Page 1

HANDBOOK FOR COMPACT

OVERLOCK MACHINE

MANUAL DE INSTRUCCIONES DE LA

MAQUINA COMPACTA OVERLOCK

6

6

6

6

5

5

4

4

5

5

4

4

Page 2

"IMPORTANT SAFETY INSTRUCTIONS"

When using the sewing machine, basic safety precautions should always be followed,

including the following.

"Read all instructions before using."

DANGER – To reduce the risk of electric shock.

1. The sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electrical outlet immediately after using and before cleaning.

2. Always unplug before relamping. Replace bulb with same type rated 15 watts.

WARNING – To reduce the risk of burns, fire, electric shock, or injury to persons.

1. Do not allow to be used as a toy. Close attention is necessary when the sewing machine is used by or near

children.

2. Use this sewing machine only for its intended use as described in this manual. Use only accessories

recommended by the manufacturer as contained in this manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer

or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from

outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch the sewing machine to the symbol “O” position when making any adjustments in the needle area, such

as threading needle, changing needle, or changing presser foot, and the like.

15. Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

16. This sewing machine is not intended for use by young children or infirm persons without supervision.

17. Young children should be supervised to ensure that they do not play with this sewing machine.

CAUTION – This appliance has a polarized plug (one blade wider than the other) to reduce the

risk of electric shock, this plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit. Contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

"SAVE THESE INSTRUCTIONS"

"This sewing machine is intended for household."

Page 3

• When leaving this sewing machine unattended,

the main switch of the machine must be switched

off or the plug must be removed from the socketoutlet.

• When servicing the sewing machine, or when

removing covers or changing lamps, the machine or the electrical set must be disconnected

from the supply by removing the plug from the

socket-outlet.

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS ONLY.

If your sewing machine is fitted with a 3 pin non rewireable BS plug then please read the following.

IMPORTANT

If the available socket outlet is not suitable for the

plug supplied with this equipment, it should be cut off

and an appropriate three pin plug fitted. With alternative plugs an approved fuse must be fitted in the plug.

NOTE: The plug severed from the mains lead must

be destroyed as a plug with bared flexible cords is

hazardous if engaged in a live socket outlet. In the

event of replacing the plug fuse, use a fuse approved

by ASTA to BS 1362, i.e. carrying the

ASA

mark, rating

as marked on plug.

Always replace the fuse cover, never use plugs with

the fuse cover omitted.

WARNING: DO NOT CONNECT EITHER WIRE

TO THE EARTH TERMINAL WHICH IS MARKED

WITH THE LETTER ‘E’, BY THE EARTH SYMBOL

OR COLOURED GREEN OR YELLOW.

The wires in this mains lead are coloured in accordance with the following code:

Blue Neutral

Brown Live

As the colours of the wiring in the mains lead of this

appliance may not correspond with the coloured

markings identifying the terminals in your plug, proceed as follows.

The wire which is coloured blue must be connected

to the terminal which is marked with the letter ‘N’ or

coloured black or blue.

The wire which is coloured brown must be connected

to the terminal which is marked with the letter ‘L’ or

coloured red or brown.

Page 4

CONGRATULATIONS ON

CHOOSING THIS COMPACT

OVERLOCK MACHINE

FELICITACIONES POR HABER

ELEGIDO ESTA COMPACTA

MAQUINA OVERLOCK

Your machine is a high quality, easy-to-use

product. To fully enjoy all the features, we

suggest that you study this booklet.

If you need more information regarding the use

of your machine, your nearest authorized dealer

is always happy to be of service.

Enjoy yourself!

CAUTION!

WHEN THREADING, REPLACING NEEDLE

OR LIGHT BULB, BE SURE TO TURN OFF

THE MAIN POWER SWITCH OF THE MACHINE.

WHEN THE MACHINE IS NOT IN USE, IT IS

RECOMMENDED THAT THE ELECTRIC SUPPLY PLUG IS DISCONNECTED FROM THE

WALL SOCKET TO AVOID ANY POSSIBLE

HAZARDS.

Su máquina es de una eficacia y calidad excelentes; así pues, a fin de disfrutar completamente de todas las características incorporadas, le sugerimo estudie el manual.

Si se necesitara mayor información sobre el

uso de esta máquina, el proveedor autorizado

más cercano estará encantado de ofrecerle

sus servicios.

¡PRECAUCION!

ASEGURARSE DE QUE EL INTERRUPTOR

GENERAL DE LA MAQUINA ESTE APAGADO

CUANDO SE ENHEBRE, REEMPLACE LA

AGUJA O CAMBIE LA LAMPARITA.

CUANDO NO SE UTILICE LA MAQUINA, SE

RECOMIENDA QUE EL ENCHUFE ESTE DESCONECTADO DE LA RED DE LA CORRIENTE, A FIN DE EVITAR CUALQUIER PELIGRO.

Page 5

Notes on the motor

NOTAS SOBRE EL

MOTOR

• The normal operating speed of this sewing ma-

chine is 1,300 stitches per minute, which is quite

fast compared to the normal operating speed of

300 to 800 stitches per minute for the ordinary

foot-operated sewing machine.

• The bearings in the motor are made of a special

sintered, oil-impregnated alloy mounted in oilsoaked felt to withstand long hours of continuous

operation.

• Continuous operation of the sewing machine can

cause heat to build in the motor area, but not

enough to adversely affect its performance.

It is important to keep fabric and paper away from

the ventilating holes on the back and sides of the

machine so air can get to these holes.

• When the motor is running, sparks can be seen

through the ventilating hole in the motor bracket

on the side opposite the hand wheel. These

sparks are produced by the carbon brushes and

the commutator, and are part of the machines

normal operation.

CAUTION

WHEN THREADING THE MACHINE, REPLACING A NEEDLE, OR WHEN THE MACHINE IS NOT IN USE, WE RECOMMEND

DISCONNECTING THE ELECTRIC SUPPLY

PLUG TO AVOID ANY POSSIBLE HAZARDS.

•

La velocidad normal de funcionamiento de esta

máquina de coser es de 1.300 puntadas por

minuto, lo que resulta bastante rápido comparado con la velocidad normal de 300 a 800 puntadas por minuto de las máquinas de coser normales que funcionan con pedal.

•

Los cojinetes del motor están hechos de una

aleación especial impregnada en aceite sintético

y montada en un fieltro impregnado en aceite,

para poder funcionar continuamente durante

muchas horas.

•

Un funcionamiento continuo de la máquina puede contribuir a calentar algo la máquina en la

zona del motor, pero no lo suficiente como para

alterar su rendimiento y funcionamiento.

Sin embargo, es menester mantener los orificios

de ventilación de la parte trasera y en los lados de

la máquina sin tapar con tejido o papel durante el

uso, para que el aire pueda circular por los

orificios.

•

Durante el funcionamiento del motor, se pueden

ver chispas a través del orificio de ventilación de

la abrazadera del motor, en el lado contrario a la

ruedecilla. Estas chispas son producidas por las

escobillas de carbón que entran en contacto con

el conmutador, y forman parte del funcionamiento normal de la máquina.

PRECAUCION

Al enhebrar la máquina, cambiar una aguja o

al dejar la máquina sin usar, le recomendamos desenchufar la máquina para evitar

cualquier peligro de corto circuito.

