Bruno SRE-2700, ELECTRA-RIDE LT SRE-2700 Installation Manual

SRE-2700

ELECTRA-RIDE™ LT

STAIRWAY ELEVATOR

1780 EXECUTIVE DR., P.O., BOX 84, OCONOMOWOC, WI 53066 USA

TEL.: (262) 567-4990 FAX: (262) 953-5501

Bruno invites your calls at:

Technical Service

Technical Service fax: 262-953-5503

DEALER:

1-800-882-8183

Toll free number valid throughout the U.S. and Canada

email: service@bruno.com

www.bruno.com

INSTALLATION MANUAL

MAN-2700

REVISED 06-11-2004

IMPORTANT NOTES

This stairway elevator is intended

for indoor use only

in a heated, enclosed location

above 35° F (2° C).

NOTE

The warranty for the Electra-Ride™ LT

Stairway Elevator is

rendered null and void

if the unit is installed by

anyone other than an authorized Bruno dealer.

Electra-Ride™ is a trademark of Bruno Independent Living Aids, Inc.®

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

2

SRE-2700 06-11-2004

TABLE OF CONTENTS

IMPORTANT NOTES................................................................................... 2

INTRODUCTION.......................................................................................... 4

TECHNICAL SPECIFICATIONS.................................................................. 5

CARTON CONTENTS................................................................................. 6

OVERVIEW.................................................................................................. 7-8

INSTALLATION .......................................................................................... 9-30

Tools Necessary for Installation................................... 9

Bumper Bracket Installation......................................... 10

Fitting the Rail.............................................................. 10

