Bryant 926TA, 926TA30040V14, 926TA36040V17, 926TA36060V14, 926TA42060V17 Product Data

...

926TA

PREFERREDt TWO--STAGE

4--WAY MULTIPOISE, VARIABLE SPEED

CONDENSING GAS FURNACE, SERIES A

Product Data

A11264

The 926TA Multipoise Variable--Speed Condensing Gas Furnace

features the two--stage Preferredt Series System. The Perfect

HeatR technology two--stage gas valve is at the heart of the

comfort provided by this furnace, along with the variable--speed

ECM blower motor, and two--speed inducer motor. With an

Annual Fuel Utilization Efficiency (AFUE) up to 96.5%, the

Preferredt Series two--stage gas furnace provides exceptional

savings as well when compared to standard gas furnaces. This

Preferredt Series Gas Furnace also features 4--way multipoise

installation flexibility, and is available in eight model sizes. The

926TA can be vented for direct vent/two--pipe, ventilated

combustion air, or single--pipe applications. All units meet

California Air Quality Management District emission requirements.

All sizes are design certified in Canada.

STANDARD FEATURES

S All sizes meet ENERGY STARR Version 4.0 criteria for gas

furnaces: 95+AFUE; AMACF electrical rating; 2% or less

cabinet airflow leakage.

S Quiet operation. Compare for yourself at HVACpartners.com.

S Ideal height 35” (889 mm) cabinet: short enough for taller coils,

but still allows enough room for service.

S Silicon Nitride Perfect Light Hot Surface Igniter.

S SmartEvap technology helps control humidity levels in the

home when used with a compatible humidity control system.

S FanOn Plus technology allows control of continuous fan speed

from a compatible thermostat.

S 4--way multipoise design for upflow, downflow or horizontal

installations, with unique vent elbow and optional through-the--cabinet downflow venting capability.

S Full--featured variable--speed blower motor, two--speed inducer

motor, and two--stage gas valve.

S Self--diagnostics.

S Adjustable blower speed for cooling, continuous fan, and

dehumidification.

S Aluminized--steel primary heat exchanger.

S Stainless--steel condensing secondary heat exchanger.

S Propane convertible (See Accessory list).

S Factory--configured ready for upflow applications.

S Fully--insulated casing including blower section.

S Convenient Air Purifier and Humidifier connections.

S Direct--vent/sealed combustion, single--pipe venting or

ventilated combustion air.

S Installation flexibility: sidewall or vertical vent.

S Residential installations may be eligible for consumer financing

through the Retail Credit Program.

S Certified to leak 2% or less of nominal air conditioning CFM

delivered when pressurized to 1--in. water column with all

present air inlets, air outlets, and condensate drain port(s) sealed.

CERTIFIED

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org.

