Page 1

Main Menu

Page 2

Page 3

BRP US Inc.

Technical Publications

250 Sea Horse Drive

Waukegan, Illinois 60085 United States

† AMP, Superseal 1.5, Super Seal, Power Timer, and Pro-Crimper II

are registered trademarks of Tyco International, Ltd.

† Amphenol is a registered trademark of The Amphenol Corporation.

† Champion is a registered trademark of Federal-Mogul Corporation.

† Deutsch is a registered trademark of The Deutsch Company.

† Dexron is a registered trademark of The General Motors Corporation.

† Fluke is a registered trademark of The Fluke Corporation

† GE is a registered trademark of The General Electric Company.

† GM is a registered trademark of The General Motors Corporation.

† Locquic and Loctite are registered trademarks of The Henkel Group.

† Lubriplate is a registered trademark of Fiske Brothers Refining Company.

† NMEA is a registered trademark of the National Marine Electronics Association.

† Oetiker is a registered trademark of Hans Oetiker AG Maschinen.

† Packard is a registered trademark of Delphi Automotive Systems.

† Permatex is a registered trademark of Permatex.

† STP is a registered trademark of STP Products Company.

† Snap-on is a registered trademark of Snap-on Technologies, Inc.

The following trademarks are the property of BRP US Inc. or its affiliates:

Evinrude

Johnson

Evinrude

®

®

®

E-TEC

®

Nut Lock™

Screw Lock™

Ultra Lock™

FasTrak™ Gel-Seal II™

S.A.F.E.™ Moly Lube™

SystemCheck™

Triple-Guard

®

Grease

I-Command™ DPL™ Lubricant

Evinrude

Evinrude

Evinrude

®

/ Johnson ® XD30™ Outboard Oil 2+4 ® Fuel Conditioner

®

/ Johnson ® XD50™ Outboard Oil

®

/ Johnson ® XD100™ Outboard Oil

Carbon Guard™

HPF XR™ Gearcase Lubricant

Twist Grip™

Printed in the United States.

© 2008 BRP US Inc. All rights reserved.

TM, ® Trademarks and registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

Page 4

TABLE

OF

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 INSTALLATION AND PREDELIVERY . . . . . . . . . . . . . . 27

3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 ENGINE COVER SERVICE . . . . . . . . . . . . . . . . . . . . . . 89

5 ENGINE MANAGEMENT MODULE (EMM) . . . . . . . . . . 93

6 SYSTEM ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7 ELECTRICAL AND IGNITION . . . . . . . . . . . . . . . . . . . . 125

8 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9 OILING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

10 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

11 POWERHEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

12 MIDSECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13 GEARCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

GEARCASE – STANDARD ROTATION . . . . . . . . . . . . 295

GEARCASE – COUNTER ROTATION . . . . . . . . . . . . . 317

14 TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S–1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I–1

TROUBLE CHECK CHART . . . . . . . . . . . . . . . . . . . . . . . . T–1

DIAGRAMS

EMM SERVICE CODE CHART

2

Page 5

INTRODUCTION

INTRODUCTION

CONTENTS

ABBREVIATIONS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

UNITS OF MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

LIST OF ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ENGINE EMISSIONS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MANUFACTURER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

DEALER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OWNER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

EPA EMISSION REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MODEL DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

MODELS COVERED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

IDENTIFYING MODEL AND SERIAL NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

STANDARD TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PRODUCT REFERENCE AND ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3

Page 6

SAFETY INFORMATION

Before working on any part of the outboard, read the SAFETY section at the end of this manual.

This manual is written for qualified, factory-trained

technicians who are already familiar with the use

of Evinrude

ual is not a substitute for work experience. It is an

organized guide for reference, repair, and maintenance of the outboard(s).

This manual uses the following signal words identifying important safety messages.

®

/Johnson® Special Tools. This man-

DANGER

Indicates an imminently hazardous situation which, if not avoided, WILL result in

death or serious injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, CAN result in severe

injury or death.

Always follow common shop safety practices. If

you have not had training related to common shop

safety practices, you should do so to protect yourself, as well as the people around you.

It is understood that this manual may be translated into other languages. In the event of any discrepancy, the English version shall prevail.

To reduce the risk of personal injury, safety warnings are provided at appropriate times throughout

the manual.

DO NOT make any repairs until you have read the

instructions and checked the pictures relating to

the repairs.

Be careful, and never rush or guess a service procedure. Human error is caused by many factors:

carelessness, fatigue, overload, preoccupation,

unfamiliarity with the product, and drugs and alcohol use, to name a few. Damage to a boat and

outboard can be fixed in a short period of time, but

injury or death has a lasting effect.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor

or moderate personal injury or property

damage. It also may be used to alert

against unsafe practices.

IMPORTANT: Identifies information that will

help prevent damage to machinery and appears

next to information that controls correct assembly

and operation of the product.

These safety notices mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

When replacement parts are required, use

Evinrude/Johnson Genuine Parts or parts with

equivalent characteristics, including type, strength

and material. Using substandard parts could

result in injury or product malfunction.

Torque wrench tightening specifications must be

strictly followed. Replace any locking fastener

(locknut or patch screw) if its locking feature

becomes weak. Definite resistance to turning

must be felt when reusing a locking fastener. If

replacement is specified or required because the

locking fastener has become weak, use only

authorized Evinrude/Johnson Genuine Parts.

If you use procedures or service tools that are not

recommended in this manual, YOU ALONE must

decide if your actions might injure people or damage the outboard.

Page 7

DANGER

Contact with a rotating propeller is likely to result in serious injury or death. Assure the

engine and prop area is clear of people and objects before starting engine or operating boat.

Do not allow anyone near a propeller, even when the engine is off. Blades can be sharp and

the propeller can continue to turn even after the engine is off. Remove propeller before servicing and when running the outboard on a flushing device.

DO NOT run the engine indoors or without adequate ventilation or permit exhaust fumes to

accumulate in confined areas. Engine exhaust contains carbon monoxide which, if inhaled,

can cause serious brain damage or death.

WARNING

Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172

kPa).

The motor cover and flywheel cover are machinery guards. Use caution when conducting

tests on running outboards. DO NOT wear jewelry or loose clothing. Keep hair, hands, and

clothing away from rotating parts.

During service, the outboard may drop unexpectedly. Avoid personal injury; always support

the outboard’s weight with a suitable hoist or the tilt support bracket during service.

To prevent accidental starting while servicing, disconnect the battery cables at the battery.

Twist and remove all spark plug leads.

The electrical system presents a serious shock hazard. DO NOT handle prima ry or secondary

ignition components while outboard is running or flywheel is turning.

Gasoline is extremely flammable and highly explosive under certain conditions. Use caution

when working on any part of the fuel system.

Protect against hazardous fuel spray. Before starting any fuel system service, carefully

relieve fuel system pressure.

Do not smoke, or allow open flames or sparks, or use electrical devices such as cellular

phones in the vicinity of a fuel leak or while fueling.

Keep all electrical connections clean, tight, and insulated to prevent shorting or arcing and

causing an explosion.

Always work in a well ventilated area.

Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak.

Definite resistance to tightening must be felt when reusing a locking fastener. If replacement

is indicated, use only authorized replacement or equivalent.

Page 8

INTRODUCTION

ABBREVIATIONS USED IN THIS MANUAL

ABBREVIATIONS USED IN THIS MANUAL

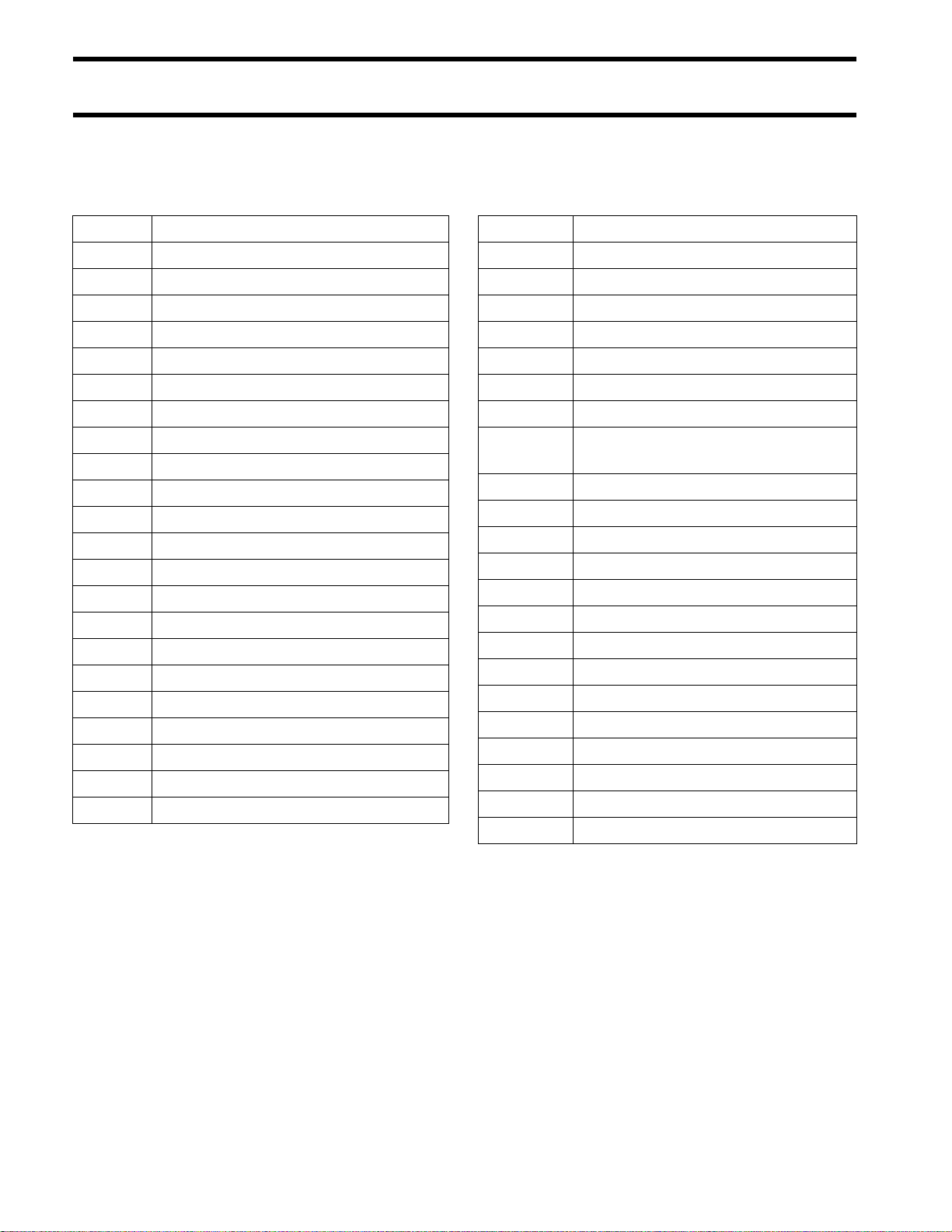

Units of Measurement List of Abbreviations

A Amperes

amp-hr Ampere hour

fl. oz. fluid ounce

ft. lbs. foot pounds

HP horsepower

in. inch

in. Hg inches of mercury

in. lbs. inch pounds

kPa kilopascals

ml milliliter

mm millimeter

N·m Newton meter

P/N part number

psi pounds per square inch

RPM revolutions per minute

°C degrees Celsius

°F degrees Fahrenheit

ms milliseconds

µs microseconds

Ω Ohms

VVolts

VAC Volts Alternating Current

VDC Volts Direct Current

ABYC American Boat & Yacht Council

ATDC after top dead center

AT air temperature sensor

BPS barometric pressure sensor

BTDC before top dead center

CCA cold cranking amps

CPS crankshaft position sensor

EMM Engine Management Module

ICOMIA International Council of Marine

Industry Associations

MCA marine cranking amps

MWS modular wiring system

NMEA National Marine Electronics Assoc.

NTC negative temperature coefficient

PTC positive temperature coefficient

ROM read only memory

S.A.F.E.™ speed adjusting failsafe electronics

SAC start assist circuit

SAE Society of Automotive Engineers

SYNC synchronization

TDC top dead center

TPS throttle position sensor

WOT wide open throttle

WTS water temperature sensor

6

Page 9

INTRODUCTION

ENGINE EMISSIONS INFORMATION

ENGINE EMISSIONS

INFORMATION

Maintenance, replacement, or repair of the

emission control devices and systems may be

performed by any marine SI (spark ignition)

engine repair establishment or individual.

Manufacturer’s Responsibility

Beginning with 1999 model year outboards, manufacturers of marine outboards must determine

the exhaust emission levels for each outboard

horsepower family and certify these outboards

with the United States of America Environmental

Protection Agency (EPA). An emissions control

information label, showing emission levels and

outboard specifications, must be placed on each

outboard at the time of manufacture.

Dealer’s Responsibility

When performing service on all 1999 and more

recent Evinrude/Johnson outboards that carry an

emissions control information label, adjustments

must be kept within published factory specifications.

Replacement or repair of any emission related

component must be executed in a manner that

maintains emission levels within the prescribed

certification standards.

Dealers are not to modify the outboard in any

manner that would alter the horsepower or allow

emission levels to exceed their predetermined

factory specifications.

Exceptions include manufacturer’s prescribed

changes, such as altitude adjustments, for example.

Owner’s Responsibility

The owner/operator is required to have outboard

maintenance performed to maintain emission levels within prescribed certification standards.

The owner/operator is not to, and should not allow

anyone to, modify the outboard in any manner

that would alter the horsepower or allow emissions levels to exceed their predetermined factory

specifications.

Tampering with the fuel system to change horsepower or modify emission levels beyond factory

settings or specifications will void the product warranty.