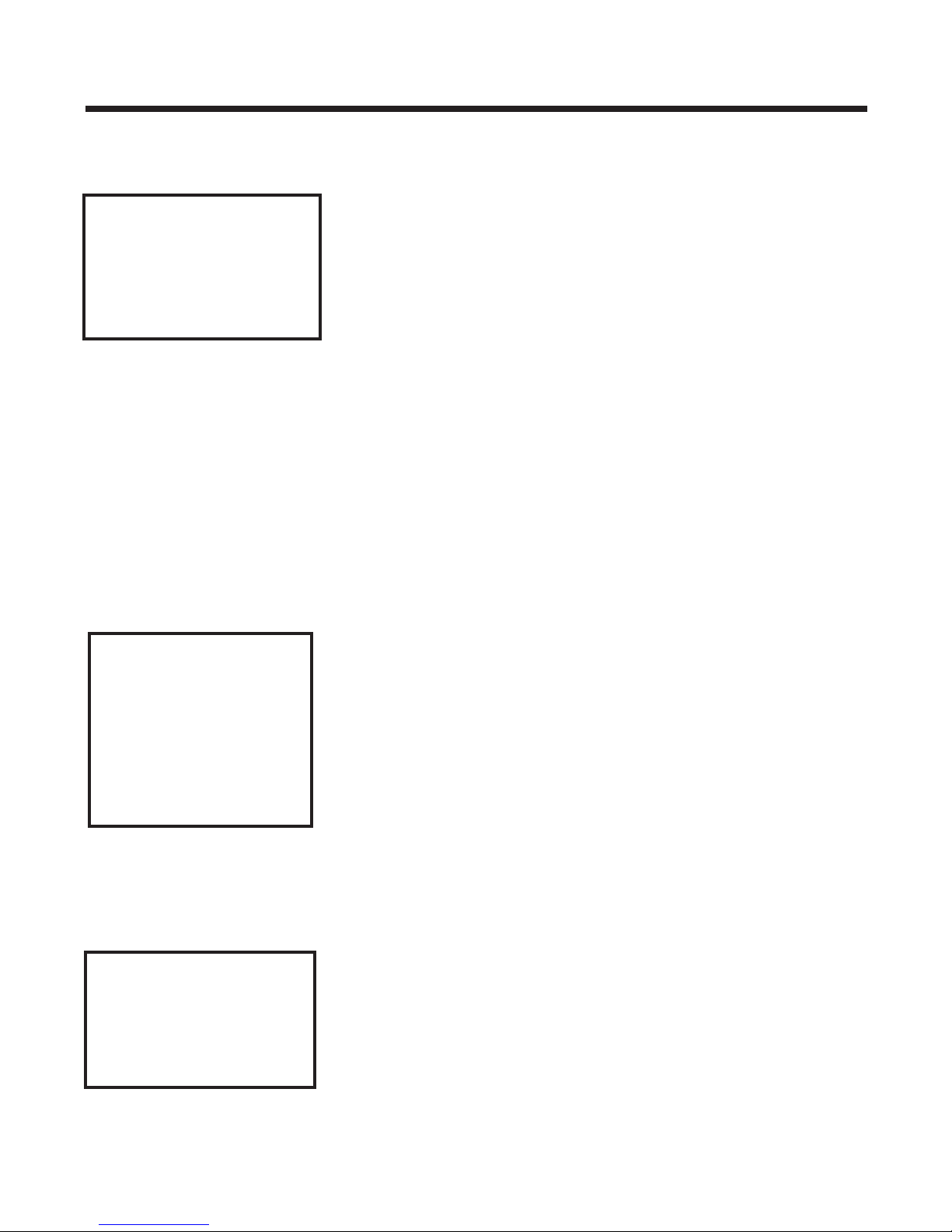

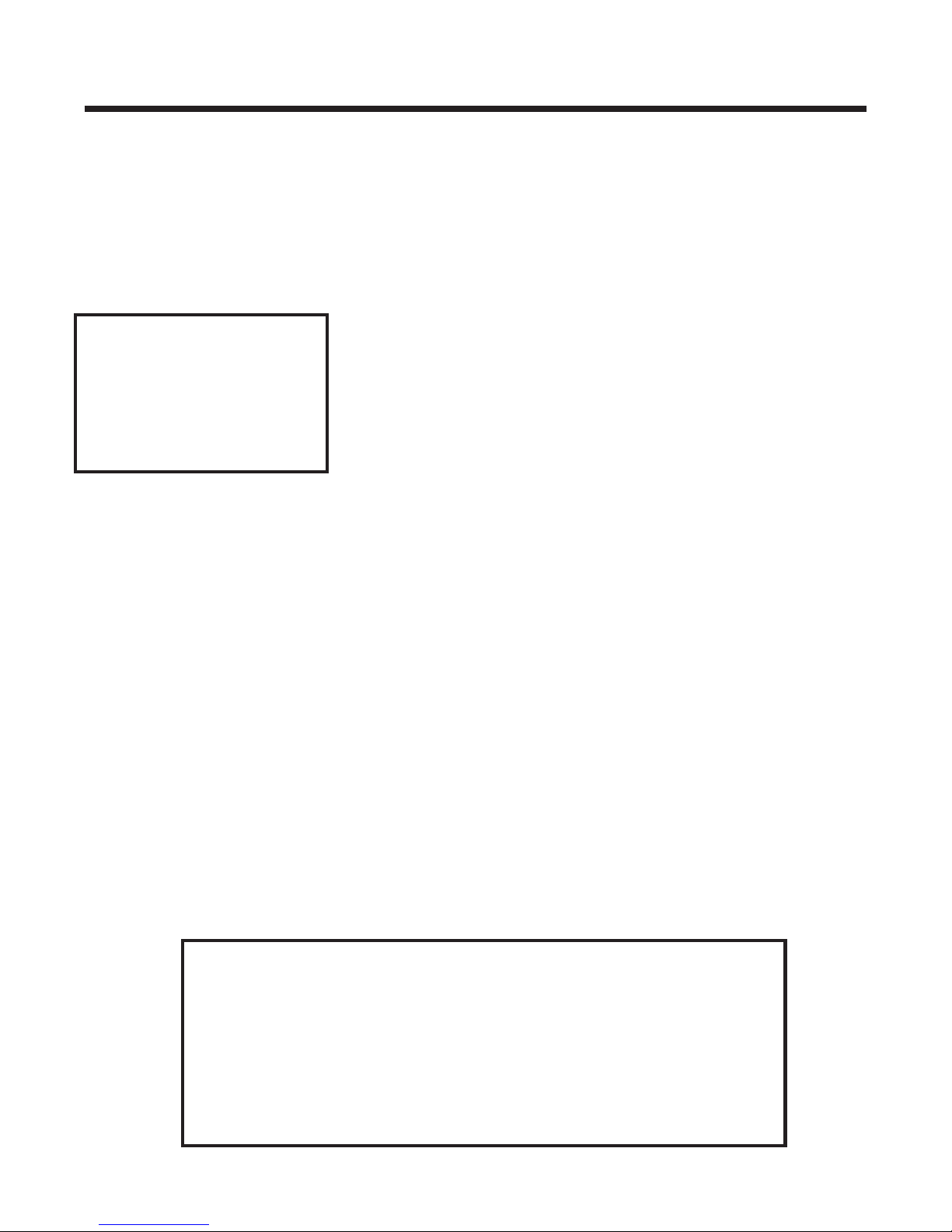

Application Guide......................................................... 11-12

Cutting the Rail............................................................. 13

Rail Joint Assembly...................................................... 14

Positioning Foot Clamp Assemblies............................. 15-17

Mounting the Carriage on the Upper Rail..................... 18-19

Adjusting the Carriage Angle........................................20

Installing the Seat Assembly........................................ 20-22

Installing the Final Limit Ramp and Switch.................. 22

Connecting the Power Source..................................... 23-24

Testing the Unit............................................................ 25

Infrared Call/Send Transmitter..................................... 26

Mounting the Standard Call/Send Transmitter............. 27

Learning the Standard Call/Send Transmitter.............. 28-29

When the Installation is Complete............................... 29

Lubrication................................................................... 30

ELECTRICAL............................................................................................... 31-34

Converting Rail/Carriage for Right-Hand Operation..... 31

Converting Rocker Switch to Left Armrest................... 32

Circuit Breaker............................................................. 33

Wiring Schematic......................................................... 34

LONG-TERM STORAGE............................................................................. 35

TROUBLESHOOTING................................................................................. 36-37

YEARLY MAINTENANCE OPERATIONS................................................... 38

EXPLODED VIEW AND BILL OF MATERIALS.......................................... 39-56

LIMITED WARRANTY................................................................................. 57

SRE-2700 06-11-2004

3

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INTRODUCTION

Thank you for purchasing an SRE-2700 Electra-Ride™ LT Stairway Elevator. Be sure to

check carton contents for shipping damage as soon as they are received.

