Page 1

nstallation Instructions

451

SERIES A

■

GAS-FIRED AIR CONDITIONER

Installation of the Model 451 Gas Air Conditioning

Absorption unit consists of the following steps:

I. Locate and mount absorption unit.

II. Connect chilled water lines.

III. Electrical connections.

IV. Gas connections.

V. Charge system with water.

VI. Check-out and Operation.

VII. Adjust gas input.

VIII. Balance system.

IX. Purge Non-Condensibles.

Each of the above steps is discussed in detail in

this irtstructiofl. Read entire instruction before

starting installation.

Position unit and remove wooden shipping crate

base as shown in Figure 1.

1. Saw wood stringers as shown.

FMijJTTJjyMl

39451D1

I

2. Remove unit access panels and remove 3 shiping bolts from crate base.

3. Tilt one end of unit and remove half-section of

crate base; then reiiiove remaining section while

tilting the other end.

I. LOCATE AND MOUNT ABSORPTION UNIT

The absorption unit may be located at ground lével

or on the roof. Consult local codes for information

concerning proximity to property lines, height

above roof, obstructions, etc.

A. MOUNTING BASE

1. Use non-combustible materials.

2. Base should be large enough that unit will not

overhang.

3. A poured concrete slab, minimum 4" thick, is

recommended for ground installation.

4. On roof installations leave süfficieíit clearance

between unit base and roof top for proper air circu-

, lation.

5. A unit supported on concrete blocks will require

a block at each corner plus a fifth block under the

front, midway betweèn the front corner blocks.

B. CLEARANCES

See Figures 2 and 3 for typical locations.

1. Absorption unit should have a minimum clear

ance of 2 feet on all sides from any adjacent ob

struction.

2. Avoid locating the unit where hot condenser

discharge air can impinge on nearby obstructions

and mix with the inlet air supply. The condenser

air discharges upward at a small angle toward the

front of the unit. With the condenser facing the

wall the unit can be located at, or outside of the

plumb line from any over-hang.

