Page 1

INTRODUCTION

www.MilitaryAtv.com

INTRODUCTION

This Shop Manual covers the following BRP made

2013 Can-Am side by side vehicles.

MODEL

Commander

800R

Commander

1000

The information and component/system descriptions contained in this manual are correct at time

of writing. BRP however, maintains a policy of

continuous improvement of its products without

imposing upon itself any obligation to install them

on products previously manufactured.

Duetolat

ences bet

descript

BRP reserves the right at any time to discontinue

or change specifications, designs, features, models or equipment without incurring obligation.

ENGINE

TYPE

810

1010

e changes, there may be some differ-

ween the manufactured product and the

ion and/or specifications in this document.

MODEL NUMBER

6CDA, 6CDB, 6CDC, 6TDA,

6DDA, 6DDB, 6

6ADA, 6ADB, 6PDA, 6BDA,

6BDB, 6BDD,

6BDG, 6BDH, 6EDA,

6EDB, 6EDC, 6EDD, 6GDA,

6GDB, 6GDC,

DDC

6BDE, 6BDF,

6GDD

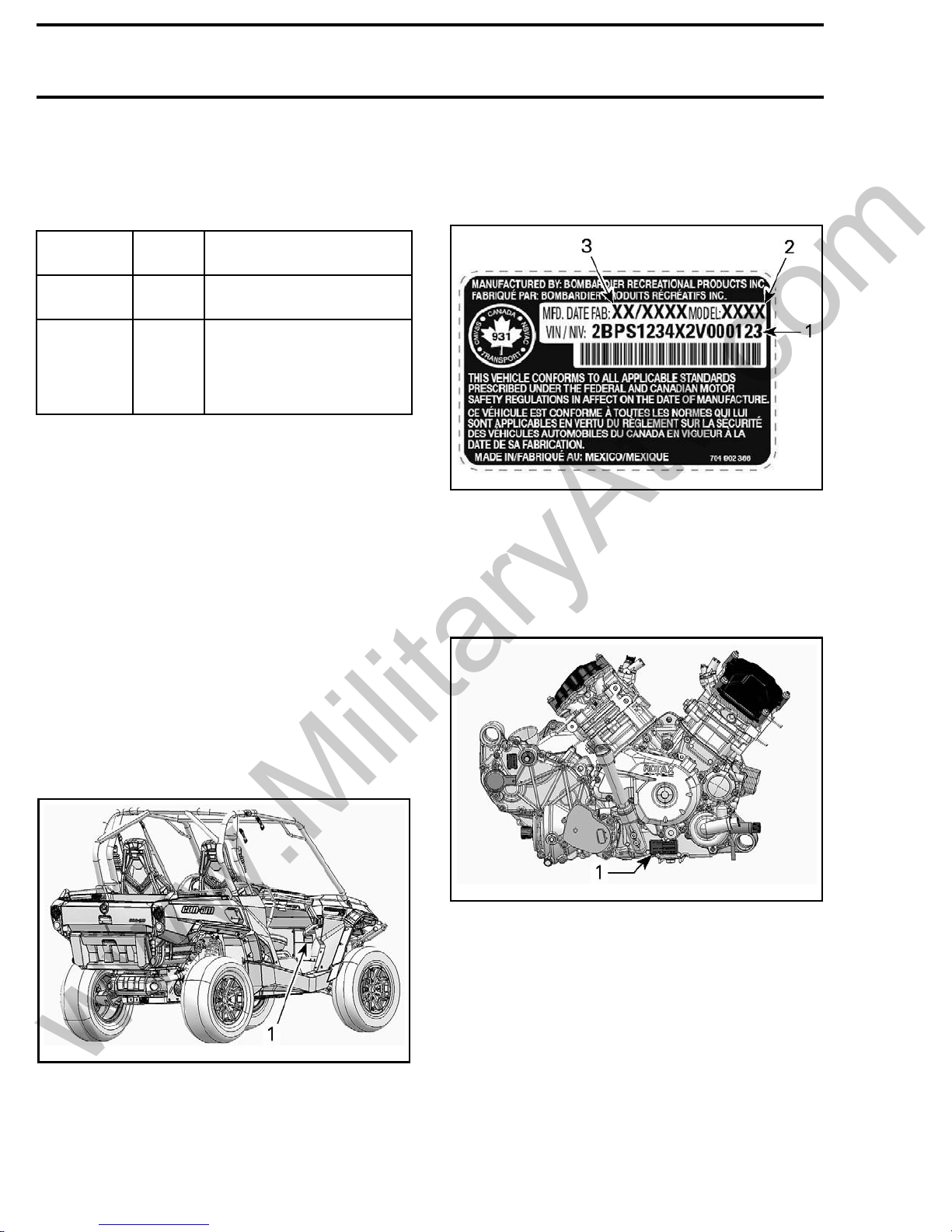

VIN Decal Description

tmr2011-002-005_a

TYPICAL — VEHICLE IDENTIFICATION NUMBER LABEL

1. VIN (Vehic

2. Model number

3. Manufacturing date

le Identification Number)

ENGINE IDENTIFICATION

NUMBER (EIN)

VEHICLE INFORMATION

VEHICLE IDENTIFICATION

NUMBER (VIN)

11-002-001_a

tmr20

TYPICAL

1. VIN (Vehicle Identification Number) location

The VI

cate

N (Vehicle Identification Number) decal is lo-

d under the glove box on the passenger side.

