Page 1

SINGLE-PACKAGE

GAS HEATING/ELECTRIC

COOLING UNITS

UNIT 583B

Single-Package Rooftop Products with Energy-Saving Features

and Puron® refrigerant.

• Direct Spark Ignition

• Low Sound Levels

• Up to 81% AFUE

• 12 SEER

• Variable Speed Blower Option

FEATURES/BENEFITS

One-piece heating and cooling units with low sound levels, easy

installation, low maintenance, and dependable performance.

Puron® Environmentally Sound Refrigerant

unique refrigerant designed to help protect the environment.

Puron is an HFC refrigerant which does not contain chlorine that

can harm the ozone layer. The most important advantage of

Puron refrigerant is that it has not been banned in future air conditioning systems as the traditional refrigerant R-22 has been.

Puron refrigerant is in service in thousands of systems proving

highly reliable, environmentally sound performance.

Perfect Heat, Perfect Humidity™ featuring Variable Speed

Blower motors

You can expect up to 30 times better dehumidification; a SEER

boost of up to 12.7; economical constant fan for less than $30 a

year, which provides improved indoor air quality and more even

temperatures from room to room; and reduced indoor noise due

to lower air velocity. In addition, you’ll realize improved installation

flexibility with 3 different airflow choices for best overall comfort.

EASY INSTALLATION

provides better comfort and energy efficiency.

—Factory-assembled package is a com-

is Bryant’s

Model 583B

Sizes 024-060

2 to 5 Nominal Tons

Low NOx Models Available

pact, fully self-contained, combination gas heating/electric cooling unit that is pre-wired, pre-piped, and pre-charged for

minimum installation expense.

These units are available in a variety of standard and optional

heating/cooling size combinations with voltage options to meet

residential and light commercial requirements. Units are lightweight and install easily on a rooftop or at ground level. The high

tech composite basepan eliminates rust problems associated

with ground level applications.

CONVERTIBLE DUCT CONFIGURATION

for easy use in either downflow or horizontal applications. Each

unit is easily converted from horizontal to downflow.

EFFICIENT OPERATION

High-efficiency design

ciency Ratios) of 12.0 and AFUE (Annual Fuel Utilization Efficiency) ratings as high as 81%.

Energy-saving, direct spark ignition

only when the room thermostat calls for heating. Standard units

are furnished with natural gas controls. A low-cost field-installed

kit for propane conversion is available for all units.

583B units with an “N” in the thirteenth position of model #

are dedicated Low NOx units

tions. These models meet the California maximum oxides of nitrogen (NOx) emissions requirement of 40 nanograms/joule or

less as shipped from the factory and MUST be installed in California Air Quality Management Districts where a Low NOx rule

exists.

DURABLE, DEPENDABLE COMPONENTS

Compressors

sor is hermetically sealed against contamination to help promote

longer life and dependable operation. Each compressor also has

vibration isolation to provide quieter operation. All compressors

have internal high pressure and overcurrent protection.

Monoport inshot burners

which provides for clean and efficient combustion. The large

monoport on the inshot (or injection type) burners seldom, if

ever, requires cleaning. All gas furnace components are accessible in one compartment.

Turbo-tubular™ heat exchangers

nized steel for corrosion resistance and optimum heat transfer

for improved efficiency. The tubular design permits hot gases to

make multiple passes across the path of the supply air.

In addition, dimples located on the heat exchanger walls force

the hot gases to stay in close contact with the walls, improving

heat transfer.

Direct-drive multi-speed, PSC (permanent split capacitor)

blower motor

Direct-drive, PSC condenser-fan motors

reduce energy consumption and provide for cooling operation

down to 40°F outdoor temperature. Motormaster® II low ambient

kit is available as a field-installed accessory.

are designed for high efficiency. Each compres-

is standard on all 583B models.

offers SEER (Seasonal Energy Effi-

designed for California installa-

produce precise air-to-gas mixture,

—Unit is designed

saves gas by operating

are constructed of alumi-

are designed to help

Form No. PDS 583B.24.3

Page 2

P

E

P

Corporate thermostats include the Time Guard® II anti-short

cycle protection circuitry. If a non-corporate thermostat without

anti-short cycle protection is used the Time Guard II field installed anti-short cycle kit is recommended.

Refrigerant system is designed to provide dependability. Liquid

filter dryers are used to promote clean, unrestricted operation.

Each unit leaves the factory with a full refrigerant charge. Refrigerant service connections make checking operating pressures

easier.

HIGH AND LOW PRESSURE SWITCHES

provide added reli-

ability for the compressor.

Evaporator and condenser coils

are computer-designed for

optimum heat transfer and cooling efficiency. The evaporator

coil is fabricated from copper tube and aluminum fins and is located inside the unit for protection against damage. The condenser coil is internally mounted on the top tier of the unit.

Copper fin coils and pre-coated fin coils are available from the

factory by special order. These coils are recommended in applications where aluminum fins are likely to be damaged due to

corrosion. They are ideal for seacoast applications.

Low sound ratings

ensure a quiet indoor and outdoor environ-

ment with sound ratings as low as 72 dB. (See page 3.)

Easy to service cabinets provide easy single-panel accessibility

to serviceable components during maintenance and installation.

The basepan with integrated drain pan provides easy ground level

installation with or without a mounting pad. Convenient handholds

are provided to manipulate the unit on the jobsite. A nesting feature ensures a positive basepan to roof curb seal when the unit is

roof mounted. A convenient 3/4-in. wide perimeter flange makes

frame mounting on a rooftop easy.

Standard metal duct covers with insulation come with the unit

and cover the horizontal duct openings. These can be left in place

if the units are converted to downflow.

Downflow operation is easily provided in the field to allow ver-

tical ductwork connections. The basepan utilizes knockout style

seals on the bottom openings to ensure a positive seal in the

horizontal airflow mode.

Integrated Gas Control (IGC) board provides safe and efficient

control of heating and simplifies trouble-shooting through its

built-in diagnostic function.

Cabinets are constructed of heavy-duty, phosphated, zinc-

coated prepainted steel capable of withstanding 500 hours in

salt spray. Interior surfaces of the evaporator/heat exchanger

compartment are insulated with cleanable semi-rigid insulation

board, which keeps the conditioned air from being affected by

the outdoor ambient temperature and provides improved indoor

air quality. (Conforms to American Society of Heating, Refrigeration and Air Conditioning Engineers No. 62P.) The sloped drain

pan minimizes standing water in the drain, which is provided with

an external drain.

Louvered Grille

provides hail and vandalism protection.

Model Number

583B – Single

Packaged Gas

Heating/Electric

Cooling

Electrical Supply

N – *208/230-1-60

– 208/230-3-60

– 460-3-60

Fuel

W – Natural Gas

– Propane Gas

Nominal Cooling Capacity

024 – 2 ton

030 – 2.5 ton

036 – 3 ton

042 – 3.5 ton

048 – 4 ton

060 – 5 ton

MODEL NUMBER NOMENCLATURE

583B N W 024 040 N VS

Options

BT

– AL evap, vinyl condens

CC

– AL evap, CU condens

CU

– CU evap & condens

VS

– Variable speed (VS) Unit

VT

– VS, AL evap, vinyl condens

VC

– VS, AL evap, CU condens

VU

– VS, CU evap & condens

Only used if ordering an option

Low NO

N

Only used if ordering NO

Heat Input Size

040 – 40,000

060 – 60,000

090 – 90,000

115 – 115,000

130 – 130,000

Indicator

x

– Low NO

Unit

x

units

x

*Variable speed models are only available in

208/230-1-60 (N)

