Page 1

wiring diagrams

A

A

C

C

C

C

C

G

SINGLE PACKAGE ROOFTOP

ELECTRIC COOLING

UNITS

Cancels: New WD 558F.36.1

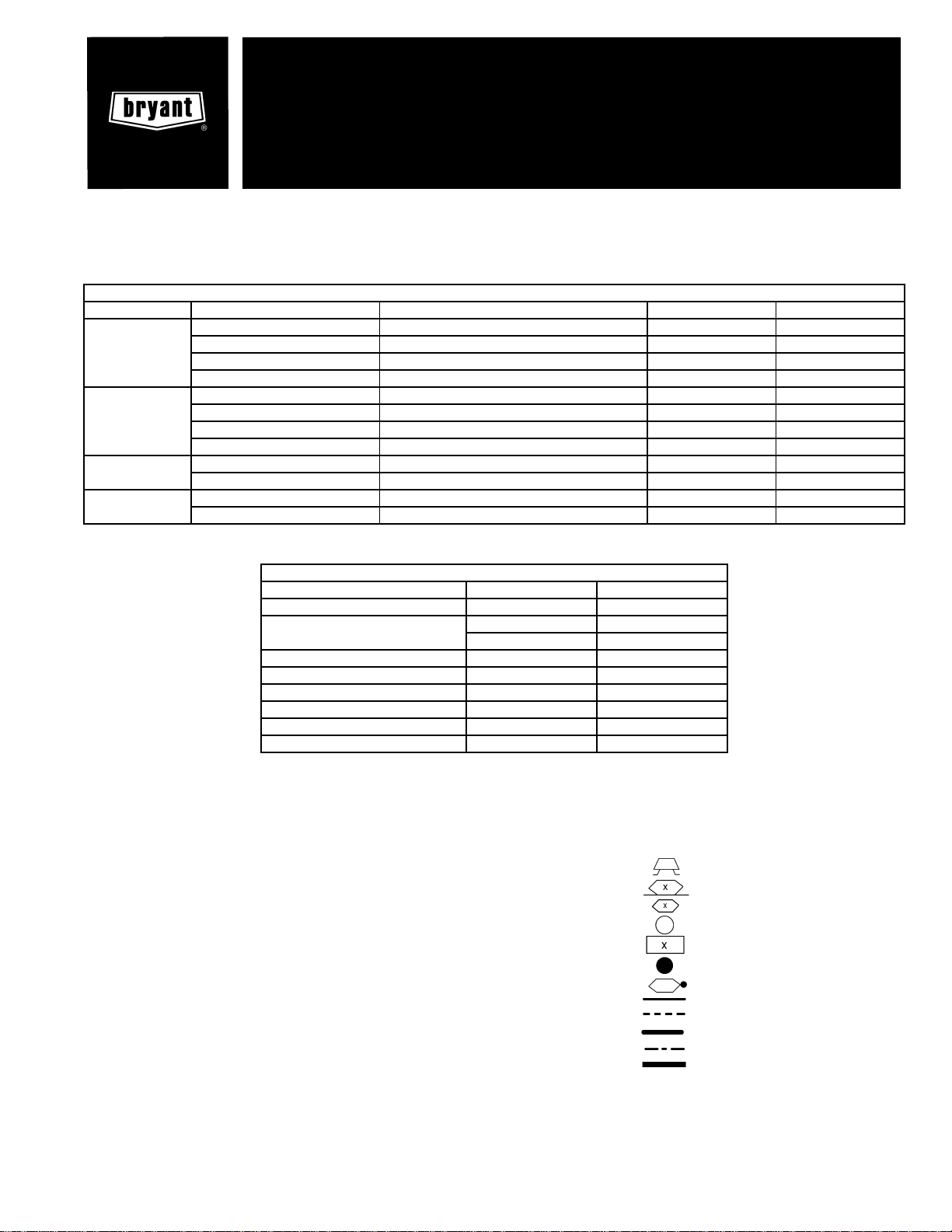

DIAGRAM INDEX

UNIT LABEL DIAGRAM

Unit 558F Voltage-Phase-Hertz Type Label Diagram Figure No.