1-002-002_a

tmr201

TYPICAL - RH SIDE OF ENGINE

1. Engine Identification Number (EIN)

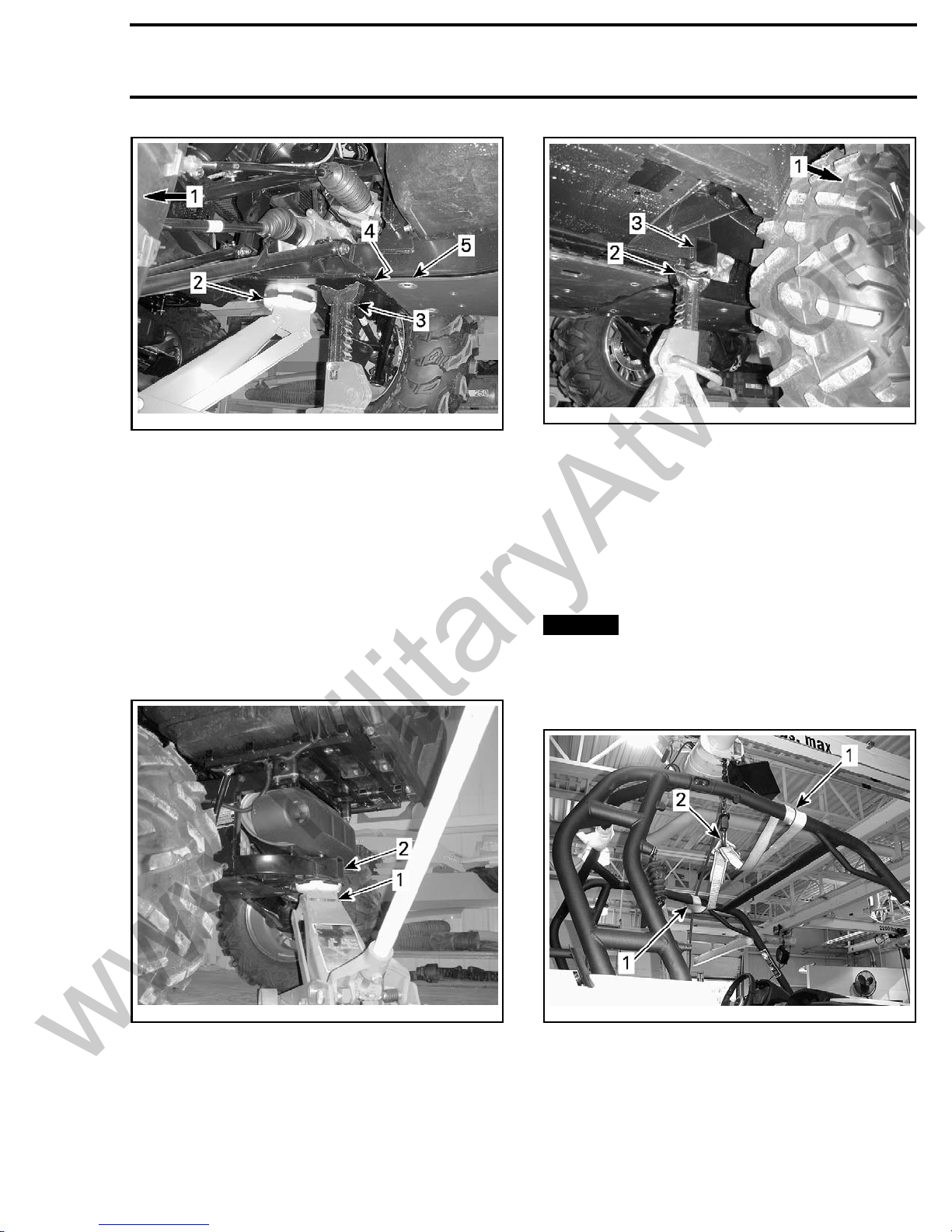

LIFTING AND SUPPORTING THE

VEHICLE

Front

1. Place vehicle on a flat non slippery ground.

2. Ensure vehicle shift lever is set to PARK.

3. Inst

4. Lift front of vehicle and install a jack stand on

of Vehicle

all an hydraulic jack under front skid plate.

each side under frame section in front of the lip

for center skid plate.

