Bryant 1625, 2025, PERFECT AIR GAPAAXBB1625, PERFECT AIR GAPAAXBB2025 Installation Instructions Manual

GAPAA

PERFECT AIRt PURIFIER

SIZES 1625 AND 2025

Installation Instructions

NOTE: Read the entire instruction manual before starting the

install.

TABLE OF CONTENTS

PAGE

INTRODUCTION 1...................................

HOW IT WORKS 1...................................

SAFETY CONSIDERATIONS 1.........................

APPLICATION CONSIDERATIONS 2....................

INSTALLATION 3....................................

START--UP AND OPERATION 6........................

MAINTENANCE 7....................................

TROUBLESHOOTING 9...............................

SPECIFICATIONS AND DIMENSIONS 10................

WARRANTY 11......................................

INTRODUCTION

Congratulations for selecting the Perfect Air Purifier for your home

comfort system! The Perfect Air Purifier is proven to remove and

kill airborne germs and allergens, including viruses, bacteria, and

mold spores. The Perfect Air Purifier is a cornerstone of Bryant

Healthy Home Solutions for providing healthier, cleaner air in your

home.

HOW IT WORKS

The Perfect Air Purifier provides extremely high filtration

performance while killing captured contaminants, including

viruses, bacteria, and mold spores. The purifier treats the entire

air--stream through a state of the art, three--stage process.

In stage one, the particles are electrically charged by a

precision--point ionization array as they enter the purifier.

In stage two, the charged particles are electrically attracted to the air

purification cartridge, which is located within an electric field.

In stage three, captured particles are killed by electrical current

flow and ion bombardment.

The purifier is CSA certified for shock and electrical fire hazard

only.

La purifier certification CSA vise uniquement les risques de choc

electrique et.

A06054

Fig. 1 -- GAPAA UNIT

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings and cautions

included in literature and attached to the unit. Consult local

building codes and the current edition of the National Electrical

Code (NEC) NFPA 70.

In Canada, refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. When you see this symbol

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand the signal words DANGER,

WARNING,andCAUTION. These words are used with the

safety--alert symbol. DANGER identifies the most serious hazards,

which will result in severe personal injury or death. WARNING

signifies hazards, which could result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result

in minor personal injury or product and property damage. NOTE

is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

on

APPLICATION CONSIDERATIONS

!

The Perfect Air Purifier is designed for use in the return air duct of

a forced air heating, cooling, and ventilation system. Models

GAPAAXBB1625 and GAPAAXBB2025 are specifically

designed for use in systems with a forced air gas furnace.

Air Conditioning

The purifier should be installed in a system so that all the return air

is circulated through the air purifier. It should be located upstream

of both the furnace and the air conditioning evaporator coil. This

will help keep the furnace and evaporator coil clean and prevent

condensation from forming within the purifier.

Humidifiers

An evaporative humidifier can be mounted upstream of the

purifier. It is best to install atomizing humidifiers downstream of

the air purifier because hard water salt deposits and water droplets

may damage air purifier. If an atomizing humidifier must be

mounted upstream of the purifier, it should be mounted as far

upstream as possible (at least 6 ft./1.8 m recommended), and a

GAPAA

standard disposable furnace filter should be mounted between the

humidifier and the air purifier to trap hard water salt deposits and

water droplets.

Ensure that the humidifier installation will not allow water or water

droplets to enter the air purifier because it may cause electrical

arcing or damage the air purifier.

NOTE: For fan coil installations, do not install the humidifier in

the fan coil access doors or cabinet.

Inspect for plugged drains and maintain humidifier drain lines on a

regular basis to avoid overflow of water into the air purifier. The

recommended inspection should be done at every change of the air

purifier cartridge (minimum, annually).

HIGH VOLTAGE HAZARD

Failure to follow this warning could result in personal injury

or death.

This air purifier utilizes high voltage. If you notice water

running into or around the air purifier, water stains on the

purifier cartridge or on the Enhancement Module walls or

cabinet, shut off the air purifier and call your service provider.

Transitions

If the return air duct or furnace openings do not fit the purifier

cabinet openings, gradual transitions are recommended to reduce

air turbulence and maximize efficiency. No more than 45_ (about

8.5 in. per running ft.) of expansion should be used on each side of

the transition fitting.

Turning Vanes

If the purifier is installed adjacent to a 90_ duct elbow, turning

vanes should be added inside duct to improve air distribution

across the face of the air purifier.

Electrical Power

The purifier should only be powered when airflow is present. The

furnace control EAC terminals provide power only when the

furnace blower is operating. Perfect Air Purifier models

GAPAAXBB1625 and GAPAAXBB2025 are designed to be

powered from the electronic air cleaner (EAC) terminals on a

furnace electronic control. If EAC terminals are not available, an

alternative airflow sensing mechanism must be used to ensure the

purifier is only powered when airflow is present. Contact local

Bryant distributor for information on approved alternatives.

