40GRQ / 619FB / 38GRQ / 538FR

High- Wall Ductless Split System

Sizes 09 - 18

Installation Instruction

NOTE: Read the entire instruction manual before starting the installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 2.........................

GENERAL 2.........................................

SYSTEM REQUIREMENTS 2...........................

Piping 2.........................................

DIMENSIONS- INDOOR 4.............................

DIMENSIONS- OUTDOOR 5...........................

CLEARANCES- INDOOR 6............................

CLEARANCES- OUTDOOR 6..........................

INSTALLATION GUIDE 7..............................

INDOOR UNIT INSTALLATION 7.......................

Install Mounting Plate 7.............................

Drill Hole in Wa ll for Interconnecting Piping, Drain

and Wiring 7.....................................

OUTDOOR UNIT INSTALLATION 8.....................

Piping Connections to Outdoor Unit 8.................

INSTALL ALL POWER, INTERCONNECTING WIRING AND

PIPING TO INDOOR UNIT 9...........................

SYSTEM VACUUM AND CHARGE 9....................

START- UP 11........................................

WIRING DIAGRAMS 12...............................

TROUBLESHOOTING 13..............................

The following parts are included in your indoor unit. Please

contact your dealer if any parts are damaged or missing.

Tabl e 1— P art s Li st

Mounting Plate 1

Mounting Hardware 7

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

Parts Qty

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air- conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start- up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and current editions of the National Electrical

Code (NEC) NFPA 70. In Canada, refer to current editions of the

Canadian electrical code CSA 22.1.

!

Recognize safety information. This is the safety- alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.Understand

these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety- alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

a 6 in. (152 mm) vertical rise to the valve connections on

.

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start- up.

GENERAL

These instructions cover the installation, start- up and servicing of

outdoor and indoor units ductless systems.

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit. See Fig. 4 for

minimum required distances between unit and walls or ceilings.

Piping

IMPORTANT: Both refrigerant lines must be insulated

separately.

S Minimum refrigerant line length between the indoor and outdoor

units is 10 ft. (3 m).

S The following maximum lengths are allowed.

