CM5A/CM5B COILS

KMABA BLOWERS

For Manufactured Homes

4THE CM5A/CM5B INDOOR COIL

To complete your cooling or heating system, the model CM5A

or CM5B Coil is installed inside your Evcon/Coleman, Nordyne/Miller/Intertherm or AirPro gas or electr ic downflow furnace. Both coils are uncased, and designed for installation

within the manufactured home furnace casing or inside a factory-installed plenum. These indoor coils are designed to be

used in conjunction with blower kits and other accessories.

The CM5A and CM5B coils are designed for quick and easy installation by a qualified service technician.

The CM5A comes with factory-installed mechanical connections. The CM5B comes with factory-installed sweat connections. Both coils utilize a Check-Flo-Rater® piston for refrigerant flow control. Both coils can be used in cooling-only

applications or as part of a heat pump system.

When heating in conjunction with a heat pump, the outdoor

heat pump unit recovers heat from the outdoor air, and transmits it to the CM5A or the CM5B indoor coil for distribution to

the living space. The CM5A and CM5B coils are not activated

when heating in conjunction with a furnace without a heat

pump in the system.

Built-in drainage assembly ensures leak-free condensate removal. Periodic cleaning of filter and drainage sections is recommended to avoid possible sediment b loc kage . The A-shape

design of the coil provides maximum cooling-heating transfer

surface and ease of handling at installation. F our coil siz es are

available from 024 though 048, covering a wide range of cooling-heating capacities to meet varying manufactured home requirements.

THE KMABA BLOWER

KMABA Blower Kits and Accessories are designed and built to

meet the needs of the manufactured housing market. The kits

are used to upgrade Nordyne and Evcon gas and electric furnaces (see note). For cooling and heat pump duty, kits available include blowers f or up to 4 tons of air conditioning, control

boxes, insulation kits, filter kits, and evaporator coil shelves.

Blower kits for gas furnaces are shipped without controls. Order

the control box from accessory usage chart. Blower kits for electric furnaces are shipped with or without controls. See accessory usage chart for details. All control box kits are designed to

operate with a minimum 4-wire thermostat.

Quick connect wire harnesses are shipped with the appropriate blower kit or control box for ease of installation. Sheet

metal adapter plates also are included with the blower kits that

are needed to adapt the blower with the furnace.

NOTE: Intertherm, Miller, Coleman, and AirPro brands.

