Bryant 4-WAY MULTIPOISE FIXED-CAPACITY CONDENSING GAS FURNACE 345MAV Service And Maintenance Procedures Manual

service and

maintenance procedures

4-WAY MULTIPOISE

FIXED-CAPACITY

CONDENSING GAS FURNACE

Cancels: SP05-36 SP05-42

®

ama

345MAV

Series B

5-99

A93040

NOTE: Read the entire instruction manual before performing any

service or maintenance.

Index Page

SAFETY CONSIDERATIONS..................................................1-2

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS........2

GENERAL......................................................................................2

CARE AND MAINTENANCE................................................2-10

Cleaning and/or Replacing Air Filter ...................................2-3

Blower Motor and Wheel Maintenance................................3-4

Cleaning Burners ......................................................................4

Cleaning Heat Exchangers....................................................4-5

Primary Heat Exchangers ................................................4-5

Secondary Heat Exchangers................................................5

Flushing Collector Box and Drainage System.....................5-7

Servicing Hot Surface Ignitor ..................................................7

Electrical Controls and Wiring.................................................7

Troubleshooting.....................................................................7-9

Checking Heat Tape Operation (If Applicable) ......................9

Winterizing..............................................................................10

WIRING DIAGRAM...................................................................11

SERVICE LABEL .......................................................................12

TROUBLESHOOTING GUIDE............................................13-14

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code (NFGC) NFPA

54-1996/ANSI Z223.1-1996 and the Installation Standards, Warm

Air Heating and Air Conditioning Systems (NFPA 90B)

ANSI/NFPA 90B. In Canada, refer to the CAN/CGA-B149.1- and

.2-M95 National Standard of Canada, Natural Gas and Propane

Installation Codes (NSCNGPIC). Wear safety glasses and work

gloves. Have a fire extinguisher available during start-up and

adjustment procedures and service calls.

CANADIAN GAS ASSOCIATION

APPROVED

R

As an ENERGY STAR®

Partner, BRYANT has determined that this product meets

the ENERGY STAR® guidelines for energy efficiency.

REGISTERED QUALITY SYSTEM

Fig. 1—Multipoise Furnace in Upflow Orientation

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

WARNING: The ability to properly perform maintenance on this equipment requires certain expertise, mechanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance

on this equipment other than those procedures recommended in the User’s Manual. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN POSSIBLE

DAMAGE TO THIS EQUIPMENT, SERIOUS PERSONAL INJURY, OR DEATH.

A98187

.

—1—

WARNING: Never store anything on, near, or in contact

with the furnace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds, plastic or plastic containers, gasoline, kerosene, cigarette lighter fluid, dry cleaning fluids, or other

volatile fluids.

3. Paint thinners and other painting compounds, paper

bags, or other paper products.

Failure to follow this warning can cause corrosion of the

heat exchanger, fire, personal injury, or death.

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

CAUTION: Electrostatic discharge can affect electronic

components. Take precautions during furnace installation

and servicing to protect the furnace electronic control.

Precautions will prevent electrostatic discharges from

personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same electrostatic potential.

1. Disconnect all power to the furnace. DO NOT TOUCH

THE CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY’S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held in

a person’s hand during grounding will be satisfactorily

discharged.

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touching control or wires.