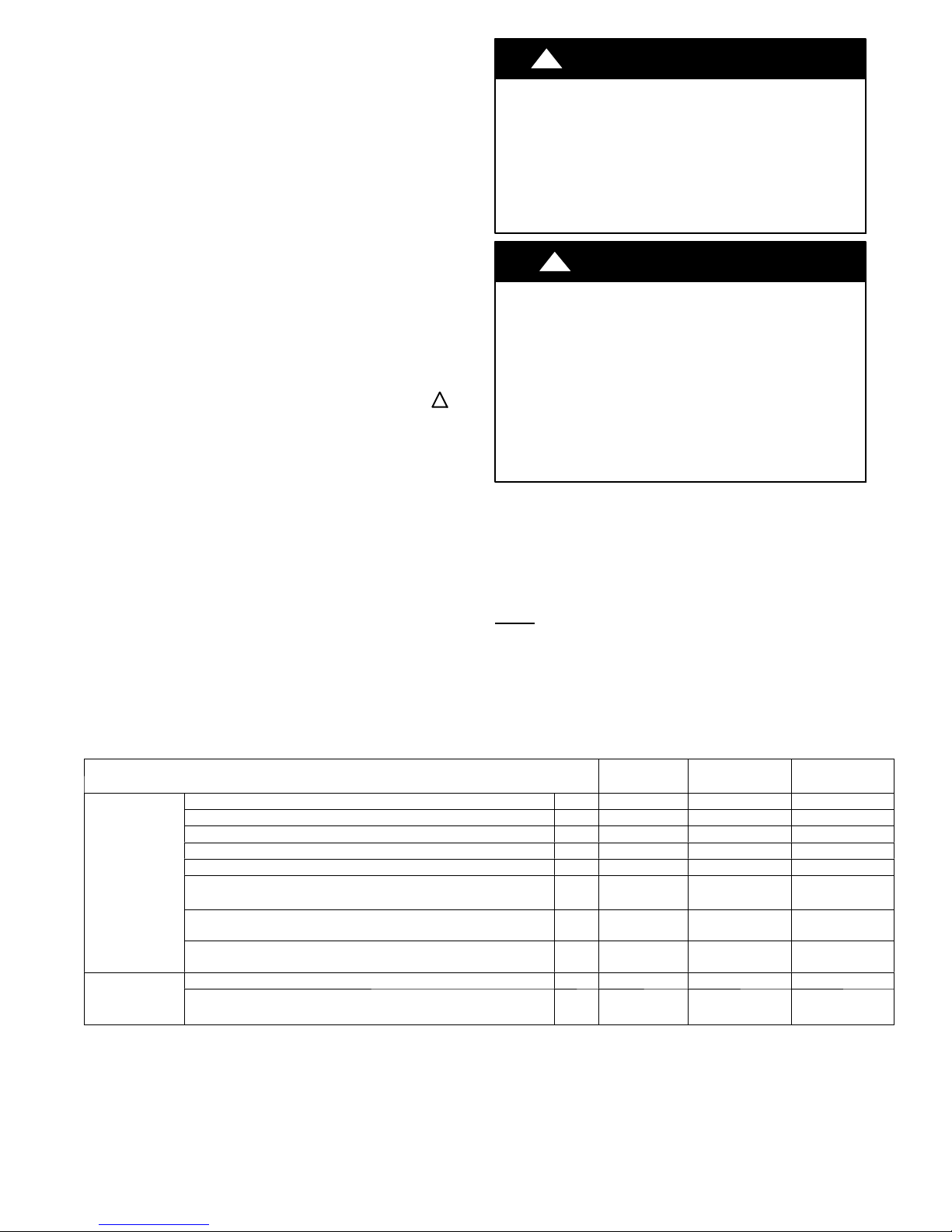

Table 2— Maximum Lengths

System Size

Min. Piping Length ft (m) 10 (3) 10 (3) 10 (3)

Standard Piping Length ft (m) 25 (7.6) 25 (7.6) 25 (7.6)

Max. outdoor- indoor height difference ft (m) 32.8 (9.9) 32.8 (9.9) 32.8 (9.9)

Max. Piping Length with no additional refrigerant charge ft (m) 25 (7.6) 25 (7.6) 25 (7.6)

Max. Piping Length ft (m) 82 (25) 82 (25) 82 (25)

Piping

Refrigerant

* Charge is for piping that runs up to 25 ft. (7.6 m)

** For piping runs greater than 25 ft. (7.6 m), add specified amount of charge per foot of extra piping, up to the allowable length.

*** EXV - Electronic Expansion Device, Capillary tubes are used as metering devices

Additional refrigerant charge (between Standard – Max piping length)

Gas Pipe (size - connection type) in

Liquid Pipe (size - connection type) in

Refrigerant Type R410A R410A R410A

Charge Amount

Oz/ft

(g/M)

Lbs

(kg)

9K

(208- 23 V)

0.2 (18.6) 0.2 (18.6) 0.2 (18.6)

1/4 flare

connection

1/2 flare

connection

3.1 (1.4) 3.1 (1.4) 3.1 (1.4)

12K

(208- 230 V)

1/4 flare

connection

1/2 flare

connection

18K

(208- 230 V)

1/4 flare

connection

5/8 flare

connection

2

All wires must be sized per NEC (National Electrical Code) or

CEC (Canadian Electrical Code) and local codes. Use Electrical

Data table MCA (minimum circuit amps) and MOCP (maximum

over current protection) to correctly size the wires and the

disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300 volt

rating and 2/64- -inch thick insulation must be used. The use of

BX cable is not recommended.

Recommended Connection Method for Power

Communication Wiring - Power and Communication W

and

iring:

The main power is supplied to the outdoor unit. The field supplied

14/3 power/communication wiring from the outdoor unit to indoor

unit consists of four (4) wires and provides the power for the

indoor unit. Two wires are high voltage AC power, one is

communication wiring and the other is a ground wire.

Recommended Connection Method for Power

Communication Wiring (To minimize communication

interfer

ence)

and

wiring

Power Wiring:

The main power is supplied to the outdoor unit. The field supplied

power wiring from the outdoor unit to indoor unit consists of three

(3) wires and provides the power for the indoor unit. Two wires are

high voltage AC power and one is a ground wire.

To minimize voltage drop, the factory recommended wire size is

14/2 stranded with a ground.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64- inch thick insulation, must be used as the

communication wire from the outdoor unit to the indoor unit.

Please use a separate shielded 16GA stranded control wire.

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Be sure to comply with local codes while running wire

from indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction.

A fire hazard may also exist. Therefore, be sure all

wiring is tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting means must be provided and shall be

located within sight and readily accessible from the air

conditioner.

S Connecting cable with conduit shall be routed through

hole in the conduit panel.