Form No. PDS CM5A.24.2

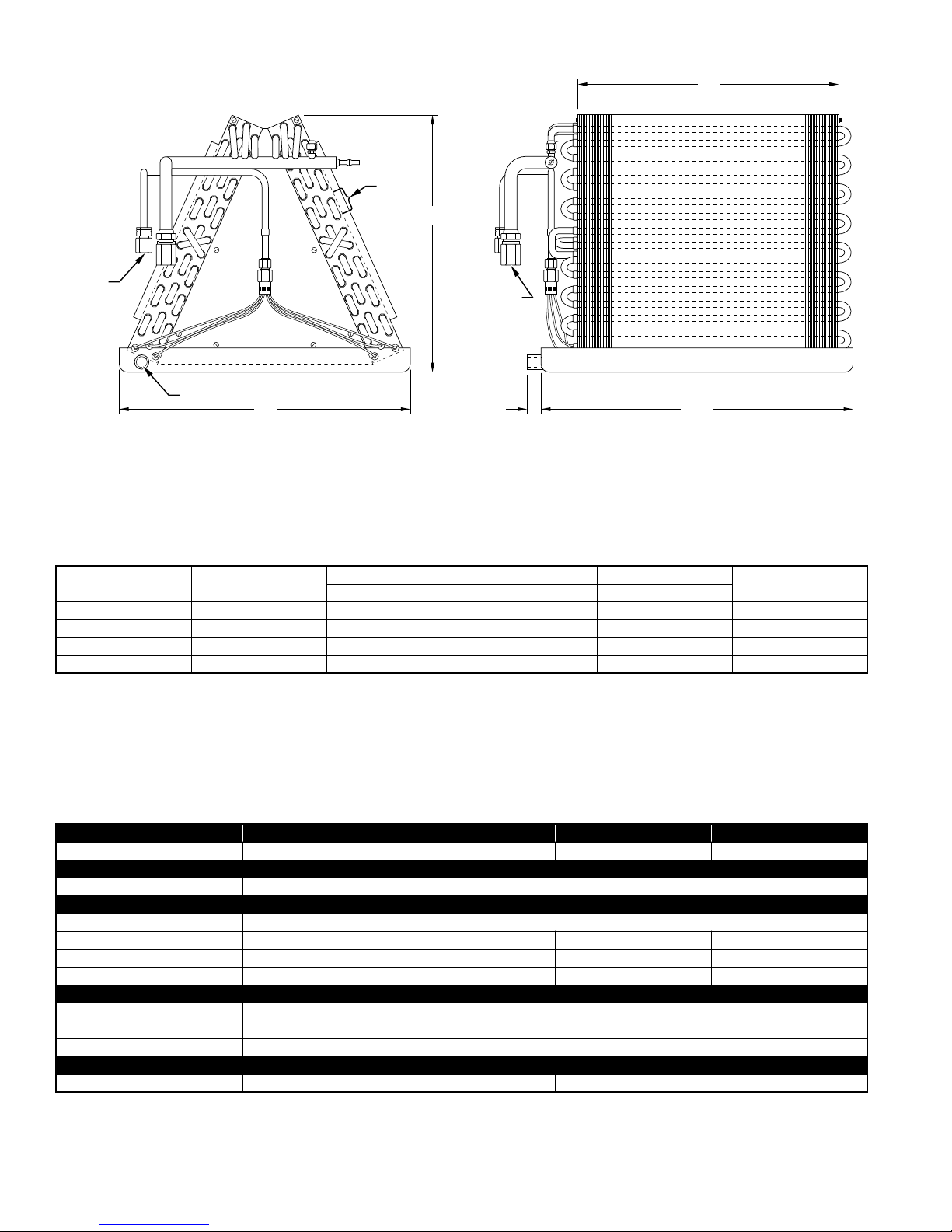

3

⁄8″ DIA

LIQUID

FITTING

7

⁄8″ OD DRAIN

CM5A DIMENSIONS

16″

"C" ROWS

"A"

"B" DIA

VAPOR

FITTING

7

⁄8″18″

FRONT RIGHT SIDE

19 1⁄4″

UNIT DIMENSIONS (In.) NUMBER OF ROWS

SHIPPING WEIGHT

UNIT SIZE SERIES

024 A 14 5/8 3 30

036 A 16 3/4 3 32

042 A 18 3/4 3 35

048 A 18 3/4 4 37

NOTE: Series designation is the 14th position of unit model number.

