Page 1

Bryant

Airconditioning

Company

installation instructions

SELF-CONTAINED

ELECTRIC COOLING UNITS

559B

Sizes 024, 030,

036, 042, & 048

Series E

The Model 559B unit is a complete cooling system, with

provisions for addition of accessory electric heaters. Units

are air cooled, designed for outdoor installation, and may

be connected into existing duct system. Required con

nections include air ducts, condensate drain, and high- and

low-voltage wiring. A field-supplied filter box must be in

stalled in return air duct.

When optional electric heaters are being installed, see

instructions beginning on page 8 of this publication

for procedures.

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is damaged

or incomplete. Move unit to installation site in upright

position.

Important—Read Before Installing

1. Check all local codes and ordinances that could affect

installation of equipment.

2. Be sure power supply available (voltage, hertz, and

phase) corresponds to that specified on unit rating

plate.

3. Check electrical service provided by utility for building

to be sure service capacity is sufficient to handle load

imposed by unit.

4. Refer to dimensional drawing for locations of elec

trical, condensate drain, and duct connections before

setting unit in place.

Installation consists of the following steps;

I. Locating and Mounting Unit

II. Connecting Ductwork

III. Connecting Condensate Drain

IV. Electrical Connections

V. Startup and Adjustment

VI. Maintenance

VII. Instructions to Owner

I. LOCATING AND MOUNTING UNIT

Place unit on a solid, level, concrete pad. Pad should be

minimum of 3 inches high, extend about 6 inches from both

sides and front of unit, and must not extend more than 1

inch from back (duct side) of unit. Insert sheet of tar-base

construction felt paper between unit and pad.

Unit does not need to be secured to pad because there are

no refrigerant lines extending outside of unit that could be

damaged.

Be sure grass and shrubs do not interfere with condenser

airstream. If necessary, extend gravel apron around pad.

Place duct side against building structure so ductwork can

not be seen from outside.

When installing unit, allow sufficient space for condenser

airflow clearance, wiring, and servicing unit. See Figure 2.

Position unit so water from roof will not pour directly on

top of unit. Do not locate unit under eaves.

Recornmended minimum service clearance;

18 inches all sides except duct side

0 inches bottom

36 inches top

Cancels: 39559D47

Figure 1—Model 559B

II. CONNECTING DUCTWORK

39559DP61

6/1/74

Flanges are provided on unit for duct connections. See

Figure 2 for unit connection sizes and locations. Use

weathertight connectors between ductwork and unit to

prevent transmission of vibration.

Ductwork should be selected and sized according to Part 2

of Bryant Air Distribution Manual. All ductwork in un

conditioned space should be insulated and weatherproof if

used outdoors.

t'.\l”JT()\; D'l nol opi-rau* unit longer than .“) minutes

Filters must be located in return airstream. Recommended

sizes are shown in Table II. When electric heaters are

installed, use an asbestos (or similar heat-resistant ma

terial) connector between ductwork and unit supply duct

connection.

When flexible duct is used, friction loss in straight runs is

approximately double amount found in Bryant Air

Distribution Manual, Part 2, for air duct design.

It is recommended that rigid elbows should be used for

bends. If rigid elbows are not used, ratio of centerline bend,

radius to duct diameter (R/D) should be at least 1.5 for

minimum friction loss. If rectangular ducts are used over

unit round connections, unit entering pressure loss must be

considered when designing system.

\\ \KMN(i l><> iiol •lull hull-- III ,11-1.1 sliiiMM in

It is also recommended that abrupt duct expansions and

contractions be avoided.

NOTE: Mobile home duct kits (which include a return air

filter box, filter, floor grille, flexible duct sections, and in

stallation hardware) are available for mobile home in

stallation. See your Bryant Distributor.

Mobile Home Duct Design

Design duct system to have friction loss of between 0.25 in.

wc and 0.70 in. wc for proper unit operation. Insulated

flexible ductwork (1-ft inside diameter) of weatherproof

type is recommended. Do not reduce duct inside diameter

below 1 ft. Combined length of supply and return ducts

should not exceed 20 ft, with minimum supply duct length

Page 2

^CONDENSER AIR DISCHARGE

20" DIAMETER

, 1

DIMENSIONS IN INCHES

SIZE

024

C

17-5/8

030 17-5/8 12

036 19-5/8 14 14

042 27-5/8 14

048 27-5/8

D

12

14

E F G H

12 10-1/4 14-1/2

12 10-1/4 14-1/2

11-1/4 16-1/2

14 12-1/4

14

12-1/4 24-1/2

24-1/2 9-5/8

8-5/8 25-5/16

8-5/8

8-5/8 25-5/16

9-5/8

J

25-5/16

24-5/16

24-5/16

LOW-VOLT CONN (2) )î:NOCKOUTS

’(RUBBER TUBE)

Figure 2 — Dimensional Drawing

Q RETURN AIR FLOOR GRILLE

(T) 20x25 xl DISPOSABLE FILTER

Q) RETURN AIR FILTER BOX

(4) QUICK-CONNECT COLLAR

(5) flexible DUCT

(i) TAP-IN COLLAR

DETAIL A

(RETURN ASSEMBLY)

DETAIL B

(SUPPLY ASSEMBLY)

Figure 3 — Typical Installation

-2-

--------

CONTROL WIRING

--------

POWER WIRING

CONDENSER AIRFLOW

EVAPORATOR AIRFLOW

Page 3

MODEL

Rated Cooling Capacity* Btuh

Nameplate Voltage-Freq-Phase

Operating Voltage Range

Compressor Motor FLA

Locked Rotor Amps

Condenser Fan Motor** HP

Full Load Amps

Evaporator Blower Motor** HP

Full Load Amps

Rated Total Power Consumption KWH

Electrical Connections

Unit Full Load Amps

Unit Ampacity for Electrical

Conductor Sizing

Min Branch Circuit Wire

Size 60°C Temp Rating Copper

Conductor*** AWG No.

Max Line Length**** Ft

Largest Wire Size Line-Voltage Con

nections Will Accommodate AWG No.

