Page 1

USE AND CARE MANUAL

Room Air Conditioner Model 463 Series

(j Ci/lAXjiyf V"

For Models

463AAC005BA

463AAC008BA

Owen’s guide.

Read instructions completely before installing

Table of contents Pg1

Tabla de contenido Pg16

1 -800-428-4326

Ì

Page 2

Table of Contents

Page

Parts Identification

Introduction

-----------

------

Electrical Specifications

Energy-saving Tips Installation Instructions

Operating Instructions

Care and Maintenance

Trouble Shooting Guide

2

3

4

5

6

13

14

15

- 1

Page 3

Part Identification

1. Parts Identification for Model 463AAC005BA

Front Panel

Cabinet

Interior

Air Inlet

Grille

Air Fitter

2. Parts Identification for Model 463AAC008BA

Front Panel

Exterior

Air Inlet

Interior Air Outlet

Fresh Air

Vent Lever

Auto Air

Swing Switch

Control Pane!

Power Cord

Cabinet

Interior

Air inlet

Grille

Exterior

Air Inlet

Air Outlet

Fresh Air

Vent Lever

Auto Air

Swing Switch

Control Panel

Power Cord

Air Filter

Page 4

introduction

Thank you for choosing this Bryant Room Air Conditioner to cool your home This USE AND CARE MANUAL

provides information necessary for the proper care and maintenance of your new Room Air Conditioner If

properly maintained, your air conditioner will give you many years of trouble free operation To avoid installation

difficulties, read instructions completely before starting This manual contains inforrnation tor the installation

and operation of your Bryant Room Air Conditioner

For easy reference, you may want to attach a copy of your sales receipt to this page Note following

information provided (on the manufacturer's nameplate located on the right side of the unit above the power

cord) This information will be needed when you contact a Bryanf s Customer Service Representative

Model number.

Serial number:

________

_______

Date of Purchase

Dealer's Name and Address

Refer to the trouble shooting-section of this USE AND CARE MANUAL if the unit is not operating correctly

If these suggestions do not solve the problem, contact an authorized service representative or call

1-800-428-4326.

Keep these instructions for future reference.

This symbol denotes a caution or warning.

Specifications:

Model number

Unit Specifications'

Voltage

Cooling Capacity(Btu/h) 5,000

Input Wattage

Energy Efficiency Rating (EER)

Fan/Cooling Speeds

Cooling Area Coverage (Sq ft)

Noise Level (dB) 49 5

Unit Dimensions

Window Kit Dimensions

Shipping Weight 65lb

Width

Depth

Height

Maximum Width 35 0"

Minimum Width 22 4"

Height

463AAC005BA

115V/60HZ

515

97

2/2 2/2

100 350

17 7"

15 9"

12 6" 13 6”

13 5"

463AAC008BA

115V/60HZ

8,000

815

98

52

19 7"

21 1"

37 0"

24 4"

14 5"

981b

NOTE* Specifications are subject to change without further notice

- 3 -

Page 5

Electrical Specifications

1 All wiring must comply with local and national

electrical codes and must be installed by a

qualified electrician If you have any questions

regarding the following instructions, contact a

qualified electrician

2 Check available power supply and resolve any

wiring problems BEFORE installing and operating

this unit

3 This 115V air conditioner uses 12 0 or less

nameplate amps and may be used in any

properly wired, general purpose household

receptacle See (Table 1) for specifications for

individual branch circuit

4 For your safety and protection This unit is

grounded through the power cord when

plugged into a matching wall outlet If you are

not sure weather your wait outlet is properly

grounded, please consult a qualified

electrician

Suggested Individual Branch Circuit

Hameplate Amps

5 Oto 12

AWG- American Wire Gage

* Based on copper wire at 60° C temperature rating

Table 1

Receptacle and Fuse Types

Rated Volts

AMPS

Walt Outlet

AWG Wire Size*

14

125

15

(5)

Fuse Size

Time Delay Fuse

(or circuit breaker)

Table 2

15

Pfug type

5 The wall outlet(3-pin) must match the plug

(3-pin) on the service cord supplied with the unit

DO NOT use plug adapters See (Table 2) for

receptacle and fuse infomnatton

6 The rating plate on the unit contains electrical

and other technical data. The rating plate is located

on the right side of the unit, above the power cord

If missing, a second nameplate is located on front

chassis (also as known as basepan)

Electric Shock Hazard

To avoid the possibility of personal

injury, disconnect power to the unit

before installing or servicing

4 -

Page 6

Energy-Saving Tips

Your Room Air Conditioner unit is designed to be highly efficient and save energy.

Follow these recommendations for greater efficiency.

