Page 1

PLUS 80t with Perfect Heat™

DOWNFLOW

California Approved

331JAV

Sizes 060 thru 100

INDUCED-COMBUSTION FURNACE

The Plus 80t Downflow Furnace achieves 80 percent Annual

Fuel Utilization Efficiency (AFUE) rating. The benefits of Perfect

Heat operation in reducing sound and improving comfort put it in

a class well ahead of the competition. The Plus 80t has the kind

of overall performance needed in today’s homes. All models are

GAMA efficiency rating certified and certified for use in California

Air Quality Management Districts.

FEATURES

EFFICIENCY — The Plus 80t Induced-Combustion Gas Fur-

nace provides the efficiency customers want with 80.0% AFUE.

HOT SURFACE IGNITION — No pilot to waste gas with this

field-proven ignition system.

ALUMINIZED HEAT EXCHANGER — The patented 4-pass

heat exchanger is made of aluminized steel and backed by a

20-year Limited Warranty.

INTELLIGENT CONTROL — The Plus 80t has an intelligent

control that monitors the operation of the furnace. This control

also has a component-test feature that enables the servicing

technician to verify operation of the control; the high and low inducer; the hot surface ignitor; and high-, medium-, and lowspeed blower operation. The control features a 3-amp fuse that

protects the transformer and control. We guarantee the reliability

of the control with a 3-year Limited Warranty.

40-IN. HEIGHT — The Plus 80t cabinet height is only 40 in.

This simplifies installation in alcoves, attics, basements (ideal

for short basement), closets, and utility rooms, especially with

a taller high-efficiency cooling coil.

PREPAINTED CABINET — The Plus 80t uses prepainted sheet

metal for the cabinet. This is the same high-quality finish found

on refrigerators and other appliances today. We ensure its durability by using a galvanized steel substrate to provide superior

rust protection.

PATENTED BLOCKED VENT SAFEGUARD — Our induced-

combustion furnace has a patented blocked vent safeguard. The

safeguard switch will stop furnace operation if the vent system

becomes blocked or is not operating properly. An exclusive with

the Plus 80t furnace.

EASY INSTALLATION — The Plus 80t has many features that

make installation easier: left or right gas and electrical connections, heating and cooling blower speed selector, matching coil

sizes, accessory low-voltage connections, and many more.

QUIET OPERATION — A soft mount inducer assembly and 2-

stage slow-opening gas valve reduce sound level. The Perfect

Heat operation capability minimizes furnace and air noise for

total home comfort.

