Page 1

T6--PRH, T6--NRH

PREFERREDt SERIES

THERMIDISTAT

Installation Instructions

A07045 A07044

Programmable Control Non--- Programmable Control

NOTE: Read the entire instruction manual before starting the installation.

Page 2

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 2....................................

INTRODUCTION 3..............................................

INSTALLATION CONSIDERATIONS 4..............................

INSTALLATION 8...............................................

SYSTEM START--UP AND CHECKOUT 40..........................

OPERATIONAL INFORMATION 51................................

TROUBLESHOOTING 54.........................................

WIRING DIAGRAMS 58..........................................

THERMIDISTAT CONFIGURATION RECORD 78.....................

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Follow all local electrical

codes during installation. All wiring must conform to local and national electrical

codes. Improper wiring or installation may damage Thermidistatt Control.

Recognize safety information. This is the safety--alert symbol

this symbol on the equipment and in the instruction manual, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING,andCAUTION.These

words are used with the safety--alert symbol. DANGER identifies the most

serious hazards which will result in severe personal injury or death. WARNING

signifies a hazard which could result in personal injury or death. CAUTION is

used to identify unsafe practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

. When you see

2

Page 3

INTRODUCTION

Bryant’s 7--day, 5/2--day, 1--day programmable and non--programmable

Preferred Series Thermidistat Control is a wall--mounted, low--voltage control

which combines temperature and humidity control in either a single unit or a

two--piece unit. In two--piece configuration, the relays are located near the

equipment and a two--wire connection is used between the Display Module and

the Equipment Control Module. Single--piece installation requires more wiring

and results in a higher profile. The Preferred Series Thermidistat has no need for

batteries to store user--configured settings in memory. During power loss its

internal memory saves settings for unlimited time, and the clock continues to run

for at least 24 hours. An extension of Bryant’s proven line of thermostats; it

provides separate setpoints for heating and cooling in addition to humidification

and dehumidification.

In the Preferred Series Thermidistat Control’s programmable configuration,

different heating and cooling setpoints and times are programmable for 4 periods

per day or 2 periods per day. Programming can be done for 7 days per week, 5/2

days per week, or 1 day. The programmable Thermidistat Control can also be

user configured as a non--programmable Thermidistat Control. When operating

as non--programmable, the Thermidistat Control will still have both temperature

and humidity control.

The non--programmable Thermidistat Control features Touch ’N’ Got settings

for quick and easy temperature change without complicated programming

schedules. The non--programmable Thermidistat Control will still have both

temperature and humidity control. And, its Touch ’N’ Go technology enables the

user to switch between three different user--configurable settings through

intuitive buttons located just below the display.

3

Page 4

INSTALLATION CONSIDERATIONS

Power

This control is powered by 24VAC only. It requires 24VAC (Rh and/or Rc and C

terminals) of the low--voltage transformer to be connected to it for proper

operation. It will not operate without these 2 connections. Rh and Rc are

connected via PCB breakout jumper. See Fig. 1. For applications using two

24VAC transformers, one in the indoor unit and one in the outdoor unit, connect

the common from each to the C terminal. Connect R from the indoor unit to the

Rh terminal. Connect R from the outdoor unit to the Rc terminal. Then, break

jumper on the circuit board. The W and HUM signals are taken from the Rh

power and the G signal is taken from the Rc power. If Thermidistat Control has

been installed in a two--transformer application that is later changed to a

single--transformer installation, installer must install a field supplied jumper

between Rc and Rh. Depending on the installation, up to 14 wires may be

required. Installation as two--piece unit is recommended. Only 2 wires are

required for connection between Display Module and Equipment Control

Module. These two wires (V+ and Vg) do not provide ordinary 24VAC. They

carry a combination of power and communications data that is unique to these

products.

4

Page 5

A07052

Fig. 1 -- PCB Breakout Jumper

Models

There are programmable and non--programmable models for all applications.

They can be configured for AC or HP, 1--or 2--speed compressor, and for Hybrid

Heatt installations, allowing it to be used in place of all Bryant thermostats.

Programmable Thermidistat Controls may be configured as non--programmable

if user desires.

Humidify Equipment and Connections

The humidify output connects directly to 24VAC operated humidifiers. No other

connection or interlock is required. Any of several installer--selectable operating

modes are available.

5

Page 6

!

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury or death.

DO NOT connect furnace HUM terminal directly to Thermidistat Control

HUM terminal. This will bypass furnace safety controls. See Low Voltage

Wiring Diagrams and notes for proper connection.

WARNING

Dehumidify Equipment and Connections

The dry contact output connects to the dehumidify input on variable--speed

furnaces and fan coils. Additional dehumidification is done by controlling the

compressor. A variety of operating modes are available. The dry contact must be

configured for dehumidification in setup Option 19. See Wiring Diagrams for

more information.

Outdoor Temperature Sensor

Outdoor air temperature sensor is included in the box with the Thermidistat

Control. Optimum performance is obtained when an outdoor temperature sensor

is used with the Thermidistat Control. Plan installation so that 2 wires can be run

from Equipment Control Module to an outdoor location, preferably on the north

side of the house or refer to Installation Instructions included with the outdoor

temperature sensor for simplified connection. Sensor can be mounted to outdoor

unit and existing control wires may be used for its connection. Details are

provided in sensor instructions.

6

Page 7

Remote Indoor Temperature Sensor

A remote temperature sensor may be used with the programmable model, where

it is desirable to install the Thermidistat Control in a limited access location while

measuring the temperature in the living space. The remote room sensor may be

used as a stand alone or average with local sensor.

Two--Piece Thermidistat Configuration

The Preferred Series Thermidistat Control can be installed in one of two

configurations. The control may be installed as a single--piece Thermidistat or it

may be split into two pieces and mounted in separate locations. As a single--piece

unit, all required wiring must be brought to the Equipment Control Module for

connection to the terminal strip. In two--piece configuration, the Display Module

can be mounted in the living space while the Equipment Control Module may be

mounted near the indoor furnace or fan coil. Connection from the display to the

Equipment Control Module requires only two wires. All other control wires are

connected to the Equipment Control Module from the HVAC equipment. This

configuration results in a slimmer display and locates the Equipment Control

Module containing the switching relays away from the main living space where

relay clicking will not be heard.

7

Page 8

INSTALLATION

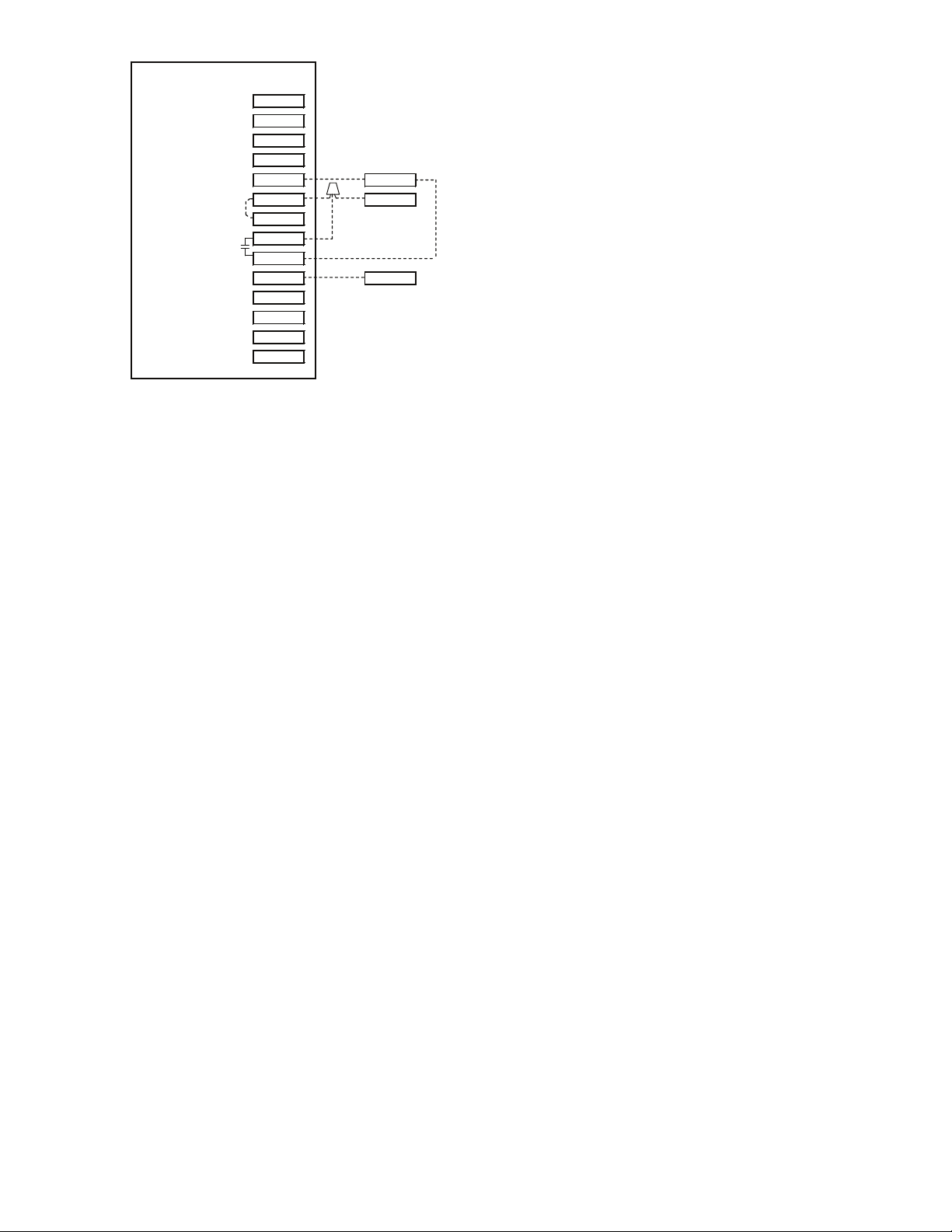

Carton contains the following components. See Fig. 2 for T6--PRH or Fig. 3 for

T6-- NRH.

A07752

Fig. 2 -- T6--PRH Carton Contents

1. Display Module

2. Stand--off for Equipment Control Module

3. Outside Air Temperature Sensor, screws and pigtail.

4. Equipment Control Module

8

Page 9

Fig. 3 -- T6--NRH Carton Contents

1. Display Module

2. Stand--off for Equipment Control Module

3. Outside Air Temperature Sensor, screws and pigtail.

4. Equipment Control Module

Thermidistat Control Location

Thermidistat Control should be mounted:

S Approximately 5 ft (1.5m) from floor.

S Close to or in a frequently used room, preferably on an inside parti-

tioning wall.

S On a section of wall without pipes or duct work.

Thermidistat Control should NOT be mounted:

S Close to a window, on an outside wall, or next to a door leading to the

outside.

9

A07753

Page 10

S Exposed to direct light or heat from a lamp, sun, fireplace, or other

temperature--radiating objects which could cause a false reading.

S Close to or in direct airflow from supply registers and return--air regis-

ters.

S In areas with poor air circulation, such as behind a door or in an al-

cove.

