Page 1

4-WAY MULTIPOISE

FIXED-CAPACITY

CONDENSING GAS FURNACE

combustion. The extracted heat lowers the temperature of the

combustion products to a point (typically below 115°F) that any

of the approved types of pipe can also be used for venting

combustion products outside the structure. The combustion-air

and vent pipes can terminate through a side wall or through the

roof when using 1 of our approved vent termination kits.

Flow-Through Secondary Heat Exchangers —Each cell is

laminated with our patented Everlastic

greater resistance to corrosion. This breakthrough in heating

technology helps extend the life of the furnace for years of

dependable performance. The heat exchanger is positioned in

the furnace to extract additional heat from the combustion

products regardless of furnace orientation.

Perfect Light™ Igniter —Bryant’s unique SiN igniter is not only

physically robust but it is also electrically robust. It is capable of

running at line voltage and does not require complex voltage

regulators as do other brands. This unique feature further

enhances the reliability of 340AAV gas furnace and continues

Bryant’s tradition of technology leadership and innovation in

providing a reliable and durable product.

340AAV

Sizes 040 thru 140

TM

polypropylene for

A05086

The model 340AAV Multipoise Condensing Furnace is specifically designed to meet the needs of the new construction

market. This high-efficiency furnace utilizes a unique 4-way

multipoise design and compact size to fit where other furnaces will not. The model 340AAV can be installed in any of 4

positions including horizontally in attics or crawlspaces, freeing space formerly used as a utility or furnace room. Except

for the 140 size, all sizes of the model 340AAV can be

installed in a manufactured (mobile) home when the optional

kit is used. With the exception of the 180 size, all sizes can be

installed with 2-pipe or 1-pipe venting. The 140 size can be

insalled only as a 2-pipe system. Sidewall or through-the-roof

venting options and the use of PVC pipe eliminate the need

for dedicated chimneys or chaseways to facilitate furnace

venting. Time-saving installation features yield a very cost

effective way to provide new home buyers with a high-efficiency and high-quality home comfort system.

FEATURES

3-Pass Primary Heat Exchangers —This design accelerates

heat transfer and extracts heat that conventional heat exchangers waste up the flue. The primary heat exchanger is made of

aluminized steel for corrosion resistance.

Combustion Air and Ventilation —The 340AAV advanced

design allows Schedule 40PVC, PVC-DWV, SDR-21 PVC,

SDR-26 PVC (not approved in Canada), ABS-DWV, or ABSF628 Schedule 40 pipe to bring outdoor air into the furnace for

Warranty —Limited Lifetime Warranty on the heat exchangers

for the lifetime of original owner in single family residence; 20

years in other residential and commercial applications. 5 year

Limited Warranty on entire unit.

Control Center —The printed-circuit board and all internal wir-

ing are factory installed. Convenient terminals permit quickconnection of a thermostat and air conditioning control circuits.

Connections for a humidifier and air cleaner are also provided.

4-Way Multipoise Design —Allows a model 340AAV to be

installed in an upflow, downflow, or horizontal orientation.

The model 340AAV is available in 12 heat/airflow combinations,

and when combined with the 4-way design, allows for 48 different

applications. Factory configured for upflow application, this furnace

can easily be made ready for downflow or horizontal installations.

Direct or Non-direct Venting —The 340AAV can be installed

as a 1 pipe/Non-Direct vent or 2 pipe/Direct vent furnace

except the 140 size which can be installed as 2-pipe only. This

provides added flexibility to meet diverse installation needs.

Insulated Casing —Foil-faced insulation in the heat exchanger

section cuts heat loss. The casing also has the required openings for left- or right-side connection of gas, electric, drain, and

vent connections.

Certifications —The 340AAV units are CSA (A.G.A./C.G.A.)

design certified for use with natural and propane gases, as well

as GAMA efficiency rating certified. The furnace is factoryshipped for use with natural gas. A CSA (A.G.A./C.G.A.) listed

gas conversion kit is required to convert furnace for use with

propane gas. The model 340AAV meets California Air Quality

Management District emission requirements. Except for the

140 size unit, all 340AAV models can be installed in a manufactured (mobile) home when the optional kit is used, and in

elevations up to 10,000 ft (140 size unit limitation of 7,000 ft).

Quality Registration —The 340AAV is engineered and manu-

factured under an ISO 9001 registered quality system.

Catalog No. PDS 340A.40.1

Page 2

"

8

⁄

"

16

"

16

⁄

13

⁄

5

"

8

⁄

5

7

39

1"

"

"

16

⁄

16

⁄

7

11

"

16

⁄

5

19"

"

22

4

⁄

1

"

16

⁄

26

15

"

2

⁄

26

1

OUTLET

2-IN. COMBUSTION-

AIR CONN

1

⁄2-IN. DIA

GAS CONN

7

⁄8-IN. DIA

POWER CONN

1

⁄2-IN. DIA

THERMOSTAT ENTRY

28

"

16

⁄

9

TYP

1

(DOWNFLOW &

OR ALTERNATE

TRAP LOCATION

"

16

/

13

A

D

"

16

/

13

OUTLET

AIRFLOW

HORIZONTAL RIGHT)

CONDENSATE DRAIN

-IN. DIA GAS CONN

2

⁄

1

"

4

⁄

1

TYP

33

"

8

⁄

5

TYP

32

"

16

⁄

13

30

2-IN. VENT CONN

"

2

⁄

30

11

"

16

⁄

11

22

SIDE INLET

1

" TYP

4

⁄

22

"

16

⁄

3

24

BOTTOM INLET

"

4

⁄

1

18

HANGING

(UPFLOW)

CONDENSAT E

DRAIN LOCATION

FOR HORIZONTAL

DIMPLE LOCATORS

"

16

/

11

-in. rectangle.

-in. rectangle.

/ 2

/ 4

1

1

x 19

x 23

x 12-in. rectangle.

/ 2

/ 2

1

1

/ 2

1

INLET

11

E

"

16

/

DIMENSIONS (In.)

"

16

⁄

TYP

29

"

8

⁄

5

27

"

16

⁄

9

TYP

"

27

2

⁄

1

24

"

16

⁄

5

17

see flex duct manufacturerís recommendations for equivalent diameters.