208/230-1-60 Schematic/Component Arrangement 50DK508524 1

036,048

060

072

090-150

208/230-3-60 Schematic/Component Arrangement 50DK508526 2

460-3-60 Schematic/Component Arrangement 50DK508529 3

575-3-60 Schematic/Component Arrangement 50DK508531 4

208/230-1-60 Schematic/Component Arrangement 50DK508525 5

208/230-3-60 Schematic/Component Arrangement 50DK508527 6

460-3-60 Schematic/Component Arrangement 50DK508530 7

575-3-60 Schematic/Component Arrangement 50DK508532 8

208/230-3-60, 460-3-60 Schematic/Component Arrangement 50DK508528 9

575-3-60 Schematic/Component Arrangement 50DK508533 10

208/230-3-60, 460-3-60 Schematic/Component Arrangement 50DK508793 11

575-3-60 Schematic/Component Arrangement 50DK508794 12

3 to 121/2 Tons

558F

036-150

11/15/00

ACCESSORY WIRING

Description Unit Size Fig. No.

Motormaster® I Control 036-150 13

Motormaster II Control

Time Guard® II Device 036-150 16

Solid-State Enthalpy Control 036-150 17

Differential Enthalpy Control 036-150 18

EconoMi$er 036-072 19

EconoMi$er Sensor Wiring 036-150 20

Power Exhaust 036-072 21

036-072 14

090-150 15

LEGEND

HA — Adjustable Heat Anticipator

WG — American Wire Gage

— Contactor, Compressor

AP. — Capacitor

B—Circuit Breaker

C—Cooling Compensator

OMP — Compressor Motor

D—Diode

EC — Enthalpy Control

ECON — Economizer

EPS — Emergency Power Supply

EQUIP — Equipment

ER — Economizer Relay

FPT — Freeze-Up Protection Thermostat

FU — Fuse

ND — Ground

HC — Heater Contactor (Strip Heat)

HPS — High-Pressure Switch

IFC — Indoor-Fan Contactor

IFM — Indoor-Fan Motor

IFMOVL— Indoor-Fan Motor Overload

(Nine-Volt Battery)

IFR — Indoor-Fan Relay

LPS — Low-Pressure Switch

LSM — Limit Switch (Manual Reset)

MTR — Motor

OAT — Outdoor-Air Thermostat

OFC — Outdoor-Fan Contactor

OFM — Outdoor-Fan Motor

OLR — Overload Relay

P—Plug

PL — Plug Assembly

QT — Quadruple Terminal

R—Relay

SAT — Supply-Air Thermostat

SEN — Sensor

ST — Start Thermistor

SW1 — Switch Fully Open

SW2 — Switch Fully Closed

SW3 — Switch Minimum Vent Position

SW4 — Switch Maximum Vent Position

TB — Terminal Block

TC — Thermostat, Cooling

TDR — Time-Delay Relay

TH — Thermostat, Heating

TRAN — Transformer

Field Splice

Marked Wire

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To indicate common potential only.

Not to represent wiring.

