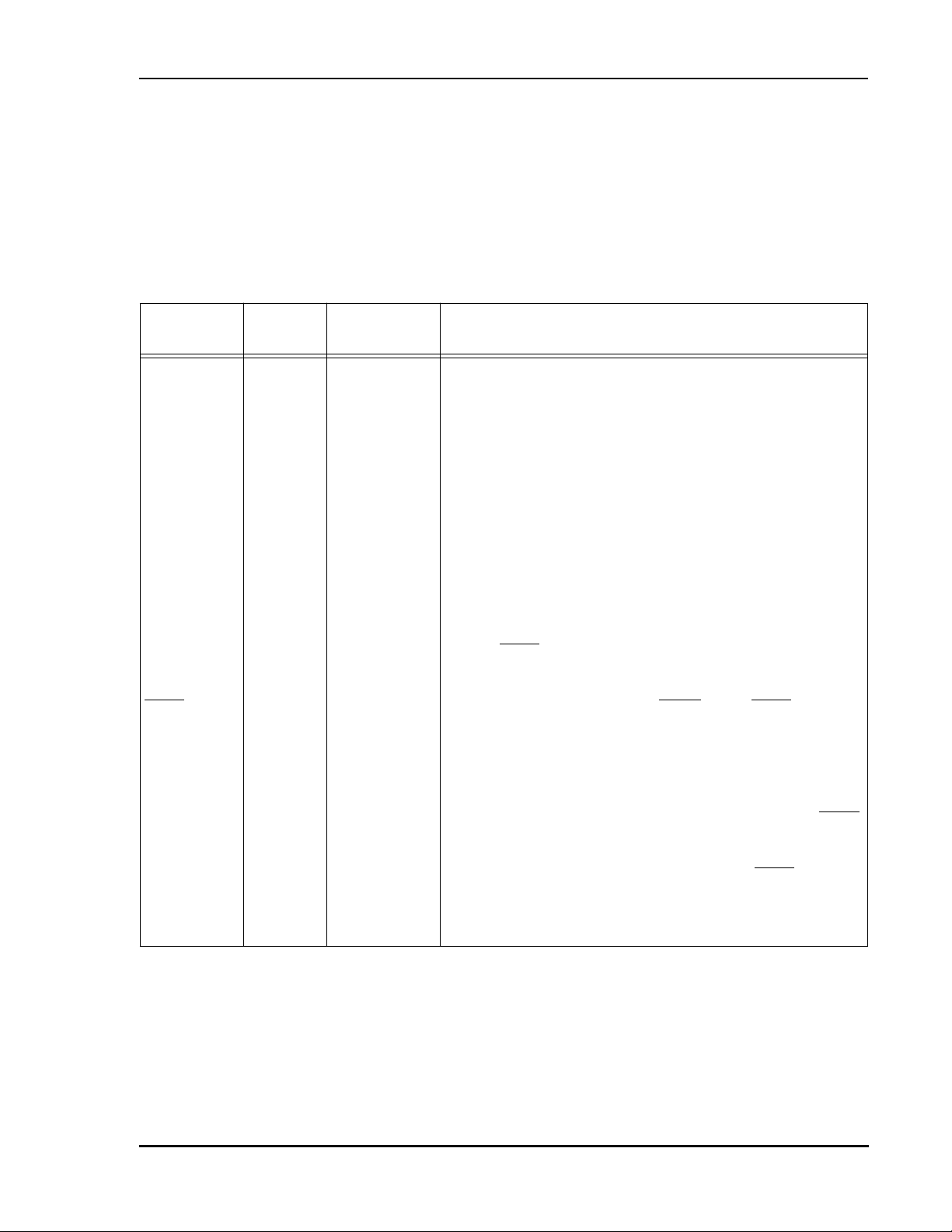

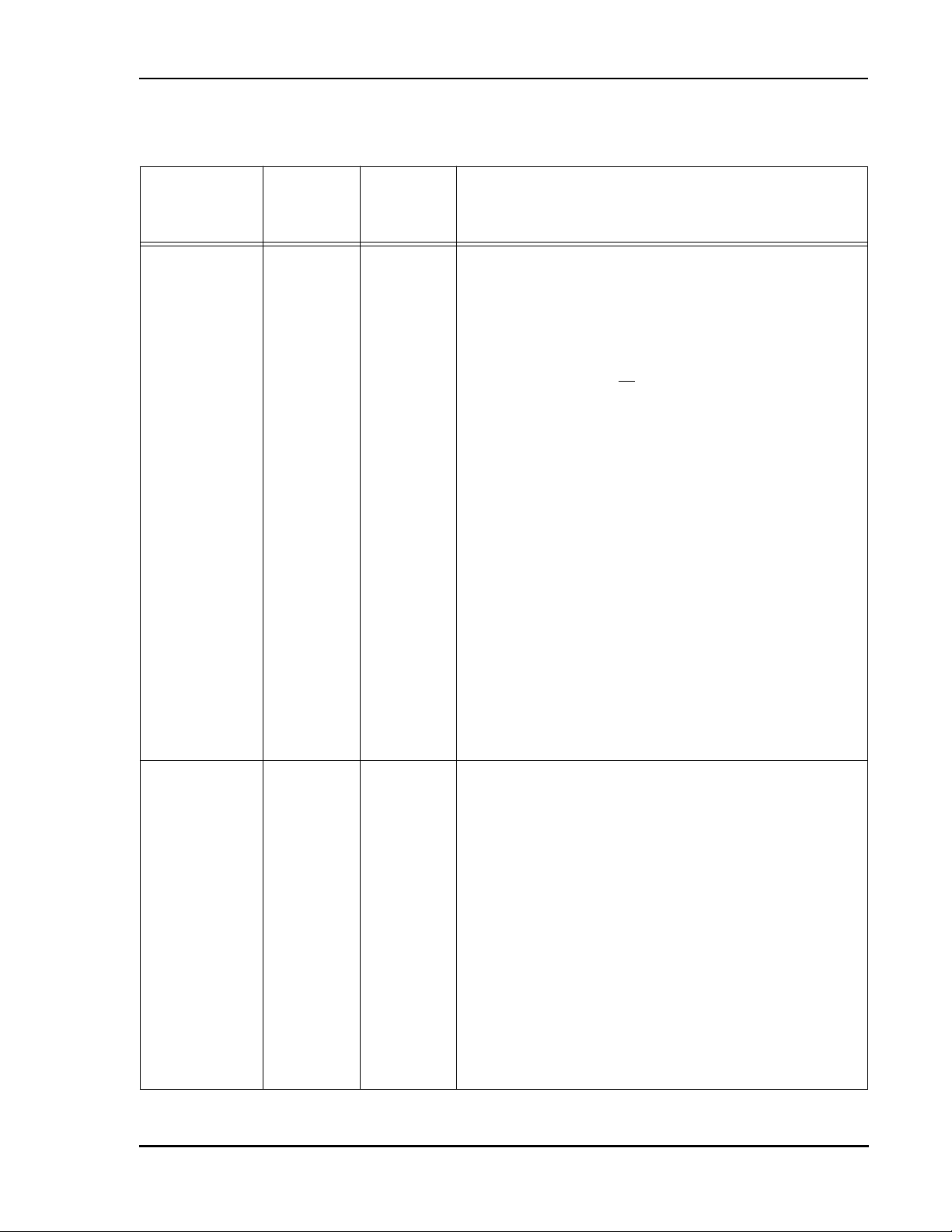

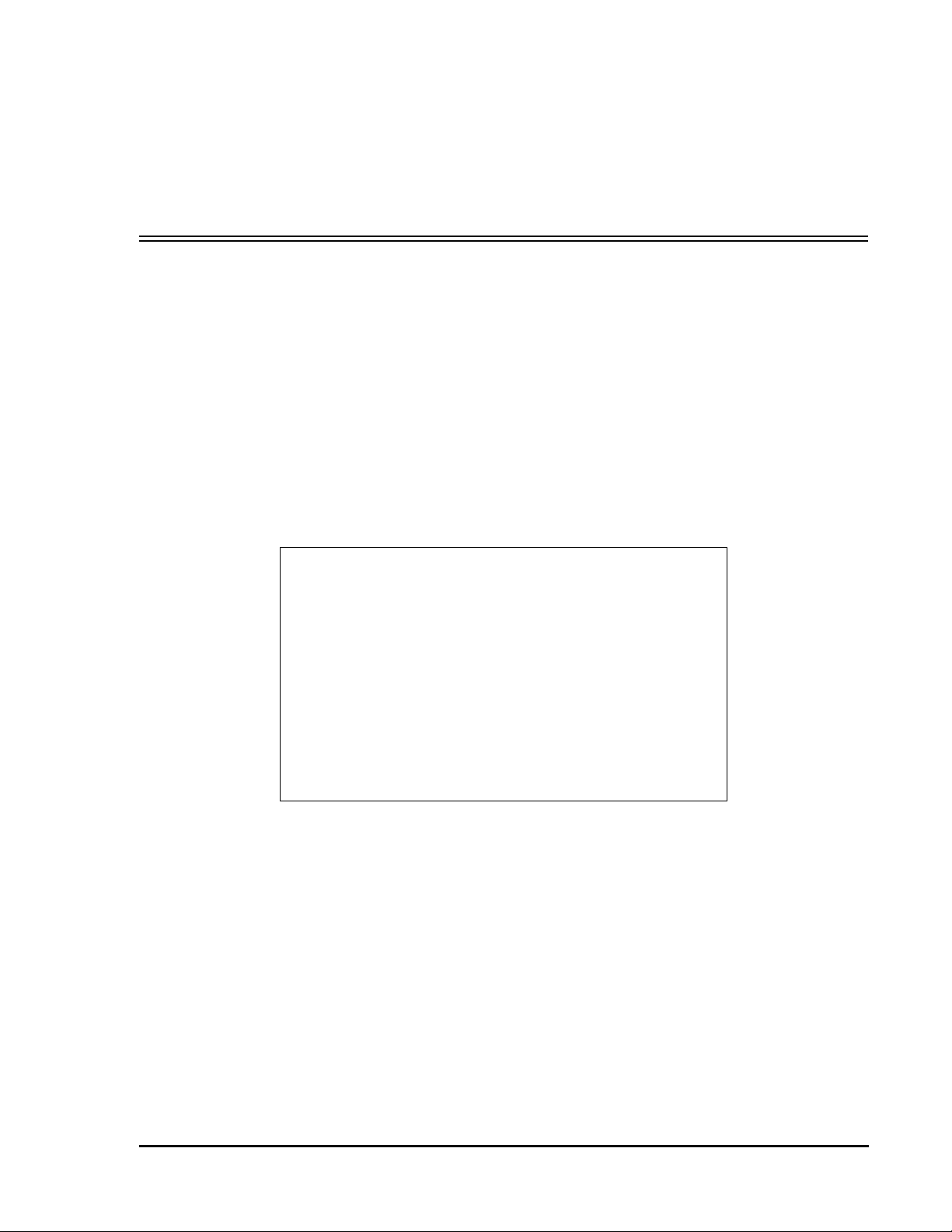

Motorola designed the Symphony family of high-performance, programmable Digital Signal

Processors (DSPs) to support a variety of digital audio applications, including Dolby ProLogic,

ATRAC, and Lucasfilm Home THX processing. Software for these applications is licensed by

Motorola for integration into products like audio/video receivers, televisions, and automotive

sound systems with such user-developed features as digital equalization and sound field

processing. The DSP56007 is an MPU-style general purpose DSP, composed of an efficient 24-bit

Digital Signal Processor core, program and data memories, various peripherals optimized for

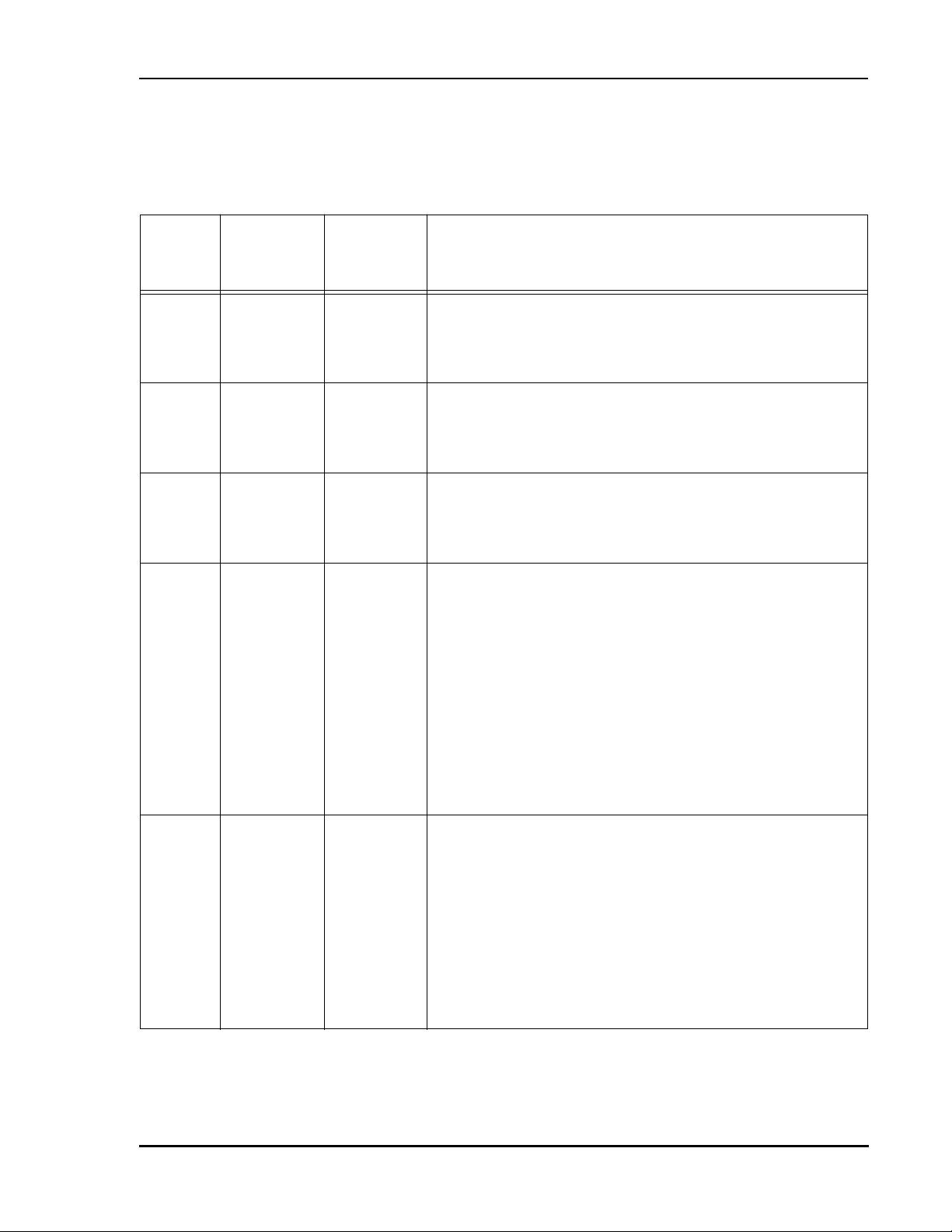

audio, and support circuitry. As illustrated in

DSP is fed by program memory, two independent data RAMs and two data ROMs, a Serial

Audio Interface (SAI), Serial Host Interface (SHI), External Memory Interface (EMI), dedicated

I/O lines, on-chip Phase Lock Loop (PLL), and On-Chip Emulation (OnCE

DSP56007 has significantly more on-chip memory than the DSP56004.

4 9 5 29

General

Purpose

Input/

Output

Serial

Audio

Interface

(SAI)

Serial

Host

Interface

(SHI)

Figure 1 , the DSP56000 core family compatible

) port. The

ˇ

16-Bit Bus

24-Bit Bus

External

Memory

Interface

(EMI)

Program

Memory*

X Data

Memory*

Y Data

Memory*

Program

Address

PAB

XAB

YAB

Data ALU

24 × 24 + 56 → 56-Bit MAC

Two 56-Bit Accumulators

Refer to Table 1 for memory configurations.

*

AA0248

24-Bit

DSP56000

Core

Internal

Switch

OnCETM Port

Clock

PLL

Gen.

Data

Bus

Address

Generation

Interrupt

Control

Program Control Unit

43

4

IRQA, IRQB, NMI, RESET

Unit

Program

Decode

Controller

GDB

PDB

XDB

YDB

Generator

Figure 1 DSP56007 Block Diagram

©1996, 1997 MOTOROLA, INC.

T

TABLE OF CONTENTS

SECTION 1 SIGNAL/CONNECTION DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . .1-1

SECTION 2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

SECTION 3 PACKAGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

SECTION 4 DESIGN CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

SECTION 5 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

FOR TECHNICAL ASSISTANCE:

Telephone: 1-800-521-6274

Email: dsphelp@dsp.sps.mot.com

Internet: http://www.motorola-dsp.com

Data Sheet Conventions

his data sheet uses the following conventions:

OVERBAR Used to indicate a signal that is active when pulled low (For example, the RESET pin is

active when low.)