Max Branch Circuit Fuse Size Amps

Refrigerant type/lbs-ozs

Evaporator Airflow CFM

Approximate Shipping Weight lbs

TABLE I—RATINGS AND PERFORMANCE

559B-024-E

24,000

230-60-1

207-254 207-254

15.7 19.5

72 88

1/5 1/5

1.3

1/4 1/3

2.0

3.5

19.0 23.9

22.9 28.8

10 10

119 95

4 4

25

R-22/2-6

900 1125

265

230-60-1 208-60-3

R-22/3-0

285

1.3 1.4

3.1

4.6

30

559B-030-E

30,000

187-229

12.3 11.1

70

1/5

1/3

2.9

4.6

16.6

19.7

12 12 8 10

92 110

4

25 20 40 30 25

R-22/3-0

1125 1125 1350

285 285 305 305

230-60-3 230-60-1

207-254 207-254

60 100 80

1/5

1.3 1.8 2.1

1/3 1/3 1/3

3.1 3.6 3.8

4.6

15.5

18.3 35.4 24.9

4

R-22/3-0

24.0

1/4

5.7

29.4

122 115

4 4

R-22/3-10

5S9B-036-E

35,000

208-60-3

187-229

15.2

1/4

5.7

21.1

R-22/3-10

1350 1350

R-22/3-10

230-60-3

207-254

14.0

70

1/4

1.8

1/3

3.6

5.7

19.4

22.9

10

142

4

305

MODEL

Nameplate Voltage-Freq-Phase

Operating Voltage Range

Locked Rotor Amps

Full Load Amps

Full Load Amps

Electrical Connections

Unit Full Load Amps

Unit Ampacity for Electrical

Conductor Sizing 37.4

Min Branch Circuit Wire

Size 60°C Temp Rating Copper

Max Line Length**** Ft

Largest Wire Size Line-Voltage Con

nections Will Accommodate AWG No.

Max Branch Circuit Fuse Size Amps

Rated Cooling Capacity* Bfuh

Compressor Motor FLA

Condenser Fan Motor** HP

Evaporator Blower Motor** HP

Rated Total Power Consumption KWH

Conductor*** AWG No.

Refrigerant type/lbs-ozs

Evaporator Airflow CFM

Approximate Shipping Weight lbs 345

230-60-1

R-22/4-13 R-22/4-13

42,000 . 41,000 42,000 48,000

207-254

25.0

111

1/4 1/4 1/4

1.8

1/2

4.2

6.3 6.3

31.0

8 10

116

4

40 30

1570 1570 1570 1800

559B-042-E

208-60-3 230-60-3

187-229

16.9 15.3

92

2.1

1/2 1/2 1/2 1/2 1/2 1/2

4.4

23.4

27.6

103

4 4 4

345 345

207-254

92 118 90 78.5 39.3

1.8

4.2 4.9 5.1 4.9 4.9

6.3 7.2 7.2 7.2

21.3

25.1 40.0 33.3

10 8

130

30

R-22/4-13

230-60-1 208-60-3

207-254 187-229

26.5

1/4

1.9

33.3

108

45

R-22/4-11

367

559B-048-E

20.9 18.0 9.1

1/4 1/4

2.1 1.8 1.8

28.1 24.7

8 10 12

137

4

35 30 20

R-22/4-11 R-22/4-11 R-22/4-11

1800 1800 1800

367 367 367

*Rated in Accordance with ARI Standard 210-66.

**Condenser fan and evaporator motors are single phase.

***If other than 60 °C copper conductor is used, determine size from unit ampacity and the National Electrical Code. Voltage drop of

wire must be less than 2% of unit rated voltage.