EH 451

Cancels: New

Effective 2/1/64,

Page 2

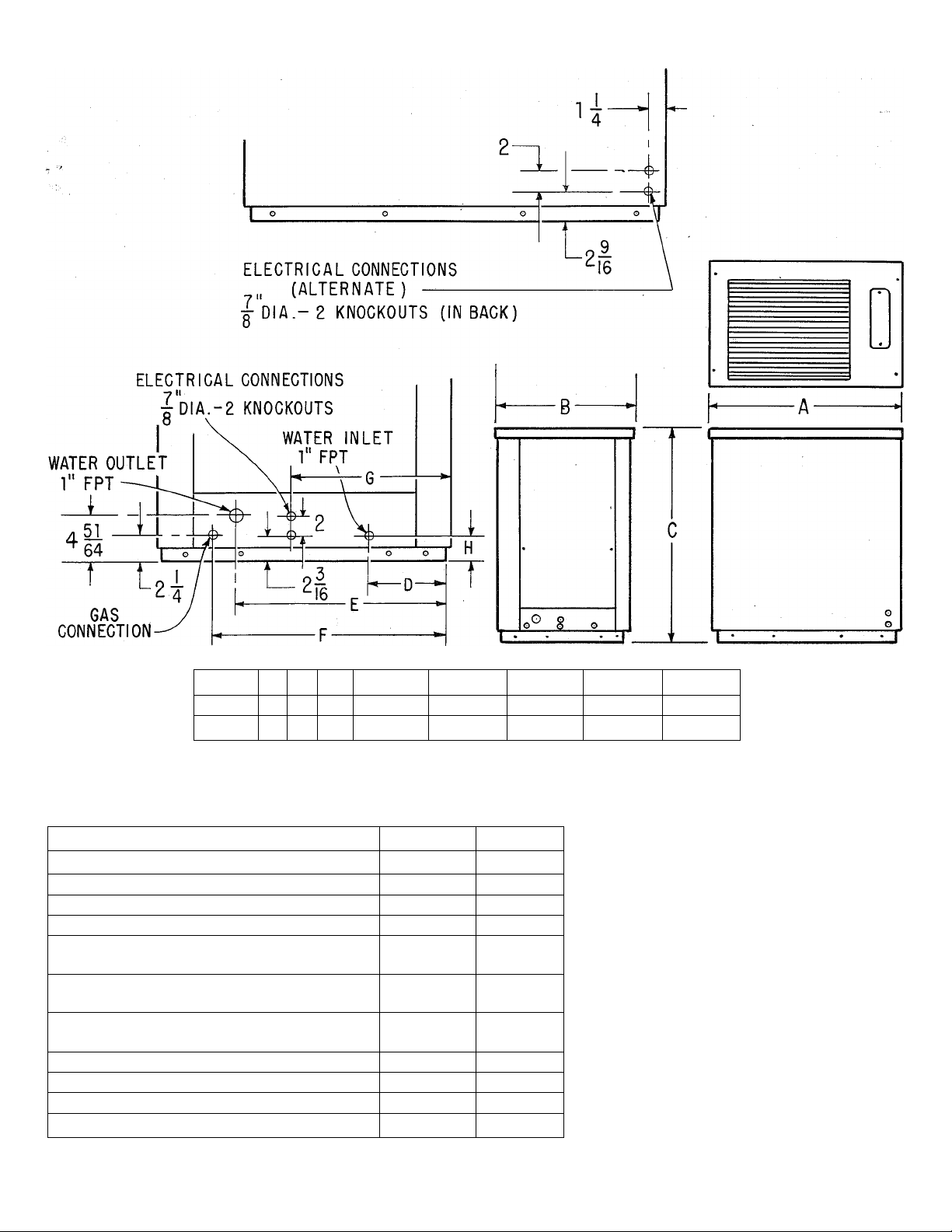

Model A

36-451

46 31 52

54-451 55

B

C

38 59

D

E

9-1/16 23-9/64

11-1/16 28-3/4

F

G

26-1/8 17-5/16

32-7/16

22

H

3-7/64

3-39/64

Cooling Capacity

Heat Input

Condenser Air Delivery

Water Flow (Min. Required)

Max. Frictional Loss Handled

by Chiller Pump

Max., Elevation of Coil

above Chiller Ft

Pump and Fan Drive

115V, 60 Cy., 1 Phase

Minimum Wire Size *

Refrigerant Type

Refrigerant Amount

Approximate Shipping Wt. Lb

EH 451

36-451

Btuh

Btuh

Cfm

Gpm

Ft Head 23 20

35,000 53,000

110,000 165,000

4,500 6,700

7.5 11

22

HP

AWG

1/3

14 *

54-451

22

1/2

12 *

717 717

Lb

18

750

- 2

31

1,125

^Satisfactory where distance, measured along

wire path, between unit and connection into

main panel does not exceed 100 ft. Where

distances are longer, wire sizes should be

increased accordingly.

Page 3

TABLE

Nominal

Pipe Size

Inches

3/4

1

1-1/4

* Note: Values shown in above table are for one direction only. The total length of pipe from chiller to coil

and return would be double the above table values. The above table applies to single unit installations only.

Figure 1

Polyethy ene Pipe Copper Pipe

Size 36

40'

150'

530'

Size 54

—

45' 140' 40'

145'

Allowable Distance* between Coil and Chiller

Size 36

35'

Size 54

—

360' 100'

SLEEPING

□

AVOID

OPEN

WINDOWS

QUARTERS

LIVING

AREA

Galvanized Pipe

Size 36

25'

90'

370'

AVOID

'ells"

□

GARAGE

Size 54

—

30 '

90'

□

GOOD

LOCATION

II. CONNECT CHILLED WATER LINES

A. MATERIALS

Refer to section on “Cold Weather Protection” at

the end of this instruction.

1. Piping

Figure 3

b. Copper - satisfactory substitute.

c. Galvanized - satisfactory substitute.

2. Fittings

a. Nylon - use when possible.

b. Brass - satisfactory substitute.

c. Galvanized - satisfactory substitute.

B. PIPE LENGTH AND DIAMETER

Table I shows maximum length of pipe of different

diameters that can be used between the pump dis

charge and the coil inlet and still maintain mini

mum allowable (design) water flow rate.

1. Multiply table values by two to obtain the total

length of pipe from chiller to coil ond return.