“asserted” Means that a high true (active high) signal is high or that a low true (active low) signal

is low

“deasserted” Means that a high true (active high) signal is low or that a low true (active low) signal

is high

Examples:

Signal/Symbol Logic State Signal State Voltage

PIN True Asserted VIL/V

PIN False Deasserted VIH/V

PIN True Asserted VIH/V

OL

OH

OH

PIN False Deasserted VIL/V

Note: Values for VIL, VOL, VIH, and VOH are defined by individual product specifications.

OL

ii DSP56007/D MOTOROLA

×

×

FEATURES

Digital Signal Processing Core

• Efficient, object code compatible with the 24-bit DSP56000 core family engine

• Up to 44 Million Instructions Per Second (MIPS)—22.7 ns instruction cycle at

88 MHz

• Highly parallel instruction set with unique DSP addressing modes

• Two 56-bit accumulators including extension byte

DSP56007

Features

Memory

• Parallel 24

• Double precision 48

• 56-bit addition/subtraction in 1 instruction cycle

• Fractional and integer arithmetic with support for multiprecision arithmetic

• Hardware support for block floating-point Fast Fourier Transforms (FFT)

• Hardware nested DO loops

• Zero-overhead fast interrupts (2 instruction cycles)

• Four 24-bit internal data buses and three 16-bit internal address buses for

simultaneous accesses to one program and two data memories

• Fabricated in high-density CMOS

• On-chip modified Harvard architecture, which permits simultaneous accesses

to program and two data memories

• Bootstrap loading from Serial Host Interface or External Memory Interface

24-bit multiply-accumulate in 1 instruction cycle (2 clock cycles)

48-bit multiply with 96-bit result in 6 instruction cycles

Table 1 Memory Configuration (Word width is 24 bits)

Mode Program X Data Y Data

PE ROM RAM ROM RAM ROM RAM

0 6400 None 512 1024 512 2176 52

1 5120 1024 512 1024 512 1152 52

Bootstrap

ROM

MOTOROLA DSP56007/D iii

×

×

×

×

DSP56007

Features

Peripheral and Support Circuits

• Serial Audio Interface (SAI) includes two receivers and three transmitters,

master or slave capability, implementation of I

protocols; and two sets of SAI interrupt vectors

• Serial Host Interface (SHI) features single master capability, 10-word receive

FIFO, and support for 8-, 16-, and 24-bit words

• External Memory Interface (EMI), implemented as a peripheral supporting:

– Page-mode DRAMs (one or two chips): 64 K

and 4 M

– SRAMs (one to four): 256 K

– Data bus may be 4 or 8 bits wide

– Data words may be 8, 12, 16, 20, or 24 bits wide

• Four dedicated, independent, programmable General Purpose Input/Output

(GPIO) lines

• On-chip peripheral registers memory mapped in data memory space

• Three external interrupt request pins

• On-Chip Emulation (OnCE) port for unobtrusive, processor speedindependent debugging

4 bits

8 bits

2

S, Sony, and Matsushita audio

4, 256 K × 4,

• Software-programmable, Phase Lock Loop-based (PLL) frequency synthesizer

for the core clock

• Power-saving Wait and Stop modes

• Fully static, HCMOS design for operating frequencies down to DC

• 80-pin plastic Quad Flat Pack surface-mount package; 14

(2.15–2.45 mm range); 0.65 mm lead pitch

• Complete pinout compatibility between DSP56009, DSP56004,

DSP56004ROM, and DSP56007 for easy upgrades

• 5 V power supply

14 × 2.20 mm

iv DSP56007/D MOTOROLA

Product Documentation

PRODUCT DOCUMENTATION

Table 2 lists the documents that provide a complete description of the DSP56007 and

are required to design properly with the part. Documentation is available from a local

Motorola distributor, a Motorola semiconductor sales office, a Motorola Literature

Distribution Center, or through the Motorola DSP home page on the Internet (the

source for the latest information).