WARNING

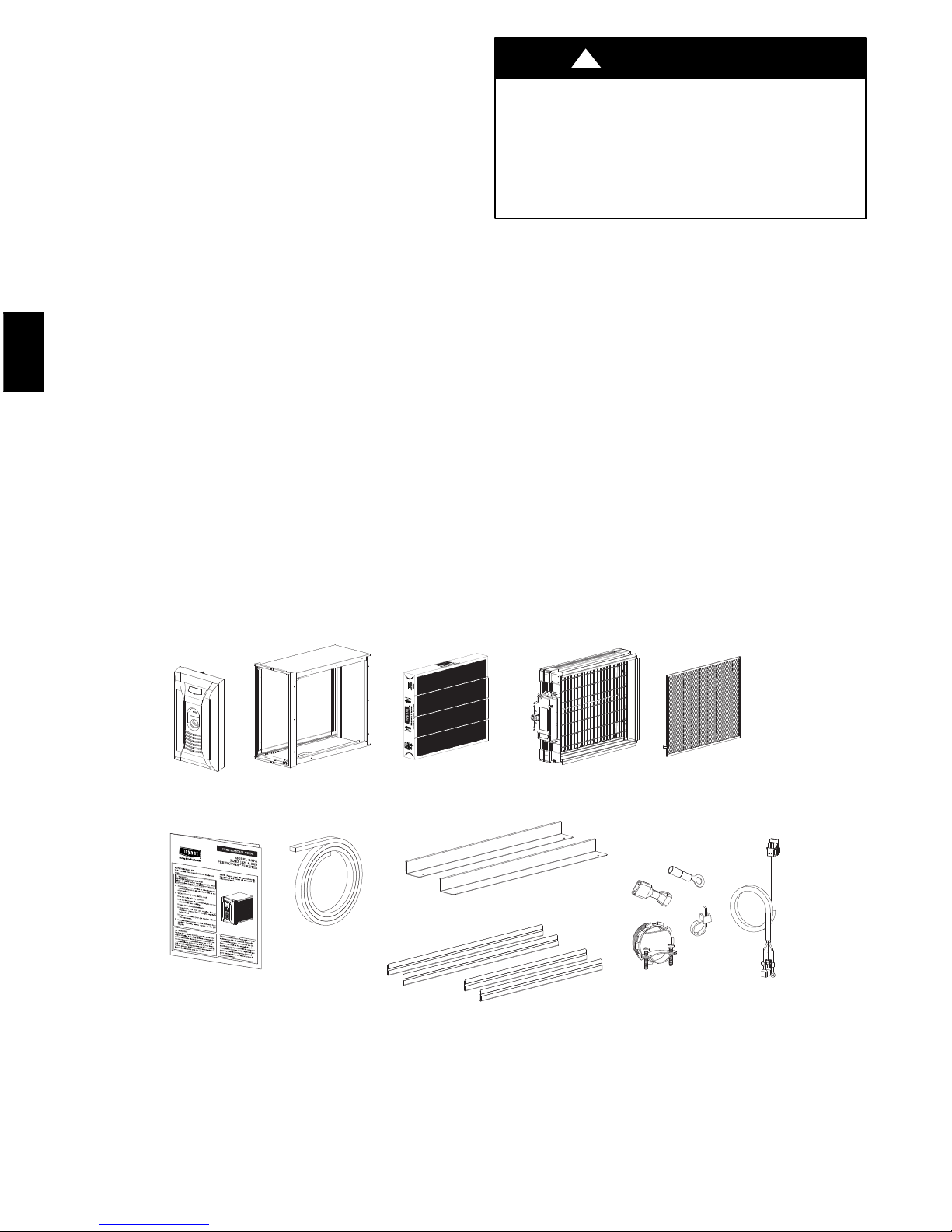

Door (x1) Cabinet (x1) Enhancement Module (x1) Safety Screen (x1)

Duct Gasket Tape

(1 roll)

Installation Manual

Air Purification Cartridge (x1)

Furnace Adapters (x2)

Return Duct Adapters:

Long (x2) / Short (x2)

Fig. 2 -- Perfect Air Purifier Components

2

(x1)

(x2)

(x2)

Installation Components

(in bag attached to power cord)

(x1)

(x2)

A06064

INSTALLATION

A

Check Perfect Air Purifier Components

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling parts.

Carefully remove all items from the box.