****Wire length shown is measured one way along the wire path between unit and service panel for minimum voltage drop.

230-60-3

207-254 414-508

29.2 18.1

112 225

4

460-60-3

1/4

7.2

15.8

4

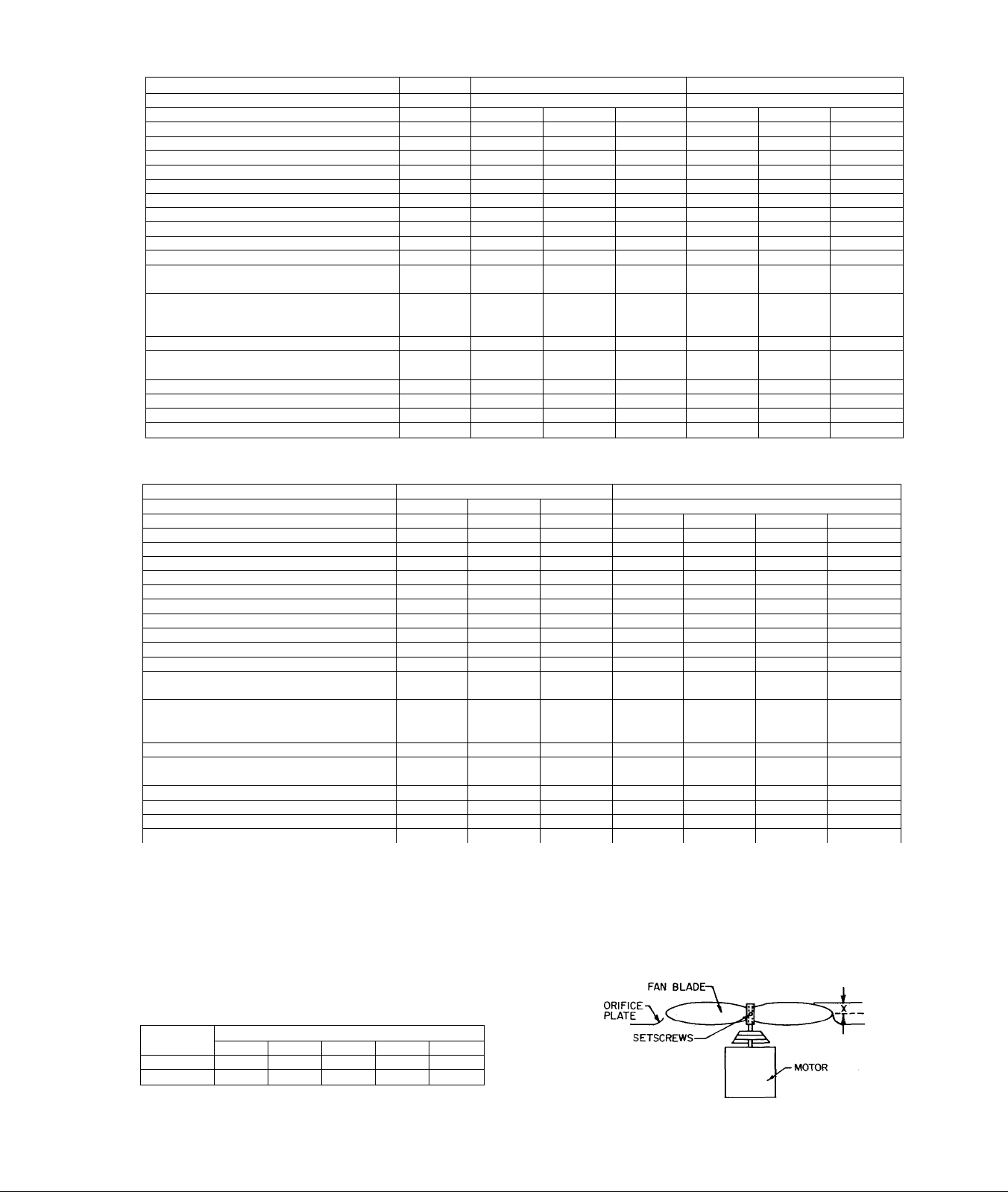

Unit Size

Disposable

Permanent

TABLE II—FILTER DIMENSIONS

Minimum Filter Size or Equivalent, Inches

024 030

16x20x1 20x20x1

12x20x1 16x20x1 20x20x1 20x20x1 20x25x1

036

20x25x1

042

25x25x1

048

25x25x1

X = Size 024, 030, & 036................................................................................1-3/4 in.

Size 042 & 048 ............................................................................................2 in.

Figure 4—Required Condenser

Fan Position

-3-

Page 4

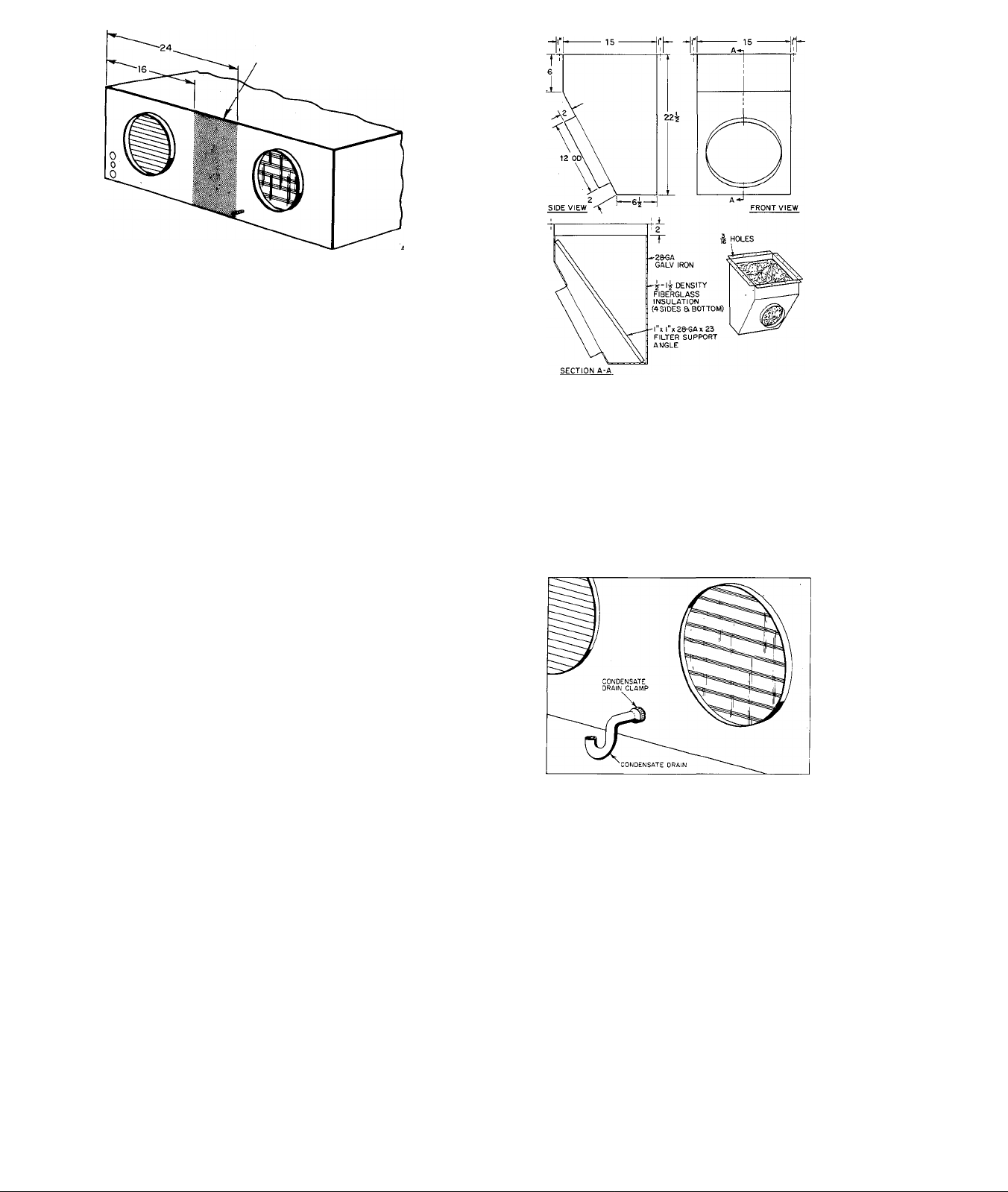

DO NOT DRILL HOLES IN SHADED

AREA WHEN INSTALUNG

RECTANGULAR DUCTS

Figure 5

of 6 ft and minimum return duct length of 3 ft. Do not

operate unit longer than 5 minutes without ductwork.

