Page 1

installation, start-up and

service instructions

COMMERCIAL AIR-COOLED

CONDENSING UNITS

IMPORTANT —READ BEFORE INSTALLING

1. Read and become familiar with these installation

instructions before installing this unit (Fig. 1).

2. Be sure the installation conforms to all applicable local

and national codes.

3. These instructions containimportantinformation for the

proper maintenance and repair of this equipment. Retain these instructions for future use.

CONTENTS

Page

SAFETY CONSIDERATIONS ....................... 1

INSTALLATION .................................1-9

I. Locate the Unit ............................ 2

II. Rig and Place Unit ......................... 2

III. Compressor Mounting ...................... 2

IV. Unit Refrigerant Piping Connections .......... 2

V. Electrical Connections ...................... 6

VI. Accessory Installation ...................... 9

PRE-START-UP ..................................9

START-UP ..................................... 10

I. Start-Up and Adjustments .................. 10

CARE AND MAINTENANCE ...................... 10

SERVICE .....................................11-13

I. Cleaning ................................ 11

II. Lubrication .............................. 11

III. Condenser-Fan Adjustment ................ 11

IV. Capacity Control .......................... 12

V. Compressor Removal ..................... 12

VI. Crankcase Heater ......................... 12

VII. Refrigerant Charge ........................ 12

VIII. Refrigerant Service Ports ...................12

TROUBLESHOOTING GUIDE ....................14,15

SAFETY CONSIDERATIONS

WARNING:

ation, service, maintenance, or use can cause explosion, fire, electric shock, or other occurrences which may

injure you or damage your property. Consult a qualified installer or service agency for information or assistance. The qualified installer or agency must use only

factory-authorized kits or accessories when repairing this

product.

Recognize safety information. This is the safety-alert symbol. ( ) When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal injury.

Improper installation, adjustment, alter-

569C

576B

Cancels: II 569C-72-3 II 569C-72-4

5/1/99

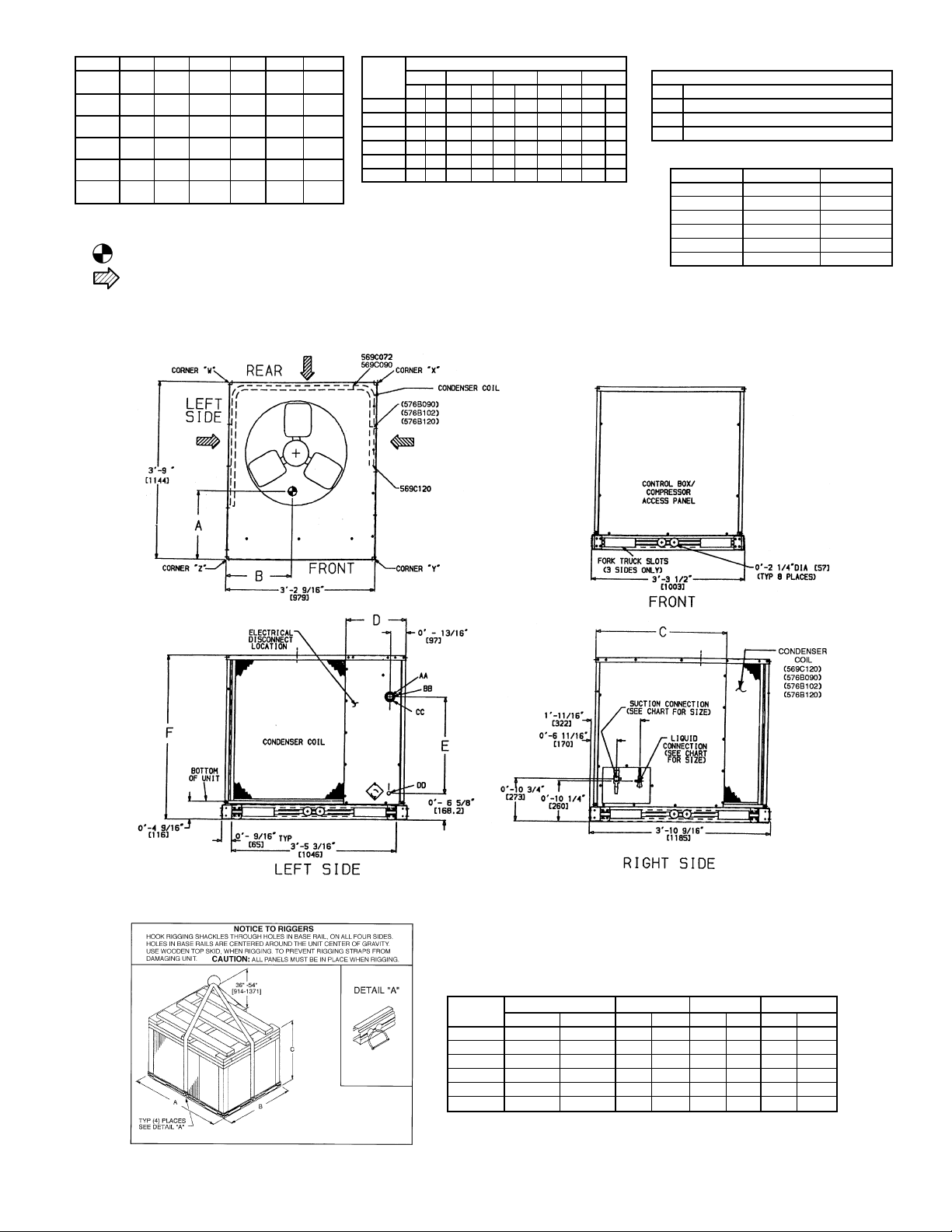

Fig.1—Typical Unit (569C072 Shown)

Understand the signal words — DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol. Danger identifies the most serious hazards which will

result in severe personal injury or death. Warning indicates

a condition that could result in personal injury. Caution is

used to identify unsafe practices which would result in minor

personal injury or product and property damage.

WARNING:

nance operations on unit, turn off main power switch

to unit. Electrical shock could cause personal injury.

1. The power supply (volts, hertz, and phase) must correspond to that specified on unit rating plate.

2. The electrical supply provided by the utility must be sufficient to handle load imposed by this unit.

3. Refer to the Locate the Unit section on page 2 and

Fig. 2 and 3 for locations of electrical inlets, required

clearances, and weight distribution based on recommended support points before setting unit in place.

4. This installation must conform with local building codes.

Refer to local plumbing or wastewater codes and other

applicable local codes.

NOTE: When installing any accessory item, see the manufacturer’s installation instructions packaged with the accessory. A qualified agency must use factory-authorized kits or

accessories when modifying this unit.

The 569C072,090, and 120 units use hermetic compressors.

The 576B090,102, and 120 units use semi-hermetic compressors. Refer to Tables 1A and 1B.