Identify Mounting Location

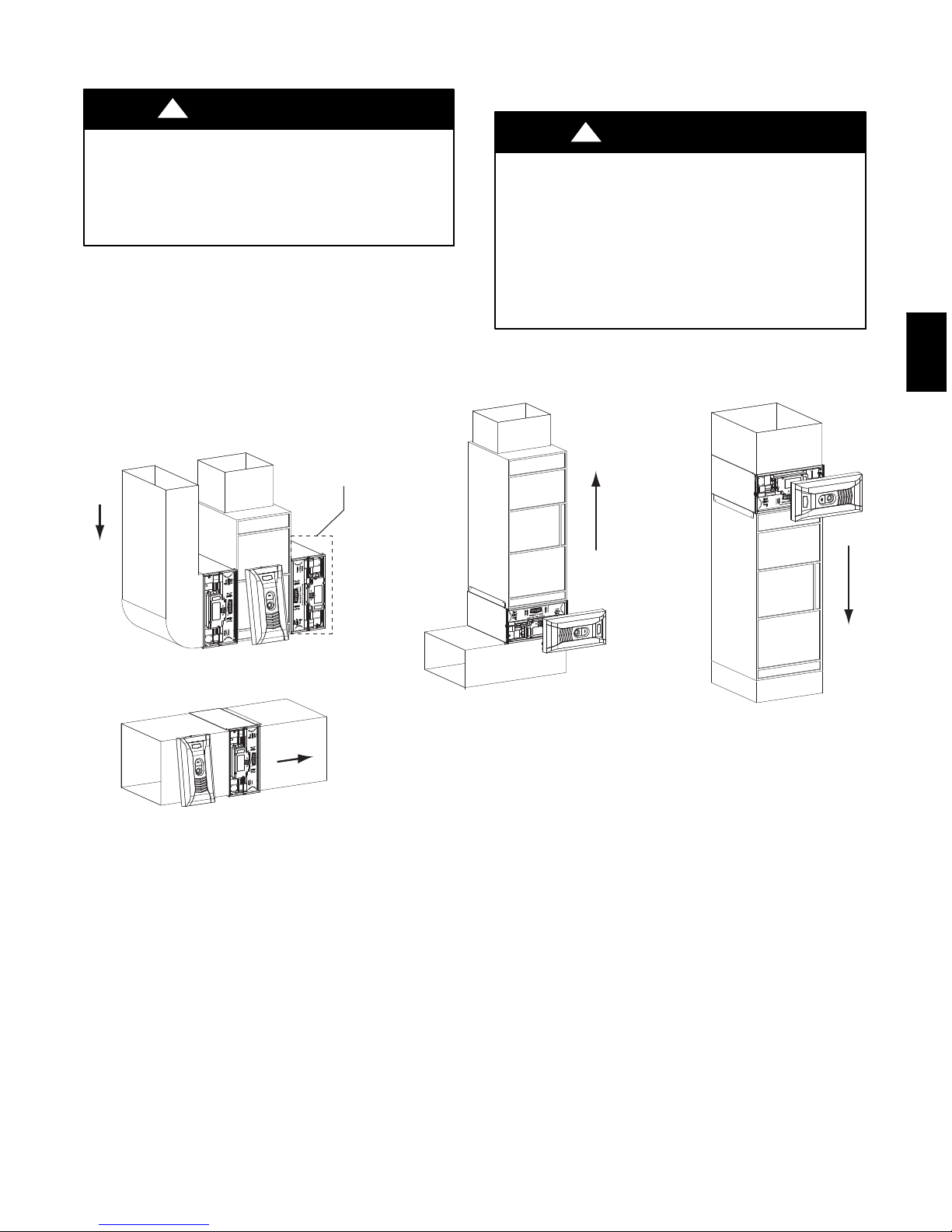

a. Identify a mounting orientation for the purifier in the return

air duct (see Figures 3 and 4).

b. Ensure airflow direction through the purifier matches the ar-

rows on the face of the air purifier cartridge. The purifier

can be rotated 180_ to accommodate the cabinet orientation.

NOTE:

Mounting on this side

requires the cabinet

to be rotated 180° for

correct air flow.

irflow

c. The location of the purifier should be readily accessible.

Enough room should be provided for periodic replacement

of the air purifier cartridges.

!

WARNING

ELECTRIC SHOCK AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury

or death.

Only a trained, experienced service person should install the

purifier. A thorough check of the unit installation should be

completed before unit operation. Before performing

installation, service or maintenance operations on unit, turn off

all power to unit. Tag disconnect switch with lockout tag.

