Page 1

Application Guide and

Service Manual

AIR CONDITIONERS AND HEAT PUMPS

USING R-22 REFRIGERANT

Cancels: AP01-3, SM01,02-4 SM01,02-5

10-00

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................1

INTRODUCTION..........................................................................2

INSTALLATION GUIDELINE....................................................2

Residential New Construction..................................................2

Add-On Replacement (Retrofit)...............................................2

Seacoast (For Air Conditioners Only) .....................................2

ACCESSORY DESCRIPTIONS...................................................2

Compressor Crankcase Heater..................................................2

Evaporator Freeze Thermostat..................................................2

Winter Start Control .................................................................2

Compressor Start Assist—PTC................................................2

Compressor Start Assist Capacitor/Relay................................2

Low-Ambient Controller ..........................................................2

MotorMaster™ Control ............................................................2

Low-Ambient Pressure Switch.................................................2

Wind Baffle...............................................................................3

Coastal Filter.............................................................................3

Support Feet..............................................................................3

Liquid-Line Solenoid Valve.....................................................3

Thermostatic-Expansion Valve.................................................3

Isolation Relay..........................................................................3

LOW-AMBIENT GUIDELINE.....................................................3

LONG-LINE GUIDELINE............................................................3

Approved Systems....................................................................3

Interconnecting Tubing Sizing .................................................3

Metering Device Sizing............................................................6

Liquid-Line Solenoid And Tubing Configuration...................7

Charging Information................................................................8

2–Speed Applications ...............................................................8

UNIT IDENTIFICATION .............................................................8

Product Number Stamped on Unit-Rating Plate......................8

Serial Number Identification....................................................9

CABINET.....................................................................................10

Remove Top Cover—Before 1/1/92......................................10

Remove Fan-Motor Assembly—Before 1/1/92.....................10

Information Plate—Reliant Products......................................10

Control-Box Cover—Cube Products......................................10

Remove Top Cover— After 1/1/92 .......................................10

Remove Fan-Motor Assembly—After 1/1/92........................11

ELECTRICAL..............................................................................12

Aluminum Wire......................................................................12

Contactors................................................................................13

Capacitors................................................................................14

Cycle Protector........................................................................15

Crankcase Heater....................................................................16

Time-Delay Relay...................................................................16

Pressure Switches....................................................................17

Defrost Thermostats................................................................18

Defrost-Control Board............................................................18

Fan Motors..............................................................................21

Service Alarm Control Board.................................................21

Outdoor Thermostat(s)............................................................22

Compressor Plug.....................................................................24

Low-Voltage Terminals..........................................................25

RECIPROCATING COMPRESSOR ..........................................25

Mechanical Failures................................................................25

Electrical Failures ...................................................................26

System Cleanup After Burnout..............................................27

Compressor Removal And Replacement ...............................27

COPELAND SCROLL COMPRESSOR ....................................28

Features ...................................................................................28

Troubleshooting ......................................................................28

Discharge Thermostat.............................................................28

Discharge Solenoid Valve......................................................28

MILLENNIUM SCROLL COMPRESSOR................................29

Features ...................................................................................29

Compressor Protection............................................................29

Troubleshooting ......................................................................29

Scroll Compressor, 3–Phase Monitor.....................................29

TWO-SPEED SYSTEM ..............................................................29

Cautions and Warnings...........................................................29

System Functions....................................................................29

Factory Defaults......................................................................33

Major Components..................................................................33

LED Function/Malfunction Lights.........................................34

Troubleshooting ......................................................................34

REFRIGERATION SYSTEM .....................................................35

Refrigeration Cycle.................................................................35

Leak Detection........................................................................35

Brazing....................................................................................37

Service Valves ........................................................................38

Check-Flo-Rater™ (Bypass-Type) Heat Pumps Only...........39

Reversing Valve......................................................................39

Thermostatic-Expansion Valves (TXV).................................40

Thermostatic-Expansion Valve (Bi-Flow TXV)....................41

Coil Removal..........................................................................41

Liquid-Line Strainer (Heat Pumps Only) ..............................41

Accumulator............................................................................43

Contaminant Removal ............................................................43

System Charging.....................................................................43

Checking Charge.....................................................................43

CARE AND MAINTENANCE...................................................45

SAFETY CONSIDERATIONS

Service and repair of these units should be attempted only by

trained service technicians familiar with Bryant standard service

instructions and training manual.

All equipment should be installed in accordance with accepted

practices and unit Installation Instructions, and in compliance with

all national and local codes.

Power should be turned off when servicing or repairing electrical

components. Extreme caution should be observed when troubleshooting electrical components with power on. Observe all warning notices posted on equipment.

—1—

Page 2

Refrigeration system contains refrigerant under pressure. Extreme

caution should be observed when handling refrigerants. Wear

safety glasses and gloves to prevent personal injury. During

normal system operation, some components are hot and can cause

burns. Rotating fan blades can cause personal injury. Appropriate

safety considerations are posted throughout this manual where

potentially dangerous techniques are addressed.

It is important to recognize safety information. This is the

safety-alert symbol

. When you see this symbol on the unit and

in instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

WARNING: Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion,

fire, electrical shock, or other conditions which may

cause personal injury, death, or property damage. Consult

a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or agency must use factory-authorized kits or

accessories when modifying this product.

INTRODUCTION

This service manual enables a service technician to service, repair,

and maintain a family of similar air conditioners and heat pumps.

It covers standard single-speed products and 2–speed products

only. For variable-speed products, refer to the respective service

manuals.

INSTALLATION GUIDELINE

I. RESIDENTIAL NEW CONSTRUCTION

Specifications for this unit in the residential, new-construction

market require the outdoor unit, indoor unit, refrigerant-tubing

sets, metering device, and filter drier listed in Product Data Sheet

(PDS). DO NOT DEVIATE FROM PDS. Consult unit Installation

Instructions for detailed information.

II. ADD-ON REPLACEMENT (RETROFIT)

Specifications for this unit in the add-on replacement/retrofit

market require change-out of outdoor unit, metering device, and all

capillary-tube coils. Change-out of indoor coil is recommended.

There can be no deviation.

1. If system is being replaced due to compressor electrical

failure, assume acid is in system. If system is being replaced

for any other reason, use approved acid test kit to determine

acid level. If even low levels of acid are detected, install

factory-approved, suction-line filter drier in addition to the

factory-supplied, liquid-line filter drier. Remove the

suction-line filter drier as soon as possible, with a maximum

of 72 hr.

2. Drain oil from low points or traps in suction-line and

evaporator if they were not replaced.

3. Change out indoor coil or verify existing coil is listed in the

Product Data Sheets.

4. Replace outdoor unit.

5. Install liquid-line filter drier.

6. If suction-line filter drier was installed for system clean up,

operate system for 10 hr. Monitor pressure drop across

drier. If pressure drop exceeds 3 psig, replace suction-line

and liquid-line filter driers. Be sure to purge system with

dry nitrogen and evacuate when replacing filter driers.

Continue to monitor pressure drop across suction-line filter

drier. After 10 hr of run time, remove suction-line filter

drier and replace liquid-line filter drier. Never leave

suction-line filter drier in system longer than 72 hr

(actual time).

7. Charge system. (See unit information plate.)

III. SEACOAST (FOR AIR CONDITIONERS ONLY)

Installation of these units in seacoast locations requires the use of

a coastal filter. (See section on cleaning.)

ACCESSORY DESCRIPTIONS

Refer to Table 1 for an Accessory Usage Guide for Air Conditioners and Heat Pumps. See Model-specific product literature for

any kit part number. Refer to the appropriate section below for a

description of each accessory and its use.

I. COMPRESSOR CRANKCASE HEATER

An electric heater which mounts to base of compressor to keep

lubricant warm during off cycles. Improves compressor lubrication

on restart and minimizes chance of refrigerant slugging and oil

pumpout. The crankcase heater may or may not include a

thermostat control. For units equipped with crankcase heaters,

apply power for 24 hr before starting compressor.

II. EVAPORATOR FREEZE THERMOSTAT

An SPST temperature-activated switch stops unit operation when

evaporator reaches freeze-up conditions.

III. WINTER START CONTROL

An SPST delay relay which bypasses the low-pressure switch for

approximately 3 minutes to permit startup for cooling operation

under low-load conditions.

IV. COMPRESSOR START ASSIST—PTC

Solid-state electrical device which gives a ″soft″ boost to the

compressor at each start.

V. COMPRESSOR START ASSIST CAPACITOR/RELAY

Start capacitor and start relay gives ″hard″ boost to compressor

motor at each start. Required with Liquid-Line Solenoid or

hard-shutoff TXV for all equipment.

VI. LOW-AMBIENT CONTROLLER

Low-ambient controller is a cycle-control device activated by a

temperature sensor mounted on a header tube of the outdoor coil.

It is designed to cycle the outdoor fan motor in order to maintain

condensing temperature within normal operating limits (approximately 100°F high, and 60°F low). The control will maintain

working head pressure at low-ambient temperatures down to 0°F

when properly installed.

VII. MOTORMASTER™ CONTROL

A fan speed-control device activated by a temperature sensor. It is

designed to control condenser fan-motor speed in response to the

saturated, condensing temperature during operation in cooling

mode only. For outdoor temperature down to -20°F, it maintains

condensing temperature at 100°F±10°F. Requires a ball-bearing

fan motor.

VIII. LOW-AMBIENT PRESSURE SWITCH

A long-life pressure switch which is mounted to outdoor unit

service valve. It is designed to cycle the outdoor fan motor in

response to condenser pressure in cooling mode in order to

maintain head pressure within normal operating limits (approximately 100 psig to 225 psig). The control will maintain working

head pressure at low-ambient temperatures down to 0°F when

properly installed.

