Page 1

Form No. 5900-1

Bryan “Flexible Water Tube”

Boiler Comparison Guide

Flexible Tube Steel Boilers

Firetube Steel Boilers

Cast Iron Boilers

(Rev. 7/08)

BRYAN® BOILERS

Originators of the “Flexible Water Tube” design

Page 2

Boiler Comparison Guide

Firetube

steel boilers

Bryan fl exible water

tube steel boilers

Installation

Minimal assembly required for new building installations x x x x

Will pass through standard doorway in existing buildings x x

Right hand or left hand construction x

35

Estimated years of service life to 25 35 ?

40

Full 5 sq ft heating surface per boiler HP or more x ? ? ?

Cast iron boilers

Competitive water

tube boilers

Space Requirements

Minimal fl oor space needed to set and service x ? x ?

Maintenance

No major disassembly required for cleaning x

No welding or rolling required to remove and replace tubes x x

No repairs to damage caused by thermal shock x

25 year non-prorated warranty x

Effi ciency

Highest operating effi ciency based on combustion effi ciency x ? ? ?

and burner motor horsepower

Close match to specifi c load based on numerous sizes available x ? ? ?

Size range from 6 HP through 500 HP x x ? ?

Fuels

Oil, gas or gas/oil x x x x

Atmospheric gas x x

Each of above available with electric if desired x

Specialty applications

Large buildings x x x x

High-rise buildings regardless of boiler location x x x

Process steam, high pressure x x x

Process steam, low pressure x x x x

Low temperature return water application not requiring external pump x

*

Replacement of sections requires extensive labor and downtime.

