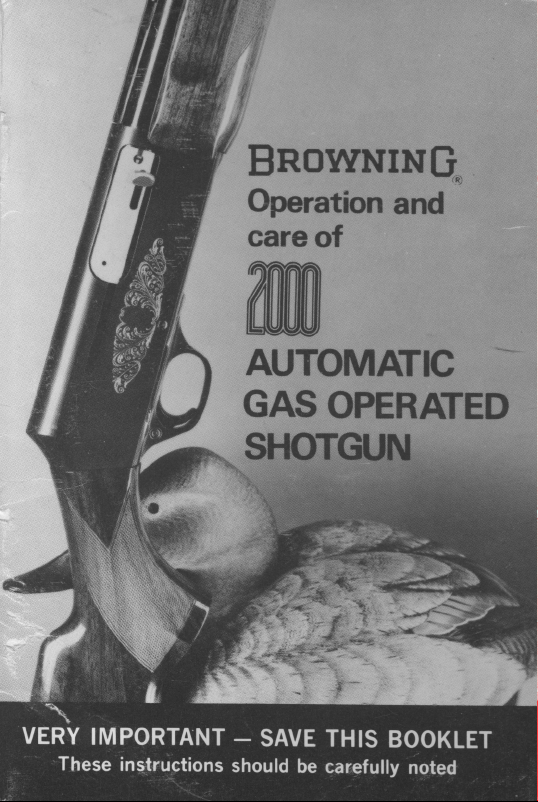

Page 1

Page 2

BROYYNING

R

We are proud that you have chosen a

Browning. In its manufacture we have endeavored to incorporate the very finest in materials

and craftsmanship, and with just reasonable

care this gun should provide you with many

years of pleasure and dependable service. If,

by any chance, you have any observations to

make regarding its performance or appearance,

we hope you will write us immediately.

We would also like to know more about you

as a Browning owner and would be grateful if

you could take but a moment to complete and

return the marketing survey card found on

the inside back cover.

Thank you.

BROWNING

BROWNING

Browning Model.

New Gun Owner’s Record

Keep

this

record for

future

Gauge..

Purchase Price..

Date of Purchase

Please fill out and mail the Marketing Survey

back of the booklet.

BROWNING

Route

#

Distributed

in Canada by:

5350

1, Morgan, Utah 84050

Ferrier

8rowning

Street, Montreal, Que.

Arms Co. of Canada, ltd.

reference

H4P

1L9

Card

at

the

Page 3

GAS OPERATED AUTOMATIC SHOTGUN

NOMENCLATURE

In conventional gun terminology, the position and movement of gun parts are described

as they occur with the gun horizontal, in

normal firing position; i.e., the muzzle is for-

ward or front; butt stock is rearward or rear;

trigger is underneath; the rib is on top.

CAUTION

ALWAYS VISUALLY CHECK

a.

YOUR SHOTGUN

that it does not inadvertently contain

any ammunition. Whenever you pick

up a gun, immediately make sure the

gun is on safe and the chamber and

magazine are unloaded.

ALWAYS KEEP YOUR GUN’S

b.

SAFETY IN THE “ON SAFE”

TION - even if you are certain the

gun is unloaded.

check, frequently while you are hunting. Be sure contact with a twig, a

tumble on slippery terrain, the moment of excitement after a shot, or a

dozen other seemingly innocent incidents have not left

“off safe.”

Never point a gun you are certain

is

“on safe” at anything you do not

intend to shoot. Safe gun handling

does not stop with your gun’s mechanical safety. It starts there. Handle

your gun at all times with deep respect

-

to be certain

Check and double

you

with a gun,

1

POSI-

Page 4

and with alert consideration to all

within its range.

c. ALWAYS KEEP THE MUZZLE OF

YOUR GUN POINTED IN A SAFE

DIRECTION

certain the gun is unloaded and “on

safe.” Never point your gun at anything you do not intend to shoot.

d. ALWAYS UNLOAD YOUR SHOT-

GUN WHEN NOT IN USE

safety precaution it is preferable to

disassemble your gun for storage.

Store your gun and ammunition separately - beyond the reach of children.

e. DO NOT PUT A 20 GAUGE SHELL

IN A 12 GAUGE GUN - if you value

your gun and yourself. We strongly

recommend that all shells of different

gauges be stored in completely separate

NEVER store shells of mixed gauges

in a common container or IN YOUR

POCKETS. EXAMINE EVERY

SHELL YOU PUT IN YOUR GUN.

The most certain way to bulge or rupture the finest barrel is to drop a 20

gauge shell into a

The 20 gauge shell, unfortunately, will

not fall completely through the barrel;

its rim is caught by the FRONT of a

12 gauge chamber. Your gun will misfire, and under conditions of carelessness made lethal by haste, a 12 gauge

shell can be loaded behind the 20.

You could not deliberately have

and well-marked containers.

-

even though you are

-

12

gauge chamber.

2

As a

creat-

Page 5

ed a more serious hazard to your gun

and yourself.

f. BEWARE OF BARREL OBSTRUC-

TIONS

gun and yourself.

Mud, snow and an infinite variety of

other objects may inadvertently lodge

in a barrel bore. It takes only one

small obstruction to ruin (swell or

rupture) the finest of shotgun barrels.

g.

DO NOT SNAP THE HAMMER ON

AN EMPTY CHAMBER

CHAMBER MAY NOT BE EMPTY!

Treat every gun with the respect due

a loaded gun

certain the gun is unloaded.

It is unnecessary to snap the hammer

to prevent weakening of the main

spring. It will not weaken even though

the hammer is left cocked indefinitely.

Neither will snapping the hammer on

an empty chamber damage or break

the firing pin.

AMMUNITION: The gauge and maximum acceptable load are stamped on

the right side of the barrel. Never

use a load that exceeds these specifications.

so long as the cartridge length does

not exceed the length stamped on the

barrel. That is, a 12 gauge shotgun

stamped

inches”

Magnum loads but not 3 inch 12

gauge Magnum loads.

-

for the safety of both your

-

THE

-

even though you are

Magnum shells may be used

“12

gauge shells -2 3/4

may use

2 3/4

inch 12 gauge

3

Page 6

CAUTION: Do not take the measurement of an unfired shell to determine the length. An unfired

2 3/4"

shell,

for example, only measures about 2 1/2".