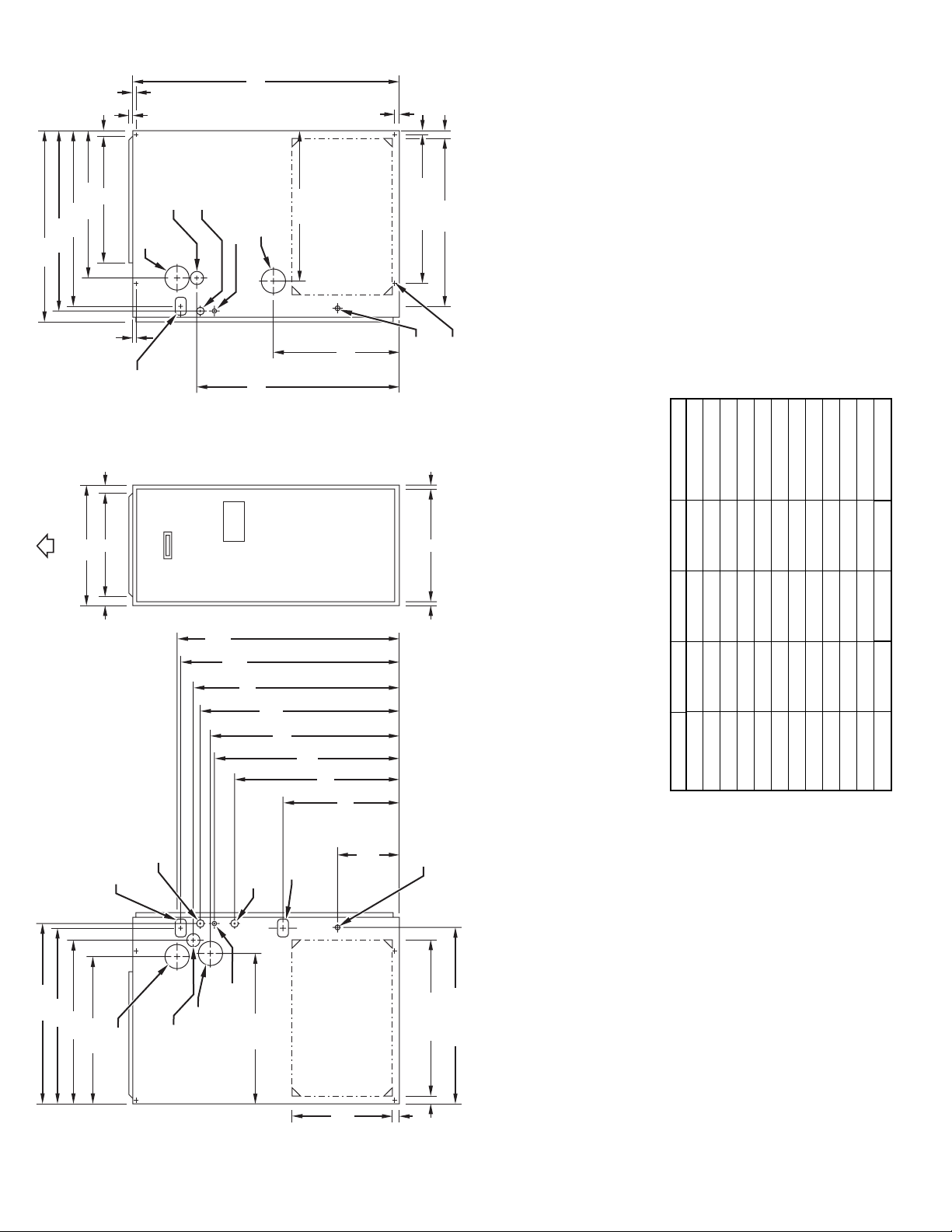

a.For 800 CFM–16-in. round or 14

2. Minimum return-air opening at furnace:

b. For 1200 CFM–20-in. round or 14

c. For 1600 CFM–22-in. round or 14

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data

literature for specific use of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only will ensure adequate

return air openings for airflow requirements above 1800 CFM at 0.5” W.C. ESP.

024040 17-1/2 15-7/8 16 165

036040 17-1/2 15-7/8 16 166

024060 17-1/2 15-7/8 16 172

UNIT SIZE A D E SHIP. WEIGHT (Lb)

036060 17-1/2 15-7/8 16 174

048060 17-1/2 15-7/8 16 174

036080 17-1/2 15-7/8 16 188

048080 17-1/2 15-7/8 16 194

060080 21 19-3/8 19-1/2 206

048100 21 19-3/8 19-1/2 219

060100 21 19-3/8 19-1/2 221

060120 24-1/2 22-7/8 23 250

060140 24-1/2 22-7/8 23 250

A05070

"

16

(ALTERNATE

UPFLOW)

⁄

7

9

SIDE INLET

"

2

⁄

1

TYP

14

TYP

"

4

⁄

1

1

CONDENSAT E

DRAIN LOCATION

" TYP

4

⁄

1

23

SIDE INLET

1"

(UPFLOW)

" TYP

16

⁄

15

NOTES: 1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

26

⁄8-IN. DIA

7

POWER CONN

CONDENSAT E

DRAIN TRAP

CONDENSATE DRAIN

TRAP LOCATION

(DOWNFLOW &

HORIZONTAL LEFT)

"

16

⁄

"

15

4

⁄

1

"

26

2

⁄

1

26

"

16

⁄

24

5

22

⁄2-IN. DIA

2-IN. COMBUSTION-

AIR CONN

1

GAS CONN

2-IN. VENT CONN

⁄8-IN. DIA

7

ACCESSORY

ENTRY

"