*

2

Page 3

Boiler Comparison Guide

Selecting the Proper Boiler

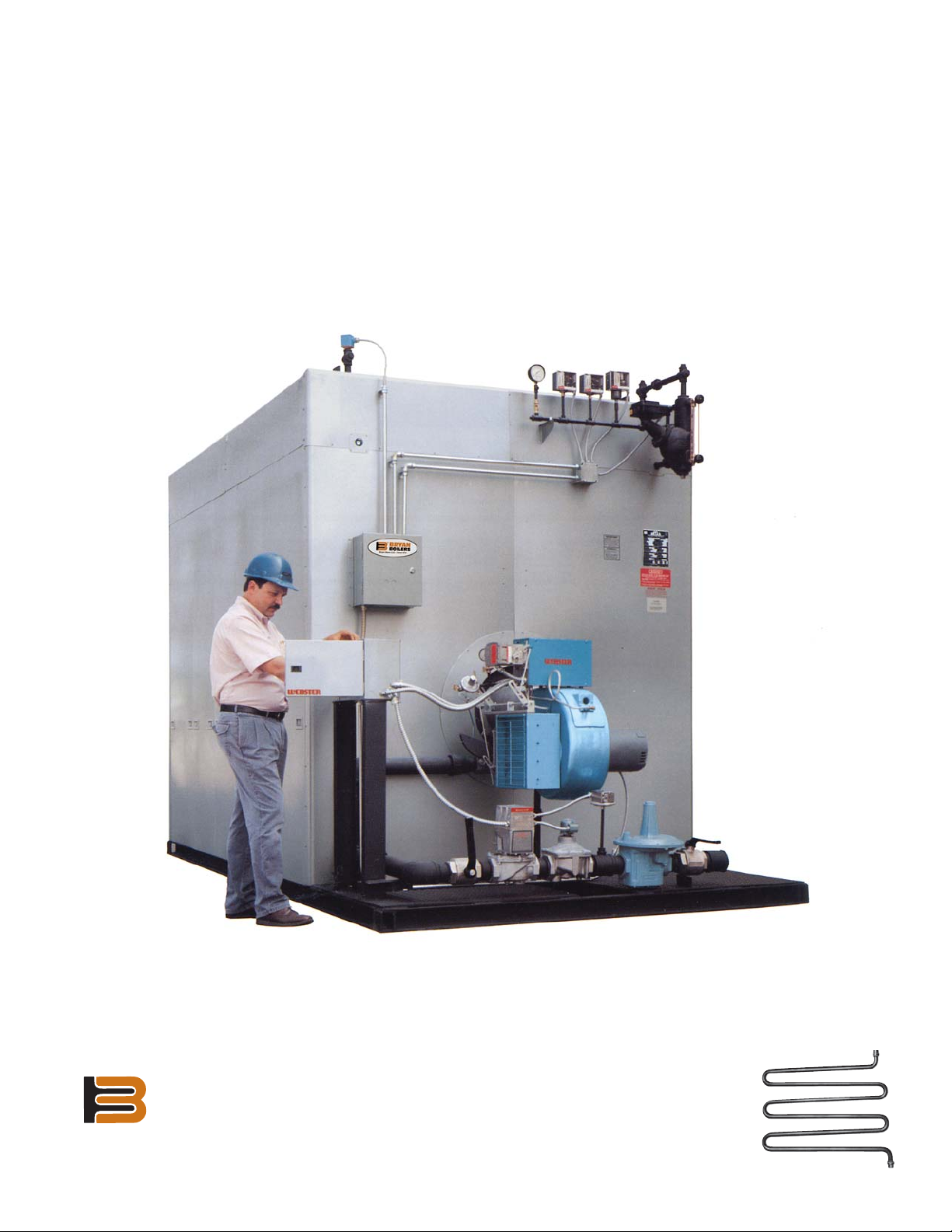

If you’re an engineer, an architect, a mechanical

contractor or a building owner, selecting or specifying

the right boiler is probably one of your many concerns.

Steel? Cast iron? Watertube? Firetube? With all the

confl icting opinions, reports and literature in circulation,

it’s no easy task.

Economy

Installation costs. Because cast iron boilers come as

sectional units, substantial time-consuming assembly is

required. Steel boilers are shipped completely fi nished

and may require that walls be opened in existing buildings

or new buildings which have already been enclosed.

Bryan fl exible water tube steel boilers, however, are

prepackaged units that may be easily disassembled

(“Knockdown™”) to precisely the degree necessary.

Service life. The best estimates we have on boiler

life expectancy are thirty-fi ve years for cast iron units

and twenty-fi ve years for fi retube steel models. With

many boilers still on the job after forty to fi fty years of

service, Bryan’s fl exible water tube steel design has

demonstrated longevity equal to or better than that of

either alternative.

At Bryan, we understand the problem. That’s why we’ve

put together this guide. It’s a summary of how our fl exible

water tube boilers compare to fi retube, cast iron and

other water tube boilers in several important areas. We

think you’ll fi nd it helpful.

40 years

Bryan

fl exible

water

tube

boilers

35 years

cast

iron

boilers

25 years

Firetube

steel

boilers

Boiler Longevity*

*Competitive fl exible tube boilers not shown

due to inadequate experience.

3

Page 4

Boiler Comparison Guide

36"

72"

How to put a new boiler through a 26 x 56 inch opening.

Convenience

New building installation and assembly. While

sectional cast iron boilers often cause storage problems

and the loss of parts by arriving at the job site in several

pieces at different times, Bryan fl exible water tube steel

boilers are shipped as complete, prepackaged units. That

means the boiler arrives at the job site assembled and

ready for installation. In addition, Bryan boilers may be

shipped with or without tubes installed and, unlike cast

iron units, do not require any complicated assembly.

Bryan Knockdown™ construction allows entry into existing

buildings. You simply choose the degree of knock down

needed.

Replacement installations in existing buildings.

The opening of a wall required to replace an ineffi cient

or worn-out boiler with an assembled steel boiler is a

troublesome, costly and time-consuming operation. Most

Bryan fl exible water tube steel boilers, however, feature

Knockdown™ design which allows the unit to be easily

disassembled in stages. If necessary, the boiler may be

knocked down so it can be carried through entryways

smaller than a standard door.

Space saving standard and

reverse construction

allows Bryan boilers to

share common service

space as in this renovated

boiler installation in a

middle school.

4

Page 5

Boiler Comparison Guide

Space Requirements – 3,000 MBH Boiler

BRYAN

Competitive water tube boilers can require twice as much

space for service for half as much capacity. Bryans' standard

and reverse combination make it the best investment.