Most shell boxes are stamped as to

the length of the shells they contain

and some shells are actually individually marked as to their length.

The Browning 2000 must be used only

with the gauge of ammunition stamped

on the barrel. The barrel and action

of this shotgun have been made with

large safety margins over the pressures

developed by established commercial

loads. Nevertheless, Browning can assume no responsibility for incidents

which occur through the use of cartridges of non-standard dimension or

those developing excessive pressures.

GENERAL OPERATION

This shotgun is gas-operated. A portion of

the expanding powder gases is bled off

through gas ports in the barrel and used to

operate the mechanism. During rearward

travel, the bolt extracts and ejects the spent

shell and cocks the hammer. During forward

travel, a new round is fed from the magazine

to the chamber.

This operation is semi-automatic; the

trigger must be released and pulled to fire

each successive shot. After the last shell has

been fired, the breech bolt locks open. This

of course, facilitates speedy reloading.

4

Page 7

MOUNTING THE BARREL TO ACTION

Your Browning 2000 is packaged and

shipped with the forearm attached to the receiver and magazine tube. In order to install

the barrel it is necessary to remove the forearm from the magazine tube and affix the

forearm on the barrel before mounting the

barrel to the action. Follow the

1.

THOROUGHLY CLEAN ALL ANTI-

stens

below:

RUST COMPOUND FROM THE

BARREL,THE BORE AND OTHER

METAL SURFACES. Remove with

any good quality gun oil or gun cleaning solvent.

2.

Unscrew the forearm cap and remove

the forearm from the magazine tube.

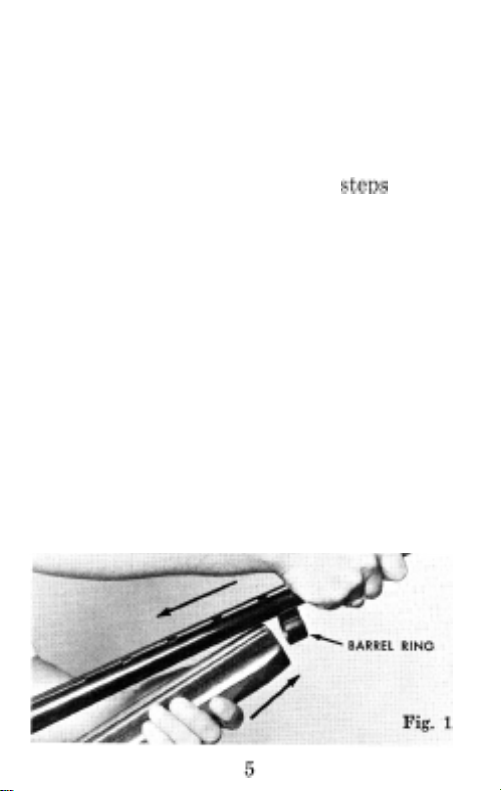

3.

Affix the forearm to the barrel by locating the entire forearm rearward of

the barrel ring and gently sliding the

forearm forward until the barrel ring is

seated against the rubber forearm bush-

ing (Figure 1). Do not force the rearward end of the forearm upward around

the barrel as this could split the fore-

arm.

Page 8

Draw the breech bolt rearward so that

4.

it remains locked back. Be sure the

safety is “on safe”.

5.

Grasp the butt stock by the pistol grip

and anchor the butt end on your hip.

With your other hand grasp the forearm and barrel and after a final glance

through the bore to be sure there is no

barrel obstruction, carefully work the

forearm down the magazine tube and

introduce the barrel extension into the

receiver (Figure 2).

6

Page 9

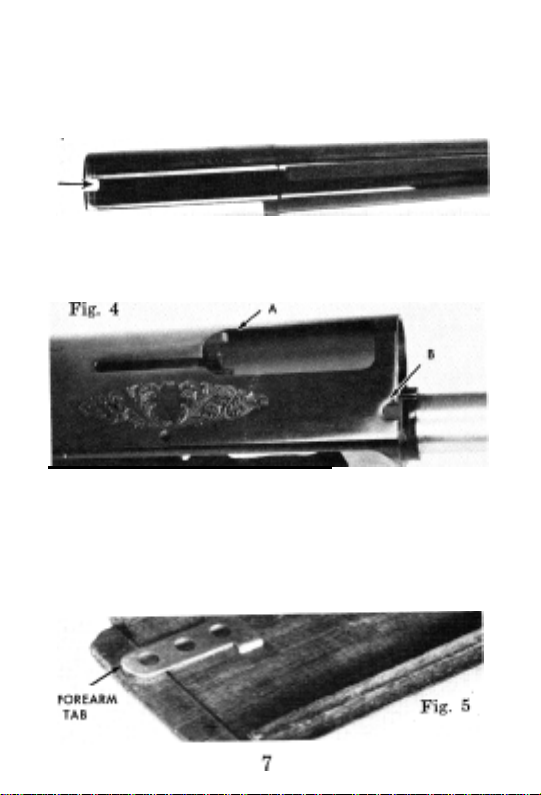

6. As the barrel and forearm are seated

into final position, be certain the

shaped cut in the barrel extension

(Figure 3) mates fully against the

Fig. 3

barrel guide in the upper inside of the

receiver (Point A, Figure 4). Also

check that the metal forearm tabs in

the rearward end of the forearm (Figure 5) slide into the opposing receiver

recesses (Point B, Figure 4).

7. Screw the forearm cap onto the magazine tube. HAND TIGHTEN ONLY.

U-

Page 10

Never apply a wrench or any kind of

severe force.

Removing the barrel is simply done by

reversing the above procedure. If you

prefer to store your gun with the ac-

tion and barrel separated, it is suggested that the forearm be attached to the

magazine tube and receiver. This secures your forearm and prevents it

from possible damage.

CLOSING THE BREECH

Do not press the carrier latch and let the

breech bolt ride home under its own force, unless the bolt is actually feeding a round into

the chamber. It is always advisable, whenever

the bolt is being closed on an empty chamber

or being closed after the barrel has been removed from the action, to hook your thumb

or finger around the bolt operating handle and

let the bolt ease forward.