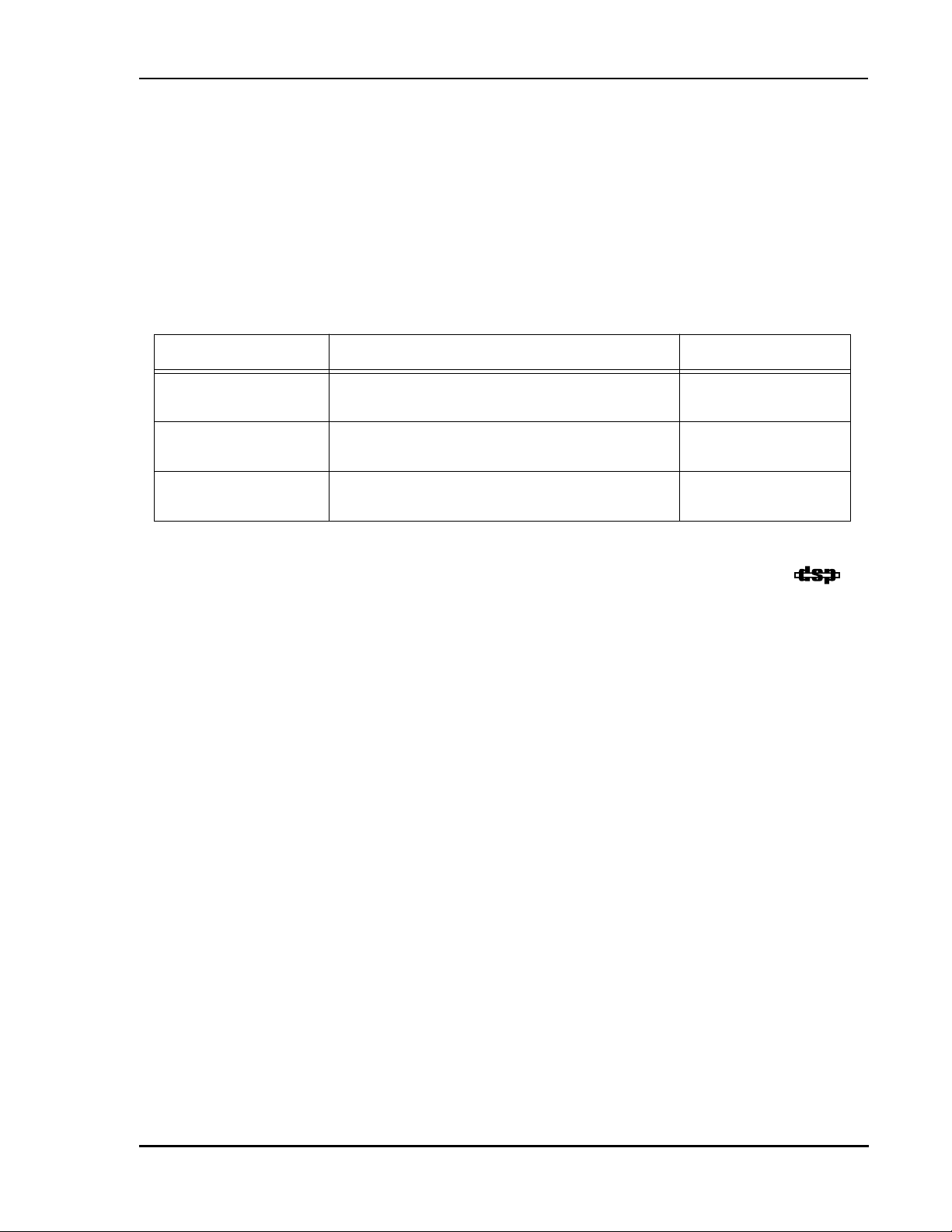

Table 2 DSP56007 Documentation

Document Name Description of Content Order Number

DSP56007

DSP56000 Family

Manual

DSP56007 User’s

Manual

DSP56007 Technical

Data

DSP56000 core family architecture and the 24-bit

core processor and instruction set

Memory, peripherals, and interfaces DSP56007UM/AD

Electrical and timing specifications,

and pin and package descriptions

DSP56KFAMUM/AD

DSP56007/D

MOTOROLA DSP56007/D v

DSP56007

Product Documentation

vi DSP56007/D MOTOROLA

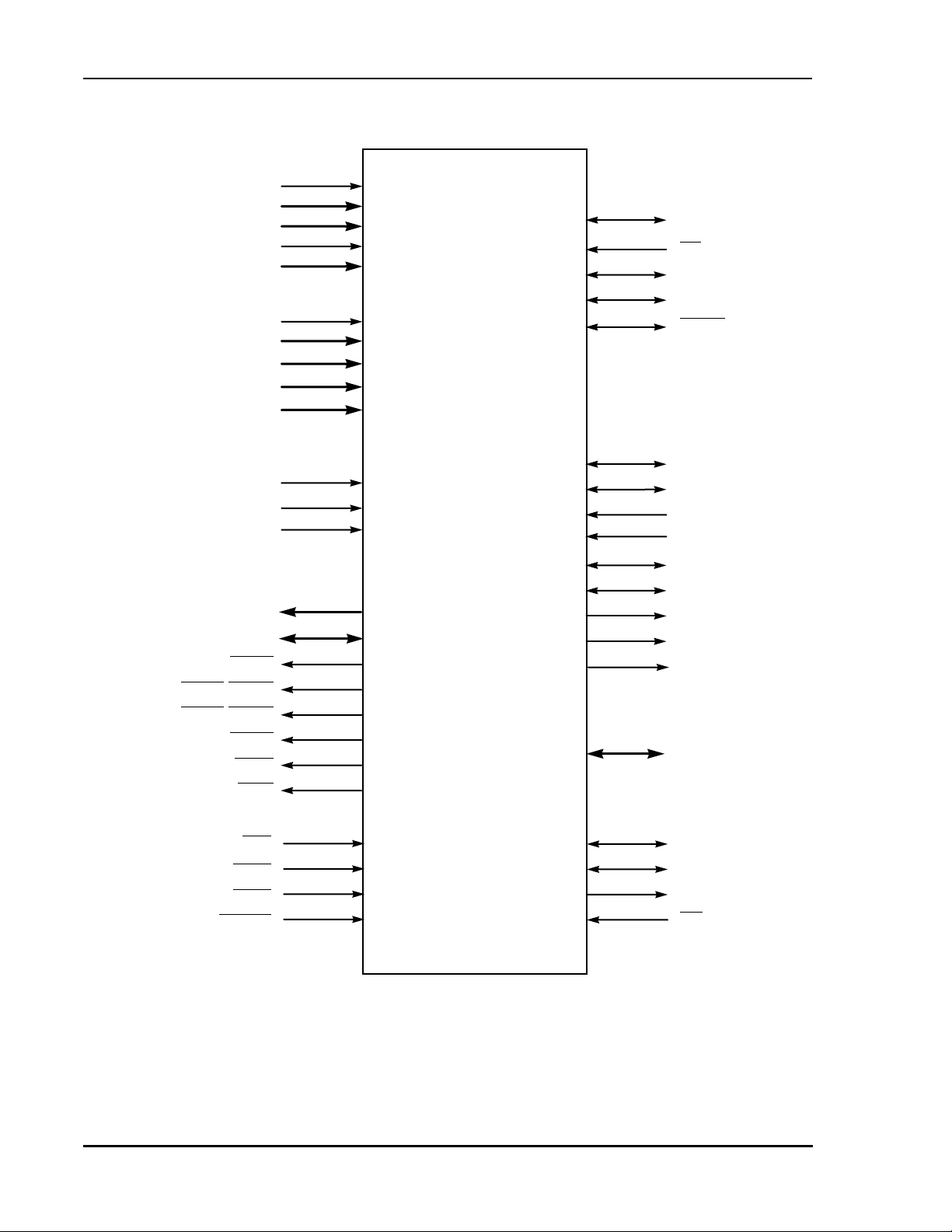

SECTION 1

SIGNAL/CONNECTION DESCRIPTIONS

SIGNAL GROUPINGS

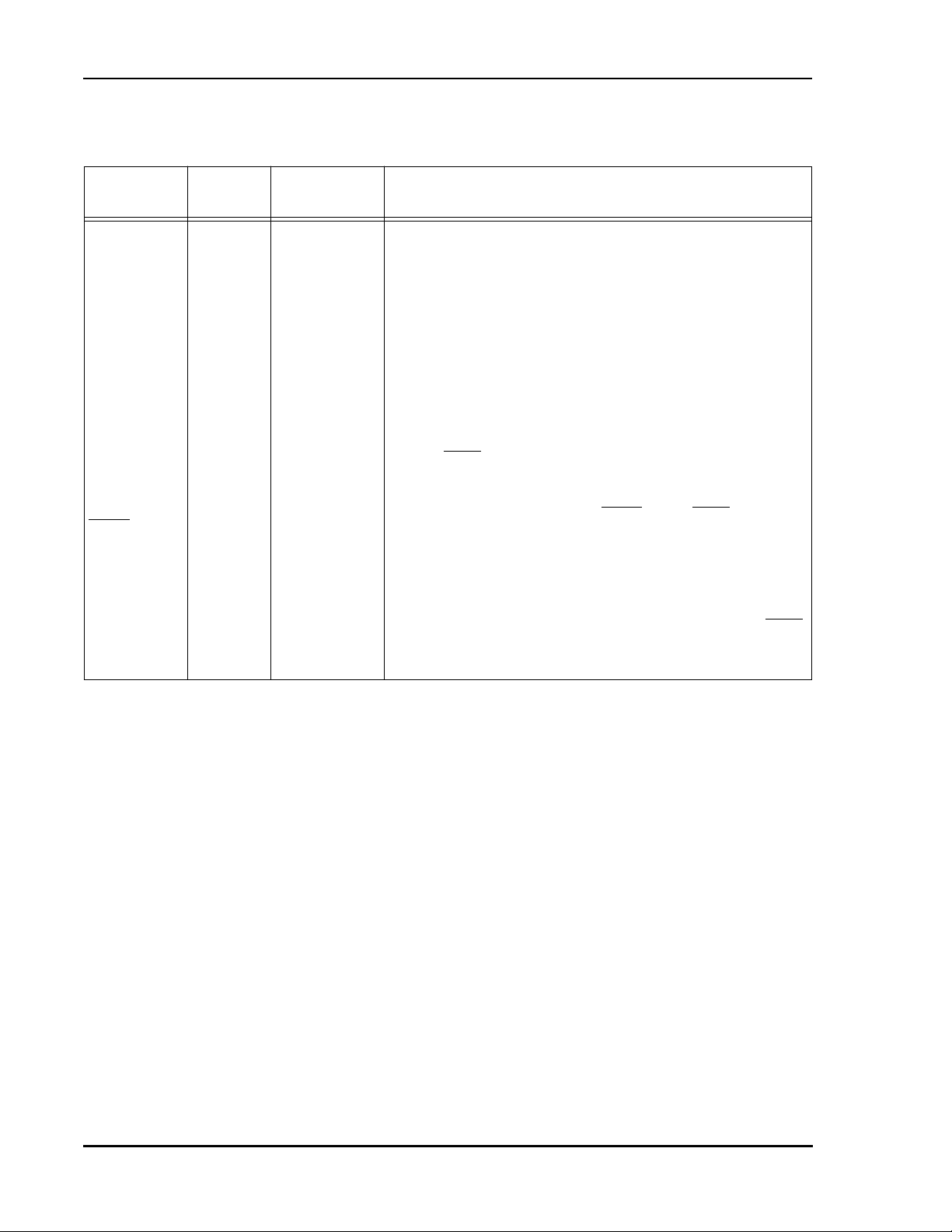

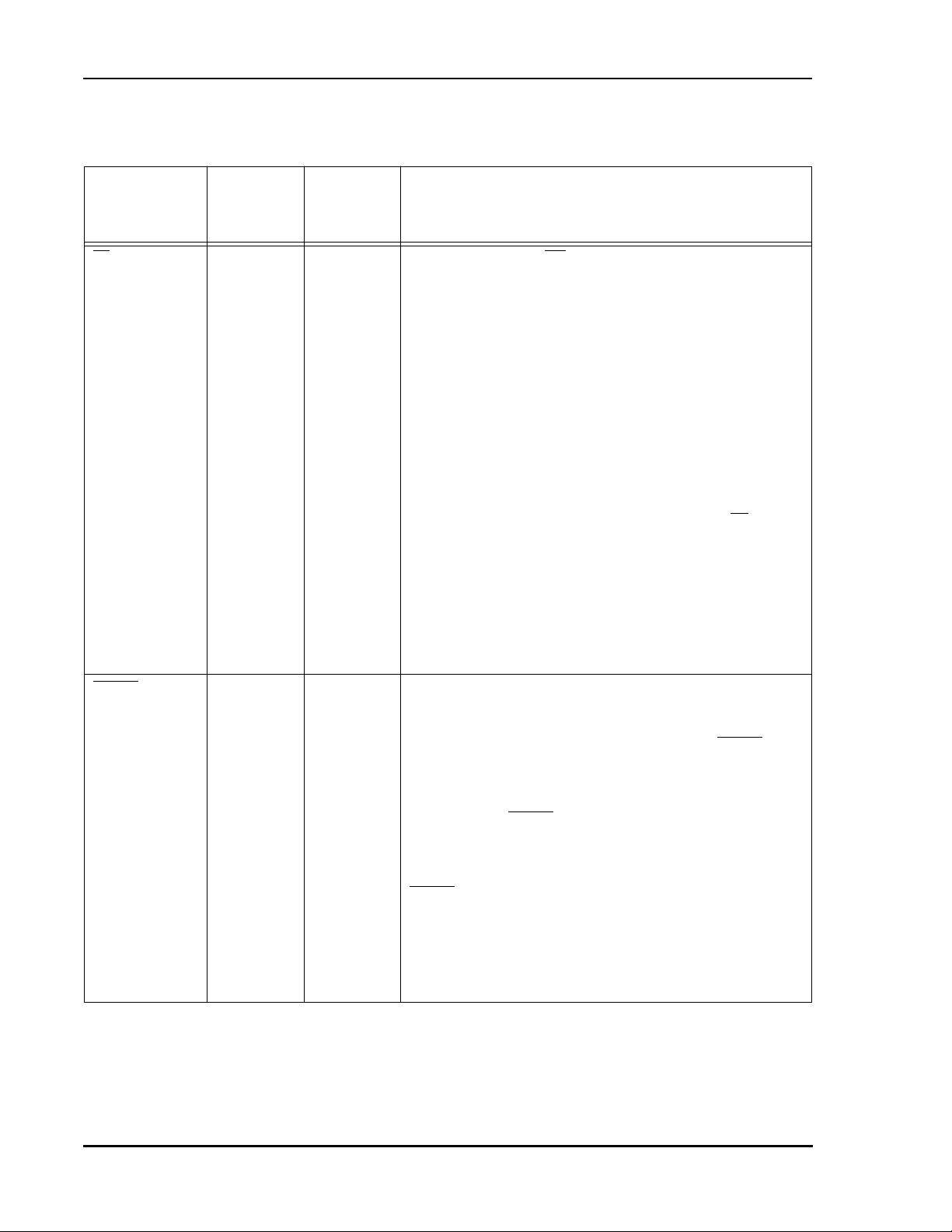

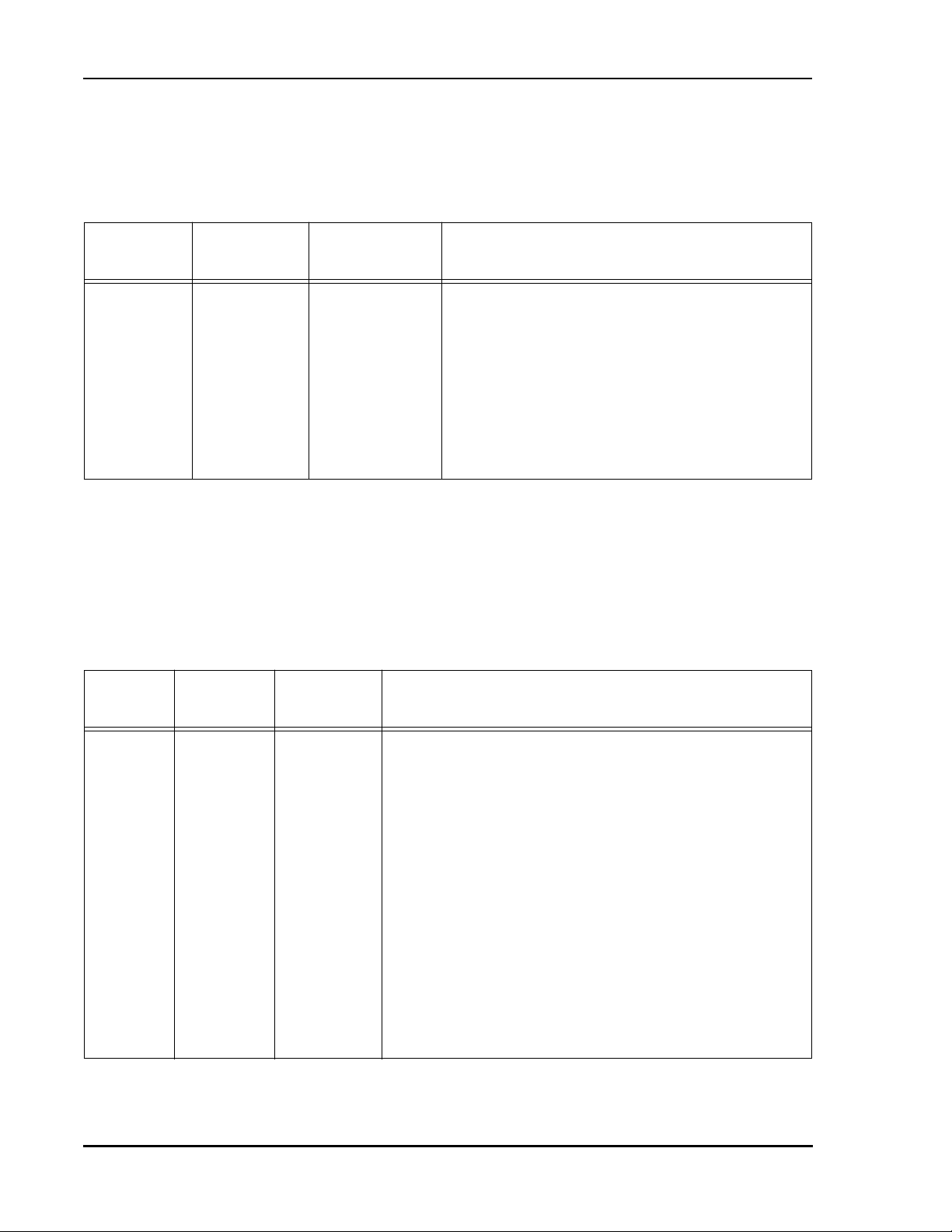

The DSP56007 input and output signals are organized into the nine functional

groups, as shown in

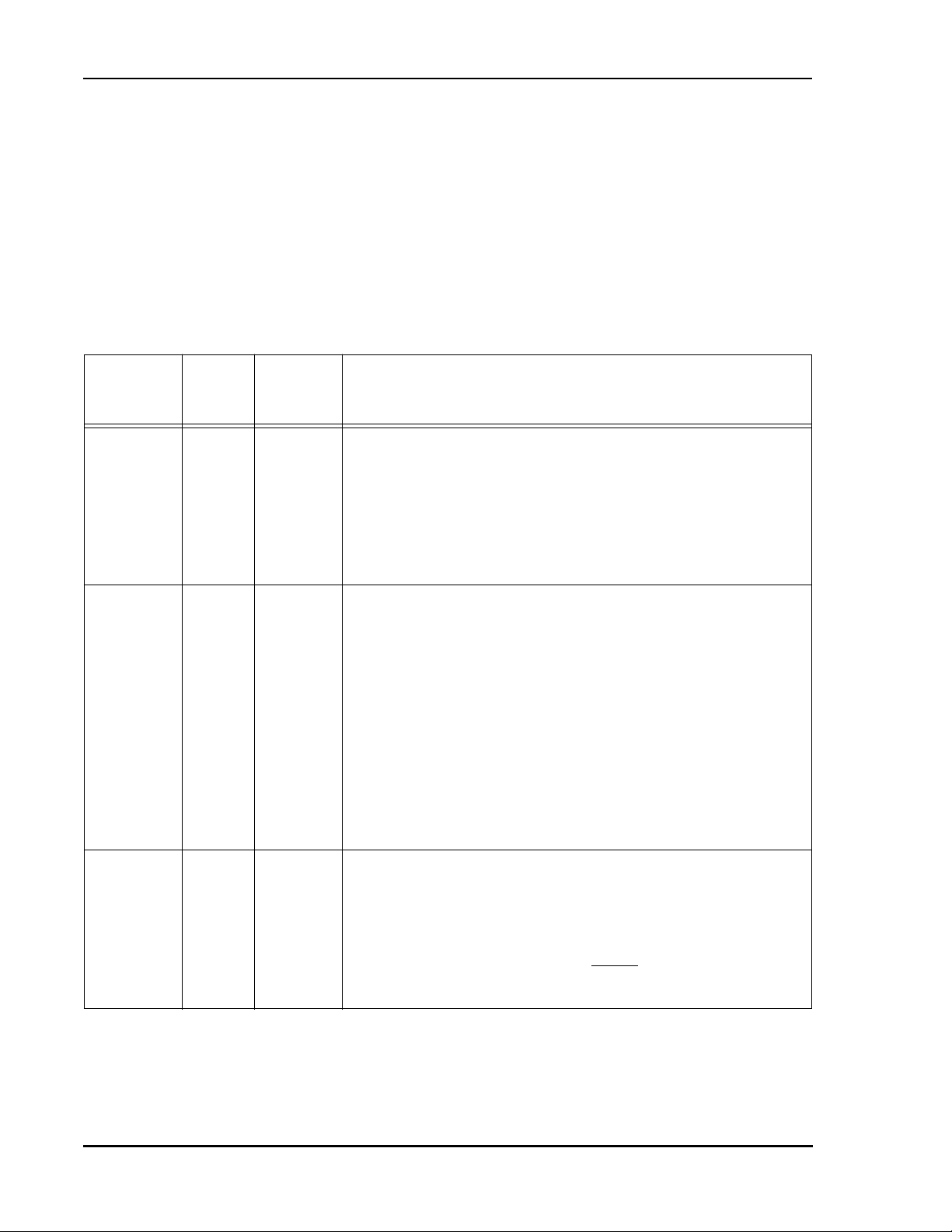

Table 1-1 DSP56007 Functional Group Signal Allocations

Functional Group Number of Signals Detailed Description

Table 1-1 . The individual signals are illustrated in Figure 1-1 .

Power (V

Ground (GND) 13

Phase Lock Loop (PLL) 3

External Memory Interface (EMI) 29

Interrupt and Mode Control 4

Serial Host Interface (SHI) 5

Serial Audio Interface (SAI) 9

General Purpose Input/Output (GPIO) 4

On-Chip Emulation (OnCE) port 4

)9

CC

Total 80

Table 1-2

Table 1-3

Table 1-4

Table 1-5

Table 1-6

Table 1-7

Table 1-8

Table 1-9

Table 1-10

Table 1-11

Table 1-12

and

and

MOTOROLA DSP56007/D 1-1

Signal/Connection Descriptions

Signal Groupings

Power Inputs

V

CCP

V

CCQ

V

CCA

V

CCD

V

CCS

Ground

GND

GND

GND

GND

GND

PCAP

PINIT

EXTAL

MA0–MA14

MD0–MD7

MA15/MCS3

MA16/MCS2/MCAS

MA17/MCS1/MRAS

MCS0

MWR

MRD

DSP56007

3

2

2

Port B

Serial Host

Interface

P

3

Q

4

A

2

D

3

S

Port C

MOSI/HA0

SS/HA2

MISO/SDA

SCK/SCL

HREQ

Serial Audio

Interface

WSR

SCKR

PLL

Rec0

Rec1

SDI0

SDI1

WST

15

8

Tran0

Tran1

Tran2

SCKT

SDO0

SDO1

SDO2

Port A

External Memory

Interface

GPIO

4

GPIO0–GPIO3

MODC/NMI

MODB/IRQB

MODA/IRQA

RESET

Mode/Interrupt

Control

Reset

80 signals

OnCE™

Port

DSCK/OS1

DSI/OS0

DSO

DR

AA0249G

Figure 1-1 DSP56007 SIgnals

1-2 DSP56007/D MOTOROLA

POWER

Table 1-2 Power Inputs

Power Name Description

Signal/Connection Descriptions

Power

V

CCP

V

CCQ

V

CCA

V

CCD

V

CCS

GROUND

PLL Power —V

provides isolated power for the Phase Lock Loop (PLL). The

CCP

voltage should be well-regulated and the input should be provided with an

extremely low impedance path to the V

Quiet Power —V

provides isolated power for the internal processing logic. This

CCQ

power rail.

CC

input must be tied externally to all other chip power inputs. The user must provide

adequate external decoupling capacitors.

Address Bus Power —V

provides isolated power for sections of the address bus

CCA

I/O drivers. This input must be tied externally to all other chip power inputs. The

user must provide adequate external decoupling capacitors.

Data Bus Power —V

provides isolated power for sections of the data bus I/O

CCD

drivers. This input must be tied externally to all other chip power inputs. The user

must provide adequate external decoupling capacitors.

Serial Interface Power—V

provides isolated power for the SHI and SAI. This

CCS

input must be tied externally to all other chip power inputs. The user must provide

adequate external decoupling capacitors.

Table 1-3 Grounds

Ground Name Description

GND

P

PLL Ground—GNDP is ground dedicated for PLL use. The connection should be

provided with an extremely low-impedance path to ground. V

should be

CCP

bypassed to GNDP by a 0.47 µF capacitor located as close as possible to the chip

package.

GND

Q

Quiet Ground—GNDQ provides isolated ground for the internal processing logic.

This connection must be tied externally to all other chip ground connections. The

user must provide adequate external decoupling capacitors.

GND

A

Address Bus Ground—GNDA provides isolated ground for sections of the address

bus I/O drivers. This connection must be tied externally to all other chip ground

connections. The user must provide adequate external decoupling capacitors.

GND

D

Data Bus Ground—GNDD provides isolated ground for sections of the data bus I/O

drivers. This connection must be tied externally to all other chip ground

connections. The user must provide adequate external decoupling capacitors.

GND

S

Serial Interface Ground—GNDS provides isolated ground for the SHI and SAI. This

connection must be tied externally to all other chip ground connections. The user

must provide adequate external decoupling capacitors.

MOTOROLA DSP56007/D 1-3

Signal/Connection Descriptions

Clock and PLL signals

CLOCK AND PLL SIGNALS

Note: While the PLL on this DSP is identical to the PLL described in the

Family Manual

, two of the signals have not been implemented externally.

DSP56000

Specifically, there is no PLOCK signal or CKOUT signal available. Therefore,

the internal clock is not directly accessible and there is no external indication

that the PLL is locked. These signals were omitted to reduce the number of

pins and allow this DSP to be put in a smaller, less expensive package.

Table 1-4 Clock and PLL Signals

Signal

Name

EXTAL Input Input External Clock/Crystal—This input should be connected to an

PCAP Input Input PLL Filter Capacitor—This input is used to connect a high-

Signal

Type

State

during

Reset

Signal Description

external clock source. If the PLL is enabled, this signal is

internally connected to the on-chip PLL. The PLL can multiply

the frequency on the EXTAL pin to generate the internal DSP

clock. The PLL output is divided by two to produce a four-phase

instruction cycle clock, with the minimum instruction time being

two PLL output clock periods. If the PLL is disabled, EXTAL is

divided by two to produce the four-phase instruction cycle clock.

quality (high “Q” factor) external capacitor needed for the PLL

filter. The capacitor should be as close as possible to the DSP with

heavy, short traces connecting one terminal of the capacitor to

PCAP and the other terminal to V

value is specified in Table 2-6 on page 2-6.

. The required capacitor

CCP

Note: When short lock time is critical, low dielectric absorption

capacitors such as polystyrene, polypropylene, or teflon are

recommended.

If the PLL is not used (i.e., it remains disabled at all times), there is

no need to connect a capacitor to the PCAP pin. It may remain

unconnected, or be tied to either Vcc or GND.

PINIT Input Input PLL Initialization (PINIT)—During the assertion of hardware

reset, the value on the PINIT line is written into the PEN bit of the

PCTL register. When set, the PEN bit enables the PLL by causing

it to derive the internal clocks from the PLL voltage controlled

oscillator output. When the bit is cleared, the PLL is disabled and

the DSP’s internal clocks are derived from the clock connected to

the EXTAL signal. After hardware RESET is deasserted, the

PINIT signal is ignored.

1-4 DSP56007/D MOTOROLA

EXTERNAL MEMORY INTERFACE (EMI)

Table 1-5 External Memory Interface (EMI) Signals

Signal/Connection Descriptions

External Memory Interface (EMI)

Signal Name

MA0–MA14 Output Table 1-6 Memory Address Lines 0–14—The MA0–MA10 lines provide

MA15

MCS3

MA16

MCS2

MCAS

MA17

Signal

Type

Output Table 1-6 Memory Address Line 15 (MA15)—This line functions as the

Output Table 1-6 Memory Address Line 16 (MA16)—This line functions as the

Output Table 1-6 Memory Address Line 17 (MA17)—This line functions as the

State during

Reset

Signal Description

the multiplexed row/column addresses for DRAM accesses.