X tmr2013-002

Page 2

INTRODUCTION

www.MilitaryAtv.com

tmo2011-001-315_a

1. Front of vehicle

2. Hydraulic jack

3. Jack stand

4. Lip for center skid plate

5. Center skid plate

5. Lower hydraulic lift and ensure vehicle is supported safely onto both jack stands.

Rear of Vehicle

1. Place vehicle on a flat non slippery ground.

2. Activate 4WD mode.

3. Ensure vehicle shift lever is set to PARK.

4. Install a hydraulic jack under the trailer hitch.

tmo2011-001-316_a

1. Rear of vehicle

2. Jack stand

3. Frame section

6. Lower hydraulic lift and ensure vehicle is supported safely onto both jack stands.

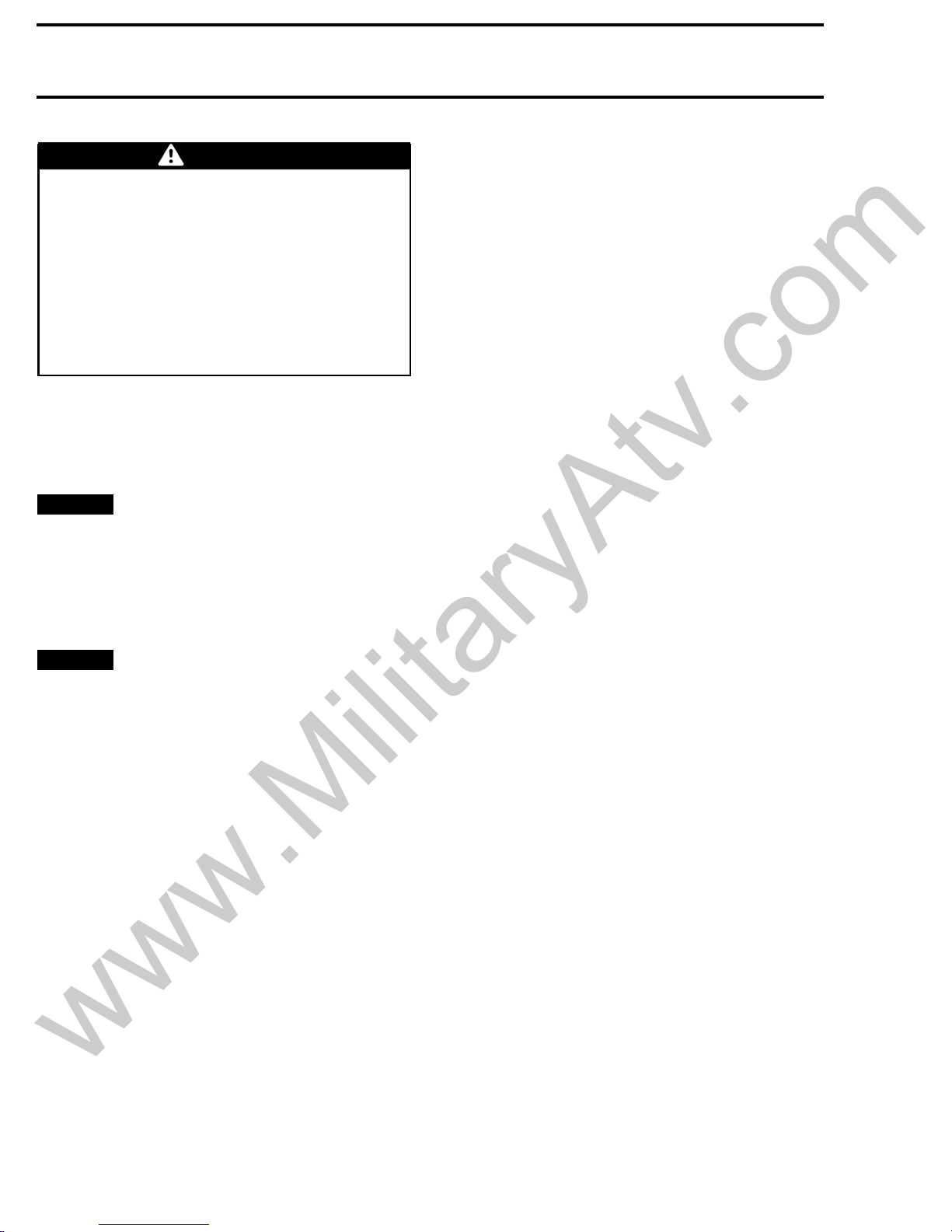

HOISTING THE VEHICLE

The vehicle may be lifted off the ground by the

cage using a hoist and a lifting strap.

NOTICE

around the horizontal side tubes at the top of

the cage, NOT fore and aft. Lifting vehicle by

the fore and aft tubes of the cage can cause

damage.

The lifting strap must be wrapped

2011-001-317_a

tmo

1. Hydraulic jack

2. Trailer hitch

t rear of vehicle and install a jack stand on

5. Lif

h side under frame section in front of rear

eac

eel.

wh

tmr2013-002 XI

tmr2011-002-004_a

1. Lifting strap around horizontal side tubes (top)

2. Hoist hook

Page 3

INTRODUCTION

www.MilitaryAtv.com

WARNING

– Ensure hoist a

lifting the to

plicable man

– Ensure lifting strap is in good condition be-

fore lifting vehicle.

– Do not allow anyone in the vehicle or under

any portion of the vehicle while it is suspended by a hoist.

– Do not perfo

while it is

nd lifting strap are rated for

tal vehicle weight. Refer to ap-

ufactures instructions.

rm any work on the vehicle

suspended by a hoist.

TRANSPORTING THE VEHICLE

If the vehicle needs to be transported, it should be

carried inside a full size pick-up box or on a flatbed

trailer of the appropriate size and capacity.

NOTICE

seriously damage the vehicle drive system.

When contacting a towing or transporting service,

be sure to ask for tie-down straps, a flatbed trailer,

loading ramp or power ramp to safely lift and secure the vehicle. Ensure the vehicle is properly

transported as specified in this section.

NOTICE

vehicle - they may damage the surface finish

or plastic components.

To load the vehicle for transport, proceed as follows:

1. Set gear shift lever to NEUTRAL (N).

2. Remove the key from the ignition switch.

3. If the vehicle is equipped with a winch, use the

winch to roll the vehicle onto the transport vehicle.

4. If the vehicle is not equipped with a winch, proceed as follows:

4.1 Put a strap around the lower arm of each

4.2 Attach the straps to the winch cable of the

4.3 Pull the vehicle on the flatbed trailers with

.

NOTE: Be sure to leave the gear shift lever in

NEUTRAL (N).

5. Set ACS suspension setting to 1 (softest).

6. Tie down the front wheels to the front of the

trailer using tire towing straps.

Do not tow this vehicle - towing can

Avoid using chains to tie down the

front suspension.

towing vehicle.

the winch.

7. Pass a tie-down strap inside each rear wheel.

8. Firmly attach the rear wheels tie-down straps to

both sides of the rear of the trailer with ratchets.

9. Ensure that both the front and rear wheels are

firmly secured to the trailer.

ENGINE EMISSIONS

INFORMATION

MANUFACTURER'S

RESPONSIBILITY

Manufacturers of engines must determine the

exhaust emission levels for each engine horsepower family and certify these engines with

the United States of America Environmental

Protection Agency (EPA). An emissions control

information label, showing emission levels and

engine specifications, must be placed on each

vehicle at the time of manufacture.

DEALER RESPONSIBILITY

When servicing any vehicle that carry an emissions control information label, adjustments must

be kept within published factory specifications.

Replacement or repair of any emission related

component must be executed in a manner that

maintains emission levels within the prescribed

certification standards.

Dealers are not to modify the engine in any manner that would alter the horsepower or allow emission levels to exceed their predetermined factory

specifications.

Exceptions include manufacturer's prescribed

changes, such as altitude adjustments.

OWNER RESPONSIBILITY

The owner/operator is required to have engine

maintenance performed to maintain emission

levels within prescribed certification standards.

The owner/operator is not to, and should not allow anyone else to modify the engine in any manner that would alter the horsepower or allow emissions levels to exceed their predetermined factory

specifications.

