Bryant PLUS 90X 353AAV User Manual

353AAV Plus 90x

4--Way Multipoise Condensing Gas Furnace

Input Rates: 40,000 Only

Product Data

4--WAY MULTIPOISE DESIGN ALLOWS

MORE APPLICATIONS

the furnace resulting in lower electrical usage. The high

efficiency achieved by superior heat transfer is made only

better—by optimizing the efficient ECM motor speed tap

locations.

A standard media filter cabinet accessory is provided with the

Plus 90x in order to provide an opportunity to enhance indoor air

quality. As with all other Bryant furnaces, this model is designed

to work as a part of the total home comfort system which includes

elements for cooling, air cleaning, humidification, ventilation and

zoning. Boosting the unit’s efficiency with the ECM motor and

Bryant’s deluxe features show the Plus 90x has been designed

with the homeowner in mind.

PLUS 90X FEATURES & BENEFITS

EverlasticTM— Exclusive Everlastic coating, a patented

polypropylene laminate is used on the secondary heat exchanger

and greatly reduces maintenance.

Perfect Light™ Igniter — Bryant’s unique Perfect Light™

igniter is not only physically robust but it is also electrically

robust. It is capable of running at line voltage and does not

require complex voltage regulators as do other brands. This

unique feature further enhances the reliability of the Plus 90x gas

furnace and continues Bryant’s tradition of technology leadership

and innovation in providing a reliable and durable product.

FanOn™ — Improves comfort all year long by allowing the

homeowner to select different fan speeds during continuous fan

A05085

operation to achieve more or less airflow. This is done right at the

thermostat.

A UNIQUE SEER SOLUTION

The Plus 90x is an exciting addition to your product line. This

high--efficiency 4--way multipoise design furnace allows more

applications while the ECM motor and Bryant’s control logic

combine to provide a SEER increase of up to 1.5 points.*

Some of Bryant’s best--engineered components contribute to the

efficient performance of this condensing furnace. The Plus 90x

utilizes Power Lightt hot surface ignition (HSI), which ignites

the burners directly. HSI eliminates gas waste that typical

continuous--pilot designs can bring. Hot surface ignition has

proven to contribute to reliable start--up and operation of Bryant

furnaces.

Another deluxe feature included with this furnace is Bryant’s

trusted Everlastict secondary heat exchanger; a patented

polypropylene laminate that provides exceptional heat transfer

and corrosion resistance. Using the exclusive flow--through

design, the secondary heat exchanger reduces the pressure drop in

*as compared to the Air--- Conditioning, Heating and Refrigeration Institute’s standard coil--- only rating (A/Cs up to 3.5 tons) when paired with selected Bryant

evaporator coils.

SmartEvap™ — This feature allows your system to reduce

summertime humidity levels by nearly 10% over standard

systems.

Media Filter Cabinet — Enhanced indoor air quality in your

home is made easier with our media filter cabinet—a standard

accessory on all Deluxe furnaces. When installed as a part of your

system, this cabinet allows for easy and convenient addition of a

Bryant high--efficiency air filter.

Control Center — Microprocessor controls sequencing and

furnace operation. Equipped with a component test feature and

status indicator light to assist in troubleshooting. Microprocessor

controls blower times to start blower after main burners ignite to

eliminate cold air blowing into rooms.

1

Direct or Non--direct Venting —ThePlus 90x can be installed

as a 1 pipe/Non--Direct vent (except 140 size unit and in

manufactured/mobile home installations) or 2 pipe/Direct vent

furnace. All direct vent Plus 90x models can be installed in a

manufactured (mobile) home when the optional kit is used. This

provides added flexibility to meet diverse installation needs.

Casing — One piece, seamless wrap--around construction of

heavy, galvanized steel that resists corrosion.

Adjustable Blower Speed — For precise airflow selection of

heating or cooling operation.

Insulated Blower Compartment —The acoustical insulation

reduces air and motor noise to promote quiet operation.

Combustion Products Venting — The combustion--air and vent

pipes can terminate through a side wall or through the roof when

used with a factory--authorized vent termination kit.

Insulation — Foil--faced insulation in heat exchanger section of

the casing minimizes heat loss.

Bottom Closure — Factory--installed for side return; easily

removable for bottom return.

353AAV

Filter — Cleanable filter with retainer is standard.

Blower Access Panel Switch — Shuts off all 115--v power

through furnace components whenever blower access panel is

opened.