Before performing service or mainte-

INSTALLATION

Page 2

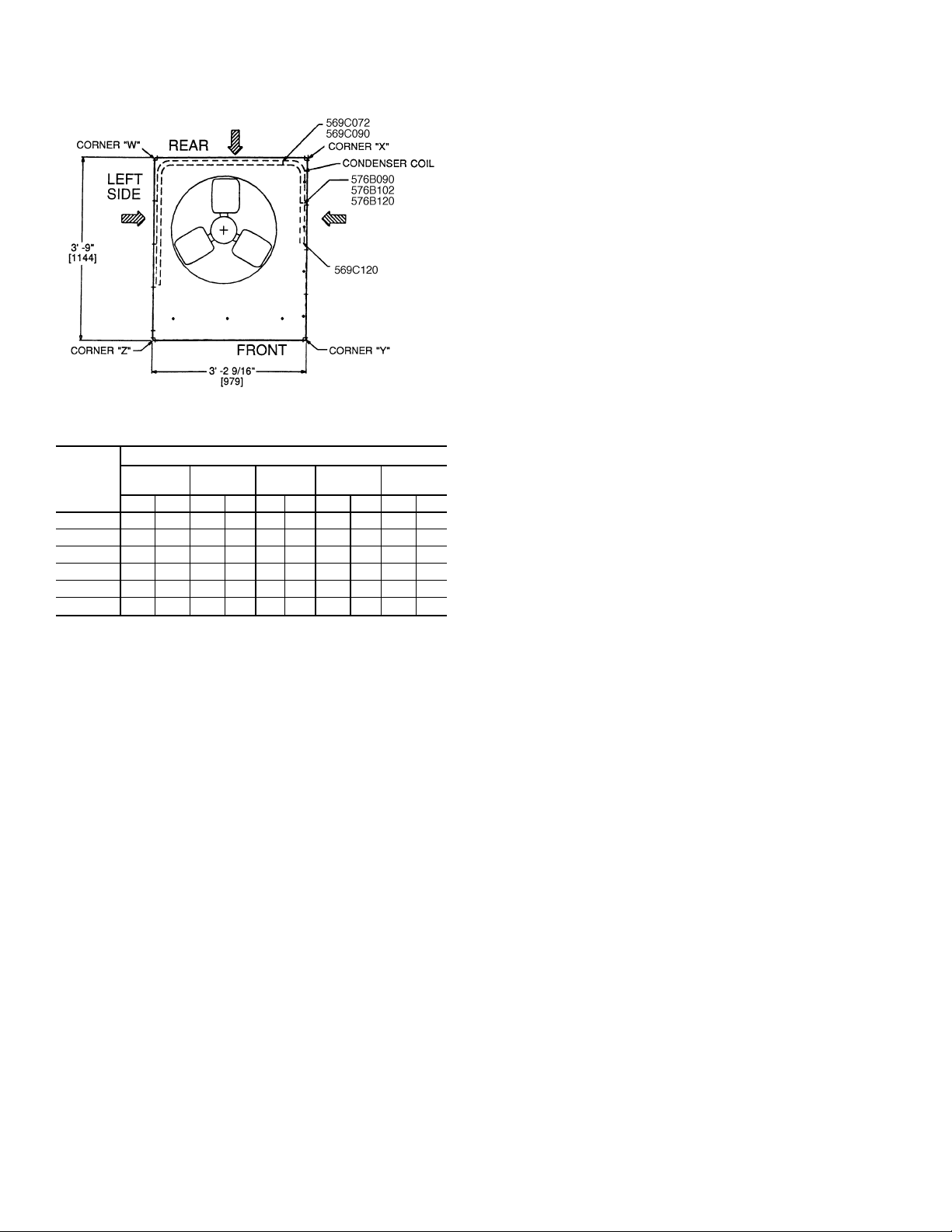

NOTE: If vibration isolators are required for a particular in-

stallation, use corner weight information in Fig. 2 to make

proper selection.

NOTES:

1. Dimensions in [ ] are in millimeters.

2. See Fig. 3 for additional information.

WEIGHT CHART*

UNIT

569C072 340 154 86 39 53 24 77 35 124 56

569C090 370 168 86 39 78 35 99 45 107 49

569C120 395 179 89 40 92 42 109 49 105 48

576B090 510 231 115 52 89 40 133 60 173 87

576B102 564 256 133 50 97 44 141 64 193 88

576B120 564 256 133 60 97 44 141 64 193 88

*Weights are for aluminum coils.

Std Unit

Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg

CornerWCornerXCornerYCorner

Z

Fig.2—Weight Distribution

I. LOCATE THE UNIT

A. Clearance

Maintain clearance around and above unit to provide minimum distance from combustible materials, proper airflow,and

service access. Refer to Fig. 2 and 3.

Minimum clearance (local codes or jurisdiction may prevail):

a. Bottom to combustible surfaces 0 inches.

b. Condenser coil, for proper airflow, 36 in. (914 mm) one side,

12 in. (305 mm) the other. The left or rear side receiving

the greater clearance is optional.

c. Overhead, 60 in. (1524 mm) to ensure proper condenser

fan operation.

d. Between units, control box side, 42 in. (1067 mm) per NEC

(National Electrical Code, U.S.A. Standard).

e. Between unit and ungrounded surfaces, control box side,

36 in. (914 mm) per NEC.

f. Between unit and block or concrete walls and other grounded

surfaces, control box side, 42 in. (1067 mm) per NEC.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

Slab-mounted units should be at least 4 in. (102 mm) above

the highest expected water level (flood and runoff). Do not

use the unit if it has been under water.

II. RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency. Keep unit upright and do not drop.

Spreader bars are not required if top crating is left on unit.

Rollers may be used to move unit across a roof. Level by using unit frame as a reference. See Tables 1A and 1B and Fig. 4

for additional information. Operating weight is shown in

Tables 1A and 1B.

These units are designed for overhead rigging only. Rig with

packaging assembly and wood bumper strips in place to prevent unit damage by rigging cable. As further protection for

coil faces, plywood sheets may be placed against sides of unit,

behind cables. Run cables to a central suspension point so

that angle from the horizontal is not less than 45 degrees.

Raise and set unit down carefully.

If it is necessary to roll unit into position,mount unit on longitudinal rails, using a minimum of 3 rollers. Apply force to

rails, not unit. If unit is to be skidded into position, place it

on a large pad and drag it by the pad. Do not apply any force

to unit.

Raise from above to lift unit from rails or pad when unit is in

final position.

Lifting holes are provided in base rails as shown in Fig. 4.

Refer to rigging instructions on unit.

IMPORTANT: If unit has forklift protection skids, be sure to

remove forklift protection skids from under unit before setting unit in place.

After unit is in position, remove shipping materials and rigging skids.