1

Always Ask For

CASING

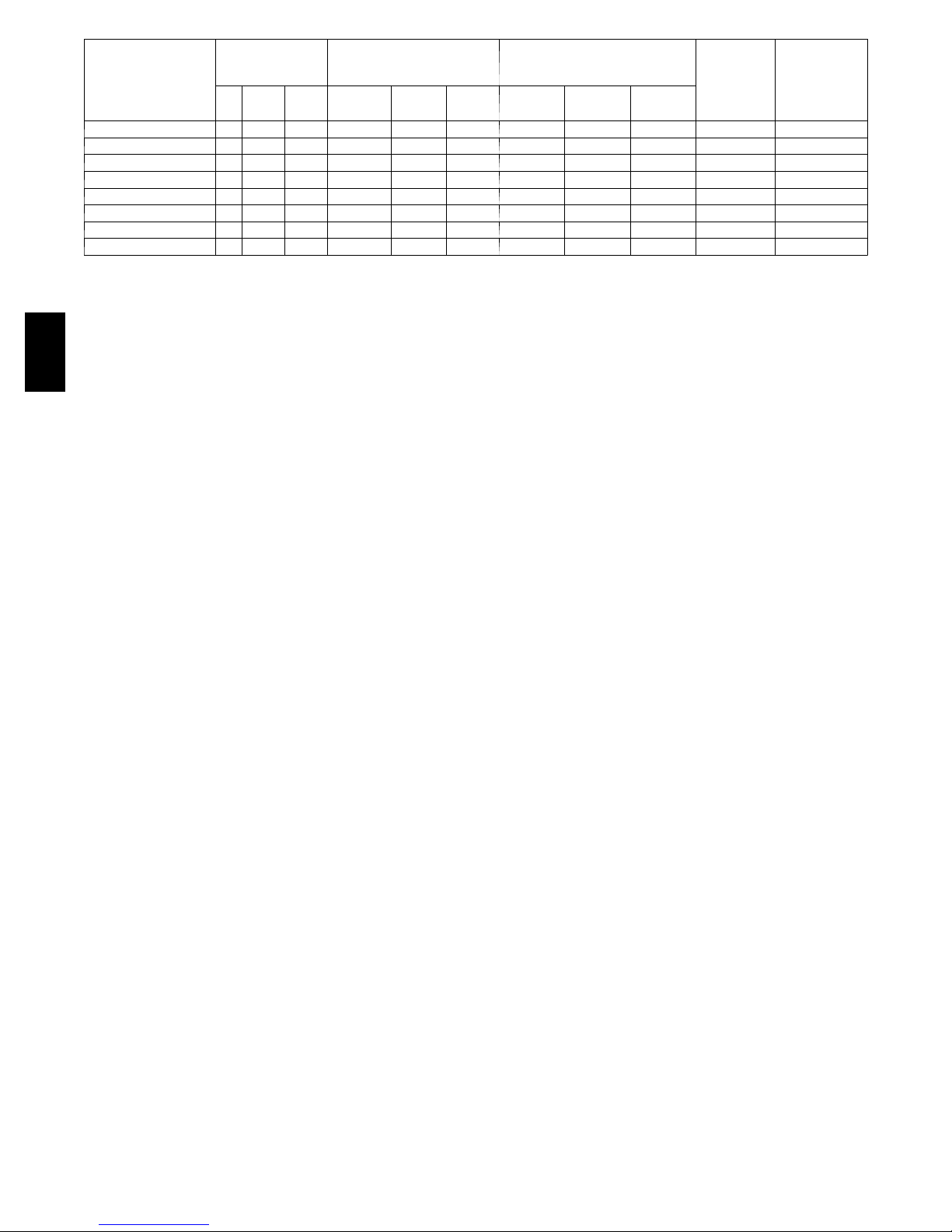

SAP ORDERING

NO.

926TA30040V14 35 29.5 14.2 39,000 25,000 96.5% 815 660 0.10 905 1/2

926TA36040V17 35 29.5 17.5 39,000 25,000 96.0% 860 660 0.10 1065 1/2

926TA36060V14 35 29.5 14.2 58,000 38,000 95.0% 1120 910 0.12 1065 1/2

926TA42060V17 35 29.5 17.5 58,000 38,000 96.3% 1135 860 0.12 1475 3/4

926TA48080V17 35 29.5 17.5 78,000 50,000 96.2% 1505 1160 0.15 1610 3/4

926TA60080V21 35 29.5 21.0 78,000 51,000 96.5% 1555 1200 0.15 2005 1

926TA60100V21 35 29.5 21.0 97,000 63,000 96.1% 1865 1435 0.20 2005 1

926TA66120V24 35 29.5 24.0 117,000 76,000 96.5% 2375 1675 0.20 2115 1

{Capacity in accordance with DOE test procedures. Ratings are position dependent. See rating plate.

‡Minimum h eat CFM when low ---heat rise adjustment switch (SW 1 - -- 3) and comfort/efficiency adjustment switch (SW1 ---4) on control center are OFF.

ESP --- External Static Pressure

DIMENSIONS

(IN.)

H D W High Low AFUE

RATED HEATING OUTPUT†

(BTUH)

HEATING AIRFLOW

CFM‡ (High

Heating

CFM (Low

Heating)

High Heating

ESP

(in. W.C.)

COOLING

CFM @ 0.5

(in. W.C.)

FEATURES AND BENEFITS

Perfect HeatR Technology — This feature with Adaptive Control

is a proprietary function that promotes homeowner comfort

926TA

through two stages of heating. This Bryant furnace offers a

patented algorithm that continually monitors and adjusts furnace

operation by looking at both current and past conditions to

determine the most effective stage of heating and the amount of

time to run each stage, every cycle.

SmartEvapt Technology — When paired with a compatible

thermostat, this dehumidification feature overrides the cooling

blower off-delay when there is a call for dehumidification. By

deactivating the blower off-delay, SmartEvap technology prevents

condensate that remains on the coil after a dehumidification cycle

from re-humidifying throughout the home. This results in reduced

humidity and a more comfortable indoor environment for the

homeowner.

Unlike competitive systems, SmartEvap technology only overrides

the cooling blower off delay when humidity control is needed.

Once humidity is back in control, SmartEvap re-enables the

energy-saving cooling blower off-delay.

FanOnPlust Technology — Sometimes the constant fan setting

on a standard furnace system can actually reduce homeowner

comfort by providing too much or too little air! Fan On Plus

technology improves comfort all year long by allowing the

homeowner to select the continuous fan speed of their choice using

a compatible thermostat.

HYBRID HEATR Dual Fuel system — This system can provide

more control over your monthly energy bills by automatically

selecting the most economical method of heating. With HYBRID

HEAT, our system automatically switches between the gas furnace

and the electric heat pump as outside temperatures change to

maintain greater efficiency and comfort than with any traditional

single-source heating system. The heat pump also delivers

high-efficiency cooling in the summer.

Power Heatt Igniter — Bryant’s unique SiN igniter is not only

physically robust but it is also electrically robust. It is capable of

running at line voltage and does not require complex voltage

regulators as do other brands. This unique feature further enhances

the gas furnace reliability and continues Bryant’s tradition of

technology leadership and innovation in providing a reliable and

durable product.