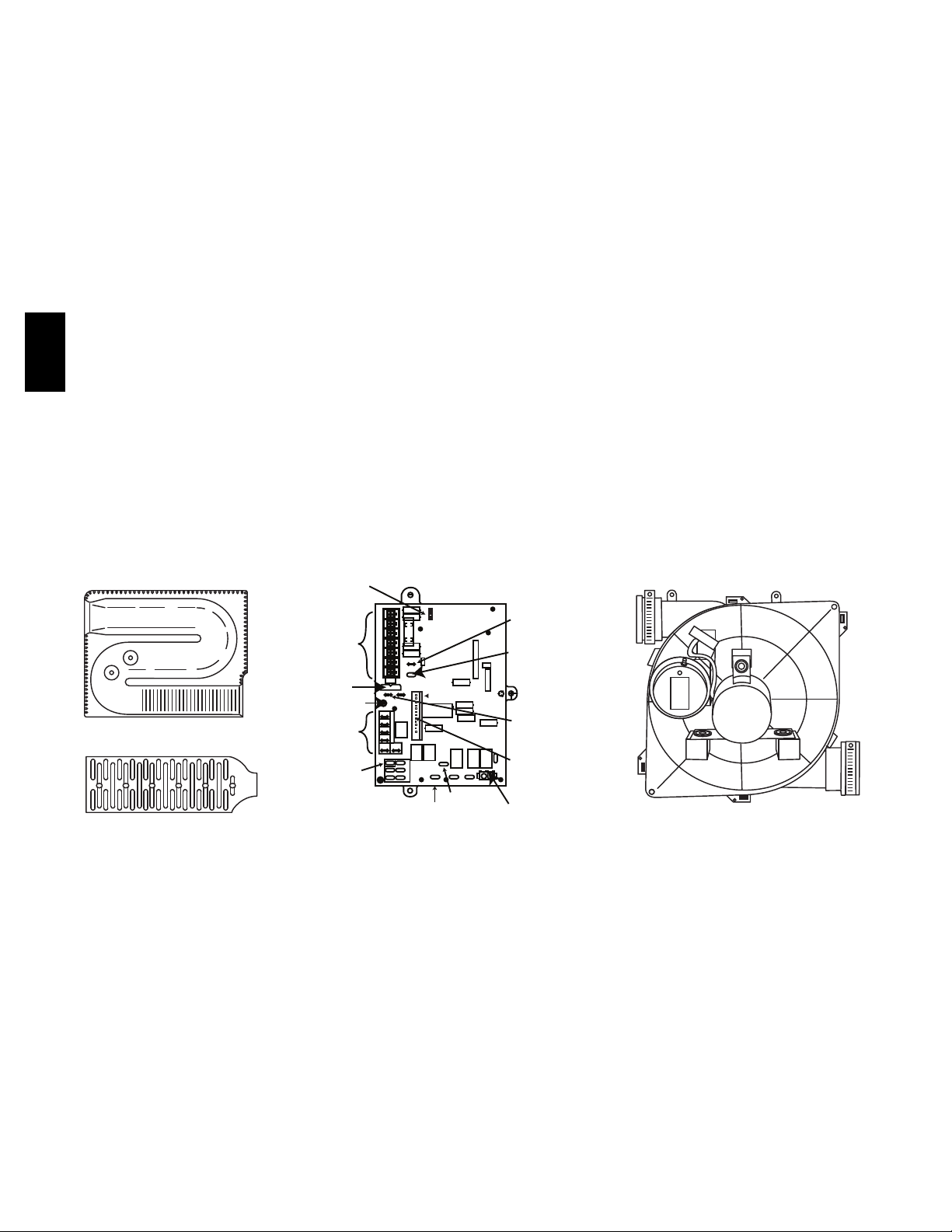

BLOWER OFF-DELAY

T1 DHUM G COM W TIT2 R

115-VAC (L2)

NEUTRAL

CONNECTIONS

24V

SPARE 2SPARE 1

A92505

24-V THERMOSTAT

TERMINALS

3-AMP FUSE

LED OPERATION

& DIAGNOSTIC LIGHT

BLOWER SPEED

SELECTION

TERMINALS

SEC-2 SEC-1

COM 24VAC

COM

HEAT

COOL

FAN

EAC-2

Monoport Burners — The burners are finely tuned for smooth,

quiet combustion plus economical gas usage.

Slow Opening Redundant Gas Valve — Shuts off gas to burners

if any of the valves fails to close completely for any reason. The

slow opening feature reduces start--up noise from rapid ignition.

Quality Registration —ThePlus 90x is engineered and

manufactured under an ISO 9001 registered quality system.

Certifications —ThePlus 90x Model units are CSA (A.G.A.

and C.G.A.) design certified for use with natural and propane

gases. The furnace is factory--shipped for use with natural gas. A

CSA (A.G.A./C.G.A.) listed gas conversion kit is required to

convert furnace for use with propane gas. The efficiency is

GAMA efficiency rating certified. The Plus 90x meets California

Air Quality Management District emission requirements. Refer to

Vent Table, for elevation limitations.

BLOWER OFF-DELAY

90 150

120 180

PLT

TEST / TWIN

HUH

PL1

24V MTR TAPS

1

EAC-1

L1 BL-1 PR-1

EAC-1 TERMINAL

(115-VAC 1.0 AMP. MAX0

115-VAC (LI)

NUETRAL

CONNECTIONS

PL2

PL1-HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTION

TWINNING AND/OR

COMPONENT TEST

TERMINAL

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP. MAX

TRANSFORMER

24-VAC CONNECTION

PL1-LOW VOLTAGE

MAIN HARNESS

CONNECTOR

A08345

)

