Page 1

Installation Instructions

479

Sizes 180 & 240

Series D

ALL WEATHER HEATING and COOLING UNIT

Figure 1—Model 479,

Cancels: 39479D6

brqant

39479D8

9/20/71

I

A70680

Important - Read before Installing

1. Check all local or other applicable codes for infor

mation concerning proximity to property lines, height

above roof, obstructions, etc.

2. Be sure the power supply available (voltage,

frequency and phase) corresponds to that specified on

the unit.

3. Check the electrical service provided by the utility

for the building to be sure that the service capacity is

sufficient to handle the load imposed by this unit.

4. Refer to the regulations of the serving gas supplier

and the local building, heating, plumbing or other

codes in effect in the area in which installation is to

be made.

5. Refer to the dimensionah drawing on page 2 for

electrical, gas, duct and drain connections prior to set

ting the unit in place.

GENERAL

The Bryant Model 479 is an all weather heating and

cooling unit designed for outdoor installation only. It

can be installed at ground level or on a rooftop. The

479 is factory assembled, pre-wired and charged with

the primary refrigerant. Installation consists of the

following:

Locating the Unit

I.

Installing Vent Caps

II.

III. Duct Connections

IV.

Gas Connections

V. Electrical Connections

VI. Chilled Water System

VII. Start-Up and Adjustments

VIII. Furnace Operation

IX, Cooling Operation

X.

Maintenance

Read the entire Installation Instructions before star

ting installation.

I. LOCATE AND MOUNT THE UNIT

The condenser air discharges upward; therefore,

avoid locations where obstructions will deflect the hot

condenser discharge air back into the condenser inlet

air supply. In all cases, the condenser should be at

least 2 feet from any wall or obstruction and outside

of the plumb line from any overhang.

Use caution to prevent damage when moving the unit.

Use an adequate rope or cable sling and keep the unit

in an upright position at all times during rigging and

moving operations.

CAUTION: Protect the top and sides so that the

rigging sling will not damage the unit.

Page 2

22|^

.THERMOMETER WELL (4)

15

Í16

SIZE

180

240

A B

175 68

195 88

C

39-1/8 16-15/16

39-13/16

Approximate Shipping Weights

180-479.

240-479.

...

..........

...

..................

...................

...............

....

4900 lbs.

5700 lbs,

D

21-1/32

fil

lio

V M.RT GAS

CONNECTION

28á

f4-

-76-^

f

/3;

ERT. DRAIN CONNECTION

18-^

Figure 2—Dimensional Drawing

HEATING RATINGS and CAPACITIES 180/240-479

Input 1st stage

Output 1st Stage

Input 1st and 2nd Stage

Output 1st and 2nd Stage

Approved Temp Rise

Model 180-479

Model 240-479

-B-

®16

66^

TABLE I

Btuh

Btuh

Btuh

Btuh 337,000

°F 45 - 75

°F 20 - 50

225,000

168,000

450,000

TABLE II

COOLING RATINGS and CAPACITIES

MODEL 180-479 240-479

Capacity (Total Cooling) Btuh

Air Flow

External Static Pressure

Entering Air Temperature

Entering Water Temperature

Gas Input (Total)

Electrical Input (Total)

Refrigerant Type

Amount per Chiller Lbs.

Total Solution per Chiller Lbs. 55 79

CFM

In. wg. 0.3 0.4

°F

°F

Btuh 450,000 600,000

KW 5.0

180,000

6,000 8,000

80/67 80/67

45 45

R717

18

240,000

6.0

R717

26

-2-

Page 3

Mounting Bases

The mounting base should comply with local codes

and be made of noncombustible material. The recom

mended types of mounting bases for all installations

are:

a. Precase concrete lintels. Use three lintels run the

depth of the unit; one under the right end, one under

the left end, and one at the center of the unit.

b. Steel beams. Use three I-beams run the depth of

the unit; one under each end and one at the center.

c. Concrete Slab. A minimum thickness of four inches

is required.

Rooftop Installation

When installing the 479 on a roof or other com

bustible material, use noncombustible supports and

allow a 6 inch clearance beneath the unit’s subbase

for proper air circulation. Be sure the roof construc

tion will support the weight of the equipment. Locate

the unit above a load-bearing wall whenever possible.

Condensate Drain

The 479 is furnished with a 3/4 inch FPT drain con

nection. If the installation requires draining the con

densate away from the roof of the building, connect

tubing, pipe, hose or trough and pitch downward one

inch for every ten feet of horizontal run.

Ground Level Installation

The 479 should be placed on a concrete slab at least 4

inches thick. Level the unit on the slab and be sure

there is adequate drainage away from its base.

Clearances

The minimum clearances are 6 inches from the duct

side and 24 inches from all other sides.