—2—

Page 3

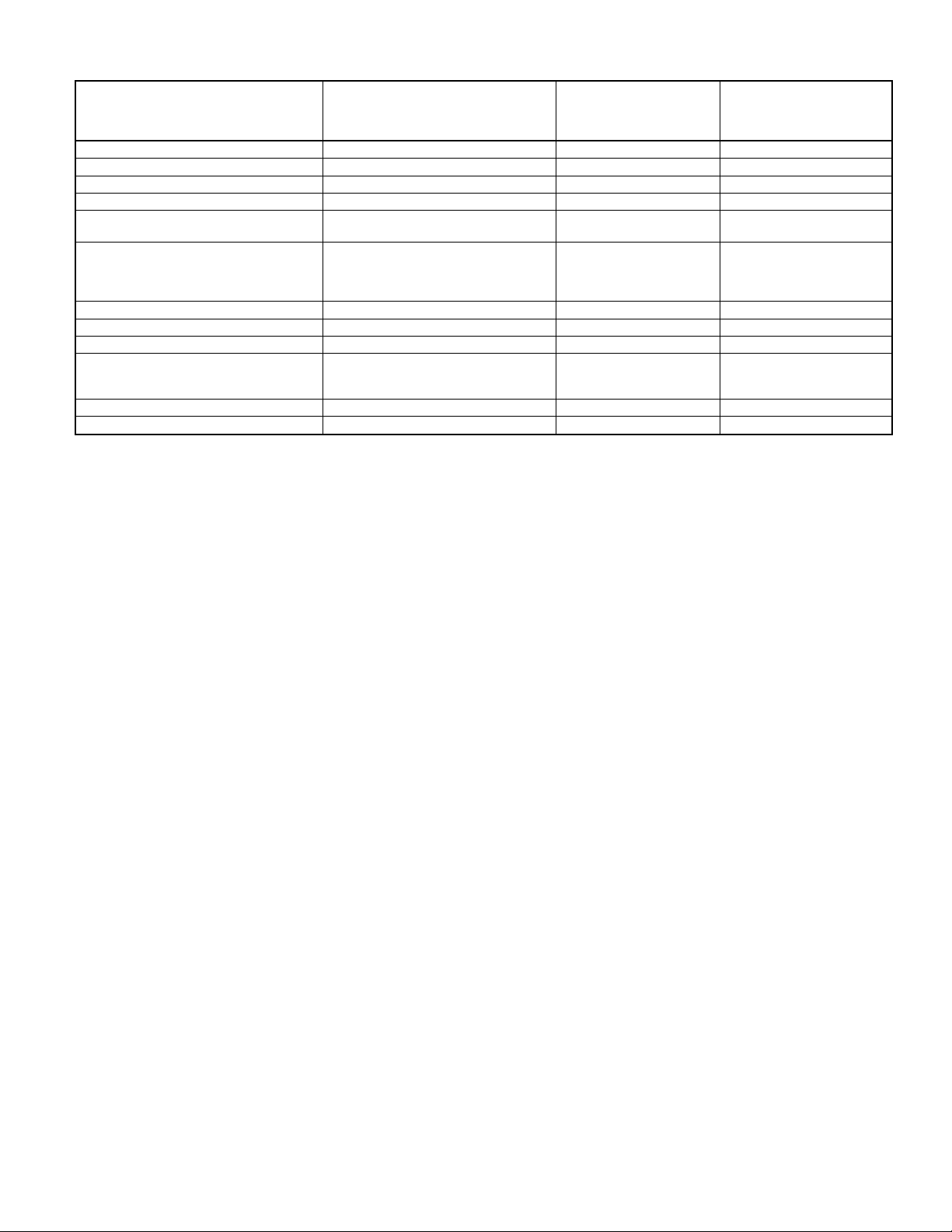

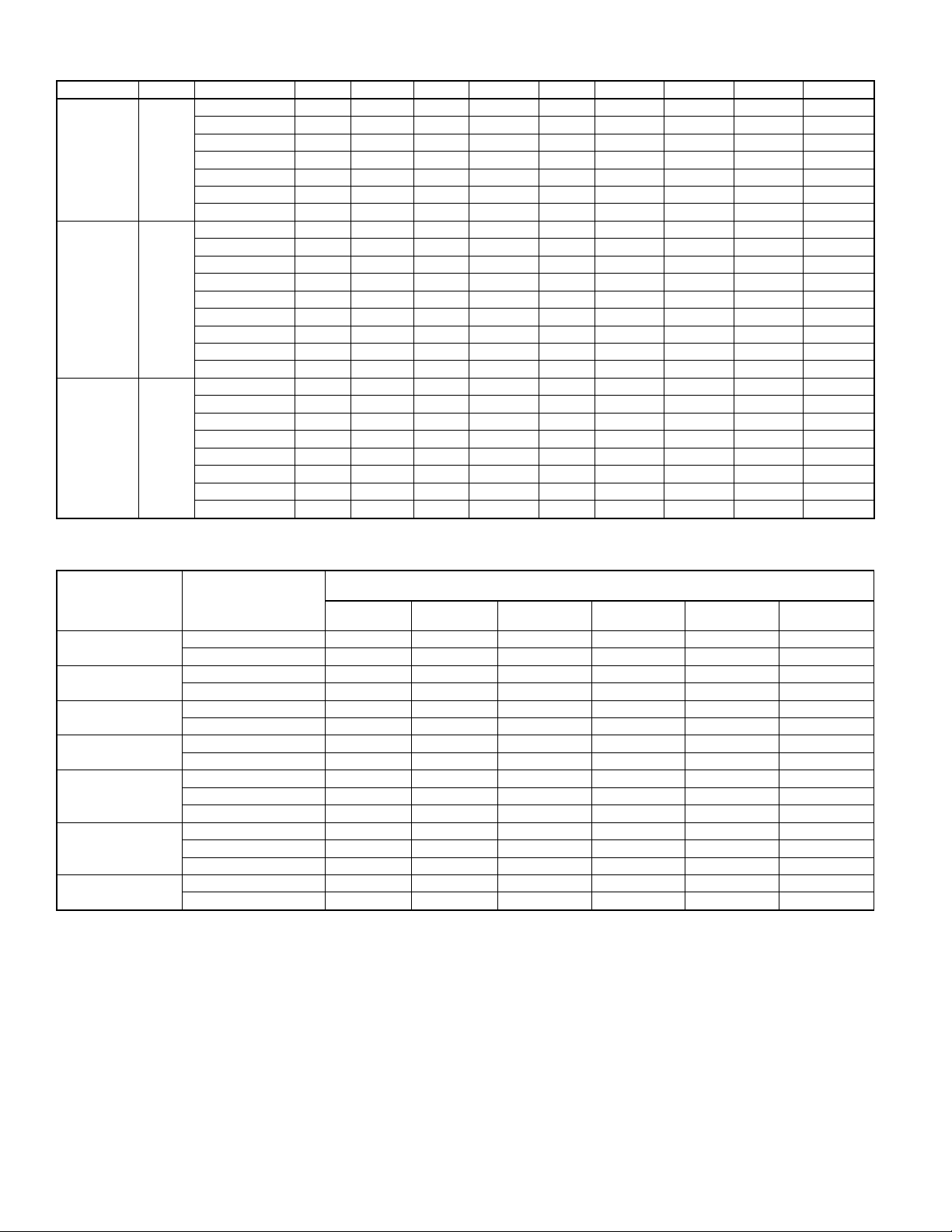

TABLE 1—REQUIRED FIELD-INSTALLED ACCESSORIES FOR AIR CONDITIONERS AND HEAT PUMPS

REQUIRED FOR

ACCESSORY

Crankcase Heater Yes Yes No

Evaporator Freeze Thermostat Yes No No

Winter Start Control Yes† No No

Accumulator No No No

Compressor Start Assist

Capacitor and Relay

Low Ambient Controller,

MotorMaster™ Control,

Low-Ambient Pressure Switch

Liquid-Line Solenoid Valve

Ball-Bearing Fan Motor Yes‡ No No

*For tubing line sets between 50 and 175 ft, refer to Residential Split-System Long-Line Application Guideline.

†Only when low-pressure switch is used.

‡Required for Low-Ambient Controller (full modulation feature) and MotorMaster™ control only.

** Required on Heat Pumps only.

or

Wind Baffle See Low-Ambient Instructions No No

Coastal Filter No No Yes

Support Feet Recommended No Recommended

or

Hard-Shutoff TXV

Isolation Relay Yes** No No

LOW-AMBIENT

APPLICATIONS

(BELOW 55°F)

Yes Yes No

Yes No No

No

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(OVER 50 FT)

See Long-Line

Application

Guideline

REQUIRED FOR

SEA COAST

APPLICATIONS

(WITHIN 2 MILES)

No

IX. WIND BAFFLE

A field-fabricated sheet-metal cover used to stop prevailing winds

or where outdoor ambient temperature is less than 55°F during unit

operation of cooling mode.

X. COASTAL FILTER

A mesh screen inserted under top cover and inside base pan to

protect condenser coil from salt damage without restricting airflow.

XI. SUPPORT FEET

Four adhesive plastic feet which raise unit 4 in. above mounting

pad. This allows sand, dirt, and other debris to be flushed from unit

base; minimizes corrosion.

XII. LIQUID-LINE SOLENOID VALVE

An electrically operated shutoff valve to be installed at outdoor or

indoor unit (depending on tubing configuration) which stops and

starts refrigerant liquid flow in response to compressor operation.

Maintains a column of refrigerant liquid ready for action at next

compressor-operation cycle and prevents liquid migration during

the off cycle.

XIII. THERMOSTATIC-EXPANSION VALVE

A modulating flow-control device which meters refrigerant flow

rate into the evaporator in response to the superheat of the

refrigerant gas leaving the evaporator. Only use factory-specified

TXV’s.

XIV. ISOLATION RELAY

A DPDT relay which switches the low-ambient controller out of

the outdoor fan-motor circuit when the heat pump switches to

heating mode.

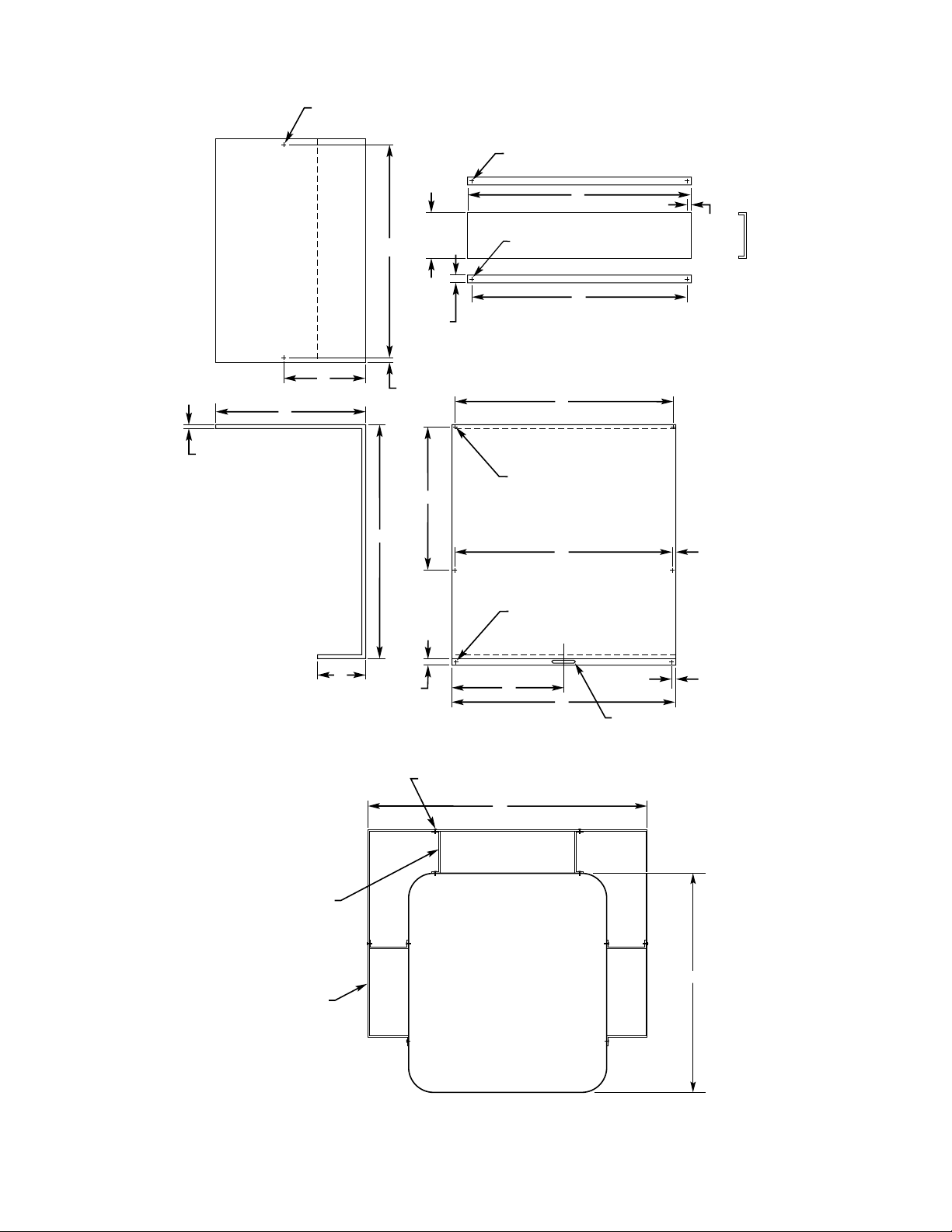

LOW-AMBIENT GUIDELINE

The minimum operating temperature for these units in cooling

mode is 55°F outdoor ambient without additional accessories. This

equipment may be operated in cooling mode at ambient temperatures below 55°F when the accessories listed in Table 1 are

installed. Wind baffles are required when operating in cooling

mode at ambients below 55°F. Refer to Fig. 1 or 2 and Table 2 or

3 for wind baffle construction details.

LONG-LINE GUIDELINE

This Long-Line Application Guideline applies to all Bryant

residential air conditioner and heat pump split systems that have a

nominal capacity of 18,000 to 60,000 Btuh. This guideline

provides required system changes and accessories necessary for

any residential product having piping requirements greater than 50

ft or installations where indoor unit is located above outdoor unit.

This guideline is intended to cover applications outside the

standard Installation Instructions. This guideline is for standard,

single-speed products. For applications involving 2-speed products, refer to Section VI first.

NOTE: The presale literature for outdoor unit must be referred to

in conjunction with this guideline.

I. APPROVED SYSTEMS

Any residential indoor/outdoor unit combination listed in the

outdoor unit presale literature is an approved system, EXCEPT the

following:

• Indoor coils with capillary-metering devices

• All equipment less than nominal 18,000 Btuh

• All 1/4-in. and 5/16–in. liquid-line applications

• Any indoor furnace coil/fan coil not listed in outdoor unit

presale literature

• Any application which has interconnecting tubing with an

equivalent length greater than 175 ft

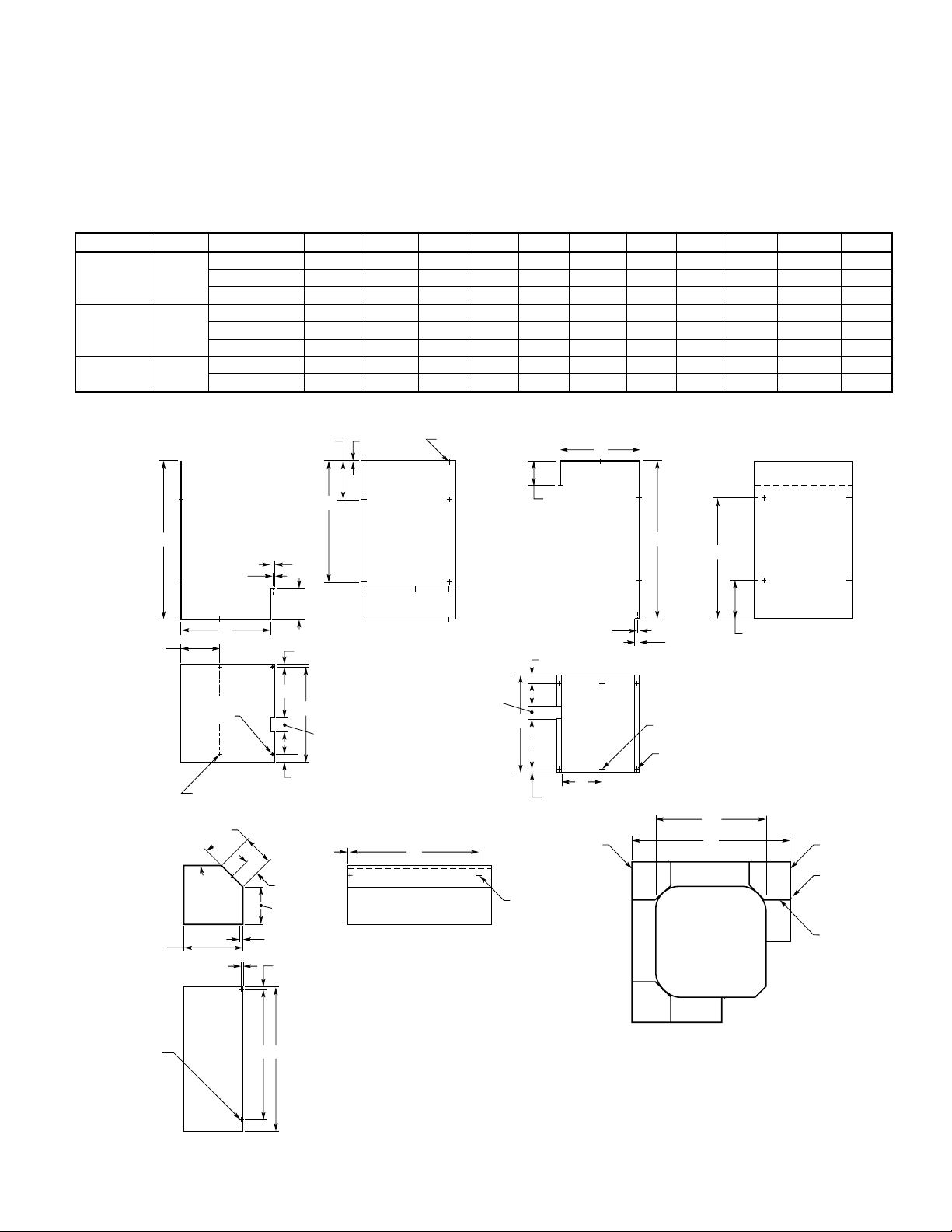

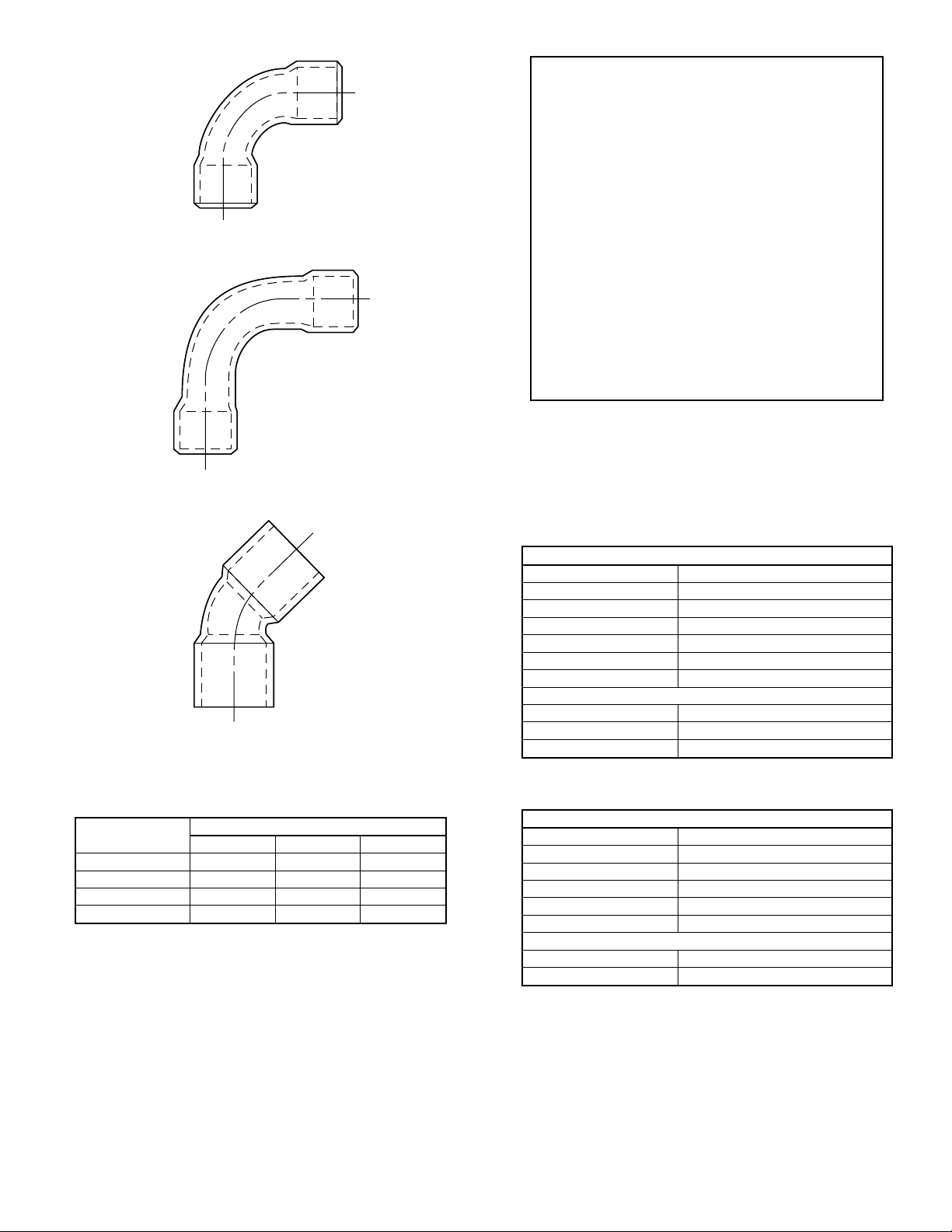

II. INTERCONNECTING TUBING SIZING

Table 4 lists recommended interconnecting vapor-line diameters

for equivalent total-line lengths. All residential split systems

installed in long-line applications must use only 3/8-in. liquid

lines. Equivalent line length equals the linear length (measured) of

interconnecting vapor tubing plus losses due to elbows. (See Table

5 and Fig. 3.) Liquid lines larger than 3/8-in. OD greatly increase

charge quantity of the system. Excessive charge increases risk of

migration and compressor damage. Table 4 provides the estimated

percentage of nominal cooling-capacity losses based on the standard, required vapor line size versus what is selected for the

long-line application. Since the vapor line is the discharge line in

heating mode, losses are minimal.

—3—

Page 4

1

/4″ x 3/8″ (5.56 x 9.53) SLOT

4 REQ'D

5

5/16″

(151.5)

J

1

/8″ (3.45) DIA HOLE

2 REQ'D

H

1

/4″ (5.56) DIA HOLE 2 REQ'D

3

/8″

(9.6)

1

/2″

(12.7)

1

/2″

(12.7)

TYP

7

C

/16″

(11.6)

SUPPORT

MAT'L: 18 GA STEEL

A

1

/8″ (3.45) DIA HOLE

K

1 REQ'D

B

1

/4″ (5.56) DIA HOLE

G

E

7

/16″

J

(11.6)

3 REQ'D

6″

(152.4)

1

/4″

(6.3)

BAFFLE

L

D

1

/4″ x 2″

(5.56 x 50.8) SLOT

3

/8″ (9.6)

MAT'L: 20 GA STEEL

SCREW

10 REQ'D

F

SUPPORT

4 REQ'D

OUTDOOR

BAFFLE

2 REQ'D

UNIT

BAFFLE ASSEMBLY

Fig. 1—Wind Baffle Construction for Reliant Units

—4—

AA

A95445

Page 5

Calculate the linear length of vapor tube required, adding any

losses for the total number of elbows for application. (See Table

5.) Using this equivalent length, select desired vapor-line size from

Table 4. Subtract the nominal percentage loss from outdoor-unit

All standard accessory-tubing kits are supplied with 3/8-in. insulation on vapor line.

For minimal capacity loss in long-line application, 1/2-in. insulation should be specified.

presale-literature Detailed Cooling Capacities data for the given

indoor/outdoor combination. Reference all notes of Table 4.

NOTE: When specifying vapor-line insulation, be aware of the

following standard practice:

TABLE 2—WIND BAFFLE DIMENSIONS FOR RELIANT UNITS WITH AEROQUIET-SYSTEM TOP (IN.)

UNIT SIZE AA UNIT HEIGHT A B C D E F G H J K L

23-13/16 17-1/4 24-5/16 10-1/4 19-3/4 20-1/2 34-1/2 19-5/8 20-3/8 19-5/8 0 0

Small 26-3/16

Medium 33

Large 42-1/16

27-13/16 17-1/4 24-5/16 10-1/4 23-3/4 24-1/2 34-1/2 23-5/8 24-3/8 23-5/8 0 11-7/8

33-13/16 17-1/4 24-5/16 10-1/4 29-3/4 30-1/2 34-1/2 29-5/8 30-3/8 29-5/8 0 14-7/8

27-13/16 21 30-5/8 10-1/4 23-3/4 24-1/2 42 23-5/8 24-3/8 23-5/8 17-1/8 11-7/8

33-13/16 21 30-5/8 10-1/4 29-3/4 30-1/2 42 29-5/8 30-3/8 29-5/8 17-1/8 14-7/8

39-13/16 21 30-5/8 10-1/4 35-3/4 36-1/2 42 35-5/8 36-3/8 35-5/8 17-1/8 17-7/8

33-13/16 25-5/16 39-3/4 10-1/4 29-3/4 30-1/2 50-9/16 29-5/8 30-3/8 29-5/8 21-11/16 14-7/8

39-13/16 25-5/16 39-3/4 10-1/4 35-3/4 36-1/2 50-9/16 35-5/8 36-3/8 35-5/8 21-11/16 17-7/8

5

8

/64″ (205.3)

TYP

7

7

/8″

(199.9)

C

1

/4″

(6.4)

B

1

/4″ (5.56) DIA

2 REQ'D

1

/4″ x 3/8″ (5.56 x 9.53) SLOT

6 REQ'D

9

4

/64″ (105.2)

45°

TYP

1

/4″

(6.4)

(200.0)

1

(12.7)

3

5

/64″

(128.0)

25

D

A

21

1

5

2

/64″

(52.6)

57

4

⁄

64

(124.2) TYP

1

/2″ (12.7)

TYP

23

/64″ (9.2)

7

7

/8″

E

/2″

/64″ (10.0)

1

2

/2″

(63.5)

/32″ (42.1)

23

/64″

(9.2)

″

3

/16″

(4.6)

BAFFLE - LEFT

MAT'L: 20 GA STEEL

1

/8″ (3.45) DIA

2 REQ'D

J

SUPPORT

MAT'L: 18 GA STEEL

1

2

/2″

(63.5)

3

5

(128.0)

21

1

A

D

25

⁄64″ (10.0)

1

/4″ (5.56) DIA

2 REQ'D

/64″

13

/64″

(5.4)

TYP

/32″ (42.1)

G

LEFT

SIDE

F

C

E

1

/2″

(12.7)

29

7

/32″ (200.8)

TYP

BAFFLE - RIGHT

MAT'L: 20 GA STEEL

1

/4″ x 3/8″ (5.56 x 9.53) SLOT

6 REQ'D

1

/4″ (5.56) DIA

4 REQ'D

AA

C

OUTDOOR

UNIT

RIGHT

SIDE

SCREW

14 REQ'D

SUPPORT

3 REQ'D

1

/8″ (3.45) DIA.

4 REQ'D

J

H

BAFFLE ASSEMBLY

A95446

Fig. 2—Wind Baffle Construction for Cube Units

—5—

Page 6

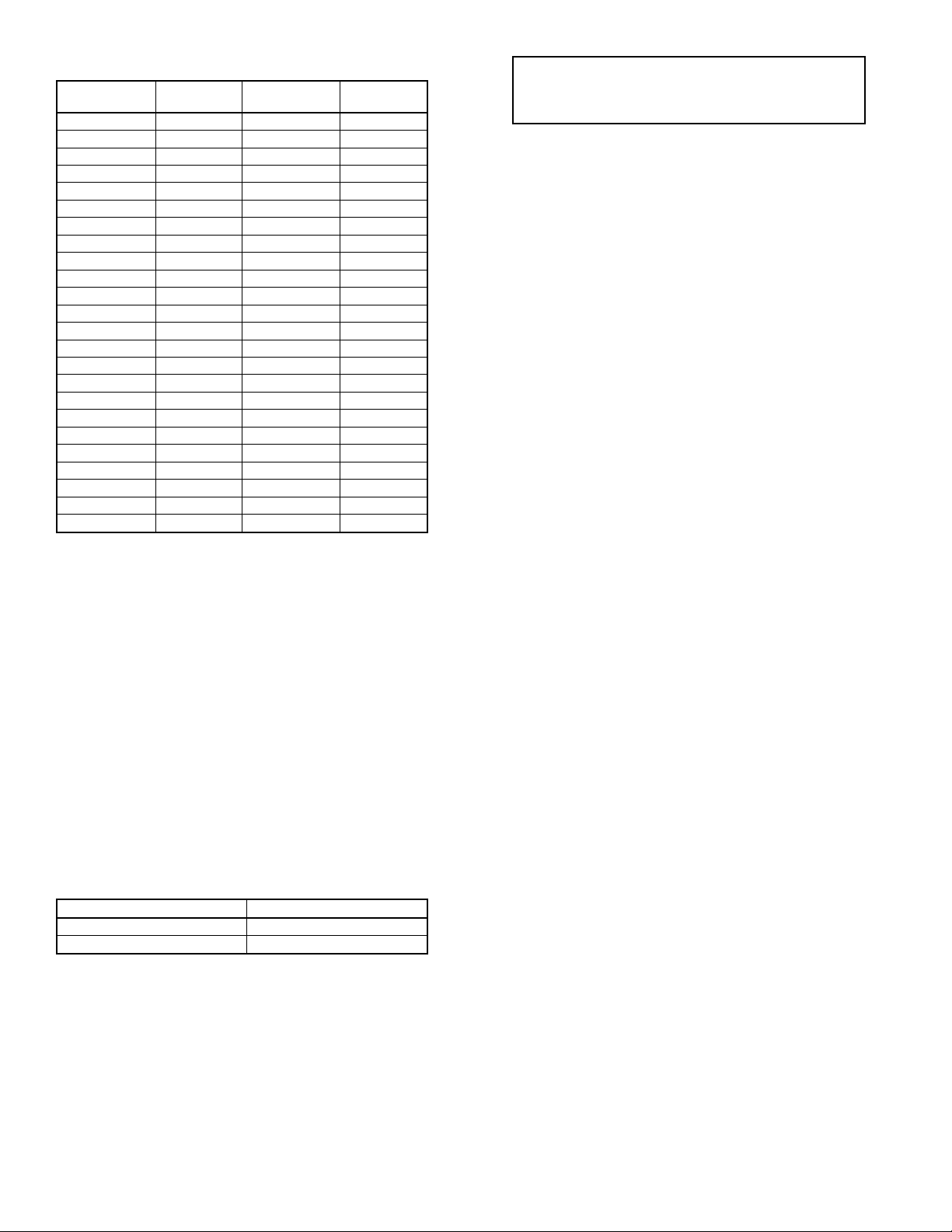

TABLE 3—WIND BAFFLE DIMENSIONS FOR CUBE UNITS (IN.)