S

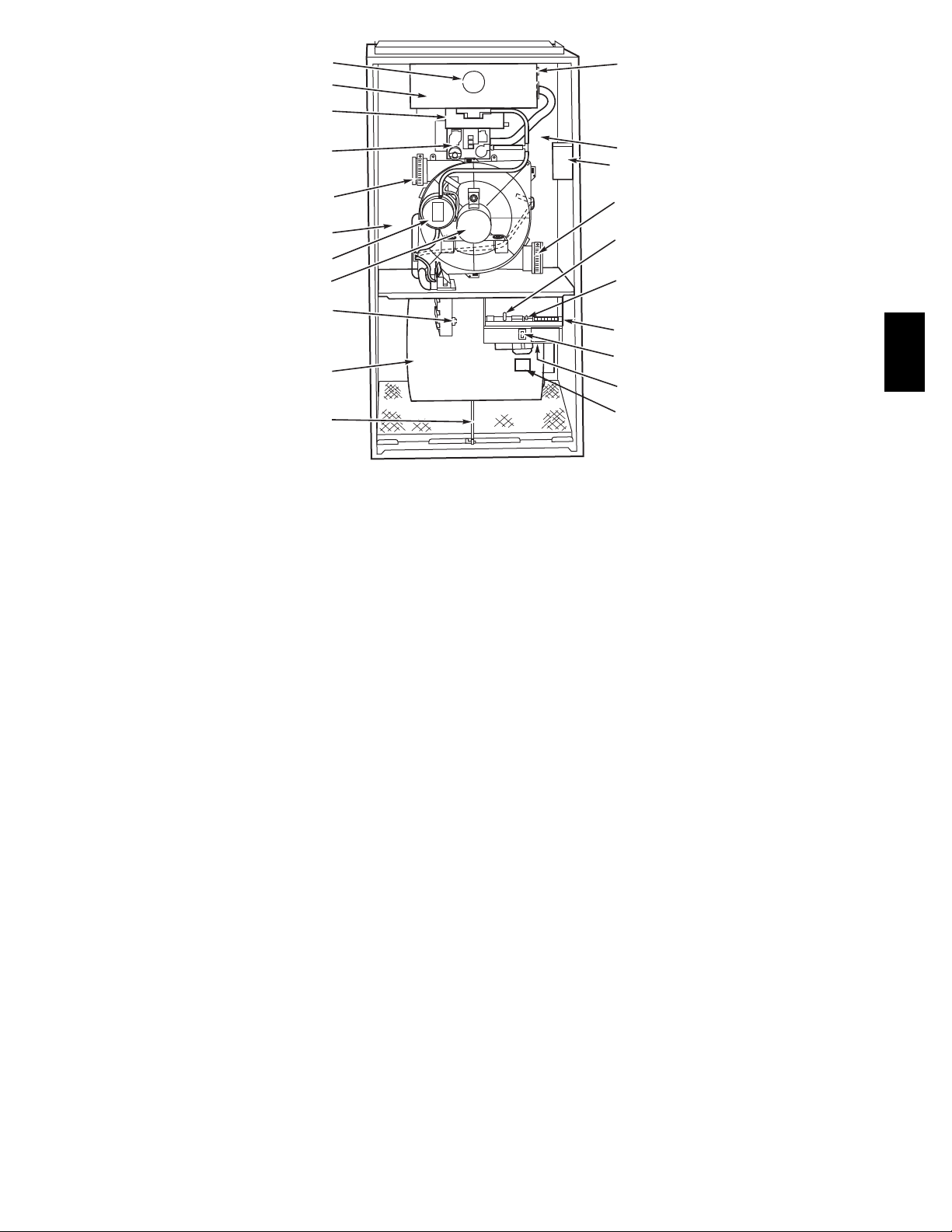

A02172

2

1

13

2

3

4

6

7

8

9

10

11

12

1. Burner sight glass for viewing burner flame.

2. Burner assembly (inside), operates with energy--sav-

ing, inshot burners and hot surface igniter for safe,

dependable heating.

14

5

6

15

16

17

18

19

20

A08421

11. Heavy--duty blower circulates air across the heat

exchangers to transfer heat into the home.

12. Air filter and retainer may be used for side or bottom

return application.

353AAV

3. Combustion--air intake connection to ensure contam-

inant--free air (right or left side).

4. Redundant gas valve, safe, efficient, features 1 gas

control with 2 internal shutoff valves.

5. Junction box for 115--v electrical power supply.

(right or left side)

6. Vent outlet uses sealed PVC pipe to carry vent gases

from the furnace’s combustion system (right or left

side).

7. Secondary condensing heat exchanger (inside),

wrings out more heat through condensation of gases.

Constructed with polypropylene--laminated steel to

ensure durability.

8. Pressure switch ensures adequate flow of flue

products through furnace and out vent system.

9. Inducer motor pulls hot flue gases through the heat

exchangers, maintaining negative pressure for added

safety.

13. Rollout switch (manual reset) to prevent overtemper-

ature in burner area.

14. Primary serpentine heat exchanger (inside). Stretches

fuel dollars with the S--shaped heat--flow design. Solid weld--free construction of corrosion--resistant aluminized steel means reliability.

15. A 3--amp fuse provides electrical and component

protection.

16. Light emitting diode (LED) on control center. Code

lights are for diagnosing furnace operation and service requirements.

17. Control center.

18. Blower access panel safety interlock switch.

19. Transformer (24v) behind control center provides

low--voltage power to furnace control center and

thermostat.

20. Power choke (used with 1 HP and 3/4 HP motors.)

10. Condensate drain connection collects moisture con-

densed during the combustion process.