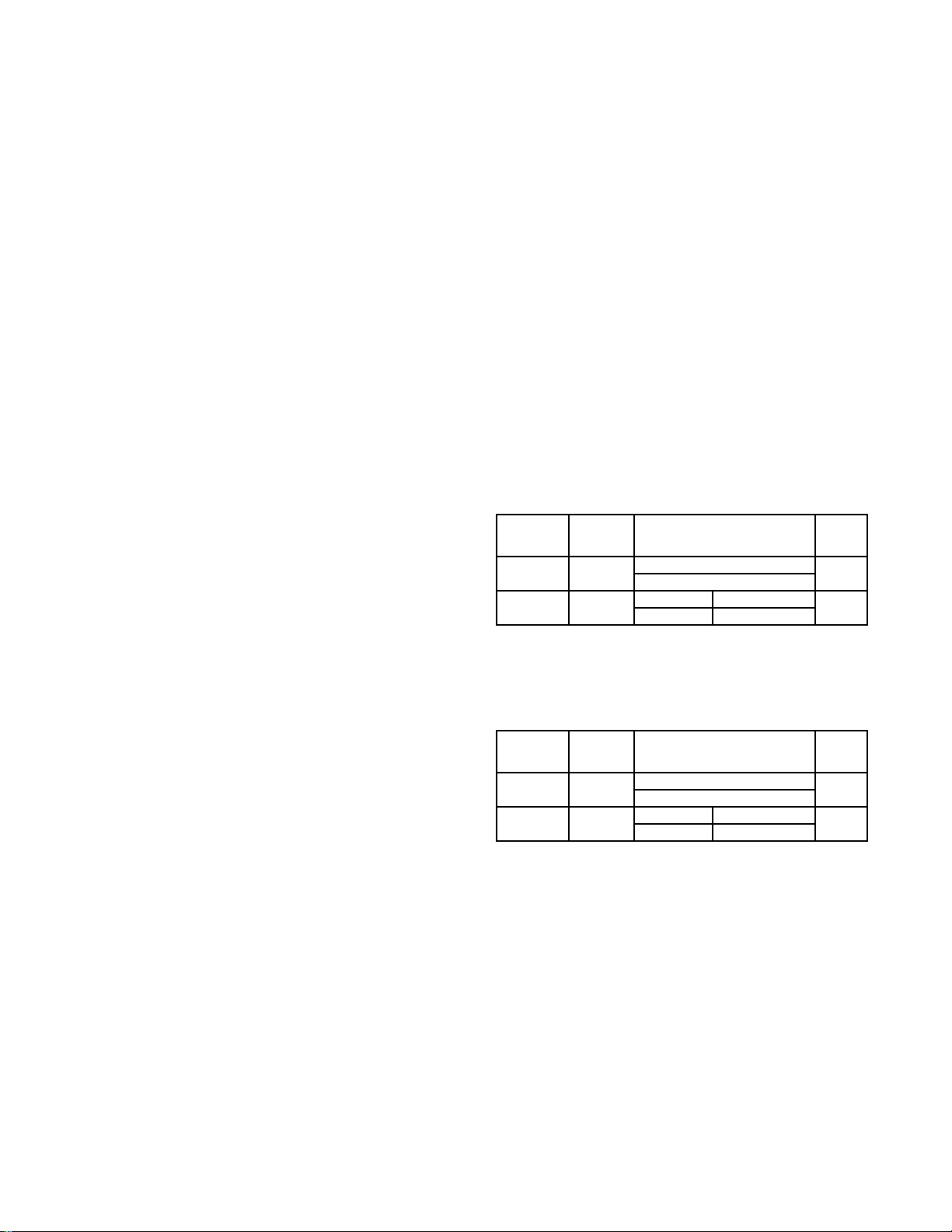

Page 2

NOTES FOR FIG. 1, 2, 5, 6, 9

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90 C wire or its equivalent.

2. Three-phase motors are protected under primary single-phasing

conditions.

3. Thermostat:

HH07AT170, 172, 174, and P272-2783

Subbase:

HH93AZ176, 178, and P272-1882, 1883

NOTES FOR FIG. 3, 4, 7, 8, 10

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90 C wire or its equivalent.

2. Three-phase motors are protected under primary single-phasing

conditions.

3. Thermostat:

HH07AT170, 172, 174, and P272-2783

Subbase:

HH93AZ176, 178, and P272-1882, 1883

NOTES FOR FIG. 11

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90 C wire or its equivalent.

2. Three-phase motors are protected under primary single-phasing

conditions.

3. Thermostat:

HH07AT170, 172, 174, and P272-2783

Subbase:

HH93AZ176, 178, and P272-1882, 1883

4. Set heat anticipator at 1 amp.

5. Use copper conductors only.

6. Use copper, copper-clad aluminum or aluminum conductors.

4. Set heat anticipator at 1 amp.

5. Use copper conductors only.

6. Use copper, copper-clad aluminum or aluminum conductors.

7. For 208/230-3-60 v units: TRAN is wired for 230-v unit. If unit is to be

run with 208-v power supply, disconnect BLK wire from 230-v tap

(RED) and connect to 208-v tap (BLU). Insulate end of 230-v tap.

4. Set heat anticipator at 1 amp.

5. Use copper conductors only.

6. Use copper, copper-clad aluminum or aluminum conductors.

7. For 208/230-3-60 v units: TRAN is wired for 230-v unit. If unit is to be

run with 208-v power supply, disconnect BLK wire from 230-v tap

(RED) and connect to 208-v tap (BLU). Insulate end of 230-v tap.

8.

CIRCUIT

BREAKER

CB 24 V

CB1 150 460-3-60

VOLTS MFG. PT. NO.

Potter & Brumfield

Heinemann Airpax

MUST

TRIP

AMPS

3.2W2BX-1024-3.2

8.5CF3-Z228-4 219-3-2600-486

NOTES FOR FIG. 12

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90 C wire or its equivalent.

2. Three-phase motors are protected under primary single-phasing

conditions.

3. Thermostat:

HH07AT170, 172, 174, and P272-2783

Subbase:

HH93AZ176, 178, and P272-1882, 1883

4. Set heat anticipator at 1 amp.

5. Use copper conductors only.

6. Use copper, copper-clad aluminum or aluminum conductors.

7.

CIRCUIT

BREAKER

CB 24 V

CB1 150 460-3-60

VOLTS MFG. PT. NO.

