Brother VX1140 Owner’s Manual

GENERAl- INFORMATION

°This service manual was compi[ed for use when repairing

the VXl120, VXll40 and VX1250 Zigzag Stitch Sewing Machines.

• Usethis manual, together with the Pal_s Catalogr

when making repairs.

• This manual was wri[_en based on the most up-to-date

product specifications at the time of printing.

Some machine specifications may have been changed to

improve the quality of the product.

Cont_lct the manufacturer or you_ local sales representative

for information on such changes.

Brother Industries, Ltd.

Nagoya, ;apan

• Symbols used

T - ! M°ve[nepartinthedirecti°n°f[hearrow

--_ Set the clearance as indicated.

Move the part to it5 highest _r

lowest position.

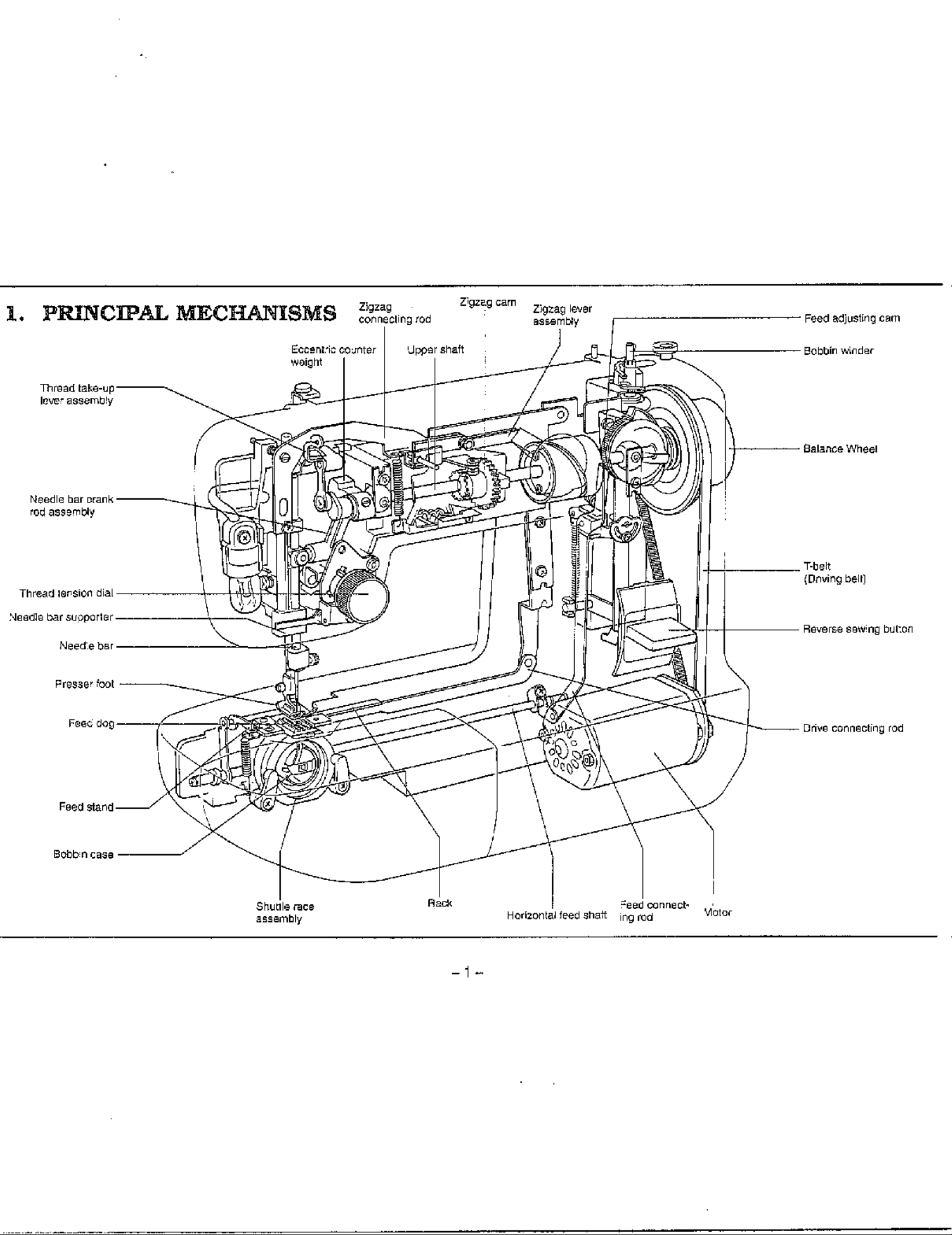

1. PRINCIPAL MECHANISMS COnnsclingrOd

Zigzag

Bobbin winder

T-belt

(BaYing bell)