123456

3

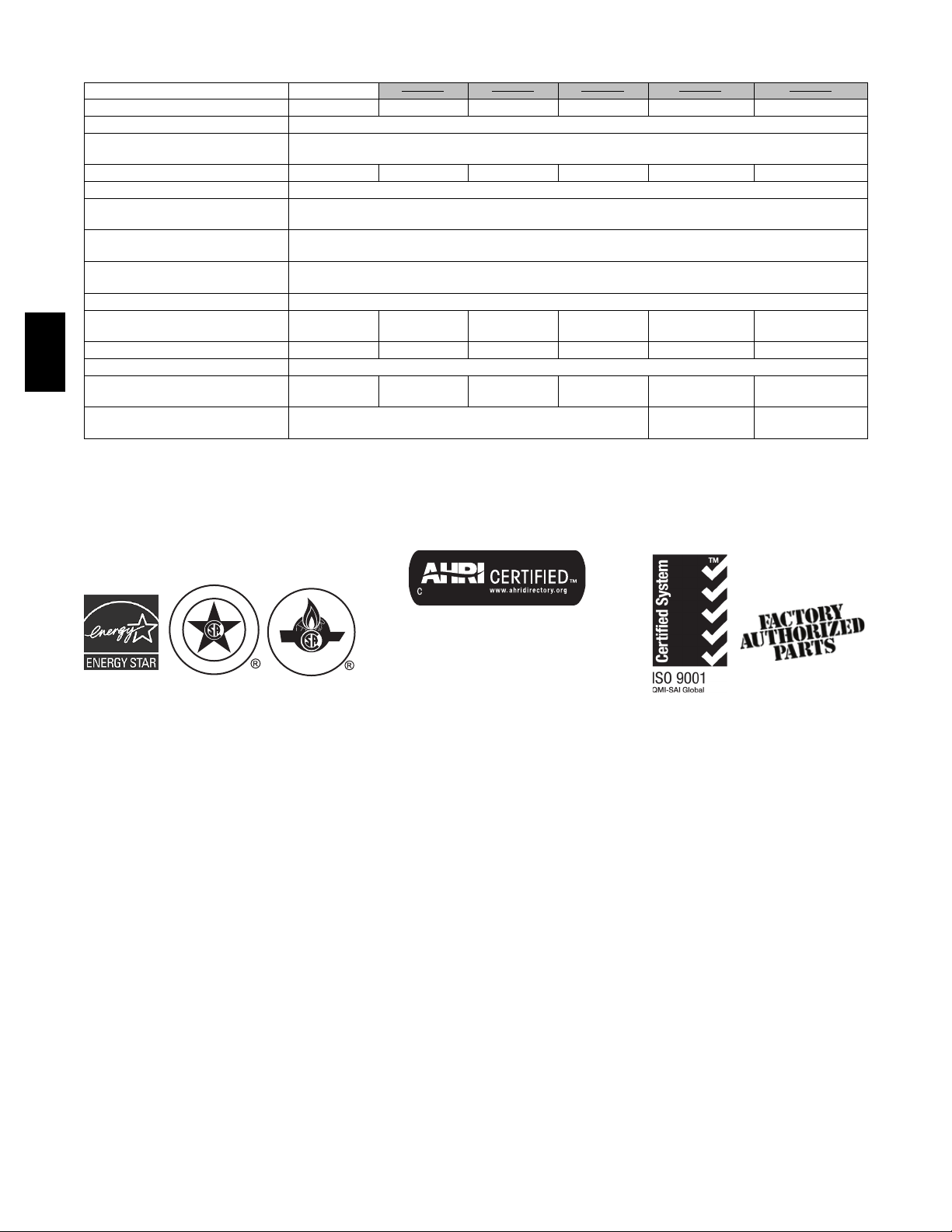

PHYSICAL DATA

**Note: 060--120 Sizes are phasing out.**

UNIT SIZE 036040 036060 036080 048080 060100 060120

SHIPPING WEIGHT LB. (KG) 175 (47) 182 (57) 198 (64) 205 (69) 232 261 (74)

LIMIT CONTROL SPST

HEATING BLOWER CONTROL

(Off Delay)

BURNERS (Monoport) 2 3 4 4 5 6

GAS CONNECTION SIZE 1/2--- in. NPT

GAS VALVE(Redundant)

Manufacturer

Minimum Inlet Pressure

(in. wc)

Maximum Inlet Pressure

(in. wc)

IGNITION DEVICE Hot Surface

DIRECT---DRIVE MOTOR

( E C M X --- 1 3 )

MOTOR FULL LOAD AMPS 6.8 6.8 6.8 8.4 10.9 10.9

R P M ( N o m i n a l ) --- S P E E D S 1050--- 5

353AAV

BLOWER WHEEL DIAMETER X

W I D T H --- I N ( m m )

F I L T E R S I Z E ( W a s h a b l e ) --IN (mm)

1/2 1/2 1/2 3/4 1 1

10 X 7

(254 X 178)

10 X 7

(254 X 178)

(1) 16 X 25 X 3/4

(406 X 635 X 19)

Solid--- State Time Operation

W h it e --- R o d g e rs

4.5 (Natural Gas)

13.6 (Natural Gas)

10 X 7

(254 X 178)

11 X 8

(279 X 203)

11 X 10

(279 X 254)

(1) 20 X 25 X 3/4

(508 X 635 X 19)

11 X 10

(279 X 254)

(1) 24 X 25 X 3/4

(610 X 635 X 19)

I

G

S

E

N

D

Always Ask For

Use of the AHRI Certified TM Mark indicates a

C

E

R

D

E

I

T

F

I

CERTIFIED

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org.