Series C

Form No. PDS 331J.60.4

Page 2

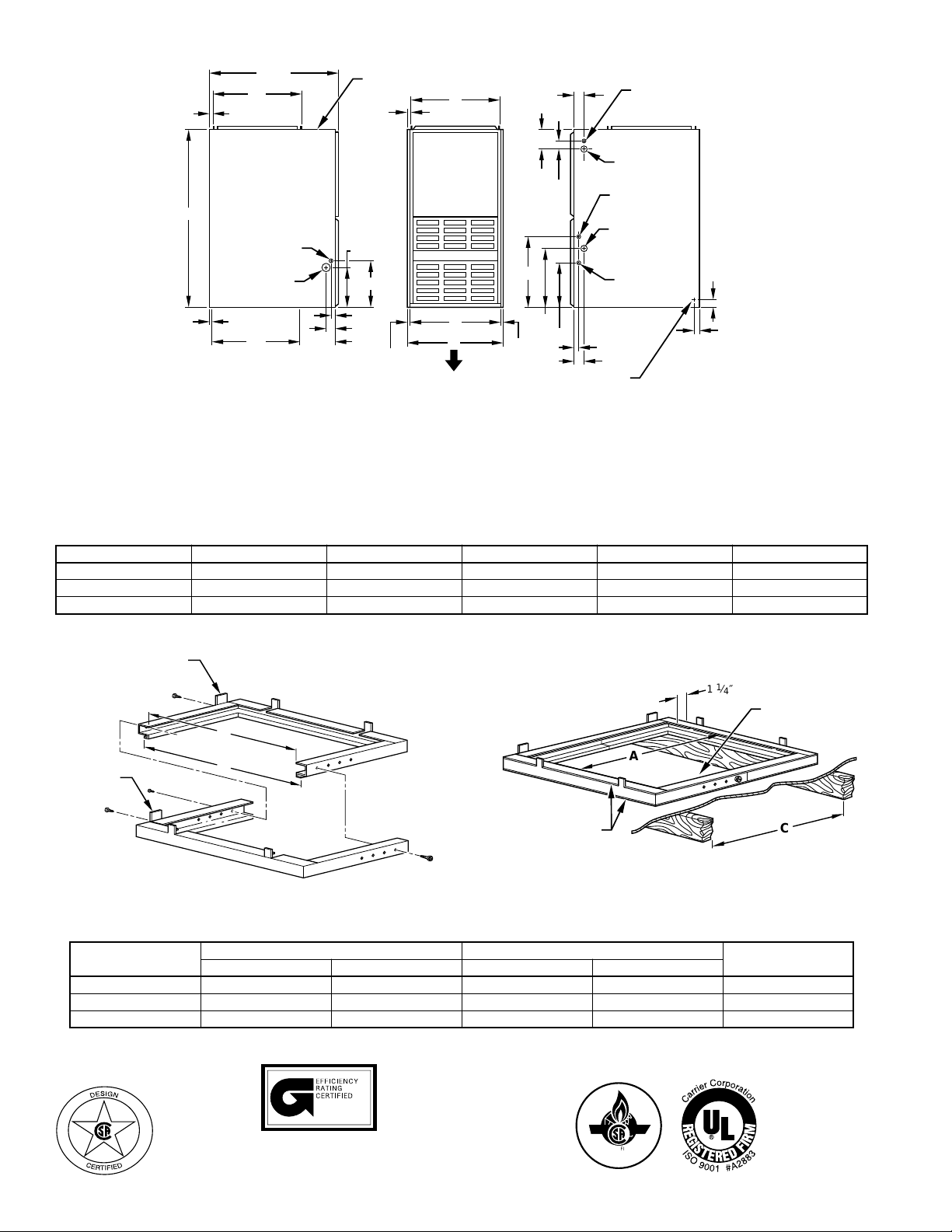

*

1

28

⁄2″

20″

13

⁄16″

7

39

⁄8″

11

⁄16″

INLET

7

⁄8″ DIA

ACCESSORY

3

1

⁄4″ DIA HOLE

GAS ENTRY

OUTLET

19″

ADDITIONAL

NOTE:

LOCATED IN THE TOP PLATE

AND BOTTOM PLATE

NOTES:

1. Two additional 7⁄8-in. dia holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

a. For 800 CFM–16-in. round or 14

b. For 1200 CFM–20-in. round or 141⁄2 x 191⁄2-in. rectangle.

c. For 1600 CFM–22-in. round or 14

d. For airflow requirements above 1800 CFM, must use entire return air opening.

7

⁄8″ DIA K.O. ARE

VENT CONNECTION

13

⁄16″

1

9

⁄8″

1

10

⁄4″

1

1

⁄16″

1

2

⁄8″

1

8

⁄4″

11

⁄16″

AIRFLOW

D

E

A

DIMPLES TO DRILL HOLES

FOR HANGER BOLTS (4 PLACES)

IN HORIZONTAL POSITION

1

⁄2 x 12-in. rectangle.

1

⁄2 x 231⁄4-in. rectangle.

11

16

⁄16″

1

13

4

⁄16″

3

⁄16″

15

2

⁄16″

5

⁄16″

1

10

⁄4″

1

⁄2″ DIA

2″

THERMOSTAT

WIRE ENTRY

7

⁄8″ DIA

ACCESSORY

7

⁄8″ DIA HOLE

POWER ENTRY

1

1

⁄2″ DIA

R.H. GAS ENTRY

7

⁄8″ DIA

ACCESSORY

1

1

⁄16″

1

2

⁄8″

1

″ TYP

5

⁄8″ TYP

DIMENSIONS (In.)

UNIT SIZE A D E VENT CONN (Dia) SHIPPING WEIGHT (Lb)

036060 14-3/16 12-9/16 12-11/16 4 145

048080 17-1/2 15-7/8 16 4 154

060100 21 19-3/8 19-1/2 4 181

A99109

ACCESSORY DOWNFLOW SUBBASE

LOCATING

TAB

B

A

Assembled

LOCATING

TAB

D

Disassembled

4

3

2

1

FACTORY-SUPPLIED

3

4

A88207

1

2

FIELD-INSTALLED

INSULATION

DIMENSIONAL DATA (In.)