2. Length is measured along the pipe path and

therefore includes vertical distance between the

water coil and the chiller.

a. Polyethylene Plastic Pipe - use medium density

flexible pipe whose wall thickness approximates

Schedule 40 pipe (Commercial Standard CS 197-60).

Pipe must be virgin plastic. Do not use pipe manu

factured from re-claimed plastic.

- 3 -

3. Lengths shown in Table I are based on using a

total of eight elbows in the entire water line

(chiller to coil and return). Lengths are predicated

on the use of a Bryant matching water coil. For

greater distances use larger pipe or add a pump.

EH 451

Page 4

CLARIFICATION

On page 4 of this Instruction under Section III Electric Connections,

item 3 should read;

3. Provide a fused disconnect switch within sight of and

not more than 50 feet from the absorption unit.

FIL

C

Page 5

CORRECTION

Paragraph 6 on page 4 under Electric Connections should read as follows:

6. Disconnect pump electrical lead at terminal 7 in control box before energizing

unit when ready to check field wiring. Do not operate the pump dry.

Figure 6 on page 8 is NOT correct. Use the wiring diagram below instead of that on page

FOR EH 451

o

<

□

I

E

o

Ui

O

O)

c

Page 6

C. INSULATION

Ill, ELECTRIC CONNECTIONS

1. Insulate supply and return lines separately.

2. Material should be of good quality and be

covered with a good vapor barrier. Armaflex or

equivalent is recommended.

Wall thickness:

1/2" wall thickness - south of 40 ° N. latitude

3/8" wall thickness - north of 40° N. latitude

D. HEIGHT OF COIL

ABOVE ABSORPTION UNIT

Maximum vertical distance from chiller outlet to

top of coil is 22 feet for both sizes. For greater

heights, a greater pumping head is required. In

creasing the pipe size will not help.

E. WATER COIL CONNECTIONS

1. If coil is located in warm air stream, do not

connect polyethylene pipe directly to coil. Connect

a minimum of 24 inches copper or galvanized pipe

to both the coil inlet and outlet. Then connect the

plastic pipe to these nipples.

2. On installations where the outside piping

freezes and the coil is in a heated air stream, pre

cautions must be taken to provide for water expan

sion. The connecting polyethylene plastic pipe

acts as an expansion vessel if there is enough foot

age of this pipe in the heated space (space not

subject to freezing). The following table shows

the minimum lengths (total inlet and outlet) of

plastic piping of various diameters that are re

quired for both sizes of coils to provide adequate

expansion volume.

1. Make all electric connections in accordance

with the National Electrical Code and any local

ordinances or codes that might apply.

2. Provide a separate power supply for the air

conditioner.

3. Provide a fused disconnect switch within easy

reach of the absorption unit.

Size 36 - use 30 amp. Standard fuse or 15 amp.

fusetron.

Size 54 - use 35 amp. standard fuse or 20 amp.

fusetron.

4. The absorption unit is shipped fully wired from

the factory. Connection of 115V power and low

voltage connection to the thermostat control are

required in the field. Before proceeding, inspect

factory wiring for loose connections which may

have resulted during shipment.

5. Figure 6 is the Wiring Diagram. Do not fasten

power leads to hot tubing since wire insulation

could be damaged and a short circuit could result.

6. Disconnect pump electrical leads at terminals

6 and 7 in control box before energizing unit when

ready to check field wiring. Do not operate the

pump dry.

IV. GAS CONNECTIONS

Consult local gas company before making any gas

connections. In case of conflict with this instruc

tion, local requirements should be followed.

Nominal Pipe Size

Inches

%

1

Vk

Length of Plastic Pipe

in Feet

Size 36 Size 54

24

15

56

35

8.5 20

6.5

14.5

If the total plastic chilled water line footage in

the heated space is not as long as the minimum

values shown in the table, tee a vertical pipe of

sufficient volume into either of the coil connec

tions to provide for expansion, or the line should

be drained.

EH 451

Before selecting the size and type of pipe that is

to be used for installing the absorption unit, be

sure to check with local gas company for the

necessary information. The size of the gas pipe

to be used will depend upon the length of run and

the allowable pressure loss established by the

utility.