4

BRYANT ACCESSORIES*

ACCESSORIES

GAS CONVERSION KIT --NATURAL TO PROPANE

GAS CONVERSION KIT --PROPANE TO NATURAL

MANUFACTURED (MOBILE)

HOME KIT

DOWNFLOW BASE

(For Combustible Floors)}

VENT TERMINATION KIT

(Bracket Only for 2 Pipes)

CONCENTRIC TERMINATION

KIT (Single Exit)

CONDENSATE FREEZE

PROTECTION KIT

CONDENSATE NEUTRALIZER

KIT (Obtained thru RCD)

ELECTRONIC AIR CLEANER

(EAC)

AIR PURIFIER Models GAPAAXBB1625, GAPAAXBB2025

MECHANICAL AIR CLEANER Models EZXCAB, FILCAB

HUMIDIFIER Model HUM

HEAT RECOVERY VENTILATOR Model HRV

ENERGY RECOVERY

VENTILATOR

UV LIGHTS Model UVL

VENT/EXHAUST PIPE

EXTERNAL TRAP KIT

DOOR GASKET KIT KGBAC0110DGK

UNFRAMED FILTER,

PERMANENT WASHABLE 3/4”

(19mm)

16 x 25 (406 x 635 mm)

UNFRAMED FILTER,

PERMANENT WASHABLE 3/4”

(19mm)

16 x 25 (508 x 635 mm)

UNFRAMED FILTER,

PERMANENT WASHABLE 3/4”

(19mm)

16 x 25 (610 x 635 mm)

F o r u s e w i t h 1 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r --- T 6 --- N A C , T 2 --- N A C

T H E R M O S T A T --NON---PROGRAMMABLE

T H E R M O S T A T --PROGRAMMABLE

ZONING CONTROL

*Factory---authorized and field--- installed. Gas conversion kits are CSA (A.G.A./C.G.A.) recognized

Required for installation on combustible floors when no coil box is used, or when any coil box other than a Bryant cased coil is used.

*Model HP and 2S thermostat must be field converted to air conditioner operation.

{Thermidistatt Contro

}Dual Fuel thermostat is used with furnace and heat pump application.

l control can be configured for multiple use and staging. It must be configured for each specific application.

F o r u s e w i t h 1 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r --- T 6 --- N H P --- T 2 --- N H P *

F o r u s e w i t h 2 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r --- T 6 --- N R H *

For use with multi--- use / stage configurations --- deg. F/C, Auto Changeover/Temperature and

H u m i d i t y Co n t r o l --- T 6 --- P R H

F o r u s e w i t h 1 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r , 7 --- D a y P r o g r a m m a b l e ---

T 6 --- P A C

F o r u s e w i t h 1 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r , 7 --- D a y P r o g r a m m a b l e ---

T6---PHP*

F o r u s e w i t h 2 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , A u t o C h a n g e o v e r , 7 --- D a y P r o g r a m m a b l e ---

T 6 --- P R H *

F o r u s e w i t h 1 --- s p e e d A i r C o n d i t i o n e r --- d e g . F / C , 5 --- 2 D a y P r o g r a m m a b l e --- T 2 --- P A C

F o r u s e w i t h mu l t i --- s t a g e a p p l i c a t i o n s --- d e g . F / C , A u t o C h a n g e o v e r, 7 --- D a y Pr o g r a m m a b l e ---

T 6 --- P H P

F o r m u l t i --- u s e / s t a g e c o n f i g u r a t i o n s --- d e g . F / C , A u t o Ch a n g e o v e r , 7 --- D a y P r o g r a m m a b l e /

Temperature and Humidity Control --- T6 --- PRH

Comfort Series Three---Zone Zone Kit --- ZONEBB3ZAC01, ZONEBB3ZHP01

2---Performance Series Zoning/Temperature and Humidity Control --- ZONEBB2KIT01 --- B

4---Performance Series Zoning/Temperature and Humidity Control --- ZONEBB4KIT01 --- B

8---Performance Series Zoning/Temperature and Humidity Control --- ZONEBB8KIT01 --- B