16

⁄

11

22

⁄2-IN. DIA THERMOSTAT

1

LOCATION

POWER ENTRY

—2—

Page 3

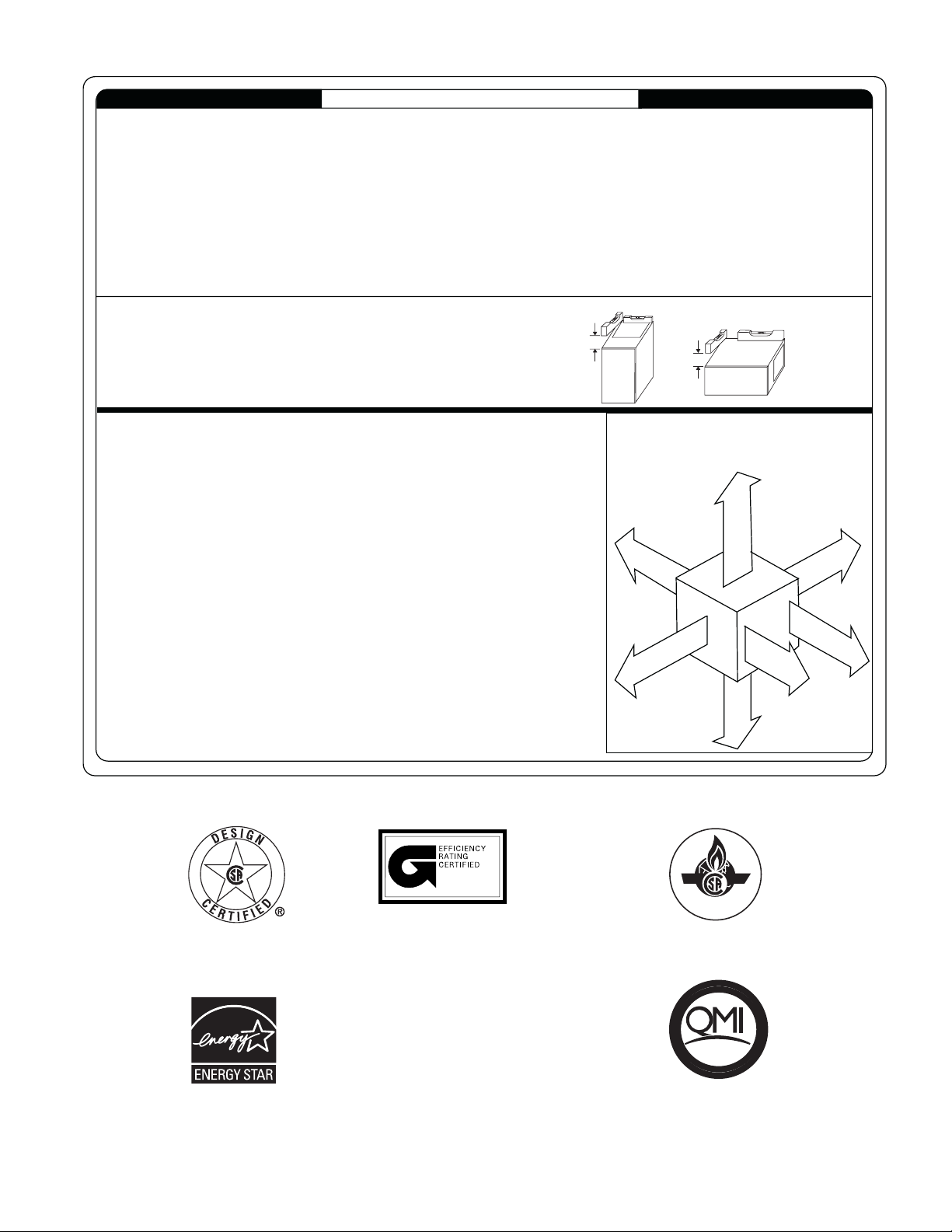

CLEARANCE TO COMBUSTIBLES

This forced air furnace is equipped for use with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m), except 140 si ze Furnaces are only approved for altitudes 0 - 7,000 ft. (0 - 2,135m).

INSTALLATION

An accessory kit, supplied by the manuf acturer, shall be used to convert to propane gas use or may be required for some natural gas appli cations.

This furnace i s for i ndoor inst allati on in a buildi ng constr ucted on si te. Thi s furnace may be i nstalled in a manuf actured (mob ile) home when stated on rating plate and using factory

authorized kit.

This furnace may be ins talled on combustibl e flooring i n alcove or closet at minimum clearanc e from combust ible material .

This appliance requires a special venting system. Refer t o the install ation i nstructions for parts l ist and method of instal lation. This f urnace is for use wi th schedul e-40 PVC, PVC-DWV,

CPVC, or ABS-DWV pipe, and must not be vented in common wit h other gas-fired appli ances. Construction through which vent/ air i ntake pipes may be installed is maximum 24 inches

(600 mm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

Cette fournaise à air pulsé est équipée pour utilisation avec gaz naturel et altitudes comprises entre 0 - 3,050m

(0-10,000 pi), excepté queles fournaises de 140 taille sont pour altitudes comprises entre 0 - 2,135m (0 - 7,000 pi).

Utiliser une trousse de conversion, f ournie par le fabr icant, pour pas ser au gaz propane ou pour ce rtaines installat ions au gaz naturel.

Cette fournaise à air pulsé est pour installation à l´intérieur dans un bâti ment construit sur place. Cette fournaise à air pulsé peut êt re inst allée dans une maison préfabriquée

(maison mobile) si prescrit par la plaque signalétique et si l´on utilise une trousse specifiée par le fabricant.

Cette fournaise peut être installée sur un plancher combustible dans un enfoncement ou un placard en observant les dégagements minimums avec les matériaux combustibles.

Cet appareil nécessite un système d´évacuation spécial. La méthode d´installation et la liste des pièces nécessaires figurent dans les instructions d´installation.Cette fournaise doit

s´utiliser avec la tuyauterie des nomenclatures 40 PVC, PVC-DWV, CPVC, ou ABS-DWV et elle ne peut pas être ventilée conjointm ent avec d´autres appareils à gaz. Épaisseur de la

constr uction au travers de laque lle il est poss ible de fair e passer l es tuyaux d´aération (admi ssion/évacuat ion): 24 po (600 mm) maximum, 3/4 po (19 mm) mi ni mum (y compri s la toit ure).

For upflow and downflow applications, furnace must be installed level, or pitched within 1/2"

of level. For a horizontal application, the furnace must be pitched minimum 1/4" to

maximum of 1/2" forward for proper drainage. See Installation Manual for IMPORTANT unit

support details on horizontal applications.

Pour des applications de flux ascendant et descendant, la fournaise doit être installée de

niveau ou inclinée à pas plus de 1/2" du niveau. Pour une application horizontale, la

fournaise doit être inclinée entre minimum 1/4" et maximum 1/2" du niveau pour le drainage

approprié. En cas d'installation en position horizontale, consulter les renseignements

IMPORTANTS sur le support dans le manuel d'installation.

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSITIONS:

Minimum front clearance for service 30 inches (762mm).

*

†

†

140 size furnaces require 1 inch back clearance to combustible materi als.

R

DOWNFLOW POSITIONS:

For installation on combustible floors only when installed on special base No. KGASB0201ALL, Coil

†

Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

HORIZONTAL POSITIONS:

Line contact is permissi bl e only between lines formed by int ersections of top and t wo sides of furnace

jacket, and building joists, studs, or framing.

Clearance shown is for air inlet and air outlet ends.

§

120 and 140 size furnaces require 1 inch bottom clearance to combustible materials.

Ø

DÉGAGEMENT MINIMUM EN POUCES AVEC ÉLÉMENTS DE CONSTRUCTION COMBUSTIBLES

POUR TOUS LES POSITIONS:

Dégagement avant minimum de 762mm (30 po) pour l´entretien.

*

Pour les fournaises de 140 taille, 1 po (25mm) dégagement des matériaux combustibles est requis

†

†

au-arriere.

POUR LA POSITION COURANT DESCENDANT:

Pour l´instal lation sur le plancher combustible seulement quand on utilise la base spéciale, pièce

†

n° KGASB0201ALL, l´ensemble serpentin, pièce n° CD5 ou CK5, ou le carter de serpentin, pièce

n° KCAKC.

POUR LA POSITION HORIZONTALE:

Le contact n´est permis qúentre les lignes formées par les intersections du dessus et des deuxcôtés de la

chemise de la fournaise, et des solives, des montants ou de la charpente du bátiment.

La distance indiquée concerne l´extrémité du tuyau d´arrivée d´air et l´extrémité du tuyau de sortie d´air.

§

Pour les fournaises de 120 et 140 taille, 1 po (25mm) dégagement des matériaux combustibles est requis

Ø

au-dessous.

324999-201 REV. D (LIT TOP)

LEVEL (0")

TO

1/2" MAX

UPFLOW OR

DOWNFLOW

MIN 1/4"

TO

1/2" MAX

FRONT

This furnace is approved for UPFLOW, DOWNFLOW and

HORIZONTAL i nstall ations.

Cette fournaise est approuvée pour l´installation HORIZONTALE

et la ci rculati on d´air VERS LE HAUT et VERS LE BAS.

Clearance arrows

do not change with

furnace orientat ion.

†

†

0"

B

A

A

C

R

K

R

I

E

R

I

S

O

C

0"

§

Clearance in inches

Dégagement (po).

FRONT

1"

TOP/PLENUM

E

E

D

S

E

T

F

BOTTOM

0"

†

HORIZONTAL

Les fléches de dégagement

ne change pas avec

l´orientation de la

générateur d´air chaud.

I

DESSUS/ CHAMBRE D´AI

N

R

U

R

U

O

F

F

F

A

V

DESSOUS

Ø

S

O

E

C

C

E

A

S

I

A

N

T

N

O

T

R

N

A

V

A

S

E

L

È

N

R

T

O

N

T

A

N

T

3"

Vent clearance to

combustibles 0".