5. Use this procedure for installed and uninstalled (ungrounded) furnaces.

6. Before removing a new control from its container, discharge your body’s electrostatic charge to ground to protect

the control from damage. If the control is to be installed in

a furnace, follow items 1 through 5 before bringing the

control or yourself into contact with the furnace. Put all

used AND new controls into containers before touching

ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

GENERAL

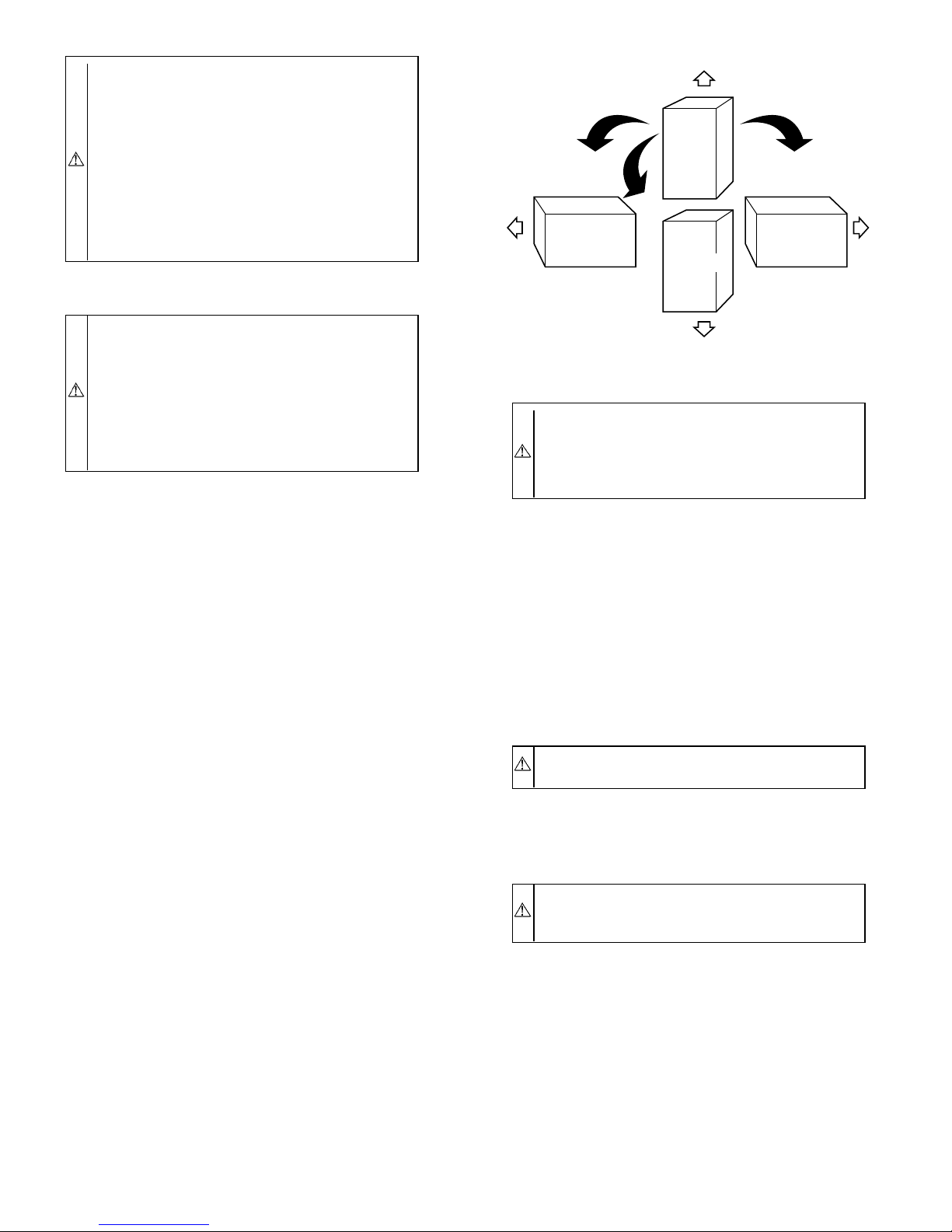

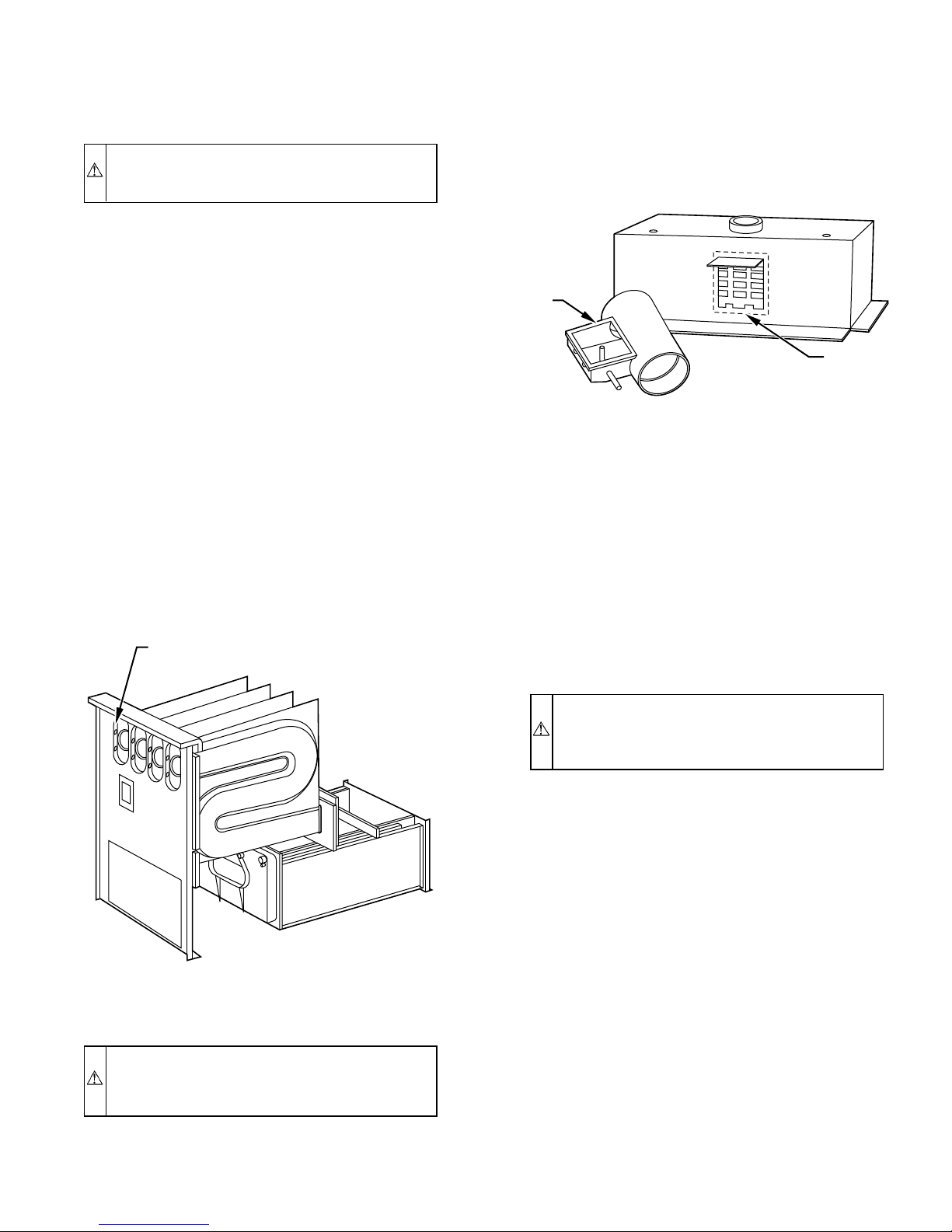

These instructions are written as if the furnace is installed in an

upflow application. An upflow furnace application is where the

blower is located below the combustion and controls section of the

furnace, and conditioned air is discharged upward. Therefore,

since this furnace can be installed in any of the 4 positions shown

in Fig. 2, you must revise your orientation to component location

accordingly.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equipment failure, it is essential that maintenance be performed annually

on this equipment. Consult your local dealer for maintenance and

maintenance contract availability.

AIRFLOW

UPFLOW

AIRFLOW

HORIZONTAL

LEFT

DOWNFLOW

AIRFLOW

HORIZONTAL

RIGHT

AIRFLOW

A93041

Fig. 2—Multipoise Orientations

WARNING: Turn off the gas and electrical supplies to

the unit before performing any maintenance or service.

Follow the operating instructions on the label attached to

the furnace. Failure to follow this warning could result in

personal injury or death.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month as required.

2. Check blower motor and wheel for cleanliness annually.

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage. Clean as necessary.

5. Check for blockages in combustion-air and vent pipes

annually.

6. Check burners for cleanliness annually.

CAUTION: Personal injury could result from sharp

metal edges, etc. Use care when removing parts.

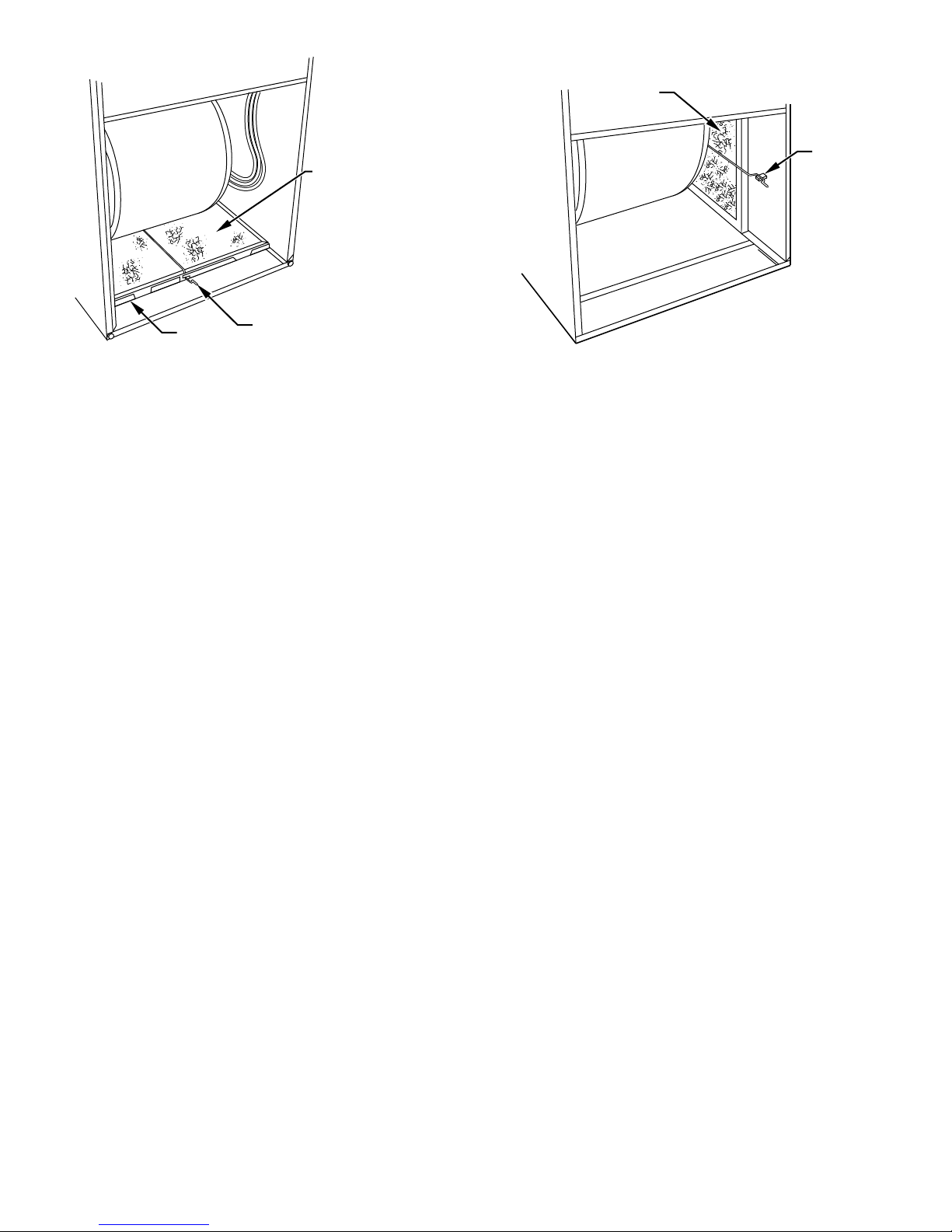

I. CLEANING AND/OR REPLACING AIR FILTER

The air filter arrangement may vary depending on the application

or orientation.

CAUTION: Never operate unit without a filter or with

the blower access panel removed. Failure to follow this

warning could result in a fire or personal injury.

To clean or replace the filters, proceed as follows:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

3. Release filter retainer wire. (See Fig. 3 and 4.)

4. Slide filter out of furnace.

5. Furnaces are equipped with permanent, washable filter(s).

Clean filter by spraying cold tap water through filter in

opposite direction of airflow.