Full-Featured, Variable Speed Motors — Our variable--speed

ECM (Electronically Commutated Motor) optimizes comfort levels

in the home year round; features such as passive/active

dehumidification, ramping profiles, and quiet operation. They can

provide cooling match enhancements to increase the effective

SEER of select Bryant air conditioner or heat pump system. This

motor does not report back RPM and static pressure to enablestatic

pressure reporting to the UI or zoning system, which is required for

zoning, active filter monitoring and system static pressure

reporting.

Reliable Heat Exchanger Design — The aluminized steel, clam

shell primary heat exchanger was re--engineered to achieve greater

efficiency out of a smaller size. The first two passes of the heat

exchanger are based on the current 80% product, a design with

more than ten years of field-proven performance and success.

These innovations, paired with the continuation of a crimped,

no-weld seam create an efficient, robust design for this essential

component.

The condensing heat exchanger, a stainless steel fin and tube

design, is positioned in the furnace to extract additional heat.

Stainless steel coupling box componentry between heat exchangers

has exceptional corrosion resistance in both natural gas and

propane applications.

Optional Media Filter Cabinet — Enhanced indoor air quality in

the home is made easier with our media filter cabinet When

installed as a part of the system, this cabinet allows for easy and

convenient addition of a Bryant high efficiency air filter.

4-Way Multipoise Design — One model for all applications –

there is no need to stock special downflow or horizontal models

when one unit will do it all. The new heat exchanger design allows

these units to achieve the certified AFUE in all positions.

Direct or Single-pipe Venting, or Optional Ventilated

Combustion Air — This furnace can be installed as a 2-pipe

(Direct Vent) furnace, in an optional ventilated combustion air

application, or in single-pipe, non-direct vent applications. This

provides added flexibility to meet diverse installation needs.

Sealed Combustion System — This furnace brings in combustion

air from outside the furnace, which results in especially quiet

operation. By sealing the entire combustion vestibule, the entire

furnace can be made quieter, not just the burners.

Insulated Casing — Foil-faced insulation in heat exchanger

section of the casing minimizes heat loss. The acoustical insulation

in the blower compartment reduces air and motor noise for quiet

operation.

Monoport Burners — The burners are specially designed and

finely tuned for smooth, quiet combustion and economical

operation.

Bottom Closure — Factory--installed for side return; easily

removable for bottom return. The multi-use bottom closure can

also serve for roll-out protection in horizontal applications, and act

as the bottom closure for the optional return air base accessory.

Certifications — This furnace is CSA (AGA and CGA) design

certified for use with natural and propane gases. The furnace is

factory--shipped for use with natural gas. A CSA listed gas

conversion kit is required to convert furnace for use with propane

gas. The efficiency is AHRI efficiency rating certified. This furnace

meets California Air Quality Management District emission

requirements.

ESP

MOTOR H P -

SPEED

(VARIABLE

SPEED)

2

1 - 2

Family/Tier

92

91 - Legacy

92 - Preferred

98 - Evolution

3

Base Eff.

6

0 - +90 AFUE

2 - +92 AFUE

3 - +93 AFUE

5 - +95 AFUE

6 - +96 AFUE

7 - +97 AFUE

4

Htg. Stages

T

S - Single Stage

T - Two Stage

M - Modulating

MODEL NUMBER NOMENCLATURE

Example of a Model Number

5

Major Series

A

Major Series

6 - 7

Clg. Cap.

30

24 - 800 CFM

30 - 1000 CFM

36 - 1200 CFM

42 - 1400 CFM

48 - 1600 CFM

54 - 1800 CFM

60 - 2000 CFM

66 - 2200 CFM

(@ 0.5” ESP)

Not all familes have these models.

8 - 10

Htg. Cap.

040

040= 40,000 BTU

060= 60,000 BTU

080= 80,000 BTU

100=100,000 BTU

120=120,000 BTU

140=140,000 BTU

11

Motor

V

S - Standard

E - Energy Efficient

V - Variable Speed

14 - 14.2”

17 - 17.5”

21 - 21.0”

24 - 24.5”