0 (po) Dégagement

d´évent avec combustibles.

D

R

§

0"

E

S

E

T

R

V

I

C

E

E

T

I

E

*

N

30

MIN

As an ENERGY STAR

SM

Partner, Bryant

Heating & Cooling Systems has

determined that this product meets the

ENERGY STAR guidelines for energy

efficiency.

ama

MEETS DOE RESIDENTIAL

CONSERVATION SERVICES

PROGRAM STANDARDS.

Before purchasing this appliance,

read important energy cost and

efficiency information available from

your retailer.

—3—

A02148

CERTIFIED

ISO 9001:2000

REGISTERED

®

REGISTERED QUALITY SYSTEM

These products are engineered and

manufactured under an ISO 9001

registered quality system.

Page 4

Controls—Thermostats and Zoning

Non-Programmable Thermostat Selection

TSTATBBNAC01-C

TSTATBBNHP01-C

TSTATBBN2S01-C

TSTATBBBAC01-B

TSTATBBPRH01-B**

* Model HP and 2S thermostat must be field converted to air conditioner operation.

**Thermidistat Control is versatile and can be configured for multiple use and staging, it must be configured for each specific application.

TSTATBBPAC01-B

TSTATBBPHP01-B*

TSTATBBP2S01-B*

TSTATBBSAC01

TSTATBBPDF01-B**

TSTATBBPRH01-B***

* Model HP and 2S thermostat must be field converted to air conditioner operation.

**Dual Fuel thermostat is used with furnace and heat pump application

***Thermidistat Control can be configured for multiple use and staging, it must be configured for each specific application.

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 2-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 1-spd. Air Conditioner - deg. F/C

For multi-use / stage configurations - deg. F/C, Auto Changeover/Temperature and Humidity Control

Programmable Thermostat Selection

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 2-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 1-spd. Air Conditioner - deg. F/C, 5-2 Day Programmable

For use with multi-stage applications - deg. F/C, Auto Changeover, 7-Day Programmable

For multi-use / stage configurations - deg. F/C, Auto Changeover, 7-Day Programmable/Temperature and Humidity Control

ZONEBB3Z(AC/HP)01

ZONEBB2KIT01-B

ZONEBB4KIT01-B

ZONEBB8KIT01-B

Zoning Control Selection

Zone Perfect Two-Zone kit

Zone Perfect Plus 2-Zone kit/Temperature and Humidity Control

Zone Perfect Plus 4-Zone kit/Temperature and Humidity Control

Zone Perfect Plus 8-Zone kit/Temperature and Humidity Control

—4—

Page 5

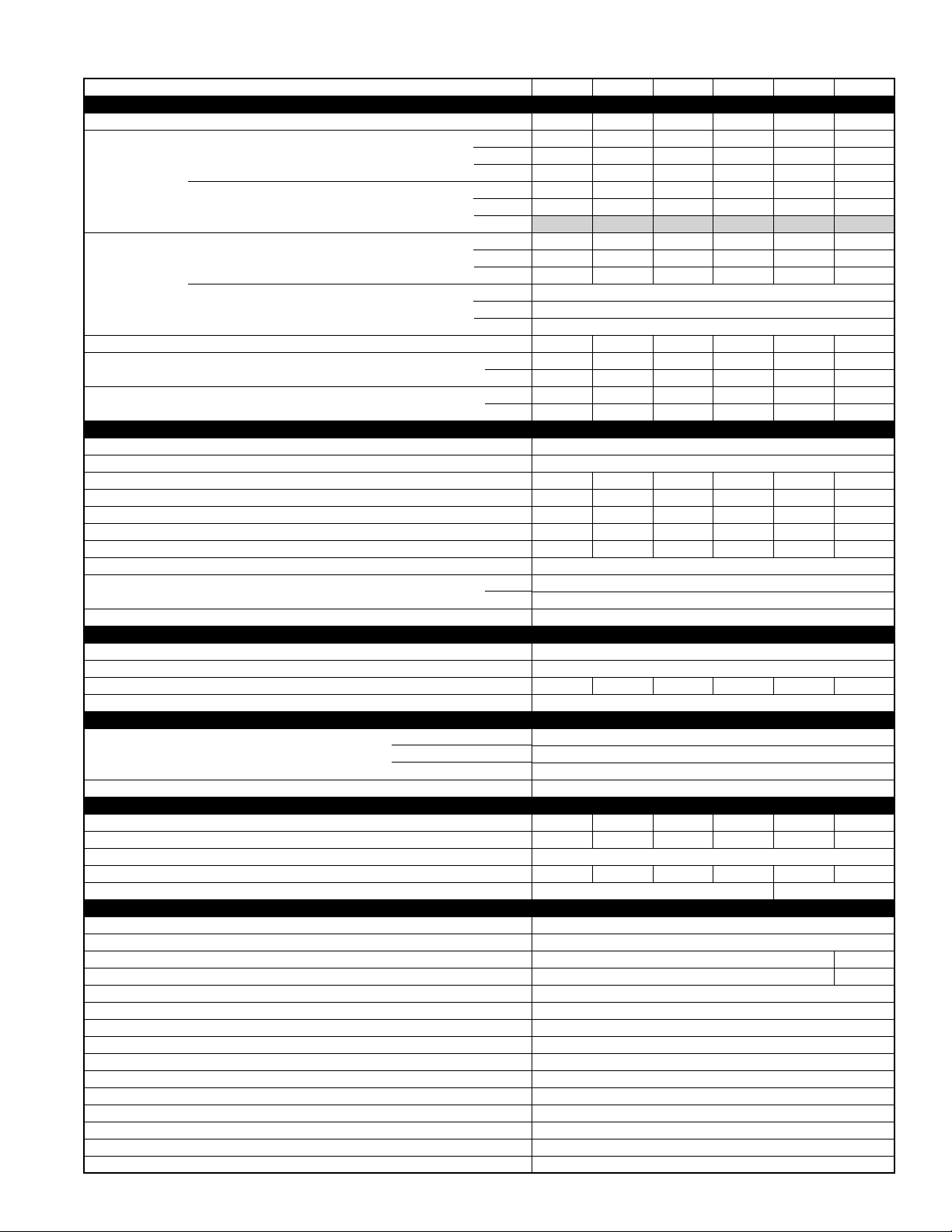

SPECIFICATIONS

UNIT SIZE 024040 036040 024060 036060 048060 036080

RATINGS AND PERFORMANCE

Input Btuh* 40,000 40,000 60,000 60,000 60,000 80,000

Output Capacity

BTUH* (ICS)

(Shaded capacities

are specified on rating plate)

AFUE%

Nonweatherized ICS

Certified Temperature Rise Range °F 30—60 15—45 45—75 30—60 20—50 40—70

Certified External Static Pressure Heating 0.10 0.10 0.12 0.12 0.12 0.15

Airflow CFM‡ Heating 850 1125 885 1065 1320 1190

ELECTRICAL

Unit Volts—Hertz—Phase 115—60—1

Operating Voltage Range Min—Max** 104—127

Maximum Unit Amps 10.0 14.1 10.2 14.8 14.6 14.3

Unit Ampacity†† 13.4 18.4 13.5 19.3 19.1 18.8

Minimum Wire Size 14 12 14 12 12 12

Maximum Wire Length (Ft)‡‡ 28 31 27 30 30 30

Maximum Fuse Size or Ckt Bkr Amps (Time-Delay Type Recommended) 20 15 20 20 20 20