Installer should determine whether control will be installed as single--piece or

two--piece. In single-- piece configuration, as many as 14 wires may need to run

to wall mounting location for connection to the control. In two--piece

configuration, the Display Module and Equipment Control Module are

connected by two wires.

Install Ther midistat Control

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing Thermidistat Control, turn off all power to

equipment. There may be more than 1 power disconnect.

10

Page 11

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Improper wiring or installation may damage Thermidistat

Control. Check to make sure wiring is correct before

proceeding with installation or turning on power.

1. Turn off all power to equipment.

2. If an existing Thermidistat Control is being replaced

a. Remove existing control from wall.

b. Disconnect wires from existing control, 1 at a time.

c. As each wire is disconnected, record wire color and terminal marking.

d. New or additional wire may be needed to accommodate added hu-

midity outputs.

e. Discard or recycle old control.

11

Page 12

!

CAUTION

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

damage.

Mercury is a hazardous waste. Federal regulations require that

Mercury be disposed of properly.

Two--Piece Installation

The following steps should be followed for the installation of the two--piece

configuration.

NOTE: The 2--wire pigtail is not intended to support the weight of the User

Interface. Do not hang the User Interface from the Equipment Control Module

screw terminals.

1. Remove mounting plate from back of Display Module by pressing the

two tabs on the bottom edge and pulling away. See Fig. 4 and 5.

12

Page 13

Fig. 4 -- Press Tabs to Remove Backplate

Fig. 5 -- Take Apart

13

A07225

A07226

Page 14

2. Route wires through large hole in mounting base. Level mounting base

against wall (for aesthetic value only—Display Module need not be leveled for proper operation) and mark wall through 2 mounting holes. See

Fig. 6.

A07165

Fig. 6 -- Backplate Mounting

3. Drill two 3/16--in. mounting holes in wall where marked. Thermidistat

may be mounted to a standard junction box, if desired. Hole pattern on

Thermidistat Control mounting base matches junction box mounting

holes.

4. Secure rear plastic mounting base to wall with 2 screws and anchors provided. Additional mounting holes are available for more secure mounting

if needed. Make sure all wires extend through hole in mounting base.

5. Adjust length and routing of each wire to reach proper connector block

and terminal on mounting base with 1/4-- in. extra wire.

14

Page 15

6. Match and connect equipment wires to proper terminals of each connector

block, being careful not to over tighten the screws. Correct polarity must

be observed when connecting the two wires from the Equipment Control

Module to the Thermidistat Control mounting base. If wires are connected incorrectly, the Display Module will not operate. See Fig. 7, 8 and

9.

OAT /

OAT /

RRS

RRS

return

return

dry

dry

contact

contact

connect

connect

to user

to user

interface

interface

{

{

SRTN

SRTN

Control Module Wiring Guide

Control Module Wiring Guide

OAT

OAT

RRS

RRS

HUM

HUM

D1

D1

D2

D2

V+

V+

Vg

Vg

Rc

Rc

Rh

Rh

W / W1

W / W1

G

G

Y/Y2

Y/Y2

C

C

O/W2/B

O/W2/B

Y1

Y1

Y1 used for

Y1 used for

multi-speed

multi-speed

cooling

cooling

Y1 = stage 1

Y1 = stage 1

Y2 = stage 2

Y2 = stage 2

Relays

Relays

Y used for

Y used for

single stage

single stage

cooling

cooling

Fig. 7 -- Control Module Wiring Guide

S Red is V+

S Black is Vg

A07687

15

Page 16

Fig. 8 -- Secure Wires to Terminal Strip

Fig. 9 -- Connect Pigtail Wires to Display Module

16

A07166

A07167

Page 17

NOTE: The 2--wire pigtail is not intended to support the weight of the User

Interface. Do not hang the User Interface from the Equipment Control Module

screw terminals.

S Red of the pigtail is V+

S Black of the pigtail is Vg

7. Push any excess wire into wall and against mounting base. Seal hole in

wall to prevent air leaks. Leaks can affect operation and cause incorrect

temperature and/or humidity measurement.

8. Make sure 2--wire pigtail is attached to Display Module mounting base.

This should come attached from the factory. Attach two--wire pigtail to

the back of the Display Module via 2 pin, keyed connector.

9. Reattach Display Module body to mounting base by first setting on at top

of mounting base and then push bottom corners of Display Module to

snap into place. See Fig. 10.

A07169

Fig. 10 -- Attach Display to Backplate

17

Page 18

10. Find suitable indoor mounting location for Equipment Control Module,

either near or on equipment. See Fig. 11.

IMPORTANT NOTE: Equipment Control Module should not be mounted

to duct work or below any other controls or equipment (i.e. humidistat,

humidifier, etc.).

A07217

Fig. 11 -- Equipment Control Module on Equipment

11. Route wires through rear of Equipment Control Module using either a

clearance hole or supplied standoff. See Fig. 12.

18

Page 19

A07227

Fig. 12 -- Standoff

12. Match and connect equipment wires to proper terminals of each connector

block being careful not to over tighten the screws. Correct polarity must

be observed when connecting the two wires from the Equipment Control

Module to the Thermidistat Control mounting base. If wires are connected incorrectly, the Display Module will not operate. See Fig. 7, 8 and

9.

13. Snap cover over top of Equipment Control Module. See Fig. 13.

19

Page 20

A07218

Fig. 13 -- Cover on Equipment Control Module

14. Turn on power to equipment. On power up, all display segments will

light for 5 sec. For the next 5 sec a 2--digit code appears on large display

which identifies Thermidistat Control configuration. Refer to Option 33.

a. AC — 1--stage air conditioner

b. HP — 1--stage heat pump

c. A2 — 2-- stage air conditioner

d. H2 — 2--stage heat pump

e. hh — Hybrid Heat system with 1--stage heat pump

f. h2 — Hybrid Heat system with 2--stage heat pump

g. H — heating only system

h. C — cooling only system

20

Page 21

Single--Piece Installation

The following steps should be followed for the installation of the single--piece

configuration.

1. Remove cover from Equipment Control Module by pressing the two tabs

on the bottom edge and pulling away. Route wires through large hole in

Equipment Control Module. Level Equipment Control Module against

wall (for aesthetic value only -- Equipment Control Module need not be

leveled for proper operation) and mark wall through 2 mounting holes.

2. Drill two 3/16--in. mounting holes in wall where marked. Thermidistat

Control may be mounted to a standard junction box if desired. Hole pattern on Equipment Control Module matches junction box mounting

holes.

3. Secure rear plastic Equipment Control Module to wall with 2 screws and

anchors provided. Additional mounting holes are available for more secure mounting if needed. Make sure all wires extend through hole in

Equipment Control Module.

4. Adjust length and routing of each wire to reach proper connector block

and terminal on Equipment Control Module with 1/4--in. extra length.

See Fig. 14.

21

Page 22

A07219

Fig. 14 -- Equipment Control Module

5. Match and connect equipment wires to proper terminals of each connector

block.

6. Push any excess wire into wall and against Equipment Control Module.

Seal hole in wall to prevent air leaks. Leaks can affect operation and cause

incorrect temperature and/or humidity measurement.

7. Remove 2-- wire pigtail from Thermidistat Control mounting base and attach to Equipment Control Module terminal block (terminals V+ and

Vg). Attach two-- wire pigtail to the back of the Display Module via 2 pin,

keyed connector.

8. Reattach Display Module body to Equipment Control Module by first

setting on at top and then push bottom corners to snap into place. See Fig.

15.

22

Page 23

A07221

Fig. 15 -- Reattach Display Module

9. Turn on power to equipment. On power up, all display segments will

light for 5 sec. For the next 5 sec a 2--digit code appears on large display

which identifies Thermidistat Control configuration. Refer to Option 33.

a. AC — 1--stage air conditioner

b. HP — 1--stage heat pump

c. A2 — 2-- stage air conditioner

d. H2 — 2--stage heat pump

e. hh — Hybrid Heat system with 1--stage heat pump

f. h2 — Hybrid Heat system with 2--stage heat pump

g. H — heating only system

h. C — cooling only system

23

Page 24

Set Thermidistat Control Configuration

Configuration options enable the installer to configure the Thermidistat Control

for a particular installation. Most are not presented to the homeowner and

therefore must be properly set by the installer. (Only those marked with an

asterisk * below are available to the homeowner.) The homeowner

configurations are described in the owner’s manual. A special procedure allows

entry into the configuration mode. While in configuration mode, up to 33

selections can be made. Description of each selection and how to use the

configuration mode follows.

CONFIGURATION OPTIONS -- SUMMARY

Option 01 — Equipment Type

Option 02 — Clean Filter Timer Adjustment

Option 03* — Fahrenheit/Centigrade Selection

Option 04 — Fan (G) on with W/W1 Selection

Option 05 — Room Air Temperature Sensing (programmable

models only)

Option 06 — Cooling Lockout Below 55_F Selection (only

available if outdoor air sensor is present)

Option 07 — Zoning

Option 08 — Auxiliary Heat Lockout Temperature Setting (only

available when heat pump is used and when

outdoor air temperature sensor is present)

Option 09 — Heat Pump Lockout Temperature

Option 10 — Reversing Valve

24

Page 25

Option 11 — Adjustable Setpoint Deadband (not available on

heat only and cool only systems)

Option 12 — Smart Recovery (programmable models only)

Option 13 — Room Temperature Offset Adjustment

Option 14 — Humidity Offset Adjustment

Option 15 — Enable Auto Mode

Option 16 — Cycles Per Hour

Option 17 — Time Between Stages

Option 18* — Backlight Configuration

Option 19 — Dry Contact

Option 20 — Outdoor Air Temperature Offset Adjustment

Option 21* — Keypad Lockout

Option 22 — High Cool Latch Temperature

Option 23 — High Heat Latch Temperature

Option 24* — Programmable/Non--Programmable

(programmable models only)

Option 25* — Number of Programmable Periods per Day

(programmable models only)

Option 26 — Minimum Cooling Setpoint

Option 27 — Maximum heating Setpoint

Option 28 — UV Light Reminder

Option 29 — Humidifier Pad Reminder

Option 30* — Programmable Fan (programmable models only)

25

Page 26

Option 31* — Daylight Savings Time Configuration

(programmable models only)

Option 32 — Furnace Heat Staging

Option 33 — Single or Two--Piece Installation

Option 99 — Reset to Factory Defaults

TO ENTER CONFIGURATION MODE

Press and hold FAN button for approximately 10 sec. The Display Module is

now in configuration mode. It will automatically exit this mode if no button is

pressed for 3 minutes. Pressing the DONE button will exit configuration mod e

immediately.

WHILE IN CONFIGURATION MODE

The option number is displayed in the heat setpoint location and the

configuration setting is displayed in the cool setpoint location. On the T6 -- PRH

(programmable) model, a box will surround the option number. The mode

button is used to move the box between the two displayed values. The soft keys

below the listed values may also be used to move the box between selected

values. The value inside the box is changed by using the UP/DOWN buttons. On

the T6--NRH (non--programmable) model, one of the values will be flashing.

The mode button is used to change which value is flashing or the Home and

Sleep buttons may also be used to select which value to flash. The value that is

flashing is changed by using the UP/DOWN buttons. All changes made are

saved at the time of selection and will be saved in the event of the 3 minute

time-- out or when installer exits from configuration menu.