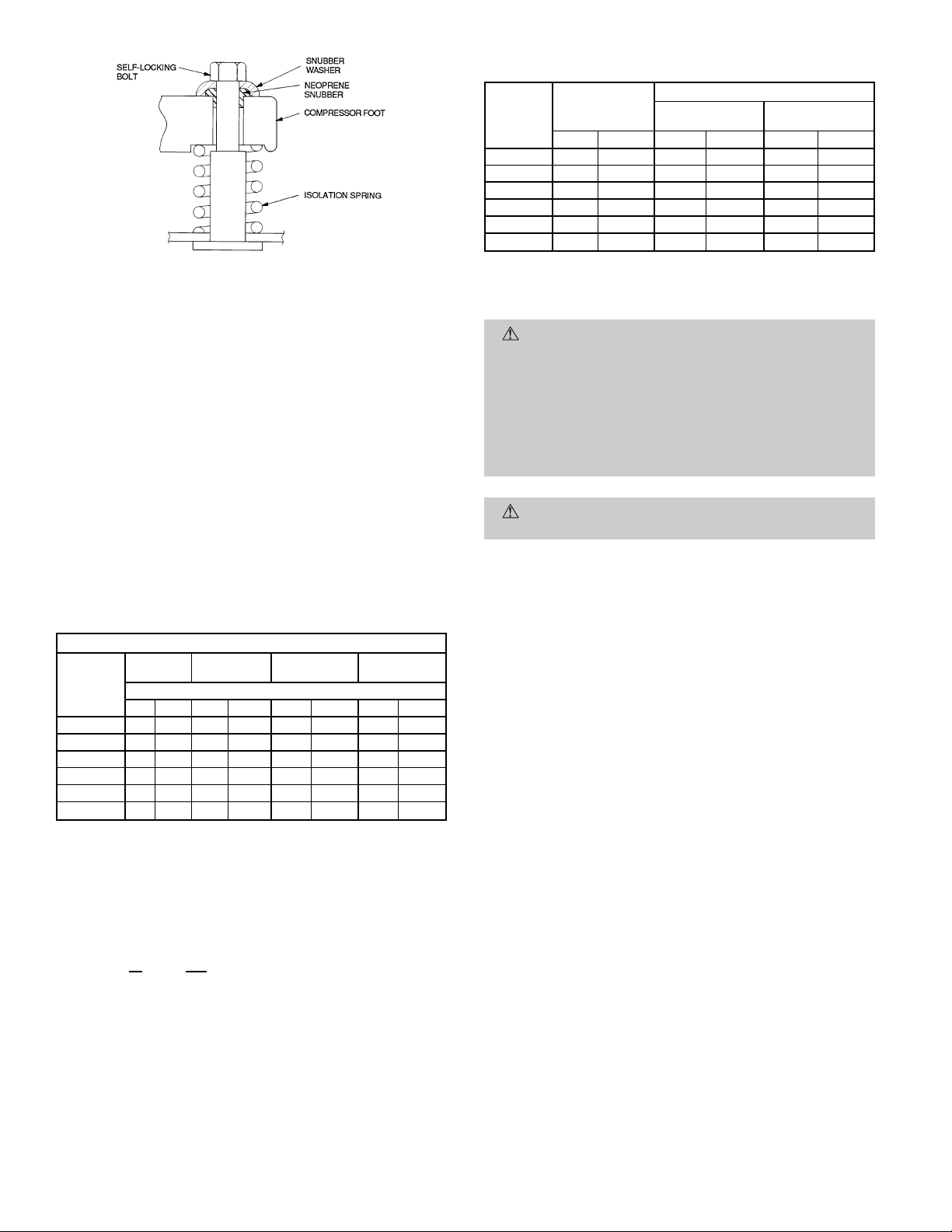

III. COMPRESSOR MOUNTING

Compressors are shipped from the factory held down by 4 bolts.

After unit is installed, loosen each bolt until the snubber washer

can be moved with finger pressure (376B units only). See Fig. 5.

IV. UNIT REFRIGERANT PIPING CONNECTIONS

Suction connection is sweat with plastic cap; liquid connection is sweat with plastic cap. Refer to Table 2 for refrigerant

piping sizes. Follow standard piping practices.

A. Size Refrigerant Lines

Consider length of piping required between condensing unit

and evaporator, amount of liquid lift, and compressor oil

return. See Table 3 for design details and line sizing. Refer

to evaporator installation instructions for additional

information.

—2—

Page 3

Table 1A — Specifications (English)

UNIT 569C072 569C090 569C120 576B090 576B102 576B120

NOMINAL CAPACITY (Tons) 67

OPERATING WEIGHT (lb)

Aluminum Coils (Standard) 340 370 395 510 564 564

Copper Coils (Optional) 386 438 472 578 632 632

RIGGING WEIGHT (lb)

Aluminum Coils (Standard) 390 420 445 560 614 614

Copper Coils (Optional) 436 488 522 628 682 682

1

⁄

2

10 71⁄

2

81⁄

2

10

REFRIGERANT* R-22

COMPRESSOR Bristol, Reciprocating Copeland, Scroll Copeland, Scroll Reciprocating, Semi-Hermetic

Quantity...Type 1...H26A72Q 1...ZR94KC 1...ZR125KC 1...06DA818 1...06DA824

Quantity Cylinders 2——4 6

Speed (Rpm) 3500 3500 3500 1750 1750

Oil Charge (oz) (ea) 65 85 110 88 128

CONDENSER FAN Propeller; Direct Drive

Quantity...Rpm 1...850 1...1100

Diameter (in.) 26 26

Motor Hp (NEMA)

Nominal Airflow (cfm) 3800 6500 7000 6500 6500 6500

CONDENSER COIL Enhanced Copper Tubes, Aluminum Lanced Fins

Face Area (sq ft) 12.24 15.75 20.5 18.0 18.0 18.0

Storage Capacity (lb)† 11.26 14.88 18.87 16.56 16.56 16.56

CONNECTIONS (sweat)

Suction (in.) 1

Liquid (in.)

CONTROLS

Pressurestat Settings (psig)

High Cutout 426 6 7

Cut-in 320 6 20

Low Cutout 7 6 3

Cut-in 22 6 5

LEGEND

NEMA — National Electrical ManufacturingAssociation

*Unit is factory supplied with holding charge only.

†Storage capacity of condenser coil with coil 80% full of liquid R-22 at

124 F.

1

⁄

3

1

⁄

8

1

⁄

2

11⁄

8

1

⁄

2

NOTE: Unit 576B120 has one step of unloading. Full load is 100% capacity, and one step of unloading is 67% capacity. Unit 576B120 has

the following unloader settings: load is 70 6 1 psig and unload is

60 6 2 psig.

11⁄

8

5

⁄

8

3

⁄

4

11⁄

8

1

⁄

2

11⁄

8

5

⁄

8

1...06DH824

(See Note)

11⁄

8

5

⁄

8

—3—

Page 4

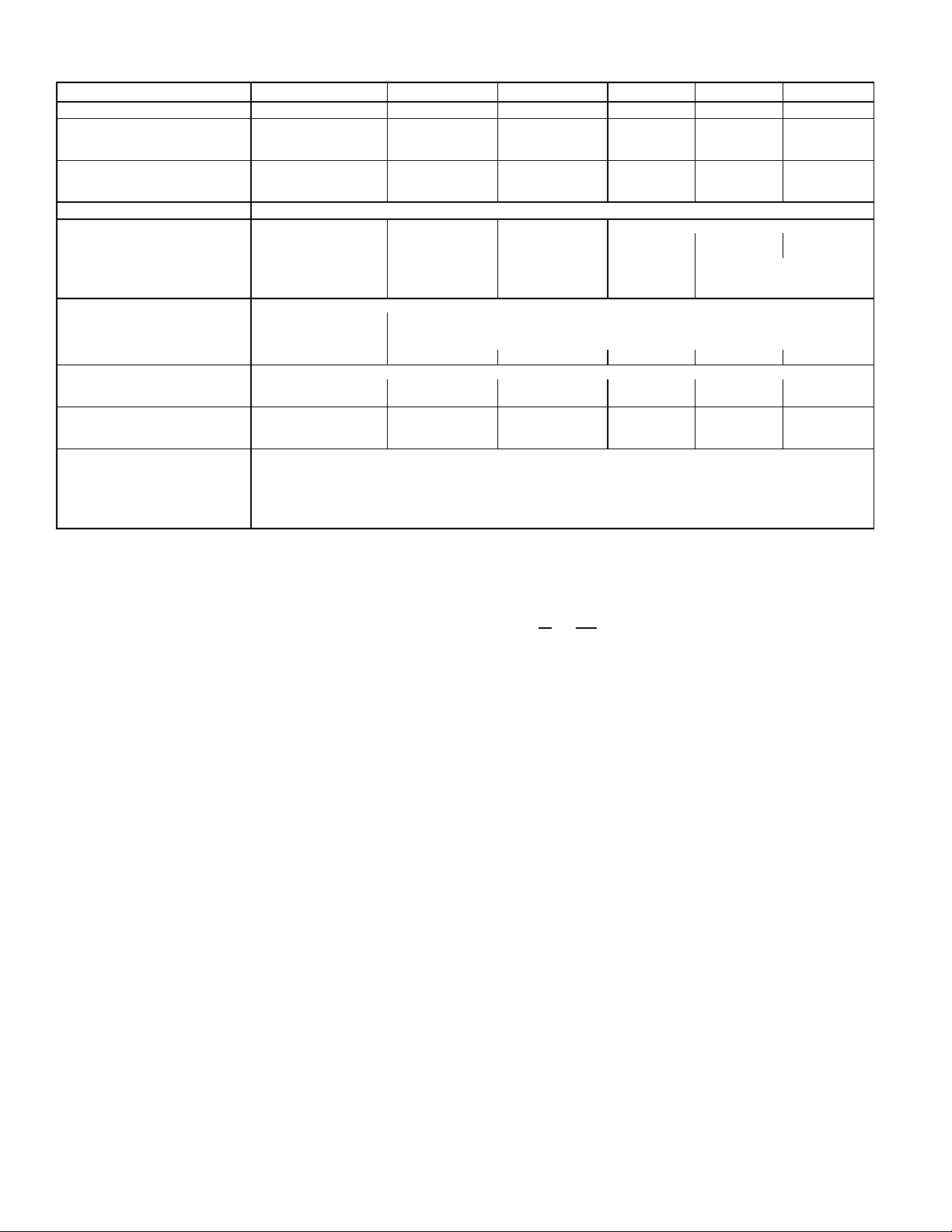

Table 1B — Specifications (SI)