CM5A SPECIFICATIONS

UNIT SIZE-SERIES 024-A 036-A 042-A 048-A

Operating Weight (Lb) 21 23 26 28

REFRIGERANT

Control Check-Flo-Rater® Piston

COIL

Type Uncased A-Type with Aluminum Fins

Rows-Fins/In. 3–15 3–15 3–15 4–13

Face Area (Sq Ft) 3.11 3.56 4.00 3.56

Nominal CFM 800 1200 1200 1200

CONNECTIONS

Type Mechanical

Vapor (In. ID) 5/8 3/4

Liquid (In. ID) 3/8

OPTIONAL EQUIPMENT

TXV (Hard Shutoff) KSATX0801HSO KSATX0901HSO

A96627

(Lb)ABC

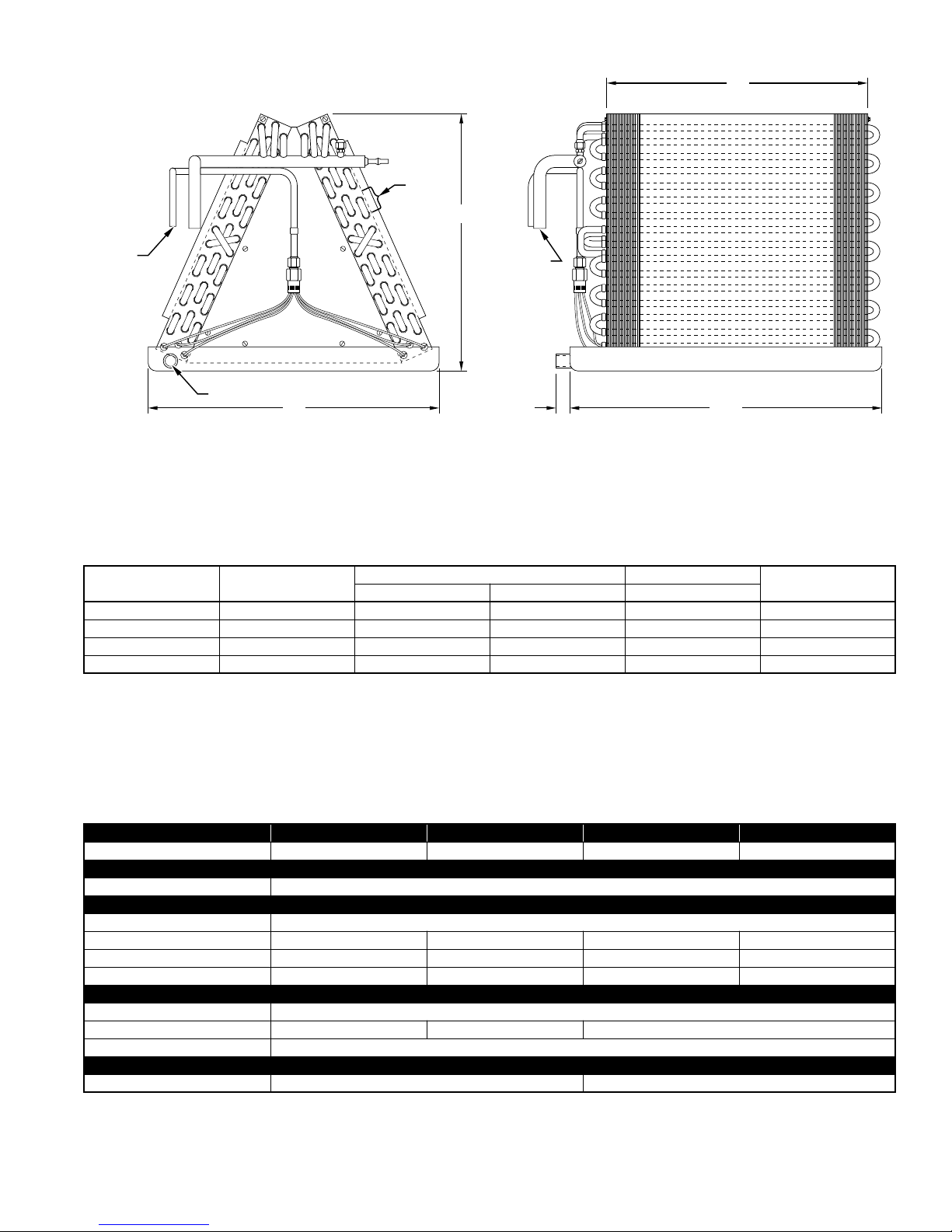

—2—

3

⁄8″ DIA

LIQUID

FITTING

7

⁄8″ OD DRAIN

CM5B DIMENSIONS

16″

"C" ROWS

"A"

"B" DIA

VAPOR

FITTING

7

⁄8″18″

FRONT RIGHT SIDE

19 1⁄4″

UNIT DIMENSIONS (In.) NUMBER OF ROWS

SHIPPING WEIGHT

UNIT SIZE SERIES

024 A 14 5/8 3 30

036 A 16 3/4 3 32

042 A 18 7/8 3 35

048 A 18 7/8 4 37

NOTE: Series designation is the 14th position of unit model number.