Nsed e bsr

Horlzor3taJ feed 8ha4t ing foal

-1-

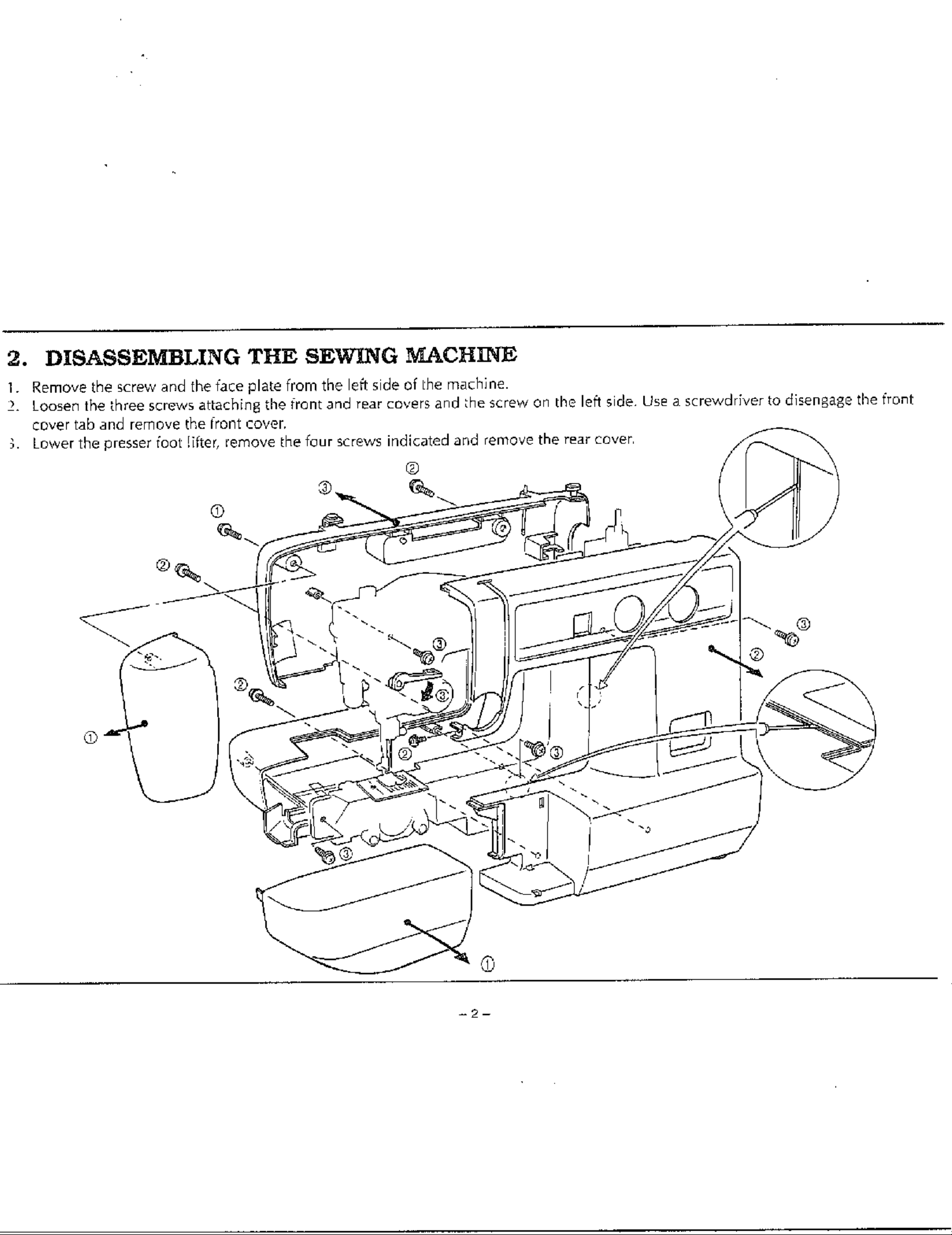

2. DISASSEMBLING THE SEWING MACHINE

I. Remove_hescr_w_ndthef_cepJmefromtbeJeit_ided_emachine.

_. Loosen lhe [hree screws a[[achin 8 the front and rear carets _nd _hescrew on the levi side Use a screwdriver to disenBa_e the front

cgver tab and remove the [font c_)ver.