UNIT 569C072 569C090 569C120 576B090 576B102 576B120

NOMINAL CAPACITY (kW) 21 26 35 26 29.9 35

OPERATING WEIGHT (kg)

Aluminum Coils (Standard) 154 168 179 231 256 256

Copper Coils (Optional) 175 199 214 262 287 287

RIGGING WEIGHT (kg)

Aluminum Coils (Standard) 176 191 202 254 279 279

Copper Coils (Optional) 198 221 237 285 309 309

REFRIGERANT* R-22

COMPRESSOR Bristol, Reciprocating Copeland, Scroll Copeland, Scroll Reciprocating, Semi-Hermetic

Quantity...Type 1...H26A72Q 1...ZR94KC 1...ZR125KC 1...06DA818 1...06DA824

Quantity Cylinders 2——4 6

Speed (R/s) 58.4 58.4 58.4 29.2 29.2

Oil Charge (L) (ea) 1.92 2.51 3.25 2.60 3.78

CONDENSER FAN Propeller; Direct Drive

Quantity...R/s 1...14.2 1...18.3

Diameter (mm) 660 660

Motor Hp (NEMA)

Nominal Airflow (L/s) 1800 3050 3300 3050 3050 3050

CONDENSER COIL Enhanced Copper Tubes, Aluminum Lanced Fins

Face Area (sq m) 1.14 1.46 1.90 1.67 1.67 1.67

Storage Capacity (kg)† 5.1 6.75 8.6 7.5 7.5 7.5

CONNECTIONS (sweat)

Suction (in.) 1

Liquid (in.)

CONTROLS

Pressurestat Settings (kPa)

High Cutout 2937 6 48

Cut-in 2206 6 138

Low Cutout 48 6 20

Cut-in 152 6 34

LEGEND

NEMA — National Electrical ManufacturingAssociation

*Unit is factory supplied with holding charge only.

†Storage capacity of condenser coil with coil 80% full of liquid R-22 at

51 C.

1

⁄

3

1

⁄

8

1

⁄

2

11⁄

8

1

⁄

2

NOTES:

1. Unit576B120 has one step of unloading. Full load is 100% capacity,

2. Equivalent mm values for connectors are as follows:

11⁄

8

5

⁄

8

and one step of unloading is 67% capacity. Unit 576B120 has the

following unloader settings: load is 483 6 6.9 kPa and unload is

414 6 13.8 kPa.

3

⁄

4

11⁄

8

1

⁄

2

11⁄

8

5

⁄

8

in. mm

1

⁄212.7

5

⁄815.9

11⁄828.6

1...06DH824

(See Note 1)

11⁄

8

5

⁄

8

—4—

Page 5

UNIT DIM. A DIM. B DIM. C DIM. D DIM. E DIM. F

569C072

569C090

569C120

576B090

576B102

576B120

NOTES:

1. Dimensions in [ ] are in millimeters.

1

⁄29 18-23⁄49 —18-21⁄49 18-45⁄169 28-95⁄

18-6

[470.0] [375.0] — [362] [415] [846.5]

18-89 18-6

[508.0] [470.0] — [381] [613] [1052.5]

18-99 18-89 28-09 18-39 28-

[533.4] [508.0] [609.6] [381] [613] [1052.5]

18-69 18-4

[457.2] [425.5] [858.8] [381] [613] [1052.5]

18-79 18-59 28-9

[482.6] [431.8] [858.8] [381] [613] [1052.5]

18-79 18-59 28-9

[482.6] [431.8] [858.8] [381] [613] [1052.5]

1

⁄29 —18-39 28-5⁄169 38-57⁄

5

⁄169 38-57⁄

3

⁄49 28-913⁄169 18-39 28-5⁄169 38-57⁄

13

⁄169 18-39 28-5⁄169 38-57⁄

13

⁄169 18-39 28-5⁄169 38-57⁄

16

9

16

9

16

9

16

9

16

9

16

9

2. Center of Gravity. See chart for dimensions.

3. Direction of Airflow.

4. Minimum clearance (local codes or jurisdiction may prevail):

a. Condenser coil, for proper airflow, 36 in. [914] one side, 12 in. [305]

the other.The left or rear side getting the greater clearance is optional.

b. Overhead, 60 in. [1524] to assure proper condenser fan operation.

UNIT

Std Unit Corner W Corner X Corner Y Corner Z

Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg

569C072 340 154 86 39 53 24 77 35 124 56

569C090 370 168 86 39 78 35 99 45 107 49

569C120 395 179 89 40 92 42 109 49 105 48

576B090 510 231 115 52 89 40 133 60 173 87

576B102 564 256 133 60 97 44 141 64 193 88

576B120 564 256 133 60 97 44 141 64 193 88

*Weights are for aluminum coils.

c. Between units, control box side, 42 in. [1067]

per NEC (National Electrical Code) (U.S.A.

Standard).

d. Between unit and ungrounded surfaces, con-

trol box side, 36 in. [914] per NEC.

e. Betweenunit and block or concrete walls and

other grounded surfaces, control box side,

42 in. [1067] per NEC.

5. With the exception of the clearance for the condenser coil as stated in note 4b, a removable

fence or barricade requires no clearance.

6. Unitsmay be installed on combustible floors made

from wood or Class A, B, or C roof covering

material.

WEIGHT CHART*

ELECTRICAL CONNECTIONS

CONNECTION SIZES

3

AA 1

⁄89 DIA [35] FIELD POWER SUPPLY HOLE

BB 29 DIA [51] POWER SUPPLY KNOCK-OUT

1

⁄29 DIA [64] POWER SUPPLY KNOCK-OUT

CC 2

7

⁄89 DIA [22] FIELD CONTROL WIRING HOLE

DD

SERVICE VALVE CONNECTIONS — 60 Hz

UNIT SUCTION LIQUID

569C072 1

569C090 1

569C120 1

576B090 1

576B102 1

576B120 1

1

⁄89 [28.6]

1

⁄89 [28.6]

1

⁄89 [28.6]

1

⁄89 [28.6]

1

⁄89 [28.6]

1

⁄89 [28.6]

1

⁄29 [12.7]

1

⁄29 [12.7]

5

⁄89 [15.9]

1

⁄29 [12.7]

5

⁄89 [15.9]

5

⁄89 [15.9]

Fig. 3 — Base Unit Dimensions

UNIT

569C072 390 176 45.0 1143 38.5 978 35.5 904

569C090 420 191 45.0 1143 38.5 978 43.5 1105

569C120 445 202 45.0 1143 38.5 978 43.5 1105

576B090 560 254 45.0 1143 38.5 978 43.5 1105

576B102 614 279 45.0 1143 38.5 978 43.5 1105

576B120 614 279 45.0 1143 38.5 978 43.5 1105

*Weights are for aluminum coils.

RIGGING WEIGHT* A B C

lb kg in. mm in. mm in. mm

Fig. 4 — Rigging Label

—5—

Page 6

Table 3 — Liquid Line Data

Fig.5—Typical Compressor Mounting (576B Units)

B. Filter Drier and Moisture Indicator

The filter drier is factory installed. Moisture indicator is a

field-installed accessory and should be installed just after liquid line shutoff valve. Do not use a receiver. A receiver is not

supplied with the unit and should not be used.

NOTE: Unit is shipped with R-22 holding charge. System pressure must be relieved before removing caps. Recover refrigerant prior to brazing.

Pass nitrogen or other inert gas through piping while brazing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve(s) in evaporator section. It is recommended that a field supplied liquid line solenoid be positioned in the main liquid line (near

the evaporator coil). It should be wired to close when compressor stops to minimize refrigerant migration during the

‘‘OFF’’ cycle.