LEGEND

CU

— Copper

AL

— Aluminum

—2—

Page 3

db

wb

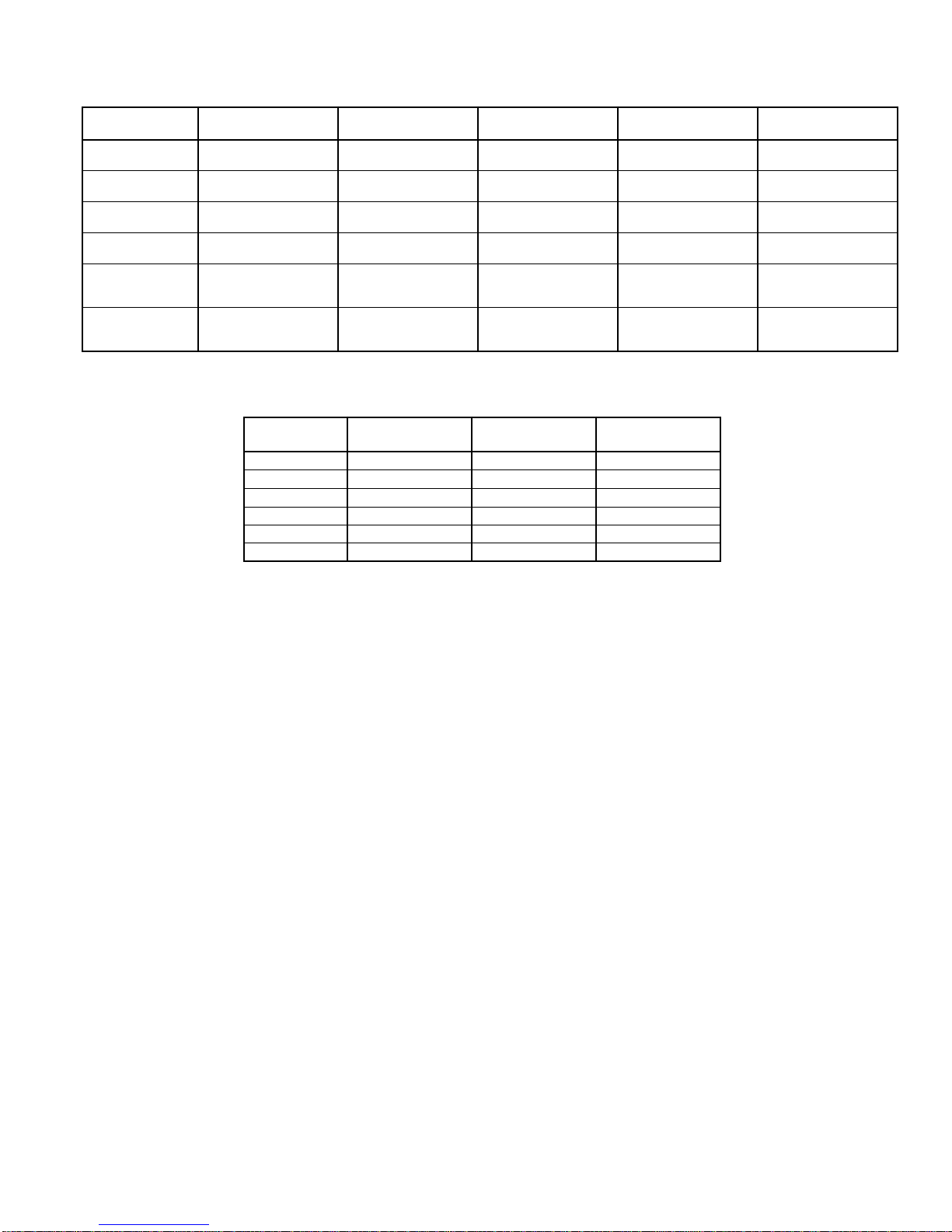

ARI* CAPACITIES

COOLING CAPACITIES AND EFFICIENCIES

UNIT 583B NOMINAL TONS STANDARD CFM

024040

024060

030040

036060

036060

036090

042060

042090

048090

048115

048130

060090

060115

060130

2 800 24,000 12.0 72

2-1/2 1000 29,000 12.0 72

3 1200 35,000 12.0 72

3-1/2 1400 41,000 12.0 73

4 1600 48,000 12.0 78

5 1750 59,000 12.0 76

583B with ICM FIOP

Unit

583B

024

030

036

042

048

060

‡“A” Capacity– 80°F db/67°Fwb indoor & 95°Fdb outdoor.

“A”‡

Capacity

24,000 10.7 12.7

29,000 10.7 12.7

35,000 10.6 12.5

41,000 10.7 12.5

48,000 10.5 12.3

59,000 10.4 12.3

NET COOLING

CAPACITIES (Btuh)

“A”‡

EER

SEER

SEER†

SOUND RATINGS**

(dB)

LEGEND

dB — Decibels

— Dry Bulb

SEER — Seasonal Energy Efficiency Ratio

— Wet Bulb

* Air Conditioning & Refrigeration Institute.

† Rated in accordance with U.S. Government DOE (Department of

Energy) test procedures and/or ARI Standard 210/240-89.

** Tested in accordance with ARI Standard 270-95 (not listed in ARI).

TABLE OF CONTENTS

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . .2

ARI Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,4

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,6

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,8

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,10

Accessory Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Selection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Typical Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . 22-25

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27,28

NOTES:

1. Ratings are net values, reflecting the effects of circulating fan heat.

Ratings are based on:

Cooling Standard: 80°F db, 67°F wb indoor entering-air tempera-

ture and 95°F db outdoor entering-air temperature.

2. Before purchasing this appliance, read important energy cost and

efficiency information available from your retailer.

Page

—3—

Page 4

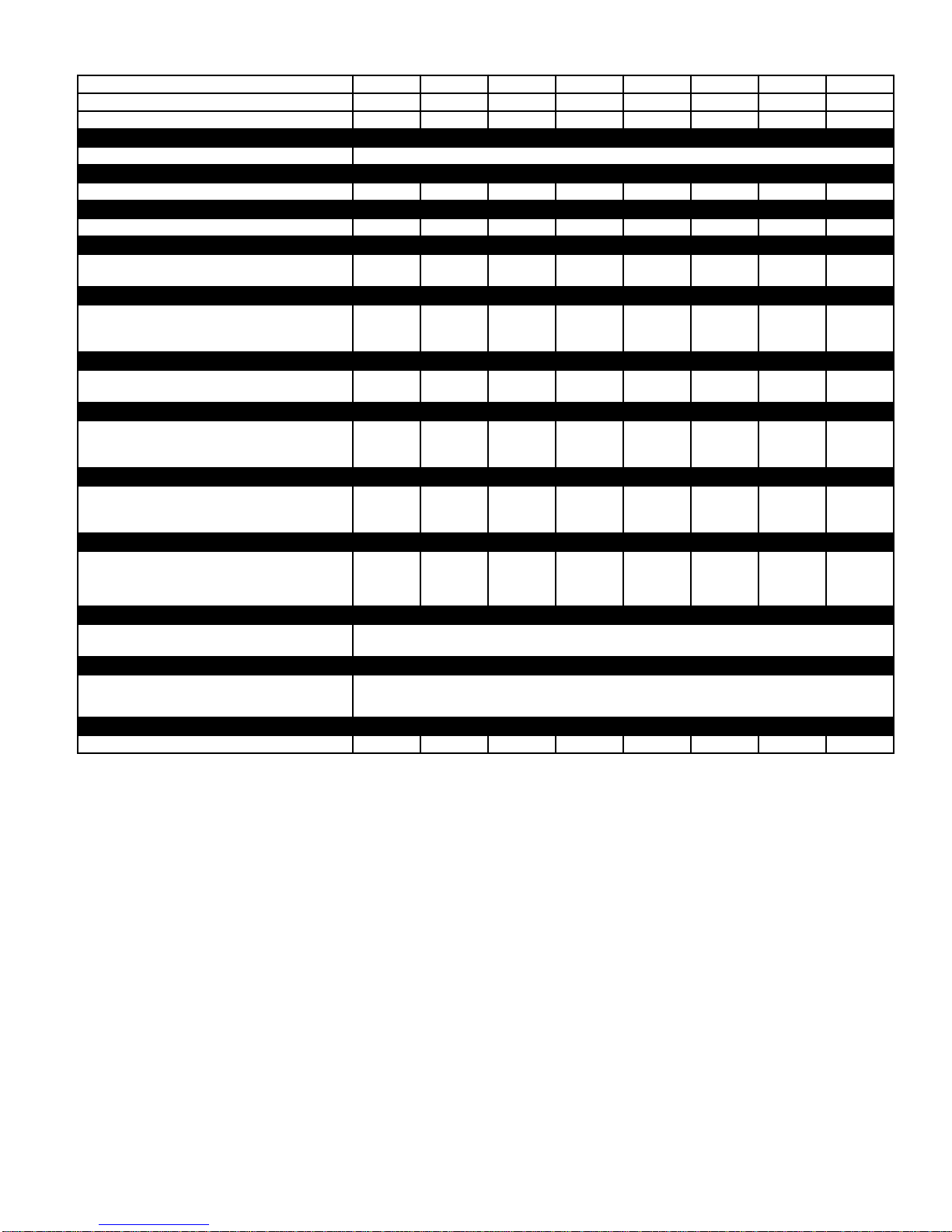

ARI* CAPACITIES (cont)

HEATING CAPACITIES AND EFFICIENCIES

UNIT 583B

024040

030040

024060

030060

036060

042060

036090

042090

048090

060090

048115

060115

048130

060130

HEATING INPUT

(Btuh)

40,000 31,000 20-50 80.1

60,000

90,000

90,000

90,000

90,000

115,000 92,000 35-65 81.1

130,000

OUTPUT CAPACITY

(Btuh)

46,000

46,000

46,000

47,000

70,000

71,000

70,000

70,000

104,000

103,000

TEMPERATURE RISE

RANGE (°F)

35-65

35-65

25-55

20-50

45-75

35-65

25-55

25-55

40-70 80.3

LEGEND

AFUE — Annual Fuel Utilization Efficiency

NOTE: Before purchasing this appliance, read important energy cost and efficiency information available from your retailer.

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

R

U

T

C

A

F

U

N

A

5

2

3

2

A

M

A

R

C

O

A

M

I

R

C

P

O

Y

R

A

T

I

N

U

I

S

T

L

N

D

Y

I

T

I

N

I

O

G

N

I

N

W

G

I

T

E

H

T

Q

N

U

E

I

P

M

0

1

2

D

A

R

N

A

D

AFUE

78.4

78.4

78.7

78.7

79.9

79.9

78.6

78.6

OUTDOOR SOUND: OCTAVE BAND DATA — DECIBELS (Lw(A))

UNIT 583B

Frequency (Hz) 024 030 036 042 048 060

63

125

250

500

1000

2000

4000

8000

44.8 48.0 50.0 49.1 51.4 53.7

60.4 58.2 60.4 63.9 65.2 62.6

58.3 59.2 61.6 65.2 69.7 65.9

64.8 65.8 66.9 67.9 72.7 70.6

66.9 67.7 67.8 66.7 72.9 71.6

64.3 64.8 64.6 63.8 69.8 68.2

59.8 61.8 60.7 60.2 65.8 65.8

51.8 53.6 52.8 50.7 57.9 58.3

—4—

Page 5

1

PHYSICAL DATA

UNIT SIZE 583B 024040 024060 030040 030060 036060 036090 042060 042090

NOMINAL CAPACITY (ton)

OPERA TING WEIGHT (lb)

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb)

REFRIGERANT METERING DEVICE

Orifice ID (in.) AccuRater® Piston

CONDENSER COIL

Rows—Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows—fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

EVAPORATOR BLOWER (ICM FIOP ONLY)

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

FURNACE SECTION

Burner Orifice No. (Qty…Drill Size)

Natural

Burner Orifice No. (Qty…Drill Size)

Propane

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS (in.)