;. Lower the presse_ _oot [iftel, Iemove [he four screws indicated and remove the rear cover¸

0

®

®

-2-

/

0

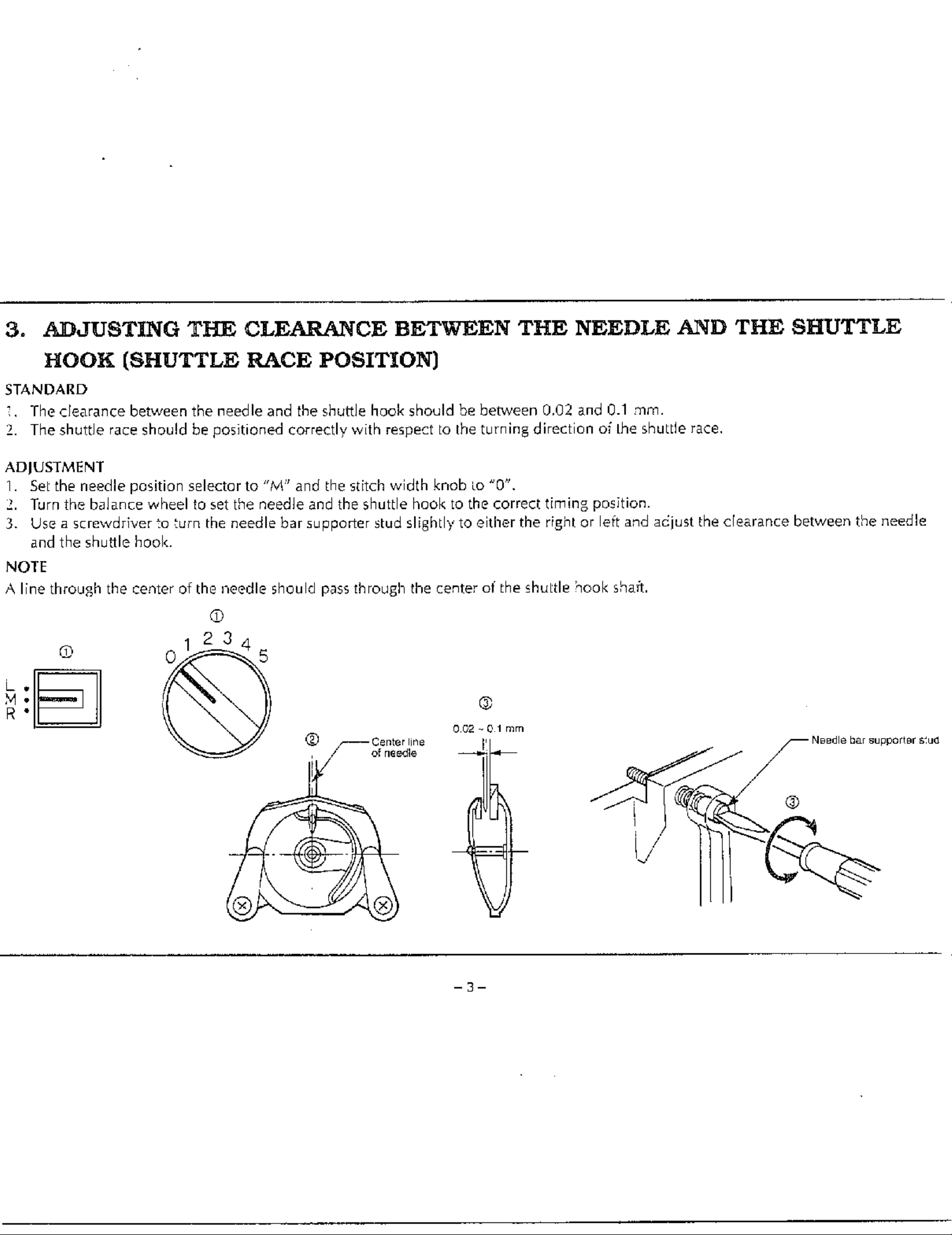

3. ADJUSTING THE CLEARANCE BETWEEN THE NEEDLE AND THE SHUTTLE

HOOE (SHUTTLE RACE POSITION)

STANDARD

_. Theclearance between the needle and the shutt]e hook should be between 0.02 and 0.1 ram.

2. The shuttle race should be posl ioned correc ly wL h respee o he urnmg dlrec ion of he shuLLle race.

ADJUSTMENT

1. SeLthe needle position selector to "M" and the stitch width knob LO"0".

_. Turn the baJ_nce wheel to set the needle and the shuttle hook to the correct timing position.

3. Use a screwdriver to _um the needle bar supporter stud slightly to either the right or left and a_just the crearance between the needle

and the shuttle hook.