Table 2 — Refrigerant Piping Sizes

LINEAR LENGTH OF PIPING — FT (M)

0-25

UNIT

(0-7.6)

LSLSLSLS

569C072

1

⁄211⁄

569C0901⁄211⁄

569C1205⁄811⁄

576B0901⁄211⁄

576B1025⁄811⁄

576B1205⁄811⁄

LEGEND

L—Liquid Line S—Suction Line

NOTES:

1. Pipe sizes are based on a 2° F (1° C) loss for liquid and suction

lines.

2. Pipe sizes are based on the maximum linear length shown for each

column, plus a 50% allowance for fittings.

3. Chargeunits with R-22 in accordance with unit installation instructions.

4. Line size conversion to mm is:

in. mm

1

⁄

2

5

⁄

8

1

1

⁄

8

13⁄

8

8

8

8

8

8

8

12.7

15.9

28.6

34.9

25-50

(7.6-15.2)

Line Size (in. OD)

1

⁄211⁄

⁄211⁄

⁄813⁄

⁄211⁄

⁄811⁄

⁄811⁄

8

8

8

8

8

8

1

5

1

5

5

50-75

(15.2-22.9)

1

⁄

2

11⁄

5

⁄

8

11⁄

5

⁄

8

13⁄

5

⁄

8

11⁄

5

⁄

8

13⁄

5

⁄

8

13⁄

8

8

8

8

8

8

75-100

(22.9-30.5)

1

⁄

2

11⁄

5

⁄

8

13⁄

5

⁄

8

13⁄

5

⁄

8

13⁄

5

⁄

8

13⁄

5

⁄

8

13⁄

8

8

8

8

8

8

LIQUID LINE

Max Allowable

Temp Loss

UNIT

MAX

ALLOWABLE

LIQUID LIFT

Max Allowable

Pressure Drop

Ft M psi kPa F C

569C072 86 26.2 7 48.3 2 1

569C090 60 18.3 7 48.3 2 1

569C120 70 21.3 7 48.3 2 1

576B090 60 18.3 7 48.3 2 1

576B102 65 19.8 7 48.3 2 1

576B120 65 19.8 7 48.3 2 1

NOTE: Values shown are for units operating at 45 F (7.2 C) saturated

suction and 95 F (35 C) entering air.

V. ELECTRICAL CONNECTIONS

WARNING:

The unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of personal injury if an electrical fault should

occur. This ground may consist of electrical wire connected to the unit ground lug in the control compartment or conduit approved for electrical ground when

installed in accordance with the NEC and local electrical codes. Failure to adhere to this warning could result in personal injury.

CAUTION:

Failure to follow these precautions could

result in damage to the unit being installed:

A. Field Power Supply (Fig. 6-8)

1. Make all electrical connections in accordance with NEC

ANSI/NFPA (American National Standards Institute/

National Fire ProtectionAssociation) 70, latest edition,

and local electrical codes governing such wiring. Refer

to unit wiring diagram.

2. Use only copper or copper-clad conductor fan connections between field-supplied electrical disconnect switch

and unit. DO NOT USE ALUMINUM WIRE. Maximum

wire size is no. 2 AWG (American Wire Gage).

3. Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Table 4). On 3-phase units, voltages between phases

must be balanced within 2% and the current within 10%.

Use the formula shown inTable 4, Note 2, to determine

the percent voltage imbalance. Operation on improper

line voltage or excessive phase imbalance constitutes abuse

and may cause damage to electrical components. Such

operation would invalidate any applicable warranty.

4. Insulate low-voltage wires for highest voltage contained within conduit when low-voltage control wires are

run in same conduit as high-voltage wires.

5. Donot damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

—6—

Page 7

All units except 208/230-v units are factory wired for the voltage shown on the nameplate. If the 208/230-v unit is to be

connected to a 208-v power supply, the transformer must be

rewired by moving the black wire from the 230-v orange wire

on the transformer and connecting it to the 200-v red wire

from the transformer. The end of the orange wire must then

be insulated.

Refer to unit label diagram for additional information. Pigtails are provided for field wire connections. Use factorysupplied splices or UL (Underwriters’Laboratories) approved

copper/aluminum connector.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local

requirements.

Install field wiring as follows:

1. Install conduit through side panel openings.

2. Install power lines to terminal connections as shown in

Fig. 6.

B. Control Voltage Connections

Install an accessory thermostat assembly according to installation instructions included with the accessory. Locate thermostat assembly on a solid wall in the conditioned space to

sense average temperature in accordance with thermostat

installation instructions.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 7) as described in Steps 1 through 4

below.

NOTE: Refer to Table 5 for wire conversion information.

NOTE: For wire runs up to 50 ft (15.2 m), use no. 18 AWG

(0.82 mm) insulated wire (35 C minimum). For 50 to 75 ft

(15.2 to 22.9 m), use no. 16 AWG (1.30 mm) insulated wire

(35 C minimum). For over 75 ft (22.9 m), use no. 14 AWG

(2.08 mm) insulated wire (35 C minimum). All wire larger

than no. 18 AWG (0.82 mm) cannot be directly connected to

the thermostat and will require a junction box and splice at

the thermostat.

1. Connect thermostat wires to screw terminals of low voltage connection board.

2. Pass the control wires through the hole provided in the

corner post. See Fig. 8.

3. Feed wire through raceway built into the corner post

and into the 24-v thermostat connection board. The 24-v

thermostat connection is located on the left side of the

low voltage connection compartment. The raceway provides the UL required clearance between the high- and

low-voltage wiring.

4. Total combined amperage draw of the field-installed liquid line solenoid valve and indoor fan contactor must

not exceed 22 va. If the specified va must be exceeded,

use a remote relay to switch the load.

LEGEND

C—Contactor

NEC — National Electrical Code (U.S.A. Standard)

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Fig. 6 — Power Wiring Connections

AHA — Adjustable Heat Anticipator

C—Contactor, Compressor

CB — Circuit Breaker

CC — Cooling Compensator

CLO — Compressor Lockout

HPS — High-Pressure Switch

IFC — Indoor (Evaporator) Fan Contactor

Fig.7—Typical Control Wiring Connections (569C Shown)

LEGEND

LLSV — Liquid Line Solenoid Valve

LPS — Low-Pressure Switch

TB — Terminal Block

TC — Thermostat-Cooling

TDR — Time-Delay Relay

TH — Thermostat-Heating

TRAN — Transformer

Terminal (Marked)

Splice

Factory Wiring

Field Control Wiring

To Indicate Common Potential Only,

Not To Represent Wiring

—7—

Page 8

Table 4 — Electrical Data

UNIT

569C072

569C090

569C120

576B090

576B102

576B120

CSA — Canadian Standards Association

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code (U.S.A. Standard)

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

UL — Underwriters’ Laboratories

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%.

voltage imbalance.

= 100 x

NOMINAL VOLTAGE

(V-Ph-Hz)

208/230-3-60 187 254 21.8 142 1.9 25.6 35

460-3-60 414 508 9.6 72 1.0 12.9 15

575-3-60 518 632 7.6 58 1.9 11.4 15

220-3-50 198 242 19.0 142 1.0 25.6 35

400-3-50 360 440 9.5 72 1.0 12.9 15

208/230-3-60 187 254 28.8 195 3.8 39.8 45

460-3-60 414 508 14.7 95 1.9 20.3 20

575-3-60 518 632 10.8 80 1.9 15.4 15

220-3-50 198 242 28.8 195 1.5 37.5 45

400-3-50 360 440 14.7 90 1.5 19.9 20

208/230-3-60 187 254 37.8 239 3.1 46.2 60

460-3-60 414 508 17.2 125 1.4 22.7 30

575-3-60 518 632 12.3 80 1.4 19.3 25

220-3-50 198 242 37.8 239 1.4 46.2 60

400-3-50 360 440 17.2 114 1.4 22.7 30

208/230-3-60 187 254 31.5 160 3.1 42.5 50

380-3-60 342 418 19.0 75 2.2 26.0 35

460-3-60 414 508 15.7 80 1.4 21.0 25

575-3-60 518 632 12.6 64 1.4 17.2 20

220-3-50 198 253 31.5 160 1.4 42.5 50

400-3-50 342 460 15.7 80 1.4 21.0 25

208/230-3-60 187 254 39.7 198 3.1 52.7 70

380-3-60 342 418 24.0 93 2.2 32.2 40

460-3-60 414 508 19.9 99 1.4 26.3 35

575-3-60 518 632 15.9 79 1.4 21.3 25

220-3-50 198 253 39.7 198 1.4 52.7 70

400-3-50 342 460 19.9 99 1.4 26.3 35

208/230-3-60 187 254 39.7 198 3.1 52.7 70

380-3-60 342 418 24.0 93 2.2 32.2 40

460-3-60 414 508 19.9 99 1.4 26.3 35

575-3-60 518 632 15.9 79 1.4 21.3 25

220-3-50 198 253 39.7 198 1.4 52.7 70

400-3-50 342 460 19.9 99 1.4 26.3 35

LEGEND

Use the following formula to determine the percent

max voltage deviation from average voltage

average voltage

VOLTAGE RANGE COMPRESSOR OFM POWER SUPPLY

Min Max RLA LRA FLA MCA MOCP

Example: Supply voltage is 460-3-60.