1 Select thermostat setting that suits your

comfort needs and leave the thermostat at

that chosen setting

2 The filter is very efficient in removing airborne

particles Keep air filter clean Normally, filter

should be cleaned once a month More

frequent cleaning may be necessary depending

on outdoor and Indoor air quality

3 Use drapes, curtains, or shades to keep

direct sunlight from heating your room, but

DO NOT obstruct the air conditioner Allow air to

circulate around the unit without obstructions

4 Start your air conditioner before outdoor

air becomes hot and uncomfortable This

avoids an initial period of discomfort while

the unit is cooling off the room

5 When outdoor temperature is cool

enough, use HIGH or LOW FAN

only (depending on your model) This

circulates indoor air, providing some

cooling comfort, and utilizes less

electricity than when operating on a

cooling setting

To avoid installation/operating difficulties,

№ad the instructions thoroughly.

Your Bryant Room Air Conditioner was designed

for easy installation in a single or double-hung

window NOTE: This unit is NOT designed for

vertical (slider type) windows-

NOTE* Save the shipping carton and packing

materials for future storage or transport of the unit

Please check the contents of hardware kit against

the corresponding model check list, prior to

installation of the unit

See Usts below, depending on model

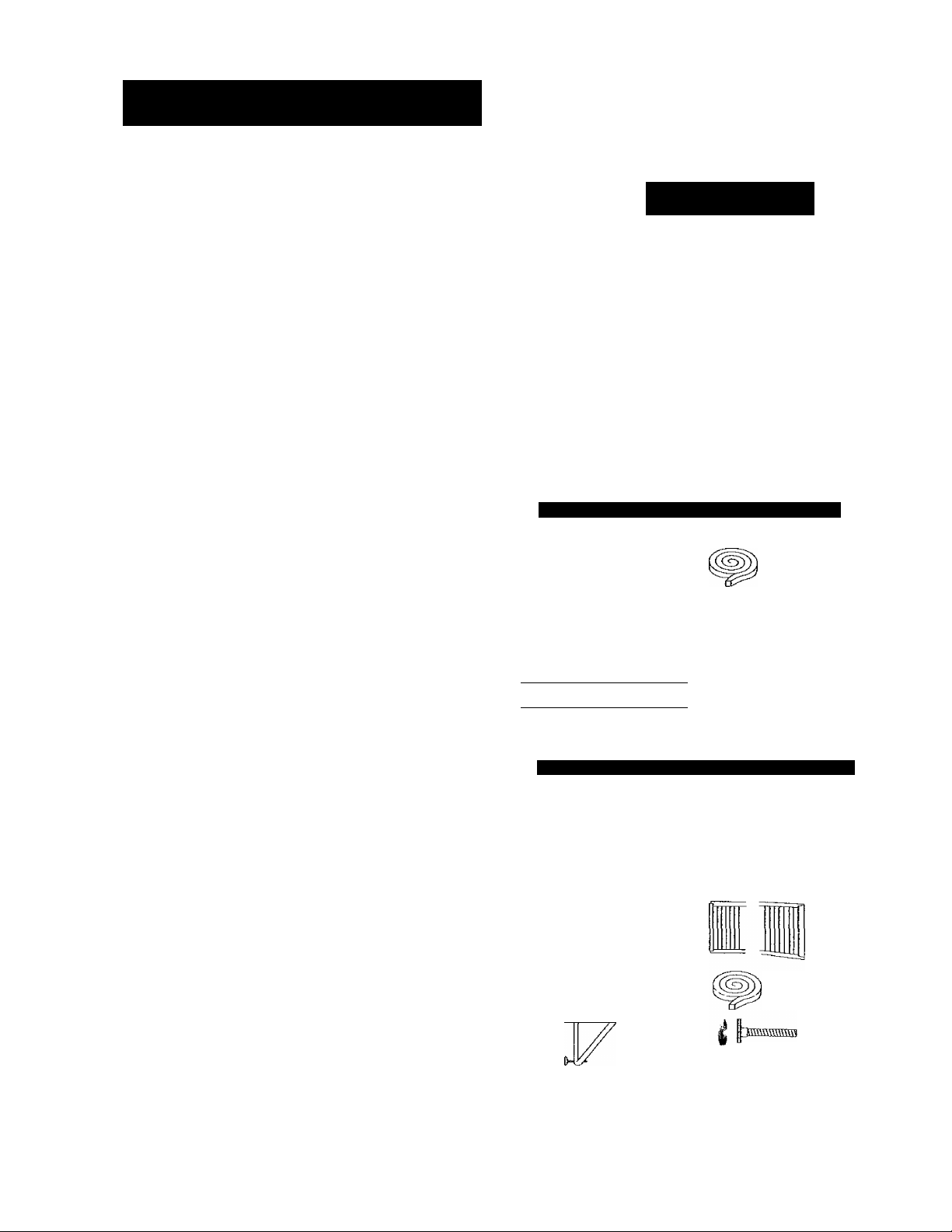

Fig. 11nstaliation Hardware Model 463AAC005BA

3/4'*Screws (10)