Also, check the carton contents against the packing list before leaving the shop to install

product on site.

Report any discrepancies to Bruno Independent Living Aids immediately.

Bruno encourages you to read through the installation manual before installing the Stairway

Elevator. Doing so will help you install the elevator more quickly and avoid the frustration of

getting to the job site only to discover that you are missing a critical tool or piece of equipment.

MATERIAL DATA SAFETY SHEET(S) ON

MATERIALS USED ON THIS UNIT CAN BE

REQUESTED THROUGH OUR TECHNICAL SERVICE

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

NOTE:

DEPARTMENT

4

SRE-2700 06-11-2004

SPECIFICATIONS

Technical Specifications

Weight Capacity 275 lbs. (125 kg)

Speed 18 - 23 fpm (5.5-7.0 m/mn)

Power Source two (2) 12-volt sealed, maintenance-free

batteries with 24-volt continuous-duty

charger

Motor 24 VDC, 2-pole, 1.32 hp

Drive self-locking gearbox, rack-and-pinion

drive

Control constant pressure (armrest and

2 transmitters)

Brake self-locking worm gear

Maximum incline 45 degrees

Rail steel channel with integral drive gear

rack

Seat Swivel 0, 45 and 90 degrees at top and bottom

Power Supply 100-240 VAC, 50/60 Hz, 0.85 amp power

supply input, 33 VDC 1-amp transformer

output, 29.6 to 27.6 VDC charging at

850 mA max., continuous monitoring.

SRE-2700 06-11-2004

5

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

PACKING LIST

CARTON CONTENTS

The ELECTRA-RIDE™ LT is shipped in 4 cartons. Check the

contents of the cartons to be sure you have all of the components

before beginning an installation.

CHECK CARTON

CONTENTS FOR

SHIPPING DAMAGE

IMMEDIATELY UPON

RECEIPT

*MSDS (Material Safety

Data Sheet) available

from Bruno upon

request. Contact

Service

Department.

Check the carton contents for shipping damage upon receipt.

Damage claims must be filed by the dealer, not the manufacturer.

Bruno Independent Living Aids, Inc.® cannot be responsible for shipping

damage.

CARTON 1

(1) complete carriage assembly including footrest

CARTON 2

(1) complete seat assembly

(2) IR transmitters

Box A

(1) tube

(1)

final limit switch ramp assembly

(1) SRE-K-1553 bumper assembly parts kit

(2) bumper assemblies

(2) pieces of Velcro®

(10) 11" lg wire ties

(1) SRE-K-2705 electrical parts kit (16' rail)

(or SRE-K-2706 for 20' rail)

(1) custom-length charge harness

(2) transmitter mounting brackets

(2) SRE-K-2701 transmitter mounting hardware kit

(1) power supply

(1) SRE-K-1518 power supply hardware kit

Box B

(9) foot clamp sets (16' RAIL) • 11 (20' RAIL)

• TBD** (CUSTOM RAIL)

**DEPENDS UPON RAIL LENGTH

(36) sheet metal screws (M 6.3 X 50 mm)(16' rail);

QTY.44 for (20' rail)

white lithium grease per rail set

***NOTE:

Rail sections must have

matching numbers

stamped on the

sections.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

( ) UPON REQUEST

CARTON 3

(1) rail half (upper)

CARTON 4

(1) rail half (lower)

(1) joint plate

(1) SRE-K-1502 joint plate hardware kit

CARTON 5 (OPTIONAL)

(1) rail half (lower)

(1) joint plate

(1) SRE-K-1502 joint plate hardware kit

6

clamps, adjustable, 9 lbs. ea.

SRE-2700 06-11-2004

INSTALLATION

OVERVIEW

OVERVIEW

OVERVIEW OF INSTALLATION

Installation of the ELECTRA-RIDE™ LT Stairway Elevator consists of the following:

* Determine whether the elevator should be a left- or right-side installation. "Left"

or "right" installation is determined by the side of the stairway on which the rail is

installed (viewed from the bottom of the stairs). THE GEAR RACK WILL BE

TOWARD THE CENTER OF THE STAIRS. Unless specified otherwise, Bruno

Stairway Elevators are set up for left-side installation when shipped, but can easily

be converted to right-side installation. Instructions for converting the unit for

right-hand installation are included later in this manual.

* Identify and locate lower rail section and bumper bracket assembly.

* Assemble and tighten the rail joint. CAUTION: RAILS CANNOT BE MIXED.

CHECK ID NUMBERS STAMPED AT ENDS OF RAILS.

* Determine the correct length for the rail (using Steps 2 & 4 from the APPLICATION

GUIDE), and cut the rail.

* Install lower bumper assembly.

* Position rail on left or right side of stairway using rail clamp assemblies.

* Mount the carriage on the upper rail.