UNIT SIZE AA UNIT HEIGHT A B C D E F G H J

21-15/16 19-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 19-13/16 17-13/16

23-15/16 21-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 21-13/16 19-13/16

25-15/16 23-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 23-13/16 21-13/16

Small 18

Medium 22-1/2

Large 30

27-15/16 25-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 25-13/16 23-13/16

29-15/16 27-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 27-13/16 25-13/16

31-15/16 29-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 29-13/16 27-13/16

33-15/16 31-7/8 13-3/4 28-1/8 10-11/16 20-1/4 11-11/16 3-13/16 31-13/16 29-13/16

21-15/16 19-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 19-13/16 17-13/16

23-15/16 21-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 21-13/16 19-13/16

25-15/16 23-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 23-13/16 21-13/16

27-15/16 25-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 25-13/16 23-13/16

29-15/16 27-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 27-13/16 25-13/16

31-15/16 29-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 29-13/16 27-13/16

33-15/16 31-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 31-13/16 29-13/16

35-15/16 33-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 33-13/16 31-13/16

37-15/16 35-7/8 18-5/16 32-5/8 10-11/16 24-3/4 16-3/16 8-1/4 35-13/16 33-13/16

25-15/16 23-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 23-13/16 21-13/16

27-15/16 25-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 25-13/16 23-13/16

29-15/16 27-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 27-13/16 25-13/16

31-15/16 29-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 29-13/16 27-13/16

33-15/16 31-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 31-13/16 29-13/16

35-15/16 33-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 33-13/16 31-13/16

37-15/16 35-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 35-13/16 33-13/16

39-15/16 37-7/8 25-3/4 40-1/8 10-11/16 32-1/4 23-11/16 15-13/16 37-13/16 35-13/16

TABLE 4—ESTIMATED PERCENTAGE OF NOMINAL COOLING-CAPACITY LOSSES*

UNIT

NOMINAL

SIZE

(BTUH)

18,000

24,000

30,000

36,000

42,000

48,000

60,000

*The estimated percentage of cooling capacity that must be subtracted from the Detailed Cooling Capacities data specified in outdoor unit-presale literature for any given

indoor/outdoor combination.

†Vapor-line diameter that may be selected for a long-line application. If smaller vapor lines are selected but not specified within the table, large capacity losses will occur

and defrost capabilities will be reduced. If larger vapor lines are selected but not specified within the table, refrigerant oil return will be impaired due to velocity losses.

N/R—Not recommended due to excessive loss of capacity.

For reference only, the close cell insulation material specified for

accessory tubing kits is a compound of vinyl, neoprene, or nitrile

blends of these polymers. Performance requirements include

thermal range of 0° Fto200°F (-17.8° Cto93° C) and a maximum

thermal conductivity of 0.28.

NOTE: Special consideration must be given to isolating interconnecting tubing from building structure. Isolate tubing so that

vibration or noise is not transmitted into structure.

III. METERING DEVICE SIZING

The metering device for a long-line application must be flexible

enough to compensate for frictional losses due to long refrigerant

LONG-LINE

VAPOR-LINE

DIAMETER

(IN.)†

5/8 5 7 9 12 12 14

3/4 1 3 4 5 5 7

5/8 6 9 13 16 19 22

3/4 0 1 1 2 3 4

5/8 6 8 10 13 15 17

3/4 2 3 4 5 6 7

3/4 7 10 14 17 21 N/R

7/8 2 4 6 8 10 11

3/4 7 10 13 17 20 23

7/8 3 4 6 7 8 10

1-1/8 0 0 1 1 2 2

3/4 10 14 18 22 N/R N/R

7/8 4 6 7 9 11 13

1-1/8 0 0 1 1 2 2

7/8 7 9 11 14 16 19

1-1/8 1 2 2 3 3 4

50 75 100 125 150 175

EQUIVALENT LINE LENGTH (FT)

lines and installed system design (indoor coil above or below

outdoor unit.) The piston or TXV provides such flexibility.

The piston should be changed for both indoor coil and outdoor heat

pump unit, depending on system configuration and line length.

Tables 6 and 7 provide necessary changes for a given application.

Use Tables 6 and 7 when selecting correct piston size. Outdoorunit presale literature must be consulted to determine metering

devices specified for standard applications. After determining

standard application piston size(s), refer to Tables 6 and 7 as they

relate to system design (outdoor unit above or below indoor unit)

per equivalent length of tubing.

—6—

Page 7

90° STD

90° LONG RAD

EXAMPLE:

An 042 size heat pump is 75 ft above an 042 size fan coil.

The 042 size heat-pump presale literature specifies a size

80 indoor piston and size 63 outdoor piston.

To establish correct indoor piston size for a 75 ft vertical

A

separation, refer to Table 6. For a 75 ft equivalent line

length, the piston change is -5. Therefore subtract 5 from

the original indoor piston size of 80:

80 – 5=75

Table 8 provides common piston sizes. In this instance, 75

is not listed, therefore round DOWN to next piston size,

which would be 74.

To establish correct outdoor piston size for a 75 ft vertical

separation, refer to Table 7. For a 75 ft equivalent line

length, the piston change is +4. Therefore add 4 to the

original outdoor piston size of 63:

63+4=67

Since 67 is listed in Table 8, that is the piston which should

be used. If a 67 size piston were not listed, it would be

necessary to round UP to next piston size.

B

TXVs may be used instead of pistons for indoor-metering devices.

Some fan coils are equipped with a hard-shutoff, bi-flow TXV

standard, and no change is required. When sizing an accessory

TXV for long-line applications, TXV should be the same nominal

tonnage as outdoor unit. Refer to presale literature for kit part

numbers.

C

45° STD

A92498

Fig. 3—Tube Bend Losses

TABLE 5—FITTING LOSSES IN EQUIVALENT FT

TUBE SIZE OD

(IN.)

5/8 1.6 1.0 0.8

3/4 1.8 1.2 0.9

7/8 2.0 1.4 1.0

1-1/8 2.6 1.7 1.3

REFERENCE DIAGRAM IN FIG. 1

ABC

NOTE: If total equivalent horizontal length is 100 ft or longer,

both indoor and outdoor pistons must be increased 1 full piston

size, in addition to changes required by Tables 6 and 7.

After finding appropriate change in piston size, add or subtract the

change from original piston number. If piston size is decreased,

round new piston number down to nearest common piston number

found in Table 8. If piston size is increased, round new piston

number up to nearest common piston number found in Table 8.

TABLE 6—CALCULATION OF INDOOR PISTON NO.

OUTDOOR UNIT ABOVE INDOOR

FT PISTON CHANGE

0-25 0

26-50 -3

51-75 -5

76-100 -7

101-125 -9

126-150 -10

OUTDOOR UNIT BELOW INDOOR

FT PISTON CHANGE

0-25 0

26-50 +4

TABLE 7—CALCULATION OF OUTDOOR PISTON NO.

OUTDOOR UNIT ABOVE INDOOR

FT PISTON CHANGE

0-50 0

51-75 +4

76-100 +6

101-125 +8

126-150 +10

OUTDOOR UNIT BELOW INDOOR

FT PISTON CHANGE

0-50 0

IV. LIQUID-LINE SOLENOID AND TUBING CONFIGURATION

There are 2 types of liquid-line solenoids: 1 for single-flow

applications and the other for bi-flow applications. The purpose of

having 2 solenoids is to minimize the valve internal-pressure drop

in accordance with refrigerant flow direction and liquid migration

to the compressor. The bi-flow solenoid is designed to have

minimal refrigerant-pressure drop in either flow direction, which

makes it suitable for heat pump usage. Refer to Table 9 for

liquid-line solenoid kit part numbers.

—7—

Page 8

TABLE 8—COMMON PISTON SIZES

CHECK-FLO-

RATER™

— 32 65 65

— 33 67 67

35 35 — 68

— 36 70 70

— 37 — 71

38 38 73 73

— 39 — 74

40 40 76 76

— 41 78 78

42 42 80 80

— 43 — 81

— 45 82 82

46 — 84 84

— 47 86 86

49 49 88 88

51 51 — 89

52 52 90 90

— 53 — 92

55 55 93 93

57 57 96 96

59 59 98 98

61 61 101 101

— 62 104 104

63 63 109 —

CHATLEFF

CHECK-FLO-

RATER™

CHATLEFF

NOTE: When installing a liquid-line solenoid, the system may

require a minimum 60va low-voltage transformer.

Each type of solenoid has an indicator flow arrow stamped on the

valve body. When solenoid is closed (not energized) and pressure

is applied in direction of flow arrow, complete shutoff occurs. If

pressure is applied against direction of flow arrow, leakage

through valve occurs. When determining proper installation of

valve within liquid line, 2 considerations must be made:

1. Direction of flow arrow

2. Where solenoid is installed in system.

TXVs can only be substituted for liquid-line solenoids in singleflow air conditioning systems. Bi-flow TXVs allow liquid migration to coldest point during off cycles, which could allow liquid

into compressor.

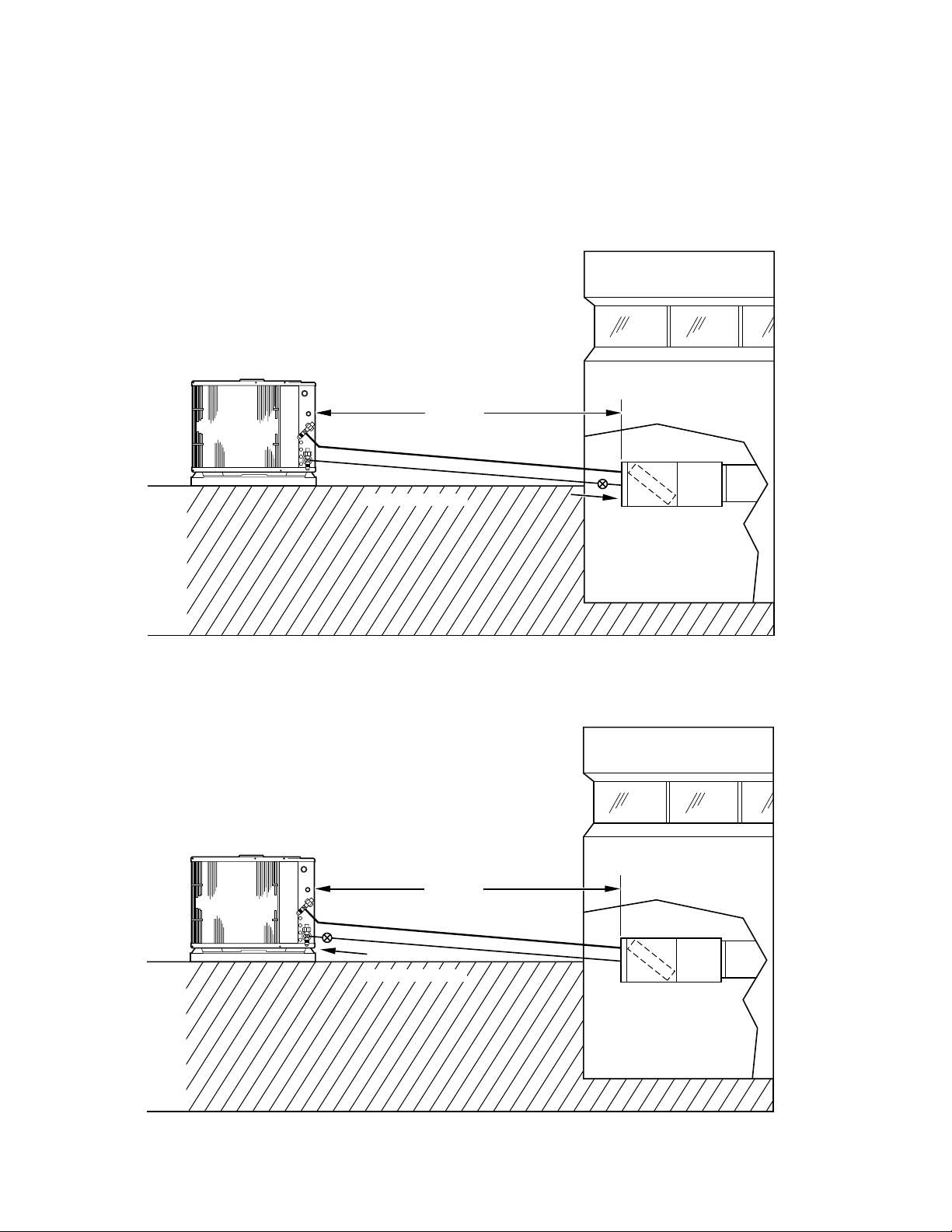

Fig. 4 through 7 detail proper installation of liquid-line solenoid

and provide applications where TXVs may be substituted. Reference all notes of the appropriate figures.

TABLE 9—LIQUID-LINE SOLENOID KIT PART NUMBERS

TYPE OF VALVE PART NO.

Single Flow KAALS0101LLS

Bi-Flow KHALS0401LLS

V. CHARGING INFORMATION

Weigh in appropriate refrigerant charge, then use the standard

practices of superheat-charging method for piston applications and

subcooling-charging method for TXV applications to confirm

correct charge. The standard charging methods can be found on

outdoor unit-information plate, in unit Installation Instructions, or

in the Service Manual. Since total system charge is increased for

long-line applications, it may be necessary to calculate the

additional refrigerant charge. Since long-line applications only

involve 3/8-in. liquid lines, the additional refrigerant charge

required is 0.6 oz of Refrigerant 22 (R-22) per ft of 3/8-in. liquid

line over 15 ft.

EXAMPLE:

To calculate additional charge required for a 25–ft line set:

25 ft – 15 ft = 10 ft X 0.6 oz/ft=6ozofadditional charge

The rating-plate charge of a given outdoor unit is for a standard

application of 15 ft of interconnecting tubing. The rating-plate

charge can be found on outdoor unit-rating plate or in outdoor

unit-presale literature. Long-line applications do not require additional oil charge.

VI. 2–SPEED APPLICATIONS

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. In long–line applications, 2–speed units are

handled basically the same way as the single-speed units. There are

2 major differences:

1. For tubing up to 100 ft:

Liquid tube diameters and refrigerant connection diameters

for all sizes are 3/8 in.

Vapor tube diameter for the 036 and 048 is 7/8 in.; 060 is

1–1/8 in.

Vapor refrigerant connection diameter for all sizes is 7/8 in.