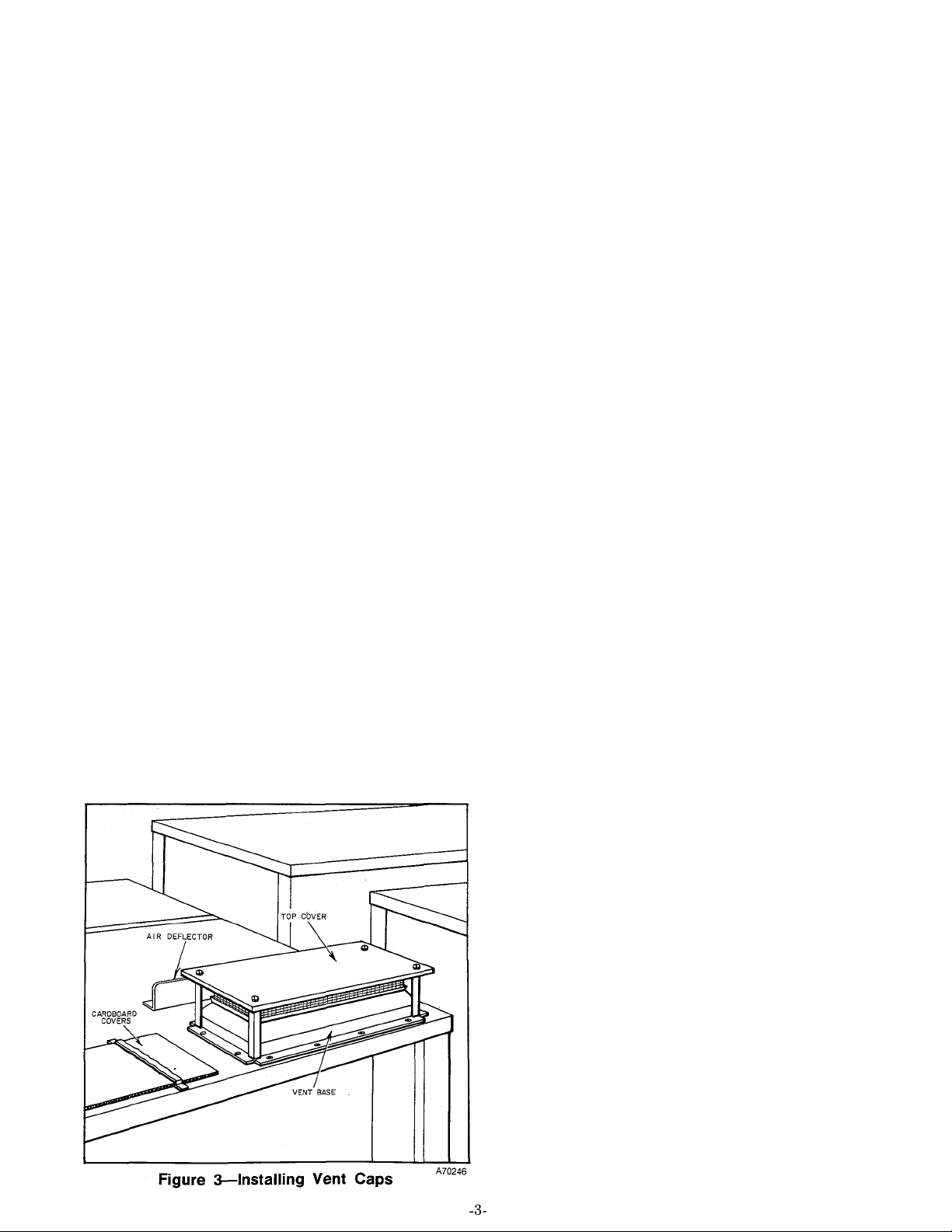

II. INSTALLING VENT CAPS

The vent cap assemblies are packaged and shipped in

the heating section coil compartment. Install the vent

cap assemblies as follows. See Figure 3.

1. Remove the cover on each of the vents on the roof

of the unit.

2. Use the FAJ5606B screws supplied with the assem

blies to fasten the base section of the vent cap assem

bly.

3. Remove the three self-tapping screws in the top

cover, located approximately 7 inches behind each

vent cap. Attach one of the air deflectors in this

location for each vent cap, using the screws removed.

III. DUCT CONNECTIONS

Before attaching the ducting to the unit, remove the

sheet metal panel that is used to protect the outlet

and return openings. The ductwork may be screwed or

bolted to the unit flange with suitable gaskets to in

sure a weathertight seal. Be sure the sheet metal

overlaps the flange on the unit.

CAUTION: Take care not to puncture the evaporator

coil when drilling the duct flange.

All duct work external of the structure must be

properly insulated and water-proofed.

All openings in the structure must be properly flashed

and vibration isolated in accordance with local codes

and good building practices. Supply and return duct

work should be provided with an approved vibration

eliminator. The vibration eliminator must be located

within the structure.

IV. GAS CONNECTIONS

The gas supply pipe for the Model 479 should be a

direct line from the gas meter or propane supply tank.

The gas supply pipe should terminate at the unit with

a tee.

The size of the gas pipe used depends upon the length

of run and allowable pressure loss established by the

utility. Never use pipe smaller than the gas connection

to the unit manifold.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. It is best to

grade all pipe 1/4 inch in every 15 feet to prevent

traps. All horizontal runs should grade up to risers.

2. A drip leg must be provided at any point in the line

of pipe where condensate may collect. Such drip leg or

drip legs shall be installed in locations readily ac

cessible to permit cleaning or emptying. The drip legs

should not be located where they are subject to

freezing. See Figure 4. Check local codes for size and

capacity of drip legs.

