Brother VX 511, VX 541, VX 561, VX 661 Service Manual

CONTENTS

page

.

HOW TO USE THIS MANUAL

A

.

B TROUBLE AND CHECK POINTS 3

.

Skipping stitches

1

.

Material not feeding

2

3 . Breaking needle

.

4 Heavy running

5 . Machine noise

6

.

Needle sewing over the maximum width

.

Uneaven seems of back and forth at manual

7

.

Improper position of needle drop slot at

8

the max

9 . Needle swing in straight stitch sewing

.

Feeding at bar tack sewing of buttonhole

10

11 . Not smooth working of pattern selecting dial

12 . Imperfect automatic patterns

.

Uneven seams of reverse patterns

13

.

Breaking of upper thread

14

15

.

Breaking of lower thread

.

How to assemble the parts correctly

16

.

HOW TO ADJUST THE ELEMENTS

C

1-1 . Height of presser bar 8

1-2 . Height of presser bar 8

2 . Height of needle bar 8

.

3-1 Clearance between needle and hook point 9

.

3-2 Clearance between needle and hook point 9

4-1 . Position of shuttle hook 10

.

4-2 Position of shuttle hook 10

.

51 Clearance between shuttle driver shaft and race way 11

.

52 Clearance between shuttle driver shaft and race way 11

.

6-1 Position of vertical feed cam 12

6-2 . Position of vertical feed cam 1 2

7.1 . Heightoffeeddog

7-2 . Height of feed dog 13

.

8 Forth seam 14

9-1 . Back and forth seam 14

9.2 . Back and forth seam 14

.

stitch width

...........................

.........................

............................

............................

.............................

.........................

..........................

..........................

...............................

....................

..................

...........

.........

........................

.............

...........

........

...................

................

.....................

......................

..............

........................

........................

..........

..........

......................

......................

....

....

...................

...................

13

........................

........................

10.1

Back and forth seam at automatic reverse patterns

2

3

3

3

4

4

4

4

5

5

5

5

5

6

6

6

7

.

.

Back and forth seam at automatic reverse patterns

10.2

.

Adjustment of button hole seams

11

.

Needle swing in straight stitch sewing

12.1

12.2 . Needle swing in straight stitch sewing

12.3 . Needle swing in straight stitch sewing

.

13.1 Centering of the needle

.

13.2 Centering of the needle

.

14 Position of feed cam

.

15.1 Setting of maximum stitch width

15.2 Setting of maximum stitch width

.

.

15.3 Setting of maximum stitch width

.

16.1 Position of the maximum needle swing

.

16.2 Position of the maximum needle swing

. ............

Position of the maximum needle swing

16.3

17.1 . Contact of upper shaft gear, pattern cam and feed cam

17.2 . Contact of upper shaft gear, pattern cam and feed cam

17.3 . Contact of upper shaft gear, pattern cam and feed cam

18.1 Sewing timing of the needle

.

.

Sewing timing of the needle

18.2

18.3 . Sewing timing of the needle

19.1A . Clearance between cam finger and pattern cam

19-1 B . Clearance between cam finger and feed cam

20.1A . Position of cam finger for pattern cam

20-1 B . Position of cam finger for feed cam

21.1 . Setting of upper thread tension dial

21.2 . Setting of upper thread tension dial

22 . Adjustment of feed dog movement at buttonhole sewing

.

23.1 Setting of pattern dial

.

23.2 Setting of pattern dial

24.1 . How to take off stitch width, stitch length dial

and arm panel

24.2 . How to take off stitch width, stitch length dial

and arm panel

24.3 . How to take off stitch width, stitch length dial

and arm panel

.

Adjusting of the drive belts

25.1

25.2 . Adjusting of the drive belts

25.3 . Adjusting of the drive belts

.............................

............................

.......................

.......................

........................

.......................

.......................

............................

.....

.....

................

.............

.............

.............

................

................

................

............

............

. .

. .

. .

....................

....................

....................

.......

.........

.............

...............

..............

..............

....................

....................

....................