(AB) 457 - 452=5v

(BC) 464 - 457=7v

(AC) 457 - 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%,

contact your local electric utility company immediately.

3. The 575-v units are CSA only.

4. The 380-v units are

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

= 1.53%

457

not

UL or CSA listed.

452 + 464 + 455

3

1371

=

3

= 457

—8—

Page 9

PRE-START-UP

Fig. 8 — Field Control Wiring Raceway

(576B Unit Shown)

Table 5 — American/European Wire Conversions

AMERICAN EUROPEAN

Industry

Standard Size

18 AWG 0.82 1.0

16 AWG 1.30 1.5

14 AWG 2.08 2.5

12 AWG 3.30 4.0

10 AWG 5.25 6.0

8AWG 6.36 10.0

6AWG 13.29 16.0

4AWG 21.14 25.0

3AWG 26.65 —

2AWG 33.61 35.0

1AWG 42.39 50.0

1/0 AWG 53.49 —

2/0 AWG 67.42 70.0

3/0 AWG 85.00 95.0

4/0 AWG 107.19 120.0

250 kcmil 126.64 150.0

300 kcmil 151.97 —

350 kcmil 177.90 185.0

400 kcmil 202.63 240.0

500 kcmil 253.29 300.0

600 kcmil 303.95 —

LEGEND

AWG — American Wire Gage

kcmil — Thousand Circular Mils

American

Conversion

2

(mm

)

Industry

Standard

Size (mm2)

VI. ACCESSORY INSTALLATION

At this time any required accessories should be installed on

the unit. Refer to Table 6 for available accessories. Control

wiring information is provided in the unit wiring book.

Table 6 — Accessory List

ACCESSORY

Gage Panel

Winter-Start Relay Package

Weatherprobe™ II Low Ambient Kit

Hail Guard Package (072)

Hail Guard Package (090,102,120)

Thermostats

Subbase

WARNING:

Failure to observe the following warn-

ings could result in serious personal injury:

1. Follow recognized safety practices and wear protective goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is

in place and secured.

3. Do not remove compressor terminal cover until all

electrical sources have been disconnected.

4. If refrigerant leak is suspected around compressor terminals, recover refrigerant whenever possible and relieve all pressure from system before

touching or disturbing anything inside terminal box.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System contains oil and refrigerant under pressure.

To remove a component, wear protective goggles

and proceed as follows:

a. Shut off electrical power to unit.

b. Recover refrigerant. Relieve all pressure from

system.

c. Cut component-connecting tubing with tubing

cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Proceed as follows to inspect and prepare the unit for initial

start-up:

1. Field electrical power source must agree with unit nameplate rating.

2. Check voltage imbalance as shown in Table 4, Note 2.

3. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

4. Ensure all service valves are open. On 576B units, be

sure all compressor service valves are backseated.

5. Verify thatcompressor holddown boltshave been loosened and that flat/snubber washers can be rotated by

applying finger pressure (snug, but not tight).

6. On 569C and 576Bunits, verify compressor crankcase

heater is securely in place.Crankcase heater must operate for a least 24 hours before start-up.

7. Note that compressor oil level is visible in the sight

glass (576B units only).

8. Check for leaks in refrigerant system by using soap

bubbles and/or electronic leak detector.

9. Check that liquid line solenoid valve is located at evaporator coil as shown in Filter Drier and Moisture Indicator section, page 6.

10. Check that both outdoor and indoor units are properly

mounted in accordance with installation instructions

and applicable codes.

—9—

Page 10

START-UP

I. START-UP AND ADJUSTMENTS

CAUTION:

in the Pre-Start-Up section before starting the unit.

Do not jumper any safety devices when operating the

unit.

Do not operate the compressor when the outdoor tem-

perature is below 25 F (24 C) (unless accessory low ambient kit is installed).

A. Checking Cooling Control Operation

Start and check the unit for proper cooling control operation

as follows:

1. Place room thermostat SYSTEM switch in OFF position. Observe that blower motor starts when FAN switch

is placed in ON position and shuts down when FANswitch

is placed in AUTO. position.

2. Place SYSTEM switch in COOL position and FAN switch

in AUTO. position. Set cooling control below room temperature. Observe that compressor and condenser- and

evaporator-fan motors start. Observe that cooling cycle

shuts down when control setting is satisfied.

B. Unit Controls

All units have the following internal-protection controls:

Compressor Overload

This overload interrupts power to the compressor when

either the current or internal motor winding temperature become excessive, and automatically resets when the internal

temperature drops to a safe level. This overload may require

up to 60 minutes (or longer) to reset. If the internal overload

is suspected of being open, disconnect the electrical power to

the unit and check the circuit through the overload with an

ohmmeter or continuity tester.

Time Guardt II Device

The unit is equipped with accessory Time Guard II recycle

timer. The device will cause a 5-minute delay between compressor starts.

Cycle-LOC™ Device

When high-pressure or low-pressure fault occurs, the Cycle-

LOC device will protect the system by not allowing the compressor to start.

Low-Pressure/Loss of Charge Switch (LPS)

When the liquid line pressure drops below 7 psig (48 kPa),

the LPS opens 24-v power to the compressor contactor and

stops the compressor. When the pressure reaches 22 psig

(152 kPa), the switch resets and the compressor is allowed to

restart.

High-Pressure Switch (HPS)

When the refrigerant high-side pressure reaches 426 psig

(2937 kPa), the HPS opens 24-v power to the compressor contactor and stops the compressor. When the pressure drops to

320 psig (2206 kPa), the switch resets and the compressor is

allowed to restart.

C. Sequence of Operation

At start-up, the thermostat calls for cooling. When all safety

devices are satisfied, the compressor contactor (fan contactor) will energize causing the compressor and outdoor (condenser) fan motor to operate.Terminal 9G9 at thethermostat

is also energized, allowing the field-supplied and -installed

(24v) indoor (evaporator) fan contactor to function. A fieldsupplied and -installed liquid line valve (connected between

Complete the required procedures given

Terminals G and C) will also open, allowing the system to

function in cooling. As cooling demand is satisfied, the thermostat contacts break, deenergizing the contactor causing the

system to shut off. The liquid line solenoid (LLS) valve closes,

minimizing the potential for refrigerant migration at this time.

The compressor does not restart until the thermostat again

calls for cooling. If a demandfor cooling occurs within 5minutes after the thermostat is satisfied, the system will not restart due to the feature of Time Guard II device. After the

5-minute time period, the system will restart as normal upon

thermostat demand.

The system is protected with a Cycle-LOC device so that the

compressor will not start if a high-pressure or low-pressure

fault occurs. To reset the Cycle-LOC device, set the thermostat to eliminate the cooling demand then return to the original set point. This should be done only once, and if system

shuts down due to the same fault, determine the problem before attempting to reset the Cycle-LOC device.

The crankcase heaters must be energized for a minimum of

24 hours before starting a 569C and 576B unit.