DO NOT INSTALL EQUIVALENT INTERCONNECTING TUBING LENGTHS GREATER THAN 100 FT.

2. Do not increase or decrease tubing sizes.

For other applications see the previous sections under Long-Line

Guidelines.

UNIT IDENTIFICATION

I. PRODUCT NUMBER STAMPED ON UNIT-RATING

PLATE

The unit product number has 16 positions containing groups of

numbers and letters that indicate specific information about the

unit. Listed below is the breakdown of the 16 positions.

Positions 1, 2, and 3—Product Series

Example:

A 500–series number indicates a split-system condensing unit and

a 600–series number indicates a split-system heat pump.

Position 4—Model Letters

New models are introduced with the letter A, and subsequent

model changes are identified by changing to the next letter, as B,

then C, and so forth.

Position 5—Electrical Characteristics

Example:

J—208–230, 1 Phase, 60 Hertz

N—208/230, 208/240, 1 Phase, 60 Hertz

P—208/230, 208/240, 3 Phase, 60 Hertz

E—460, 3 Phase, 60 Hertz

Q—220, 3 Phase, 50 Hertz

S—220/240, 1 Phase, 50 Hertz

Z—380/415, 3 Phase, 50 Hertz

Position 6—Fuel and Controls

Not applicable on condensing units or heat pumps, so the letter ’X’

is used to signify ’none.’

Positions 7, 8, and 9—Nominal Cooling Capacity (in thousands

Btuh)

Example: 036 = 36,000 Btuh or 3–ton capacity.

Positions 10, 11, and 12—Not applicable on condensing units or

heat pumps, so the number ’zero’ is used to signify ’none.’

Position 13—Brand Name

Example:

A—Common unit —U.S.A. Only

Position 14—Unit Series

New units are introduced with the letter A, and subsequent major

component variations, such as in compressor, fan motor, coil

circuitor size, etc., are identified by changing to the next letter, as

B, then C, and so forth.

—8—

Page 9

Positions 15 and 16—Product Variations

Example:

AA—Standard unit

Other letters—For product variations from standard

II. SERIAL NUMBER IDENTIFICATION

The unit serial number has 10 positions containing groups of

numbers and a letter that indicate specific information about the

unit. Listed below is the breakdown of the 10 positions.

Positions 1 and 2—Week of Manufacture

Example:

01—First week of a year

175' MAX.

GROUND LEVEL

52—Last week of a year

Positions 3 and 4—Year of Manufacture

Example:

94—1994

Position 5—Manufacturing Site

Example:

A–Indianapolis

E–Collierville

Positions 6 through 10—Serial Number

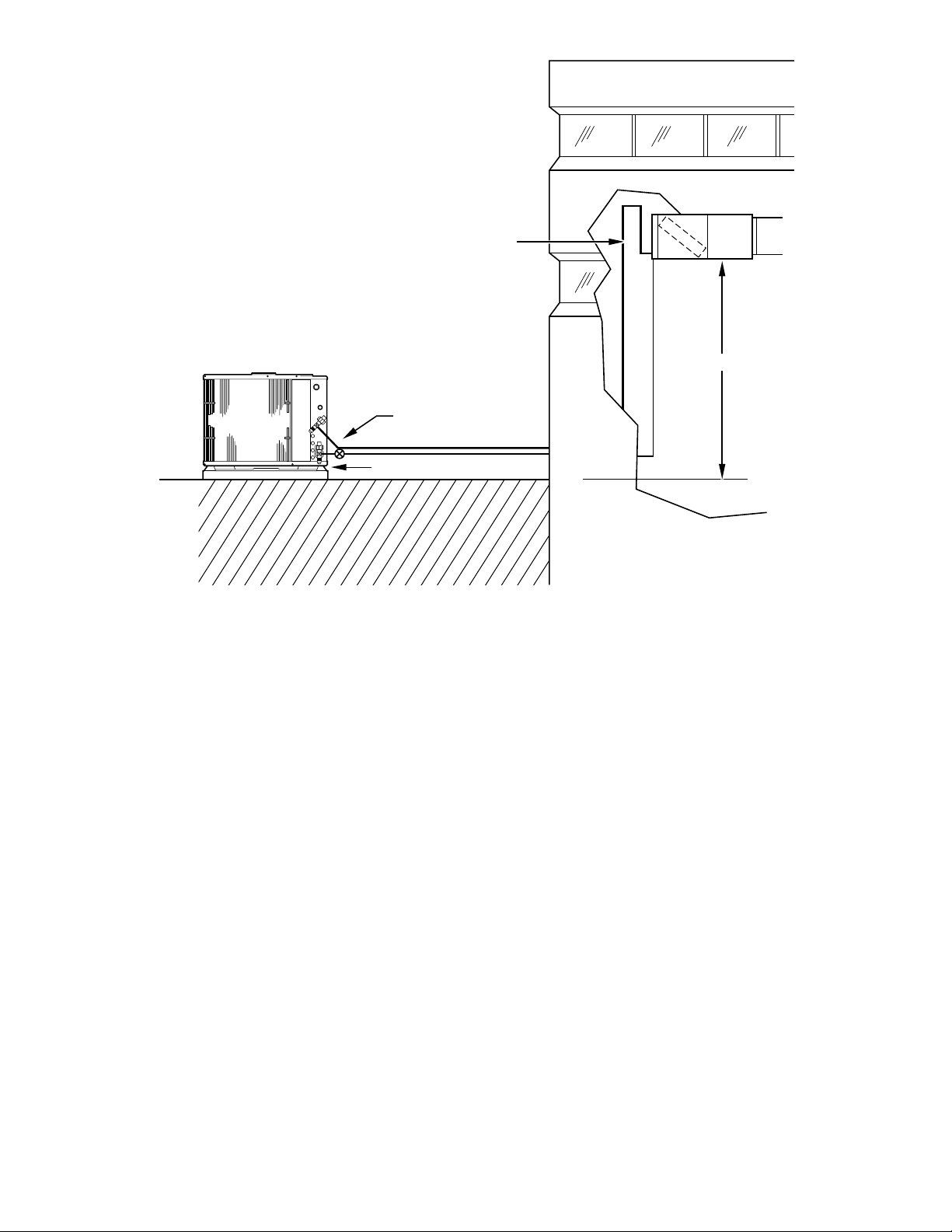

BASEMENT

Fig. 4—Application with Air Conditioner Installed in a Horizontal Configuration

175' MAX.

GROUND LEVEL

A90074

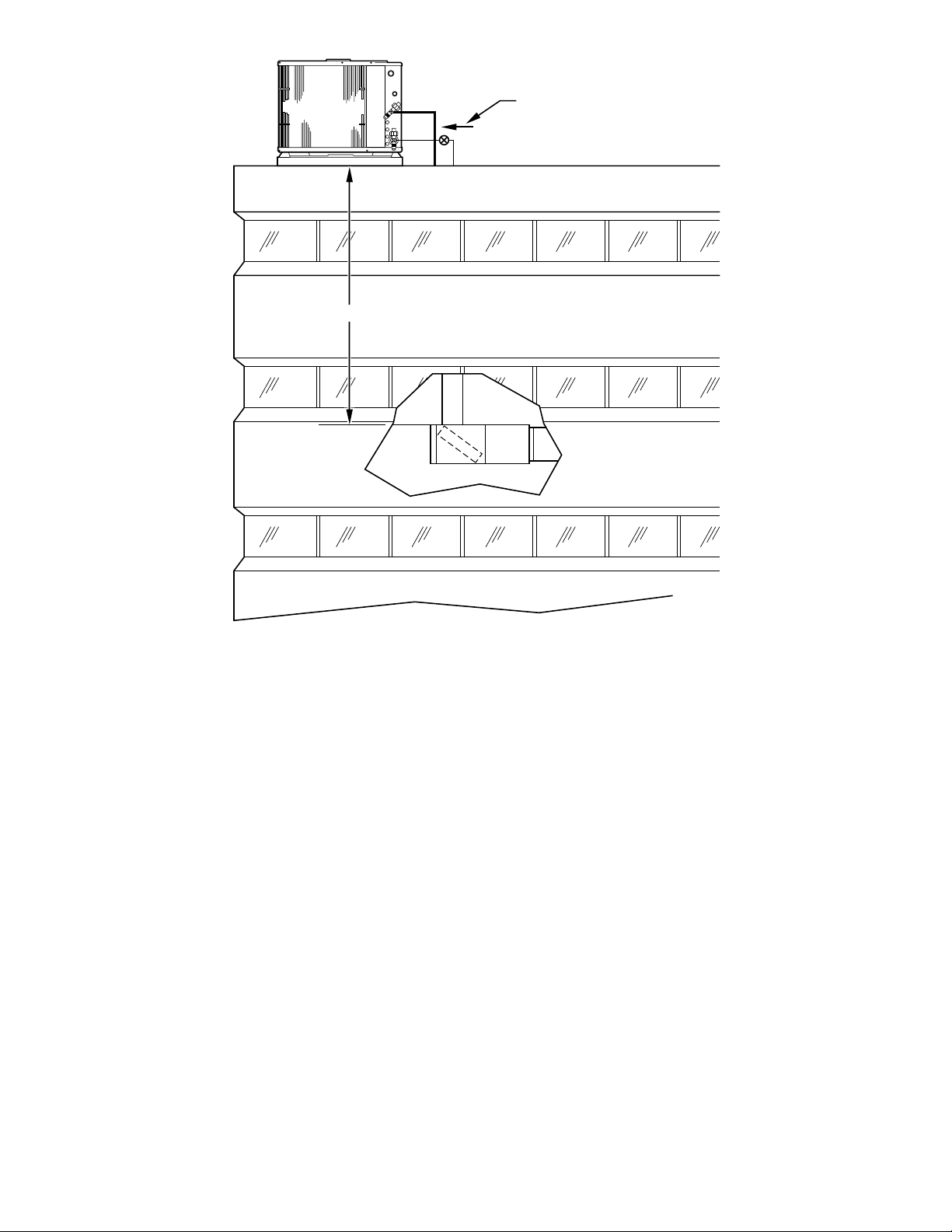

BASEMENT

Fig. 5—Application with Heat Pump Installed in a Horizontal Configuration

—9—

A90075

Page 10

HEAT PUMP ONLY

GROUND LEVEL

Fig. 6—Application with Air Conditioner or Heat Pump Installed with Indoor Unit Above Outdoor Unit

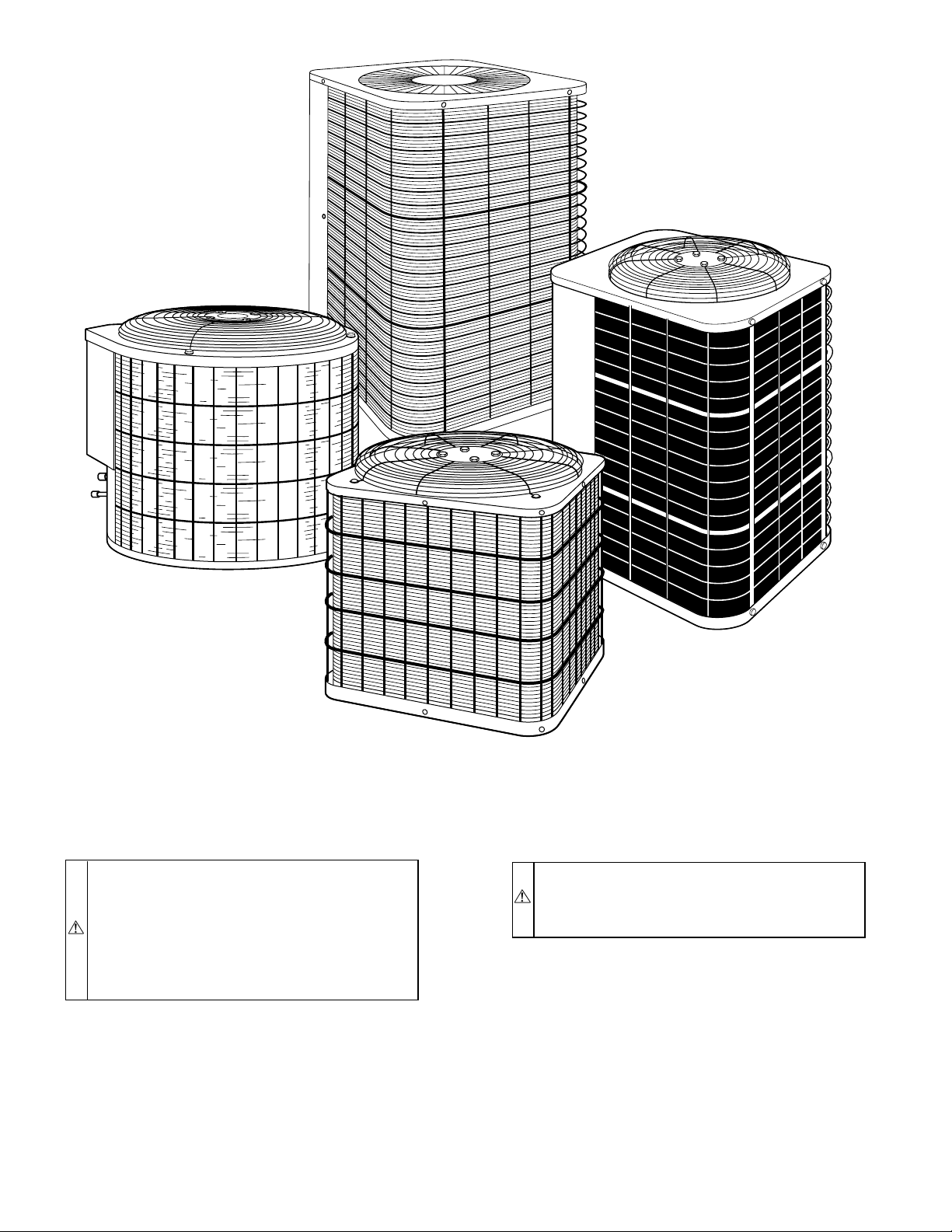

CABINET

Certain maintenance routines and repairs require removal of

cabinet panels. There are 4 basic cabinet designs for air conditioners and heat pumps. (See Fig. 8.) The horizontal discharge unit will

be discussed in a separate section of this manual. Note that

separate sections apply according to date of manufacture.

