Page 1

wiring diagrams

559F/579F

SINGLE-PACKAGE ROOFTOP

GAS HEATING/ELECTRIC COOLING

AND ELECTRIC COOLING UNITS

Cancels: New WD 559F.180.1

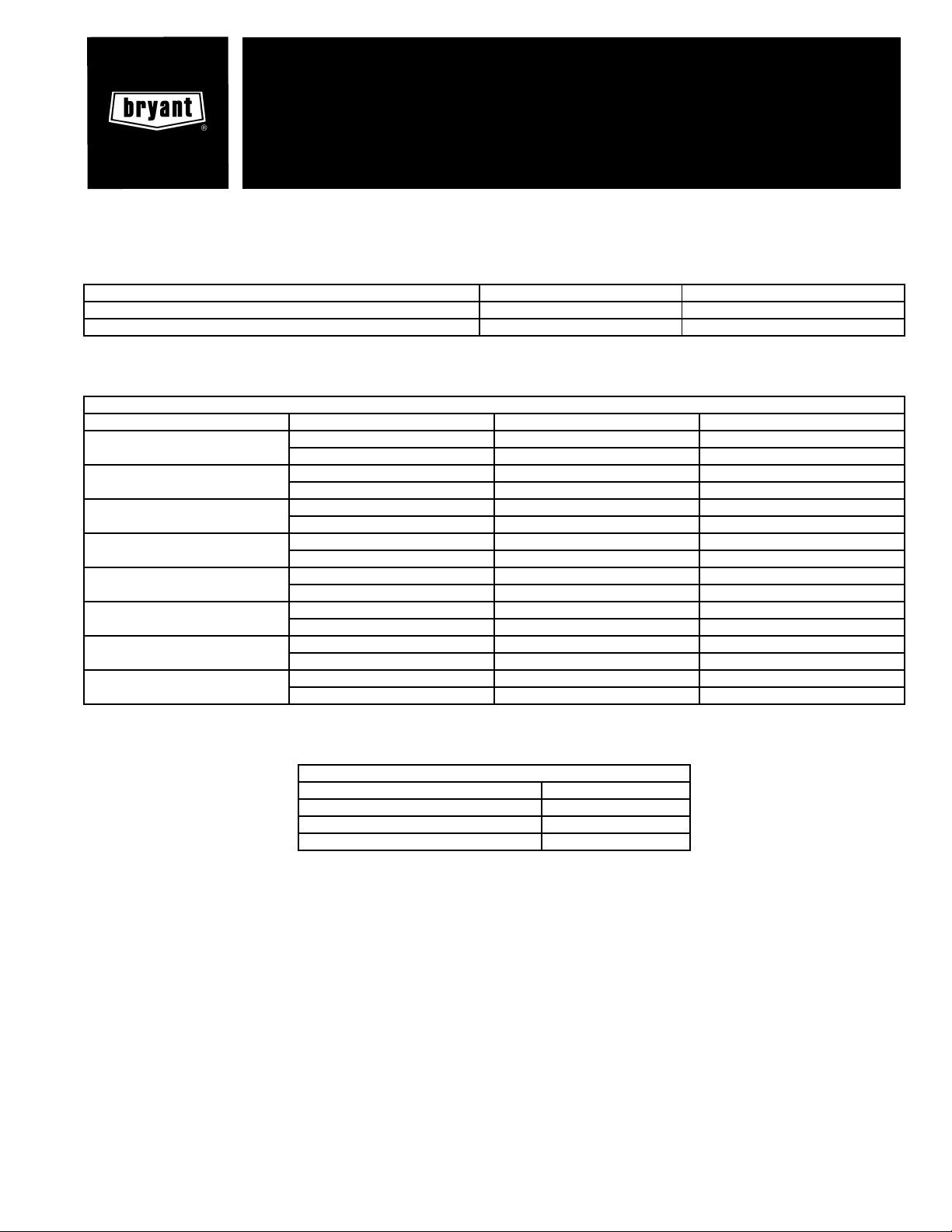

USAGE TABLE

UNIT PRODUCTION START DATE UNIT SERIAL NUMBER

559F180,240 and 579F180,240

559F216,300 and 579F216,300

DIAGRAM INDEX

UNIT LABEL DIAGRAM

Unit Voltage-Phase-Hertz Label Diagram Figure No.

559F180

559F216

559F240

559F300

579F180

579F216

579F240

579F300

208/230-3-60 50TJ500413 1

460-3-60 50TJ500463 2

208/230-3-60 50TJ500470 3

460-3-60 50TJ500471 4

208/230-3-60 50TJ500466 5

460-3-60 50TJ500467 6

208/230-3-60 50TJ500479 7

460-3-60 50TJ500480 8

208/230-3-60 48TJ500505 9

460-3-60 48TJ500506 10

208/230-3-60 48TJ500498 11

460-3-60 48TJ500499 12

208/230-3-60 48TJ500496 13

460-3-60 48TJ500497 14

208/230-3-60 48TJ500507 15

460-3-60 48TJ500544 16

11/16/98 4798F and later

12/7/98 5098F and later

15 to 25 Tons

8/1/00

ACCESSORY WIRING

Item Fig. No.

Power Exhaust

Time Guard® II Device

Smoke Control/Fire Shutdown*

*Requires both economizer and power exhaust.

17,18

19

20,21

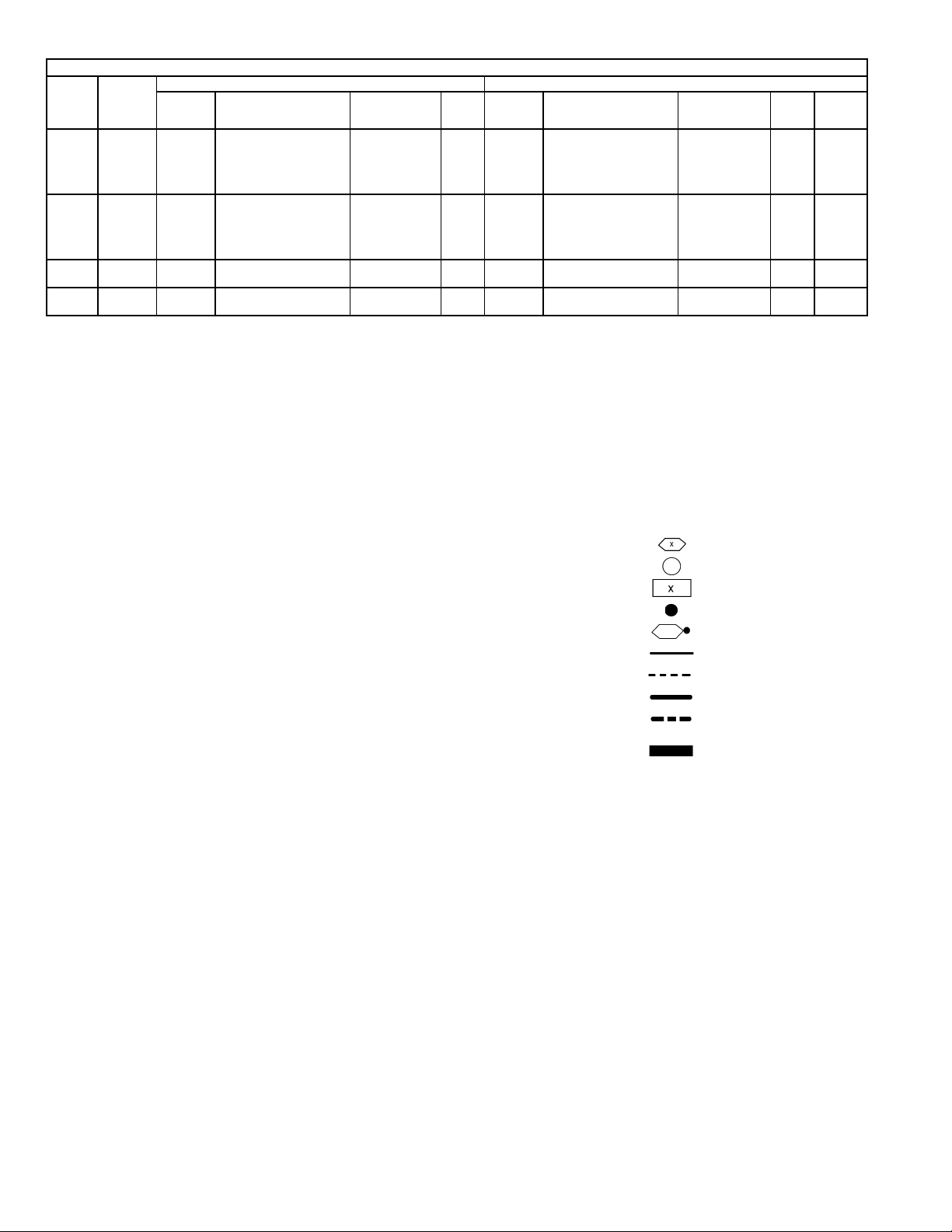

Page 2

Unit

g

559F/

579F

180

216

240

300

Std Min.

