Page 1

installation, start-up and

service instructions

SINGLE PACKAGE ROOFTOP

ELECTRIC HEATING/ELECTRIC COOLING UNITS

Cancels: II 558F-90-3 II 558F-90-4

558F

Dura

Pac

Series

Sizes 090-151

71/2 to 121/2 Tons

9/15/05

IMPORTANT — READ BEFORE INSTALLING

Read and become familiar with these installation instructions before installing this unit.

Be sure the ins tallation conforms to al l applicab le local an d

national codes.

These instructions contain important information for the

proper maintenance and repair of this equipment. Retain

these instructions for future use.

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -53

I. Step 1 — Provide Unit Support. . . . . . . . . . . . . . . . . 1

II. Step 2 — Field Fabricate Ductwork . . . . . . . . . . . . . 1

III. Step 3 — Install External Trap for

Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . 2

IV. Step 4 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . 2

V. Step 5 — Make Electrical Connections . . . . . . . . . . 9

VI. Step 6 — Adjust Factory-Installed

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

VII. Step 7 — Adjust Evaporator-Fan Speed . . . . . . . . 31

PRE-START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54,55

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56-61

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . .61-65

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Installation and servicing air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or servic e air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations sh o uld be perfor me d by trai ne d se rvi ce personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels

attached to the unit, and other safety precautions that may

apply.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire

extinguishers available for all brazing operations.

WARNING: Before performing service or maintenance operations on unit, turn off main power switch

to unit and install lockout tag. Electrical shock could

cause personal injury.

CAUTION: Ensure voltage listed on unit data

plate agrees with electrical supply provided for the

unit.

INSTALLATION

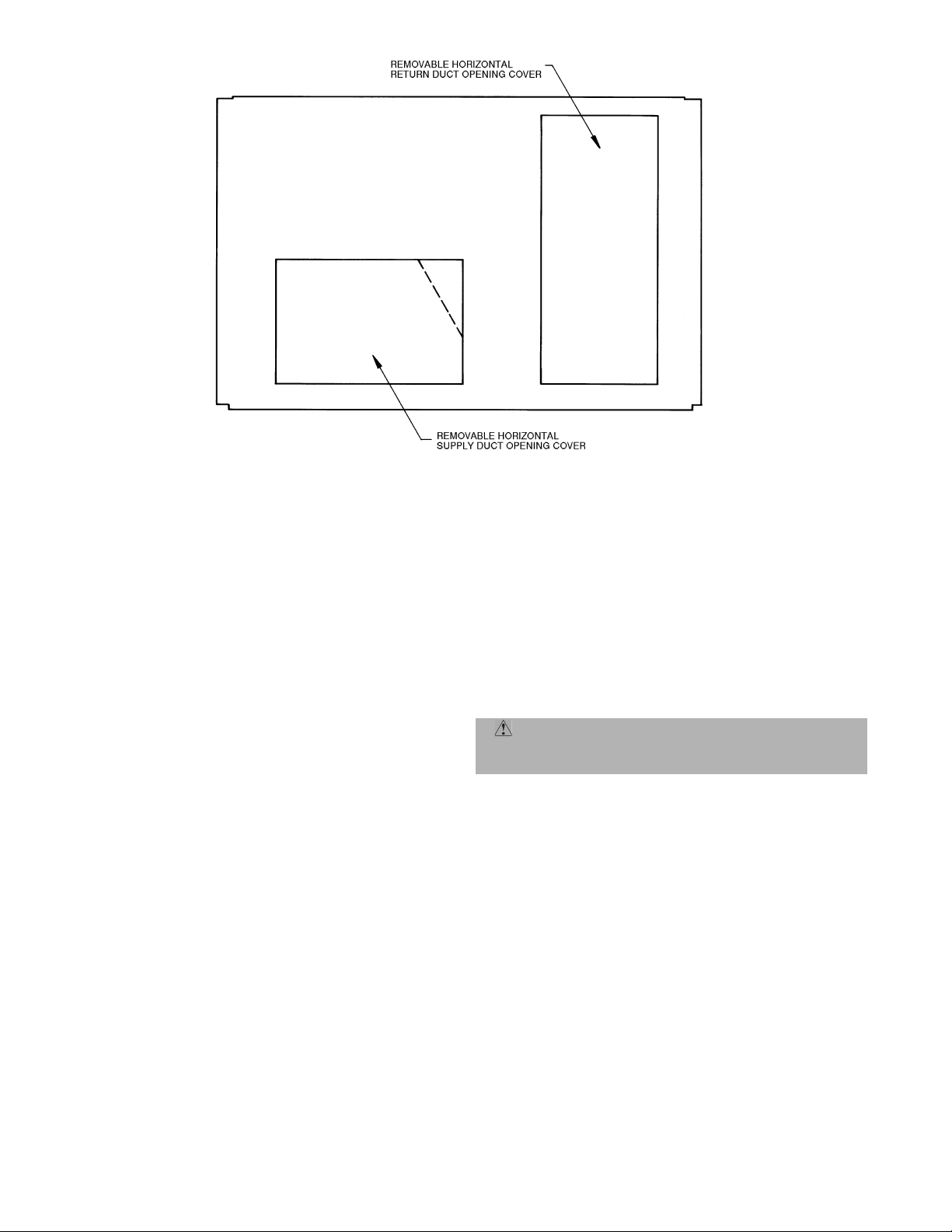

Unit is shipped in the vertical discharge configuration. To

convert to horizontal configu rat ion, remov e scre ws from horizontal duct opening covers and remove covers. Using the

same screws, install covers on duct openings in basepan of

unit with the insulation-side down. Seals around duct openings must be tight. See Fig. 1.

Confirm before installation of unit that voltage, amperage

and circuit protection requirements listed on unit data plate

agree with power supply provided.

I. STEP 1 — PROVIDE UNIT SUPPORT

A. Roof Curb

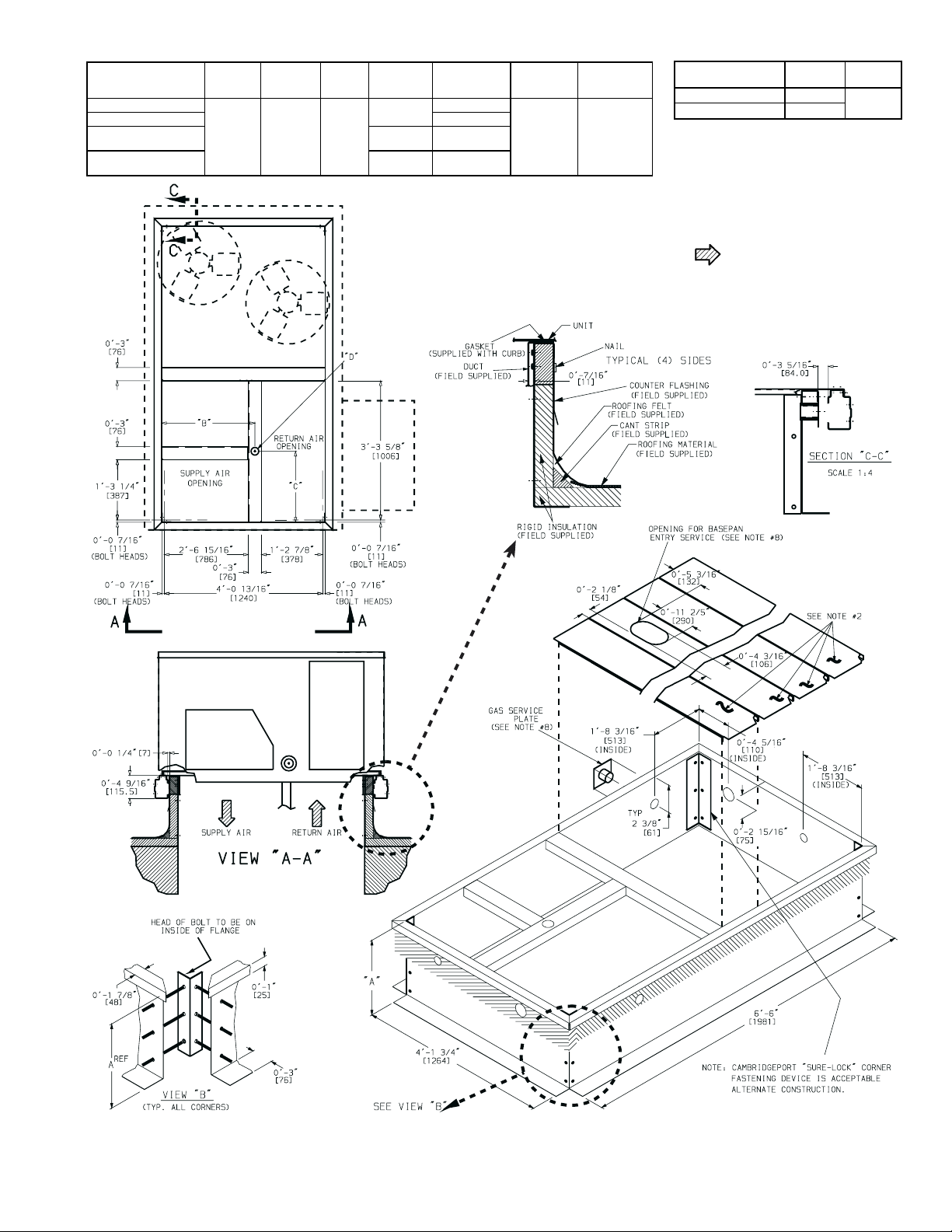

Assemble and install access ory roof curb in accorda nce with

instructions shipped with curb. See Fig. 2. Install insulation,

cant strips, roofi ng fe lt, and counter flashing as shown. Duct-

work must be attached to curb, not to unit. If electric control

power is to be routed through the basepan, attach the accessory thru-the-bottom service connec tions to the roof curb in

accordance with the accessory installa tion instructions. Connection must be installed before unit is set on roof curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasket supplied with the

roof curb as shown in Fig. 2. Improperly applied gasket can

also result in air leaks and poor unit performance.

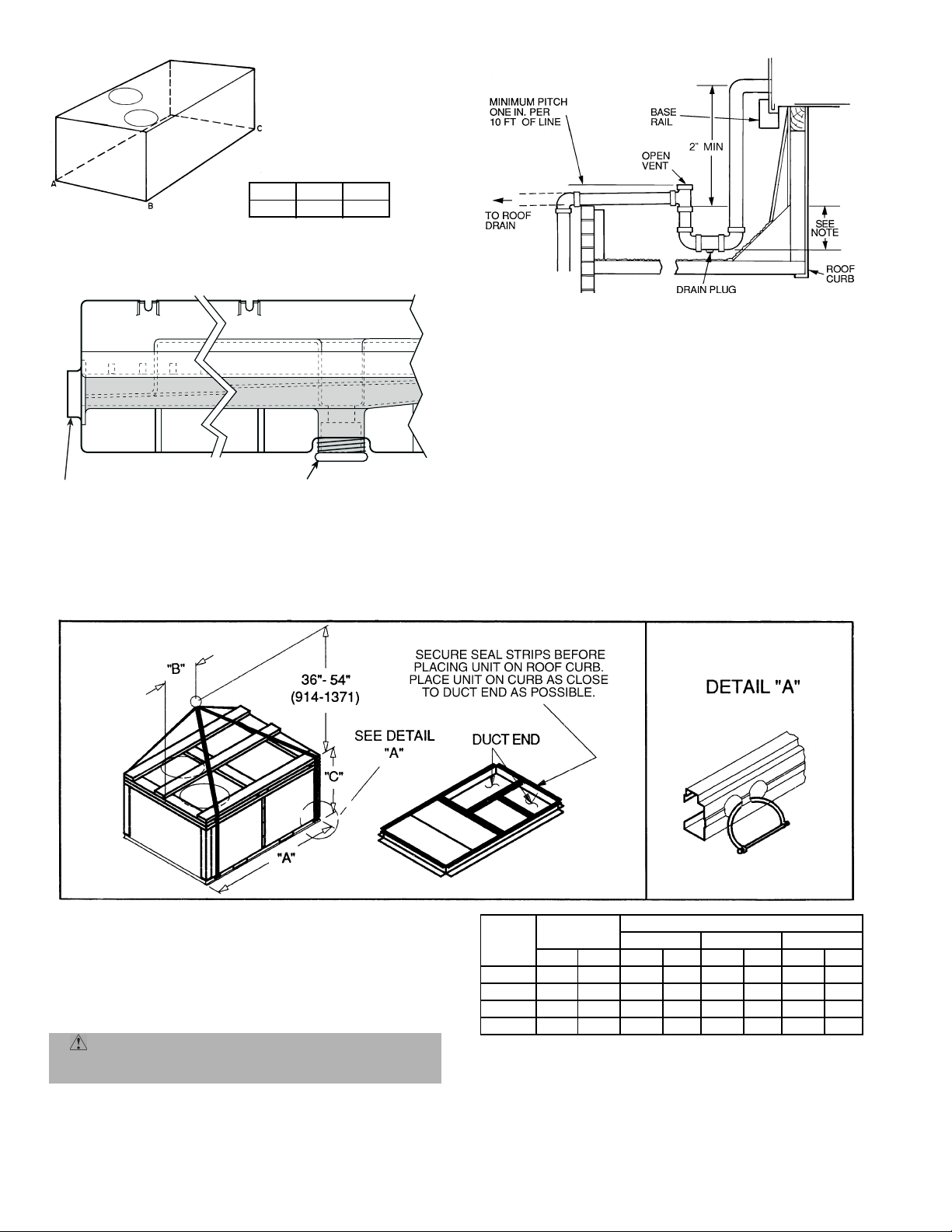

Curb should be level. This is necessar y for unit drain to function properly. Unit leveling tolerances are shown in Fig. 3.

Refer to Accessory Roof Curb Installation Instructions for

additional information as required.

B. Alternate Unit Support

When the curb or adapter cannot be used, support unit with

sleeper rails using unit curb or adapter support area. If

sleepers cannot be used, support long sides of unit with a

minimum of three 4-in. x 4-in. pads, 2 at the unit’s corners

and one at the center of gravity. If more than 3 are used,

equally space out pads along unit side.

C. Slab Mount (Horizontal Units Only)

Provide a level concrete slab that ex te nds a m ini mum o f 6 i n.

beyond unit cabinet. Install a 6-in. gravel apron in front of

outdoor-coil air inlet to prevent grass and foliage from

obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

II. STEP 2 — FIELD FABRICATE DUCTWORK

On vertical discharge un its, secure all ducts to ro of c urb and

building structure. Do not connect ductwork to unit. For horizontal applications, field-supplied isolation flanges should b e

attached to horizontal discharge openi ngs and all ductwork

attached to the flanges. Insulate and weatherproof all e xternal ductwork, joints, and roof openings with counter flashing

and mastic in accordance with applicable codes.

Page 2

Fig. 1 — Horizontal Conversion Panels

Ducts passing through a n unc ondit i one d spa ce must be insulated and covered with a vapor barrier.

If plenum return is used on a vertical unit, the return should

be ducted through the roo f deck to comply with applicable

fire codes.

If electrical connections are to be routed thro ugh the bottom of

the unit, atta ch ac cess ory th ru-t he- bottom s ervi ce con nect ions

to the basepan in accordance with installation instructions.

A minimum clearance is not required around ductwork. Cabinet return-air static pressure (a negative condition) should

not exceed 0.30 in. wg with economizer or 0.45 in. wg

without economizer.

III. STEP 3 — INSTALL EXTERNAL TRAP FOR

CONDENSATE DRAIN

The unit’s

3

/4-in. condensate drain connections are located on

the bottom and side of the unit. Unit discharge connections

do not determine the use of drain connections; either

drain connection can be used with vertical or horizontal

applications.

When using the standard side drain connection, ensure the

plug in the alternate bottom connection (in center of pan) is

tight before installing the unit.

To use the bottom drain connection for a roof curb installation, relocate the factory-installed plug from the bottom connection to the side connection. See Fig. 4. The piping for the

condensate drain and external trap can be completed after

the unit is in place.

All units must have an external trap for condensate drainage. Install a trap at least 4 in. deep and protect against

freeze-up. If a dra in line is installe d downstream from the

external trap, pitch the line away from the unit at 1 in. per

10 ft of run. Do not use a pipe size smaller than the unit

connection (

3

/4-in.). See Fig. 5.

The center drain plug looks lik e a star conne ctio n, however it

can be removed with a

1

/2 in. socket drive extensio n.