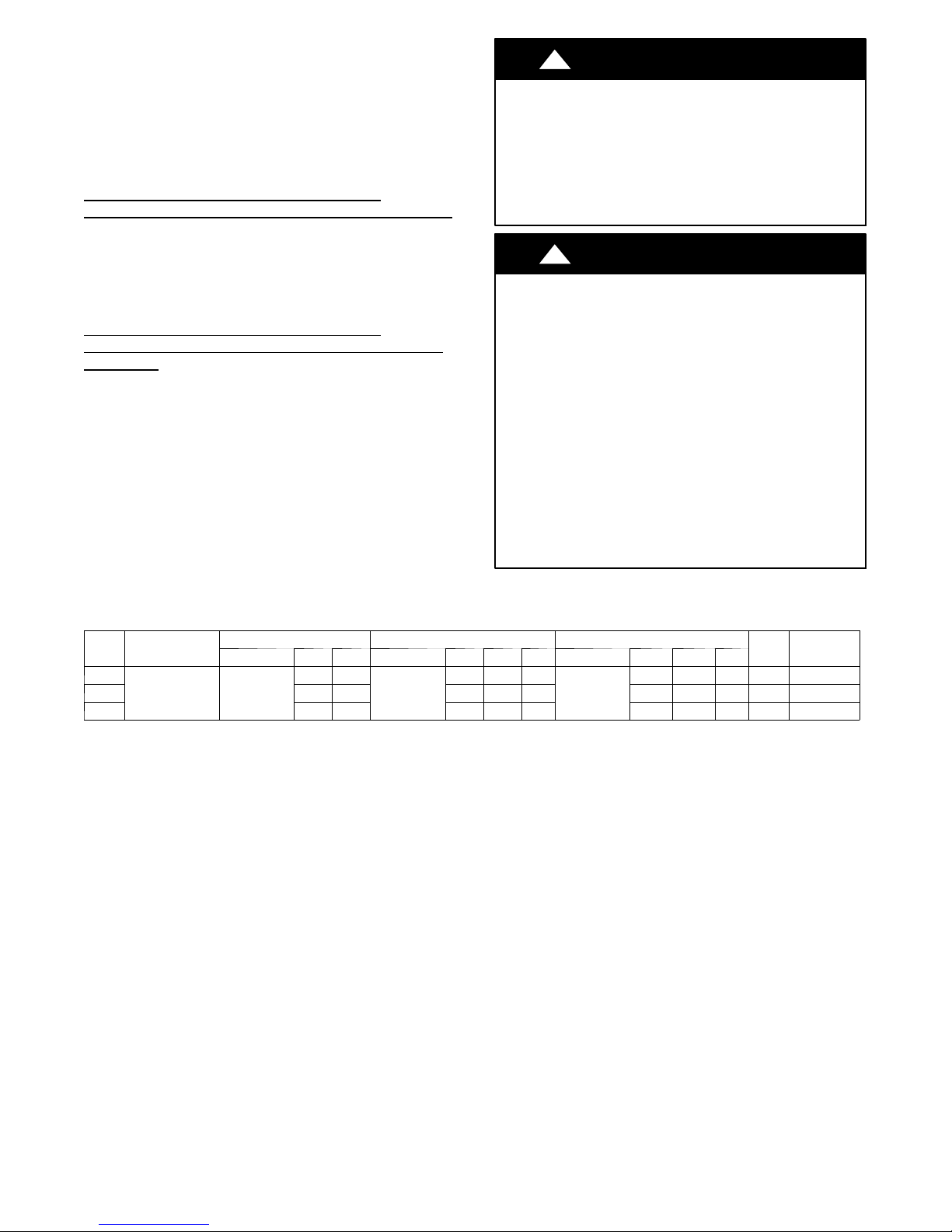

Table 3—Electrical Data

UNIT

OPERVOLTAGE-

SIZE

9K

12K 9.5 40 0.37 0.04 30 0.1 0.027 20 13 20

18K 14.5 30 0.48 0.12 90 0.1 0.027 20 19 30

MAX / MIN*

253 / 187 208-230/1/60

COMPRESSOR OUTDOOR FAN INDOOR FAN

V/PH/HZ RLA LRA V/PH/HZ FLA HP W V/PH/HZ FLA HP W

8.5 35

208-230/1/60

0.37 0.04 30

0.1 0.027 20 12 15

208-230/1/60

MCA

MAX FUSE

CB AMP

3

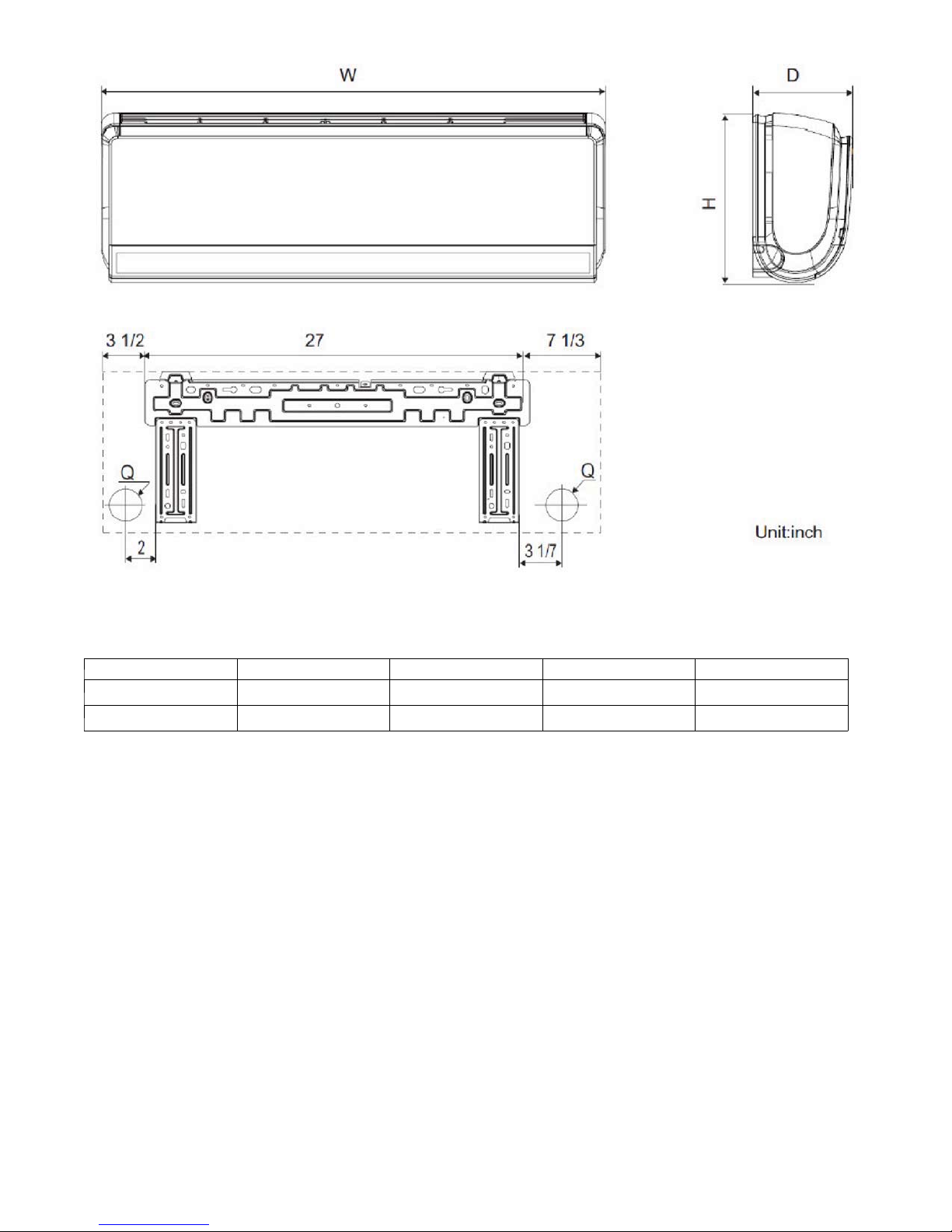

DIMENSIONS - INDOOR

Fig. 1 - Indoor Unit Dimensions

Table 4—Indoor Unit Dimensions

Model

09/12K 37 4/5 12 3/5 8

18K 37 4/5 12 3/5 8

W H D Q

21/6

23/4

4

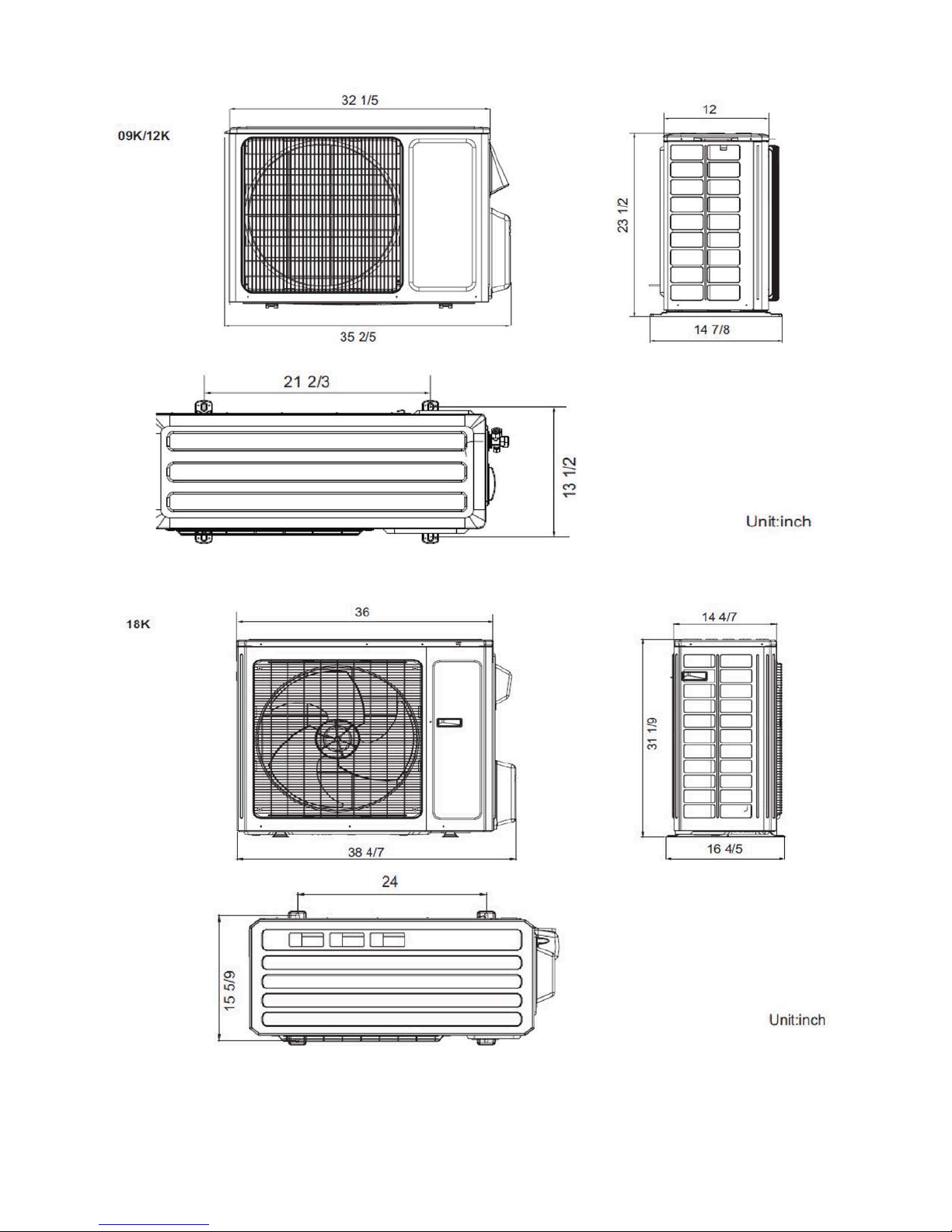

DIMENSIONS - OUTDOOR

Fig. 2 - Outdoor Unit (Sizes 9 and 12)

Fig. 3 - Outdoor Unit (Size 18)

5

CLEARANCES - INDOOR

"

5

(0.13m)

min.

CEILING

6" (0.15m) min.

(1.8m)

6'

FLOOR

Fig. 4 - Indoor Unit Clearances

5

"

(0.13m)

min.

CLEARANCES - OUTDOOR

A

D

UNIT

A 24 (609)

B 24 (609)

C 24 (609)

D 4 (101)

E 4 (101)

B

Fig. 5 - Outdoor Unit Clearances

Table 5—Outdoor Clearances

Air-inlet

E

C

Air-outlet

Minimum Value in. (mm)

6

INSTALLATION GUIDE

Ideal installation locations include:

Indoor

Unit

S A location where there are no obstacles near inlet and outlet area.

S A location which can bear the weight of indoor unit.