1/4"Screws (22)

CH

Top Channel(l)

CL

Bottom Channel(1)

Shutter damp

, * Mounting

^ Brackets{2)

CAUTION A

Foam

Seal(4)

Side Curtain RH(1)

Side Curtain LH(1)

Leveling tegs (2)

Tools Needed for Window Installation

Screw drivers: Both Philips and flat head

Power drill: 1/8 inch diameter drill bit

Pencil

Measuring tape

Scissors

Carpenters level

Adjustable wrench

Fig. 1A (nstalJation Hardware Model 463AAC008BA

3/4"Screws (10)

1/4"Screvifs (18)

Top Channel(l)

a

Bottom Channel(1)

(Factory Installed)

Lock Washers{4)

1-1/2"x1/4Boits{4)

1/4" Nuts(4)

a

Mounting

Brackets(2)

Angle

Brackets (2)

Shutter Ciamp(2)

Side Curtain RH(1)

Side Curtain LH(1)

Foam

Seal(4)

End Cap &

Leveling Legs(2)

Page 7

Instal latîon Instructions

CAUTION A

Because the compressor is located on the

controls side of the unit (right side), this side

will be heavier and more awkward to manipulate

Inadequate support on control side of the unit

can result in personal injury and damage to your

unit and property Therefore, it is recommended

to have someone assist you during the installation

of this unit

1. Select the Best Location

A Your Bryant room air conditioner was designed to

fit easily into a single or double hung window However,

since window designs vary, it may be necessary to

make some modifications for safe and proper

installation

B Make sure window and frame is structurally

sound and free from dry and rotted wood

F Your Bryant unit was designed to evaporate

condensation under normal conditions However,

under extreme humidity conditions, excess condensation

may cause basepan to overflow to the outside

The unit should be installed where condensation

run-off cannot drip on pedestrians or neighboring

properties

G A drain connection{exciuding hose) is provided

If you need to redirect condensation overflow

(See Fig 23 on Page 12)