GAPAA

Airflow

Airflow

Upflow Furnace with Side Return

Upflow Furnace with Bottom Mount Downflow Furnace with Top Mount

Airflow

Horizontal Application

A06067

Fig. 3 -- Perfect Air Purifier Cabinet Orientation

3

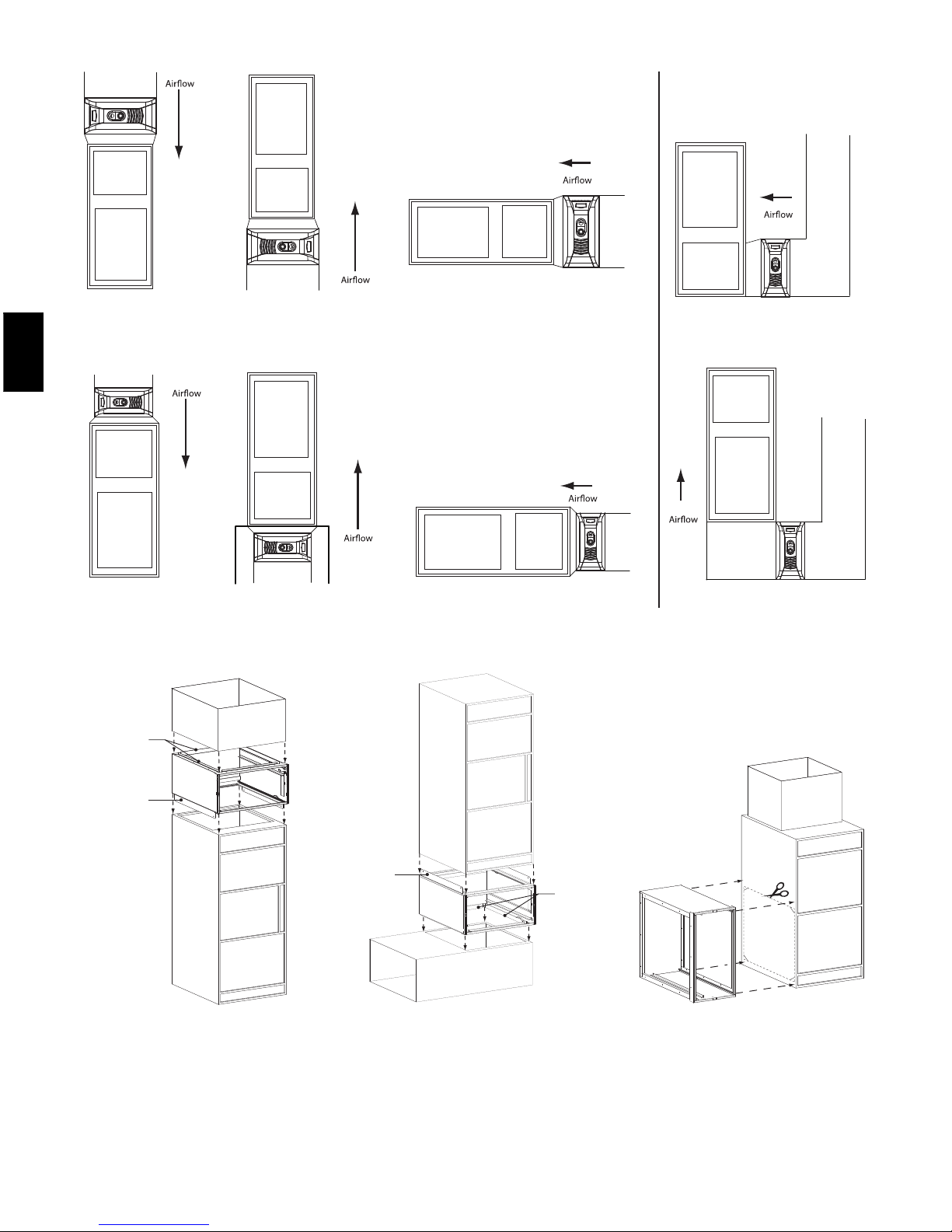

Note: When transitioning between two dierent sized components (furnace & purer), the

A

minimum transition angle at the larger of the two components must be no less than 45 degrees.

Downflow 14” Furnace

with Top Mount

Upflow 14” Furnace

with Bottom Mount

Horizontal 14” Furnace

with Side Mount

Upflow Furnace

GAPAA

Plenum

Box

Downflow 24” Furnace

with Top Mount

Return Duct

dapters (x4)

Upflow 24” Furnace On Stand

with Bottom Mount

Fig. 4 -- Perfect Air Purifier Cabinet Orientation with Transition

Return Duct

Horizontal 24” Furnace

Upflow Furnace

with Plenum Box

A09022

Furnace

Adapters (x2)

Top Mount Bottom Mount Side Mount

Furnace

Adapters (x2)

Return Duct

Adapters (x4)

Return Duct

Fig. 5 -- Mounting Perfect Air Purifier Cabinet

4

A06029

Mount Cabinet

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than 1 disconnect switch.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Cabinets will support a maximum weight of 400 lbs/181 kg

when installed beneath a vertical furnace or air--handling

unit. When setting furnace on cabinet, do not drop it into

place. Position the furnace correctly on the cabinet to prevent

a corner from slipping down and damaging the cabinet or its

components.

a. Turn off power to the heating and cooling system.

b. Remove the existing furnace filter and discard. Excessive

system static may result if the purifier is used with other filtration devices.

c. Remove the air purifier cartridge and enhancement module

from the purifier cabinet.

d. Position the cabinet between the furnace and return air duct

(see Figures 3, 4, 5 and 6). A transition duct may be required.

e. Furnace adapters have been included for installer conveni-

ence. They are designed for top or bottom mount installations (see Fig. 6).

Furnace

Adapters

Airow

g. Install foam tape between the furnace and the air purifier

cabinet.

h. Mounting holes are provided for ductwork and furnace at-

tachment.

Note: Slip

S-cleats onto anges

on air return duct side.

A05277

Fig. 7 -- Use of Return Duct Adapters

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

Mounting holes are provided for duct work and furnace

attachment. The screws on the down--stream side of the

cabinet should be installed so that the screw heads are inside

air purifier cabinet to prevent damage to the air purifier

cartridge.

i. Seal seams with tape or caulking after the purifier cabinet

has been secured.