D. Oil Charge

576B Units

Allow unit to run for about 20 minutes. Stop unit and check

compressor oil level.Add oil only if necessary to bring oil into

view in sight glass. Use only approved compressor oil.

Approved oils are:

Suniso 3GS

WF32-150

If oil is added, run unit for an additional 10 minutes. Stop

unit and check oil level. If level is still low, add oil only after

determining that piping system is designed for proper oil return and that system is not leaking oil.

569C Units

The 569C units do not have a sight glass and are factory charged

with the correct amount of oil.

All Units

Do not reuse drained oil or use any oil that has been exposed

to the atmosphere. Procedures for adding or removing oil are

given in the Standard Service Techniques Manual, Chapter 1,

Refrigerants.

CARE AND MAINTENANCE

To ensure continuing high performance and to minimize the

possibility of premature equipment failure, periodic maintenance must be performed on this equipment. This cooling unit

should be inspected at least once each year by a qualified service person.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING:

nance on this equipment requires certain expertise,

mechanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance on this equipment other than those procedures

recommended in the User’sManual. FAILURE TO HEED

THIS WARNING COULD RESULT IN SERIOUS PERSONAL INJURYAND POSSIBLEDAMAGE TO THIS

EQUIPMENT.

The ability to properly perform mainte-

—10—

Page 11

SERVICE

WARNING:

When servicing unit, shut off all electrical power to unit to avoid shock hazard or injury from

rotating parts.

I. CLEANING

Inspect unit interior at the beginning of each cooling season

and as operating conditions require.

A. Condenser Coil

Inspect coil monthly. Clean condenser coil annually, and as

required by location and outdoor-air conditions.

Clean coil as follows:

1. Turn off unit power.

2. Remove and save top panel screws on condensing unit.

3. Remove condenser coil corner post. See Fig. 9. To hold

top panel open, place coil corner postbetween top panel

and side panel. See Fig. 10.

4. Remove bracket holding coil sectionstogether at return

end of condenser coil. Carefully separate the outer coil

section 3 to 4 in.(75 to 100 mm) from the inner coil section. See Fig. 11.

5. Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and

debris. Clean the outer surfaces with a stiff brush in the

normal manner.

6. Reposition the outer coil section, attach the bracket removed in Step 4, and remove the coil corner post from

between the top panel and side panel. Secure the sections together. Install the coil corner post and replace

all screws (removed in Step 2).

Fig. 10 — Propping Up Top Panel

II. LUBRICATION

A. Compressors

Each compressor is charged withthe correct amount of oil at

the factory. Refer to the Oil Charge section on page 10 for additional information.

B. Fan Motor Bearings

Fan motor bearings are of the permanently-lubricated type.

No further lubrication is required.

Fig. 9 — Cleaning Condenser Coil

Fig. 11 — Separating Coil Sections

III. CONDENSER-FAN ADJUSTMENT (Fig. 12)

1. Shut off unit power supply.

2. Removecondenser-fan assembly (grille, motor,motor cover,

and fan).

3. Loosen fan hub setscrews.

4. Adjust fan height as shown in Fig. 12.

5. Tighten set screws.

6. Replace condenser-fan assembly.

NOTE: Fan height adjustments are as follows:

UNIT in. mm

569C072 4.50 114

All Units

(except 569C072)

6.42 163

Fig. 12 — Outdoor (Condenser) Fan Adjustment

—11—

Page 12

IV. CAPACITY CONTROL (576B120 Only)

Asuction pressure-actuated unloader controls 2 cylinders and

provides capacity control. Unloaders are factory set (see

Table 1A or 1B), but may be field adjusted:

A. Control Set Point

The control set point (cylinder load point) is adjustable from

0 to 85 psig (586 kPa). To adjust, turn control set point adjustment nut (Fig. 13) clockwise to its bottom stop. In this

position, set point is 85 psig (586 kPa). Then, turn adjustment counterclockwise to desired control set point. Every full

turn counterclockwise decreases set point by 7.5 psig (51.7 kPa).

B. Pressure Differential

The pressure differential (difference between cylinder load and

unload points) is adjustable from 6 to 22 psig (41.4 to 152 kPa).

To adjust, turn pressure differential adjustment screw (Fig. 13)

counterclockwise to its back stop position. In this position,

differential is 6 psig (41.4 kPa). Then, turn adjustment screw

clockwise to desired pressure differential. Every full turn clockwise increases differential by 1.5 psig (10.3 kPa).

Fig. 13 — Compressor Capacity Control Unloader

V. COMPRESSOR REMOVAL

See Tables 1A and 1B for compressor information.

Follow safety codes and wear safety glasses and work gloves.

1. Shut off power to unit. Remove unit access panel (front

of unit).

2. Remove refrigerant from system using refrigerant removal methods described in GTACII, Module 5, Charging, Recovery, Recycling, and Reclamation.

3. Disconnect compressor wiring at compressor terminal

box.

4. Remove bolts from suction flange and discharge service valve (576B Units).

CAUTION:

compressor may cause higher levels of vibration when

unit is restored to service.

5. Remove crankcase heater from compressor base (576B

units only).

6. Remove compressor holddown bolts.

7. Remove compressor from unit.

Excessive movement of copper lines at

8. Clean system. Add new liquid line filter drier.

9. Install new compressor in unit.

10. Connect suction and discharge lines to compressor.Ensure that compressor holddown bolts are in place.

11. Connect wiring.

12. Install crankcase heater.

13. Evacuate and recharge unit, per Step VII.

14. Restore unit power.

VI. CRANKCASE HEATER (Except 569C072)

The crankcase heater prevents refrigerant migration and compressor oil dilution during shutdownwhen compressor is not

operating.

Close both compressor service valves if applicable when crankcase heater is deenergized for more than 6 hours.

VII. REFRIGERANT CHARGE

Unit panels must be in place when unit is operating during

charging procedure. Unit is shipped with a holding charge

only. Weighin 7 lbs (3 kg) of R-22 to start unit. Refer to GTACII,

Module 5, Charging, Recovery, Recycling, and Reclamation

for additional information.

See Troubleshooting Guide on page 14 for additional

information.

A. Low Charge Cooling

Using Cooling Charging Charts, Fig. 14 and 15, vary refrigerant until the conditions of the appropriate chart are met.

Note the charging charts are different from type normally used.

The charts are based on charging the units to the correct subcooling for the various operating conditions. Accurate pressure gage and temperature sensing device are required. Connect the pressure gage to the service port on the liquid line

service valve. Mount the temperature sensing device on the

liquid line, close the liquid line service valve, and insulate it

so that outdoor ambient temperature does not affect the reading. Indoor-air cfm must be within the normal operating range

of the unit.

Operate unit a minimum of 15 minutes. Ensure that temperature and pressure have stabilized. Plot liquid pressure

and temperature on chart and add or reduce charge as required. Do not vent refrigerant to the atmosphere. Recover

any excess charge. Operate the unit until the system stabilizes.Adjust charge to conform with charging chart, using liquid pressure and temperature to read chart.

B. Refrigerant Leaks

Proceed as follows to repair a refrigerant leak and to charge

the unit:

1. Locate the leak and ensure that refrigerant system pres-

sure has been relieved.

2. Repair leak following accepted practices.

NOTE: Install a new filter drier in the liquid line whenever

the system has been opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system

and leak-test unit.

4. Evacuate refrigerant system if additional leaks are not

found.

5. Charge unit with R-22 refrigerant.

NOTE: Do not vent refrigerant to the atmosphere. Recover

any excess charge.

VIII. REFRIGERANT SERVICE PORTS

Each unit has 3service ports: one on the suction line, one on

the liquid line, and one on the compressor discharge line. Be

sure caps on the ports are tight.

—12—

Page 13

Fig. 14 — Cooling Charging Chart — 569C072

Fig. 15 — Cooling Charging Chart — 569C090,120

and 576B090,102,120

—13—

Page 14

SYMPTOM CAUSE REMEDY

Compressor does not run —

Contactor open

Power off. Restore power.

Fuses blown. Replace with correct fuses after finding cause

Transformer open/shorted. Replace transformer if primary windings are

Thermostat circuit open. Check thermostat setting.