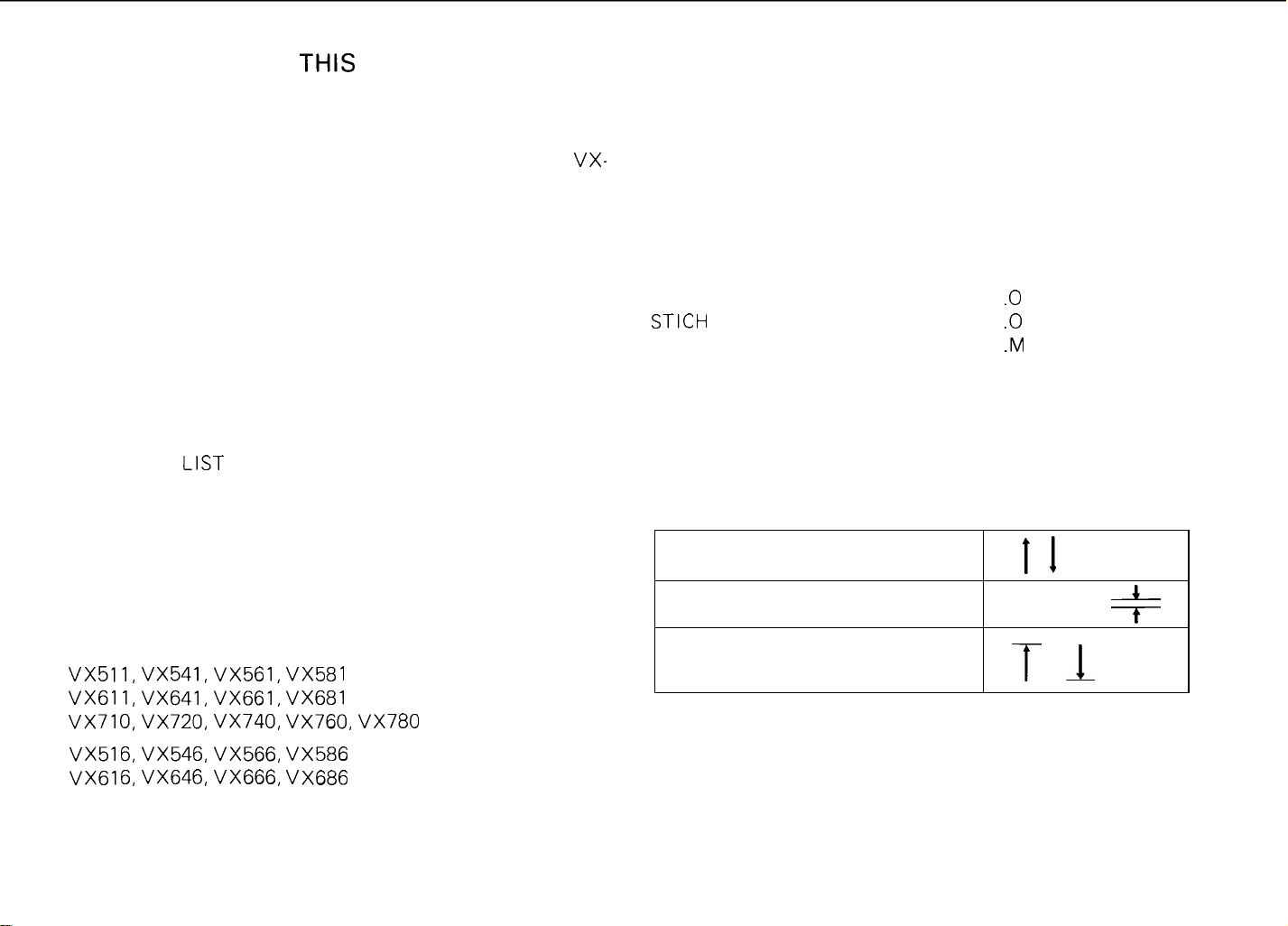

A. HOW TO USE THIS MANUAL

This service manual is compiled for repairing service for

SERIES SEWING MACHINE and consisting of;

B. TROUBLES AND CHECK POINTS

C. HOW TO ADJUST THE ELEMENTS

In case of home

blems brought from consumers will be solved by following the

instruction book, because the causes in many cases are due to

-

use or carelessness. Therefore, we recommend you to refer

mis

to

"

CHECK LIST FOR BETTER SEWING" in the instruction

book before you try to repair.

Suggest to use this manual with "PARTS CATALOGUE

when you try to repair and pick up a point or points.