12 - 13

Width

14

Voltage

Voltage

14

A

15

Features

--

L - Low NOx

16

Minor Series

A

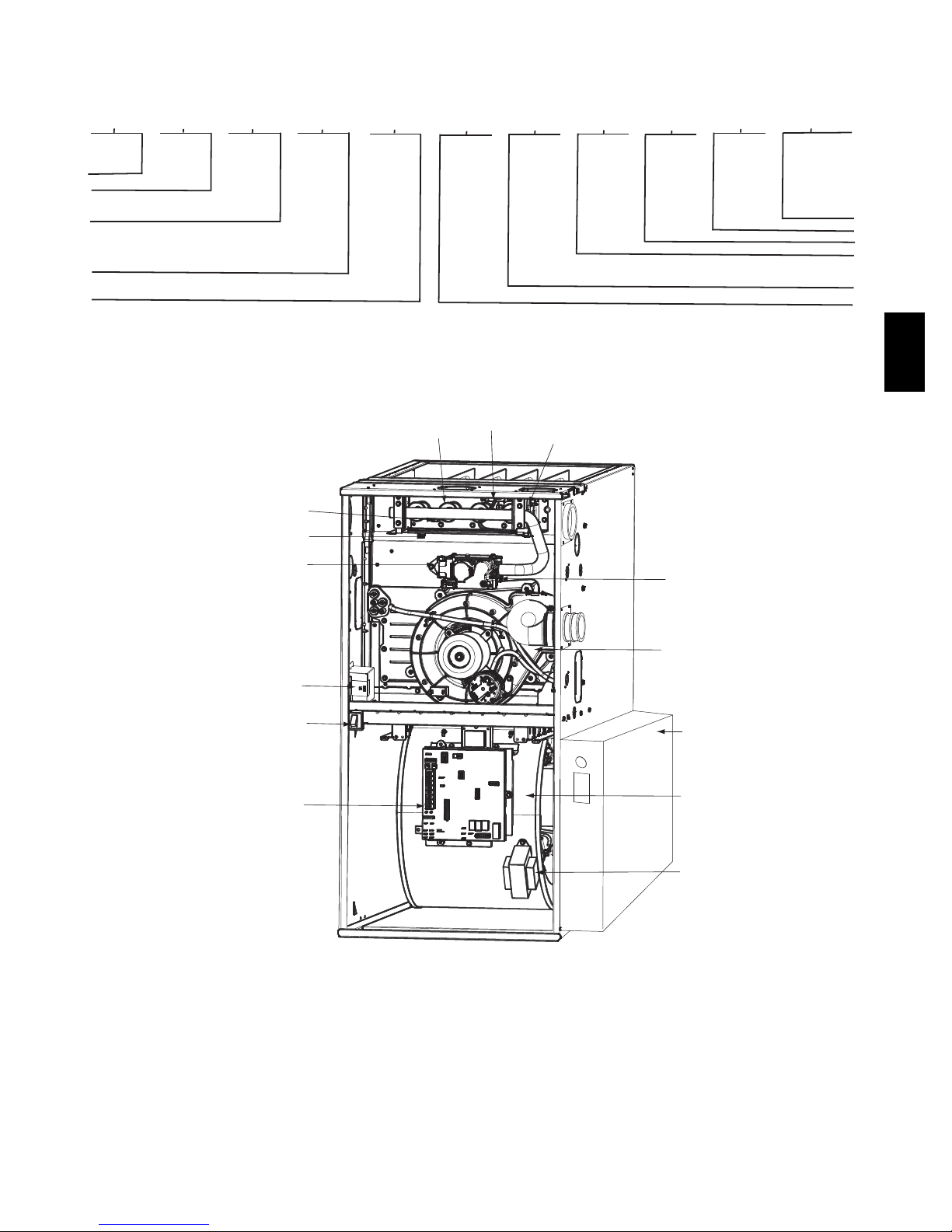

FLAME

SENSOR

MANUAL RESET

ROLLOUT SWITCH

GAS VALVE

OPERATING INSTRUCTIONS

NOT SHOWN (LOCATED ON

MAIN FURNACE DOOR, SEE

OPERATING INSTRUCTIONS

INSIDE DOOR FIGURE).

ELECTRICAL JUNCTION

BOX (IF REQUIRED,

LOCATION MAY VARY)

BLOWER DOOR

SAFETY SWITCH

FURNACE

CONTROL

BOARD

FURNACE COMPONENTS

HOT SURFACE

IGNITER

GAS BURNER

MANUAL RESET

ROLLOUT SWITCH

MAIN LIMIT SWITCH

(BEHIND GAS VALVE)

INDUCER MOTOR

ASSEMBLY

MEDIA CABINET

BLOWER AND

MOTOR

A14367

926TA

RATING PLATE NOT SHOWN

(LOCATED ON BLOWER DOOR)

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY IN APPEARANCE.

3

CAPACITOR/

POWER CHOKE

(IF USED)