Throwaway

2 2 2-1/2 2-1/2 3 3 3-1/2 3-1/2

290 290 313 313 321 321 382 382

Scroll

5.0 5.0 5.5 5.5 6.9 6.9 9.0 9.0

.057 .057 .057 .057 .065 .065 .070 .070

1/17

10.9

2350

22

1/8 (825)

3/15

3.7

800

10 x 10

1/4 (1075)

800

10 x 10

1/2

2…44

2…50

20 x 24 x 1 20 x 24 x 1 20 x 24 x 1 20 x 24 x 1 20 x 24 x 1 20 x 24 x 1 24 x 30 x 1 24 x 30 x 1

1/17

10.9

2350

22

1/8 (825)

3/15

3.7

800

10 x 10

1/4 (1075)

800

10 x 10

1/2

2…38

2…46

1/17

12.7

2350

22

1/8 (825)

3/15

3.7

1000

10 x 10

1/4 (1075)

1000

10 x 10

1/2

2…44

2…50

1/17

12.7

2350

22

1/8 (825)

3/15

3.7

1000

10 x 10

1/4 (1075)

1000

10 x 10

1/2

2…38

2…46

610 ± 15

420 ± 25

45 ± 10

20 ± 5

2/17

9.1

2350

22

1/8 (825)

3/15

3.7

1200

10 x 10

1/2 (1075)

1200

11 x 10

3/4

2…38

2…46

2/17

9.1

2350

22

1/8 (825)

3/15

3.7

1200

10 x 10

1/2 (1075)

1200

11 x 10

3/4

3…38

3…46

2/17

12.3

2350

22

1/8 (825)

3/15

4.7

1400

11 x 10

3/4 (1075)

1400

11 x 10

3/4

2…38

2…46

2/17

12.3

2350

22

1/8 (825)

3/15

4.7

1400

11 x 10

3/4 (1075)

1400

11 x 10

3/4

3…38

3…46

—5—

Page 6

PHYSICAL DATA (cont)

UNIT SIZE 583B 048090 048115 048130 060090 060115 060130

NOMINAL CAPACITY (ton)

OPERA TING WEIGHT (lb)

COMPRESSORS

Quantity

REFRIGERANT (R-410A)

Quantity (lb)

REFRIGERANT METERING DEVICE

Orifice ID (in.) AccuRater® Piston

CONDENSER COIL

Rows—Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows—fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

EVAPORATOR BLOWER (ICM FIOP ONLY)

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

FURNACE SECTION

Burner Orifice No. (Qty…Drill Size)

Natural Gas

Burner Orifice No. (Qty…Drill Size)

Propane Gas

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS (in.)

Throwaway 24 x 30 x 1 24 x 30 x 1 24 x 30 x 1 24 x 30 x 1 24 x 30 x 1 24 x 30 x 1

444555

421 421 421 468 468 468

Scroll

9.5 9.5 9.5 10.0 10.0 10.0

.073 .073 .073 .086 .086 .086

2/17

12.3

3300

22

1/4 (1100)

4/15

4.7

1600

11 x 10

3/4 (1075)

1600

11 x 10

3/4

3…38

3…46

2/17

12.3

3300

22

1/4 (1100)

4/15

4.7

1600

11 x 10

3/4 (1075)

1600

11 x 10

3/4

3…33

3…42

2/17

12.3

3300

22

1/4 (1100)

4/15

4.7

1600

11 x 10

3/4 (1075)

1600

11 x 10

3/4

3…31

3…41

610 ± 15

420 ± 25

20 ± 5

45 ± 10

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11 x 10

1.0 (1040)

1750

11 x 10

1.0

3…38

3…46

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11 x 10

1.0 (1040)

1750

11 x 10

1.0

3…33

3…42

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11 x 10

1.0 (1040)

1750

11 x 10

1.0

3…31

3…41

1

—6—

Page 7

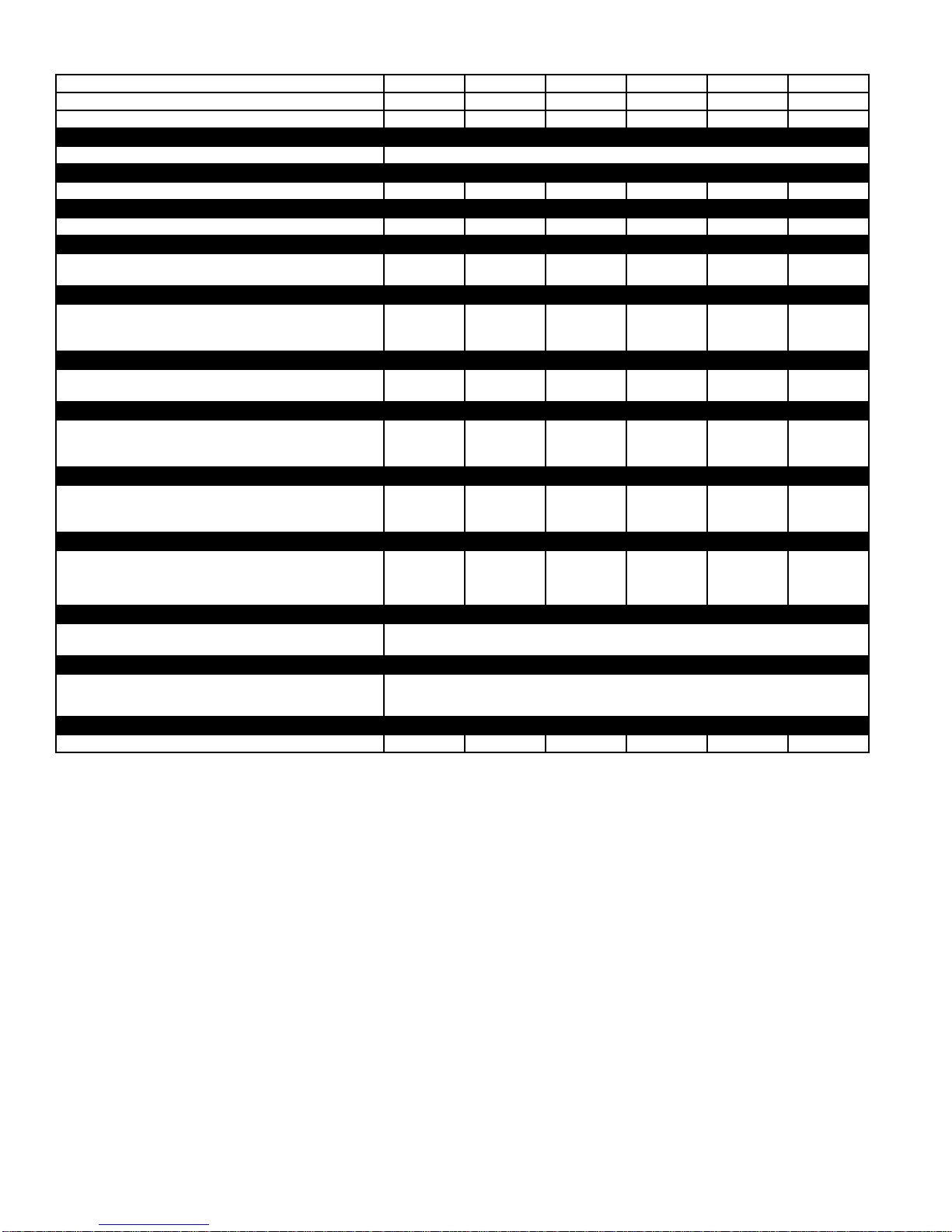

OPTIONS AND ACCESSORIES

Factory-installed options

Coil options include copper/copper and vinyl-coated construc-

tion for refrigerant coils. Units are shipped standard with copper

tube/aluminum fin construction. See model number nomenclature for coil options.

Electronic Variable-Speed Motor — ICM Motors (Integrated

Control Motor) provide variable-speed operation to optimize

comfort levels year round. They are also more economical to operate than standard motors.

Field-installed accessories

Economizer with Solid-State Controls and Barometric Relief Dampers

Manual Air Damper (25% open)

Filter Rack

Roof Curbs (8-in. and 14-in.)

Square-to-Round Duct Transition Kit

Thermostats

Crankcase Heater

Compressor Hard Start Kit (for use on single-phase units only)

LP Conversion Kit

High Altitude Kit

Low Ambient Kit (Motormaster® II Control)

Solid-State Time Guard® II Device

Lifting Kit

LP to Natural Conversion Kit

Economizer with solid-state controls and barometric relief

dampers includes filter racks and provide outdoor air during

cooling and reduce compressor operation.

Manual outside air damper includes hood and filter rack with

adjustable damper blade for up to 25% outdoor air.

Flat roof curbs in both 8 in. and 14 in. sizes are available for

roof mounted applications.

Square-to-round duct transition kit enables 024-048 size

units to be fitted to 14 in. round ductwork.

Compressor hard start kit assists compressor start-up by providing additional starting torque on single phase units and prolongs compressor motor life.

Thermostats provide control for the system heating and cooling

functions. Thermostat models are available in both programmable and non-programmable versions.

Crankcase heater provides anti-floodback protection for lowload cooling applications.

LP (liquid propane) conversion kit allows for conversion from

natural gas to liquid propane fuel.

Low-ambient kit (Motormaster® II control) allows the use of

mechanical cooling down to outdoor temperatures as low as 0°F.

Solid-state Time Guard® II device provides short-cycling protection for the compressor. Not required with corporate electronic thermostats.

Filter rack features easy installation, serviceability, and highfiltering performance for vertical applications.

High altitude kit is for use at 2001 to 6000 ft above sea level.

Kit consists of natural gas orifices that compensate for gas heat

operation at high altitude.

LP to natural gas conversion kit allows conversion back to

natural gas.

Lifting kit includes lifting brackets which are inserted into the

basepan handholds to rig unit for rooftop applications.