3. Three manual shutoff valves should be installed;

one valve between the gas supply pipe and heating

section, and one between each chiller and the gas sup

ply pipe.

4. A ground joint union should be installed between

the individual gas controls manifold and each manual

shutoff valve.

Page 4

DRIP LEG

WITHIN'STRUCTURE

Figure 4—Drip Leg Location

5. The joint compound (pipe dope) used must be

resistant to the action of propane gas.

6. Support all piping with appropriate hangers. Use a

minimum of one hanger every ten feet.

7. After all gas connections are made, check for

leakage using soap and water solution, or leak-check

unit in accordance with local utility regulations.

WARNING: NEVER USE A MATCH OR OPEN

FLAME FOR LEAK TESTING.

Purging Gas Lines

After making all gas connections and checking for

leaks, it is now necessary to purge the supply lines to

eliminate trapped air.

WARNING: NEVER PURGE GAS LINES INTO

THE COMBUSTION CHAMBERS OF THE FUR

NACE OR CHILLERS.

1. With the furnace manual gas valve and pilot

shutoff valve closed, disconnect the pilot supply tube

at the pilot shutoff valve on the furnace.

2. Open the manual shutoff valve; then open the pilot

shutoff valve and allow the supply line to purge until

the odor of gas is detected. Immediately upon detec

ting a gas odor, turn off the gas and reconnect the

pilot supply tube. Allow at least five minutes to elapse

before lighting pilot.

3. Purge the gas line to each chiller in the same man

ner as described for the furnace.

V. ELECTRICAL CONNECTIONS

The Model 479 requires a 3 wire, 230 volt, 60 cycle, 3

phase power supply. Check the unit rating plate to

make sure the power supply meets all the electrical

specifications. Electrical connections must be made in

accordance with the National Electrical Code and the

electrical code of the local area.

The field high voltage connections are made to the

disconnect box located between the two chillers at the

right end of the unit.

The field low voltage wiring consists of running seven

wires from the thermostat subbase to the low voltage

terminal block in the furnace. See Figure 5 for low

voltage field wiring.

Thermostat P/N 34427D55

and

Subhase P/N 34427D59

-4-

Page 5

VI. CHILLED WATER SYSTEM

The cooling section of Model 180-479 is comprised of

two 90,000 BTUH chillers and a 180,000 BTUH

cooling coil which is divided into two separate 90,000

BTUH sections (top and bottom). The bottom section

of the chilled water coil is supplied chilled water by

one chiller (1st stage cooling) while the top section of

the chilled water coil is supplied chilled water by the

other chiller (2nd stage cooling). The chilled water

circuit of each chiller is independent of the other;

therefore, each chiller must be charged with water

before the cooling section can be operated.

The design of Model 240-479 is basically the same as

that of Model 180-479 except the 240-479 utilizes two

120,000 BTUH chillers and a 240,000 BTUH cooling

coil which is divided into two separate 120,000 BTUH

sections. Each chiller of the Model 240-479 must also

be charged with water since the chilled water circuit

of each chiller is independent of the other.

CAUTION: The water seals will be damaged if the

pumps are operated without water in the system.

Freezing conditions will not damage the pumps;

however, do not operate the pumps when the chillers

or chilled water lines are frozen.

Charging the System with Water

Charge the chilled water system with water as

follows:

1. Turn off manual gas valves to both chillers and

turn off electrical power at disconnect switch.

2. Remove access panel from both of the chillers at'

the chiller tank end. Remove chilled water tank lids.

3. Fill both chiller tanks with water having less than

100 ppm chlorides until distributor pans are covered,

or add 12.2 gallons to each chiller of Model 180-479

or 13.6 gallons to each chiller of Model 240-479.

NOTE: If the local tap water has more than 100 ppm

chlorides, charge the chilled water system with

distilled or deionized water. Check the local water

company and/or county agricultural agent for analysis

of tap water being used in your area.

CAUTION: Never use home soft water, water sof

tening additives, water cleaning compounds, coloring

additives, acidizing materials, stop leak additives, or

other commercial water additives in the chilled water

system.

WARNING: To prevent personal injury, disconnect

condenser fan motor lead in the control box of each

chiller at this time.

4. Replace both chiller tank lids, then start water

pumps.

If water of either chiller does not circulate when the

pumps are started, air may be trapped in the system.

Most chillers are equipped with a Gorman-Rupp

water pump (plastic). On these chillers, it is necessary

to disconnect the chilled water line at the chiller tank

to bleed the air. Operate water pumps until water ap

pears at the disconnected water line, then reconnect

water line to chiller tank.

If the chiller with the trapped air is equipped with a

Wayne water pump (metal), it is not necessary to

disconnect the water line to bleed the trapped air.

Bleed the air from the pump through the 1/4-inch slot

ted head valve located on top of the pump discharge.

See Figure 6. Open valve with a screwdriver. Close

valve when a steady stream of water appears.

5. Leak test the chilled water system.

6. Remove operating level drain plug (located on side

of tank) from both chilled water tanks and continue

to operate pumps until water stops flowing from drain

openings.

NOTE: With the pumps running, the water level is

correct for each chiller when water stops flowing from

its drain opening.

7. Replace operating level drain plugs, then turn off

pumps.