Page 6

TABLE OF CONTENTS

CONTENTS

TABLE OF

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Chapter 10

Chapter 11

Chapter 12

Chapter 13

Chapter 14

Chapter 15

Chapter 16

Chapter 17

Chapter 18

Names of parts and their functions ............................................................................... 1

Accessories included with your serger ..................................................................................... 3

Needle ...................................................................................................................................... 5

Turning direction of motor ........................................................................................................ 7

Opening and closing the front cover ........................................................................................ 7

Operating .............................................................................................................................. 8

Powering the machine.............................................................................................................. 8

Removing the Bed Extension for Free-Arm Sewing ............................................ 9

Removing the bed extension.................................................................................................... 9

Stitch Length...................................................................................................................... 10

Stitch Width ........................................................................................................................ 10

Instructions for the Differential Feed Mechanism

(Models with Differential Feed) ..................................................................................... 11

Before Threading .............................................................................................................. 14

Preparation before threading ................................................................................................. 14

How to use the thread spool cap............................................................................................ 15

How to use the thread net ...................................................................................................... 15

Tension release button........................................................................................................... 15

Before threading..................................................................................................................... 16

Threading the upperlooper ..................................................................................................... 17

Threading the lowerlooper...................................................................................................... 19

Threading the right needle (on Two-needle models).............................................................. 21

Threading the left needle .......................................................................................................23

Comparison Chart of Sewing Materials, Threads and Needles............................ 25

Thread Tension.................................................................................................................. 27

Chart of Thread Tension Adjustment .......................................................................... 29

Test-sewing ........................................................................................................................ 33

Chaining-off ............................................................................................................................ 34

Sewing ................................................................................................................................. 35

To start sewing ....................................................................................................................... 35

To remove work...................................................................................................................... 36

If threads break during sewing ............................................................................................... 36

To sew heavy materials..........................................................................................................37

To sew fine materials ............................................................................................................. 37

Presser foot pressure ............................................................................................................. 38

Troubleshooting................................................................................................................ 39

Stitch Selection ................................................................................................................. 41

Narrow overlock stitch/rolled edge stitch................................................................................ 42

Chart of Narrow Overlock/Rolled Edge Stitch .......................................................... 45

Examples of Sewing Applications for this Serger ................................................... 47

Blind stitching with blind stitch presser foot............................................................................ 48

Flatlock stitching with blind stitch presser foot ....................................................................... 50

Pin tuck stitching with blind stitch presser foot ....................................................................... 52

Decorative stitching ................................................................................................................ 54

Upper Knife and Lower Knife ........................................................................................ 55

Retracting upper knife ............................................................................................................ 55

Replacing the knives .............................................................................................................. 56

Oiling .................................................................................................................................... 57

Changing the Light Bulb ................................................................................................. 58

Machine Specifications ................................................................................................... 59

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 7

INDICE

Capítulo 1 Nombres de las partes y sus funciones

Accesorios incluidos con la máquina de coser ........................................................................ 3

Aguja ........................................................................................................................................ 5

Para cambiar la dirección del motor......................................................................................... 7

Abre y cierre de la tapa delantera ............................................................................................ 7

Capítulo 2 Funcionamiento

Encendido de la máquina.........................................................................................................8

.................................................................................................................. 8

....................................................................... 1

Extraiga el suplemento para la mesa para realizar la costura sin brazo ...........

Extraiga el suplemento para la mesa ....................................................................................... 9

Capítulo 3 Largo de puntada

Ancho de puntada

.............................................................................................................. 10

............................................................................................................ 10

Capítulo 4 Instrucciones para el mecanismo de alimentación con diferencial

(Modelos con alimentador diferencial)

Capítulo 5 Antes del enhebrado

Preparación antes del enhebrado .......................................................................................... 14

Como utilizar el tope del carrete............................................................................................. 15

Como utilizar la malla para hilo .............................................................................................. 15

Botón de liberación de la tensión ........................................................................................... 15

Antes de enhebrar.................................................................................................................. 16

Enhebrado del áncora superior .............................................................................................. 17

Enhebrado del áncora inferior ................................................................................................ 19

Enhebrado de la aguja derecha (los modelos de dos agujas) ............................................... 21

Enhebrado de la aguja izquierda ........................................................................................... 23

........................................................................................................ 14

Capítulo 6 Tabla de relación entre los distintos tejidos, hilos y agujas

Capítulo 7 Tensión del hilo

................................................................................................................. 27

Capítulo 8 Tabla de ajuste de tensión de los hilos

Capítulo 9 Costura de prueba

Cadeneta................................................................................................................................ 34

Capítulo 10 Costura

Para empezar a coser ............................................................................................................35

Para retirar el trabajo.............................................................................................................. 36

Si el hilo se rompe al coser ....................................................................................................36

Para coser tejidos gruesos..................................................................................................... 37

Para coser tejidos finos .......................................................................................................... 37

Presión del prensatelas.......................................................................................................... 38

................................................................................................................................35

Capítulo 11 Guía de localización de fallas

............................................................................................................ 33

........................................................................................ 40

Capítulo 12 Selección de las distintas puntadas

Puntada overlock estrecha/puntada de borde enrollado........................................................ 42

Capítulo 13 Tabla para puntadas overlock estrechas/de borde enrollado

....................................................................... 11

................................ 26

...................................................................... 29

............................................................................ 41

.............................. 46

Capítulo 14 Ejemplos de aplicaciones de costuras para estas máquinas de coser

Puntadas invisibles con prensatelas multipropósito............................................................... 48

Costura Overlock plana con prensatelas multipropósito ........................................................ 50

Costuras de pliegues pequeños con prensatelas multipropósito ........................................... 52

Puntadas decorativas............................................................................................................. 54

Capítulo 15 Cuchillas superior e inferior

Meter la cuchilla superior ....................................................................................................... 55

Cambio de las cuchillas.......................................................................................................... 56

Capítulo 16 Engrasado

........................................................................................................................... 57

Capítulo 17 Cambio de la bombilla de luz

Capítulo 18 Especificaciones técnicas de la máquina

.......................................................................................... 55

........................................................................................ 58