—7—

Page 8

Economizer

A99315

Filter Rack

A99314

Manual Outside Air Damper

REPLACEMENT

PANEL

MANUAL OUTSIDE

AIR HOOD

DAMPER

BLADE

A99317

A99316

—8—

Page 9

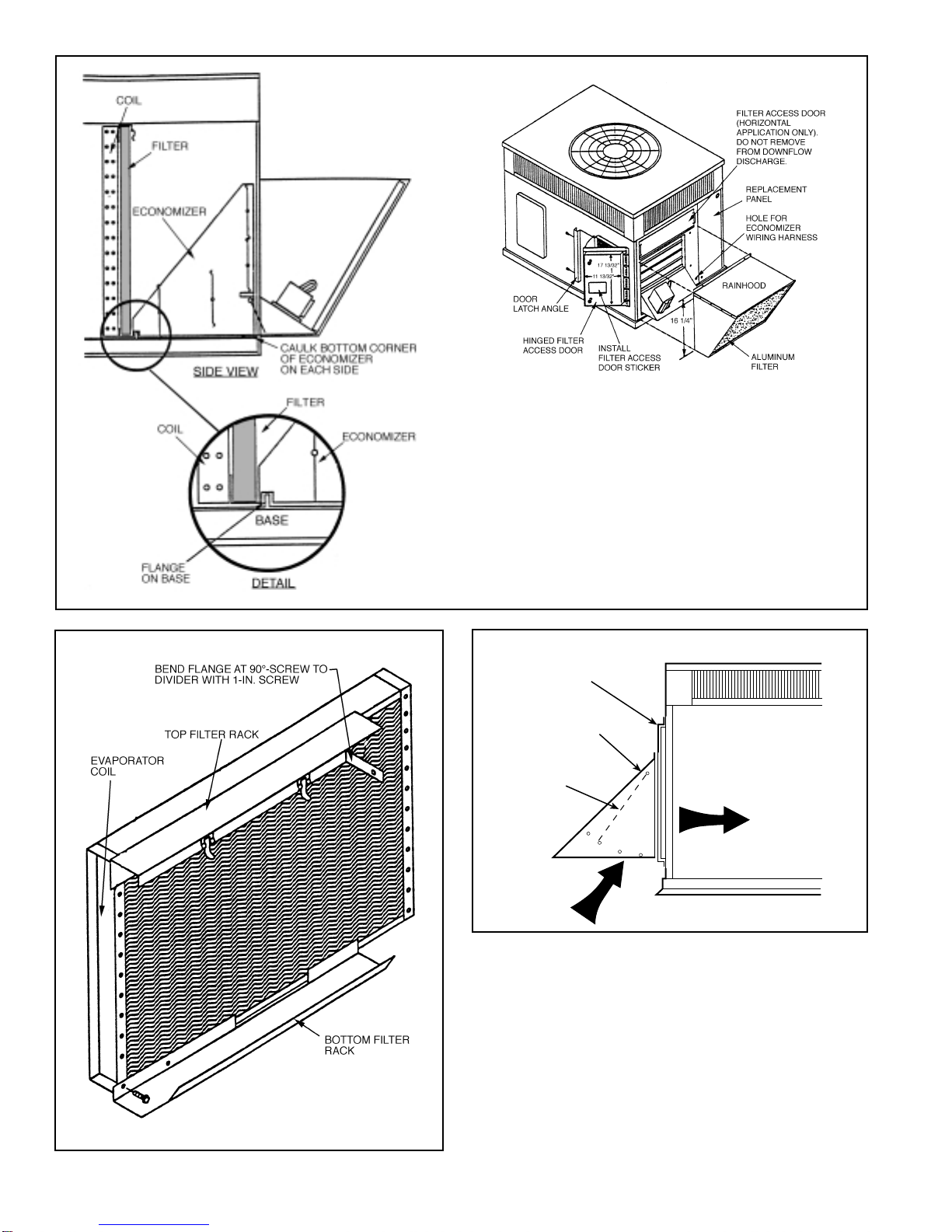

BASE UNIT DIMENSIONS — 583B024-036

REQ’D CLEARANCES FOR OPERATION AND SERVICING. in. (mm)

Evaporator coil access side ..................36(914)

Power entry side (except for NEC requirements) .........36(914)

Unit top ..........................48(1219)

Side opposite ducts .....................36(914)

Duct panel ........................12(304.8)*

*Minimum distances: If unit is placed less than 12 in. (304.8 mm) from wall

system, then the system performance may be compromised.

LEGEND

CG - Center of Gravity

COND - Condenser

EVAP - Evaporator

NEC - National Electrical Code

REQ'D - Required

Note: Dimensions are in in. (mm)

REQ’D CLEARANCES TO COMBUSTIBLE MAT’L. in. (mm)

Top of unit .........................14(355.6)

Duct side of unit .......................2(50.8)

Side opposite ducts .....................14(355.6)

Bottom of unit .......................0.50 (12.7)

Flue panel .........................36(914.4)

NEC REQ’D CLEARANCES. in. (mm)

Between units, power entry side ..............42(1066.8)

Unit and ungrounded surfaces, power entry side .........36(914)

Unit and block or concrete walls and other grounded

control box side

surfaces,

.................42(1066.8)

UNIT

ELECTRICAL

CHARACTERISTICS

583B024040/060 208/230-1-60 290 131.5 37.02 [940.3] 22.0 [558.8] 14.5 [368.3] 16.0 [406.4]

583B030040/060

208/230-1-60

208/230-3-60

208/230-1-60

583B036060/090

208/230-3-60

460-3-60

UNIT WEIGHT

lb. kg. X Y Z

UNIT HEIGHT

IN. [MM]

“A”

CENTER OF GRAVITY

IN. [MM]

313 142.0 39.02 [991.1] 22.0 [558.8] 15.3 [387.4] 17.6 [447.0]

321 145.6 35.02 [889.5] 22.0 [558.8] 15.3 [387.4] 16.5 [419.1]

—9—

Page 10

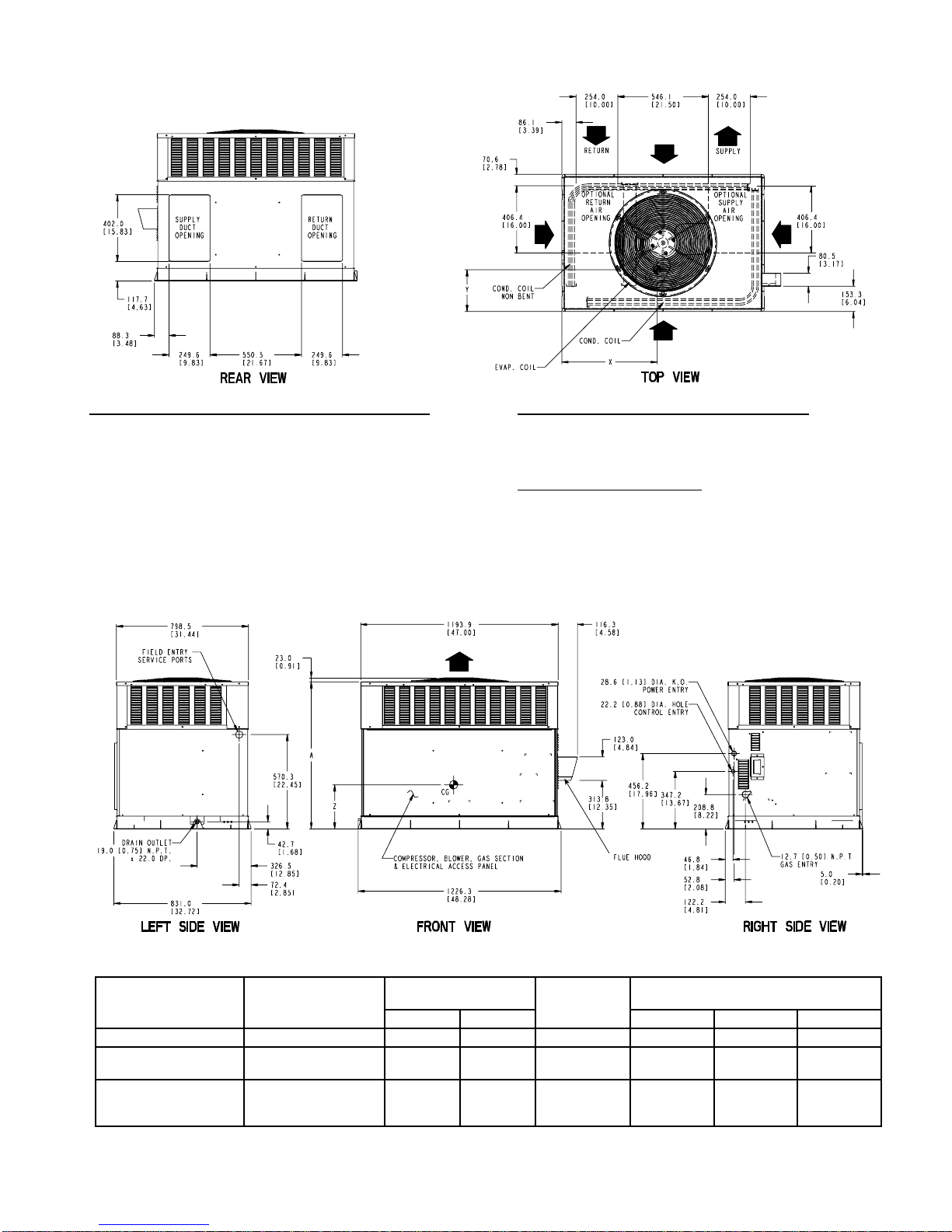

BASE UNIT DIMENSIONS – 583B042-060

C99074

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAP. COIL ACCESS SIDE..............................................................36.00 [914.0]

POWER ENTRY SIDE......................................................................36.00 [914.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP.........................................................................................36.00 [914.0]

SIDE OPPOSITE DUCTS ................................................................36.00 [914.0]

DUCT PANEL...................................................................................12.00 [304.8] *

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12.00 in. [304.8 mm.]

FROM WALL THEN SYSTEM PERFORMANCE MAYBE COMPR OMISED.

in. [mm]

REQUIRED CLEARANCE TO COMBUSTIBLE MATL.

TOP OF UNIT...................................................................................14.00 [355.6]

DUCT SIDE OF UNIT.........................................................................2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................14.00 [355.6]

BOTTOM OF UNIT.............................................................................0.50 [12.7]

ELECTRIC HEAT PANEL.................................................................36.00 [914.4]

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE....................................42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE ...36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE.........................42.00 [1066.8]

FLUE HOOD

MILLIMETERS [IN.]

in. [mm]

UNIT

ELECTRICAL

CHARACTERISTICS

208/230-1-60

583B042060/090

208/230-3-60

460-3-60

208/230-1-60

583B048090/115/130

208/230-3-60

460-3-60

208/230-1-60,

583B060090/115/130

208/230-3-60,

460-3-60

UNIT WEIGHT

lb. kg. X Y Z

UNIT HEIGHT

IN. [MM]

“A”

CENTER OF GRAVITY

IN. [MM]

382 173.3 38.98 [990.2] 23.0 [584.2] 16.3 [412.8] 16.6 [421.6]

421 191.0 38.98 [990.2] 21.5 [546.1] 16.6 [422.1] 18.0 [457.2]

468 212.3 42.98 [1091.7] 23.5 [596.9] 16.3 [412.8] 17.6 [447.0]

—10—

Page 11

ACCESSORY DIMENSIONS

HVAC unit

base

Screw

(NOTE A)

*Gasketing

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant strip

field supplied

*Provided with roofcurb

Gasketing

inner flange*

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Duct work

field supplied

Roof

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

Supply opening

(B x C)

5

44

/16"

B Typ .