XII tmr2013-002

Page 4

EPA EMISSION REGULATIONS

www.MilitaryAtv.com

Vehicles manufactured by BRP are certified to the

EPA standards as conforming to the requirements

of the regulations for the control of air pollution

emitted from new vehicle engines. This certification is contingent on certain adjustments being

set to factory standards. For this reason, the

factory procedure for servicing the product must

be strictly followed and, whenever practicable,

returned to the original intent of the design.

The responsibilities listed above are general and

in no way a complete listing of the rules and regulations pertaining to the EPA requirements on exhaust emissions. For more detailed information

on this subject, you may contact the following locations:

FOR ALL COURIER SERVICES:

U.S. Environmental Protection Agency

Office of Transportation and Air Quality

1310 L Street NW

Washington D.C. 20005

REGULARUSPOSTALMAIL:

1200 Pennsylvania Ave. NW

Mail Code 6403J

Washington D.C. 20460

INTERNET: http://www.epa.gov/otaq/

E-MAIL: otaqpublicweb@epa.gov

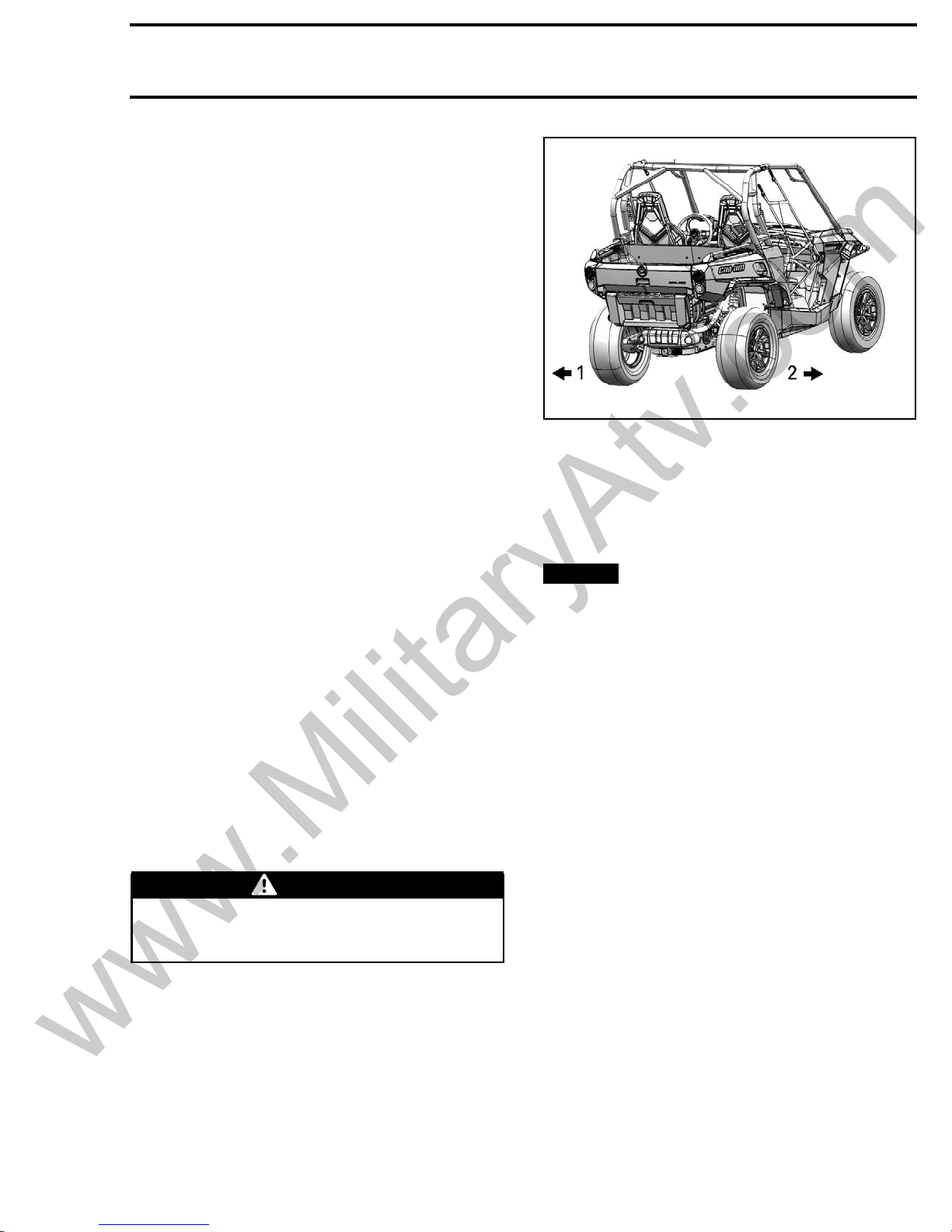

INTRODUCTION

tmr2011-002-003_a

TYPICAL

1. Left

2. Right

This manual uses technical terms which may be

different from the ones of the

When ordering parts always refer to the specific

model

NOTICE

components are built with parts dimensioned

using the metric system. Consult the appropriate

rect parts and fasteners. Mismatched or incorrect fasteners could cause damage to the vehicle.

PART S C ATAL O G S

Most fasteners are metric, and most

PARTS CATALOG

to obtain and use the cor-

PARTS CATALOGS

.

.

MANUAL INFORMATION

MANUAL PROCEDURES

Many of the procedures in this manual are interrelated. Before undertaking any task, you should

read and thoroughly understand the entire section

or subsection in which the procedure is contained.

WARNING

Unless otherwise specified, the engine

should be turned OFF and cold for all maintenance and repair procedures.

A number of procedures throughout the book require the use of special tools. Before starting any

procedure, be sure that you have on hand all required tools, or their approved equivalents.

The use of RIGHT and LEFT indications in the text

are always referenced to the driving position (sitting on the vehicle).

MANUAL LAYOUT

This manual is divided into many major sections as

can be seen in the main table of contents at the

beginning of the manual.

Each section is divided into various subsections,

and again, each subsection has one or more divisions.