.................................................................. 59

9

............. 47

Page 8

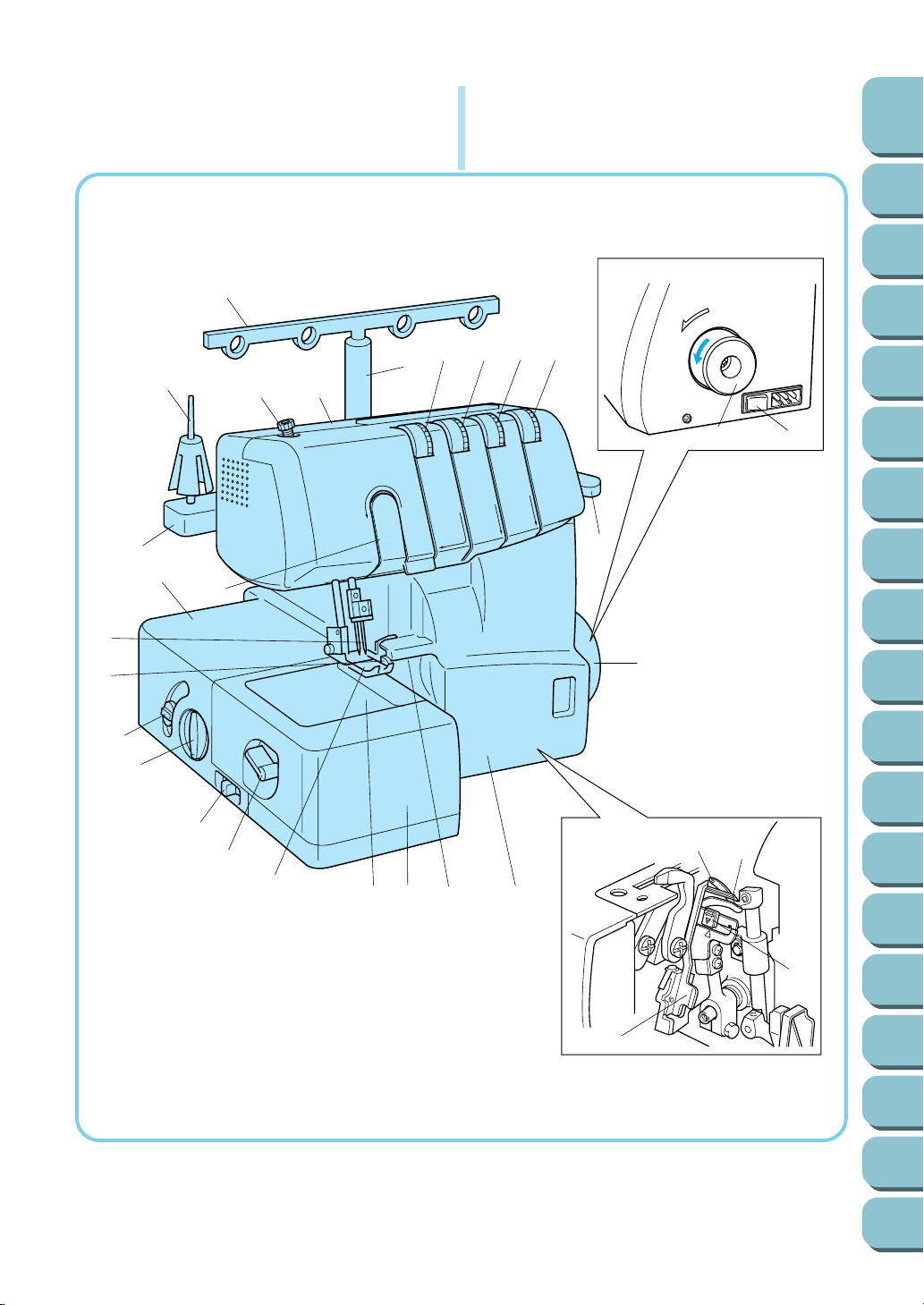

Names of parts and

Nombres de las partes

CONTENTS

TABLE OF

their functions

1

4

5

0

7

8

3

6

2

BCDG

A

6

6

5

5

4

4

y sus funciones

Chapter

1

Chapter

2

Chapter

3

F

6

6

5

5

4

4

E

JE

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

L

K

T

O

9

Chapter

10

Chapter

11

Chapter

P

Q

SR

HI

M

N

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

1

Page 9

1 Thread tree

2 Handle

3 Presser foot pressure adjustment screw

4 Spool pin

5 Spool support

6 Thread take-up cover

7 Needles

8 Upper knife

9 Presser foot

0 Material plate cover

A Spool stand (thread tree support)

B Left needle thread tension dial

C Right needle thread tension dial

D Presser foot lifting lever

E Hand wheel

F Upperlooper thread tension dial

G Lowerlooper thread tension dial

H Front cover

I Material slide plate (for overlock stitch)

J Main power switch and light switch

K Stitch length adjustment dial

L Differential feed ratio adjustment lever

M Lowerlooper threading lever

N Stitch finger

O Stitch width lever

P Upperlooper

Q Lowerlooper

R Free-arm cover

S Bed extension

T Knife lever

1

Arbol del hilo

2

Asa

3

Tornillo de ajuste de la presión del prensatelas

4

Portabobina

5

Soporte de la bobina

6

Tapa de toma de hilo

7

Agujas

8

Cuchilla superior

9

Prensatelas

0

Tapa de tejido

A

Filete para la canilla (soporte del árbol del hilo)

B

Disco de tensión del hilo de la aguja izquierda

C

Disco de tensión del hilo de la aguja derecha

D

Palanca de levantamiento del prensatelas

E

Ruedecilla

F

Disco de tensión del hilo del áncora superior

G

Disco de tensión del hilo del áncora inferior

H

Tapa delantera

I

Placa de deslice del tejido (para puntadas

Overlock)

J

Interruptor de alimentación principal e interruptor

de luz

K

Disco de ajuste del largo de las puntadas.

L

Palanca diferencial de ajuste de la velocidad de

alimentación

M

Palanca de enhebrado del áncora inferior

N

Uñeta de puntadas

O

Palanca de anchura de las puntadas.

P

Ancora superior

Q

Ancora inferior

R

Cubierta del brazo

S

Suplemento para la mesa

T

Palanca de cuchilla

CONTENTS

TABLE OF

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Chapter

10

Chapter

11

Chapter

12

Chapter

13

Chapter

14

2

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Page 10

CONTENTS

TABLE OF

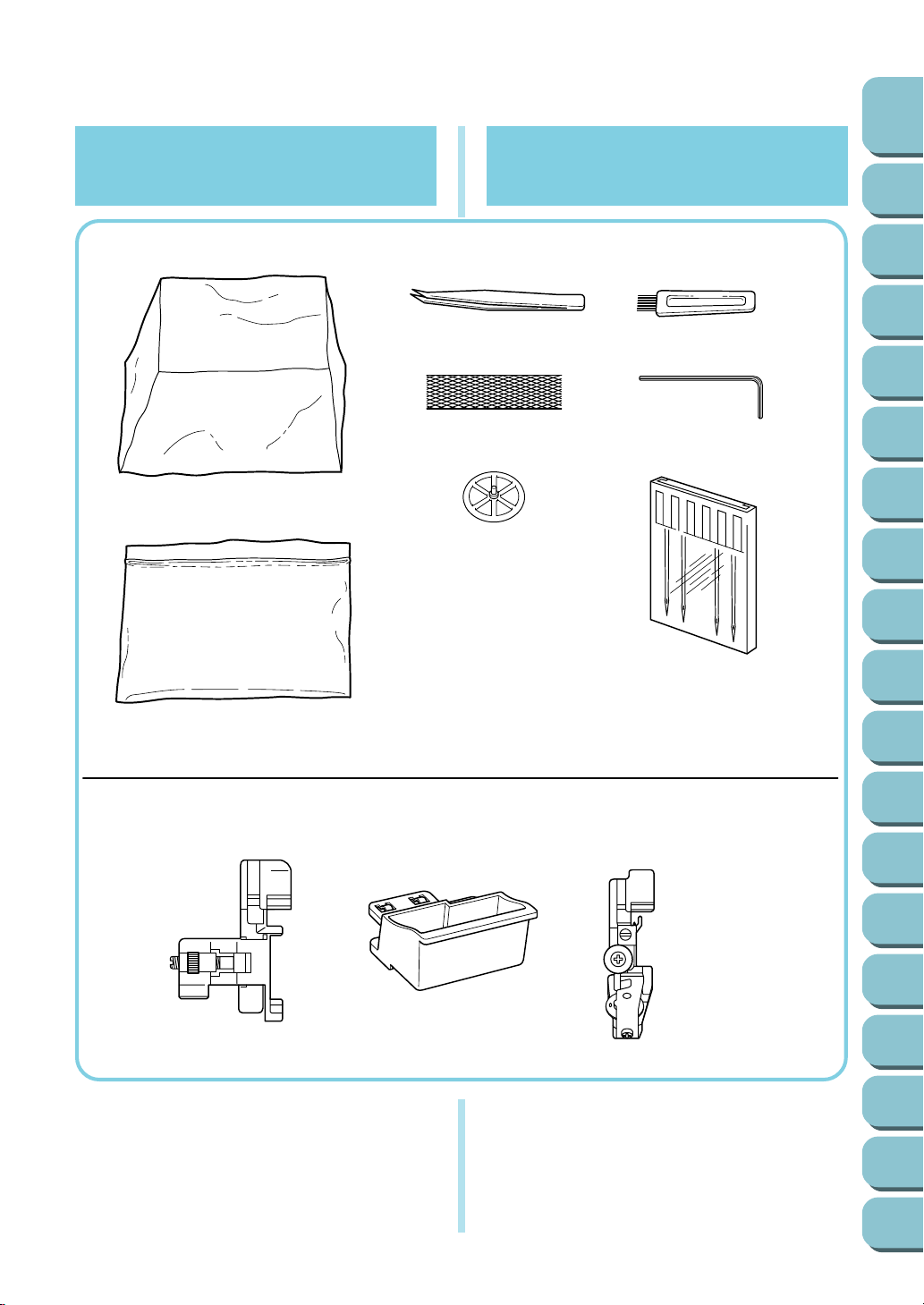

Accessories included

with your serger

1 X77871-000

2 122991002

Accesorios incluidos con

la máquina de coser

3 X75902001

4 X75904000

5 X77260000

6 X75906001

7 X77128001

8 X75917001

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

OPTION / OPTATIVO

9 X76590002

9, 0, A OPTION

0 XB0958001

9, 0, A

A X76663001

SA212 (U.S.A., CANADA)

SA212 (

EE.UU, CANADÁ

OPTATIVO

Chapter

10

Chapter

11

Chapter

12

)

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

3

Page 11

CONTENTS

TABLE OF

The number represents the parts code

1 Soft cover

2 Accessory bag

3 Tweezers

4 Thread net

Two-needle models (4)

One-needle models (3)

5 Thread spool cap

Two-needle models (4)

One-needle models (3)

6 Cleaning brush

Hexagonal (Allen) wrench (on Two-needle mod-

7

els)

8 Needle set: SCHMETZ 130/705M

80/12: 2 pcs.