8. Refer to “Freezing Weather Protection” on page

6. If freeze protection is required, decide on which

type of antifreeze to use.

The procedure for adding Ucar-17 is given in Step 9.

The procedure for adding methanol antifreeze is given

in Step 10. If antifreeze is not required, disregard

Steps 9 and 10.

9. Adding Ucar-17 Antifreeze - Refer to Table III.

Drain out amount of water from each chiller tank,

equal to amount of antifreeze to be added. Add

required amount of Ucar-17 to each chiller tank.

Recheck operating water level and correct. Do not use

any chilled water additive when using Ucar-17 in the

recommended concentration. Omit Steps 10 and 11.

10. Adding Methanol Antifreeze - Refer to Table III.

Drain out amount of water from each chiller, equal to

amount of antifreeze to be added. Add required

amount of methanol antifreeze. Add the contents of

the chilled water additive package as described in

Step 11.

-5-

Page 6

11. Remove chiller tank lids, and add contents of

chilled water package (one package to each chilled

water tank is sufficient).

12. Replace both chiller tank lids and reconnect con

denser fan motor leads in the chiller control boxes.

13. Turn on water pumps. Pumps should operate a

minimum of 10 minutes to dissolve all chilled water

additive when chilled water additive is used.

14. Replace access panels and tirrn on manual gas

valves to both chillers. Cooling section is now ready to

operate.

Corrosion Protection

The metallic components of the chilled water system

must be protected from corrosion by the addition of

an inhibitor to the chilled water circuit of each chiller.

Two packages of chilled water additive are furnishèd

with the unit. The contents of one package of Chilled

Water Additive P/N 62875D1 must be added to the

chilled water circuit of each chiller when water only

or when water and methanol antifreeze are used in

the chilled water system.

Do not add any chilled water additive to the system

when Ucar-17 is used for freeze protection. Ucar-17

contains sufficient inhibitor when used in the recom

mended concentrations as shown in Table III.

Freezing Weather Protection

Freeze protection is only required when the chilled

water coil is subjected to freezing temperatures or

when the unit is to operate under freezing conditions.

The cooling section is equipped with galvanized

chillers. Ucar-17 is the only permanent (glycol-base)

antifreeze approved for use in the chilled water

system. When Ucar-17 is used for freeze protection,

the minimum concentration must be 33% by volume.

Table III gives the types of antifreeze, percent of an

tifreeze concentration, and amount of antifreeze to

use in each chiller of the 180 and 240-479 at various

outdoor temperatures.

APPROVED ANTIFREEZE TYPES

VII. START-UP AND ADJUSTMENTS

Important: Before starting the heating or cooling sec

tion, make certain all electrical connections have been

made and the gas piping has been connected, purged

and leak tested.

CAUTION; Recheck all factory and field connections,

making sure they are tight.

Pilot Adjustment

Remove necessary access panels from furnace and

chillers.

Light pilots according to instructions on furnace and

chillers.

For Natural Gas. Flame should be of sufficient length

to provide good impingement on the monometal of the

Bryant pilot. The flame should extend upward bet

ween the carryover ports of the two adjacent burners.

For Propane Gas. Flame should surround tip of the

thermocouple element of the pilot and extend down

ward to include 3/8” to 1/2” of the thermocouple. The

flame must not come in contact with any other part of

the thermocuple or its lead wire. The flame lies under

the carryover ports of the burners and merges with the

carryover flames.

The pilot flame can be adjusted if it does not have the

appearance described above. The pilot adjusting

screw for natural and propane units (chillers and fur

nace) is located under a screw cap in the handle of the

manual pilot shut off valve. Adjust as follows;

1. Remove the screw cap to expose the adjusting

screw, then turn pilot flame to full on position.

2. Turn the adjusting screw until the flame has the

desired appearance.

TABLE III

Lowest Outdoor

Temperature (°F)

20

15

10

5

0

-5

'10

-15

-20

-25

-30

^Chilled water Additive (Borax and Chromate) P/N 62875D1 must also be used. Refer

to “Corrosion Protection” on page 6.

**No chilled water additive required. Refer to “Corrosion Protection” on page 6.

Percent of Concentration

^Methanol

20 33 2-1/2 4-1/4

20 33 2-1/2 4-1/4

22

26

29 33

32 36

34 39 4-1/4 4-3/4

36 42

38 45

43 47

44 49

**Ucar-17 Methanol

33 2-3/4

33 3-1/4 4-1/4

-6-

180-479 (Each Chiiier) 240-479 (Each Chiller)

3-3/4 4-1/4

4

4-1/2 5-1/4

4-3/4

5-1/4

5-1/2

Amount Required (Galions)

Ucar-17

4-1/4 3-1/4

4-1/2

5-1/2

5-3/4

6

Methanol Ucar-17

2-3/4 4-1/2

2-3/4 4-1/2

3-3/4

4-1/2 5

4-3/4 5-1/4

5-1/4 6-1/4

4-1/2

4-1/2

4

5

6

6 6-3/4

4-1/2

5-3/4

6-1/2

Page 7

Adjusting Gas Input

Gas input of the furnace and each chiller must be

checked and adjusted if necessary to agree with that

shown on the rating plates. The burners are equipped

with fixed orifices.

CAUTION: The chillers may be run for short periods

with the panels removed. Prolonged operation with

panels removed should be avoided.