CM5B SPECIFICATIONS

UNIT SIZE-SERIES 024-A 036-A 042-A 048-A

Operating Weight (Lb) 21 23 26 28

REFRIGERANT

Control Check-Flo-Rater® Piston

COIL

Type Uncased A-Type with Aluminum Fins

Rows—Fins/In. 3–15 3–15 3–15 4–13

Face Area (Sq Ft) 3.11 3.56 4.00 3.56

Nominal CFM 800 1200 1200 1200

CONNECTIONS

Type Sweat

Vapor (In. ID) 5/8 3/4 7/8

Liquid (In. ID) 3/8

OPTIONAL EQUIPMENT

TXV (Hard Shutoff) KSATX0801HSO KSATX0901HSO

A96628

(Lb)ABC

—3—

A

B

C

D

A97119

BLOWER MODEL ABCD

KMABA01013TG

KMABA02014TG 7-1/2 10

KMABA03013TE 7-3/8 9-5/8

KMABA04014TE 7-1/2 10

KMABA05013TE 7-3/8 9-5/8

KMABA06014TE 7-1/2 10

17-3/4 15-1/4

7-3/8 9-5/8

KMABA SPECIFICATIONS

BLOWER MODEL 01013TG 02014TG 03013TE 04014TE 05013TE 06014TE

Shipping Weight (Lb) 30 38 33 39 35 41

ELECTRICAL

Volts—Phase 115/1 115/1 208–230/1 208–230/1 208–230/1 208–230/1

Operating V oltage Range 104–127 104–127 187–253 187–253 187–253 187–253

Full Load Amps 7.20 9.00 3.00 4.30 3.00 4.30

BLOWER MOTOR

Motor Hp (PSC) 1/2 1/2 1/2 3/4 1/2 3/4

RPM—Speeds 1075/3

Blower Type Direct Drive

BLOWER WHEEL

Diameter (In.) 10-1/2 11-1/2 10-1/2 11-1/2 10-1/2 11-1/2

Width (In.) 8

Air Discharge Downflow

Maximum Cooling Capacity 3 Ton 4 Ton 3 Ton 4 Ton 3 Ton 4 Ton

ACCESSORIES

Control Box Kit KMACC02014WG KMACC0401E14 KMACC0601FE4

Filter Kit N/A KMAFK0101NFK

Insulation Kit N/A KMAIK0101E1I N/A

Coil Shelf Kit N/A KMACR0101CRI

NOTE: Refer to Accessory Usage chart for exact kit application.

N/A—Not applicable

—4—

BF

°

°

°

PERFORMANCE DATA

GROSS COOLING CAPACITIES (MBH)