90/14: 2 pcs.

9 Blind stitch foot (Option)

0 Trim trap (Option)

A Tape presser foot (Option)

Foot controller: J01780051 (110/120V Area)

XA6406051 (220/240V Area)

XA6408051 (U.K.)

XA6410051 (Australia, New Zealand)

XA6420051 (Germany)

El número corresponde al código de los elementos

1

Funda

2

Bolsa de accesorios

3

Pinzas

4

Malla

Modelos de dos agujas (4)

Modelos de una aguja (3)

5

Tope del carrete

Modelos de dos agujas (4)

Modelos de una aguja (3)

6

Cepillo limpiador

7

Llave de tuerca hexagonal (Allen) (Modelos de

das agujas)

8

Juego de agujas: SCHMETZ 130/705M

80/12: 2 unidades

90/14: 2 unidades

9

Prensatelas para puntadas invisibles (Optativo)

0

Orificio de corte (Optativo)

A

Prensatelas para cintas (Optativo)

Pedal: J01780051 (zona con 110/120V)

XA6406051 (zona con 220/240V)

XA6408051 (Reino Unido)

XA6410051 (Australia, Nueva Zelanda)

XA6420051 (Alemania)

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

4

Page 12

CONTENTS

6

7

5

TABLE OF

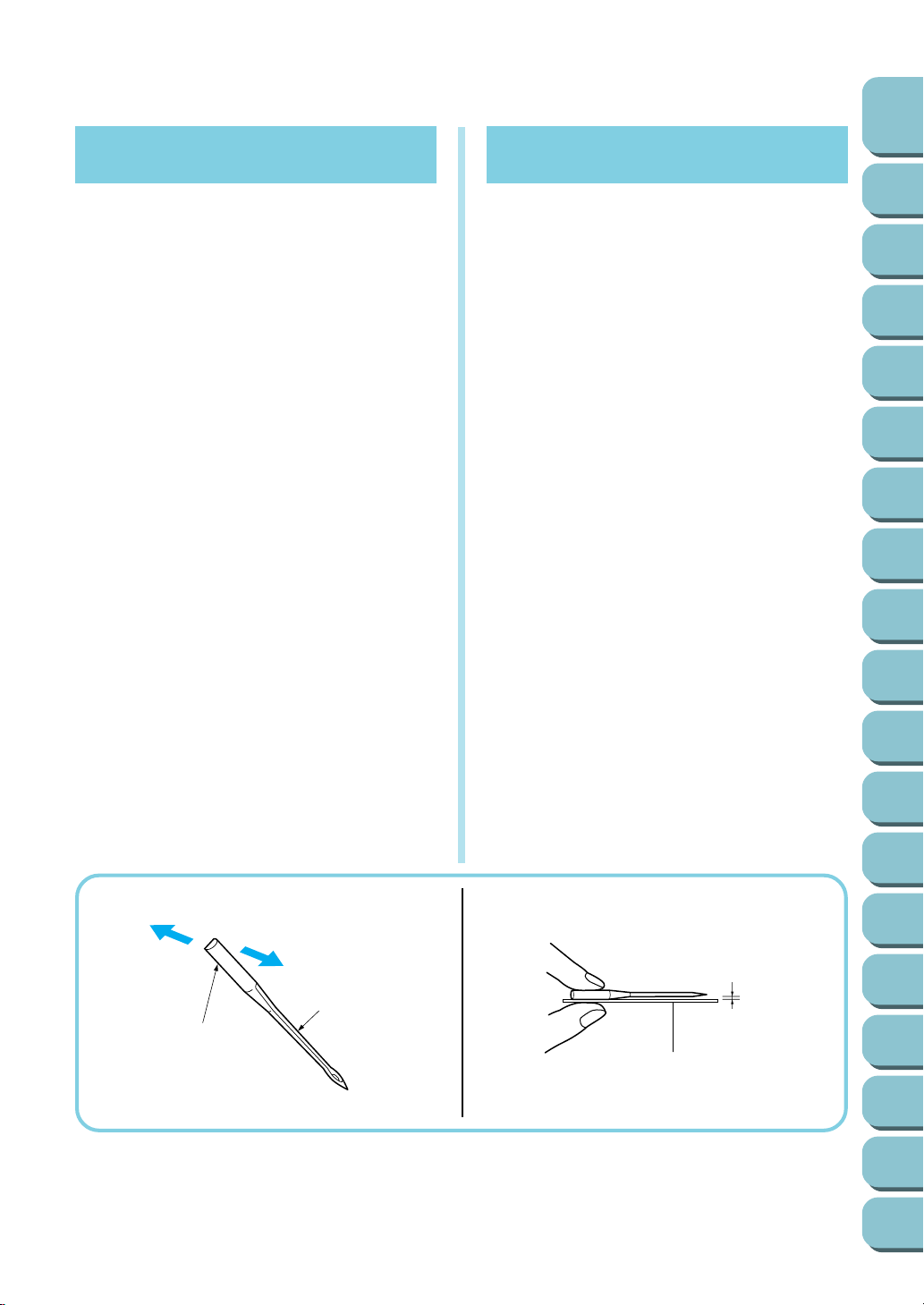

Needle

This machine uses a standard home sewing machine needle.

The recommended needle is SCHMETZ 130/705H.

To remove the needle

(1)Turn the main power switch to the OFF position.

(2)Turn the hand wheel counter-clockwise by hand

until the needle is at its highest position.

(3)Loosen the needle set screw with hexagonal

wrench and remove the needle.

1 Back

2 Front

3 Flat side

4 Groove

To insert the needle

(1)Turn the main power switch to the OFF position.

(2)Turn the hand wheel until the needle bar is at its

highest position.

(3)Hold the needle with its flat side away from you

and insert it up as far as it will go.

(4) Tighten the needle set screw securely with the

hexagonal wrench.

5 Place the needle on its flat side and check

to see if the space is parallel.

6 Flat side

7 (needle-plate, glass, etc.)

Aguja

Está máquina funciona con una aguja normal para

máquinas domésticas. Así mismo, se recomienda el

uso de una aguja SCHMETZ 130/705H.

Para sacar la aguja

(1)Apague el interruptor principal (posición OFF).

(2)Gire la ruedecilla a mano, en contra de las mane-

cillas del reloj hasta que la aguja alcance la

posición más elevada.

(3)Afloje el tornillo de instalación de la aguja con la

llave hexagonal y saque la aguja.

1

Parte trasera

2

Parte delantera

3

Parte llana

4

Canal

Para introducir la aguja

(1)Apague el interruptor principal (póngalo en OFF).

(2)Gire la ruedecilla hasta que la barra de la aguja

alcance la posición más alta.

(3)Sujete la aguja con la parte curvada de cara a Vd.

e insértela hacia arriba hasta el tope.

(4)Vuelva a apretar firmemente el tornillo de instala-

ción de la aguja con la llave hexagonal.

5

Coloque la aguja en su parte llana y compruebe que el espacio sea paralelo.

