Page 1

SRE-2700

ELECTRA-RIDE™ LT

STAIRWAY ELEVATOR

1780 EXECUTIVE DR., P.O., BOX 84, OCONOMOWOC, WI 53066 USA

TEL.: (262) 567-4990 FAX: (262) 953-5501

Bruno invites your calls at:

Technical Service

Technical Service fax: 262-953-5503

DEALER:

1-800-882-8183

Toll free number valid throughout the U.S. and Canada

email: service@bruno.com

www.bruno.com

INSTALLATION MANUAL

MAN-2700

REVISED 06-11-2004

Page 2

IMPORTANT NOTES

This stairway elevator is intended

for indoor use only

in a heated, enclosed location

above 35° F (2° C).

NOTE

The warranty for the Electra-Ride™ LT

Stairway Elevator is

rendered null and void

if the unit is installed by

anyone other than an authorized Bruno dealer.

Electra-Ride™ is a trademark of Bruno Independent Living Aids, Inc.®

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

2

SRE-2700 06-11-2004

Page 3

TABLE OF CONTENTS

IMPORTANT NOTES................................................................................... 2

INTRODUCTION.......................................................................................... 4

TECHNICAL SPECIFICATIONS.................................................................. 5

CARTON CONTENTS................................................................................. 6

OVERVIEW.................................................................................................. 7-8

INSTALLATION .......................................................................................... 9-30

Tools Necessary for Installation................................... 9

Bumper Bracket Installation......................................... 10

Fitting the Rail.............................................................. 10

