p

ALL WEATHER

HEATING & COOLING UNIT

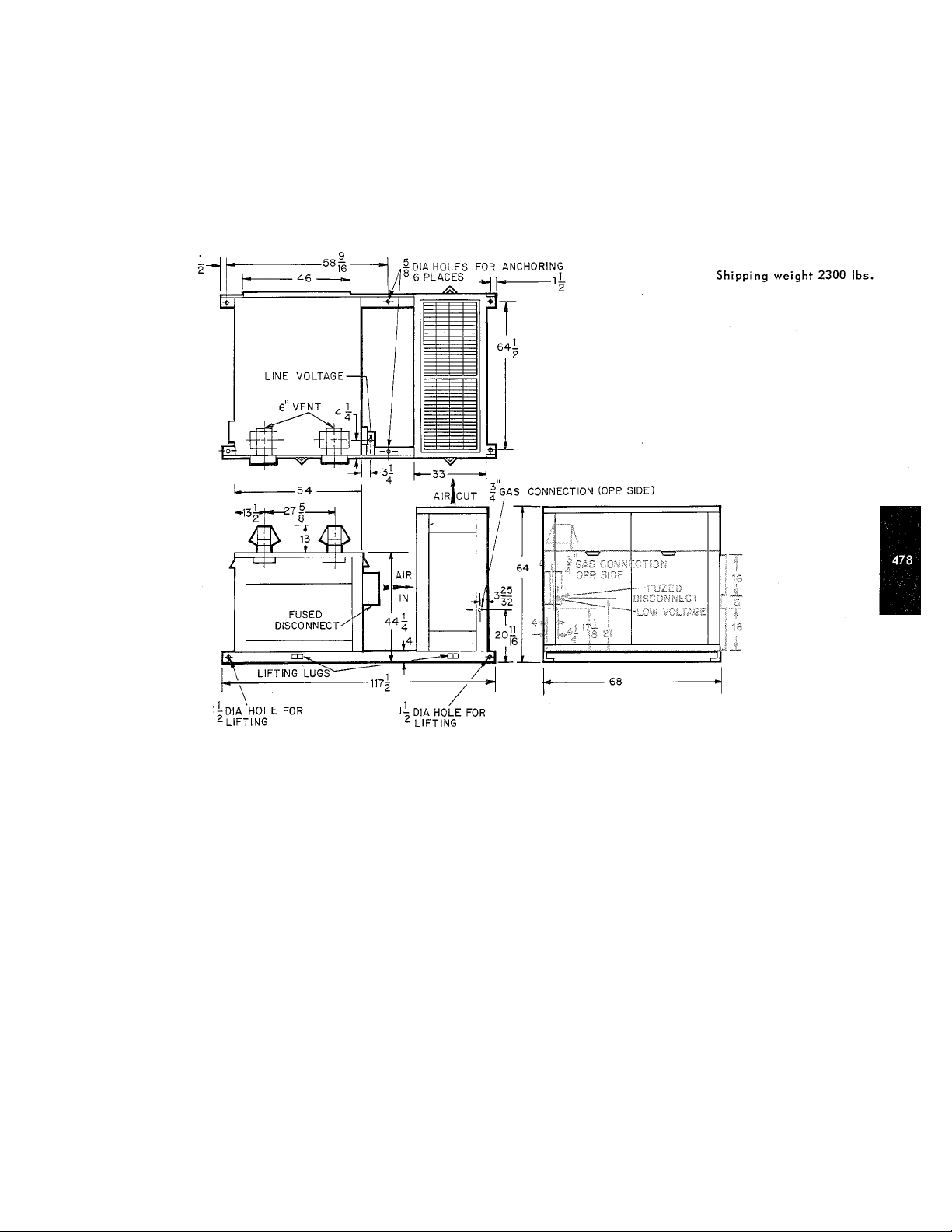

0 478

§ Size 90

PDS 478.90.1 10/11/68

__ ..i

SPECIFICATIONS

This equipment is a gas heating and gas cooling all-weather unit designed for roof-top or ground

level installations.