6

Parte llana

7

Placa de aguja (Vidrio, etc.)

1

2

3

4

5

6

7

8

9

10

11

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

5

1

3

2

4

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 13

CONTENTS

TABLE OF

NOTE:

Two-needle models

• On two-needle models, we suggest you hold the

two needles with one hand and then insert them

both at the same time.

• If the needles have been inserted correctly, the

right needle should be set slightly lower than the

left one.

CAUTION

The needle set screw holds both needles.

Keep this in mind when you loosen the set

screw to exchange one or both needles.

8 Needle set screw

9 Tighten

0 Loosen

A Hexagonal wrench

9

8

NOTA:

Modelos de dos agujas

•

En los modelos de dos agujas, le sugerimos

sujetar ambas agujas en una sola mano e insertarlas simultáneamente.

•

Si las agujas fueron introducidas correctamente,

la aguja de derecha debería quedar un poco más

abajo de la izquierda.

PRECAUCION

El tornillo de instalación de las agujas sujeta

ambas agujas. No se lo olvide al aflojar

dicho tornillo para cambiar una o ambas

agujas.

8

Tornillo de instalación de las agujas

9

Apretar

0

Aflojar

A

Llave de tuerca hexagonal

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

One-needle models

B Needle set screw

C Tighten

D Loosen

E Hexagonal wrench

0

A

B

Modelos de una aguja

B

Tornillo de instalación de las agujas

C

Apretar

D

Aflojar

E

Llave de tuerca hexagonal

C

D

E

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

6

Page 14

CONTENTS

TABLE OF

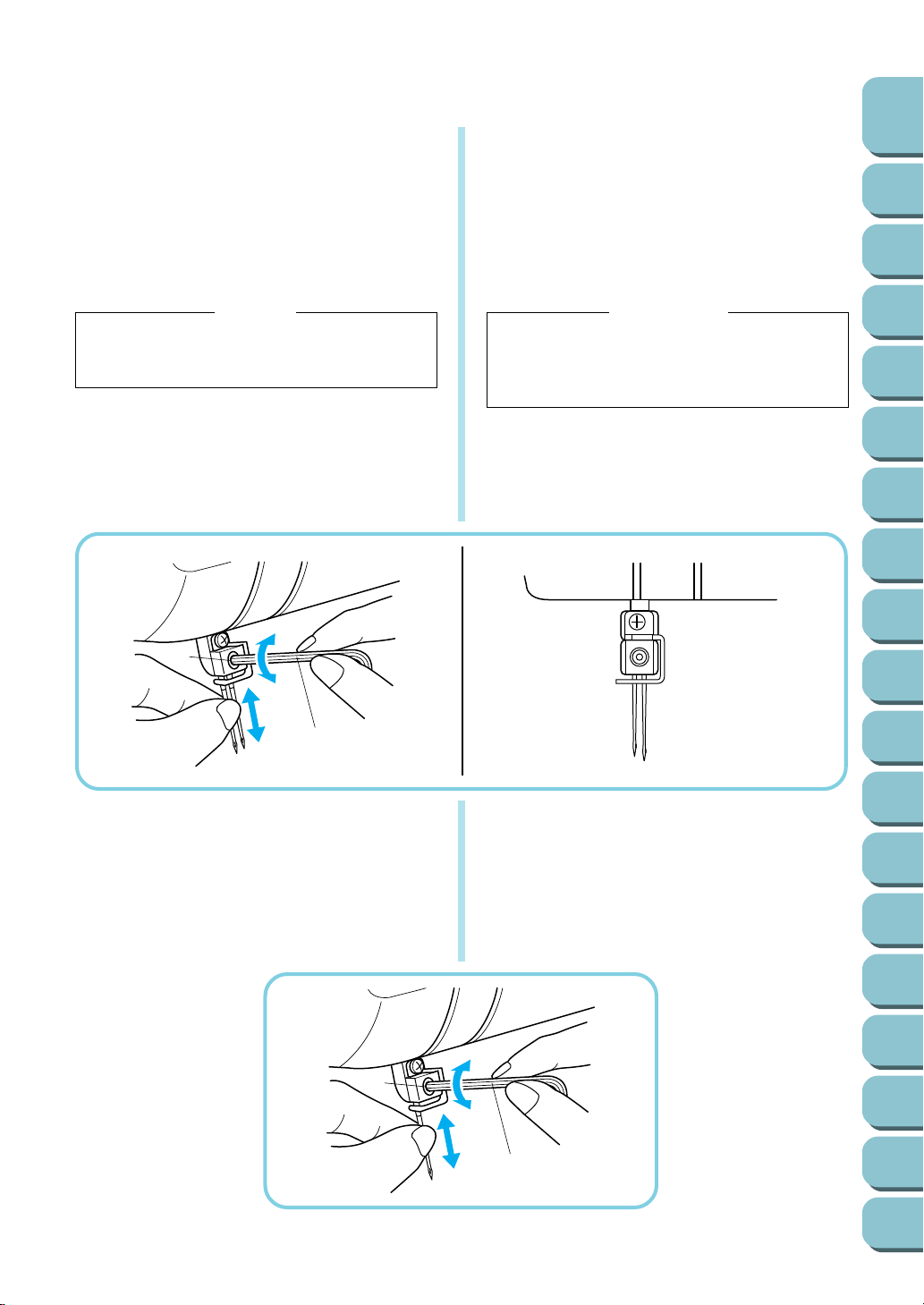

Turning direction of motor

• The motor and hand wheel of this machine turn in

a counterclockwise direction (direction of arrow).

This is the same direction as an ordinary home

sewing machine.

1 Hand wheel

Para cambiar la dirección

del motor

•

El motor y la ruedecilla de esta máquina funcionan en el sentido contrario al de las manecillas

del reloj (dirección de la flecha), como es el caso

con la mayoría de las máquinas de coser domésticas.

1

Ruedecilla

1

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Opening and closing the

front cover

It is necessary to open the front cover when threading this machine.

NOTE:

For your safety, make sure that the front cover is

closed when operating the machine.

Abre y cierre de la tapa

delantera

Es necesario abrir la tapa delantera para enhebrar la

máquina.

NOTA:

Para su propia seguridad, averigue siempre que la

tapa delantera esté bien cerrada antes de hacer

funcionar la máquina.