A11408

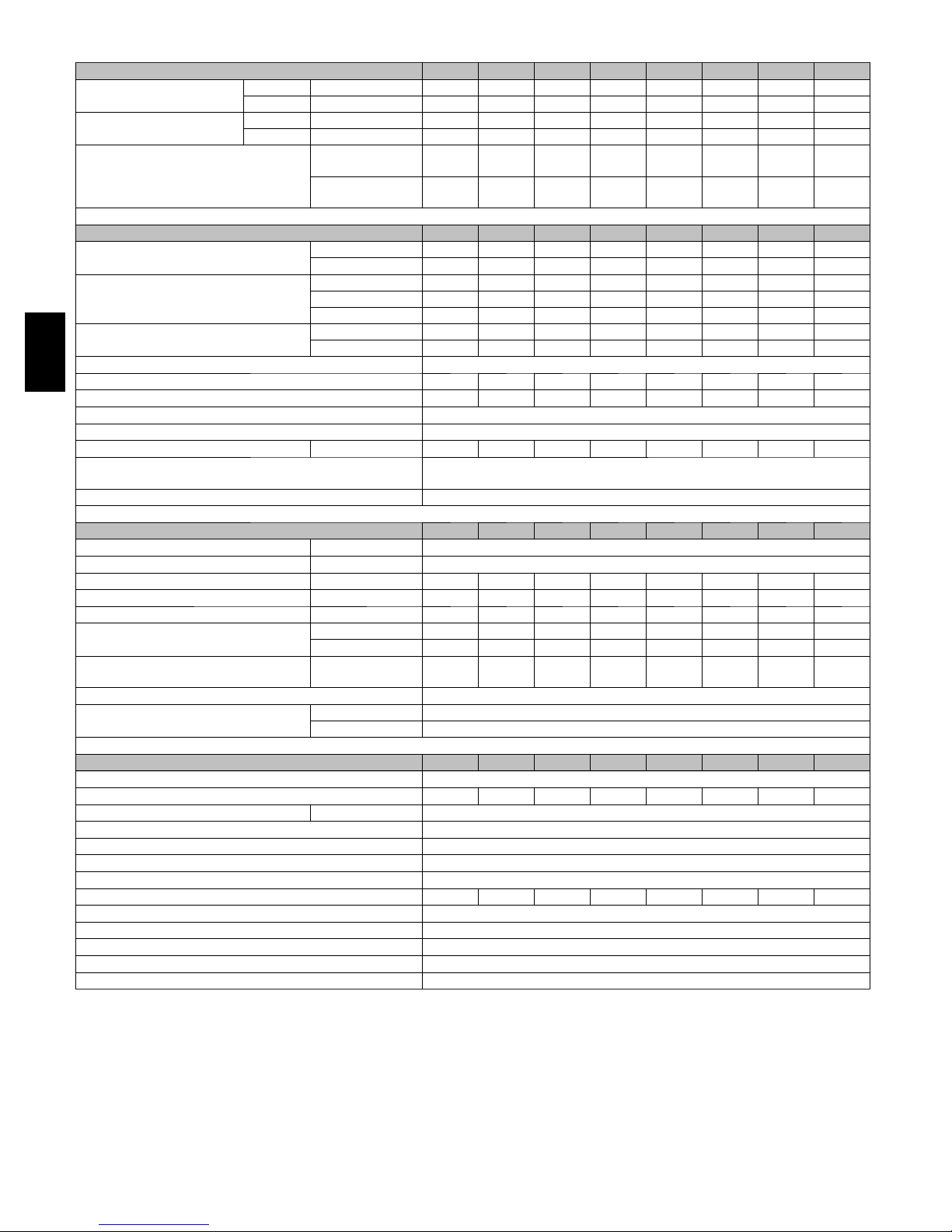

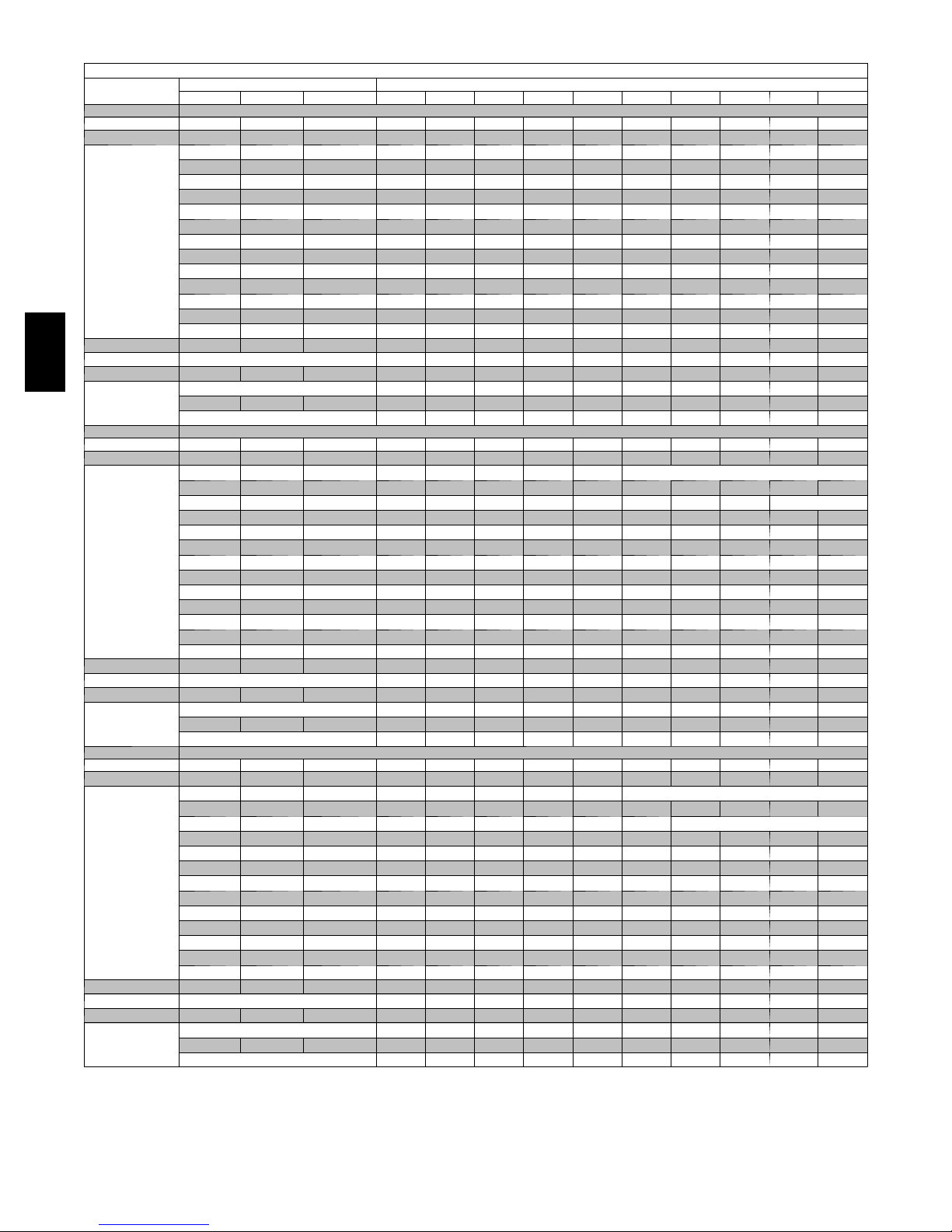

SPECIFICATIONS

Heating Capacity and Efficiency 30040 36040 36060 42060 48080 60080 60100 66120

Input

Output

Certified Temperature

Rise Range ºF (ºC)

Airflow Capacity and Blower Data 30040 36040 36060 42060 48080 60080 60100 66120

Rated External Static

Pressure (in. w.c.)

Airflow Delivery

@ Rated ESP (CFM)

Cooling Capacity (tons)

@ 400, 350 CFM/ton

Direct-Drive Motor Type Electronically Communicated Motor (ECM)

926TA

Direct-Drive Motor HP 1/2 1/2 1/2 /4 3/4 1 1 1

Motor Full Load Amps 6.8 6.8 6.8 8.4 8.4 10.9 10.9 10.9

RPM Range 600 - 1200

Speed Selections Variable (PWM)

Blower Wheel Dia x Width in. 11 x 7 11 x 8 11 x 7 11 x 8 11 x 8 11 x 10 11 x 10 11 x 11

Air Filtration System

Filter Used for Certified Watt Data KGAWF1506UFR

High Heat (BTUH) 40,000 40,000 60,000 60,000 80,000 80,000 100,000 120,000

Low Heat (BTUH) 26,000 26,000 39,000 39,000 52,000 52,000 65,000 78,000

High Heat (BTUH) 39,000 39,000 58,000 58,000 78,000 78,000 97,000 117,000

Low Heat (BTUH) 25,000 25,000 38,000 38,000 50,000 51,000 63,000 76,000

High Heat

Low Heat

Heating 0.10 0.10 0.12 0.12 0.15 0.15 0.20 0.20

Cooling 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

High Heat 815 860 1120 1135 1505 1555 1865 2375

Low Heat 660 660 910 860 1160 1200 1435 1675

Cooling 905 1065 1065 1475 1610 2005 2005 2115

400 CFM/ton 2 2.5 2.5 3.5 4 5 5 5

350 CFM/ton 2.5 3 3 4 4.5 5.5 5.5 6

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