6. Rinse filter and let dry. Oiling or coating of filter is not

recommended.

—2—

WASHABLE

FILTER

WASHABLE

FILTER

FILTER

RETAINER

FILTER

SUPPORT

FILTER

RETAINER

A93046

Fig. 3—Bottom Filter Arrangement

7. Place filter in furnace.

8. Replace blower access panel and main furnace door.

9. Turn on electrical supply to furnace.

NOTE: If the filter has cross-mesh binding, the binding must face

the blower. If the filter has an air direction arrow, the arrow must

point toward the blower.

II. BLOWER MOTOR AND WHEEL MAINTENANCE

To ensure long life, economy, and high efficiency, clean accumulated dirt and grease from blower wheel and motor annually.

The inducer and blower motors are pre-lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician.

Clean blower motor and wheel as follows:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

3. Disconnect wires.

All factory wires can be left connected, but field thermostat

connections may need to be disconnected depending on

their length and routing.

4. Position control box, transformer, and door switch assembly

to right side of furnace casing.

5. If condensate trap is located in left- or right-hand side of

furnace casing, proceed to item 6, otherwise remove trap

and tubing as described below.

a. Disconnect field drain connection from condensate trap.

b. Disconnect drain and relief port tubes from condensate

trap.

c. Remove condensate trap from blower shelf.

6. Remove screws securing blower assembly to blower shelf

and slide blower assembly out of furnace.

7. Clean blower wheel and motor by using a vacuum with soft

brush attachment. Be careful not to disturb balance weights

(clips) on blower wheel vanes. Do not bend wheel or blades

as balance will be affected.

8. If greasy residue is present on blower wheel, remove wheel

from the blower housing and wash it with an appropriate

degreaser. To remove wheel:

A93045

Fig. 4—Filter Installed for Side Inlet

a. Mark blower wheel location on shaft before disassembly

to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms and blower housing so each

arm is positioned at the same hole location during reassembly.

c. Mark blower wheel orientation and cutoff plate location

to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove cutoff

plate from housing.

e. Remove bolts holding motor mounts to blower housing

and slide motor and mounts out of housing. Disconnect

capacitor and ground wire attached to blower housing

before removing motor.

f. Remove blower wheel from housing.

g. Clean wheel per instructions on degreaser cleaner.

9. Reassemble motor and blower wheel by reversing items 8b

through 8f. Ensure wheel is positioned for proper rotation.

Be sure to reattach ground wire.

10. Reinstall blower assembly in furnace.

11. Reinstall condensate trap and tubing if previously removed.

a. Reinstall condensate trap in hole in blower shelf.

b. Connect condensate trap drain tubes. See Fig. 8 or tubing

diagram on main furnace door for proper tube location.

(1.) Connect 1 tube (blue or blue and white striped)

from collector box.

(2.) Connect 1 tube (violet or unmarked) from inducer

housing.

(3.) Connect 1 tube (relief port, green or pink) from

collector box.

c. Connect field drain to condensate trap.

NOTE: Ensure tubes are not kinked or pinched, as this will affect

operation.

12. Reinstall control box, transformer, and door switch assembly on blower shelf.

13. Reconnect wires.

Refer to furnace wiring diagram, and connect thermostat

leads if previously disconnected. (See Fig. 16.)

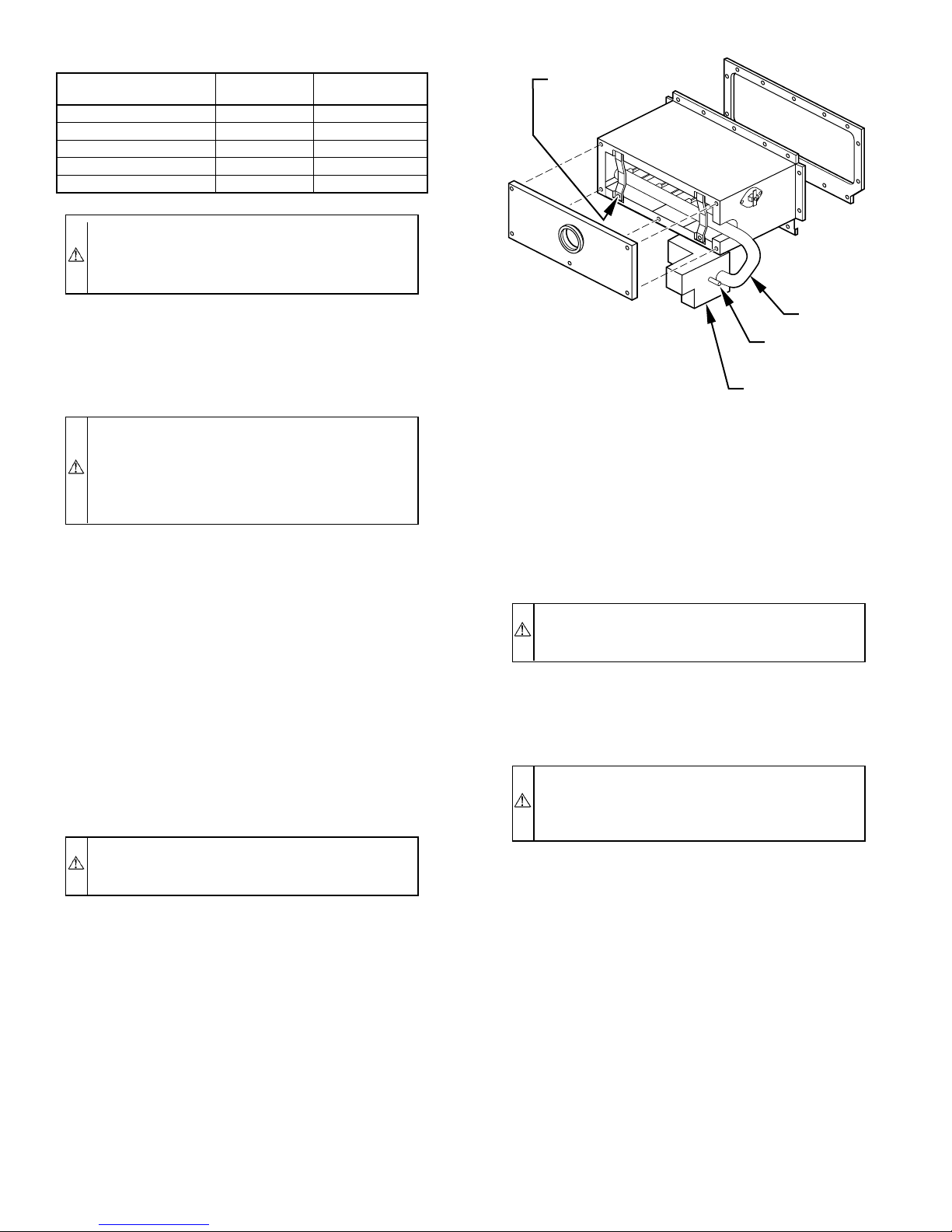

NOTE: Refer to Table 1 for motor speed lead relocation if leads

were not identified before disconnection.

—3—

TABLE 1—SPEED SELECTOR

COLOR SPEED

Black High Cool

Yellow (When Present) Medium High Spare

Blue Medium Low Heat

Red Low Spare

White Common Com

FACTORY

ATTACHED TO

CAUTION: Heating speed selection MUST be adjusted

to provide proper temperature rise as specified on the

rating plate. Failure to adjust the heating speed may

shorten heat exchanger life.

14. Turn on electrical supply. Manually close blower access

panel door switch. Use a piece of tape to hold switch closed.

Check for proper rotation and speed changes between

heating and cooling by jumpering R to G and R to Y on

control center thermostat terminals. (See Fig. 12.)

WARNING: Blower access panel door switch opens

115-v power to control center. No component operation

can occur. Caution must be taken when manually closing

this switch for service purposes. Failure to follow this

warning could result in electrical shock, personal injury,

or death.

15. If furnace is operating properly, release blower access panel

door switch, replace blower access panel, and replace main

furnace door.

III. CLEANING BURNERS

The following items should be performed by a qualified service

technician. If the burners develop an accumulation of light dirt or

dust, they may be cleaned by using the following procedure:

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Remove burner box cover.