Lines MA0–MA14 provide the non-multiplexed address lines

0–14 for SRAM accesses.

non-multiplexed address line 15.

Memory Chip Select 3 (MCS3)—For SRAM accesses, this line

functions as memory chip select 3.

non-multiplexed address line 16 or as memory chip select 2 for

SRAM accesses.

Memory Chip Select 2 (MCS2)—For SRAM access, this line

functions as memory chip select 2.

Memory Column Address Strobe (MCAS)—This line

functions as the Memory Column Address Strobe (MCAS)

during DRAM accesses.

non-multiplexed address line 17.

MCS1

MRAS

MCS0 Output Table 1-6 Memory Chip Select 0—This line functions as memory chip

MWR Output Table 1-6 Memory Write Strobe—This line is asserted when writing to

MRD Output Table 1-6 Memory Read Strobe—This line is asserted when reading

Memory Chip Select 1 (MCS1)—This line functions as chip

select 1 for SRAM accesses.

Memory Row Address Strobe (MRAS)—This line also

functions as the Memory Row Address Strobe during DRAM

accesses.

select 0 for SRAM accesses.

external memory.

external memory.

MOTOROLA DSP56007/D 1-5

Signal/Connection Descriptions

External Memory Interface (EMI)

Table 1-5 External Memory Interface (EMI) Signals (Continued)

Signal Name

Signal

Type

MD0–MD7 Bidi-

rectional

State during

Reset

Signal Description

Tri-stated Data Bus—These signals provide the bidirectional data bus for

EMI accesses. They are inputs during reads from external

memory, outputs during writes to external memory, and tristated if no external access is taking place. If the data bus width

is defined as four bits wide, only signals MD0–MD3 are active,

while signals MD4–MD7 remain tri-stated. While tri-stated,

MD0–MD7 are disconnected from the pins and do not require

external pull-ups.

.

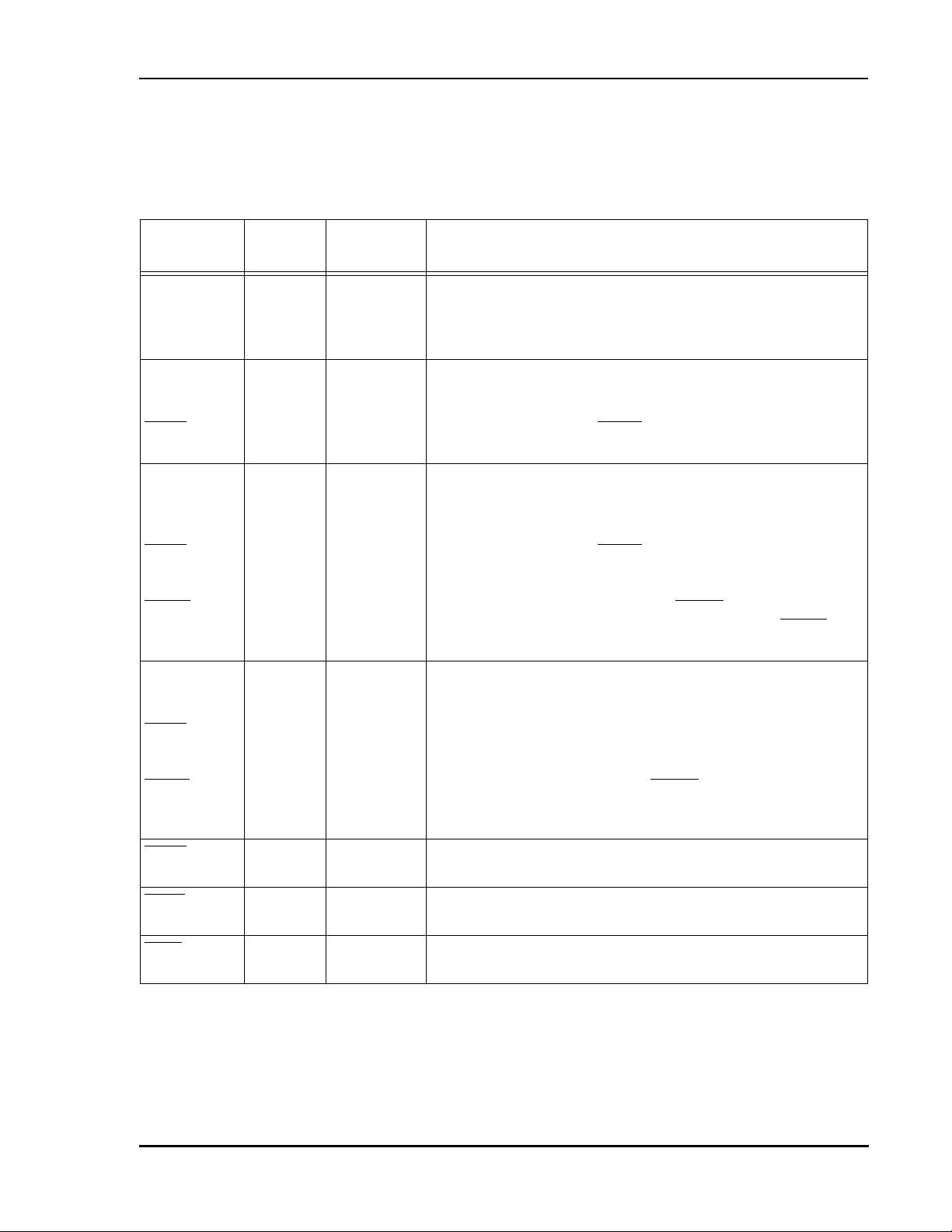

Table 1-6 EMI States during Reset and Stop States

Operating Mode

Signal

Hardware Reset Software Reset Individual Reset Stop Mode

MA0–MA14 Driven High Previous State Previous State Previous State

MA15

MCS3

MA16

Driven High

Driven High

Driven High

Driven High

Driven High

Driven High

Previous State

Driven High

Previous State

Previous State

Driven High

Previous State

MCS2

Driven High

Driven High

Driven High

Driven High

MCAS:

DRAM refresh disabled

DRAM refresh enabled

MA17

MCS1

Driven High

Driven High

Driven High

Driven High

Driven High

Driven High

Driven High

Driven High

Driven High

Driven Low

Previous State

Driven High

Driven High

Driven High

Previous State

Driven High

MRAS:

DRAM refresh disabled

DRAM refresh enabled

Driven High

Driven High

Driven High

Driven High

Driven High

Driven Low

Driven High

Driven High

MCS0 Driven High Driven High Driven High Driven High

MWR Driven High Driven High Driven High Driven High

MRD Driven High Driven High Driven High Driven High

1-6 DSP56007/D MOTOROLA

INTERRUPT AND MODE CONTROL

The interrupt and mode control signals select the DSP’s operating mode as it comes

out of hardware reset and receives interrupt requests from external sources after

reset.

Table 1-7 Interrupt and Mode Control Signals

Signal/Connection Descriptions

Interrupt and Mode Control

Signal Name

MODA

IRQA

Signal

Type

Input Input (MODA) Mode Select A—This input signal has three functions:

State during

Reset

Signal Description

• to work with the MODB and MODC signals to select

the DSP’s initial operating mode,

• to allow an external device to request a DSP

interrupt after internal synchronization, and

• to turn on the internal clock generator when the DSP

is in the Stop processing state, causing the DSP to

resume processing.

MODA is read and internally latched in the DSP when the

processor exits the Reset state. The logic state present on the

MODA, MODB, and MODC pins selects the initial DSP

operating mode. Several clock cycles after leaving the Reset

state, the MODA signal changes to the external interrupt

request IRQA. The DSP operating mode can be changed by

software after reset.

External Interrupt Request A (IRQA)—The IRQA input is a

synchronized external interrupt request. It may be

programmed to be level-sensitive or negative-edgetriggered. When the signal is edge-triggered, triggering

occurs at a voltage level and is not directly related to the fall

time of the interrupt signal. However, as the fall time of the

interrupt signal increases, the probability that noise on IRQA

will generate multiple interrupts also increases.

While the DSP is in the Stop mode, asserting IRQA gates on

the oscillator and, after a clock stabilization delay, enables

clocks to the processor and peripherals. Hardware reset

causes this input to function as MODA.

MOTOROLA DSP56007/D 1-7

Signal/Connection Descriptions

Interrupt and Mode Control

Table 1-7 Interrupt and Mode Control Signals (Continued)

Signal Name

MODB

IRQB

Signal

Type

Input Input (MODB) Mode Select B—This input signal has two functions:

State during

Reset

Signal Description

• to work with the MODA and MODC signals to select

the DSP’s initial operating mode, and

• to allow an external device to request a DSP

interrupt after internal synchronization.

MODB is read and internally latched in the DSP when the

processor exits the Reset state. The logic state present on the

MODA, MODB, and MODC pins selects the initial DSP

operating mode. Several clock cycles after leaving the Reset

state, the MODB signal changes to the external interrupt

request IRQB

software after reset.

External Interrupt Request B (IRQB)—The IRQB input is a

synchronized external interrupt request. It may be

programmed to be level-sensitive or negative-edgetriggered. When the signal is edge-triggered, triggering

occurs at a voltage level and is not directly related to the fall

time of the interrupt signal. However, as the fall time of the

interrupt signal increases, the probability that noise on IRQB

will generate multiple interrupts also increases. Hardware

reset causes this input to function as MODB.

. The DSP operating mode can be changed by

1-8 DSP56007/D MOTOROLA

Signal/Connection Descriptions

Interrupt and Mode Control

Table 1-7 Interrupt and Mode Control Signals (Continued)

Signal Name

MODC

NMI

Signal

Type

Input,

edge-

triggered

State during

Reset

Input (MODC) Mode Select C—This input signal has two functions:

• to work with the MODA and MODB signals to select

the DSP’s initial operating mode, and

• to allow an external device to request a DSP

interrupt after internal synchronization.

MODC is read and internally latched in the DSP when the

processor exits the Reset state. The logic state present on the

MODA, MODB, and MODC pins selects the initial DSP

operating mode. Several clock cycles after leaving the Reset

state, the MODC signal changes to the Non-Maskable

Interrupt request, NMI

changed by software after reset.

Non-Maskable Interrupt Request—The NMI input is a

negative-edge-triggered external interrupt request. This is a

level 3 interrupt that can not be masked out. Triggering

occurs at a voltage level and is not directly related to the fall

time of the interrupt signal. However, as the fall time of the

interrupt signal increases, the probability that noise on NMI

will generate multiple interrupts also increases. Hardware

reset causes this input to function as MODC.

Signal Description

. The DSP operating mode can be

RESET input active RESET—This input causes a direct hardware reset of the

processor. When RESET is asserted, the DSP is initialized and

placed in the Reset state. A Schmitt-trigger input is used for

noise immunity. When the reset signal is deasserted, the initial

DSP operating mode is latched from the MODA, MODB, and

MODC signals. The DSP also samples the PINIT signal and

writes its status into the PEN bit of the PLL Control Register.

When the DSP comes out of the Reset state, deassertion

occurs at a voltage level and is not directly related to the rise

time of the RESET signal. However, the probability that

noise on RESET will generate multiple resets increases with

increasing rise time of the RESET signal.

For proper hardware reset to occur, the clock must be active,

since a number of clock ticks are required for proper

propagation of the hardware Reset state.

MOTOROLA DSP56007/D 1-9

Signal/Connection Descriptions

Serial Host Interface (SHI)

SERIAL HOST INTERFACE (SHI)

Signal Name

SCK

SCL

The Serial Host Interface (SHI) has five I/O signals, which may be configured to

2

operate in either SPI or I

C mode. Table 1-8 lists the SHI signals.

Table 1-8 Serial Host Interface (SHI) signals

Signal

Type

Input or

Output

Input or

Output

State

during

Reset

Tri-stated SPI Serial Clock (SCK)—The SCK signal is an output

when the SPI is configured as a master, and a Schmitttrigger input when the SPI is configured as a slave. When

the SPI is configured as a master, the SCK signal is

derived from the internal SHI clock generator. When the

SPI is configured as a slave, the SCK signal is an input,

and the clock signal from the external master

synchronizes the data transfer. The SCK signal is ignored

by the SPI if it is defined as a slave and the Slave Select

(SS) signal is not asserted. In both the master and slave

SPI devices, data is shifted on one edge of the SCK signal

and is sampled on the opposite edge where data is stable.

Edge polarity is determined by the SPI transfer protocol.

I2C Serial Clock (SCL)—SCL carries the clock for bus

transactions in the I2C mode. SCL is a Schmitt-trigger

input when configured as a slave, and an open-drain

output when configured as a master. SCL should be

connected to VCC through a pull-up resistor. The

maximum allowed internally generated bit clock

frequency is

I2C mode where F

maximum allowed externally generated bit clock

frequency is

I2C mode. This signal is tri-stated during hardware reset,

software reset, or individual reset (no need for external

pull-up in this state).

Signal Description

Fosc

/4 for the SPI mode and

is the clock on EXTAL. The

osc

Fosc

/3 for the SPI mode and

Fosc

/6 for the

Fosc

/5 for the

1-10 DSP56007/D MOTOROLA

Signal/Connection Descriptions

Serial Host Interface (SHI)

Table 1-8 Serial Host Interface (SHI) signals (Continued)

Signal Name

MISO

SDA

Signal

Type

Input or

Output

Input or

Output

State

during

Signal Description

Reset

Tri-stated SPI Master-In-Slave-Out (MISO)—When the SPI is

configured as a master, MISO is the master data input

line. The MISO signal is used in conjunction with the

MOSI signal for transmitting and receiving serial data.

This signal is a Schmitt-trigger input when configured

for the SPI Master mode, an output when configured for

the SPI Slave mode, and tri-stated if configured for the

SPI Slave mode when SS

is deasserted.

I2C Serial Data and Acknowledge (SDA)—In I2C mode,

SDA is a Schmitt-trigger input when receiving and an

open-drain output when transmitting. SDA should be

connected to VCC through a pull-up resistor. SDA carries

the data for I2C transactions. The data in SDA must be

stable during the high period of SCL. The data in SDA is

only allowed to change when SCL is low. When the bus

is free, SDA is high. The SDA line is only allowed to

change during the time SCL is high in the case of Start

and Stop events. A high-to-low transition of the SDA line

while SCL is high is an unique situation, and is defined

as the Start event. A low-to-high transition of SDA while

SCL is high is an unique situation, and is defined as the

Stop event.

MOSI

HA0

Input or

Output

Input

Note: This line is tri-stated during hardware reset, software

reset, or individual reset (no need for external pull-up

in this state).

Tri-stated SPI Master-Out-Slave-In (MOSI)—When the SPI is

configured as a master, MOSI is the master data output

line. The MOSI signal is used in conjunction with the

MISO signal for transmitting and receiving serial data.

MOSI is the slave data input line when the SPI is

configured as a slave. This signal is a Schmitt-trigger

input when configured for the SPI Slave mode.

I2C Slave Address 0 (HA0)—This signal uses a Schmitttrigger input when configured for the I2C mode. When

configured for I2C Slave mode, the HA0 signal is used to

form the slave device address. HA0 is ignored when the

SHI is configured for the I2C Master mode.

Note: This signal is tri-stated during hardware reset,

software reset, or individual reset (no need for

external pull-up in this state).

MOTOROLA DSP56007/D 1-11

Signal/Connection Descriptions

Serial Host Interface (SHI)

Table 1-8 Serial Host Interface (SHI) signals (Continued)

Signal Name

SS

HA2

Signal

Type

Input

Input

State

during

Reset

Tri-stated

Signal Description

SPI Slave Select (SS)—This signal is an active low

Schmitt-trigger input when configured for the SPI

mode. When configured for the SPI Slave mode, this

signal is used to enable the SPI slave for transfer.

When configured for the SPI Master mode, this

signal should be kept deasserted. If it is asserted

while configured as SPI master, a bus error

condition will be flagged.

2

C Slave Address 2 (HA2)—This signal uses a

I

Schmitt-trigger input when configured for the I

2

mode. When configured for the I

C Slave mode, the

2

C

HA2 signal is used to form the slave device address.

2

HA2 is ignored in the I

C Master mode. If SS is

deasserted, the SHI ignores SCK clocks and keeps

the MISO output signal in the high-impedance

state.

Note: This signal is tri-stated during hardware reset,

software reset, or individual reset (no need for

external pull-up in this state).

HREQ Input or

Output

Tri-stated Host Request—This signal is an active low Schmitt-

trigger input when configured for the Master mode, but

an active low output when configured for the Slave

mode. When configured for the Slave mode, HREQ is

asserted to indicate that the SHI is ready for the next data

word transfer and deasserted at the first clock pulse of

the new data word transfer. When configured for the

Master mode, HREQ is an input and when asserted by

the external slave device, it will trigger the start of the

data word transfer by the master. After finishing the data

word transfer, the master will await the next assertion of

HREQ to proceed to the next transfer.