Configuration Options —Selection

Option 01 — Equipment Type

Range: H2, A2, HP, AC, hh, h2, H, C

26

Page 27

H2 — operates a two--speed heat pump with a fan coil

HP — operates a single--speed heat pump with a fan coil

A2 — operates a two--speed AC

AC — operates a single--speed AC

hh — operates a single--speed heat pump with a furnace

h2 — operates a two--speed heat pump with a furnace

H — operates a heat--only system. Furnace or fan coil only;

no outdoor unit.

C — operates a cool only--system. Outdoor AC unit with an

indoor fan coil with no strip heaters.

Default is H2.

Option 02 — Clean Filter Timer

Select hours of blower operation (heating, cooling, or fan) before CHECK

FILTER icon is displayed. With OF selected, icon will never come on, disabling

this feature. Time selection can range from 800 to 7200 hr by selecting numbers

1 through 9. (Time is 800 X number selected.) Default is 4 (3200 hr).

Recommended selections are disposable filter--800 to 2400 hr, media filter--2400

to 3200 hr, or electronic air cleaner--1600 to 2400 hr of blower operation. For

higher efficiency filters, please consult filter’s Installation Instruction for details.

Option 03 — Fahrenheit/Centigrade

Select between Fahrenheit (F) and Centigrade (C) operation. Factory default is

Fahrenheit (F).

Option 04 — Fan (G) On With W/W1

This selection determines whether fan (G) output is to be On or OFF when any

W/W1 (furnace or strip heat) output is On. Most furnaces and fan coils manage

27

Page 28

their own blowers and do not require separate G signal. For these applications,

select OFF. Some auxiliary heaters require separate G signal to turn on blower. In

this case, select On.

Default is OF (off).

Option 05 — Room Air Temperature Sensing (programmable models only)

This selection determines which sensor the control will use for measuring room

air temperature. Room air temperature can be sensed in one of three ways; the

local sensor (L) located on the Display Module, the remote room air sensor (r),

or the average of local and remote sensors (Lr). Settings are L, r, Lr.

Default is L.

Option 06 — Cooling Lockout Below 55_F

This selection disables cooling when outdoor temperature is below 55_F. I t

requires an outdoor temperature sensor. Setting is not available if valid outdoor

sensor is not connected. Set to OF (off) to allow cooling below 55_F. Set to O n

to prevent cooling below 55_F.

Factory default is OF (off).

Option 07 — Zoning

This selection should be set to On when the Thermidistat Control is to be used as

part of a zoning system. It is assumed that the zoning equipment will take care of

time guard and cycle timers. The minimum On time is still controlled by the

Thermidistat Control.

Default is OF (off).

Option 08 — Auxiliary Heat Lockout Temperature

This selection is available on heat pump systems with a valid outdoor

temperature sensor connected. Available settings are: Off, 5, 10, 15, 20, 25, 30,

35, 40, 45, 50, 55.

28

Page 29

OF (off) -- function is disabled. Auxiliary heat is allowed to operate whenever

sufficient demand for heat is available.

5--55_F -- Outdoor temperature above which the auxiliary heat is not allowed to

operate (unless MODE is set to Emergency Heat).

Default is OF (off).

Option 09 — Heat Pump Lockout Temperature

This selection is only available on Hybrid Heat systems. A Hybrid Heat system

is selected via the Option 1 Equipment Type configuration. Configurations

settings are: OF (off), 5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55.

OF (off) — the heating cycle will always start with heat pump heating.

5--55_F — the outdoor temperature below which heat pump operation is not

allowed.

When emergency heat mode is selected only auxiliary heat will operate.

Default is OF (off).

Option 10 — Reversing Valve

This selection is only available on heat pump systems. “O” terminal can be

configured to be energized in either heating mode or in cooling mode, depending

on heat pump operation. “O” is used to describe a heat pump system that

energizes its reversing valve in cooling. “B” is used to describe a heat pump

system that energized its reversing valve in heating.

H — Reversing valve output (O/W2/B) is energized when HEAT mode is

selected.

C — Reversing valve output (O/W2/B) is energized when COOL mode is

selected.

Default is C.

29

Page 30

Option 11 — Deadband Setting Between Heat & Cool

This option is not available on Heat Only and Cool Only systems. The selection

allows the installer to choose how much differential exists between the heating

and cooling setpoints. Allowable selections are 1-- 6.

Default is 2.

Option 12 — Smart Recovery

Smart Recovery OF (off) means setpoints change precisely at setback recovery

time. Thirty, 60, or 90 selects the number of minutes recovery starts before

programmed recovery time. Recovery takes place smoothly during the selected

recovery time, ending at the recovery time and temperature which is

programmed. Not available with non-- programmable Thermidistat Controls or

when Thermidistat Control is configured as non--programmable.

Default is 90.

Option 13 — Room Air T emperature Offset Adjust

The number of _F to be added to the displayed temperature to calibrate or

deliberately miscalibrate the measured room temperature ( --5 to +5_F).

Default is 0.

Option 14 — Humidity Display Offset Adjust

The percentage to be added to the displayed humidity to calibrate or deliberately

miscalibrate the measured room humidity (--9% to +9% RH).

Default is 0.

Option 15 — Enable Auto Mode

This selection is not available if the Thermidistat Control is configured as Heat

Only or Cool Only in Option 1. This allows the homeowner to select auto

changeover mode in addition to heat and cool. This allows the Thermidistat

30

Page 31

Control to automatically change between heating mode and cooling mode when

sufficient demand for heating or cooling exists.

On — Auto mode is available.

OF — Auto mode is not available.

Default is On.

Option 16 — Maximum Cycles Per Hour

This selection limits the number of cycles per hour that the Thermidistat Control

allows the system to operate. Selections are 2, 4, 6.

2 — The heating and cooling outputs will be energized no more than 2 times per

hour. When an output is energized, it will not be energized again for 30 minutes.

4 — The heating and cooling outputs will be energized no more than 4 times per

hour. When an output is energized, it will not be energized again for 15 minutes.

6 — The heating and cooling outputs will be energized no more than 6 times per

hour. When an output is energized, it will not be energized again for 10 minutes.

Default is 4.

Option 17 — Time Between Equipment Stages

This selection is only available for heat pump systems. This determines the

minimum number of minutes of equipment operation on the highest compressor

stage before allowing the transition to auxiliary heat. Available selections are 10,

15, 20, and 25. The time between stages of any individual piece of equipment,

such as low speed and high speed compressor or fan coil stages, will be fixed at

10 minutes.

Default is 15.

31

Page 32

Option 18 — Backlight Configuration

When OF (off), the backlight will be lit for 10 seconds after a button is pressed.

After 10 seconds of no button presses, the backlight turns off. When On, the

backlight will normally be on and dim in appearance. The backlight brightness

becomes brighter when a button is pressed. After 10 seconds of no button

presses, the backlight will return to the dimmer level until another button press

occurs. The range of brightness is 1 through 5 with 5 being full brightness.

Default is 3.

Option 19 — Dry Contact Configuration (programmable models only)

There are 3 available selections, OF, 1 and 2.

OF — The dry contact is always de--energized.

1 — The dry contact will be energized for the specified number of minutes per

hour. This selection is programmable by period. When this selection is changed

from OF to 1, the period icons are shown and the minute segments of the clock

display are shown. The triangle icon next to the WAKE period will be on and a

value between 0 and 60 will be shown in the minutes display. See Operational

Information and Wiring Diagrams for further explanation of dry contact

configuration and use. To change the period or minutes, press the soft key below

the period or minutes and then use the UP/DOWN buttons to change to the

desired value.

2 — The dry contact will operate as a DEHUM relay. This relay is reverse logic.

When the humidity level is above the dehumidify setpoint, the dry contact

D1--D2 will be opened. When the humidity level is below the dehumidify

setpoint, D1--D2 will be closed. There is a +/-- 2% hysteresis around the

dehumidify setpoint to prevent rapid on/off cycling of the DEHUM output.

When configured for dehumidification, the Rc terminal must be connected to

one of the dry contact terminals. This provides power to energize the dehumidify

32

Page 33

terminal on the cooling equipment when the dry contact is closed. See Wiring

Diagrams for more information.

Default is OF (off).

Option 19 — Dry Contact Configuration (non--programmable models only)

OF — The dry contact is always de--energized.

ON — The dry contact will operate as a DEHUM relay. This relay is reverse

logic. When the humidity level is above the dehumidify setpoint, the dry contact

D1--D2 will be opened. When the humidity level is below the dehumidify

setpoint, D1--D2 will be closed. There is a +/-- 2% hysteresis around the

dehumidify setpoint to prevent rapid on/off cycling of the DEHUM output.

When configured for dehumidification, the Rc terminal must be connected to

one of the dry contact terminals. This provides power to energize the dehumidify

terminal on the cooling equipment when the dry contact is closed. See Wiring

Diagrams for more information.

Default is OF (off).

Option 20 — Outdoor Air Temperature Offset Adjustment

This selection allows the calibration, or deliberate miscalibration of the outdoor

air temperature sensor reading. The selection ranges from --5 to +5_F.

Default is 0.

Option 21 — Keypad Lockout (programmable models only)

This selection allows the installer to limit access to the keypad. Selections are OF

(off), 1, 2, 3.

OF (off) — The user has full access to the keypad.

1 — The user has access to modify setpoints, time of day.

2 — The user has access to change the setpoints only.

33

Page 34

3 — The entire keypad is locked. When a button is pressed, the backlight will

turn on but none of the operating parameters will be changed.

When the keypad lock selection is turned on, the padlock icon will be displayed.

To unlock the keypad, press and hold the UP/DOWN buttons simultaneously for

five seconds. When the keypad is unlocked, the padlock icon will turn off. The

keypad will remain unlocked for two minutes after the last button press. After

two minutes with no button presses, the keypad will lock again. The keypad will

not lock in the software configuration mode or in the installer test mode.

Default is OF (off).

Option 21 — Keypad Lockout (non--programmable models only)

This selection allows the installer to limit access to the keypad. Selections are OF

(off), 1, 2.

OF (off) — The user has full access to the keypad.

1 — The user has access to change the setpoints.

2 — The entire keypad is locked. When a button is pressed, the backlight will

turn on but none of the operating parameters will be changed.

When the keypad lock selection is turned on, the padlock icon will be displayed.

To unlock the keypad, press and hold the UP/DOWN buttons simultaneously for

five seconds. When the keypad is unlocked, the padlock icon will turn off. The

keypad will remain unlocked for two minutes after the last button press. After

two minutes with no button presses, the keypad will lock again. The keypad will

not lock in the software configuration mode or in the installer test mode.

Default is OF (off).

34

Page 35

Option 22 — High Cool Latch Temperature

An outdoor sensor is required for high cool latch feature.

This selection is only available when Option 1 is set to H2, A2, or h2 and when

Option 7 (zoning) is set to OF (off). Configuration settings are OF (off), 80, 85,

90, 95, 100, 105, 110, On.

OF (off) — Cooling always starts in low stage (Y1) and stages up to high stage

(Y1 and Y/Y2) when demand is sufficient and staging timer constraints have

been satisfied.