Refer to Bryant Air Distribution Manual, Part 2, for air

duct design.

Flanges are provided on unit for duct connections. See

Figure 2 for connection sizes and Figure 3 for typical duct

installation.

Supply Air Connection in Mobile Home

Connect flexible duct to unit supply air connection at ap

proximate center of trailer. Install turning vanes in main

supply duct directly above elbow connection, using stan

dard sheet metal practices.

Return Air Connection in Mobile Home

Purchase or field-fabricate a filter box. Suggested minimum

filter box dimensions are shown in Figure 6. At ap

proximate center of trailer, cut a return air opening in floor.

Locate opening where it will not be obstructed by furniture.

Size opening to accept filter box. Cut a hole in carpet or

floor covering to sarne size as filter box floor opening. En

sure electrical wiring or main structural supports are not

accidentally cut. Insert filter box thru floor opening.

Weather-seal floor connection in accordance with good con

struction practice. Insert filter in filter box, and cover with

return air grille.

Connect flexible duct to filter box. Extend duct from filter

box to unit return air connection. When existing furnace is

kept in system: During heating season, insert sheet metal

panel beneath return air grille and over filter to prevent air

movement thru cooling unit.

When furnace is removed from system, blank-off original

furnace floor connection.

III. CONNECTING CONDENSATE DRAIN

The unit is designed to dispose of accumulated water

through condensate drain hose on unit. It is recommended

that a drain line that includes a trap should be installed to

avoid possibility of abnormal negative fan pressure preven

ting complete drainage of condensate. If drain connection is

not practical or feasible, a factory-supplied condensate trap

(taped at supply duct connection) must be installed for

proper drainage. See Figure 7.

IV. ELECTRICAL CONNECTIONS

Field wiring must comply with National Electrical Code

and local codes. Install a branch circuit fused disconnect of

adequate size to handle unit current load. Provide separate

fused disconnect for electric heaters.

Voltage to unit during operation must be within ±10% of

voltage indicated on rating plate.

W.-VRNI.N'Ci: Failure berause of operation of unit on im

proper line voltage constitutes abuse and is not coveretl by

Brvant warr.mtv.

Figure 6 — Minimum Dimensions-Return

Air Filter Box

Connect line-power leads from fused disconnect(s) to line

power leads located in junction box. Screw connectors,

which are suitable for aluminum or copper wires, are

provided. See Figures 8 and 9. Tape screw connectors after

connections are completed. Table I is provided to assist in

staller in selecting proper wire and fuse sizes.

Thermostat connections are made to color-coded wires

located in junction box. See Figures 8 and 9. Be sure colorcoded wires not used are adequately and individually taped

at end.

Rgure 7 —Condensate Drain Connection

NOTE: When using Model 883 (P/N 34427D03O) ther

mostat with optional electric heat package, W and J ter

minals on thermostat must be jumpered to ensure fan

operation when thermostat is in HEAT position.

V. STARTUP AND ADJUSTMENT

Before starting system, make an initial overall inspection.

1. Check to be sure all wiring connections, including fac

tory connections, have been completed and are tight.

2. Inspect all supply ducts and grilles to ensure proper

adjustment.

3. Check to ensure air filters are in place.

4. Inspect refrigerant piping for damage or leaks that

might have occurred during shipment.

5. Check for correct position of condenser fan blade in fan

orifice plate. See Figure 4 for setting.

6. Check to ensure all tools and loose parts have been

removed.

7. Check to ensure all panels and covers are in place.

Following initial inspection, unit may be started and ad-

-4-

Page 5

justed for proper airflow.

Recommended evaporator airflow is 350 to 450 CFM per

12,000 Btuh.

1. Set thermostat to call for cooling, thus energizing unit.

2. Measure static pressure in duct system at unit.

3. To determine airflow across evaporator coil, see Tables

III through VII.

Model 559B utilizes a direct-drive blower, factory-wired on

high-speed tap. If airflow is incorrect, blower speed can be

adjusted as follows:

1. Disconnect electric power to unit.

2. Disconnect cooling relay lead from high-speed tap

(black wire). Tape end of wire removed.

3. Refer to appropriate Air Delivery Performance Table

and connect relay lead to correct speed tap.

Blue wire med speed

Orange wire med-low speed

Red Wire low speed

4. Recheck system static pressure.

The air conditioner has been tested and factory sealed.

There is no need to check refrigerant charge. If it is

necessary to open refrigerant circuit, contact your Bryant

Distributor for proper procedure. The type and amount of

refrigerant are listed on rating plate.

Typical Sequence of Operation

Do not leave installation until unit has been observed

throughout one or two complete cycles. Installer, should

make certain during this time that all components are

operating in correct sequence. Refer to line-to-line wiring

diagrams. Figure 10 or 11. The following sequence of

operation pertains to the units shown; however, the

sequence of operation of all units is very similar.

NOTE: Although the unit wiring may vary slightly from

that shown in Figure 10 or 11, the sequence of operation

will not be affected.

Sizes 024, 030, and 036, 230V-60-1

Line voltage is supplied through terminals LI and L2 to

compressor contactor (2D) and to primary of control trans

former (lAl). An external low-voltage thermostat is con

nected across low-voltage wires R, Y, and G.

Set system switch to COOL and fan switch to AUTO on

thermostat. On call for cooling, power is supplied from con

trol transformer (lAl) through wire R, external thermostat,

wire Y, low-pressure switch (7C), and contactor holding coil

(2D) to other side of control transformer (lAl), closing con

tactor contacts (2D).

When contactor contacts (2D) close, condenser fan motor

(3C) is energized through run capacitor (4A2), starting con

denser fan. In addition, power flows through compressor

motor run capacitor (4A3), compressor start capacitor

(4Cl), start relay (2K), and compressor motor (3J), starting

compressor motor.

When cooling fan relay contacts (2A) close, power flows

through run capacitor (4A1) and blower motor (3D1)

starting blower motor.

When thermostat ceases to require cooling, it breaks circuit

between wires R and Y and wires R and G, shutting down

unit.