The cross bolt safety blocks the trigger

CROSS-BOLT SAFETY

from operating.

In the “off safe” or “fire”

position a red warning band is visible, on the

left side of the trigger guard_, alerting the

shooter of the gun’s ready-to-fire status.

To accommodate left hand shooters, this

safety can be reversed by a gunsmith in a

matter of minutes. When reversed, of course,

the red warning band will then appear on the

8

Page 11

right side of the trigger guard. Unlike many

other guns with cross bolt safeties, no extra

parts are necessary for this conversion.

LOADING

BE SURE THE MUZZLE IS POINTED

SAFE

IN A

DIRECTION, AND THE

SAFETY I§ “ON SAFE.”

The Browning

2000

is equipped with the

speed loading system Browning Automatic

shotguns are famous for. It is not necessary

to jiggle the first round into the chamber and

then trip the carrier latch (bolt release) to

ready the first round for firing. Nor is it necessary to insert a round into the magazine and

then cycle the bolt to chamber the first round

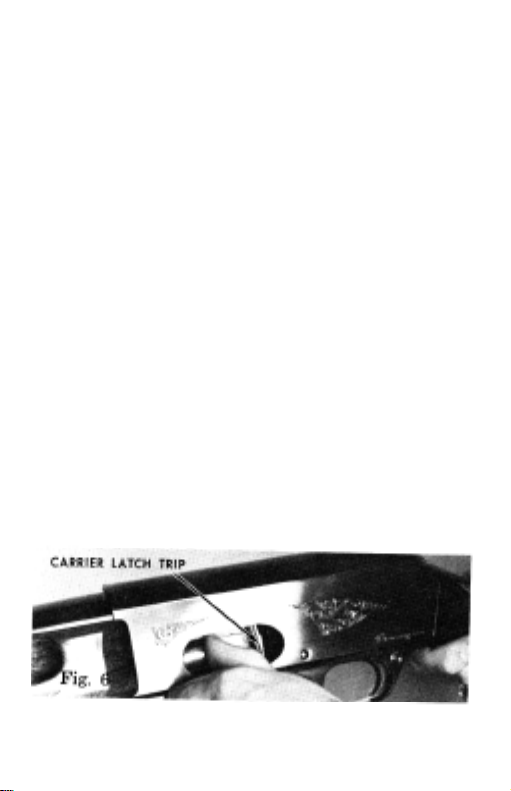

After being sure the breech bolt is locked

open,

all

you do is thumb the first round into

the loading port on the left side of the receiver.. Push this first round forward so that

the brass head of the shell is about an

inch forward of the carrier latch trip (Figure

6).

Release the shell by withdrawing your

thumb completely out of the loading port and

letting the shell slam rearward against the

carrier latch trip.

Instantly this round will

be whisked into the chamber ready for firing!

9

Page 12

(Remember to keep your fingers away from

the ejection port on the opposite side of the

receiver. The bolt drives forward with force

during the loading of this first round.)

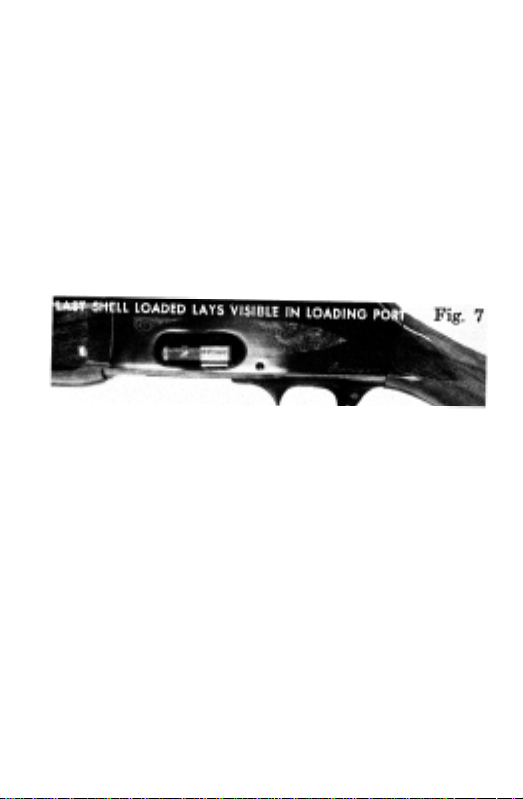

The second, third and fourth shells to be

loaded are then thumbed completely into the

magazine. You will not be able to insert the

fifth shell you load completely into the magazine. This fifth shell (the second shell in lineup for firing) is inserted so that it lays in the

loading port with the crimped end protruding

only partly into the magazine (Figure 7). Be

certain that this shell lays straight and is en-

tirely within the loading port. It is held firmly in this position and will not fall out or

rattle.

This is also true when

-

the third (last) shell to be loaded (second

the

plug is installed

in firing sequence) lays visible in the loading

port.

The shell

SWITCH LOADS FAST

which lays visible in the loading

port can be quickly removed, if you want to

switch loads in a hurry. Suppose your 2000 is

loaded with duck loads and geese decide to veer

your way. Simply pluck the visible shell from

the loading port and insert a goose load. Cycle

the bolt. Your chambered duck load will eject,

and the goose load will be chambered.

10

Page 13

FIRING

Once loaded, all that is necessary to fire

the gun, of course, is to push the safety to the

“fire” position and pull the trigger. The first

shell will fire and be ejected. The second will

automatically be chambered. The trigger must

be released and pulled to fire each successive shot.

THE BREECH REMAINS OPEN after the last

shot has been fired. This allows you to reload

quickly, if you desire to.

BREAKING IN WITH LIGHT LOADS

If the initial shooting of your 12 ga.

B-2000 is done with trap, skeet or light field

loads, you may experience a few malfunctions

in the first box or two of shells. After this

short break-in period your B-2000 will operate well with light or heavy loads.

UNLOADING

As well as speed loading, the Browning

2000 features speed unloading. Before unloading, BE SURE THE SAFETY IS “ON

SAFE” AND THE MUZZLE IS POINTED

IN A SAFE DIRECTION.