I. REMOVE TOP COVER—BEFORE 1/1/92

NOTE: This section applies to all Reliant products made prior to

January 1, 1992.

1. Turn off all power to outdoor and indoor units.

2. Remove screws holding top cover to coil grille and corner

posts.

3. Remove access panel.

4. Remove information plate.

5. Disconnect fan motor wires, cut wire ties, and remove wire

ties from control box. Refer to unit-wiring label.

6. Lift top cover from unit.

7. Reverse sequence for reassembly.

II. REMOVE FAN-MOTOR ASSEMBLY—BEFORE 1/1/92

NOTE: This section applies to all Reliant products made prior to

January 1, 1992.

1. Perform items 1 through 6 above.

2. Remove nuts holding fan-motor top cover.

3. Remove motor and fan blade assembly.

4. Reverse sequence for reassembly.

5. Prior to applying power, check that fan rotates freely.

TRAP

50' MAX.

A90076

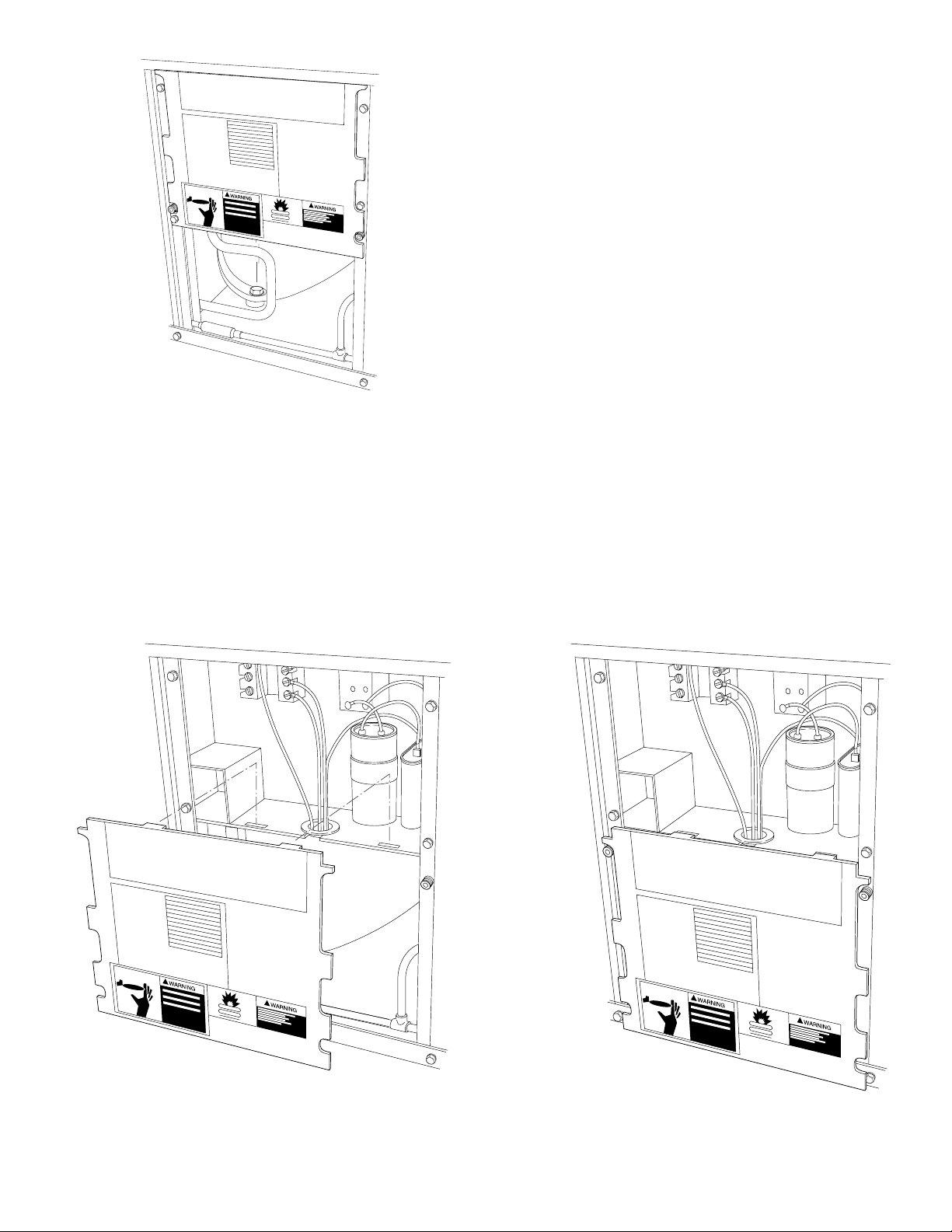

III. INFORMATION PLATE—RELIANT PRODUCTS

The information plate is secured to the front of the control box and

provides a cover for it. (See Fig. 9.) This plate also provides a

surface to attach the wiring schematic, superheat-charging tables

with instructions, and warning labels. The plate has 2 tabs on the

top edge that are bent down at slightly more than 90°. When the

information plate is removed, these tabs can be inserted into 2

mating slots in the bottom-front edge of the control box, and the

plate will hang down, forming a lower front panel. (See Fig. 10.)

This is convenient where access to the controls is required while

the unit is operating. The information plate on the small size casing

completely covers the opening below the control box. On larger

models, the information plate may not cover the entire opening. In

this instance, the top cover can be removed and placed on its side

to cover the additional space.

IV. CONTROL-BOX COVER—CUBE PRODUCTS

This panel contains much of the same information as the information plate mentioned previously, but is designed only to cover the

control box.

V. REMOVE TOP COVER— AFTER 1/1/92

NOTE: The section applies to all Reliant Products made after

January 1, 1992.

1. Turn off all power to outdoor and indoor units.

2. Remove 5 screws holding top cover to coil grille and coil

tube sheet.

3. Remove 2 screws holding control-box cover.

4. Remove 2 screws holding information plate.

5. Disconnect fan motor wires, cut any wire ties, and move

wires out of control box and through tube clamp on back of

control box.

—10—

Page 11

150' MAX.

HEAT PUMP ONLY

Fig. 7—Application with Air Conditioner or Heat Pump Installed Above Indoor Unit

6. Lift top cover from unit.

7. Reverse sequence for reassembly.

VI. REMOVE FAN-MOTOR ASSEMBLY—AFTER 1/1/92

NOTE: This section applies to all Reliant products made after

January 1, 1992

1. Perform items 1, 3, 4, and 5 above. (Note item 2 is not

required.)

2. Remove 4 screws holding wire basket to top cover.

3. Lift wire basket from unit.

4. Remove nuts holding fan motor to wire basket.

5. Remove motor and fan blade assembly.

6. Pull wires through wire raceway to change motor.

7. Reverse sequence for reassembly.

8. Prior to applying power, check that fan rotates freely.

A90077

—11—

Page 12

Fig. 8—Basic Cabinet Designs

A94003

ELECTRICAL

WARNING: Exercise extreme caution when working on

any electrical components. Shut off all power to system

prior to troubleshooting. Some troubleshooting techniques require power to remain on. In these instances,

exercise extreme caution to avoid danger of electrical

shock. ONLY TRAINED SERVICE PERSONNEL

SHOULD PERFORM ELECTRICAL TROUBLESHOOTING.

Troubleshooting charts for air conditioning and heat pump units

are provided in the back of this manual. They enable the service

technician to use a systematic approach to locate the cause of a

problem and correct system malfunctions.

I. ALUMINUM WIRE

CAUTION: Aluminum wire may be used in the branch

circuit (such as the circuit between the main and unit

disconnect), but only copper wire may be used between

the unit disconnect and the unit on Bryant systems.

Whenever aluminum wire is used in the branch-circuit wiring with

this unit, adhere to the following recommendations.

Connections must be made in accordance with the National

Electrical Code (NEC), using connectors approved for aluminum

wire. The connectors must be UL-approved (marked Al/Cu with

the UL symbol) for the application and wire size. The wire size

selected must have a current capacity not less than that of the

copper wire specified and must not create a voltage drop between

the service panel and the unit in excess of 2 percent of the

unit-rated voltage.

To prepare the wire before installing the connector, all aluminum

wire must be ″brush scratched″ and coated with a corrosion

inhibiter such as Pentrox A. When it is suspected that the

—12—

Page 13

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ

SEFL JOSDJ ATC

SEFL JOSDJ

SEFL JOSDJ UTUHD

SEFL JOSDJ

SEFL JOSDJC MD

SEFL JOSDJ

SEFL JOSDJHR ITYALK

SEFL JOSDJ

SEFL JOSDJ

A88411

Fig. 9—Information Plate

connection will be exposed to moisture, it is very important to

cover the entire connection completely to prevent an electrochemical action that will cause the connection to fail very quickly. Do

not reduce the effective size of wire, such as cutting off strands so

that the wire will fit a connector. Proper size connectors should be

used. Check all factory and field electrical connections for

tightness. This should also be done after the unit has reached

operating temperatures, especially if aluminum conductors are

used.

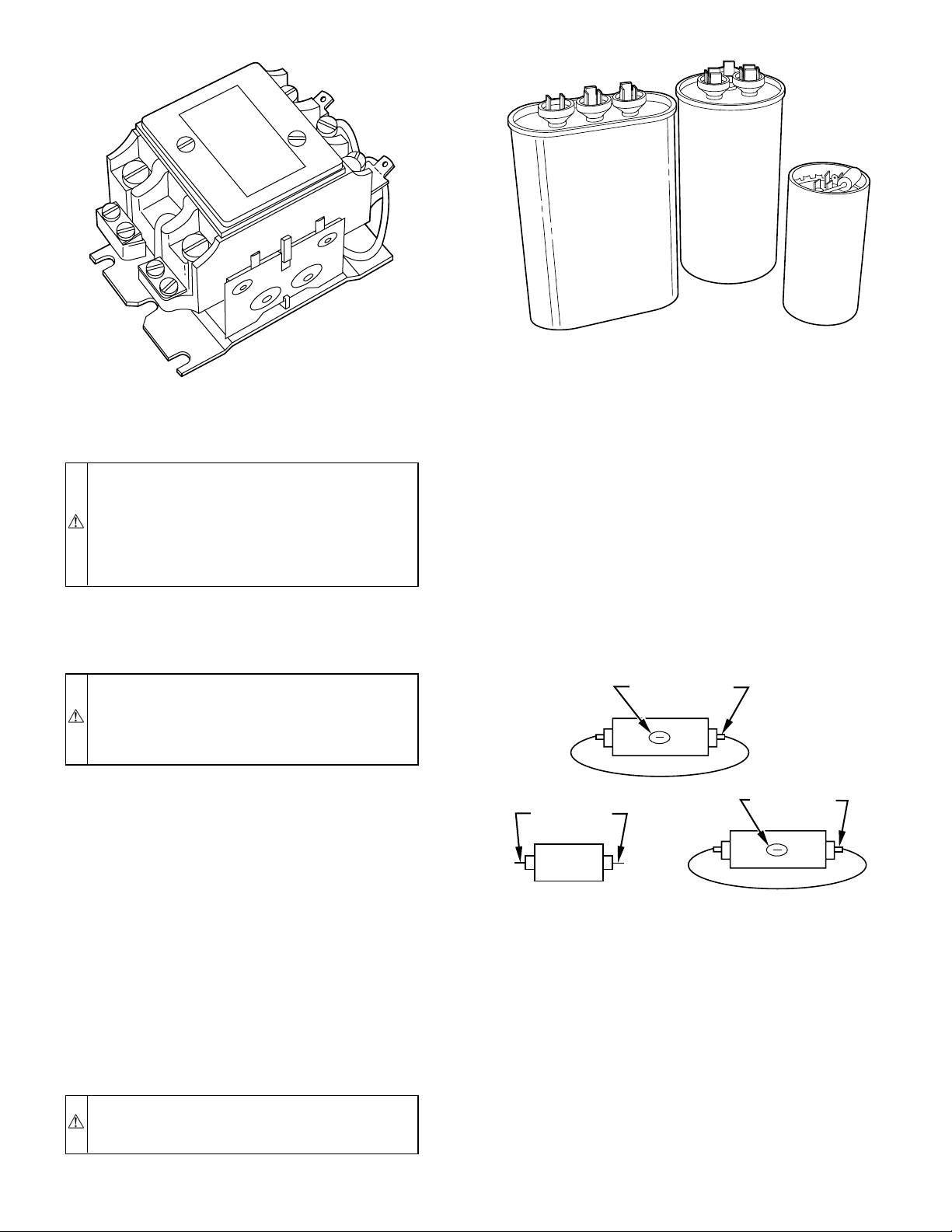

II. CONTACTORS

NOTE: The section applies to single-speed models only.

The contactor provides a means of applying power to unit using

low voltage (24v) from transformer in order to power the contactor

coil. (See Fig. 11.) Depending on unit model, you may encounter

single-, double-, or triple-pole contactors to break power. One side

of the line may be electrically energized, so exercise extreme

caution when troubleshooting.

The contactor coil for residential air-conditioning units and heat

pumps is powered by 24vac. If contactor does not operate:

1. With power off, check whether contacts are free to move.

Check for severe burning or arcing on contact points.

2. With power off, use ohmmeter to check for continuity of

coil. Disconnect leads before checking. A low-resistance

reading is normal. Do not look for a specific value, as

different part numbers have different resistance values.

3. Reconnect leads and apply low-voltage power to contactor

coil. This may be done by leaving high-voltage power to

outdoor unit off, and turning thermostat to heat or cool.

Check voltage at coil with voltmeter. Reading should be

between 20v and 30v. Contactor should pull in if voltage is

correct and coil is good. If contactor does not pull in,

change contactor.

4. With high-voltage power off and contacts pulled in, check

for continuity across contacts with ohmmeter. A very low or

zero resistance should be read. Higher readings could

indicate burned or pitted contacts which may cause future

failures.