EPA Emission Regulations

All new 1999 and more recent Evinrude/Johnson

outboards are certified to the EPA as conforming

to the requirements of the regulations for the control of air pollution from new watercraft marine

spark ignition outboards. This certification is contingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followed

and, whenever practical, returned to the original

intent of the design. The responsibilities listed

above are general and in no way a complete listing of the rules and regulations pertaining to the

EPA requirements on exhaust emissions for

marine products. For more detailed information on

this subject, you may contact the following locations:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW

Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3rd St. NW

Washington, DC 20001

EPA INTERNET WEB SITE:

www.epa.gov

7

Page 10

INTRODUCTION

MODEL DESIGNATION

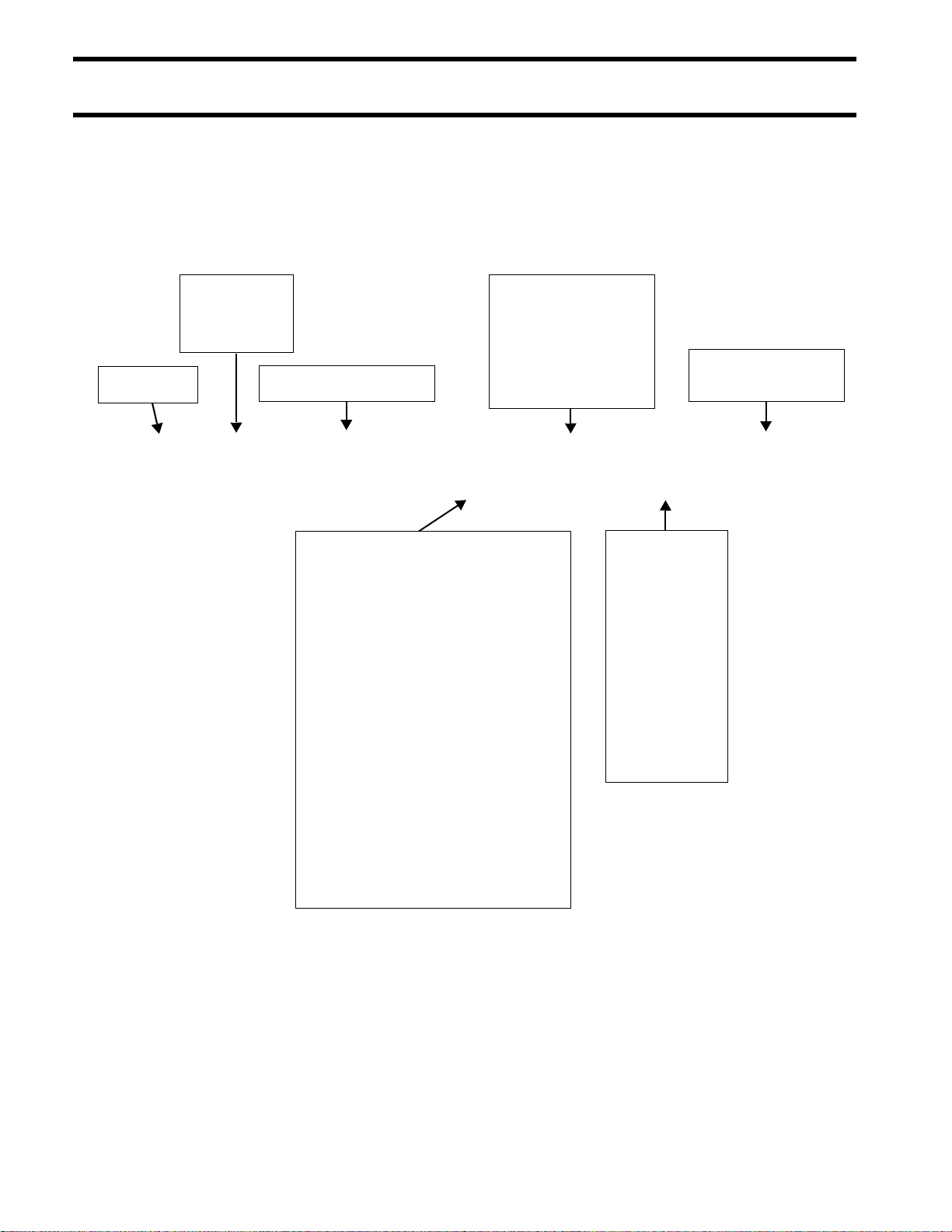

MODEL DESIGNATION

PREFIX

STYLE:

J = Johnson

E = Evinrude

HORSEPOWER

LENGTH:

= 15” Std.

L = 20” Long

Y = 22.5” Special

X = 25” X-long

Z = 30” XX-long

MODEL RUN

or SUFFIX

B E 200 DP X SE E

DESIGN FEATURES:

AP = Advanced Propulsion

B = Blue Paint

C = Counter Rotation

D = Evinrude E-TEC™

E = Electric Start w/Remote Steering

F = Direct-Injection

G = Graphite Paint

H = High Output

J = Jet Drive

M = Military

P = Power Trim and Tilt

R = Rope Start w/Tiller Steering

S = Saltwater Edition

T = Tiller Steering

TE = Tiller Electric

V = White Paint

W = Commercial Model

MODEL YR:

I= 1

N= 2

T= 3

R= 4

O= 5

D= 6

U= 7

C= 8

E= 9

S= 0

Ex: SE = 2009

8

Page 11

INTRODUCTION

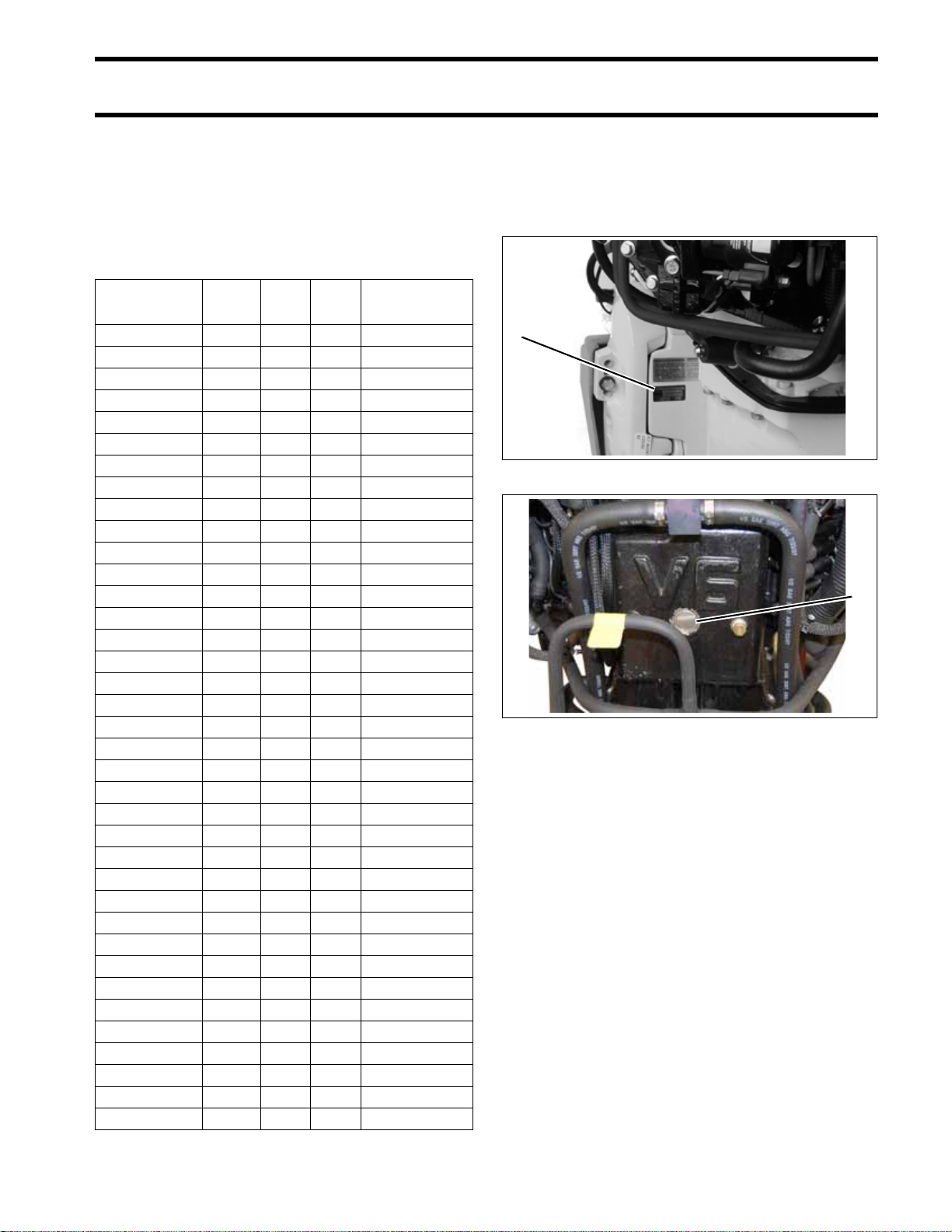

MODELS COVERED IN THIS MANUAL

MODELS COVERED IN

THIS MANUAL

This manual covers service information on all

200.1 and 210 cubic inch, 90° V Evinrude E-TEC

models.

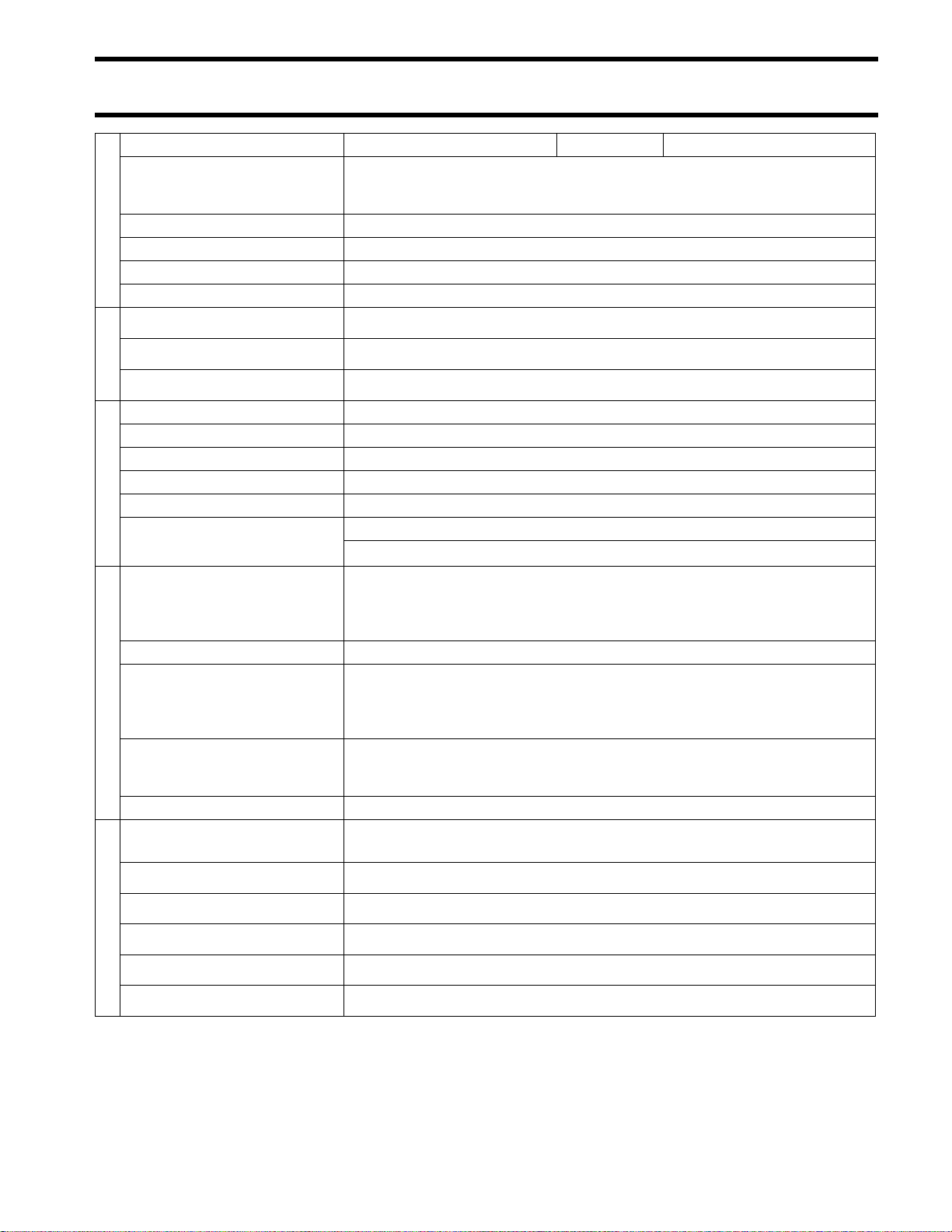

Model Shaft Color G earcase

E200DHLSEB 3.3 L 20” BL .54 L2

E200HSLSEA 3.3 L 20” WH .54 L2

E200HVLSEC 3.3 L 20” WH .54 M2

E200DHXSEA 3.3 L 25” WH .54 M2

E200HCXSEA 3.3 L 25” WH .54 M2 CR

E225DPLSEB 3.3 L 20” BL .54 M2

E225DHLSEB 3.3 L 20” BL .58 L2

E225HSLSEC 3.3 L 20” WH .58 L2

E225DHXSEM 3.3 L 25” BL .58 L2

E225DPXSEB 3.3 L 25” WH .54 M2

E225DCXSEB 3.3 L 25” WH .54 M2 CR

E225DPZSEB 3.3 L 30” WH .54 M2

E225DCZSEB 3.3 L 30” WH .54 M2 CR

E250DPLSEB 3.3 L 20” BL .54 M2

E250DPXSEB 3.3 L 25” WH .54 M2

E250DCXSEB 3.3 L 25” WH .54 M2 CR

E250DPZSEB 3.3 L 30” WH .54 M2

E250DCZSEB 3.3 L 30” WH .54 M2 CR

E250HSLSES 3.4 L 20” WH .58 L2

E250HSLSEF 3.4 L 20” WH .58 L2

E250DHLSEC 3.4 L 20” BL .58 L2

E250DHLSEF 3.4 L 20” BL .58 L2

E250DHXSEC 3.4 L 25” BL .58 L2

E250DHXSEF 3.4 L 25” BL .58 L2

E250HGLSES 3.4 L 20” SM .58 L2

E250HGLSEF 3.4 L 20” SM .58 L2

E250HGXSES 3.4 L 25” SM .58 L2

E250HGXSEF 3.4 L 25” SM .58 L2

E300DSLSES 3.4 L 20” WH .54 M2

E300DSLSEF 3.4 L 20” WH .54 M2

E300DPXSEC 3.4 L 25” WH .54 M2

E300DPXSEF 3.4 L 25” WH .54 M2

E300DPZSEC 3.4 L 30” WH .54 M2

E300DPZSEF 3.4 L 30” WH .54 M2

E300DCXSEC 3.4 L 25” WH .54 M2 CR

E300DCXSEF 3.4 L 25” WH .54 M2 CR

E300DCZSEC 3.4 L 30” WH .54 M2 CR

E300DCZSEF 3.4 L 30” WH .54 M2 CR

Identifying Model and Serial Numbers

Outboard model and serial numbers are located

on the swivel bracket and on the powerhead.