C Typ .

HVAC unit

Screw

(NOTE A)

*Gasketing

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant strip

field supplied

*Provided with roofcurb

base

Gasketing

inner flange*

Duct work

field supplied

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Roof

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

retainer bracket must also be used.

D

A

Short

Long

Support

Support

Return opening

(B X C)

Insulated

deck pan

Roof Curb Dimensions

Side View

UNIT SIZE ODS ORDER NUMBER

ROOF CURB

024-036

042-060

Notes:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required to unit being installed.

3. Dimensions in [ ] are in millimeters.

4. Roof curb is made of 16 gage steel.

5. Table lists only the dimensions per part number that have changed.

6. Attach ductwork to curb (flanges of duct rest on curb).

7. Insulated panels: 1-in. thick fiberglass 1 lb. density.

8. Dimensions are in inches.

9. When unit mounting screw is used (Note A), a retainer bracket must be used as

well. This bracket must also be used when required by code for hurricane or

seismic conditions. This bracket is available through Micrometl.

CPRFCURB006A00 8 [203] 11 [279] 16 1/2 [419] 28 3/4 [730]

CPRFCURB007A00 14 [356] 11 [279] 16 1/2 [419] 28 3/4 [730]

CPRFCURB008A00 8 [203] 16 3/16 [411] 17 3/8 [441] 40 1/4 [1022]

CPRFCURB009A00 14 [356] 16 3/16 [411] 17 3/8 [441] 40 1/4 [1022]

R/A

Insulated

deck pan

A

IN. [MM]

Gasket around

duct

Gasket around

outer edge

B

IN. [MM]

C

IN. [MM]

S/A

D

IN. [MM]

—11—

Page 12

583B CORNER WEIGHTS

12

y

43

CORNER # 024 030 036 042 048 060

1 55.1 59.5 61.0 72.6 80.0 88.9

2 52.2 56.3 57.8 68.8 75.8 84.2

3 89.9 97.0 99.5 118.4 130.5 145.1

4 92.8 100.2 102.7 122.2 134.7 149.8

TOTAL WEIGHT 290 313 321 382 421 468

SELECTION PROCEDURE (WITH EXAMPLE)

I DETERMINE COOLING AND HEATING REQUIREMENTS

AT DESIGN CONDITIONS:

Given:

Required Cooling Capacity (TC).....................35,000 Btuh

Sensible Heat Capacity (SHC).........................25,000 Btuh

Required Heating Capacity..............................60,000 Btuh

Condenser Entering Air Temperature......................... 95°F

Indoor-Air Temperature ........................80°F edb 67°F ewb

Evaporator Air Quantity .....................................1200 CFM

External Static Pressure....................................... 0.1 in. wg

Electrical Characteristics.......................................230-1-60

II SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY.

Enter Net Cooling Capacities table at condenser entering

temperature of 95 F. Unit 583B036 at 1200 cfm and 67 F

ewb (entering wet bulb) will provide a total capacity of

35,900 Btuh and a SHC of 26,700 Btuh. Calculate SHC

correction, if required, using Note 3 under Cooling

Capacities tables.

III SELECT HEATING CAPACITY OF UNIT TO PROVIDE

DESIGN CONDITION REQUIREMENT.

In the Heating Capacities and Efficiencies table on page 4,

note that the unit 583B036090 will provide 70,000 Btuh

with an input of 90,000 Btuh.

x

IV DETERMINE FAN SPEED AND POWER REQUIRE–

MENTS AT DESIGN CONDITIONS.

Before entering the air delivery tables, calculate the total

static pressure required. From the given example, the Wet

Coil Pressure Drop Table, and the Filter Pressure Drop table

on page 16, find at 1200 cfm:

External Static Pressure 0.1 in. wg

Filter 0.13 in. wg

Total Static Pressure 0.23 in. wg

Enter the table for Wet Coil Air Delivery — Horizontal and

Downflow Discharge on page 16. For 208 v operation,

deduct 10% from value given. At .23 ESP (external static

pressure), the fan will deliver 1327 cfm at low speed. The

fan speed should be set at low speed.

V SELECT UNIT THAT CORRESPONDS TO POWER

SOURCE AVAILABLE.

The Electrical Data table on page 21 shows that the unit is

designed to operate at 208/230-1-60.

—12—

Page 13

583B024 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

62 67 72 62 67 72 62 67 72

23.7

19.6

1.74

22.4

18.9

1.91

21.2

18.4

2.11

19.1

17.1

2.37

16.9

15.9

2.73

14.7

14.7

3.16

600 / 0.08 800 / 0.10 1000 / 0.12

PERFORMANCE DATA

STANDARD INDOOR PSC MOTOR

COOLING CAPACITIES

Evaporator Air — CFM / BF

Evaporator Air — Ewb (F)

26.0

16.8

1.76

25.0

16.3

1.96

23.7

15.8

2.17

21.5

14.6

2.45

19.3

13.5

2.82

16.8

12.5

3.28

28.1

13.9

1.78

27.2

13.4

1.97

26.2

13.0

2.21

23.8

12.0

2.47

21.8

11.1

2.89

19.2

10.2

3.38

24.7

22.3

1.88

23.6

21.8

2.07

22.3

21.1

2.25

20.1

19.5

2.52

18.2

18.2

2.88

16.1

16.1

3.34

26.9

18.6

1.90

25.8

18.2

2.09

24.6

17.7

2.31

22.3

16.4

2.61

20.0

15.4

3.01

17.4

14.2

3.46

28.7

14.5

1.91

27.7

14.2

2.11

26.7

13.8

2.35

24.2

12.8

2.61

22.3

11.9

3.02

19.6

11.1

3.51

25.2

24.4

2.04

24.1

24.1

2.22

23.0

23.0

2.40

21.0

21.0

2.68

19.2

19.2

3.07

16.9

16.9

3.54

26.9

19.7

2.09

25.9

19.4

2.29

24.7

19.0

2.52

22.3

17.8

2.81

20.1

16.8

3.21

17.5

15.7

3.68

28.7

14.9

2.11

27.5

14.6

2.30

26.4

14.1

2.52

24.1

13.1

2.81

22.1

12.6

3.23

19.4

11.6

3.72

583B030 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

TC

75

85

95

105

115

125

See Legend and Notes on page 15.

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

62 67 72 62 67 72 62 67 72

29.0

25.2

2.11

27.5

24.5

2.34

25.9

23.7

2.58

23.3

22.0

2.90

21.5

21.2

3.14

19.7

19.7

3.55

Evaporator Air — CFM / BF

750 / 0.08 1000 / 0.11 1250 / 0.15

Evaporator Air — Ewb (F)

32.2

21.5

2.14

30.7

20.9

2.38

29.4

20.4

2.65

26.2

18.7

3.00

24.4

17.9

3.28

22.2

16.8

3.69

34.3

17.2

2.15

33.3

16.8

2.44

31.9

16.3

2.67

29.1

15.1

3.01

26.9

14.2

3.33

24.7

13.4

3.70

30.4

29.0

2.28

28.7

28.1

2.52

27.5

27.5

2.78

24.8

24.8

3.07

23.1

23.1

3.39

21.4

21.4

3.78

32.8

23.5

2.32

31.7

23.3

2.60

30.0

22.7

2.84

27.0

31.1

3.19

24.9

20.2

3.49

22.7

19.2

3.86

34.6

18.0

2.33

33.4

17.6

2.62

32.3

17.2

2.85

29.4

16.0

3.20

27.5

15.2

3.48

24.8

14.3

3.89

31.1

31.1

2.46

29.8

29.8

2.68

28.5

28.5

2.95

25.9

25.9

3.31

24.2

24.2

3.62

22.3

22.3

4.00

32.6

24.7

2.58

31.5

24.4

2.87

29.8

24.3

3.09

27.0

22.9

3.43

24.8

22.0

3.74

22.5

21.0

4.10

34.2

18.1

2.59

33.3

18.0

2.84

31.9

17.7

3.12

29.1

16.4

3.47

26.8

15.7

3.79

24.6

14.8

4.10

—13—

Page 14

583B036 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

62 67 72 62 67 72 62 67 72

35.2

30.3

2.58

32.9

28.7

2.83

31.0

27.9

3.11

27.9

26.0

3.49

25.5

24.7

3.85

22.2

22.2

4.48

PERFORMANCE DATA (cont)

STANDARD INDOOR PSC MOTOR

COOLING CAPACITIES (cont)

Evaporator Air — CFM/BF

900/0.09 1200/0.13 1500/0.18

Evaporator Air — Ewb (F)

38.7

25.5

2.61

36.9

24.8

2.88

34.9

24.0

3.19

31.5

22.2

3.59

28.8

21.0

3.96

24.6

19.1

4.59

41.6

20.7

2.61

39.9

20.1

2.89

37.9

19.3

3.20

34.3

17.7

3.60

31.4

16.5

3.96

27.0

14.8

4.61

36.6

34.0

2.79

34.8

33.3

3.05

32.4

30.8

3.33

29.3

28.3

3.73

27.5

27.5

4.07

24.0

24.0

4.71

39.8

28.0

2.84

37.9

27.4

3.11

35.9

26.7

3.42

32.2

24.8

3.82

29.4

23.4

4.19

25.0

21.5

4.79

41.9

21.6

2.83

40.2

21.0

3.12

38.3

20.3

3.43

34.6

18.6

3.82

31.5

17.5

4.19

27.0

15.8

4.84

37.3

37.3

3.03

35.5

35.5

3.28

33.8

33.8

3.56

30.7

30.7

3.97

28.3

28.3

4.34

24.5

24.5

4.98

39.5

29.3

3.14

37.7

28.8

3.43

35.7

28.0

3.74

32.0

26.5

4.15

29.2

25.2

4.46

24.8

23.0

5.09

41.5

21.6

3.14

39.8

21.1

3.43

37.8

20.5

3.73

34.0

18.7

4.13

31.0

17.6

4.51

26.3

15.8

5.15

583B042 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

TC

75

85

95

105

115

125

See Legend and Notes on page 15.