4. Using backup wrench, disconnect gas supply pipe from gas

valve.

5. Remove wires from gas valve. Note location for reassembly.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

6. Remove burner box pressure tube from gas valve regulator

fitting.

7. Remove screws that secure manifold to burner box. (See

Fig. 5.)

8. Remove manifold, orifices, and gas valve as 1 assembly.

9. Remove screws attaching burner assembly in burner box.

10. Remove burner assembly from burner box.

NOTE: All burners are attached to burner bracket and can be

removed as 1 assembly.

11. Clean burners with soft brush and vacuum.

12. Reinstall manifold, orifice, and gas valve assembly in

burner box. Ensure manifold seal grommet is installed

properly and burners fit over orifices.

MANIFOLD

MOUNTING

SCREW

MANIFOLD

GAS VALVE

REGULATOR

FITTING

GAS VALVE

A93295

Fig. 5—Burner Box Assembly

13. Reconnect wires to gas valve. Refer to furnace wiring

diagram for proper wire location.

14. Reinstall burner box pressure tube to gas valve regulator

fitting.

15. Reinstall gas supply pipe to gas valve using backup wrench

on gas valve to prevent rotation and improper orientation.

NOTE: Use propane gas resistant pipe dope to prevent gas leaks.

DO NOT use Teflon tape.

WARNING: Gas valve switch or knob MUST be facing

forward or tilted upward. Failure to follow this warning

could result in property damage, personal injury, or death.

16. Replace burner box cover.

17. Turn on gas and electrical supplies to furnace.

18. Check for gas leaks.

WARNING: Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

19. Replace main furnace door.

IV. CLEANING HEAT EXCHANGERS

The following items should be performed by a qualified service

technician.

A. Primary Heat Exchangers

If the heat exchangers get an accumulation of light dirt or dust on

the inside, they may be cleaned by the following procedure:

NOTE: If the heat exchangers get a heavy accumulation of soot

and carbon, both the primary and secondary heat exchangers

should be replaced rather than trying to clean them thoroughly due

to their intricate design. A build-up of soot and carbon indicates

that a problem exists which needs to be corrected, such as

improper adjustment of manifold pressure, insufficient or poor

quality combustion air, improper vent termination, incorrect size

or damaged manifold orifice(s), improper gas, or a restricted heat

exchanger (primary or secondary). Action must be taken to correct

the problem.

—4—

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect wires or connectors to rollout switch, gas valve,

ignitor, and flame sensor.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

4. Disconnect combustion-air intake pipe from intake housing.

5. Remove the pressure switch tube from intake housing.

6. Remove screws attaching intake housing to burner box, and

rotate intake housing away from burner box for removal.

7. Using backup wrench, disconnect gas supply pipe from gas

valve.

8. Disconnect pressure tubing from gas valve.

9. Remove 2 screws attaching top filler panel and rotate

upwards to gain access to screws attaching burner box to

cell panel.

10. Remove screws attaching burner box to cell panel. (See Fig.

5.)

NOTE: Burner box cover, manifold, gas valve, and burner

assembly should be removed as 1 assembly.

11. Clean heat exchanger openings with a vacuum and a soft

brush. (See Fig. 6.)

NOTE: After cleaning, inspect the heat exchangers to ensure they

are free of all foreign objects that may restrict flow of combustion

products.

12. Reverse items 4 through 10 for reassembly.

PRIMARY HX

INLET OPENINGS

NOTE: Inspect combustion-air intake housing. If foamed gasket

was removed, check for any damage. If gasket is damaged in any

way, it must be repaired. To repair, remove damaged gasket

section, apply sealant releasing agent such as PAM cooking spray

or equivalent (must not contain corn or canola oil, aromatic or

halogenated hydrocarbons or inadequate seal may occur) to burner

box and apply a small bead of G.E. RTV 162, G.E. RTV 6702, or

Dow-Corning RTV 738 sealant to edge of combustion-air intake

housing. (See Fig. 7.)

RTV

PAM

A93087

Fig. 7—Combustion-Air Intake Housing Gasket

Repair

13. Refer to furnace wiring diagram and connect wires to

rollout switch, gas valve, ignitor, and flame sensor.

14. Reconnect pressure switch tubes to gas valve and intake

housing. Refer to tube routing label on main furnace door

for proper tube location. Be sure tubes are not kinked. (See

Fig. 8.)

15. Turn on gas and electrical supplies to furnace.

16. Check furnace operation through 2 complete heat operating

cycles. Look through sight glass in burner enclosure to

check burners. Burner flames should be clear blue, almost

transparent. (See Fig. 9.)

17. Check for gas leaks.

A93080

Fig. 6—Cleaning Inlet Openings of Primary Heat

Exchangers

WARNING: The ground wire from the gas valve MUST

be attached to the burner box attachment screw. Failure to

attach this ground wire to an adequate casing ground will

cause the furnace control to lock out.

NOTE: Be sure burner box gasket is installed between burner box

and cell panel. If gasket is damaged, replace it.

WARNING: Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

18. Replace main furnace door.

B. Secondary Heat Exchangers

NOTE: The condensing side (inside) of the secondary heat

exchangers CANNOT be serviced or inspected. A small number of

bottom outlet openings can be inspected by removing the inducer

assembly. See Flushing Collector Box and Drainage System

section for details on removing inducer assembly.

V. FLUSHING COLLECTOR BOX AND DRAINAGE

SYSTEM

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect inducer motor and pressure switch wires or

connectors.

4. Disconnect pressure switch tubes.

→

5. Disconnect vent pipe from inducer housing outlet by

loosening coupling clamp on inducer outlet.

6. Disconnect drain tube from inducer housing. (See Fig. 8.)

7. Remove inducer housing assembly by removing 4 bolts

attaching assembly to cell panel.

—5—

Furnace is shipped from factory in upflow configuration. Pressure tube and drain tube routing MUST match the diagrams below.

Condensate Trap; Factory Installed

in Blower Shelf

(Blower access panel removed)

COLLECTO R BO X TU BE

(PINK)

COLLECTOR BOX TUBE

INDUCER HOUSING (MOLDE D) DRAIN TUBE

(BEHIND COLLECTOR BO X DRAIN T UBE)

FIELD-INSTALLED FACTORY-SUPP LIED

BURNER ENCLOSURE PRES SURE

REFERENCE TUBE ASSEMBLY

(GREEN)

COLLECTOR BOX DRAIN TUBE

(BLUE)

FIELD-INSTALLED

FACTORY-SUPP LIED DRAIN TUBE

COUPLING (LEFT DRAIN OPTION)

DRAIN TUBE

Condensate Trap on

LEFT Side

CAP

COLLECTO R BO X

TUBE (GREEN)

COLLECTOR BOX DRAIN TUBE

(BLUE & WHITE STRIPE D)

COLL ECTOR BOX

EXTENSI ON TUBE

CONDENSATE TRAP

INDUCER HOUSING DRAIN TUBE (VIOLET)

T ube location when used on

HORIZONTAL - LEFT ap plication

AUXILIARY "J" BOX RE LOCATED HERE

BURNER ENCLOSURE

PRESSURE REFE RENCE

TUBE ASSEMBLY

COLLECTOR BOX EXTENSION DRAIN TUBE

PLUG

CAP

COLLECTOR BOX

EXTENSIO N TUBE

CONDENSATE TRAP

NOTE:

1. All tubing must be connected securely and routed to avoid kinks and traps.

2. Pressure tubing must always slope away from pressure switch to collector box connection as shown.

3. HORIZONTAL-LEFT installations require the collector box pressure tube to be relocated between the inducer housing and the blow er shelf to

prevent a trap.Refer to the Installation Instructions for further details.

T ube location when used in UPFLOW application

BURNER ENCLOSURE

PRESSURE REFERENCE

TUBE ASSEMBLY

CAP

PLUG

COLLECTOR BOX DRAIN

TUBE

(BLUE & WHITE STRIPED )

CONDENSATE TRA P

FIELD-INSTALLED

FACTORY-SU PPL IE D

DRAIN TUBE COUPLING

(RIGHT DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED 1/2-IN.