Operating

Tem p

40 10

40 10

40 25

40 25

Min.

Operating

Tem p (F )

Acy Kit Part No.

Required (Quantity)

CRWINSTR001A00,

CRLOWAMB001A00

CRWINSTR001A00† (2),

CRLOWAMB001A00

CRWINSTR001A00,

CRLOWAMB002A00

CRWINSTR001A00,

CRLOWAMB002A00

LEGEND

Motormaster® Head Pressure Control Device

MM —

LOWER OUTDOOR AMBIENT OPERATION ACCESSORIES

Mild Ambient Control Low Ambient Control

Accessory

Name

Winter Start Kit

10 F Ambient Kit

Winter Start Kit

10 F Ambient Kit

Winter Start Kit

25 F Ambient Kit

Winter Start Kit

25 F Ambient Kit

Wiring

Fig.

No.

22,23 –20

22,23 –20

22,26 –20

22,26 –20

Min.

Operating

Tem p (F )

Acy Kit Part No.

Required (Quantity)

CRWINSTR001A00,

CRLOWAMB001A00,

32LT900301

OR

32LT900611*†

CRWINSTR001A00 (2),

CRLOWAMB001A00,

32LT900301

OR

32LT900611*†

CRWINSTR001A00 (2),

30GT910079††

CRWINSTR001A00 (2),

30GT910079††

Accessory

Name

Winter Start Kit,

10 F Ambient Kit,

–20 F MM I

Winter Start Kit,

10 F Ambient Kit,

–20 F MM I

Winter Start Kit,

–20 F MM III

Winter Start Kit,

–20 F MM III

*Use the 32LT900301 for 208/230 units. Use the 32LT900611 for 460-v

units.

†Not required on models with the loss-of-charge switch on the liquid

line.

LEGEND (FIG. 1-16, 20 AND 21)

Wiring

Sensor

Fig.

Location

No.

Fig. No.

22,23,

24

22,23,

24

22,27 28

22,27 28

25

25

AHA —

BR —

BRK W/AT —

C—

CAP —

CB —

CC —

CH —

CLO —

CLS —

COMP —

CPM —

CR —

CT —

DM —

DU —

EAS —

EMC —

EQUIP —

FL —

FLA —

FPT —

FS —

FU —

GND —

GVR —

HC —

HPS —

HS —

Adjustable Heat Anticipator

Burner Relay

Breaks With Amp Turns

Contactor, Compressor

Capacitor

Circuit Breaker

Cooling Compensator

Crankcase Heater

Compressor Lockout

Compressor Lockout Switch

Compressor Motor

Compressor Protection Module

Control Relay

Current Transformer

Damper Motor

Dummy Terminal

Economizer Actuator

Auxiliary Switch

Economizer Motor Contactor

Equipment

Fuse Link

Full Load Amps

Freeze-Protection Thermostat

Flame Sensor

Fuse

Ground

Gas Valve Relay

Heater Contactor

High-Pressure Switch

Hall Switch

HTR —

HV —

I—

IDM —

IFC —

IFCB —

IFM —

IFR —

IGC —

L—

LED —

LLS —

LOR —

LPS —

LS —

MAT —

MGV —

NEC —

NEUT —

OAT —

OFC —

OFM —

OP —

PL —

PRI —

QT —

RS —

SEN, SN —

SR —

Heater

High-Voltage

Ignitor

Induced-Draft Motor

Indoor (Evaporator) Fan Contactor

Indoor (Evaporator) Fan

Circuit Breaker

Indoor (Evaporator) Fan Motor

Indoor (Evaporator) Fan Relay

Integrated Gas Controller

Light

Light-Emitting Diode

Liquid Line Solenoid

Lockout Relay

Low-Pressure Switch

Limit Switch

Mixed-Air Thermostat

Main Gas Valve

National Electrical Code

Neutral

Outdoor-Air Thermostat

Outdoor (Condenser) Fan Contactor

Outdoor (Condenser) Fan Motor

Overcurrent Protection

Plug Assembly

Primary

Quadruple Terminal

Rollout Switch

Sensor

Solenoid Relay

SW —

TB —

TC —

TH —

TRAN —

U—

UR —

Switch

Terminal Block

Thermostat Cooling

Thermostat Heating

Transformer

Unloader

Unloader Relay

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wirin

To indicate common poten-

tial only, not to represent

wiring.

—2—

Page 3

OPERATING SEQUENCE

Cooling, Units Without Economizer

When thermos tat calls for cool ing, terminals G and Y1 are

energized. The indoor (evaporator) fan contactor (IFC) and

compressor contactor no. 1 (C1) are energized, and

evaporator-fan motor (IFM), compressor no. 1 and condenser

fan(s) start. The condenser-fan motor(s) runs continuously

while unit is c ooli ng. When t he th e rmo s tat call s fo r a sec on d

stage of cooling by energizi ng Y2, comp ressor con tacto r no. 2

(C2) is energized and compressor no. 2 starts.

Heating, Units Without Economizer (579F180-300)

NOTE: The 579F180-300 units have 2 stages of heat.

When the thermostat calls for heating, power is sent to W on

the IGC (integrated gas unit controller) board. An LED

(light-emitting diode) on the IGC board will be on during

normal operation. A check is ma de to ensure that the rol lout

switch and limit switch are closed. The induced-draft motor

is then energized, and when speed is proven with the hall

effect sensor on the motor, the ignition activation period

begins. The burners will ignite within 5 seconds.

If the burners do not light, there is a 22-second delay before

another 5-second attempt. If the burners still do not light,

this sequence is repeated for 1 5 minutes. After the 15 minutes have elapsed, if the burners still have not lighted, heating is locked out. To reset the control, br eak 24-v power to

the thermostat.

When ignition occ urs the IGC board will continue to mo nitor the condition of the rollout and limit switches, the hall

effect sensor, as well as the flame sensor. If the unit is controlled through a room thermostat set for fan auto., 45 seconds after ignition occurs, the indoor-fan motor will be

energized. If for some reason the overtemperature limit

opens prior to the start of the indoor fan blower, on the next

attempt, the 45-second delay will b e shortened to 5 seconds

less than the time from initiation of heat to when the limit

tripped. Gas will not be interrupted to the burners and heating will continue. Once modified, the fan on delay will

not change back to 45 seconds unless power is reset to the

control.

When additional heat is required, W2 closes and initiates

power to the second stage of the main gas valve. When the

thermostat is satisfied, W1 and W2 open and the gas valve

closes, interrupting the flow of gas to the main burners. If

the call for W1 lasted less than 1 m inute, the heating cycle

will not terminate until 1 minute after W1 became active. If

the unit is controlled through a ro om thermostat set for fan

auto., the indoor-fan motor will continue to operate for an

additional 45 seconds then stop. If the overtemperature limit

opens after the indoor motor is stopped within 10 minutes of

W1 becoming inactive, on the next cycle the time will be

extended by 15 seconds. The maximum delay is 3 minutes.

Once modified, the fan off delay will not change back to

45 seconds unless power is reset to the control.

An LED indicator is provided on the IG C to monitor operation. The IGC is located by removing the side panel and

viewing the IGC through the view port located in the control

box access panel. During normal operation, the LED is continuously on.

Heating, Units Without Economizer (559F180-300, If Accessory or Optional Heater is Installed)

Upon a call for heating through terminal W1, IFC and

heater contactor no. 1 (HC1) are energized. On units

equipped for 2 stages of heat, when additional heat is

needed, HC2 is energized through W2.

Cooling, Units With Economizer

Upon a call for cooling, when outdoor ambient is above the

temperature control setting, the economizer damper moves

to VENT position. The co mpres sors an d evapo rator a nd condenser fans energize.

Upon a first call for cooli ng, when outdoor ambient is be low

the temperature control setting, the evaporator fan starts

and the economizer opens to maintain 53 F leaving-air temperature. The compressors remain off.

Upon a second-stage call for cooling, compressor no. 1 is

energized and mechanical cooling is integrated with economizer cooling. If the outdoor-air temperature drops below

50 F, a cooling lockout switch prevents the compressors from

running.