INDOOR

COIL AIR

CFM EWB (

72 50.4 24.2 0.00 45.8 21.8 0.00 40.9 19.4 0.00 35.3 16.9 0.09 28.8 14.3 0.06

600

800

1000

1000

1200

1400

1000

1200

1400

1200

1400

1600

67 41.5 24.8 0.08 37.0 22.4 0.06 32.0 19.9 0.05 26.2 17.3 0.05 19.9 14.7 0.06

62 33.7 25.4 0.05 29.1 22.9 0.05 24.1 20.4 0.06 18.5 17.5 0.08 14.8 14.8 0.19

72 61.9 29.4 0.00 56.7 26.8 0.00 50.8 24.1 0.00 44.0 21.1 0.11 36.0 17.9 0.08

67 51.6 30.9 0.10 46.2 28.1 0.08 39.9 25.1 0.07 32.7 22.0 0.07 24.9 18.7 0.08

62 42.1 32.1 0.07 36.4 29.1 0.07 30.1 26.0 0.08 23.2 22.4 0.11 19.0 19.0 0.22

72 71.5 33.8 0.00 65.4 30.9 0.00 58.6 27.8 0.00 51.1 24.7 0.12 42.2 21.2 0.10

67 59.7 36.0 0.12 53.7 33.0 0.10 46.7 29.8 0.09 38.4 26.2 0.09 29.2 22.3 0.10

62 49.2 38.1 0.09 42.7 34.7 0.09 35.4 31.1 0.10 27.6 26.9 0.13 22.9 22.9 0.25

72 74.8 35.4 0.00 68.7 32.5 0.00 61.7 29.3 0.00 54.0 26.1 0.11 44.8 22.5 0.09

67 62.6 37.7 0.10 56.4 34.7 0.09 49.2 31.4 0.08 40.8 27.7 0.07 31.3 23.7 0.09

62 51.3 39.7 0.08 44.7 36.3 0.08 37.5 32.7 0.09 29.1 28.3 0.12 23.9 23.9 0.24

72 83.4 39.4 0.00 76.9 36.3 0.00 69.2 33.0 0.19 60.4 29.4 0.12 50.5 25.6 0.10

67 70.1 42.6 0.11 63.1 39.3 0.10 55.3 35.7 0.09 46.2 31.8 0.09 35.7 27.4 0.10

62 57.6 45.4 0.09 50.5 41.8 0.09 42.5 37.8 0.10 33.4 32.8 0.14 27.8 27.8 0.26

72 90.6 42.8 0.00 83.6 39.7 0.00 75.5 36.2 0.17 65.9 32.4 0.13 55.4 28.4 0.12

67 76.3 46.9 0.12 68.9 43.5 0.11 60.3 39.6 0.11 50.8 35.6 0.10 39.6 30.9 0.12

62 62.9 50.5 0.10 55.4 46.7 0.11 46.9 42.5 0.12 37.4 37.1 0.16 31.5 31.5 0.29

72 77.4 36.7 0.00 71.5 33.8 0.00 64.7 30.7 0.00 56.8 27.4 0.11 47.8 23.8 0.08

67 65.2 39.2 0.09 59.0 36.1 0.08 51.6 32.7 0.07 43.3 29.0 0.06 33.6 25.0 0.07

62 54.2 41.6 0.07 47.4 38.1 0.07 39.9 34.4 0.07 31.2 29.9 0.09 25.5 25.5 0.21

72 85.9 40.6 0.00 79.8 37.7 0.00 72.1 34.4 0.20 63.3 30.7 0.11 53.6 27.0 0.10

67 72.8 44.2 0.10 65.5 40.7 0.09 57.9 37.2 0.09 48.9 33.3 0.08 38.2 28.8 0.09

62 60.4 47.2 0.08 53.3 43.7 0.08 45.1 39.6 0.09 35.7 34.7 0.11 29.7 29.7 0.23

72 93.1 44.0 0.00 86.6 41.1 0.00 78.5 37.6 0.16 69.1 33.9 0.12 58.5 29.8 0.11

67 79.0 48.5 0.11 71.5 45.0 0.10 63.1 41.2 0.10 53.6 37.2 0.09 42.3 32.5 0.10

62 65.7 52.4 0.09 58.1 48.7 0.10 49.6 44.4 0.10 39.9 39.2 0.13 33.6 33.6 0.25

72 86.4 40.9 0.00 79.2 37.4 0.00 71.2 33.8 0.00 62.0 29.9 0.11 51.3 25.7 0.09

67 72.3 43.5 0.11 64.9 39.8 0.09 56.5 35.8 0.08 46.7 31.5 0.07 36.0 27.1 0.09

62 59.6 45.8 0.08 51.5 41.6 0.08 42.7 37.2 0.09 34.2 32.8 0.11 28.6 28.6 0.20

72 94.5 44.6 0.00 86.8 40.9 0.00 77.8 37.0 0.00 68.0 33.0 0.14 56.6 28.5 0.12

67 79.1 47.8 0.13 71.2 44.0 0.12 62.1 39.8 0.11 51.6 35.2 0.10 39.8 30.3 0.11

62 65.1 50.6 0.10 56.9 46.5 0.10 47.4 41.8 0.11 38.3 37.2 0.12 32.4 32.4 0.22

72 101.0 47.6 0.00 93.1 43.9 0.00 83.7 39.9 0.00 73.1 35.6 0.16 61.2 31.0 0.14

67 84.9 51.6 0.15 76.3 47.5 0.14 67.0 43.3 0.13 55.9 38.6 0.12 43.2 33.4 0.13

62 70.0 55.1 0.12 61.5 50.9 0.12 51.5 46.0 0.13 42.4 41.6 0.14 36.0 36.0 0.25

30 35 40 45 50

F) TCG SHG BF TCG SHG BF TCG SHG BF TCG SHG BF TCG SHG BF

SATURATED TEMPERATURE LEAVING EVAPORATOR (

CM5A/CM5B024

CM5A/CM5B036

CM5A/CM5B042

CM5A/CM5B048

— Bypass Factor

CFM — Cubic Ft per Minute

EWB — Entering Wet Bulb ( ° F)

SHG — Gross Sensible Capacity 1000 Btuh

TCG — Gross Cooling Capacity 1000 Btuh

NOTES:

1. Contact manufacturer for cooling capacities at conditions other than

shown in table.