* Adjust the carriage angle by loosening the (2) Angle Adjustment Bolts.

* Install seat assembly and make electrical connections.

* When installing a right-side ELECTRA-RIDE™ LT , follow instructions for

Changing to Right-Hand Operation

* Perform a 5-6 trial runs of the ELECTRA-RIDE™ LT to determine final location of

the rail.

SRE-2700 06-11-2004

7

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

OVERVIEW

OVERVIEW (CON'T.)

* Determine the appropriate location for the remaining mounting clamps and

brackets for attaching the rail to the stairs then loosely assemble the clamps

and brackets to the Stairway Elevator rail.

* Adjust and tighten the rail clamps and mounting brackets.

* Anchor the mounting brackets to the stairs.

* Locate and drill holes for the top bumper bracket.

* Install the top bumper bracket.

* Determine where the power supply will be positioned, and install rail wire lead

accordingly.

* Position power supply at upper or lower landing.

* Route wire to household outlet.

* Mount remote call/send transmitters.

* Test unit for proper operation.

* Train customer in safe and convenient operation of the Stairway Elevator.

REMEMBER:

No installation is complete until the customer has been trained to use the Elevator

smoothly and safely. After demonstrating correct operation, have the customer

operate the Elevator several times while you are available to answer questions.

BE SURE THE CUSTOMER UNDERSTANDS ALL SAFETY ASPECTS OF

USING THE ELEVATOR. Patience and thoroughness in this phase of the

installation are often rewarded with repeat business and customer referrals.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

8

SRE-2700 06-11-2004

INSTALLATION

Tools Necessary for Installation

[ ] Protractor level, builder's level

[ ] Socket set, metric (10 mm through 22 mm)

[ ] Ratchet, with 6" extension

[ ] Combination wrench set, metric (10 mm through 22 mm)

INSTALLATION

NOTE:

The standard stairway

elevator is suitable for

stairway angles up to

45 degrees.

[ ] Phillips screwdrivers

[ ] 5/16" socket (clamp screws)

[ ] 9/16" and 5/8" open-end wrench (limit switch adjustment)

[ ] 5/16" open-end wrench

[ ] Electric drill with letter `O' (.316") and 1/4" bit

[ ] Hacksaw with 2 or 3 blades, or metal cutting bandsaw

[ ] 20' tape measure

[ ] Small dead blow hammer

[ ] Rubber mallet

[ ] C-clamp

[ ] Wire crimper and stripper

[ ] Flashlight

[ ] Needle nose pliers

[ ] Scissors or knife

TIPS FOR A FASTER, SMOOTHER INSTALLATION:

• Be sure you have all necessary parts and tools before

traveling to installation site.

• Loosely assemble the foot clamp assemblies before

traveling to the installation site.

SRE-2700 06-11-2004

[ ] Extension cord

[ ] Double-sided foam tape

[ ] File

[ ] 12" adjustable wrench

[ ] 90-degree needle-nose pliers

9

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

INSTALLATION

ASSEMBLY

1) Determine whether a left- or right-side installation is appropriate for the site. "Left" or

"right" refers to the side of the stairway on which the rail is installed (as viewed from the

bottom of the stairs). Unless otherwise specified Bruno Stairway Elevators are shipped

from the factory in the left-side configuration. Conversion to right-side installation is

easy (instructions included later in this manual ).

2) Identify and locate lower rail section appropriate to the installation (left or right).

BUMPER BRACKET INSTALLATION

1) Assemble lower rail.

2) Install lower bumper bracket.

bumper bracket

FITTING THE RAIL

1) Determine the correct length for the rail by measuring along a straight line placed on the

stairs. (SEE STEP 2 IN THE APPLICATION GUIDE) To that amount, add Measurement B

(STEP 4 IN THE APPLICATION GUIDE). This process will allow you to custom fit the

Elevator to your customer by determining the most comfortable seat-to-floor height within

the space available at the top of the stairs.

NOTE: The rail must rest approximately 2" above the step nosing, and extend from the lower floor to a

point beyond the nosing of the top step (see Step No. 4 of the Application Guide). In some cases where

the bottom landing is made of material such as concrete, ceramic tile or slate, the last bracket on the

landing may be omitted. In this case, a bracket must be added on the second-to-last step ( bottom), and

at the top of the stairway.

REMINDER:

THIS RAIL MUST BE INSTALLED APPROXIMATELY 2" ABOVE STAIR NOSING.