When supply-air temperature drops below a fixed set point,

the economizer damp er modulate s to maintain the tempera ture at the fixed set point.

Freeze protection thermostats (FPT) are located on the evaporator coil. They detect frost build-up and turn the c ompressors off locking them out an d re qu ir ing a man ual res et. Onc e

frost has melted, the compressors can be reenergized.

Heating, Units With Economizer

Outdoor-air damper stays at VENT position while evaporator fan is operating. Refer to Heating, Units Without

Economizer (579F180-300) and Heating, Units Without

Economizer (559F1 80-300 , If Ac cessor y or O ptio nal He ater i s

Installed) sections on this page for remainder of operating

sequence.

—3—

Page 4

NOTES FOR FIG. 1, 3, 5, 7

1. Compressor and/or fan motors are thermally protected.

Three-phase motors are protected against primary single phasing

conditions.

2. If any of the original wire furnished must be replaced, it must be

replaced with type 90 C or its equivalent.

3. On 208/230-v unit, TRAN1 is factory wired to ORN lead for 230-v

power supply. If unit is to be run on 208-v power supply, TRAN1 must

be rewired. Disconnect the BLK wire on TRAN1 and connect wire to

208-v RED wire. Insulate 230-v ORN wire.

5. Indoor fan circuit breaker must trip amps value is equal to or less

than 140% FLA.

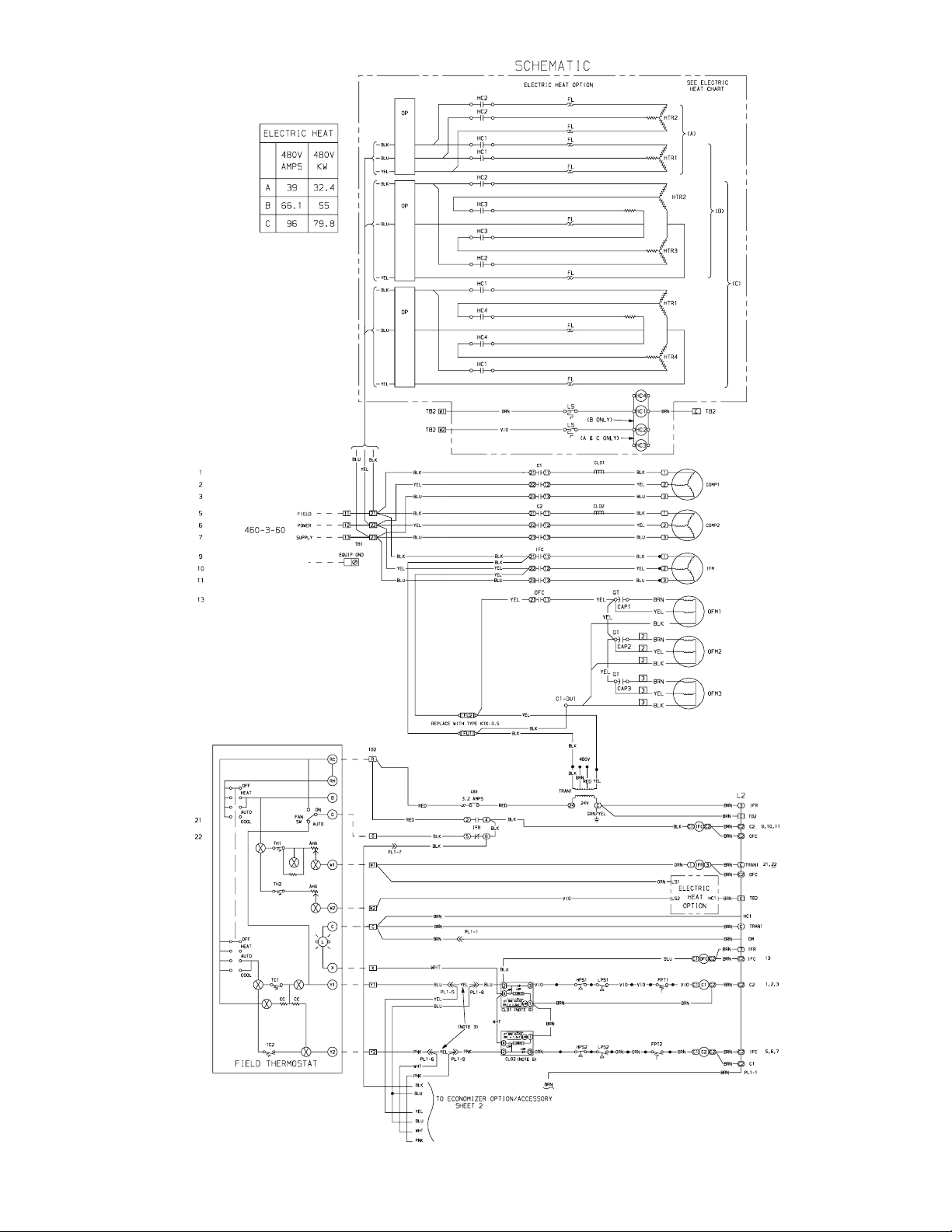

NOTES FOR FIG. 2, 4, 6, 8

1. Compressor and/or fan motors are thermally protected.

Three-phase motors are protected against primary single phasing

conditions.

2. If any of the original wire furnished must be replaced, it must be

replaced with type 90 C or its equivalent.

3. Jumpers are omitted when unit is equipped with an economizer.

5. Indoor fan circuit breaker must trip amps value is equal to or less

than 140% FLA.

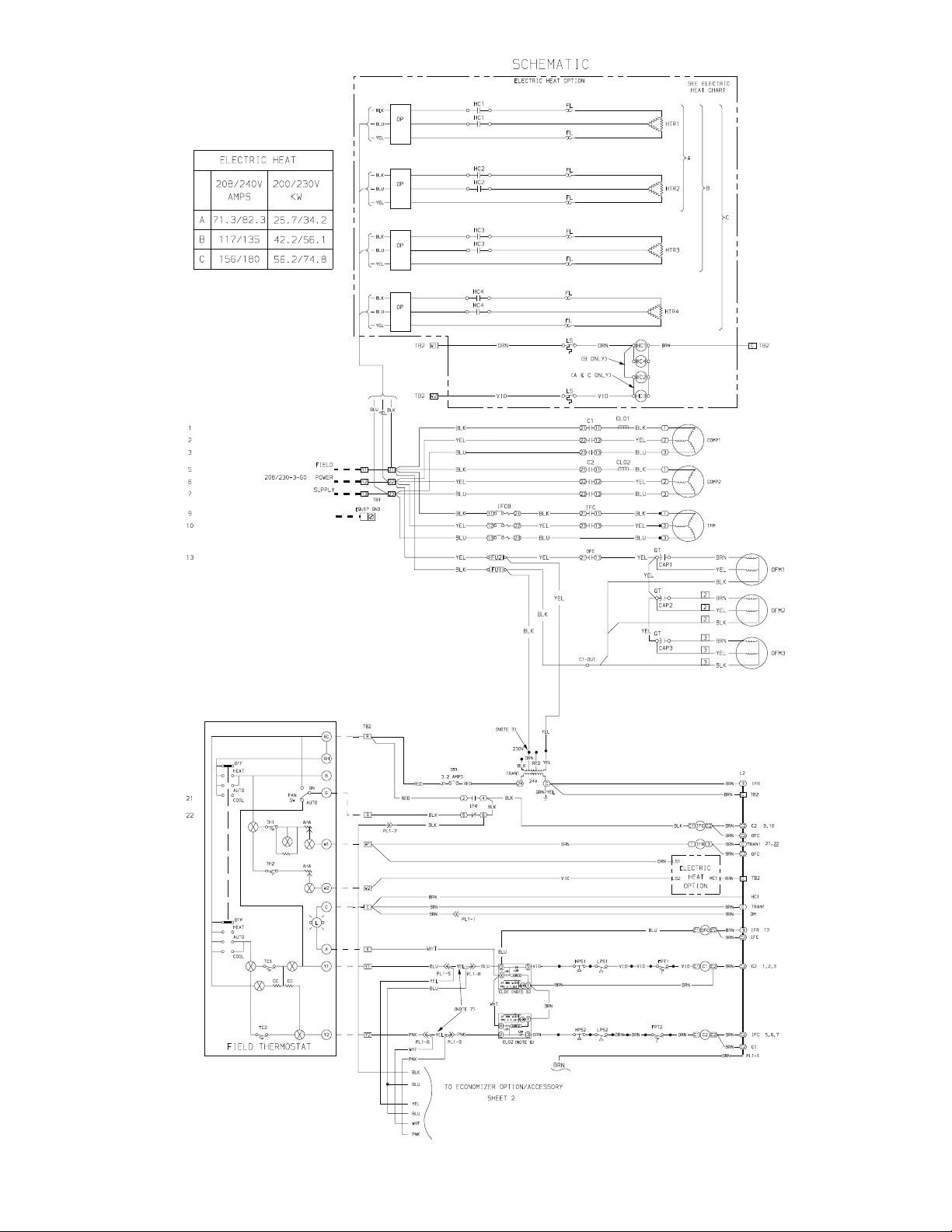

NOTES FOR FIG. 9, 11, 13, 15

1. Compressor and/or fan motors are thermally protected.

Three-phase motors are protected against primary single phasing

conditions.