Potter & Brumfield

Heinemann Airpax

MUST

TRIP

AMPS

3.2W2BX-1024-3.2

8.5CF3-Z228-4 219-3-2600-486

—2—

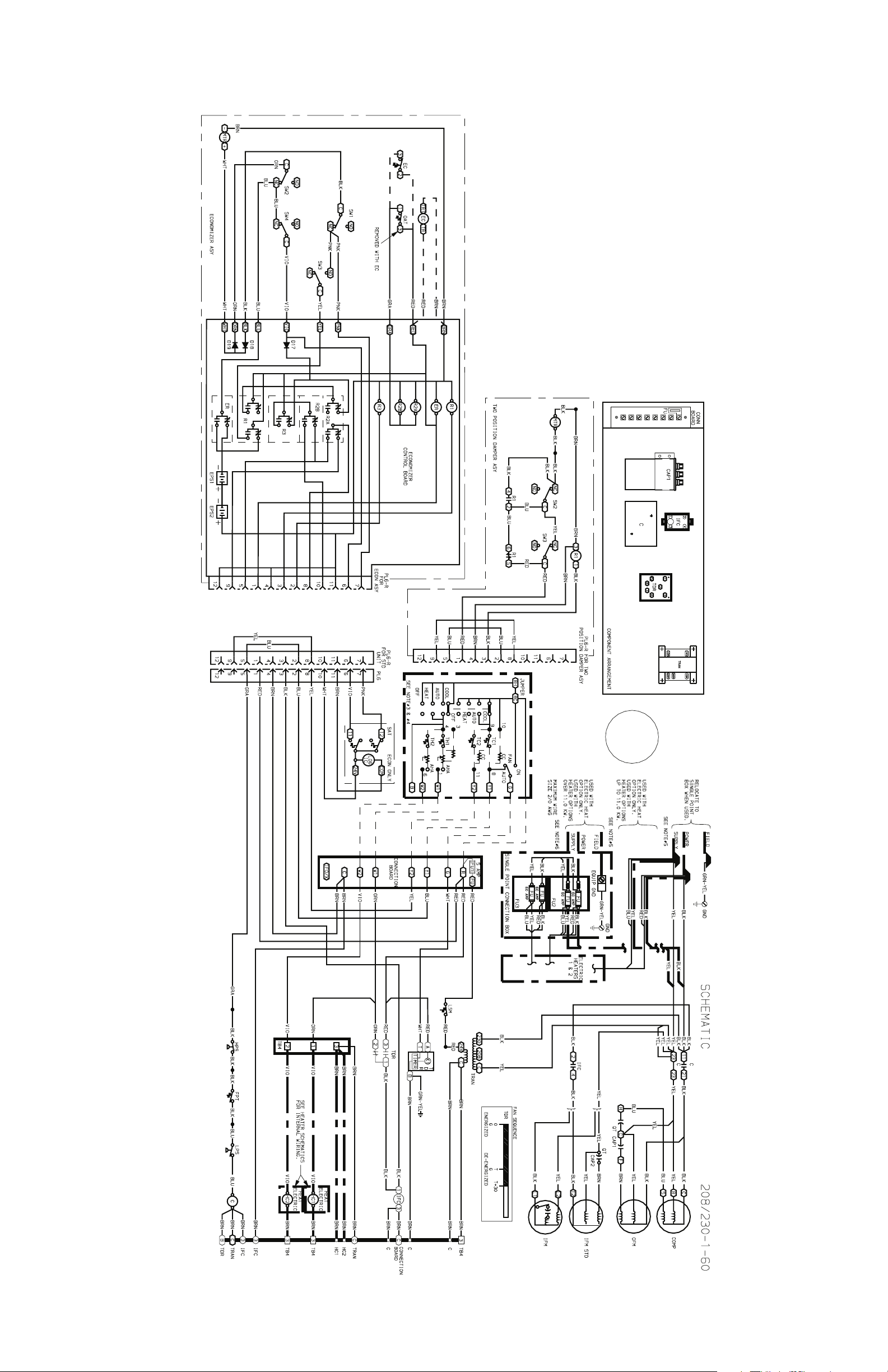

Page 3

—3—

Fig. 1 — Schematic/Component Arrangement; 558F036,048; 208/230-1-60

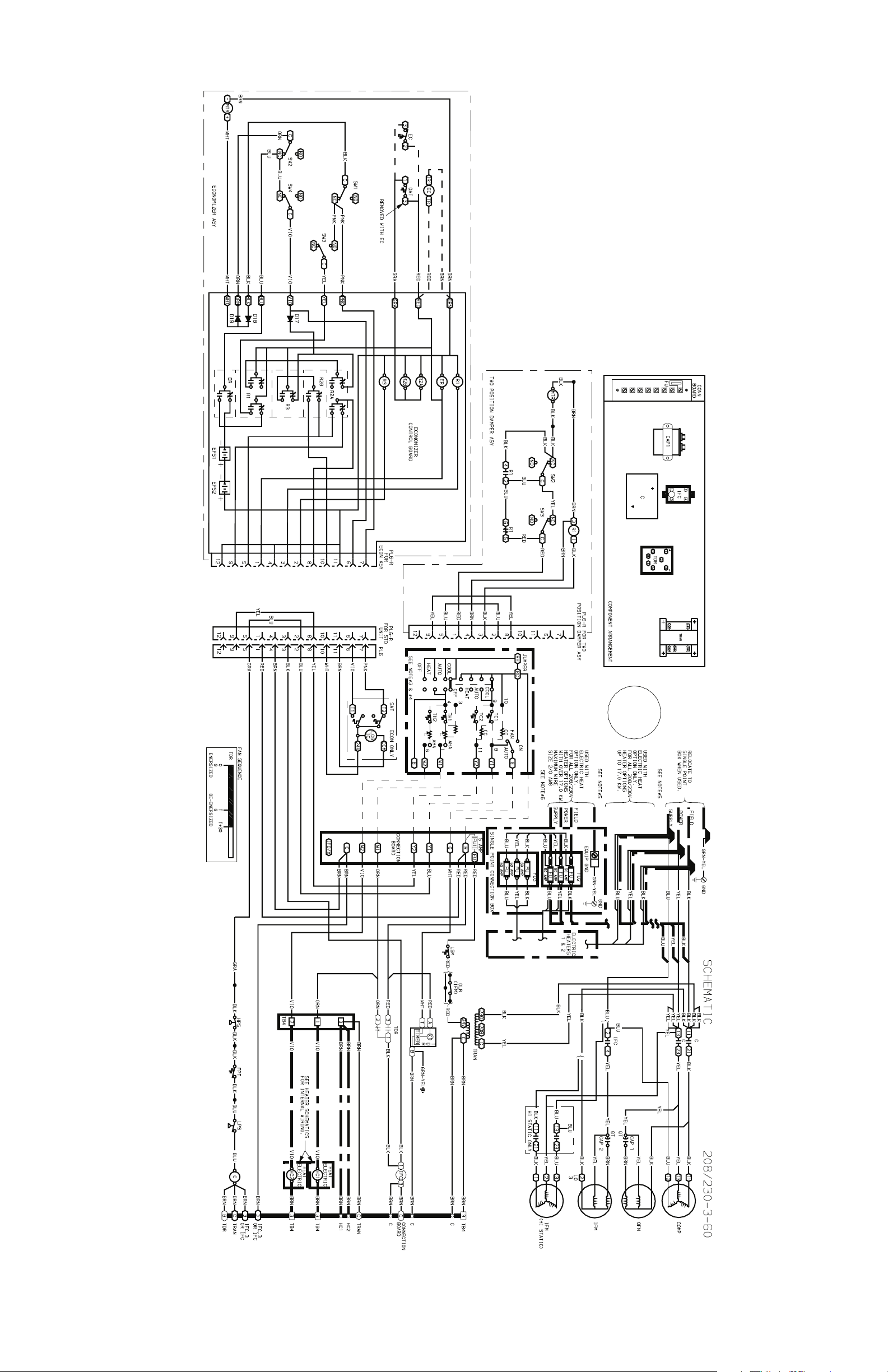

Page 4

—4—

Fig. 2 — Schematic/Component Arrangement; 558F036,048; 208/230-3-60

Page 5

—5—

Fig. 3 — Schematic/Component Arrangement; 558F036,048; 460-3-60

Page 6

—6—

Fig. 4 — Schematic/Component Arrangement; 558F036,048; 575-3-60

Page 7

—7—

Fig. 5 — Schematic/Component Arrangement; 558F060; 208/230-1-60

Page 8

—8—