80--110_F — Outdoor temperature above which both first and second stages of

the compressor are energized to satisfy all cooling demands. When a cycle starts

under a high cool latch, it will finish the cooling cycle on high stage. If the

cooling equipment is energized to satisfy a dehumidify demand only (no cooling

demand), the latch will not be applied.

On — The Y1 and Y/Y2 outputs are simultaneously energized to satisfy all

cooling demands.

Default is OF (off).

Option 23 — High Heat Latch Temperature

This selection is only available when Option 1 is set to H2, or h2 and Option 7

(zoning) is set to OF (off). Configuration settings are OF (off), 20, 25, 30, 35, 40,

45, 50, On.

OF (off) —Heating always starts in low stage (Y1) and stages up to high stage

(Y1 and Y/Y2) when demand is sufficient and staging timer constraints have

been satisfied.

20--50_F — Outdoor temperature below which both first and second stages of

the compressor are energized to satisfy all heating demands. When a cycle starts

under a high heat latch, it will finish the heating cycle on high stage.

35

Page 36

On — The Y1 and Y/Y2 outputs are simultaneously energized to satisfy all

heating demands.

Default is OF (off).

Option 24 — Programmable/Non--Programmable (programmable models

only)

This selection allows the installer to configure the Thermidistat Control as either

programmable or non-- programmable. Selections are P, nP.

Default is P.

Option 25 — Number of Programmable Periods (programmable models

only)

This selection allows the installer to configure the Thermidistat Control for two

or four periods per day. Two periods is a common commercial application and

four periods is more common for residential. This selection is not available if

Option 24 has been set to nP to configure the Thermidistat Control for

non--programmable operation.

2 — Periods DAY and SLEEP are available

4 — Periods WAKE, DAY, EVE, and SLEEP are available.

Default is 4.

Option 26 — Minimum Cooling Setpoint

This selection allows the installer to configure the minimum cooling setpoint that

the user is allowed to set. The range is based on the value of the adjustable

deadband Option 11, such that the minimum of the range is 50_Fplusthe

adjustable deadband and the maximum is 90_F.

Default is 52_F (based on the adjustable deadband default = 2).

36

Page 37

Option 27 — Maximum Heating Setpoint

This selection allows the installer to configure the maximum heating setpoint.

The range is based on the adjustable deadband value Option 11, such that the

minimum of the range is 50_F and the maximum is 90_F minus the deadband.

Default is 88_F (based on the adjustable deadband default = 2).

Option 28 — UV Light Reminder

This selection allows the installer to select the number of months after which the

UV Light icon will be displayed to indicate to the homeowner that it is time to

call the dealer to have the UV Lights replaced. Selections available are OF (off),

6, 12, 18, 24, 30, 36, 42, 48.

OF (off) — The UV Light reminder is turned off and will never be displayed.

6--48 — The number of months after which the UV Light reminder will be

displayed, “CHECK UV LIGHT”.

Default is OF (off).

Option 29 — Humidifier Pad Reminder

This selects the number of months after which the Humidifier Pad Reminder

icon will be displayed. This is not based on run time.

OF (off) — The Humidifier Pad Reminder is disabled and will never be

displayed.

1--24 — The number of months after which the Humidifier Pad Reminder icon

will be displayed, “CHECK HUM PAD”.

Default is OF (off).

37

Page 38

Option 30 — Programmable Fan (programmable models only)

This selection allows the homeowner to program the fan selection to “Auto” or

“On” fan operation for each of the program schedule periods. This selection is

only available on programmable Thermidistat Controls.

OF (off) — Programmable fan is disabled and the homeowner must manually

select “Auto” or “On” for fan operation.

On — Programmable fan is enabled. The homeowner can program “Auto” or

“On” fan operation along with the heat and cool setpoints for each programmed

period. When the program schedule is running, the programmed heat setpoint,

cool setpoint, and fan selection for that period will be used. If the homeowner

“overrides” the programmed fan setting by pressing the fan button, the override

selection will remain in effect until the next programmed period time.

Default is OF (off).

Option 31 — Daylight Savings Time Configuration (programmable models

only)

This selection allows the installer to set the Thermidistat Control to automatically

change by one hour on the specified day, month, and week specified.

OF (off) — Daylight Savings Time Function disabled.

1,2 On — The first time the UP/DOWN button is pressed, the value of this

selection changes from OF (off) to 1. When 1 is displayed, the days of the week

and clock digits will be turned on. The installer will set the start date (Spring) for

Daylight Savings Time by setting the day of the week by selecting the

appropriate triangle icon next to the days of the week, the month of the year will

be set in the clock hours location (range 1--12) and the week of the month will be

set in the clock minutes location. The week of the month selections will be F, 2,

3, 4, and L for First, 2nd, 3rd, 4th, and Last. So for the first Sunday in April, the

display would show SUN, 4, F. When 2 is displayed, the installer will then

38

Page 39

choose the end date for daylight savings time (Fall). To activate the function, the

installer changes the “2” by pressing the up button and “On” is displayed. The

setting shall be left “On” to enable the Daylight Savings Time function.

Default is On (on).

Option 32 — Furnace Heat Staging Control (available only when the

Thermidistat Control is configured to operate AC or A2 equipment).

1 — Thermidistat Control controls W1 output only and furnace controls the turn

on and turn off of higher stages of heat.

2 — Thermidistat Control will control the W1 and O/W2/B outputs.

Default is 1.

Option 33 — Single or Two--Piece Installation

This configuration allows the Thermidistat Control to compensate for the

amount of heat generated by the Thermidistat Control electronics to allow more

accurate sensing of the temperature sensor. The amount of heat compensation

will be different between single installation and two--piece installation.

Range: 1P or 2P

1P — The installation is single piece.

2P — The installation is two separate pieces.

Default is 2P.

Option 99 — Reset to Factory Defaults

Use this capability to reset the Thermidistat to “out of the box” conditions.

BEWARE! All configuration settings, program settings, clock, and calendar

which have been manually entered will be lost!

When this option is selected, the configuration number (99), will appear on the

left and 10 will appear on the right. To perform the reset, first use the MODE key

39

Page 40

to move the box from the 99 to the 10 (programmable model) or to flash the 10

(non--programmable model). Then press and hold the DOWN key. The 10 will

start counting down toward zero. If the DOWN key is kept pressed until the

count reaches zero, the reset will be performed. When the value reaches zero, the

heat setpoint shall display -- -- . The cool setpoint shall display -- and the room air

temperature shall display Fd. When the factory defaults have been restored, the

Thermidistat Control will act as if power was cycled and return to normal

operation. If the DOWN key is released early, the number will return to 10 and

the reset will not occur.

SYSTEM START--UP AND CHECKOUT

The Thermidistat Control is designed with a built--in installer test capability. It

allows easy operation of equipment without delays or setpoint adjustments to

force heating or cooling. To enable installer test mode, press and hold the fan

button for 15 seconds. After 10 seconds, the Thermidistat Control will enter

Configuration Mode. Continuing to hold the Fan button through 15 seconds will

cause the Thermidistat Control to enter Installer Test Mode. Pressing the Mode

button will change the system operating mode to test the heating and cooling

equipment. Auto Mode is not available during Installer Test Mode. If no buttons

are pressed for 15 minutes, the installer test mode will be terminated. Pressing

DONE at any time will exit installer test mode.

Heat -- The first stage of heating will be energized for three minutes, then the first

and second stages (if a second stage exists) will turn on for an additional three

minutes. During the first stage of heating, the HEAT ON icons will be displayed.

During the second stage of heating (if one exists), the “2” next to the “On” will

be displayed if the system has a two--stage compressor (A2, h2, or H2 unit

types). The “auxiliary heat on” icon will be displayed if the second stage is

electric heat (HP unit type). For Hybrid Heat installation or heat pump

40

Page 41

installation, only 1 stage of auxiliary heat is available. Any staging of auxiliary

heat must be managed by the furnace or fan coil. While the heating test is active,

the humidify output can be toggled. On the programmable models, pressing the

button below the humidify icon shall toggle the state of the humidify output. On

the non--programmable models, pressing the features button shall toggle the state

of the humidify output.

Installer test for cooling is the same as described for heating above. COOL ON

will be displayed during cooling in Installer Test Mode. While the cooling test is

active, the dehumidify icon shall be displayed if the dry contact has been

configured as a DEHUM output. On the programmable models, pressing the

button below the dehumidify icon shall toggle the state of the dry contact output.

On the non--programmable models, pressing the features button shall toggle the

state of the dry contact.

In a heat pump application, when the mode is set to “em heat” the auxiliary heat

will turn on for 3 minutes. The clock display will count down from 180 to 0

during this test.

TO TEST FAN

Fan button switches FAN icon between AUTO and On. While On is displayed,

G output will be energized, turning fan on. Allow up to 10 sec after button is

pressed for fan to turn On and off. On some fan coils, fan continues to operate

for 90 sec after G signal is removed.

Final Settings

Be sure to press DONE to exit installer setup mode. If the system is to be left in

operation after installation is complete, use MODE button to select between

HEAT, COOL, or AUTO to provide desired operation of heating, cooling, or

auto.

41

Page 42

On the programmable models, the default setpoints and programmed schedule

conform to the Energy Starr requirements of the U.S. Department of Energy for

both heating and cooling. These provide energy saving temperature settings.

Refer to Table 1.

Table 1 – Energy Star Default Schedule

SCHEDULE HEAT COOL

Wake 6:00 AM 68_F 78_F

Day 8:00 AM 60_F 85_F

Evening 5:00 PM 68_F 78_F

Sleep 10:00 PM 60_F 82_F

If the programmed schedule is to be used, make sure the triangle icon next to the

FOLLOW SCHEDULE icon is turned on. Pressing the Schedule button will

cycle the triangle icon through the FOLLOW SCHEDULE, HOLD and

VACA TION selections.

If fixed temperatures are desired, use SCHEDULE button to turn on arrow icon

next to HOLD. This will maintain setpoints, not allowing them to change with

programmed schedule.

The FAN button may be used to select between AUTO (fan on only with

equipment) and On (fan on continuously) fan modes. For further information on

temperature selection and programming, refer to Homeowner’s Guide.

Setting The Clock, Calendar, Daily Schedule, and Vacation

Settings (programmable models only)

To set the clock, press the SET button once. The Clock will be displayed at the

bottom center of the screen. Use the soft keys to move the box around the digits

to be set and the UP/DOWN buttons to change the setting. Concurrent presses of

42

Page 43

the set button will cycle through the calendar, daily schedule, and vacation

settings.

Calendar may be changed by using the soft keys to select the Month, Day, or

Year. The UP/DOWN buttons are used to change the Month, Day , or Year setting

when the box surrounds it. Day of the week (Mon--Sun) is determined by

calendar settings and is not directly adjustable.

When changing daily schedule settings, the soft keys are used to set the days,

period times, heating setpoints, and cooling setpoints. The UP/DOWN buttons

are used to change the setting with the box around it. ALL PROGRAM

PERIODS (WAKE, DAY, EVE, SLEEP) MUST OCCUR WITHIN THE SAME

24 HOUR PERIOD.

When changing Vacation settings, the soft keys are used to choose the selection

to be adjusted and the UP/DOWN buttons are used to change the setting.