PLENUM OPENING *

FURNACE WIDTH

14-3/16 11-13/16 19 13-7/16 20-3/8 4

17-1/2 15-1/8 19 16-3/4 20-3/8 3

21 18-5/8 19 20-1/4 20-3/8 2

The plenum should be constructed 1/4 in. smaller in width and depth than the plenum dimensions shown above.

FRAMED FLOOR HOLE

1 1⁄4″ TYP

WIDTH ADJUSTMENTABCD

PLENUM

OPENING

C

A88206

HOLE NO. FOR

ama

MEETS DOE RESIDENTIAL CONSERVATION

SERVICES PROGRAM STANDARDS.

Before purchasing this appliance, read important

energy cost and efficiency information available

from your retailer.

CERTIFIED

—2—

Page 3

*

**

SPECIFICATIONS

UNIT SIZE 036060 048080 060100

RATINGS AND PERFORMANCE

Gas Input (Btuh) *

Output Capacity (Btuh)† High Stage 51,000 69,000 86,000

Nonweatherized ICS Low Stage 33,000 44,000 55,000

AFUE† Nonweatherized ICS 80.0 80.0 80.0

Certified Temperature Rise High Stage 30—60 30—60 35—65

Range (°F) Low Stage 15—45 15—45 20—50

Certified External Static Pressure Heat/Cool 0.10/0.50 0.15/0.50 0.20/0.50

Airflow CFM Heating High/Low 1195/1030 1355/1170 1735/1500

High Stage 63,000 84,000 105,000

Low Stage 40,500 54,000 67,500

Cooling 1195 1580 1950

ELECTRICAL

Unit Volts— Hertz— Phase 115—60—1

Operating Voltage Range Min—Max 104—127

Maximum Unit Amps 10.5 14.2 17.9

Maximum Wire Length (Measured 1 Way) Ft 35 26 32

Minimum Wire Size 14 12

Maximum Fuse Size 15 20

Transformer (24v) 40va

External Control Heating 19va

Power Available Cooling 35va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST (Auto-Reset)

Heating Blower Control Solid-State Time Operation

Inducer 2-Speed

Burners (Monoport) 3 4 5

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

2-Stage Redundant Gas Valve White-Rodgers

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (PSC) 1/3 1/2 3/4

Motor Full Load Amps 5.1 7.4 11.0

RPM (Nominal)—Speeds 1075—5

Blower Wheel Diameter x Width (In.) 10 x 6 10 x 8 10 x 6

Filter Size (In.)—Permanent Washable (Supplied) (2) 14 x 20 x 1 (2) 16 x 20 x 1

DEALER-INSTALLED ACCESSORIES

Downflow Subbase **

High-Altitude Pressure Switch Kit‡ KGAH5601PSW

Gas Conversion Kit—Natural-to-Propane KGANP26012SP

Gas Conversion Kit—Propane-to-Natural KGAPN21012SP

Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 4% for each 1000 ft above sea level. Refer to National

Fuel Gas Code Table F4. In Canada, derate the unit 10% for elevations 2000 ft to 4500 ft above sea level.

† Capacity in accordance with U.S. Government DOE test procedures.

‡ 5500 ft and higher above sea level.

Required for installation on combustible floors when no coil box is used, or when any coil box other than a Bryant cased coil is used.

ICS—Isolated Combustion System

KGASB0201ALL

CONTROLS—THERMOSTATS AND ZONING

Auto Changeover, °F/°C, 1-Stage Heat/1-Stage cool — TSTATBBNAC01-B

Auto Changeover, °F/°C, 2-Stage Heat/1-Stage Cool — TSTATBBNHP01-B

THERMOSTAT—NON-PROGRAMMABLE

Auto Changeover, 7-Day Programmable, °F/°C, 1-Stage heat/1-Stage cool — TSTATBBPAC01-B

Auto Changeover, 7-Day Programmable, °F/°C, 2-Stage Heat/1-Stage Cool — TSTATBBPHP01-B