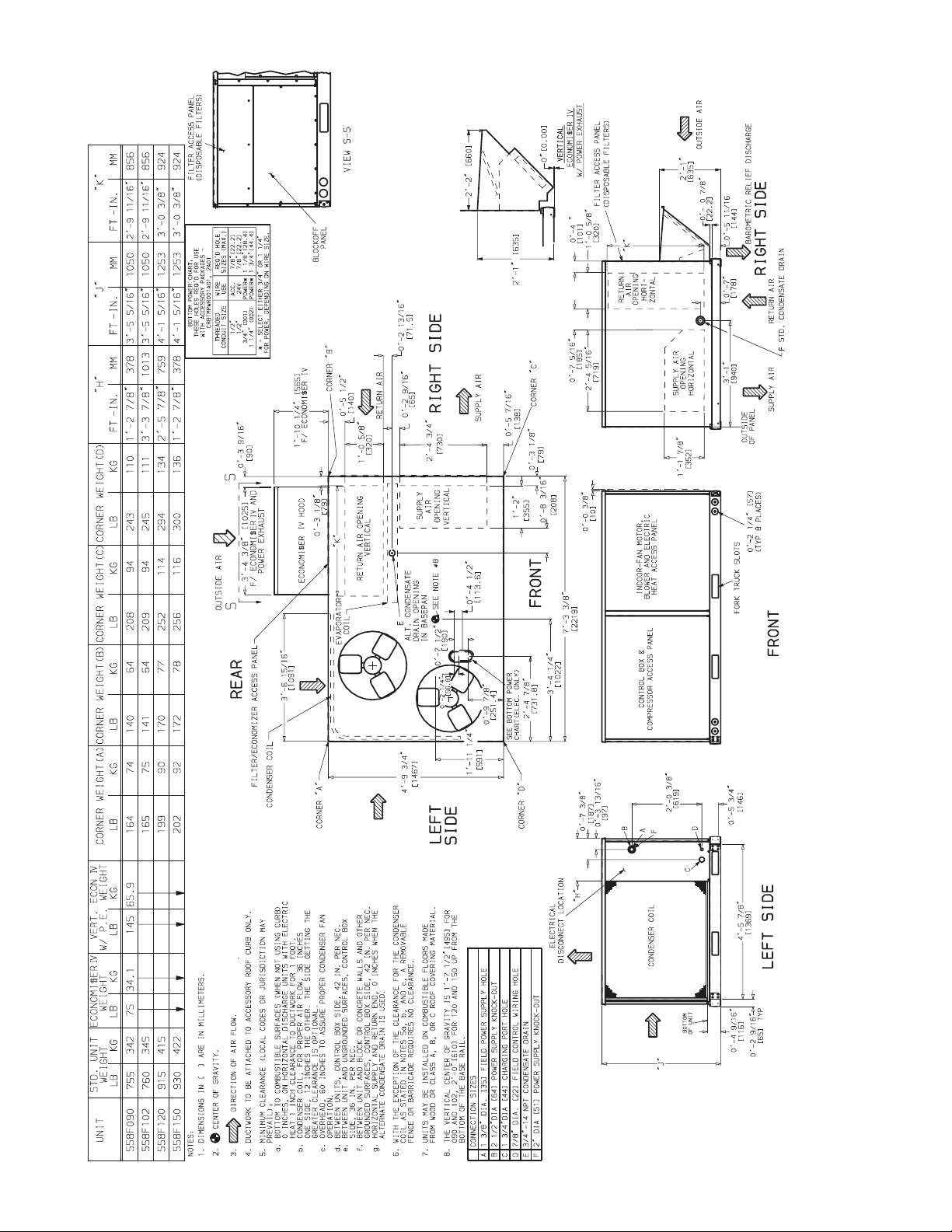

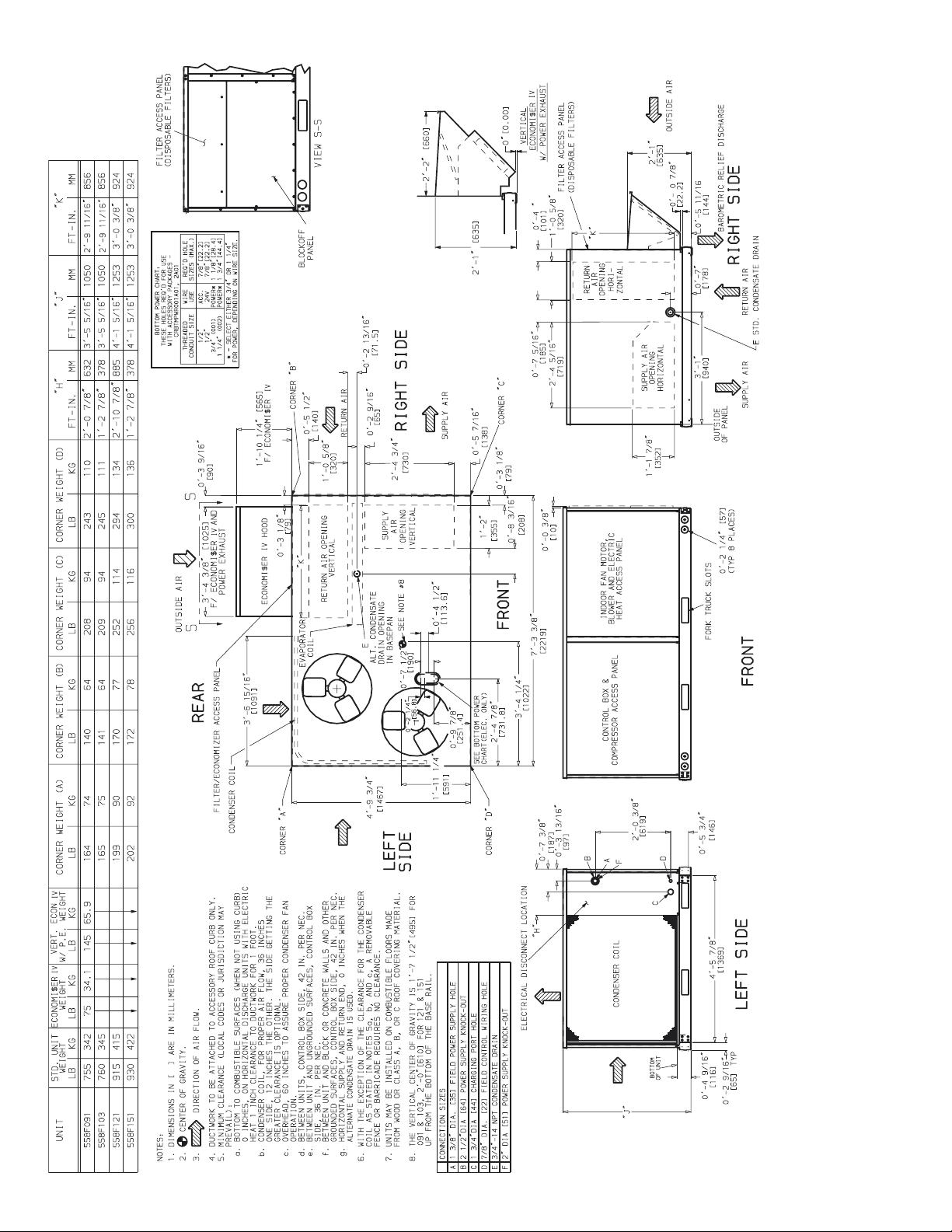

IV. STEP 4 — RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency. Keep unit upright and do not drop.

Spreader bars are not required if top crating is left on unit.

Rollers may be used to move unit across a roof. Level by

using unit frame as a reference. See Tables 1A and 1B and

Fig. 6 for additional inf ormat ion. Op era ting we ight is s hown

in Tables 1A and 1B and Fig. 6.

Lifting holes are provided in base rails as shown in Fig. 6

and 7A and 7B. Refer to rigging instructions on unit.

CAUTION: All panels m ust be in place when rigging and lifting. Unit is not designed for handling by a

fork truck. Damage to unit may result.

A. Positioning

Maintain clearance around and above unit to provide proper

airflow and service access. See Fig. 7A and 7B.

Position unit on roof curb so that the following clearances are

maintained:

1

/4-in. clearance between roof curb and base

rails on duct end, front and back of unit; 35/16-in. clearance

between roof curb and condenser fan end of un it (see Fig. 2,

sections A-A and C-C).

Do not install unit in an indoor l ocation. Do not locate unit

air inlet near exhaust vents or other sources o f c ontam ina t ed

air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

After unit is in position, remove shipping materials and rigging skid.

—2—

Page 3

CONNECTOR

PKG. ACCY.

BC

CRBTMPWR001A01

CRBTMPWR002A01 1

CRBTMPWR003A01

2′-8

7

[827]

/16″

1′-1015/16″

[583]

CRBTMPWR004A01

D ALT

DRAIN

HOLE

13/4″

[44.5]

GAS POWER CONTROL

3

/4″

[19] NPT

1

/2″

[12.7] NPT

3

/4″

[19] NPT

3

/4″ [19] NPT

1

/4″ [31.7]

3

/4″ [19] NPT

11/4″ [31.7]

1

/2″

[12.7] NPT

ACCESSORY

POWER

1

/2″

[12.7]

NPT

ROOF CURB

ACCESSORY

“A”

CRRFCURB003A01 1′-2″ [356]

CRRFCURB004A01 2′-0″ [610]

NOTES:

1. Roof curb accessory is shipped

disassembled.

2. Insulated panels: 1-in. thick polyurethane

3. Dimensions in [ ] are in millimeters.

4. Roof curb: 16-gage steel.

5. Attach ductwork to curb (flanges of duct rest

6. Service clearance 4 ft on each side.

foam, 1

on curb).

3

/4 lb density.

UNIT

SIZE

558F

090-151

7. Direction of airflow.

8. Connector packages CRBTMPWR001A01

and 2A01 are for thru-the-curb gas type.

Packages CRBTMPWR003A01 and 4A01

are for the thru-the-bottom type gas

connections.

Fig. 2 — Roof Curb Details

—3—

Page 4

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

0.5 1.0 1.0

Fig. 3 — Unit Leveling Tolerance

NOTE:

Trap should be deep enough to offset maximum unit static differ-

ence. A 4-in. trap is recommended.

Fig. 5 — Condensate Drain Piping Details

DRAIN OUTLET

NOTE: Drain plug is shown in factory-installed position.

DRAIN PLUGHORIZONTAL

Fig. 4 — Condensate Drain Connection (Side View)

NOTES:

1. Dimension in ( ) is in millimeters.

2. Hook rigging shackles through holes in base rail, as shown in detail

‘‘A.’’ Holes in base rails are centered around the unit center of gravity. Use wooden top skid when rigging to prevent rigging straps

from damaging unit.

3. Unit weights do not include economizer. See Tables 1A and 1B for

unit weight of economizer.

CAUTION: All panels must be in place when rigging. Unit

is not designed for handling by a fork truck. Damage to unit may

result.

OPERATING

UNIT

558F

090,091 755 342 77.42 1967 40.25 1022 41.31 1050

102,103 760 345 77.42 1967 40.25 1022 41.31 1050

120,121 915 415 77.42 1967 40.25 1022 49.31 1253

150,151 930 422 77.42 1967 40.25 1022 49.31 1253

WEIGHT

lb kg in. mm in. mm in. mm

‘‘A’’ ‘‘B’’ ‘‘C’’

DIMENSIONS

Fig. 6 — Rigging Details

—4—

Page 5

—5—

Fig.7A — Base Unit Dimensions — 558F090,102,120,150

Page 6

—6—

Fig. 7B — Base Unit Dimensions — 558F091,103,121,151

Page 7

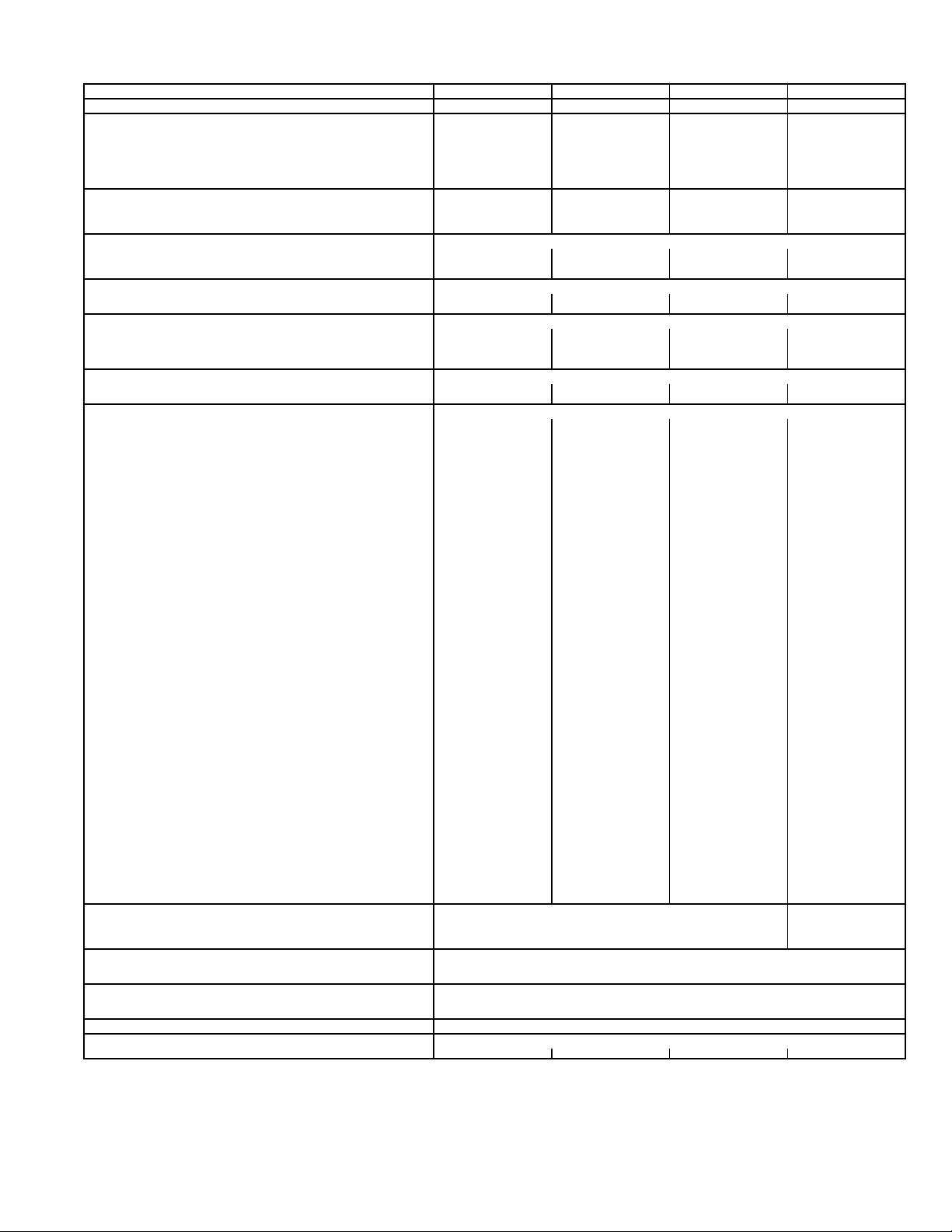

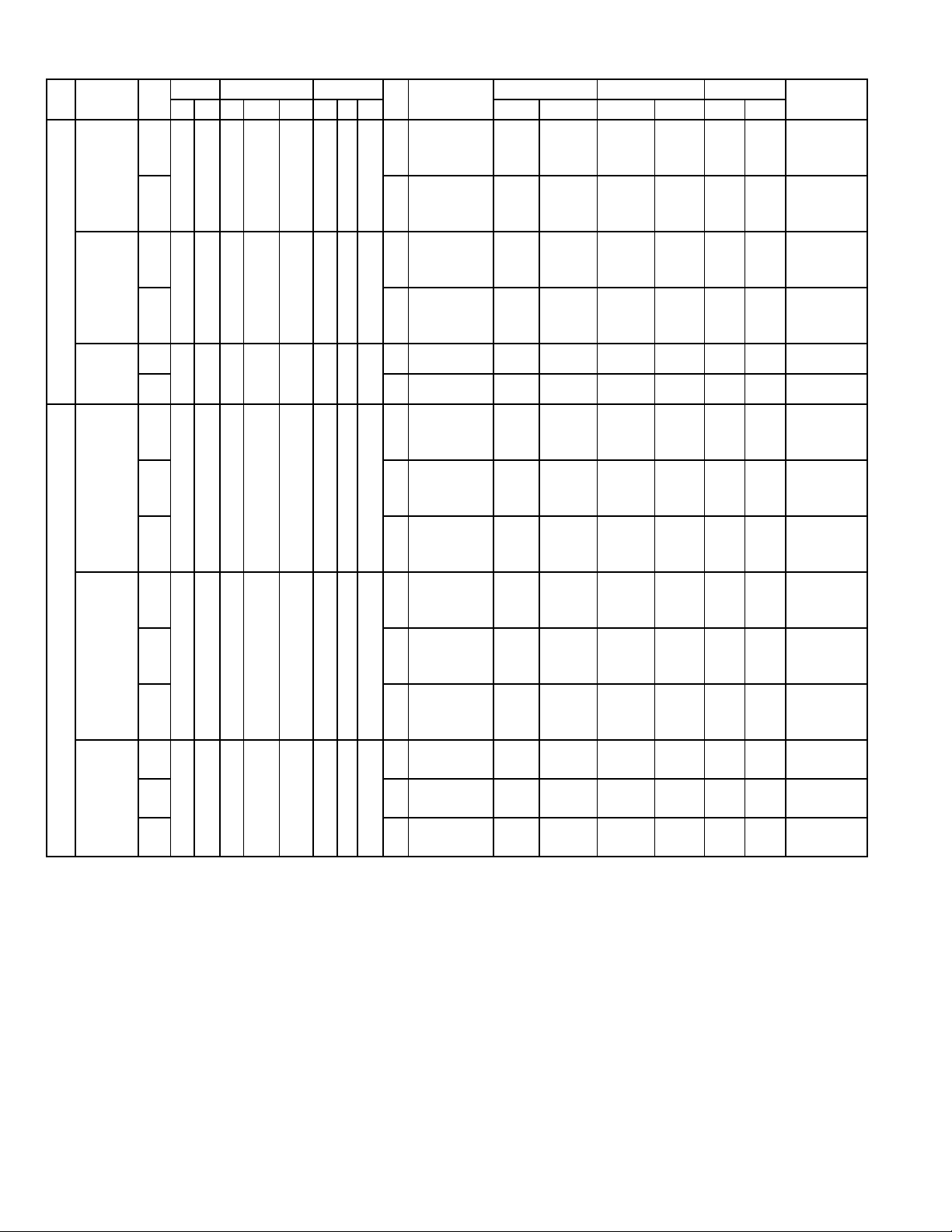

Table 1A — Physical Data — 558F090,102,120,150 Units

558F UNIT SIZE 090 102 120 150

NOMINAL CAPACITY (tons) 7

OPERATING WEIGHT (lb)