Humidify setting may only be changed when heat mode is selected and

Dehumidify setting may only be changed when cool mode is selected.

Humidity Control Features

The various humidity control features of the Thermidistat Control are explained

below. They are grouped into 2 sections, humidification and dehumidification.

Instructions on how to select each feature are given at the end of each section.

Humidification

The Thermidistat Control directly connects to a standard 24VAC humidifier to

control humidification in the home. A humidify setpoint between 10 and 46% in

2% increments relative humidity is selected by the homeowner, or all

humidification can be turned off. When humidity in home drops below setpoint,

humidifier will be turned on to raise humidity level. Humidification can only

occur while heating. See Table 2 for reference.

43

Page 44

Table 2 – Humidification Selections

SELECTION FAN DISPLAY

Normal Humidify Blank 10---46

Auto Humidify AUT O 1 --- 9

Humidify Off Blank OF (Off)

HUMIDIFY SETPOINT

DISPLAY

1. Humidify

In normal humidify, humidifier will be on if there is humidity demand

and any heating equipment is on. This will include furnace, heat pump, or

auxiliary heat.

2. Auto Humidify

Thermidistat control will automatically adjust the humidity setpoint according to the outdoor temperature. As the outdoor temperature decreases, the humidity setpoint also decreases. Settings ranging from 1 to

9, 1 being the lowest and 9 the highest, will be visible to the homeowner.

See Fig. 15 for outdoor temperature/indoor humidity relationship in auto

humidify mode.

3. Humidify Off

The humidify function can be turned off completely. This does not require changing existing setpoints.

To Select Humidification (programmable)

Press the soft key below the humidify icon to bring up humidity select screen.

Humidify options are only available when in Heating mode. When system is in

AUTO mode, humidify options are available if the last system operation was a

call for heat.

44

Page 45

To Select Humidification (non--programmable)

Press the features button twice. The first press displays the outdoor air

temperature and the second press displays the humidity value and humidify

target.

Pressing the mode button shall cycle through the available humidification

selections (Off, Humidify and Auto Humidify).

Additional Humidify Comments

The humidifier is actually turned on when humidity is 1% below setpoint and

turned off when it reaches 1% above setpoint. This built--in hysteresis prevents

humidify output from toggling on and off when humidity level is near setpoint.

Dehumidification

Dehumidification is done only during cooling. Depending on type of equipment

used, compressor speed, blower speed, setpoint adjustment, and equipment

cycling are modified to provide added dehumidification. A dehumidification

setpoint (separate from humidification setpoint) is available to the homeowner. It

can range from 46% to 66% relative humidity. When actual humidity is higher

than setpoint, a dehumidification demand exists. The Thermidistat Control

responds by activating the dry contact (when enabled in Option 19). It may also

control the compressor and blower, depending on equipment type and

dehumidify selection choice. The 3 available selections are described below. A

mandatory 5 minute blower off delay will be enforced if there has been a call for

dehumidification during a cooling call. The amount of extra dehumidification

available is very dependent on the type of equipment in the home. Without a

variable--speed blower, the system’s ability to adjust dehumidification is very

limited.

45

Page 46

1. Normal Dehumidify Operation

When normal dehumidify is selected, the compressor will not turn on

without a cooling demand. If dehumidify demand exists while cooling,

dry contact will also be active (24VAC removed). This output commands

variable--speed blowers to reduce their airflow, which improves water removal from the cooled air.

2. Cool to Dehumidify

The cool to dehumidify selection tells the system to operate the compressor, within limits, when there is a dehumidify demand even if there is no

cooling demand. The limits are that the system may overcool up to 3_F,

but no more, while attempting to satisfy a dehumidify demand. Within

this 3_F range, there is an additional balance between overcooling and

humidity satisfaction. When overcooling must occur, the dehumidify setpoint is adjusted upward by 2% per degree of overcooling. For example,

a cooling setpoint of 76_F and a dehumidify setpoint of 60% is equivalent to a cooling setpoint of 75_F and a dehumidify setpoint of 62%. This

dehumidify setpoint change is internal to the Thermidistat Control and is

not shown on the display.

46

Page 47

A06599

Fig. 16 -- Auto Humidity

3. Dehumidify Off

Dehumidification can be turned off completely. This can be done without

changing existing setpoints.

To Select Dehumidification (programmable -- between NORMAL, COOL

TO, and OFF)

Press the soft key below the dehumidify icon button to bring up dehumidify

selections. Dehumidify options are only available when in Cooling mode. When

47

Page 48

system is in AUTO mode, dehumidify options are available if the last system

operation was a call for cooling.

To Select Dehumidification (non--programmable -- between NORMAL,

COOL TO, and OFF)

Press the features button three times. The first press displays the outdoor air

temperature, the second press displays the humidify options and the third press

will display the current dehumidify selections.

The mode button is used to cycle through the dehumdify selections.

Additional Dehumidify Comments

Dehumidification can be enhanced (with some ef ficiency loss) by turning blower

off immediately at the end of each cooling cycle (eliminating normal 90 sec

blower off delay). Where maximum humidity removal is desired, this should be

done. Fan coils have the capability of removing this off delay. On FK or FV Fan

Coils, set delay tap to 0/0. On standard fan coils, a jumper can be cut to disable

off delay. Refer to fan coil Installation Instructions for details. If FAN is set for

continuous operation (fan On icon displayed), G output is turned off for 5

minutes at the end of each cooling cycle as long as dehumidify demand exists.

Like humidify, dehumidify actions are initiated when humidity is 1% above

setpoint and are terminated when humidity drops to 1% below setpoint. This

prevents unnecessary toggling of dehumidify actions when humidity is near

setpoint.

Dehumidify Output and Equipment Connections

When there is a dehumidify demand, dry contact is activated, meaning that a

24VAC signal is removed from the DHUM output terminal. In o ther words,

dehumidify output logic is reversed -- output is turned On when no dehumidify

demand exists and is turned OFF when demand exists.

48

Page 49

Bryant FK and FV series variable--speed fan coils, all variable--speed furnaces,

and select single and multi--stage furnaces with the dehumidify connection have

dehumidify inputs which connect directly to Thermidistat Control dry contact.

Refer to the furnace literature for dehumidification options.

The FK and FV series fan coils have a terminal marked DH which should be

connected to the Thermidistat control dry contact output. Jumper J1 on fan coil

MUST be removed. It is located behind the DH terminal. Additionally blower

delay tap on fan coil should be set to 0/0 (no On delay and no OFF delay) when

using cool to dehumidify. With this selection, the blower stops when G signal is

removed, preventing re-- evaporation of water from the coil which would occur

during the normal 90 sec blower off delay. See fan coil installation instructions

for more information. (See Wiring Diagram Reference Chart and Fig. 2 through

19 in Wiring Diagram section at the back of this piece literature.)

The furnace dehumidify input acts differently depending on which style of

variable speed, select single--stage or multi--stage furnace control you have.

Vacation (programmable models only)

A vacation selection is available specifically for times where the home will not

be occupied for an extended period. Vacation mode has an automatic hold,

meaning that setpoints are not affected by the programmed schedule. Vacation

mode is active for a specified period of time. While in vacation mode, the system

provides temperature and humidity protection for the home in the selected mode,

but not comfort. When vacation mode is active, an arrow will be displayed

beside “VACATION” in the upper left corner of the display.

49

Page 50

Vacation Setpoints

A special set of temperature and humidity setpoints exist which are active in

vacation mode. They are adjustable by the homeowner, are exclusively for

vacation mode, and are remembered from one vacation selection to the next. See

Table 3 for default values.

Table 3 – Vacation Setpoints Default Values

MODE AUTO

Fan Auto

Heat Setpoint 55

Cool Setpoint 85

Humidify Setpoint 20

Dehumidify Setpoint 60

Vacation Humidification

Normal humidify is available using vacation setpoints. Auto humidification is

available, adjusting its setpoint with outdoor temperature the same as when

occupied. Vacation humidification can be turned off independently of occupied

humidification. While setting the Vacation setpoints, the V acation humidify

setpoint is accessible by pressing the soft key below the humidify icon when the

box is around the heating setpoint.

Vacation Dehumidification

Normal Dehumidify, Cool to Dehumidify, and Dehumidify OFF are all available

in vacation mode, and selection of one of these can be different from that of

occupied. Vacation dehumidification selection and setpoints are remembered the

next time vacation is used. While setting Vacation setpoints, the Vacation

dehumidify setpoint is accessible by pressing the soft key below the dehumidify

icon when the box is around the cooling setpoint.

50

Page 51

OPERAT IONAL INFORMATION

Timers

Five--Minute Compressor Timeguard

This timer prevents compressor from starting unless it has been off for at least 5

minutes. It can be overridden for 1 cycle by simultaneously pressing FAN and

UP buttons.

Cycle Timer

Based on the selection of 2, 4, or 6 cycles per hour, this timer is set to 30, 15, or

10 minutes. This much time must elapse from the start of one cycle before

another cycle can start. It serves to impose the cycles per hour limits. It can be

defeated for one cycle by simultaneously pressing the FAN and UP buttons.

Ten--Minute Staging Timer

In multistage heating or cooling, this timer prevents any higher stage from

turning on until preceding stage has been on for 10 minutes. When staging

between compressor and electric heat or between compressor and furnace heat,

the time is configurable. The timer is configurable via Option 17. This timer is

overridden if temperature error is greater than 5_F (usually due to a large change

in desired temperature) and equipment stages up in 60 second intervals.

Defrost

When defrost occurs in a Hybrid Heat system, the furnace will operate during the

defrost cycle. At the end of the defrost cycle, the furnace and heat pump will be

de--energized while the fan is energized for 2 minutes allowing the heat

exchanger to cool down. At the end of the 2 minute time, the heat pump will be

re--energized if a call for heat still exists.

Detection of defrost will not work properly if the installer has configured the

O/W2/B output to function as a B output. During heat pump heating, a defrost

51

Page 52

signal shall be considered valid if the compressor output is energized and the

defrost signal has been active for less than 15 consecutive minutes. Any defrost

signal present for longer than 15 minutes shall be considered invalid.

Heat pump/fan coil and hybrid heat systems shall use this input to:

S Detect that defrost is in progress and energize the auxiliary heat to

provide homeowner comfort during the defrost cycle

S Allow a defrost cycle to run to completion regardless of the system

demand

Three--Minute Minimum on Time

In normal operation, when a stage turns on, it will not turn off for a minimum of

3 minutes. If the setpoint is changed, this timer is canceled, allowing the

equipment to turn off immediately when the demand is removed.

Heat/Cool Setpoints (Desired Temperature)

A minimum difference of 1_F and maximum of 6_F is enforced between heating

and cooling desired temperatures. This is done by allowing 1 setting to “push”

the other, to maintain this difference. This difference is adjustable via

Configuration Option 11.

Equipment On Indicators

When cooling equipment is on, a COOL ON icon is displayed. While cooling

equipment operation is delayed by the time guard or cycle timer, COOL ON will

flash. The same is true for HEAT ON icon.