Transformer (24v) 40va

External Control Heating 12va

Power Available Cooling 21va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control (Off Delay) Factory-Set at 135 Sec

Burners (Monoport) 445566

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

Gas Valve (Redundant) Manufacturer White-Rodgers

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (Permanent Split Capacitor) 1/2 3/4 1/2 3/4 3/4 3/4

Motor Full Load Amps 7.9 11.1 7.9 11.1 11.1 11.1

RPM (Nominal)—Speeds 1075—4

Blower Wheel Diameter x Width (In.) 11 x 8 11 x 10 11 x 8 11 x 10 11 x 10 11 x 10

Filter Size (In.)—Permanent Washable (1) 20 x 25 x 1 (2)16 x 25 x 1

FACTORY-AUTHORIZED AND LISTED, DEALER-INSTALLED OPTIONS

Gas Conversion Kit—Natural-to-Propane KGANP4001ALL

Gas Conversion Kit—Propane-to-Natural KGAPN3301ALL

Twinning Kit KGATW0601HSI

Manufactured (Mobile) Home Kit KGAMH0102KIT

Downflow Base*** KGASB0201ALL

Vent Termination Kit (Bracket Only for 2 Pipes) 2-in.—KGAVT0101BRA 3-in.—KGAVT0201BRA

Concentric Vent Termination Kit (Single Exit) 2-in.—KGAVT0501CVT 3-in.—KGAVT0601CVT

Condensate Freeze Protection Kit KGAHT0101CFP

Condensate Neutralizer Kit (Obtained Thru RCD) P908-0001

Side Filter Rack (Without Filter)—Upflow ONLY KGAFR0206ALL

Electronic/Mechanical Air Cleaner Model EACA, EZXCAB, or FILCAB

Humidifier Model HUM

Heat/Energy Recovery Ventilator Model HRV

UV Lights Model UVL

Door Gasket Kit KGBAC0110DGK

See notes on page 7.

Direct Vent (2-Pipe) Upflow

Downflow

Horizontal

Non-Direct Vent (1-Pipe) Upflow

Downflow

Horizontal

Direct Vent (2-Pipe) Upflow

Downflow

Horizontal

Non-Direct Vent (1-Pipe) Upflow

Downflow

Horizontal

Cooling 0.50 0.50 0.50 0.50 0.50 0.50

Cooling 895 1215 900 1200 1545 1245

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

—5—

37,000 37,000 56,000 56,000 56,000 74,000

37,000 37,000 56,000 56,000 56,000 74,000

37,000 37,000 56,000 56,000 56,000 74,000

37,000 37,000 56,000 56,000 56,000 74,000

37,000 37,000 56,000 56,000 56,000 74,000

37,000 37,000 56,000 56,000 56,000 74,000

92.3 92.3 92.3 92.3 92.3 92.3

91.2 91.2 91.2 91.2 91.2 91.2

92.1 92.1 92.1 92.1 92.1 92.1

92.1

91

91

N/A

N/A

Page 6

SPECIFICATIONS

UNIT SIZE 048080 060080 048100 060100 060120 060140

RATINGS AND PERFORMANCE

Input Btuh*

Output Capacity

BTUH* (ICS)

(Shaded capacities

are specified on rating plate)

AFUE%

Nonweatherized ICS

Certified Temperature Rise Range °F 30—60 15—45 45—75 30—60 20—50 40—70

Certified External Static Pressure Heating 0.10 0.10 0.12 0.12 0.12 0.15

Airflow CFM‡ Heating 850 1125 885 1065 1320 1190

ELECTRICAL

Unit Volts—Hertz—Phase 115—60—1

Operating Voltage Range Min—Max** 104—127

Maximum Unit Amps 6.1 7.3 6.1 7.1 9.5 7.6

Unit Ampacity†† 8.4 10.0 8.4 9.8 12.8 10.4

Minimum Wire Size 14 14 14 14 14 14

Maximum Wire Length (Ft)‡‡ 44 37 44 38 29 36

Maximum Fuse Size or Ckt Bkr Amps

(Time-Delay Type Recommended) 15 15 15 15 15 15

Transformer (24v) 40va

External Control Heating 12va

Power Available Cooling 21va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control (Off Delay) Factory-Set at 135 Sec

Burners (Monoport) 223334

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

Gas Valve (Redundant) Manufacturer White-Rodgers

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (Permanent Split Capacitor) 1/5 1/3 1/5 1/3 1/2 1/3

Motor Full Load Amps 4.9 5.8 4.9 5.8 7.9 5.8

RPM (Nominal)—Speeds 1075—3 1075—4 1075—3 1075—4

Blower Wheel Diameter x Width (In.) 10 x 6 10 x 7 10 x 6 10 x 7 11 x 8 10 x 7

Filter Size (In.)—Permanent Washable (1) 16 x 25 x 1

FACTORY-AUTHORIZED AND LISTED, DEALER-INSTALLED OPTIONS

Gas Conversion Kit—Natural-to-Propane KGANP4001ALL

Gas Conversion Kit—Propane-to-Natural KGAPN3301ALL

Twinning Kit N/A

Manufactured (Mobile) Home Kit KGAMH0101KIT

Downflow Base*** KGASB0201ALL

Vent Termination Kit (Bracket Only for 2 Pipes) 2-in.—KGAVT0101BRA 3-in.—KGAVT0201BRA

Concentric Vent Termination Kit (Single Exit) 2-in.—KGAVT0501CVT 3-in.—KGAVT0601CVT

Condensate Freeze Protection Kit KGAHT0101CFP

Condensate Neutralizer Kit (Obtained Thru RCD) P908-0001

Side Filter Rack (Without Filter)—Upflow ONLY KGAFR0206ALL

Electronic/Mechanical Air Cleaner Model EACB, EZXCAB, or FILCAB

Humidifier Model HUM

Heat/Energy Recovery Ventilator Model HRV

UV Lights Model UVL

Door Gasket Kit KGBAC0110DGK

Direct Vent (2-Pipe) Upflow

Downflow

Horizontal

Non-Direct Vent (1-Pipe) Upflow

Downflow

Horizontal

Direct Vent (2-Pipe) Upflow

Downflow

Horizontal

Non-Direct Vent (1-Pipe) Upflow

Downflow

Horizontal

Cooling 0.50 0.50 0.50 0.50 0.50 0.50

Cooling 895 1215 900 1200 1545 1245

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

See notes on page 7.

80,000 80,000 100,000 100,000 120,000 140,000

74,000 74,000 93,000 93,000 112,000 127,000

74,000 74,000 93,000 93,000 112,000 127,000

74,000 74,000 93,000 93,000 112,000 127,000

74,000 74,000 93,000 93,000 112,000 NA

74,000 74,000 93,000 93,000 112,000 NA

74,000 74,000 93,000 93,000 112,000 NA

92.3 92.3 92.3 92.3 92.3 92.3

91.2 91.2 91.2 91.2 91.2 91.2

92.1 92.1 92.1 92.1 92.1 92

92.1 NA

91 NA

91 NA

KGATW0601HSI

N/A

—6—

Page 7

* Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 2% for each 1000 ft above sea level. In Canada, derate the unit

5% from 2000 to 4500 ft above sea level.