Optional Media Cabinet

Field Supplied Filter

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

40 - 70

(22 - 39)

30 - 60

(17 - 33)

Electrical Data 30040 36040 36060 42060 48080 60080 60100 66120

Input Voltage Volts-Hertz-Phase 115-60-1

Operating Voltage Range Min-Max 104-127

Maximum Input Amps Amps 7.5 7.5 7.6 9.2 9.2 11.7 11.8 11.8

Unit Ampacity Amps 10.3 10.2 10.3 12.4 12.4 15.5 15.6 15.6

Minimum Wire Size AWG 14 14 14 14 14 12 12 12

Maximum Wire Length

@ Minimum Wire Size

Maximum Fuse/Ckt Bkr

(Time-Delay Type Recommended)

Transformer Capacity (24vac output) VA

External Control Power

Available

Controls 30040 36040 36060 42060 48080 60080 60100 66120

Gas Connection Size 1/2" - NPT

Burners (Monoport) 2 2 3 3 4 4 5 6

Gas Valve (Redundant) Manufacturer White Rodgers

Minimum Inlet Gas pressure (in. wc) 4.5

Maximum Inlet Gas pressure (in. wc) 13.6

Manufactured (Mobile) Home Kit not approved for MH use

Ignition Device Silicon Nitride

Limit Control 165 180 165 180 170 200 180 160

Heating Blower Control (Heating Off-Delay) Adjustable: 90, 120, 150, 180 seconds

Cooling Blower Control (Time Delay Relay) 90 seconds

Communication System None

Thermostat Connections R, W/W1, W2 Y/Y2, Y1, G, Com 24V, DHUM

Accessory Connections EAC (115vac); HUM (24vac); 1-stg AC (via Y/Y2)

Feet 36 36 36 29 29 37 36 36

(M) (11.0) (11.0) (11.0) (8.8) (8.8) (11.3) (11.0) (11.0)

Amps 15 15 15 15 15 20 20 20

Heating .3 VA

Cooling .6 VA

* See Accessory List for part numbers available.