During second stage compressor operation a “2” will be displayed with the

HEAT ON or COOL ON icon. This is displayed when the Thermidistat Control

is configured as H2, A2, or h2.

When the W is energized in a heat pump or Hybrid Heat system, the “auxiliary

heat on” icon will be displayed.

52

Page 53

Humidify and Dehumidify Indicators

When the Display Module door is closed, the humidify icon will be displayed

when humidification is active and the dehumidify icon will be displayed when

dehumidification is active.

Auto Changeover

When auto changeover mode is selected, a change from heat to cool (or vice

versa) will not occur until an opposite mode demand has existed for 20 minutes.

If setpoint is changed, 20--minute requirement is deleted.

Emergency Heat Mode

When Thermidistat Control is configured as a heat pump and emergency heat is

selected, all Y signals are locked out, and W becomes energized upon a call for

heat.

Programmable Fan (programmable models only)

The fan output can be programmed based on period of the day. When

programming for each day and period the fan can be set to On or AUTO.

Dry Contact

On the programmable models, the dry contact that can be used for control of an

auxiliary device. The dry contact may be configured to be closed for a specific

number of minutes per hour for each period of the program schedule. This can

be used to operate a ventilator, damper, system blower, or other auxiliary device.

There are two terminals, D1 and D2.

On both the programmable and non--programmable models, when configured as

a dehumidify output, it will operate cooling equipment capable of dehumidify

function. When configured for dehumidification, the Rc terminal must be

connected to one of the dry contact terminals. The other dry contact terminal is

connected to the dehumidify terminal on the furnace or fan coil. This provides

53

Page 54

power to energize the dehumidify terminal on the cooling equipment when the

dry contact is closed.

If it is desired to operate a ventilator or other device, the D1 and D2 terminals

can be connected directly to the equipment. This will provide a closed contact

for the specified number of minutes per hour. See Option 19.

If timed control of the system blower is required, the dry contact can be used for

this function. The G terminal can be connected to one of the dry contact

terminals with the other terminal being connected to Rc and/or Rh for timed

control of the fan. Note that this is not the same as programmable fan Option 30.

See Wiring Diagrams for more information.

TROUBLESHOOTING

If the display module doesn’t power up after power is applied, check the Rc/Rh

and C terminals for 24VAC. If 24VAC is present, check the voltage between Vg

and V+. This voltage will be approximately 12--20VDC. If voltage is present,

check the polarity to make sure it is wired correctly. The display will not power

up if polarity is reversed.

Error Codes

“-- -- ” -- If Thermidistat Control cannot properly read room temperature, display

will indicate “----” and all outputs (except fan, if on) will turn off. In the case

where the installer has selected to average the local sensor and the remote room

sensor, the Thermidistat Control display will alternate between “----” for the

failed sensor and the temperature sensed by the working sensor every 10

54

Page 55

seconds. The control will operate from the temperature sensed by the working

sensor.

E1 -- If the Display Module and the Equipment Control Module cannot

communicate via two--wire connection, an E1 will be displayed.

E2 --ThereisnoE2errormessage.

E3 -- If Thermidistat Control cannot properly read outdoor temperature, and it is

needed for proper operation, display will indicate “-- --” in the outdoor

temperature location.

E4 -- If Thermidistat Control’s internal memory fails, E4 will be displayed.

Replace Thermidistat Control.

E5 -- If Thermidistat Control cannot properly read humidity, E5 will be

displayed. Replace Thermidistat Control. If both Humidify and Dehumidify

have been set to OF, the humidity value will be shown as “-- -- ” when viewed

from the humidity menu, but no E5 will be shown in the display.

Table 4 can be used as a troubleshooting tool for determining which outputs will

be active for a particular configuration and each operating mode.

55

Page 56

Table 4 – Equipment Configuration Outputs

EQUIPMENT

CONFIGURATION

OPTION #1

Single -- stage AC AC Y/Y2 -- W/W1 -- -- --

Single -- stage AC

Single -- stage HP

RVS = C

Single -- stage HP

RVS = H

Single -- stage HP

RVS = C

Single -- stage HP

RVS = H

Two--stage AC 2S Y1

Two--stage HP

RVS = C

Two--stage HP

RVS = H

Single -- stage

Hybrid Heat

RVS = C

Single -- stage

Hybrid Heat

RVS = H

HARDWARE

CONFIGURATION

HP

2S

HP

HP Y/Y2 --

2S

2S Y/Y2 --

2S

2S Y1

2S

2S Y/Y2 --

COOL

STAGE

O/W2/B

O/W2/B

O/W2/B

O/W2/B

COOL

STAGE

1

Y/Y2 -- W/W1

Y/Y2

Y/Y2

Y1

O/W2/B

Y/Y2

STAGE

2

-- Y/Y2

O/W2/B

-- Y/Y2

O/W2/B

Y/Y2

Y1

Y1

Y/Y2

Y1

Y/Y2Y1O/W2/B

-- Y/Y2 W/W1 -- W/W1

O/W2/B

HEAT

Y/Y2

Y/Y2

W/W1

Y1

Y/Y2

HEAT

STAGE

1

2

W/W1

O/W2/B

Y/Y2

W/W1

Y/Y2

W/W1

O/W2/B

Y/Y2

W/W1

Y/Y2

W/W1

O/W2/B

W/W1

O/W2/B

Y1

Y/Y2

Y1

Y/Y2

O/W2/B

W/W1 -- W/W1

HEAT

STAGE

3

-- --

-- W/W1

-- W/W1

-- W/W1

-- W/W1

-- --

Y1

Y/Y2

W/W1

Y1

Y/Y2

O/W2/B

W/W1

EM

HEAT

STAGE

1

W/W1

W/W1

56

Page 57

Table 4 -- Equipment Configuration Outputs (cont)