Awning

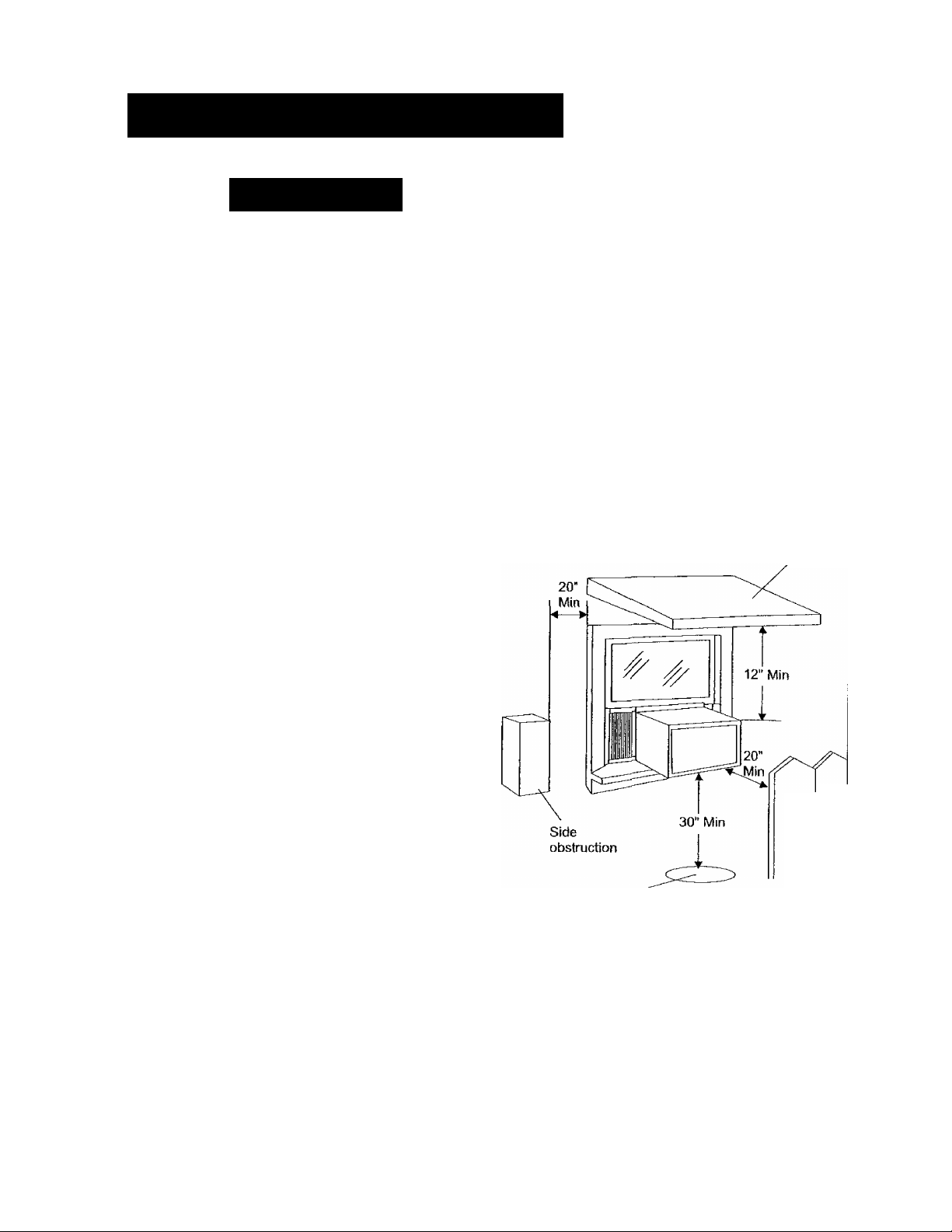

C For maximum efficiency, install the air conditioner

on side of the house or building which favors more

shade than sunlight If the unit Is in direct sunlight,

it is advisable to provide an awning over the unit

D Provide sufficient clearance around the cabinet

to allow for ample air circulation through the unit

See (Dwg 1) The rear of the unit should be outdoors

and not in a garage nor inside of a building

Keep unit as far away as possible from obstacles

obstructions and at least 30" above the floor or ground

Curtains and other objects within a room should be

prevented from blocking the air flow

E Be certain the proper electrical outlet is within reach

of the installation Use only a single outlet circuit rated

at 15 amps All wiring should be in accordance with local

and national electrical codes

Fence,

wail, or

other

obstacle

Ground

Dwg 1

Page 8

I nsta 11 at! o n I ns tru ctl o n s

2. Preparation to remove the

Air Conditioner Slide-Out Chassis

(Mode) 4S3AAC005BA)

A Tilt the unit on its back {Fig 1) be careful not

to damage the drain on the back

B Locate the finger indents on the underside of

the interior air inlet griHe(F/ig 2)

C Lift the air inlet gritle{fully open) until it

disengages from the top edge of the front

panel{F/g 2)

D- Remove the Philips screw located at the lower

(right hand) corner of the front grille and the Philips

screws from both sides of the cabinet {Fig 3)

E Grasp the lower front comer of the front panel,

pulling (gently) outward and upward Repeat

this step on the 3 remaining comers {Fig 4)

F Grasp the pull handle at the front of the

slide-out chassis and carefully slide the air

conditioner out of the cabinet {Fig 4)

Fig 1

Fig 2

3. Preparation to Remove the

Air Conditioner Slide-Out Chassis

(Mode) 463AAC008BA)

A Remove the (2) Philips screws on each side of

the cabinet The set of screws closest to the

front of the unit, secure the front panel to the

cabinet The set of screws closest to the rear of

the unit, secure the cabinet to the chassis

See {Fig 5)

B Remove the front panel assembly from the

cabinet by gently pulling it

C Grasp the pull pane) at the front of the

slide-out chassis and carefully slide the

air conditioner out of the cabinet {Fig 6)

NOTE* Screws must be reinstalled upon

completion of the window installation to secure

slide-out chassis.

Please seek assistance for this procedure

Page 9

Instailation Instructions

4. Assembly of the upper & lower channels to

the cabinet

A. " L" Shaped Top Channel: Install the "L" shaped

top channel to the cabinet as shown in {Fig 7) using

(4) 1/4" screws

B. *‘U" Shaped Bottom Channel: Install the "U"

shaped bottom channel to the cabinet as shown in

(Fig 7) using (4) 1/4” screws

5 Assembly of the side shutters (curtains) to the cabinet.

Slide the shutters into the top and bottom

channels as shown in {Fig 8) The shutters are

identified (on each frame) as "left" & "right". Attach the

shutters to the cabinet using (2) 1/4" screws on

each side

6. Installation of Mounting Brackets and

First Sealing Strip

(Model 463AAC005BA)

NOTE; Windows come in a

variety of different styles Therefore, it may be

necessary to modify or improve your particular

installation

A Assemble the leveling screw bracket to the

bracket assembly as shown in (Fig 9), using

two 1/4” screws provided Install the leveling

screws into each of the leveling screw brackets

(This will require the use of an adjustable wrench)