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

62 67 72 62 67 72 62 67 72

40.9

35.2

2.93

38.8

34.2

3.26

36.5

33.1

3.60

31.9

30.3

4.26

28.6

28.6

4.92

25.3

26.6

5.62

Evaporator Air — CFM/BF

1050 / 0.10 1500 / 0.13 1750 / 0.17

Evaporator Air — Ewb (F)

44.6

29.5

2.97

42.7

28.7

3.31

40.7

27.8

3.70

35.8

25.3

4.42

32.0

23.6

5.10

28.4

21.8

5.84

48.1

23.4

2.99

46.3

22.8

3.35

44.2

22.0

3.73

39.4

20.0

4.46

35.6

18.6

5.18

32.0

17.1

5.97

42.3

39.8

3.20

40.4

39.0

3.53

38.1

38.1

3.87

33.9

33.9

4.50

30.8

30.8

5.06

27.8

27.8

5.66

45.8

32.4

3.27

43.8

31.7

3.62

41.7

30.9

4.01

36.8

28.5

4.75

32.9

26.9

5.47

29.1

25.1

6.24

49.1

24.6

3.30

47.1

24.0

3.66

45.0

23.3

4.03

40.0

21.3

4.78

36.0

20.0

5.49

32.1

18.5

6.26

43.1

43.1

3.48

41.5

41.5

3.76

39.8

39.8

4.15

35.5

35.5

4.91

32.2

32.2

5.63

29.0

29.0

6.41

45.9

34.4

3.70

43.9

33.8

4.04

41.6

33.0

4.43

36.5

30.7

5.17

32.7

29.1

5.84

28.9

27.2

6.57

48.8

25.1

3.72

46.9

24.5

4.07

44.7

23.9

4.45

39.8

22.1

5.21

35.5

20.6

5.94

31.3

19.0

6.73

—14—

Page 15

583B048 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

75

85

95

105

115

125

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

62 67 72 62 67 72 62 67 72

47.9

41.5

3.38

45.7

40.4

3.77

43.3

39.1

4.15

39.2

36.4

4.67

35.3

34.4

5.32

32.0

32.0

6.16

1200 / 0.06 1600 / 0.08 2000 / 0.11

PERFORMANCE DATA (cont)

STANDARD INDOOR PSC MOTOR

COOLING CAPACITIES (cont)

Evaporator Air — CFM/BF

Evaporator Air — Ewb (F)

52.3

34.8

3.43

50.2

34.1

3.80

47.9

33.1

4.23

43.7

30.8

4.79

39.6

29.0

5.50

35.2

27.0

6.31

56.8

28.2

3.48

54.7

27.4

3.86

52.3

26.5

4.28

47.9

24.6

4.82

43.7

23.0

5.54

38.7

21.0

6.34

49.6

47.4

3.68

47.5

46.5

4.03

45.3

45.3

4.41

41.5

41.5

4.93

38.2

38.2

5.65

34.4

34.4

6.47

53.7

38.7

3.78

51.6

37.9

4.16

49.2

37.1

4.57

44.6

34.6

5.14

40.3

32.8

5.85

35.5

30.8

6.63

58.1

29.9

3.82

56.1

29.3

4.21

53.7

28.5

4.63

48.9

26.4

5.19

44.3

24.7

5.89

39.3

22.8

6.69

50.5

50.5

4.01

48.9

48.9

4.36

47.0

47.0

4.78

42.9

42.9

5.34

39.3

39.3

6.06

35.0

35.0

6.89

54.0

41.6

4.23

51.6

40.9

4.63

48.9

39.9

5.07

44.3

37.5

5.60

40.1

35.7

6.27

35.2

33.4

7.04

57.7

30.7

4.27

56.0

30.3

4.68

53.5

29.5

5.11

48.9

27.6

5.66

44.0

26.0

6.36

38.8

24.0

7.16

583B060 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

TC

75

85

95

105

115

125

BF — Bypass Factor

Ewb — Entering Wet-Bulb

kW — Total Unit Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Cooling Capacity (1000 Btuh)

PSC — Permanent Split Capacitor

NOTES:

1. Ratings are net; they account for the effects

of the evaporator-fan motor power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

TC

SHC

kW

LEGEND

1500 / 0.05 1750 / 0.06 2000 / 0.07 2500 / 0.08

62 67 72 62 67 72 62 67 72 62 67 72

57.6

50.6

4.63

54.4

49.0

5.06

51.2

47.5

5.54

45.8

44.0

6.17

41.9

41.9

6.75

38.6

38.6

7.36

64.3

43.0

4.69

60.9

41.6

5.17

57.5

40.0

5.68

51.9

37.0

6.35

47.6

35.1

6.94

43.2

33.2

7.64

69.9

34.4

4.75

67.0

33.4

5.21

63.7

32.2

5.72

57.7

29.5

6.39

53.2

27.8

6.98

48.3

25.8

7.67

59.8

55.5

4.67

56.4

53.6

5.10

53.1

51.9

5.58

47.8

47.8

6.23

44.5

44.5

6.83

41.1

41.1

7.58

Evaporator Air — CFM/BF

Evaporator Air — Ewb (F)

66.1

46.2

4.71

63.0

45.0

5.17

59.4

43.5

5.68

53.4

40.3

6.36

49.0

38.3

6.95

44.5

36.3

7.64

71.7

36.3

4.78

68.6

35.2

5.23

65.3

34.0

5.74

59.1

31.4

6.41

54.4

29.6

6.99

49.4

27.6

7.68

t=t

ldb edb

t = Wet-bulb temperature corresponding to enthalpy of air leaving

lwb

evaporator coil (h )

h=h

lwb ewb

Where: h = Enthalpy of air entering evaporator coil

4. The SHC is based on 80°F edb temperature of air entering evaporator

coil. Below 80°F edb, subtract (Corr Factor x CFM) from SHC above

80°F edb, add (Corr Factor x CFM) to SHC Correction Factor = 1.10 x

(1 + BF) x (edb + 80)

61.7

59.8

4.68

58.0

58.0

5.14

55.1

55.1

5.64

50.2

50.2

6.30

46.8

46.8

6.82

43.1

43.1

7.63

sensible capacity (Btuh)

1.10 x cfm

lwb

total capacity (Btuh)

4.5 x cfm

ewb

67.6

49.3

4.73

64.5

48.2

5.18

60.7

46.8

5.69

54.6

43.4

6.37

50.1

41.5

6.95

45.4

39.3

7.64

73.1

38.1

4.80

69.9

37.0

5.26

66.5

35.8

5.76

60.1

33.1

6.42

55.2

31.3

7.01

50.0

29.1

7.69

65.0

65.0

4.70

62.3

62.3

5.17

59.3

59.3

5.68

53.8

53.8

6.36

50.0

50.0

6.94

46.0

46.0

7.64

69.6

54.8

4.75

66.4

54.0

5.21

62.7

52.8

5.71

56.2

49.3

6.38

51.6

47.1

6.95

46.7

44.5

7.65

—15—

75.1

41.3

4.84

71.6

40.2

5.29

68.1

39.1

5.79

61.4

36.2

6.44

56.5

34.5

7.03

51.0

32.1

7.71

Page 16

583B STANDARD UNIT—WET COIL AIR FLOW DELIVERY

230 AND 460 VOLT

Unit

583B

024

030

036

042

048

060

NOTE: *Air delivery values are without air filter.

Deduct field-supplied air filter pressure drop to obtain external static pressure available for ducting.

Deduct 10% for 208 volts.

Dashes indicate portions of table that are not recommended.

Motor

Speed

Watts 279 282 280 277 276 ——————

Low

CFM 882 801 738 674 604 ——————

Watts ———373 367 361 356 351 ———

Med

CFM ———936 868 797 719 626 ———

Watts —————463 452 439 428 ——

High

CFM —————956 878 794 702 ——

Watts 243 244 242 ————————

Low

CFM 885 842 786 ————————

Watts 353 339 333 330 326 320 —————

Med

CFM 1195 1134 1070 997 911 818 —————

Watts ———443 436 426 416 406 397 ——

High

CFM ———1230 1145 1061 977 888 786 ——

Watts 490 463 446 432 418 403 389 378 ———

Low

CFM 1431 1398 1347 1281 1205 1118 1024 921 ———

Watts — 513 501 488 474 459 443 428 ———

Med

CFM — 1491 1426 1351 1267 1175 1077 976 ———

Watts ——645 636 627 616 605 593 583 ——

High

CFM ——1484 1410 1330 1243 1147 1044 936 ——

Watts 634 618 608 598 583 562 534 502 473 454 457

Low

CFM 1669 1599 1545 1498 1448 1391 1326 1257 1189 1132 1101

Watts ———733 704 672 638 604 574 550 536

Med

CFM ———1746 1688 1630 1566 1492 1399 1279 1120

Watts ——————797 773 751 727 696

High

CFM ——————1727 1632 1537 1423 1308

Watts 591 578 573 568 559 544 524 500 ———

Low

CFM 1554 1523 1496 1467 1432 1387 1332 1269 ———

Watts 755 737 719 699 678 653 627 602 579 562 556

Med

CFM 1834 1802 1758 1706 1648 1585 1520 1455 1392 1332 1276

Watts ———890 858 828 801 777 756 734 709

High

CFM ———1943 1870 1793 1711 1624 1531 1433 1329

Watts 589 576 569 566 559 541 499 ————

Low

CFM 1946 1891 1836 1779 1718 1651 1577 ————

Watts 750 733 715 695 673 648 623 598 577 ——

Med

CFM 2189 2097 2021 1952 1883 1809 1727 1635 1530 ——

Watts — 879 850 821 795 772 750 728 701 ——

High

CFM — 2337 2159 2050 1974 1905 1824 1722 1597 ——

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

External Static Pressure (in. wg)

FILTER SIZE

20 X 20 X 1 0.05 0.07 0.08 0.10 0.12 0.13 0.14 0.15 ———————————

20 X 24 X 1 ————0.09 0.10 0.11 0.13 0.14 0.15 0.16 ————————

24 X 30 X 1 ———————0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

FILTER PRESSURE DROP (In. wg)