Model numbers covered by this manual are

VX511, VX541, VX561, VX581

VX611, VX641, VX661, VX681

VX710, VX720, VX740, VX760, VX780

-

use sewing machine, almost all troubles or pro

(Free arm sewing machine)

VX-

"

NOTE:

1.

Set the machine

ELEMENTS

elements.

STITCH WIDTH REGULATOR

STlCH LENGTH REGULATOR.

NEEDLE POSITION SELECTOR.

-

2.

Adjust following numbers in circle in each instruction.

3.

Symbols used are:

Move the part as this way

Set the clearance as indicated

Move the parts to its highest or

lowest position

"

when there

as

below in "HOW TO ADJUST THE

is

no special instruction on each

. .

.

.

. . .

.O (straight stitch)

.

. .

.

.

.

.O (no feeding)

. . . . .

.M

(center)

tl

+

L

t

T

1

VX516, VX546, VX566, VX586

VX616, VX646, VX666, VX686

(Flat bed sewing machine)

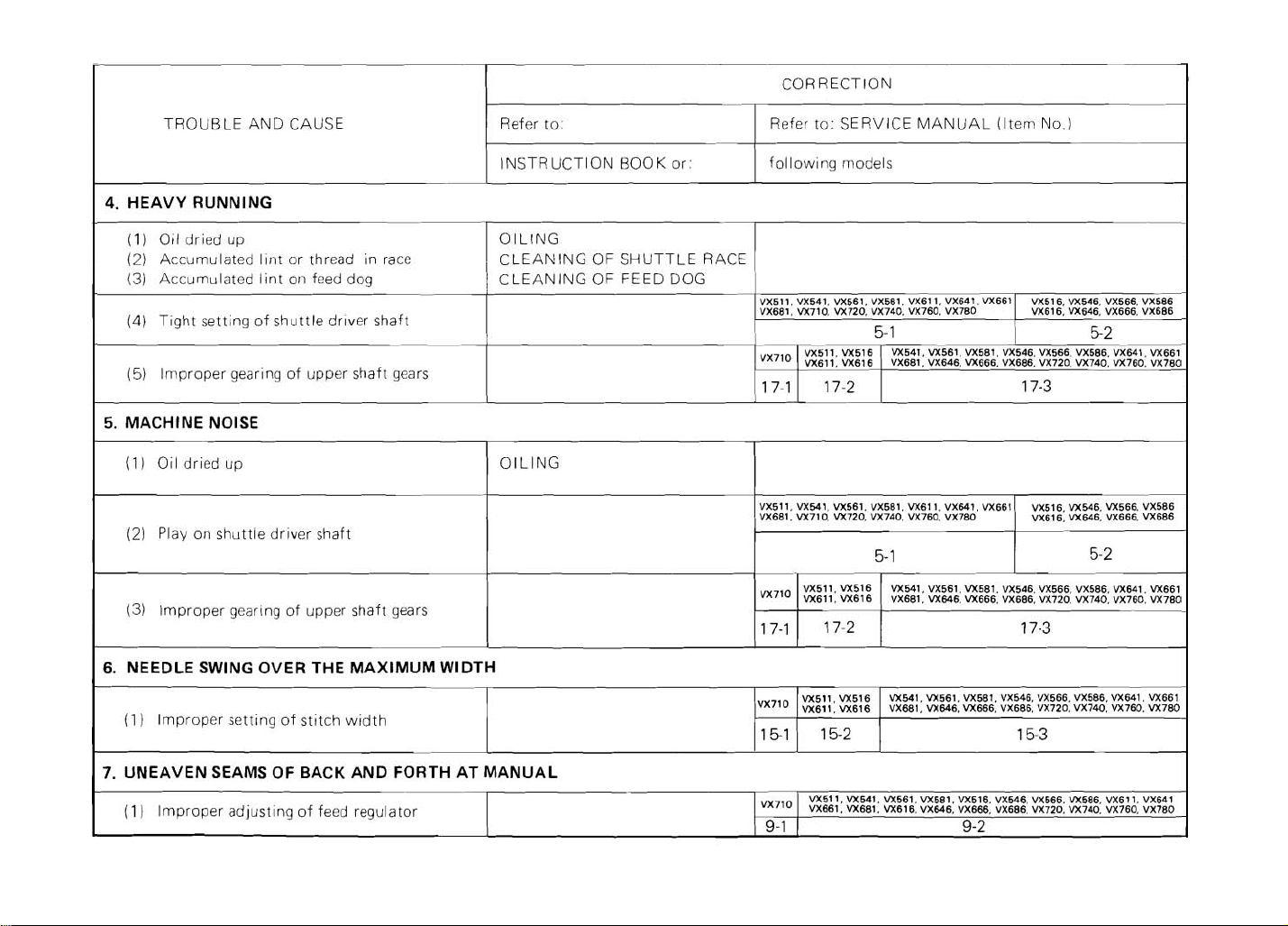

B.