Natural gas units are equipped with adjustable gas

pressure regulators. Propane gas units are not equip

ped with a pressure regulator.

One of the following two methods may be used to

check natural gas input on both the furnace and

chillers.

A. Measuring Gas Flow at Meter

All gas appliances must be turned off except the bur

ners on the manifold being checked when measuring

the gas flow at the meter to adjust the gas input.

Proceed as follows:

1. Determine the number of seconds required for the

gas meter test dial to complete one revolution.

2. Divide 3600 by the number of seconds in Step 1.

3. Multiply the result in Step 2 by the number of

cubic feet of gas flow per hour.

4. Multiply the result of Step 3 by the Btu heating

value of the gas (consult local utility for value). This

is the total measured Btu/hr input.

Compare this value with the one shown on the rating

plate.

Example: Suppose the size of the test dial is 5 cu. ft.;

it takes 40 seconds for the dial to complete one

revolution; heating value of the gas is 1050 Btu/cu. ft.

Proceed as follows:

40 seconds to complete one revolution

3600 divided 40 equals 90

90 X 5 - 450 cu. ft. per hour of gas flow

450 X 1050 - 472,5000 Btuh input

Only minor changes should have to be made at the

pressure regulator to bring it within the rated input of

the unit. If the manifold pressure must be changed

more than 0.3” w.c. to obtain the rated input, the

orifices should be changed accordingly.

B. Using Water Manometer

Proceed as follows when using a water manometer to

measure the manifold pressure when adjusting the gas

input:

1. Connect a water manometer to the 1/8” pressure

tap on the manifold or gas valve.

2. With the burners fired, set the correct manifold

pressure as shown in Table IV. Check with the gas

utility for the Btu valve and specific gravity of gas in

the area.

TABLE IV—MANIFOLD PRESSURE

(Inches W.C.)

Specific Gravity

0.59 0.61 0.63 0.65 0.67

900 3.9” 4.0”

950 3.5” 3.6” 3.7”

1000 3.1”

1025 3.0”

1050 2.8” 2.9” 3.0” 3.1”

1100 2.6”

Adjusting Pressure Regulator

3.2” 3.3”

3.1”

2.7” 2.8”

4.1”

3.2” 3.3” 3.4”

4.2” 4.3”

3.8” 3.9”

3.4” 3.5”

3.2”

2.9” 3.0”

If the measured and rated input are not ap

proximately the same, the gas pressure regulator may

be adjusted as follows:.

To increase input. Remove regulator sealing cap

and turn gas pressure regulator adjusting screw

clockwise.

To decrease input. Remove regulator sealing cap and

turn gas pressure adjusting screw counterclockwise.

Checking Propane Gas Input

The burner orifices are sized for rated input with a

manifold pressure of 11.0” w.c. for propane gas. Con

nect a manometer of the 1/8” pressure tap on the

chiller manifold gas valve. With the burners fired, ad

just regulator at the supply tank to provide a pressure

of 11.0” w.c. Check manifold pressure of each chiller.

Cheek the furnace manifold pressure to see that it is

also 11.0 inches w.c.

Burner Adjustment

To adjust the primary air to each burner, partially

close the air shutter until there is a slight yellow tip at

the top of each ñame, then open the air shutter until

the yellow tip just disappears. This should be done af

ter the burners have been operating at full input for 5

minutes.

VIII. FURNACE OPERATION

In order to check the furnace for proper performance,

the following sequence of control operation is given.

CAUTION: The pilot valve and main burner manual

valve must be closed for at least five minutes before

starting the furnace.

1. Set the thermostat system switch to “heat”, set the

fan switch to “auto” and set the thermostat below

room temperature.

2. Turn on electricah power to the unit.

3. Open pilot gas valve. Gas will flow to the pressure

switch and to the pilot. The electrical contacts in the

pressure switch close, energizing the reignition coil

which ignites the pilot gas. (Natural gas only; pilots

on propane unit must be lighted manually per instruc

tion on rating plate.)

The pilot flame causes the monometal contacts in the

Bryant 733 pilot to “Break” the re-ignition coil circuit

-7-

Page 8

and “make” the circuit to, but not through, the first

stage gas valve. On propane units, with themocouple

energized, the pilot relay switch action makes the cir

cuit to gas valve.

4. Set the thermostat above room temperature. This

completes the circuit and energizes the gas valve.

5. Gas flows through the gas valve to the burners via

bypass where it ignites. If the conditioned space tem

perature continues to drop, the second stage of the

thermostat closes and opens the second gas valve

bringing the unit to full input.

With the furnace operating, make the following

checks:

The automatic pilot should turn the main gas off if

the pilot flame goes out.

Check this while the furnace is operating by shutting

off the pilot gas. The main burners should shutdown.

Allow the furnace to cool and the blowers to stop,

then check the upper limit switch.

Limit Control

The furnace is equipped with a lower and upper limit

control. When the lower limit opens, the first stage gas

valve is de-energized, shutting off the gas. The upper

limit control has a dual function; its primary action

is to shut off the first stage gas valve if the unit

overheats; as the gas valve is shut off, the fan delay

relay is energized, starting the blower. The upper

limit is a single pole double throw switch.