The gas connection to the unit is made at the com

bination regulator-shut-off. On the size 36 use a

V2" X 3" nipple and then a elbow. The supply

pipe enters the knockout on the other end of the

unit and will then be lined Up for final connection

if the nipple and elbow are used as described. On

the size 54 use aVi" x 2 "nipple and then a^/i" x

reducing ell and 3/4 inch pipe.

- 4 -

Page 7

A wrench-type shut-off valve should be installed

in the gas line within sight of, and convenient to,

the 451. Provide a ground joint union upstream of

the combination regular shut-off, and preferably

outside the unit.

Install a drip leg trap in the gas supply riser lead

ing to the unit. After gas pipe connections have

been made, purge the lines and check for leakage.

Use a soap and water solution or other such mater

ial.

Never use matches, candles, flame or other source

of ignition to check leakage.

PILOT

Light the pilot using the procedure outlined on the

Lighting Instruction Plate attached to generator.

The pilot flame should be soft blue in color. The

flame should be of sufficient length to provide good

impingment on the unimetal element of the Bryant

pilot. Flame should extend upward between the

carry-over ports of the two adjacent burners.

If the pilot flame does not have the appearance

described above, it may be adjusted by means of

the manual pilot shut-off valve which is equipped

with an adjustable screw. Turn the handle to the

full-open position and remove the screw cap on the

valve handle, thus exposing the adjustable screw.

Turn adjusting screw until flame has the desired

appearance. Replace screw cap.

V. CHARGING THE SYSTEM WITH WATER

Caution: Do not run the pump dry. Freezing condL

tions will not damage the pump; however, do not

attempt to operate the pump when chiller or chilled

water lines are frozen.

1. Turn off main manual gas shut-off valve.

2. Remove the filler cap from water chiller tank.

3. Disconnect line at chiller inlet. (When install

ing the chilled water lines, it is advisable to leave

this connection open until lines have been flushed).

4. Fill the tank with tap water by inserting a

garden hose into the filler tube about 12 inches

and running water into the chiller until it gushes

out around the hose. See Figure 4.

5. Start pump. Allow pump to operate until all

foreign matter has been flushed from the pipes.

Continue to supply water to the tank during this

cleaning period.

Note: If water does not circulate when the pump

is started, air may be trapped in the pump. Bleed

the air from pump through the 1/8" slotted head

bleed valve located on top of the pump discharge.

Open valve with screw driver. Close valve when

the trapped air is removed and water appears.

6. Turn off pump and hose. Make pipe connection

to chiller inlet.

7. Turn on hose and fill tank until water gushes

out around hose. Remove hose and replace filler

cap.

8. Start pump and while water is circulating, check

for leaks throughout the chilled water system.

9. Stop pump and remove filler cap. Insert one end

of a piece of water hose into the tank at least 12".

Insert a clean plastic or metal funnel in the other

end of the hose.

10. Start pump and pour carton of borax into funnel.

Flush borax into chiller with water from water

hose used for filling until tank over-flows. Remove

hose and replace filler cap. The package of borax

supplied is sufficient for chilled water systems

containing up to 20 gallons of water. For systems

- 5-

EH 451

Page 8

larger than 20 gallon capacity, add one-half (1/2)

package for each additional 10 gallon capacity or

fraction thereof. (Consult Bryant distributor for

estimating chilled water circuit capacities.)

11. The system is now ready to operate.

Note: The condenser fan belt is factory set and

is self-adjusting. No field adjustment is necessary.

VI. CHECK OUT AND OPERATION

1. Be sure main manual gas valve is off. Light

pilot as described on instruction plate.

2. Set thermostat to “cool”; set thermostat fan

switch to “auto”; set thermostat below room

temperature.

3. Turn on main electric switch to unit.

4. Check indoor fan operation by turning thermo

stat fan switch to “on” for continuous fan opera

tion. Move thermostat above room temperature and

observe that the indoor fan remains on.

5. To place the system in operation, open the main

manual gas valve, replace all panels, and set the

thermostat at the desired temperature.

To measure gas input, proceed as follows:

1. Adjust primary air if necessary.

2. Measure the gas input at the meter. Be sure all

other gas appliances are turned off. Input at the

burners may be increased or decreased slightly

by adjustment of the regulator in the burner supply

line.