Note: This signal is tri-stated during hardware, software,

individual reset, or when the HREQ[1:0] bits (in the

HCSR) are cleared (no need for external pull-up in this

state).

1-12 DSP56007/D MOTOROLA

SERIAL AUDIO INTERFACE (SAI)

The SAI is composed of separate receiver and transmitter sections.

SAI Receiver Section

Table 1-9 Serial Audio Interface (SAI) Receiver signals

Signal/Connection Descriptions

Serial Audio Interface (SAI)

Signal

Name

SDI0 Input Tri-stated Serial Data Input 0—While in the high impedance

SDI1 Input Tri-stated Serial Data Input 1—While in the high impedance

SCKR Input or

Signal

Type

Output

State during

Reset

state, the internal input buffer is disconnected from

the pin and no external pull-up is necessary. SDI0 is

the serial data input for receiver 0.

Note: This signal is high impedance during hardware or

software reset, while receiver 0 is disabled

(R0EN = 0), or while the DSP is in the Stop state.

state, the internal input buffer is disconnected from

the pin and no external pull-up is necessary. SDI1 is

the serial data input for receiver 1.

Note: This signal is high impedance during hardware or

software reset, while receiver 1 is disabled

(R1EN = 0), or while the DSP is in the Stop state.

Tri-stated Receive Serial Clock—SCKR is an output if the

receiver section is programmed as a master, and a

Schmitt-trigger input if programmed as a slave. While

in the high impedance state, the internal input buffer

is disconnected from the pin and no external pull-up is

necessary.

Signal Description

Note: SCKR is high impedance if all receivers are

disabled (individual reset) and during hardware or

software reset, or while the DSP is in the Stop state.

MOTOROLA DSP56007/D 1-13

Signal/Connection Descriptions

Serial Audio Interface (SAI)

Table 1-9 Serial Audio Interface (SAI) Receiver signals (Continued)

Signal

Name

Signal

Type

WSR Input or

Output

State during

Reset

Signal Description

Tri-stated Word Select Receive (WSR)—WSR is an output if the

receiver section is configured as a master, and a

Schmitt-trigger input if configured as a slave. WSR is

used to synchronize the data word and to select the

left/right portion of the data sample.

Note: WSR is high impedance if all receivers are disabled

(individual reset), during hardware reset, during

software reset, or while the DSP is in the Stop state.

While in the high impedance state, the internal

input buffer is disconnected from the signal and no

external pull-up is necessary.

1-14 DSP56007/D MOTOROLA

SAI Transmitter Section

Table 1-10 Serial Audio Interface (SAI) Transmitter signals

Signal/Connection Descriptions

Serial Audio Interface (SAI)

Signal

Name

Signal

Type

State

during

Reset

SDO0 Output Driven

High

SDO1 Output Driven

High

SDO2 Output Driven

High

SCKT Input or

Tri-stated Serial Clock Transmit (SCKT)—This signal provides the

Output

Signal Description

Serial Data Output 0 (SDO0)—SDO0 is the serial output for

transmitter 0. SDO0 is driven high if transmitter 0 is disabled,

during individual reset, hardware reset, and software reset,

or when the DSP is in the Stop state.

Serial Data Output 1 (SDO1)—SDO1 is the serial output for

transmitter 1. SDO1 is driven high if transmitter 1 is disabled,

during individual reset, hardware reset and software reset, or

when the DSP is in the Stop state.

Serial Data Output 2 (SDO2)—SDO2 is the serial output for

transmitter 2. SDO2 is driven high if transmitter 2 is disabled,

during individual reset, hardware reset and software reset, or

when the DSP is in the Stop state.

clock for the SAI. SCKT can be an output if the transmit

section is configured as a master, or a Schmitt-trigger input if

the transmit section is configured as a slave. When the SCKT

is an output, it provides an internally generated SAI transmit

clock to external circuitry. When the SCKT is an input, it

allows external circuitry to clock data out of the SAI.

Note: SCKT is high impedance if all transmitters are disabled

(individual reset), during hardware reset, software reset, or

while the DSP is in the Stop state. While in the high

impedance state, the internal input buffer is disconnected

from the pin and no external pull-up is necessary.

WST Input or

Output

Tri-stated Word Select Transmit (WST)—WST is an output if the

transmit section is programmed as a master, and a Schmitttrigger input if it is programmed as a slave. WST is used to

synchronize the data word and select the left/right portion of

the data sample.

Note: WST is high impedance if all transmitters are disabled

(individual reset), during hardware or software reset, or

while the DSP is in the Stop state. While in the high

impedance state, the internal input buffer is disconnected

from the pin and no external pull-up is necessary.

MOTOROLA DSP56007/D 1-15

Signal/Connection Descriptions

General Purpose I/O

GENERAL PURPOSE I/O

Table 1-11 General Purpose I/O (GPIO) Signals

Signal

Name

GPIO0–

GPIO3

Signal

Type

Standard

Output,

Open-drain

Output, or

Input

State during

Reset

Disconnected GPIO lines can be used for control and handshake

ON-CHIP EMULATION (OnCE

There are four signals associated with the OnCE port controller and its serial

interface.

Table 1-12 On-Chip Emulation Port Signals

Signal

Name

Signal

Type

State during

Reset

TM

) PORT

Signal Description

functions between the DSP and external circuitry.

Each GPIO line can be configured individually as

disconnected, open-drain output, standard output,

or an input.

Note: Hardware reset or software reset configures all

the GPIO lines as disconnected (external

circuitry connected to these pins may need pullups until the pins are configured for operation).

Signal Description

DSI

OS0

Input

Output

Output,

Driven Low

Debug Serial Input (DSI)—The DSI signal is the signal

through which serial data or commands are provided to the

OnCE port controller. The data received on the DSI signal

will be recognized only when the DSP has entered the

Debug mode of operation. Data must have valid TTL logic

levels before the serial clock falling edge. Data is always

shifted into the OnCE port Most Significant Bit (MSB) first.

Operating Status 0 (OS0)—When the DSP is not in the Debug

mode, the OS0 signal provides information about the DSP

status if it is an output and used in conjunction with the OS1

signal. When switching from output to input, the signal is

tri-stated.

Note: If the OnCE port is in use, an external pull-down resistor

should be attached to the DSI/OS0 signal. If the OnCE

port is not in use, the resistor is not required.

1-16 DSP56007/D MOTOROLA

Signal/Connection Descriptions

On-Chip Emulation (OnCETM) Port

Table 1-12 On-Chip Emulation Port Signals (Continued)

Signal

Name

DSCK

OS1

DSO Output Driven High Debug Serial Output (DSO)—The DSO line provides the

Signal

Type

Input

Output

State during

Reset

Output,

Driven Low

Debug Serial Clock (DSCK)—The DSCK/OS1 signal,

when an input, is the signal through which the serial clock

is supplied to the OnCE port. The serial clock provides

pulses required to shift data into and out of the OnCE port.

Data is clocked into the OnCE port on the falling edge and

is clocked out of the OnCE port on the rising edge.

Operating Status 1 (OS1)—If the OS1 signal is an output

and used in conjunction with the OS0 signal, it provides

information about the DSP status when the DSP is not in the

Debug mode. The debug serial clock frequency must be no

greater than 1/8 of the processor clock frequency. The

signal is tri-stated when it is changing from input to output.

Note: If the OnCE port is in use, an external pull-down resistor

data contained in one of the OnCE port controller registers

as specified by the last command received from the

command controller. The Most Significant Bit (MSB) of the

data word is always shifted out of the OnCE port first. Data

is clocked out of the OnCE port on the rising edge of DSCK.

Signal Description

should be attached to the DSCK/OS1 pin. If the OnCE

port is not in use, the resistor is not required.

The DSO line also provides acknowledge pulses to the

external command controller. When the DSP enters the

Debug mode, the DSO line will be pulsed low to indicate

that the OnCE port is waiting for commands. After

receiving a read command, the DSO line will be pulsed low

to indicate that the requested data is available and the

OnCE port is ready to receive clock pulses in order to

deliver the data. After receiving a write command, the DSO

line will be pulsed low to indicate that the OnCE port is

ready to receive the data to be written; after the data is

written, another acknowledge pulse will be provided.

Note: During hardware reset and when idle, the DSO line is

held high.

MOTOROLA DSP56007/D 1-17

Signal/Connection Descriptions

On-Chip Emulation (OnCETM) Port

Table 1-12 On-Chip Emulation Port Signals (Continued)

Signal

Name

DR Input Input Debug Request (DR)—The debug request input provides a

Signal

Type

State during

Reset

Signal Description

means of entering the Debug mode of operation. This signal,

when asserted (pulled low), will cause the DSP to finish the

current instruction being executed, to save the instruction

pipeline information, to enter the Debug mode, and to wait

for commands to be entered from the debug serial input line.

While the DSP is in the Debug mode, the user can reset the

OnCE port controller by asserting DR

acknowledge pulse on DSO, and then deasserting DR. It

may be necessary to reset the OnCE port controller in cases

where synchronization between the OnCE port controller

and external circuitry is lost. Asserting DR when the DSP is

in the Wait or the Stop mode, and keeping it asserted until

an acknowledge pulse in the DSP is produced, puts the DSP

into the Debug mode. After receiving the acknowledge

pulse, DR must be deasserted before sending the first OnCE

port command. For more information, see Methods Of

Entering The Debug Mode in the

Manual

Note: If the OnCE port is not in use, an external pull-up resistor

.

should be attached to the DR

, waiting for an

DSP56000 Family

line.

1-18 DSP56007/D MOTOROLA

SECTION 2

SPECIFICATIONS

INTRODUCTION

The DSP56007 is fabricated in high density CMOS with Transistor-Transistor Logic

(TTL) compatible inputs and outputs.

MAXIMUM RATINGS

This device contains circuitry protecting

against damage due to high static voltage or

electrical fields; however, normal precautions

should be taken to avoid exceeding maximum

voltage ratings. Reliability is enhanced if

unused inputs are tied to an appropriate logic

voltage level (e.g., either GND or V

Note: In the calculation of timing requirements, adding a maximum value of one

specification to a minimum value of another specification does not yield a

reasonable sum. A maximum specification is calculated using a worst case

variation of process parameter values in one direction. The minimum

specification is calculated using the worst case for the same parameters in the

opposite direction. Therefore, a “maximum” value for a specification will

never occur in the same device that has a “minimum” value for another

specification; adding a maximum to a minimum represents a condition that

can never exist.

CAUTION

CC

).

MOTOROLA DSP56007/D 2-1

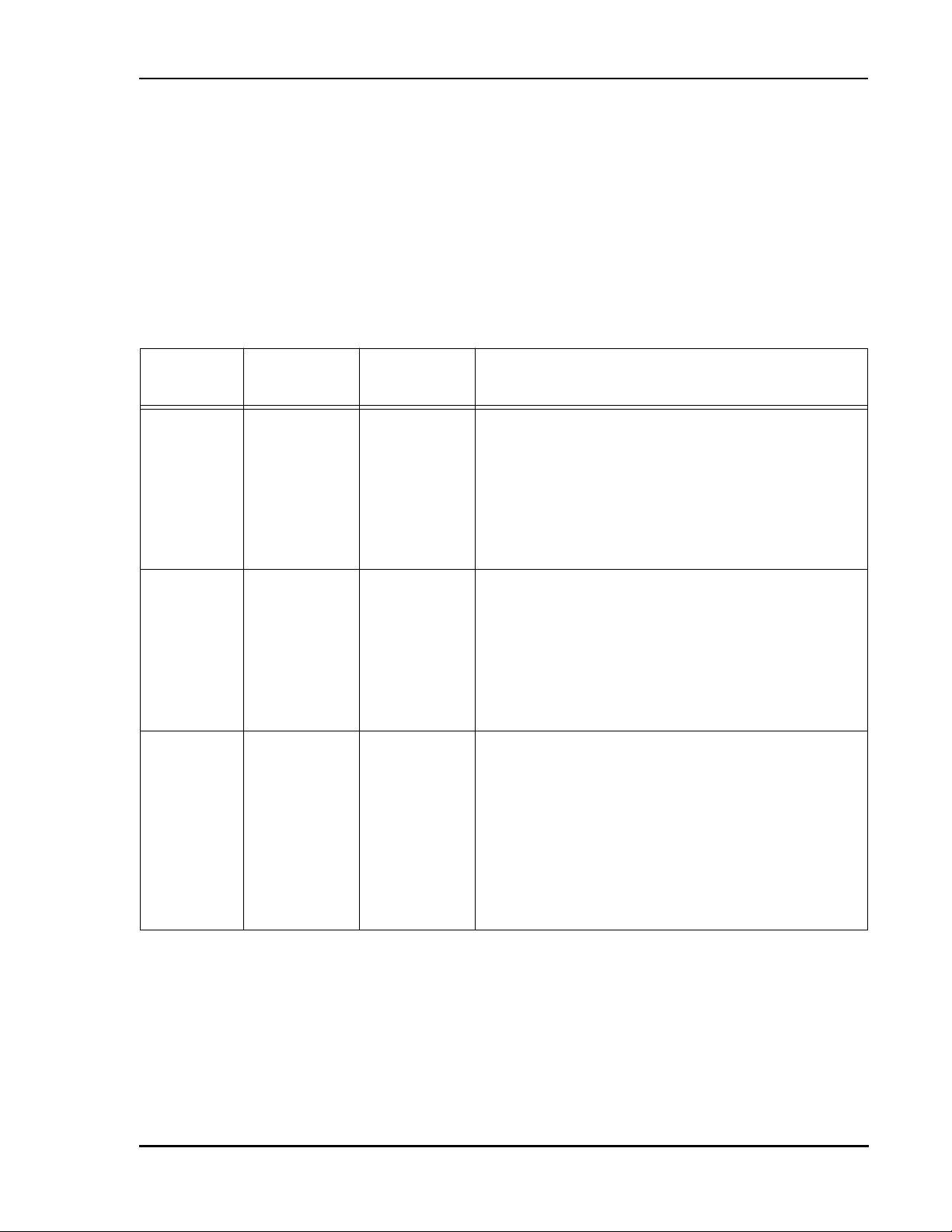

Specifications

Thermal characteristics

Table 2-1 Maximum Ratings (GND = 0 V

Rating Symbol Value Unit

Supply Voltage V

All Input Voltages V

Current Drain per Pin excluding V

and GND I 10 mA

CC

Operating Temperature Range:

• 50 and 66 MHz

• 88 MHz

Storage Temperature T

THERMAL CHARACTERISTICS

Table 2-2 Thermal Characteristics

Characteristic Symbol QFP Value

Junction-to-ambient thermal resistance

Junction-to-case thermal resistance

1

R

or

JA

θ

2

R

or

JC

θ

)

dc

CC

IN

T

J

STG

θ

JA

θ

JC

(GND – 0.25) to (V

61.5 37

11.8 —

–0.3 to +7.0 V

+ 0.25) V

CC

–40 to +125

–40 to +110

–55 to +125

3

QFP Value

4

Unit

˚

C/W

˚

C/W

° C

° C

° C

Thermal characterization parameter

Notes: 1. Junction-to-ambient thermal resistance is based on measurements on a horizontal-single-sided

Printed Circuit Board per SEMI G38-87 in natural convection.(SEMI is Semiconductor Equipment

and Materials International, 805 East Middlefield Rd., Mountain View, CA 94043, (415) 964-5111)

2. Junction-to-case thermal resistance is based on measurements using a cold plate per SEMI G3088, with the exception that the cold plate temperature is used for the case temperature.

3. These are measured values. See note 1 for test board conditions.

4. These are measured values; testing is not complete. Values were measured on a non-standard

four-layer thermal test board (two internal planes) at one watt in a horizontal configuration.