The recommended method for checking the limit con

trols is to gradually block off the return air after the

furnace has been operating for a period of at least five

minutes. As soon as the limit has proven safe, the

return air openings should be unblocked to allow nor

mal air circulation through the unit. Whether or not

the limit is functioning properly, and will “fail-safe”

in case of motor failure or overheating of the unit can

be determined using this method.

Fan Relay

The unit is equipped with a fan delay relay switch

located in the control box. When the observer faces

the control, the adjustment lever is moved upward to

lengthen the off cycle. When the off cycle is

lengthened, the on cycle is shortened automatically.

Reverse the process to shorten the off cycle.

Airflow and Temperature Rise

The temperature rise is the difference between the

temperature of the air in the return duct and that in

the discharge duct near the furnace. This temperature

rise, measured after equilibrium has been attained

(approximately five minutes), should be within the

range of 45°F to 75°F for Model 180-479 and 20°F to

50°F for Model 240-479.

An adjustable sheave on the blower motor pulley is

used to adjust the blower speed as follows:

CAUTION: Turn off electric power to unit before

removing or replacing blower belt. Proceed as follows:

r

1. Loosen the motor from the base and slide the

motor toward the blower housing. Remove the belt

from the blower.

2. Loosen the set screw in the movable flange of the

sheave. Screw the movable flange toward the fixed

flange to increase the blower speed, away from the

fixed flange to reduce the blower speed. Tighten the

set screw on one of the two flat surfaces on the pulley

hub.

Important: Increasing the blower speed will impose a

greater load on the blower motor. Do not exceed the

rated current draw of the motor.

3. Replace the belt and adjust for proper tension. The

belt should have approximately 1” sag under normal

finger pressure.

4. Check motor pulley and blower pulley for proper

alignment.

IX. COOLING OPERATION

Perform the following steps to check the cooling sec

tion for proper operation.

WARNING: The main manual gas valve for

both chillers must be closed for at least 5 minutes

before operating the cooling sections.

1. Be sure the manual gas valves for both chillers are

in the OFF position. Light pilots as described on In

struction Plate.

2. With the thermostat subbase switch levers on

COOL and AUTO, turn on both manual gas valves.

Set thermostat at its lowest setting. Make certain both

chillers are operating. To check for correct operation

of the electrical circuit; observe operation of gas valve

and solution pump of each chiller, all condenser fan

motors and the blower. Increase the setting of the

thermostat gradually until one chiller shuts off. Set

thermostat above room temperature and observe that

the other chiller shuts off.

3. Set thermostat subbase fan switch to ON and check

blower operation. The blower should run continually

with the thermostat set above or below room tem

perature.

4. To place the system in operation, replace all panels

and set thermostat at the desired temperature.

SEQUENCE OF OPERATION

(Cooling Section)

Both the 180-479 and 240-479 are equipped with two

stage cooling. Chiller No. 1 operates on the initial call

for cooling (single stage cooling). When additional

cooling is required, Chiller No. 2 is also activated

(two-stage cooling).

Refer in Figures 7 and 8. When the thermostat system

switch is in the COOL position and the fan switch is in

the AUTO position, the first stage cooling bulb in the

thermostat will close the circuit between terminals Y1

and R, and between terminals Yl and G when the

thermostat calls for cooling.

Closing the circuit between terminals Yl and G

energizes the blower relay (2A1) and closes its nor

-8-

Page 9

mally open contacts. This causes current to flow

through the contactor (2M) winding and energizes the

contactor. The energized contactor starts the blower

motor (3E).

Closing the circuit between terminals Y1 and R com

pletes the control circuit for Chiller No. 1 and turns

this chiller on for single stage cooling. Chiller No. 2 is

inactive and will not operate until the temperature in

the conditioned space rises and calls for additional

cooling.

If the cooling load of the conditioned space is too

large for Chiller No. 1 to provide sufficient cooling,

the thermostat’s second stage cooling bulb will close

the circuit between Y2 and R.

Closing the circuit between Y2 and R, places the con

trol relay (2A2) across the secondary of Chiller No. 1

transformer (lAl). The energized control relay (2A2)

completes the control circuit of Chiller No. 2 and

turns this chiller on (two stage operation).

When the thermostat is satisfied, the thermostat’s

second bulb will break the circuit between terminals

R and Y2. This action de-energizes the control relay

(2A2) which opens the control circuit of Chiller No. 2

and turns off Chiller No. 2. Chiller No. 2 will remain

idle until additional cooling is required.

HIGH TEMPERATURE CUTOFF

(Model 180-479)

Refer to Figure 7. Each chiller of Model 180-479 is

equipped with a high temperature limit switch (7H1

on Chiller No. 1 and 7H3 on Chiller No. 2) located on

the front of the generator, plus a circuit breaker (2Jl

on Chiller No. 1 and 2J2 on Chiller No. 2). The circuit

breaker for each chiller is located in the chiller con

trol box.

If the generator of either chiller becomes overheated,

its associated limit switch (7H1 or 7H3) will open,

providing a current path through heater element of

the circuit breaker (2Jl or 2J2) of the respective

chiller. The current flow through the heater element

of the circuit breaker will cause its normally closed

contacts to open and break the 24-volt circuit to the

magnetic gas valve (5B1 or 5B2). The de-energized

gas valve will turn off the gas supply to the burners of

the overheated generator. The remaining normally

operating chiller will continue to operate.