CPVC STREET ELBOWS (2)

FOR LEFT DRAIN OPTION

COLLECTOR BOX TUBE

(PINK)

COLLECTOR BO X TUBE (GR EEN )

COLLECTOR BOX DRAIN TUB E

(BLUE)

CONDENSATE TRAP

T ube location when used in DOWNF LO W application

COLL ECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX DRAIN TUBE

DRAIN TUBE

COUPLING

PLUGGED END

PLUG

COLLECTOR BOX

EXTENSIO N TUBE

COLL ECTOR BOX

TUBE ( PINK)

(BLUE & WHITE STRIPED )

COLLECTOR BOX

TUBE (GREEN)

INDUCER HOUSING

DRAIN TUBE

(VIOLET)

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX TUBE (PINK)

RELOCATE TUBE BET W EEN BLOWER

SHELF AND INDUCER HOU SING FOR

040,060, AN D 080 HEA TIN G IN P UT

FURNACES

COLLECTO R BO X D R AIN

TUBE

(BLUE & WHITE STRIPED)

INDUCER HOUSING DRAIN

TUBE (VIOLET)

DRAIN TUBE COUPLING

DRAIN TUBES ROUT ED IN

FRONT OF GAS VALVE

COLLECTOR BOX DRAIN TUB E

(BLUE)

PLUG

CAP

COLLECTOR BOX

TUBE (GREEN)

COLLECTOR BOX DRAIN TUBE

(BLUE AND WHITE STRIPED)

T ube location when used on

HORIZONTAL - RIGHT appl i cation

→ Fig. 8—Furnace Pressure and Drain Tubing Diagram

TUBE ROUTING

Condensate Trap on LEFT

Side Optional

BURNER ENCLOSURE

PRES SURE REFERENCE

TUBE ASSEMBLY

CAP

PLUG

COLLECTOR BOX DRAIN TUBE

(BLUE & WHITE STRIPED )

INDUCER HOUSING DRAIN TUBE

Condensate Trap on

PLUG

CAP

COLLECTOR BOX DRAIN TUB E

(BLUE)

COLL ECTOR BOX TUBE

(PINK)

COLLECTO R BO X TU BE

(GREEN)

COLLECTO R BO X EXT ENSION TUBE

BURNER ENCLOSURE PRES SURE

REFERENCE TUBE ASSEMBLY

CONDENSATE TRAP

COLLECTO R BO X

GAS VALVE

INDUCER HOUSING DRAIN TUBE (VIOLET)

EXTENSION DRAIN TUBE

COLLECTOR BOX EXTENSION TUBE

COLLECTOR BOX TUBE (PINK)

BURNER ENCLOSURE

PRESSURE REF ERENCE

TUBE ASSEMBL Y

COLLECTO R BO X

EXTENSIO N TUBE

CONDENSATE TRAP

324999-201 REV. A

(LIT. BOTTOM)

(VIOLET)

RIGHT Side

A99102

BURNER FLAME

MANIFOLD

Fig. 9—Burner Flame

BURNER

A89020

—6—

8. Flush inside of collector box with water until discharge

from condensate trap is clean and runs freely.

NOTE: Ensure the drain tube disconnected from the inducer

housing is higher than the collector box opening or water will flow

out tube.

9. Inspect inside area of collector box for any pieces of foreign

materials and remove if present.

CAUTION: DO NOT use wire brush or other sharp

object to inspect or dislodge materials in secondary heat

exchangers as failure of the secondary heat exchanger

will occur. Flush with water only.

10. Reassemble inducer assembly by reversing items 5-7.

→

Tighten the vent coupling clamp screw(s) to 15 in.-lb.

torque.

NOTE: If seal between the inducer housing and the collector box

is damaged in any way, it must be repaired. To repair, apply

sealant releasing agent such as PAM cooking spray or equivalent

(must not contain corn or canola oil, aromatic or halogenated

PAM

RTV

A93081

Fig. 10—Gasket on Collector Box

hydrocarbons or inadequate seal may occur) to inducer housing.

(See Fig. 10.) Apply a small bead of G.E. RTV 162, G.E. RTV

6702, or Dow-Corning RTV 738 sealant to groove in collector

box.

11. Refer to furnace wiring diagram and connect wires to

inducer motor and pressure switch or connectors.

12. Reconnect pressure tubes to pressure switch. See diagram

on main furnace door for proper location of tubes. Be sure

tubes are not kinked. (See Fig. 8.)

13. Turn on gas and electrical supplies to furnace.

14. Check furnace operation through 2 complete heat operating

cycles. Check area below inducer housing, vent pipe, and

condensate trap to ensure no condensate leaks occur. If

leaks are found, correct the problem.

15. Check for gas leaks.

WARNING: Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

16. Replace main furnace door.

VI. SERVICING HOT SURFACE IGNITOR

The ignitor does NOT require annual inspection. Check ignitor

resistance before removal.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect ignitor wire connection.

4. Check ignitor resistance.

a. Using an ohm meter, check resistance across both ignitor

leads in connector.

b. Cold reading should be between 45 ohms and 90 ohms.

c. If ohm reading is higher than 110 ohms, ignitor is

cracked and must be replaced.

5. Remove ignitor assembly.

a. Do not remove ignitor from bracket while assembly is in

furnace. Using a 1/4 in. nutdriver, remove screw securing bracket and ignitor assembly to bottom of burner

box. The screw in the bracket is always located toward

outside of burner box. The screw may be hidden by inlet

box or inlet pipe, but can be removed without removing

either. After removing screw, slide ignitor and bracket

toward outside of burner box and pull straight out.

CAUTION: The ignitor is fragile. DO NOT allow it to

hit the side of the burner box opening while removing or

replacing it.

b. Inspect ignitor for a white area indicating a crack may be

present. If found, replace ignitor.

NOTE: A small crack cannot be seen on a new ignitor. After a

period of operation, a white area will be visible around the crack.

c. If replacement is required, replace ignitor on ignitor

bracket external to furnace to avoid damage as the

silicon portion is very brittle and will easily crack or

shatter.

d. To remove ignitor from ignitor bracket, remove screw

holding ignitor ceramic block to bracket and pull ceramic block out of bracket.

6. To replace ignitor/ignitor assembly, reverse items 5a

through 5d.

7. Reconnect ignitor wire connection.

8. Turn on gas and electrical supplies to furnace.

9. Verify ignitor operation by initiating control board self-test

feature or by cycling thermostat.

10. Replace main furnace door.

VII. ELECTRICAL CONTROLS AND WIRING

CAUTION: There may be more than 1 electrical supply

to the unit. Check accessories and cooling unit for

additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 11 for field wiring information

and to Fig. 15 for unit wiring information.

NOTE: If the polarity is not correct, the STATUS LED on the

control center will flash rapidly and prevent the furnace from

operating. The control system also requires an earth ground for

proper operation of the control center and flame sensing.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the control center. (See Fig. 12.) Any direct shorts of the 24-v

wiring during installation, service, or maintenance will cause this

fuse to blow. If fuse replacement is required, use ONLY a fuse of

identical size.

With power to the unit disconnected, check all electrical connections for tightness. Tighten all screws on electrical connections. If

any smoky or burned connections are found, disassemble the

connection, clean all parts, strip wire, and reassemble properly and

securely.

Reconnect electrical supply to unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation; if there are any discrepancies in

the operating cycle, contact your dealer and request service.

VIII. TROUBLESHOOTING

For an explanation of fault codes, refer to service label located on

back of main furnace door or Fig. 16, and the Troubleshooting

Guide.

—7—

BLK

WHT

WHT

GND

115-V

FIELD-SUPPLIED

DISCONNECT

THREE-WIRE

BLK

AUXILIARY

J-BOX

FIVE

WIRE

HEATING-

ONLY

GND

CONTROL

BOX

FURNACE

NOTE 2

W

R

G

C

Y

24-V

TERMINAL

BLOCK

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

WCR GY

NOTE 1

THERMOSTAT

TERMINALS

CONDENSING

FIELD-SUPPLIED

DISCONNECT

GND

UNIT

TWO

WIRE

NOTES: Connect Y-terminal as shown for proper operation.

1.

2.

Some thermostats require a "C" terminal connection as shown.