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ

SEFL JOSDJ ATC

SEFL JOSDJ

SEFL JOSDJ UTUHD

SEFL JOSDJ

SEFL JOSDJC MD

SEFL JOSDJ

SEFL JOSDJHR ITYALK

SEFL JOSDJ

A88412

Fig. 10—Information Plate Removed/Installed Below Control Box

—13—

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ ATC

SEFL JOSDJ UTUHD

SEFL JOSDJC MD

SEFL JOSDJHR ITYALK

SEFL JOSDJ

A88413

Page 14

A88350

Fig. 11—Contactor

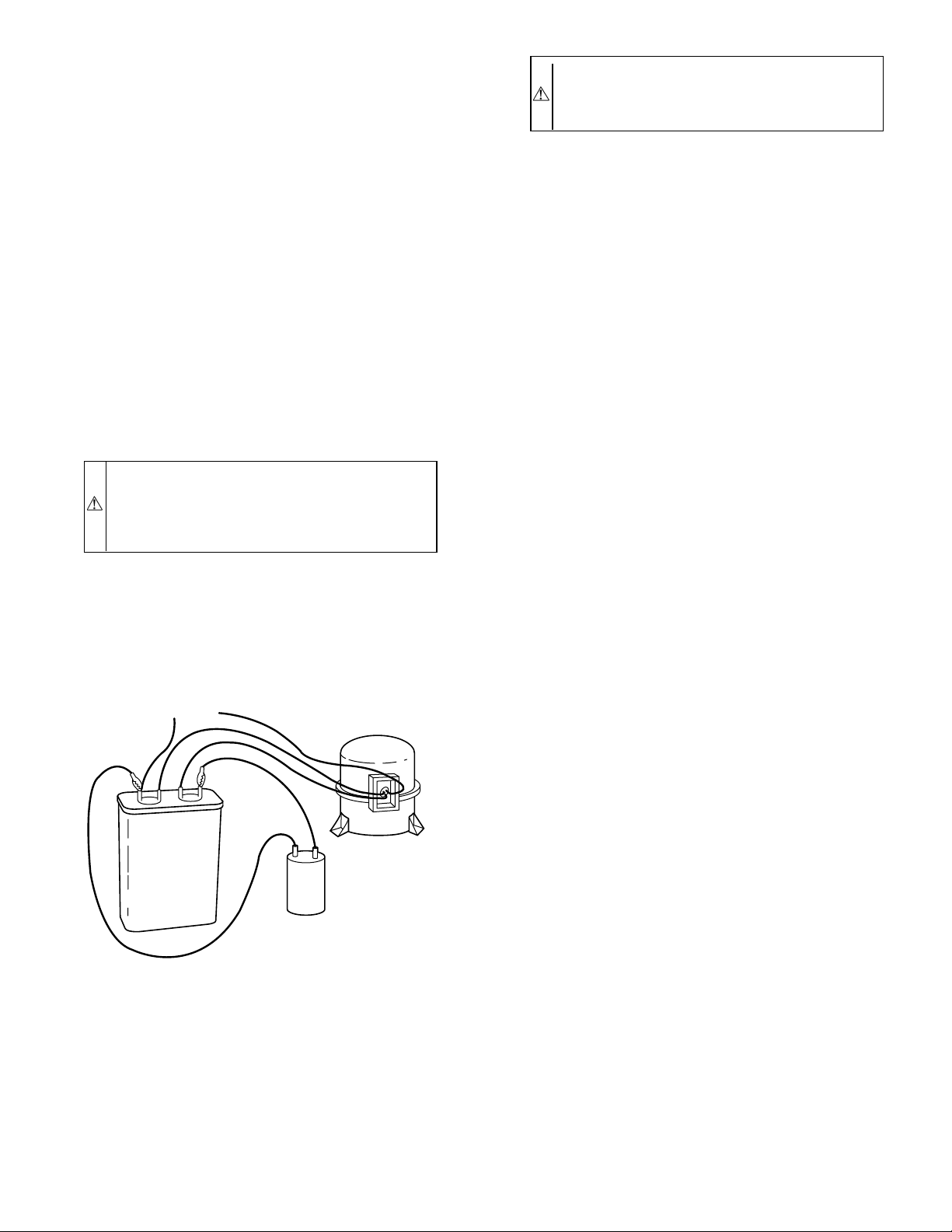

III. CAPACITORS

CAUTION: Capacitors can store electrical energy when

power is off. Electrical shock can result if you touch the

capacitor terminals and discharge the stored energy.

Exercise extreme caution when working near capacitors.

With power off, discharge stored energy by shorting

across the capacitor terminals with a 15,000-ohm, 2-watt

resistor.

NOTE: If bleed resistor is wired across start capacitor, it must be

disconnected to avoid erroneous readings when ohmmeter is

applied across capacitor. (See Fig. 12.)

A91455

Fig. 12—Capacitors

Use the following formula to calculate capacitance:

Capacitance (mfd) = (2650 X amps) divided by (volts)

3. Remove any capacitor that shows signs of bulging, dents, or

leaking. Do not apply power to a defective capacitor as it

may explode.

START CAPACITORS AND PTC DEVICES

Sometimes under adverse conditions, a standard run capacitor in a

system is inadequate to start compressor. In these instances, a

start-assist device is used to provide an extra starting boost to

compressor motor. The first device is called a positive-temperature

coefficient (PTC) or thermistor. (See Fig. 13.) It is a resistor wired

in parallel with the run capacitor. As current flows through the

PTC at start-up, it heats up. As it heats up, its resistance increases

greatly until it effectively lowers the current through it to an

extremely low value. This, in effect, removes it from the circuit.

CAUTION: Always check capacitors with power off.

Attempting to troubleshoot a capacitor with power on can

be dangerous. Defective capacitors may explode when

power is applied. Insulating fluid inside is combustible

and may ignite, causing burns.

Capacitors are used as a phase-shifting device to aid in starting

certain single-phase motors. Check capacitors as follows.

1. After power is off, discharge capacitors as outlined above.

Disconnect capacitor from circuit. Put ohmmeter on R X

10k scale. Using ohmmeter, check each terminal to ground

(use capacitor case). Discard any capacitor which measures

1/2–scale deflection or less. Place ohmmeter leads across

capacitor and place on R X 10k scale. Meter should jump to

a low-resistance value and slowly climb to higher value.

Failure of meter to do this indicates an open capacitor. If

resistance stays at zero or a low value, capacitor is internally shorted.

2. Capacitance testers are available which read value of

capacitor. If value is not within ± 10 percent value stated on

capacitor, it should be changed. If capacitor is not open or

shorted, the capacitance value is calculated by measuring

voltage across capacitor and current it draws.

WARNING: Exercise extreme caution when taking

readings while power is on. Electrical shock can cause

personal injury or death.

20-36

OHMS

BLUE

20 OHM

(BLUE COLOR)

12.5-22.5

12.5 OHM

(BEIGE COLOR)

OHMS

25-45

OHMS

25 OHM

(BLUE COLOR)

A88414

Fig. 13—PTC Devices

After system shutdown, resistor cools and resistance value returns

to normal until next time system starts. If indoor coil does not have

a bleed-type expansion device, it may be necessary to remove start

thermistor and replace with accessory start capacitor and relay.

Consult pre-sale literature for application of start kits. Thermistor

device is adequate for most conditions; however, in systems where

off-cycle is short, device cannot cool fully and becomes less

effective as a start device. It is an easy device to troubleshoot.

1. Shut off all power to system.

2. Check thermistor with ohmmeter as described below.

3. Shut off all power to unit.

—14—

Page 15

4. Remove PTC from unit. Wait at least 10 minutes for PTC to

cool to ambient temperature.

5. Measure resistance of PTC with ohmmeter as shown in

Fig.13.

The cold resistance (RT) of any PTC device should be approximately 100 – 180 percent of device ohm rating.

12.5–ohm PTC = 12.5–22.5 ohm resistance — beige color

25–ohm PTC = 25–45 ohm resistance — blue color

20–ohm PTC = 20–36 ohm resistance — blue color

If PTC resistance is appreciably less than rating or more than 200

percent higher than rating, device is defective.

If thermistor is good and compressor does not start:

1. Disconnect thermistor from starting circuit.

2. Give compressor a temporary capacitance boost (see next

section).

3. Run compressor for 10 minutes, shut off, and allow system

pressure to equalize.

4. Reconnect start thermistor.

5. Try restarting compressor without boost capacitor. If after 2

attempts compressor does not start, remove thermistor. Add

an accessory start-capacitor relay package.

TEMPORARY CAPACITANCE BOOST

WARNING: Do not under any circumstances attach a

temporary boost capacitor directly to the compressor

terminals. Serious personal injury can result. Exercise

extreme caution with this procedure when high-voltage

power is on.

There are times when a temporary capacitance boost is needed to

get compressor started. (See Fig. 14.) If compressor motor does not

start, it may be due to low-line voltage, improper pressure

equalization, weak run capacitor, or a seized compressor. Check

each possibility and attempt capacitance boost before adding

auxiliary start capacitor and relay.

220-V FROM UNIT

CONTACTOR

COMP. RUN

CAPACITOR

START (BOOST)

CAPACITOR

A88349

Fig. 14—Capacitance Boosting

1. Turn off all power to unit. There may be more than one

power source to condensing unit.

NOTE: If a PTC is already installed, remove it from the system

by pulling PTC wires from H and C terminals on run capacitor.

2. Check compressor for ground or open windings. If winding’s resistance is within manufacturer’s recommendations,

proceed. (See Reciprocating Compressor Section IIElectrical Failures for proper compressor-winding check.)

CAUTION: Do not check winding at compressor terminals with pressure in the system. Check resistance by

removing wires attached at the compressor contactor and

run capacitor.

3. Obtain a start capacitor in the range of

150–180µF[@0330] volts rating. Connect 8–gauge wires

with insulated clips or terminals to the H and C terminals of

the run capacitor.

4. Turn power on to unit. If compressor starts, immediately

remove start-capacitor wires from H and C terminals of run

capacitor, using a pair of insulated, needle-nose pliers. DO

NOT leave start capacitor attached to run capacitor for more

than 3 seconds, even if compressor doesn’t start.

5. Discharge start capacitor by using a pair of insulated,

needle-nose pliers and shorting a 15,000 ohm, 2 watt

resistor across terminals.

NOTE: Some start capacitors already have a bleed resistor

attached. If so, it will discharge itself over a short period of time.

6. Run compressor 10 minutes. Stop and allow unit to sit idle

for 5 minutes.

7. Check system pressure equalization.

8. Attempt to restart without capacitance boost.

If PTC thermistor device is inadequate as start device, a start

capacitor and relay may be added to system to ensure positive start.

Capacitor is wired in parallel with run capacitor through normally

closed set of contacts on a device called start relay. The relay coil

is wired across start and common terminals of compressor. The

added capacitance gets the compressor started. As compressor

comes up to speed, voltage across start and common terminals

increases to a value high enough to cause start relay to energize.

This opens normally closed contacts and removes start capacitor

from circuit. In actual practice, this occurs in a fraction of a

second.

NOTE: If bleed resistor is wired across start capacitor, it must be

disconnected to avoid erroneous readings when ohmmeter is

applied across capacitor.

To check start relay and capacitor:

1. Turn off all power to unit.

2. Discharge start and run capacitors as outlined earlier.

3. Most start capacitors will have a 15,000 ohm, 2 watt bleed

resistor. Disconnect these devices from system.

Start capacitor can be inspected visually. It is designed for short

duration or intermittent duty. If left in circuit for prolonged period,

start capacitor blows through a specially designed bleed hole. If it

appears blown, check for welded contacts in start relay. Start

capacitor can be checked by ohmmeter method discussed earlier.

Start relay is checked with ohmmeter. Check for continuity across

coil of relay. You should encounter a high resistance. Since relay

contacts are normally closed, you should read low resistance

across them. Both PTC device and capacitor-relay start system are

standard equipment on some of these units. They are also available

as accessories and may be field-installed.

IV. CYCLE PROTECTOR

Solid-state cycle-protector device protects unit compressor by

preventing short cycling. After a system shutdown, cycle protector

provides fora5±2-minute delay before compressor restarts. On

normal start-up, a 5-minute delay occurs before thermostat closes.

After thermostat closes, cycle protector device provides a 3-sec

delay on HN67PA025, HN67ZA003, and HN67ZA008. (See Fig.

15, 16, and 17.)

—15—

Page 16

T3 T1 T2

HN67ZA002

T2

T1

T3

A91438

HN67ZA008

T1 YEL T2 VIO

T2

T1

T3

A94005

T3 BLK

T3 BLK

HN67ZA003

A91439

Fig. 15—Cycle-Protector Device

Cycle-protector device is simple to troubleshoot. Only a voltmeter

capable of reading 24v is needed. Device is in control circuit;

therefore, troubleshooting is safe with control power (24v) on and

high-voltage power off.

With high-voltage power off, attach voltmeter leads across T1 and

T3 and set thermostat so that Y terminal is energized. Make sure

all protective devices in series with Y terminal are closed.

Voltmeter should read 24v across T1 and T3. With 24v still

applied, move voltmeter lead from T1 terminal to T2 terminal

across T2 and T3. After5±2minutes, voltmeter should read 24v,

indicating control is functioning normally. If no time delay is

encountered or device never times out, change control.

V. CRANKCASE HEATER

Crankcase heater is a device for keeping compressor oil warm. By

keeping oil warm, refrigerant does not migrate to and condense in

compressor shell when the compressor is off. This prevents

flooded starts which can damage compressor.

Crankcase heaters come in 2 basic types: wraparound-(bellyband)

type that is wrapped externally around compressor shell, and

insertion-type that is inserted into compressor oil well in shell of

compressor. Both types are used in outdoor units.