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

7

Page 15

Operating

Funcionamiento

CONTENTS

TABLE OF

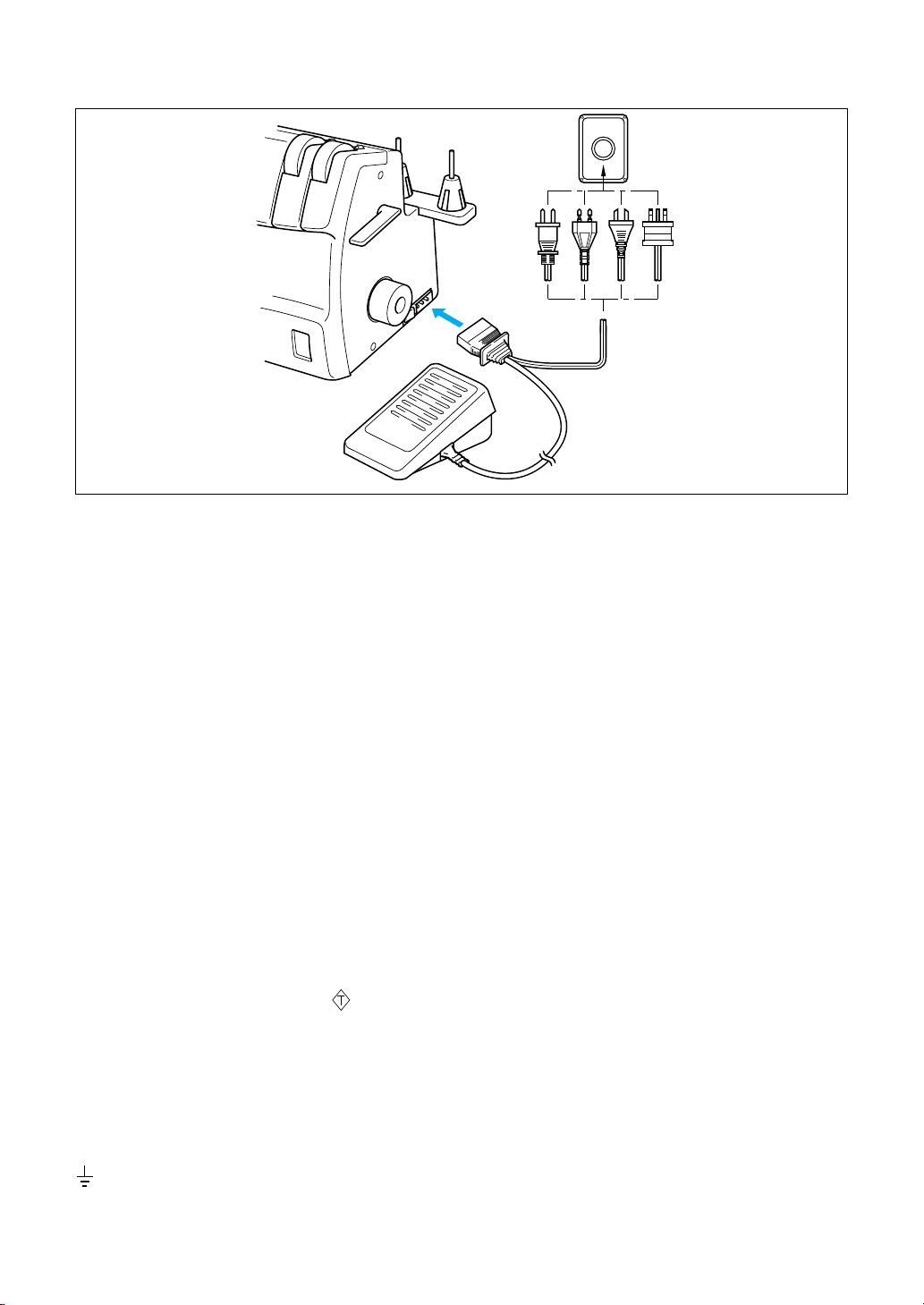

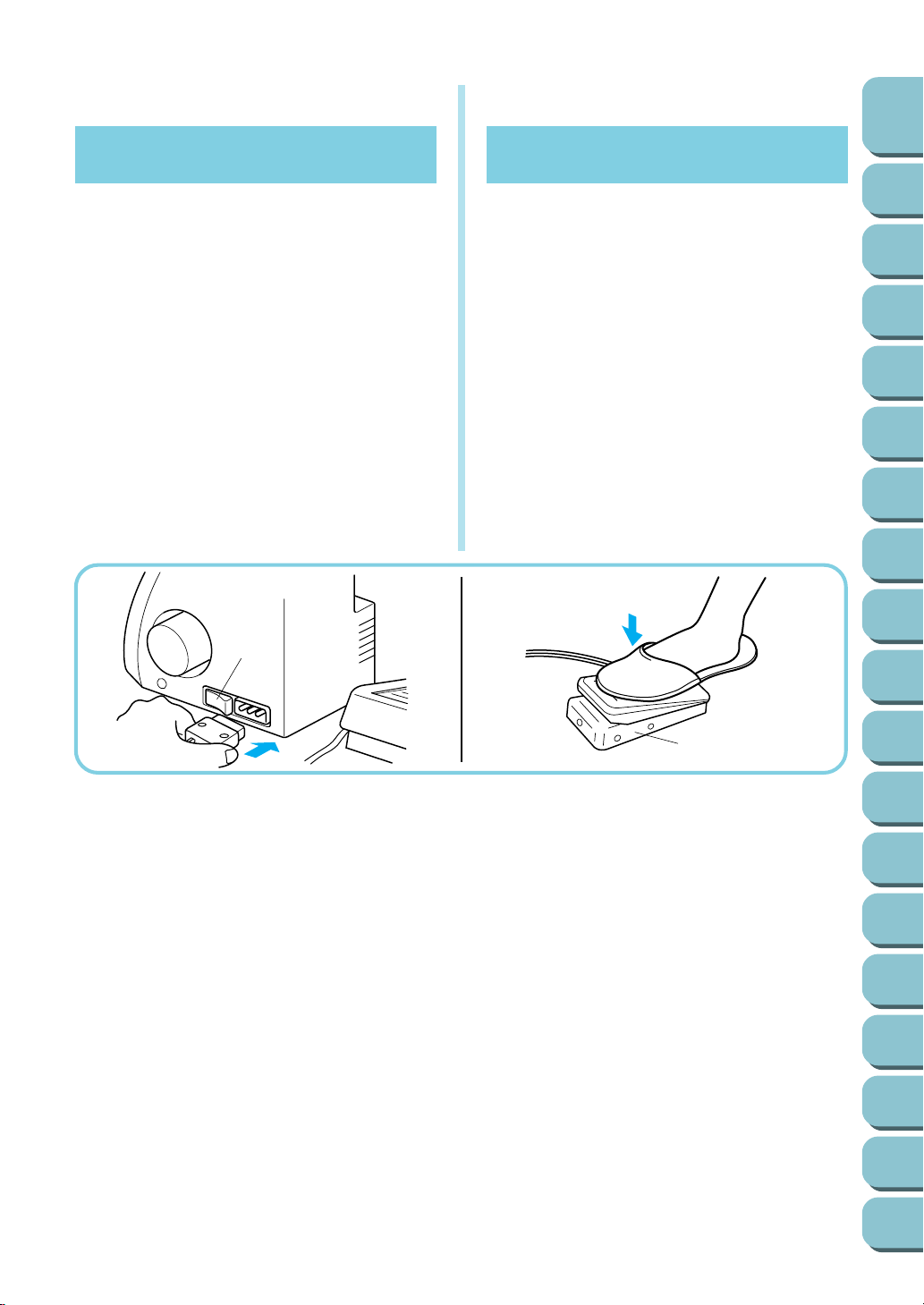

Powering the machine

Preparation

• Insert the three-pin plug into the socket on the

bottom right side of the machine. Insert the power

supply plug into a power outlet.

Main Power and Sewing Light Switch

This switch turns the power and sewing light on or off.

To turn on push toward “1” mark. To turn off push

toward “0” mark.

1 Main Power and Sewing Light Switch

Operation

When the pedal is pressed lightly, the machine runs

at a low speed. As the pedal is pressed further, the

machine will increase speed. When the pedal is

released, the machine stops.

2 Foot Controller: Model N

Note (For U.S.A. only):

This foot controller can be used for sewing machine

models 1034D, 1034, 1030D and 1030.

1

Encendido de la máquina

Preparación de la máquina

•

Introduzca el zócalo de tres puntas en el enchufe

que se encuentra abajo, en el lado derecho de la

máquina e inserte el zócalo de alimentación en

una toma de corriente.

Interruptor principal y de luz

Este interruptor permite apagar y encender la máquina así como la luz. Para encender, empuje hacia

la marca “1”; para apagar, póngalo en la marca “0”.

1

Interruptor principal y de luz

Funcionamiento

Al oprimir ligeramente el pedal, la máquina funcionará a baja velocidad. A medida que se apriete más, la

máquina incrementará su velocidad. La máquina se

parará tan pronto como se suelte el pedal.