}

2---IN. --- KGAVT0101BRA 3---IN. --- KGAVT0201BRA

2---IN. --- KGAVT0701CVT 3 --- IN. --- KGAVT0801CVT

{

KGANP4601ALL

KGANP3901ALL

KGAMH0301KIT

KGASB0301ALL

KGAHT01010CFP

P908---0001

Model EACB

Model ERV

KGAET0106ETK

KGAWF1301UFR

KGAWF1401UFR

KGAWF1501UFR

{

353AAV

5

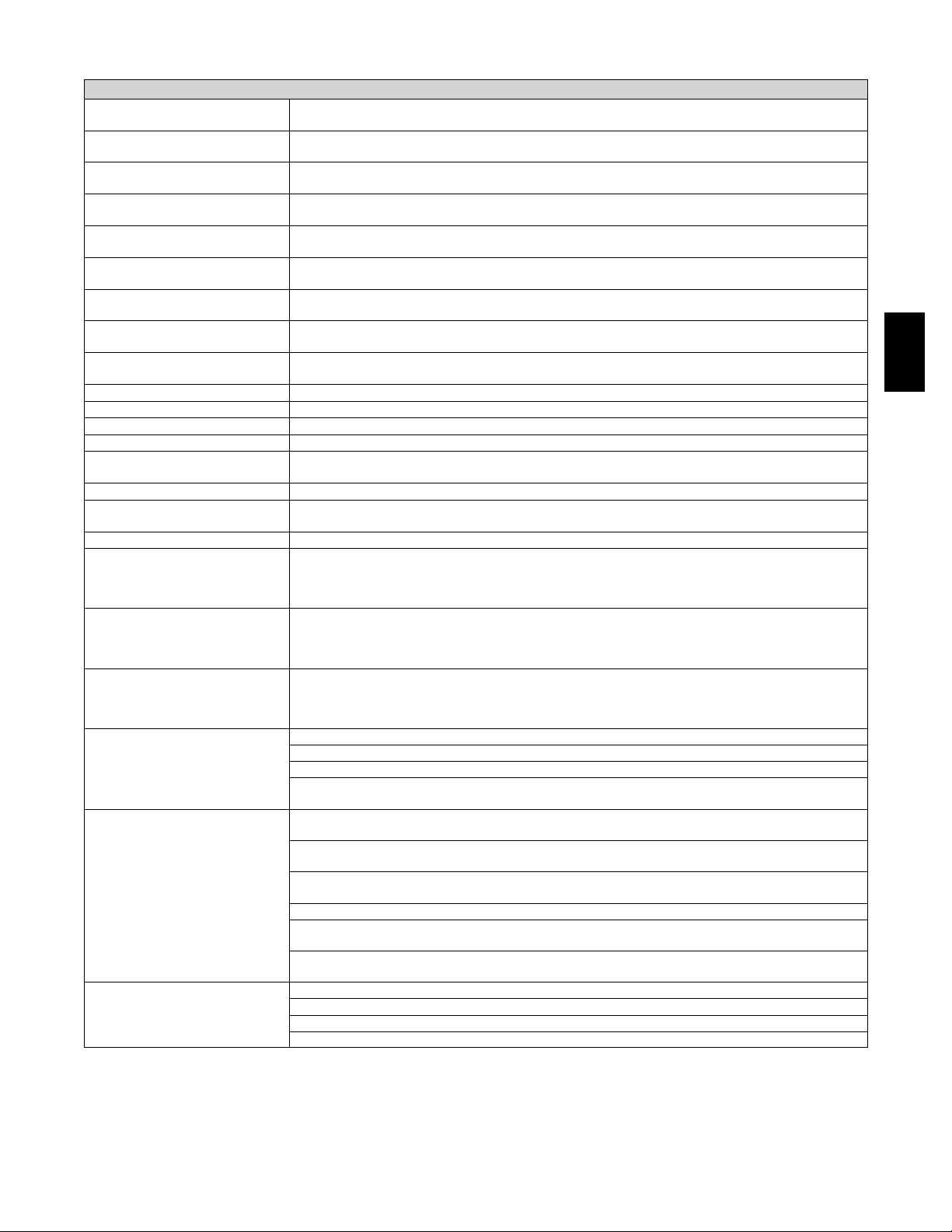

CONCENTRIC

VENT (DIRECT VENT/

2-PIPE ONLY)

A concentric vent kit allows vent

and combustion-air pipes to

terminate through a single exit

in a roof or side wall.

353AAV

One pipe runs inside the other

allowing venting through the

inner pipe and combustion air to

be drawn in through the outer

A93086

DOWNFLOW

SUBBASE

One base fits all furnace sizes.

The base is designed to be installed between the furnace and a

combustible floor when no coil

box is used or when a coil box

other than a Bryant cased coil is

used. It is CSA (A.G.A./C.G.A.)

design certified for use with select

Bryant furnaces when installed in

downflow applications.

A88202

BRYANT CASED

A96214

N-COIL

(as shown)

The Bryant Cased N-Coil or

A-Coil is an upflow/downflow

furnace coil which can also

replace the downflow subbase

when installing select Bryant

furnaces on combustible flooring

in the downflow orientation.

pipe.