2. If any of the original wire furnished must be replaced, it must be

replaced with type 90 C or its equivalent.

3. Jumpers are omitted when unit is equipped with an economizer.

4. Indoor fan circuit breaker must trip amps value is equal to or less

than 140% FLA.

5. On 208/230-v unit, TRAN1 is factory wired to ORN lead for 230-v

power supply. If unit is to be run on 208-v power supply, TRAN1 must

6. The CLO locks out the compressor to prevent short cycling on compressor overload and safety devices. Before replacing CLO, check

these devices.

7. Jumpers are omitted when unit is equipped with an economizer.

8. Number(s) indicate the line location of used contacts. A bracket over

2 numbers signifies a single-pole, double-throw contact. An underlined number signifies a normally closed contact. A plain (no line)

number signifies a normally open contact.

6. The CLO locks out the compressor to prevent short cycling on compressor overload and safety devices. Before replacing CLO, check

these devices.

7. Number(s) indicate the line location of used contacts. A bracket over

2 numbers signifies a single-pole, double-throw contact. An underlined number signifies a normally closed contact. A plain (no line)

number signifies a normally open contact.

be rewired. Disconnect the BLK wire on TRAN1 and connect wire to

208-v RED wire. Insulate 230-v ORN wire.

6. The CLO locks out the compressor to prevent short cycling on compressor overload and safety devices. Before replacing CLO, check

these devices.

7. Number(s) indicate the line location of used contacts. A bracket over

2 numbers signifies a single-pole, double-throw contact. An underlined number signifies a normally closed contact. A plain (no line)

number signifies a normally open contact.

NOTES FOR FIG. 10, 12, 14, 16

1. Compressor and/or fan motors are thermally protected.

Three-phase motors are protected against primary single phasing

conditions.

2. If any of the original wire furnished must be replaced, it must be

replaced with type 90 C or its equivalent.

3. Jumpers are omitted when unit is equipped with an economizer.

4. Indoor fan circuit breaker must trip amps value is equal to or less

than 140% FLA.

5. If unit is to be run on 460-v power supply, TRAN1 must be wired to

BLK wire.

6. The CLO locks out the compressor to prevent short cycling on compressor overload and safety devices. Before replacing CLO, check

these devices.

7. Number(s) indicate the line location of used contacts. A bracket over

2 numbers signifies a single-pole, double-throw contact. An underlined number signifies a normally closed contact. A plain (no line)

number signifies a normally open contact.

—4—

Page 5

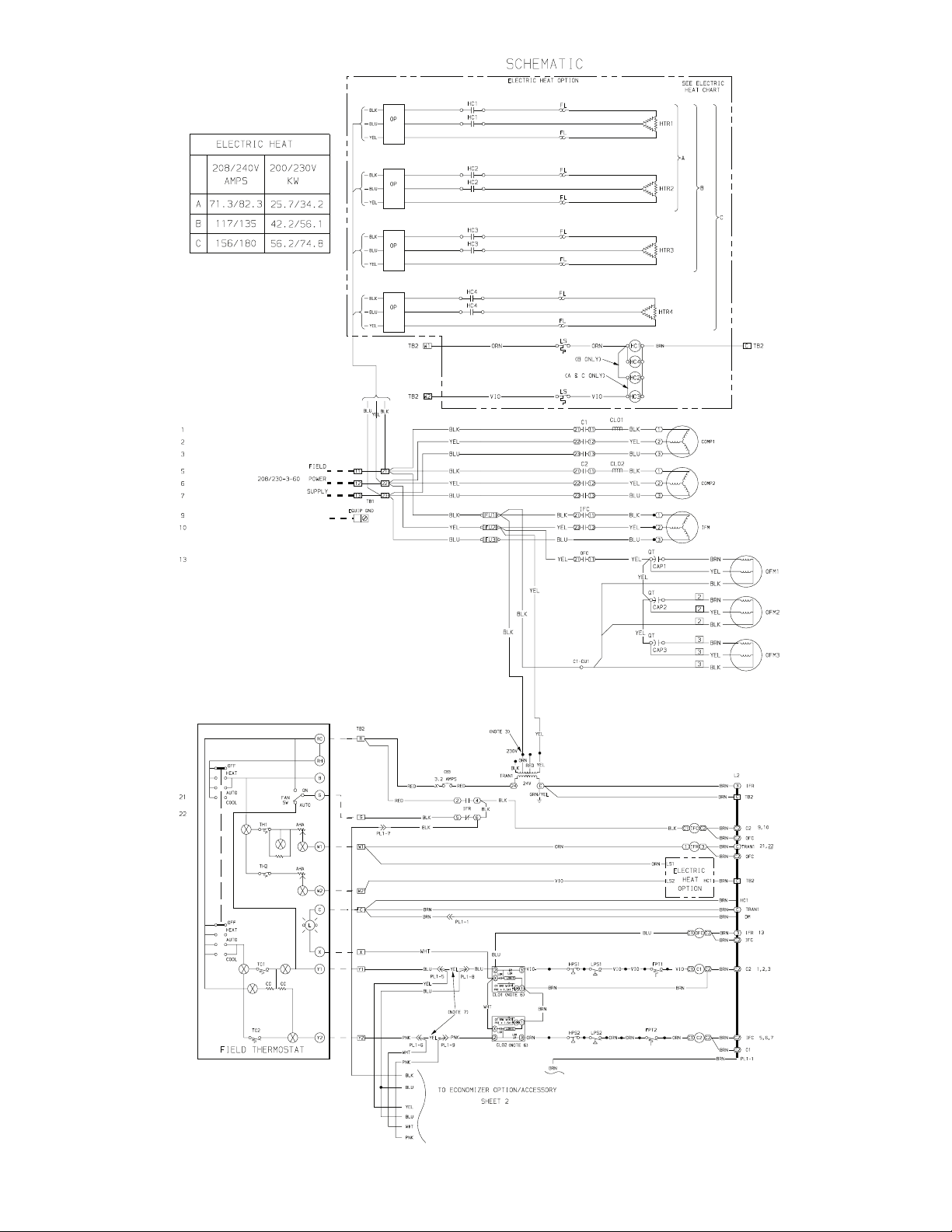

Fig. 1 — Label Diagram — 559F180, 208/230-3-60 Units

—5—

Page 6

Fig. 1 — Label Diagram — 559F180, 208/230-3-60 Units (cont)