Ψ

JT

2.7 —

˚

C/W

2-2 DSP56007/D MOTOROLA

×

×

×

×

×

×

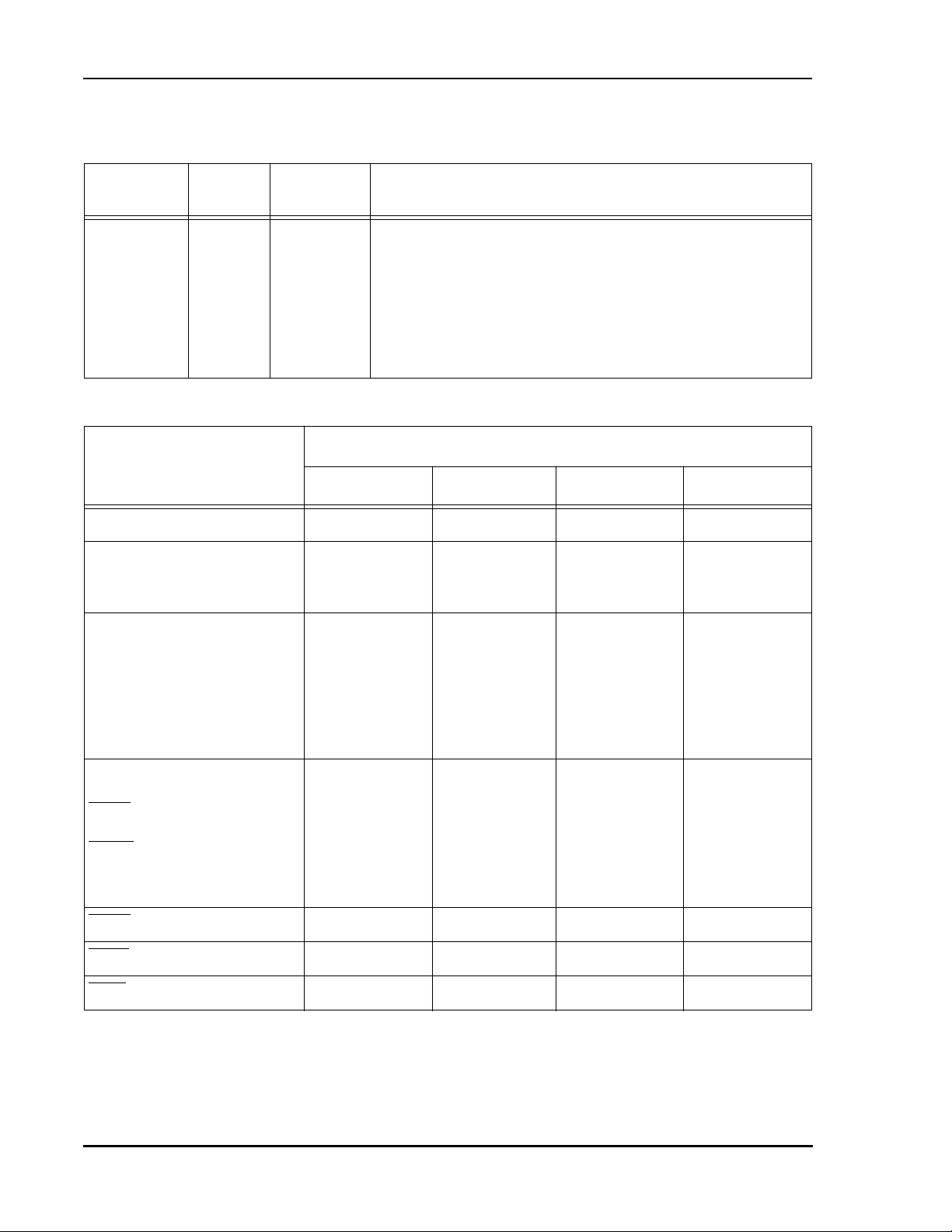

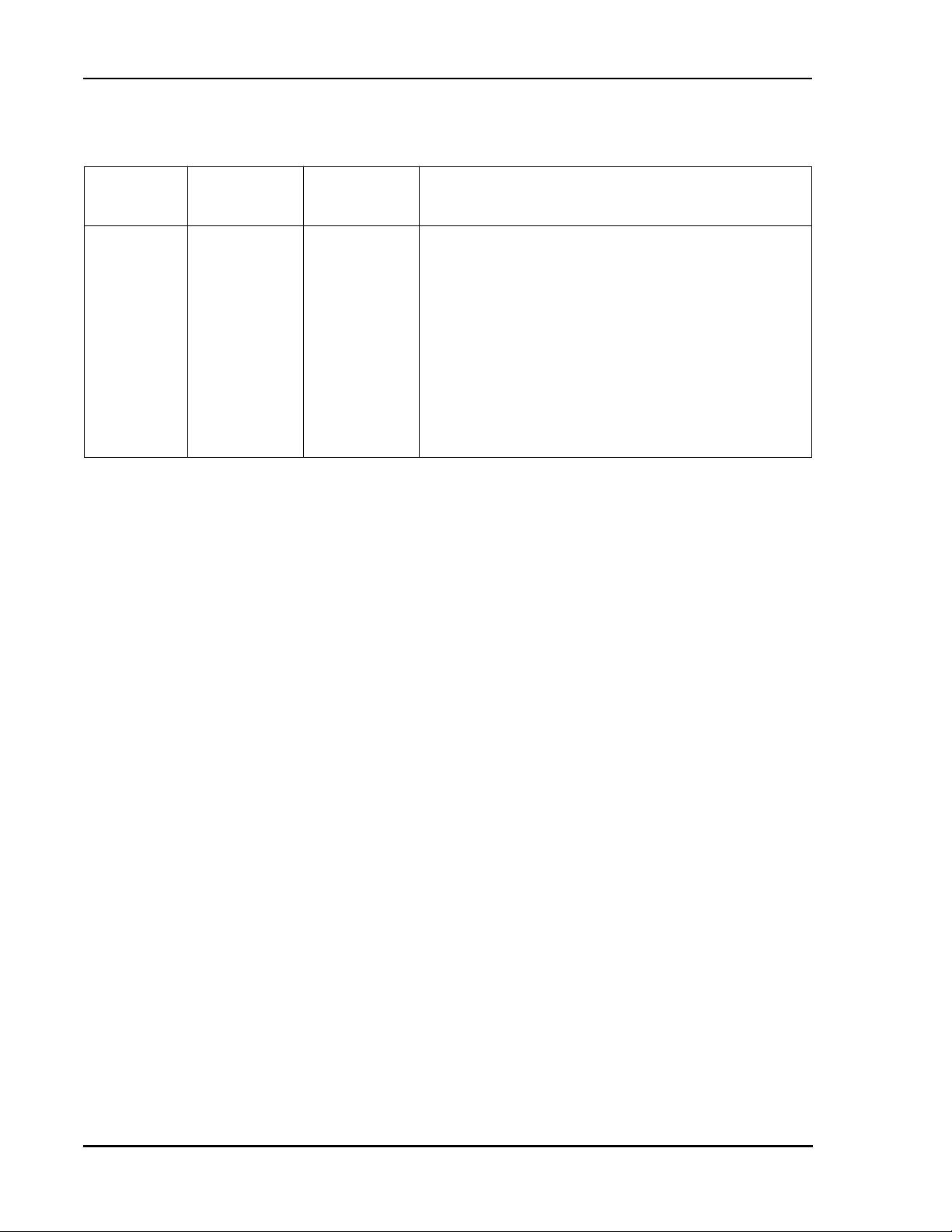

DC ELECTRICAL CHARACTERISTICS

Table 2-3 DC Electrical Characteristics

50 MHz 66 MHz 88 MHz

Characteristics Symbol

Min Typ Max Min Typ Max Min Typ Max

Specifications

DC Electrical Characteristics

Unit

Supply voltage V

Input high voltage

• EXTAL

• RESET

• MODA, MODB,

V

V

V

MODC

• SHI inputs

1

V

• All other inputs

Input low voltage

• EXTAL

• MODA, MODB,

MODC

• SHI inputs

1

V

V

• All other inputs

Input leakage current

• EXTAL, RESET,

MODA, MODB,

MODC, DR

• Other Input Pins

(@ 2.4 V/0.4 V)

High impedance (off-state)

input current (@ 2.4 V / 0.4 V)

IHM

V

V

V

I

I

CC

IHC

IHR

IHS

IH

ILC

ILM

ILS

IL

IN

TSI

4.75 5.0 5.25 4.75 5.0 5.25 4.75 5.0 5.25 V

—

—

—

—

—

—

—

—

V

V

V

V

V

0.3

4.0

2.5

3.5

0.7

V

CC

2.0

–0.5

–0.5

–0.5

V

–0.5

—

–1

–10——110

CC

CC

CC

CC

CC

0.4

2.0

CC

0.8

0.7

V

–0.5

–0.5

–0.5

–0.5

—

—

—

—

—

—

—

—

V

V

V

V

V

0.4

2.0

0.3

4.0

2.5

3.5

CC

2.0

V

—

0.8

–1

–10——110

4.0

CC

2.5

CC

3.5

CC

0.7

CC

V

2.0

CC

–0.5

–0.5

–0.5

CC

–0.5

–1

–10——110

CC

—

V

V

V

V

V

0.4

2.0

0.3

V

0.8

CC

CC

CC

CC

CC

CC

—

—

—

—

—

—

—

—

–10 — 10 –10 — 10 –10 — 10 µ A

V

V

V

V

V

V

V

V

V

µ A

µ A

Output high voltage

(I

= –0.4 mA)

OH

Output low voltage

(I

= 3.2 mA)

OL

SCK/SCL I

MISO/SDA I

HREQ I

OL

= 6.7 mA

OL

= 6.7 mA

OL

= 6.7 mA

V

OH

V

OL

2.4 — — 2.4 — — 2.4 — — V

— — 0.4 — — 0.4 — — 0.4 V

Internal Supply Current

• Normal mode

• Wait mode

• Stop mode

2

I

CCI

I

CCW

I

CCS

—

—

—

80

14

4

105

25

5

110

—

—

—

110

18

5

130

30

110

4

—

147

—

24

—

5

169

33

110

4

mA

mA

µ A

MOTOROLA DSP56007/D 2-3

Specifications

AC Electrical Characteristics

Table 2-3 DC Electrical Characteristics (Continued)

50 MHz 66 MHz 88 MHz

Characteristics Symbol

Min Typ Max Min Typ Max Min Typ Max

PLL supply current — 0.7 1.1 — 1.0 1.5 — 1.3 2.2 mA

Input capacitance

Notes: 1. The SHI inputs are: MOSI/HA0, SS/HA2, MISO/SDA, SCK/SCL, and HREQ.

2. In order to obtain these results, all inputs must be terminated (i.e., not allowed to float). PLL signals are

3. Periodically sampled and not 100% tested

4. Maximum values are derived using the methodology described in

3

disabled during Stop state.

application dependent and may vary widely from these numbers.

C

IN

—10— —10— —10— pF

Section 4

. Actual maximums are

Unit

AC ELECTRICAL CHARACTERISTICS

The timing waveforms in the AC Electrical Characteristics are tested with a V

maximum of 0.5 V and a V

MODA, MODB, MODC, and SHI pins (MOSI/HA0, SS

SCL, HREQ

). These pins are tested using the input levels set forth in the DC Electrical

minimum of 2.4 V for all pins, except EXTAL, RESET,

IH

/HA2, MISO/SDA, SCK/

IL

Characteristics. AC timing specifications that are referenced to a device input signal

are measured in production with respect to the 50% point of the respective input

signal’s transition. DSP56007 output levels are measured with the production test

machine V

OL

and V

reference levels set at 0.8 V and 2.0 V, respectively.

OH

All output delays are given for a 50 pF load unless otherwise specified.

For load capacitance greater than 50 pF, the drive capability of the output pins

typically decreases linearly:

1. At 1.5 ns per 10 pF of additional capacitance at all output pins except

MOSI/HA0, MISO/SDA, SCK/SCL, HREQ

2. At 1.0 ns per 10 pF of additional capacitance at output pins MOSI/HA0,

MISO/SDA, SCK/SCL, HREQ

(in SPI mode only)

2-4 DSP56007/D MOTOROLA

INTERNAL CLOCKS

Specifications

Internal Clocks

For each occurrence of T

, TL, TC, or I

H

, substitute with the numbers in Table 2-4.

CYC

Table 2-4 Internal Clocks

Characteristics Symbol Expression

Internal Operation Frequency f —

Internal Clock High Period

• with PLL disabled

• with PLL enabled and MF ≤ 4

• with PLL enabled and MF > 4

Internal Clock Low Period

• with PLL disabled

• with PLL enabled and MF ≤ 4

• with PLL enabled and MF > 4

Internal Clock Cycle Time T

Instruction Cycle Time I

T

H

T

L

C

CYC

ET

(Min) 0.48 × T

(Max) 0.52 × T

(Min) 0.467 × T

(Max) 0.533 × T

ET

(Min) 0.48 × T

(Max) 0.52 × T

(Min) 0.467 × T

(Max) 0.533 × T

(DF /MF) × ET

2 × T

H

C

C

C

C

L

C

C

C

C

C

C

EXTERNAL CLOCK (EXTAL PIN)

The DSP56007 system clock is externally supplied via the EXTAL pin. Timings shown

in this document are valid for clock rise and fall times of 3 ns maximum.

Table 2-5 External Clock (EXTAL Pin)

50 MHz 66 MHz 88 MHz

No. Characteristics Sym.

Min Max Min Max Min Max

— Frequency of External Clock (EXTAL Pin) Ef 0 50 0 66 0 88 MHz

1 External Clock Input High—EXTAL Pin1

• with PLL disabled

ET

H

9.3

7.1

5.3

(46.7%–53.3% duty cycle)

• with PLL enabled

8.5∞235500

6.4∞235500

4.8∞235500

(42.5%–57.5% duty cycle)

Unit

ns

ns

MOTOROLA DSP56007/D 2-5

Specifications

Phase Lock Loop (PLL) Characteristics

Table 2-5 External Clock (EXTAL Pin) (Continued)

No. Characteristics Sym.

50 MHz 66 MHz 88 MHz

Unit

Min Max Min Max Min Max

2 External Clock Input Low—EXTAL Pin1

• with PLL disabled

ET

L

9.3

7.1

5.4

ns

(46.7%–53.3% duty cycle)

• with PLL enabled

8.5∞235500

6.4∞235500

4.8∞235500

ns

(42.5%–57.5% duty cycle)

3 External Clock Cycle Time

• with PLL disabled

• with PLL enabled

4 Instruction Cycle Time = I

• with PLL disabled

• with PLL enabled

Note: 1. External Clock Input High and External Clock Input Low are measured at 50% of the input transition.

1

= 2 × T

cyc

ET

C

20

20∞409600

1

C

I

cyc

40

40∞819200

15.15

15.15∞409600

30.3

30.3∞819200

11.4

11.4∞409600nsns

22.7

22.7∞819200nsns

EXTAL

1 2

ET

H

3

ET

ET

L

C

4

AA0250

Figure 2-1 External Clock Timing

PHASE LOCK LOOP (PLL) CHARACTERISTICS

Table 2-6 Phase Lock Loop (PLL) Characteristics

Characteristics Expression Min Max Unit

VCO frequency when PLL enabled MF × Ef 10 f

PLL external capacitor

(PCAP pin to V

CCP

)

MF × C

@ MF ≤ 4

@ MF > 4

Note: 1. Cpcap is the value of the PLL capacitor (connected between PCAP pin and V

The recommended value for Cpcap is 400 pF for MF ≤ 4 and 540 pF for MF > 4.

The maximum VCO frequency is limited to the internal operation frequency, defined in Table 2-4.

PCAP

1

MF × 340

MF × 380

2-6 DSP56007/D MOTOROLA

1

MF × 480

MF × 970

) for MF = 1.