B Measure the inside window sill width and find

the center line as shown in (Fig, 10) From this

center line, measure 8 1/16” on each side and

mark these points Align the V-sIot in each bracket

on these marks and mount to sill using (2) 3/4"

screws provided per bracket Brackets should be

perpendicular to the inside window silt See(Fig 11)

Inside Window Sit

3/16' Maximum

Bracket Assembly

Fig 11

Leveling Screw

8

Page 10

Installation Instructions

C Adjust the leveling screws until the bracket tilts

no more than 3/16” downward to the outside Do

not allow the bracket to slant inward as

condensation could possibly drip on interior walls

and floors See (Fig. 11)

D- Cut the 1st foam sealing strip to fit the underside

of the bottom window sash Remove the peelofl"

backing on the foam and attach it to the sash See

(Fig 12)

7 Installation of Mounting Brackets and First Sealing Strip (Model 463AAC008BA)

NOTE' Windows come in a variety of different

styles Therefore, it may be necessary to modify

or improve your particular installation

A Attach the bracket assembly to 90°angte support

brackets {Fig 13) using (2) 1 1/2" bolts

Two bolts per bracket Secure with the (2)

1/4” lock washers and (2) 1/4"nuts DO NOT

immediately tighten these bolts as it may be

necessary to adjust the depth of the bracket

assembly, depending on the depth of your window sill

See (Fig 14} install the two leveling screws into the

90 support brackets Test the bracket assembly in the

window before cabinet installation If the leveling

screws are distanced too far away from the wall to

provide stability, it may be necessary for you to shim

this area with a solid piece 5f wood See (Fig 15)

Fig 14

Frg 15

9 -

Page 11

Installation Instructions

B Measure the inside window sili width and find the

canteras shown in (Fig 14) Measure 9 1/4” from the

center line on each side and mark these points Align

the V-slot in each bracket on these marks and mount

the brackets to the sill using 3/4** screws provided.

Brackets should be perpendicular to the inside window

sill. See (Fig 14)

C For proper condensation run-off it will be necessary

to adjust the angle/pitch of the window brackets This is

accomplished by adjusting the distance of the leveling

screw on the outer wall The maximum angle/pitch

should not exceed more than 3/16" See {Fig 16)

D Cut the first foam sealing strip to fit the

underside of the bottom window sash Remove

the peel-off backing on the foam and attach it

to this sash See (Fig 12)

CAUTION A

Use a solid piece of wood to provide stability This

will be required when sills are extra deep

See {Fig 15)

— 10

Page 12

instaliation instructions

8. Installation of the cabinet (Model 463AAC005BA and 463AAC008BA)

A Align one hole in the bottom of the cabinet with

one hole in the bracket assembly. Secure the

cabinet to the bracket using a 1/4" screw provided

Repeat the same procedure on the opposite side

of the cabinet See (Hg 17}

B. Ensure the T" shaped mounting channel is

positioned in front of the sash The "U" shaped

channel on the bottom of the cabinet should

be positioned in the track provided on the bracket

assembly Pull the window down until it rests just

behind the front of the "L" shaped mounting channel

See (Fig- 18)