† Capacity and AFUE in accordance with U.S. Government DOE test procedures.

‡ Airflow shown is for bottom only return-air supply. Air delivery above 1800 CFM may require that both sides, a combination of 1 side and bottom, or bottom only of the

furnace be used for return air, see Air Delivery table. Where 2 sets of data are listed, the first set is for bottom only return-air supply. The second set is for both sides,

or 1 side and bottom return-air supply. A filter is required for each return-air supply.

** Permissible voltage limits for proper furnace operation.

†† Unit ampacity = 125% of largest component’s full load amps plus 100% of all other potential operating components (EAC, humidifier, etc.).

‡‡ Length shown is measured 1 way along wire path between unit and service panel for maximum 2% voltage drop.

*** Required for installation on combustible floors when no coil box is used, or when any coil box other than a Bryant CD5, CK5, or KCAKC cased coil is used.

N/A—Not applicable

ICS—Isolated Combustion System

—7—

Page 8

COMBUSTION-AIR AND VENT PIPING Direct-Vent/2-Pipe (All Sizes) and

Non-Direct Vent/1-Pipe (Sizes 040 Through 120 Only) Applications

ALTITUDE (FT)

0 to 2000

ALTITUDE (FT)

2001 to 3000

ALTITUDE (FT)

3001 to 4000

See notesat end of table

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

MAXIMUM ALLOWABLE PIPE LENGTH (FT)

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

4† no disk 4†nodisk4†nodisk 707070707070

2 Pipe or 3-in.

Concentric

PIPE DIA

(IN.)*

1 1 5 NANANANANA

1-1/2 1-1/2 70 70 65 60 60 55

2 2 70 70 70 70 70 70

1-1/2 1-1/2 20 15 10 5 NA NA

2 2 70 70 70 70 70 70

1-1/2 1-1/2 10 NA NA NA NA NA

22555035 30 3020

2-1/2 2-1/2 70 70 70 70 70 70

2 2 5 NANANANANA

2-1/2 2-1/2 40 30202010NA

3370 70 70 70 70 70

2-1/2 one disk 2-1/2 10 NA NA NA NA NA

3†NA454035 302520

3†nodisk 3† 707070707070

2-1/2 one disk NA 5 NA NA NA NA NA

3†onediskNA4035 30252015

3†nodiskNA60565248 44 40

4† no disk NA 707070707070

PIPE DIA

(IN.)*

1-1/2 1-1/2 67 62 57 52 52 47

2 2 70 70 70 70 70 70

1-1/2 1-1/2 17 12 7 NA NA NA

2 2 70 67 66 61 61 61

22494430252515

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 352616 16 6 NA

3370 70 70 70 66 61

3 NA 14 9 NA NA NA NA

NA 3†63 62 62 61 61 61

3†nodiskNA707063 56 50 43

4† no disk4†nodisk 707070707070

3† one diskNA2015105NANA

3†nodiskNA39 35 312723 19

4† no disk NA 707070707070

PIPE DIA

(IN)*

1-1/2 1-1/2 64 59 54 49 48 43

2 2 70 70 70 70 70 70

1-1/2 1-1/2 16 11 6 NA NA NA

2268 63 62 57 57 56

2 2 46 41 28 23 22 13

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 33 24 15 14 5 NA

3370 70 70 66 61 56

3†nodiskNA6558 51 44 38 31

NA 3†595958 57 57 56

3† one disk NA 11 6 NA NA NA NA

3†nodiskNA302622 18 14 10

4† no disk NA 707070707070

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

1234 56

NUMBER OF 90° ELBOWS

1234 56

NUMBER OF 90° ELBOWS

1234 56

—8—

Page 9

COMBUSTION-AIR AND VENT PIPING Direct-Vent/2-Pipe (All Sizes) and

ALTITUDE (FT)

4001 to 5000‡

ALTITUDE (FT)

5001 to 6000‡

ALTITUDE (FT)

6001 to 7000‡

See notesat end of table

Non-Direct Vent/1-Pipe (Sizes 040 Through 120 Only) Applications

MAXIMUM ALLOWABLE PIPE LENGTH (FT) (CONTINUED)

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

2 Pipe or 3-in.

Concentric

PIPE DIA

(IN.)*

1-1/2 1-1/2 60 55 50 45 44 39

2 2 70 70 70 70 70 70

1-1/2 1-1/2 15 10 5 NA NA NA

2 2 64 59 58 53 52 52

22443926 21 2011

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 312213 12 NA NA

3370 70 67 62 57 52

3†nodiskNA53 46 40 33 26 20

NA 3†56555453 52 52

4† no disk 4†nodisk 707070707070

3†nodiskNA211713 95NA

4† no disk NA 696459544944

PIPE DIA

(IN.)*

1-1/2 1-1/2 57 52 47 42 40 35

2 2 70 70 70 70 70 70

1-1/2 1-1/2 14 9 NA NA NA NA

2 2 60 55 54 49 48 47

22413623 18 17 8

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 29 21 12 11 NA NA

3370 67 62 57 52 47

3†nodiskNA423529 2215 9

NA 3†53 52 50 49 48 47

4† no disk4†nodisk 707070707070

3†nodiskNA128 NA NA NA NA

4† no diskNA4237 32272217

PIPE DIA

(IN)*

1-1/2 1-1/2 53 48 4

2 2 70 70 68 67 66 64

1-1/2 1-1/2 138NA NA NA NA

2 2 57 52 50 45 44 43

2238 33 21 16 15 6

2-1/2 2-1/2 70 70 68 67 66 64

2-1/2 2-1/2 27 19 10 9 NA NA

3368 63 58 53 48 43

3†nodiskNA312418 11 NA NA

NA 3†4948 47 45 44 43

4† no disk4†nodisk 707070706762

4† no diskNA17127NANANA

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN)*

NUMBER OF 90° ELBOWS

123456

NUMBER OF 90° ELBOWS

123456

NUMBER OF 90° ELBOWS

123456

33837 32

—9—

Page 10

COMBUSTION-AIR AND VENT PIPING Direct-Vent/2-Pipe (All Sizes) and

Non-Direct Vent/1-Pipe (Sizes 040 Through 120 Only) Applications

MAXIMUM ALLOWABLE PIPE LENGTH (FT) (CONTINUED)

ALTITUDE (FT)

7001 to 8000‡

ALTITUDE (FT)

8001 to 9000‡

ALTITUDE (FT)

9001 to 10,000‡

*Disk usage-Unless otherwise specified, use perforated disk assembly (factory-supplied in loosepartsbag). If one diskisstated, separate 2 halves of perforated disk

assembly and use shouldered diskhalf. When using shouldered diskhalf, install screen side toward inlet box.

†Wide radius elbow.

‡Vent sizing for Ca

NA-Not Allowed; pressure switch will not make.

NOTES:

1. Do not use pipe size greater thanthose specified in table or incomplete combustion, flame disturbance, or flame senselockoutmay occur.

2. Size both the combustion-air and vent pipe independently, then usethel

3.Assume two 45° elbows equal one 90° elbow. Wide radius elbowsare desirable and may berequired in some cases.