It makes use of an air-cooled Bryant 90-452 gas-fired water chiller combined with a Bryant

300-378 heating unit conveniently mounted on an integral base for easy installation. 'Tie unit is

rated at 90,000 Btuh cooling and 300,000 Btuh heating input. 'The heating can be modulated to

100,000 Btuh input for natural gas by using a modulating gas control kit, Part No. 60119CO2. The

gas-fired chiller is standard with automatic fuel modulation to save gas under low load conditions.

Installation does not interfere with other building trades. No inside floor space and no special

vents are required. Just set the unit on slab or adequate roof support and connect duct, gas supply

and electric supply. 'The Bryant absorption cycle is already charged and ready for operation.

The weatherproof cabinet is made from heavy gauge zinc-coated steel; the chiller finish is baked-

on enamel, and the conditioned-air section is lined with fiberglass to insulate and assure quiet

operation.

Removable panels allow easy access to all components and controls for both heating and cooling.

Automatic pilot reignition eliminates the need for seirvice calls due to pilot outage; a stainless

chromized steel heat exchanger promises long life .

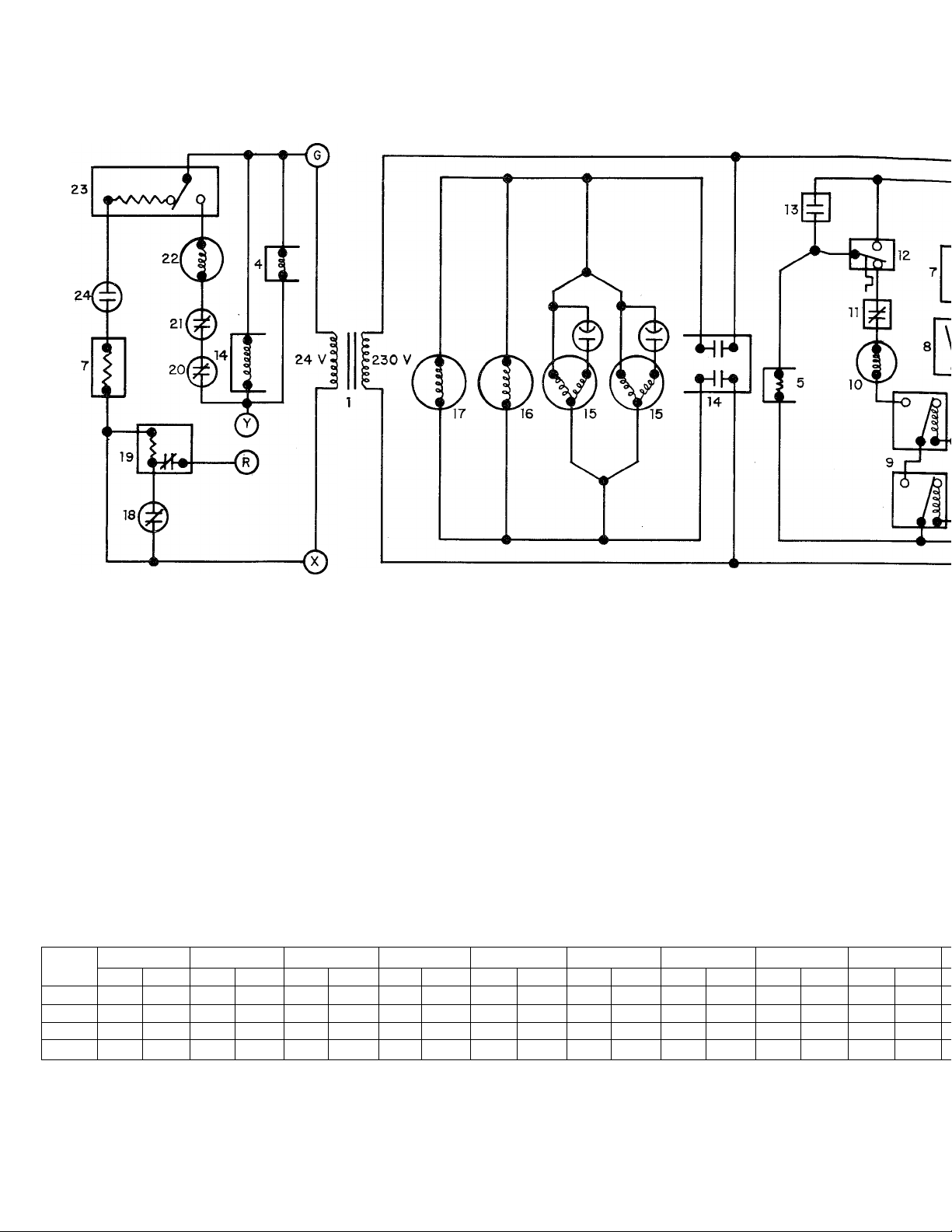

1 . Transformer

2. Blower motor

3 . Combustion air blower motor

4 . Fan relay cooling

5 . Delay relay heating

6 . Combustion air fan relay

10. Gas valve

11. Limit switch adj.

12 . Limit switch non-adj.

13 . Combustion air pressure switch 22

14 . Power relay (cooling) 23

15 . Condenser fan motor 24

7 . Resistor 16. Chilled water pump

8. Pilot gas pressure switch 17. Solution pump

9 . Pilot auto reignition 18. High temp cut-out (cooling)

AIR DELIVERY AT INDICATED EXTERNAL S.P. WITH WET COIL

CFM

2500

3000

3500

4000 835

Shaded portions of the table are beyond the standard drive range or motor horsepower. Standard drive range 540-870 RPM.