—6—

Page 7

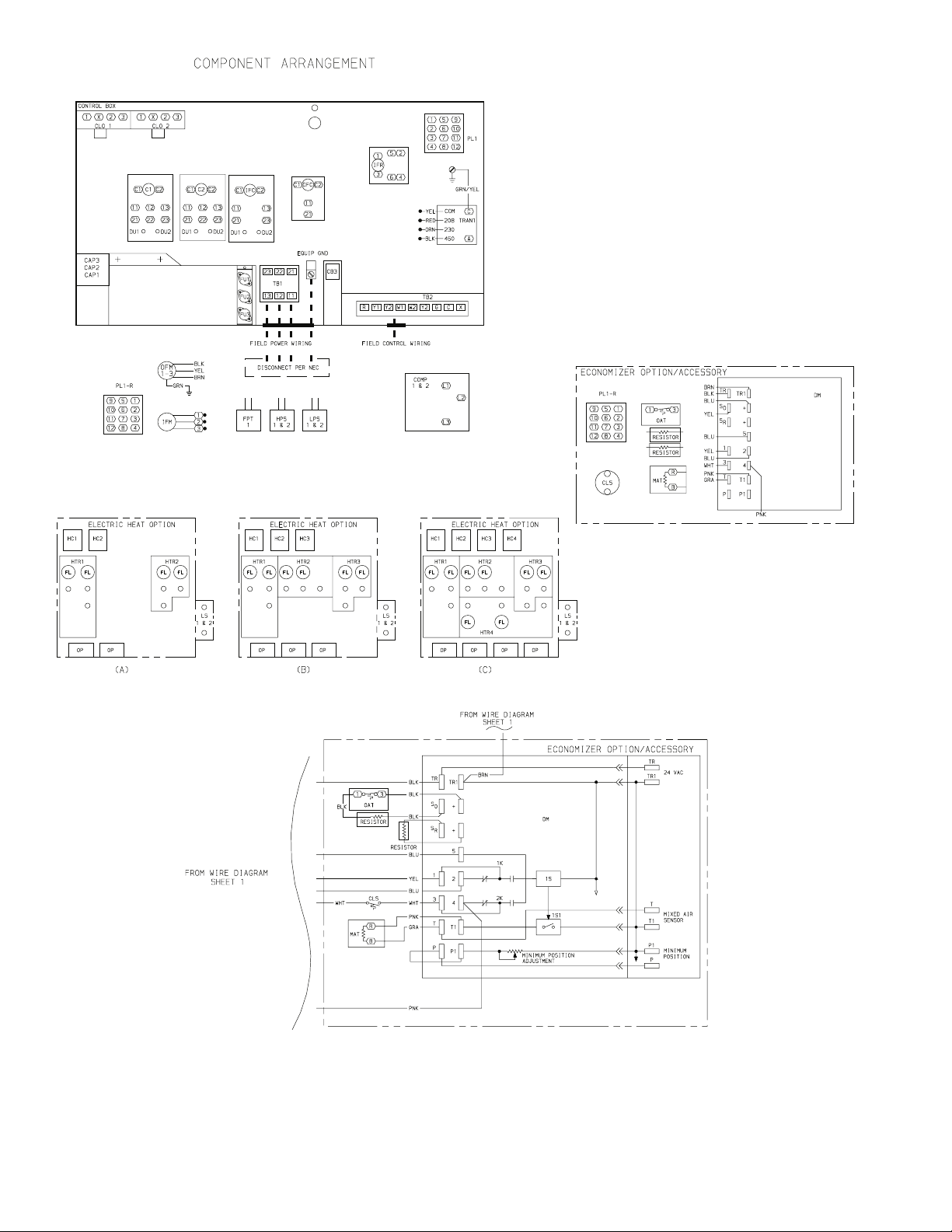

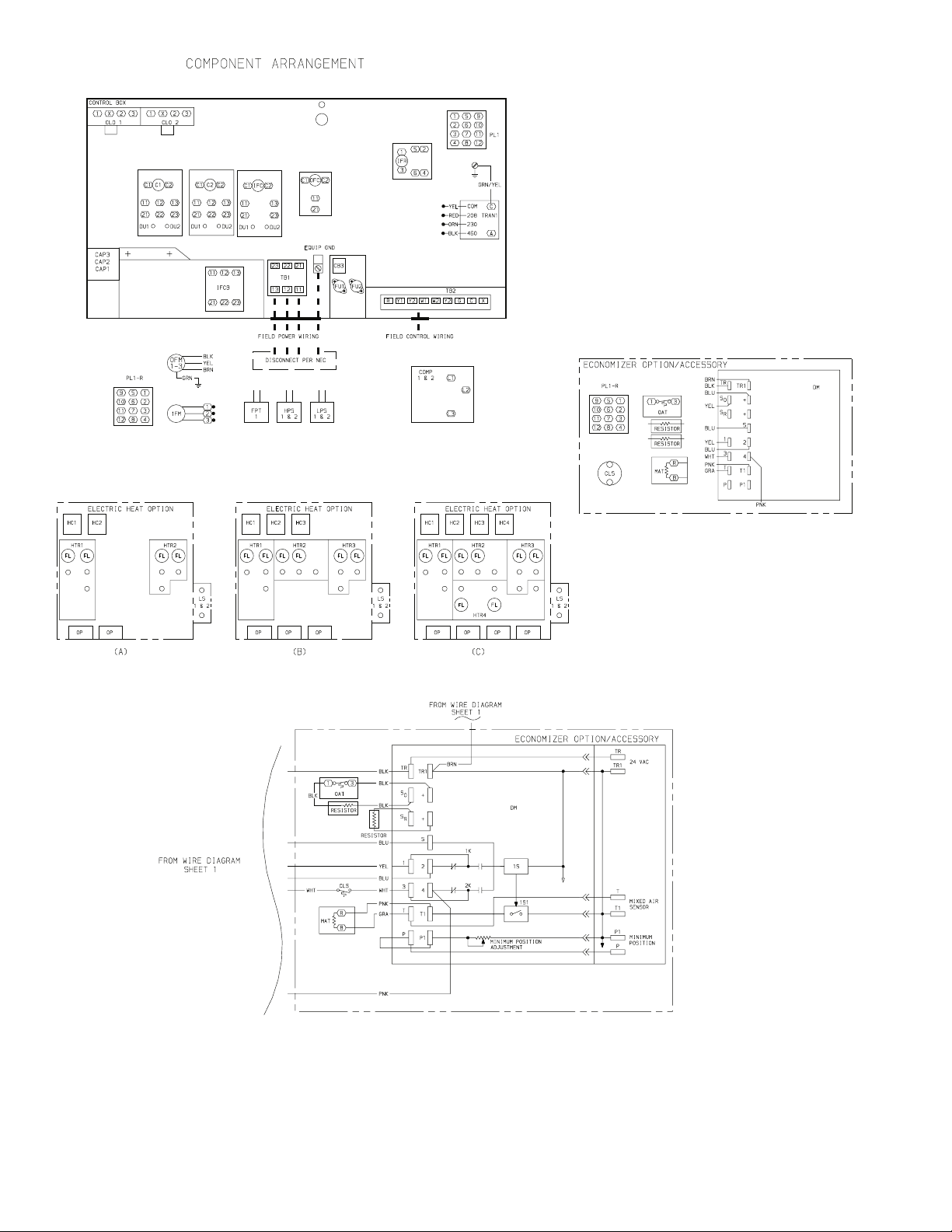

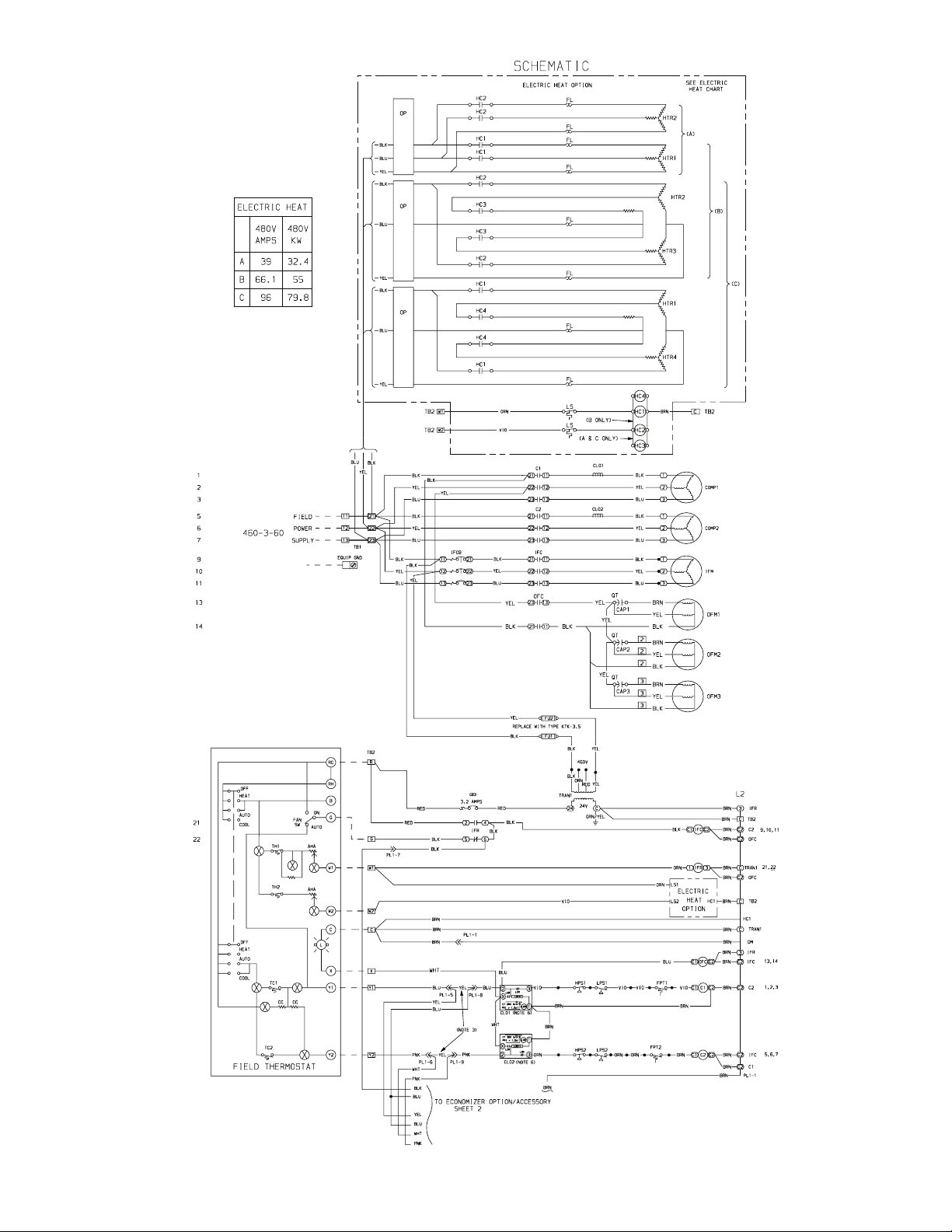