Unit

Al/Al* 755 760 915 930

Al/Cu* 766 776 937 957

Cu/Cu* 778 787 960 980

EconoMi$er IV 75 75 75 75

Roof Curb† 143 143 143 143

COMPRESSOR Reciprocating Reciprocating Reciprocating Scroll

Quantity 2222

No. Cylinders (per circuit) 222—

Oil (oz) 42 ea 65 ea 54 ea 54 ea

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1 4-13 6-14 7- 3 8-10

Circuit 2 4-14 9- 2 7-13 8- 6

CONDENSER COIL Enhanced Copper Tubes, Aluminum Lanced Fins

Rows...Fins/in. 1...17 2...17 2...17 2...17

Total Face Area (sq ft) 20.50 18.00 20.47 25.00

CONDENSER FAN Propeller Type

Nominal Cfm 6400 6400 7000 7000

Quantity...Diameter (in.) 2...22 2...22 2...22 2...22

Motor Hp...Rpm

Watts Input (Total) 600 600 600 600

EVAPORATOR COIL Enhanced Copper Tubes, Aluminum Double-Wavy Fins, Fixed Orifice Metering Device

Rows...Fins/in. 3...15 3...15 3...15 4...15

Total Face Area (sq ft) 8.0 8.0 10.0 11.1

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) Std 1...15 x 15 1...15 x 15 1...15 x 15 1...15 x 15

Type Drive Std Belt Belt Belt Belt

Nominal Cfm 3000 3100 4000 5000

Maximum Continuous Bhp Std 2.40 2.40 2.40 3.70

Motor Frame Size Std 56 56 56 56

Fan Rpm Range Std 590- 840 685- 935 685- 935 860-1080

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 2100 2100 2100 2100

Motor Pulley Pitch Diameter Min/Max (in.) Std 2.4/3.4 2.8/3.8 2.8/3.8 4.0/5.0

Nominal Motor Shaft Diameter (in.) Std

Fan Pulley Pitch Diameter (in.) Std 7.0 7.0 7.0 8.0

Belt, Quantity...Type...Length (in.) Std 1...A...49 1...A...49 1...A...49 1...A...52

Pulley Center Line Distance (in.) Std 16.75-19.25 16.75-19.25 15.85-17.50 15.85-17.50

Speed Change per Full Turn of

Movable Pulley Flange (rpm) Std 50 50 50 44

Movable Pulley Maximum Full Turns

From Closed Position Std 5555

Factory Setting Std 5555

Factory Speed Setting (rpm) Std 590 685 685 860

Fan Shaft Diameter at Pulley (in.) 1111

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief (Differential) 450 ± 50 500 ± 50

Cutout 428 428

Reset (Auto.) 320 320

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH (psig)

Cutout 7 ± 3

Reset (Auto.) 22 ± 7

FREEZE-PROTECTION THERMOSTAT (F)

Opens 30 ± 5

Closes 45 ± 5

Alt 1...15 x 15 — 1...15 x 15 1...15 x 15

High-Static 1...15 x 15 1...15 x 15 1...15 x 15 —

Alt Belt — Belt Belt

High-Static Belt Belt Belt —

Alt 2.40 — 2.90 5.25

High-Static 3.70 3.70 5.25 —

Alt 56 — 56 56

High-Static 56 56 56 —

Alt 685- 935 — 835-1085 830-1130

High-Static 860-1080 860-1080 830-1130 —

Alt 2.8/3.8 — 3.4/4.4 3.1/4.1

High-Static 4.0/5.0 4.0/5.0 2.8/3.8 —

Alt

High-Static

Alt 7.0 — 7.0 5.9

High-Static 8.0 8.0 5.8 —

Alt 1...A...49 — 1...A...49 1...BX...46

High-Static 1...A...55 1...A...55 1...BX...46 —

Alt 15.75-19.25 — 15.85-17.50 15.85-17.50

High-Static 15.75-19.25 16.75-19.25 15.85-17.50 —

Alt 50 — 50 50

High-Static 60 60 60 —

Alt 5—5 6

High-Static 556—

Alt 5—5 5

High-Static 555—

Alt 685 — 835 887

High-Static 860 860 887 —

1

1

/4...1100

5

/

5

/

7

/

/

2

8

8

8

81/

1

/4...1100

5

/

—

7

/

2

8

8

10 121/

1

/4...1100

5

/

8

7

/

8

7

/

8

1

/4...1100

7

/

7

/

—

2

8

8

OUTDOOR-AIR INLET SCREENS Cleanable. Screen size and quantity varies by option selected.

RETURN-AIR FILTERS Throwaway

Quantity...Size (in.) 4...16 x 20 x 2 4...16 x 20 x 2 4...20 x 20 x 2 4...20 x 20 x 2

LEGEND *Evaporator coil fin material/condenser coil fin material. Contact your local Bryant representa-

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

tive for details about coated fins.

†Weight of 14-in. roof curb.

NOTE: High-static motor not available on size 150 and 151 units.

—7—

Page 8

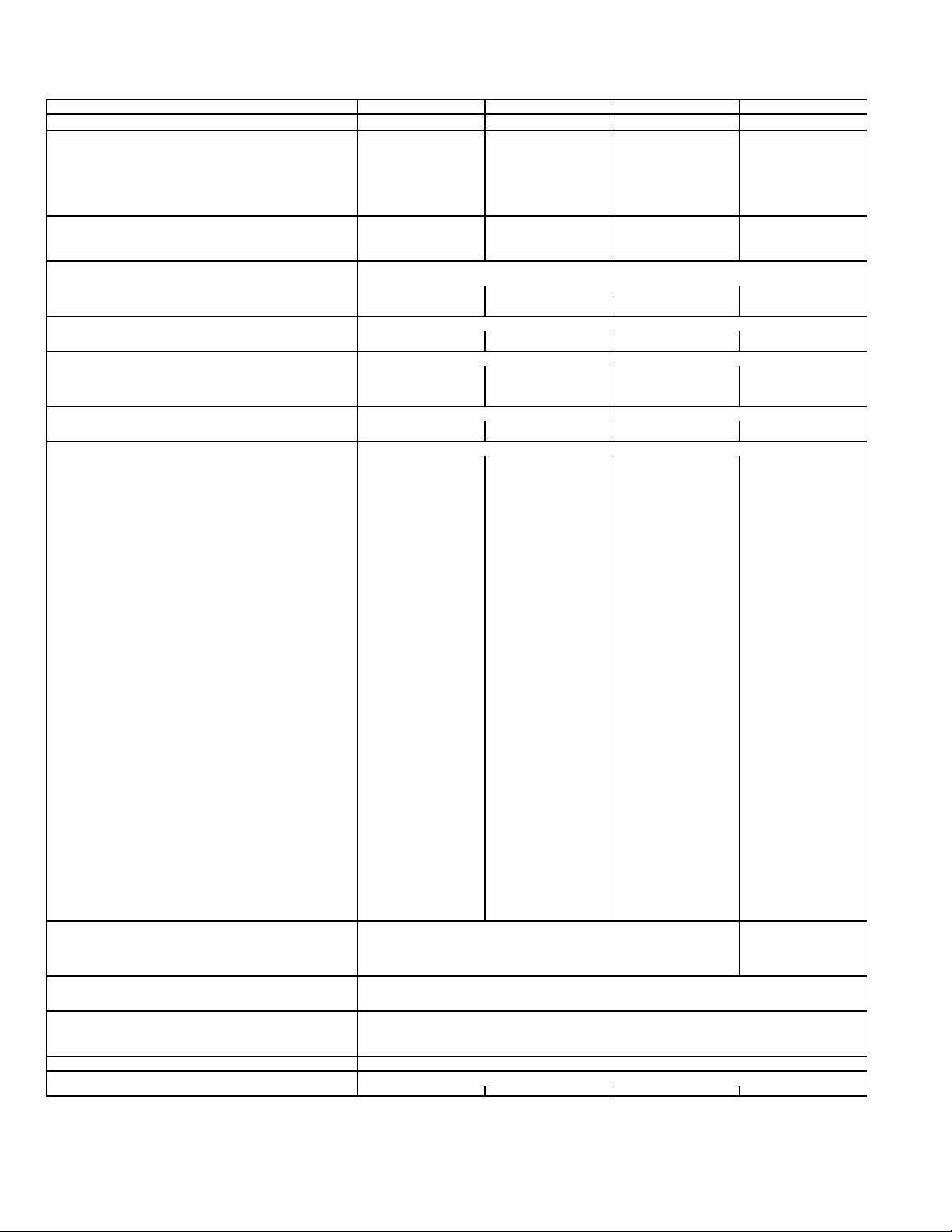

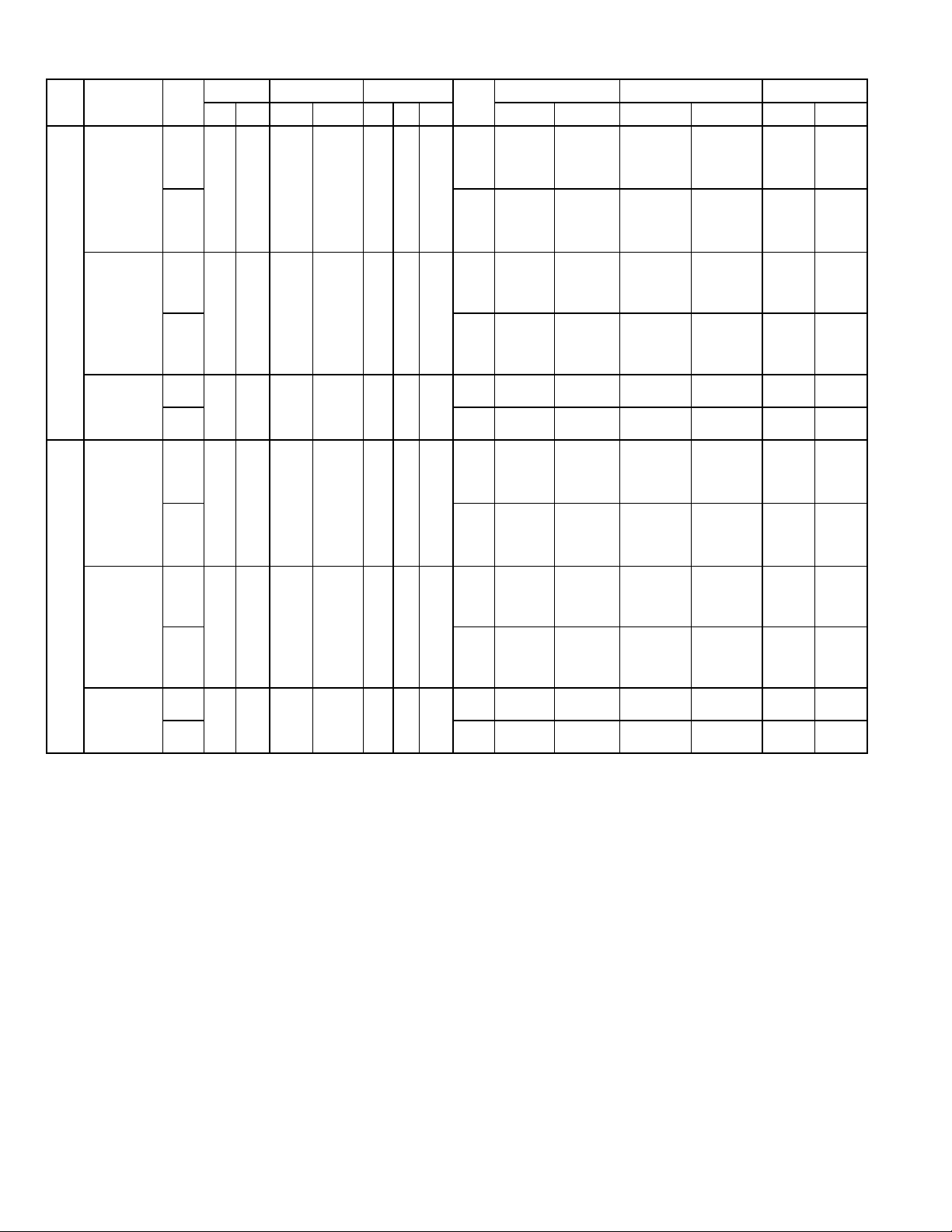

Table 1B — Physical Data — 558F091,103,121,151 Units

(ASHRAE 90.1-1999 Compliant Units)

558F UNIT SIZE 091 103 121 151

NOMINAL CAPACITY (tons) 7

OPERATING WEIGHT (lb)

Unit

Al/Al* 755 760 915 930

Al/Cu* 766 776 937 957

Cu/Cu* 778 787 960 980

Economizer

EconoMi$er IV 75 75 75 75

Roof Curb† 143 143 143 143

COMPRESSOR Reciprocating Scroll Scroll Scroll

Quantity 2222

No. Cylinders (per Circuit) 2222

Oil (oz) (each compressor) 42 53 50 60

REFRIGERANT TYPE R-22

Expansion Device Fixed Orifice Metering Device

Operating Charge (lb-oz)

Circuit 1 7-10 7-14 8-10 9-8

Circuit 2 8-2 8-5 8-8 9-5

CONDENSER COIL Enhanced Copper Tubes, Aluminum Lanced Fins

Rows...Fins/in. 2...17 2...17 2...17 2...17

Total Face Area (sq ft) 20.50 20.50 25.00 25.00

CONDENSER FAN Propeller Type

Nominal Cfm 6500 6500 7000 7000

Quantity...Diameter (in.) 2...22 2...22 2...22 2...22

Motor Hp...Rpm

Watts Input (Total) 650 650 650 650

EVAPORATOR COIL Enhanced Copper Tubes, Aluminum Double-Wavy Fins, Face Split

Rows...Fins/in. 3...15 3...15 3...15 4...15

Total Face Area (sq ft) 8.9 8.9 10.0 11.1

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) Std 1...15 x 15 1...15 x 15 1...15 x 15 1...15 x 15

Type Drive Std Belt Belt Belt Belt

Nominal Cfm 2900 3000 3200 5000

Maximum Continuous Bhp Std 2.40 2.40 2.40 3.70

Motor Frame Size Std 56 56 56 56

Fan Rpm Range Std 590-840 685-935 685-935 860-1080

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 2100 2100 2100 2100

Motor Pulley Pitch Diameter Min/Max (in.) Std 2.4/3.4 2.8/3.8 2.8/3.8 4.0/5.0

Nominal Motor Shaft Diameter (in.) Std

Fan Pulley Pitch Diameter (in.) Std 7.0 7.0 7.0 8.0

Belt, Quantity...Type...Length (in.) Std 1...A...49 1...A...49 1...A...49 1...A...52

Pulley Center Line Distance (in.) Std 16.75-19.25 16.75-19.25 15.85-17.50 15.85-17.50

Speed Change per Full Turn of Std 50 50 50 44

Movable Pulley Flange (rpm) Alt 50 — 50 50

Movable Pulley Maximum Full Turns Std 5555

From Closed Position Alt 5—5 6

Factory Setting Std 5555

Factory Speed Setting (rpm) Std 590 685 685 860

Fan Shaft Diameter at Pulley (in.) 1111

HIGH-PRESSURE SWITCH (psig)

Standard Compressor 450 ± 50 500 ± 50

Internal Relief (Differential)

Cutout 428 428

Reset (Auto.) 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 7 ± 3

Reset (Auto.) 22 ± 7

FREEZE PROTECTION

THERMOSTAT (F)

Opens 30 ± 5

Closes 45 ± 5

Alt 1...15 x 15 — 1...15 x 15 1...15 x 15

High-Static 1...15 x 15 1...15 x 15 1...15 x 15 —

Alt Belt — Belt Belt

High-Static Belt Belt Belt —

Alt 2.40 — 2.90 5.25

High-Static 3.70 3.70 5.25 —

Alt 56 — 56 56

High-Static 56 56 56 —

Alt 685-935 — 835-1085 830-1130

High-Static 860-1080 860-1080 830-1130 —

Alt 2.8/3.8 — 3.4/4.4 3.1/4.1

High-Static 4.0/5.0 4.0/5.0 2.8/3.8 —

Alt

High-Static

Alt 7.0 — 7.0 5.9

High-Static 8.0 8.0 5.8 —

Alt 1...A...49 — 1...A...49 1...BX...46

High-Static 1...A...55 1...A...55 1...BX...46 —

Alt 16.75-19.25 — 15.85-17.50 15.85-17.50

High-Static 16.75-19.25 16.75-19.25 15.85-17.50 —

High-Static 60 60 60 —

High-Static 556—

Alt 5—5 5

High-Static 555—

Alt 685 — 835 887

High-Static 860 860 887 —

OUTDOOR-AIR INLET SCREENS Cleanable. Screen size and quantity varies by option selected.