The shells in the loading port and maga-

zine are unloaded first. Simply ease the shell

Page 14

in the loading port outward with your thumb

until you can remove it. To remove the shells

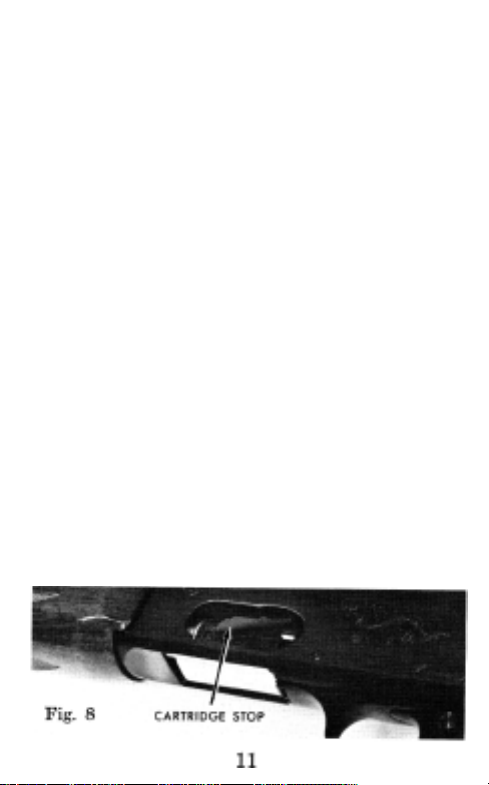

in the magazine depress the cartridge stop.

The cartridge stop (Figure 8) projects from

the bottom of the bolt slide. With the cartridge stop depressed let each shell ride rearward and out of the loading port. In this manner you can remove all the shells except the

one in the chamber. This shell is removed by

drawing the breech bolt rearward and catching the shell as it ejects.

MAGAZINE PLUG

A magazine plug, restricting the Browning

2000’s capacity to 3 shots, is furnished with

each gun.

TO INSTALL THE PLUG first remove the trig-

ger group (see pages 23 and 24). Merely push

the solid end of the magazine plug through

the opening in the follower until the plug is

MAGAZINE FOLLOWER

Page 15

completely within the magazine (Figure 9).

Important: Be certain that the split end of

the magazine plug is rearward.

TO REMOVE THE PLUG

first remove the trigger group (see pages 23 and 24). Then take an

empty shotshell and place the mouth of the

shell against the magazine follower (Figure 10).

Thumb this empty shell far enough into

the magazine to place a second empty shell

behind the first. Then press the second empty

shell into the magazine (Figure

11).

Some

pressure with the thumb will be required,

since it causes the split rearward end of the

magazine plug to compress and emerge

through the hole in the magazine follower and

into the inside of the first empty shell. Ease

the shells rearward and out of the magazine.

You will now see the plug protruding from

the follower. Simply pull the plug from the

magazine follower (Figure 9). Now reinstall

the trigger group.

CAPACITY

With the plug removed your 2000 has a

capacity of five

2 3/4"

shells. When it is set up

to fire 3" magnum shells with a 3" magnum

barrel, the capacity is four 3" shells.

13

Page 16

With the plug installed the capacity is

-

reduced to three shells

is set up to fire

2 3/4"

shells only or 3” magnum

whether the 2000

shells.

INTERNAL GAS SYSTEM

The Browning 2000 has a uniquely de-

signed, extremely reliable gas system.

It is

compactly contained within the magazine

tube. This makes it less accessible to dirt and

allows a slim forearm design.

The gas is sealed off so that it cannot

blow rearward into the forearm, along the

action bar assembly and toward the action

The gas is vented forward through the hole

in the forearm cap.

How often should you strip down the gas

system and clean it? There is no rule of

thumb. It depends somewhat on the type of

ammunition you use and how heavily you

shoot your gun. Hunters will probably want to

clean the system at the season’s end. Trap

and skeet shooters will perhaps want to clean

it more

frequently

It’s a matter of shooting

conditions and judgment.

DISMANTLING AND CLEANING THE

GAS SYSTEM

Dismantling the gas system is very simple.

Make sure the safety is on and draw the

breech bolt rearward until it locks open. Unscrew the forearm cap and remove the barrel

and forearm.

You will notice the gas piston bar

project-

14

Page 17

ing from each side of the magazine tube (Figure 12). Remove this simply by pushing it

b8Sx:9 _<”

from one side and withdrawing it from the

other (Figure 13). As you do this hold your

ARE UNDER

RETAIN THEM AS Y

WITHDRAW GAS

SPRING

Pi

finger or thumb against the gas cylinder plug

which protrudes slightly from the forward end

of the magazine tube (Figure

13).

This is

necessary because the gas system is under

spring tension.

Now ease the gas system components forward out of the magazine tube. Carefully

note the sequence of parts as you withdraw

them from the magazine tube (Figure

(Continued on page 20)

15

14).

Page 18

BROYYNING

Automatic 2000

Gas

Operated Shotgun

NOTE:

This page contains the sche-

matic for the 12 gauge B-2000. For

. . .

corresponding 20 gauge

part numbers refer to

the parts

the

@-I2394

following

list

on

page.

lMP0RTANT:

list code number, part name, gauge,

model and serial number.

When ordering parts,

16

123&

Page 19

Part #

12001

12005

l 12010

12012

12014

*12024

* 12025

*12028

*12034

*12036

12040

12042

12046

12047

12049

12052

12054

12056

12058

12060

*

12068

*

12070

12075

12079

12080

12081

12085

12087

12090

12092

12095

12098

12101

12105

12113

12113

12115

12118

12122

12124

PARTS LIST

12

AND 20 GAUGE GAS OPERATED SHOTGUN

B-2000

DESCRIPTION

8ar

Action

Action 8ar

Action Bar Right (4),

Action Spring 12 ga.

Action Spring 20 ga.

8arrel

8arrel

8arrel

8olt12ga.

8olt

Bolt Slide 12

Bolt Slide 20

8utt Plate 12 ga.

Butt Plate

8utt Stock, Trap 12 ga.

8utt

8utt Stock, Field 20 ga.

Butt Stock, Skeet 20

Carrier 12

Carrier 20 ga.