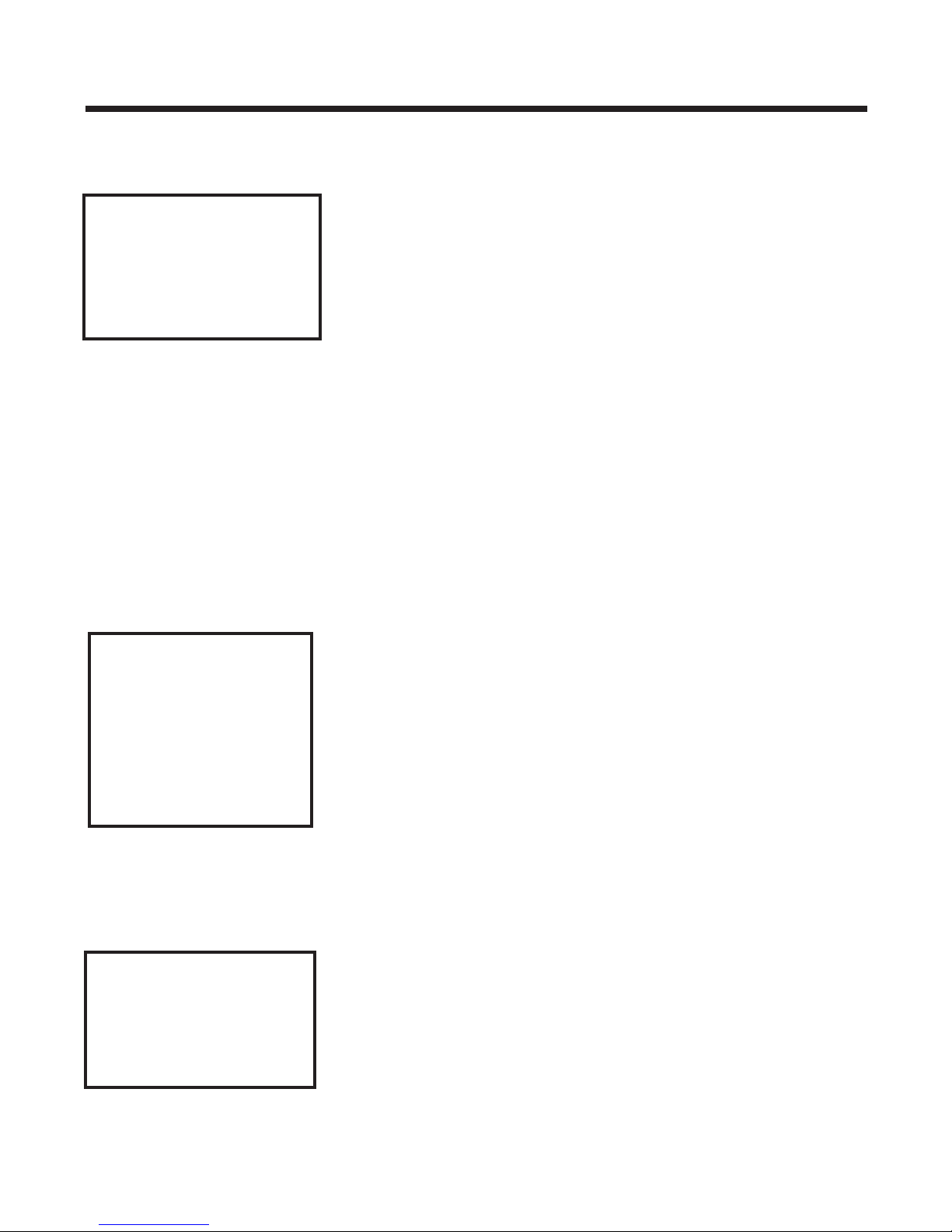

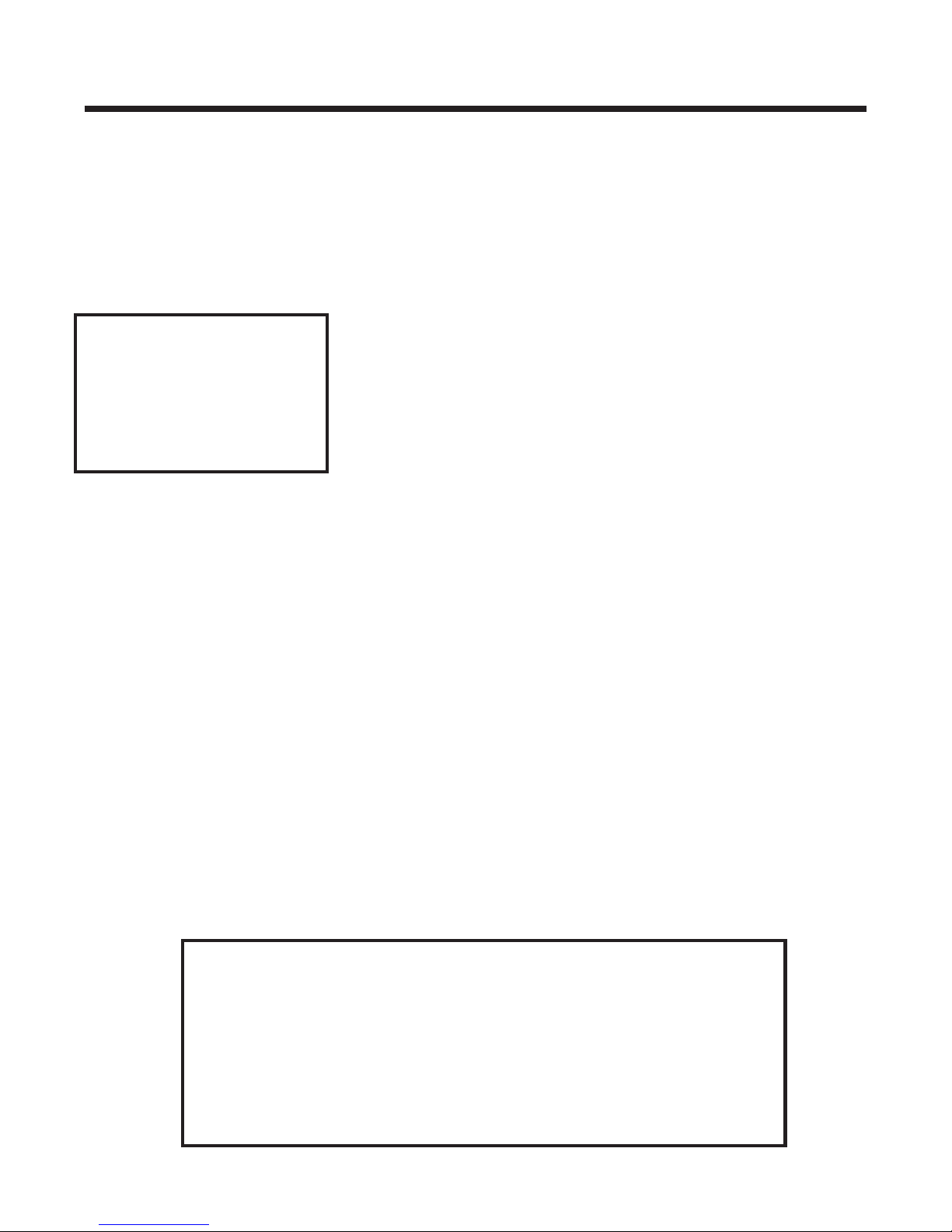

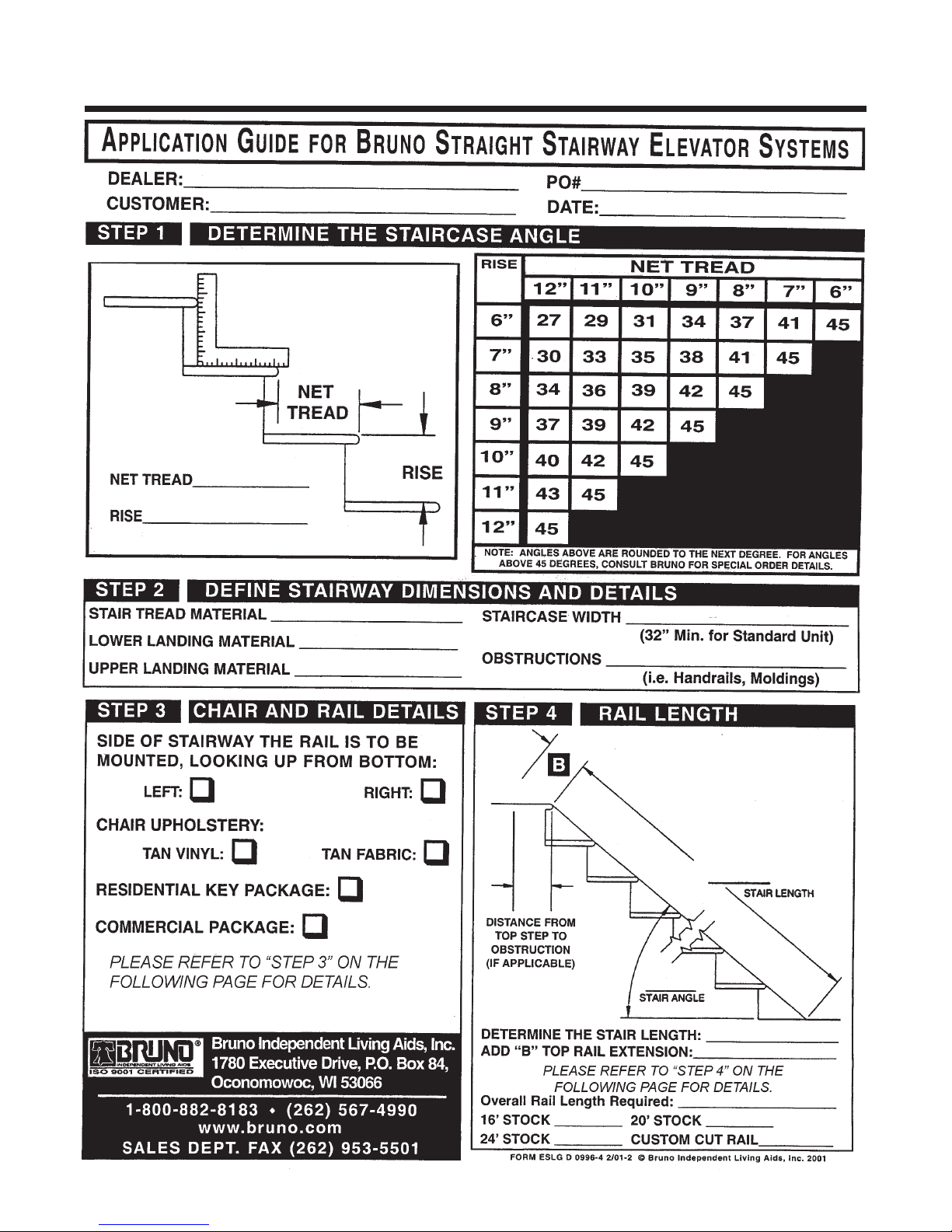

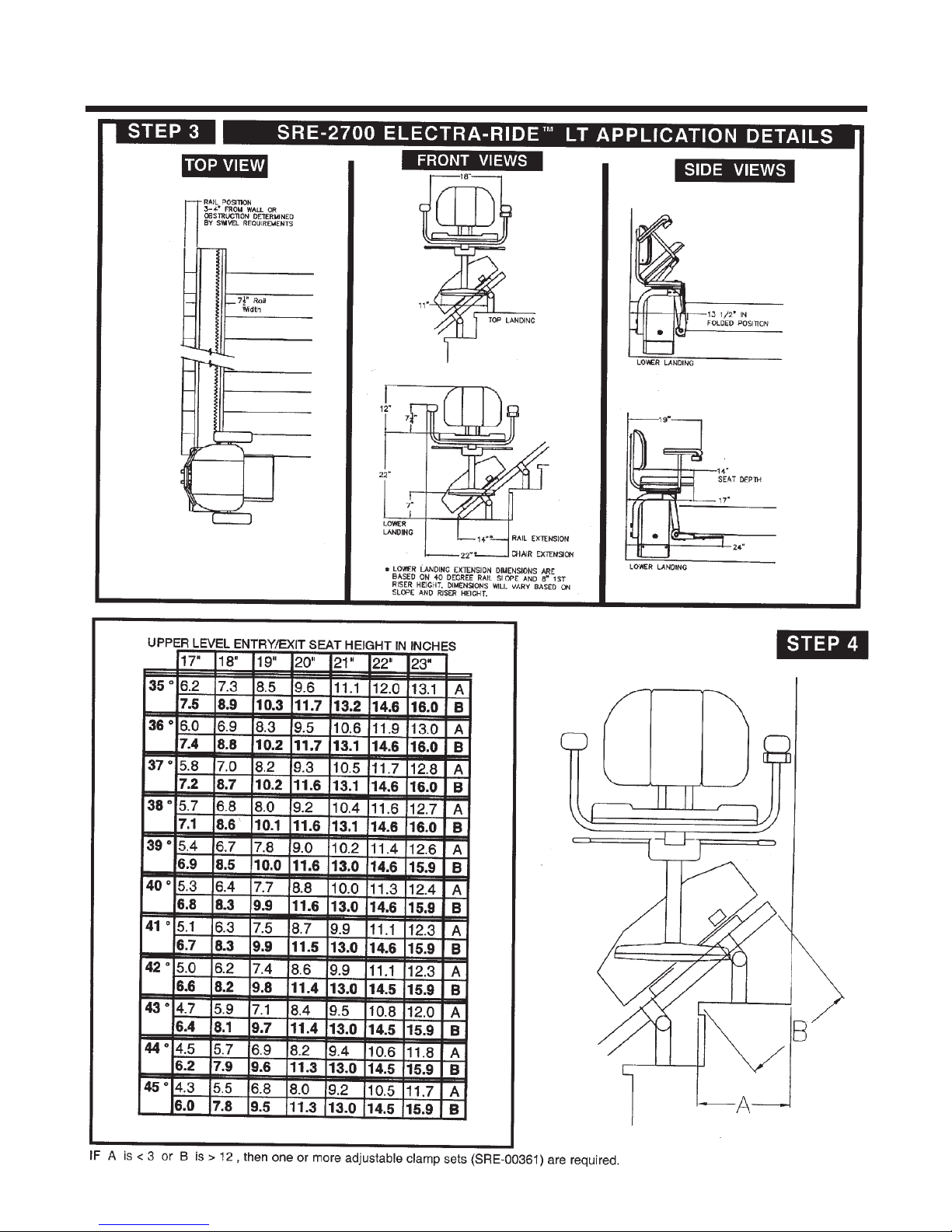

Application Guide......................................................... 11-12

Cutting the Rail............................................................. 13

Rail Joint Assembly...................................................... 14

Positioning Foot Clamp Assemblies............................. 15-17

Mounting the Carriage on the Upper Rail..................... 18-19

Adjusting the Carriage Angle........................................20

Installing the Seat Assembly........................................ 20-22

Installing the Final Limit Ramp and Switch.................. 22

Connecting the Power Source..................................... 23-24

Testing the Unit............................................................ 25

Infrared Call/Send Transmitter..................................... 26

Mounting the Standard Call/Send Transmitter............. 27

Learning the Standard Call/Send Transmitter.............. 28-29

When the Installation is Complete............................... 29

Lubrication................................................................... 30

ELECTRICAL............................................................................................... 31-34

Converting Rail/Carriage for Right-Hand Operation..... 31

Converting Rocker Switch to Left Armrest................... 32

Circuit Breaker............................................................. 33

Wiring Schematic......................................................... 34

LONG-TERM STORAGE............................................................................. 35

TROUBLESHOOTING................................................................................. 36-37

YEARLY MAINTENANCE OPERATIONS................................................... 38

EXPLODED VIEW AND BILL OF MATERIALS.......................................... 39-56

LIMITED WARRANTY................................................................................. 57

SRE-2700 06-11-2004

3

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 4

INTRODUCTION

Thank you for purchasing an SRE-2700 Electra-Ride™ LT Stairway Elevator. Be sure to

check carton contents for shipping damage as soon as they are received.

Also, check the carton contents against the packing list before leaving the shop to install

product on site.

Report any discrepancies to Bruno Independent Living Aids immediately.

Bruno encourages you to read through the installation manual before installing the Stairway

Elevator. Doing so will help you install the elevator more quickly and avoid the frustration of

getting to the job site only to discover that you are missing a critical tool or piece of equipment.

MATERIAL DATA SAFETY SHEET(S) ON

MATERIALS USED ON THIS UNIT CAN BE

REQUESTED THROUGH OUR TECHNICAL SERVICE

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

NOTE:

DEPARTMENT

4

SRE-2700 06-11-2004

Page 5

SPECIFICATIONS

Technical Specifications

Weight Capacity 275 lbs. (125 kg)

Speed 18 - 23 fpm (5.5-7.0 m/mn)

Power Source two (2) 12-volt sealed, maintenance-free

batteries with 24-volt continuous-duty

charger

Motor 24 VDC, 2-pole, 1.32 hp

Drive self-locking gearbox, rack-and-pinion

drive

Control constant pressure (armrest and

2 transmitters)

Brake self-locking worm gear

Maximum incline 45 degrees

Rail steel channel with integral drive gear

rack

Seat Swivel 0, 45 and 90 degrees at top and bottom

Power Supply 100-240 VAC, 50/60 Hz, 0.85 amp power

supply input, 33 VDC 1-amp transformer

output, 29.6 to 27.6 VDC charging at

850 mA max., continuous monitoring.

SRE-2700 06-11-2004

5

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 6

PACKING LIST

CARTON CONTENTS

The ELECTRA-RIDE™ LT is shipped in 4 cartons. Check the

contents of the cartons to be sure you have all of the components

before beginning an installation.