CCP

MHz

pF

pF

Specifications

RESET, Stop, Mode Select, and Interrupt Timing

RESET, STOP, MODE SELECT, AND INTERRUPT TIMING

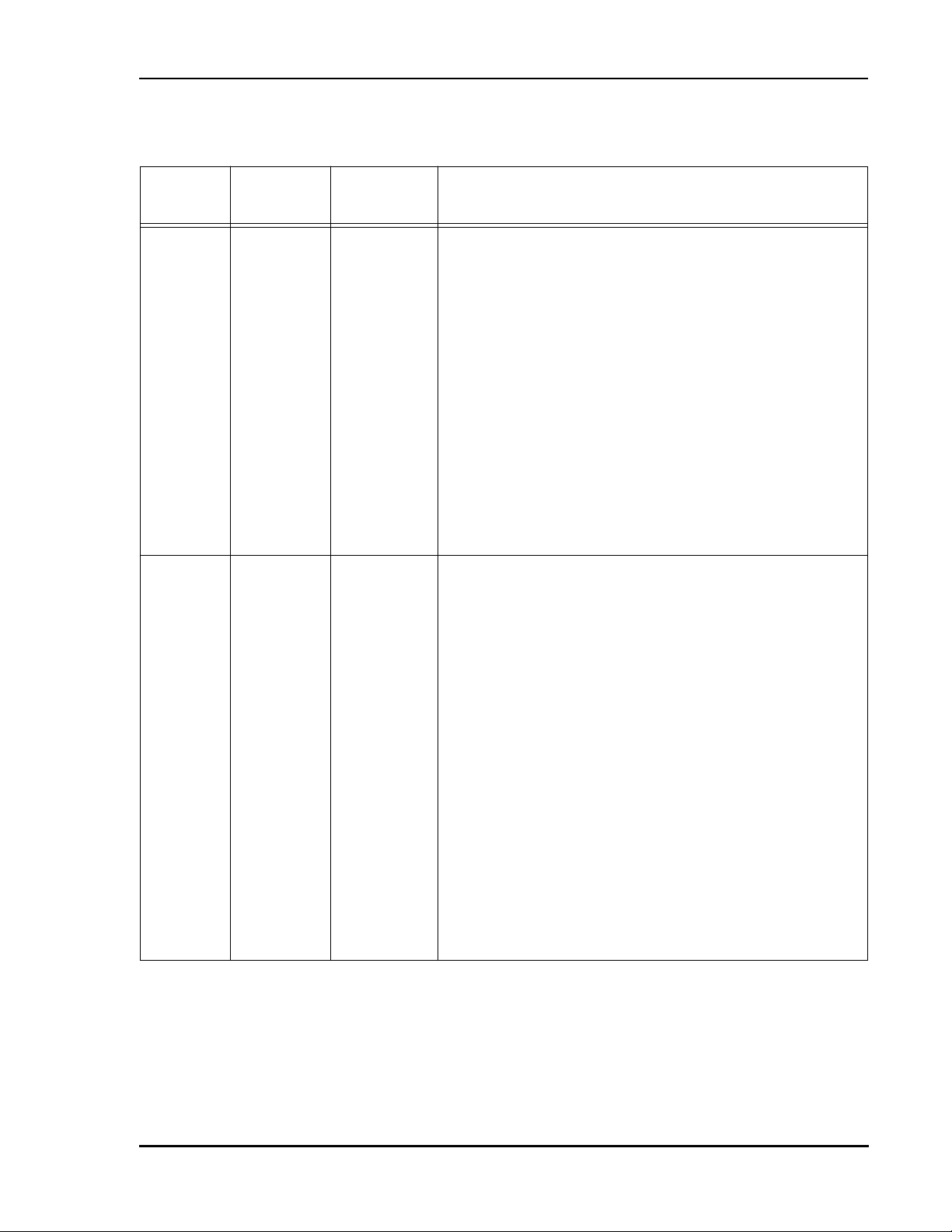

Table 2-7 Reset, Stop, Mode Select, and Interrupt Timing (CL = 50 pF + 2 TTL Loads)

No. Characteristics Min Max Unit

10 Minimum RESET assertion width:

• PLL disabled

• PLL enabled

1

14 Mode Select Setup Time 21 — ns

15 Mode Select Hold Time 0 — ns

16 Minimum Edge-triggered Interrupt Request Assertion

Width

16a Minimum Edge-triggered Interrupt Request

Deassertation Width

18 Delay from IRQA

, IRQB, NMI Assertion to GPIO Valid

Caused by First Interrupt Instruction Execution

22 Delay from General Purpose Output Valid to Interrupt

Request Deassertation for Level Sensitive Fast

Interrupts—If Second Interrupt Instruction is: 2

• Single Cycle

• Two Cycles

25 Duration of IRQA Assertion for Recovery from Stop State 12 — ns

27 Duration for Level Sensitive IRQA Assertion to ensure

interrupt service (when exiting “STOP”)

• Stable External Clock, OMR Bit 6 = 1

• Stable External Clock, PCTL Bit 17 = 1

Note: 1. This timing requirement is sensitive to the quality of the external PLL capacitor connected to the PCAP

pin. For capacitor values less than or equal to 2 nF, asserting RESET

will ensure proper processor initialization for capacitors with a deltaC/C less than 0.5%. (This is typical

for ceramic capacitors.) For capacitor values greater than 2 nF, asserting RESET

requirement will ensure proper processor initialization for capacitors with a deltaC/C less than 0.01%.

(This is typical for Teflon, polystyrene, and polypropylene capacitors.) However, capacitors with values

greater than 2 nF with a deltaC/C greater than 0.01% may require longer RESET

proper initialization.

2. When using fast interrupts and IRQA

prevent multiple interrupt service. To avoid these timing restrictions, the Negative Edge-triggered

mode is recommended when using fast interrupts. Long interrupts are recommended when using

Level-sensitive mode.

and IRQB are defined as level-sensitive, then timing 22 applies to

25 × T

C

2500 × ET

C

—

—

ns

ns

13 — ns

13 — ns

12 × TC + TH —ns

TL – 31

(2 × TC) + TL – 31nsns

6 × TC + T

L

12

according to this timing requirement

—

—

according to this timing

assertion to ensure

ns

ns

V

IHR

RESET

10

AA0251

Figure 2-2 Reset Timing

MOTOROLA DSP56007/D 2-7

Specifications

RESET, Stop, Mode Select, and Interrupt Timing

RESET

MODA, MODB

MODC

IRQA, IRQB,

NMI

IRQA, IRQB,

NMI

General

Purpose

I/O

(Output)

IRQA

IRQB

NMI

14

V

IHM

V

ILM

15

V

V

Figure 2-3 Operating Mode Select Timing

16

16A

Figure 2-4 External Interrupt Timing (Negative Edge-triggered)

2218

General Purpose I/O

V

IH

IRQA, IRQB,

NMI

IL

IHR

AA0252

AA0253

AA0254

Figure 2-5 External Level-sensitive Fast Interrupt Timing

25

IRQA

AA0255

Figure 2-6 Recovery from Stop State Using IRQA

27

IRQA

AA0256

Figure 2-7 Recovery from Stop State Using IRQA Interrupt Service

2-8 DSP56007/D MOTOROLA

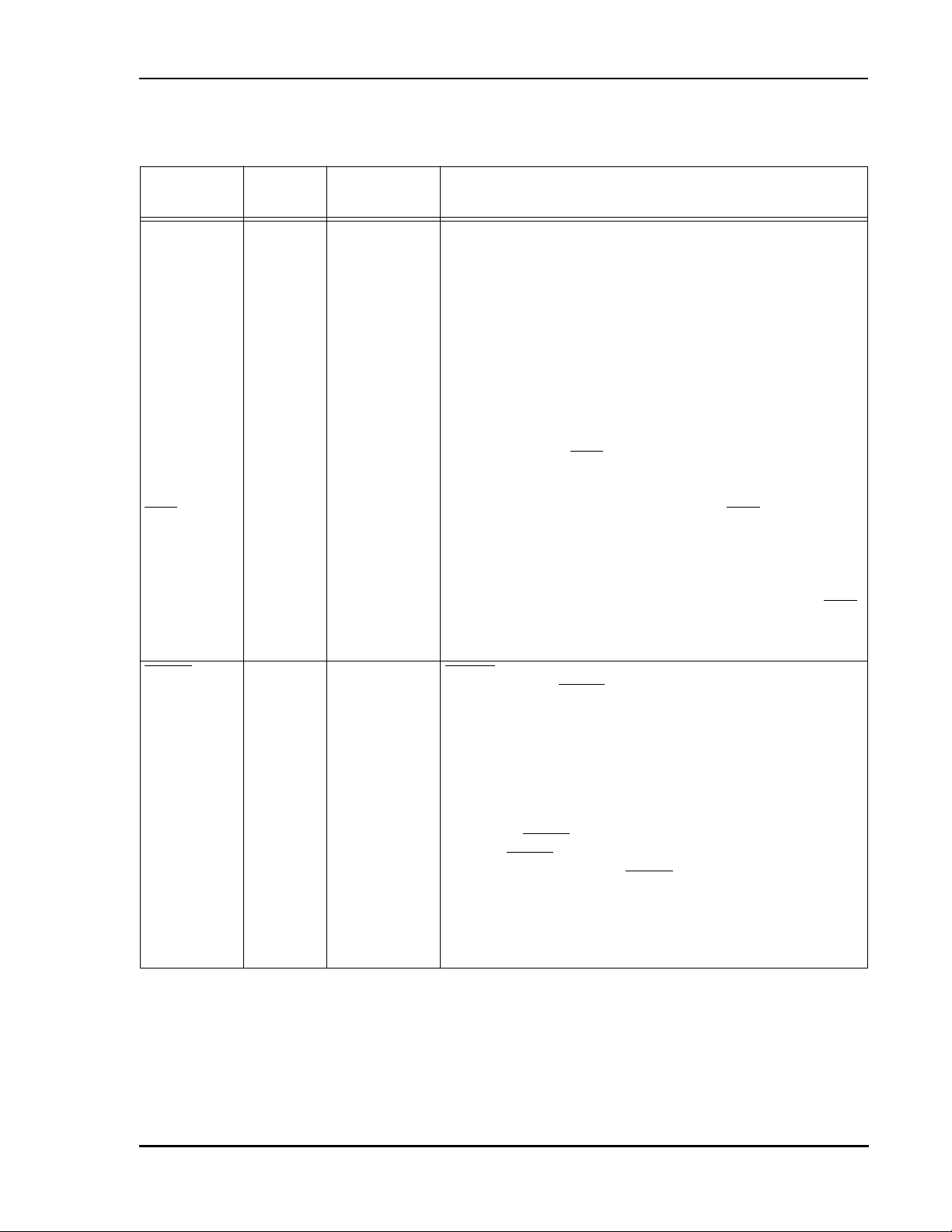

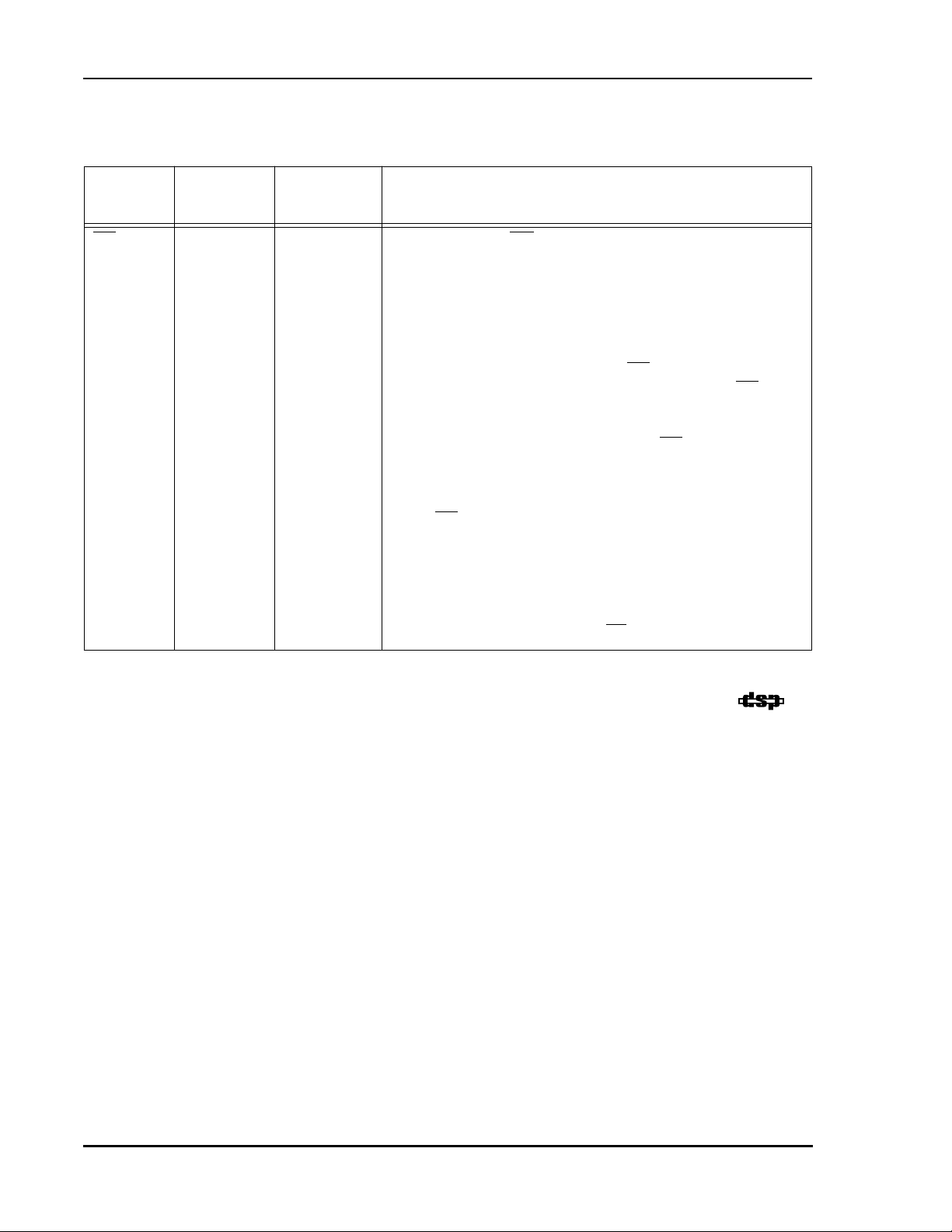

External Memory Interface (EMI) DRAM Timing

EXTERNAL MEMORY INTERFACE (EMI) DRAM TIMING

(CL = 50 pF + 2 TTL Loads)

Table 2-8 External Memory Interface (EMI) DRAM Timing

Specifications

No. Characteristics Symbol

41 Page Mode Cycle Time t

42 RAS or RD Assertion to

Data Valid

43 CAS Assertion to Data

t

RAC

t

T

PC

GA

CAC

,

Valid

44 Column Address Valid

t

AA

to Data Valid

45 CAS Assertion to Data

T

CLZ

Active

46 RAS Assertion Pulse

1

Width

t

RASP

(Page Mode Access

Only)

47 RAS Assertion Pulse

t

RAS

Width

(Single Access Only)

48 RAS or CAS

Deassertation to RAS

tRP,

T

CRP

Assertion

49 CAS Assertion Pulse

T

CAS

Width

50 Last CAS Assertion to

t

RSH

RAS Deassertation

(Page Mode Access

Only)

51

RAS or WR Assertion to

CAS Deassertation

52 RAS Assertion to CAS

T

T

t

CSH

CWL

RCD

,

Assertion

53 RAS Assertion to

t

RAD

Column Address Valid

Timing

Mode

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

50 MHz 66 MHz 88 MHz

Expression

Min Max Min Max Min Max

7

5

4 × T

3 × T

× T

× T

C

C

C

C

– 16

– 16——

8060——6146——45.5

34.1——nsns

12484——9060——63.5

3 × TC – 10

2 × TC – 10——5030——3520——

3 ×TC + TL – 7

——6343——4630——32.8

2 × TC + TL –

7

0 0—0—0—ns

3 ×TC –11

+ n × 4 × T

2 × TC –11

+ n × 3 ×T

7 × TC – 11

5 × TC – 11

5 × TC – 5

3 × TC – 59555——7040——

3 × TC – 10

2 × TC – 105030——3520——

3 × TC – 15

2 × TC – 154525——3015——

7 × TC – 15

5 × TC – 15

4 ×TC – 13

3 × TC – 136747——4732——

3 ×TC + TH –

209

C

149——

C

156

110——

12989——9565——68.5

12585——9161——64.5

5737——4025——26.8

114

79.9——nsns

45.8——nsns

51.8

29.1——nsns

24.1

12.7——nsns

19.1

7.7——nsns

41.8——nsns

32.5

21.1——nsns

13

2 ×TC + TH –

15.4——nsns

13

Unit

40.8nsns

24.1

12.7nsns

21.4nsns

MOTOROLA DSP56007/D 2-9

Specifications

External Memory Interface (EMI) DRAM Timing

Table 2-8 External Memory Interface (EMI) DRAM Timing (Continued)

No. Characteristics Symbol

54 CAS Deassertation Pulse

T

CP

Width

(Page Mode Access

Only)

55 Row Address Valid to

t

ASR

RAS Assertion

(Row Address Setup

Time)

56 RAS

Assertion to ROW

t

RAH

Address Not Valid

(Row Address Hold

Time)

57 Column Address Valid

t

ASC

to CAS Assertion

(Column Address Setup

Time)

58 CAS Assertion to

T

CAH

Column Address Not

Valid

(Column Address Hold

Time)

59

Last CAS Assertion to

T

CAH

Column Address Not

Valid (Column Address

Hold Time)

60 RAS Assertion to

t

AR

Column Address Not

Valid

61 Column Address Valid

t

RAL

to RAS Deassertation

62 CAS, RAS, RD, or WR

Deassertation to WR or

t

RCH

t

RRH

,

RD Assertion

63 CAS or RD

Deassertation to Data

t

OFF

tGZ

,

Not Valid

(Data Hold Time)

Timing

Mode

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

slow

fast

50 MHz 66 MHz 88 MHz

Expression

Min Max Min Max Min Max

TC – 5 15 — 10 — 6.4 — ns

TL – 6 4—2—0.1—ns

3 × TC + TH –

5636——3924——25.8

14

2 × TC + TH –

14.4——nsns

14

TL – 6 4—2—0.1—ns

3 × TC + TH –

5636——3924——25.8

14

2 × TC + TH –

14.4——nsns

14

7 × TC + TH –

13676——10054——71.2

14

4 × T

+ TH –

C

37.1——nsns

14

7 × TC + TH –

13696——10069——71.2

14

5 × TC + TH –

48.5——nsns

14

3 × TC + TL –

7

6343——4630——32.8

21.2——nsns

2 × TC + TL –

7

5 × TC – 11

3 × TC – 118949——6535——

45.8

23.1——nsns

0 0—0—0—ns

Unit

2-10 DSP56007/D MOTOROLA

Specifications

External Memory Interface (EMI) DRAM Timing

Table 2-8 External Memory Interface (EMI) DRAM Timing (Continued)

RC

Timing

Mode

slow

fast

Expression

12 × T

C

8 × T

C

No. Characteristics Symbol

64 Random Read or Write

t

Cycle Time (Single

Access Only)

65 WR Deassertation to

CAS Assertion

66 CAS Assertion to WR

Deassertation

67 Data Valid to CAS

t

RCS

t

WCH

t

DS

slow

fast

slow

fast

9 × TC – 11

6 × TC – 11

3 × TC – 13

2 × TC – 134727——3217——

TL – 6 4—2—0.1—ns

Assertion

(Data Setup Time)

68 CAS Assertion to Data

Not Valid (Data Hold

Time)

t

DH

slow

fast

3 × TC + TH –

14

2 × TC + TH –

14

69 RAS Assertion to Data

Not Valid

t

DHR

slow

fast

7 × TC + TH –

14

5 × TC + TH –

14

70 WR Assertion to CAS

Assertion

71 WR Assertion Pulse

Width (Single Cycle

t

WCS

t

WP

slow

fast

slow

fast

4 × TC – 14

3 × TC – 146646——4731——

7 × TC – 9

5 × TC – 9

Only)

72

RAS Assertion to WR

Deassertation

t

WCR

slow

fast

7 × TC – 15

5 × TC – 15

(Single Cycle Only)

73 WR Assertion to Data

Active

slow

fast

3 × TC + TH –

13

2 × TC + TH –

13

74 RD or WR Assertion to

RAS Deassertation

t

ROH

t

RWL

,

slow

fast

7 × TC – 13

5 × TC – 13

(Single Cycle Only)

Note: 1. n is the number of successive accesses. n = 2, 3, 4, or 6.