The circuit breaker must be reset manually by

pushing the red reset button that protrudes through

the rear of the chiller control box.

A secondary high temperature limit switch (7H2 on

Chiller No. 1 and 7H4 on Chiller No. 2) is connected

in series with the gas valve (5B1 on Chiller No. 1 and

5B2 on Chiller No. 2) to insure closing of the gas valve

in the event of a high temperature failure and the

limit switch (7H1 on Chiller No. 1 and 7H3 on Chiller

No. 2) does not open.

The secondary limit switch is located on the generator

header and must be reset manually.

HIGH TEMPERATURE CUTOFF

(Model 240-479)

Refer to Figure 8. Each chiller of the 240-479 is

equipped with two high temperature limit switches

(7H1 & 7H2 on Chiller No. 1, and 7H5 & 7H6 on

Chiller No. 2). A high temperature limit switch is

located on the front of each generator of each chiller.

If either generator of Chiller No. 1 becomes

overheated, the associated high temperature limit

switch (7H1 or 7H2) will open, causing the circuit

breaker (2J1) to go into lockout position. The open

contacts of the circuit breaker de-energizes the gas

valve and shuts off the gas supply to the burners of

both Chiller No. 1 generators.

The circuit breaker (2Jl).for Chiller No. 1 is located

in the Chiller No. 1 control box and must be reset

manually.

Two secondary high temperature limit switches (7H3

and 7H4-one on each generator header of Chiller No.

1) are connected in series with the Chiller No. 1 gas

valve (5B1). If a generator overheats and its

associated high temperature limit switch (7Hl or

7H2) does not open, the secondary high temperature

limit switch (7H3 or 7H4) on the header of this

generator will open and break the circuit to the gas

valve, de-energizing the gas valve and shutting off

the gas supply to the burners .of both Chiller No. 1

generators.

The high temperature cutoff circuit of Chiller No. 2

functions the same as the high temperature cutoff cir

cuit of Chiller No. 1. The high temperature cutoff cir

cuit of Chiller No. 2 is comprised of high temperature

limit switches 7H5 and 7H6, circuit breaker 2J2,

secondary high temperature limit switches 7H7 and

7H8.

If a high temperature failure should occur and disable

Chiller No. 1, Chiller No. 2 will continue to operate

and provide single stage cooling; likewise. Chiller No.

1 will provide single stage cooling if a high tem

perature failure should disable Chiller No. 2.

AMBISTAT PART LOAD CONTROL

(Models 180-479 and 240-479)

Refer to Figures 7 and 8. Each chiller is equipped

with an ambistat part load control (7L1 on Chiller

No. 1 and 7L2 on Chiller No. 2). The circuit consists

of a temperature sensitive switch (located in the

chiller control box) and a capillary tube. One end of

the capillary tube is connected to the switch and the

other end is inserted in the chilled water supply line.

The switch contacts open when the chilled water tem

perature drops below 40°F. and breaks the circuit to

the gas valve, shutting off the gas supply to the

burners.

The chiller power relay remains energized and the

condenser fan motors, solution pump and water pump

will continue to run.

Page 10

The ambistat switch contacts will close again when

the chilled water supply temperature rises to 42°F.

The energized gas valve turns the gas on again.

X. MAINTENANCE

Cleaning the Heating Unit.

1. Be sure that the main line disconnect switch is in

the OFF position.

TAG SWITCH WITH A SUITABLE WARNING

LABEL.

2. Remove the front access panel.

3. Turn off the manual gas valve and the pilot valve.

4. Disconnect the pilot and escapement tubing.

5. Remove the burners.

6. Remove the flue baffle retainer and the flue baf

fles.

7. Clean the flue passages with a suitable brush.

8. Reassemble the furnace by reversing the above

procedure, making sure all seals are reinstalled

properly.

9. Check belt conditions and proper tension of belt

(approximately 1/2 inch deflection).

10. Filters in the 180-479 are of the disposable type

and should be inspected periodically and replaced

when dirty with filters of the same type and size.

Filters in the 240-479 are permanent type filters and

should be cleaned periodically. Make sure the arrows

on the edge of the filter point in the direction of the

airflow.

Lubrication

Some blower motors are equipped with permanent

lubricated bearings and require no further

lubrication.

Blower motors that require lubrication are equipped

with oil cups. Oil motor bearings with SAE 10-20 non

detergent oil each heating and cooling season.

NOTE: BLOWER BEARINGS ARE OF THE PER

MANENT LUBRICATED TYPE AND DO NOT

REQUIRE ANY FURTHER OILING.

Cleaning the Condenser Coil

The condenser coil fin surfaces should be inspected

from time to time and cleaned as necessary. Cleaning

may be accomplished by washing the fins with low

pressure water from a garden hose. Detergent may be

used, prior to rinsing, when oil or grease has coated

the fin surfaces. Care must be taken to be sure that

the soft aluminum fins are not bent.

WARNING: Disconnect the electric power before

cleaning the cooling coil.

Summer Chiller Operation

It may be necessary to drain, flush and refill the

chilled water system of each chiller with tap water if

antifreeze was used for winter protection. A high an

tifreeze concentration will result in a reduction of the

cooling capacity of the unit.