Illustrations and photos show the typical construction of various assemblies and, in all cases, may

not reproduce the full detail or exact shape of the

parts used in a particular model vehicle. However,

they represent parts which have the same or a

similar function.

tmr2013-002 XIII

Page 5

INTRODUCTION

www.MilitaryAtv.com

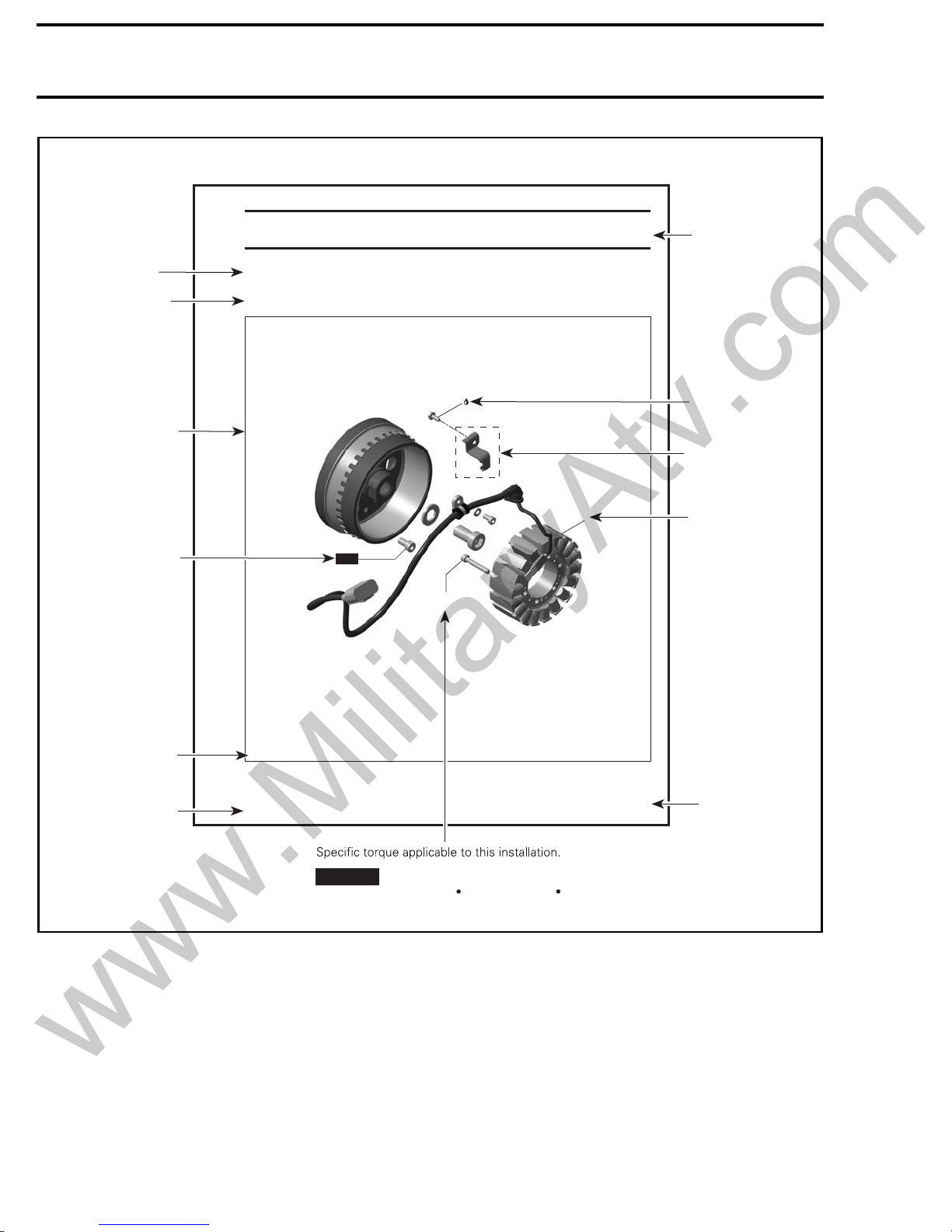

TYPICAL PAGE

Subsection title

Indicates applicable

models.

Exploded view assists

you in identifying parts

and their related

positions.

NEW indicates that the

part must be replaced

with a new one.

MAGNETO

Models

NEW

Loctite 243

5 Nm

(44 lbfin)

Section 06 ENGINE

Subsection 01 (MAGNETO)

Model

Page heading

indicates section

and subsection.

Drop represents a

service product

to be applied.

Dotted box contains

parts applicable to a

specific model.

Bold face number

1

is used to identify

a part referred to

the text.

Illustration number

for publishing process.

Document number for

publishing process.

Typical_iso_2008_en

XXX0000

mmr2008-001

Pay attention to torque specifications.

NOTICE

Some of these are in lbf in instead of lbf ft.

Use appropriate torque wrench.

55

Page number

XIV tmr2013-002

Page 6

Tittle in bold

www.MilitaryAtv.com

indicates category

of information to be

carried out.

Reference to a

specific section

or subsection.

Indicates component

procedures apply to.

Indicates specific

procedure to be

carried out.

TYPICAL PAGE

GENERAL

GENERAL

NOTE:

NOTE:

The following procedures can be done

The following procedures can be done

without removing the engine.

without removing the engine.

During assembly/installation, use the torque val-

During assembly/installation, use the torque values and service products as in the exploded

ues and service products as in the exploded

views.

views.

Clean threads before applying a threadlocker. Re-

Clean threads before applying a threadlocker. Re-

SELF-LOCKING FASTENERS

SELF-LOCKING FASTENERS

fer to the

fer to the

TITE APPLICATION

TITE APPLICATION

this manual for complete procedure.

this manual for complete procedure.

Torque wrench tightening specifications

Torque wrench tightening specifications

must be strictly adhered to.

must be strictly adhered to.

Locking devices (e.g.: locking tabs, elastic

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

stop nuts, self-locking fasteners, etc.) must

be replaced with new ones.

be replaced with new ones.