NOTE

A line through the center of the needle should pass through the center of Lhe shuLtle hook shaft.

©

@

O_O2-_lmrn

-3-

®

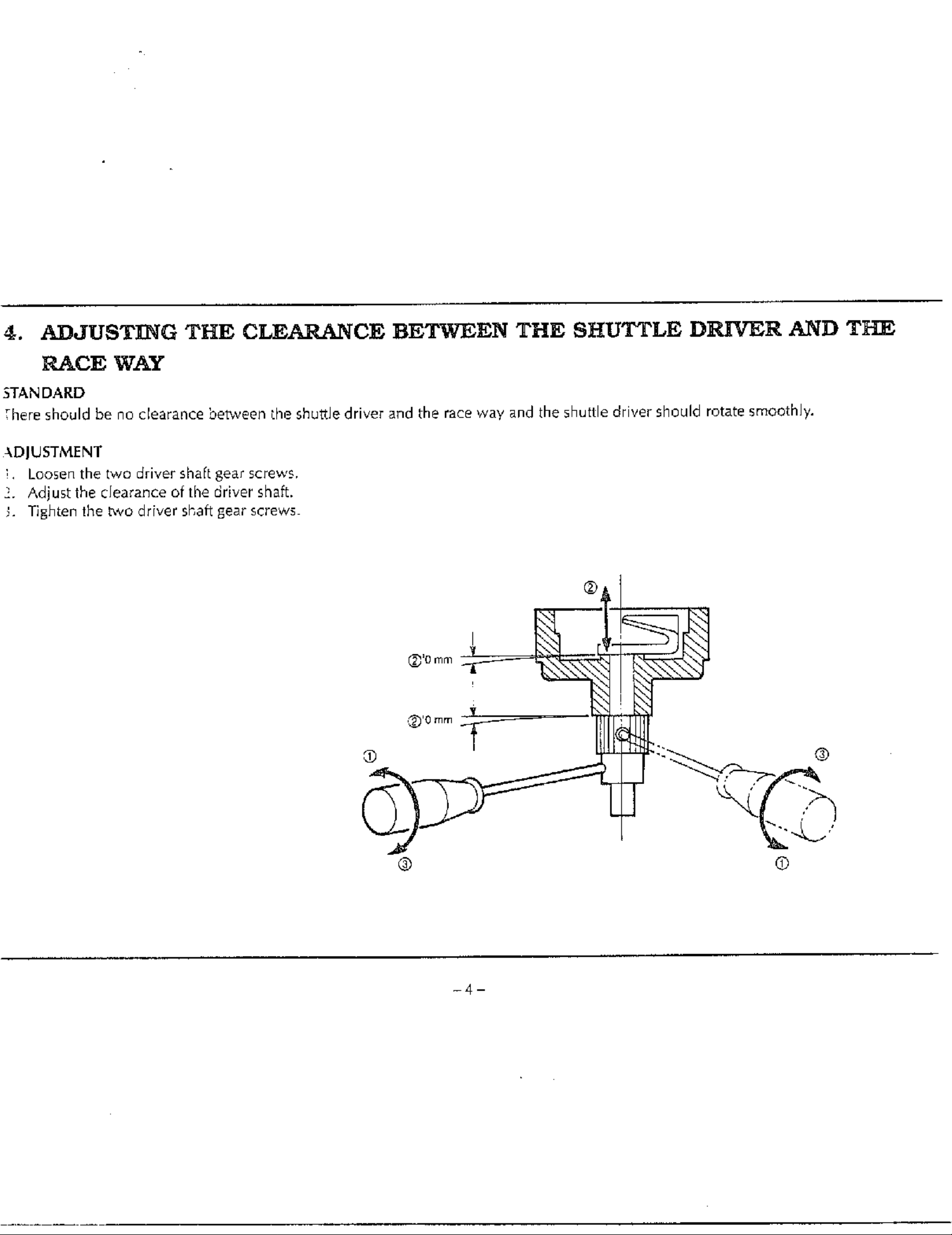

4. A.DJUSTII_G THE CLEARANCE BETWEEN THE SHUTTLE DRIVER AND THE

RACE WAY

STANDARD

There should be no clearance be_veer_ _he shuttJe driver and the race way and the shuttle driver should rotate smoothJy.

_.DILJSTMENT

_, Loosen the two driver shaf[gear screws,

2. Adjust lhe dearance of the drlver shaft.

4. Tighten the t_vo driver shaft gear screws

®

®

©

-4-

Loading...

Loading...