3.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

Fig. 11—Field Wiring

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

A98209

TEST/TWIN

3-AMP FUSE

115-VAC (L1)

POWER SUPPLY

HOT SURFACE

IGNITOR CONNECTOR

SEC-1

COOL

HEAT

24-V THERMOSTAT

TERMINALS

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX)

LED OPERATION &

OM

C

HUM

GRYW

24V

DIAGNOSTIC LIGHT

HARNESS CONNECTOR

24-V TRANSFORMER SEC-2

SPARE-1

BLOWER SPEED

SELECTION TERMINALS

SPARE-2

EAC-1

EAC-ELECTRONIC AIR CLEANER

TERMINALS (115-VAC 1.5 AMP MAX)

EAC-2

115-VAC (L2) NEUTRAL

CONNECTION

INDUCER MOTOR

CONNECTOR

Fig. 12—Control Center

A95086

—8—

The control center stores 1 fault code (the last fault to occur) for a

period of 48 hrs or until the 115- or 24-v power is interrupted.

NOTE: Removing blower access panel will open blower access

panel door switch and terminate 115-v power to control center, and

fault code will be erased. Look into blower access panel sight glass

for current LED status.

The unit’s component test is a useful troubleshooting tool since it

displays the current status (fault code) of the furnace and functionally operates all furnace components except the gas valve. The

component test and methods to initiate it are described below.

A. Component Test Sequence

NOTE: All components are functionally operated except the gas

valve.

When component test is initiated, the following sequence of events

occurs:

1. LED flashes a fault code 4 times.

2. Inducer motor starts and continues to run for remainder of

component test.

3. Hot surface ignitor is energized for 15 sec, then deenergized.

4. Main blower operates at cooling speed for 10 sec, then turns

off.

5. Main blower operates at heating speed for 10 sec, then turns

off.

6. Inducer motor stops.

Component test can be initiated by one of the following procedures.

B. Initiating ComponentTest and Retrieving Fault Code

By Removing Main Limit Switch Wire

NOTE: NO thermostat signal may be present at control center

and all blower time delay off periods must be completed.

1. Leave 115-v power to furnace turned on.

2. Remove main furnace door.

3. Look into blower access panel sight glass for current LED

status.

NOTE: Leave blower access panel installed to maintain power to

control center to view current LED status.

4. BRIEFLY remove either wire from the main limit switch

until the LED goes out, then reconnect it.

CAUTION: Make sure limit switch wire does not contact any metallic component such as the gas valve. If wire

is shorted, 3-amp fuse on control center will blow.

3. Manually close blower access panel door switch. Use a

piece of tape to hold switch closed.

WARNING: Blower access panel door switch opens

115-v power to control center. No component operation

can occur. Caution must be taken when manually closing

this switch for service purposes. Failure to follow this

warning could result in electrical shock, personal injury,

or death.

4. BRIEFLY short (jumper) TEST, 1/4-in. quick-connect

terminal on control center (adjacent to the LED diagnostic

light) and the C

OM terminal on thermostat connection block.

(See Fig. 12.)

NOTE: If TEST to C

OM terminals are jumpered longer than 2 sec,

LED will flash rapidly, and retrieval request will be ignored.

5. When above items have been completed, the component

test sequence will occur as described in the Component Test

Sequence section above.

NOTE: Be sure to record the fault code which is flashed 4 times

at start of component test for further troubleshooting.

6. After component test is completed and furnace is operating

properly, release blower access panel door switch, replace

blower access panel, and replace main furnace door.

IX. CHECKING HEAT TAPE OPERATION

(IF APPLICABLE)

In applications where the ambient temperature around the furnace

is 32°F or lower, freeze protection measures are required. If this

application is where heat tape has been applied, check to ensure it

will operate when low temperatures are present.

32°F MINIMUM INSTALLED

AMBIENT OR FREEZE

PROTECTION REQUIRED

NOTE: If wire to main limit is disconnected longer than 4 sec, the

control senses limit circuit is open. Main blower will start and

retrieval request will be ignored.

5. When above items have been completed, the component

test sequence will occur as described in the Component Test

Sequence section above.

NOTE: Be sure to record the fault code which is flashed 4 times

at start of component test for further troubleshooting.

6. After component test is completed and LED is ON continuously indicating the furnace is ready to operate when a

signal from the thermostat is received, replace main furnace

door.

C. Initiating ComponentTest and Retrieving Fault Code

By Jumpering Control TEST Terminal

1. Remove main furnace door.

2. Remove blower access panel.

A93058

CAUTION: If this furnace is installed in an unconditioned space where the ambient temperatures may be

32°F or lower, freeze protection measures must be taken.

NOTE: Heat tape, when used, should be wrapped around the

condensate drain trap and drain line. There is no need to use heat

tape within the furnace casing. Most heat tapes are temperature

activated, and it is not practical to verify the actual heating of the

tape. Check the following:

1. Check for signs of physical damage to heat tape such as

nicks, cuts, abrasions, gnawing by animals, etc.

—9—

A99119

→ Fig. 13—Inducer Housing Drain Tube

A99118

2. Check for discolored heat tape insulation. If any damage or

discolored insulation is evident, replace heat tape.

3. Check that heat tape power supply circuit is on.

X. WINTERIZING

CAUTION: Freezing condensate left in the furnace will

damage the equipment.

If the furnace will be off for an extended period of time in a

structure where the temperature will drop to 32°F or below,

winterize as follows:

1. Turn off electrical supply to furnace.

2. Remove main furnace door.

→ Fig. 14—Funnel in Drain and Antifreeze Running

Through Trap

3. Disconnect drain tube from inducer housing. (See Fig. 13.)

4. Insert funnel in drain tube and pour antifreeze, propylene

glycol (RV, swimming pool antifreeze, or equivalent) into

furnace until it is visible at point where condensate enters

open drain. (See Fig. 14.)

5. Reconnect drain tube to inducer housing.

6. Replace main furnace door.

CAUTION: Do not use ethylene glycol (Prestone II

antifreeze/coolant or equivalent automotive type). Failure

of plastic components will occur.

—10—

SW2

PCB

SEE NOTE #10

(NO T O N ALL MODE LS)

BLOWER OFF DELAY

SELECTION CHART

90 SEC

BLOWER

OFF

DELAY

TEST/TWIN

SW1

HUM

G

R

Y

W

C

LED

ORN

OM

135 SEC

PL1

WHT

BLOWER

SPEED

SELECT

L2

PR2

WHT

WHT

GRN

BLK

SEC-1

FU1

BRN

321

6

9

24 VAC-3A

COOL

HEAT

EAC-1

EAC-2

M

5

87

FUSE

CAP -2

4

SEC-2

SPARE-1

SPARE-2

C

OM

AUX

OL

1.5 AMP

BRN

IDM

180 SEC

225 SEC

GVR

HSIR IDR BLWR

PL2

VAC

120

L1

BLK

PR1

BLK

BLK

12

HSI

1

2

BLK

1

WHT

PL5

PL3

23

HI/LO

RELAY

1

2

3

WHT

GRN

PL4

LEGEND

BLWR BLOWER MOTOR RELAY, SPST-(N.O.)

BLWM BLOWER MOTOR

CAP CAPA CITOR

CPU MICROPROCESSOR AND CIRCUITRY

EAC-1 ELECTRONIC AIR CLEAN ER CONNEC TION (115 VAC 1.5 AMP MAX.)

EAC-2 ELECTRONIC AIR CLEANER CO NNECTION (COMMO N)

FRS FLAME ROLLOUT SW. -MANUAL RESET, SPST-(N.C.)

FSE FLAME PROVING ELECTRODE

FU1 FUSE, 3 AMP, AUT OM OTIVE BLADE TYPE, FACTORY INSTALLED

FU2 FUSE OR CIRCUIT BREAKER CURRENT INTERRUPT DEVICE

(FIELD INSTALLED & SUPPLIED )

GND EQUIPMENT GROUND

GV GAS VALVE-REDUNDANT OPERATORS

GVR GAS VALVE RELAY, DPST-(N .O.)

HI/LO BLOWER MOTO R SPEED CHANGE RELAY, SPDT

HSI HOT SURFACE IGNITOR (115 VAC)

HSIR HOT SURFACE IGNIT O R RELAY, SPST-(N.O.)