PROCEDURES

PROCEDURES

MAGNETO FLYWHEEL

MAGNETO FLYWHEEL

Magneto Flywheel Cleaning

Magneto Flywheel Cleaning

Clean all metal components in a non-ferrous metal

Clean all metal components in a non-ferrous metal

cleaner.

cleaner.

CAUTION:

CAUTION:

a clean cloth.

a clean cloth.

Magneto Flywheel Removal

Magneto Flywheel Removal

Remove muffler, refer to the

Remove muffler, refer to the

section.

section.

Remove acoustic panel.

Remove acoustic panel.

Remove rewind starter.

Remove rewind starter.

Remove starting pulley

Remove starting pulley

sections at the beginning of

sections at the beginning of

WARNING

WARNING

Clean magneto flywheel using only

Clean magneto flywheel using only

EXHAUST SYSTEM

EXHAUST SYSTEM

no. 2

no. 2

.

.

and

and

LOC-

LOC-

Section03ENGINE

Subsection 09 (MAGNETO SYSTEM)

Subsection 09 (MAGNETO SYSTEM)

TYPICAL

TYPICAL

1. Starting pulley

1. Starting pulley

NOTE:

NOTE:

To remove starting pulley bolts, hold mag-

To remove starting pulley bolts, hold mag-

neto flywheel with a socket as shown.

neto flywheel with a socket as shown.

mmr2007-016-002

TYPICAL

TYPICAL

Models

Models

Remove the connecting flange retaining the

Remove the connecting flange retaining the

rewind starter to the engine housing.

rewind starter to the engine housing.

Section03ENGINE

1

1

INTRODUCTION

TYPICAL

indicates a general

view which may

not represent exact

details.

Call-outs pertaining

to above illustration.

Illustration always

follows text to which

it applies.

Italic bold face type-

setting indicates a

procedure applicable

to a specific

model(s).

mmr2008-001

typical_txt_2008_en

tmr2013-002 XV

57

Bold face number following part

name refers to exploded view

at beginning of subsection.

Page 7

INTRODUCTION

www.MilitaryAtv.com

TIGHTENING TORQUE

Tighten fasteners to the torque specified in the exploded view(s) and/or in the written procedure. When

a torque is not specified, refer to the following table.

WARNING

Torque wrench tightening specifications must be strictly adhered to.

Locking devices when removed (e.g.: locking tabs, elastic stop nuts, self-locking fasteners, cotter

pins, etc.) must be replaced.

In order to avoid a poor assembly, tighten screws, bolts, or nuts in accordance with the following procedure:

1. Manually screw all screws, bolts and/or nuts.

2. Apply half the recommended torque value.

3. Tighten fastener to the recommended torque value.

NOTICE

NOTE: When possible, always apply torque on the nut.

NOTE: Always torque screws, bolts and/or nuts using a crisscross pattern when multiple fasteners are

used to secure a part (eg. a cylinder head). Some parts must be torqued according to a specific sequence

and torque pattern as detailed in the installation procedure.

Property

class and

head

markings

Property

class and

nut

markings

A00A8BS

FASTENER

SIZE

Be sure to use the recommended tightening torque for the specified fastener used.

4.8

4.8

4.8

5

5

5.8 Grade 8.8 Grade 10.9 Grade 12.9 Grade

8.8

8.8

8.8

9.8

9.8

9.8

8

8

FASTENER GRADE/TORQUE

10.9

10.9

10.9

10

10

12.9

12.9

12.9

12.9

12

12

M4

M5

M6

M8 15 N•m (133 lbf•in) 25 N•m (18 lbf•ft) 32 N•m (24 lbf•ft) 40 N•m (30 lbf•ft)

M10 29 N•m (21 lbf•ft) 48 N•m (35 lbf•ft) 61 N•m (45 lbf•ft) 73 N•m (54 lbf•ft)

M12 52 N•m (38 lbf•ft) 85 N•m (63 lbf•ft) 105 N•m (77 lbf•ft) 128 N•m (94 lbf•ft)

M14 85 N•m (63 lbf•ft) 135 N•m (100 lbf•ft) 170 N•m (125 lbf•ft) 200 N•m (148 lbf•ft)

XVI tmr2013-002

1.5 – 2 N•m

(13 – 18 lbf•in)

3–3.5N•m

(27 – 31 lbf•ft)

6.5 – 8.5 N•m

(58 – 75 lbf•ft)

2.5 – 3 N•m

(22 – 27 lbf•in)

4.5 – 5.5 N•m

(40 – 47 lbf•ft)

8–12N•m

(71 – 106 lbf•ft)

3.5 – 4 N•m

(31 – 35 lbf•ft)

7–8.5N•m

(62 – 75 lbf•ft)

10.5 – 15 N•m

(93 – 133 lbf•in)

4–5N•m

(35 – 44 lbf•ft)

8–10N•m

(71 – 89 lbf•ft)

16 N•m (142 lbf•in)

Page 8

INTRODUCTION

www.MilitaryAtv.com

FASTENER INFO

NOTICE

are built with parts dimensioned in the metric

system. Most fasteners are metric and must

not be replaced by customary fasteners or

vice-versa. Mismatched or incorrect fasteners

could cause damage to the vehicle or possible

personal injury.

Most components in the vehicles

RMATION

SELF-LOCKING FASTENERS

PROCEDURE

A00A6LA

TYPICAL — SELF-LOCKING FASTENER

The following describes common procedures

used when working with self-locking fasteners.

Use a metal brush or a tap to properly clean a

threaded hole, then use a solvent. Allow the solvent time to act, approximately 30 minutes, then

wipe off. Solvent utilization is to ensure proper

adhesion of the product used for locking the fastener.

Threadlocker Application for

Uncovered Holes (Bolts and Nuts)

1

2

A00A3LA

1. Apply here

2. Do not apply

1. Clean threads (bolt and nut) with solvent.

2. Apply

threads and allow to dry.

3. Choose proper strength Loctite threadlocker.

4. Fit bolt in the hole.

5. Apply a few drops of threadlocker at proposed

tightened nut engagement area.