Size 048, 208V- or 230V-60-3

Line voltage is supplied through terminals Ll, L2, and L3

to compressor contactors (2D) and to control transformer

(lAl). An external low-voltage thermostat is connected

across low-voltage wires R, Y, and G. Set system to COOL

and fan switch to AUTO on thermostat.

On a demand for cooling by the external thermostat, power

is supplied from control transformer (lAl) through ter

minal R. Terminal R makes to terminals Y and G through

the thermostat.

As R makes to G, the coil of the cooling fan relay (2A1) is

energized, closing the fan relay contacts (2A1). Power is

now allowed to flow through blower motor run capacitor

(4A1), and the blower motor (3D1) starts.

As terminal R makes to terminal Y through the thermostat,

the coil of cooling relay (2A2) is energized, closing the

cooling relay contacts (2A2). Power is now allowed to flow

through the low-pressure switch (7C), the compressor in

ternal thermostat (7H), compressor overload contacts (8A),

and the Bryant COMPROTEC'" circuit which includès

timer motor (3M), and the coil of the holding relay (2C).

The energized coil of the holding relay (2C) closes its nor

mally open contacts and opens its normally closed contacts.

Timer motor (3M) runs through a 15-second (approx.) cy

cle. The timer motor contacts are then switched. Power is

now allowed to flow through the coil of compressor con

tactor (2D), which closes the normally open contacts of

compressor contactor (2D).

When compressor contactor contacts (2D) are closed, power

is allowed to flow through compressor overloads (8A) and

compressor motor (3L) starts. At this same time, power is

allowed to flow through low-ambient condenser fan switch

(7K), condenser fan run capacitor (4A2), and the two-speed

condenser fan motor (3D2) starts. When outdoor tem

perature drops to 85°F, low-ambient condenser fan switch

(7K) will switch contacts, energizing a lower speed of con

denser fan motor (3D2).

When the demand for cooling is satisfied, the external ther

mostat breaks the circuit between terminal R and terminals

Y and G. Breaking this circuit deenergizes compressor

holding coil (2D), cooling relay coil (2A2), and cooling fan

relay coil (2A1). The condenser fan motor (3D2), com

pressor motor (3L), and blower motor (3D1) are now

deenergized.

At the same time, the holding relay coil (2C) is deenergized,

opening its normally open contacts and closing its normally

closed contacts. Power now flows through normally closed

contacts of holding relay (2C) and timer motor (3M). In ap

proximately 4 minutes 45 seconds, the timer motor contacts

switch, breaking circuit to timer motor. The unit is now in a

“standby” position, ready for the next demand for cooling

by the external thermostat.

-5-

Page 6

VI. MAINTENANCE

Refrigerant Charging

Unit is factory charged. When recharging is necessary, blow

any refrigerant remaining in system, then weigh in total

charge indicated on unit rating plate. Standard 1/4-inch

Schrader service connections are provided on high and

low sides of refrigerant system for evacuation and charging.

Cleaning

Before cleaning, disconnect electrical power.

Condenser Coil: Lift or remove unit top cover for access to

condenser coil. Inspect coil periodically. Clean with brush,

vacuum cleaner, low-pressure water, steam, or air.

Evaporator Coil: Lift or remove unit top cover for access

to evaporator coil. Inspect coil periodically. Clean with

brush, vacuum cleaner, or low-pressure air.

NOTE: When cleaning condenser coil or evaporator coil, be

sure to thoroughly clean out the spaces between fins.

Return Air Filter: Clean filter a minimum of twice yearly.

Flush permanent type with hot water, steam; or soak in

mild solution of soap, or detergent, and water. Allow filters

to dry, and replace. Refer to filter manufacturer’s in

structions, as required, for other types of filters.

VII. INSTRUCTIONS TO OWNER

This Bryant self-contained cooling unit is designed and in

stalled to provide maximum comfort. Adherence to

following guidelines will help promote greater efficiency

and longer operating life.

1. Do not rapid-cycle unit. Allow at least 3 minutes

before returning unit to operation after shutdown.

On size 048 units, do not manually override

COMPROTEC^.

2. If there is a general power failure, it is recommended

that electrical power supply be turned off at unit

disconnect switch until electrical power supply to

building is restored. This prevents excessive current

draw that would result from momentary low-voltage

conditions at time power is restored.

3. Air filters should be cleaned or replaced regularly to

protect against restricted airflow across cooling coil.

4. Size 048 units incorporate Bryant’s COMPROTEC™

system for compressor protection. If compressor

overloads or hi-pressure switch have cause to function,

COMPROTEC ™ system will hold unit off for approxL

mately 5 minutes. At that time, unit will try to restart.

Should original condition still exist, unit will again

cycle on COMPROTEC™ system.

TABLE III — SIZE 024 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

600 0,84

700

800 0,67

900 0,57

1000 0.45 0.17

External S tatic Pressure Available

High Med Med L ow Low High Med Med Lo w

0.76 0.69 0.56 0.25 0.79

Wet Coil No Filters Dry Co il No Filters

0.80

0,56

0.40

0.71

0.38

0.14

0.60 0.86

—

_

—

—

TABLE IV — SIZE 030 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

800 1,12

900 1,01

1000 0,89 0.61

1100

1200 0,56

External S tatic Pressure Available External S tatic Pressure Available .