®

1

1. Model and serial number 000449

1

1. Serial number 006828

9

Page 12

INTRODUCTION

SERVICE SPECIFICATIONS

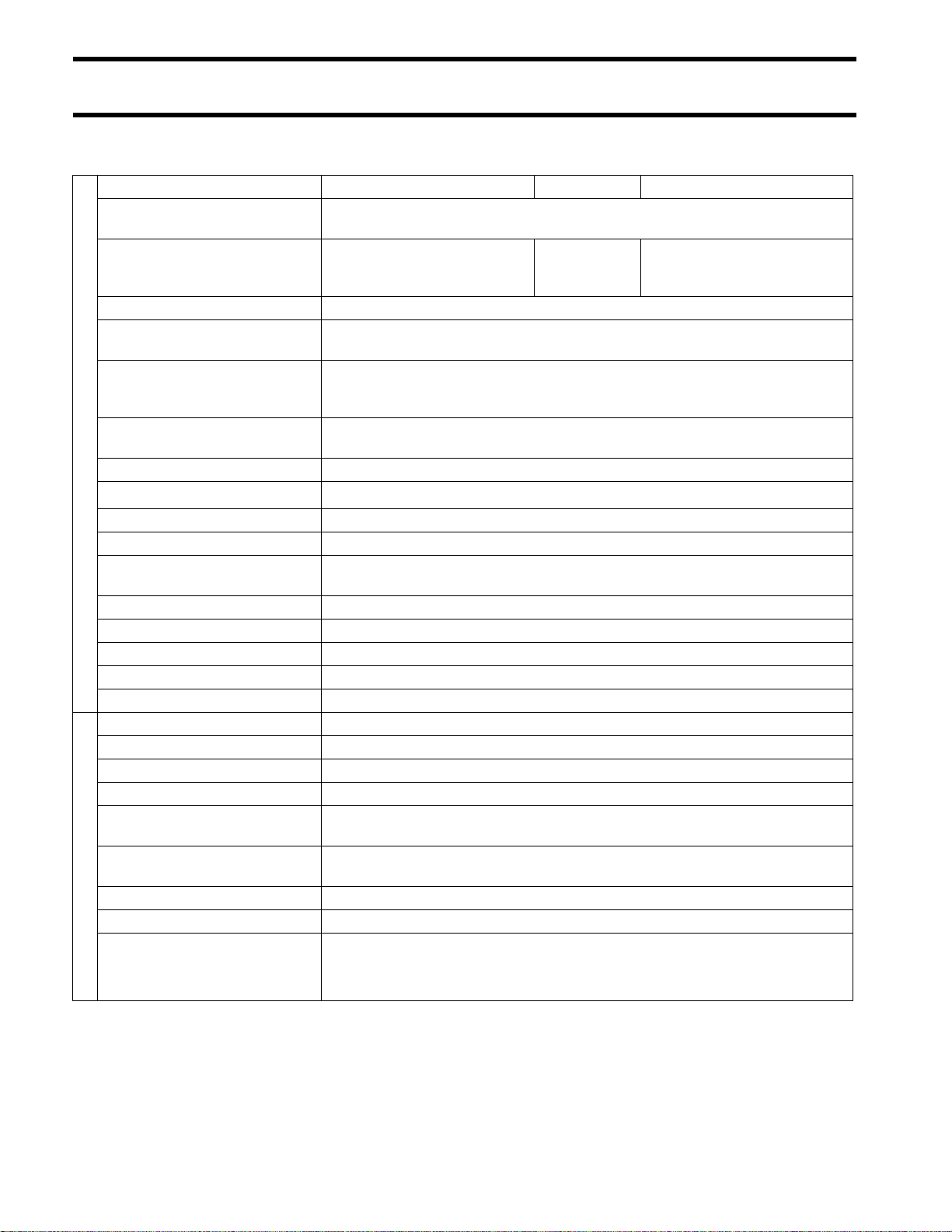

SERVICE SPECIFICATIONS

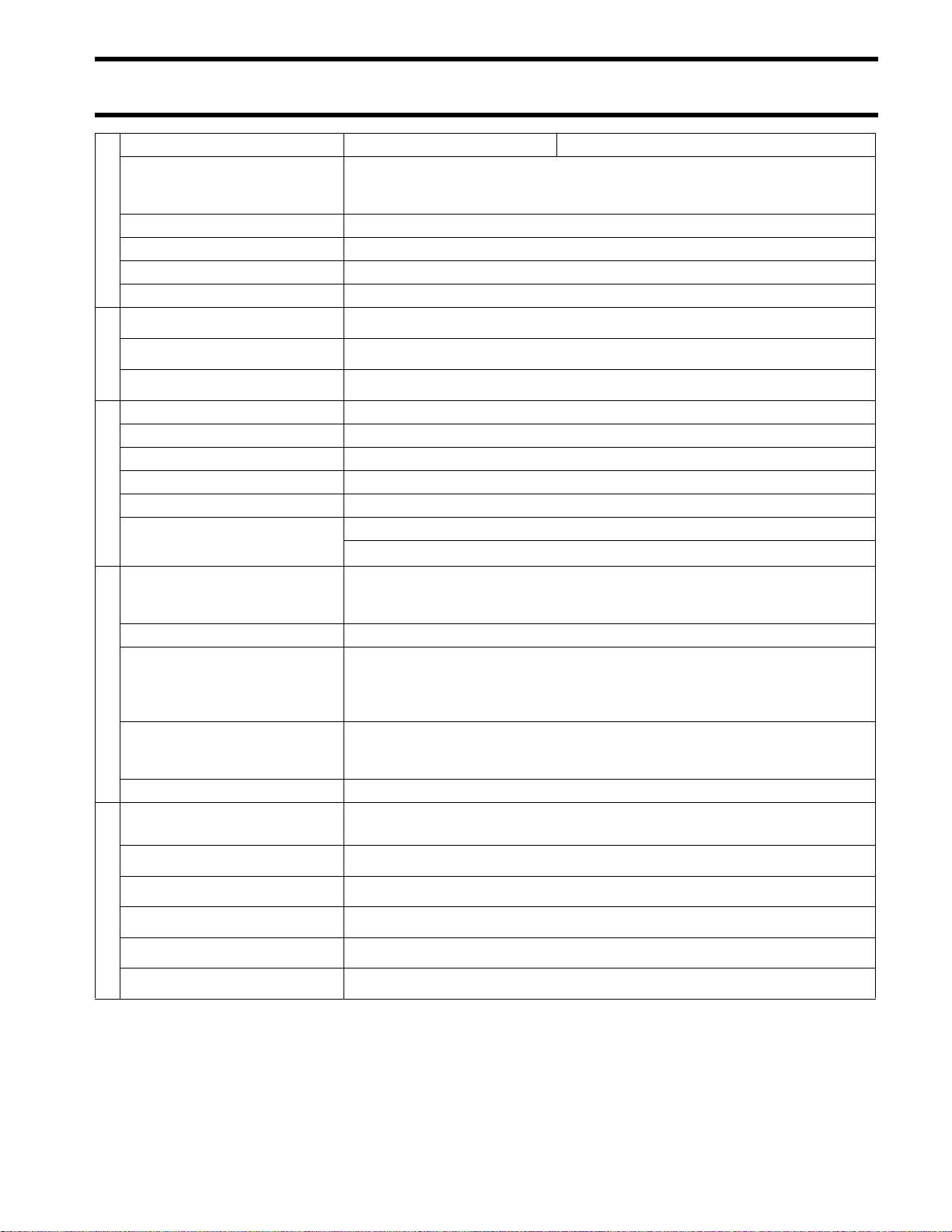

HP 200 225 250

Full Throttle

Operating Range

200 HP

Power

Idle RPM in Gear 500 ± 50

Test Propeller

Weight

(may vary depending

on model)

Lubrication

ENGINE

Minimum (High) Fuel Pressure

Minimum Fuel Lift Pump Pressure

FUEL

Maximum Fuel Inlet Vacuum 4 in. Hg. (13.5 kPa)

Engine Type 90° V 6-Cylinder Loop-Charged

Displacement

Bore 3.854 in (97.89 mm)

Stroke 2.858 in. (72.60 mm)

Standard Bore

Top Crankshaft Journal 1.6199 to 1.6204 in. (41.15 to 41.16 mm)

Center Crankshaft Journals 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Bottom Crankshaft Journal 1.5747 to 1.5752 in. (40.0 to 40.01 mm)

Rod Crankpin 1.4995 to 1.5000 in. (38.09 to 38.106 mm)

Piston Ring End Gap, Both 0.022 to 0.028 in. (0.57 to 0.72 mm)

Fuel/Oil Ratio EMM Controlled

Starting Enrichment EMM Controlled

Preferred Fuel Regular unleaded gasoline

Acceptable Fuel See Fuel Requirements on p. 58 for additional information.

@ IDLE RPM – 500 ± 50

@ IDLE RPM – 500 ± 50

Minimum Octane 87 AKI (R+M)/2 or 90 RON

Additives

(149 kw)

@ 5150 RPM

Standard Rotation Models: P/N 436080 or P/N 396277

Counter Rotation Models: P/N 436081 or P/N 398674

3.8535 to 3.8545 in. (97.87 to 97.90 mm)

To bore oversize, add piston oversize dimension to standard bore

2+4

Use of other additives may result in engine damage.

See Fuel Requirements on p. 58 for additional information.

4500–5800 RPM

225 HP

(168 kw)

@ 5150 RPM

20 in. (L) Models: 503 lbs. (228 kg)

25 in. (X) Models: 524 lbs. (238 kg)

30 in. (Z) Models: 530 lbs. (240 kg)

Evinrude/Johnson XD100 Oil

Refer to Oil Requirements on p. 59

200.1 cu. in. (3279 cm

22 to 28 psi (152 to 193 kPa)

3 psi (21 kPa)

®

Fuel Conditioner, Fuel System Cleaner

250 HP (187 kw)

3

)

@ 5150 RPM

10

Page 13

Minimum Battery

Requirements

Alternator Dual Voltage 50 Amp with Voltage Regulator and Battery Isolation

Tachometer Setting 6 pulse (12 pole)

ELECTRICAL

Charging Isolator Integral, Terminal on Engine Harness

Engine Fuse P/N 967545 – 10 A

Thermostat 143°F (62°C)

Maximum Temperature 190°F (88°C)

INTRODUCTION

SERVICE SPECIFICATIONS

HP 200 225 250

675 CCA (845 MCA); or

750 CCA (940 MCA) below 32°F (0°C)

(Use a 107 amp-hr battery for extreme applications.)

COOLING

Crankshaft Position Sensor Air Gap Fixed

IGNITION

GEARCASE

Water pressure 11 psi minimum @ 5000 RPM

Type Capacitor Discharge

Firing Order 1-2-3-4-5-6

Ignition Features EMM Controlled

RPM Limit 6050

Spark Plug

Gear Ratio

Lubricant HPF XR Gearcase Lubricant

Capacity

Shift Rod Height

Shift Cable Stroke 1.125 to 1.330 in. (28.6 to 33.8 mm) measured between NEUTRAL and FORWARD

Lubrication

Refer to Emission Control Information Label

†

Champion

“L2” Type Gearcase – 200 HP: 14:26 (.538) (1.86:1)

“L2” Type Gearcase – 225 HP: 14:24 (.583) (1.71:1)

“M2” Type – Counter Rotation: 35.8 fl. oz. (1060 ml)

20 in. (L) Models: 21 29/32 (556.25 mm) ± one-half turn

25 in. (X) Models: 26 29/32 (683.25 mm) ± one-half turn

30 in. (Z) Models: 31 29/32 (810.25 mm) ± one-half turn

QC8WEP @ 0.028 ± 0.003 in. (0.71 mm)

“M2” Type Gearca se: 13:24 (.542) (1.85:1)

Refer to GEARCASE TYPES on p. 285

“M2” Type Gearcase: 38.9 fl. oz. (1150 ml)

“L2” Type Gearcase: 32.5 fl. oz. (960 ml)

Refer to GEARCASE TYPES on p. 285

Power Trim/Tilt & Power Steering Fluid or

GM Dexron

†

II Automatic Transmission Fluid

Fluid Capacity 21 fl. oz. (622 ml)

Trim Range 0° to 21°

Tilt Range 22° to 75°

Tilt UP Stall Pressure 1500 psi (10342 kPa)

POWER TRIM/TILT

Tilt IN Stall Pressure 800 psi (5516 kPa)

11

Page 14

INTRODUCTION

SERVICE SPECIFICATIONS

HP 250 H 300

Full Throttle

Operating Range

Power

Idle RPM in Gear 500 ± 50

Test Propeller

Weight

(may vary depending

on model)

Lubrication

ENGINE

Minimum (High) Fuel Pressure

Minimum Fuel Lift Pump Pressure

FUEL

Maximum Fuel Inlet Vacuum 4 in. Hg. (13.5 kPa)

Engine Type 90° V 6-Cylinder Loop-Charged

Displacement 210.0 cu. in. (3441 cc)

Bore 3.854 in (97.89 mm)

Stroke 3.000 in. (76.20 mm)

Standard Bore

Top Crankshaft Journal 1.6199 to 1.6204 in. (41.15 to 41.16 mm)

Center Crankshaft Journals 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Bottom Crankshaft Journal 1.5747 to 1.5752 in. (40.0 to 40.01 mm)

Rod Crankpin 1.4995 to 1.5000 in. (38.09 to 38.106 mm)

Piston Ring End Gap, Both 0.022 to 0.028 in. (0.57 to 0.72 mm)

Fuel/Oil Ratio EMM Controlled

Starting Enrichment EMM Controlled

Preferred Fuel Regular unleaded gasoline

Acceptable Fuel See Fuel Requirements on p. 58 for additional information.