Be sure to add one package of Chilled Water Additive

P/N 62875D1 to the chiller tank of each chiller of

Model 180-479 or the Model 240-479 when water only

is used in the chilled water system for summer

operation.

-10-

Page 11

9E 1IB2

LEGEND

1A1 & 1 A2-Transformer (Cooling)

1 B-Transformer (Heating)

2A1-Blower Relay, SPST, (Cooling)

2A2-Control Relay, SPST

2D1 & 2D2-Power Relay, DPST, (Cooling)

2G-Heating Relay

2J1 & 2J2-Relay Circuit Breaker Lockout

2M-Blower Contactor, TPST

3A1 & 3A3-Solution Pump Motor

3A2 & 3A4-Water Pump Motor

3C1 Thru 3C4-Fan Motor, PSC

3E-Blower Motor

5B1 & 5B2-Gas Valve (Cooling)

5B3-Gas Valve (1st Stage) (Heating)

5B4-Gas Valve (2nd Stage) (Heating)

6B1 Thru 6B4-Reignition Pilot

Figure 7—Model 180-479 Wiring Diagram

7A1 & 7A2-Pressure Switch, SPST

7H1, 3, & 5-Limit Switch (High Temp Cent.)

7H2, & 4-Limit Switch (Sec. High Temp.

Manual Reset), SPST

7K-Limit Switch, Upper, SPOT

7L1 & 7L2-Ambistat (Part Load Control),

SPST

7P1 Thru 7P3-Pressure Switch,

SPST

9E-Disconnect Switch

11A1 Thru 11A3-Resistor

11B1 & 11B2-30 Amp. Fuse

11B3-50 Amp Fuse

4E1 Thru 4E4-Capacitor

Pilot Gas,

Page 12

LEGEND

A70216

1A1 & 1A2-Transformer (Cooling)

1B-Transformer (Heating)

2A1-Blower Relay, SPST, (Cooling)

2A2-Control Relay, SPST

2D1 & 2D2-Power Relay, DPST, (Cooling)

2G-Heating Relay

2J1 & 2J2-Relay Circuit Breaker Lockout

2M-Starter, Blower TPST

3A1 & 3A3-Solution Pump Motor

3A2 & 3A4-Water Pump Motor

3C1 Thru 3C6-Fan Motor, PSC

3E-Blower Motor

5B1 & 5B2-Gas Valve (Cooling)

5B3-Gas Valve (1st Stage) (Heating)

5B4-Gas Valve (2nd Stage) (Heating)

6B1 Thru 6B6-Reignition Pilot

7A1 & 7A2-Pressure Switch, SPST

Figure 8—Model 240-479 Wiring Diagram

7H1, 2, 5, 6, & 9-Limit Switch SPST (Temp

Cont.)

7H3, 4, 7 & 8-Limit Switch (Sec. Temp Cont.

Manuai Reset), SPST

7K-Limit Switch, Upper, SPOT

7L1 & 7L2-Ambistat (Part Load Control),

SPST

7P1 Thru 7P3-Pressure Switch, Pilot Gas,

SPST

8C1 Thru 8C3-Starter Overload (Manual

Reset)

9E-Disconnect Switch

11A1 Thru 11A3-Resistor

11B1 & 11B2-45 Amp. Fuse

11B3-70 Amp. Fuse

4E1 Thru 4E6-Capacitor

Page 13

479

Sizes 180 & 240

Installation Instructions

Series E

I

ATTACH TO INSTALLATION INSTRUCTIONS 39479D8

Use attached 39479D8 Installation Instructions (with changes indicated below) to in

stall sizes 180 and 240 of Model 479, Series E, units.

Models 180- and 240-479 Series E units differ from Series D units as described below.

1. GAS INPUT to the cooling section of Model 180-479 was Increased from 450,000 Btuh

to 492,000 Etuh C.246,000 Btuh input each chiller). The generator burner orifices

were changed from #39 drill size to #36 drill size on the natural gas unit. The

burner orifices on the propane unit were changed from #53 drill size to #52 drill

size.

39479D12

4/1/72

2. GAS INPUT to the cooling section of Model 240-479 was increased from 600,000 Btuh

to 640,000 Btuh C320,000 Btuh input each chiller). The generator burner orifices

were changed from #41 drill size to #39 drill size'on the natural gas unit. The

burner orifices on the propane unit were changed from #54 drill size to #53 drill

size.

3.

AUTOMATIC PILOT REIGNITION is used on both natural and propane units in both the

heating and cooling sections on both Models 180- and 240-479. The wiring diagrams

on pages 11 and 12 apply to both natural and propane gas units.

4.

FUSE SIZE was changed on Model 180-479.

30 amp fuses.

NOTE: Hydraulic Pump Heater Kit P/N 65134D01 (2 required) must be field installed on

each chiller if the cooling section is to be operated at outdoor temperatures below

40°F. Adding the heater kits permits operation of the cooling section at outdoor temp

eratures down to -30°F. Antifreeze must also be added for protection at the lowest

outdoor temperature.

The 180-479 now uses one 60 amp and two

'L E

DON

\ /1““^!

Loading...

Loading...