High Med

0,74 0.37

Wet Coil No Filters Dry Coil No Filters

0.96

0.80

Med Low

— —

0.80 0.21 1.14 0.98 0.82

0.48

—

— —

Low

—

—

—

TABLE V — SIZE 036 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

1000

1100 1.06

1200 0.95

1300

1400 0.67 0.42

External S tatic Pressure Available External S tatic Pressure Available

High Med

1.17 1.10

0.82

0.97

0.82 0.55

0.64

Wet Coil No Filters

Med Low

0,95 0.70

0,77 0.35

— —

_

Low

—

TABLE VI — SIZE 042 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

1100

1200

1300

1400

1500 1.00 0.55

1600 0.85 — — 0.93

External S tatic Pressure Available

High Med

1.15

Wet Coil No Filters

—

— —

— 1.10

0.87

—

Med Low

1.10

0.83

0.35

—

—

External S tatic Pressure Available

0.82 0.73 0.62

0.72 0.59 0.28

0.71

0.62

0.50 0.22

High M ed Med Low Low

1.04 0.83 0.51 —

0.93

0,79

0,63

High Med Med Low Low

1.21

1.11 1.02 0.82 0.40

1.01 0.88 0.61

0,89

0.76

High Med M ed Lo w

1.20 0.91

1.06

0.60 0.42

0.45

0.65

0.42

— —

Dry Co il No Filters

1.14

0.71

0.51 — —

External S tatic Pressure Available

Dry Co il No Filters

— — 1.14

—

—

0.19 —

— —

— —

0.99 0.74

—

—

1.15 0.40

0.61

— —

Low

0.23

0.87

—

—

—

—

—

—

—

TABLE VII — SIZE 048 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

1400

1500

1600 0.92

1700 0.80 0.40

1800 0.68 0.15

1900 0.53 —

External S tatic Pressure Available External S tatic Pre ssure Available

High

1.12

1.02

Wet Coil No Filters Dry Coil N o Filters

Med

0.95 0.60 1.17 1.00 0.65

0.79

0.61

Low

0.25

—

— 0.87 0.47 —

—

—

-6-

High Med Low

1.07

0.97 0.66

0.76 0.23

0.64

0.84

— —

0.30

—

—

Page 7

-FACTORY WIRING

- FIELD LOW-VOLTAGE WIRING

•FIELD HIGH-VOLTAGE WIRING

MODEL 883C

THERMOSTAT P/N34427DP78

® Ç) ©

---------

^—h

THERMOSTAT

CONNECTIONS

THERMOSTAT & SUBBASE

P/N 34427D03O

® © (^ Ç>

t—r

I

o

©

©

® ©

©

©

COLOR-CODED LEADS

(FROM UNIT)

located inside

JUNCTION BOX

Figure 9 — Low-Voltage Field Wiring (Cooling Only)

Figure 10—559B-024, -020, -030, & -036 Wiring Diagram, 230-60-1

® ©

© © ©

A72409

LEGEND

1A1-Control Transformer

1A2-460- to 230-V Transformer

2A-Cooling Fan Relay

2A1-Cooling Fan Relay

2A2-Cooling Relay

2C-Holding Relay

2D-Compressor Contactor (2 pole)

2K-Start Relay

2M-Compressor Contactor (3 pole)

3C-Condenser Fan Motor

3D1-Blower Motor

3D2-Two-speed Condenser Fan

Motor

3J-Compressor Motor with

Internal Protection

3L-Compressor Motor with

Internal Protection

3M-Timer Motor

4A1-Blower Motor Run Capacitor

4A2-Condenser Motor Run Capacitor

4A3-Compressor Motor Run

Capacitor

4C1-Compressor Motor Start

Capacitor

7C-Low-Pressure Switch

7H-lnternal Compressor Thermostat

7K-Low-Ambient Condenser Fan

Switch

8A-Com pressor Motor Overload

12-Receptacle

Figure 11 — 559B-048 Wiring Diagram, 208- or 230-60-3

-7-

Page 8

Accessory Electric Heater Installation

(For Use With 559B Self-contained Cooling Units)

T

INTRODUCTION

Single-phase electric heaters in 5-. through 15-KW sizes,

and three-phase electric heaters in 5.6- through 14.5-KW

sizes, are installed internally on 559B units. The 20- and

25-KW size single-phase heaters, and the 14.9- thru 25-KW

size three-phase heaters, are mounted externally on the

559B supply air connection. Do not use more than one

heater per unit. See Table I for heater model and 559B

usage.

I. ELECTRIC HEATER INSTALLATION

A. Internal Heaters

1. Remove fan section access panel.

2. Remove sheet metal plate covering heater installation

area (between evaporator fan discharge and supply air

connection). See Figure 5. Discard sheet metal plate.

3. Insert heater into opening provided.

NOTE: Ensure the heater support bar (Figures 1 and 5) en

ters the hole in the side of the fan discharge duct.

4. Fasten heater in place at top and bottom with two

sheet metal screws.

5. Attach heater wiring label provided to inside of fan

section access panel.

6. Installation is now ready for electrical connections.

See “Wiring”, Section III.

SCREW

CLEARANCE HOLES (7)

UNIT

HIGH-VOLTAGE LEADS

(CONNECTORS SUPPLIED)

Figure 1—Internal Heater

EXTERNAL HEmi nn

(BOTTOM)

Figure 3—Power Knockouts on

SCREW CLEARANCE

HOLES (2)

(TOP AND BOTTOM)

External Heater

•SERVICE

PANEL

I5-LINE

'POWER

KNOCKOUT

INLINE

“power

KNOCKOUT

A73166

Figure 2—Entering Air Side of

DUCT

CONNEC

FLANGE

EXTERNAL HEATER

(DUCT SIDE)

Figure 4—Duct Connection Side of

External Heater

External Heater

IIRViCE

. „NEL

151

-8-

Page 9

FAN

Section

HEATER

HEATER

TOP ELECTRICAL KNOCKOUT CONTROL WIRING HOLE

INTERNAL

ELECTRIC

HEATER

LINE POWER

LEADS

Figure 5—Internal Electric Heater Installation

B. External Heaters

CONTROL

-WIRING PLUG

SUPPLY

AIR CONN

The external heaters are self-locating on the 559B

evaporator fan supply air connection. See Figure 6. Flanges

are provided on the heater for connection to the 559B with

sheet metal screws. See Figure 2. Before installing the

heater, ensure the factory-supplied gasket is in place

around the heater entering air connection as shown in

Figures 2 and 3. Complete installation as follows;

NOTE: When installing external heaters, remove the in

ternal air baffle from the 559B. The external heaters have

their own air baffle.

1. Remove top electrical knockout on 559B. See Figure 6.

2. Place heater over 559B supply air connection. See

Figure 6.

3. Align control wiring hole in entering air side of heater

(Figure 2) with top electrical knockout in 559B. See

Figure 6.

4. Drill holes in 559B to align with screw clearance holes

in heater flanges. See Figure 2 for location of clearance

holes in flanges.

