Page 1

Bryan Electric

Indirect Water Heaters

98,300 to 1,081,100 BTUH

30 to 330 KW

Form No. 4800

(Rev. 11/06)

Note these features:

Long life indirect heat exchanger and Incoloy

sheathed electric heating elements

All brass and copper fi nned-tube, high-effi ciency heat

exchanger transfers heat from hot heater water to service

water fl owing through exchanger. This results in both long

electric heating element and long heat exchanger life with

trouble-free operation. Special Incoloy alloy also substantially contributes to electric element life as compared to

copper sheathing used in conventional electric heaters.

Economical scale-free boiler operation

Scale-free operation means higher continuous heat transfer effi ciencies and reduction of maintenance costs. Conventional electric heaters generally require periodic shutdown for descaling of elements. Bryan’s indirect closed

system heating means little or no scale build-up.

Corrosion-resistant operation

Corrosive and scale forming service water does not come

into direct contact with steel heater parts and electric

heating elements. Service water being heated circulates

only through the copper indirect heat exchanger within a

temperature range that eliminates or minimizes chemical

Model BE-210-WT4T7

reactions such as oxidation or precipitation, the principal

causes of corrosion and scale formation.

Condensation free

The Bryan indirect heater operates at water temperatures

that eliminate problems caused by moisture from surrounding air condensing as water, contributing to rusting

and wet fl oors.

Quality construction

Structural framework supports primary hot water vessel

and power panel cabinet. Vessel and frame protected by

a heavy 16 gauge steel, zinc-coated jacket attractively

fi nished with two coats of enamel.

Applications

Versatile for all typical commercial and industrial applications, such as schools, apartments, hotels and motels,

laundries, restaurants, hospitals, factories, etc. The heater

may be used in conjunction with a storage tank (the tank

and accessories may be supplied by Bryan as a packaged

“Water-Pak”) or if the application permits, may be applied

as a “tankless” installation. Available alternative to fossil

fuel units when strict emission requirements must be met.

BRYAN® BOILERS

Page 2

Bryan Electric Indirect Water Heaters

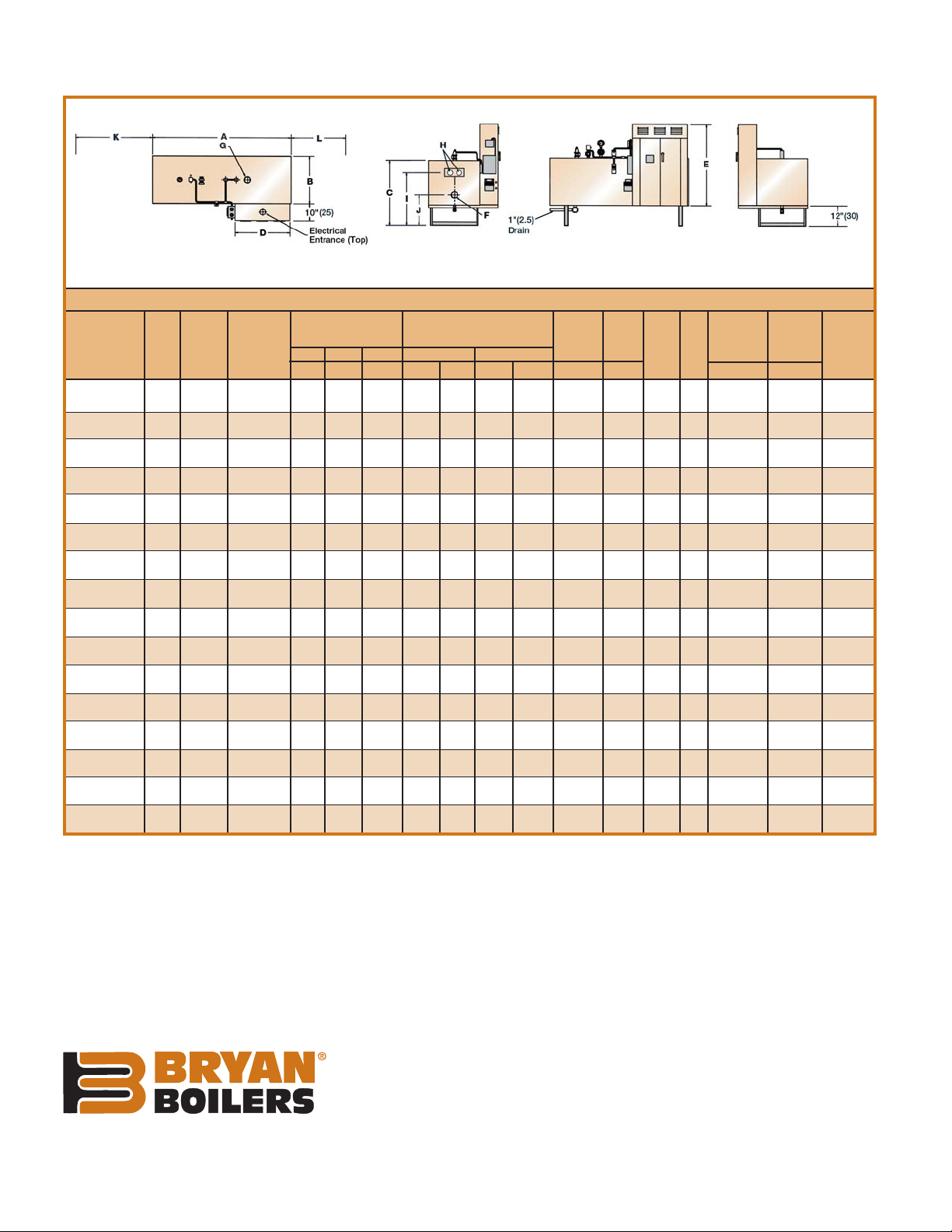

PLAN VIEW

Heat

Recovery

Model Input Output Capacity

KW MBH (GPH) length width height

Weight

40°-140°F A B C D E D E F & G H K L

BE-30-WT 30 98.3 117

(122) (51) (81) (76) (91) (51) (61) (5) (3.8) (66) (43) (66) (77) (373)