RETURN-AIR FILTERS Throwaway

Quantity...Size (in.) 4...16 x 20 x 2 4...16 x 20 x 2 4...20 x 20 x 2 4...20 x 20 x 2

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

1

1

/4...1100

5

/

5

/

7

/

/

2

8

8

8

*Evaporator coil fin material/condenser coil fin material. Contact your local Bryant repre-

sentative for details about coated fins.

†Weight of 14-in. roof curb.

81/

1

/4...1100

5

/

—

7

/

2

8

8

10 121/

1

/4...1100

5

/

8

7

/

8

7

/

8

1

/4...1100

7

/

7

/

—

2

8

8

NOTE: High-static motor not available on size 150 and 151 units.

—8—

Page 9

V. STEP 5 — MAKE ELECTRICAL CONNECTIONS

WARNING: Unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the

possibility of personal injury if an electrical fault

should occur. This ground may consist of elec tric al wire

connected to unit ground lug in control compartment,

or conduit approved for electrical ground when

installed in accordance with NEC (Nati onal Electrical

Code), ANSI/NFPA (American National Standards

Institute/National Fire Protection Association), latest

edition, and local electrical codes. Failure to follow this

warning could result in the installer being liable for

personal injury of others.

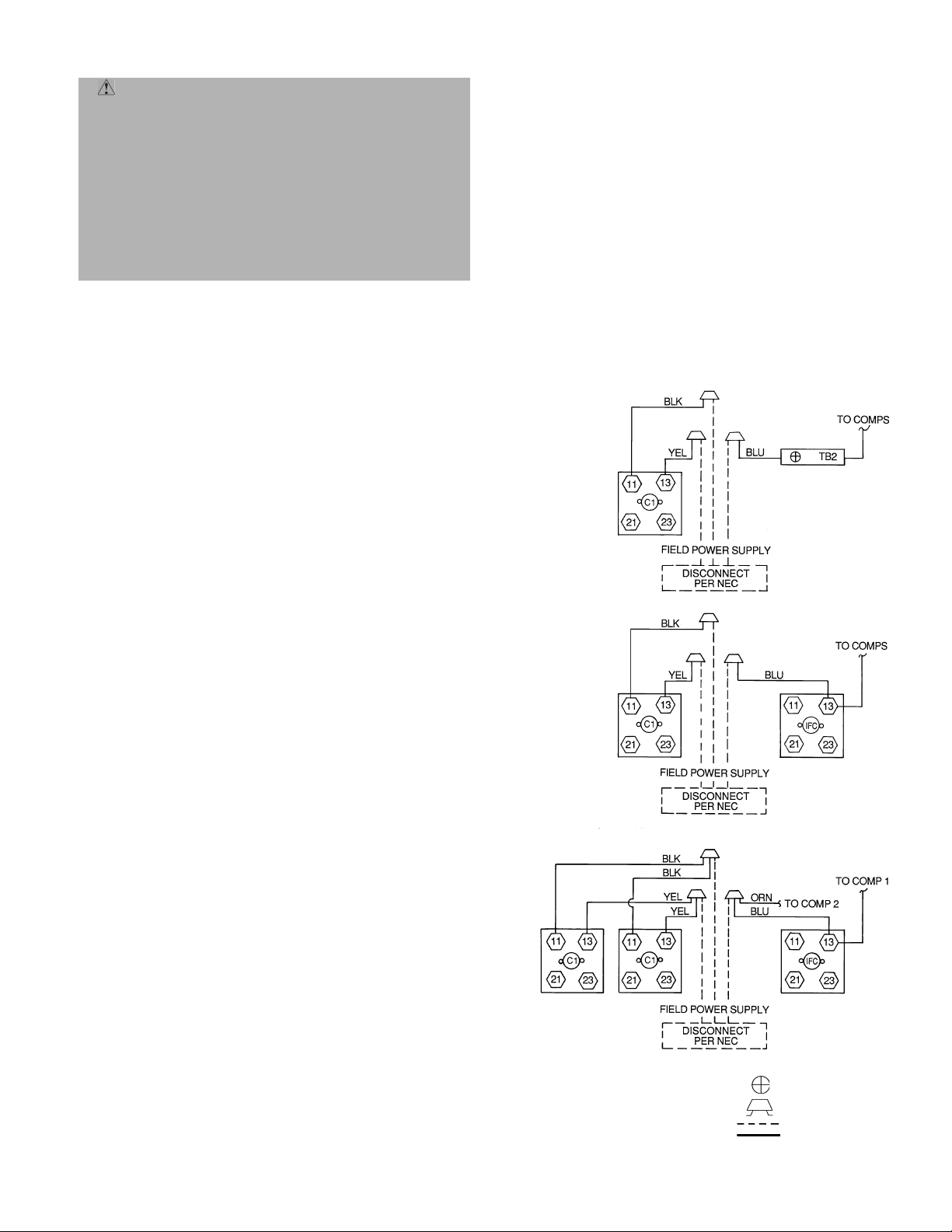

A. Field Power Supply

All units except 208/230-v units are factory wired for the

voltage shown on the na meplate. If the 208/230-v un it is to

be connected to a 208-v power supply, the transformer must

be rewired by moving the black wire from the 230-v

1

/4-in.

male spade terminal on the transformer and connecting it to

the 200-v

1

/4-in. male spade terminal on the transformer.

Refer to unit label diagram for additional information . Pigtails are provided for field wire connecti ons.

When installing units, provide a disconnect per NEC. Use

copper conductors only when splice connectors are used.

NOTE: When accessory thru-the-bottom connections are

used, refer to the accessory installation instructions for

information on power wiring. Refer to Fig. 7A and 7B for

drilling locations.

All field wiring must comply with NEC and local requirements. In Canada, electr ical connections must be in accordance with CSA (Canadian Standards Association) C22.1

Canadian Electrical Code Part One.

Install field wiring as follows (see Fig. 8-10):

1. Instal l conduit th rough side p anel opening s between

disconnect and single point box (see Fig. 9 and 10).

2. Install powe r w ire s to t erm ina l conn ect ions as sho wn

in Fig. 8.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (see

Tables 2A-2D). On 3-phase units, voltages between phases

must be balanced within 2% and the current within 10%.

Use the formula shown in the legend for Tables 2A and 2B,

Note 2 to determine the percentage of voltage imbalance.

Operation on improper line voltage or excessive phase imbalance constitutes abuse and may cause damage to electrical

components. (Such operation would invalidate any applicable Bryant warranty.)

B. Field Control Wiring

Install a Bryant-approved accessory thermostat assembly

according to installation instructions included with the

accessory. Locate thermostat assembly on a solid wall in the

conditioned space to sense average temperature in accordance with thermostat installation instructions.

Route thermostat ca ble or equivalent si ngle leads of col ored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 11) as described in Steps 1-5 below.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly c onn ected to

the thermost at and wi ll requi re a junct ion box and splic e at

the thermostat.

1. If unit is mounte d on roof curb and accessory thruthe-bottom connection is used, route wire through

connector provided in accessory kit through the unit

basepan.

2. Pass control wires thro ugh the hole prov ided on unit

(see connection D, Connection Sizes Table, Fig. 7A

and 7B).

3. Feed wire through the raceway built into the corner

post to the 24-v barrier located on the left side of the

control box. See Fig. 12. The raceway provides the

UL-required (Underwriters’ Laboratories) clearance

between the high-and low-voltage wiring.

4. Connect thermos tat wires to screw term inals of lowvoltage terminal board.

5. If unit is to be equipped with electric resistance heat,

ensure thermostat on a call for heat “W” energizes

“G” output. This allows fan operation on a call for

heat.

575-3-60

208/230-3-60

(090-121),

460-3-60

208/230-3-60

(150,151)

C—Contactor Terminal Block

IFC — Indoor (Evaporator)

NEC — National Electrical Code Field Wiring

TB — Terminal Block Factory Wiring

Fan Contactor

LEGEND

ConnectionCOMP(S) — Compressor(s)

Splice Connection

Fig. 8 — Power Wiring Connections

—9—

Page 10

558F

UNIT

SIZE

090

102

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

208/230-3-60

460-3-60

575-3-60

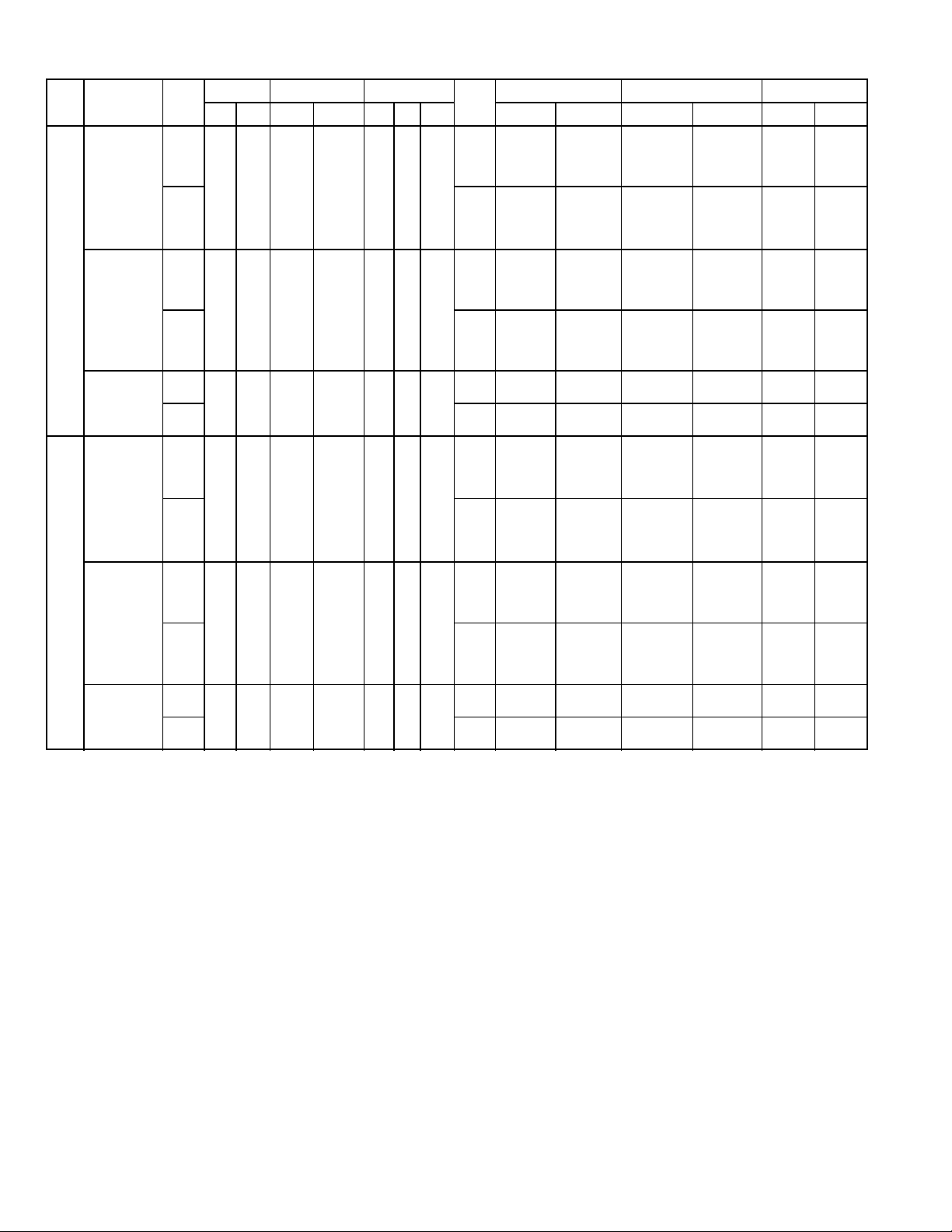

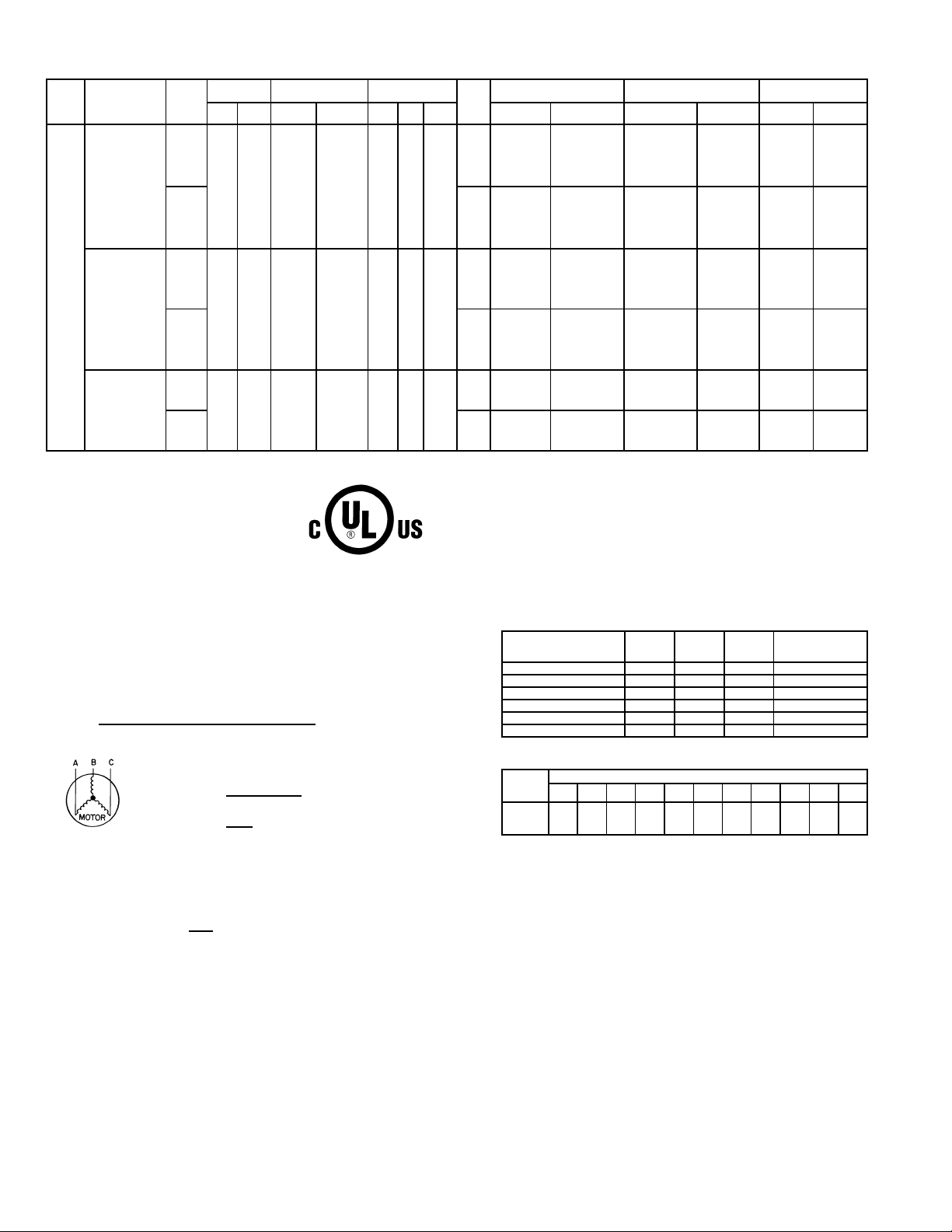

Table 2A — Electrical Data (Units Without Convenience Outlet) (558F090, 102, 120, 150)