S Do not install indoor units near a direct source of heat such as

direct sunlight or a heating appliance.

S A location which provides appropriate clearances as outlined in

Fig. 4. Be sure to leave enough distance to allow access for

routine maintenance. The installation site should be 72” or more

above the floor.

S Select a place away from potential electronic interference.

S Select a place where the filter can be easily removed.

Outdoor

Unit

S A location which is convenient to installation and not exposed to

strong wind.

S A location which can bear the weight of outdoor unit and where

the outdoor unit can be mounted in a level position.

S A location which provides appropriate clearances as outlined in

Fig. 4.

S Do not install the indoor or outdoor units in a location with

special environmental conditions.

S Make sure the outdoor unit is installed in accordance with the

installation instructions and is convenient for maintenance and

repair.

S See the refrigerant piping table for the maximum height

difference between indoor and outdoor units and the maximum

length of the connecting tubing.

INDOOR UNIT INSTALLATION

INSTALL MOUNTING PLATE

1. Carefully remove the mounting plate from the unit box.

2. The mounting plate should be located horizontally and level

on the wall. All minimum spacings shown in Fig. 6.

3. If the wall is block, brick, concrete or similar material, drill

.2” (5 mm) diameter holes and insert anchors for the

appropriate mounting screws.

4. Attach the mounting plate to the wall.

DRILL HOLE IN W ALL FOR INTERCONNECTING

PIPING, DRAIN AND WIRING

Refrigerant Line Routing

The refrigerant lines may be routed in any of the four directions

showninFig.8.

For maximum serviceability, it is recommended to have refrigerant

line flare connections and the drain connection on the outside of

the wall that the fan coil is mounted on.

rear left.

rear left

right

rear right

left

A12585

Fig. 8 - Refrigerant Line Routing

Fig. 9 - Refrigerant Line Routing

If piping is going through the back:

1. Determine pipe hole position using the mounting plate as a

template. Drill pipe hole diameter per chart below. The

outside pipe hole is 1/2- in. (13 mm) min. lower than inside

pipe hole, so it slants slightly downward.

If piping is going to exit from the left rear, it is

recommended to field- fabricate piping extensions to get the

flare connections to the outside of the wall.

Fig. 6 - 09 and 12K Mounting Plate Spacing

Wall

6 in.

See Hole

Size Tables

(Rear piping hole)

Mark middle

Level

(Rear piping hole)

Fig. 7 - 18K Mounting Plate Spacing

6 in.

See Hole

Size Tables

Wall

1/2 in. (13 mm)

Min.