4

ACCESSORIES

Venting Accessories

Vent Kit - Through the Cabinet KGADC0101BVC D D D D D D D D

Vent Terminal - Concentric - 2” (51 mm) KGAVT0701CVT

Vent Terminal - Concentric - 3” (76 mm) KGAVT0801CVT

Vent Terminal Bracket - 2” (51 mm) KGAVT0101BRA

Vent Terminal Bracket - 3” (76 mm) KGAVT0201BRA

Vent Kit --- Rubber Coupling KGAAC0101RVC See Venting Tables

Condensate Drainage Accessories

Freeze Protect Kit - Heat Tape KGAHT0101CFP D D D D D D D D

CPVC to PVC Drain Adapters - 1/2” CPVC to 3/4” PVC KGAAD0110PVC D D D D D D D D

Horizontal Trap Grommet - Direct Vent KGACK0101HCK All DV Horizontal

Condensate Neutralizer Kit P908---0001 D D D D D D D D

External Trap Kit KGAET0201ETK D D D D D D D D

Ductwork Adapter Accessories

Furnace Base Kit for Combustible Floors KGASB0201ALL D D D D D D D D

Coil Adapter Kits - -- No Offset KGADA0101ALL D D D D D D D D

Coil Adapter Kits - -- Single Offset KGADA0201ALL D D D D D D D D

Coil Adapter Kits - -- Double Offset KGADA0301ALL D D D D D D D D

Return Air Base (Upflow Applications) 14.0 --- in. wide KGARP0301B14 D D

Return Air Base (Upflow Applications) 17.5 --- in. wide KGARP0301B17 D D D

Return Air Base (Upflow Applications) 21.0 --- in. wide KGARP0301B21 D D

Return Air Base (Upflow Applications) 24.5 --- in. wide KGARP0301B24 D

IAQ Device Duct Adapters 20.0 --- in. IAQ to 16 in. Side

Return

IAQ Device Duct Adapters 24.0 --- in. IAQ to 16 in. Side

Return

Gas Conversion Accessories

Gas Conversion Kit - Nat to LP; Var-speed Products KGCNP5201VSP D D D D D D D D

Gas Conversion Kit - LP to Nat; Var-speed Products KGCPN4401VSP D D D D D D D D

GasOrificeKit-#42(NatGas) LH32DB207 D D D D D D D D

GasOrificeKit-#43(NatGas) LH32DB202 D D D D D D D D

GasOrificeKit-#44(NatGas) LH32DB200 D D D D D D D D

GasOrificeKit-#45(NatGas) LH32DB205 D D D D D D D D

GasOrificeKit-#46(NatGas) LH32DB208 D D D D D D D D

GasOrificeKit-#47(NatGas) LH32DB078 D D D D D D D D

GasOrificeKit-#48(NatGas) LH32DB076 D D D D D D D D

Gas Orifice Kit - #54 (LP) LH32DB203 D D D D D D D D

Gas Orifice Kit - #55 (LP) LH32DB201 D D D D D D D D

Gas Orifice Kit - #56 (LP) LH32DB206 D D D D D D D D

Gas Orifice Kit - 1.25mm (LP) LH32DB209 D D D D D D D D

Gas Orifice Kit - 1.30mm (LP) LH32DB210 D D D D D D D D

Control Accessories

Advanced Product Monitor - APM KGASD0301APM D D D D D D D D

Preferred™ Series Thermidistat T 6 --- P R H D D D D D D D D

Twinning Kit KGATW0801HSI D D D D

IAQ Accessories

Filter Pack (6 pack) --- Washable - 16x25x1

(406x635x25 mm)

Filter Pack (6 pack) --- Washable - 24x25x1

(610x635x25 mm)

EZ-Flex Filter - 16” (406 mm) EXPXXFIL0016 Use with EZXCAB---1016

EZ-Flex Filter - 20” (508 mm) EXPXXFIL0020 Use with EZXCAB---1020

EZ-Flex Filter - 24” (610 mm) EXPXXFIL0024 Use with EZXCAB---1024

EZ-Flex Filter with End Caps - 16” (406 mm) EXPXXUNV0016 Use with EZXCAB ---1016

EZ-Flex Filter with End Caps - 20” (508 mm) EXPXXUNV0020 Use with EZXCAB ---1020

EZ-Flex Filter with End Caps - 24” (610 mm) EXPXXUNV0024 Use with EZXCAB ---1024

Cartridge Media Filter - 16” (406 mm) FILXXCAR0016 Use with FILCABXL ---1016

Cartridge Media Filter - 20” (508 mm) FILXXCAR0020 Use with FILCABXL ---1020

Cartridge Media Filter - 24” (610 mm) FILXXCAR0024 Use with FILCABXL ---1024

Bryant Perfect Air Purifier - 16x25 (406x635 mm) GAPAAXBB1625-A08 Up to 1600 CFM

Bryant Perfect Air Purifier - 20x25 (508x635 mm) GAPAAXBB2025-A08 Up to 2000 CFM

Bryant Perfect Air Purifier Repl. Filter- 16x25

(406x635 mm)