@ IDLE RPM – 500 ± 50

@ IDLE RPM – 500 ± 50

Minimum Octane 87 AKI (R+M)/2 or 90 RON

Additives

4500–6000 RPM 5000–6000 RPM

250 HP

(187 kw)

@ 5250 RPM

Standard Rotation Models: P/N 436080 or P/N 396277

Counter Rotation Models: P/N 436081 or P/N 398674

20 in. (L) Models: 507 lbs. (230 kg)

25 in. (X) Models: 528 lbs. (239 kg)

30 in. (Z) Models: 534 lbs. (242 kg)

Evinrude/Johnson XD100 Oil

Refer to Oil Requirements on p. 59

3.8535 to 3.8545 in. (97.87 to 97.90 mm)

To bore oversize, add piston oversize dimension to standard bore

22 to 28 psi (152 to 193 kPa)

3 psi (21 kPa)

®

Fuel Conditioner, Fuel System Cleaner

2+4

Use of other additives may result in engine damage.

See Fuel Requirements on p. 58 for additional information.

300 HP

(234 kw)

@ 5500 RPM

12

Page 15

Minimum Battery

Requirements

Alternator Dual Voltage 50 Amp with Voltage Regulator and Battery Isolation

Tachometer Setting 6 pulse (12 pole)

ELECTRICAL

Charging Isolator Integral, Terminal on Engine Harness

Engine Fuses P/N 967545 – 10 A

Thermostat 143°F (62°C)

Maximum Temperature 190°F (88°C)

INTRODUCTION

SERVICE SPECIFICATIONS

HP 250 H 300

675 CCA (845 MCA); or

750 CCA (940 MCA) below 32°F (0°C)

(Use a 107 amp-hr battery for extreme applications.)

COOLING

Crankshaft Position Sensor Air Gap Fixed

IGNITION

GEARCASE

Water pressure 11 psi minimum @ 5000 RPM

Type Capacitor Discharge

Firing Order 1-2-3-4-5-6

Ignition Features EMM Controlled

RPM Limit 6050

Spark Plug

Gear Ratio

Lubricant HPF XR Gearcase Lubricant

Capacity

Shift Rod Height

Shift Cable Stroke 1.125 to 1.330 in. (28.6 to 33.8 mm) measured between NEUTRAL and FORWARD

Lubrication

Refer to Emission Control Information Label

†

Champion

“M2” Type – Counter Rotation: 35.8 fl. oz. (1060 ml)

20 in. (L) Models: 21 29/32 (556.25 mm) ± one-half turn

25 in. (X) Models: 26 29/32 (683.25 mm) ± one-half turn

30 in. (Z) Models: 31 29/32 (810.25 mm) ± one-half turn

QC8WEP @ 0.028 ± 0.003 in. (0.71 mm)

“M2” Type Gearca se: 13:24 (.542) (1.85:1)

“L2” Type Gearcase: 14:24 (.583) (1.71:1)

Refer to GEARCASE TYPES on p. 285

“M2” Type Gearcase: 38.9 fl. oz. (1150 ml)

“L2” Type Gearcase: 32.5 fl. oz. (960 ml)

Refer to GEARCASE TYPES on p. 285

Power Trim/Tilt & Power Steering Fluid or

GM Dexron

†

II Automatic Transmission Fluid

Fluid Capacity 21 fl. oz. (622 ml)

Trim Range 0° to 21°

Tilt Range 22° to 75°

Tilt UP Stall Pressure 1500 psi (10342 kPa)

POWER TRIM/TILT

Tilt IN Stall Pressure 800 psi (5516 kPa)

13

Page 16

INTRODUCTION

STANDARD TORQUE SPECIFICATIONS

STANDARD TORQUE

SPECIFICATIONS

Size In. Lbs. Ft. Lbs. N·m

No. 6 7–10 0.58–0.83 0.8–1.1

No. 8 15–22 1.25–1.83 1.7–2.5

No. 10 24–36 2–3 2.7–4.0

No. 12 36–48 3–4 4.0–5.4

1/4 in. 60–84 5–7 7-9.5

5/16 in. 120–144 10–12 13.5–16.5

3/8 in. 216–240 18–20 24.5–27

7/16 in. 336–384 28–32 38–43.5

IMPORTANT: These values apply only when

a specific torque for a specific fastener is not

listed in the appropriate section. When tightening two or more screws on the same part, DO

NOT tighten screws completely, one at a time.

WARNING

PRODUCT REFERENCE AND ILLUSTRATIONS

BRP US Inc. reserves the right to make changes

at any time, without notice, in specifications and

models and also to discontinue models. The right

is also reserved to change any specifications or

parts, at any time, without incurring any obligation

to equip same on models manufactured prior to

date of such change. Specifications used are

based on the latest product information available

at the time of publication.

The continuing accuracy of this manual cannot be

guaranteed.

All photographs and illustrations used in this manual may not depict actual models or equipment,

but are intended as representative views for reference only.

Certain features or systems discussed in this

manual might not be found on all models in all

marketing areas.

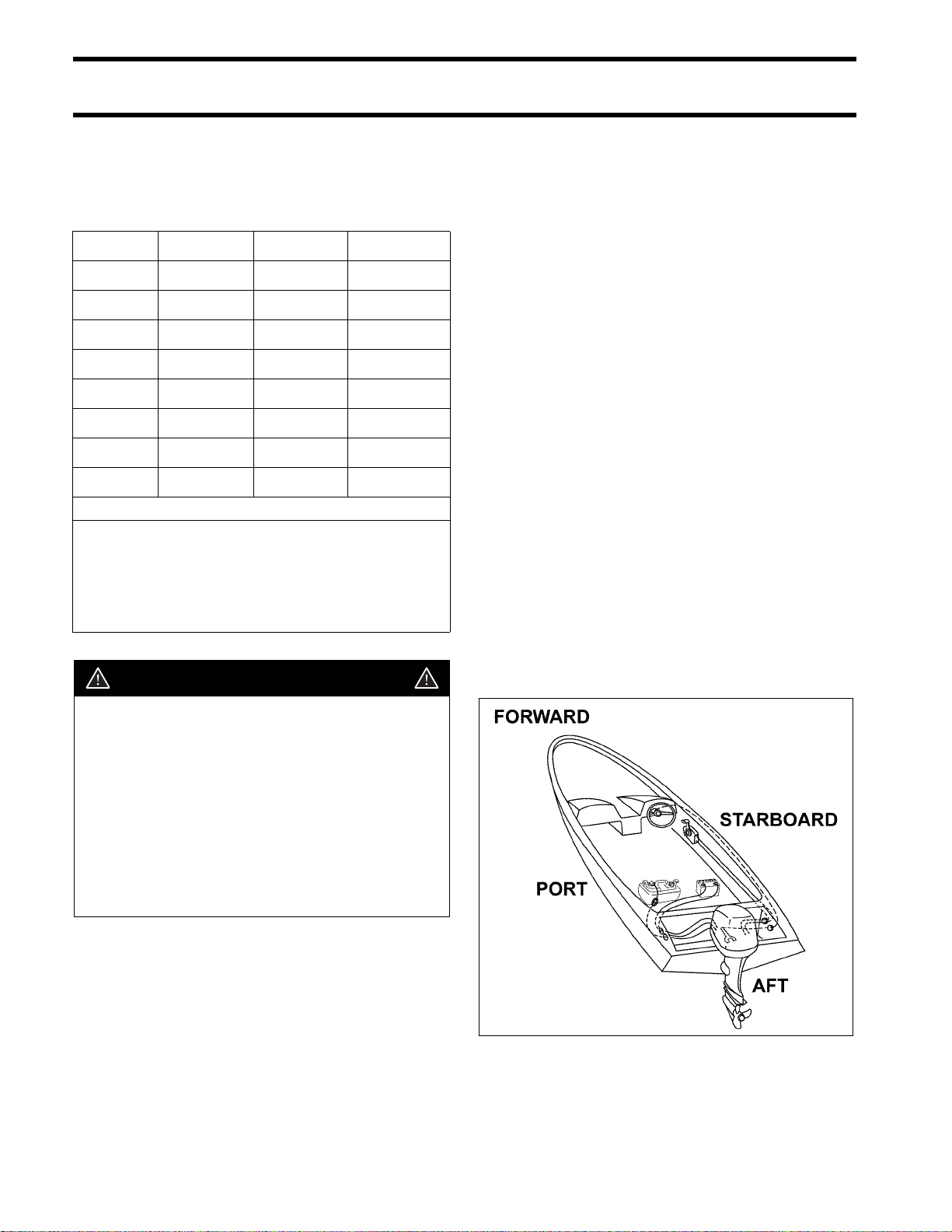

All service technicians must be familiar with nautical orientation. This manual often identifies parts

and procedures using these terms.

Torque wrench tightening specifications

must be strictly adhered to. Replace any

locking fastener (locknut or patch screw)

if its locking feature becomes weak. Definite resistance to turning must be felt

when reusing a locking fastener.

If replacement is specified or required

because the locking fastener has become

weak, use only authorized Evinrude/

Johnson Genuine Parts.

Nautical Orientation 006411

14

Page 17

SPECIAL TOOLS

SPECIAL TOOLS

TABLE OF CONTENTS

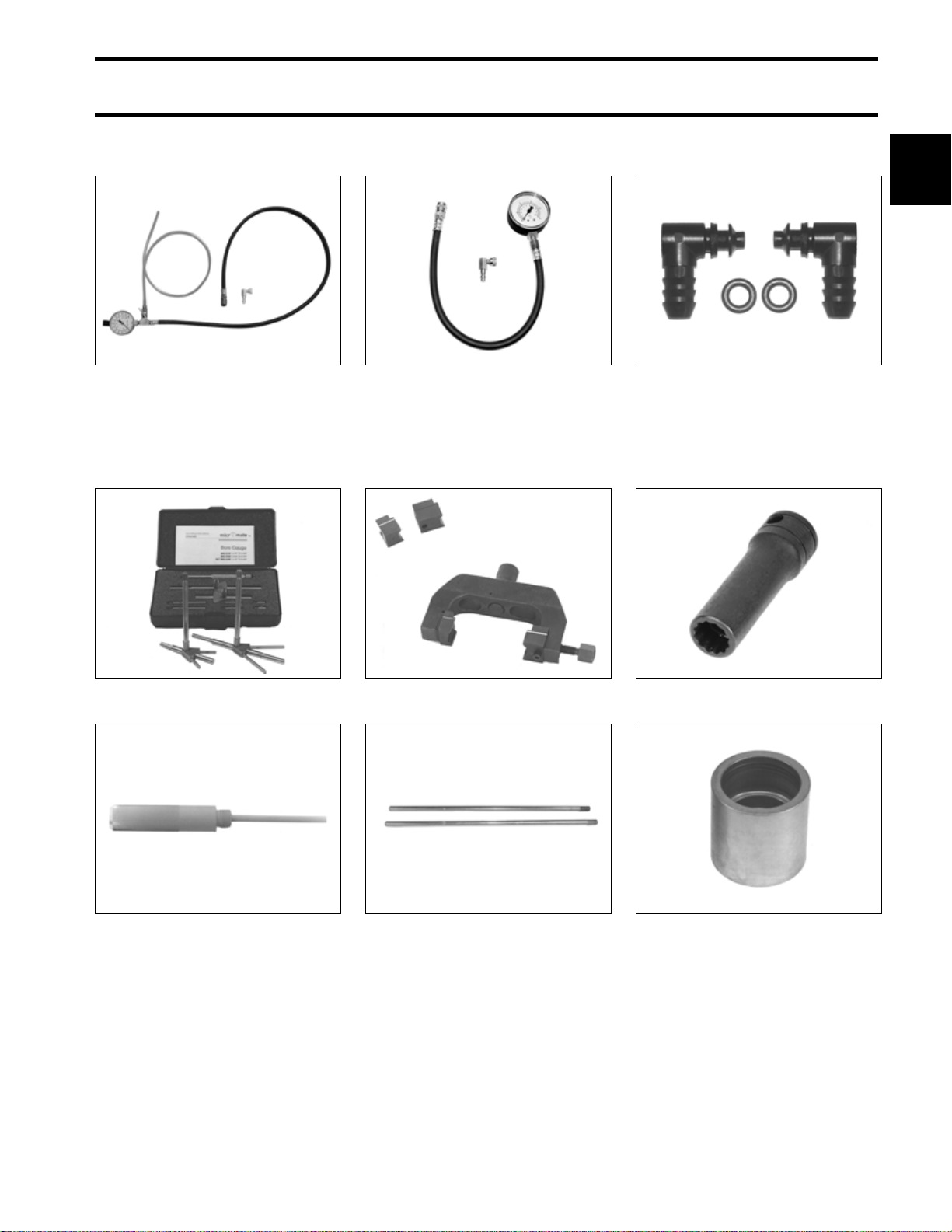

DIAGNOSTIC TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

UNIVERSAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

ELECTRICAL / IGNITION TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

FUEL /OIL SYSTEM TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

POWERHEAD TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

GEARCASE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TRIM AND TILT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SHOP AIDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1