EQUIPMENT

CONFIGURATION

OPTION #1

Two--stage

Hybrid Heat

RVS = C

Two--stage

Hybrid Heat

RVS = H

Heat Only Unit

Cool Only Unit 2S Y1

Cool Only Unit

HARDWARE

CONFIGURATION

2S

2S Y1

AC

HP

2S

AC

HP

COOL

STAGE

O/W2/B

COOL

STAGE

1

Y1

O/W2/B

-- -- W/W1 -- -- --

Y/Y2 -- -- -- -- --

HEAT

STAGE

2

Y1

Y/Y2

Y1

Y/Y2Y1O/W2/B

Y1

Y/Y2

1

Y1

-- -- -- --

HEAT

STAGE

2

Y1

Y/Y2

Y1

Y/Y2

O/W2/B

HEAT

STAGE

3

W/W1 W/W1

W/W1 W/W1

EM

HEAT

STAGE

1

57

Page 58

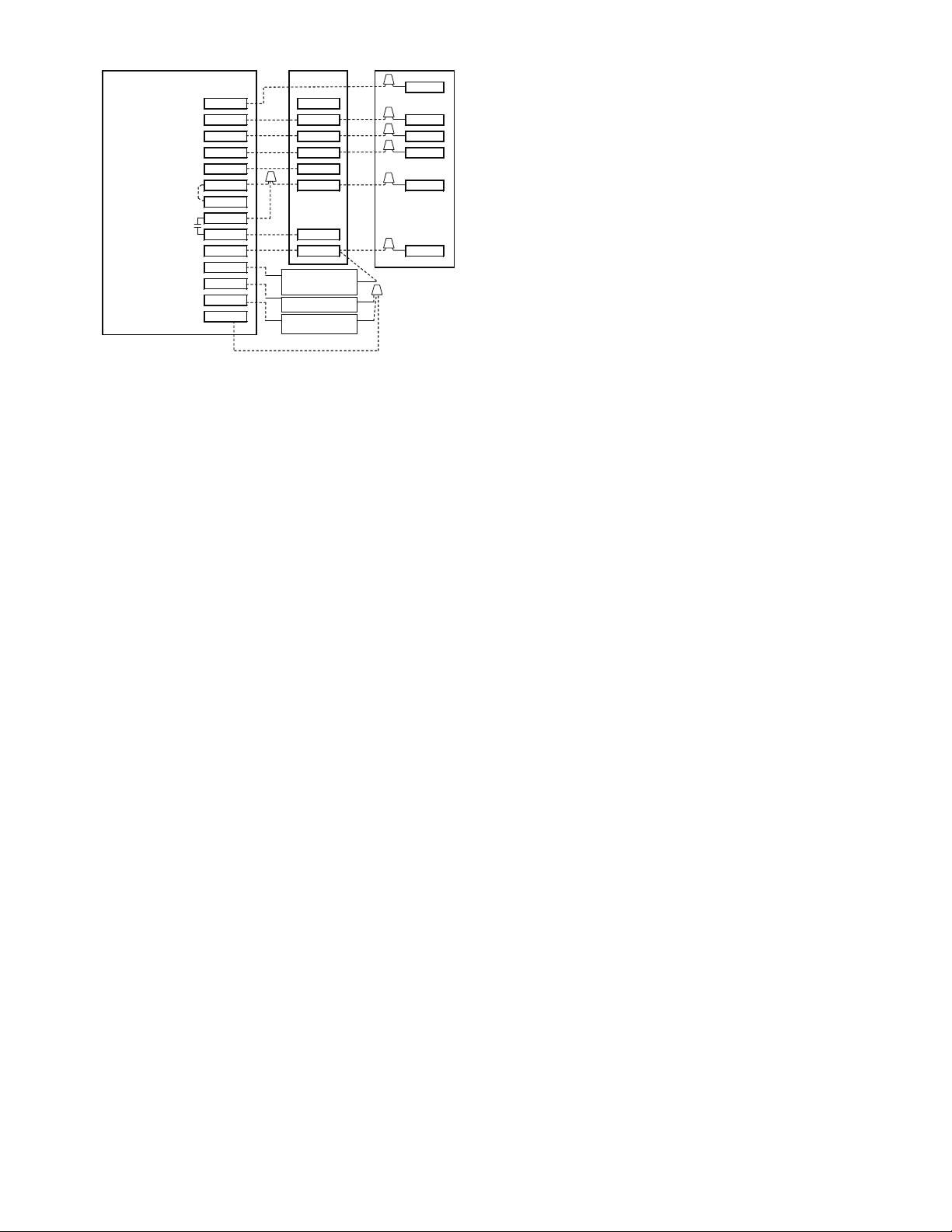

WIRING DIAGRAMS

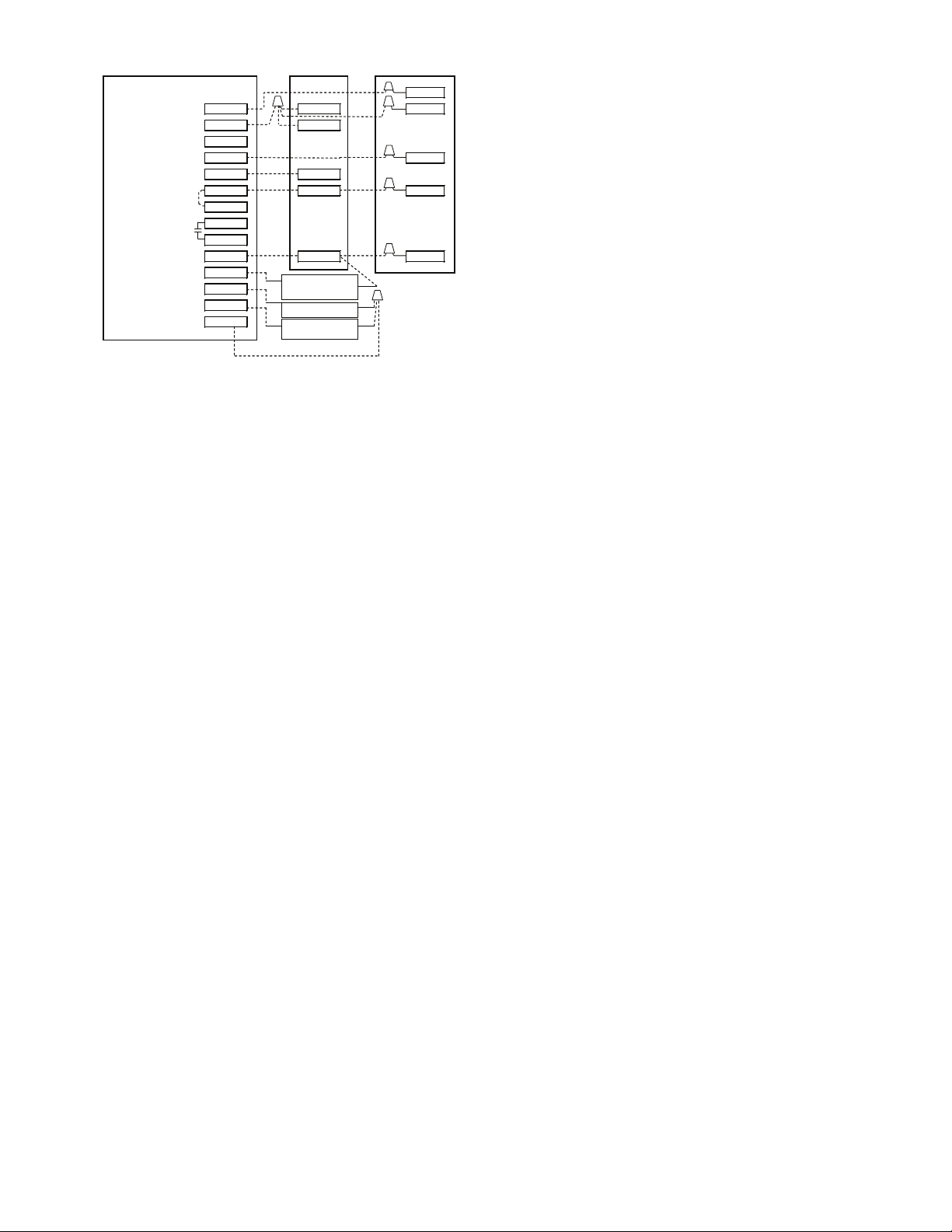

Display module

V+

Vg

* Indicates connection may not be required/available.

Display module wall mount Equipment Control Module

V+ V+

Vg Vg O O

V+ RVS/Heat Stage 2 O/B W 2 W3 W2

Vg Heat Stage 1 W/W 1 W2

Compressor Y/Y2 Y Y

Not Used Y1

Fan G G

24VAC Hot Heating Rh R R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2

24VAC Common C COM COM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Fig. 17 -- Display to Equipment Control Module Connection

Fan Coil

Outdoor Sensor *

Remote Room

*

Heat Pump

A07164

58

Page 59

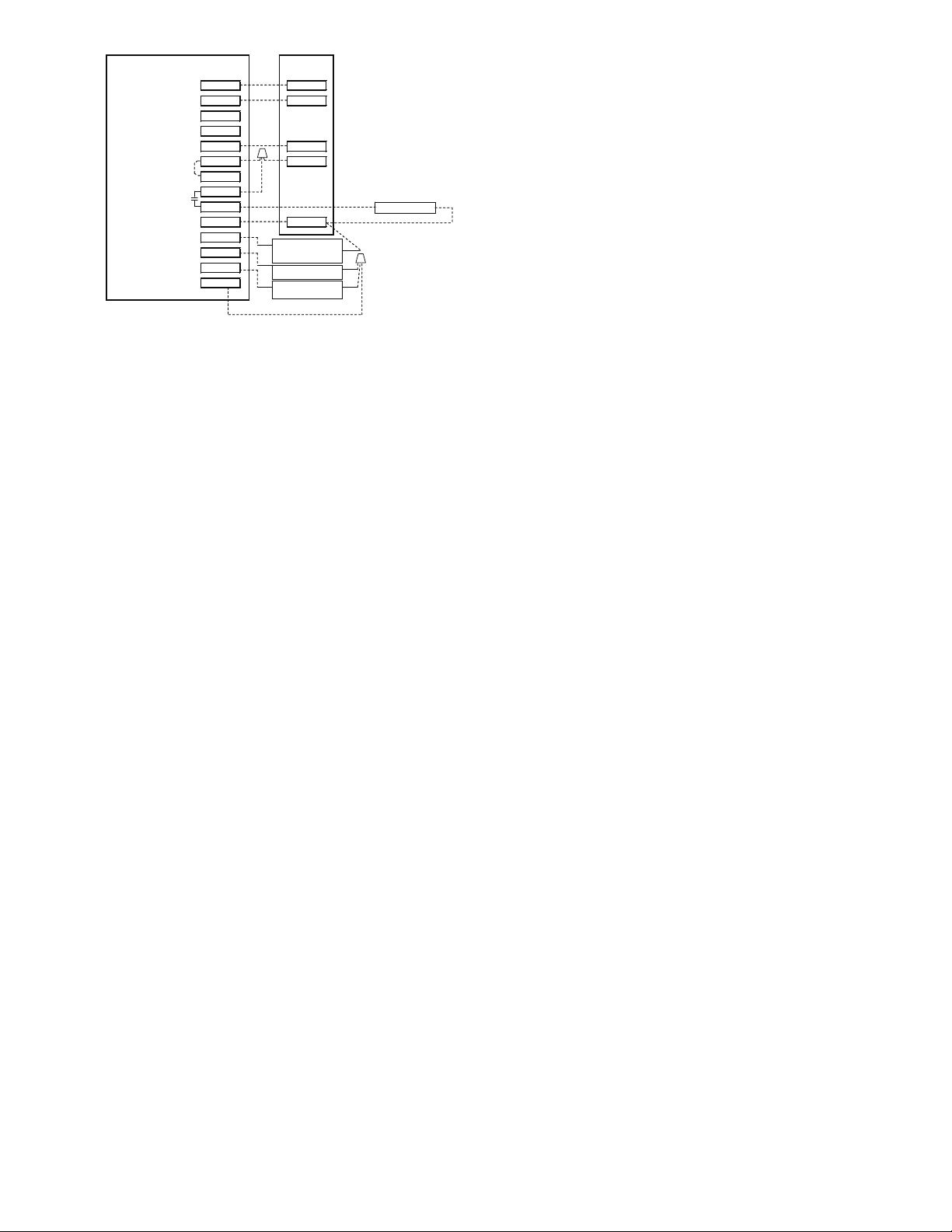

Thermostat Fan Coil Heat Pump

OO

RVS/Heat Stage 2 O/B W2 W3 W2

Heat Stage 1 W/W1 W2

Compressor Low Y1 Y1 Y1

Compres sor High Y/Y2 Y/Y2 Y/Y2

Fan G G

24VAC Hot Heating Rh R R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2 DEHUM

24VAC Common C COM COM

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

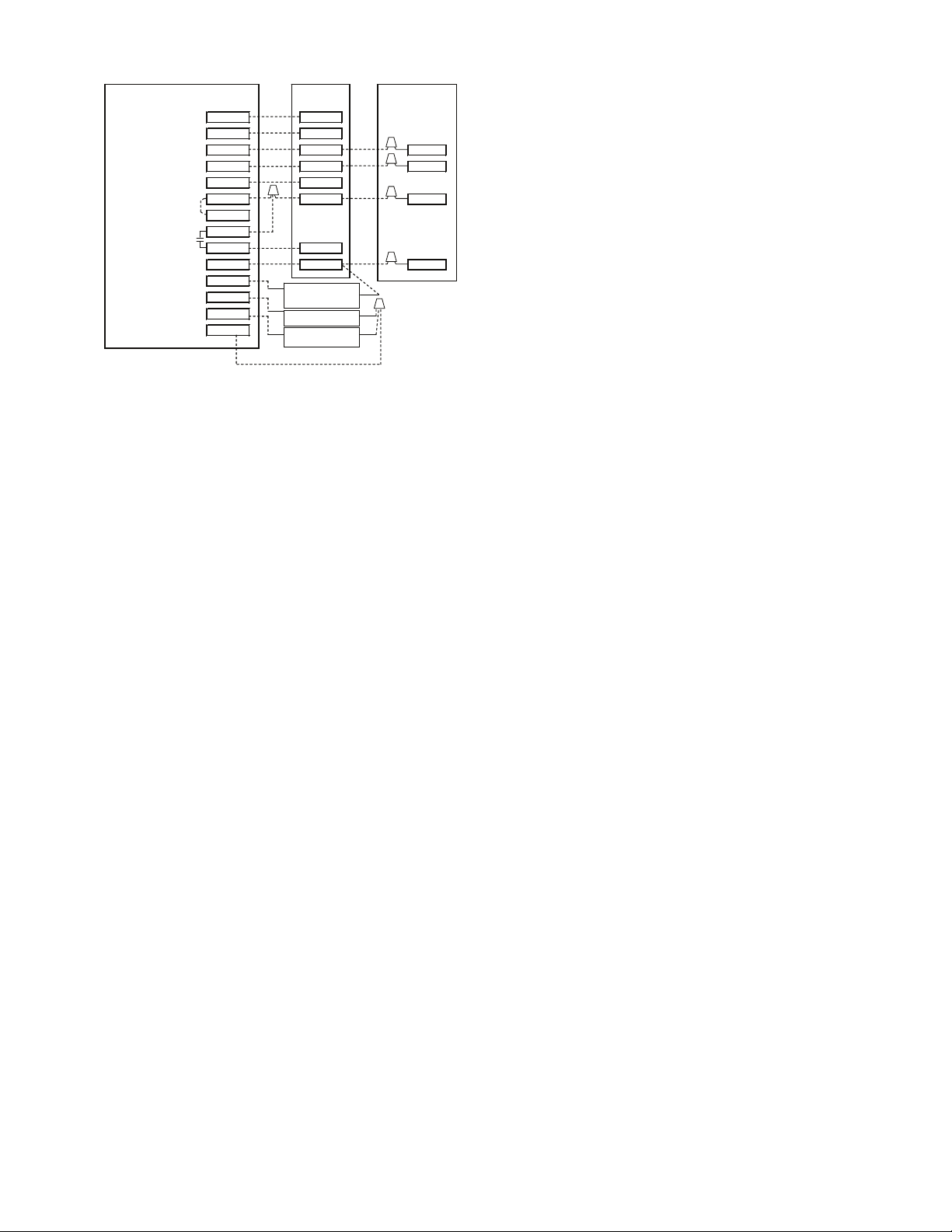

Fig. 18 -- FV/FK Fan Coil w/2-- Stage Heat Pump

* Indicates connection may not be required/available.