A08450

A97432

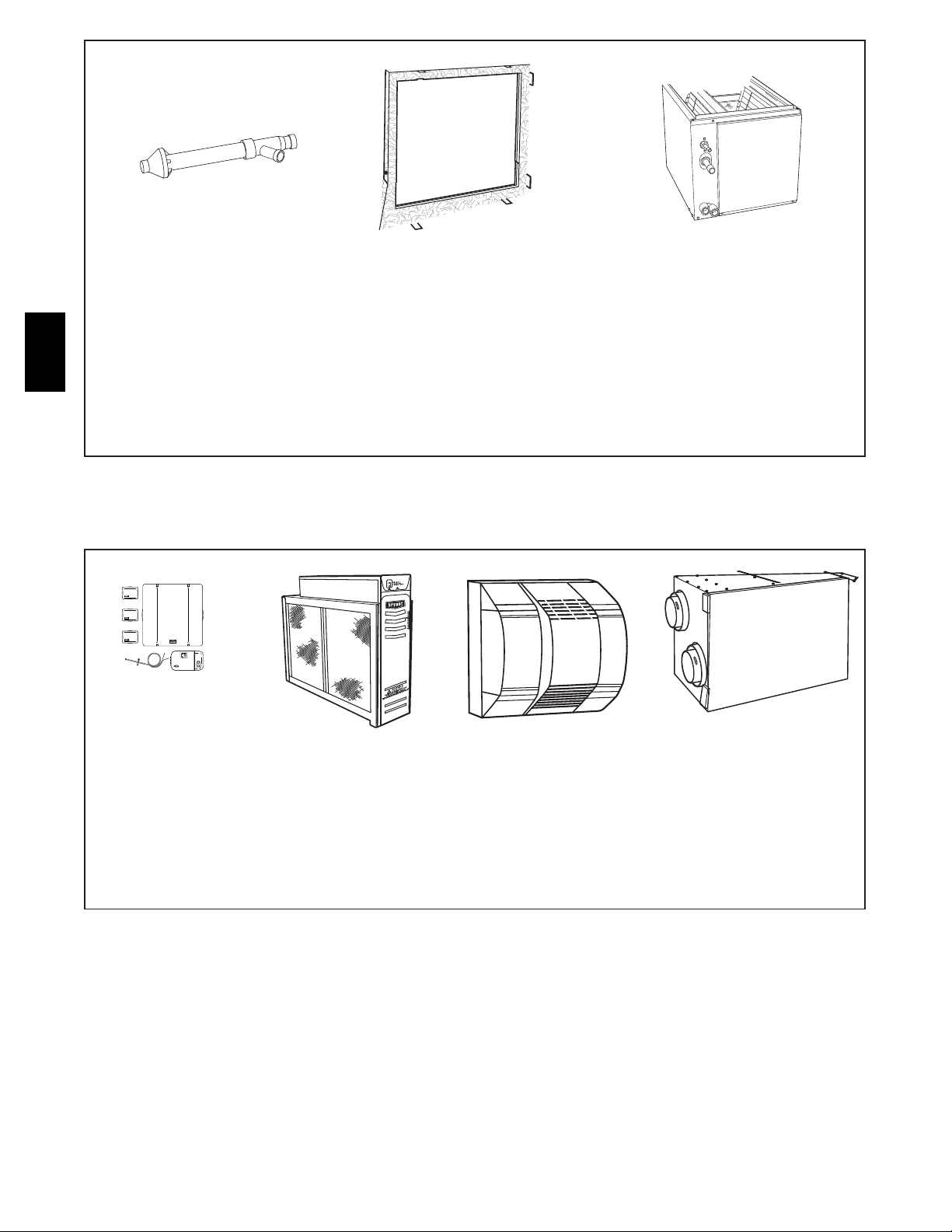

CONTROLS:

THERMOSTATS

AND ZONING

Available in programmable and

non-programmable models,

Bryant thermostats maintain a

constant, comfortable temperature level in the home.

For the ultimate in home comfort,

Bryant’s 2, 4, and 8-zone systems

allow temperature control of individual “zones” of the home. This is

accomplished through a series of

electronic dampers and

remote room sensors.

4-zone system is shown.

The

C04009

MECHANICAL

OR ELECTRONIC

AIR CLEANER

Cleans the air of smoke, dirt, and

many pollens commonly found.

Saves decorating and cleaning

expenses by keeping carpets,

furniture, and drapes cleaner.

Electronic air cleaner is shown.

A01484

HUMIDIFIER

By adding moisture to winter-dry

air, a Bryant humidifier can often

improve comfort and keep

furniture, rugs, and draperies in

better condition. Moisturizing

household air also helps to retain

normal body heat and provides

comfort at lower temperatures.

ENERGY/HEAT RECOVERY

VENTILATOR

Bryant’s energy or heat recovery

ventilators exhaust stale indoor

air and provide fresh outdoor air

to the home while minimizing

heat loss and humidity level.

Especially useful for today’s

tighter constructed houses.

Energy recovery ventilator

is shown.

A08153

6

(21mm)