15

Page 18

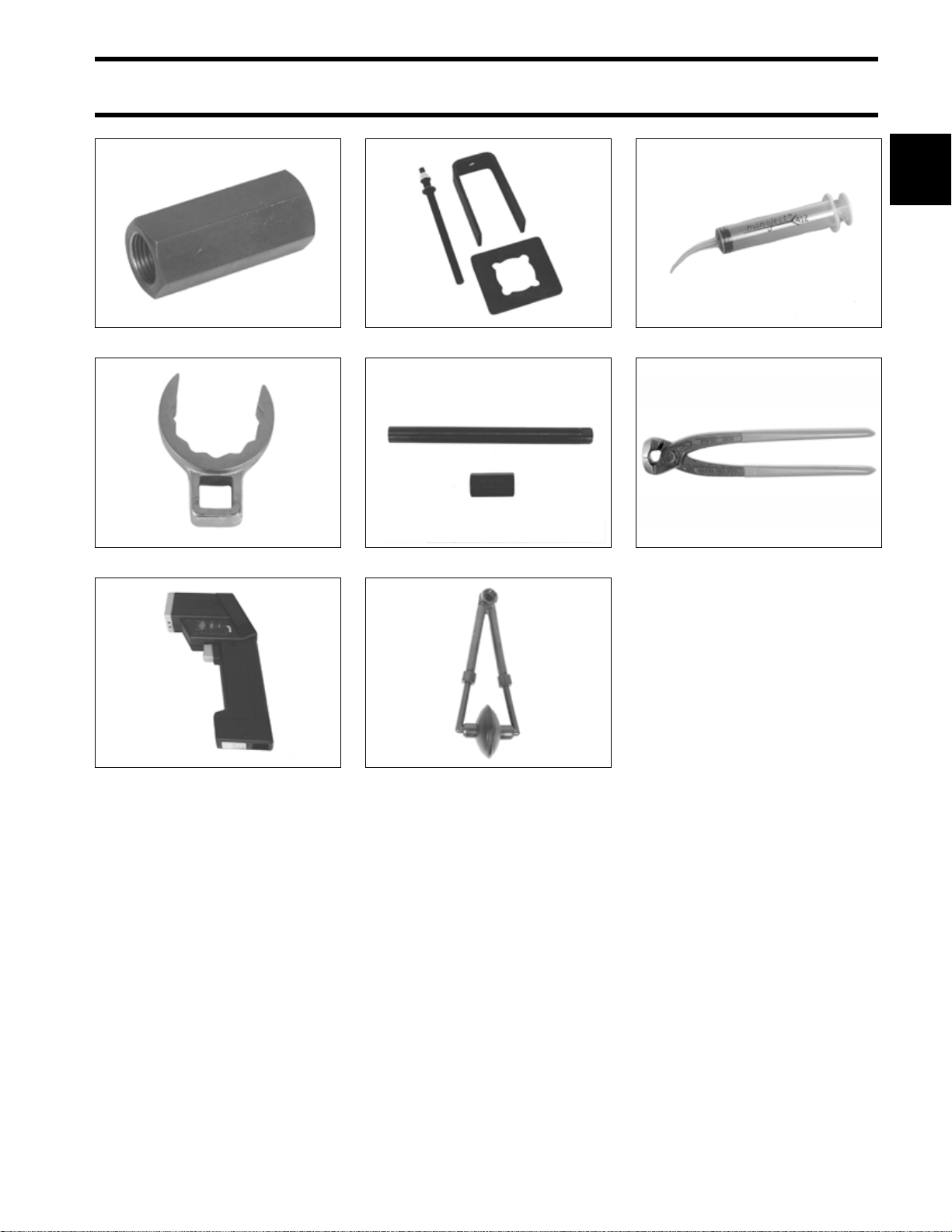

SPECIAL TOOLS

DIAGNOSTIC TOOLS

DIAGNOSTIC TOOLS

Diagnostic Software P/N 765011 765011 Bootstrap tool P/N 586551 002276 Interface cable P/N 437955 45583

UNIVERSAL TOOLS

Universal Puller Set P/N 378103 32885

Slide hammer P/N 391008 CO1577

Small puller jaws P/N 432131 23150

Lifting eye P/N 321537 23701

Slide hammer P/N 432128 15345

Large puller jaws P/N 432129 23148

Lifting ring assembly P/N 396748 000669

Flywheel holder P/N 771311 42938

Bearing puller jaws P/N 432130 23149

16

Page 19

SPECIAL TOOLS

UNIVERSAL TOOLS

1

Slide hammer adapter P/N 390898 15356

Tilt tube nut wrench P/N 342680 46879

Temperature gun P/N 772018 45240

Puller Bridge – 432127 23146

Tilt tube service kit P/N 434523 33249

Fresh water flusher P/N 500542 50110

Syringe P/N 346936 50243

†

pincers, P/N 787145

Oetiker

001081

17

Page 20

SPECIAL TOOLS

ELECTRICAL / IGNITION TOOLS

ELECTRICAL / IGNITION TOOLS

Digital multimeter

Ohms resolution 0.01

Purchase through local supplier

Crimping pliers P/N 322696 30387

DRC7265

Peak reading voltmeter

P/N 507972

Stator Test Adapter P/N 5006211 004222

49799

Test probe kit P/N 342677 45241

Tachometer/timing light P/N 507980 49789

18

Connector tool P/N 342667 42004

†

connector tools

AMP

Primary Lock Tool P/N 777077

Secondary Lock Tool P/N 777078

Release Tool P/N 351413

Lock Installer P/N 777079

002277

Page 21

FUEL /OIL SYSTEM TOOLS

SPECIAL TOOLS

FUEL /OIL SYSTEM TOOLS

1

Fuel pressure gauge (60 PSI)

P/N 5007100

90° fitting, P/N 353322

005339

Fuel pressure gauge (15 PSI)

P/N 5006397

90° fitting, P/N 353322

POWERHEAD TOOLS

Cylinder bore gauge P/N 771310 45303

Rod cap alignment fixture

P/N 396749

004560

21596

Injector test fitting kit

P/N 5005844

Torquing socket P/N 346187 50242

002465

Piston stop tool P/N 342679

Replacement tip P/N 5006098

46543

Guide rods

P/N 383175

000828

Crankshaft bearing and sleeve

installer P/N 338649

21953C

19

Page 22

SPECIAL TOOLS

GEARCASE TOOLS

1 2

Wrist pin pressing tool

P/N 396747

23668

1. Wrist pin retaining ring driver

2. Wrist pin cone P/N 331913

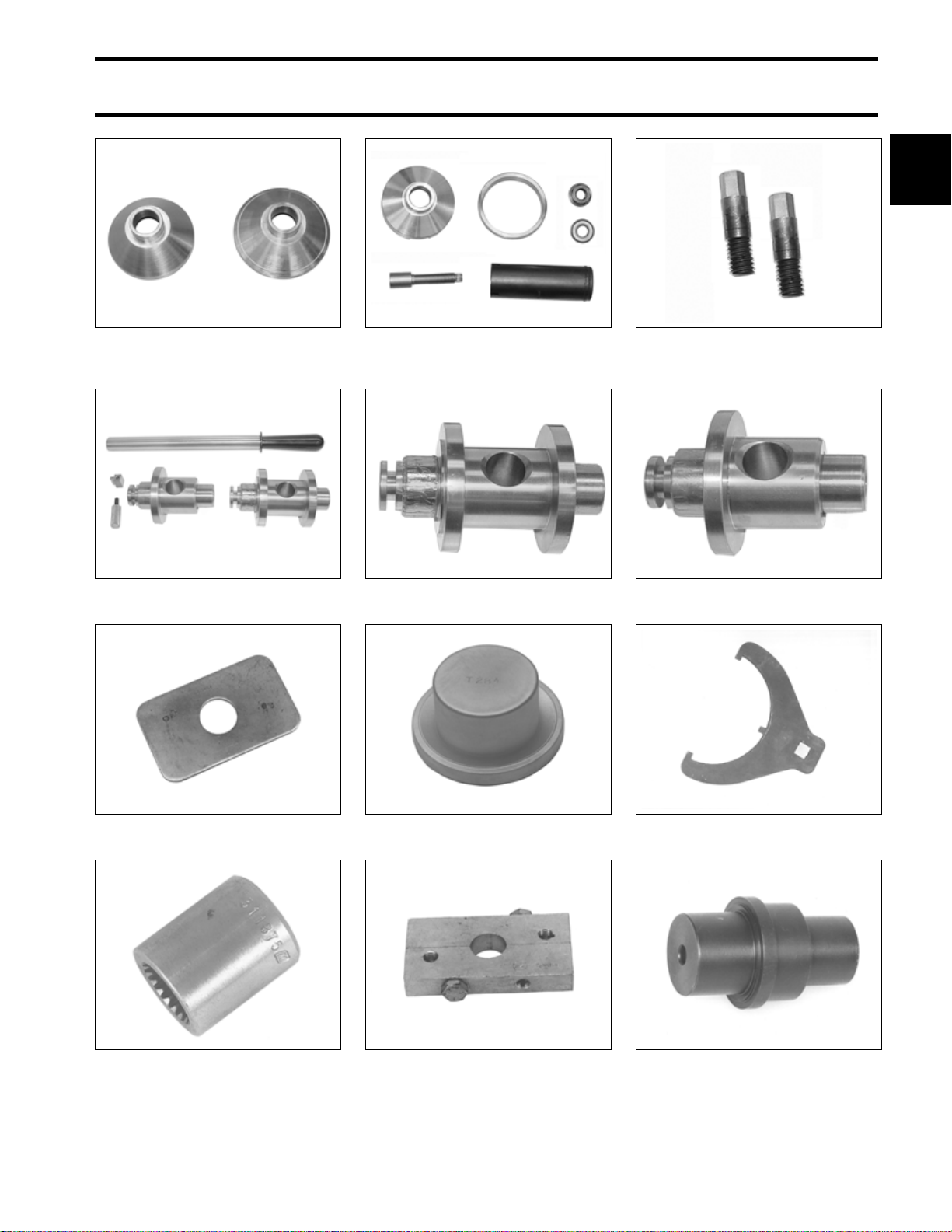

GEARCASE TOOLS

P/N 396747

DR1641

Seal installation tool P/N 325453 23651

Universal Driveshaft Shimming Tool

P/N 5005925

1. Lower Driveshaft Shimming Bolt

(S2 gearcase) P/N352878

Gearcase filler

P/N 501882

1

002601

49790

Universal Pinion Bearing Remover

and installer kit P/N 5005927

Gearcase pressure tester

P/N 507977 (Stevens P/N S-34)

Gearcase vacuum tester

P/N 507982 (Stevens P/N V-34)

002805

49794

Universal shift rod height gauge

P/N 389997

Pressing fixture P/N 354059 006782

32872

20

Page 23

SPECIAL TOOLS

GEARCASE TOOLS

1

Prop shaft bearing housing

installers P/N 354058 (L2)

P/N 354057 (M2)