2

Pedal

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

2

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

8

Page 16

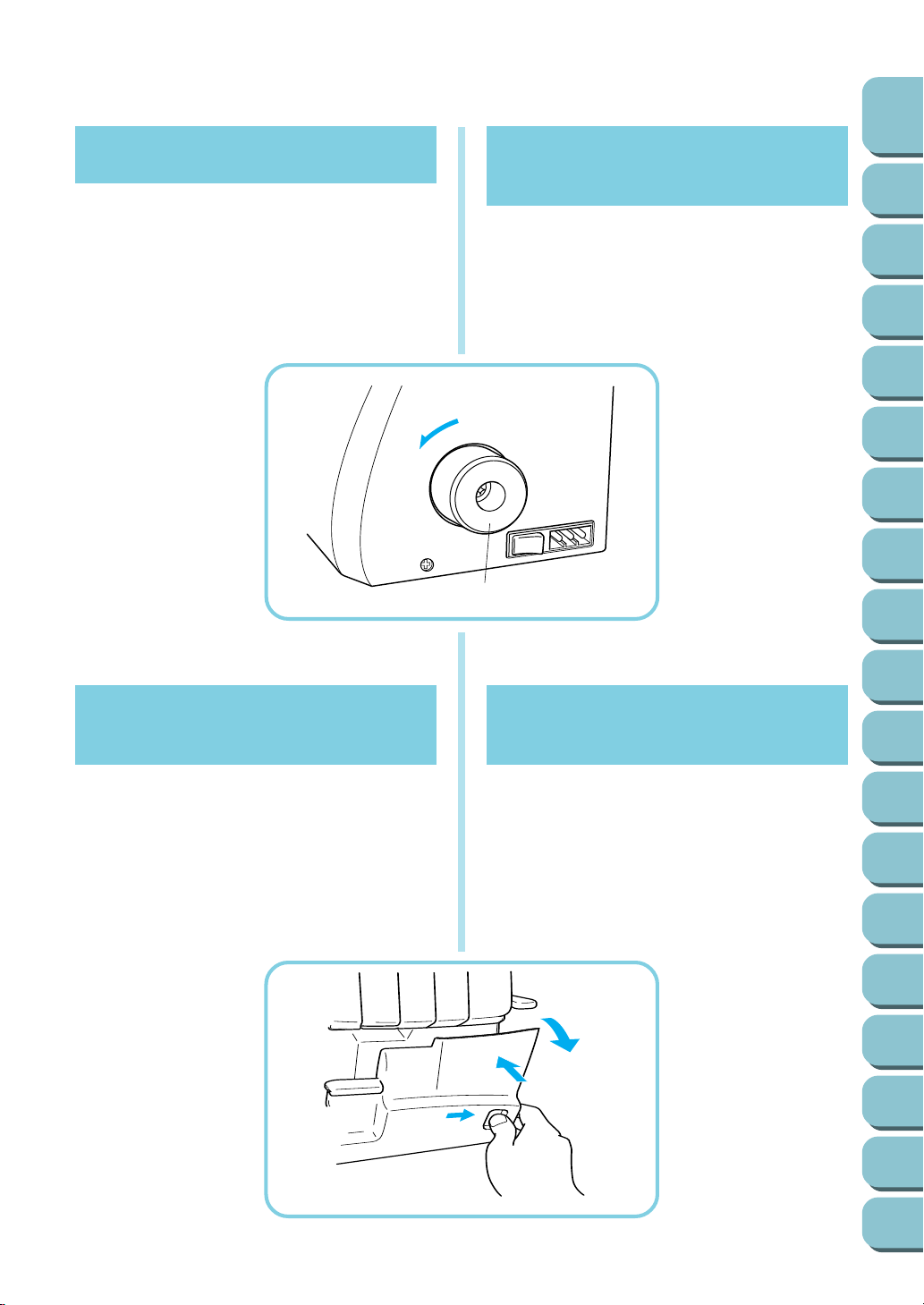

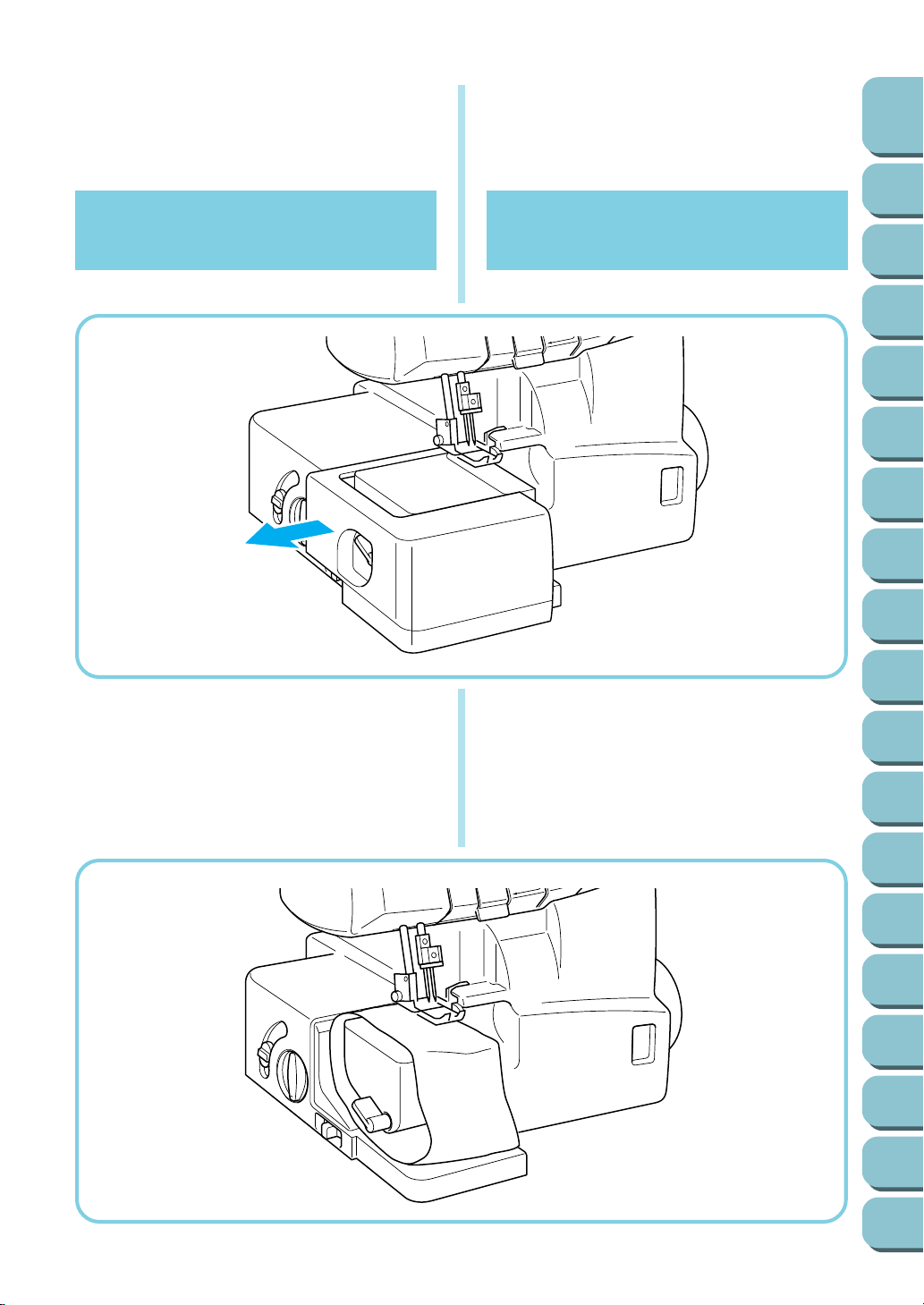

Removing the

Extraiga el suplemento

CONTENTS

TABLE OF

Bed Extension for

Free-Arm Sewing

Removing the

bed extension

para la mesa para realizar la costura sin brazo

Extraiga el suplemento

para la mesa

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Free-arm sewing enables tubular pieces to be sewn

more easily. For free-arm sewing, remove the bed

extension and position the fabric as shown in the

illustration.

La costura sin brazo permite coser trozos tubulares

de tejido de forma más sencilla. Para llevar a cabo la

costura sin brazo, extraiga el suplemento para la

mesa y coloque el tejido tal y como se indica en la

ilustración.