THERMOSTAT-PROGRAMMABLE

ZONING—2-ZONE ZONEBB2KIT01, ZONEKIT2ZBDP

ZONING—4-ZONE ZONEBB4KIT01

ZONING—8-ZONE ZONEBB8KIT01

Auto Changeover, °F/°C, 2-Stage Heat/2-Stage cool — TSTATBBN2S01-B

Air Conditioner, 1-Stage Heat/1-Stage Cool, Manual Changeover, °F/°C — TSTATBBBAC01

Heat Pump, 2-Stage Heat/1-Stage Cool. Manual Changeover, °F/°C — TSTATBBBHP01*

2-Stage Heat/2-Stage Cool in AC Mode, 3-Stage Heat/2-Stage Cool in HP Mode

Dual Fuel Thermostat. Includes Outdoor Air Temperature Sensor — TSTATBBPDF01-B*

Thermidistat™ Control — Non-Programmable/Programmable — TSTATBBPRH01-B*

Thermostat with Humidity Control (For use in Dual Fuel, AC, HP, and 2S applications.

in AC Mode, 3-Stage Heat/2-Stage Cool in HP Mode

Auto Changeover, 7-Day Programmable, °F/°C, — TSTATBBP2S01-B

Includes Outdoor Air Temperature Sensor.)

—3—

Page 4

UNIT

SIZE

036060 1/3 PSC

048080 1/2 PSC

060100 3/4 PSC

BLOWER

MOTOR HP SPEED

AIR DELIVERY— CFM (With Filter)

EXTERNAL STATIC PRESSURE (IN. WC)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

High

Med-High

Med

Med-Low

Low

High

Med-High

Med

Med-Low

Low

High

Med-High

Med

Med-Low

Low

1435

1195

1030

900

705

1855

1595

1355

1170

880

2235

1995

1735

1510

1145

1385

1165

1020

890

700

1765

1570

1345

1170

865

2185

1970

1735

1500

1140

1320

1145

1010

875

690

1710

1530

1305

1140

855

2110

1915

1675

1485

1125

1265

1105

985

855

675

1665

1485

1270

1110

830

2030

1845

1625

1455

1115

1195

1070

955

835

655

1580

1410

1220

1075

805

1950

1765

1565

1400

1100

INSTALLATION

This unit is certified for downflow installation only. See Installation Manual for

important installation instructions.

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

This forced air furnace is equipped for

use with natural gas at altitudes 0 10,000 ft

(0-3,050m).

An accessory kit, supplied by the

manufacturer, shall be used to convert to

propane gas use or may be required for

some natural gas applications.

This furnace is for indoor installation in

a building constructed on site.

This furnace may be installed on

combustible flooring in alcove or closet at

minimum clearance from combustible

material.

This furnace may be used with a Type

B-1 Vent and may be vented in common

with other gas-fired appliances.

For installation on non-combustible

†

floors only. For installation on

combustible flooring only when

installed on special base, Part No.

KGASB0201ALL, Coil Assembly,

Part No. CD5 or CK5, or Coil

Casing, Part No. KCAKC.

For furnaces wider than 14.25

#

inches (362mm) may be 0 inches.

Ø

18 inches front clearance required

for alcove.

For single wall vent type 6 inches.

##

This furnace is approved for DOWNFLOW installations only.

1"

0"

B

A

C

K

E

D

I

S

TOP / PLENUM

E

C

A

N

R

U

F

T

N

O

R

F

F

R

O

N

T

1" #

1"

BOTTOM

†

Clearance in inches.

Vent Clearance to combustibles:

For Single Wall vents 6 inches (6 po).

For Type B-1 vent type 1 inch (1 po).

##

1145

1015

915

795

625

1570

1355

1170

1025

755

1835

1680

1480

1320

1085

#

1"

E

D

I

S

S

E

R

V

I

C

E

30"

MIN

1080

955

860

755

580

1410

1280

1110

965

720

1700

1545

1370

1230

1045

1000

885

790

690

525

1310

1200

1025

890

655

1540

1415

1265

1130

990

Ø

322567-101 REV. E (LIT)

A97620

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS 331J.60.3

© 1999 Bryant Heating & Cooling Systems, 7310 W. Morris St. Indpls., IN 46231 PRINTED IN U.S.A. Catalog No. 5233-103 10-99

—4—

Loading...

Loading...