HUM 24VAC HUMIDIFIER CONNECTION (.5 AMP. MAX.)

IDM INDUCED DRAFT MOTOR

IDR INDUCED DRAFT RELAY, SPST-(N.O.)

ILK BLOWER ACCESS PANEL INTERLOCK SWITCH, SPST-(N.O.)

JB JUNCTION BOX

LED LIGHT-EMITTING DIODE F OR STATUS CODES

LGPS LOW GAS PRESSURE SWITCH, SPST-(N.O.)

LS LIMIT SWITCH, AUTO RESET, SPST(N.C.)

OL AUTO-RESET INT ERNAL MOTO R OVERLOAD TEMP. SW.

PCB PRINTED CIRCUIT BOARD

RED

WHT

BLK (HI)

YEL (MED HI)

NOTE #8

BLU (MED LO)

RED (LO)

WHT (COM)

(WHEN USED)

PRS

RED

LS

BLU

RED

OL

WHT

BLK

ILK

PL1 9-CIRCUIT CONNECTOR

PL2 2-CIRCUIT PCB CONNECTOR

PL3 3-CIRCUIT IDM CONNECTOR

PL4 3-CIRCUIT IDM EXTENSION CO N NECTOR

PL5 2-CIRCUIT HSI/PCB CONNECT OR

PRS PRESSURE SWITCH, SPST-(N.O.)

SW1 & 2 BLOWER OFF DELAY

TEST/TWIN COMPONENT TEST & TWIN TERM INAL

TRAN TRANSFORMER-115VAC/24VAC

LGPS

NOTE #6

BLU

FRS

FSE

RED

GRN

BLK

WHT

TRAN

WHT (COM)

BRN

START

BLWM

JB

GRN

GND

JUNCTION

UNMARKED TERMINAL

PCB TERMINAL

FACTORY WIRING (115VAC)

FACTORY WIRING (24VAC)

FIELD WIRING (115VAC)

FIELD WIRING (24VAC)

CONDUCTOR ON PCB

FIELD WIRING TERMINAL

FIELD EARTH GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG RECEPTACLE

CAP -1

BRN

FUSED DISCONNECT

SWITCH (WHEN REQ'D)

WHT

BLK

GRN

1-M

GRN

NOTE #4

FU2

YEL

3-P

GV

2-C

NOTE #5

NEUTRAL

TO 115VAC FIELD DIS C ON NECT

NOTE #4

NOTE #12

L1

L1

ILK

L1

TEST/TWIN

HUM

R

W

Y

G

C

OM

NEUTRAL

BLWR

HSIR

FU1

GND

EQUIPMENT GROUND

SPARE-2

HEAT

SPARE-1

HI/LO

EAC-1

EAC-2

IDR

PR1

TRAN

NOTE #7

SEC-1

GVR-2

HSIR

BLWR

IDR

CPU

COOL

PL2

115VAC

24VAC

HI/LO

NOTE #8

COM

1

SEC-2

GVR

GVR-1

NOTES:

1. IF ANY OF THE ORIGINAL EQUIPMENT WIRE IS REPLACED USE WIRE RATED FOR 105˚C.

2. INDUCER (IDM) AND BLOWER (BLWM) MOTORS CONTAIN INTERNAL

AUTO-RESET THERMAL OVERLOAD SWITCHES (OL).

3. BLOWE R MOTOR SPEED SELECTIONS ARE FOR AVER AGE CO N D ITIO N S, SEE INSTAL LATION

INSTRUCTIONS FOR DETAILS ON OPTIMUM SPEED SELECTION.

4. USE ONLY COPPER WIRE BETWEEN THE DISCONNECT SW ITCH AND THE

FURNACE JUNCTION BOX (JB).

5. THIS WIRE MUST BE CONNECTED TO FURNACE SHEETMETAL FOR CONTRO L TO PRO V E

FLAME.

6. FACTORY CONNECTED WHEN LGPS NOT USED.

7. REPLACE ONLY WITH A 3 AM P F U SE.

8. YELLOW LEAD NOT ON ALL MOTORS.

9. BLOWER-ON DELAY, GAS HEATING 60 SECONDS, COOLING OR HEAT PUMP 2 SECONDS.

10. BLOWER-OFF D ELAY, GAS H E A TIN G 90, 135, 180 OR 225 SECO N D S, COOLING OR

HEAT PUMP 90 SECONDS. (135 SECONDS ONLY ON SOME M ODELS)

11. IGNITION-LOCK O UT WILL OCCUR AFTER FOUR CO NSECUTIVE UNSUCCE SSFUL

TRIALS-FOR-IGNITION. CONTROL WILL AUTO-RESET AFTER THREE HOURS .

12. SOME MODELS MAY HAVE SPADE QU ICK CONNECT TERMINALS.

SCHEMA TIC DIAGRAM

(NATURAL GAS & PROPAN E)

LO

MED LO

MED HI

HI

OL

COM

1

HSI

2

PL52

1

PR2

1

3

3

PL3

2

2

FRS

7

1

LGPS

4

PL1

PRS

3

3-P

2

1-M

8

5

6

9

BRN

PL4

NOTE #6

322854-101 R EV . D (LIT)

START

M

CAP-1

BLWM

IDM

OL

AUX

CAP -2

(WHEN USED)

GV

2-C

NOTE #5

L2

BRN

LS

FSE

→ Fig. 15—Wiring Diagram

—11—

A99106

SERVICE

If status code recall is needed, do not remove pow er or b lower do or. Brie fly remove and then

reconnect one main limit wire to display stored status code.

LED CODE

CONTINUOUS OFF - Check for 115VAC at L1 and L2, and 24VAC at SEC-1 and

CONTINUOUS ON - Con trol has 24V power.

RAPID FL ASHING - L ine voltage (115V ) polarity reversed. If twinn ed, refer to

EACH OF THE FOLLOWING STATUS CODES IS A TWO DIGIT NUMBER WITH THE FIRST

DIGIT DETERMINED BY THE NUMB ER OF SHORT FLASHES A ND THE S ECO N D D IGIT BY

THE NUMB ER O F LO NG F LASHES .

11 NO PREVIOUS CODE - Stor ed status codes are e ra sed when power

(115V or 24V) to control is interrupted or 48 hours after each fault is cleared.

12 BLOWER ON AFTER POWER U P (115V or 24V) - Blowe r runs for 90 s ec onds,

if unit is powered up dur ing a call for heat ( R -W closed).

13 LIMIT OR FLAME ROLL-OUT SWITCH LOCKOUT - Co ntrol will auto reset after

three hours unless flame roll-out switch o r f u se link is opened , r ef er to #33.

14 IGNITION LOCKOUT - Control will auto-reset after three hours. Refer to #34.

21 GAS HEATING LOCKOUT - Control will NOT auto reset.

Chec k for: - Mis-wired gas valve -Defec t ive control (valve rel ay )

22 ABNORMAL FLAME-PROVING SIGNAL - Flame is proved while gas valve is

de-energized. Inducer will run until fault is cleared.

Check for: - Leaky gas valve -Stuck-open gas valve

23 PRESSURE SWITCH (ES) DID NOT OPEN Check for:

- Obstructed pressure tubing. - Defective pressure switch (stuck closed).

24 SECONDARY VOLTAGE FUSE IS OPEN

Check for:- Short circuit in secondary voltage (24V) w ir ing.

31 PRESSURE, DRAFT SAFEGUARD, AUXILIARY-LIMIT (when used), OR BLOCKED

VENT SHUTOFF (when used) SWITCH DID NOT CLOSEOR REOPENED - If open

longer than five minutes, inducer shuts off for 15 minutes befo re retry.

Check for: - Inadequate Combustion air supply.

- Proper v ent sizing and condensate pitch or sag

- Low inducer voltag e.

- Vent restriction or high winds.

- Disconnect ed or obstructed pre ssure tubing

- Defec t ive inducer motor o r st ar t capacitor.

- Defec t ive pressure switch o r connections. If it op ens after trial for ignition

period , blower will come on for 90 second recycl e delay.

33 LIMIT OR FLAME ROLL-OUT SWITCH IS OPEN - If open longer than three

minutes, code changes to #13. Flame roll-out switch requires manual reset.