TROUBLES

AND

CHECK

POINTS

TROUBLE AND CAUSE

1.

SKIPPING STITCHES

(1) Incorrect setting of the needle

(2)

Bent or blunt needle

(3) Incorrect upper threading

(4) Improper height of the needle bar

(5) Improper clearance between the needle and

shuttle hook

(6) Improper timing of needle and hook

2.

MATERIAL NOT FEEDING

(1

)

Improper positioning of needle plate

(2) Light pressure on the presser foot

(3) lmproper positioning of feed cam

(4) lmproper positioning of vertical feed cam

(5) lmproper height of feed dog

3.

BREAKING NEEDLE

I

Refer to:

INSTRUCTION BOOK or:

TO CHANGE THE NEEDLE

TO CHECK THE NEEDLE

UPPER THREADING

TO CHANGE NEEDLE PLATE

CORRECTION

Refer to: SERVICE MANUAL (Item No.)

following models

VX511. VX541. VX561. VX581. VX611. VX641. VX661

VX681, VX710, VX720. VX740. VX760. VX780

2

3- 1

-

4

1

VX516, VX546. VX566. VX586

VX616. VXM6. VX666. VX686

2

-

2

3

-

2

4

(1) Incorrect setting of the needle

(3) Improper clearance between the needle and

shuttle hook

(4) Improper

(5) lmproper swing timing of the needle

max. needle swing

---

(

TO CHANGE THE NEEDLE

I

vX710

--

16-1

18

-541.