CHECK CARTON

CONTENTS FOR

SHIPPING DAMAGE

IMMEDIATELY UPON

RECEIPT

*MSDS (Material Safety

Data Sheet) available

from Bruno upon

request. Contact

Service

Department.

Check the carton contents for shipping damage upon receipt.

Damage claims must be filed by the dealer, not the manufacturer.

Bruno Independent Living Aids, Inc.® cannot be responsible for shipping

damage.

CARTON 1

(1) complete carriage assembly including footrest

CARTON 2

(1) complete seat assembly

(2) IR transmitters

Box A

(1) tube

(1)

final limit switch ramp assembly

(1) SRE-K-1553 bumper assembly parts kit

(2) bumper assemblies

(2) pieces of Velcro®

(10) 11" lg wire ties

(1) SRE-K-2705 electrical parts kit (16' rail)

(or SRE-K-2706 for 20' rail)

(1) custom-length charge harness

(2) transmitter mounting brackets

(2) SRE-K-2701 transmitter mounting hardware kit

(1) power supply

(1) SRE-K-1518 power supply hardware kit

Box B

(9) foot clamp sets (16' RAIL) • 11 (20' RAIL)

• TBD** (CUSTOM RAIL)

**DEPENDS UPON RAIL LENGTH

(36) sheet metal screws (M 6.3 X 50 mm)(16' rail);

QTY.44 for (20' rail)

white lithium grease per rail set

***NOTE:

Rail sections must have

matching numbers

stamped on the

sections.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

( ) UPON REQUEST

CARTON 3

(1) rail half (upper)

CARTON 4

(1) rail half (lower)

(1) joint plate

(1) SRE-K-1502 joint plate hardware kit

CARTON 5 (OPTIONAL)

(1) rail half (lower)

(1) joint plate

(1) SRE-K-1502 joint plate hardware kit

6

clamps, adjustable, 9 lbs. ea.

SRE-2700 06-11-2004

Page 7

INSTALLATION

OVERVIEW

OVERVIEW

OVERVIEW OF INSTALLATION

Installation of the ELECTRA-RIDE™ LT Stairway Elevator consists of the following:

* Determine whether the elevator should be a left- or right-side installation. "Left"

or "right" installation is determined by the side of the stairway on which the rail is

installed (viewed from the bottom of the stairs). THE GEAR RACK WILL BE

TOWARD THE CENTER OF THE STAIRS. Unless specified otherwise, Bruno

Stairway Elevators are set up for left-side installation when shipped, but can easily

be converted to right-side installation. Instructions for converting the unit for

right-hand installation are included later in this manual.

* Identify and locate lower rail section and bumper bracket assembly.

* Assemble and tighten the rail joint. CAUTION: RAILS CANNOT BE MIXED.

CHECK ID NUMBERS STAMPED AT ENDS OF RAILS.

* Determine the correct length for the rail (using Steps 2 & 4 from the APPLICATION

GUIDE), and cut the rail.

* Install lower bumper assembly.

* Position rail on left or right side of stairway using rail clamp assemblies.

* Mount the carriage on the upper rail.

* Adjust the carriage angle by loosening the (2) Angle Adjustment Bolts.

* Install seat assembly and make electrical connections.

* When installing a right-side ELECTRA-RIDE™ LT , follow instructions for

Changing to Right-Hand Operation

* Perform a 5-6 trial runs of the ELECTRA-RIDE™ LT to determine final location of

the rail.

SRE-2700 06-11-2004

7

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 8

INSTALLATION

OVERVIEW

OVERVIEW (CON'T.)

* Determine the appropriate location for the remaining mounting clamps and

brackets for attaching the rail to the stairs then loosely assemble the clamps

and brackets to the Stairway Elevator rail.

* Adjust and tighten the rail clamps and mounting brackets.

* Anchor the mounting brackets to the stairs.

* Locate and drill holes for the top bumper bracket.

* Install the top bumper bracket.

* Determine where the power supply will be positioned, and install rail wire lead

accordingly.

* Position power supply at upper or lower landing.

* Route wire to household outlet.

* Mount remote call/send transmitters.

* Test unit for proper operation.

* Train customer in safe and convenient operation of the Stairway Elevator.

REMEMBER:

No installation is complete until the customer has been trained to use the Elevator

smoothly and safely. After demonstrating correct operation, have the customer

operate the Elevator several times while you are available to answer questions.

BE SURE THE CUSTOMER UNDERSTANDS ALL SAFETY ASPECTS OF

USING THE ELEVATOR. Patience and thoroughness in this phase of the

installation are often rewarded with repeat business and customer referrals.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

8

SRE-2700 06-11-2004

Page 9

INSTALLATION

Tools Necessary for Installation

[ ] Protractor level, builder's level

[ ] Socket set, metric (10 mm through 22 mm)

[ ] Ratchet, with 6" extension

[ ] Combination wrench set, metric (10 mm through 22 mm)

INSTALLATION

NOTE:

The standard stairway

elevator is suitable for

stairway angles up to

45 degrees.

[ ] Phillips screwdrivers

[ ] 5/16" socket (clamp screws)

[ ] 9/16" and 5/8" open-end wrench (limit switch adjustment)

[ ] 5/16" open-end wrench

[ ] Electric drill with letter `O' (.316") and 1/4" bit

[ ] Hacksaw with 2 or 3 blades, or metal cutting bandsaw

[ ] 20' tape measure

[ ] Small dead blow hammer

[ ] Rubber mallet

[ ] C-clamp

[ ] Wire crimper and stripper

[ ] Flashlight

[ ] Needle nose pliers

[ ] Scissors or knife

TIPS FOR A FASTER, SMOOTHER INSTALLATION:

• Be sure you have all necessary parts and tools before

traveling to installation site.

• Loosely assemble the foot clamp assemblies before

traveling to the installation site.

SRE-2700 06-11-2004

[ ] Extension cord

[ ] Double-sided foam tape

[ ] File

[ ] 12" adjustable wrench

[ ] 90-degree needle-nose pliers

9

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 10

INSTALLATION

INSTALLATION

ASSEMBLY

1) Determine whether a left- or right-side installation is appropriate for the site. "Left" or

"right" refers to the side of the stairway on which the rail is installed (as viewed from the

bottom of the stairs). Unless otherwise specified Bruno Stairway Elevators are shipped

from the factory in the left-side configuration. Conversion to right-side installation is

easy (instructions included later in this manual ).

2) Identify and locate lower rail section appropriate to the installation (left or right).

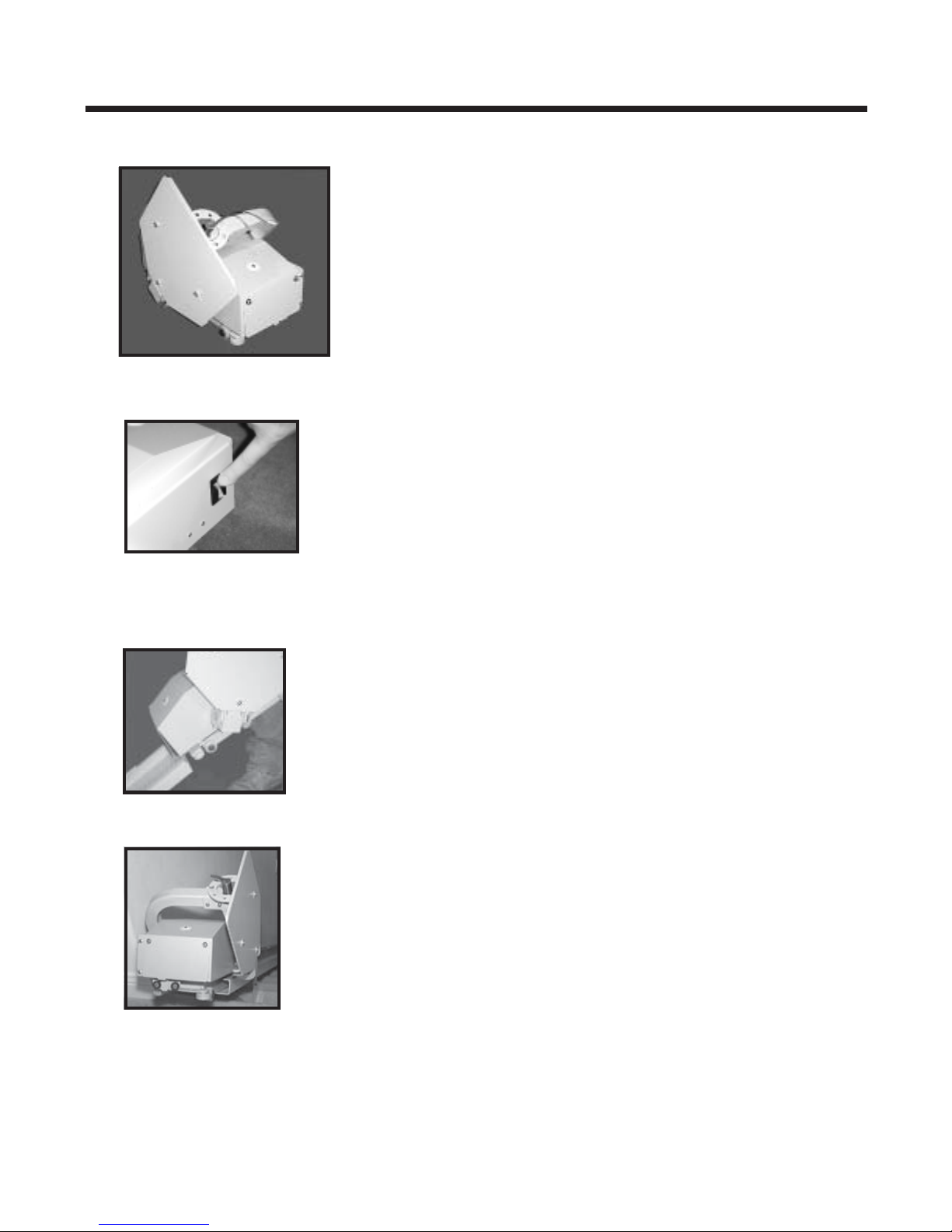

BUMPER BRACKET INSTALLATION

1) Assemble lower rail.