Check for: - Defective blower motor or capacitor.

- Dirty filter or restricted duct sy st em.

- Loose blower wheel.

- Defective switch or connec tions.

- Inadequate Combustion air supply (Flame Roll-out Switch or fuse link).

- Open Fla me Roll-out switch,or fuse link. Manu al r eset or replace.

34 IGNITION PROVING FAILUR E - Control will try three more times before a

lockout #14 oc curs. If flame signal lost after trial for ignition period, blower

will come on for 90 second recycle delay. Check for:

- Oxide buildup on flame sensor (clean wit h f ine steel wool).

- Prope r fla me sense microam ps (.5 microamps D.C . min., 4.0 - 6.0 nomina l) .

- Gas valve defective or gas va lve turned off.

- Defective Hot Surface Ignitor

- Manual valve shut-off.

- Low inlet gas pressure.

- Green wire MUST be connected to furna ce sheet metal.

- Inadequate flame carr yov er or rough ignition.

SEC-2.

twinning k it instr u ct io ns .

COMPONENT TEST

To initia te the component test sequence,shut OFF the room thermo st at or

disconnect the "R" thermostat lead. Briefly short the TEST terminal to the "Com

24V" terminal. Status LED will flash code and then tur n ON the inducer motor. The

inducer motor will r un for the ent ire componen t test. The hot s u rf ace ignitor,

blower motor-heat speed, and blower motor-coo l speed will be turned ON for

10-15 seconds each. Gas Valve and Humidifier will not be turned on.

6

3

9

2

8

5

1

7

4

STATUS

TEST

HUM

STATUS

Com

W

24V

Y

R

320615-102 R EV . J

G

A99107

→ Fig. 16—Service Label

—12—

NO

Close circuit breaker and

go back to start.

YES

Close door switch and go to start.Is red LED status light on? Is door switch closed?

NO

NO

Is circuit breaker closed?

NO

YES

YES

Is there 115v going to switch?

NO

YES

Is 24 vac present at W, Y, or G

terminals on the control?

Replace control if it does not

respond to 24-vac signal at W, Y,

or G screw terminals.

Check for continuity in wire from circuit

breaker to furnace.

NO

Check room thermostat or

interconnecting cable.

NO

YES

Replace door switch.Replace control center.

Replace transformer.

Does control respond to W, Y,

or G 24-vac thermostat signals?

Run system through a heating or

cooling cycle to check operation.

Status codes are erased after 48

hrs or whenever power (115v

or 24v) is interrupted.

NO

→ Troubleshooting Guide

YES

Is there 115v at L1 and L2?

NO

START

YES

Is there 24v at SEC-1 and SEC-2?

YES

Check for correct line voltage

polarity. If units are twinned,

check for proper low-voltage

(24v) transformer phasing.

Check for previous fault by

momentarily shorting the TEST

terminal and the C terminal until

the LED goes out. LED will flash

YES

NO

NO

Is red LED status light blinking

ON/OFF slowly with a

combination of short and long

Is red LED status light blinking

rapidly without a pause?

flashes?

—13—

the status code of any previous

fault or the code No. 11 (1 short

and 1 long flash) if no previous

fault. After the control repeats the

code 3 times, the control will go

through a brief component test

sequence. The inducer will start

and run for the entire component

test. The HSI, blower motor heat

speed, and blower motor cool

speed will run for 10-15 sec each.

YES

Determine status code. The

status code is a 2 digit number

with the first digit determined by

the number of short flashes and

the second digit by the number of

long flashes.

YES

Was there a previous fault code

other than No. 11?

Go to section with status code

determined.

A99123

Replace control center.

NO

YES

Unplug ignitor harness from control

center and inititate another

component test sequence. Check

for 115v between pins 1 and 2 on

the control center. Was 115v present

for the 17-sec period?

Check for continuity in the harness

and ignitor. Replace defective

component.

Check connections. If OK, replace

control center.

NO

Reconnect the R thermostat lead

and set thermostat to call for heat.

Connect voltmeter across gas valve

connections. Does gas valve

Check that all gas valves are turned

on. Replace valve.

NO

YES

receive 24v?

YES

Does gas valve open and allow gas

to flow?

NO

rough ignition.

• Low inlet gas pressure.

• Inadequate flame carryover on

Check for:

NO

YES

Do main burners ignite?

Repeat call for heat and check flame

sensor current during trial for ignition

NO

YES

Do main burners stay on?

Allow blower to come on and repeat

Check connections and retry. If

current is near typical value and

control will not stay on, replace

control center.

YES

period. Is the DC microamps

below 0.5?

test to check for intermittent

operation.

Replace electrode.

NO

Clean flame sensor with fine

sandpaper and recheck current.

Current is nominally 4.0 to 6.0 microamps.

Is current near typical value?

Replace control center.

NO

YES

YES

Will main burner ignite and stay on?

Fixed.

NOT CLOSE OR REOPEN - If

open longer than 5 minutes,

inducer shuts off for 15 minutes

31 PRESSURE SWITCH WILL

are erased after 48 hrs or

11 NO PREVIOUS FAULT - Faults

sag.

before retry.

Check for:

• Proper vent sizing or pitch or

whenever power (115v or 24v) is

interrupted. Run system through

a heating or cooling cycle to

check system.

connections. If it opens after

trial for ignition period, blower

will come on for 90 sec

• Vent restrictions or high winds.

• Defective inducer motor.

• Low line voltage (115v).

• Motor start capacitor.

• Low inlet gas pressure.

• Defective pressure switch or

UP (115V OR 24V) - Normal

operation. Blower will run for 90

sec when furnace power is

12 BLOWER ON AFTER POWER

recycle delay.

interrupted during a call for heat,

R-W closed.

13 LIMIT OR FLAME ROLLOUT

• Inadequate combustion air.

SWITCH IS OPEN - If

limit switch is open longer than 3

minutes, code changes to No. 13.

Check for:

• Blower motor failure.

33 LIMIT OR FLAME ROLLOUT

SWITCH LOCKOUT -

Limit switch was open longer

than 3 minutes. Auto-reset will

occur after 3 hrs. Flame rollout

switch requires manual reset.

See No. 33

14 IGNITION LOCKOUT - System

manual reset.

Inadequate combustion air

supply (flame rollout switch

• Motor start capacitor.

• Open flame rollout switch,

•

failed to ignite gas and prove

flame in 4 attempts. Control will

auto-reset in 3 hrs.

See No. 34

connections.

only).

• Dirty filter.

• Defective limit switch or

Turn off power and wait 5

minutes to retry.

Check for:

21 GAS HEATING LOCKOUT -

• Loose blower wheel.

If flame is not sensed during the

trial for ignition period, the control

will repeat the ignition sequence

3 more times before going into

lockout, No. 14.

If flame signal is lost after trial for

34 IGNITION PROVING FAILURE -

wire.

on control.

• Miswire or short to gas valve

• Stuck closed gas valve relay

SIGNAL - Flame was sensed

while gas valve was

de-energized. Inducer will run

22 ABNORMAL FLAME PROVING

NO

ignition period, blower will come

on for 90-sec recycle delay.

Check for the following items first

before proceding to the next step.

or leak.

until fault is cleared.

Check for:

• Stuck open gas valve solenoid

to furnace sheet metal.

• Gas valve turned off.

• Manual shut-off valve.

• Green wire must be connected

To determine whether the

problem is in the gas valve,

ignitor, or flame sensor, the

• Defective control center.

pressure tubing.

NOT OPEN - Check for:

• Disconnected or obstructed

23 PRESSURE SWITCH WILL

system can be operated in the

component test mode to check

the ignitor. First, remove the

R thermostat connection from the

control center and initiate the

component test sequence. Does

the ignitor glow orange/white hot

by the end of the 17-sec warm-up

period?

including thermostat leads

shorting to ductwork or

furnace cabinet. Disconnect

• Defective pressure switch.

OPEN - Check for:

• Short in low-voltage wiring

24 LOW-VOLTAGE FUSE IS

thermostat leads to isolate

YES

short circuit.

—14—

—15—

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

© 1999 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

—16—

Printed in U.S.A. sp0542 Catalog No. 5334-506

Loading...

Loading...