Carrier Cartridge Limit Pin

Carrier Cartridge Pin 12

Carrier Cartridge Pin 20 ga.

Carrier Cartridge Spring 12,

Carrier Cartridge Stop

Carrier Cartridge

Carrier Dog 12 ga.

Carrier Dog 20 ga.

Carrier Dog Pin 12, 20 ga.

Carrier Dog Spring 12,

Carrier Dog Spring Guide 12,

Carrier Latch 12 ga.

Carrier Latch Pin 12 ga.

Carrier Latch Pin.20 ga.

Carrier Latch Spring

Carrier Latch Spring Plunger

Carrier Latch Trip 12 ga.

Left 12, 20 ga.

Right 12, 20

12,

Ring 12 ga.

Ring 20

ga.

Guide 12, 20 ga.

20 ga.

ga.

Butt Plate 20

Butt Stock, Field 12 ga.

12, 20 ga.

20 ga.

12 ga.

20 ga.

20 ga.

Carrier Latch 20 ga.

12, 20 ga.

Carrier Latch Trip 20 ga.

ga.

ga.

Screw 12, 20ga.

Stock, Skeet 12 ga.

ga.

ga.

Stop

12,

ga.

ga.

PART

12128 Carrier Latch Trip Pin 12 ga.

12130 Carrier Latch Trip Pin 20 ga.

12132 Carrier Pin 12, 20 ga.

12136 Carrier

12138

12142 Carrier Release Pin 12,

12146 Carrier Spring 12, 20 ga.

12150 Cartridge Stop 12, 20 ga.

12156 Cartridge Stop Pin 12,

12159 Cartridge Stop Spring 12,

*12162

12168 Disconnector

12171

12173 Disconnector Spring Plunger

12186

12190

12198 Firing Pin Bushing Pin 12,

12202 Firing Pin Spring 12, 20 ga.

12206

12208

12212

12214

12216

12220 Forearm Bushing Washer

12222

12223

12224 Forearm Cap 20 ga.

12225 Forearm Cap

12227 Forearm Cap Buffer 12 ga.

12229

12232 Forearm Cap Plunger 12,

DESCRIPTION

#

Release 12

Carrier Release 20 ga.

20 ga.

20 ga.

20 ga.

Disconnector

Disconnector

20 ga.

12. 20

12176

12231

ga.

Extractor

Extractor

Extractor Spring Plunger 12,

ga.

Firing

20 ga.

Forearm,

Field 12 ga.

Forearm, Semi Beavertail

12 ga.

Forearm, Field 20 ga.

Forearm, Semi Beavertail

20 ga.

Forearm Bushing 12 ga.

Forearm Bushing 20 ga.

20 ga. only

Forearm Cap 12

Forearm Cap w/Eyelet

12

ga.

20 ga.

Forearm Cap Buffer 20 ga.

Forearm Cap Buffer Washer

20 onlyga.

20 ga.

18

ga.

12, 20 ga.

Pin 12, 20 ga.

Spring 12,

12,20 ga.

Spring

12, 20 ga.

12, ga. 12,

ga.

w/Eyelet

20

ga.

Page 20

ga.

ga.

PART

12358

12360

12362

12366

12370

12374

*l2378

*l2384

12394

12396

12398

12402

12406

12408

*12415

*12417

12420

12421

12422

12424

12428

*12432

*12434

12438

12442

12445

12452

12453

12454

12458

12462

12464

PART #

12237

*12240

*12242 Forearm Liner 20 ga.

*12246

*12248

12252 Gas Cylinder Plug 12 ga.

12254 Gas Cylinder Plug 20 ga.

12262 Gas Piston 12 ga.

12264 Gas Piston 20 ga.

12268 Gas Piston Bar 12 ga.

12270 Gas Piston Bar 20 ga.

12272 Gas Piston Bar Guide 12

12274 Gas Piston Bar Guide 20

12276 Gas Piston Buffer 12 ga.

12278 Gas Piston Buffer 20

12282

12284

12287

12289

*12292

* 12294

12298

12299

12302

12304

123O8

12310

12312

12315

12318 Magazine Base 20 ga.

12320 Magazine Base Pin 12 ga.

12322 Magazine Base Pin 20 ga.

12324 Magazine Follower 12 ga.

12326 Magazine Follower 20 ga.

12330 Maaazine

12332 Magazine Spring 20

*12336

*12338

12342 Ma&spring-Right or Left

12348 Mainspring Guide-Right or

12352 Mainspring

12354

12356 Mainspring Pin-Trigger

In

part.

In

May

*Indicates part must be fitted by our Service Department or Qualified Gunsmith.

DESCRIPTION

Forearm Cap Plunger

Spring

12,20

Forearm Liner 12 ga.

Forearm Tabs 12 ga.

Forearm Tabs 20 ga.

Gas Piston Spring 12

Gas Piston Spring 20 ga.

Gas Piston Valve 12

Gas Piston Valve 20 ga.

Hammer 12 ga.

Hammer 20 ga.

Hammer Pin 12 ga.

Hammer Pin 20 ga.

Inertia Piece 12

Inertia Piece 20 ga.

Locking Block 12 ga.

Locking Block 20 ga.

Magazine Adaptor Three

Shot 12, 20

Magazine Base

Magazine Tube 12 ga.

Maaazine Tube 20

12, 20 ga.

Left 12. 20

12 ga.

Mainspring

Guard 12 ga.

‘1977 production, these two parts will be combined to form one integral

1977 production, forearm tabs will be part of one integral piece.

be purchased only by holder of valid Federal Firearms license.

ga.

ga.

ga.

ga.

ga.

ga.

12 ga.

Spring

12

ga.

ga.

ga.

ga.

Pin-Hammer

Pin-Hammer

DESCRIPTION

#

Mainspring Pin-Trigger

Guard 20 ga.

Operating Handle 12 ga.

Operating Handle 20 ga.

Operating Handle Retainer

Pin 12,

20

Operating Handle Retainer

Pin 12, 20 ga.

Operating Handle Retainer

Spring 12, 20 ga.

Receiver

Receiver 12 ga. Field Type 2

Receiver Assembly 12 ga.