VX611, VX616

-

1

16-2

-

2

18

2

3 41

VX561. VX581. VX546, VX566. VX586. VX641. VX661

VX681. VX646, VX666. VX686, VX720. VX740. -760. VX780

-

1

16-3

-

18

3-2 & 4-2

3

I

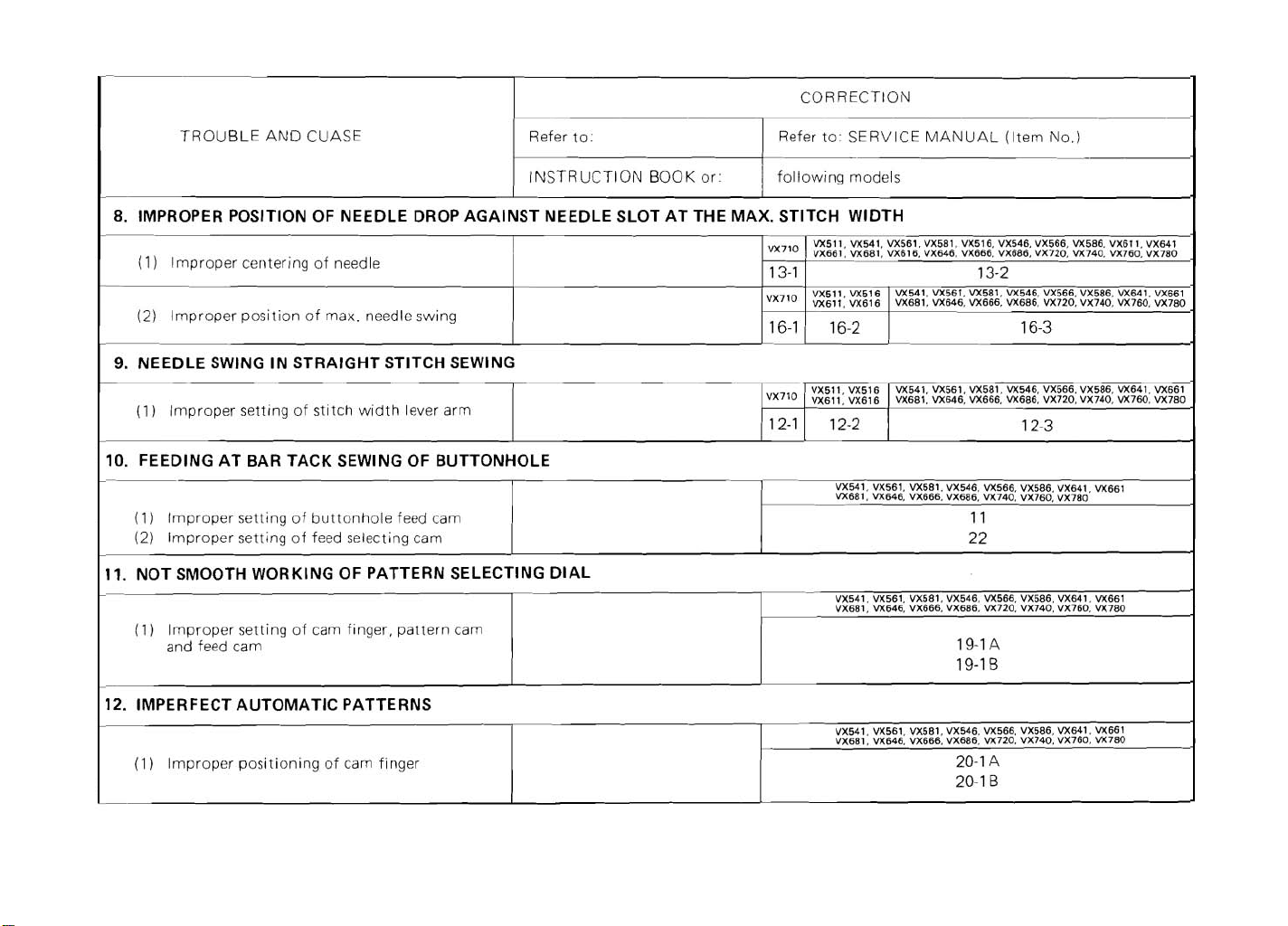

CORRECTION

TROUBLE AND CAUSE

13.

UNEVEN SEAMS OF REVERSE PATTERNS

(1

)

Improper setting of reverse feed devices

14.

BREAKING OF UPPER THREAD

(1 ) Incorrect relation of needle & thread

(2) Bent or blunt needle

(3) Inferior needle eye

(4) Incorrect threading

(5)

Inferior needle slot of needle plate

(6) Upper thread tension too tight

(7)

Scratch on the shuttle hook

15.

BREAKING LOWER THREAD

(1 ) Not smooth running of bobbin

(2) Scratch on tension spring of bobbin case

(3) Scratch on the shuttle hook

(4) Lower thread tension too tight

Refer to:

INSTRUCTION

BOOK or:

Relative chart

Change the needle

Change the needle

Upper threading

Change needle plate

Thread tension

Change the shuttle hook

Change the bobbin

Change the spring

Change the shuttle hook

Thread tension

Refer to: SERVICE MANUAL (Item No.)

following models

VX511. VX541. VX561. VX581. VX516. VX546. VX566. VX586. VX611. VX641

vX710

VX661. VX681. VX616. VX646. VX666. VX686. VX720. VX740. VX760. VX780

9-1

VX720

10-1

VX541. VX561. VX581. VX546, VX566. VX586. VX641, VX661

VX681, VX646. VX666. VX686. VX740. VX760. VX780

9-2

10-2

TROUBLE AND CAUSE Refer to: Refer to: SERVICE MANUAL (Item No.)