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

and

Alt

187 254 14.0 91.0 21/41.4

High 10.6

Std

and

Alt

414 508 6.4 42.0 21/40.7

High 4.8

Std

and

Alt

518 632 5.2 39.0 21/40.7

High 4.8

Std

187 254 16.0 137.0 21/41.4

High 10.6

Std

414 508 8.3 69.0 21/40.7

High 4.8

Std

518 632 6.4 58.0 21/40.7

High 4.8

COMPRESSOR

(ea)

OFM

(ea)

ELECTRIC

IFM

FLA

5.8

2.6

2.6

5.8

2.6

2.6

HEAT

Nominal

kW

— — 40.1/ 40.1 45/ 45 42/ 42

7.8/10.4 21.7/ 25.0 40.1/ 40.1 45/ 45 42/ 42

12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 45/ 51

18.6/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75

24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95

31.8/42.4 88.4/102.0 117.7/134.8 125/150** 108/124

— — 44.9/ 44.9 50/ 50 48/ 48

7.8/10.4 21.7/ 25.0 44.9/ 44.9 50/ 50 48/ 48

12.0/16.0 33.4/ 38.5 54.9/ 61.4 60/ 70** 51/ 56

18.6/24.8 51.7/ 59.7 77.9/ 87.8 80/ 90** 72/ 81

24.0/32.0 66.7/ 77.0 96.6/109.5 100/110** 89/101

31.8/42.4 88.4/102.0 123.7/140.8 125/150** 114/129

— — 18.4 25 19

13.9 16.7 24.1 25 22

16.5 19.8 28.1 30 26

27.8 33.4 45.0 50 41

33.0 39.7 52.9 60 49

41.7 50.2 65.9 70** 61

— — 20.6 25 22

13.9 16.7 26.9 30 25

16.5 19.8 30.8 35 28

27.8 33.4 47.8 50 44

33.0 39.7 55.6 60 51

41.7 50.2 68.7 70** 63

— — 14.9 20 16

34.0 34.1 45.3 50 42

— — 16.7 20 18

34.0 34.1 47.5 50 44

— — 44.6/ 44.6 50/ 50 47/ 47

7.8/10.4 21.7/ 25.0 44.6/ 44.6 50/ 50 47/ 47

12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 47/ 51

18.6/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75

24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95

31.8/42.4 88.4/102.0 117.7/134.8 125/150** 108/124

— — 49.4/ 49.4 60/ 60 52/ 52

7.8/10.4 21.7/ 25.0 49.4/ 49.4 60/ 60 52/ 52

12.0/16.0 33.4/ 38.5 54.9/ 61.4 60/ 70** 52/ 56

18.6/24.8 51.7/ 59.7 77.9/ 87.8 80/ 90** 72/ 81

24.0/32.0 66.7/ 77.0 96.6/109.5 100/110** 89/101

31.8/42.4 88.4/102.0 123.7/140.8 125/150** 114/129

— — 22.7 25 24

13.9 16.7 24.1 25 24

16.5 19.8 28.1 30 26

27.8 33.4 45.0 50 41

33.0 39.7 52.9 60 49

41.7 50.2 65.9 70** 61

— — 24.9 30 26

13.9 16.7 26.9 30 26

16.5 19.8 30.8 35 28

27.8 33.4 47.8 50 44

33.0 39.7 55.6 60 51

41.7 50.2 68.7 70** 63

— — 17.6 20 18

34.0 34.1 45.3 50 42

— — 19.4 25 20

34.0 34.1 47.5 50 44

FLA MCA MOCP† FLA LRA

POWER

SUPPLY

DISCONNECT

SIZE*

229/229

273/273

108

130

11417.0 17.1 26.1 30 24

321/321

365/365

162

184

13517.0 17.1 23.9 25 22

15217.0 17.1 26.1 30 24

9717.0 17.1 23.9 25 22

—10—

Page 11

Table 2A — Electrical Data (Units Without Convenience Outlet) (558F090, 102, 120, 150) (cont)

558F

UNIT

SIZE

120

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

187 254 15.8 130.0 2

Alt 7.5

High 15.0

Std

Alt

414 508 7.9 64.0 2

High

Std

Alt 3.4

518 632 6.6 52.0 2

High 7.4

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compres sor no. 1 is shown in table.

208/230-3-60: Compressor no. 2 RLA is 14.1 amps and LRA is 105 amps.

460-3-60: Compressor no. 2 RLA is 7.1 amps and LRA is 55 amps.

575-3-60: Compressor no. 2 RLA is 6.4 amps and LRA is 40 amps.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer

to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or

HACR breaker. Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

7

457

452 + 464 + 455

1371

=

= 457

3

COMPRESSOR

3

(ea)

OFM

(ea)

1

/41.4

1

/40.7

1

/40.7

Use

ELECTRIC

IFM

FLA

5.8

2.6

3.4

7.4

2.6

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric

utility company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include

4. Determine heater capacity using multiplication factors table below:

HEAT

Nominal

kW

— — 43.1/ 43.1 50/ 50 45/ 45

7.8/10.4 21.7/ 25.0 43.1/ 43.1 50/ 50 45/ 45

12.0/16.0 33.4/ 38.5 48.9/ 55.4 60/ 60 45/ 51

24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95

31.8/42.4 88.4/102.0 117.7/134.8 125/150** 108/124

37.6/50.0 104.2/120.3 137.5/127.5 150/150**

— — 44.8/ 44.8 50/ 50 47/ 47

7.8/10.4 21.7/ 25.0 44.8/ 44.8 50/ 50 47/ 47

12.0/16.0 33.4/ 38.5 51.1/ 57.5 60/ 60 47/ 53

24.0/32.0 66.7/ 77.0 92.8/105.6 100/110** 85/ 97

31.8/42.4 88.4/102.0 119.9/136.9 125/150** 110/126

37.6/50.0 104.2/120.3 139.7/129.7 150/150** 128/147

— — 52.3/ 52.3 60/ 60 56/ 56

7.8/10.4 21.7/ 25.0 52.3/ 52.3 60/ 60 56/ 56

12.0/16.0 33.4/ 38.5 60.4/ 66.9 60/ 80** 56/ 62

24.0/32.0 66.7/ 77.0 102.1/115.0 110/125** 94/106

31.8/42.4 88.4/102.0 129.2/146.3 150/150** 119/135

37.6/50.0 104.2/120.3 149.0/139.0 150/175** 137/156

— — 21.0 25 22

16.5 19.8 28.1 30 26

27.8 33.4 45.0 50 41

33.0 39.7 52.9 60 49

41.7 50.2 65.9 70** 61

50.0 60.1 63.4 70** 72

— — 21.8 25 23

16.5 19.8 29.1 30 27

27.8 33.4 46.0 50 42

33.0 39.7 53.9 60 50

41.7 50.2 66.9 70** 62

50.0 60.1 64.4 70** 73

— — 25.8 30 27

16.5 19.8 34.1 35 31

27.8 33.4 51.0 60 47

33.0 39.7 58.9 60 54

41.7 50.2 71.9 80** 66

50.0 60.1 69.4 80** 78

— — 17.9 20 19

17.0 17.1 23.9 25 22

34.0 34.1 45.3 50 42

51.0 51.2 53.8 60 61

— — 18.5 25 19

17.0 17.1 24.7 25 23

34.0 34.1 46.1 50 42

51.0 51.2 54.6 60 62

— — 21.7 25 23

17.0 17.1 28.7 35 26

34.0 34.1 50.1 60 46

51.0 51.2 58.6 70** 66

power exhaust MCA and MOCP. Check MCA and MOCP when power exhaust is powered

through the unit (must be in accordance with NEC and/or local codes). Determine the

new MCA including the power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MOCP, then MOCP would not change.

The MOCP in this example is 45 amps, the MCA New is below 45, therefore the MOCP is

acceptable. If “MCA New” is larger than the published MOCP, raise the MOCP to the next

larger size. For separate power, the MOCP for the power exhaust will be 15 amps per

NEC.

POWER EXHAUST

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

HEATER

RATING

VO LTAGE

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA MOCP† FLA LRA

PAR T N O.

200 208 230 240 380 440 460 480 550 575 600

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

POWER

SUPPLY

MCA

(230 v)

MCA

(460 v)

ACTUAL HEATER VOLTAGE

MCA

(575 v)

DISCONNECT

SIZE*

127/145

MOCP

(for separate

power source)

307/307

326/326

374/374

152

191

185

107

139

134

—11—

Page 12

Table 2A — Electrical Data (Units Without Convenience Outlet) (558F090, 102, 120, 150) (cont)

558F

UNIT

SIZE

150

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

187 254 23.0 146.0 21/41.4

Alt 15.0

Std

414 508 10.4 73.0 21/40.7

Alt 7.4

Std

518 632 8.3 58.4 21/40.7

Alt 7.4

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compres sor no. 1 is shown in table.

208/230-3-60: Compressor no. 2 RLA is 14.1 amps and LRA is 105 amps.

460-3-60: Compressor no. 2 RLA is 7.1 amps and LRA is 55 amps.

575-3-60: Compressor no. 2 RLA is 6.4 amps and LRA is 40 amps.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer

to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or

HACR breaker. Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

=

7

457

452 + 464 + 455

1371

3

= 457

COMPRESSOR

3

(ea)

OFM

(ea)

Use

ELECTRIC

IFM

FLA

10.6

4.8

4.8

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric

utility company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include

4. Determine heater capacity using multiplication factors table below:

HEAT

Nominal

kW

— — 65.2/ 65.2 80/ 80** 68/ 68

7.8/10.4 21.7/ 25.0 65.2/ 65.2 80/ 80** 68/ 68

12.0/16.0 33.4/ 38.5 65.2/ 65.2 70/ 70** 68/ 68

24.0/32.0 66.7/ 77.0 96.6/109.5 100/110** 89/101

31.8/42.4 88.4/102.0 123.7/140.8 125/150** 114/129

37.6/50.0 104.2/120.3 143.5/133.5 150/150** 132/151

— — 69.6/ 69.6 80/ 80** 73/ 73

7.8/10.4 21.7/ 25.0 69.6/ 69.6 80/ 80** 73/ 73

12.0/16.0 33.4/ 38.5 69.6/ 69.6 80/ 80** 73/ 73

24.0/32.0 66.7/ 77.0 102.1/115.0 110/125** 94/106

31.8/42.4 88.4/102.0 129.2/146.3 150/150** 119/135

37.6/50.0 104.2/120.3 149.0/139.0 150/175** 137/156

— — 29.6 40 31

16.5 19.8 30.8 40 31

27.8 33.4 47.8 50 44

33.0 39.7 55.6 60 51

41.7 50.2 68.7 70** 63

50.0 60.1 66.1 80** 75

— — 32.2 45 34

16.5 19.8 34.1 45 34

27.8 33.4 51.0 60 47

33.0 39.7 58.9 60 54

41.7 50.2 71.9 80** 66

50.0 60.1 69.4 80** 78

— — 23.6 30 25

17.0 17.1 26.1 30 25

34.0 34.1 47.5 50 44

51.0 51.2 56.0 60 63

— — 25.7 30 27

17.0 17.1 28.7 35 27

34.0 34.1 50.1 60 46

51.0

power exhaust MCA and MOCP. Check MCA and MOCP when power exhaust is powered

through the unit (must be in accordance with NEC and/or local codes). Determine the

new MCA including the power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MOCP, then MOCP would not change.

The MOCP in this example is 45 amps, the MCA New is below 45, therefore the MOCP is

acceptable. If “MCA New” is larger than the published MOCP, raise the MOCP to the next

larger size. For separate power, the MOCP for the power exhaust will be 15 amps per

NEC.

POWER EXHAUST

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

HEATER

RATING

VO LTAGE

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA MOCP† FLA LRA

51.2 58.6 70** 66

PAR T N O.

200 208 230 240 380 440 460 480 550 575 600

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

POWER

SUPPLY

MCA

(230 v)

MCA

(460 v)

ACTUAL HEATER VOLTAGE

MCA

(575 v)

DISCONNECT

SIZE*

383/383

406/406

MOCP

(for separate

power source)