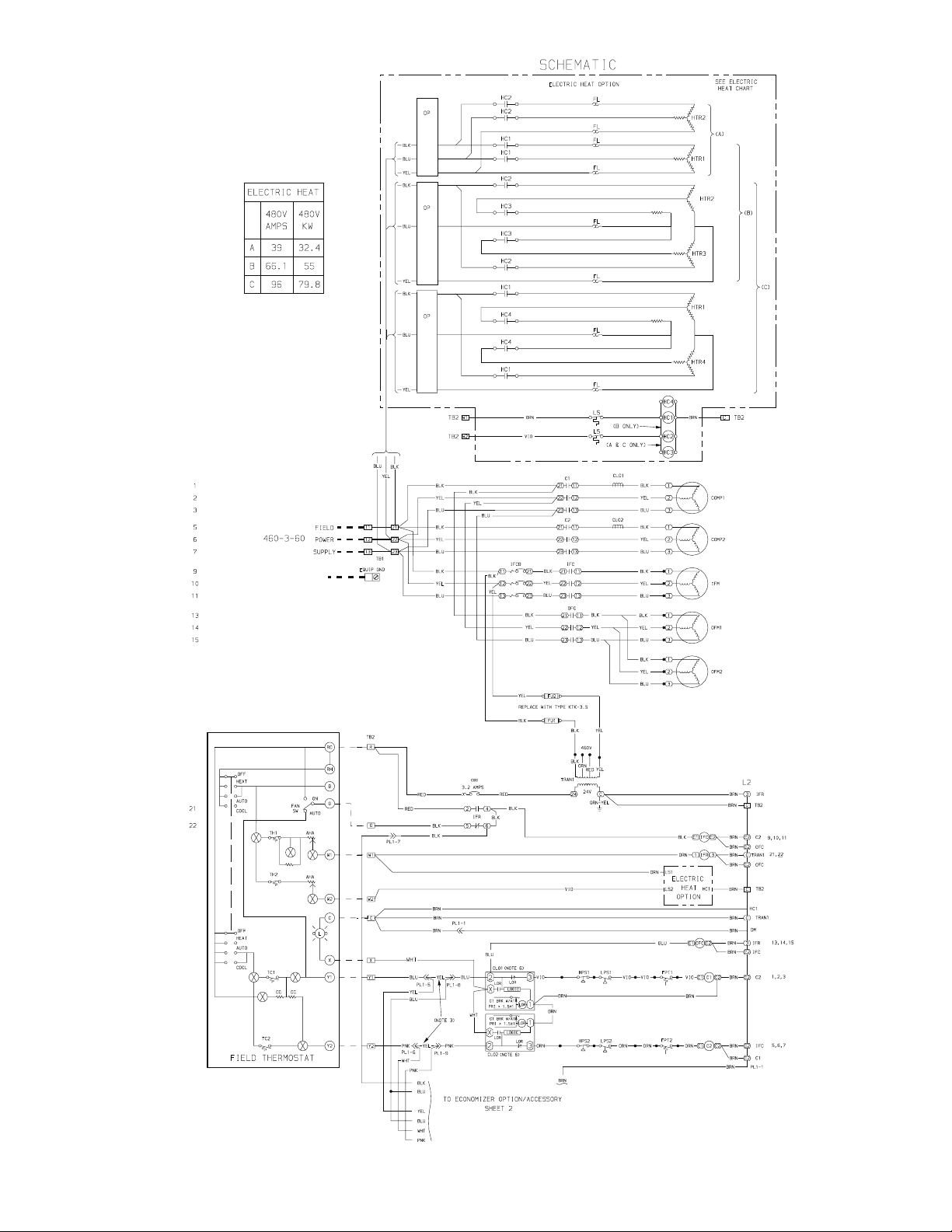

Fig. 2 — Label Diagram — 559F180, 460-3-60 Units

—7—

Page 8

Fig. 2 — Label Diagram — 559F180, 460-3-60 Units (cont)