C Check to make sure that the cabinet is slanted

slightly downward on the outside If necessary,

re-adjust support bracket as shown in {Fig 11}

Fig 18

11

Page 13

installation instructions

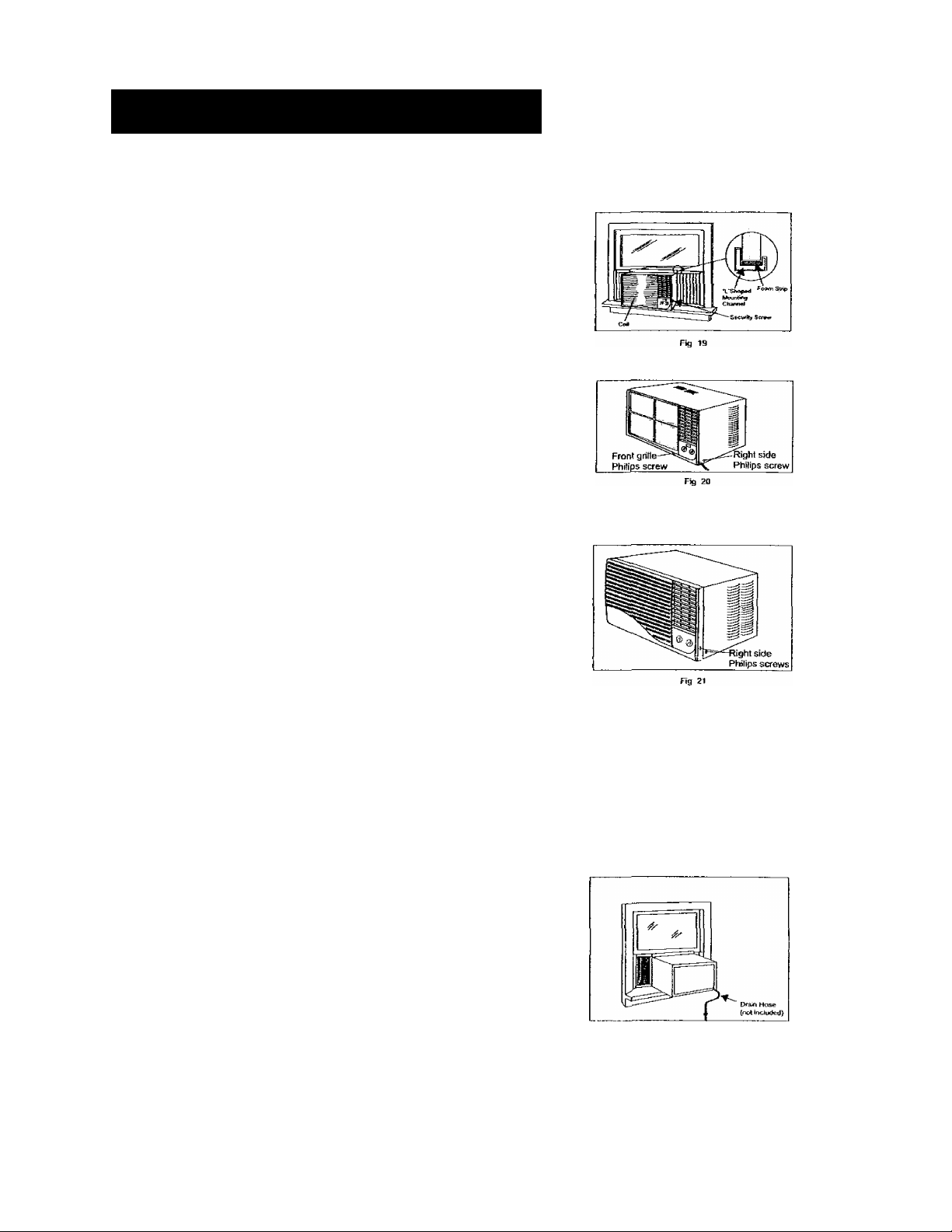

9. Secure Shutters

A Carefully slide the air conditioner back into the cabinet.

(Please seek assistance for this procedure)

Reinstall the slide-out-chassis security screws (removed

earlier) on both sides of the cabinet See {Fig 19)

Secure the top of the frames to the window sash

with (2) 3/4” screws

B Now, secure bottom frame of shutters using one shutter

clamp and one 3/4" screw on each side(F/fir 19).

10. Reinstalling Front Panel and Air Inlet Grille (Model 463AAC005BA):

A Position the front panel on the cabinet starting at the

top The front panel lock tabs must be inserted into the

retaining slots in the cabinet Repeat this procedure on

all sides

B Secure the front grille to the cabinet using the Philips

screws removed eariier(Fig 20)

C Replace the air filter

D Position air inlet grille on the cabinet and gently

press on it

11. Reinstalling Front Panel Assembly (Model 463AAC008BA)

A Position the front panel on the cabinet starting at the

top The front panel lock tabs must be inserted into the

retaining slots in the cabinet Repeat this procedure on

alt sides

B Secure the front grille to the cabinet using the Philips

screws removed earlier(F/g 21)

12. Complete the installation

A Cut the second foam seal to fit the opening between

the top of the inside and outside window See {Fig 22)

B Some installations may require additional sealing around

the window and air conditioner Check for any air teaks

and seal where necessary

C In very humid areas, the water removal may be excessive

enough to overflow the unit or increase the noise of the

air conditioner If this occurs, you may wish to attach a

drain hose (not included) to the drain plug allowing

condensations to run off conveniently See (Fig 23)

ng 22

Rg 23

— 12-

Page 14

operating Instructions

MODE

The mode knob controls fan speeds and cooling

speeds To set desired cooling temperature, simply

rotate the mode knob dial to the appropriate

setting

AUTO AIR SWING Switch

When the Swing switch is turned to the

"ON" position, the vertical louvers automatically

oscillate sweeping the cold air for comfortable cooling

The vertical louvers may be stopped at any position

when the Swing switch is turned "OFF"