Space requirements. Bryan fl exible water tube steel

boilers generally require less fl oor space than comparable

cast iron units. The bent tube, removable from only one

side, requires approximately 24 to 32 inches of service

area, the same as most cast iron boilers.

With a fi retube steel boiler, the fl oor space used by

the unit itself must be doubled in order to accommodate

tube replacement.

An additional space-saving benefi t of Bryan fl exible

water tube steel boilers is reverse construction. This

optional design allows two boilers to face each other,

thus sharing the same service area and saving space in

the mechanical room.

Cleaning. Generally speaking, easy access makes Bryan

fl exible water tube steel boilers more convenient to clean

than either cast iron or fi retube units.

Removing a Bryan boiler’s jacket access door and tube

panel exposes the entire bank of fl exible water tubes.

An ordinary fl ue brush and vacuum cleaner are all that

is needed for complete cleaning.

Maintenance. With cast iron or fi retube boilers, replacing

the unit or tubes often means complete disassembly,

welding, rolling and an outside contractor. The water

tubes in a Bryan fl exible water tube steel boiler, on the

Cast IronOther Water Tubes

Cast iron boilers require a

section width area for service,

equals wider foot print.

Firetube boilers require

fl oor space equal to boiler

size for tube removal.

Firetube

other hand, can be replaced by a general maintenance

worker in about thirty minutes.

Replacement tubes are available from Bryan

representatives within twenty-four hours. And, most

temporary tube repairs may be made in minutes allowing

operations to continue until replacement tubes arrive.

Bryan design provides easy access

for the service and maintenance of

tubes and burner.

5

Page 6

Boiler Comparison Guide

Our Effi ciency is Guaranteed

Favorable or superior operating effi ciencies are frequently

reported for all types of boiler, particularly in advertising

and promotional materials. Most often, these claims are

based on factory laboratory tests.

Bryan fl exible water tube steel boilers achieve 86%

effi ciency in operation on actual job sites with normal

140° - 160°F return water temperature.

It should be noted that differences in effi ciency will

always occur between water boilers and steam boilers

or gas-fi red boilers and oil-fi red boilers.

Versatility

Multi-boiler installations and expansion. Because

Bryan fl exible water tube boilers are available in capacities

from 6 to 500 hp, they are well-suited for multi-unit

installations.

When more than one boiler is used — whether due to

expansion or in an original installation — Bryan can supply

a lead/lag demand analyzer system that

protects effi ciency by enabling the owner

to sequence only those boilers required to

meet the current load demand.

For instance, a Bryan oil-fi red hot water boiler can

be expected to operate in the 85% to 86% range, and

a forced draft gas hot water model in the 85% range.

Again, these are on-the-job effi ciencies rather than factory

laboratory results.

The Bryan fl exible water tube steel boiler is offered in

ratings from 6 to 500 hp. This wide selection also helps

promote higher effi ciency by allowing you to select a

boiler to match your requirements more closely.

In addition, the optional Bryan Energy Selector

provides oil and/or gas fi ring or alternate electric

power at the fl ip of a switch. This versatile feature is

not available in cast iron or fi retube boilers.

Fuel and fi ring options. Bryan fl exible

water tube boilers are offered with either

forced draft or atmospheric gas fi ring.

Either mode is available for use on multiple

fuels; natural/methane/propane gas and oil

or combination gas/oil.

Bryan lead/lag

demand analyzer.

Bryan’s Energy

Selector lets user

choose gas, oil or

electric fi ring with

the fl ip of a switch.

6

Page 7

Boiler Comparison Guide

Specialty Applications

High-rise buildings. Cast iron boilers are generally

limited to operating pressure around 80 pounds. Bryan

fl exible water tube boilers, however, can be provided for

working pressures up to or exceeding 150 psi, making

them ideal for high-rise buildings.

Steam process applications. Unlike low pressure cast

iron boilers, Bryan boilers are also available for nearly any

steam process application from 15 to 300 psi.