—8—

Page 9

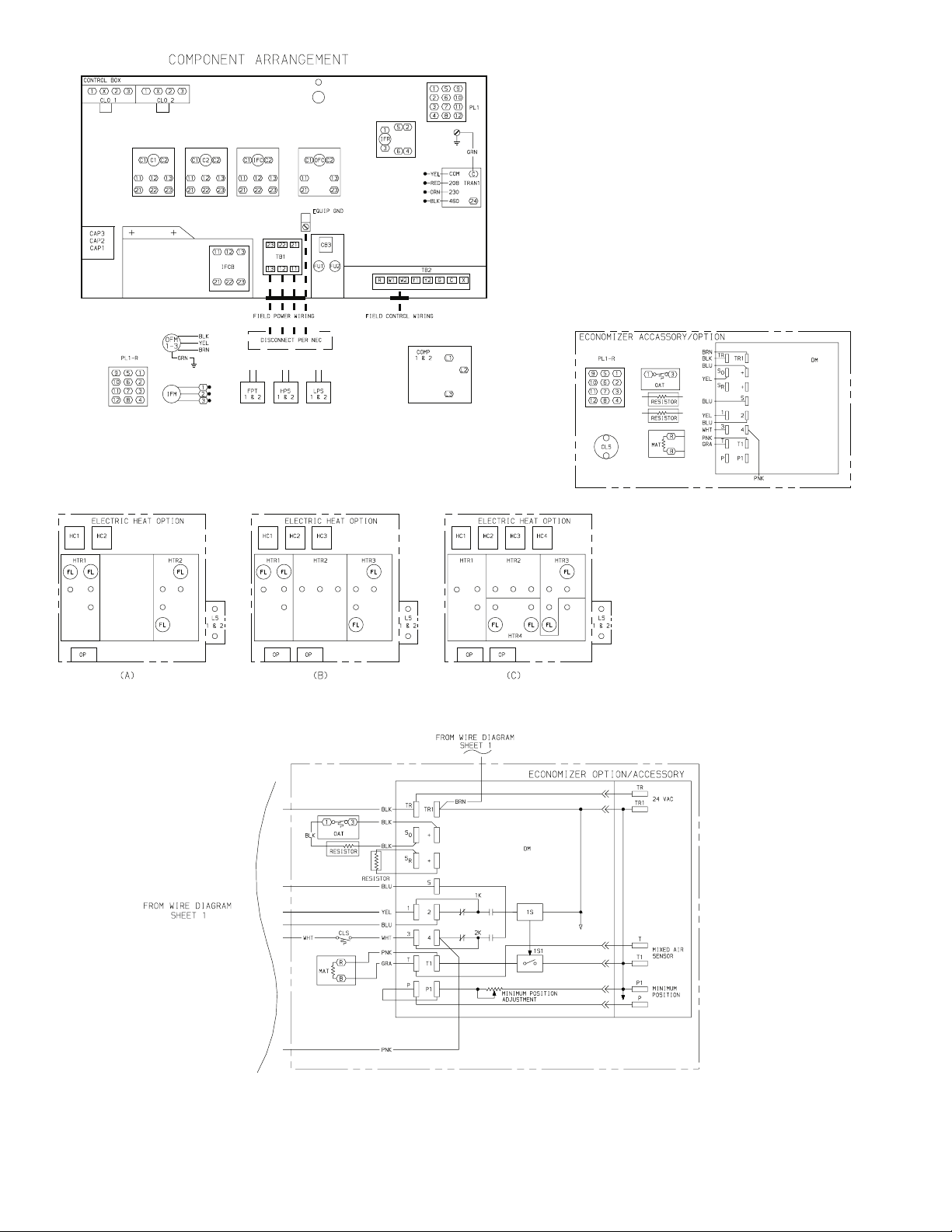

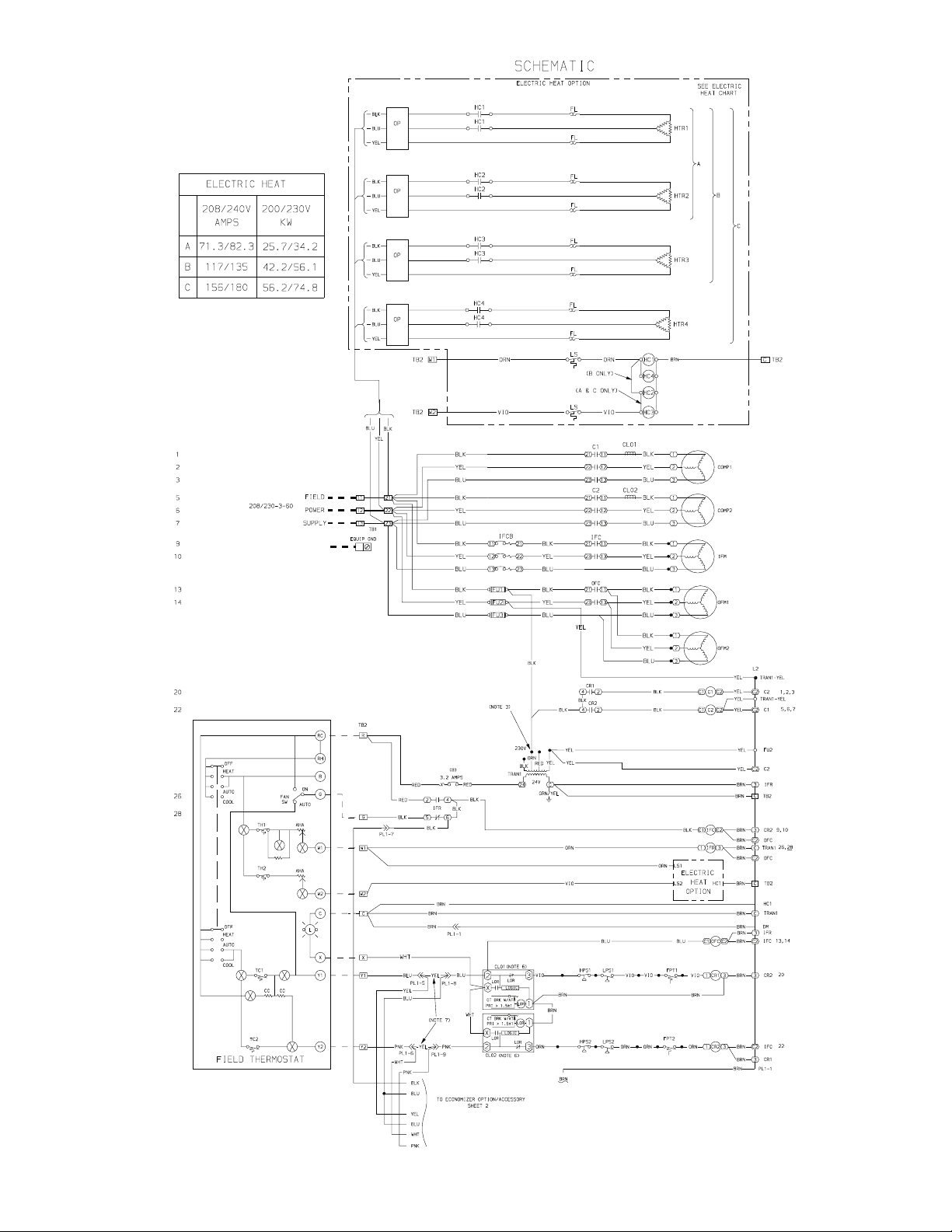

Fig. 3 — Label Diagram — 559F216, 208/230-3-60 Units

—9—

Page 10

Fig. 3 — Label Diagram — 559F216, 208/230-3-60 Units (cont)

—10—

Page 11

Fig. 4 — Label Diagram — 559F216, 460-3-60 Units

—11—

Page 12

Fig. 4 — Label Diagram — 559F216, 460-3-60 Units (cont)

—12—

Page 13

Fig. 5 — Label Diagram — 559F240, 208/230-3-60 Units

—13—

Page 14

Fig. 5 — Label Diagram — 559F240, 208/230-3-60 Units (cont)

—14—

Page 15

Fig. 6 — Label Diagram — 559F240, 460-3-60 Units

—15—

Page 16

Fig. 6 — Label Diagram — 559F240, 460-3-60 Units (cont)

—16—

Page 17

Fig. 7 — Label Diagram — 559F300, 208/230-3-60 Units

—17—

Page 18

Fig. 7 — Label Diagram — 559F300, 208/230-3-60 Units (cont)

—18—

Page 19

Fig. 8 — Label Diagram — 559F300, 460-3-60 Units

—19—

Page 20

Fig. 8 — Label Diagram — 559F300, 460-3-60 Units (cont)

—20—

Page 21

Fig. 9 — Label Diagram — 579F180, 208/230-3-60 Units

—21—

Page 22

Fig. 9 — Label Diagram — 579F180, 208/230-3-60 Units (cont)

—22—

Page 23

Fig. 10 — Label Diagram — 579F180, 460-3-60 Units

—23—

Page 24

Fig. 10 — Label Diagram — 579F180, 460-3-60 Units (cont)

—24—

Page 25

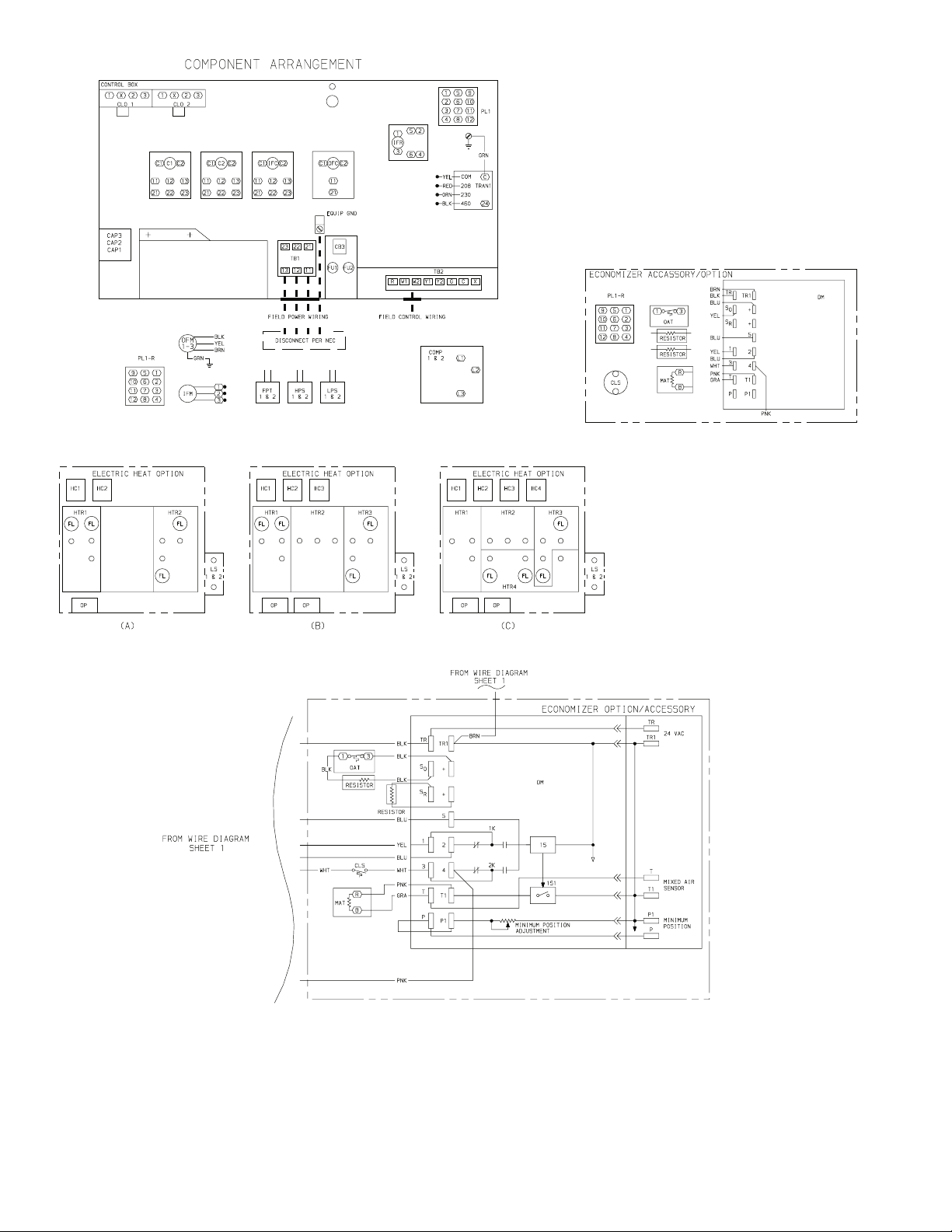

Fig. 11 — Label Diagram — 579F216, 208/230-3-60 Units

—25—

Page 26

Fig. 11 — Label Diagram — 579F216, 208/230-3-60 Units (cont)