BE-45-WT 45 147.4 176

(122) (51) (81) (76) (91) (51) (61) (5) (5.08) (66) (43) (66) (77) (387)

BE-60-WT 60 196.6 235

(122) (51) (81) (76) (91) (51) (61) (5) (5.08) (66) (43) (66) (77) (400)

BE-90-WT 90 294.8 354

(122) (71) (102) (76) (91) (51) (73) (8) (5.08) (79) (51) (66) (77) (476)

BE-105-WT 105 344.0 413

(122) (71) (102) (76) (122) (51) (76) (8) (5.08) (79) (51) (66) (77) (496)

BE-120-WT 120 393.1 472

(122) (71) (102) (76) (122) (76) (91) (8) (5.08) (79) (51) (66) (77) (521)

BE-135-WT 135 441.0 531

(122) (71) (102) (76) (168) (76) (91) (8) (6.35) (79) (51) (66) (77) (610)

BE-150-WT 150 491.4 590

(122) (71) (102) (76) (168) (76) (91) (8) (6.35) (79) (51) (66) (77) (618)

BE-165-WT 165 539.1 649

(122) (71) (102) (76) (168) (76) (91) (8) (6.35) (79) (51) (142) (77) (632)

BE-180-WT 180 589.7 708

(122) (71) (102) (76) (168) (76) (91) (8) (6.35) (79) (51) (142) (77) (654)

BE-195-WT 195 637.2 767

(122) (71) (102) (76) (168) (76) (122) (8) (6.35) (79) (51) (142) (77) (801)

BE-210-WT 210 688.0 826

(193) (71) (102) (76) (122) (8) (6.35) (79) (51) (142) (140) (1157)

BE-240-WT 240 789.5 948

(193) (71) (102) (76) (122) (8) (6.35) (79) (51) (142) (140) (1180)

BE-270-WT 270 884.5 1,062

- (193) (71) (102) (76) (168) (8) (6.35) (79) (51) (142) (140) (1202)

BE-300-WT 300 982.0 1,180

(193) (71) (102) (76) (168) (8) (6.35) (79) (51) (142) (140) (1224)

BE-330-WT 330 1,081.1 1,298

Specifi cations subject to change without notice. Consult factory to consult on other boiler options.

BRYAN ELECTRIC INDIRECT WATER HEATER RATINGS AND DIMENSIONS — in (cm)

Boiler

Dimensions

48 20 32 30 36 20 24 2 1-1/2 26 17 26 30 840

48 20 32 30 36 20 24 2 2 26 17 26 30 870

48 20 32 30 36 20 24 2 2 26 17 26 30 900

48 25 40 30 36 20 30 3 2 32 20 26 30 1070

48 28 40 30 48 20 30 3 2 32 20 26 30 1115

48 28 40 30 48 20 30 3 2 32 20 26 30 1170

48 28 40 30 66 30 36 3 2-1/2 32 20 26 30 1370

48 28 40 30 66 30 36 3 2-1/2 32 20 26 30 1390

48 28 40 30 66 30 36 3 2-1/2 32 20 56 30 1420

48 28 40 30 66 30 36 3 2-1/2 32 20 56 30 1470

48 28 40 30 66 30 48 3 2-1/2 32 20 56 30 1800

76 28 40

76 28 40

76 28 40

76 28 40

76 28 40

LEFT END VIEW

208-230/3/60 380, 460/575

Power Panel

Dimensions

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

30 48 3 2-1/2 32 20 56 55 2600

30 48 3 2-1/2 32 20 56 55 2650

30 66 3 2-1/2 32 20 56 55 2700

30 66 3 2-1/2 32 20 56 55 2750

30 66 3 2-1/2 32 20 56 55 2800

Boiler Coil Exchanger Element

Inlet & Inlet & Removal Removal

FRONT VIEW

Outlet Outlet

RIGHT END VIEW

I J

Clearance Clearance

Shipping

lbs. (kg)

Size range: 30-330 KW (98,300 to 1,081,100 BTUH) with the following voltage options:

30 KW to 120 KW — 240 volt/1 phase; 30 KW to 180 KW — 208 or 240 volts/3 phase; 30 KW to 330 — 460 or 480 volts/3 phase.

Equipment furnished: Combination boiler thermometer and pressure gauge, low water cutoff, operating temperature control, high limit temperature control, indirect heat exchanger, automatic boiler fi ll valve, boiler relief valve, boiler drain cock, magnetic contactors, pilot switch,

power panel, insulated jacket and expansion tank. All equipment installed and wired. Expansion tank (shipped loose). A fused disconnect

switch to be furnished by installer.

When ordering: Please specify model, KW, type of system (tank or tankless). Initial and fi nal temperature water required, water fl ow rate (gal./

hr. or gal./min.), electrical characteristics (volts, phase, cycles), optional equipment or special requirements. Refer to BE Series brochure No.

3600 for further information.

Bryan Steam LLC — Leaders Since 1916

783 N. Chili Ave., Peru, Indiana 46970 U.S.A.

Phone: 765-473-6651 • Internet:www.bryanboilers.com

•

Fax: 765-473-3074

Form No. 4800 ©2006 Bryan Steam LLC Printed in USA

E-mail: bryanboilers@iquest.net

116-8350

Loading...

Loading...