Trap

Receiver

Receiver 20 ga. Field Type 2

Receiver

Receiver Buffer 12 ga.

Receiver Buffer 20 ga.

Safety Crossbolt 12, 20 ga.

Safety Spring 12, 20 ga.

Safety Spring Plunger 12,

20 ga.

Safety Spring Retaining

Pin

Sear 12

Sear 20 ga.

Sear Pin 12, 20 ga.

Sight Base Front 12, 20 ga.

Sight Bead Front 12, 20 ga.

Stock Bolt 12, 20 ga.

Stock Bolt Washer 12, 20 ga.

Trigger 12 ga.

Trigger 20 ga.

Trigger Pin 12, 20 ga.

Trigger Guard 12 ga.

Trigger Guard 20 ga.

Trigger Guard Retaining Pin

12 ga.

Trigger Guard Retaining Pin

20 ga.

Trigger Guard Retaining Pin

Bushing 12, 20 ga.

Trigger Guard Retaining Pin

Spring 12, 20 ga.

Trigger Guard Shield 12 ga.

Trigger Guard Shield 20 ga.

ga.

Assembly 12 ga.

&

Skeet

Assembly 20 ga.

Assembly 20 ga.

12,

20

ga.

ga.

19

Page 21

CAUTION: Do not trip the carrier latch

and let the bolt fly home when the gas piston

bar is removed. The operating handle of the

bolt will slam into the front of the receiver

and damage it. If you wish to close the bolt

at this time, make sure you hold onto the

operating handle and let the bolt very slowly

ride forward until the operating handle rests

against the forward edge of the ejection port.

You are now ready to wipe out the maga-

zine tube and clean the components. The gas

piston and gas cylinder plug are bronze. If

you decide to scrub these components with a

brush, be sure you use a typical brass bore

cleaning

type brush and not a steel brush or

any other type that will scratch these components.

Use a good quality powder solvent, such as

Browning Liquid Gunsmith, to clean the gas

system components. Do not use gun oil. This

will collect foreign matter. Keep these components clean and dry.

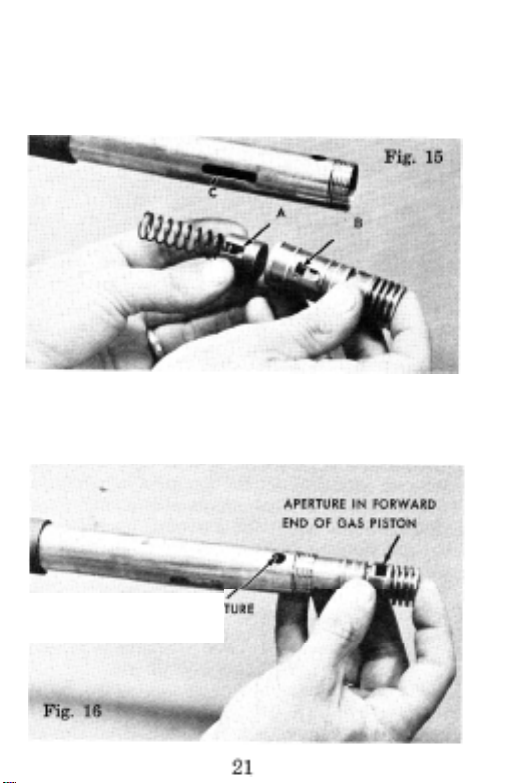

Reassemble the gas system components in

the exact order as you removed them. Pay

20

Page 22

particular attention to lining up the slot in

15)

the gas piston bar guide (A, Figure

the holes in the gas piston

the magazine tube

(C,

(B,

Figure

Figure 15) so that you

with

15)

and

can easily insert the gas piston bar. Be cer-

tain that the slot in the gas piston bar guide

(A, Figure 15) is rearward. This is critical

for proper functioning. Also be certain that

the aperture in the forward end of the gas

GAS ENTRANCE

IN MAGAZINE TUBE

APER

Page 23

piston is located upward and in alignment

with the gas entrance aperture in the top of

the magazine tube (Figure

that you install the gas piston with this aper-

ture upward, the slot C in the magazine tube

and the slots A

gas piston bar guide are machined off center

If after installing the gas system in the magazine tube, you cannot easily install the gas

piston bar, you have not assembled the components properly. Remove them and be certain the aperture is located upward.

&

B

i

n

16). To insure

the gas piston and

Never

under any circumstances tap the gas piston

bar with a hammer or other object. If you

cannot insert the bar with your fingers, you

are not assembling the gas system correctly

Also during assembly be sure the concave

surface of the gas cylinder plug bears against

the gas piston.

(Of Interest: During disassembly of the

gas system you will have noticed the white gas

piston buffer. Buffers are also located in the

forearm cap and in the rearward portion of

the receiver. These act as shock absorbers

greatly cushioning the forceful operation

the gas system and the energy it imparts to

the bolt. They help to soften recoil, making

your 2000 very pleasant to shoot.)

TO SHOOT 3" MAGNUMS

If the barrel of your Browning 2000 is

chambered for 2 3/4" shells, all you need to

shoot 3” magnum

chambered for 3” shells. You do

loads is an extra barrel

not need to

of

purchase a different action nor alter the gas

22

Page 24

system

barrels

2 3/4"

barrels

installed

reliably

no harm can come from shooting

num Ioads

barrel,

mechanism built into the

of the 3"

ridges

tion with the

shooter

the

num

in any way. The gas ports in the

differ, so that you can interchange

chambered barrels and 3" chambered

on the same action

NOTE:

ejector

With the 3

the B-2000

with 3

inch

in the 3 inch chambered

it is not advised since the ejector

barrel

to

specifically

is

not

totally dependabIe

shorter cartridges.

not

mind an

port with the shorter

shells

he indeed may

*

inch

Magnum

is

designed to function

Magnum

barrel

shells While

2 3 /4"

Magnum

extension

eject 3" cart-

upon ejec-

Should

occasional

hang up

2 3/4"

also use them if

barrel

Mag

Mag_

the

in

desired.