2) Install lower bumper bracket.

bumper bracket

FITTING THE RAIL

1) Determine the correct length for the rail by measuring along a straight line placed on the

stairs. (SEE STEP 2 IN THE APPLICATION GUIDE) To that amount, add Measurement B

(STEP 4 IN THE APPLICATION GUIDE). This process will allow you to custom fit the

Elevator to your customer by determining the most comfortable seat-to-floor height within

the space available at the top of the stairs.

NOTE: The rail must rest approximately 2" above the step nosing, and extend from the lower floor to a

point beyond the nosing of the top step (see Step No. 4 of the Application Guide). In some cases where

the bottom landing is made of material such as concrete, ceramic tile or slate, the last bracket on the

landing may be omitted. In this case, a bracket must be added on the second-to-last step ( bottom), and

at the top of the stairway.

REMINDER:

THIS RAIL MUST BE INSTALLED APPROXIMATELY 2" ABOVE STAIR NOSING.

OTHERWISE, FOOTREST WILL HIT THE STEPS, CAUSING INTERMITTENT

OPERATION.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

10

SRE-2700 06-11-2004

Page 11

INSTALLATION

SRE-2700 06-11-2004

11

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 12

INSTALLATION

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

12

SRE-2700 06-11-2004

Page 13

INSTALLATION

INSTALLATION

CUTTING THE RAIL

IMPORTANT NOTE!

Under no circumstances should a rail section be cut shorter than

18” (46 cm).

There must be at least (2) clamps on a short rail section (1 at the rail

joint and 1 at the rail end). Cutting a rail shorter than 18” (46 cm)

would not allow enough room for the (2) necessary clamps.

Example:

After measuring the staircase, you determine you need 9 feet of rail.

With your (2) 8-foot sections you decide to use (1) 8-foot section and

cut the remaining (1) foot from the second 8-foot section. Doing this

could yield a rail piece with insufficient weld.

Instead, Bruno recommends cutting at least one foot off one of the

8-foot sections (leaving 7 feet of rail) and then cutting 2 feet from the

second 8-foot section. You will have a (1) 7-foot section and (1) 2-foot

section, both of which are long enough to be properly mounted

(2 clamps minimum per short rail).

NEVER CUT OFF THE JOINT END!

The M6 bolts securing the gear rack must remain intact.

Cut off the end with the pre-drilled charge contact mounting holes.

Then, using the provided template, redrill (2) holes on each end of the rail.

1) Use a metal-cutting power saw or manual

hacksaw to cut the rail to length. Cut off

the end of the rail to be located at the top of the

stairway.

2) Use a file or other appropriate tool to deburr the

cut end of the rail. Soften any sharp edges

which might abrade the insulation of the wiring to

be routed to the bumper at the end of the rail.

use “O” size drill bit

(8.03mm/.316")

SRE-2700 06-11-2004

3) Use a C-clamp to hold the upper bumper bracket in

place at the cut end of the rail. Use the holes in

the bumper bracket as guides to drill mounting

holes in the rail using an“O” size (8.03 mm/.316")

drill bit.

13

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 14

INSTALLATION

RAIL JOINT ASSEMBLY

NOTE:

The rail is always installed

with the gear rack towards the

center of the stairs and gear

teeth facing the wall.

INSTALLATION

SUGGESTION

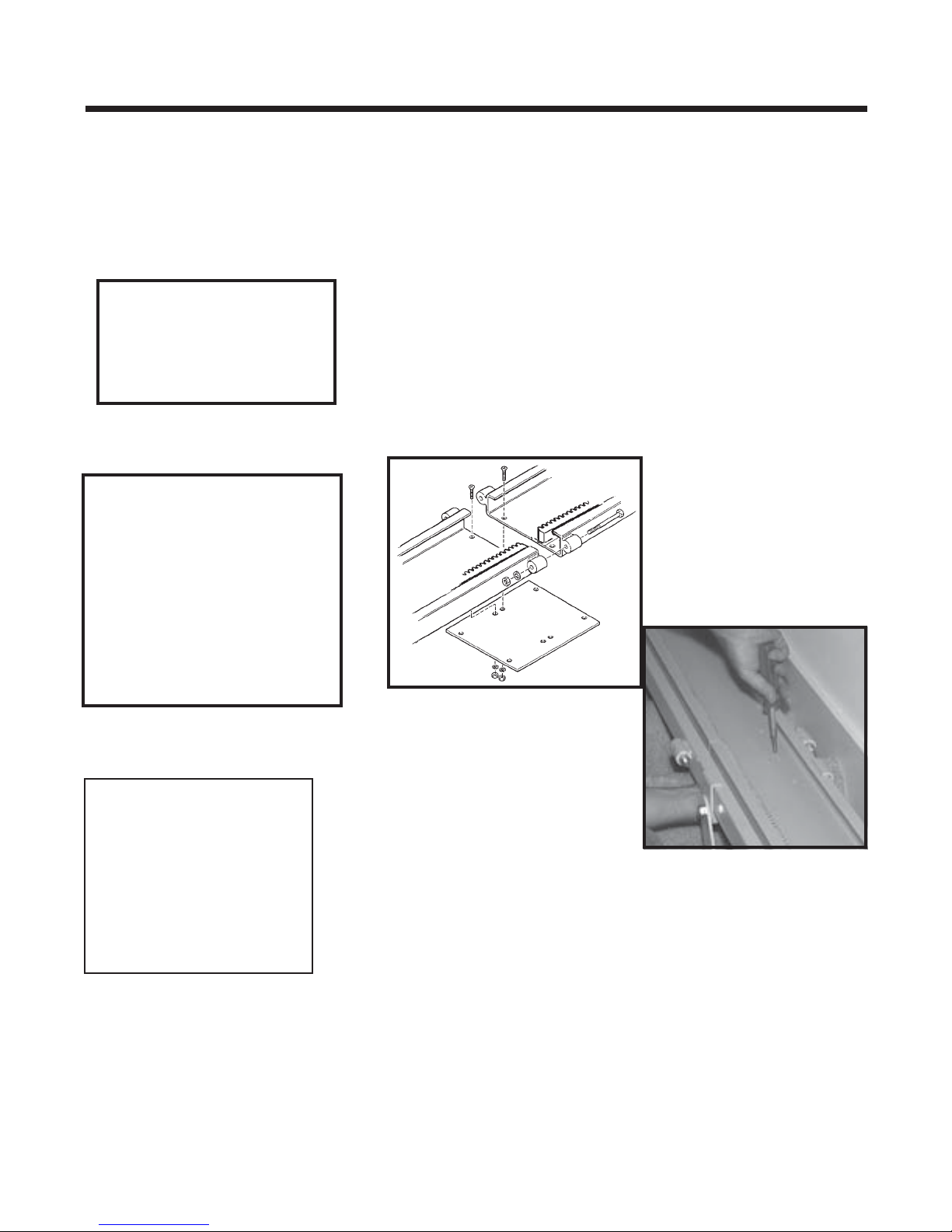

1) Assemble the rail joint by attaching the bottom plate to

the rail with the screws, lock washers and hex nuts

provided with the unit. Install the bolts, internal-tooth

washers and hex nuts through the joint blocks on both

sides of the rail. Tighten all bolts securely and make sure

screw heads are flush with the surface of the inside of the

rail. PLEASE REFER TO EXPLODED VIEWS AT

BACK OF MANUAL.

Once two sections of rail

are installed, and before

installing the carriage, run a

plomb line along the rail. If

the rail bows, insert shims

or readjust clamps.

NOTE:

The chamfered

edges of the

holes must face

"up" toward

the bottom of

the rail.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

14

SRE-2700 06-11-2004

Page 15

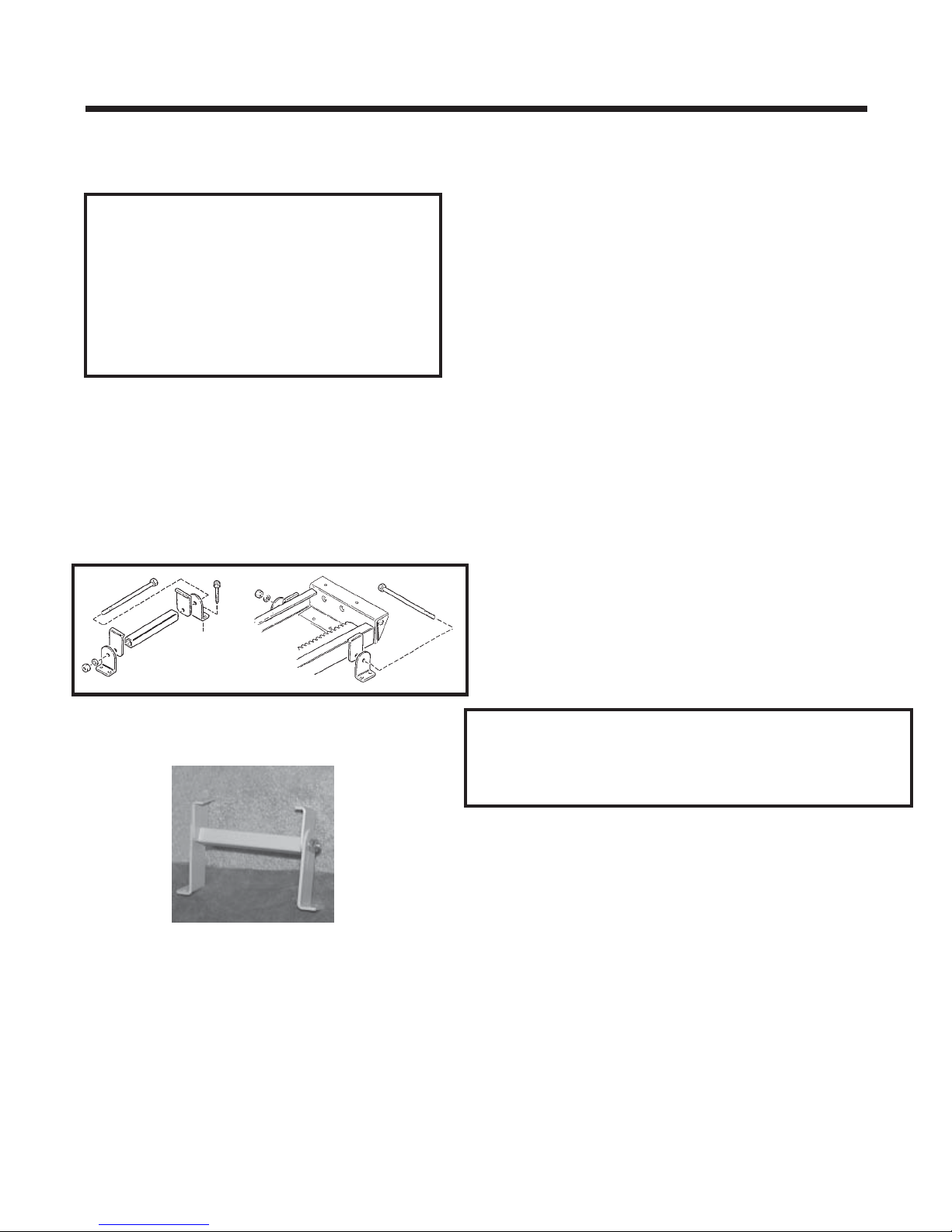

POSITIONING FOOT CLAMP ASSEMBLIES

1) Place rail mounting foot clamps in the

pattern as indicated.

clamp placement order

INSTALLATION

Be sure to leave a minimum space of 4"*,

as measured from the back edge of the

rail to the wall.

•bottom landing

•first tread up from bottom

landing

•top landing

•first tread down from top

landing

•closest tread above and

below the rail joint(s)

•minimum of every third

tread over remainder

of staircase.

*The 4" clearance is needed if the seat is

to swivel 90 degrees. For installations

where the seat will swivel less than

90 degrees, the rail-to-wall clearance

may be reduced to between 3" and

3-1/2". Frequently check the seat-wall

clearance during installation.

Note: If top or bottom clamp is omitted

because the landing is cement or

ceramic tile, or in the event that the

owner wishes not to drill holes in the

landing, a set of clamps should be

added on the second-to-last step and at

the top of stairway.

4" as measured from

back edge of rail to wall.

SRE-2700 06-11-2004

15

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 16

INSTALLATION

INSTALLATION ON CARPET

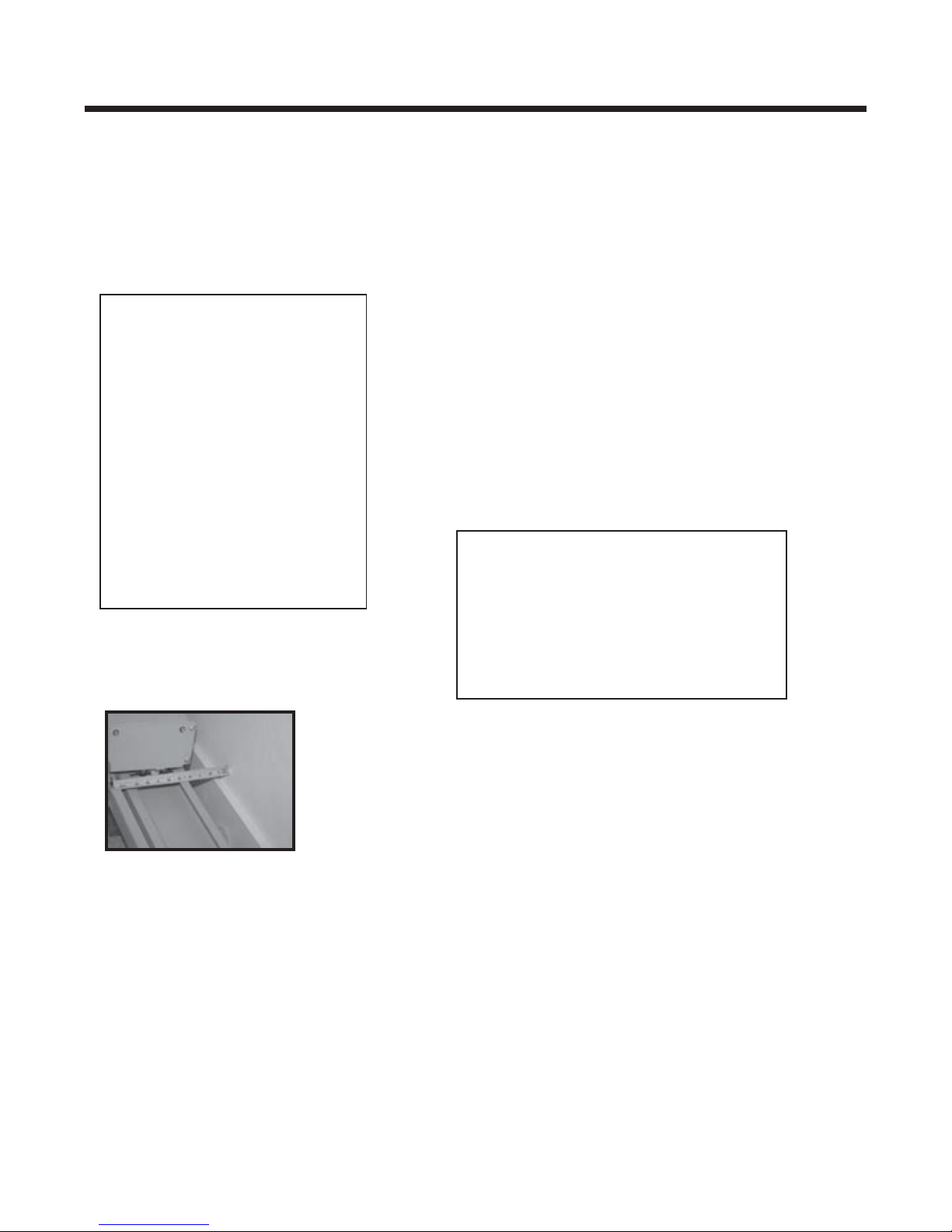

Before securing the foot clamp

assemblies with hardware, seat them

using a deadblow hammer. Use a

rubber mallet to compress the rug and

pad before anchoring the clamp.

2) For ease of installation, finger tighten all

clamp assemblies to rail. The clamp

assembly should be positioned so the nut

is closest to the wall.

3) Slide top and bottom clamps down on the rail

until firmly seated on step. When installing on

carpeted stairs, use a rubber mallet on the

clamps to compress carpet and pad before

anchoring to steps.

4) Drill in one screw in the foot nearest the wall

of each of the top and bottom of foot of clamp

assemblies.

This will enable the installer to change the

position of the rail if necessary and minimize

the number of holes drilled in the wrong location.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Bruno recommends installing the screws in the

back clamp (the one closer to the wall) first,

then the screws in the front of the clamp.