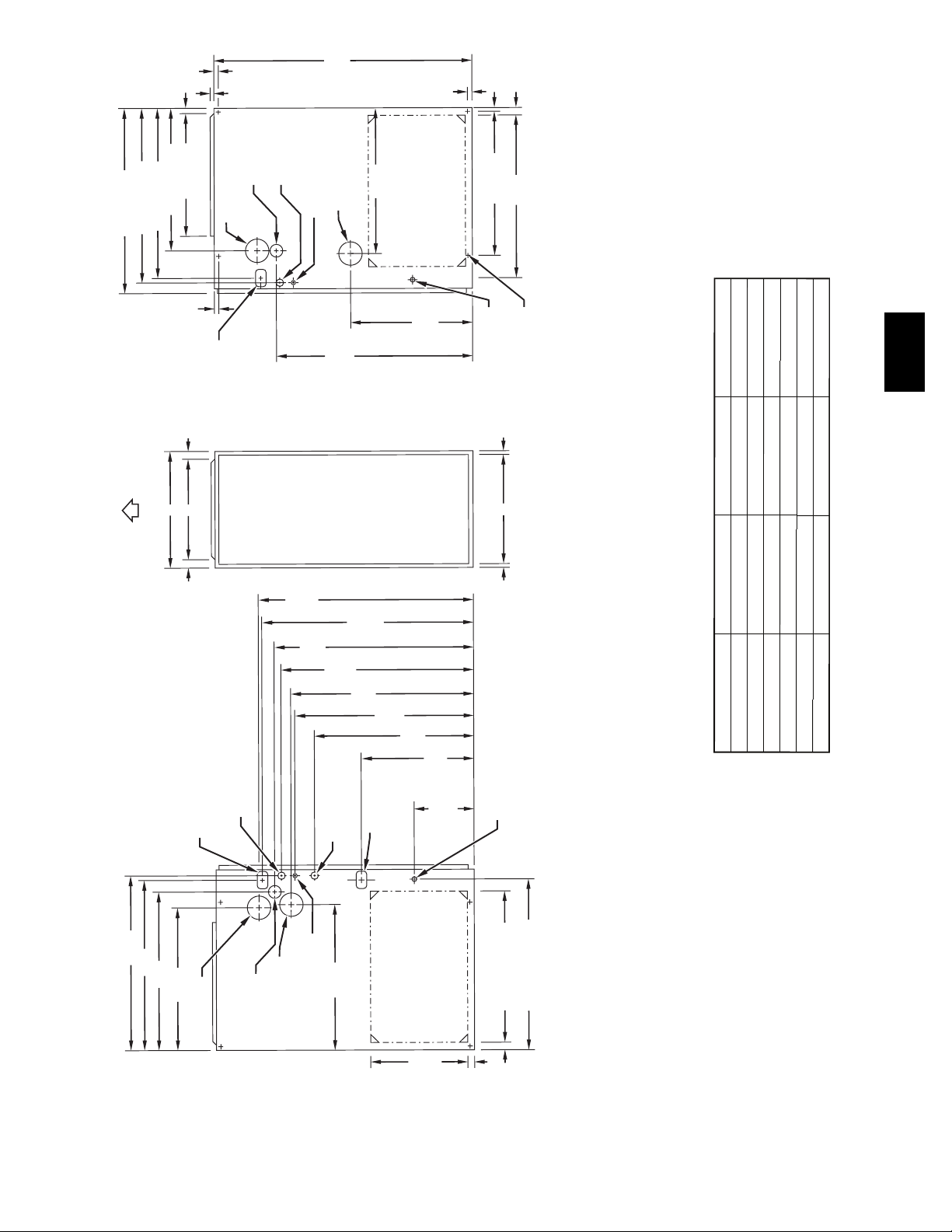

UNIT SIZE A D E

040-12 / 036040 17-1/2 (445) 15-7/8 (403) 16 (406)

060-12 / 036060 17-1/2 (445) 15-7/8 (403) 16 (406)

080-12 / 036080 17-1/2 (445) 15-7/8 (403) 16 (406)

080-16 / 048080 17-1/2 (445) 15-7/8 (403) 16 (406)

100-20 / 060100 21 (25.4) 19-3/8 (492) 19-1/2 (495)

120-20 / 060120 24-1/2 (622) 22-7/8 (581) 23 (584)

(16mm)

"

"

16

⁄

8

⁄

5

13

"

8

⁄

"

16

⁄

5

(8mm)

7

39

(1013mm)

1"

(25mm)

(11mm)

"

16

⁄

7

(17mm)

"

16

⁄

11

(694mm)

"

(724mm)

16

⁄

"

2

⁄

15

1

26

28

5

(667mm)

"

4

⁄

1

26

"

16

⁄

9

A

AIRFLOW

(567mm)

(483mm)

"

16

⁄

19"

22

TYP

(14mm)

"

16

⁄

13

D

"

16

⁄

13

OUTLET

2-IN. COMBUSTION-

TRAP LOCATION

CONDENSATE DRAIN

OUTLET

(21mm) (21mm)

HORIZONTAL LE FT)

(DOWNFLOW &

TRAP LOCATION

CONDENSATE DRAIN

-IN. DIA

2

⁄

GAS CONN

1

AIR CONN

(DOWNFLOW &

OR ALTERNATE

-IN. DIA GAS CONN

2

⁄

1

HORIZONTAL RIGHT)

(22mm)

-IN. DIA

8

⁄

POWER CONN

7

-IN. DIA

8

⁄

POWER CONN

7

"

4

⁄

1

TYP

33

-IN. DIA

2

⁄

1

(845mm)

"

16

⁄

13

(783mm)

30

THERMOSTAT ENTRY

11

2-IN. VENT CONN

"

2

⁄

1

30

(775mm)

"

16

⁄

TYP

29

(22mm)

-IN. DIA

8

⁄

ACCESSORY

7

11

"

8

⁄

5

TYP

32

(754mm)

"

8

⁄

5

27

(702mm)

CONDENSATE

POWER ENTRY

"

16

⁄

22

(829mm)

"

16

⁄

9

TYP

"

27

2

(700mm)

⁄

1

24

UPFLOW)

(ALTERNATE

LOCATION

DRAIN TRAP

SIDE INLET

"

4

⁄

1

18

(464mm)

"

(622mm)

16

⁄

5

17

(440mm)

"

16

⁄

7

TYP

9

(240mm)

1

CONDENSATE

INLET

" TYP

4

⁄

(565mm)

22

(UPFLOW)

DRAIN LOCATION

"

16

⁄

11

E

"

16

⁄

11

DRAIN LOCATION

CONDENSATE

"

16

⁄

3

24

BOTTOM INLET

DIMPLE LOCATORS

(17mm) (17mm)

(UPFLOW)

(614mm)

HANGING

FOR HORIZONTAL

-in. (495mm) rectangle.

-in.(591mm) rectangle.

2

4

/

/

1

1

(368mm) x 19

(368mm) x 23

2

(368mm) x 12-in. (305mm) rectangle.

2

/

2

/

1

/

1

1

round or 14

round or 14

round or 14

c. For 1600 CFM 22-in .(559mm)

b. For 1200 CFM 20-in . (508mm)

a. For 800 CFM 16-in . (406mm)

see flex duct manufacturer‘s recommendation for equivalent diameters.

2. Minimum return-air opening at furnace:

NOTES: 1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

return air openings for airflow requirements above 1800 CFM at 0.5 in. W.C. ESP.

combination of 1 side and the bottom, or the bottom only will ensure adequate

literature for specific use of single side inlets. The use of both side inlets, a

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data

353AAV

(684mm)

"

16

⁄

15

26

(667mm)

"

4

⁄

1

26

"

2

⁄

1

24

(666mm)

(567mm)

"

16

⁄

5

22

(51mm)

-IN. COMBUSTION2

AIR CONN

(13mm)

-IN. DIA

2

⁄

1

GAS CONN

CONN

-IN. VENT

(51mm)

2

-IN. DIA THERMOSTAT

2

⁄

1

ENTRY

"

16

⁄

11

22

(13mm)

(576mm)

SIDE INLET

"

2

⁄

1

TYP

14

(368mm)

(591mm)

" TYP

4

⁄

1

23

1"

(32mm)

"

4

⁄

1

1

7

(684mm)

" TYP

16

SIDE INLET

⁄

15

26

(25mm)

A08321

Loading...

Loading...