DISASSEMBLY OF THE

PeriodicalIy

disassemble

thorough

pletely

stripped down without any

YOU may wish to

your Browning

cleaning

Your

ACTION

2000 for a

2000

can be

completely

com-

tools ex-

ceptmg a drive punch or any similar object

which

wiII

enable you to remove the

guard

retaining pin.

Be sure

your gun is

1. Remove the b

Follow

unloaded

arrel

the

and on safe.

and forearm and

trigger

steps below:

dismantle the gas system as described

on page 17.

2. Hold

onto the

trip

the

carrier latch and

the

bolt

forward

handle rests

bolt

operating

handle

softly

unti1

the operating

against the forward

ease

part

23

Page 25

of the receiver. DO NOT LET THE

BOLT SLAM FORWARD.

3. Remove the trigger guard retaining

pin (Figure 17).

Fig. 17

TRIGGER GUARD RETAINING PIN

4. Draw the bolt rearward about

inches (Figure 18).

CARRIER LATCH

24

1 1/2

Page 26

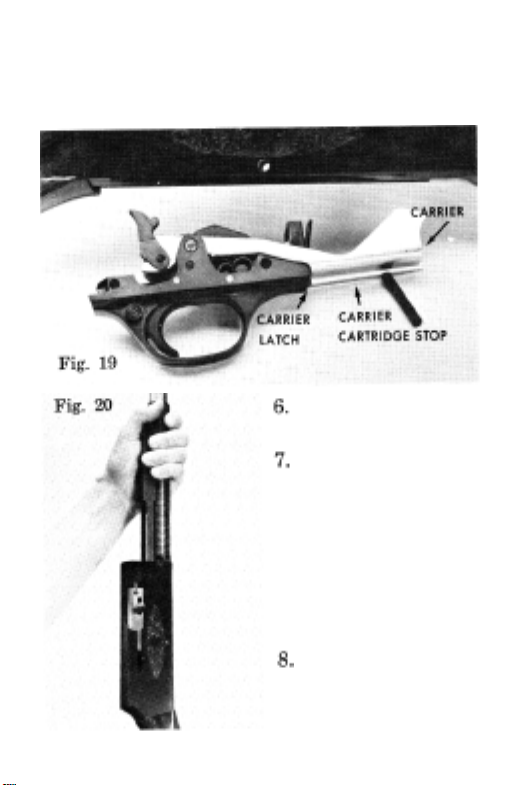

5. With your other hand trip the carrier

latch, grasp the trigger guard (Figure

18)

and remove by forcing it

slightly

forward before attempting to lift it out

of the receiver (Figure 19).

Ease the bolt forward again.

With

the butt

stock resting firmly

on a workbench or

table, grasp the

action bar assembly and compress

the action spring

several inches

(Figure 20).

Remove the bolt

operating handle

with your other

hand. Firm finger

25

Page 27

pressure removes it easily (Figure 21).

To remove the bolt

9.

and bolt slide ease

the action bar assembly forward off

the magazine tube

while depressing

the cartridge stop

with your finger

(Figure 22). The

cartridge stop pro-

jects from the bottom of the bolt

slide. Particularly

notice how the

double action bars

separate from the

bolt. This will help

you during reas-

sembly later.

26

Page 28

You can now easily clean all of these com-

ponents as well as the inside of the receiver.

(See Figure 23.) Again a good solvent is

BOLT

SLIDE

CARTRIDGE STOP

ACTION SPRING

recommended. Further disassembly of the

trigger group is not recommended.

NOTE: Do not apply large quantities

of oil to the trigger group or other areas of

the action. Excessive oil is not necessary and

serves to collect dust and minute particles of

dirt. Excessive oil could also soak into the

stock; softening the walnut and loosening the

stock. Only a very, very light film of fine

quality gun oil is needed to protect these

working parts.

REASSEMBLY OF THE ACTION

Follow the steps below:

1. Slide the action spring onto the magazine tube, compress the action spring

and start the action bar assembly onto

the magazine tube. Grasp the action

bar assembly keeping the spring

slightly compressed.

2. Assemble the bolt and bolt slide and

align the action bars in their respective

27

Page 29

recesses in the bolt slide. This is done

just forward of the receiver before the

bolt is completely inserted into the

receiver.

Notice that the left (loading port side)

action bar enters from the top of the bolt

slide (Figure 24) while the right action bar

LEFT

ACTION

BOLT SLIDE FROM TOP

BAR

ENTERS

attaches from the bottom (Figure 25). It is

RIGHT ACTION

BAR ENTERS

BOLT SLIDE

FROM BOTTOM

28

Fig. 25

Page 30

easiest to cant the bolt assembly to the left

and attach the left action bar first, then

rotate the bolt assembly to the right and

downward until the right action bar is en-

gaged.

3. Keeping the action bars located in the

bolt slide with your fingers (Figure

26) carefully orient the bolt assembly

in the appropriate receiver channels

and push rearward on the action bar

assembly until the bolt assembly slides

into the receiver.

Fig.

26

4. Insert the bolt operating handle and

gradually release pressure on the action bar assembly.

5. Draw the bolt partially rearward and

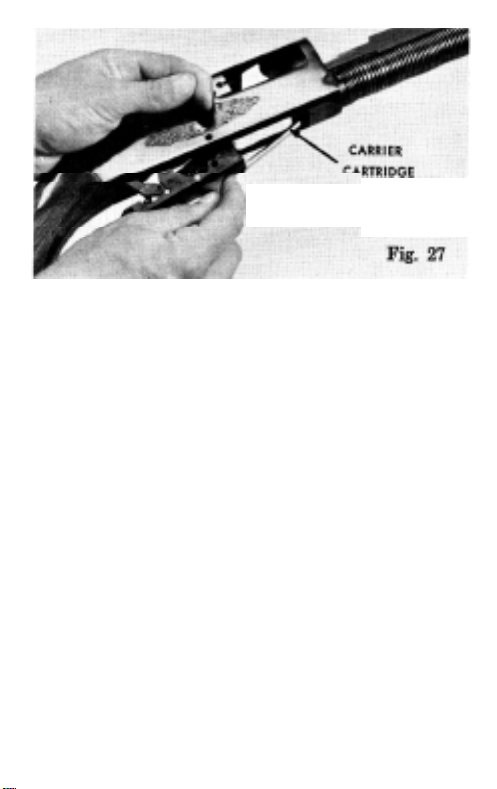

insert the trigger group (Figure 27).