Fig. 6 — Schematic/Component Arrangement; 558F060; 208/230-3-60

Page 9

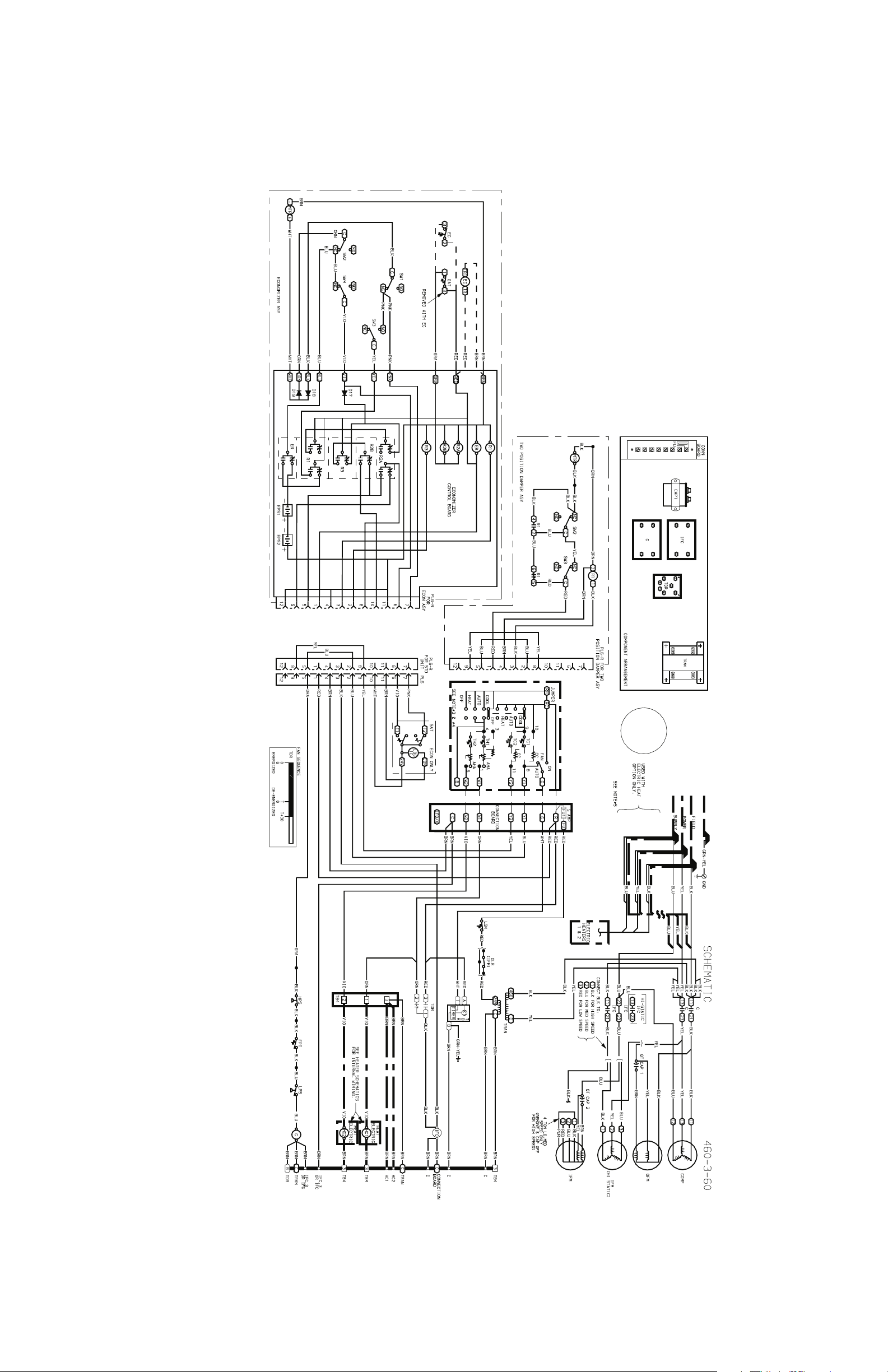

—9—

Fig. 7 — Schematic/Component Arrangement; 558F060; 460-3-60

Page 10

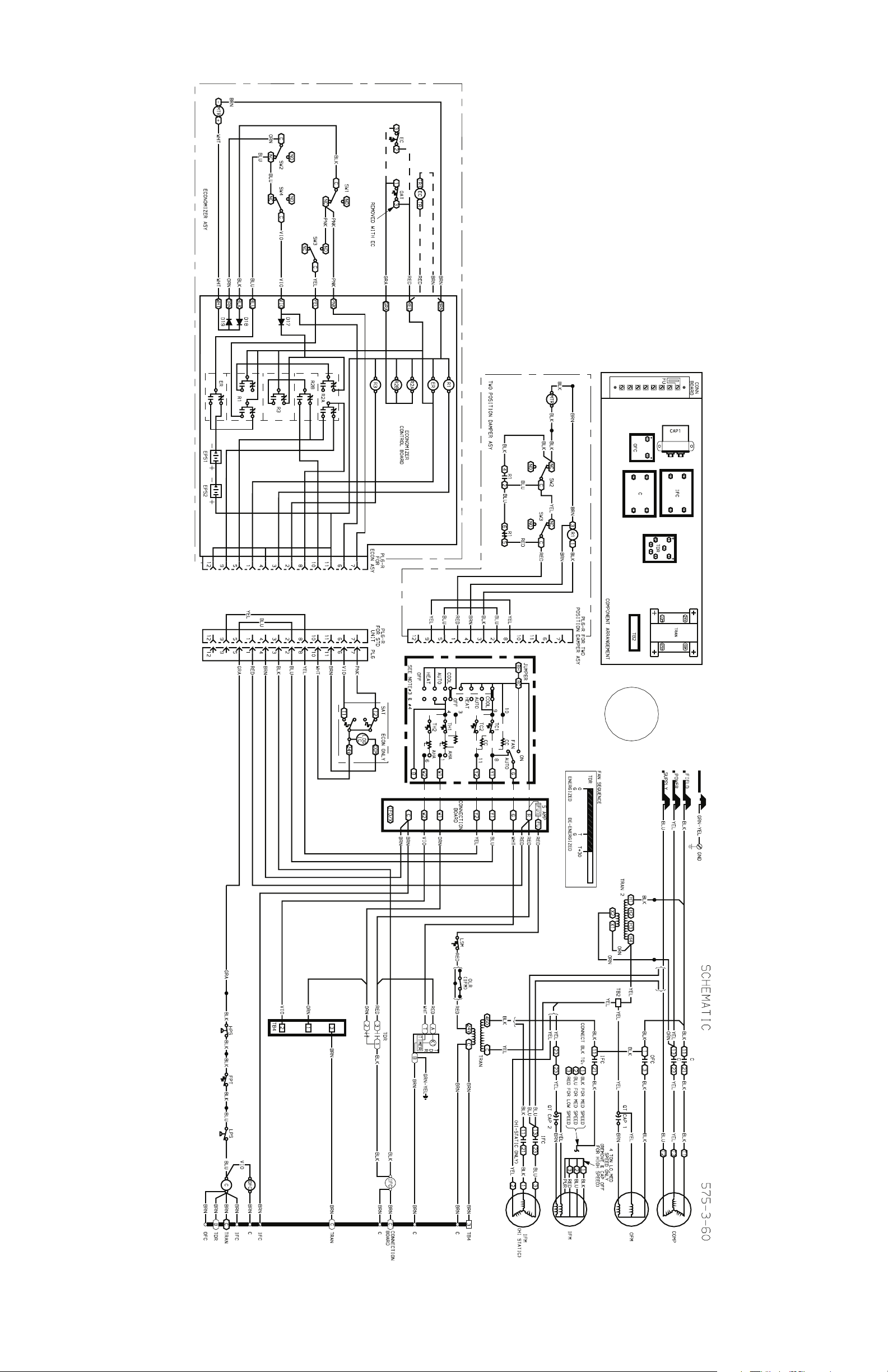

—10—

Fig. 8 — Schematic/Component Arrangement; 558F060; 575-3-60

Page 11

—11—

Fig. 9 — Schematic/Component Arrangement; 558F072; 208/230-3-60 and 460-3-60

Page 12

—12—

Fig. 10 — Schematic/Component Arrangement; 558F072; 575-3-60

Page 13

—13—

Fig. 11 — Schematic/Component Arrangement; 558F090-150; 208/230-3-60 and 460-3-60

Page 14

—14—

Fig. 12 — Schematic/Component Arrangement; 558F090-150; 575-3-60

Page 15

LEGEND

C — Contactor

558F036-072

558F090-150

Fig. 13 — Motormaster® I Wiring Details

LEGEND

C—Contactor

OFC — Outdoor-Fan Contactor

TRAN — Transformer

NOTE: Motormaster II transformer is wired for 460-v supply; it must be rewired for 208/230-v application.

Be sure to insulate unused tap. Refer to color code.

Fig. 14 — Motormaster II Wiring Schematic; 558F036-072

—15—

Page 16

LEGEND

C—Contactor

OFC — Outdoor-Fan Contactor

TRAN — Transformer

*The Motormaster II head pressure controller is equipped with an alternate operating mode. When

this mode is selected, the controller shifts the fan cycle sequence to effectively raise the average

condensing temperature approximately 20 F higher than the standard operating mode. In this

alternate mode, the outdoor fan begins cycling at higher outdoor ambient temperatures. This

mode should only be used if the evaporator coil shows signs of frosting at low outdoor ambient

temperatures.

To select the alternate operating mode, move the jumper wire on the Motormaster II control board

from reset T1 to reset T2.

NOTE: Motormaster® II transformer is wired for 460-v supply; it must be rewired for 208/230-v

application. Be sure to insulate unused tap. Refer to color code.