OTHERWISE, FOOTREST WILL HIT THE STEPS, CAUSING INTERMITTENT

OPERATION.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

10

SRE-2700 06-11-2004

INSTALLATION

SRE-2700 06-11-2004

11

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

12

SRE-2700 06-11-2004

INSTALLATION

INSTALLATION

CUTTING THE RAIL

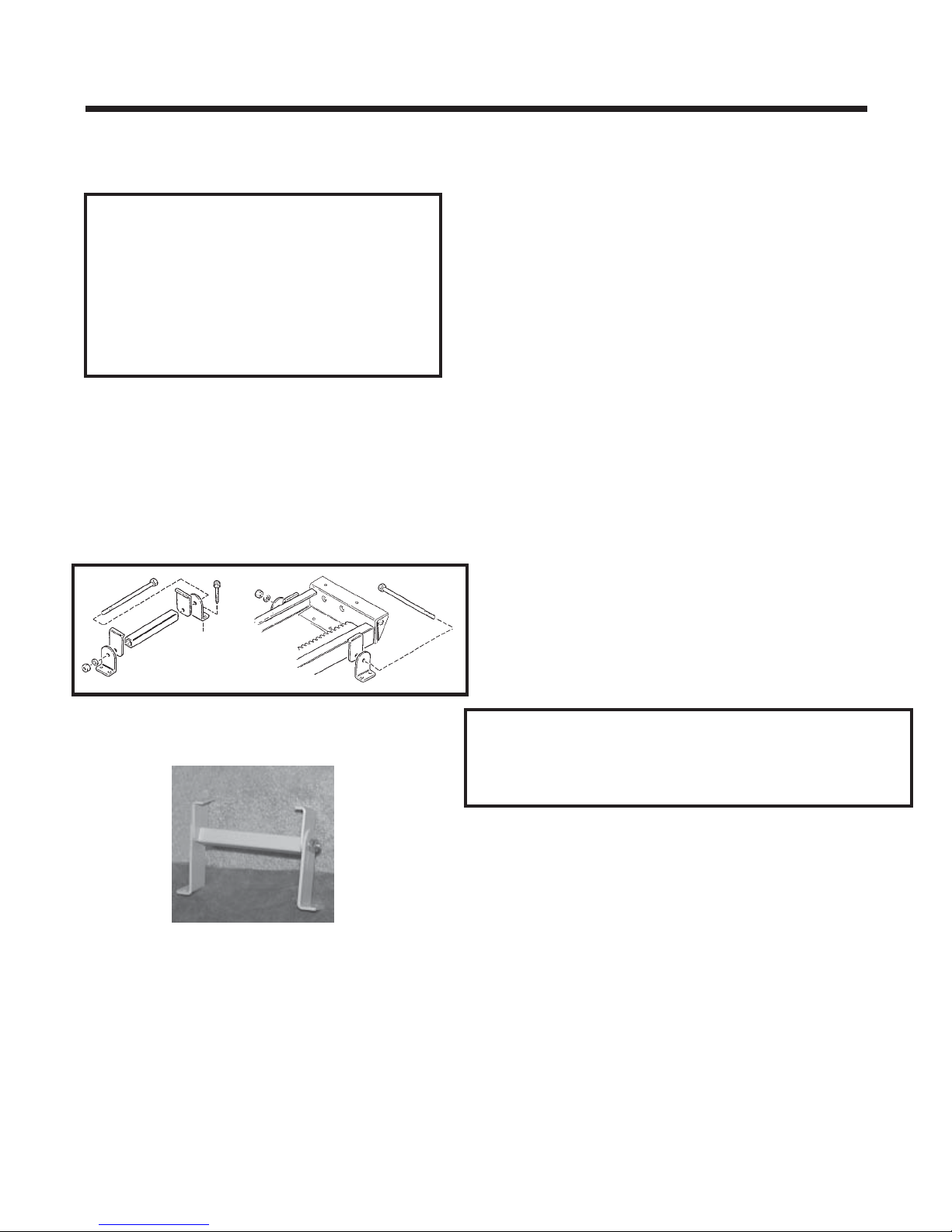

IMPORTANT NOTE!

Under no circumstances should a rail section be cut shorter than

18” (46 cm).

There must be at least (2) clamps on a short rail section (1 at the rail

joint and 1 at the rail end). Cutting a rail shorter than 18” (46 cm)

would not allow enough room for the (2) necessary clamps.

Example:

After measuring the staircase, you determine you need 9 feet of rail.

With your (2) 8-foot sections you decide to use (1) 8-foot section and

cut the remaining (1) foot from the second 8-foot section. Doing this

could yield a rail piece with insufficient weld.

Instead, Bruno recommends cutting at least one foot off one of the

8-foot sections (leaving 7 feet of rail) and then cutting 2 feet from the

second 8-foot section. You will have a (1) 7-foot section and (1) 2-foot

section, both of which are long enough to be properly mounted

(2 clamps minimum per short rail).

NEVER CUT OFF THE JOINT END!

The M6 bolts securing the gear rack must remain intact.

Cut off the end with the pre-drilled charge contact mounting holes.

Then, using the provided template, redrill (2) holes on each end of the rail.

1) Use a metal-cutting power saw or manual

hacksaw to cut the rail to length. Cut off

the end of the rail to be located at the top of the

stairway.

2) Use a file or other appropriate tool to deburr the

cut end of the rail. Soften any sharp edges

which might abrade the insulation of the wiring to

be routed to the bumper at the end of the rail.

use “O” size drill bit

(8.03mm/.316")

SRE-2700 06-11-2004

3) Use a C-clamp to hold the upper bumper bracket in

place at the cut end of the rail. Use the holes in

the bumper bracket as guides to drill mounting

holes in the rail using an“O” size (8.03 mm/.316")

drill bit.