192

203

154

163

—12—

Page 13

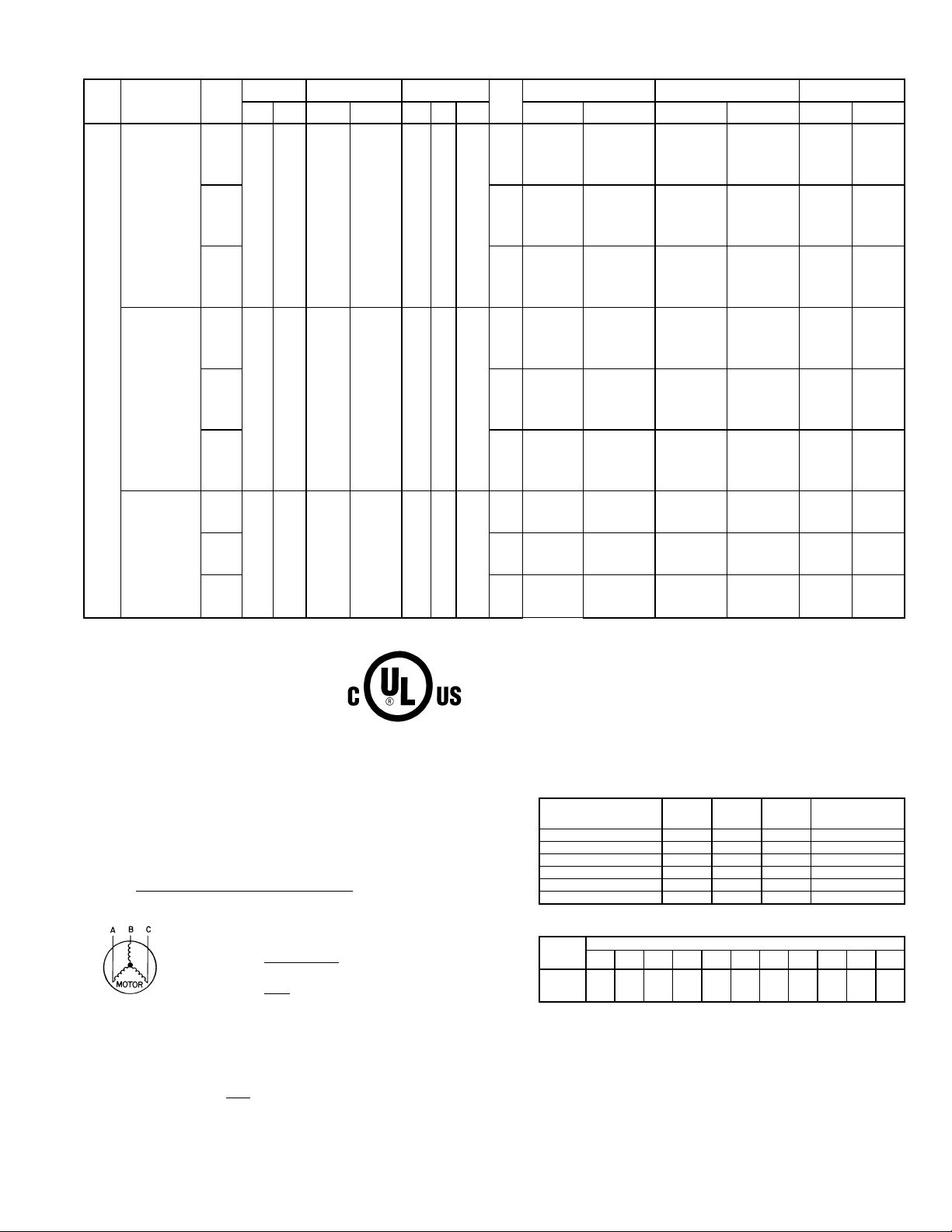

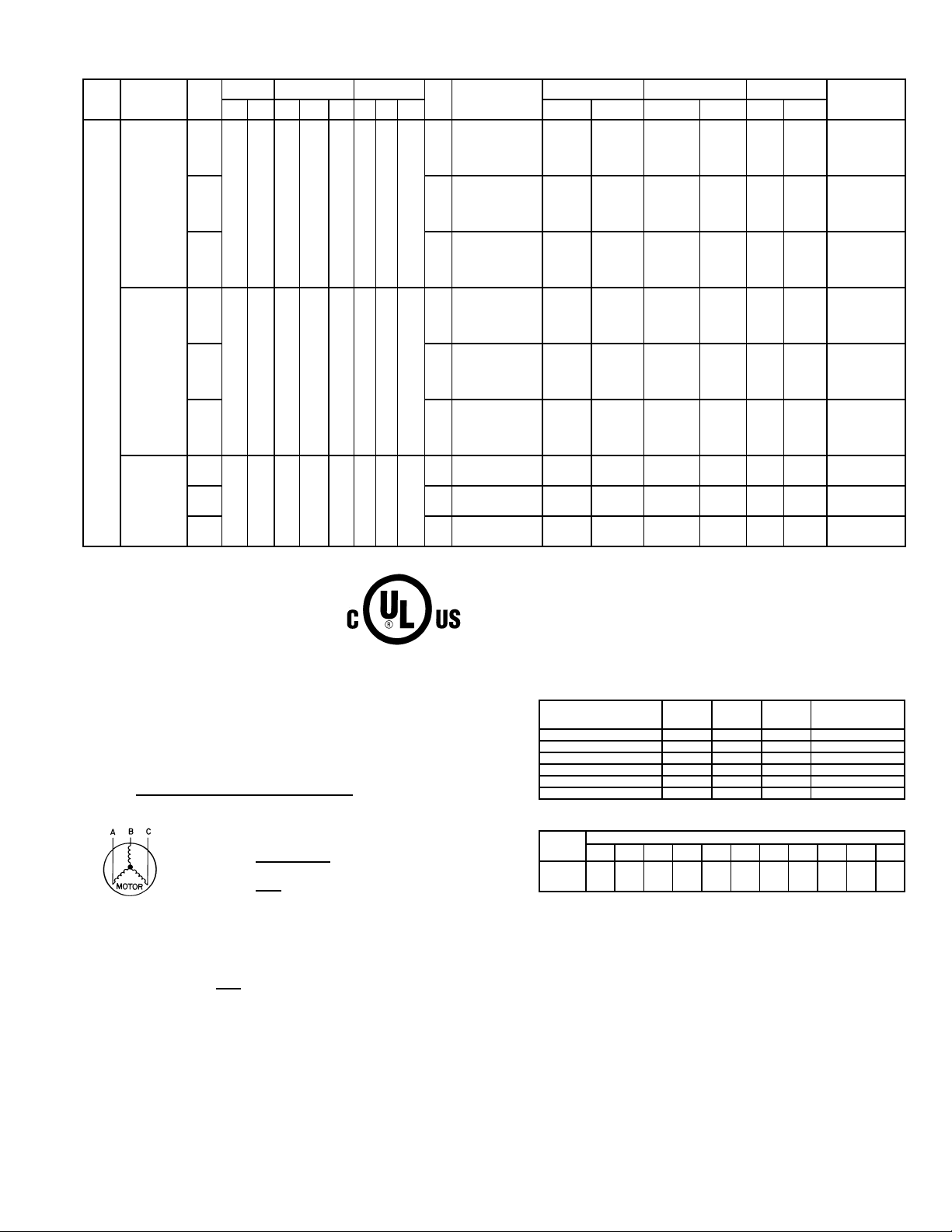

Table 2B — Electrical Data (Units Without Convenience Outlet) (558F091, 103, 121, 151)

558F

NOMINAL

UNIT

SIZE

FLA — Full Load Amps

HACR — Heating, Air Conditionin g and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maxim um Overcurrent Protection

NEC — National Electrical C ode

OFM — Outdoo r (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compressor no. 1 is shown in table.

208/230-3-60: Com pressor no. 2 RLA is 14.1 am ps and LRA is 105 am ps.

460-3-60: Compres sor no. 2 RLA is 7.1 amps an d LRA is 55 amps.

575-3-60: Compres sor no. 2 RLA is 6.4 amps an d LRA is 40 amps.

NOTES:

1. In compliance with NEC requirem ents for multimotor a nd combination lo ad equipment ( refer to NEC

2. Unbalanced 3-Phase Supply Voltage

V-P H-H z

208/230-3-60

091

460-3-60

575-3-60

LEGEND

Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

Never operate a motor where a ph ase imbalance in sup ply voltage is greater than 2%.

following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine perc ent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phas e imbalance is satisfacto ry as it is below the max imum allowable 2%.

max voltage deviation from averag e voltage

Example: Supply voltag e is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

VO LTAGE

RANGE

IFM

TYPE

Min Max Qty RLA LRA Qty Hp FLA

STD

187 254 2 14 91 2

ALT 5.8

HIGH 10.6

STD

414 5 08 2 6.4 42 2

ALT 2.6

HIGH 4.8

STD

518 6 32 2 5.2 39 2

ALT 2.6

HIGH 4.8

average voltage

7

457

= 1.53%

452 + 464 + 455

1371

=

3

= 457

COMPRESSOR

(ea)

3

OFM (ea)

1

/41.4

1

/40.7

1

/40.7

IFM

FLA

5.8

2.6

2.6

Use the

MCA

(460 v)

DISCONNECT

SIZE*

MCA

(575 v)

SINGLE POINT

CRSINGLE---A00

(for separate

power source)

HEATER

MODEL NO.

CRHEATER---A00

NONE

017 7.8/10.4 21.7/ 25.0 40.1/ 40.1 45/ 45 42/ 42 229/229 006

010 12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 45/ 51 229/229 006

011 18.4/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75 229/229 007

012 24.0/32.0 66.7/ 77.0 9 0.6/103.5 100/110** 83/ 95 229/229 007

012 and 017 31.8/42.4 88.4/102.0 117.7/13 4.8 1 25/150** 108/12 4 229/229 009

NONE —/— —/— 40.1/ 40.1 45/ 45 42/ 42 229/229 —

017 7.8/10.4 21.7/ 25.0 40.1/ 40.1 45/ 45 42/ 42 229/229 006

010 12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 45/ 51 229/229 006

011 18.6/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75 229/229 006

012 24.0/32.0 66.7/ 77.0 9 0.6/103.5 100/110** 83/ 95 229/229 007

012 and 017 31.8/42.4 88.4/102.0 117.7/13 4.8 1 25/150** 108/12 4 229/229 009

NONE —/— —/— 44.9/ 44.9 50/ 50 48/ 48 273/273 —

017 7.8/10.4 21.7/ 25.0 44.9/ 44.9 50/ 50 48/ 48 273/273 006

010 12.0/16.0 33.4/ 38.5 54.9/ 61.4 60/ 70** 51/ 56 273/273 007

011 18.6/24.8 51.7/ 59.7 77.9/ 87.8 80/ 90** 72/ 81 273/273 007

012 24.0/32.0 66.7/ 77.0 9 6.6/109.5 100/110** 89/ 101 273 /273 007

012 and 017 32.3/42.4 88.4/102.0 123.7/14 0.8 1 25/150** 114/12 9 273/273 009

NONE — — 18.4 20 19 108 —

016 13.9 16.7 24.1 25 22 108 006

013 16.5 19.8 28.1 30 26 108 006

014 27.8 33.4 45.0 50 41 108 006

015 33.0 39.7 52.9 60 49 108 006

014 and 016 41.7 50.2 65.9 70** 61 10 8 008

NONE — — 18.4 20 19 108 —

016 13.9 16.7 24.1 25 22 108 006

013 16.5 19.8 28.1 30 26 108 006

014 27.8 33.4 45.0 50 41 108 006

015 33.0 39.7 52.9 60 49 108 006

014 and 016 41.7 50.2 65.9 70** 61 10 8 008

NONE — — 20.6 25 22 130 —

016 13.9 16.7 26.9 30 25 130 006

013 16.5 19.8 30.8 35 28 130 006

014 27.8 33.4 47.8 50 44 130 006

015 33.0 39.7 55.6 60 51 130 006

014 and 016 41.7 50.2 68.7 70** 63 11 0 008

NONE — — 14.9 20 16 97 —

018 17.0 17.1 23.9 25 22 97 006

019 34.0 34.1 45.3 40 42 97 006

NONE — — 14.9 20 16 97 —

018 17.0 17.1 23.9 25 22 97 006

019 34.0 34.1 45.3 40 42 97 006

NONE — — 16.7 20 18 114 —

018 17.0 17.1 26.1 30 24 114 006

019 34.0 34.1 47.5 45 44 114 006

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electr ic utility

company immediately.

ELECTRIC HEAT POWER SUPPLY

Nominal

kW

—/— —/— 40.1/ 40.1 45/ 45 42/ 42 229/229 —

3. For units with power exhaust: If a single power source is to be used, size wire to include power

exhaust MCA and MOC P. Check MCA and MOCP whe n power exhaust is powered throu gh the

unit (must be in accordance with NEC and/or local codes). Determine the new MCA including the

power exhaust using the following form ula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MO CP, then MOCP would not change. The MOCP

in this example is 45 amps, the MCA New is below 45, therefore the MOCP is acceptable. If “MCA

New” is larger than the published MOCP, raise the MOCP to the next larger size. For separate

power, the MOCP for the power exhaust will be 15 amps per NEC.

POWER EXHAUST

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

4. Deter mine heater capa city using multiplicatio n factors table below:

HEATER

RATING

VOLTAGE

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA MOCP† FLA LRA

PART NO.

200 208 230 240 380 440 460 480 550 575 600

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

MCA

(230 v)

ACTUAL HEATER VOLTAGE

BOX P/N

MOCP

—13—

Page 14

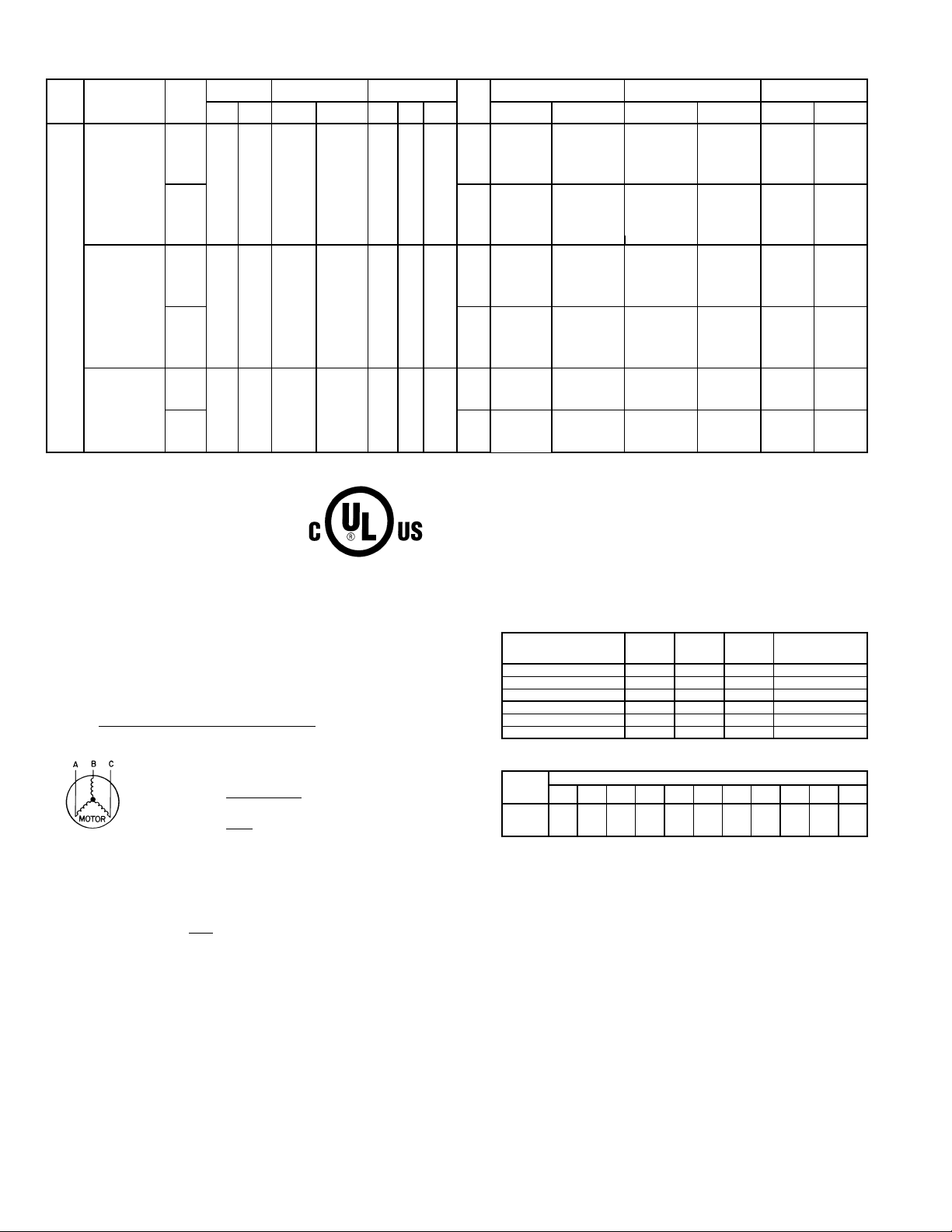

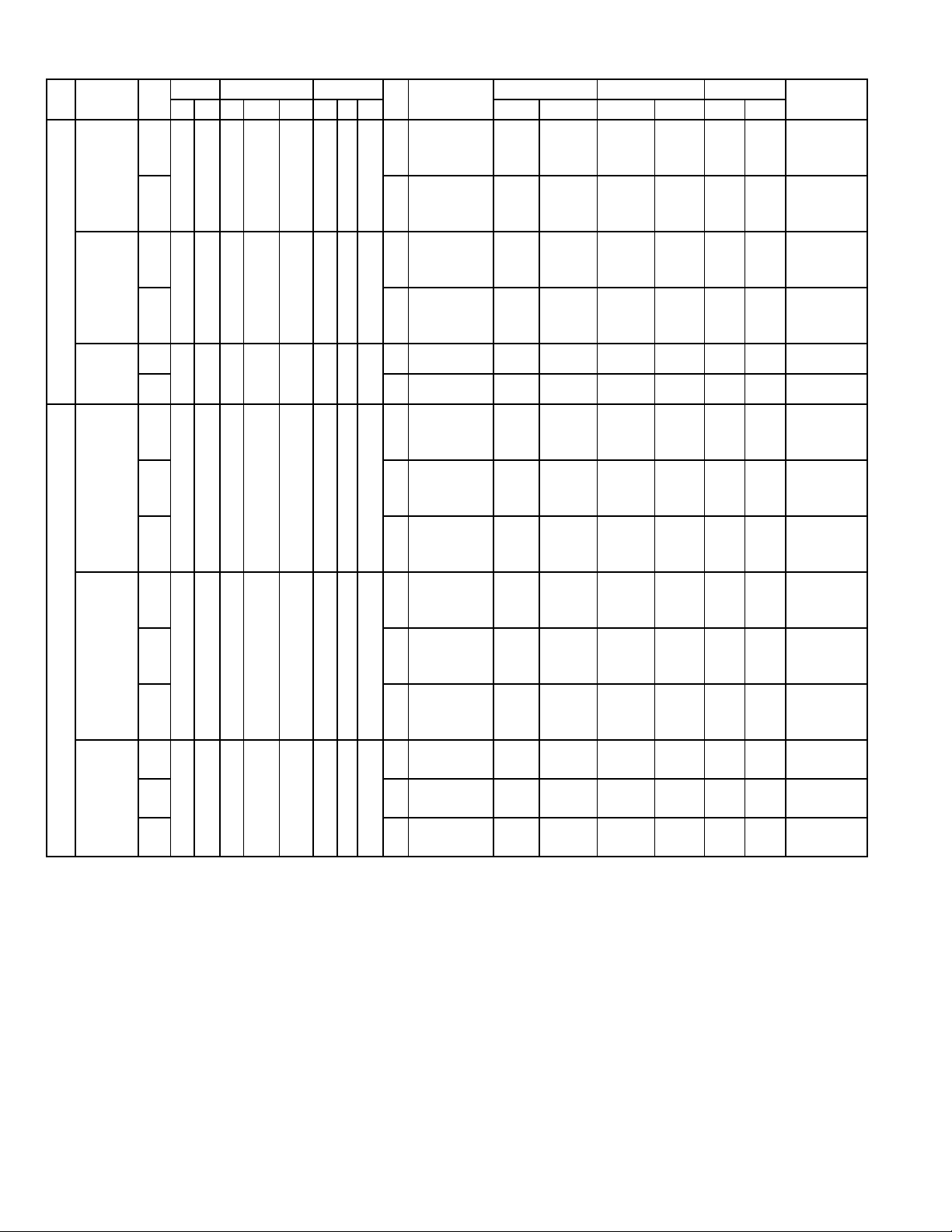

558F

UNIT

SIZE

103

121

NOMINAL

V-P H-H z

208/230-3-60

460-3-60

575-3-60

208/230-3-60

460-3-60

575-3-60

Table 2B — Electrical Data (Units Without Convenience Outlet) (558F091, 103, 121, 151) (cont)

VOLTAGE

RANGE

IFM

TYPE

Min Max Qty RLA LRA Qty Hp FLA

STD

187 254 2 17.3†† 120†† 2

HIGH 10.6

STD

414 508 2 7.9† † 70†† 2

HIGH 4.8

STD

518 632 2 5.5† † 50†† 2

HIGH 4.8

STD

ALT 7.5

187 254 2 16 125 2

HIGH 15

STD

414 508 2 8 62.5 2

ALT 3.4

HIGH 7.4

STD

518 632 2 6.3 50 2

ALT 3.4

HIGH 7.4

COMPRESSOR

(ea)

OFM (ea)

1

/41.4

1

/40.7

1

/40.7

1

/41.4

1

/40.7

1

/40.7

HEATER

IFM

MODEL NO.