—26—

Page 27

Fig. 12 — Label Diagram — 579F216, 460-3-60 Units

—27—

Page 28

Fig. 12 — Label Diagram — 579F216, 460-3-60 Units (cont)

—28—

Page 29

Fig. 13 — Label Diagram — 579F240, 208/230-3-60 Units

—29—

Page 30

Fig. 13 — Label Diagram — 579F240, 208/230-3-60 Units (cont)

—30—

Page 31

Fig. 14 — Label Diagram — 579F240, 460-3-60 Units

—31—

Page 32

Fig. 14 — Label Diagram — 579F240, 460-3-60 Units (cont)

—32—

Page 33

Fig. 15 — Label Diagram — 579F300, 208/230-3-60 Units

—33—

Page 34

Fig. 15 — Label Diagram — 579F300, 208/230-3-60 Units (cont)

—34—

Page 35

Fig. 16 — Label Diagram — 579F300, 460-3-60 Units

—35—

Page 36

Fig. 16 — Label Diagram — 579F300, 460-3-60 Units (cont)

—36—

Page 37

CAP —

EFM —

EMC —

FU —

A. 460 V (PART NO. CRPWREXH008A00)

B. 208/230 V (PART NO. CRPWREXH009A00 OR CRPWREXH008A00 WITH FIELD REWIRING)

LEGEND

Capacitor

Exhaust Motor Contactor

Exhaust Fan Motor

Fuse

Fig. 17 — Power Exhaust Power Wiring

LEGEND

EMC —

IFC —

Exhaust Motor Contactor

Indoor (Evaporator) Fan Contactor

Fig. 18 — Accessory Power Exhaust Control Wiring

—37—

Page 38

C—

CLO —

CPM —

CR —

FPT —

*Time Guard II device connections.

Contactor

Cooling Lockout

Compressor Protection Module

Control Relay

Freeze Protection Thermostat

Fig. 19 — Time Guard® II Device Wiring

LEGEND

HPS —

LPS —

PL —

TB —

TG II —

High-Pressure Switch

Low-Pressure Switch

Plug

Terminal Block

Time Guard II Device

—38—

Page 39

LEGEND

Field Wiring

Field-Supplied Switch

See Legend on page 2.

*Included in power exhaust accessory.

OPERATING MODES

Building Pressurization: Evaporator fan on, economizer energized to fully open position,

BP —

Evacuation: Evaporator fan off, economizer energized to fully closed position,

E—

Complete Unit Shutdown: Breaks 24-v power to the thermostat.

SD —

Smoke Purge: Evaporator fan on, economizer energized to fully open position,

SP —

power exhaust disabled.

power exhaust on (open).

power exhaust on.

Fig. 20 — Smoke Control/Fire Shutdown Wiring; 559F180-300

—39—

Page 40

CLOSED ON

BP,SP,E

OPEN

ON SD

OPEN ON E

CLOSED ON BP

OPEN

ON BP

*

EMC

EAS

See Legend on page 2.

*Included in power exhaust accessory.

All switches are field supplied.

NOTE:

OPERATING MODES

Building Pressurization: Evaporator fan on, economizer energized to fully open position,

BP —

Evacuation: Evaporator fan off, economizer energized to fully open position,

E—

Complete Unit Shutdown: Breaks 24-v power to the thermostat.

SD —

Smoke Purge: Evaporator fan on, economizer energized to fully open position,

SP —

power exhaust disabled.

power exhaust on (open).

power exhaust on.

COMPRESSOR WIRING

SWITCH CLOSES

ON BP,SP,E

Fig. 21 — Smoke Control/Fire Shutdown Wiring; 579F180-300

—40—

Page 41

C—

CLO —

CPM —

CR —

FPT —

NOTE:

correct application.

Contactor

Compressor Lockout

Compressor Protection Module

Control Relay Factory-Supplied Wiring

Freeze Protection Thermostat Field-Supplied Wiring

See Lower Outdoor Ambient Operation Accessories table on page 2 for

LEGEND

HPS —

LPS —

TDR —

High-Pressure Switch

Low-Pressure Switch

Time-Delay Relay

Fig. 22 — Winter Start Kit Wiring

LEGEND

SW —

NOTE:

Switch

Field Wiring

Factory Wiring

See Lower Outdoor Ambient Operation Accessories table on page 2 for correct application.

Fig. 23 — Mild/Low Ambient Control — 559/579F180 and 216 Units (10 F Ambient Control)

—41—

Page 42

LEGEND

OFM —

NOTE:

Outdoor (Condenser) Fan Motor

Field Wiring

Factory Wiring

See Lower Outdoor Ambient Operation Accessories table on page 2 for correct application.

Fig. 24 — Motormaster® I Head Pressure Control Wiring; 559/579F180 and 216 Units

(–20 F Ambient Control)

SENSOR

LOCATION

HAIRPIN END

559/579F180 559/579F216

NOTES:

1. All sensors are located on the eighth hairpin up from the bottom.

2. See Lower Outdoor Ambient Operation Accessories table on page 2 for correct application.

SENSOR

LOCATION

Fig. 25 — Motormaster I Control Sensor Locations;

559/579F180 and 216 Units

—42—

HAIRPIN END

Page 43

NOTES:

Accessories table on page 2 for correct

application.

1. CR1 is replaced by C1 in 460-v units.

2. See Lower Outdoor Ambient Operation

Plug

Primary

Time-Delay Relay

PL —

PRI —

TDR —

—43—

LEGEND

High-Pressure Switch

Indoor (Evaporator) Fan Contactor

Indoor (Evaporator) Fan Relay

Lockout Relay Factory-Supplied Wiring

Low-Pressure Switch Field-Supplied Wiring

Outdoor (Condenser) Fan Contactor

Outdoor (Condenser) Fan Motor

HPS —

IFC —

IFR —

LOR —

LPS —

OFC —

OFM —

Breaks with Amps

Contactor

Compressor Lockout

Control Relay

Circuit

Freeze Protection Thermostat

Head Pressure Control Thermostat

BRK W/AT —

C—

CLO —

CR —

CT —

FTP —

HPCT —

Fig. 26 — HPCT, OFC2, and TDR Wiring — 25 F Ambient Kit; 559/579F240 and 300 Units

Page 44

559/579F240 AND 300, 208/230-3-60 UNITS

559/579F240 AND 300, 460-3-60 UNITS

C—

FU —

IFCB —

MMSN —

Contactor

Fuse

Indoor Fan Circuit Breaker

Motormaster Sensor

LEGEND

OFC —

OFM —

TB —

Outdoor (Condenser) Fan Contactor

Outdoor (Condenser) Fan Motor

Terminal Block

NOTE:

Operation Accessories table on page 2

for correct application.

Fig. 27 — Motormaster® III Control Wiring; 559/579F240 and 300 Units

—44—

See Lower Outdoor Ambient

Page 45

SENSOR

LOCATION

SENSOR

LOCATION

HAIRPIN END

559/579F240 559/579F300

NOTES:

1. All sensors are located on the eighth hairpin up from the bottom.

2. See Lower Outdoor Ambient Operation Accessories table on page 2 for correct application.

Fig. 28 — Motormaster® III Control Sensor Locations;

559/579F240 and 300 Units

HAIRPIN END

—45—

Page 46

Page 47

Page 48

Copyright 2000 Bryant Heating & Cooling Systems CATALOG NO. 5355-901

Loading...

Loading...