THERMOSTAT

The thermostat automatically controls the cooling

cycle (compressor) of the air conditioner to maintain

room temperature However, the fan motor will

continue to operate after the compressor (cooling

cycle) is completed

LOW FAN will circulate the air at a minimum speed

without cooling

HIGH FAN will circulate the air at a maximum speed

without cooling

LOW COOL provides cooling, automatically with

minimum air circulation Recommended for night

time use

HIGH COOL provides cooling, automatically with

quick cooling or for extremely hot days Once room

is cooled, reduce setting to LOW COOL

OFF will completely shut-off the unit

NOTE' After setting the mode, allow 3

minutes before switching to another mode

Fresh Air Ventilation is usually kept in the dosed

position Use only when clearing smoke and/or

odors from the room Puli to open

CAUTION A

When using FAN control, turn slowly allowing unit

to adjust i

When using THERMOSTAT, be sure to allow threei

minutes before changing temperature Adjusting j

too quickly may cause an overload resulting in a

blown fuse

MODEL 463AAC005BA, 463AAC008BA

j

- 13-

Page 15

Care and Maintenance

When servicing the air conditioner, be sure to

turn the mode switch to the "OFF” position and

disconnect the power cord from the electncai outlet

1 DOT NOT use gasoline, benzine, thinner or

other chemicals on the air conditioner as these

substances may cause damage to the paint finish

and deformation of plastic parts

2 Never attempt to pour water directly to the

front of the unit as this will cause deterioration of

the electrical insulation

Cleaning the Air Filter Removal of Air Filter

If the air filter becomes clogged with dust, air-flow

is obstructed and reduces efficiency The air filter

should be cleaned once a month More frequent

cleaning may be necessary depending on outdoor

and indoor air quality

Air Filter Removal,

(Model 463AAC005BA)

The air filter on the above models is located

behind the air intake front grill To remove the

air filter, locate the finger indents on bottom

side of air inlet grill Pul! forward and lift off

front grill To remove the air fitter, grasp the

filter handle, lift and pull fonA/ard To reinstall

the air filter, reverse the above procedure

The air filter may be vacuumed or washed

by-hand in warm water Dry thoroughly before

installing

CAUTION

DO NOT forget to install thé air filter If the air

conditioner is left to operate without the air filter,

dust is not removed from the room and may

cause your air conditioner to fail

When the air filter inlet grill and cabinet are dirty,

wipe with lukewarm water (below 40°C) Use of

mild detergent is recommended

Cleaning of Air Filter

1 Remove dust clogged in the filter by

tapping it or vacuum clean it

2 Wash the fitter well with lukewarm water below

40*^0 (104‘’F) while rubbling lightly To get better

results, wash it with soapy water or a neutral

cleaning agent

3 Rinse the filter well using clean water then

dry completely

End-of-Season Care

1 Operate the fan alone for half a day to dry out

the inside of the unit

2 Turn off power and remove plug from wall socket

3 Clean fitter

4 Store in a dry location

Air Filter Removal (Model 463AAC008BA)

The air filter on the above models is located

behind the air intake front grill

To remove the air filter, grasp the filter hand!e(tab)

located on the right (center) side of the air inlet grille

and slide the air fitter to the right

To reinstall the air filter, reverse the above

procedure

-14-

Page 16

Troubleshooting Guide

Frequently, a problem is minor and a service call may not be necessary, use this troubleshooting guide fort

possible solution If the unit continues to operate improperly, call 1-800-428-4326 for assistance, or call you

closest dealer

PROBLEM

Air conditioner will

not operate

Inefficient or no cooling

Noisy unit

Odors

POSSIBLE CAUSE

No power to the unit

Dirty air filter

Inappropriate capacity

for application

Blocked air flow

Power interruption, settings

change too quickly, or

compressor overload tripped

Loose parts

Inadequate support

Formation of mold, mildew, or

algae on wet surfaces

SUGGESTED SOLUTION

Check connection of power cord to

power source.

Check fuse or circuit breaker

Set FAN CONTROL to position other

than "OFF"

Clean or replace air fitter

Check with dealer to determine proper unit

capacity for application

Remove obstruction from grill or

outdoor louvers

Let fan run to restart compressor

{in approximately 10 minutes )

Tighten loose parts

Provide additional support to unit

Remove drain plug and drain base pan

Replace drain plug

Clean unit thoroughly

Water dripping outside

Water dripping inside

Ice or frost build-up

NOTE:

1 !f circuit breaker is tripped repeatedly, or fuse is blown more than once, contact a qualified technician

Condensation run-off is normal

during hot and humid weather

Unit is not properly angled to

allow water to drain outside

Low outside temperature

Unit air filter is dirty

- 15

Add flexible tubing to redirect water flow,

see (Fig 23 Page 12)

Unit must be installed on an angle for prope

condensation run-off Check the unit and

make adjustments

When outdoor temperature is approximately

65T or below, frost may form when unit is in

cooling mode Switch unit to FAN (only)

operation until frost melts

Remove and clean filter

Page 17

Room Air Conditioner Limited Warranty

One-Year Full Warraniy - BRYANT warrants to the user that this product wilt be free from defects of workmanship under normal

use and maintenance for a period of one year from the date of original purchase BRYANT through and independent servicing

dealer or service station, will either repair or replace a defective product (as decided solely by BRYANT) free of charge to the user,