4. Elbowsand pipe sections within the furnace casing and at the vent termination should not be included in vent length or elbow count.

5. The minimum pipe length is 5ftforall applications.

6. Use 3-in. diameter vent termination kit for in

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000 NA

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000 NA

UNIT SIZE

(BTUH)

40,000

60,000

80,000

100,000

120,000

140,000 NA

nadianinstallations over 4500 ft (1370 m) above sea level are subject to acceptance bythelocal authorities having jurisdiction.

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

stallations requiring 4-in diameter pipe.

PIPE DIA

(IN.)*

1-1/2 1-1/2 49 44 39 34 33 28

2 2 66 65 63 62 60 59

1-1/2 1-1/2 12 7 NA NA NA NA

2253 48 46 41 40 38

2236 31191412NA

2-1/2 2-1/2 66 65 63 62 60 59

2-1/2 2-1/2 25 17 8 7NANA

3363 58 53 48 4338

3†nodiskNA2013 7NANANA

NA 3†464443 41 40 38

4† no disk4†nodisk615651464136

PIPE DIA

(IN.)*

1-1/2 1-1/2 46 41 36 312924

2 2 62 60 58 56 55 53

1-1/2 1-1/2 11 6 NA NA NA NA

2 2 49 44 42 37 35 34

2233 28 17 12 10 NA

2-1/2 2-1/2 62 60 58 56 55 53

2-1/2 2-1/2 23 15 7 5 NA NA

3359 54 49 44 39 34

3†nodisk NA 10NANANANANA

NA 3†43 41 39 37 35 34

4† no disk4†nodisk 35 3025201510

PIPE DIA

(IN.)*

1-1/2 1-1/2 42 37 32272520

2 2 57 55 53 51 49 47

2 2 45 40 38 33 3129

223025 14 9 7 NA

2-1/2 2-1/2 57 55 53 51 49 47

2-1/2 2-1/2 21 13 5NANANA

3354 49 44 39 3429

NA 3† 39 37 35 33 3129

4† no disk 4†nodisk 10 5 NA NA NA NA

arger diameter for both pipes.

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

NUMBER OF 90° ELBOWS

123456

NUMBER OF 90° ELBOWS

123456

—10—

Page 11

(

MAXIMUM ALLOWABLE EXPOSED VENT PIPE LENGTH (FT) WITH AND WITHOUT INSULATION

IN WINTER DESIGN TEMPERATURE AMBIENT*

WINTER DESIGN

UNIT SIZE

TEMPERATURE

°F)

20 1-1/2 51 70

024040

036040

0 1-1/2 28 70

–20 1-1/2 16 70

024060

036060

048060

036080

048080

060080

20 2 65 70

0 2 35 70

–20 2 20 70

20 2-1/2 70 70

0 2-1/2 47 70

–20 2-1/2 28 70

20 3 70 70

048100

060100

0 3 50 70

–20 3 28 70

20 4 70 70

060120

0 4 48 70

–20 4 23 70

20 4 70 70

060140

0 4 57 70

–20 4 30 70

* Pipe length (ft) specified for maximum vent pipe lengths located in unconditioned spaces. Vent pipes located in unconditioned space cannot exceed the

total allowable pipe length as specified in Maximum Allowable Pipe Length table.

† Insulation thickness based on R value of 3.5 per in.

MAX PIPE

DIAMETER

(IN.)

WITHOUT

INSULATION

WITH 3/8-IN. OR

THICKER INSULATION†

BLOWER SHELF

CONDENSATE

TRAP (INSIDE)

ALTERNATE DRAIN

TUBE LOCATION

CONDENSATE TRAP

DRAIN TUBE LOCATION

UPFLOW APPLICATIONS

CONDENSATE TRAP

FURNACE

DOOR

FIELD

DRAIN

CONN

SIDE VIEW FRONT VIEW END VIEW FRONT VIEW

DOWNFLOW AND ALTERNATE

EXTERNAL UPFLOW APPLICATIONS

SLOT FOR SCREW

HORIZONTAL

APPLICATION

(OPTIONAL)

1

1

2

3

4

3

1

4

WIRE TIE

GUIDES

(WHEN USED)

FRONT VIEW SIDE VIEW

CONDENSATE

TRAP

1

26

4

7

FURNACE

1

7

8

8

2

SIDE

1

1

1

4

FURNACE

DOOR

7

4

8

2

1

⁄4 OD

COLLECTOR BOX TO

TRAP RELIEF PORT

1

⁄2 OD

INDUCER HOUSING

DRAIN CONNECTION

5

⁄8 OD

COLLECTOR BOX

DRAIN CONNECTION

SCREW HOLE FOR

UPFLOW OR DOWNFLOW APPLICATIONS

(OPTIONAL)

1

⁄2-IN. PVC OR CPVC

FIELD

DRAIN

CONN

4

26

HORIZONTAL

APPLICATIONS

3

5

4

1

4

4

3

FURNACE

SIDE

3

5

4

A93026

4

—11—

Page 12

ACCESSORIES

CONCENTRIC VENT FOR DIRECT VENT (2-PIPE) APPLICATION

(ALL MODEL SIZES)

B IN. DIA PVC

VENT/EXHAUST

F

E

21

SIDE FILTER RACK*

3

1

⁄8″

1 1⁄4″ (TYP)

1 1⁄4″

TABS

25 1⁄8″

⁄2″

2 3⁄8″

3

⁄4″

13/16

1

/2

1

B IN. DIA PVC

INTAKE/COMBUSTION AIR

C IN. DIA

D

A

DIMENSIONS (In.)

PART NO. A* B C D† E F

KGAVT0501CVT 33-3/8 2 3-1/2 16-5/8 6-1/4 5-3/4

KGAVT0601CVT 38-7/8 3 4-1/2 21-1/8 7-3/8 6-1/2

* Dimension A will change accordingly as dimension D is lengthened or shortened.

† Dimension D may be lengthened to 60 in. maximum. Dimension D may also be shortened by

cutting the pipes provided in the kit to 12 in. minimum.

NOTE: See furnace Installation Instructions when venting multiple

furnaces near each other.

LENGTH OF STRAIGHT

PIPE PORTION OF COMBUSTION

AIR INLET PIPE ASSEMBLY (IN.)

CASING WIDTH A

17-1/2

24-1/2

8-1/2 ± 1/2

10-1/2 ± 1/2

12 ± 1/2

17 1⁄8″

23 1⁄8″

OPENING

14 1⁄

2

OPENING

16

″

A80199

1

⁄8″

* Accepts one 16 x 25 x 1 in. filter.

Combination-Air Pipe for Non-Direct Vent (1-Pipe)

Application (Sizes 040 Through 120 Only)

FIELD-SUPPLIED

2-IN. DIAMETER

PVC 90° ELBOW

COMBUSTION-AIR DISC

(FACTORY-SUPPLIED IN

LOOSE PARTS BAG)

FIELD-SUPPLIED

2-IN. DIAMETER

PVC PIPE

A

A96211

A96211

ACCESSORY DOWNFLOW SUBBASE

A88207

4

3

2

1

A

LOCATING

TAB

LOCATING

TAB

B

D

FACTORY-SUPPLIED

1

2

3

4

FIELD-INSTALLED

INSULATION

Disassembled Assembled

FURNACE

CASING

WIDTH FURNACE IN DOWNFLOW APPLICATION

17-1/2

21

24-1/2

Furnace with or without Cased Coil

Assembly or Coil Box

Furnace with or without Cased Coil

Assembly or Coil Box

Furnace with or without Cased Coil

Assembly or Coil Box

* The plenum should be constructed 1/4 in. smaller in width and depth than the plenum dimensions shown above.