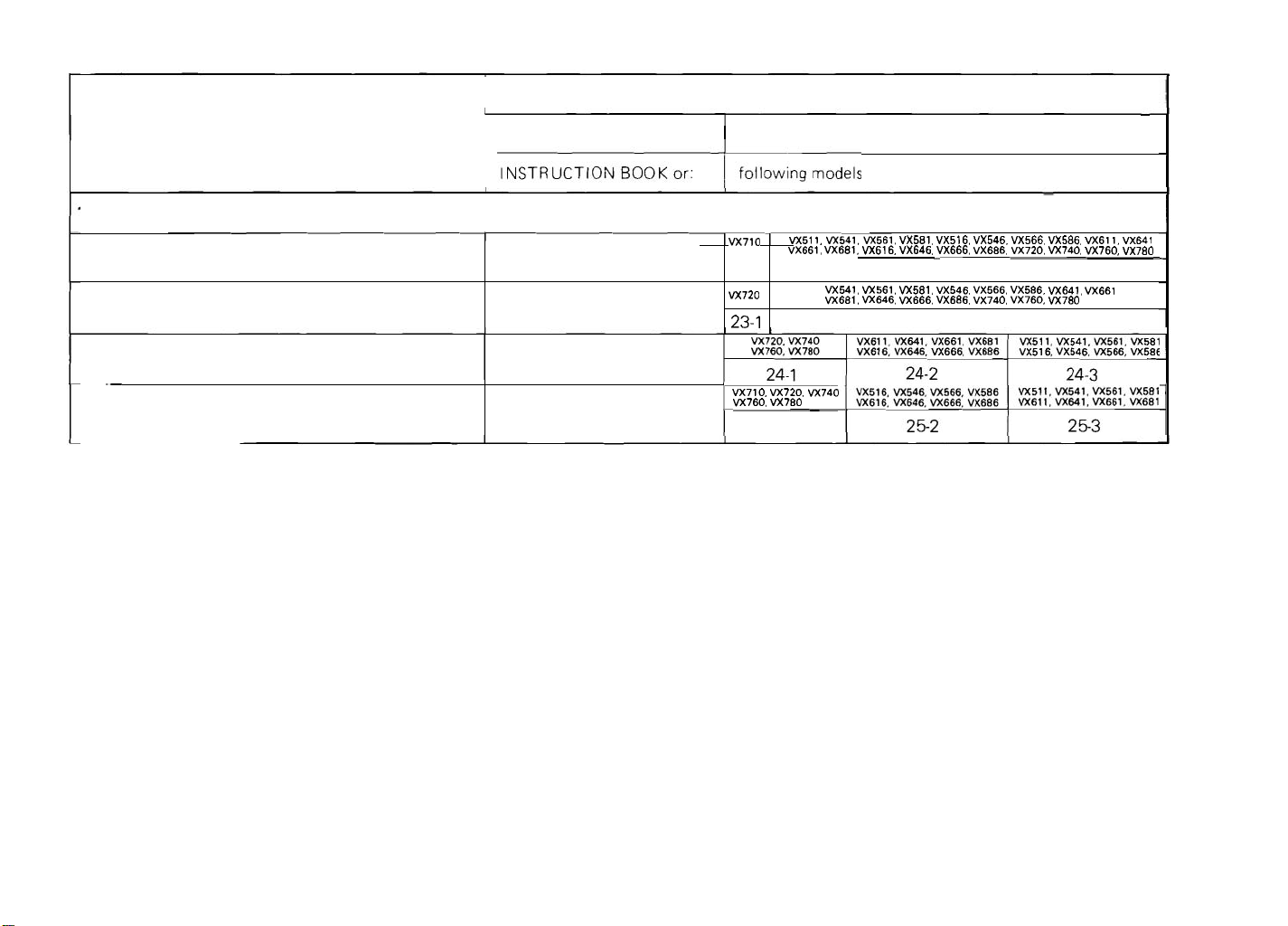

16.

HOW TO ASSEMBLE THE PARTS CORRECTLY

~541.~561.

(1) Upper thread tension dial

(2)

Setting of pattern dial

(3) Decoration panel

~-

(4)

Drive belts

CORRECTION

vx710

VX661. VX681. VX616. VX646. VX666. VX686. VX720. VX740, VX760, VX780

21 -1

VX720

23-1

VX710. VX720. VX740

VX760. VX780

251

VX581. VX516. VX546. VX566. VX586. VX611, VX641

-

21 -2

VX541. VX561. VX581. VX546. VX566. VX586. VX641, VX661

VX681. VX646. VX666. VX686. VX740. VX760. VX780

23-2

C.