INDOOR

OUTDOOR

A07371

Fig. 10 - Drill Holes

Table6—HoleDiameter

Model Size

9k, 12k and 18k 2.2 (56)

Hole Diameter

in. (mm)

If piping is going through the right or left side:

1. Use a small saw blade to carefully remove the

corresponding plastic covering on side panel and drill the

appropriate size hole where the pipe is going through the

wall. See Fig. 16.

2. Remove knockout (see Fig. 8).

NOTE: If required, a condensate pump is available for the

application.

7

OUTDOOR UNIT INSTALLATION

1. Use a rigid base to support unit in a level position.

2. Locate outdoor unit and connect piping and wiring.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Excessive torque can break flare nut depending on

installation conditions.

Piping Connections to Outdoor

IMPORTANT: Use refrigeration grade tubing ONL Y. No other

type of tubing may be used. Use of other types of tubing will

void manufacturer’s warranty.

Make sure there is enough piping to cover the required length

between the outdoor and indoor unit.

Only use piping suitable for high side pressure for both high

side and low side connections.

Piping Guide:

S Do not open service valves or remove protective caps from

tubing ends until all the connections are made.

S Bend tubing with bending tools to avoid kinks and flat spots.

S Keep the tubing free of dirt, sand, moisture, and other

contaminants to avoid damaging the refrigerant system.

S Avoid sags in the suction line to prevent the formation of oil

traps. Insulate each tube with minimum 3/8- in. (10 mm) wall

thermal pipe insulation. Inserting the tubing into the insulation

before making the connections saves time and improves

installation quality.

1. Remove service valve cover if provided with unit.

2. Cut tubing with tubing cutter.

3. Install correct size flare nut onto tubing and make flare

connection.

4. Apply a small amount of refrigerant oil to the flare

connection on the tubing.

5. Properly align tubing in with service valve.

6. Tighten flare nut and finish installation using two wrenches

as shown in Fig. 11.

CAUTION

Unit

A07354

Fig. 11 - Tighten Flare Nut

Outdoor Unit Wiring

1. Mount outdoor power disconnect.

2. Run power wiring from main box to disconnect per NEC

and local codes. Set outdoor unit in place.

3. Remove field wiring cover from unit by removing screws.

4. Connect conduit to the conduit panel. (See Fig. 13)

5. Properly connect both power supply and control lines to

terminal block per the connection diagram.

6. Ground unit in accordance with NEC and local electrical

codes.

7. Use lock nuts to secure conduit.

8. Reinstall field wiring cover.

lock nut

conduit

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Be sure to comply with local codes while running wire

from indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction.

A fire hazard may also exist. Therefore, be sure all wiring

is tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting means must be provided and shall be

located within sight and readily accessible from the air

conditioner.

S Connecting cable with conduit shall be routed through

hole in the conduit panel.

Connections

Field Wiring Cover

Conduit Panel

Finish

Fig. 13 - Field Wiring

CAUTION

A12539

Strong

wind

Fig. 12 - High Wind Installation

A07350

8

INSTALL ALL POWER, INTERCONNECTING

WIRING, AND PIPING TO INDOOR UNIT

1. Run interconnecting piping and wiring from outdoor unit to

indoor unit.

2. Pass interconnecting cable through hole in wall (outside to

inside).

3. Lift indoor unit into position and route piping and drain

through hole in wall (inside to outside). Fit interconnecting

wiring into back side of indoor unit.

4. Hang indoor unit on upper hooks of wall mounting plate (as

shown in Fig. 14 and Fig. 17).

Fig. 14 - Hanging Indoor Unit

A08283

Fig. 16 - Remove Knockouts

Fixing hook

Mounting

plate

Fig. 17 - Hang Indoor Unit

!

CAUTION

Mounting

plate

A12408

5. Open front cover of indoor unit and remove field wiring terminal block cover (see Fig. 15).

Field Wiring

Cover

Interconnecting

Cable

A08279

Fig. 15 - Field Wiring Cover

6. Pull interconnecting wire up from back of indoor unit and

position in close to the terminal block on indoor unit.

7. Push bottom of indoor unit onto mounting plate to

complete wall mount.

8. Connect wiring from outdoor unit per connection diagram

(see Fig. 23).

NOTE: Polarity of power wires must match original

connection on outdoor unit.

9. Replace field wiring cover and close front cover of indoor

unit.

10. Connect refrigerant piping and drain line outside of indoor

unit. Refer to Fig. 11 for proper installation of flare

connections. Complete pipe insulation at flare connection

then fasten piping and wiring to the wall as required.

Completely seal the hole in the wall.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

SYSTEM VACUUM AND CHARGE

Using Vacuum Pump

1. Completely tighten flare nuts A, B, C, D, connect manifold

gage charge hose to a charge port of the low side service

valve. (See Fig. 18.)

2. Connect charge hose to vacuum pump.

3. Fully open the low side of manifold gage. (See Fig. 19)

4. Start vacuum pump

5. Evacuate using either deep vacuum or triple evacuation

method.