CFM

—16—

Page 17

UNIT

SIZE

024

030

036

UNIT

SIZE

042

048

060

583B COOLING DRY COIL ICM AIRFLOW—SMALL CABINET

CFM ADJUST

PIN SELECT

EXTERNAL STATIC

PRESSURE RANGE

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

583B COOLING DRY COIL ICM AIRFLOW—LARGE CABINET

CFM ADJUST

PIN SELECT

EXTERNAL STATIC

PRESSURE RANGE

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

COOLING

COOLING

DEHUMIDIFY

LO PIN NOM PIN HI PIN

0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0

745 675 — 835 750 690 940 880 815

675 625 — 675 650

940 860 785 1020 965 895 1185 1100 1010

820 785 735 820 800

1025 935 — 1145 1085 1005 1320 1260 1180

925 885 — 925 900

LO PIN NOM PIN HI PIN

0.1–1.0 0.1–1.0 0.1–1.0

1035 1095 1280

880 880 1025

1150 1285 1500

1025 1025 1200

1480 1630 1920

1305 1305 1535

600 755 730 705

770 955 920 880

870 1060 1040 1010

EASY SELECT™

BOARD SETTING (CFM)

UNIT

SIZE

024

030

036

UNIT

SIZE

042

048

060

EXTERNAL STATIC

PRESSURE

GAS HEAT SIZE

EASY SELECT™

BOARD SETTING (CFM)

583B HEATING ICM AIRFLOW—SMALL CABINET

700 800 1100 1250

0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0 0.0–0.4 0.4–0.7 0.7–1.0

040 ———855 770 710 ——————

060 ———

040 ———

060 ——————1030 970 910 ———

060 ——————

090 —————————1170 1110 1025

———1020 890 835 ———

880 840

805 ——————

1035 995 955 ———

583B HEATING ICM AIRFLOW—LARGE CABINET

1000 1250 1600 1750 1800

EXTERNAL STATIC

PRESSURE

GAS HEAT SIZE

060

090

090

115

130

090

115

130

0.0–1.0 0.0–1.0 0.0–1.0 0.0–1.0 0.0–1.0

1000 ————

— 1250 ———

— 1250 ———

——1600 ——

———1750 —

— 1250 ———

——1600 ——

————1800

—17—

Page 18

583B ICM AIR FLOW VS. TEMPERATURE RISE CHART

UNIT COOLING SIZE

583B 024 40 800 36.5 20 50 175

583B 024 60 1100 40 35 65 165

583B 030 40 800 36.5 20 50 175

583B 030 60 1100 40 35 65 165

583B 036 60 1100 40 25 55 165

583B 036 90 1200 54 45 75 175

583B 042 60 1000 44 20 50 165

583B 042 90 1250 53 35 65 170

583B 048 90 1250 53 25 55 165

583B 048 115 1600 53 35 65 170

583B 048 130 1750 54 40 70 175

583B 060 90 1600 41 25 55 155

583B 060 115 1600 53 35 65 170

583B 060 130 1800 53 40 70 175

RATED GAS

INPUT RATE

(X 1000)

AIRFLOW SETTING

EAST SELECT™

(SCFM)

CALCULATED

TEMPERATURE

RISE

MIN.

TEMP

RISE

MAX

TEMP

RISE

MAX

DISCH.

TEMP

PERFORMANCE DATA (CONT)

ECONOMIZER/1-IN. FILTER PRESSURE DROP (in. wg)

UNIT 583B PRESSURE DROP

024-036 0.20

042-060 0.25

HIGH ALTITUDE COMPENSATION

NATURAL GAS ONLY

ORIFICE CONVERSION — 3.5 in. wc

MANIFOLD PRESSURE*

ALTITUDE (ft)

0-2000

2001-6000

* As the height above sea level increases, there is less oxygen per cubic ft of air.

Therefore, heat input rate should be reduced at higher altitudes.

†Orifices available through your Bryant distributor.

INPUT

(Btuh)

40,000 31,000 #44

60,000 46,000 #38

90,000 70,000 #38

115,000 92,000 #33

130,000 103,000 #31

32,075 24,858 #48

48,547 37,219 #42

72,820 56,638 #42

90,094 72,075 #37

102,630 81,315 #34

OUTPUT

(Btuh)

ORIFICE

NUMBER†

583B ICM FIOP WET COIL PRESSURE DROP

UNIT

SIZE

024 0.005

030 —

036

042

048

060

600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100

0.007 0.010 0.012 0.015 ———————————

0.007 0.010 0.012 0.015 0.018 0.021 0.024 ————————

———0.019 0.023 0.027 0.032 0.037 0.042 0.047 ——————

————0.014 0.017 0.020 0.024 0.027 0.031 0.035 0.039 0.043 ———

——————0.027 0.032 0.036 0.041 0.046 0.052 0.057 0.063 0.068 —

—————————0.029 0.032 0.036 0.040 0.045 0.049 0.053

STANDARD CFM

ORIFICE CONVERSION — 3.5 in. wc

ALTITUDE (ft)

0-2000

2001-6000

LIQUID PROPANE ONLY

MANIFOLD PRESSURE*

INPUT

(Btuh)

40,000 31,000 #50

57,000 43,720 #46

85,500 66,520 #46

115,000 92,000 #42

127,000 100,580 #41

33,834 26,221 #52

49,238 37,766 #48

73,856 57,461 #48

94,571 75,657 #44

101,284 80,214 #43

OUTPUT

(Btuh)

ORIFICE

NUMBER†

—18—

Page 19

ROOF-MOUNTING

CURB

SUPPLY-AIR

FLEXIBLE DUCT

TYPICAL PIPING AND WIRING

ROOF

RETURN-AIR

FLEXIBLE DUCT

CONCENTRIC DIFFUSER BOX

(FIELD-SUPPLIED)

TOP COVER

CEILING

C00023

INDOOR

THERMOSTAT

RETURN

AIR

FROM

POWER

SOURCE

—19—

FROM

GAS LINE

*NEC - NATIONAL ELECTRICAL CODE

DISCONNECT

PER NEC*

C00022

Page 20

APPLICATION DATA

Condensate trap — A 2-in. condensate tr ap must be field

supplied.

1” MIN.

TRAP

OUTLET

2” MIN.

Ductwork — Secure downflow discharge ductwork to roof

curb. For horizontal discharge applications, attach

ductwork to unit with flanges.

To convert a unit to downflow discharge — Units are

equipped with factory-installed inserts in the down-flow

openings. Remov al of the inserts is similar to removing an

electrical knock-out. The unit is factory equipped with duct

covers to seal the horizontal discharge openings in the

unit. Units installed in horizontal discharge orientation do

not require duct covers.

Maximum cooling airflow — To minimize the possibility

of condensate blow-off from the evaporator, airflow

through the units should not exceed 450 cfm per ton.

Minimum cooling airflow — The minimum cooling

airflow is 350 cfm per ton.

Minimum cooling ambient operating temperature — All

standard units have a minimum cooling ambient operating

temperature of 40°F. Units with the ICM Indoor Motor FIOP

have a minimum cooling outdoor operating temperature of

55°F. With accessory low ambient temperature kit, units

can operate at temperatures down to 0°F.

Maximum operating outdoor air temperature — fo r

cooling is 125°F.

—20—

Page 21

ELECTRICAL DATA

583B (STANDARD) ELECTRICAL DATA

UNIT

SIZE

583B

024 208/230-1-60 187 253 13.5 61.0 0.8 2.0 19.7 30

030

036

042

048

060

V-PH-Hz

208/230-1-60 187 253 14.7 73.0 0.8 2.1 21.3 35

208/230-3-60 187 253 9.6 63.0 0.8 2.1 14.9 20

208/230-1-60 187 253 15.4 83.0 0.8 3.6 23.7 35

208/230-3-60 187 253 12.2 77.0 0.8 3.6 19.7 30

460-3-60 414 506 5.1 35.0 0.8 1.9 9.1 15

208/230-1-60 187 253 18.6 105.0 0.9 4.1 28.3 45

208/230-3-60 187 253 13.8 88.0 0.9 4.1 22.3 35

460-3-60 414 506 6.3 39.0 0.9 2.0 10.8 15

208/230-1-60 187 253 20.5 109.0 1.6 4.1 31.3 50

208/230-3-60 187 253 14.7 91.0 1.6 4.1 24.1 35

460-3-60 414 506 6.5 46.0 0.9 2.0 11.0 15

208/230-1-60 187 253 27.6 158.0 1.6 6.2 42.3 60

208/230-3-60 187 253 18.1 137.0 1.6 6.2 30.4 45

460-3-60 414 506 9.0 62.0 0.9 3.2 15.4 20

VOLTAGE

RANGE

Min Max RLA LRA FLA FLA MCA

COMPRESSOR

OUTDOOR FAN

MOTOR

INDOOR FAN

MOTOR POWER SUPPLY

MAX FUSE

OR BKR

583B WITH ICM FIOP ELECTRICAL DATA

UNIT SIZE

583B

024 208/230–1–60 187 253 13.5 61.0 0.9 4.3 22.1 35

030 208/230–1–60 187 253 14.7 73.0 0.9 4.3 23.6 35

036 208/230–1–60 187 253 15.4 83.0 0.9 6.8 27.0 40

042 208/230–1–60 187 253 18.6 105.0 0.9 6.8 31.7 45

048 208/230–1–60 187 253 20.5 109.0 1.6 6.8 34.0 50

060 208/230–1–60 187 253 27.6 158.0 1.6 9.2 45.2 60

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA

—

*Heater capacity (KW) based on heater voltage of 208v, 240v, & 480v.

If power distribution voltage to unit varies from rated heater voltage,

heater KW will vary accordingly.

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. The CGA (Canadian Gas

Association) units may be fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percentage of voltage imbalance.

% Voltage imbalance

= 100 x

V-PH-HZ

LEGEND

Rated

Load Amps

Use the following formula to determine

max voltage deviation from average voltage

average voltage

VOLTAGE RANGE COMPRESSOR

MIN MAX RLA LRA FLA FLA MCA

®

OUTDOOR FAN

MOTOR

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457

(BC) 464

(AC) 457

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

452=5v

457=7v

455=2v

INDOOR

FAN

MOTOR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

POWER SUPPLY

452 + 464 + 455

1371

=

3

= 457

MAX FUSE OR

CKT. BKR.