0

RPM BMP RPM

500

650

740

.464

.650

.900

1.20

0.1 " 0.2"

BHP RPM BHP RPM BHP

620

700

790 .966 825

890

.500

695

750 .798 800

.734

1.30 920 1.38 960

.560

1.05

0.3"

RPM BHP

725 .665 775

840 .932 870

.866

870

1.10

1.45

900 1.20 940

990

0.4" 0.5" 0.6" 0.7"

RPM BHP

.732

1.55 1025

805 .798

1.00

1.30 980

1.70 1060 1.80

RPM

BHP

860

.865 900 .932

910 1.10

1.33 1005 1.43

RPM BHP

1.20 1000

955

- -

19

20

; 21

RPM

940

1050

0.8"

-

High t

Part 1(

High p

Gas Vc

Auto p

Pilot g

BHP

1.00

1.25

1.50

-

COOLING CAPACITY

Capacity Total

Air Flow

External S.P.

Entering Water Temp

Entering Air (C.W. Coil) °F

Water Flow

Outdoor Ambient

BTUH

CFM

In. wg.

°F

GPM

°F 95

HEATING CAPACITY

Input BTUH

Output BTUH

Approved Temp Rise °F

CFM at 75°F Rise

* May be modulated to 100,000 Input.

*300,000 - 200,000

225,000 - 150,000

20 - 75

2780 at 225,000 Output

1850 at 150,000 Output

ELECTRICAL CONNECTIONS

Power Supply

Branch Circuit Wire Size Minimum

Branch Circuit Fuses (2) 35 A Cart. Fusetron

208/230-60-1

8 AWG

90,000

3,000

.5

45

80/67

18.5

19. High temp lock-out manual reset (cooling)

20 . Part load control

21 . High pressure switch (cooling)

22 . Gas valve (cooling)

23 . Auto pilot reignition

24. Pilot gas pressure switch

\ WET COIL

3

2

0.8"

RPM BHP RPM BHP RPM BHP RPM

940 1.00

1000

1.25

1050

1.50

- - -

0.9"

1.10 1000

975

1040

1.35

1100 1.50

- -

1 0" 1

1.20

1.40

1075

1130 1.80

- - -

1040

1105

1 "

BHP

1.25 1075

1.50 1140

- - - -

1.2"

RPM BHP

1.30

1.60

- -

GAS CONTROL INFORMATION

Burners - Heating Unit Steel Slotted Port

Number

Orifice - Natural »41 (300,000)

Orifice - Propane

Orifice - Natural »47 (200,000)

Orifice - Propane

Burners - Chiller Aluminum Dipped Steel

Number 8

Orifice - Natural

Orifice - Propane

Valve - Heating Unit Bryant 3/4" A639B

Valve - Chiller

Limit Heating (2)