Bryant Perfect Air Purifier Repl. Filter- 20x25

(508x635 mm)

Bryant Preferred Air Purifier - 16x25 (508x635 mm) PGAPXX1625 Up to 1600 C FM

Bryant Preferred Air Purifier - 20x25 (508x635 mm) PGAPXX2025 Up to 2000 C FM

Bryant Preferred Air Purifier Repl Filter - 16x25

(406x635 mm)

Bryant Preferred Air Purifier Repl. Filter - 20x25

(508x635 mm)

D = Used with the model furnace

DESCRIPTION PAR T NU M BER 30040 36040 36060 42060 48080 60080 60100 66120

See Venting Tables

KGAAD0101MEC 20”x25” IAQ Devices

KGAAD0201MEC 24”x25” IAQ Devices

KGAWF1306UFR D D D D D D D D

KGAWF1506UFR D D D D D D D D

GAPABBCAR1625-A05 Use with GAPAAXBB1625

GAPABBCAR2025-A05 Use with GAPAAXBB2025

PGAPAXXCAR1625 Use with PGAPXX1625

PGAPAXXCAR2025 Use with PGAPXX2025

926TA

5

AIR DELIVERY -- CFM

Unit Size

Cooling Switch Settings External Static Pre ssure (ESP)

SW2-8 SW2-7 SW2-6 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.030

30040

Clg Default: OFF OFF OFF 1125 1080 1020 970 905 855 805 755 700 635

OFF OFF ON 615 555 510 475 440 395 355 270 230 note 8

OFF ON OFF 785 740 695 665 630 590 565 520 485 450

OFF ON ON 990 950 910 875 850 815 770 720 670 615

(SW1-5 and SW2 --- 2 set to OFF, except as indicated. See notes 1 and 2)

926TA

Cooling (SW2)

ON OFF OFF 1125 1080 1020 970 905 855 805 755 700 635

ON OFF ON 1125 1080 1020 970 905 855 805 755 700 635

ON ON OFF 1125 1080 1020 970 905 855 805 755 700 635

ON ON ON 1125 1080 1020 970 905 855 805 755 700 635

Clg SW2: Maximum Clg Airflow

High Heat Airflow

Heating

(SW1)

Low Heat Airflow

2

3

3

1125 1080 1020 970 905 855 805 755 700 635

815 770 725 695 660 625 595 550 510 475

660 605 560 530 495 450 415 340 300 Note 7

36040

Clg Default: OFF OFF OFF 1250 1210 1165 1115 1065 1015 965 915 860 810

OFF OFF ON 575 540 490 435 385 Seenote4

OFF ON OFF 770 725 685 640 600 560 515 480 Seenote4

OFF ON ON 945 910 875 835 800 770 735 695 665 635

Cooling (SW2)

ON OFF OFF 1140 1105 1075 1040 1005 970 930 885 835 790

ON OFF ON 1250 1210 1165 1115 1065 1015 965 915 860 810

ON ON OFF 1250 1210 1165 1115 1065 1015 965 915 860 810

ON ON ON 1250 1210 1165 1115 1065 1015 965 915 860 810

Clg SW2: Maximum Clg Airflow

High Heat Airflow

Heating

(SW1)

Low Heat Airflow

2

3

3

1250 1210 1165 1115 1065 1015 965 915 860 810

860 825 785 745 705 670 630 595 565 525

650 595 545 500 460 415 365 320 275 note 7

36060

Clg Default: OFF OFF OFF 1250 1210 1165 1115 1065 1015 955 895 815 745

OFF OFF ON 605 565 510 455 420 Seenote4

OFF ON OFF 785 750 705 675 630 585 Seenote4

OFF ON ON 955 920 895 860 825 785 755 720 685 650

Cooling (SW2)

ON OFF OFF 1135 1110 1080 1055 1020 990 935 880 825 745

ON OFF ON 1250 1210 1165 1115 1065 1015 955 895 815 745

ON ON OFF 1250 1210 1165 1115 1065 1015 955 895 815 745

ON ON ON 1250 1210 1165 1115 1065 1015 955 895 815 745

Clg SW2: Maximum Clg Airflow

High Heat Airflow

Heating

(SW1)

Low Heat Airflow

2

3

3

1250 1210 1165 1115 1065 1015 955 895 815 745

1125 1100 1070 1045 1010 980 925 875 820 740

900 865 835 800 760 720 690 650 610 580

6

Loading...

Loading...