A06573

59

Page 60

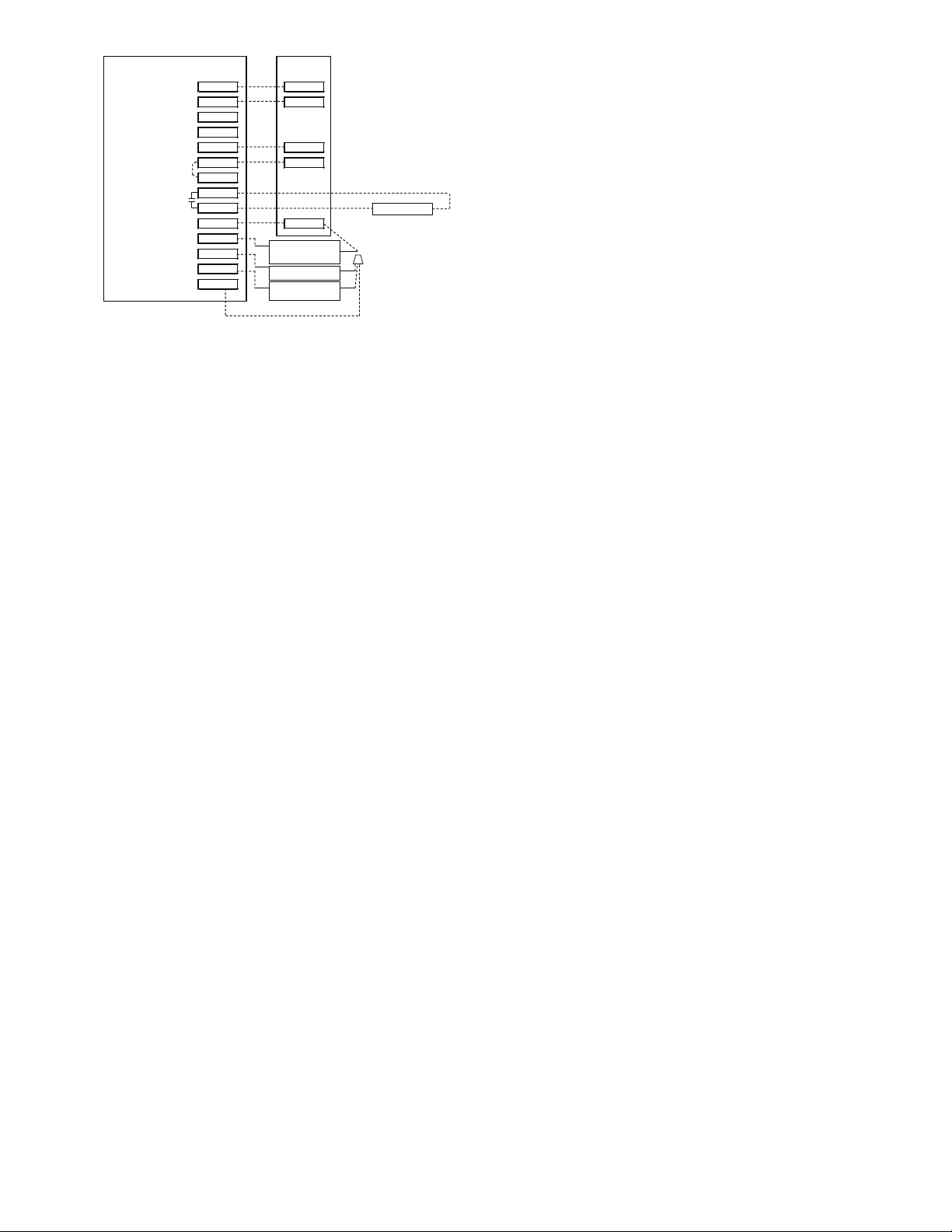

Thermostat Fan Coil Heat Pump

RVS/Heat Stage 2 O/B W2 W 3 W2

Heat Stage 1 W/W 1 W2

Compressor Low Y1

Compressor High Y/Y2 Y

Fan G G

24VAC Hot Heating Rh R R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2

24VAC Common C COM COM

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Typical Single-Stage

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 19 -- Typical Fan Coil w/Heat Pump

* Indicates connection may not be required/available.

O

A06574

60

Page 61

Thermostat

RVS/Heat Stage 2 O/B W2 W3

Heat Stage 1 W/W 1 W2

Compressor Low Y1

Compressor High Y/Y2

Fan G G

24VAC Hot Heating Rh R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2 Aux. Connection

24VAC Common C COM

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com O AT/RRS

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 20 -- Fan Coil Shown w/Aux. Connection #1

(Heat Pump/Air Conditioner removed for clarity.)

* Indicates connection may not be required/available.

A06575

61

Page 62

Thermostat Fan Coil Air Conditioner

O

RVS/Heat Stage 2 O/B W2 W 3

Heat Stage 1 W/W 1 W2

Compressor Low Y1 Y1 Y1

Compres sor High Y/Y2 Y/Y2 Y/Y2

Fan G G

24VAC Hot Heating Rh R R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2 DEHUM

24VAC Common C COM CO M

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 21 -- FV/FK Fan Coil w/2--Stage Air Conditioner

* Indicates connection may not be required/available.

A06576

62

Page 63

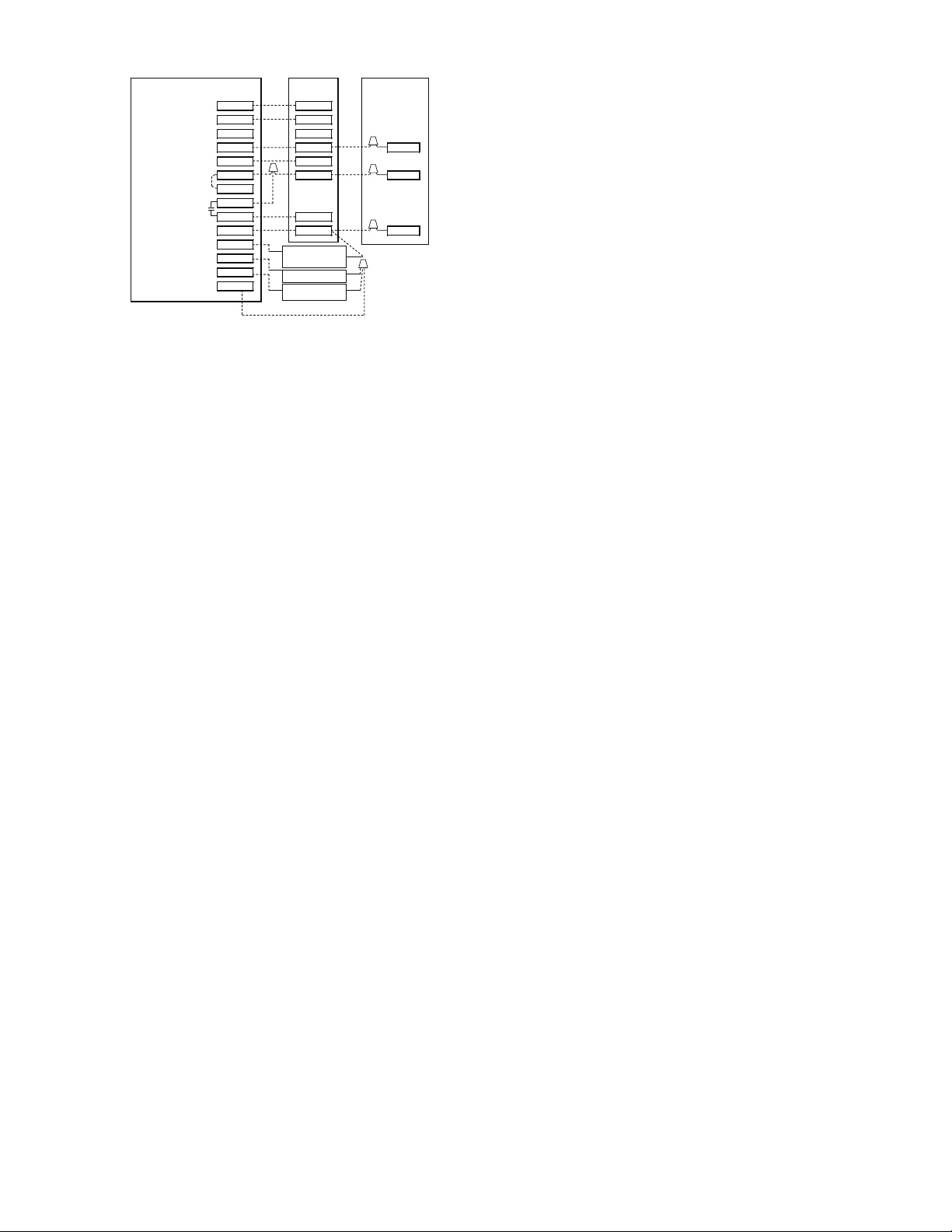

Thermostat Fan Coil Air Conditioner

RVS/Heat Stage 2 O/B W2 W 3

Heat Stage 1 W/W 1 W2

Compressor Low Y1

Compressor High Y/Y2 Y

Fan G G

24VAC Hot Heating Rh R R *

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2

24VAC Common C COM CO M

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Typical Single-Stage

O

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 22 -- Typical Fan Coil w/Air Conditioner

* Indicates connection may not be required/available.

A06577

63

Page 64

Thermostat

RVS/Heat Stage 2 O/B W 2 W 3

Heat Stage 1 W/W 1 W2

Compressor Low Y1

Compressor High Y/Y2

Fan G G

24VAC Hot Heating Rh R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2 Aux. Connection

24VAC Common C COM

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com O AT/RRS

Fan Coil

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 23 -- Fan Coil Shown w/Aux. Connection #2

(Heat Pump/Air Conditioner removed for clarity.)

* Indicates connection may not be required/available.

A06578

64

Page 65

Thermostat Fan Coil Heat Pump

OO

RVS/Heat Stage 2 O/B W2 W 3 W2

Heat Stage 1 W/W 1 W2

Compressor Low Y1 Y1

Compres sor High Y/Y2 Y/Y2 Y

Fan G G

24VAC Hot Heating Rh R R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2 DEHUM

24VAC Common C COM CO M

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

*

Fig. 24 -- FV/FK Fan Coil w/1-- Stage Heat Pump

* Indicates connection may not be required/available.

A06579

65

Page 66

Thermostat Fan Coil

RVS/Heat Stage 2 O/B W2 W 3

Heat Stage 1 W/W 1 W2

Compressor Low Y1

Compressor High Y/Y2

Fan G G

24VAC Hot Heating Rh R

24VAC Hot Cooling Rc

Dry Contact 1 D1

Dry Contact 2 D2

24VAC Common C COM

Humidify HUM

Outdoor Air Temp OAT

Remote Room Sensor RRS

OAT/RRS Com OAT/RRS

Typical

Humidifier Solenoid

Valve *

Outdoor Sensor *

Remote Room

Fig. 25 -- Typical Fan Coil Heating Only