6. After evacuation is complete, fully close the low side of

manifold gage and stop operation of vacuum pump.

7. The factory charge contained in the outdoor unit is good for

up to 25 ft. (8 m) of line length. For refrigerant lines longer

than 25 ft (8 m), add 0.2 oz. per foot of extra piping up to

the maximum allowable length.

8. Disconnect charge hose from charge connection of the low

side service valve.

9. Fully open service valves B and A.

10. Securely tighten caps of service valves.

9

Outdoor Unit

t

Service Valve

Refrigerant

Low Side

A

High Side

B

Indoor Uni

C

D

A07360

Fig. 18 - Service Valve

Manifold Gage

500 microns

Low side valve

Charge hose

Low side valve

High side valve

Charge hose

Vacuum pump

A07361

Fig. 19 - Manifold

Deep Vacuum

Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water. (See Fig. 20)

5000

4500

4000

3500

3000

LEAK IN

SYSTEM

2500

2000

MICRONS

1500

1000

500

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

Triple Evacuation

Method

The triple evacuation method should only be used when vacuum

pump is only capable of pumping down to 28 in. of mercury

vacuum and system does not contain any liquid water.

Refer to Fig. 21 and proceed as follows:

1. Pump system down to 28 in. of mercury and allow pump to

continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr.

During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 21. The system is

then free of any contaminants and water vapor.

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

RELEASE CHARGE INTO SYSTEM

A95425

Fig. 21 - Triple Evacuation Method

Final Tubing

Check

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes are

not rubbing against each other or any sheet metal. Pay close

attention to feeder tubes, making sure wire ties on feeder tubes are

secure and tight.

01234567

MINUTES

Fig. 20 - Deep Vacuum Graph

A95424

10

START- UP

Tes t Operation

Perform test operation after completing gas leak and electrical

safety check.

1. Push the “ON/OFF” button on Remote Control to begin

testing.

NOTE: A protection feature prevents the air conditioner from

being activated for approximately 3 minutes.

2. Push MODE button, select COOLING, HEATING, FAN

mode to check if all functions work correctly.

SYSTEM CHECKS

1. Conceal the tubing where possible.

2. Make sure that the drain tube slopes downward along its entire length.

3. Ensure all tubing and connections are properly insulated.

4. Fasten tubes to the outside wall, when possible.

5. Seal the hole through which the cables and tubing pass.

INDOOR UNIT

1. Do all Remote Control buttons function properly?

2. Do the display panel lights work properly?

3. Does the air deflection louver function properly?

4. Does the drain work?

OUTDOOR UNIT

1. Are there unusual noises or vibrations during operation?

Explain Following Items To Customer With The Aid Of The

Owner’s Manual:

1. How to turn air conditioner on and off; selecting

COOLING, HEATING and other operating modes; setting

a desired temperature; setting the timer to automatically start

and stop air conditioner operation; and all other features of

the Remote Control and display panel.

2. How to remove and clean the air filter.

3. How to set air deflection louver.

4. Explain care and maintenance.

5. Present the Owner’s Manual and installation instructions to

customer.

INSTALLATION AND MAINTENANCE OF FILTER

1. Grasp the front panel by its two ends and lift the panel and

then remove the air filter.

2. Install a clean air filter along the arrow direction and close

the panel.

Air filter

Auxiliary filter

A12541

Fig. 22 - Install Air Filter

11

Outdoor

Unit

Terminal

Block

Power to

Indoor Uni t

Power to

Indoor Unit

Main Pow er

Supply

208/230-1-60 208/230-1-60

Control to

Indoor Uni t

Control to

Indoor Unit

Power to

Indoor Uni t

Power to Indoor

Unit

Main Pow er Supply

Main Power Supply

WIRING DIAGRAMS

09 &12 208/230-1-60 Connection Diagram

CONNECTING CABLE

OUTDOOR TO INDOOR

CAUTION

Attention

Use Copper Conductors Only

WithMinimum 300 Volt,2/64"

Thick Insulation.

Utilisezseulementdes

conducteur s e n cuivre d'un

minimum de 300 volt d'une

isola tion d' è paiss eur de 2/64 ".

DNG1L2L

Ground

Fig. 23 - 09K & 12K Unit Wiring Diagrams

208/230-1-60 Connection Diagram

CONNECTING

CABLE OUTDOOR

TO INDOOR

CAUTION

CAUTION

Atte nti on

Atte nti on

Use Copper Conductors Only

Use Copper Conductors Only

WithMinimum 300 Volt,2/64"

WithMinimum 300 Volt,2/64"

Thick Ins ulation.

Main Power

Supply

Thick Ins ulation.

Utilisez s euleme nt des

Utilisez s euleme nt des

conducteurs en cuivre d'un

conducteurs en cuivre d'un

minimum de 300 voltd'une

minimum de 300 voltd'une

isolation d' èpaiss eur de 2/64 ".

isolation d' èpaiss eur de 2/64 ".