16

SRE-2700 06-11-2004

Page 17

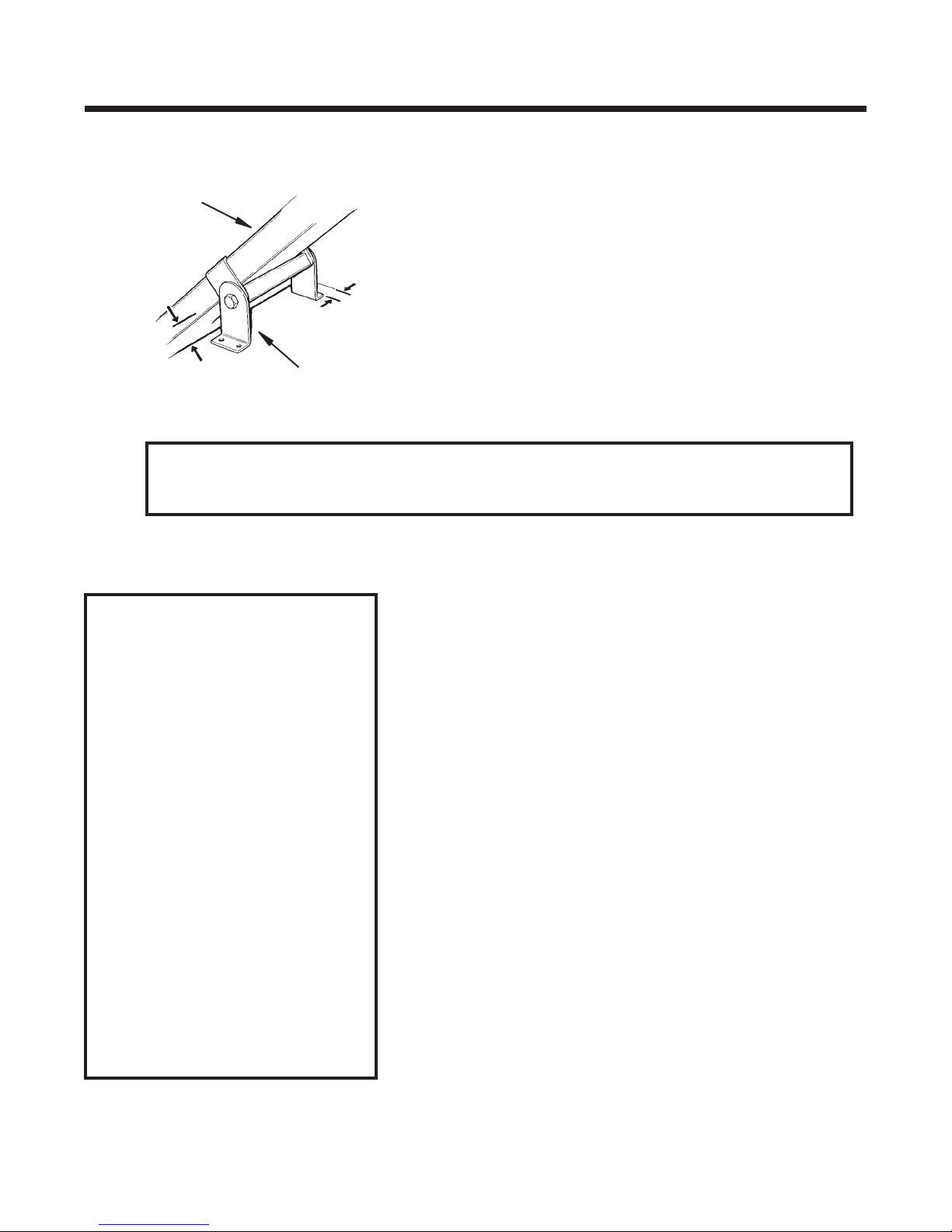

INSTALLATION

INSTALLATION

rail

approx.

2" above

nosing

foot clamp assembly

*Install foot clamps at least 2-1/2” from wall (approx. 4" between the back

edge of the rail and the wall). Provide additional foot clamp-to-wall

clearance if seat needs to swivel against wall.

INSTALLATION NOTES

For installations on hardwood

stairs, Bruno recommends

drilling a pilot hole before

inserting fasteners.

5) Frequently check the measurements at the key

locations indicated to ensure proper positioning

of the clamp assemblies.

*see note below

If threaded fastener

extends below a stair

tread that is exposed, it

can be trimmed flush

with pliers.

Bruno ships the Stairway

Elevator with fasteners

appropriate for

wooden stair treads only.

Other stair material may

require different fasteners.

Please contact Bruno

Independent Living Aids, Inc.

for information.

SRE-2700 06-11-2004

17

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 18

INSTALLATION

MOUNTING CARRIAGE ON UPPER RAIL

1) Remove the carriage from the shipping carton.

2) Make sure circuit breaker is OFF.

circuit breaker off

sliding carriage on rail

3) Manually slide the carriage onto the rail until

approximately half of the carriage is on the rail.

4) Manually turn the motor pulley to fully engage the

entire carriage onto the rail.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

18

SRE-2700 06-11-2004

Page 19

INSTALLATION

5) To ensure that the carriage remains in the appropriate

position on the rail while completing the installation,

mount the upper rail bumper. Use the M8 x 1.25 x

20 mm hex head cap screws and a 13 mm wrench.

carriage on rail

Before tightening the brackets,

check to make sure that the

bumper wires are not trapped

under the bumper bracket at the

lower landing.

SRE-2700 06-11-2004

19

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 20

INSTALLATION

INSTALLATION

ADJUSTING THE CARRIAGE ANGLE

1) Fold down the footrest

.

2) With the footrest folded down, LOOSEN BUT DO NOT

REMOVE the (2) M14 x 2 x 70mm hex head cap screws

using a 22 mm wrench.

3) Place a level on the footrest.

4) Pivot the seat support tube forward or backward

as necessary to level the footrest.

5) While holding the seat support tube steady, tighten

the (2) screws loosened in Step 9 to a torque of 80 ft. lbs.

REMINDER:

Recheck with level after tightening

adjustment bolts.

INSTALLING THE SEAT ASSEMBLY

1) Make sure the rocker switch and seat safety switch wires

are tucked into the seat swivel tube.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

2) Clip the shipping tie securing the swivel cover assembly.

20

SRE-2700 06-11-2004

Page 21

INSTALLATION

INSTALLING THE SEAT ASSEMBLY (con't.)

3) Using a Phillips head screwdriver, remove the

(2) cylinder bumpers and (4) screws securing the

swivel cover.

INSTALLATION

INSTALLATION

• footrest down

• seat cushion folded up

• lift up swivel lever

• slide seat post over

wires and tube

4) Put the swivel cover to the side.

MAKE SURE FOOTREST IS DOWN!

5) With the SEAT FOLDED UP and while LIFTING UP

THE SWIVEL LEVER, slide seat post over the wires

and onto the seat support tube.

6) To make sure the seat assembly is completely

seated on the support tube, rotate the seat

assembly back and forth while gently pushing

the seat post down onto the tube.

SRE-2700 06-11-2004

21

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 22

INSTALLATION

INSTALLATION

INSTALLING THE SEAT ASSEMBLY (con't.)

7) Connect the rocker switch lead first.

8) Pick up the swivel cover.

9) Plug in the seat safety switch.

10) Insert (1) wire tie through the hole in the swivel

stop as shown.

11) Tighten this wire tie around the wire harness (see

illustration to left).

12) Insert a second wire tie through the anchor as shown.

13) Tighten this second wire tie around the wire harness.

ramp just touches the roller

carriage against upper bumper

14) Trim the wire ties.

15) Tuck the wires to route them away from the spring and

seat safety switch to avoid pinching.

16) Make sure the spring sits in the opening of the swivel

switch actuator.

17) Remount the swivel cover.

18) Using a Phillips head screwdriver, insert and tighten

the (2) cylinder bumpers and (4) screws securing the

swivel cover.

INSTALLING THE FINAL LIMIT RAMP AND SWITCH

1) Make sure the carriage is positioned against the upper

bumper.

2) Position the final limit ramp so that the down side of the

ramp just touches the roller of the final limit switch.

M6 screws

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

3) Using a 10 mm wrench, tighten the (2) M6 screws as

shown in the photo to the left.

22

SRE-2700 06-11-2004

Page 23

INSTALLATION

1) Check that:

2) Determine the location of the wall outlet for the power supply.

3) Position the power supply in a suitable permanent location

circuit breaker

near either the top or bottom end of the rail, depending on the

location of the wall outlet.

4) Place the pigtail harness end of the power cable near the

power supply.

5) Route the power cable to the end of the rail opposite the

power supply by threading it under the rail and behind the

foot clamps.

INSTALLATION

CONNECTING THE POWER SOURCE

• the circuit breaker is OFF.

• all foot clamps are in the correct position;

• the rail is straight (use a plumb line as a guide).

ribbed to red

(+) (female)

smooth to black

(-) (male)

6) Notice that the end of the cable OPPOSITE THE PIGTAIL

HARNESS has been split slightly, and includes one male

and one female connector. The sheathing of one lead is ribbed

(in photo to left, finger points to ribbed sheath). The other

lead's sheathing is smooth.

7) Now that the power cable has been routed to the end of the

rail opposite the power supply (Step 5), take that length PLUS

approx. 8". Then:

• increase the split

• cut off the excess lead

• remove and discard the existing connectors

• strip the freshly cut wire ends.

• install the new connectors (provided)

8) Connect the power source leads to the bumper charge contact

leads as shown.

9) Secure the power lead to the rear clamps (ones closest to the

wall) using the wire ties provided.

SRE-2700 06-11-2004

Be sure that this wiring is mounted securely

to avoid damage.

23

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 24

INSTALLATION

INSTALLATION

power supply

ROUTING WIRE HARNESSES

CONNECTING THE POWER SOURCE (con't.)

10) Turn the circuit breaker ON.

11) Plug power supply into a grounded 120VAC wall outlet.

12) Secure the power supply with the bracket provided.

Be sure the power supply

will not pose

a tripping hazard.

13) Mount (1) remote at the top of the rail and (1) at the

bottom of the rail. (Refer to the Standard Call/Send

Transmitter section later in this manual.)

The power supply should be plugged into a household outlet at

all times.

THE ONLY EXCEPTION IS WHEN TURNING UNIT 'OFF'

(SEE LONG TERM STORAGE SECTION).

If the power supply plug and

wire will be located in an

area where the power supply

could be

accidentally unplugged,

Bruno recommends the use

of a plug lock

(available at hardware and

home improvement stores).

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

24

SRE-2700 06-11-2004

Page 25

INSTALLATION NOTES

INSTALLATION

TESTING THE UNIT

1) Before securing, all clamps and with the seat in the central

riding position, use the rocker switch to run carriage/seat

assembly completely down and up the rail. Observe the

seat-to-wall clearance.

Direction of travel of

the seat/carriage

corresponds to the

side of the rocker

switch depressed.

A slight delay will

occur between the

time the rocker

switch is depressed

and the initiation of

carriage

movement. This is

normal and is a

function of the soft

start feature of the

controller.

The unit should travel

noticeably faster going

up than down.

A clearance of 1/2" to 1" is acceptable.

2) Repeat the run with the seat in the folded position. If

necessary, adjust the rail placement by sliding it closer

to, or further from the wall.

3) Make a total of 5 or 6 trial runs to be sure all components

are functioning correctly, and that proper seat-to-wall

clearance is maintained over the entire length of travel.

These 5-6 runs will also help clean paint chips out of the

gear rack which can be vacuumed or brushed away (see

Lubrication section).