Gearcase Alignment Gauge Kit

P/N 5006349

006783

004315

Prop shaft bearing housing

remover/puller P/N 354060

Gauging Head, “M2” Type

Gearcases, P/N 5007749

006784

006822

Prop shaft bearing housing

alignment pins P/N 354140

Gauging Head, “L2” Type

Gearcases, P/N 5007750

006788

006823

Backing plate P/N 325867 23621

Driveshaft socket P/N 311875 23261

Bearing Installation Tool

P/N 339778

Driveshaft Puller P/N 390706 32884

32519

Spanner wrench P/N 432400 15358

Prop shaft bearing installer

P/N 432401

15355

21

Page 24

SPECIAL TOOLS

GEARCASE TOOLS

Slide hammer adapter P/N 432398 15356

Driveshaft seal protector

P/N 318674

23692

1 2

1. Pinion nut holder P/N 334455

2. Wrench retainer P/N 341438

40371

Lower Driveshaft Puller P/N 342681 47257

Pinion nut starting tool P/N 342216 40372

Prop shaft bearing installer

P/N 339750

Prop shaft housing seal installer

P/N 336311

32880

32973

Seal installation tool P/N 330268 32924

Seal installation tool P/N 354056 006824

22

Page 25

TRIM AND TILT TOOLS

SPECIAL TOOLS

TRIM AND TILT TOOLS

1

Gauge and collar assembly

P/N 983975

Hydraulic cylinder rod holder

P/N 983213

33023

23665

Trim/tilt service kit P/N 390010 33013

Tilt cylinder end cap remover

P/N 352932, for single-piston

tilt systems

005340

Tilt cylinder seal protector

P/N 326005

Spanner wrench P/N 912084 32213

23694

2 1

1. Trim/tilt service kit P/N 434524

2. Replacement o-ring kit for

adapter tips P/N 434729

27340

Tilt cylinder end cap remover

P/N 326485, for three-piston

tilt systems

33741

12

1. Trim cylinder end cap

remover/installer P/N 436710

2. Replacement tip for 436710

33742A

23

Page 26

SPECIAL TOOLS

SHOP AIDS

SHOP AIDS

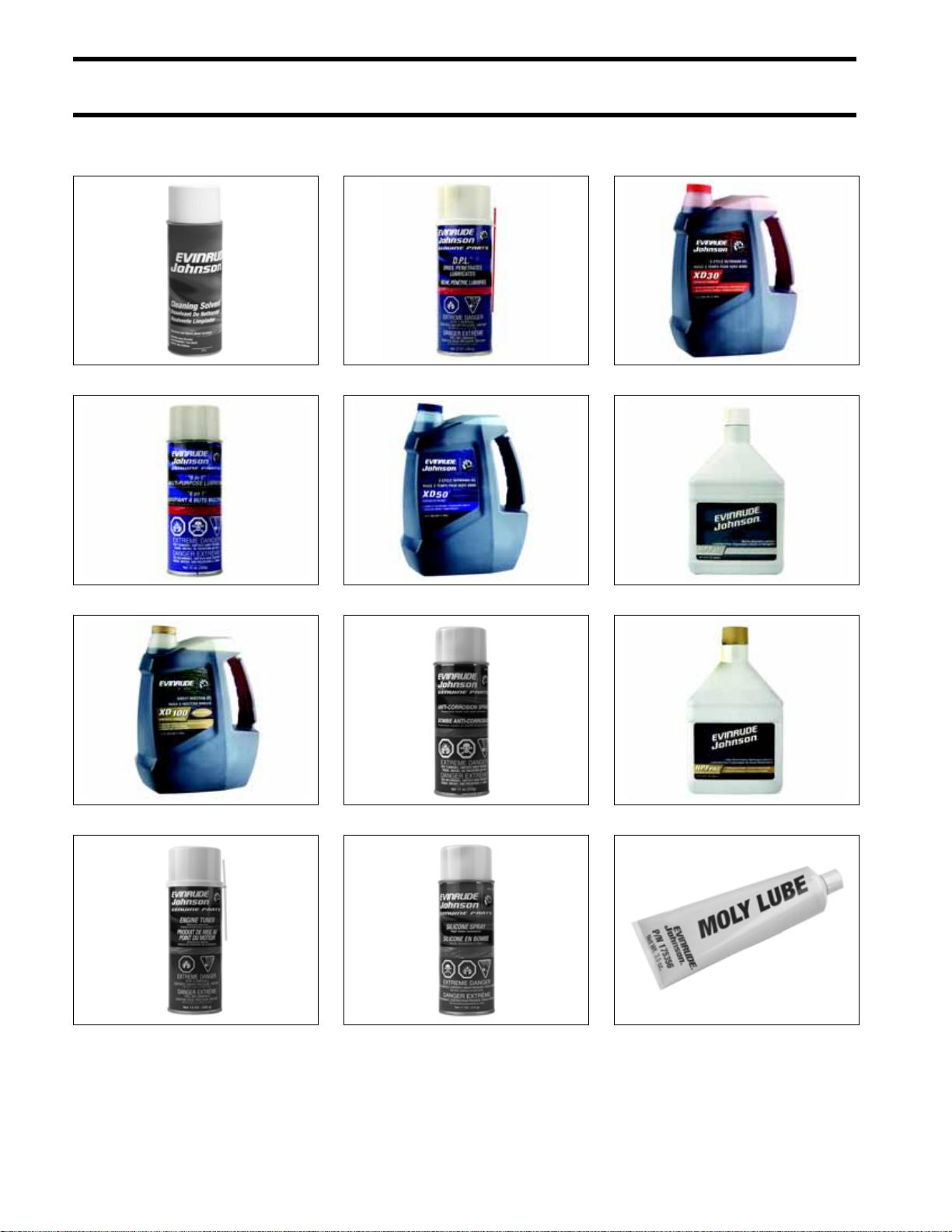

Cleaning Solvent P/N 771087

“6 in 1” Multi-Purpose Lubricant P/N 777192

Oil - XD100™ P/N 764357

D.P.L. Spray P/N 777183

Oil - XD50™ P/N 764354

Anti-Corrosion Spray P/N 777193

Oil - XD30™ P/N 764349

HPF XR™ Gear Lube P/N 778749

HPF PRO Gearcase Lube P/N 778755

Engine Tuner P/N 777185

24

Silicone spray P/N 775630

Moly Lube P/N 175356

Page 27

SPECIAL TOOLS

SHOP AIDS

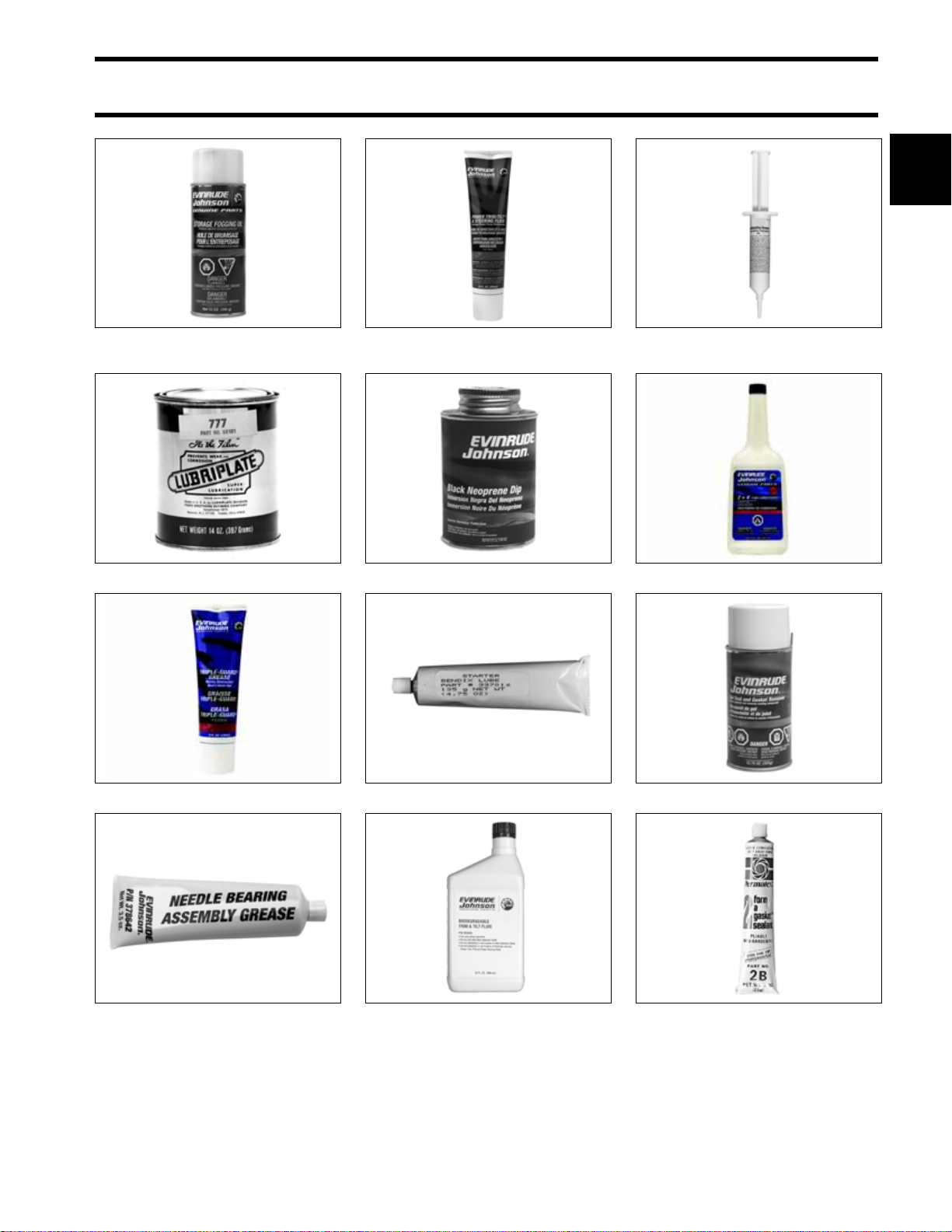

1

Storage Fogging Oil

P/N 777186

Lubriplate† 777 P/N 317619

Power Trim/Tilt and Power Steering Fluid

P/N 775612

Black Neoprene Dip P/N 909570

Electrical Grease P/N 503243

2 + 4™ Fuel conditioner P/N 775613

Triple-Guard® Grease P/N 508298

Needle Bearing Grease, P/N 378642

Starter Bendix Lube P/N 337016

Biodegradeable TNT Fluid

P/N 763439

Gel-Seal and Gasket Remover P/N 771050

†

Permatex

No. 2, P/N 910032

25

Page 28

SPECIAL TOOLS

SHOP AIDS

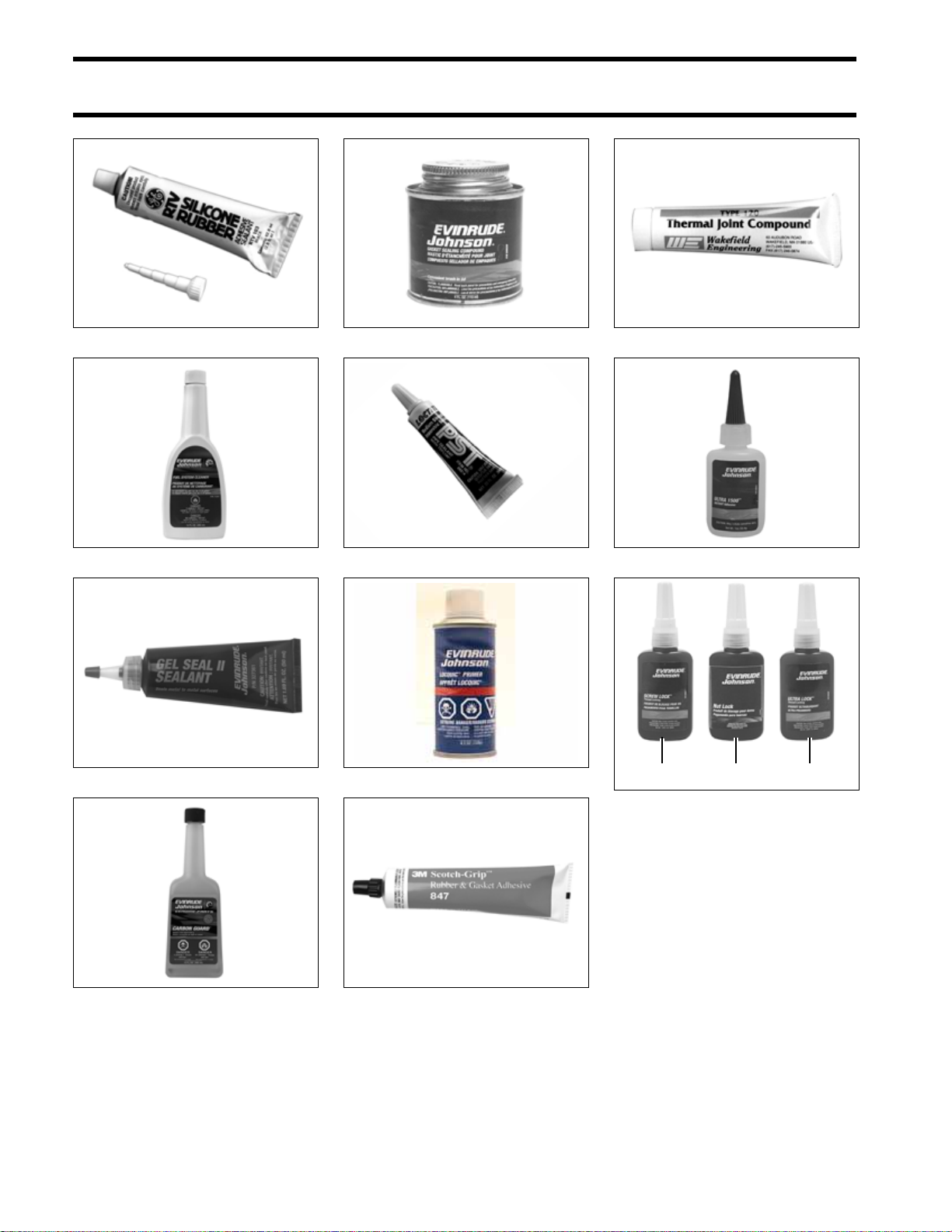

RTV Silicone Sealant P/N 263753

Fuel System Cleaner P/N 763681

Gel·Seal II P/N 327361

Gasket Sealing Compound P/N 508235

Pipe Sealant with Teflon P/N 910048

Locquic Primer P/N 772032

Thermal Joint Compound P/N 322170

Instant Bonding Adhesive P/N 509955

1 2 3

1. Screw Lock P/N 500417

2. Nut Lock P/N 500421

3. Ultra Lock P/N 500423

†

Purple 222 equivalent

(Loctite

(Loctite Blue 242 Equivalent)

(Loctite Red 271 Equivalent)

Carbon Guard™ P/N 775629

26

Adhesive 847 P/N 776964

Page 29

INSTALLATION AND PREDELIVERY

INSTALLATION AND PREDELIVERY

TABLE OF CONTENTS

BOAT RIGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

REMOTE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

BATTERY INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

BATTERY SWITCHES AND MULTIPLE BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

AUXILIARY BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

FUEL SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

OILING SYSTEM SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

CABLE AND HOSE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

OUTBOARD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

HULL PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

TRANSOM MEASURING AND DRILLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

LIFTING THE OUTBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

STEERING SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

OUTBOARD MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

OUTBOARD RIGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

CABLE, HOSE, AND WIRE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CONTROL CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

ELECTRICAL HARNESS CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

WATER PRESSURE GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

CANBUS CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

FUEL AND OIL PRIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

FUEL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

FUEL SYSTEM PRIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

OIL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

OIL INJECTION RATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

BREAK-IN OILING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

OIL SUPPLY PRIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

BEFORE START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

RUNNING CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

ENGINE MONITORING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

EMERGENCY STOP / KEY SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

START-IN-GEAR PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

TACHOMETER PULSE SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

WATER PUMP OVERBOARD INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

BREAK-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PROPELLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

PROPELLER SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

PROPELLER HARDWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

FINAL ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

TILT LIMIT SWITCH ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

TRIM SENDING UNIT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

TRIM TAB ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

DUAL-OUTBOARD ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

2

27

Page 30

INSTALLATION AND PREDELIVERY

BOAT RIGGING

BOAT RIGGING

Remote Controls

Control Selection

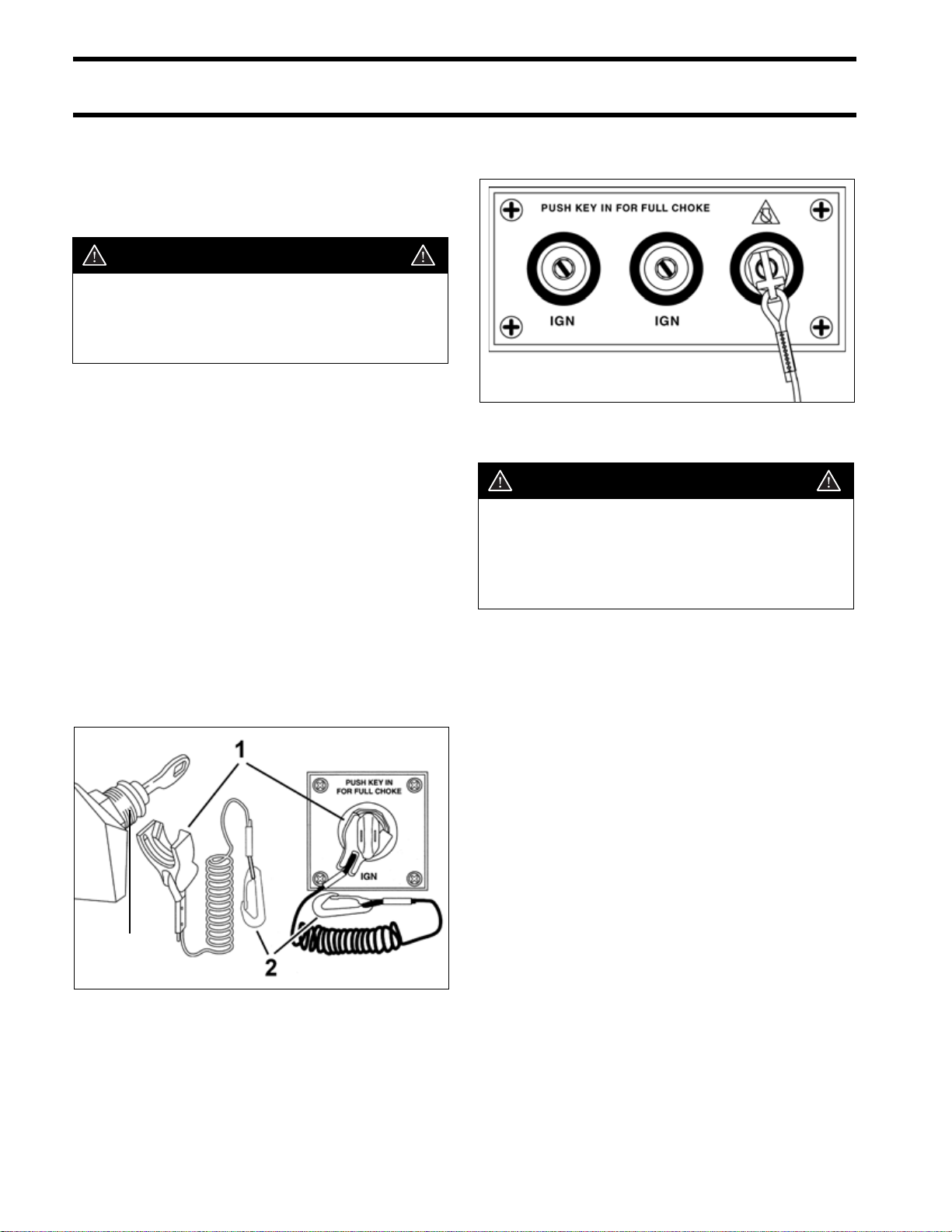

WARNING

The remote control used must have startin-gear prevention. This feature can prevent injuries resulting from unexpected

boat movement when the outboard starts.