50 MHz 66 MHz 88 MHz

Min Max Min Max Min Max

240

98.8——

169

109——

182

121——

136.4

91.0——nsns

12580——91.3

57.2——nsns

21.1

9.7——nsns

5636——3924——25.8

14.4——nsns

13696——10069——71.2

48.5——nsns

31.4

20.1——nsns

13191——9767——70.5

47.8——nsns

12585——9161——64.5

41.8——nsns

5737——4025——26.8

15.4——nsns

12787——9363——66.5

43.8——nsns

Unit

MOTOROLA DSP56007/D 2-11

Specifications

External Memory Interface (EMI) DRAM Timing

MRAS

MCAS

MA0–MA10

MWR

MRD

55

4748

64

74

52

65

53 59

Row Address Last Column Address

56

43

50

49

60

44

61

48

6257

MD0–MD7

42 63

45

Data In

AA0257

Figure 2-8 DRAM Single Read Cycle

2-12 DSP56007/D MOTOROLA

Specifications

External Memory Interface (EMI) DRAM Timing

MRAS

MCAS

MA0–MA10

MWR

MRD

48 46

60 50

65 41 54

52

54

49

51

55

Col. AddressRow Address Col. Address Last Column Address

56

57

57

44

43

43

61

49

57

48

49

59585853

62

4444

43

MD0–MD7

42 63 63 63

4545 45

Data

InDataIn Data In

Figure 2-9 DRAM Page Mode Read Cycle

AA0263

MOTOROLA DSP56007/D 2-13

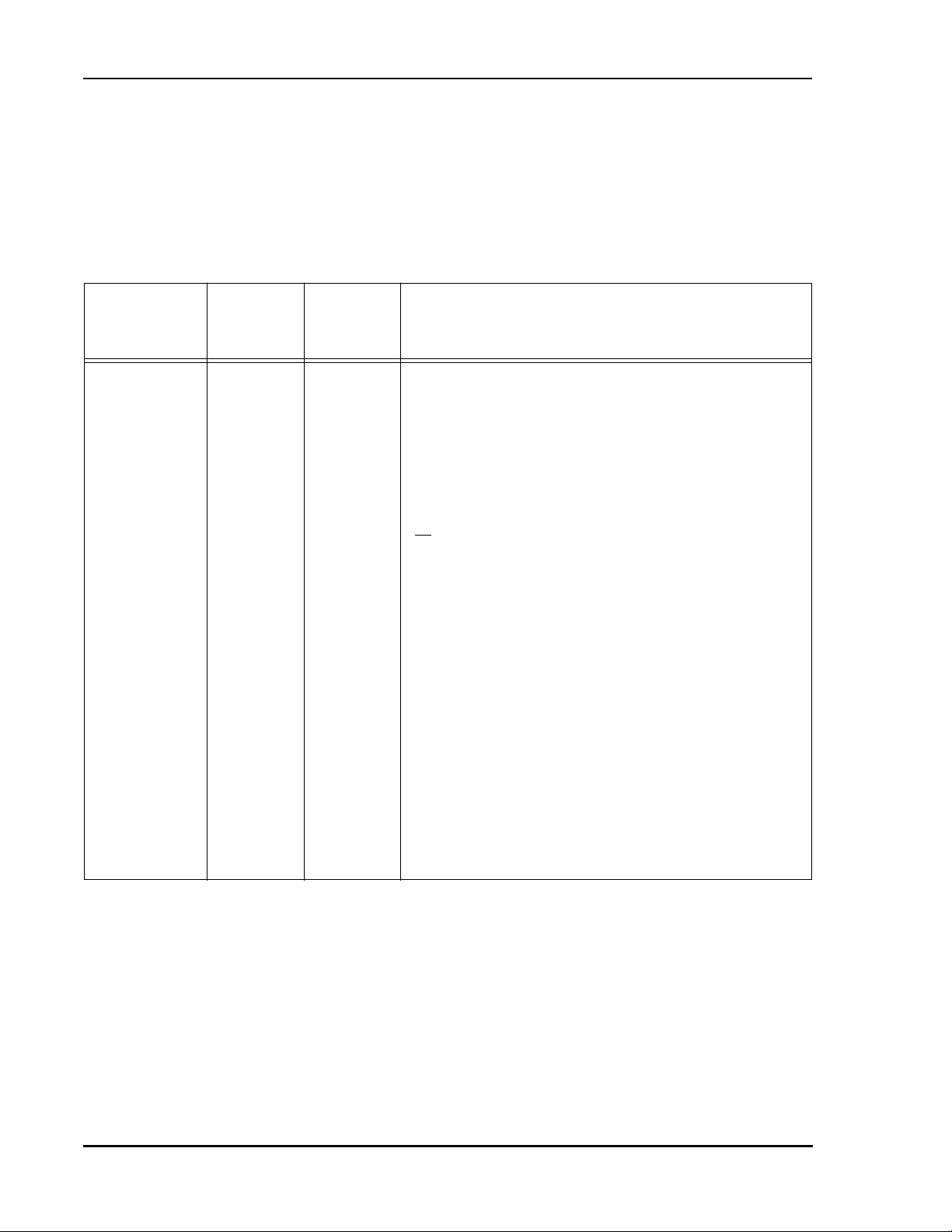

Specifications

External Memory Interface (EMI) DRAM Timing

MRAS

65

MCAS

64

47 4848

74

52 50

49

MA0–MA10

MWR

MRD

MD0–MD7

55

61

53

60

Row Address Column Address

56

57

70

72

71

69

67

73

Data Out

Figure 2-10 DRAM Single Write Cycle

66

68

59

62

AA0264

2-14 DSP56007/D MOTOROLA

Specifications

External Memory Interface (EMI) DRAM Timing

MRAS

MCAS

MA0–MA10

MWR

48 46

60 50

65 41 54

52

54

49

51

55

Col. AddressRow Address Col. Address Last Column Address

56

57

57

70

48

49

49

61

59585853

66

62

57

MRD

MD0–MD7

69

68

67

68

67

73

Data Out Data Out

Data Out

Figure 2-11 DRAM Page Mode Write Cycle

68

67

AA0265

MOTOROLA DSP56007/D 2-15

Specifications

External Memory Interface (EMI) DRAM Refresh Timing

EXTERNAL MEMORY INTERFACE (EMI) DRAM REFRESH TIMING

(CL = 50pF + 2 TTL Loads)

Table 2-9 External Memory Interface (EMI) DRAM Refresh Timing

50 MHz 66 MHz 88 MHz

Min Max Min Max Min Max

11373——84———61.2———ns

260

C

180——

C

13191——97———70.5———ns

No. Characteristics Sym.

T

t

RP

CPN

81

RAS Deassertation to

Assertion

RAS

82 CAS

Deassertation to

CAS Assertion

83 Refresh Cycle Time t

84 RAS Assertion Pulse

t

RAS

RC

Width

85 RAS Deassertation to

t

RP

RAS Assertion for

Refresh Cycle

86 CAS Assertion to RAS

2

T

CSR

Timing

Mode

slow

1

fast

slow

1

fast

slow

1

fast

slow

1

fast

slow

1

fast

Exp.

6 × TC – 7

4 × TC – 7

5 × TC – 7

3 × TC – 79353——71———

13 × T

9 × T

7 × TC – 9

5 × TC – 9

5 × TC – 5

3 × TC – 59555——70———

TC – 7 13 — 8 — 4.4 — ns

Assertion on Refresh

Cycle

87 RAS Assertion to CAS

Deassertation on

T

CHR

slow

fast

1

7 × TC – 15

5 × TC – 15

12585——91———64.5———ns

Refresh Cycle

88 RAS Deassertation to

CAS Assertion on a

t

RPC

slow

fast

5 × TC – 11

1

3 × TC – 118949——65———

Refresh Cycle

89 CAS Deassertation to

t

OFF

0 0—0—0—ns

Data Not Valid

Note: 1. Fast mode is not available for operating frequencies above 50 MHz.

2. This happens when a Refresh Cycle is followed by an Access Cycle.

Unit

ns

49.8———ns

ns

197———147.7———ns

ns

ns

51.8———ns

ns

ns

45.8———ns

ns

2-16 DSP56007/D MOTOROLA

MRAS

Specifications

External Memory Interface (EMI) SRAM Timing

83

81 84 85

88

82

MCAS

87

86

89

MD0–MD7

Data In

Figure 2-12 CAS

before RAS Refresh Cycle

EXTERNAL MEMORY INTERFACE (EMI) SRAM TIMING

(CL = 50pF + 2 TTL Loads)

Table 2-10 External Memory Interface (EMI) SRAM Timing

50 MHz 66 MHz 88 MHz

No. Characteristics Symbol Expression

Min Max Min Max Min Max

91

Address Valid and CS

Assertion Pulse Width

92 Address Valid to RD or WR

Assertion

93 RD or WR Assertion Pulse

Width

94 RD or WR Deassertation to

RD or WR Assertion

95 RD or WR Deassertation to

Address not Valid

96 Address Valid to Input Data

Valid

97 RD Assertion to Input Data

Valid

98 RD Deassertation to Data

Not Valid (Data Hold Time)

tRC, t

t

AS

t

WP

WC

4 × TC – 11 +

Ws × T

C

69 — 50 — 34.5 — ns

TC + TL – 13 17 — 10 — 4.4 — ns

2 × TC – 5 +

Ws × T

C

35 — 23 — 17.7 — ns

—2 × TC – 11 29 — 19 — 11.7 — ns

t

WR

tAA, t

t

OE

t

OHZ

AC

TH – 6 4—2—0.1— ns

3 × TC + TL –15 +

Ws × T

C

2 × TC – 15 +

Ws × T

C

— 55 — 38 — 24.8 ns

—25—15—7.7 ns

0 0—0—0—ns

AA0266

Unit

MOTOROLA DSP56007/D 2-17

Specifications

External Memory Interface (EMI) SRAM Timing

Table 2-10 External Memory Interface (EMI) SRAM Timing

No. Characteristics Symbol Expression

50 MHz 66 MHz 88 MHz

Unit

Min Max Min Max Min Max

99 Address Valid to WR

Deassertation

100 Data Setup Time to WR

Deassertation

101 Data Hold Time from WR

TCW, t

3 × TC + TL –14 +

AW

Ws × T

tDS (tDW)T

+ TL – 5 +

C

Ws × T

t

DH

TH – 6 4—2—0.1— ns

56 — 39 — 25.8 — ns

C

25 — 18 — 12.0 — ns

C

Deassertation

102 WR Assertion to Data Valid — TH + 4 — 14 — 12 — 9.7 ns

103 WR

Deassertation to Data

high impedance

1

104 WR Assertion to Data

—T

—T

+ 10 — 20 — 18 — 15.7 ns

H

– 6 4—2—0.1— ns

H

Active

Note: 1. This value is periodically sampled and not 100% tested.

MA0–MA14

MCS3

MA15/

91

MA16/MCS2/MCAS

MA17/MCS1/MRAS

94

92

95

93

MCS0

RD

94

WR

9897

96

MD0–MD7

Data In

AA0267

Figure 2-13 SRAM Read Cycle

2-18 DSP56007/D MOTOROLA

Specifications

External Memory Interface (EMI) SRAM Timing

MA0–MA14

MCS3

MA15/

MA16/MCS2/MCAS

MA17/MCS1/MRAS

MCS0

WR

RD

MD0–MD7

91

99

92

93

94

100

102

Data Out

104 101

Figure 2-14 SRAM Write Cycle

95

94

103

AA0268

MOTOROLA DSP56007/D 2-19

Specifications

Serial Audio Interface (SAI) Timing

SERIAL AUDIO INTERFACE (SAI) TIMING

(CL = 50pF + 2 TTL Loads)

Table 2-11 Serial Audio Interface (SAI) Timing

No. Characteristics Mode Expression

50 MHz 66 MHz 81 MHz

Unit

Min Max Min Max Min Max

111 Minimum Serial Clock Cycle =

t

(min)

SAICC

112 Serial Clock High Period master

113 Serial Clock Low Period master

114 Serial Clock Rise/Fall Time master

115 Data In Valid to SCKR edge

(Data In Set-up Time)

116 SCKR Edge to Data In Not

Valid (Data In Hold Time)

117 SCKR Edge to Word Select Out

master

slave

slave

slave

slave

master

slave

master

slave

4 × T

3 × TC + 5

0.5 × t

× t

0.35

× t

0.5

0.35 × t

0.15 × t

C

SAICC

SAICC

SAICC

SAICC

8

SAICC

26

4

0

14

– 8

– 8

8065——6151——45.5

3223——2218——14.7

3223——2218——14.8

——810——88——8.0

264——264——264——ns

014——014——014——ns

master 20 — 20 — 20 — 20 ns

Valid (WSR Out Delay Time)

118 Word Select In Valid to SCKR

slave 12 12 — 12 — 12 — ns

Edge (WSR In Set-up Time)

119 SCKR Edge to Word Select In

slave 12 12 — 12 — 12 — ns

Not Valid (WSR In Hold Time)

121 SCKT Edge to Data Out Valid

(Data Out Delay Time) master

122 SCKT Edge to Word Select Out

1

slave

2

slave

master 19 — 19 — 19 — 19 ns

13

40

TH + 34

—

—

—

13

40

44

—

—

—

Valid (WST Out Delay Time)

123 Word Select In Valid to SCKT

slave 12 12 — 12 — 12 — ns

Edge (WST In Set-up Time)

124 SCKT Edge to Word Select In

slave 12 12 — 12 — 12 — ns

Not Valid (WST In Hold Time)

Note: 1. When the Frequency Ratio between Parallel and Serial clocks is 1:4 or greater

2. When the Frequency Ratio between Parallel and Serial clocks is 1:3 – 1:4

39.1——nsns

13.7——nsns

13.7——nsns

13

—

40

—

41

—

5.9nsns

13

40

39.7

ns

ns

ns

ns

ns

2-20 DSP56007/D MOTOROLA

SCKR

(RCKP = 1)

SCKR

(RCKP = 0)

115

Specifications

Serial Audio Interface (SAI) Timing

111

112

114 114

113

111

113

114 114

112

116

SDI0–SDI1

(Data Input)

WSR

(Input)

WSR

(Output)

Valid

119

118

Valid

117

AA0269

Figure 2-15 SAI Receiver Timing

MOTOROLA DSP56007/D 2-21

Specifications

Serial Audio Interface (SAI) Timing

SCKT

(T

KP = 1)

C

SCKT

KP = 0)

(T

C

SDO0–SDO2

(Data Output)

WST

(Input)

111

112

114 114

113

111

113

114 114

112

121

124

123

Valid

WST

(Output)

122

AA0270

Figure 2-16 SAI Transmitter Timing

2-22 DSP56007/D MOTOROLA

Serial Host Interface (SHI) SPI Protocol Timing

SERIAL HOST INTERFACE (SHI) SPI PROTOCOL TIMING

Specifications

(CL = 50 pF; V

= 0.7 × VCC, V

IHS

Table 2-12 Serial Host Interface (SHI) SPI Protocol Timing