6. Position nut and tighten as required.

LOCTITE PRIMER N (P/N 293 800 041) on

Threadlocker Application for Blind

Holes

LOCTITE®APPLICATION

PROCEDURE

The following describes common procedures

used when working with Loctite products.

NOTE: Always use proper strength Loctite product as recommended in this shop manual.

tmr2013-002 XVII

1

2

007-040-004_a

lmr2

1. On fastener threads

2. On threads and at the bottom of hole

an threads (bolt and hole) with solvent.

1. Cle

2. Apply

threads (bolt and nut) and allow to dry for 30

seconds.

3. Choose proper strength Loctite threadlocker.

LOCTITE PRIMER N (P/N 293 800 041) on

Page 9

INTRODUCTION

www.MilitaryAtv.com

4. Apply several drops along the threaded hole

and at the bottom of the hole.

5. Apply several drops on bolt threads.

6. Tighten as required.

Threadlocker Application for Stud

Installation in Blind Holes

1

2

lmr2007-040-005_a

1. On stud thr

2. On threads and in the hole

3. On retaining nut threads

1. Clean thr

2. Apply

threads and allow to dry.

3. Put 2 or 3 drops of proper strength Loctite

threadlocker on female threads and in hole.

NOTE: To

ply too m

4. Apply several drops of proper strength Loctite

on stud threads.

5. Install stud.

6. Instal

7. Apply a few drops of proper strength Loctite on

uncovered stud threads.

8. Install and tighten retaining nut(s) as required.

eads

eads (stud and hole) with solvent.

LOCTITE PRIMER N (P/N 293 800 041) on

avoid a hydro lock situation, do not ap-

uch Loctite.

l cover, part, etc.

3

Threadlocker Application for

Pre-Assembled Parts

1

2

A00A3OA

1. Apply her

2. Do not apply

1. Clean bolts and nuts with solvent.

2. Assemble components.

3. Tighten

4. Apply a few drops of proper strength Loctite on

bolt/nut contact surfaces.

5. Avoid touching metal with tip of flask.

NOTE: Fo

ing equ

streng

e

nuts.

r preventive maintenance on exist-

ipment, retighten nuts and apply proper

th Loctite on bolt/nut contact surfaces.

Threadlocker Application for an

Adjust

ment Screw

1

2

A00A3PA

1. Apply here

2. Plunger

1. Adjust screw to proper setting.

2. Apply a few drops of proper strength Loctite

threadlocker on screw/body contact surfaces.

3. Avoid touching metal with tip of flask.

XVIII tmr2013-002

Page 10

INTRODUCTION

www.MilitaryAtv.com

NOTE: If it is difficult to readjust, heat screw with

a soldering iron (232°C (450°F)).

Application for Stripped Thread Repair

5

1

8

2

3

A00A3QA

1. Release agent

2. Stripped t

3. Form-A-Thread

4. Tapes

5. Cleaned b

6. Plate

7. New threads

8. Threadlo

Standard Thread Repair

Follow in

81668 pac

If a plate is used to align bolt:

1. Apply release agent on mating surfaces.

2. Put waxe

3. Twist bolt when inserting it to improve thread

conformation.

NOTE: NOT intended for engine stud repairs.

Repair o

Option 1: Enlarge damaged hole, then follow

cker

structions on Loctite FORM-A-THREAD

f Small Holes/Fine Threads

STANDARD THREAD REPAIR

Option 2: Apply FORM-A-THREAD on the screw

and insert in damaged hole.

Permane

1. Use a stud of the desired thread length.

2. DO NOT apply release agent on stud.

3. Follow

4. Allow 30 minutes for Loctite FORM-A-THREAD

to cure.

5. Complete part assembly.

4

hreads

olt

kage.

d paper or similar film on the surfaces.

procedure.

nt Stud Installation (Light Duty)

Standard Thread Repair procedure.

6

7

Gasket Compound Application

21

1

1

lmr2007-040-006_a

1. Proper st

2. Loctite Primer N (P/N 293 800 041) and Gasket Eliminator 518

(P/N 293 800 038) on both sides of gasket

3. Loctite P

1. Remove old gasket and other contaminants using

708 500)

essary.

NOTE: Av

2. Clean both mating surfaces with solvent.

3. Spray Loctite Primer N on both mating surfaces

and on both sides of gasket and allow to dry 1

or 2 minutes.

4. Apply

sides

5. Place gasket on mating surfaces and assemble

parts immediately.

NOTE: If the cover is bolted to blind holes, apply

proper strength Loctite in the hole and on threads.

Tighten fastener.

If hol

on bo

6. Tighten as usual.

Thre

rength Loctite

rimer N only

LOCTITE CHISEL (GASKET REMOVER) (P/N 413

. Use a mechanical means only if nec-

oid grinding.

OCTITE 518 (P/N 293 800 038)

L

of gasket, using a clean applicator.

es are sunken, apply proper strength Loctite

lt threads.

adlocker Application for Mounting

3

on both

on a Shaft

Mounting with a Press

tmr2013-002 XIX

Page 11

INTRODUCTION

www.MilitaryAtv.com

1

2

3

A00A3UA

1. Bearing

2. Proper strength Loctite

3. Shaft

1. Clean shaft external contact surface.

2. Clean internal contact surface of part to be installed on shaft.

3. Apply a strip of proper strength Loctite on circumference of shaft contact surface at insertion or engagement point.

NOTE: Retaining compound is always forced out

when applied on shaft.

4. DO NOT use antiseize Loctite or any similar

product.

5. No curing period is required.

Mounting in Tandem

1. Apply retaining compound on internal contact

surface (bore) of parts to be installed.

2. Continue parts assembly as per previous illustration.

3. Apply a strip of proper strength Loctite on leading edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

4. Install according to standard procedure.

5. Wipe off excess product.

6. Allow 30 minutes for product to cure.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

Threadlocker Application for Case-In

Components (Metallic Gaskets)

A00A3VA

1. Proper strength Loctite

1. Clean inner housing diameter and outer gasket

diameter.