Limit Chiller (2)

Ignition - Heating Unit

Ignition - Chiller

Fan Control - Heating Delay Relay

Fan Control - Cooling

Pilot - Heating

Pilot - Chiller

Gas Connection - Heating 3/4 NPT

Gas Connection - Chiller

Heat Exchanger - Heating

12

»55 (300,000)

»57 (200,000)

»39

»53

Bryant 3/4" A639B

Automatic Reset

(1) Auto Reset (1) Manual

Automatic

Automatic

S.P.S.T. Relay

Bryant 2 - H

Bryant 733

3/4 NPT

Stainless Chromized Steel

COMPONENT INFORMATION

Chilled Water Coil

Area

Height X Width

Tube OD

Rows

Fins

Pattern

Circuits

Blower Wheels No.

Diameter x Width Inches 12-5/8 X 12-5/8

Blower Motor (Std)

Speed

Frame 56

Rotation ccw

Voltage (Std) 208-230-60-1

Full Load Amps

Locked Rotor Amps 35

Blower Motor Pulley

Blower Pulley Inches

Belt Length x Width Inches

Filters

Sq. Ft. 7.92

Inches

Inches

HP & SF

RPM 3450

Inches

30 X 38

1/2

3

12/In. Flat Fan Diameter

1.25 X 1.08 Stag.

9

2

1 X 1.25 Frame

6.7

PD 2.9 - 1.9

PD 12 Full Load Amps

51 X 1/2

(4) 25 X 20 X 1

DETAILED COOLING CAPACITIES

AIR ENTERING

C.W. COIL

85

CHILLER

Capacity

CFM

EWB

Btuh X 1000

Total Sensible Total Sensible

93.5 48.1

89.5 57.8

65.9 79.3 65.1

93.6 50.2

2,500

71

67

63 81.5

71

3,000 67 92.5 62.5

63

71

3,500

67

63 87.5

71

4,000 67

63

85.5 72.3

93.7

52.5 92.2

93.0 66.2 91.0

77.9

93.8

55.3

93.4 69.6

89.5 83.4

Chilled Fan Motor

Voltage (Std)

Speed

Full Load Amps

Locked Rotor Amps

Chilled Water Pump

HP & Service Factor

Voltage

Speed

Full Load Amps

Locked Rotor Amps

Solution Pump Motor

HP & Service Factor

Voltage

Speed RPM

Frame

Locked Rotor Amps

Pump Pulley Diameter

Motor Pulley Diameter

Belt Length x Width

RPM

Inches

RPM

Inches

Inches

ENTERING AIR TEMPERATURE ° F

95

Capacity

Btuh X 1000

Total

92.0

88.0

92.1

90.0

83.7 71.6

47.5 87.0

57.2 83.5

49.9

61.6 85.7 59.9

79.5 70.0

52.2

65.4 86.0

85.7 77.1

92.3

91.5 69.1

54.4 87.3

86.5 67.4

87.5 82.5

(2) 1/2 HP

208/230-60-1

1075

3.6

10.5

(2) 22.12

1/3 - 1.75

208/230-60-1

3450

48

3.6

23.0

3/4 - 1.25

208/230-60-1

1725

55

5.4

29.5

7.84

2.3

36.42 X 3/16

105

Capacity

Btuh X 1000

Sensible

45.6

55.6

75.0

63.2

87.1 48.3

87.2

50.7

63.9

81.3

75.6

53.1

82.5

80.8

Notes:

1. Sensible heat capacities shown are based on 80 F entering air at the evaporator.

2. Direct interpolation is permissible. Do not extrapolate.

3. To interpolate:

(a) below 80 F DB, subtract 800 Btuh per 1000 cfm

for each degree below 80 F from the listed sensible capacity.

(b) above 80 F DB, add 800 Btuh per 1000 cfm

for each degree above 80 F from the listed sensible capacity.

4. Formula:

LDB = EDB -

Lh - Eh -

Sensible Heat Capacity (Btuh)

1.08 X cfm

Total Capacity (Btuh)

4.5 X cfm

where h = Enthalpy (Btu/lb)

Loading...

Loading...