Replace the trigger guard retaining pin.

CAUTION: While inserting the trigger

group be careful not to scratch the undersurface of the receiver with the carrier cartridge

29

Page 31

STOP

stop. (This is the long, slender,

unblued

piece

of metal which lies alongside the carrier; see

Figure 27.) If you will tip the trigger group

so that you introduce the carrier and the carrier cartridge stop into the receiver first, you

can easily avoid scratching the receiver.

6. Lock the bolt open.

7. Replace the gas system (see pages

19

and 20) and install barrel and forearm.

TWO OR MORE: GUNS IN ONE

BY USE OF EXTRA BARRELS

Use the same gun for multiple shooting

conditions merely by changing from one barrel to another of different choke, length and

rib. Barrels of the same gauge are completely

interchangeable, and no special fitting or

altering of the gas system is required. Thus,

by merely buying another barrel, you have

the utility of another gun at a fraction of

the cost of a new gun

. . .

a duck gun be-

comes a skeet gun or a fine upland gun by

the mere addition of an extra barrel.

30

Page 32

NOTE: As pointed out earlier, you do

not need a complete separate gun to shoot 3”

magnums. An extra 3” magnum barrel is

all

that is needed. Simply interchange barrels.

Altering the gas system is unnecessary. See

page 22.

NOTE: With the 3 inch Magnum barrel

installed the B-2000 is designed to function

reliably with 3 inch Magnum shells. While

no harm can come from shooting 2 3/4"

Magnum loads in the 3 inch chambered Magnum

barrel, it is not advised since the ejector

mechanism built into the barrel extension of

the 3” barrel to specifically eject 3” cart-

ridges is not totally dependable upon ejection

with the shorter cartridges. Should the

shooter not mind an occasional hang up in

the ejection port with the shorter 2 3/4" Magnum shells he indeed may also use them if

desired.

Please see your Browning dealer for

barrel specifications available.

CLEANING SUGGESTIONS

The correct procedure for cleaning your

shotgun is as follows:

BE CERTAIN YOUR SHOTGUN IS UNLOADED

1. Dismount barrel so that it can be

cleaned from the breech end.

2.

Using a shotgun rod with tip and patch

large enough for snug fit in bore, insert rod and patch in breech end of

barrel and run back and forth through

bore several times.

31

Page 33

3.

Inspect bore from both ends for leading

by looking through bore toward light.

Leading will appear as dull longitudinal

streaks and is usually more predominant in the constriction area of the

choke and just forward of the chamber.

4. Leading is minimal with today’s modern loads. If or when leading should

become heavy, it can be removed with

a brass bore brush. Use a good powder

solvent such as Browning Liquid Gunsmith and scrub bore until leading is

removed. To prevent brass bristles

from breaking off, the brush should be

pushed completely through bore before

being withdrawn.

5. After leading has been removed, the

bore should be wiped dry and then a

slightly oiled patch run through it for

preservation.

6. If the gun has been exposed to much

dust, dirt, mud or water, the action

and gas system should be stripped

down and cleaned as outlined in this

booklet.

7. Reassemble barrel and wipe all expos-

ed metal surfaces with an oiled cloth

making sure to wipe gun clean of all

finger marks where moisture will accumulate.

6. The wood surfaces can also be wiped

with Browning Gun Oil or they can be

polished with any quality furniture

wax.

32

Page 34

SERIAL NUMBER: The serial number

of your Browning 2000 Shotgun is found on

the underside of the receiver, just forward

of the carrier.

CHOKE MARKING

The choke of your barrel is indicated by a

clearly defined mark stamped on the right

hand side of the barrel. The code for the

choke markings is as follows:

*

Full

Improved Cylinder

Improved Modified *_ Skeet

Modified

If your shotgun should require service or repairs

we suggest you first contact a local authorized

Browning Firearms Service Center. Your Browning

Sporting Goods dealer can tell you the address of

the Service Center nearest you or you may call or

write our Consumer Information Dept. in Morgan,

Utah

-

(801)

876-2711.

Otherwise you may return your shotgun to our

own repair facility for servicing. The address is:

Browning Service Department

Route 4, Box

Arnold, Missouri 63010 (3 14) 287-6800

When returning your shotgun for servicing,

please be sure to package it securely in a cardboard

container. Send a letter to our Service Department

clearly describing the trouble experienced and the

repairs or alterations desired. If convenient, also

enclose a copy

760810

* *

Cylinder

SERVICE OR REPAIR

624-B Tenbrook

of

your letter with the gun.

Road

33

**_

**S

***

Printed in U.S.A.

Page 35

OTHER BROWNING PRODUCTS

ARCHERY EQUIPMENT-Superb-

ly engineered and crafted Browning

Bows are available in hunting, target

and all-purpose models to please

perts

and beginners

pound, take-down and standard

curves. Matched with Browning

rows and Shooting Accessories, for

top performance.

BROWNING SPORTING ARMS

World famous for handcrafted qual-

ity

and

lifetime dependability. Browning Sporting Arms include a complete

line of shotguns, high power rifles,

.22

caliber rifles and pistols in high

power and small bore calibers.

SPORTSMAN’S KNIVES -

have knives to dress big game, clean

fish,

and handle any

Folding Knives, Pocket Knives and

even a Fillet Knife with a fine cork

handle to keep it afloat. All Browning

knives are crafted from specially heat

treated High Carbon Stainless Steel

alike.

camp

ex-

Com-

re-

Ar-

we

chore.

BROWNING SPORTSMAN’S

BOOTS

terrain, plus hunting

clothing tailored for comfort, utility

and style. Also, hats, shooting gloves

an

gear with the

from Prime Northern Duck and Goose

Down, or

bags

8 CLOTHING -Rugged

boots

for

every kind of weather and

d

leather belts.

GHTWEIGHT

EAR

and 2 &

CAMPING

-

Quality crafted lightweight

camper

Dacron®

insulated sleeping

3-man

and

shooting

in mind. Choose

rugged, light-

Loading...

Loading...