4) Once the rail position is determined, place one screw in the

back foot of each clamp assembly to hold the rail in place

while securing the foot clamp assemblies. Placing this one

screw will also help prevent the clamp foot from rotating

while tightening the screws.

ALWAYS PARK THE CARRIAGE AT THE

UPPER OR LOWER END OF THE RAIL TO KEEP

SRE-2700 06-11-2004

5) Tighten the bolts securing the foot clamp assemblies

to the rail.

6) Install and tighten the screws in the remaining

foot clamps (back clamp first, then front clamp).

7) Check tightness of all screws/bolts.

8) Run the carriage/seat assembly up and down the rail

to recheck the seat-to-wall clearance, and to verify

correct operation of all elevator components.

BATTERIES FULLY CHARGED.

25

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 26

INSTALLATION

INFRARED CALL/SEND TRANSMITTER

The call/send system on the Bruno SRE-2700 is based on infrared (IR) controls,

the same type of control used for televisions and stereos.

Like a television remote, the SRE-2700 hand-held transmitter may experience

certain types of interference. Receivers are mounted on both sides of the SRE-2700

carriage to minimize intereference.

Should interference occur, the unit will stop. This feature has been integrated

into the SRE-2700 to ensure your safety.

The direct line between the transmitter to either of the (2) transmitters should

be clear of obstacles for optimal operation.

To reduce the possibility of interference:

• while riding in the seat, ALWAYS operate the Elevator using the rocker switch

on the armrest.

Operating the SRE-2700 with a transmitter while riding in the seat

can lead to signal interference.

• DO NOT mount the transmitters behind an obstacle such as a rail post.

• DO NOT allow direct sunlight to shine on the receivers (blinding the receivers

on the carriage).

• DO replace transmitter batteries regularly.

Depleted or nearly-depleted batteries alter the effective range of the transmitter.

• DO keep the transmitter and receiver lens free of dirt and debris.

Use a non-abrasive cleaner suitable for glass or acrylic surfaces.

Do not use polishes or cleaning products containing wax. These products

will leave a film on the lens that will reduce the signal transmission range.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

26

SRE-2700 06-11-2004

Page 27

INSTALLATION

INSTALLATION

STANDARD CALL/SEND TRANSMITTER

The 9V battery is inserted backwards in the IR transmitter

when shipped from the Bruno factory. Prior to operating

the SRE-2700, the installer must remove the battery and

reinsert it so that the (+) and (-) poles are properly connected.

MOUNTING THE CALL/SEND TRANSMITTERS

TO THE WALL

Remember to mount the transmitters

in locations which are out of the reach

of children, yet always visible to the

operator from the stairway elevator.

bracket and mounting hardware

(a)

hole in the back of the transmitter. Tighten, without

(b)

Step 1

Steps

2 & 3

1) On the back of the transmitter, loosen and remove the

screw (a) securing the two halves of the transmitter.

2) Place the bracket (b) on the back of the transmitter.

The base of the bracket will be flush with the

bottom of the transmitter, with the base of the

bracket pointing toward the front of the transmitter.

3) Insert the longest screw provided in the mounting

hardware kit (see illustration above left) through the top

hole in the bracket and through the corresponding

overtightening to avoid damaging the transmitter back.

4) Turn the transmitter/bracket unit over so that the

front of the transmitter is facing you.

5) Mount this unit to the wall using the two (2)

#8 x .75" lg Phillips pan head sheet metal screws and

the two (2) plastic ribbed anchors provided.

6) Run the unit up and down the stairs using the remote

call/sent transmitter. Test both transmitters.

Step 4

SRE-2700 06-11-2004

Step 5

7) Repeat the test with the installer or installer's

assistant sitting on the seat.

NOTE:

INSTALLATION OF THE

CALL/SEND UNIT MAY VARY

BY LOCAL CODE. PLEASE

REFER TO LOCAL CODES

FOR

INSTALLATION

GUIDELINES.

27

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 28

INSTALLATION

INSTALLATION

LEARNING THE REMOTE INFRARED TRANSMITTER

(not necessary when installing unit for the first time)R

The operating channel of the two (2) infrared transmitters

included with the SRE-2700 is pre-set at the Bruno factory.

Should it become necessary to re-learn the transmitters

(for example, if there are multiple units in the same location,

or in the event you have to replace tranmitters) proceed as follows:

1) Turn off the circuit breaker.

2) On the CARRIAGE COVER, locate and remove the 3/4" black plug

(center top of the carriage approximately half-way between the

two white infrared receivers). Please refer to the photo to the left.

3) Look through the hole in the carriage cover and locate the RED

BUTTON on the circuit board.

plug removed

(a)

(c)

(c)

(b)

4) Have a flat-nose screwdriver nearby. You will use it to press the

red button (through the carriage cover hole) in a later step.

5) On one of the IR TRANSMITTERS, remove the screw (a) securing

the back to the transmitter. [If the transmitter is mounted to a

wall, unscrew the (2) mounting bracket screws, turn the

transmitter over and remove screw (a) securing the mounting

bracket and the transmitter back.]

6) Remove the transmitter back and set aside with its screw.

7) On the TRANSMITTER board, locate the blue switch (b)

labelled "SW".

8) Change the configuration for switches 1 and 2.

Note: There are four possible configurations:

•1 up, 2 down (default manufacturer's setting)

•1 up, 2 up

•1 down, 2 up

•1 down, 2 down

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

28

SRE-2700 06-11-2004

Page 29

INSTALLATION

•

close-up of red button

as seen through plug hole

NOTE:

While using the remote

call/send, you may experi-

ence some

intermittent operation.

This will not harm the

unit. However, while

using the rocker switch,

operation should NOT be

intermittent.

INSTALLATION

9) Once you have changed the switch positions:

• Turn on the CARRIAGE circuit breaker.

• Wait until you hear a BEEP.

• Using a flat-nose screwdriver, reach through the hole

in the CARRIAGE COVER to press and hold the

red button on the CARRIAGE circuit board.

• AS YOU HOLD DOWN the red button, press one of

the pushbuttons on the TRANSMITTER.

• Count to five.

• Release the two buttons.

• Depress either of the transmitter buttons.

• If the carriage moves, the new configuration has been

accepted and the transmitter relearned.

• If the carriage does not move, repeats Steps 8 and 9.

10) Make sure both transmitters are set to the same switch

configuration.

11) Remount and secure the transmitter back (remount on

wall if applicable).

12) Remount the carriage cover.

13) Remount the footrest.

14) Reinsert the black plug into the hole in the carriage

cover.

WHEN THE INSTALLATION IS COMPLETE

• Verify proper operation of the power supply, call/send transmitters, on/off switch, footrest,

safety switches, and carriage limit switches.

• Inform the customer of the location of the Owner's Manual. Encourage him/her to become

familiar with its contents.

• Train the customer to use the stairway elevator correctly and safely. Be sure to have him/her

operate the unit while you are there to answer any questions and address any concerns.

TT

SRE-2700 06-11-2004

29

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 30

INSTALLATION

LUBRICATION

PRIOR TO LUBRICATION

If not already done, run the carriage up and down the rail

five to six (5-6) times. This will clean the paint chips out of

the gear rack. Vacuum or brush the gear rack and rail to

remove any paint chips loosened during this operation.

Once the gear rack and rail are clean and free of paint

debris, proceed with lubrication.

apply small dab of grease

gear rack TEETH ONLY

GEAR RACK

1. Apply a dab of white lithium grease to the gear rack TEETH ONLY (approx. every 6 inches).

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

30

SRE-2700 06-11-2004

Page 31

ELECTRICAL

REVERSING OPERATION (for right-hand installation)

As shipped from the factory, the Elevator is set up for left-hand installation (as viewed from the

bottom of the stairs.)

In the field, however, should the dealer/installer need to convert the Elevator from left-hand to righthand operation, follow the instructions given below.

Note that it is not necessary to change the rocker switch when converting to a right-hand

installation. Only in the event that the user does not have use of his/her right hand would moving

the rocker switch to the left armrest be necessary.

Instructions for changing the rocker switch from the right armrest to the left armrest immediately

follow the instructions for converting the circuit board for right-hand operation.

To convert the rail/carriage for right-hand operation:

1) Remove the 3/4" black plug (b) located in the

center top of the carriage (approx. half-way

between the two white infrared receivers).

(a & b)

carriage: top view

(b)

(a)

access hole (a) to circuit board

with plug (b) removed

(a)

(c)

(a & b)

(b)

carriage and

footrest: front view

Three pins are now exposed on the circuit board.

2) Look through the hole now exposed in the

carriage. Visually locate the jumper (c)

on the circuit board.

3) Carefully grasp the jumper (c) with a pair of

needle-nose pliers.

4) Pull up on the jumper (c) with the pliers to

disengage the jumper from the pins on the

circuit board.

5) Remove the jumper (c) from the carriage.

6) Insert the plug (b) into the hole (a) in the top

of the carriage.

7) Place the jumper in the bag with the

technical manual and give to the owner of the

SRE-2700 for future use should s/he wish to

convert the unit back to left-hand operation.

jumper (c) on circuit board as

seen through hole (a)

SRE-2700 06-11-2004

(c)

jumper

8) Removal of the jumper automatically converts

the circuit board of the SRE-2700 to right-hand

operation.

31

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 32

ELECTRICAL

To convert the rocker switch to the left armrest:

1) Remove the (4) Phillips flat head machine

screws securing the seat cushion.

2) Pull out the black, split grommet (a) located

under the rocker switch.

3) Carefully remove the rocker switch (b) from

its housing (c):

• Gently pry under the switch gasket, all

the way around the switch.