Caution: Prolonged operation of the unit should

not be attempted with the panel off. The unit

may be run for short periods with the panel re

moved.

VIII. BALANCE THE SYSTEM

After the unit is in operation and the input has

been measured and adjusted to agree with the

rating plate requirements, balance the system.

Any approved method of checking the air flow over

the water coil may be utilized. Reference is made

to the Bryant Service Manual on Gas Air Condi

tioners for a review of standard methods.

High Temperature Cut-Off

The high temperature circuit includes a high tem

perature control located on the front of the gen

erator plus a high temperature relay (lockout

relay) located in the control box. If the generator

becomes overheated the contacts in the high temp

control open, causing the high temp relay to go

into lockout position. The gas valve closes, the

fans and pump stop, and they will not recycle until

the lockout relay is reset. To reset lockout relay

turn electric power off and then back on. Be sure

to locate and correct cause of high temp cut-out.

VII. ADJUST GAS INPUT

Gas input should agree with that shown on the

rating plate of the unit. The burners are equipped

with fixed orifices intended to give the correct

gas input with a manifold pressure of 3" w.c.,

using 1030 BTU natural gas of 0.63 S.G. Before

lighting burners, inspect to be sure that they have

not become dislodged or cocked during shipment

and installation.

IX. PURGE NON-CONDENSIBLES

Purging is accomplished through valve A on inlet

tank and Valve D on purge pot.

Operate unit for a minimum of 15 minutes. While

still operating, proceed as follows:

1. Attach adapter and purge line to Valve A.

2. Run purge line to bucket of water.

3. Remove cap and open valve A about 1/8 to 1/4

turn.

4. If non-condensibles are present, bubbles will

rise to the surface of the water in the bucket.

5. Leave Valve A open as long as bubbles rise

to the surface of the water. When non-condensibles

are removed the bubbles will cease as ammonia

will be absorbed into the water.

6. Close Valve A.

7. Open Valve D about 1/8 turn. Usually there

will be some solution trapped in the valve body,

and this solution will be released as soon as the

valve is opened.

EH 451 - 6

Page 9

8. If non-condensibles are present they will follow

the initial surge of solution. When solution re

appears in quantity, the non-condensibles trapped

in the purge pot have been released.

HA RD FI TT IM G-M AX .2 .

AD AP TER

9. Close Valve D.

The installation should now be complete.

FREEZING WEATHER PROTECTION

1. GAS AIR CONDITIONER

The Gas Air Conditioner has built-in freeze pro

tection sufficient to protect the chiller and pump

plus a small amount of external hard (non-plastic)

pipe as shown in Figure 5.

2. CHILLED WATER PIPES

If hard pipe is used (instead of plastic) for the

chilled water lines, be sure that adequate steps

are taken to prevent these pipes from bursting

when they are subjected to freezing temperatures.

3. BRYANT COIL

If the Bryant coil used with the absorption unit is

subject to freezing it must be protected. Consult

Bryant distributor for recommended procedure to

follow.

PL AS TIC P IP E

AD AP TER

HA RD FI TT IN G-M AX .2 ;

HA RD NI PP LE MA X. L ENG TH 4 "

PL AN VI EW

Figure 5

4. OPERATION AT FREEZING TEMPERATURES

If the air conditioning system is required to operate

under freezing conditions, consult your Bryant

Distributor for special procedures to follow.

-7

EH 451

Page 10

m

cn

PILOT iWITCH

Figure 6 - Unit Wiring Diagram - All Gases

POWER SUPPLY

5826301

i

1 i

115 VOLTS

Page 11

..„.„y

д

СП

Page 12

w

K

■t^

cn

0

o

o

o

Y G R

0

o

¿

MODEL 451

TERMINAL BLOCK

o

FAN

REMOTE

MOTOR

FAN RELAY

1

o

c)

FAN

K

) OJ

LIMIT

cj) c

)

-o o

RELAY

o

TH

TY PI CAL S EL F G EN ER ATI NG F URN AC E CON TR OL

115V

-------

PILOT

Q

P P

r

Page 13

TYPICAL

FURNACE WITH MULTI-SPEED TAPPED BLOWER

11 -

EH 451

Loading...

Loading...