HOW TO ADJUST THE ELEMENTS

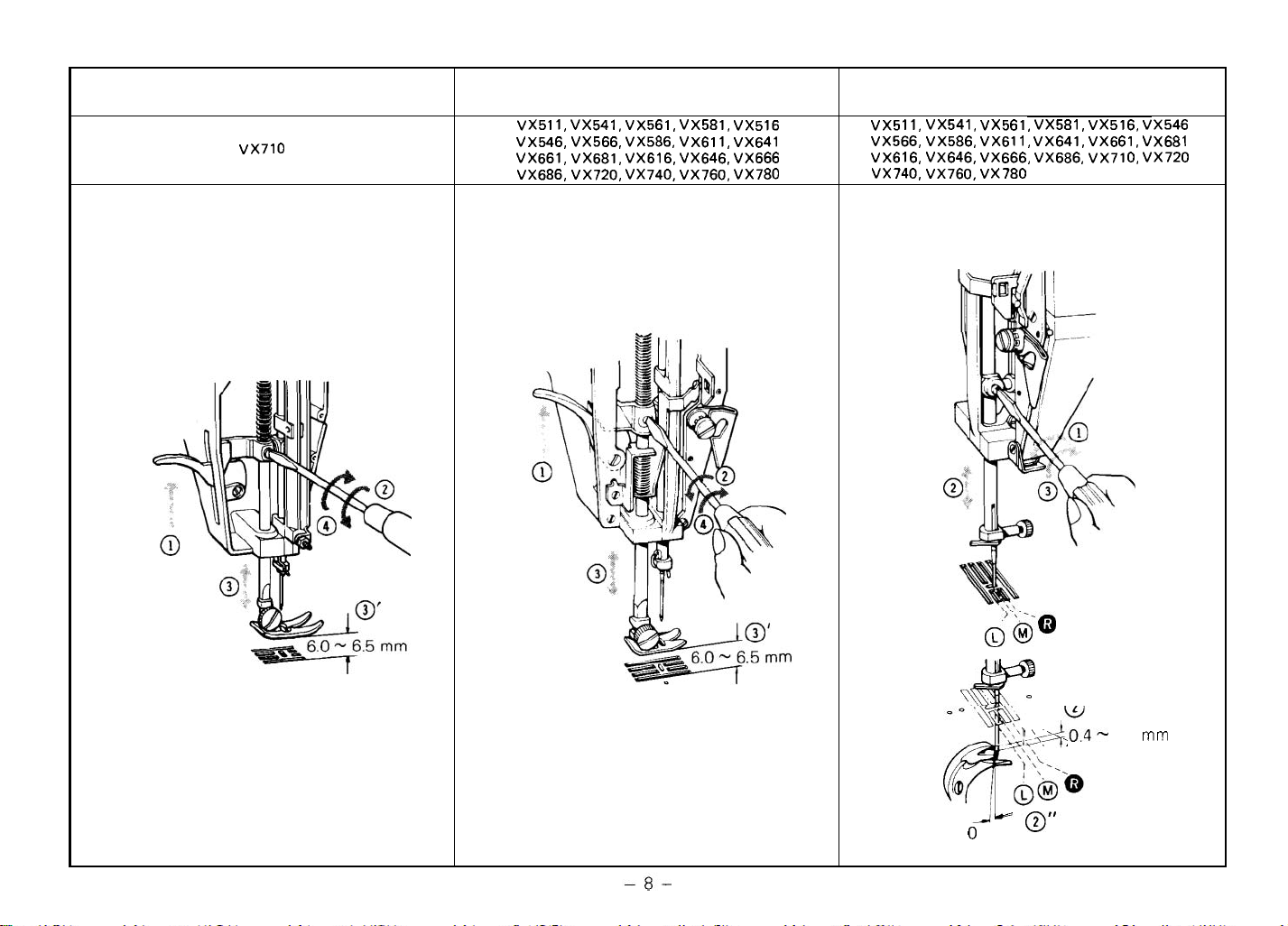

1-1. Height

of

presser bar

VX710

1-2. Height

VX511, VX541, VX561, VX581, VX516

VX546, VX566, VX586, VX611, VX641

VX661, VX681, VX616, VX646, VX666

VX686, VX720, VX740, VX760, VX780

of

presser bar

2. Height

VX511, VX541, VX561, VX581, VX516, VX546

VX566, VX586, VX611, VX641, VX661, VX681

VX616, VX646, VX666, VX686, VX710, VX720

VX740, VX760, VX780

Before adjustment: Set the stitch

width regulator at

needle comes to the right side.

of

needle bar

-

5

(Max.) and check

\q

#$;-

-

0

mm

1

\,;-.

0"

0'

1.0

mm

Loading...

Loading...