Steel boiler water heaters. All Bryan fl exible tube

steel water boilers can be ordered with single or

Bryan Benefi ts

Selection. In the full range of sizes to 500 hp, nobody

sells more water tube steel boilers than Bryan Steam.

American-made reliability. Bryan Steam’s Peru,

Indiana, manufacturing facility is one of the most

advanced boiler plants in the nation. All boiler parts are

made at this facility enabling Bryan to apply exacting

quality assurance standards in every stage of the

manufacturing process.

To assure fast service, Bryan keeps many packaged

boiler units in stock at the factory. All are available with

your choice of options, ready for immediate shipment.

multiple indirect

copper heat

exchangers for

a variety of water

temperatures.

This option gives

you the fl exibility

to include your service or process water needs in a single

unit, in most cases, regardless of the application. Such

an arrangement reduces costs and saves mechanical

room space.

A reputation for quality. Industry surveys repeatedly

show Bryan Steam fl exible steel water tube boilers

as the predominant choice of leading engineers and

architects.

After more than 90+ years of providing the HVAC

industry with the fi nest boilers available, Bryan Steam

has a quality assurance and fi eld service program

second to none. When you own Bryan boilers, more

than 120 experienced factory-trained sales and service

representative organizations located throughout

the world are always available for consultation and

assistance.

Companion Products & Accessories

Companion products and accessories. Bryan’s

complete line includes these dependable, performance

matched accessories. Design your complete system using

Bryan components for maximum reliability and value.

Condensate return and boiler feed pump systems.

These are available for use with any steam boiler, both

low and high pressure. Standard in simplex, duplex or

special arrangements for multiple boiler installations are

available. Tanks constructed of heavy-duty steel.

Bryan deaerators. Remove dissolved gasses from

incoming make-up water with minimal steam loss.

Deaerate to a maximum .005 cc/liter O2 and

0% CO

through 60,000lb/hr. Tray type deaerators

have stainless steel trays, are available in

standard capacities from 5,000 to 300,000

lb/hr.

Hot water storage tanks. Bryan offers

standard tanks in capacities up to 5,000

.

Spray type deaerators available

2

gallons, diameters to 84ⴖ, operating pressures from 30 to

250 psi. Protective linings, both phenolic and cement are

available. Insulated metal jacket optional.

Bryan exhaust heads. For oil-free

and water-free exhaust of steam. After

100 years, still the most reliable design

available. Flanged or threaded models

from 1ⴖ to 5ⴖ, as well as fl anged sizes

to 24ⴖ.

Blowdown separators and tanks. Used during

blowdown of system to separate steam from water, allows

dry steam to be vented to the atmosphere. Water may be

cooled if necessary to prevent thermal pollution.

Bryan overfl ow traps. Mechanical fl oat controlled

traps with cast iron bodies, double sealed brass valves,

stainless steel ball fl oats. Sizes from 2ⴖ to 6ⴖ for use on

pressurized deaerators.

7

Page 8

Bryan Steam

Since 1916— pioneer and leader in fl exible water tube boilers

In 1916 a locomotive engineer and steam power enthusiast named

George Bryan founded the Bryan Harvester Company, a small

manufacturing fi rm which produced steam powered tractors. The

rising popularity of the gasoline engine forced Bryan to abandon the

steam tractor in 1922, but it was not forgotten. The bent water tube

boiler which powered the tractor was extremely rugged, impervious

to thermal shock, compact, and easy to service, making it ideal

for other applications. Bryan Harvester became the Bryan Steam

Corporation and began refi ning and marketing that original boiler for

an array of uses. Today, Bryan Steam LLC continues to incorporate

many of the features found in the original Bryan Boilers. Applying the

advantages of past experience to projects for the future has made

Bryan the leader in the production of fl exible water tube boilers for

more than three quarters of a century.

Bryan Steam LLC — Leaders Since 1916

783 N. Chili Ave., Peru, Indiana 46970 U.S.A.

Phone: 765-473-6651 • Internet:www.bryanboilers.com

Fax: 765-473-3074 • E-mail: inquiry@bryansteam.com

Form No. 5900-1 © 2008 Bryan Steam LLC Printed in USA

78-8753

Loading...

Loading...