Low-pressure switch open. Check for refrigerant undercharge or system

High-pressure switch open. Check for refrigerant over charge or

Connections loose. Tighten all connections.

Compressor motor thermostat open. Check for excessive motor temperature.

Compressor does not run —

Contactor closed

Compressor leads loose, broken. Check connections with power off.

Single phasing. Replace blown fuse.

Compressor internal overload open. Allow compressor motor windings to cool down to reset

Compressor cycles on highpressure switch —

Condenser fan on

High-pressure switch faulty. Replace switch.

Airflow restricted. Dirty coil. Remove obstruction, clean condenser coil.

Air recirculating. Clear airflow area.

Noncondensables in system. Recover, evacuate and recharge as required. Refer to

Refrigerant overcharge. Recover as required.

Refrigerant system restrictions. Check or replace filter drier, expansion

Compressor cycles on highpressure switch —

Condenser fan off

Fan slips on shaft. Tighten fan hub screws.

Motor not running. Check power and capacitor

Motor bearings seized. Replace motor.

Motor overload open. Check overload rating. Check for

Motor burned out, windings open. Replace motor.

Compressor cycles on lowpressure switch —

Evaporator fan running

Filter drier plugged. Replace filter drier.

Expansion valve power head

defective.

Low refrigerant charge. Find leak, repair, evacuate system, and recharge.

Expansion valve restricted/plugged. Remove and replace expansion valve.

Airflow restricted —

Low suction pressure

Evaporator coil iced up. Check refrigerant charge.

Evaporator coil dirty. Clean coil fins.

Indoor-air filter dirty. Clean or replace filters.

Indoor-air dampers closed. Check damper operation and position.

Indoor (evaporator) fan stopped —

Low suction pressure

Electrical connections loose. Tighten all connections.

Fan relay defective. Replace relay.

Motor overload open. Check power supply.

Motor defective. Replace motor.

Fan belt broken or slipping. Replace or tighten belt.

Compressor runs but

cooling insufficient —

Suction pressure low

Refrigerant charge low. Add charge.

Head pressure low. Check refrigerant charge.

Indoor-air filters dirty. Clean or replace filters.

Expansion valve power head

defective.

Expansion valve restricted/plugged. Remove and replace expansion valve.

Evaporator coil partially iced. Check low-pressure setting.

Evaporator airflow restricted. Remove obstruction.

Compressor runs but

cooling insufficient —

Suction pressure high

Heat load excessive. Check for open doors or windows.

NOTE: See Fig. 16 and 17 for component arrangements.

TROUBLESHOOTING GUIDE

and correcting.

receiving power and no output.

leak.

obstruction of outdoor airflow.

overload. Determine cause for overload opening.

Carrier GTAC-II, Module 5, Charging, Recovery,

Recycling, and Reclamation.

valve, etc.

fan blade obstruction.

Replace power head.

Replace power head.

1

⁄3and3⁄4hp motor.

—14—

Page 15

LEGEND FOR FIG. 16 AND 17

C—Contactor, Compressor

CAP — Capacitor

CB — Circuit Breaker

CH — Crankcase Heater

CLO — Compressor Lockout

COMP — Compressor Motor

COTP — Compressor Temperature Protection

EQUIP — Equipment

GND — Ground

HPS — High-Pressure Switch

LPS — Low-Pressure Switch

NEC — National Electrical Code

OFC — Outdoor (Condenser) Fan Contactor

OFM — Outdoor (Condenser) Fan Motor

OL — Overload Relay

QT — Quadruple Terminal

TB — Terminal Block

TDR — Time-Delay Relay

TRAN — Transformer

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Factory Wiring

Field Power Wiring

Fig. 16 — Typical 569C Wiring Schematic and Component Arrangement

Fig. 17 — Typical 576B Wiring Schematic and Component Arrangement

—15—

Page 16

Page 17

Page 18

Copyright 1999 Bryant Heating & Cooling Systems CATALOG NO. 5356-902

Page 19

START-UP CHECKLIST

I. PRELIMINARY INFORMATION

OUTDOOR: MODEL NO. SERIAL NO.

INDOOR: AIR HANDLER MANUFACTURER

MODEL NO. SERIAL NO.

ADDITIONAL ACCESSORIES

II. PRE-START-UP

OUTDOOR UNIT

IS THERE ANY SHIPPING DAMAGE?

IF SO, WHERE:

WILL THIS DAMAGE PREVENT UNIT START-UP? (Y/N)

CHECK POWER SUPPLY. DOES IT AGREE WITH UNIT? (Y/N)

HAS THE GROUND WIRE BEEN CONNECTED? (Y/N)

HAS THE CIRCUIT PROTECTION BEEN SIZED AND INSTALLED PROPERLY? (Y/N)

ARE THE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? (Y/N)

HAVE COMPRESSOR HOLDDOWN BOLTS BEEN LOOSENED (Snubber washers are snug, but not tight)?

(Y/N)

(Y/N)

CONTROLS

ARE THERMOSTAT AND INDOOR-FAN CONTROL WIRING

CONNECTIONS MADE AND CHECKED? (Y/N)

ARE ALL WIRING TERMINALS (including main power supply) TIGHT? (Y/N)

HAS CRANKCASE HEATER BEEN ENERGIZED FOR 24 HOURS? (Y/N)

INDOOR UNIT

HAS WATER BEEN PLACED IN DRAIN PAN TO CONFIRM PROPER DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

HAS CORRECT FAN ROTATION BEEN CONFIRMED? (Y/N)

PIPING

IS LIQUID LINE SOLENOID VALVE LOCATED AT THE EVAPORATOR COIL AS REQUIRED? (Y/N)

HAVE LEAK CHECKS BEEN MADE AT COMPRESSOR, CONDENSER, EVAPORATOR,

TXVs (Thermostatic Expansion Valves), SOLENOID VALVES, FILTER DRIERS, AND FUSIBLE PLUGS

WITH A LEAK DETECTOR? (Y/N)

LOCATE, REPAIR,AND REPORTANY LEAKS.

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

ARE ALL 576B COMPRESSOR SERVICE VALVES FULLY OPENED (BACKSEATED)?

(Y/N)

HAVE LIQUID LINE SERVICE VALVE AND SUCTION LINE SERVICE VALVE BEEN OPENED? (Y/N)

IS THE OIL LEVEL IN COMPRESSOR CRANKCASE ON 576B UNIT IN VIEW IN THE COMPRESSOR SIGHT GLASS?

(Y/N)

CHECK VOLTAGE IMBALANCE

LINE-TO-LINE VOLTS: AB

(AB + AC + BC)/3 = AVERAGE VOLTAGE =

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE =

VOLTAGE IMBALANCE = 100 X (MAX DEVIATION)/(AVERAGE VOLTAGE) =

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START SYSTEM!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

----------------------------------------------------------------------------------------

VAC VBC V

V

V

%

—CL-1—

Page 20

III. START-UP

CHECK EVAPORATOR-FAN SPEEDAND RECORD.

CHECK CONDENSER-FAN SPEED AND RECORD.

AFTER AT LEAST 15 MINUTES RUNNING TIME, RECORD THE FOLLOWING MEASUREMENTS:

OIL PRESSURE (576B only)

SUCTION PRESSURE

SUCTION LINE TEMP

DISCHARGE PRESSURE

DISCHARGE LINE TEMP

ENTERING CONDENSER-AIR TEMP

LEAVING CONDENSER-AIR TEMP

EVAP ENTERING-AIR DB (dry bulb) TEMP

EVAP ENTERING-AIR WB (wet bulb) TEMP

EVAP LEAVING-AIR DB TEMP

EVAP LEAVING-AIR WB TEMP

COMPRESSOR AMPS (L1/L2/L3) / /

HAS REFRIGERANT CHARGE BEEN ADJUSTED PER UNIT CHARGING CHART?

NOTES:

Copyright 1999 Bryant Heating & Cooling Systems CATALOG NO. 5356-902

—CL-2—

Loading...

Loading...