Fig. 15 — Motormaster II Wiring Schematic; 558F090-150

—16—

Page 17

TIME GUARD I I DEVICE

BRN

BRN

LEGEND

C — Contactor

CLO — Compressor Lockout

CR — Control Relay

T1

T3

T2

2

1

CLO

3

COMPRESSOR

SAFETIES

HIGH EFFICIENCY 3 TO 121/2 TON ROOFTOP UNITS

TIME GUARD I I DEVICE

T3

T2

OR

CR

C

T1

STANDARD EFFICIENCY 3 TO 121/2 TON ROOFTOP UNITS

Fig. 16 — Time Guard® II Device; 558F036-150

BRN

OR

CR

C

24 VAC SUPPLY FROM

ECONOMIZER CONTROL

}

TR1

TR

B

A

C

SO +

D

+

SR

3

2

1

LED

NOTE: Switches shown in high enthalpy state. Terminals 2 and 3

close on enthalpy decrease.

SECTION (RED TO TR,

BRN TO TR1)

TO SENSOR MOUNTED

}

ON BACK OF CONTROL

620 ohm

JUMPER

GRAY WIRE FROM

ECONOMIZER HARNESS

RED WIRE FROM

ECONOMIZER SWITCH 3

(NORMALLY CLOSED)

Fig. 17 — Wiring Connections for Solid-State

Enthalpy Control (HH57AC077)

24 VAC SUPPLY FROM

ECONOMIZER CONTROL

SECTION (RED TO TR,

BRN TO TR1)

TO SENSOR MOUNTED

ON BACK OF CONTROL

S

(HH57AC078

SENSOR)

+

GRAY WIRE FROM

ECONOMIZER HARNESS

RED WIRE FROM

ECONOMIZER SWITCH 3

(NORMALLY CLOSED)

A

B

LED

C

D

SO

SR

TR TR1

2

+

+

3

1

NOTES:

1. Remove factory-installed jumper across SR and + before connecting wires from HH57AC078 sensor.

2. Switches shown in high outdoor-air enthalpy state. Terminals 2

and 3 close on low outdoor air enthalpy relative to indoor air

enthalpy.

Fig. 18 — Wiring Connections for Differential

Enthalpy Control (HH57AC077 and HH57AC078)

—17—

Page 18

LEGEND

OAT — Outdoor-Air Thermostat

Fig. 19 — EconoMi$er Wiring

ECONOMI$ER

CONTROLLER

OAT

COM

OAH

-15 V

RAT

COM

RAH

+15 V

(+)

CO

2

CO

COM

2

DAT

COM

REM POT

COM

LED

COM

Fig. 20 — EconoMi$er Sensor Wiring; 558F036-150

BROWN

VIOLET

WHITE

RED

BROWN

VIOLET

WHITE

RED

SUPPLY AIR

TEMPERATURE SENSOR

PINK

VIOLET

TEMP

TEMP

—18—

TEMP

TEMP

COM

OUT

PWR

TEMP

TEMP

COM

OUT

PWR

CO

SENSOR

2

24

V+

COM VAC

OUTDOOR

AIR

SENSOR

RETURN

AIR

SENSOR

Page 19

TO FUSED

DISCONNECT

RED

H1

(575 VAC)

HT01AH859

X4

HANDY BOX

X2

X3

SECONDARY

230VAC

2 x 4 IN.

GRAY

H2

X1

GREEN GND

OR

BLACK L1

BLUE L2

RED YELH1BLU

(460 VAC)

HT01AH850

X4

COMPRESSOR 1

CONTACTOR

11 21

13

CONNECTOR

L1

1

1

L2

22

GND

33

44

230 VAC

1 PHASE

H3

H2

X3

X2

SECONDARY

230VAC

230VAC

23

4-PIN

PLUG

GREEN

GRAY

H4

X1

BLACK

BLUE

FIELD SUPPLIED

WIRING

BROWN

C1

GREEN/

YELLOW

BROWN

C1

GREEN/

YELLOW

FAN 1

FAN 2

BLACK

BLACK

LT. BLUE

BLACK

BLUE

BLACK

LT. BLUE

BLACK

3

2

1

3

2

1

6

5

4

6

5

4

BLUE

B

9

8

7

9

8

7

R1

24 VAC

A

B

R2

24 VAC

A

3-PIN

CONNECTOR

PLUG

ORANGE

YELLOW

BROWN

1

2

3

Fig. 21 — Wiring Diagram for Power Exhaust System

—19—

Page 20

Copyright 2000 Bryant Heating & Cooling Systems CATALOG NO. 5355-810

Loading...

Loading...