NOTE: Mark the drilling locations while holding the

heater in place against the 559B.

( Al TION: I).. nol pem-lraif drill more iliaii 1 inch iusitlc

5. Fasten heater in place with sheet metal screws.

6. Installation is now ready for electrical connections.

See “Wiring”, Section III.

II. DUCTWORK REQUIREMENTS

Refer to Connecting Ductwork section on page 1 of these

instructions for complete duct installation details. The

following ductwork recommendations pertain to electric

heater applications:

1. Flexible connectors are required between duct con

nection flanges and ductwork to prevent transmission

of vibration. When electric heater is installed, it is

recommended that asbestos (or similar heat-resistant

material) connector be used between ductwork and

heater duct connection flange. If non-heat-resistant

flexible duct is used, it is recommended that a sheet

metal sleeve be inserted inside of duct. Heat-resistant

Figure 6—External Heater Installation

duct connector (or sheet metal sleeve) should extend 24

inches from electric heater element.

2. Single-phase external heaters are provided with

means for attachment of circular ductwork only.

Three-phase external heaters are provided with

means for attachment of circular or square ductwork.

3. When electric heater is used, the ductwork must be

capable of handling minimum air quantities shown in

Table III.

III. WIRING

Field wiring must be made in accordance with the National

Electrical Code and local electrical codes governing such

wiring. Provide a separate fused disconnect for each electric

heater circuit. See Table II. Refer to heat package wiring

label.

A. Line-Power Connections

On internal heater installations, bring the line-power

leads from the fused disconnect(s) through the power holes

in the 559B unit panel. Knockouts are provided on the ex

ternal heater cabinet for passage of the line-power leads.

See Figure 3.

Connect the line-power leads to the heater line-power

pigtails or to the heater high-voltage terminal block. See

Figure 10 and Table II for branch circuit data and line-

power connections. Use screw connectors provided for

pigtail connections, and tape each connection. The screw

connectors and terminal block are suitable for copper or

aluminum wire.

If aluminum conductors are used, the wire gauge selected

must have current capacity not less than the copper wire

specifled and must not create a voltage drop between the

service panel and the unit in excess of 2% of the unit rated

voltage.

NOTE: If aluminum conductors are used, the connections

must be made in accordance with the National Electrical

Code. In preparing the wire, just before installing the con

nector, all aluminum wire must be “brush-scratched” and

the wire coated with a corrosion inhibitor, such as Pentrox

A. When it is suspected that the connection will be exposed

to moisture, it is very important to cover the entire con

nection completely to prevent an electro-chemical action

that will cause the connection to fail very quickly. Reducing

the effective size of the wire, such as cutting off strands so

that the wire will fit a connector, is very poor practice.

Proper size connectors should be used.

-9-

Page 10

TABLE I—HEATER DATA & USAGE

Heater

Model No.

88EA0050CA00

88EA0075CAOO 7O181D02

88EA0100CA00

88EA0150CA00t

88EA12O0CAOOt

88EA1250CA00t

88EA1250LA00t

88EA0075EA00

88EA0100EAOO 7O181D011

88EA0145EA00

88EA1198EAOOt

88EA1250EA00t

88EA0160FA00

88EA1200FA00t

Bryant

P/N

7O181D01

7O181D03 10 240-60-1

7O181D04

7O181D05 20 240-60-1 — 62,690

70181D06

7O181D08

7O181D01O 5.6/7.5

7O181D012 10.9/14.5

7O181D013 14.9/19.8

7O181D014

7O181D016 10

7O181D018

KW* Phase

5 240-60-1

7.5

15 240-60-1

25 240-60-1 — 78,363

25 208-60-3

7.5/10

18.75/25

20

Voltage-

Hertz-

240-60-1

208/240-60-3 19,227

208/240-60-3

208/240-60-3 37,171

208/240-60-3

208/240-60-3

480-60-3

480-60-3

208V 230V 240V 480V

—

— 23,509

—

_

85,325

25,635

50,758

64,089

—

—

Btuh Output

15,673

31,345

47,018 51,195 —

—

23,509

31,345

45,450

62,063 67,577

78,363

— — 34,130

-

17,065 —

25,598

34,130

68,260

85,325

— —

25,598

34,130

49,489

85,325

—

68,260

—

—

—

—

—

—

—

—

—

*At rated voltage.

tThese heaters are wired for two-stage heating. Remaining heaters are wired for single-stage heating.

NOTE: The 18.75/25- and 25-KW heaters must be field-connected for two-stage operation. All other heaters wired for two-stage heating

may be field-connected for single- or two-stage operation.

TABLE II—HEATER ELECTRICAL DATA

KW

5t

7.5t 240-60-1 1 31.2

lot

15t

20 240-60-1

25

25

5.6/7.5t

7.5/1 Ot

10.9/14.5t

14.9/19.8 208/240-60-3 1

18.75/25 208/240-60-3

lot

20

Voltage-

Hertz-

Phase-

240-60-1 1

240-60-1

240-60-1 2 41.7

240-60-1 3 41.7

208-60-3

208/240-60-3 1

208/240-60-3

208/240-60-3 1

480-60-3 1 12.0

480-60-3 1 24.0

No. of

Circuits

1 41.7

2 41.7

2

1 ■

2 26.0/30.1

FLA

(each)

20.8 10 45 30

20.8

41.7

41.7

20.8

34.7

34.7

15.6/18.0 12/10 49/49

20.8/24.0 10/10 59/59

30.2/34.9

41.3/47.6 6/4 46/73

26.0/30.1 8/8 47/47

Branch Circuit

Wire

Size*

(AWG No.)

8 45 40

6 55 50

6 55 50

10 45 30

6 55 50

6 55 50

6 55 50

6 55

10 45 30

6 55 45

6 55

8/6 63/63 40/45

8/8 47/47 35/40

14 59 15

10

Max Wire

Length

(ft)**

74

Fuse

Amps

20/25

30/30

60/60

35/40

tThese heaters are internally installed. All others are externally installed.

*Based on 60°C copper wire. If other than 60°C copper conductor is used, determine size from unit ampacity and the

National Electrical Code. Voltage drop of wire must be less than 2% of unit rated voltage.