PLENUM OPENING* FLOOR OPENING HOLE NO.

15-1/8 19 16-3/4 20-3/8 3

18-5/8 19 20-1/4 20-3/8 2

22-1/8 19 23-3/4 20-3/8 1

—12—

1 1/

″ TYP

4

PLENUM

OPENING

C

FOR WIDTH

ADJUSTMENTABCD

Page 13

AIR DELIVERY—CFM (With Filter)*

UNIT SIZE

024040

036040

024060

036060

048060

036080

048080

060080

048100

060100

060120

060140

* A filter is required for each return-air supply.

• For horizontal and downflow applications, use “1 side or bottom” or “bottom only” as airflow reference.

RETURN-AIR

SUPPLY SPEED

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

1 side

or

bottom

both sides or

1 side and

bottom

1 side

or

bottom

1 side

or

bottom

both sides or

1 side and

bottom

bottom

only

both sides or

1 side and

bottom

1 side only

bottom

only

both sides or

1 side and

bottom

1 side only

Med-Low

Med-High

Med-Low

Med-Low

Med-High

Med-Low

Med-High

Med-Low

Med-High

Med-Low

Med-High

Med-Low

Med-High

Med-Low

Med-High

Med-High

Med-Low

Med-High

Med-Low

Med-High

Med-High

Med-Low

Med-High

Med-High

Med-High

Med-Low

Med-High

Med-High

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

Low

High

High

Low

High

Low

High

High

Low

High

High

High

Low

High

High

0.1 0.2

1075

850

740

1470

1315

1125

930

1100

890

745

1430

1270

1070

915

1700

1500

1325

1205

1535

1395

1200

1040

1750

1495

1310

1135

2200

2100

1815

1560

2360

1965

1740

1500

1340

1195

2250

2020

1725

1490

2360

1960

2350

2100

1770

1545

2435

2040

2255

1985

2285

2020

1675

1460

2310

1975

2140

1930

1040

825

700

1415

1280

1110

925

1065

865

710

1375

1260

1055

895

1695

1465

1295

1170

1470

1350

1175

1020

1685

1455

1260

1105

2175

2025

1760

1555

2280

1925

1705

1470

1315

1175

2175

1950

1690

1480

2315

1940

2250

2015

1720

1520

2360

2000

2190

1930

2210

1970

1650

1445

2255

1945

2080

1850

EXTERNAL STATIC PRESSURE (In. wc)

0.3

995

780

650

1400

1235

1085

910

1005

810

670

1325

1215

1045

885

1640

1435

1265

1145

1405

1300

1125

990

1635

1405

1225

1075

2085

1945

1720

1515

2210

1870

1660

1445

1300

1165

2090

1900

1660

1460

2265

1930

2160

1955

1675

1465

2285

1950

2115

1890

2140

1920

1620

1430

2185

1900

2025

1800

0.4

945

740

620

1285

1180

1045

850

945

765

625

1275

1160

1015

865

1580

1385

1230

1110

1330

1225

1065

960

1575

1355

1170

1040

2025

1865

1670

1460

2130

1830

1615

1410

1270

1130

2020

1840

1630

1440

2200

1900

2070

1875

1620

1415

2220

1905

2045

1840

2065

1870

1590

1400

2120

1860

1945

1740

0.5

895

685

565

1215

1115

990

830

900

705

565

1200

1105

975

840

1545

1355

1190

1080

1245

1155

1030

910

1525

1305

1125

995

1925

1785

1620

1435

2035

1760

1570

1375

1235

1100

1930

1790

1575

1380

2130

1850

2000

1810

1575

1365

2130

1835

1965

1780

1990

1805

1560

1370

2045

1835

1875

1725

0.6

840

635

515

1120

1035

915

770

805

620

505

1135

1035

920

800

1450

1300

1150

1035

1160

1080

970

860

1445

1250

1095

995

1820

1700

1550

1390

1960

1710

1500

1330

1200

1070

1855

1710

1520

1340

2055

1800

1885

1710

1515

1325

2050

1790

1890

1720

1910

1730

1510

1320

1965

1775

1795

1660

0.7 0.8

760

560

455

995

930

830

705

730

540

425

1040

950

850

720

1380

1250

1105

990

1065

985

890

785

1380

1185

1040

910

1735

1620

1480

1340

1875

1670

1425

1280

1140

1030

1760

1640

1460

1295

1965

1740

1790

1650

1450

1265

1965

1725

1800

1645

1830

1660

1450

1275

1880

1720

1725

1580

670

480

385

890

825

740

635

610

475

360

935

850

750

650

1310

1185

1050

950

935

880

780

680

1310

1120

980

860

1635

1540

1405

1270

1790

1575

1355

1210

1095

975

1670

1545

1370

1230

1890

1660

1635

1540

1365

1185

1875

1650

1710

1560

1745

1590

1390

1230

1800

1640

1625

1495

—13—

Page 14

OUTDOOR UNIT

COMBUSTION

AIR INLET

(NON-DIRECT

1-PIPE APPLICATION)

COMBUSTION AIR PIPE

(DIRECT VENT/2-PIPE APPLICATION)

A/C COIL

ELECTRONIC

AIR CLEANER

VENT PIPE

HUMIDIFIER

GAS-FIRED

WATER HEATER

AIRFLOW

ELECTRONIC

AIR CLEANER

COMBUSTION AIR

INLET (NON-DIRECT

VENT/ 1-PIPE APPLICATION

HUMIDIFIER

FRONT OF

FURNACE

A05064

VENT

COMBUSTION

AIR (DIRECT VENT/

2 PIPE APPLICATION

OUTDOOR

UNIT

A/C COIL

FRONT OF

AIRFLOW

FURNACE

A05065

—14—

Page 15

COMBUSTION-AIR INLET

(NON-DIRECT VENT/1-PIPE APPLICATION)

ELECTRONIC

AIR CLEANER

FRONT OF FURNACE

AIRFLOW

VENT PIPE

FURNACE

CONDENSATE

DRAIN

REFRIGERATION

COMBUSTION–AIR PIPE

DIRECT VENT/2-PIPE APPLICATION)

AIR CONDITIONING

COIL

PIPING

A05066

COMBUSTION - AIR INLET

(NON-DIRECT VENT/

1-PIPE APPLICATION)

REFRIGERATION

PIPING

AIR CONDITIONING

COIL

AIRFLOW

FURNACE CONDENSATE

DRAIN

FRONT OF

FURNACE

COMBUSTION– AIR PIPE

(DIRECT VENT/2-PIPE

APPLICATION)

VENT

PIPE

ELECTRONIC

AIR CLEANER

A05067

—15—

Page 16

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS 340M.40.12

© 2005 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indianapolis, IN 46231 PRINTED IN U.S.A. Catalog No. PDS340A.40.1 09-05

—16—

Loading...

Loading...