Remote control styles and applications are

described in the Evinrude/Johnson Genuine Parts

and Accessories Catalog. Plan the installation of

all remote controls carefully. Read the outboard's

Operator's Guide and the remote control's installation instructions prior to installation.

The remote control and wiring harness used must

have the following features:

• Start-in-gear prevention

• Emergency stop / key switch

• Shift stroke must measure 1.125 to 1.330 in.

(28.6 to 33.8 mm) between NEUTRAL and

FORWARD

• Throttle stroke must PUSH for open

• All wiring must be compatible with Modular Wir-

ing System (MWS) components

• Dual-outboard controls require separate key

switches with a single emergency stop switch.

Dual-outboard key switches with emergency stop

switch

DRC40118

WARNING

Always install and recommend use of an

emergency stop/key switch. Doing so will

reduce the risk of personal injury or death

should the operator fall away from the controls or out of the boat.

Engine Monitoring System

IMPORTANT: Outboards with remote controls

must be equipped with an I-Command system, a

SystemCheck gauge, or an equivalent engine

monitor. Operating the outboard without an

engine monitor will void the warranty for failures

related to monitored functions.

3

1. Emergency stop clip

2. Safety lanyard

3. Key switch with emergency stop feature

28

Refer to ENGINE MONITORING SYSTEM on

p. 101.

002817

Page 31

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Control Installation

Plan the installation of remote controls carefully,

following all instructions provided with the remote

control.

Make sure the following items are checked:

• Correct length, type and quality of control

cables and wiring harnesses

• Proper routing of cables and harnesses

• Slack in front of the outboard for remote control

cables

• Positioning and securing of cables and har-

nesses along their lengths to prevent movement

or damage.

Typical transom-mounted outboard installations

require a 12 in. (30 cm) cable loop at the front of

the outboard when the cables are routed from the

side of the splash well.

Battery Installation

Each outboard requires its own starting battery.

Select a battery that meets or exceeds the minimum requirements.

Minimum 12 Volt Battery Recommendations

Outboard Model Battery Rating

115–300 HP 675 CCA (845 MCA), or

750 CCA (940 MCA)

below 32°F (0°C)

107 amp-hr in extreme

applications

Location and Preparation

Proper installation will prevent battery movement

while underway.

• Secure all batteries in protected locations.

• Place battery as close to the outboard as possi-

ble.

• Battery location must provide access for peri-

odic maintenance.

• Use battery mounting trays or battery boxes on

all battery installations.

• Connections and terminals must be covered

with an insulator.

• Battery connections must be clean and free

from corrosion.

• Read and understand the safety information

supplied with the battery before installation.

2

123

1. Surface side-mount remote control

2. Cable support

3. 12 in. (30 cm) cable loop at front of outboard

DR4277

IMPORTANT: Cables of the proper length,

style, and quality that are correctly installed and

adjusted will eliminate most control-related operational problems.

WARNING

Keep the battery connections clean, tight,

and insulated to prevent their shorting or

arcing and causing an explosion. If the battery mounting system does not cover the

connections, install protective covers.

Check often to see that connections stay

clean and tight.

29

Page 32

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Connections

IMPORTANT: Connect the battery positive (+)

cable to the battery positive (+) post FIRST. Connect the battery negative (–) cable to the battery

negative (–) post LAST.

Install a starwasher on the threaded battery post.

Stack cables from the outboard, then cables from

accessories. Finish this connection with a hex nut.

3

2

1

Marine Style Battery Post

1. Starwasher

2. Hex nut

3. Terminal Insulator

DR5103

IMPORTANT: Do not use wing nuts to fasten

ANY battery cables. Wing nuts can loosen and

cause electrical system damage not covered

under warranty.

Tighten all connections securely. Apply Triple-

Guard grease to prevent corrosion.

Battery Cable Requirements

Evinrude outboards are shipped with stranded

copper battery cables for typical installations in

which the starting battery is positioned close to

the transom.

Specialized outboard installations with extended

length battery cables require an increased wire

size. Refer to the following table.

IMPORTANT: Inadequate battery cables can

affect the performance of an outboard’s high

amperage start circuit and the cranking speed of

the outboard. DO NOT use aluminum wire cables.

Use ONLY AWG stranded copper wire cables.

40–250 HP

1 to 10 Ft.

(.3 to 3 m)

11 to 15 Ft.

(3.4 to 4.6 m)

16 to 20 Ft.

(4.9 to 6.1 m)

4 Gauge

2 Gauge

1 Gauge

Battery Switches and Multiple Batteries

A multiple battery setup, including marine battery

selector switches, can provide flexibility in single

and dual outboard installations.

30

Refer to Battery and Switch Wiring Diagrams

on p. 33 for various battery connection options.

The battery selection function can be used for

emergency starting if a primary battery becomes

discharged.

The OFF position of the battery selector switch

can be used to minimize battery discharge during

periods of non-use.

Page 33

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Typical battery functions

IMPORTANT: Never connect an external bat-

tery isolator to the stator of an Evinrude E-TEC.

Primary

• Used as starting battery under normal operating

conditions.

• Red (+) cable connected to battery selector

switch.

• Primary battery is charged by connection to

main red (+) outboard battery cable.

Dual outboard installations can utilize the opposing outboard's primary battery as a secondary battery for emergency starting only.

Secondary

• Used as back-up starting battery under abnor-

mal operating conditions.

• Red (+) cable connected to battery selector

switch.

• Secondary battery is charged independently

from primary battery.

Accessory

• Not used as starting battery.

• Isolated from outboard start function.

• No red (+) cable connected to battery selector

switch.

Secondary and accessory batteries are often

charged by an isolated battery charging circuit.

Refer to Auxiliary Battery Charging on p. 32.

Battery Switch Requirements

Battery switches must meet the following requirements.

• The switch must be approved for marine use.

• The switch should be a “make before break”

design to protect the charging system from a

no-load condition.

• Switch amperage rating should be adequate for

the outboard it will be used on.

• Use one battery switch for each outboard

installed.

• Use the appropriate sized wire and terminals for

all connections.

• Use AWG stranded copper wire.

Battery Switch Location

• Always locate battery switch as close to the bat-

teries as possible.

• Locate switch so that it cannot be accidently

bumped or switched.

• Refer to the battery switch manufacturer’s

installation instructions for specific information

related to the installation of switch.

• Fasten all battery switches to solid surfaces.

• Route wiring as directly as possible.

• Support the battery switch as needed to prevent

abrasion.

• Use appropriate wiring and connectors.

• Seal all connections and terminals with liquid

neoprene or electrical sealer to prevent corrosion.

IMPORTANT: Insulate all battery positive (+)

terminals to prevent shorting.

2

31

Page 34

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Battery Switch Operation

• Select the primary battery for normal operation.

• Secondary batteries should only be selected for

emergency starting.

• ALL or BOTH switch position is for emergency

starting only.

Provide operator with the documentation supplied by the battery switch manufacturer. Make

sure that the operator is informed of proper

battery switch operation.

IMPORTANT: The negative (–) terminals of a

multiple 12-volt battery installation must be connected together.

3

Auxiliary Battery Charging

Evinrude E-TEC V4–V6 outboards are equipped

with isolated battery charging capability. The isolated charge connection must only be used to

charge a single 12-volt battery or two 12-volt batteries wired in parallel.

IMPORTANT: Never connect an external bat-

tery isolator to the stator of an Evinrude E-TEC

outboard.

Accessory Charge Lead Kit, P/N 5006253, is

routed from a connector on the outboard’s electrical panel to the accessory battery.

1

1 2

1. Starting battery (primary)

2. Accessory battery (secondary)

3. Cable connecting negative (–) battery terminals

DRC7284

1. Accessory battery charge connector 003912

IMPORTANT: The accessory charging kit must

never be connected to any battery of a 24-volt

electrical system.

32

Page 35

Battery and Switch Wiring Diagrams

O

t

O

INSTALLATION AND PREDELIVERY

BOAT RIGGING

ne outboard: Battery disconnec

S

ON

OFF

+

#1

PRIMARY

000135rev1

ne outboard: One primary starting

battery; one secondary battery

S

BOTH

2

OFF

+

SECONDARY

+

#1

PRIMARY

1

2

#2

Two outboards: Two starting batteries for each outboard

#1

S

BOTH

2

1

OFF

+

#1

SECONDARY

Positive (+) Battery cables

Negative (–) Battery cables

Accessory charge wires, P/N 5006253

50 amp Fuse

+

SECONDARY

+

#1

PRIMARY

1

#2

1

BOTH

2

OFF

#2

S

2

+

#2

PRIMARY

000134N

33

Page 36

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Two outboards: One primary starting battery for each outboard; one isolated accessory battery

+

#1

PRIMARY

1

BOTH

OFF

#1

1

S

BOTH

2

OFF

S

2

+

ACCESSORY

#2

+

#2

PRIMARY

Two outboards: One primary starting battery for each outboard; two isolated accessory batteries

+

#1

PRIMARY

#1

S

BOTH

2

1

OFF

+

#1

ACCESSORY

Positive (+) Battery cables

Negative (–) Battery cables

Accessory charge wire, P/N 5006253

50 AMP Fuse

+

#2

ACCESSORY

#2

S

BOTH

2

1

OFF

+

#2

PRIMARY

000086N

34

Page 37

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Fuel System Requirements

Overview

Boat fuel systems must meet minimum specifications to insure the proper delivery of fuel to the

outboard.

The guidelines established by the ABYC and U.S.

Coast Guard should always be followed.

• Permanent fuel tanks must be properly vented

outside of the hull.

• Remote fuel tank gas fills must be grounded.

• Permanent fuel tank pickups should have the

correct anti-siphon valve installed to prevent

fuel flow if a leak occurs in the fuel distribution

system. Refer to ABYC Standard H-24.

Fuel Hose

All fuel hoses must be designated as fuel hose

and approved for marine use.

• Use only fuel lines (or copper tubing) that meet

the outboard minimum I.D. requirement.

• “USCG Type A1” fuel hose must be used

between permanent fuel tanks and motor well

fittings on inaccessible routings.

• Use “USCG Type B1” for fuel hose routings in

motor well areas.

• Permanently installed fuel hoses should be as

short and horizontal as possible.

• Use corrosion-resistant metal clamps on per-

manently installed fuel hoses.

• Multi-outboard applications require separate

fuel tank pickups and hoses. (A fuel selector

switch may be used for “kicker” motors as long

as it has enough flow capacity for the larger outboard.)

Fuel System Primer

Outboards require a priming system capable of

refilling the fuel system after periods of non-use.

Primer bulbs that meet the outboard's minimum

inside diameter fuel line requirements are used on

most outboards.

Install the primer bulb in the fuel supply hose as

follows:

• The primer bulb should be installed in an acces-

sible location.

• The arrow on the primer bulb must point in the

direction of fuel flow.

• The fuel primer bulb must be positioned in the

fuel supply hose so the primer bulb can be held

with the arrow pointing “up” during priming.

1

1. Arrow indicates direction of fuel flow 000124

An alternative to a primer bulb is a U.S. Coast

Guard approved marine primer pump. Electric

primer pumps offer the convenience of outboard

priming from a dash-mounted momentary switch.

2

35

Page 38

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Fuel Filters

Boat-mounted fuel filters and water-separating

fuel filter assemblies must meet the required fuel

flow and filter specification. The filter must be

mounted to a rigid surface above the “full” level of

the fuel tank and accessible for servicing.

Fuel Filter Assembly, P/N 174176, meets all

requirements for a water-separating fuel filter.

1 2 3

Typical Fuel Supply Configuration

1. Primer bulb

2. Water separating fuel filter

3. Anti-siphon valve, in fuel pick-up of tank

DRC6797

IMPORTANT: Avoid using “in-line” fuel filters.

The filter area and flow characteristics may not be

adequate for high horsepower outboards.

Portable Fuel Tanks

Do not use portable fuel tanks for outboards larger

than 115 HP. Inadequate fuel flow to high horse-

0070

power outboards can result in serious powerhead

damage.

Outboard Fuel System Recommendations

Component 25 HP – 130 HP Models 135 HP – 250 HP Models

Fuel tank pickup tube 5/16 in. (7.9 mm) min. I.D. 3/8 in. (9.5 mm) min. I.D.

Fuel fittings 1/4 in. (6.4 mm) min. I.D. 9/32 in. (7.1 mm) min. I.D.

Fuel supply hoses 5/16 in. (7.9 mm) min. I.D. 3/8 in. (9.5 mm) min. I.D.

ALL MODELS

Fuel tank pickup screen 100 mesh, 304 grade stainless steel wire, 0.0045 in. wire diameter,

1 in. (25 mm) long

Antisiphon valve 2.5 in. (63.5 mm) Hg maximum pressure drop at 20 gph (76 l/hr)

flow

Remote fuel filter 0.4 in. Hg maximum pressure drop at 20 gph (76 l/hr) flow,

150 in.