Special consideration must be given when applying the 2025

Perfect Air Purifier to a 24 1/2--in (622 mm) wide furnace.

a. Prepare transition, following recommended transition draw-

ing (see Fig. 8). Fabricate a 2 1/4--in (57 mm) tall (minimum) transition.

b. Place transition on top of purifier. Secure with sheet metal

screws. Place furnace on top of transition. Make sure furnace rests evenly on top of transition and purifier.

c. Secure furnace to transition using sheet metal screws. See

Fig. 4.

d. Continue with normal installation practices.

Furnace Casing Width 24 1/2” (622)

B

Rear Bracket

5/8” (16)

Flanges

(Where Shown)

GAPAA

Airow

Fig. 6 -- Use of Furnace Adapters

f. Return air duct adapters have been included for installer

convenience. They should be used to connect the upstream

side of the air purifier cabinet to the return air duct (see Fig.

7).

A05274

2 1/4” (57)

5

Front Bracket

19 1/2” (495)

A

(Inside Opening)

Air Purifier Outlet

Side Bracket

Side Bracket

NOTE: Weld 3 places

in 4 corners

Fig. 8 -- Recommended Transition

24” (610)

(Outside)

A09001

Power Cord

to EAC Terminals

Alternate Power Cord

Pass-Thru Hole

Use cable connector to secure

power cord to cabinet

Power Supply Connector

Power Supply

Use wire ties to secure power cord

to power supply enclosure

Power Supply Connector

Power Cord

EAC-2 TERMINAL

Sample Furnace Circuit Board

OFF

W2

LHT

OFF

Y1 DHUM G COM

DLY

24V

TEST/TWIN

WW1 Y/Y2 R

PLT

HUM

0.5-AMP024 V AC

FUSE 3-AMP

A

T

T

S

SEC-1 SEC-2

U

D

S

E

C

L

O

E

D

NEUTRAL-L2

EA C-2

BLW

HI HEA T LO HEA T

COOL

SPARE-1 SP ARE-2

EAC-1 TERMINAL

ON

1 2 3

ACRDJ

Use terminals to connect the

power cord wires to the furnace

EAC-1 & 2, & ground terminals

PL1

1

BHT/CLRBHI/LOR

1-AMP@115 V A C

EA C-1 PR-1

PL3 1

BLWR

IDR

L1

IHI/LOR

HSIR

IDM

1

PL2

HSI HI LO

A06030

Fig. 9 -- Perfect Air Purifier Electrical Connections

GAPAA

Wiring

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system. There may be more than 1 disconnect

switch.

!

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Black Lead -- Connect to HOT (L1) or EAC--1 when

provided.

White Lead -- Connect to Neutral (L2) or EAC--2 when

provided.

Green/Ground Lead -- Connect to Appliance Ground

(Chassis).

CAUTION

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

This unit cannot be powered directly from blower motor

leads. Voltages can exceed 190 VAC (120v motors). Do not

wire directly to blower motor. Wiring to blower motor will

damage power supply and void warranty.

a. Ensure power has been removed from the heating and cool-

ing system.

b. Turn the purifier power switch off.

c. Connect the power cord to the power supply connector (see

Fig. 9).

d. Route the power cord through nearest cabinet hole and pro-

tect with enclosed cable connector. Zip ties have been enclosed to secure the power cord to the side of the power

supply.

e. Attach the quick connect terminals to the furnace EAC--1

and EAC--2 spade connections. Attach the ground ring to

furnace chassis ground.

NOTE: The purifier is to be powered by 115v/60 Hz.

NOTE: The purifier should only be powered when airflow is

present. The furnace control EAC spade connections provide

power only when the furnace blower is operating. If EAC

connections are not available, an alternative airflow sensing

mechanism must be used to ensure the purifier is only powered

when airflow is present. Contact a local Bryant distributor for

information on approved alternatives.

START--UP AND OPERATION

Checking Air Purifier Operation

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one (1) disconnect

switch.

a. Attach the purifier door to the cabinet. A magnet in the door

is used to activate a safety switch in the power supply when

the door is installed. The power supply will not energize the

air purifier unless the safety switch is activated.

!

WARNING

CARBON MONOXIDE HAZARD

Failure to follow this warning could result in personal injury

or death.

Do not remove door during blower operation or operate

blower with door removed or improperly latched.

b. Turn the HVAC system power on and adjust the thermostat

or Perfect Air System Control to activate the system fan.

c. Turn the purifier power switch to on position.

d. The power indicator light above the air purifier power

switch should illuminate (see Fig. 10).

6

e. Check to ensure the light goes off when the purifier power

switch is set to off, when the blower goes off, or when the

HVAC system power is turned off.

Evolutiont Air Control

When the Perfect Air Purifier is used with an Evolution Control,

the Evolution Control can be configured to remind the homeowner

when it is time to change the purifier cartridge. This maintenance

reminder can be based on either the TrueSenset dirty filter

algorithm or time. The installer should use their discretion to select

the most appropriate option based on the initial system static

pressure.

Maximizing Performance

Maximum air purification performance is obtained when the

furnace blower is set for continuous operation on the thermostat or

Evolution Control.

MAINTENANCE

The purifier is designed to require minimal maintenance.

Maintenance is limited to the replacement of the air purification

cartridge and inspection/brush cleaning of the ionization array.