2. Formulas:

Leaving db = entering db —

Leaving wb = wb corresponding to enthalpy of air leaving coil (h

h

= h

lwb

where h

total capacity (Btuh)

—

ewb

ewb

4.5 x CFM

= enthalpy of air entering coil.

sensible heat cap.

1.09 x CFM

lwb

F)

3. Direct interpolation is permissible. Do not extrapolate.

4. SHC is based on 80 ° F db temperature of air entering coil.

Below 80 ° F db, subtract (Correction Factor x CFM)

from SHC. Above 80 ° F db, add (Correction Factor x CFM) to SHC

5. All data points are based on 10 ° F superheat leaving coil.

SHC CORRECTION FACTOR

ENTERING AIR DRY-BULB TEMPERATURE (

BYPASS

FACTOR

0.10

0.20

)

0.30

Interpolation is permissible.

79 78 77 76 75 Under 75

81 82 83 84 85 Over 85

Correction Factor

0.98

1.96

2.94

0.87

0.76

1.74

1.53

2.62

2.29

3.92

3.49

3.05

Correction Factor = 1.09 x (1 – BF) x (db – 80)

4.91

4.36

3.82

F)

Use formula

shown below.

—5—

COIL STATIC PRESSURE DROP (IN. WC)

UNIT SIZE BULB AIR QUANTITY (CFM)

024

036

042

048

WET

DRY

WET

DRY

WET

DRY

WET

DRY

600 700 800 900 1000

0.11

0.09

1000 1100 1200 1300 1400

0.22

0.19

1100 1200 1300 1400 1500

0.24

0.20

1200 1300 1400 1500 1600

0.30

0.27

0.14

0.12

0.28

0.23

0.28

0.24

0.35

0.29

0.19

0.15

0.32

0.27

0.32

0.29

0.40

0.33

0.23

0.19

0.37

0.31

0.38

0.33

0.45

0.38

0.27

0.22

0.42

0.36

0.43

0.39

0.51

0.43

—6—

ACCESSORY USAGE

USED WITH

Evcon/Coleman/AirPro Nordyne/Miller/Intertherm

Gas Furnaces Electric Furnaces Gas Furnaces Electric Furnaces

ACCESSORY

KIT

NO.

BLOWER PACKAGES

KMABA01013TG X* X† — — X — — X† ————

KMABA02014TG X* X‡ — — X X‡ X‡ X‡ ————

KMABA03013TE —————————X**——

KMABA04014TE —————————X**——

KMABA05013TE — — X** ———————X**X**

KMABA06014TE — — X** ———————X**X**

CONTROL BOXES

KMACC02014WG X — — — X X ——————

KMACC0401E14 —————————X††——

KMACC0601FE4 ——————————X††X††

FILTER KIT

KMAFK0101NFK ————————XXXX

INSULATION KITS

KMAIK0101E1I ————————X X——

COIL SHELF KIT

KMACR0101CRI — — X X ————————

* Requires additional control box kit.

† Only required on high static 3-ton applications.

‡ Only required on 3-1/2-ton and 4-ton applications.

** Blower package comes with necessary control box. Additional control box kit not required.

†† Only required if using existing furnace blower.

X—Indicates recommended use of product.

DGRT—A

7900

DGRT—B

DGAT

3400

3400A

3500A8— EB—B MGHA MGBA MGBB MGHB E1EB E1EH

FEBA

FEBB

FEH2

FEHB

—7—

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

© 1997 Bryant Heating and Cooling Systems, 7310 W. Morris St., Indianapolis, IN 46231 PRINTED IN U.S.A. Catalog No. 12CM-5A1 5-97

—8—

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: PDS CM5A.24.1

Loading...

Loading...