FLA

CRHEATER---A00

NONE —/— —/— 44.3/ 44.3 50/ 50 46/ 46 272/272 —

017 7.8/10.4 21.7/ 25.0 44.3/ 44.3 50/ 50 46/ 46 272/272 006

5.8

2.6

2.6

5.8

2.6

2.6

010 12. 0/16.0 33.4/ 38.5 48 .9/ 55.4 50/ 60 46/ 51 272/272 006

011 18. 6/24.8 51.7/ 59.7 71 .9/ 81.8 80/ 90** 66/ 75 272/27 2 007

012 24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95 272/272 007

012 and 017 31.8/42. 4 88.4/102.0 117.7/134.8 125/150* * 108/124 27 2/272 009

NONE —/— —/— 49.1/ 49.1 60/ 60 52/ 52 316/316 —

017 7.8/10.4 21.7/ 25.0 49.1/ 49.1 60/ 60 52/ 52 316/316 006

010 12. 0/16.0 33.4/ 38.5 54 .9/ 61.4 60/ 70** 52/ 56 316/31 6 007

011 18. 6/24.8 51.7/ 59.7 77 .9/ 87.8 80/ 90** 72/ 81 316/31 6 007

012 24. 0/32.0 66.7/ 77.0 96 .6/109.5 100/110* * 89/101 316/ 316 007

012 and 017 31.8/42. 4 88.4/102.0 123.7/140.8 125/150* * 114/129 31 6/316 009

NONE — — 21.0 25 22 149 —

016 13.9 16.7 24.1 25 22 149 006

013 16.5 19.8 28.1 30 26 149 006

014 27.8 33.4 45.0 50 41 149 006

015 33.0 39.7 52.9 60 49 149 006

014 and 016 41.7 50.2 65 .9 70 ** 61 149 008

NONE — — 23.2 30 24 171 —

016 13.9 16.7 26.9 30 25 171 006

013 16.5 19.8 30.8 35 28 171 006

014 27.8 33.4 47.8 50 44 171 006

015 33.0 39.7 55.6 60 51 171 006

014 and 016 41.7 50.2 68 .7 70 ** 63 171 008

NONE — — 16.7 20 17 109 —

018 17.0 17.1 23.9 25 22 109 006

019 34.0 34.1 45.3 40 42 109 006

NONE — — 18.5 25 19 126 —

018 17.0 17.1 26.1 30 24 126 006

019 34.0 34.1 47.5 45 44 126 006

NONE —/— —/— 44.6/ 44.6 50/ 50 47/ 47 297/297 —

017 7.8/10.4 21.7/ 25.0 44.6/ 44.6 50/ 50 47/ 47 297/297 011

010 12. 0/16.0 33.4/ 38.5 48 .9/ 55.4 50/ 60 47/ 51 297/297 011

012 24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95 297/297 012

012 and 017 31.8/42. 4 88.4/102.0 117.7/134.8 125/150* * 108/124 29 7/297 015

010 and 012 37.6/50. 0 104.2/120.3 137.5/157.6 150/175* * 127/145 29 7/297 015

NONE —/— —/— 46.3/ 46.3 60/ 60 49/ 49 316/316 —

017 7.8/10.4 21.7/ 25.0 46.3/ 46.3 60/ 60 49/ 49 316/316 011

010 12. 0/16.0 33.4/ 38.5 51 .1/ 57.5 60/ 60 49/ 53 316/316 011

012 24.0/32.0 66.7/ 77.0 92.8/105.6 100/110** 85/ 97 316/316 012

012 and 017 31.8/42. 4 88.4/102.0 119.9/136.9 125/150* * 110/126 31 6/316 015

010 and 012 37.6/50. 0 104.2/120.3 139.7/159.7 150/175* * 128/147 31 6/316 015

NONE —/— —/— 53.8/ 53.8 60/ 60 57/ 57 364/364 —

017 7.8/10.4 21.7/ 25.0 53.8/ 53.8 60/ 60 57/ 57 364/364 011

010 12. 0/16.0 33.4/ 38.5 60 .4/ 66.9 70/ 80** 57/ 62 364/36 4 012

012 22. 9/32.0 66.7/ 77.0 102 .1/115.0 110/125** 94/106 364/36 4 012

012 and 017 31.8/42. 4 88.4/102.0 129.2/146.3 150/150* * 119/135 36 4/364 015

010 and 012 37.6/50. 0 104.2/120.3 149.0/169.1 150/175* * 137/156 36 4/364 015

NONE — — 22.0 25 23 149 —

013 16.5 19.8 28.1 30 26 149 011

014 27.8 33.4 45.0 40 41 149 011

015 33.0 39.7 52.9 60 49 149 011

014 and 016 41.7 50.2 65 .9 70 ** 61 149 014

013 and 015 50.0 60.1 78 .4 80 ** 72 149 014

NONE — — 22.8 25 24 188 —

013 16.5 19.8 29.1 30 27 188 011

014 27.8 33.4 46.0 45 42 188 011

015 33.0 39.7 53.9 60 50 188 011

014 and 016 41.7 50.2 66 .9 70 ** 62 188 014

013 and 015 50.0 60.1 79 .4 80 ** 73 188 014

NONE — — 26.8 30 29 182 —

013 16.5 19.8 34.1 40 31 182 011

014 27.8 33.4 51.0 60 47 182 011

015 33.0 39.7 58.9 60 54 182 011

014 and 016 41.7 50.2 71 .9 80 ** 66 182 014

013 and 015 50.0 60.1 84 .4 90 ** 78 182 014

NONE — — 17.4 20 18 119 —

018 17.0 17.1 23.9 25 22 119 011

019 34.0 34.1 45.3 40 42 119 011

018 and 019 51.0 51.2 66 .6 70 ** 61 119 014

NONE — — 18.0 20 19 151 —

018 17.0 17.1 24.7 25 23 151 011

019 34.0 34.1 46.1 45 42 151 011

018 and 019 51.0 51.2 67 .4 70 ** 62 151 014

NONE — — 21.2 25 23 146 —

018 17.0 17.1 28.7 35 26 146 011

019 34.0 34.1 50.1 50 46 146 011

018 and 019 51.0 51.2 71 .4 80 ** 66 146 014

ELECTRIC HEAT POWER SUPPLY

Nominal

kW

FLA MCA MOCP† FLA LRA

DISCONNECT

SIZE*

SINGLE POINT

BOX P/N

CRSINGLE---A 00

—14—

Page 15

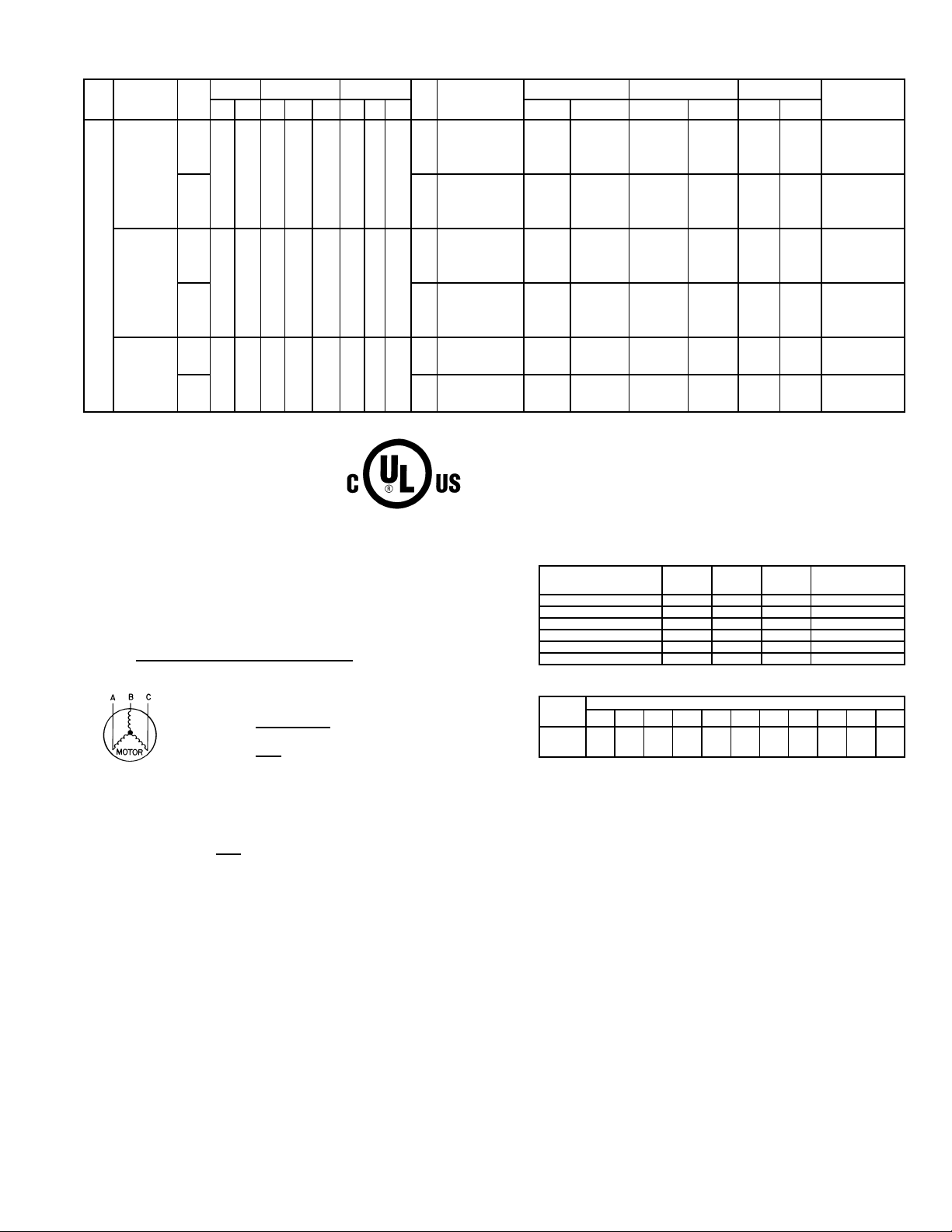

Table 2B — Electrical Data (Units Without Convenience Outlet) (558F091, 103, 121, 151) (cont)

558F

NOMINAL

UNIT

V-P H-H z

SIZE

208/230-3-60

151

460-3-60

575-3-60

FLA — Full Load Amps

HACR — Heating, Air Conditionin g and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maxim um Overcurrent Protection

NEC — National Electrical C ode

OFM — Outdoo r (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compressor no. 1 is shown in table.

208/230-3-60: Com pressor no. 2 RLA is 14.1 am ps and LRA is 105 am ps.

460-3-60: Compres sor no. 2 RLA is 7.1 amps an d LRA is 55 amps.

575-3-60: Compres sor no. 2 RLA is 6.4 amps an d LRA is 40 amps.

NOTES:

1. In compliance with NEC requirem ents for multimotor a nd combination lo ad equipment ( refer to NEC

Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a ph ase imbalance in sup ply voltage is greater than 2%.

following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine perc ent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phas e imbalance is satisfacto ry as it is below the max imum allowable 2%.

LEGEND

max voltage deviation from averag e voltage

VOLTAGE

RANGE

IFM

TYPE

Min Max Qty RLA LRA Qty Hp FLA

STD

187 254 2 19 156 2

ALT 15

STD

414 508 2 9 75 2

ALT 7.4

STD

518 632 2 7.4 54 2

ALT 7.4

average voltage

Example: Supply voltag e is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

457

= 1.53%

7

COMPRESSOR

452 + 464 + 455

1371

=

3

= 457

(ea)

3

OFM (ea)

1

/41.4

1

/40.7

1

/40.7

IFM

FLA

10.6

HEATER

MODEL NO.

CRHEATER---A00

012 and 017 31.8/42.4 88.4/102.0 123.7/140.8 125/150** 114/129 359/359 015

010 and 012 37.6/50.0 104.2/120.3 143.5/163.6 150/175** 132/151 359/359 015

012 and 017 31.8/42.4 88.4/102.0 129.2/146.3 150/150** 119/135 378/378 015

010 and 012 37.6/50.0 104.2/120.3 149.0/169.1 150/175** 137/156 378/378 015

4.8

014 and 016 41.7 50.2 68.7 70** 63 174 014

013 and 015 50.0 60.1 81.2 90** 75 174 014

014 and 016 41.7 50.2 71.9 80** 66 213 014

013 and 015 50.0 60.1 84.4 90** 78 213 014

4.8

018 and 019 51.0 51.2 68.8 70** 63 127 014

018 and 019 51.0 51.2 71.4 80** 66 159 014

Use the

MCA

(460 v)

DISCONNECT

SIZE*

MCA

(575 v)

SINGLE POINT

BOX P/N

CRSINGLE---A0 0

MOCP

(for separate

power source)

ELECTRIC HE AT POWER SU PPLY

Nominal

NONE —/— —/— 56.2/ 56.2 70/ 70** 59/ 59 359/359 —

017 7.8/10.4 21 .7/ 25.0 56.2/ 56.2 7 0/ 70** 59/ 59 359/359 01 2

010 12.0/16.0 33.4/ 38.5 56.2/ 61.4 70/ 70** 59/ 59 359/359 012

012 24.0/32.0 66.7/ 77.0 96.6/109.5 100/110** 89/101 359/359 012

NONE —/— —/— 60.6/ 60.6 70/ 70** 64/ 64 378/378 —

017 7.8/10.4 21 .7/ 25.0 60.6/ 60.6 7 0/ 70** 64/ 64 378/378 01 2

010 12.0/16.0 33.4/ 38.5 60.6/ 66.9 70/ 80** 64/ 64 378/378 012

012 24.0/32.0 66.7/ 77.0 102.1/115.0 110/125** 94/106 378/378 012

NONE — — 26.5 30 28 174 —

013 16.5 19.8 30.8 35 28 174 011

014 27.8 33.4 47.8 45 44 174 011

015 33.0 39.7 55.6 60 51 174 011

NONE — — 29.1 35 31 213 —

013 16.5 19.8 34.1 40 31 213 011

014 27.8 33.4 51.0 60 47 213 011

015 33.0 39.7 58.9 60 54 213 011

NONE — — 21.6 25 23 127 —

018 17.0 17.1 26.1 30 24 127 011

019 34.0 34.1 47.5 45 44 127 011

NONE — — 23.7 30 25 159 —

018 17.0 17.1 28.7 35 26 159 011

019 34.0 34.1 50.1 50 46 159 011

kW

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electr ic utility

company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include power

exhaust MCA and MOC P. Check MCA and MOCP whe n power exhaust is powered throu gh the

unit (must be in accordance with NEC and/or local codes). Determine the new MCA including the

power exhaust using the following form ula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MO CP, then MOCP would not change. The MOCP

in this example is 45 amps, the MCA New is below 45, therefore the MOCP is acceptable. If “MCA

New” is larger than the published MOCP, raise the MOCP to the next larger size. For separate

power, the MOCP for the power exhaust will be 15 amps per NEC.

4. Deter mine heater capa city using multiplicatio n factors table below:

HEATER

VOLTAGE

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA MOCP† FLA LRA

POWER EXHAUST

PART NO.