2. Spray housing and gasket with

N (P/N 293 800 041)

XX tmr2013-002

1

LOCTITE PRIMER

.

Page 12

SERVICE TOOLS INDEX

www.MilitaryAtv.com

ADAPTER HOSE

(P/N 529 035 652)

Page: 54

BACK PROBE TEST WIRES

(P/N 529 036 063)

Page: 87

BACKLASH MEASUREMENT TOOL

(P/N 529 035 665)

BLIND HOLE PULLER KIT

(P/N 529 036 056)

Page: 77

CAMSHAFT TIMING TOOL

(P/N 529 036 231)

Page: 129–130

CLUTCH HOLDER

(P/N 529 036 238)

COUNTERSHAFT OIL SEAL PUSHER

(P/N 529 036 222)

Page: 192

CRANKCASE SUPPORT MAG/PTO

(P/N 529 036 031)

Page: 151

CRANKSHAFT LOCKING BOLT

(P/N 529 035 617)

Page: 88, 117, 154

Page: 326, 340

BLIND HOLE BEARING PULLER SET

(P/N 529 036 117)

Page: 199

Page: 166, 173, 179

CLUTCH PULLER

(P/N 529 035 746)

Page: 166

CRANKSHAFT PROTECTOR

(P/N 529 036 034)

Page: 88

CRANKSHAFT TDC POSITION TOOL

(P/N 529 036 201)

Page: 133

1

Page 13

SERVICE TOOLS INDEX

www.MilitaryAtv.com

CRIMPING TOOL (HEAVY GAUGE

WIRE)

(P/N 529 035 730)

Page: 293

CV BOOT CLAMP PLIER

(P/N 529 036 120)

Page: 325, 337

CV JOINT EXTRACTOR

(P/N 529 036 005)

Page: 325, 337

DIGITAL INDUCTION TACHOMETER

(P/N 529 014 500)

DPS COUPLER PULLER

(P/N 529 036 247)

Page: 373

DPS POSITIONING ADAPTOR

(P/N 529 036 248)

Page: 372

DRIVE SHAFT OIL SEAL INSTALLER

(P/N 529 036 028)

ECM ADAPTER TOOL

(P/N 529 036 166)

Page: 188, 247, 259, 261–264, 277,

291, 297, 304, 416

ECM TERMINAL REMOVER 2.25

(P/N 529 036 175)

Page: 291

ECM TERMINAL REMOVER 3.36

(P/N 529 036 174)

Page: 143–144

Page: 244

DISCONNEC

(P/N 529 03

Page: 54

2

TTOOL

5714)

DRIVE SHAFT OIL SEAL PROTECTOR

(P/N 529 036 029)

Page: 142

Page: 291

ENGINE LE

(P/N 529 0

Page: 103

ENGINE LIFTING TOOL

(P/N 529 036 022)

Page: 41

AK DOWN TEST KIT

35 661)

Page 14

SERVICE TOOLS INDEX

www.MilitaryAtv.com

FLUKE 115 MULTIMETER

(P/N 529 035 868)

Page: 86–87, 186, 190, 247, 253, 259,

262–263, 276, 296, 305, 364, 366,

400–404, 406–408

FUEL HOSE ADAPTER

(P/N 529 036 023)

Page: 271

HANDLE

(P/N 420 877 650)

MPI-2 DIAGNOSTIC CABLE

(P/N 710 000 851)

Page: 223

MPI-2 INTERFACE CARD

(P/N 529 036 018)

Page: 223

OETIKER PLI

(P/N 295 000

ERS

070)

OIL SEAL PUSHER

(P/N 529 035 757)

Page: 78

PISTON CIRCLIP INSTALLER

(P/N 529 035 921)

Page: 121

PISTON CIRCLIP INSTALLER

(P/N 529 036 153)

Page: 121

PISTON RING COMPRESSOR

(P/N 529 035 919)

Page: 78, 192

LARGE HOSE PINCHER

(P/N 529 032 500)

Page: 66–67

MAGNETO PULLER

(P/N 529 035 748)

Page: 88

Page: 256, 274, 431

OIL SEAL INSTALLER (GEARBOX)

(P/N 529 035 758)

Page: 192

OIL SEAL INSTALLER

(P/N 529 036 204)

Page: 19

3

Page: 117

PITMAN ARM JIG

(P/N 529 036 225)

Page: 372–373

3

Page 15

SERVICE TOOLS INDEX

www.MilitaryAtv.com

PLAIN BEARING

REMOVER/INSTALLER

(P/N 529 035 917)

Page: 151

PLAIN BEARING

REMOVER/INSTALLER

(P/N 529 036 032)

Page: 146

PRESSURE GAUGE

(P/N 529 035 709)

ROTARY SEAL PUSHER PLATE

(P/N 529 036 130)

Page: 75

SEAL PUSHER

(P/N 529 035 766)

Page: 75, 79

SPANNER SO

(P/N 529 03

CKET

5649)

TDC DIAL INDICATOR

(P/N 414 104 700)

Page: 103

TEST CAP

(P/N 529 035 991)

Page: 20

VACUUM/PRESSURE PUMP

(P/N 529 021 800)

Page: 54, 271

PTO COVE

(P/N 529 0

Page: 145

PULLER/LOCKING TOOL

(P/N 529 036 098)

R OIL SEAL INSTALLER

36 033)

Page: 328, 342

SPRING COMPRESSOR

(P/N 529 036 184)

Page: 383

STEERING

(P/N 529 0

Page: 352

ALIGNMENT TOOL

36 059)

Page: 20, 31, 270, 281

VALVE GUI D

(P/N 529 03

Page: 116

VALVE GUIDE REMOVER 5 MM

(P/N 529 035 924)

Page: 115

E INSTALLER

6140)

Page: 165, 180

4

Page 16

VALVE SPRING COMPRESSOR CUP

www.MilitaryAtv.com

(P/N 529 035 764)

Page: 112

VALVE SPRING COMPRESSOR

(P/N 529 035 724)

Page: 112

SERVICE TOOLS INDEX

5

Loading...

Loading...