BRYANT may replace any defective pad with either a new or remanufactured part, at BRYANT’s sole option

EXTENDED FOUR-YEAR WARRANTY ON SEALED REFRIGERATION SYSTEM ONLY - During the second through fifth years

after date of original purchase BRYANT further warrants to the user that the compressor, condenser evaporator and connecting

tubing will be free from defects in material, or workmanship under normal use and maintenance ONLY PARTS ARE COVERED

IN YEARS 2 THROUGH 5 NO LABOR COSTS WILL BE COVERED BRYANT will either repair or replace (as decided solely

by BRYANT) any defective compressor, condenser, evaporator, and connecting tubing However, THIS LIMITED WARRANTY

DOES NOT INCLUDE costs incurred for diagnosing, removing installing, shipping, or transporting the product or any parts User

is responsible for these costs, however, SUCH COSTS MAY BE COVERED by a separate warranty or service agreement

provided by the seller or another third party, such agreement being separate and distinct from this factory warranty

LIMITATION OF WARRANTIES - ALL IMPLIED WARRANTIES (INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ) ARE HEREBY LIMITED IN DURATION TO THE PERIOD FOR WHICH THE

APPLICABLE PRODUCT COMPONENT IS EXPRESSLY WARRANTED HEREIN Some states do not allow limitations on how

tong an implied warranty lasts, so the above limitations may not apply to you THE EXPRESS WARRANTIES MADE IN THIS

WARRANTY ARE EXCLUSIVE AND MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBUTOR DEALER,

OR OTHER PERSON WHATSOEVER BRYANT WILL NOT BE RESPONSIBLE FOR ANY SPECIAL INCIDENTAL, OR

CONSËQUENTIOAL PROPERTY OR COMMERCIAL DAMAGES OF ANY NATURE WHATSOEVER Some states do not allow

the exclusion of incidental or consequential damages so the above limitation may not apply to you Alt work provided for by this

warranty shall be performed during normal working hours All replacement parts, whether nevi or remanufactured, assume as

their warranty period only the remaining time period for which the applicable component is expressly warranted herein

BRYANT WILL NOT BE RESPONSIBLE FOR

1 Damage due to failure to perform normal maintenance as outlined in the Owner’s guide

2 Instruction on methods of control and use of air conditioner unit after initial installation

3 Damage or repairs needed as a consequence of faulty installation or apptication This is the responsibility of the

4 Failure to start due to voltage conditions blown fuses open circuit breakers or any other damages due to the

5 Damage or repairs needed as a consequence of any misapplication abuse unauthorized alteration improper service

6 Damage as a result of floods winds, fires lightning, accident corrosive environments, or other conditions beyond the

7 Any parts not supplied or designated by BRYANT

8 BRYANT products installed outside the continental USA , Alaska Hawaii and Canada

9 Shipping damage or damage as a result of storing or transporting the unit

installer

inadequacy or interruption of electrical service

or operation

control of BRYANT

Page 18

Owner’s Guide Update

Please Note the following changes

for the instructions on pages 8 and 9

Before installing the “L” shaped top window channel shown in step 4A

(page 8), please apply a piece of window sash seal strip to the bottom of

the channel. Do this so the rubber seal is between the top channel and

the cabinet.

Cut the foam seal strip with scissors to fit the underside of the top

channel before removing the peel off backing. After cutting, remove the

peel off backing and apply the foam seal to the underside of the top

channel. You may omit the foam seal strip at the bottom of the window

sash shown in step 6D (page 9) and use it for this location. Step 6D has

been eliminated.

Page 19

Owner’s Guide Update

In order to provide maximum wind and rain protection, please apply the sealer compound

provided with your window unit.

This sealer can be applied directly from the tube Form a ‘bead' of sealer compound on the

outside of the unit, at the places shown below Form a continuous bead of material along the top of the

unit, where the cabinet joins the top window channel. Extend the bead around the comer and down

each side, covering the joint between each side window panel and the cabinet

Sealing can be done before the cabinet is installed You may also apply the sealer after the cabinet is

installed, taking care to reach outside, but do not lean out of the window. You may lift the window

sash, and the cabinet will stay in place. Apply the sealer along the top channel. Compress each side

curtain, and apply the sealer by reaching around the side of the curtain on each side

The sealer compound can be formed with the tip of the tube, with a disposable plastic spoon, or with

your finger. You may rework the sealer with your fìnger or plastic spoon for seveial minutes before it

starts to set Follow the directions on the tube of sealer for cleanup

SEALER COMPOUND

OUTSIDE

Rev A

Loading...

Loading...