**Length shown is for one way along the wire path from unit to service panel for minimum voltage drop.

Size Unit

Used With

024, 030, & 036

024 thru 048

024 thru 048

030 thru 048

042 & 048

,042 & 048

042 & 048

030 thru 048

030 thru 048

030 thru 048

042 & 048

042 & 048

048

048

50

45

30

B. Control Wiring (24V)

Between Heater and 559B

A low-voltage control-wiring plug is provided on the heater

for connection to the receptacle in the 559B control-wiring

terminal box.

On internal heater installations, extend the control-wiring

plug through the hole provided in the 559B control-wiring

terminal box and connect to the receptacle. On external

heaters, feed the plug through the control-wiring hole

provided in the heater cabinet (Figures 2 and 6) and into

the 559B. Extend the plug into the 559B control-wiring ter

minal box and connect the plug to the receptacle.

NOTE: When heater installation is completed, be sure to

seal holes around all electrical openings to prevent air

leakage.

C. Thermostat leads

The thermostat leads are brought through the grommeted

hole, provided in the 559B, into the control-wiring terminal

box. Connect the thermostat leads to the low-voltage

pigtails. See Figure 8 or 9 for thermostat connection

diagrams. Tape unused pigtails separately. When

aluminum field wire is used, lubricate splices with a

suitable splice compound, and use approved copper-toaluminum splice connectors. Set the thermostat heat an

ticipator as described in “Determining Heat Anticipator

Setting”, Section V.

IV. SERVICE

A. Limit Switch

The limit switch provides overtemperature protection. A

switch malfunction prevents the heating elements from

being energized. Replace the limit switch if a malfunction

occurs.

B. Time-Delay Relay

The 14.9- through 25-KW heaters are sequenced. The time-

-10-

Page 11

TABLE III

SIZE UNIT

024 600

030

036 900

042

048

' *Minimum unit cfm for safe

heater operation.

CFM*

750

1050

1200

delay relay provides a time delay between the heater

elements coming on or shutting off. A relay malfunction

will prevent the heaters from being energized or prevent the

heaters from being deenergized. Replace the time-delay

relay if a malfunction occurs.

C. Safety Fan Relay (14.9- through 25-KW heaters)

The safety fan relay ensures the operation of the evaporator

fan while the sequenced heater elements are energized. A

malfunction will cause excess heat problems; the fan motor

will not start or will not shut off. Replace the safety fan

relay if a malfunction occurs.

V. DETERMINING HEAT ANTICIPATOR SETTING

Because of the numerous combinations of components that

a heating control circuit may contain, it is necessary to

measure the load in amperes, so that the thermostat heat

anticipator (s) can be set properly after the installation is

completed. A hook-around ammeter is used to measure the

heating control circuit load in this procedure.

Figure 7 shows the proper use of a hook-around ammeter to

determine the load. This illustration shows the circuit with

five turns around the jaws of the ammeter. Five turns

should be used to obtain an accurate reading.

To obtain correct heat anticipator setting, divide the am

meter reading by the number of turns around the jaws of

the ammeter.

Example:

3.5 amperes

0.7 amperes setting

5 turns around jaws

Procedure for two-stage heating units:

1. Disconnect lead from thermostat terminal W1 and

make five turns around ammeter jaws. See Figure 7.

2. Disconnect lead from thermostat terminal Rh and

connect to W1 as shown in Figure 7.

3. Obtain ammeter reading for calculating first-stage

heat anticipator setting.

4. Reconnect W1 lead and disconnect W2 lead from

thermostat.

5. Follow same procedure used above to obtain ammeter

reading for calculating second-stage heat anticipator

setting.

6. Reconnect W2 and Rh leads to thermostat terminals.

NOTE: The procedure for single-stage heating units is the

same, except the leads from thermostat terminals W and 4R are connected together.

NOTE: For accurate load calculations, the ammeter

readings should be taken at the thermostat as shown in

Figure 7. The thermostat hookup leads must be in the cir

cuit when taking these readings.

THERMOSTAT a SUBBASE

JUMPER

*N0TE; W2 CONNECTION

FOR l5-a20-KW

HEATERS ONLY

Figure 8—Cooling and Single-Stage Heating

P/N34427D03O

COLOR-CODED LEADS

(FROM UNIT)

LOCATED INSIDE

JUNCTION BOX

Thermostat Connections

THERMOSTAT

CONNECTIONS

-11-

BRYANT

THERMOSTAT

P/N 34427D54 8

SUBBASE

P/N 34427D66

@ @

I

_l UJ 5

CD >- $

Figure 9—Cooling and Two-Stage Heating

i

_______

1

r—

» • (

o I <

SI®

cc 3

(D CD

Thermostat Connections

1

r-J

ÜJ

cr

Page 12

SINGLE-PHASE HEATERS

TO FUSED

DISCONNECT

TO FUSED

DISCONNECT

TO FUSED .

DISCONNECT

KW Voltage-

5 240-1

7.5

10

15 240-1

20

25

Phase

240-1

240-1

240-1 2

240-1 3 .

*Based on 60°C copper wire. See Table II.

Circuits

Used

1 A

1 A 8

1 A 6

2 A 6

B . 10

A 6

B 6

A 6

B 6

C 10

Wire

Size*

10

THREE-PHASE HEATERS

(PIGTAIL CONNECTIONS)

THREE-PHASE HEATERS

(TERMINAL BOARD CONNECTIONS)

LEGEND

CIRCUITA

TO FUSED

DISCONNECT

CIRCUIT B

TO FUSED

KW Voltage-

25

14.9/19.8 208/240-3 1 A 6/4

18.75/25

20

Phase

208-3 2 A '6

208/240-3 2 A 8/8

480-3

DISCONNECT *Based on 60°C copper wire. See Table II.

FACTORY LINE-VOLTAGE WIRING

FIELD LINE-VOLTAGE WIRING

FIELD SPLICE

Circuits

Used

1 A

Wire

Size*

B 6

B 8/8

10

Figure 10—Line-Power Connections

-12-

Loading...

Loading...