Frequency of air purifier cartridge replacement and cleaning of the

ionization array may vary depending on ductwork design and local

environmental conditions, generally 8--12 months.

!

WARNING

FIRE HAZARD

Failure to follow this warning could result in personal injury

or equipment damage.

Use of non--factory approved filter cartridge will void the

warranty and may causedamage due to fire.

To replace the air purifier cartridge, complete the

following

Turn the heating and cooling system power

off.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one (1) disconnect

switch.

Turn the purifier switch to the off position.

Remove the purifier door.

Slide out the old air purifier cartridge and discard.

Install the new air purifier cartridge. Make sure the power cord is

flexed out of the way to avoid damage to the air purifier cartridge

pleats during insertion.

NOTE: Verify that the air purifier cartridge is installed correctly.

Make sure that the arrows on the air purifier cartridge point toward

the fan coil. This should be in the same direction as airflow and

match the arrows on the sticker inside the cabinet.

Replace the purifier door.

Turn the purifier switch to the on position.

Turn heating and cooling system power on.

steps:

!

WARNING

!

WARNING

CARBON MONOXIDE HAZARD

Failure to follow this warning could result in personal injury

or death.

Do not remove door during blower operation or operate

blower with door removed or improperly latched.

Power Indicator

A06065

Fig. 10 -- Power Indicator

At the time of air purifier cartridge replacement, if a powdery

residue is noticed on the tips of the points in the ionization array,

proceed to clean them by completing the following steps.

Turn heating and cooling system power off.

!

WARNING

ELECTRICAL SHOCK AND HIGH VOLTAGE

HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one (1) disconnect

switch.

Turn the purifier switch to the off position.

Remove the purifier door.

Unplug the power cord from the enhancement module.

Slide out the enhancement module assembly and safety screen.

!

WARNING

CUT HAZARD

Failure to follow this warning could result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling parts.

Slide out the safety screen and set aside.

NOTE: Best cleaning tools: 5--in (127 mm) handle paint brush

with 2--in (51 mm) width (or greater) brush point (synthetic or

GAPAA

7

natural bristle) or vacuum cleaner with brush attachment. See Fig.

11.

Gently stroke the ionization pins on the top plane of each bar with

enough brush depth to hit front and back tips of the points in the

ionization array. Use a gentle back and forth brushing motion to

clean any small accumulations from the tips of the points. If

desired, use vacuum cleaner with brush attachment to gently

vacuum the frame and components of enhancement module.

Reinstall the safety screen. Do not operate the unit without the

Safety Screen.

Slide in enhancement module.

Reconnect power cord.

Replace the purifier door.

Turn the purifier switch to the on position.

Turn heating and cooling system power on.

GAPAA

30°

POINTS ARE SHARP! BE VERY CAREFUL DURING CLEANING.

Tip of point with residue

Fig. 11 -- Removal of Deposits from Ionization Pins

TROUBLESHOOTING

!

CAUTION

SAFETY HAZARD

Failure to follow this caution may result in personal injury or

equipment damage.

The following instructions are for use by qualified personnel

only.

Tip of point after cleaning

A06671

The purifier is equipped with a power indicator light located on the

door (see Fig. 10). This power indicator light will illuminate when

the purifier door is installed, the power switch is in the on position,

AND the furnace blower is running. If the power indicator light is

not illuminated, follow the troubleshooting steps below.

See Table 1.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

The following procedures will expose electrical components.

Disconnect power between checks and proceed carefully.

8

Be sure to inspect the unit before proceeding with these steps. Start with problem 1, then problem 2 and so on.

Table 1 – Troubleshooting

Problem: S Possible causes: S You should try this:

1 Infinity Air Purifier power indicator light

located on the door is off.

2 Power Indicator light cycles on and off

intermittently.

3 Air PurifierCartridgehas smallsingeorchar

marks on the frame.

4 The wall controlwill not work.

5 The 20-minute lighted push- button switch

doesn’t work OR its indicator light doesn’t

stay on.

S Power switch is not in the on (closed) position.

S Door is not closed. A magnet in the door is used

to activate safety reed switches in the power

supply when the door is installed.

S The door magnet is missing or has fallen out.

S The door safety reed switches may be defective.

S Furnace blower is not operating. Power willnot

be supplied from the furnace control’s EAC

terminals unless the blower is running.

S Bent pins or loose connection in the molex plug

of the service cord.

S The power supply may be defective.

S The light pipe transferring the light from the

LED’s on the power supply to the door may be

broken.

S Overload condition activating the safety

circuitry

S Unit is wet. (Water may be entering the unit from

a source such as condensate or dripping from a

frozen evaporator coil.)

S Grounding paths in the unit are interrupted due

to breakage ,corrosion or loose contact.

S Arcing to ground (such as unit cabinet ) is

occurring.

S Arcing to ground is occurring due to debris

lodged in the safety screen or across ionization

grid.

S Ionization grid is not centeredor isloose andnot

clipped in place, possibly touching the air

purifier cartridge or safety screen.

S Electrode wire is loose and making contact with

the enhancement module wall.