On units that have a single-pole contactor, the crankcase heater is

wired parallel with the contactor contacts and in series with the

compressor. (See Fig. 18.) When the contacts are open, a circuit is

completed from the line side of the contactor, through the

crankcase heater, through the run windings of the compressor, and

to the other side of the line. When the contacts are closed, there is

HN67PA025

A91440

no circuit through the crankcase heater because both leads are

connected to the same side of the line. This allows the heater to

operate when the system is not calling for heating/cooling. The

heater does not operate when the system is calling for

heating/cooling. On units with 2 or 3 pole contactors, the crankcase heater is connected to the line side of the contactor and is not

controlled by the contactor contacts.

The crankcase heater is powered by high-voltage power of unit.

Use extreme caution troubleshooting this device with power on.

The easiest method of troubleshooting is to apply voltmeter across

crankcase heater leads to see if heater has power. Do not touch

heater. Carefully feel area around crankcase heater. If warm,

crankcase heater is probably functioning. Do not rely on this

method as absolute evidence heater is functioning. If compressor

has been running, the area will still be warm.

With power off and heater leads disconnected, check across leads

with ohmmeter. Do not look for a specific resistance reading.

Check for resistance or an open circuit. Change heater if an open

circuit is detected. Some crankcase heaters in this series of units

are equipped with a crankcase-heater switch. This energy-saving

device shuts off power to heater when temperatures are high

enough that heater is not needed. Be sure this switch is functioning

normally before condemning crankcase heater.

VI. TIME-DELAY RELAY

The time-delay relay (TDR) is a solid-state-controlled, recycledelay timer which keeps the indoor blower operating for 90 sec

after thermostat is satisfied. This delay enables the blower to

remove residual cooling in the coil after compression shutdown,

—16—

Page 17

T1

T2

OPERATING

TIME

_

5 MIN

T1

_

T2

3

SEC

OPERATING

TIME

5 MIN

BLK DENOTES CLOSED CONTACTS

HN67ZA002

YEL

TERMINAL

BOARD

CONNECTION

SAFETY

CONTROL

A91436

Fig. 16—Cycle-Protector Sequence

CUT YELLOW WIRE

BETWEEN CONTACTOR AND

LOW-PRESSURE SWITCH

YEL C BRNYEL

YEL

T1 T3

LOGIC

VIO

T2

Fig. 17—Cycle-Protector Wiring

BLK DENOTES CLOSED CONTACTS

HN67PA025, HN67ZA003, HN67ZA008

A91437

CY

TERMINAL

BOARD

CONNECTION

BLK

A88415

DSV

CH

2111

A91426

Fig. 18—Wiring for Single-Pole Contactor

thereby improving the efficiency of the system. The sequence of

operation is that on closure of the wall thermostat and at the end of

a fixed on-delay of 1 sec, the fan relay is energized. When the

thermostat is satisfied, an off-delay is initiated. When the fixed

delay of 90 ± 20 sec is completed, the fan relay is de-energized and

fan motor stops. If the wall thermostat closes during this delay, the

TDR is reset, and the fan relay remains energized. The TDR is a

24v device that operates within a range of 15 to 30v and draws

about 0.5 amps.

If the blower runs continuously instead of cycling off when the fan

switch is set on AUTO, the TDR is probably defective and must be

replaced.

VII. PRESSURE SWITCHES

Pressure switches are protective devices wired into control circuit

(low voltage). They shut off compressor if abnormally high or low

pressures are present in the refrigeration circuit. Depending on unit

model, you may find a low- and/or high-pressure switch in system.

LOW-PRESSURE SWITCH

Located on suction line of condensing unit only, the low-pressure

switch protects against low-suction pressures caused by such

events as loss of charge, low airflow across indoor coil, dirty

filters, etc. It opens on a pressure drop at about 27 psi. If system

pressure is above this, switch should be closed. To check switch,

turn off all power to unit, disconnect leads on switch, and apply

ohmmeter leads across switch. You should have continuity on a

good switch. Because these switches are attached to refrigeration

system under pressure, it is not advisable to remove this device for

troubleshooting unless you are reasonably certain that a problem

exists. If switch must be removed, remove and recover all system

charge so that pressure gages read 0 psi.

—17—

Page 18

CAUTION: Wear safety glasses and gloves when working with refrigerants.

Apply heat with torch to solder joint and remove switch. Wear

safety glasses when using torch. Have quenching cloth available.

Oil vapor in line may ignite when switch is removed. Braze in

1/4-in. flare fitting and screw on replacement pressure switch.

HIGH-PRESSURE SWITCH

Located on discharge line, the high-pressure switch protects

against high-discharge pressures caused by such events as overcharge, condenser-fan motor failure, system restriction, etc. It

opens on pressure rise at about 435 psi. If system pressures go

above this setting during abnormal conditions, the switch opens.

Do not attempt to simulate these system abnormalities as high

pressures pose a serious safety hazard. High-pressure switch is also

checked with an ohmmeter similar to checking low-pressure

switch. If system pressure is below 435 psi, the switch shows

continuity. It is replaced in the same manner as low-pressure

switch. Observe all safety precautions.

LIQUID-LINE PRESSURE SWITCH

Located on liquid line of heat pump only, the liquid-line pressure

switch functions similar to conventional low-pressure switch.

Because heat pumps experience very low suction pressures during

normal system operation, a conventional low-pressure switch

cannot be installed on suction line. This switch is installed in liquid

line instead and acts as loss-of-charge protector. The liquid line is

the low side of the system in heating mode. It operates identically

to low-pressure switch except it opens at 7 psi when the heating

piston is in the liquid valve or 27 psi when the heating piston is in

the liquid line. Troubleshooting and removing this switch is

identical to procedures used on other switches. Observe same

safety precautions.

VIII. DEFROST THERMOSTATS

Defrost thermostat signals heat pump that conditions are right for

defrost or that conditions have changed to terminate defrost. It is

a thermally actuated switch clamped to outdoor coil to sense its

temperature. Normal temperature range is closed at 30° ±3°F and

open at 80° ±5°F.

NOTE: The defrost thermostat must be located on the liquid side

of the outdoor coil on the bottom circuit and as close to the coil as

possible.

IX. DEFROST-CONTROL BOARD

Solid-state defrost boards used on heat pumps replace electromechanical timer and defrost relay found on older defrost systems.

The defrost-control board can be field-set to check need for defrost

every 30, 50, or 90 minutes of operating time by connecting the

jumper (labeled W1 on the circuit board) to the terminal for the

defrost time desired. The board is set at factory for 90 minutes. The

defrost period is field-selectable, depending upon geographic areas

and defrost demands. Two types of defrost boards are used, and

functions are described in the sections to follow.

Troubleshooting defrost control involves a series of simple steps

that indicate whether or not board is defective.

NOTE: This procedure allows the service technician to check

control board and defrost thermostat for defects. First troubleshoot

to make sure unit operates properly in heating and cooling modes.

This ensures operational problems are not attributed to the defrostcontrol board.

HK32FA003, 006 DEFROST CONTROL

This control board utilizes screw terminals for the low-voltage

field wiring. The board has a feature that allows the heat pump to

restart in defrost if room thermostat is satisfied during defrost. To

troubleshoot the board, perform the following items.

1. Turn thermostat to OFF. Shut off all power to outdoor unit.

2. Remove control-box cover for access to electrical components and defrost-control board.

3. Disconnect defrost-thermostat leads from control board and

connect to ohmmeter. Thermostat leads are the black,

insulated wires connected to DFT and R terminals on

control board. Resistance reading may be zero (indicating

closed defrost thermostat) or infinity (∞ for open thermostat) depending on outdoor temperature.

4. Jumper between DFT and R terminals on control board as

shown in Fig. 19.

5. Disconnect outdoor fan motor lead from OF2. Tape lead to

prevent grounding.

6. Turn on power to outdoor unit.

7. Restart unit in heating, allowing frost to accumulate on

outdoor coil.

8. After a few minutes in heating, liquid-line temperature at

defrost thermostat should drop below closing set point of

defrost thermostat of approximately 30°F. Using ohmmeter,

check resistance across defrost-thermostat leads. Resistance

of zero indicates defrost thermostat is closed and operating

properly.

9. Remove protective cover from TP1 and TP2 speed-up

terminals. Install jumper wire on speed-up terminals. This

reduces the timing sequence to 1/60 of original time. (See

Fig. 20.) Since Fig. 20 shows timing cycle set at 30 minutes,

unit initiates defrost within approximately 30 sec; if setting

is at 50 minutes, within 50 sec; 90 minutes, within 90 sec.

When you hear the reversing valve change position, remove

protective cover/jumper. Otherwise, control will terminate

normal 10-minute defrost cycle in approximately 10 sec.

CAUTION: Exercise extreme caution when shorting

speed-up pins. If pins are accidentally grounded, damage

to the control board will occur.

10. Unit is now operating in defrost mode. Using voltmeter,

check between C and W2 as shown in Fig. 21. Reading on

voltmeter should indicate 24v. This step ensures defrost

relay contacts have closed, energizing supplemental heat

(W2) and reversing valve solenoid (O).

11. Unit should remain in defrost no longer than 10 minutes.

Actual time in defrost depends on how quickly speed-up

jumper is removed. If it takes 3 sec to remove speed-up

jumper after unit has switched to defrost, only 7 minutes of

defrost cycle remains.

12. After a few minutes in defrost (cooling) operation, liquid

line should be warm enough to have caused defrostthermostat contacts to open. Check resistance across defrost

thermostat. Ohmmeter should read infinite resistance, indicating defrost thermostat has opened at approximately 80°F.

13. Shut off unit power and reconnect fan lead.

14. Remove jumper wire from speed-up terminal and reinsert

cover on speed-up terminals. Failure to remove jumper

causes unit to speed up operating cycles continuously.

15. Remove jumper between DFT and R terminals. Reconnect

defrost thermostat leads.

16. Replace control-box cover. Restore power to unit.

If defrost thermostat does not check out following above items or

incorrect calibration is suspected, check for a defective thermostat

as follows.

1. Follow items 1-5 above.

—18—

Page 19

G

E

W2

L

W3

R

Y

O

14

OF2

OF1

G

R

R

Y

OF2

OF1

C

C

O

T2 YTIDFTCTEST

C

C

R

50 90

30

W1

W1

C

50

30

HK32FA003/HK32FA006

DFT

O

A88402

Fig. 19—Jumper DFT and R Terminals

2. Using thermocouple temperature-measuring device, route

sensor or probe underneath coil (or other convenient location). Attach to liquid line near defrost thermostat. Insulate

for more accurate reading.

3. Turn on power to outdoor unit.

4. Restart unit in heating mode.

5. Within a few minutes, liquid-line temperature drops within

a range causing defrost thermostat contacts to close. Temperature range is from 33°Fto27°F. Notice temperature at

which ohmmeter reading goes from ∞ to zero ohms.

Thermostat contacts close at this point.

6. Remove protective cover from TP1 and TP2 speed-up

terminals, and install jumper wire on the speed-up terminals.

7. Unit changes over to defrost within 90 sec (depending on

timing cycle setting). Liquid-line temperature rises to range

where defrost thermostat contacts open. Temperature range

is from 75°Fto85°F. Resistance goes from zero to ∞ when

contacts open.

8. If either opening or closing temperature does not fall within

above ranges or thermostat sticks in 1 position, replace

thermostat to ensure proper defrost operation.

CES0110063 DEFROST CONTROL

Some heat pumps built in 1991 and later incorporate a new defrost

control. The screw terminals found on the previous control board

have been replaced by a connector plug with stripped-wire leads.

This control board also contains the feature that allows the heat

pump to restart in defrost if the room thermostat is satisfied during

defrost. The board also contains a 5-minute cycle protector that

prevents the unit from short cycling after it cycles off or after a

power interruption. To troubleshoot the board, perform the following items.

1. Turn thermostat to OFF. Shut off all power to outdoor unit.

2. Remove control-box cover for access to electrical components and defrost-control board.

3. Disconnect defrost-thermostat leads from control board,

and connect to ohmmeter. Thermostat leads are the black,

insulated wires connected to DFT and R terminals on

control board. Resistance reading may be zero (indicating

closed-defrost thermostat), or infinity (∞ for open thermostat) depending on outdoor temperature.

O

R

W2

Y

C

CES0110063,

CES0130024

A91442

4. Jumper between DFT and R terminals on control board as

shown in Fig. 21.

5. Disconnect outdoor fan-motor lead from OF2. Tape lead to

prevent grounding.

6. Turn on power to outdoor unit.

7. Restart unit in heating mode, allowing frost to accumulate

on outdoor coil.

8. After a few minutes in heating mode, liquid-line temperature at defrost thermostat should drop below closing set

point of defrost thermostat of approximately 30°F. Check

resistance across defrost thermostat leads using ohmmeter.

Resistance of zero indicates defrost thermostat is closed and

operating properly.

9. Short between the speed-up terminals using a thermostat

screwdriver. This reduces the timing sequence to 1/256 of

original time. (See Fig. 20 and Table 10.)

NOTE: Fig. 20 shows timing cycle set at 30 minutes; however,

for the CES30110063 board the timing cycle will be set for 90 min

and unit initiates defrost within approximately 21 sec. When you

hear the reversing valve change position, remove screwdriver

immediately. Otherwise, control will terminate normal 10-minute

defrost cycle in approximately 2 sec.

CAUTION: Exercise extreme caution when shorting

speed-up pins. If pins are accidentally shorted to other

terminals, damage to the control board will occur.

10. Unit is now operating in defrost mode. Check between C

and W2 using voltmeter as shown in Fig. 21. Reading on

voltmeter should indicate 24v. This step ensures defrostrelay contacts have closed, energizing supplemental heat

(W2) and reversing valve solenoid (O).

11. Unit should remain in defrost no longer than 10 minutes.

Actual time in defrost depends on how quickly speed-up

jumper is removed. If it takes 2 sec. to remove speed-up

jumper after unit has switched to defrost, the unit will

switch back to heat mode.

12. After a few minutes in defrost (cooling) operation, liquid

line should be warm enough to have caused defrostthermostat contacts to open. Check resistance across defrost

thermostat. Ohmmeter should read infinite resistance, indicating defrost thermostat has opened at approximately 80°F.