3

C99024

—21—

Page 22

TYPICAL WIRING SCHEMATIC—208/230-1-60 SHOWN

C99076

—22—

Page 23

TYPICAL WIRING SCHEMATIC—208/230-3-60 SHOWN

C99077

—23—

Page 24

TYPICAL WIRING SCHEMATIC—460-3-60 SHOWN

C99078

—24—

Page 25

ICM FIOP WIRING SCHEMATIC—208/230-1-60

YEL

YEL

YEL

BLK

BLK

BLK

YEL

BLU

BRN

I

—25—

Page 26

CONTROLS

OPERATING SEQUENCE

Heating — On a call for heating, terminal “W” of the thermostat

is energized, starting the induced-draft motor. When the halleffect sensor on the induced-draft motor senses that it has

reached the required speed, the burner sequence begins. This

function is performed by the integrated gas control (IGC). The

evaporator fan motor is energized 45 seconds after flame is established. When the thermostat is satisfied and “W” is deenergized, the burners stop firing and the evaporator fan motor

shuts off after a 45-second time-off delay.

Cooling — When the room temperature rises to a point that is

slightly above the cooling control setting of the thermostat, the

thermostat completes the circuit between thermostat terminal R

to terminals Y and G. These completed circuits through the thermostat connect contactor coil (C) (through unit wire Y) and blower relay coil (BR) (through unit wire G) across the 24-v

secondary of transformer (TRAN).

The normally open contacts of energized contactor (C) close and

complete the circuit through compressor motor (COMP) to condenser (outdoor) fan motor (OFM). Both motors start instantly.

The set of normally open contacts of energized relay BR close

and complete the circuit through evaporator blower (indoor) fan

motor (IFM).

NOTE: Once the compressor has started and then has stopped,

it should not be started again until 5 minutes have elapsed.

The cooling cycle remains “on” until the room temperature drops

to a point that is slightly below the cooling control setting of the

room thermostat. At this point, the thermostat “breaks” the circuit

between thermostat terminal R to terminals Y and G. These

open circuits de-energize contactor coil C and relay coil BR. The

condenser and compressor motors stop. After a 30-second delay, the blower motor stops. The unit is in a “standby” condition,

waiting for the next “call for cooling” from the room thermostat.

The ICM FIOP indoor blower operation with a call

ation (G) in cooling mode will perform by the on/off delay profile

selected on the Easy Select™ circuit board.

for fan oper-

—26—

Page 27

GUIDE SPECIFICATIONS

PACKAGED GAS HEATING/ELECTRIC COOLING

UNITS CONSTANT VOLUME APPLICATION

HVAC GUIDE SPECIFICATIONS

SIZE RANGE: 2 TO 5 TONS, NOMINAL COOLING

40,000 TO 130,000 BTUH,

NOMINAL HEATING INPUT

BRYANT MODEL NUMBER: 583B

PART 1 — GENERAL

1.01 SYSTEM DESCRIPTION

Outdoor rooftop mounted, gas heating/electric cooling unit

utilizing a scroll compressor for cooling duty. Unit shall

discharge supply air vertically or horizontally as shown on

contract drawings. Condenser fan/coil section shall have a

draw-thru design with vertical discharge for minimum

sound levels.

1.02 QUALITY ASSURANCE

A. Unit shall be rated in accordance with ARI Standards

210/240-94 and 270-95 (Sound ratings for 270-95 are

not listed with ARI).

B. Unit shall be designed in accordance with UL Standard

1995.

C. Unit shall be manufactured in a facility registered to

ISO 9001 manufacturing quality standard.

D. Unit shall be UL listed and certified under Canadian

Standards as a total package for safety requirements.

E. Roof curb shall be designed to conform to NRCA

Standards.

F. Insulation and adhesives shall meet NFPA 90A

requirements for flame spread and smoke generation.

G. Cabinet insulation shall meet ASHRAE Standard 62P.

1.03 DELIVERY, STORAGE AND HANDLING

Unit shall be stored and handled per manufacturer’s

recommendations.

PART 2 — PRODUCTS

2.01 EQUIPMENT

A. General:

Factory-assembled, single-piece, heating and cooling unit.

Contained within the enclosure shall be all factory wiring,

piping, controls, refrigerant charge with R-410A refrigerant,

and special features required prior to field start-up.

B. Unit Cabinet:

1. Unit Cabinet shall be constructed of phosphated,

zinc-coated, pre-painted steel capable of withstanding 500 hours in salt spray.

2. Normal service shall be through a single removable

cabinet panel.

3. The unit shall be constructed on a rust proof

basepan that has an externally trapped, integrated

sloped drain pan.

4. Evaporator fan compartment top surface shall be

insulated with a minimum 1/2-in. thick, flexible

fiberglass insulation, coated on the air side and

retained by adhesive and mechanical means. The

evaporator wall sections will be insulated with a

minimum semi-rigid foil-faced board capable of

being wiped clean. Aluminum foil-faced fiberglass

insulation shall be used in the entire indoor air

cavity section.

5. Unit shall have a field-supplied condensate trap.

C. Fans:

1. The evaporator fan shall be 3-speed, direct-drive,

as shown on equipment drawings or factory

optional variable speed motor and control.

2. Fan wheel shall be made from steel, and shall be

double-inlet type with forward curved blades with

corrosion resistant finish. Fan wheel shall be

dynamically balanced.

3. Condenser fan shall be direct drive propeller type

with aluminum blades riveted to corrosion resistant

steel spiders, be dynamically balanced, and

discharge air vertically.

D. Compressor:

1. Fully hermetic compressors with factory-installed

vibration isolation.

2. Scroll compressors shall be standard on all units.

E. Coils:

Evaporator and condenser coils shall have aluminum

plate fins mechanically bonded to seamless copper

tubes with all joints brazed. (Copper/copper and vinylcoated construction available as option). Tube sheet

openings shall be belled to prevent tube wear.

F. Heating Section:

1. Induced-draft combustion type with energy saving

direct spark ignition system and redundant main

gas valve.

2. Induced-draft motors shall be provided with solidstate hall-effect sensor to ensure adequate airflow

for combustion.

3. The heat exchangers shall be constructed of

aluminized steel for corrosion resistance.

4. Burners shall be of the in-shot type constructed of

aluminum coated steel.

5. All gas piping and electric power shall enter the unit

cabinet at a single location.

G. Refrigerant Components:

Refrigerant expansion shall be of the fixed orifice type.

H. Filters:

Filter section shall consist of field-installed, throwaway,

1-in. thick fiberglass filters of commercially available

sizes.

I. Controls and Safeties:

1. Unit controls shall be complete with a selfcontained low voltage control circuit.

2. Compressors shall incorporate a solid-state

compressor protector that provides reset

capability.

3. Unit shall provide high and loss-of-charge/low

pressure safety protection.

J. Operating Characteristics:

1. Unit shall be capable of starting and running at

125°F ambient outdoor temperature exceeding

maximum load criteria of ARI Standard 210.

2. Compressor with standard controls shall be capable of operation down to 40 F ambient outdoor temperature. (55°F with ICM FIOP)

3. Units shall be provided with fan time delay to prevent cold air delivery before the heat exchanger

warms up.

4. Unit shall be provided with 30-second fan time delay after the thermostat is satisfied with standard indoor blower.

5. On ICM FIOP fan off delay for cooling is selected

on Easy Select™ Board.

—27—

Page 28

GUIDE SPECIFICATIONS continued

K. Electrical Requirements:

All unit power wiring shall enter the unit cabinet at a single

location.

L. Motors:

1. Compressor motors shall be of the refrigerant-cooled

type with line-break thermal and current overload protection.

2. All fan motors shall have permanently lubricated bearings, and inherent, automatic reset, thermal overload

protection.

3. Condenser fan motor shall be totally enclosed.

M. Grille:

1. Louvered Grille:

Louvered grille shall be factory-installed to provide hail

guard and vandalism protection.

N. Duct Conversion:

Shall be available with the use of included duct covers.

O. Special Features:

1. ICM Indoor Blower FIOP:

Integral control motor shall be a factory installed option

for optimizing comfort levels in all operating modes and

increasing system efficiency.

2. Coil Options:

Shall include factory-installed optional copper/

copper and vinyl-coated refrigerant coils.

3. Economizer:

a. Economizer controls capable of providing free cool-

ing using outside air.

b. Equipped with low leakage dampers not to exceed

3% leakage, at 1.0 in. wg pressure differential.

c. Spring return motor shuts off outdoor damper on

power failure.

4. Flat Roof Curb:

Curbs shall have seal strip and a wood nailer for flash-

ing and shall be installed per manufacturer’s instructions.

5. Manual Outdoor Air Damper:

Package shall consist of damper, birdscreen, and rain-

hood which can be preset to admit outdoor air for yearround ventilation.

6. Thermostat:

To provide for one-stage heating and cooling in addition

manual or automatic changeover and indoor fan control.

7. Natural-to-Propane Conversion Kit:

Shall be complete with all required hardware to convert

to liquid propane (LP) operation.

8. Low Ambient Package:

Shall consist of a solid-state control and condenser coil

temperature sensor for controlling condenser-fan motor operation, which shall allow unit to operate down to

0° F outdoor ambient temperature.

9. Filter Rack Kit:

Shall provide filter mounting for downflow applications.

10. Square-To-Round Duct Transitions:

Shall have the ability to convert the supply and return

openings from rectangular to round.

11. Compressor Protection (Time Guard® II Kit)

Solid-state control shall protect compressor by prevent-

ing “short cycling.”

12. Crankcase Heater:

Shall provide anti-floodback protection for low-load

cooling applications.

13. High Altitude Kit:

Shall consist of natural gas orifices to compensate for

gas heat operation at 2001 to 6000 ft above sea level.

14. Low NO

Shall provide NO

(Natural Gas only) option:

x

reduction to values below 40 nano-

x

grams/joule to meet California emission requirements.

15. Compressor Hard Start Kit:

Shall provide additional starting torque for single-phase

compressors. (Single phase only).

16. Rigging kit includes lifting brackets which are inserted

into the basepan handholds to rig unit for rooftop applications.

© 2001 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indpls., IN 46231 PRINTED IN U.S.A. Catalog No. 5258-305 5-01

—28—

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS 583B.24.2

Form PDS 583B.24.3

Loading...

Loading...