S Field electrode wire is damaged or nicked.

S The cartridge is installed backwards

S The wire in the wall OR the wall control may be

defective.

S The wires may be in reverse position.

S Thewiresmaybebroken.

S There may be a short-circuit.

S The switch may be defective.

S The wires may be defective OR may not be

connected properly.

S Make sure the switch is on and using a

multimeter check to see that 115 Volt power is

available.

S Re-cement loose door magnet with a suitable

adhesive.

S If the unit switch is on and 115 Volt power is

available through the service cord, a door

magnet moved in close proximity of the power

supply will cause the reed switches to audibly

click and the power supply will turn on.

S Make sure the furnace blower is operating.

S Replace Service cord or replace entire power

supply / field enhancement module assembly if

required.

S Replace entire powersupply / field enhancement

module assembly.

S Replace access door.

S

S Remove the access door and the air purifier

cartridge. Power the unit then use a spare door

magnet or “service” magnet to activate the air

purifier power supply. Turn out the lights and

observe for arcing.

S Make sure all three grounding clips (FEM to

cabinet, safety screen to cabinet, cartridge to

cabinet on the leaving air side) are securely in

place and making clean contact.

S Make sure the safety screen is clear and remove

debris.

S Make surethe ionizationgrid is secured in place

with all four clips and centered in the FEM

housing.

S Verify thatthe ionization grid is clean andintact.

S Make sure the field electrode wire is wound

through the spools on the enhancement module

with sufficient tension and tied to itself at the end

termination. If it is loose rewind and retie it.

S If the field electrode wire is damaged or nicked,

replace entire power supply /field enhancement

module assembly.

S Turn off the unit and remove the access panel.

S Replace the air purifier cartridge with Factory

Authorized Replacement Cartridge and ensure

airflow direction arrows are correct.

S Remove the wall control and test it right beside

the unit using another shorter wire. If the wall

control works there, change the wire. If it does

not, change the wall control.

S Ensure that the color coded wires have been

connected to their appropriate places.

S Inspect every wire and replace any that are

damaged.

S With the help of a multimeter, check for

continuity.

S Jump the OL and OC terminals. If the unit

switchesto high speed, thenthe wiresare not the

problem. Replace the push-button.

S Ensure that the color-coded wires have been

connected to their appropriate places.

GAPAA

9

SPECIFICATIONS AND DIMENSIONS

Table 2 – Specifications and Dimensions

SPECIFICATIONS GAPAAXBB1625 GAPAAXBB2025

Color Taupe Metallic Taupe Metallic

Cabinet Material 20 Ga. Powder Coated Steel 20 Ga. Powder Coated Steel

Electrical 115v/60 Hz (from furnace EAC terminals) 115v/60 Hz (from furnace EAC terminals)

Maximum Airflow (CFM) 1600 2000

Efficiency MERV 15 MERV 15

Replacement Cartridge GAPCCCAR1625 GAPCCCAR2025

Pressure Drop @ Maximum Airflow .25 InH20 .25 InH20

Dimensions GAPAAXBB1625 GAPAAXBB2025

A 18-- -3/8 ---in (466.7mm) 21-- -7/8 ---in (555.6mm)

B 15--- 1/8 --- in (384.1mm) 18---5/8 ---in (473.1mm)

C 11---1/8--- in (282.6mm) 11---1/8--- in (282.6mm)

GAPAA

D 17--- 1/2--- in (444.5mm) 21-- -in (533.4mm)

E 22-- 1/8--in (562mm) 22--1/8--in (562mm)

F 25--- 1/4- -- in (642.4mm) 25--- 1/4--- in (642.4mm)

1 3/16" (30.2mm)

A

7/16" (11.1mm) (Typical Top & Bottom)*

C

1 15/16” (49.2mm)

E

F

D

B

1 3/16” (30.2mm)

1 3/16” (30.2mm)

A09021

Fig. 12 -- Dimensions

10

Limited Warranty for Air Purifier

FOR WARRANTY SERVICE OR REPAIR:

Contact the installer. You may find the installer’s name on the equipment or in your Owner’s Packet.

For help, contact: CAC / BDP, Consumer Relations, P.O. Box 4808, Syracuse, New York 13221, Phone 1-800-227-7437

PRODUCT REGISTRATION: You can register your product online at www.cac-bdp.com

Model No. ____________________________________________

Date of Installation _____________________________________

Name of Owner _______________________________________ Address of Installation __________________________________

CAC / BDP (hereinafter “Company”) warrants this product against failure due to defect in materials or workmanship under normal use and maintenance

as follows. All warranty periods begin on the date of original installation. If a part fails due to defect during the applica ble warranty period Company

will provide a new or remanufactured part, at Company’s option, to replace the failed defective part at no charge for the part. Alternatively, and at its

option, the Company will allow a credit in the amount of the then factory selling price for a new equivalent part toward the retail purchase price of a new

Company product. Except as otherwise stated herein, those are Company’s exclusive obligations under this warranty for a product failure. This limited

warranty is subject to all provisions, conditions, limitations and exclusions listed below and on the reverse (if any) of this document.