13

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

RAIL JOINT ASSEMBLY

NOTE:

The rail is always installed

with the gear rack towards the

center of the stairs and gear

teeth facing the wall.

INSTALLATION

SUGGESTION

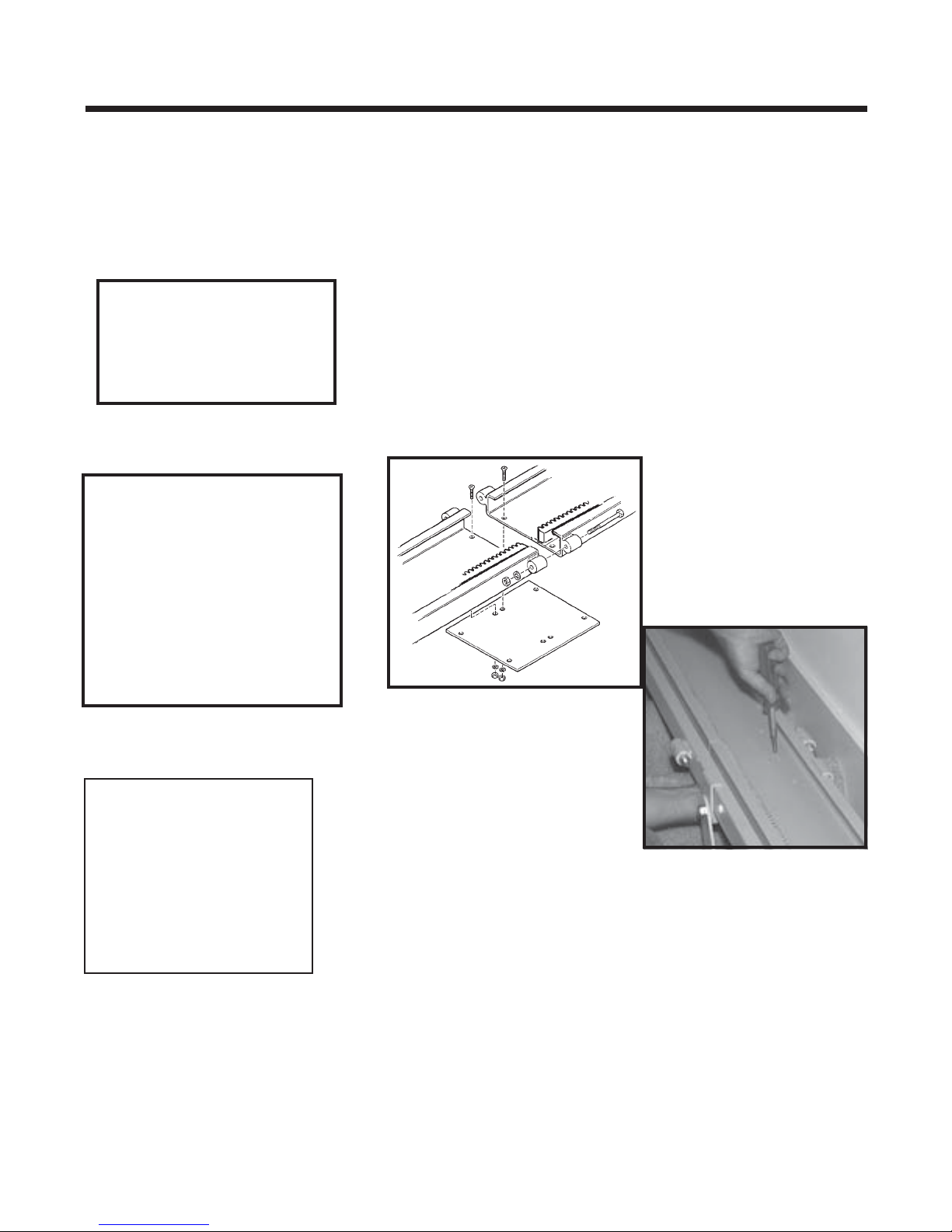

1) Assemble the rail joint by attaching the bottom plate to

the rail with the screws, lock washers and hex nuts

provided with the unit. Install the bolts, internal-tooth

washers and hex nuts through the joint blocks on both

sides of the rail. Tighten all bolts securely and make sure

screw heads are flush with the surface of the inside of the

rail. PLEASE REFER TO EXPLODED VIEWS AT

BACK OF MANUAL.

Once two sections of rail

are installed, and before

installing the carriage, run a

plomb line along the rail. If

the rail bows, insert shims

or readjust clamps.