(d)

(a)

ELECTRICAL

(g)

• Once the switch is free from the housing,

carefully pull it out of the housing.

4) Disconnect the rocker switch wire harness.

NOTE WIRE COLOR LOCATIONS AND SWITCH ORIENTATION

5) Unscrew the screw (d) securing the rocker switch housing to the armrest tube.

6) Remove the black grommet from the back of the rocker switch housing.

7) Place the wire harness connectors one behind the other (in line). Use masking tape to

hold in this position.

8) Pull the taped end of the wire harness through the back of the housing.

9) Remove the black, split grommet (e) from the hole in the center of the armrest weldment.

10) From the hole in the center of the armrest weldment, pull the wire harness out of the right

armrest weldment.

11) Pop out the black dome cap plug (f) from the LEFT armrest tube. Insert it in the hole in the

RIGHT armrest tube (hole created by the removal of the bushing in Step No. 2).

12) Carefully thread the taped end of the wire harness into the center hole and up the left

armrest tube.

11) When the taped end becomes visible through the hole in the armrest tube (hole created by

removal of the cap plug in Step No. 11), carefully extract the harness using needle-nose pliers.

(b)

(c)

(e)

(f)

12) Mount the rocker switch housing (c) on the left armrest tube using screw (d) removed in

Step No. 5.

13) Gently feed the rocker switch wire harness through the back on the rocker switch housing

until it comes out the front of the housing.

14) Untape the wire harness connectors and connect to the rocker switch.

15) Carefully push the rocker switch into the housing until it "snaps" securely into place.

16) Reinsert the black, split grommets: 2 in the rocker switch housing and 1 in the center of the

armrest weldment.

17) Before securing seat cushion, make sure the wire harness will lie in the channel (g) in the

bottom of the seat.

18) Secure the seat cushion using the (4) Phillips flat head machine screws removed in Step No. 1.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

32

SRE-2700 06-11-2004

Page 33

CIRCUIT BREAKER

circuit breaker with

on/off switch built in

ELECTRICAL

The on/off switch is built into the circuit breaker

which is provided to protect the battery,

controller and motor circuits in the Elevator

carriage. It is unlikely that this circuit breaker will

ever “trip” during normal use, but if the Elevator

should fail to operate, check the circuit breaker

and reset it if necessary. If the circuit breaker

should trip, determine the cause and correct the

situation.

The most likely cause of a tripped circuit breaker

would be a foreign object jamming the rail or gear

rack or overloading the elevator by exceeding its

rated load capacity.

SRE-2700 06-11-2004

33

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 34

ELECTRICAL

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

34

SRE-2700 06-11-2004

Page 35

LONG-TERM STORAGE

TURNING THE UNIT OFF

When the Elevator will not be in use for an extended period of time:

1) move the seat/carriage 2"-3" away from the lower charge contacts,

2) turn off the circuit breaker, then

3) unplug the power supply from the wall outlet.

DO NOT unplug the power supply from the wall outlet without first turning off the circuit

breaker. Failure to first turn off the circuit breaker will result in battery discharge or premature

battery failure.

TURNING THE UNIT ON

To turn the Elevator back on:

1) turn on the circuit breaker, then

2) plug the power supply back into the wall outlet.

NOTE: The batteries may require recharging before normal use if the Elevator has

remained in the `off ' position for an extended period of time. To do so, simply move

the unit to the LOWER charge contacts, and reconnect the power supply to the wall

outlet (circuit breaker `on').

SRE-2700 06-11-2004

35

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 36

TROUBLESHOOTING

TROUBLESHOOTING

Unit fails to

operate

Unit operates slowly,

lacks power

Check circuit breaker, reset if necessary.

Check battery connections.

Check footrest safety switches to see if one of these limit

switches is depressed. Sliding safety tray below footrest should

slide freely and should not stick in a position which would depress one of the safety switches.

Check for discharged batteries. Battery voltage should be in a

range of 21-29 VDC. Unit will "cut out" at 16.5V and

will require 21V to restart.

Check for discharged batteries.

Check for loose connections.

Check to make sure power supply is plugged in and working.

Controls operate

backwards and unit goes

"up" slowly and "down" fast

red button

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Check to make sure that jumper is on the left and middle pins.

Refer to the section on conversion to Right-Hand

Operation.

jumper covers left and

middle pins

36

SRE-2700 06-11-2004

Page 37

TROUBLESHOOTING

TROUBLESHOOTING

Unit operates

erratically or

intermittently with a

rider using the

armrest-mounted

control switch

Unit will not

operate unless

the seat is

positioned so that

it faces the open side of the

stairs

Check to see that the footrest safety tray is not dragging on the

stair nosing or hitting debris on the stairs. Clear debris and, if

necessary, reposition the stair rail mounting brackets to correct

the problem.

This is correct lift operation, a safety switch in the seat swivel

prevents the unit from operating with the seat "out of position".

Unit will not

operate with

call / send

remote transmitter

Unit does not shut off

when it hits the bumper

at the end of the rail

Check batteries in remote call / send unit.

Check IR receiver.

Check for loose connection.

Check that transmitters are `learned' to the same switch position

(see Learning the Transmitter).

Check limit switch in carriage assembly for proper operation.

SRE-2700 06-11-2004

37

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 38

MAINTENANCE

MAINTENANCE

YEARLY MAINTENANCE OPERATIONS

STAIRWAY ELEVATORS

Clean rail, rack, and wheels.

Apply a small dab of grease to the gear rack TEETH ONLY.

Check for dry and/or worn belts. Lubricate.

Check rail wear. There should be no groove.

Clean charging contacts (both carriage and rail ends)

with Scotch Brite®.

Check battery voltage (load test).

Check safety switches (footrest, carriage, seat).

Check armrest switch and keyswitch (if applicable).

Check power supply output:

• Load test using remote controls: check voltage

while carriage is traveling up.

• Test with carriage against contacts.

• Test with carriage away from contacts.

• Check contacts.

Check speed.

Check seat belt for wear and proper operation.

Examine exposed wiring. Are there any cuts or abrasions?

Verify operation of seat swivel mechanism. Does it move easily and

lock in place correctly?

Check that all hardware is properly tightened.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

38

SRE-2700 06-11-2004

Page 39

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

39

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 40

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

40

SRE-2700 06-11-2004

Page 41

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

41

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 42

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

42

SRE-2700 06-11-2004

Page 43

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

43

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 44

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

44

SRE-2700 06-11-2004

Page 45

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

45

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 46

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

46

SRE-2700 06-11-2004

Page 47

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

47

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 48

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

48

SRE-2700 06-11-2004

Page 49

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

49

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 50

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

50

SRE-2700 06-11-2004

Page 51

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

51

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 52

EX VIEW & BOM

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

52

SRE-2700 06-11-2004

Page 53

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

53

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 54

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

54

SRE-2700 06-11-2004

Page 55

EXPLODED VIEW AND BILL OF MATERIALS

SRE-2700 06-11-2004

55

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Page 56

EXPLODED VIEW AND BILL OF MATERIALS

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

56

SRE-2700 06-11-2004

Page 57

WARRANTY

FIVE YEAR MAJOR COMPONENTS WARRANTY

TWO YEAR LIMITED WARRANTY

for

Bruno Stairlifts

Bruno Independent Living Aids, Inc. (“Bruno”), warrants to the original purchaser of a Bruno

Stairlift that the Bruno Stairlift is free from defects in material and workmanship for a period of

two years from date of purchase. In addition, Bruno warrants that the motor, gear box and

rail (the “Major Components”) will be free from defects in materials and workmanship for a

period of five years from the date of purchase.

The exclusive remedy for a defect in a Bruno Stairlift shall be the repair or replacement, at the

option of Bruno, of the defective part or component. After the first 30 days of this warranty,

only parts and components are covered. This warranty does not cover labor and other

services after the initial 30 days. If repair or replacement of a Bruno Stairlift is not commercially practical or cannot be timely made, Bruno may elect to refund the purchase price of the

Bruno Stairlift instead of repairing or replacing the Bruno Stairlift.

IN NO EVENT SHALL BRUNO BE RESPONSIBLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, WHETHER SUCH DAMAGES ARISE FROM CLAIMS

BASED ON CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE), STRICT

LIABILITY OR PRODUCT LIABILITY. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

ALL IMPLIED WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN THEIR DURATION TO THE

LENGTH OF THE WARRANTY STATED ABOVE FOR THE AFFECTED COMPONENT.

Some states do not allow limitations on how long an implied warranty lasts so the above

limitation may not apply to you.

To obtain warranty service, you must follow these procedures:

1. Obtain return authorization by calling your local Bruno dealer or Bruno at

1-800-882-8768;

2. Return the Bruno Stairlift, freight prepaid, to the address provided by your

Bruno dealer or Bruno with proof of purchase indicating the date purchased.

Bruno will pay for shipping back to the purchaser within the continental United States

and Canada if a defect in material or workmanship is discovered. Return freight and repair

charges will be the responsibility of the purchaser if the problem is not covered by warranty.

This warranty does not cover damage or failure caused by misuse, abuse, accidents,

physical damage, modifications not made by Bruno, damage in shipment, or repairs undertaken by anyone other than Bruno factory employees or authorized distributors. The “original

purchaser” of a Bruno Stairlift that is leased or rented shall be the person or entity acting as

the lessee or rental provider.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state. Bruno specifically does not authorize any person to extend the time

or scope of this warranty.

For further information regarding this limited warranty, please contact Bruno by calling

1-800-882-8768 or writing to Bruno at the following address:

Bruno Independent Living Aids, Inc.

Attention: Service Department

1780 Executive Drive, Post Office Box 84

Oconomowoc, WI 53066 USA

SRE-2700 06-11-2004

57

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Loading...

Loading...