OWNER-OCCUPIED, RESIDENTIAL APPLICATIONS

This warranty is to the original purchasing owner and is transferable only to the extent and as stated in the Warranty Conditio ns and below. The

warranty period in years, depending on the part and the claimant, is as shown in the chart below.

OTHER RESIDENTIAL APPLICATIONS (Apartments, Rental Properties, etc.)

The warranty period is five (5) years and is not transferable.

OTHER APPLICATIONS

This warranty is non-transferable. The warranty period is one (1) year on all such applications.

LEGAL REMEDIES - The owner must

Syracuse, New York 13221, of any defect or complaint with the product, stating the defect or complaint and a specific request f or repair, replacement,

or other correction of the product under warranty, mailed at least thirty (30) days before pursuing any legal rights or remedies.

39004DP452

01/10

Unit Serial No. ________________________________________

Installed by ___________________________________________

Product Original Owner Subsequent Owner

* If properly registered within 90 days, otherwise 5 years (except in California and Quebec and other jurisdictions that prohibit warranty benefits

conditioned on registration, registration is not required to obtain longer warranty periods). See Warranty Conditions below.

** If properly transferred within 90 days, otherwise 5 years. See Warranty Conditions below. In California and Quebec and other jurisdictions that

prohibit warranty benefits conditioned on registration, registration is not required for a transfer and all warranty periods for subsequent owners are

five years from original installation.

notify the Company in writing, by certified or registered letter to CAC / BDP, Warranty Claims, P.O. Box 4808,

.

Limited Warranty (Years)

)5 ro( **01 )5 ro( *01 reifiruP riA APAG

GAPAA

11

A

A

WARRANTY CONDITIONS:

1. To obtain the longer warranty periods as shown in the table under original owner, for the original purchaser, the product must

registered at www.cac-bdp.com

registration are prohibited by law, registration is not required and the longer warranty period shown will be apply.

2. Where a product is installed in a newly constructed home, the date of installation is the date the homeowner purchased the home from the

builder.

3. If the date of original installation cannot be verified, then the warranty period begins ninety (90) days from the date of product manufacture (as

indicated by the model and serial number). Proof of purchase may be required at time of service.

4. The remainder of the first five years of warranty is freely transferable without registration. To obtain a transfer of the longer warranty periods

as shown in the table under subsequent owner, a subsequent owner must register the transfer at www.cac-bdp.com

change in ownership and payment of a transfer fee. Not applicable in all jurisdictions. See website for details.

5. Product must be installed properly and by a licensed HVAC technician.

6. The warranty applies only to products remaining in their original installation location.

7. Installation, use, care, and maintenance must be normal and in accordance with instructions contained in the Installation Instructions, Owner’s

Manual and Company’s service information.

8. Defective parts must be returned to the distributor through a registered servicing dealer for credit.

LIMITATIONS OF WARRANTIES: ALL IMPLIED WARRANTIES AND/OR CONDITIONS (INCLUDING IMPLIED WARRANTIES OR

CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR USE OR PURPOSE) ARE LIMITED TO THE DURATION OF THIS

LIMITED WARRANTY. SOME STATES OR PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY OR

CONDITION LASTS, SO THE ABOVE MAY NOT APPLY TO YOU. THE EXPRESS WARRANTIES MADE IN THIS WARRANTY ARE

EXCLUSIVE AND MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBUTOR, DEALER, OR OTHER PERSON,

GAPAA

WHATSOEVER.

THIS WARRANTY DOES NOT COVER:

1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of either defective parts, or

replacement parts, or new units.

2. Any product purchased over the Internet.

3. Normal maintenance as outlined in the installation and servicing instructions or Owner’s Manual, including filter cleaning and/or replacement

and lubrication.

4. Failure, damage or repairs from faulty installation, misapplication, abuse, improper servicing, unauthorized alteration or improper operation.

5. Failure to start due to voltage conditions, blown fuses, open circuit breakers, or damages due to the inadequacy or interrup tion of electrical

service.

6. Failure or damage due to floods, winds, fires, lightning, accidents, corrosive environments (rust, etc) or other conditions beyond the control of

Company.

7. Parts not supplied or designated by Company, or damages resulting from their use.

8. Products installed outside the U.S.A. or its territories and Canada.

9. Electricity or fuel costs, or increases in electricity or fuel costs from any reason whatsoever, including additional or unusual use of

supplemental electric heat.

10. Any cost to replace, refill or dispose of refrigerant, including the cost of refrigerant.

11. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGE OF ANY NATURE WHATSOEVER.

states or provinces do not allow the exclusion of incidental or consequential damages, so the above limitation may not apply to you.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state or province to province.

within ninety (90) days of original installation. In jurisdictions where warranty terms conditioned on

be properly

within 90 days of the

Some

39004DP452

01/10

E2010 Bryant Heating & Cooling Systems D 7310 W. Morris St. D Indianapolis, IN 46231 Printed in China Edition Date: 10/10

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

12

Catalog No. IIGAP

Replaces: IIGAPAA--- 05

--- 0 6

Loading...

Loading...