NOTE:

The chamfered

edges of the

holes must face

"up" toward

the bottom of

the rail.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

14

SRE-2700 06-11-2004

POSITIONING FOOT CLAMP ASSEMBLIES

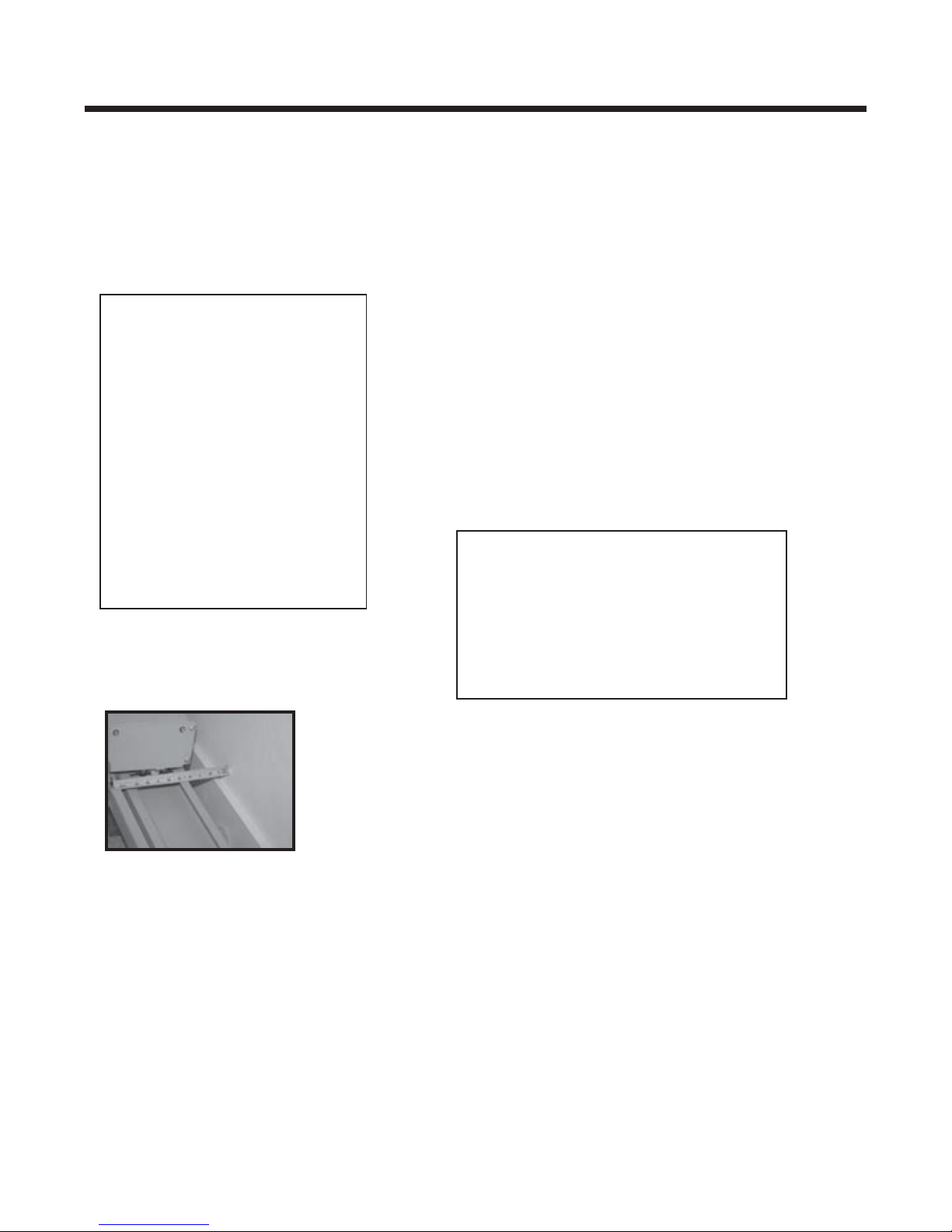

1) Place rail mounting foot clamps in the

pattern as indicated.

clamp placement order

INSTALLATION

Be sure to leave a minimum space of 4"*,

as measured from the back edge of the

rail to the wall.

•bottom landing

•first tread up from bottom

landing

•top landing

•first tread down from top

landing

•closest tread above and

below the rail joint(s)

•minimum of every third

tread over remainder

of staircase.

*The 4" clearance is needed if the seat is

to swivel 90 degrees. For installations

where the seat will swivel less than

90 degrees, the rail-to-wall clearance

may be reduced to between 3" and

3-1/2". Frequently check the seat-wall

clearance during installation.

Note: If top or bottom clamp is omitted

because the landing is cement or

ceramic tile, or in the event that the

owner wishes not to drill holes in the

landing, a set of clamps should be

added on the second-to-last step and at

the top of stairway.

4" as measured from

back edge of rail to wall.

SRE-2700 06-11-2004

15

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

INSTALLATION ON CARPET

Before securing the foot clamp

assemblies with hardware, seat them

using a deadblow hammer. Use a

rubber mallet to compress the rug and

pad before anchoring the clamp.

2) For ease of installation, finger tighten all

clamp assemblies to rail. The clamp

assembly should be positioned so the nut

is closest to the wall.

3) Slide top and bottom clamps down on the rail

until firmly seated on step. When installing on

carpeted stairs, use a rubber mallet on the

clamps to compress carpet and pad before

anchoring to steps.

4) Drill in one screw in the foot nearest the wall

of each of the top and bottom of foot of clamp

assemblies.

This will enable the installer to change the

position of the rail if necessary and minimize

the number of holes drilled in the wrong location.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

Bruno recommends installing the screws in the

back clamp (the one closer to the wall) first,

then the screws in the front of the clamp.