Power from

Outdoor

Unit

Control from

Outdoor

Unit

Power from

Outdoor

Unit

'1LS'2LDNG'1LS'2L

Power from

Outdoor

Unit

Control from

Outdoor

Unit

06-1-032/802CDVwoL06-1-032/802CDVwoL

dnuorGdnuorG

'1LS'2LDNG2L1L'1LS'2L

Power from

Outdoor

Unit

Indoor

Unit

Terminal

Block

dnuorGdnuorG

06-1-032/802CDVwoL06-1-032/80206-1-032/80206-1-032/80206-1-032/802CDVwoL06-1-032/802

Fig. 24 - 18K Unit Wiring Diagrams

NOTE: Polarity of power wires must match original connection on outdoor unit.

kcolBlanimreTtinUroodnI81eziSkcolBlanimreTtinUroodtuO81eziS

12

TROUBLESHOOTING

This unit has on- board diagnostics. Error codes appear on the LED display on the front panel of the indoor unit in place of the temperature

display. Error codes are also displayed on the outdoor unit microprocessor board with colored LED lights. The table below explains the error

codes for both units.

Table 7—Diagnostic Codes

Display table for error status

Error name Error definition Error code display

Freon recovery mode Operation status is displayed immediately Fo

Malfunction of indoor fan Malfunction of hardware H6

Malfunction of middle temperature sensor of indoor evaporator Malfunction of hardware F2

Malfunction of indoor ambient temperature sensor Malfunction of hardware F1

Communication malfunction between indoor unit and outdoor unit Malfunction of hardware E6

Malfunction of jumper cap Malfunction of hardware C5

Limit/decrease frequency due to module current protection Display through adjustment with remote controller En

Limit/decrease frequency due to module temperature protection Display through adjustment with remote controller EU

Limit/decrease frequency due to overload protection Display through adjustment with remote controller F6

Limit/decrease frequency due to freeze prevention protection Display through adjustment with remote controller FH

Limit/decrease frequency due to discharge protection Display through adjustment with remote controller F9

Limit/decrease frequency due to AC current protection of outdoor unit Display through adjustment with remote controller F8

Malfunction overload temperature sensor Malfunction of hardware FE

Malfunction of outdoor discharge temperature Malfunction of hardware F5

Malfunction of outdoor ambient temperature sensor Malfunction of hardware F3

Malfunction of outdoor condenser temperature sensor Malfunction of hardware F4

Circuit malfunction of module temperature sensor Malfunction of hardware P7

Overload protection of compressor Other malfunction H3

Discharge protection Other malfunction E4

Overload protection Other malfunction E8

AC current protection of outdoor unit Other malfunction E5

Module current protection Other malfunction H5

Module temperature protection Other malfunction P8

Freeze prevention protection Other malfunction E2

High power protection Other malfunction L9

Lacking/inverse phase protection of compressor Other malfunction U2

PFC current malfunction Other malfunction HC

High DC bus bar voltage protection Other malfunction PH

Low DC bus bar voltage protection Other malfunction PL

Freon-lacking protection Other malfunction FO

Mode shock Malfunction of hardware E7

Non-matching between indoor unit and outdoor unit Malfunctionof hardware LP

Read-write malfunction of memory chip Malfunction of hardware EE

Abnormal changeover for 4-way valve Malfunction of hardware U7

Malfunction of outdoor fan 2 Malfunction of hardware LA

Malfunction of outdoor fan 1 Malfunction of hardware L3

Low pressure protection Other malfunction E3

High pressure protection Other malfunction E1

Drop malfunction of DC bus bar voltage Other malfunction U3

Current detection malfunction for the complete unit Malfunction of hardware U5

Charing malfunction for capacity Malfunction of hardware PU

Phase current detection malfunction of compressor Malfunction of hardware U1

De synchronizingof compressor Other malfunction H7

Demagnetizing protection of compressor Other malfunction HE

Failure start up of compressor Other malfunction Lc

High peak current of compressor Other malfunction P5

Conglutination malfunction of relay of refrigerant electric heater of OU Malfunction of hardware A2

Refrigerator heater of outdoor unit is invalid Display through adjustment with remote controller A3

Malfunction of temperature sensor of refrigerant heater Malfunction of hardware A4

Malfunction exit tube temperature sensor for condenser Malfunction of hardware A5

Oil return Display through adjustment with remote controller F7

Nominal cooling and heating (capacity test code) Operation status is displayed immediately P1

Maximum cooling and heating (capacity test code) Operation status is displayed immediately P2

Medium cooling and heating (capacity test code) Operation status is displayed immediately P3

Minimum cooling and heating (capacity test code) Operation status is displayed immediately PO

13

Copyright 2015 CAC/BDP. S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Edition Date: 06/15

Catalog No:GRQ- 619FB - 01SI

Replaces: NEW

14

Loading...

Loading...