Maximum fuel pump lift height Fuel pump should not be located more than 30 in. (76.2 cm) above

bottom of fuel tank

2

(1290 cm2) of filter area

36

Page 39

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Oiling System Set-Up

Location

IMPORTANT:

of the oil tank carefully. The oil tank is vented to

the atmosphere. To avoid serious powerhead

damage, be sure the oil tank is installed in a location that does not allow constant exposure to sunlight, rain, bilge water or spray.

Select a mounting location that provides:

• A solid place to mount the tank;

• A dry location that prevents exposure to rain or

spraying water;

• Access for adding oil;

• Access to oil-primer bulb; and

• Interference-free hose and wire routing to out-

board.

If necessary, the oil tank can be mounted further

from the outboard than the supplied hoses and

harness allow. The maximum length of oil supply

hose that can be fitted to the oil tank is 25 ft.

(7.6 m).

Consider the installation location

• Replacement hose must be designated for fuel

or oil use and approved for marine use.

• Extend wiring harness with 16 gauge AWG

wire.

• Protect connections with heat shrink tube.

• Maintain wire color and polarity when extending

harness.

An appropriately sized battery box may be used to

conceal and protect the oil tank, if desired.

IMPORTANT: Be sure box includes drain holes

so it does not fill with water and contaminate oil.

2

IMPORTANT: Do not add hose to an existing oil

supply hose.

If the oil tank requires a longer oil supply hose:

• Oil supply hose between the primer bulb and

outboard must be replaced with one continuous

length of 1/4 in. (6.4 mm) hose.

• Maximum length of hose is 25 ft. (7.6 m).

000074

Mounting

Place tank in selected position. Mark one line

under groove in tank bottom and lines at each end

of tank.

1

2

1. Center line of oil tank

2. Ends of tank

Make sure hole locations provide enough clearance for fastening screws. Screws should not contact or penetrate hull.

2

44737

37

Page 40

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Place floor bracket on center line between end

lines. Use the inner bracket holes as guides to drill

two 5/32 in. (4 mm) pilot holes.

COB5381

3 GALLON (11.4 L) TANK

Place rods into floor bracket and secure floor

bracket with lag bolts.

1

1

1.8 GALLON TANK

Place rods into floor bracket and secure floor

bracket with lag bolts.

1

2

1. Rods

2. Lag bolts

Place oil tank onto floor bracket. If cover is not

pre-assembled, route oil supply hose and harness

through the cover and position cover on the oil

tank. Attach spring-loaded rods to cover.

1

2

22149A

2

1. Rods

2. Lag bolts

2

22241B

Place oil tank onto floor bracket. Assemble crossbar onto hook rods, install flat washers and locknuts. Tighten locknuts to securely hold tank.

1

48704

1. Crossbar DRC7418

38

Page 41

Oil Tank Profiles

INSTALLATION AND PREDELIVERY

BOAT RIGGING

1.8 Gallon Tank

P/N 176995

Remote Oil Fill Kit (Optional)

The remote oil fill kit (P/N 176461) provides a

deck-mounted fill tube, cap, a tank-mounted tube,

and nut that replace the original oil tank cap

assembly.

3 Gallon Tank

P/N 176996

2

Installation Recommendations

• Select a location on the deck of the boat that is

above the oil tank fill cap.

• Select a deck location which allows the required

length of 1½ in. I.D. fill hose to route as directly

and as vertically as possible.

• Avoid inappropriate hose routings that could

distort the fill tube or tank tube.

• Refer to installation instructions provided with

remote oil fill kit.

A slanted area of the deck will allow water to

drain away from the fill and is best suited for

the installation.

DRC8123

Additional Items Required

• 1½ in. I.D. fill hose cut to required length. Fill

hose (P/N 123956) is available in 25 ft. (7.6 m)

lengths.

• Two corrosion resistant 2 in. (50 mm) hose

clamps.

39

Page 42

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Cable and Hose Installation

Before installation, identify all required wiring,

cables, and hoses:

• Throttle and shift cables

• Instrument harnesses

• Battery cables and switches

• Oil tank sender harness

• Fuel supply hose

• Primer bulb or primer pump

• Oil supply hose

Determine whether any additional wiring or hoses

will be needed for accessory gauges or batteries:

• Speedometer pick-up hose

• Mechanical water pressure gauge hose

• Accessory battery charging kit

• CANbus adapter harnesses

• CANbus water pressure sensor kit

• CANbus oil level sensor kit

12345

Cable and Wire Harness Routing

WARNING

Improper installation and routing of outboard controls could wear, bind, and damage components, causing loss of control.

Remote control cables, wiring, and hoses must

follow a similar path into the lower motor covers.

Select the best routing for the specific application.

All cables, wiring, and hoses must be long enough

to provide adequate slack. Check clearances at all

possible combinations of trim angles and steering

positions.

6 7 8 9

Typical outboard installation

1. Oil tank

2. Anti-siphon valve

3. Water separating fuel filter

4. Starting battery

5. Accessory battery

6. Flexweave protective sleeve

7. Access cover

8. Primer bulb

9. Battery switch

Typical Small Splash Well DRC7799

DRC6487

Typical Large Splash Well DRC7797

40

Page 43

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Fuel Hose

The fuel hose may be routed outside of the protective sleeve or conduit. Electric primers or manual primers may not require this consideration.

Typical Engine Bracket DRC7798A

Protective Sleeve/Conduit

Make sure all cables, wiring, and hoses have

been identified and fitted to the appropriate

lengths. Refer to OUTBOARD RIGGING on p. 52.

Next, bundle the components that route to the outboard with appropriate shielding, such as an

expandable “flexweave” sleeve or a flexible conduit.

Route fuel hoses with enough slack to allow the

primer bulb arrow to point “up” during use.

Install the primer bulb with the arrow pointing in

the direction of fuel flow to the outboard.

Connect the fuel supply hose from the fuel tank to

the fuel supply line at the outboard.

IMPORTANT: Do not permanently fasten this

connection until the boat's fuel system has been

primed.

Oil Supply Hose

Evinrude E-TEC V4–V6 outboards use a single oil

supply hose connected to the outboard and to the

boat-mounted oil tank.

• Route the hose from the oil tank to the ¼ in. (6.4

mm) fitting of the oil supply line at the lower

motor cover.

• Install the hose on the fitting using the proper

†

size Oetiker

clamp.

2

Flexible conduit installation 005138

Battery Cables

Evinrude outboards are equipped with premium

quality battery cables that should be long enough

for most installations.

When routing battery cables, be sure to:

• Route cables through the protective sleeve.

• Use the most direct path to route the battery

cables to the battery or battery switch.

1. Fuel supply hose and fuel fitting - 3/8 in. (9 mm)

2. Oil supply hose and fitting - 1/4 in. (6 mm)

21

003963

41

Page 44

INSTALLATION AND PREDELIVERY

BOAT RIGGING

†

Oetiker

Use Oetiker† clamps for making hose connections. These clamps provide corrosion resistance,

minimize the potential for abrasion of rigging components, and provide solid, permanent connections.

The selection and installation of an Oetiker clamp

is essential in the proper sealing of hose connections. The clamp identification numbers appear in

millimeters on the side of the clamp, near the top

of the ear. Refer to Oetiker Stainless Steel Step-

less Clamps chart for actual dimensions.

Clamp Servicing

1

WARNING

1. Clamp identification numbers 000093

DO NOT re-use Oetiker clamps. Fuel leakage could contribute to a fire or explosion.

The nominal size of the clamp should be chosen

so that, when it is assembled on the connecting

part, the outside diameter of the hose lies approximately in the middle of the clamping range of the

clamp.

Oetiker Stainless Steel Stepless Clamps

CLAMP NO. NOMINAL O.D. INCHES MILLIMETERS

Replacement Clamp I.D. Inches MM Open Closed Open Closed

346930 95 3/8 9.5 0.374 0.307 9.5 7.8

348838 105 13/32 10.5 0.413 0.346 10.5 8.8

349516 113 7/16 11.3 0.445 0.378 11.3 9.6

347107 133 1/2 13.3 0.524 0.425 13.3 10.8

347108 138 17/32 13.8 0.543 0.449 13.8 11.3

346931 140 34/64 14 0.551 0.453 14 11.5

346785 145 9/16 14.5 0.571 0.472 14.5 12

346786 157 5/8 15.7 0.618 0.52 15.7 13.2

348839 170 11/16 17 0.669 0.571 17 14.5

346150 185 23/32 18.5 0.728 0.602 18.5 15.3

346151 210 13/16 21 0.827 0.701 21 17.8

346152 256 1 25.6 1.008 0.882 25.6 22.4

346153 301 1 3/16 30.1 1.185 1.063 30.1 26.9

349759 316 1 1/4 31.6 1.244 1.122 31.6 28.4

349729 410 1 5/8 41 1.614 1.492 41 37.9

42

Page 45

INSTALLATION AND PREDELIVERY

BOAT RIGGING

Clamp Installation

A constant stress should be applied to close the

ear clamps. This method ensures a positive stress

on the hose and does not result in excessive compression or expansion of the band material.

IMPORTANT: Use only Oetiker recommended

tools to close Oetiker stepless clamps.

Oetiker pincers are available in the

Evinrude/Johnson Genuine Parts and Accessories Catalog (P/N 787145).

Clamp Removal

Method 1: Position Oetiker pincers across clamp

ear and cut clamp.

2

000108

Method 2: Lift end of stepless clamp with screwdriver.

DP0886

• Position correct size clamp over hose.

• Install hose on fitting.

• Close clamp ear fully with Oetiker pincers (pli-

ers).

12

1. Open clamp

2. Closed clamp

000092

000090

Method 3: Use Oetiker pincers (pliers) to grip

clamp. Pull clamp off of connection and discard.

000091

43

Page 46

INSTALLATION AND PREDELIVERY

OUTBOARD INSTALLATION

Control Cable Identification

IMPORTANT: Control cable function must be

identified before rigging outboard.

Identify each control cable:

• Put the control handle into NEUTRAL position.

The throttle cable casing guide will retract completely and the shift cable casing guide will go to

the midpoint of its travel.

1

2

1. Shift cable casing guide extended to midpoint

2. Throttle cable casing guide retracted

Extend the control cables and lubricate them with

Triple-Guard grease.

DP0811

OUTBOARD

INSTALLATION

Hull Preparation

Maximum Capacity

WARNING

Do not overpower the boat by installing an

outboard that exceeds the horsepower

indicated on the boat’s capacity plate.

Overpowering could result in loss of control.

Before installing outboard:

• Refer to the boat manufacturer's certification

label for maximum horsepower rating.

• Refer to ABYC Standards to determine the

maximum horsepower capacity for boats without certification labeling.

44

30501

1029A

Mounting Surface

Inspect transom surface before drilling mounting

holes.

• The transom should meet ABYC Standards.

• The transom must be flat.

• The transom angle should be approximately 14

degrees.

• Check transom strength and height.

The stern brackets must contact the flat surface of

the transom. Modify trim that prevents the stern

brackets from resting against the transom surface.

Do not modify stern brackets.

Page 47

WARNING

DO NOT install an outboard on a curved or

irregular surface. Doing so can wear, bind,

and damage components, causing loss of

control.

Transom Clearances

Make sure the transom and splash well area provide adequate clearances:

• The top edge of the transom should be wide

enough to allow full steering travel. The ABYC

standard for most single outboard installations

is 33 in. (84 cm).

• Check cable and hose routing clearances.

• Make sure there is clearance for mounting bolts

and washers. Check the inside area of the transom for obstructions before drilling holes.

INSTALLATION AND PREDELIVERY

OUTBOARD INSTALLATION

Transom Brackets and Jack Plates

When mounting an outboard on boats equipped

with transom brackets or jack plates, refer to the

manufacturer's recommendations.

• Confirm maximum weight and horsepower

capacities.

• Jack plate assemblies must provide a one-piece

mounting surface to support the outboard.

DR5704

2

Water Flow

Inspect the hull area directly in front of the mounting location.

• Boat-mounted equipment should not create tur-

bulence in the water flow directly in front of the

outboard's gearcase. Turbulence or disruptions

in the water flow directly in front of the gearcase

will affect engine cooling and propeller performance.

• Avoid locating outboard centerlines within 3 in.

(76 mm) of bottom strakes on dual-outboard

installations.

Mounting Hardware

WARNING

Use all mounting hardware supplied with

the outboard to help ensure a secure

installation. Substituting inferior hardware

can result in loss of control.

The required outboard mounting bolts, backing

plates, washers, and nuts are used to attach the

outboard to the frame of the shipping pallet.

Refer to the outboard's parts catalog for alternate

length mounting bolts or replacement parts.

• Use only Evinrude/Johnson Genuine Parts or

parts of equivalent type, strength, and material.

• Use the mounting hardware provided with out-

board whenever possible.

45

Page 48

INSTALLATION AND PREDELIVERY

OUTBOARD INSTALLATION

Transom Measuring and Drilling

Hull Centerline

Use the chines of the boat as reference points to

locate the centerline of the boat transom.

Use a straightedge to draw a line connecting the

port and starboard chines.

Use a framing square to accurately place a vertical line on the transom. The centerline of the hull

should be in line with the keel, and perpendicular

to the midpoint of the line connecting the chines.

IMPORTANT: Some steering systems may

require additional spacing. Refer to steering system manufacturer for recommendations.

The top edge of the transom should be more than

twice the width of the dual-outboard centerline

spacing dimension. Bracket installations may not

require this consideration.

Measure the transom for dual-outboard spacing

after the centerline of the hull is established.

Divide the spacing dimension by two. Use the

resulting number to space the outboard centerlines from the hull centerline.

EXAMPLE: A 26 in. (660 mm) dual-outboard

spacing would result in two outboard centerlines,

each 13 in. (330 mm) from the hull centerline.

1234

1. Chine

2. Strake

3. Keel

4. Hull centerline

DR5568

Dual-Outboard Centerlines

The following table lists standard ABYC centerline

spacing between outboards in dual installations:

V4 and V6 26 in. (660 mm)

Some applications may require changes in this

dimension to avoid strakes, to adjust for transom

height, or for performance reasons. Best performance can be determined only through testing.

Refer to boat manufacturer for recommendations.

If the standard spacing does not allow full steering

travel in a particular installation, it may be necessary to increase the spacing.

1 2 3

1. Port centerline

2. Hull centerline