16

SRE-2700 06-11-2004

INSTALLATION

INSTALLATION

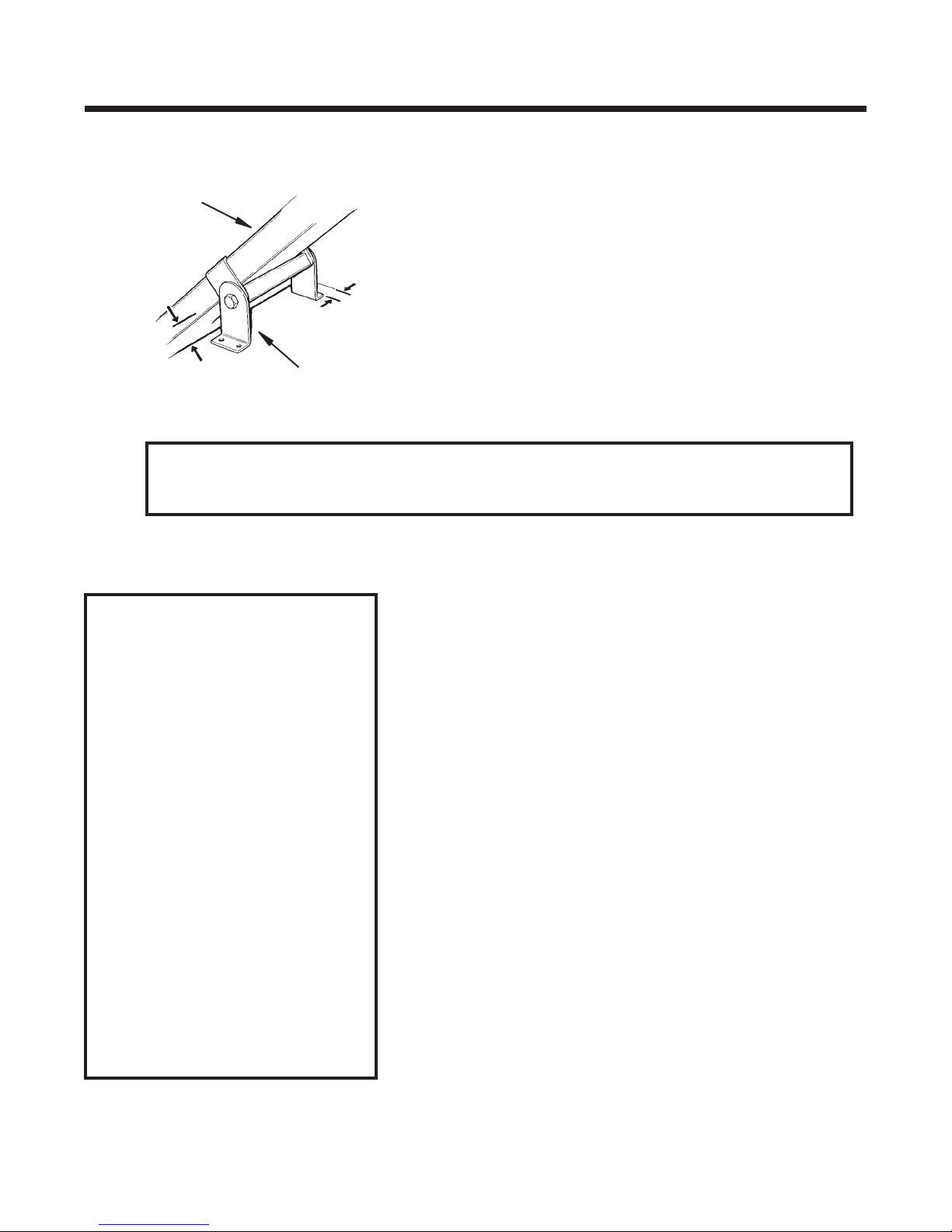

rail

approx.

2" above

nosing

foot clamp assembly

*Install foot clamps at least 2-1/2” from wall (approx. 4" between the back

edge of the rail and the wall). Provide additional foot clamp-to-wall

clearance if seat needs to swivel against wall.

INSTALLATION NOTES

For installations on hardwood

stairs, Bruno recommends

drilling a pilot hole before

inserting fasteners.

5) Frequently check the measurements at the key

locations indicated to ensure proper positioning

of the clamp assemblies.

*see note below

If threaded fastener

extends below a stair

tread that is exposed, it

can be trimmed flush

with pliers.

Bruno ships the Stairway

Elevator with fasteners

appropriate for

wooden stair treads only.

Other stair material may

require different fasteners.

Please contact Bruno

Independent Living Aids, Inc.

for information.

SRE-2700 06-11-2004

17

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

INSTALLATION

MOUNTING CARRIAGE ON UPPER RAIL

1) Remove the carriage from the shipping carton.

2) Make sure circuit breaker is OFF.

circuit breaker off

sliding carriage on rail

3) Manually slide the carriage onto the rail until

approximately half of the carriage is on the rail.

4) Manually turn the motor pulley to fully engage the

entire carriage onto the rail.

©2004,2002 BRUNO INDEPENDENT LIVING AIDS, INC.®

18

SRE-2700 06-11-2004

Loading...

Loading...