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

RATING

200 208 230 240 380 440 460 480 550 575 600

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

MCA

(230 v)

ACTUAL HEATER VOLTAGE

—15—

Page 16

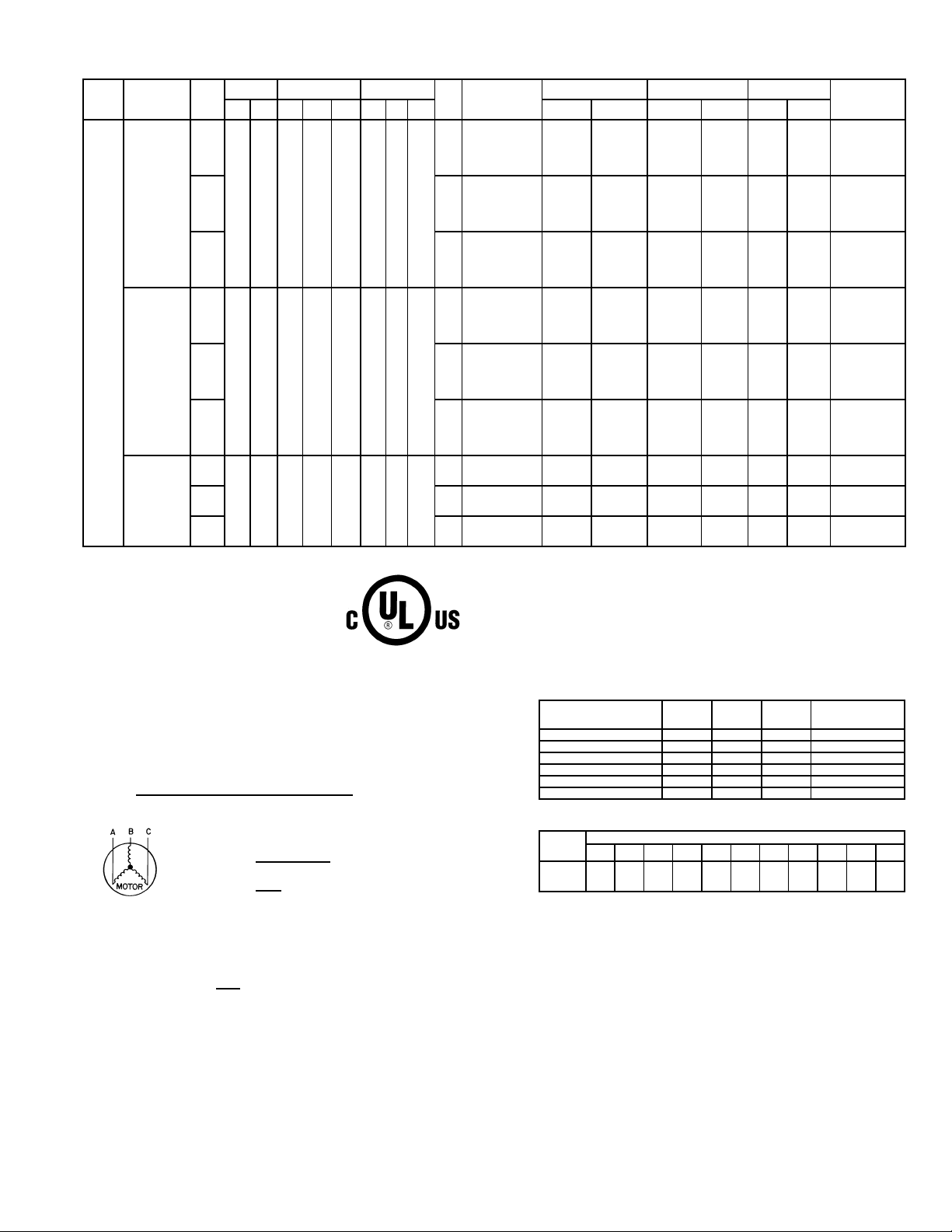

558F

UNIT

SIZE

090

102

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

208/230-3-60

460-3-60

575-3-60

Table 2C — Electrical Data (Units With Convenience Outlet) (558F090, 102, 120, 150)

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

and

Alt

187 254 14.0 91.0 21/41.4

High 10.6

Std

and

Alt

414 508 6.4 42.0 21/40.7

High 4.8

Std

and

Alt

518 632 5.2 39.0 21/40.7

High 4.8

Std

187 254 16.0 137.0 21/41.4

High 10.6

Std

414 508 8.3 69.0 21/40.7

High 4.8

Std

518 632 6.4 58.0 21/40.7

High 4.8

COMPRESSOR

(ea)

OFM

(ea)

ELECTRIC

IFM

FLA

5.8

2.6

2.6

5.8

2.6

2.6

HEAT

Nominal

kW

— — 46.1/ 46.1 50/ 50 48/ 48

7.8/10.4 21.7/ 25.0 46.1/ 46.1 50/ 50 48/ 48

12.0/16.0 33.4/ 38.5 53.9/ 60.4 60/ 70** 51/ 56

18.6/24.8 51.7/ 59.7 76.9/ 86.8 80/ 90** 72/ 81

24.0/32.0 66.7/ 77.0 95.6/108.5 100/110** 89/101

31.8/42.4 88.4/102.0 122.7/139.8 125/150** 114/130

— — 50.9/ 50.9 60/ 60 53/ 53

7.8/10.4 21.7/ 25.0 50.9/ 50.9 60/ 60 53/ 53

12.0/16.0 33.4/ 38.5 59.9/ 66.4 70/ 70** 56/ 62

18.6/24.8 51.7/ 59.7 82.9/ 92.8 90/100** 77/ 86

24.0/32.0 66.7/ 77.0 101.6/114.5 110/125** 94/106

31.8/42.4 88.4/102.0 128.7/145.8 150/150** 119/135

— — 21.1 25 22

13.9 16.7 26.8 25 25

16.5 19.8 30.8 35 28

27.8 33.4 47.8 50 44

33.0 39.7 55.6 60 51

41.7 50.2 68.6 70** 63

— — 23.3 25 24

13.9 16.7 29.5 30 27

16.5 19.8 33.5 35 31

27.8 33.4 50.4 60 46

33.0 39.7 58.3 60 54

41.7 50.2 71.3 80** 66

— — 17.6 20 18

34.0 34.1 48.0 50 44

— — 19.4 25 20

34.0 34.1 50.1 60 46

— — 50.6/ 50.6 60/ 60 52/ 52

7.8/10.4 21.7/ 25.0 50.6/ 50.6 60/ 60 52/ 52

12.0/16.0 33.4/ 38.5 53.9/ 60.4 60/ 70** 52/ 56

18.6/24.8 51.7/ 59.7 76.9/ 86.8 80/ 90** 72/ 81

24.0/32.0 66.7/ 77.0 95.6/108.5 100/110** 89/101

31.8/42.4 88.4/102.0 122.7/139.8 125/150** 114/130

— — 55.4/ 55.4 60/ 60 58/ 58

7.8/10.4 21.7/ 25.0 55.4/ 55.4 60/ 60 58/ 58

12.0/16.0 33.4/ 38.5 59.9/ 66.4 70/ 70** 58/ 62

18.6/24.8 51.7/ 59.7 82.9/ 92.8 90/100** 77/ 86

24.0/32.0 66.7/ 77.0 101.6/114.5 110/125** 94/106

31.9/42.4 88.4/102.0 128.7/145.8 150/150** 119/135

— — 25.4 30 26

13.9 16.7 26.8 30 26

16.5 19.8 30.8 35 28

27.8 33.4 47.7 50 44

33.0 39.7 55.6 60 51

41.7 50.2 68.6 70** 63

— — 27.6 30 26

13.9 16.7 29.5 30 29

16.5 19.8 33.5 35 31

27.8 33.4 50.4 60 46

33.0 39.7 58.3 60 54

41.7 50.2 71.3 80** 66

— — 20.3 25 20

34.0 34.1 49.9 50 44

— — 22.1 25 22

34.0 34.1 50.1 60 46

FLA MCA MOCP† FLA LRA

POWER

SUPPLY

DISCONNECT

SIZE*

233/233

277/277

110

132

10017.0 17.1 26.6 25 24

11717.0 17.1 28.8 30 26

325/325

369/369

164

186

13817.0 17.1 26.6 25 24

15517.0 17.1 28.8 30 26

—16—

Page 17

Table 2C — Electrical Data (Units With Convenience Outlet) (558F090, 102, 120, 150) (cont)

558F

UNIT

SIZE

120

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

Alt 7.5

187 254 15.8 130.0 21/41.4

High 15.0

Std

Alt

414 508 7.9 64.0 21/40.7

High

Std

Alt 3.4

518 632 6.6 52.0 21/40.7

High 7.4

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compres sor no. 1 is shown in table.

208/230-3-60: Compressor no. 2 RLA is 14.1 amps and LRA is 105 amps.

460-3-60: Compressor no. 2 RLA is 7.1 amps and LRA is 55 amps.

575-3-60: Compressor no. 2 RLA is 6.4 amps and LRA is 40 amps.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer

to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or

HACR breaker. Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

7

457

452 + 464 + 455

1371

=

3

= 457

COMPRESSOR

3

(ea)

OFM

(ea)

Use

ELECTRIC

IFM

FLA

5.8

2.6

3.4

7.4

2.6

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric

utility company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include

4. Determine heater capacity using multiplication factors table below:

HEAT

Nominal

kW

— — 49.1/ 49.1 60/ 60 50/ 50

7.8/10.4 21.7/ 25.0 49.1/ 49.1 60/ 60 50/ 50

12.0/16.0 33.4/ 38.5 53.9/ 60.4 60/ 70** 51/ 56

24.0/32.0 66.7/ 77.0 95.6/108.5 100/110** 89/101

31.8/42.4 88.4/102.0 122.7/139.8 125/150** 114/130

37.6/50.0 104.2/120.3 142.5/132.5 150/150** 132/151

— — 50.8/ 50.8 60/ 60 52/ 52

7.8/10.4 21.7/ 25.0 50.8/ 50.8 60/ 60 52/ 52

12.0/16.0 33.4/ 38.5 56.1/ 62.5 60/ 60 53/ 58

24.0/32.0 66.7/ 77.0 97.8/110.6 100/125** 91/103

31.8/42.4 88.4/102.0 124.9/141.9 125/150** 116/131

37.6/50.0 104.2/120.3 144.7/134.7 150/150** 134/152

— — 58.3/ 58.3 70/ 70** 61/ 61

7.8/10.4 21.7/ 25.0 58.3/ 58.3 70/ 70** 61/ 61

12.0/16.0 33.4/ 38.5 65.4/ 71.9 60/ 80** 61/ 67

24.0/32.0 66.7/ 77.0 107.1/120.0 110/125** 99/111

31.8/42.4 88.4/102.0 134.2/151.3 150/175** 124/140

37.6/50.0 104.2/120.3 154.0/144.0 175/175** 143/161

— — 23.73024

16.5 19.8 30.7 30 28

27.8 33.4 47.8 50 44

33.0 39.7 55.5 60 51

41.7 50.2 68.6 70** 63

50.0 60.1 65.6 70** 75

— — 24.53025

16.5 19.8 31.7 30 29

27.8 33.4 48.8 50 45

33.0 39.7 56.6 60 52

41.7 50.2 69.7 70** 64

50.0 60.1 66.6 70** 76

— — 28.53030

16.5 19.8 36.7 35 34

27.8 33.4 53.8 60 49

33.0 39.7 61.5 70** 57

41.7 50.2 74.6 80** 69

50.0 60.1 71.6 80** 80

— — 20.62521

17.0 17.1 26.6 25 24

34.0 34.1 47.9 50 44

51.0 51.2 56.0 60 63

— — 21.22521

17.0 17.1 27.4 30 25

34.0 34.1 48.8 50 44

51.0 51.2 56.8 60 64

— — 24.43025

17.0 17.1 31.4 35 28

34.0 34.1 52.7 60 48

51.0 51.2 60.8 70** 68

power exhaust MCA and MOCP. Check MCA and MOCP when power exhaust is powered

through the unit (must be in accordance with NEC and/or local codes). Determine the

new MCA including the power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MOCP, then MOCP would not change.

The MOCP in this example is 45 amps, the MCA New is below 45, therefore the MOCP is

acceptable. If “MCA New” is larger than the published MOCP, raise the MOCP to the next

larger size. For separate power, the MOCP for the power exhaust will be 15 amps per

NEC.

POWER EXHAUST

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

HEATER

RATING

VO LTAGE

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA MOCP† FLA LRA

PAR T N O.

200 208 230 240 380 440 460 480 550 575 600

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

POWER

SUPPLY

MCA

(230 v)

MCA

(460 v)

ACTUAL HEATER VOLTAGE

MCA

(575 v)

DISCONNECT

SIZE*

311/311

330/330

378/378

MOCP

(for separate

power source)

154

194

188

110

141

136

—17—

Page 18

Table 2C — Electrical Data (Units With Convenience Outlet) (558F090, 102, 120, 150) (cont)

558F

UNIT

SIZE

150

NOMINAL

V-P h- Hz

208/230-3-60

460-3-60

575-3-60

VO LTAGE

RANGE

IFM

TYPE

Min Max RLA LRA Qty Hp FLA

Std

187 254 23.0 146.0 21/41.4

Alt 15.0

Std

414 508 10.4 73.0 21/40.7

Alt 7.4

Std

518 632 8.3 58.4 21/40.7

Alt 7.4

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compres sor no. 1 is shown in table.

208/230-3-60: Compressor no. 2 RLA is 14.1 amps and LRA is 105 amps.

460-3-60: Compressor no. 2 RLA is 7.1 amps and LRA is 55 amps.

575-3-60: Compressor no. 2 RLA is 6.4 amps and LRA is 40 amps.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer

to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or

HACR breaker. Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

=

7

457

452 + 464 + 455

1371

3

= 457

COMPRESSOR

3

(ea)

OFM

(ea)

Use

ELECTRIC

IFM

FLA

10.6

4.8

4.8

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric

utility company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include

4. Determine heater capacity using multiplication factors table below:

HEAT

Nominal

kW

— — 71.2/ 71.2 80/ 80** 74/ 74

7.8/10.4 21.7/ 25.0 71.2/ 71.2

12.0/16.0 33.4/ 38.5 71.2/ 71.2

24.0/32.0 66.7/ 77.0 101.6/114.5

31.8/42.4 88.4/102.0 128.7/145.8

37.6/50.0 104.2/120.3 148.5/138.5

— — 75.6/ 75.6 90/ 80** 79/ 79

7.8/10.4 21.7/ 25.0 75.6/ 75.6

12.0/16.0 33.4/ 38.5 75.6/ 75.6

24.0/32.0 66.7/ 77.0 107.1/120.0

31.8/42.4 88.4/102.0 134.2/151.3

37.6/50.0 104.2/120.3 154.0/144.0

— — 32.3 45 34

16.5 19.8 33.4 45 34

27.8 33.4 50.5 60 46

33.0 39.7 58.2 60 54

41.7 50.2 71.4

50.0 60.1 68.3

— — 34.9 45 37

16.5 19.8 36.7 45 37

27.8 33.4 53.8 60 49

33.0 39.7 61.6

41.7 50.2 74.7

50.0 60.1 71.6

— — 23.6 30 27

17.0 17.1 28.8 30 27

34.0 34.1 50.1 60 46

51.0 51.2 56.0 70** 65

— — 28.4 30 29

17.0 17.1 31.4 35 29

34.0 34.1 52.8 60 48

51.0 51.2 58.6 70** 68

power exhaust MCA and MOCP. Check MCA and MOCP when power exhaust is powered

through the unit (must be in accordance with NEC and/or local codes). Determine the

new MCA including the power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MOCP, then MOCP would not change.

The MOCP in this example is 45 amps, the MCA New is below 45, therefore the MOCP is

acceptable. If “MCA New” is larger than the published MOCP, raise the MOCP to the next

larger size. For separate power, the MOCP for the power exhaust will be 15 amps per

NEC.

POWER EXHAUST

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

HEATER

RATING

VO LTAGE

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

FLA MCA M OCP† FLA LRA

PAR T N O.

200 208 230 240 380 440 460 480 550 575 600

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

POWER

SUPPLY

80/ 80**

80/ 80**

110/125**

150/150**

150/150**

90/ 80**

90/ 80**

110/125**

150/175**

175/175**

80**

80**

70**

80**

80**

MCA

(230 v)

MCA

(460 v)

ACTUAL HEATER VOLTAGE

MCA

(575 v)

DISCONNECT

SIZE*

74/ 74

74/ 74

94/106

119/135

138/156

79/ 79

79/ 79

99/111

124/140

143/161

66

77

57

69

80

(for separate

power source)

387/387

410/410

195

206

156

165

MOCP

—18—

Page 19

Table 2D — Electrical Data (Units With Convenience Outlet) (558F091, 103, 121, 151)

558F

NOMINAL

UNIT

V-P H-H z

SIZE

208/230-3-60

091

460-3-60

575-3-60

FLA — Full Load Amps

HACR — Heating, Air Conditionin g and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maxim um Overcurrent Protection

NEC — National Electrical C ode

OFM — Outdoo r (Condenser) Fan Motor

RLA — Rated Load Amps

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compressor no. 1 is shown in table.

208/230-3-60: Com pressor no. 2 RLA is 14.1 am ps and LRA is 105 am ps.

460-3-60: Compres sor no. 2 RLA is 7.1 amps an d LRA is 55 amps.

575-3-60: Compres sor no. 2 RLA is 6.4 amps an d LRA is 40 amps.

NOTES:

1. In compliance with NEC requirem ents for multimotor a nd combination lo ad equipment ( refer to NEC

Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a ph ase imbalance in sup ply voltage is greater than 2%.

following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

= 100 x

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine perc ent of voltage imbalance.

% Voltage Imbalance = 100 x