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

9

Page 17

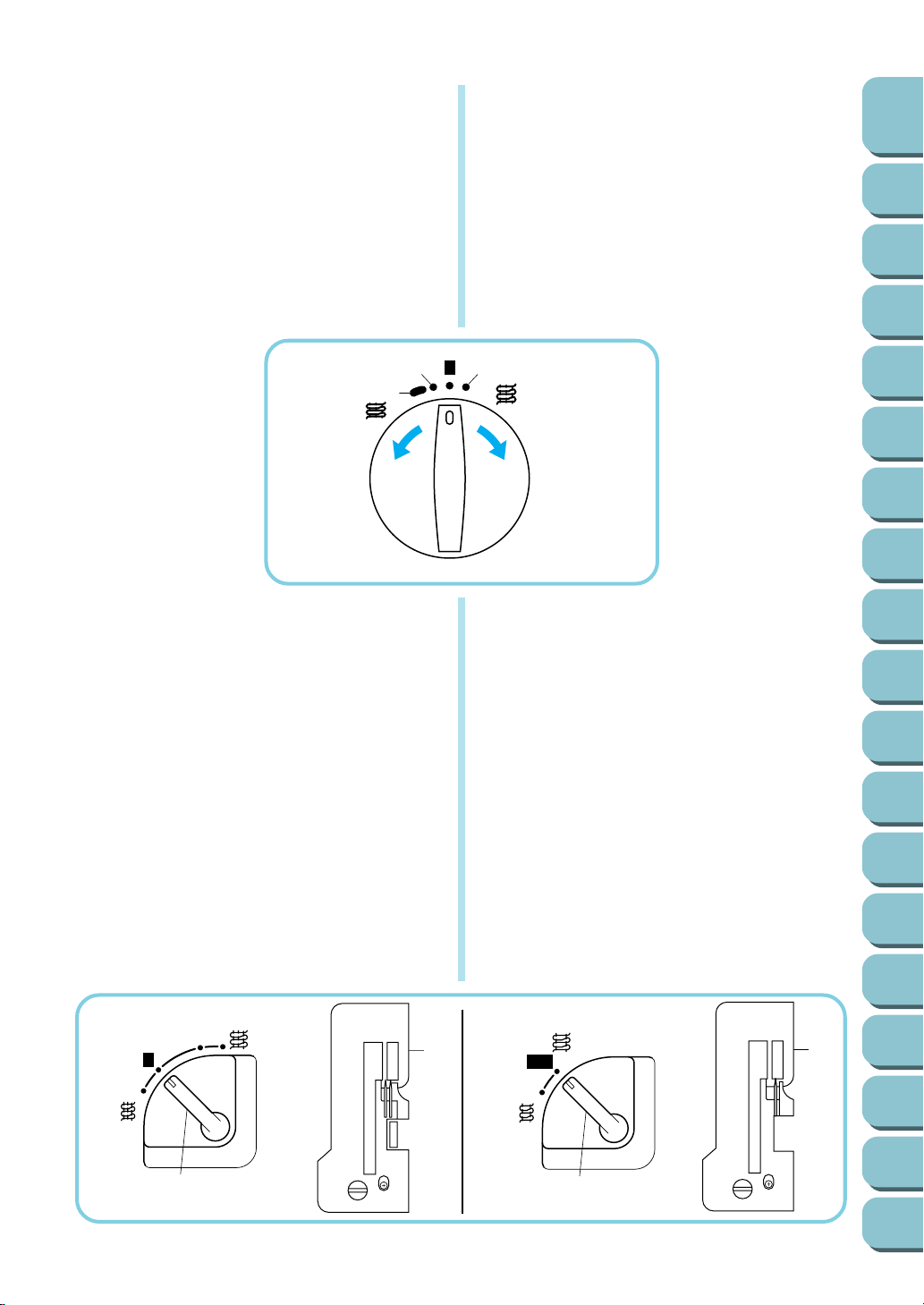

Stitch Length

To change the stitch length,

(1)Locate the stitch length adjustment dial on the left

side of the machine.

(2)Turn the stitch length adjustment dial forward to

lengthen the stitch to a maximum of 4 mm (5/32

inch).

Turn the stitch length adjustment dial backwards

to shorten the stitch length to a minimum of 2 mm

(1/8 inch).

(3) The normal stitch length setting is 2.5 mm to 3

mm.

2

R

Stitch Width

Two-needle models

To change the stitch width.

(1)Move the stitch width lever (located on the left side

of the machine toward the front) up to reduce the

stitch width or down to increase the width.

The stitch width can be set between R4.5 mm (11/

64 inch) and 7 mm (9/32 inch).

The normal stitch width setting for regular overlock

stitch is 5mm (13/64 inch).

One-needle models

• The width is factory set to 3.5mm (9/64 inch).

A Two-needle models

B One-needle models

1 Stitch width lever

2 Regular needle plate

Largo de puntada

Para cambiar el largo de las puntada:

(1)Busque el disco de ajuste del largo de las punta-

das en al lado izquierdo de la máquina.

(2)Gire el disco de ajuste del largo de las puntadas

hacia adelante para alargar la puntada a un

máximo de 4 mm.

Gire el disco de ajuste del largo de las puntadas

hacia atrás para acortar la longitud de puntada a

un mínimo de 2 mm.

* Un ajuste normal para el largo de las puntadas se

sitúa entre 2,5 y 3 mm.

3

4

Ancho de puntada

Modelos de dos agujas.

•

Para cambiar el ancho de puntada.

(1) Mueva la palanca de anchura de las puntadas

(situada a la izquierda de la máquina, hacia

adelante) hacia arriba para reducir el ancho de

puntada, o hacia abajo para aumentar el ancho

de puntada.

Puede ajustar el ancho de puntada entre R4,5

mm y 7 mm.

El ajuste normal del ancho de puntada para una

puntada overlock corriente es de 5 mm.

Modelos de una aguja.

•

El ancho de las puntadas está establecido en la

fábrica en 3,5 mm.

A

Modelos de dos agujas

B

Modelos de una aguja

1

Palanca de anchura de las puntadas

2

Place de aguja normal

CONTENTS

TABLE OF

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Chapter

10

Chapter

11

Chapter

12

Chapter

13

Chapter

14

A

Chapter

7

6

5

R

1

2

B

R

3.5

2

1

15

16

17

18

Chapter

Chapter

Chapter

10

Page 18

Instructions for the

Differential Feed

Instrucciones para el

mecanismo de alimenta-

CONTENTS

TABLE OF

Mechanism (Models

with Differential Feed)

This serger is equipped with two sets of feed dogs

under the presser foot to move the fabric through the

machine. The differential feed controls the movement of both the front and the rear feed dogs. When

set at 1, the feed dogs are moving at the same speed

(ratio of 1). When the differential feed ratio is set at

less than 1, the front feed dogs move slower than the

rear feed dogs, stretching the fabric as it is sewn.

This is effective on lightweight fabric that may pucker.

When the differential feed ratio is set at greater than

1, the front feed dogs move faster than the back feed

dogs, gathering the fabric as it is sewn. This function

assists in removing the rippling when serging stretch

fabrics.

• To adjust the differential feed.

(1) Locate the differential feed adjustment lever on

the left side of the machine.

(2)The normal setting is 1.0 on the differential feed

adjustment lever.

(3)To set less than 1.0, move the lever back.

(4)To set greater than 1.0, move the lever forward.

ción con diferencial

(Modelos con alimenta-

dor diferencial)

Esta máquina de coser está provista de dos series

de alimentadores debajo del prensatelas para guiar

el tejido por la máquina. El alimentador con diferencial controla los movimientos de los alimentadores

delanteros y traseros. Al ajustarlo en 1, los

alimentadores se desplazarán a una velocidad idéntica (relación de 1). Al ajustar la relación del alimentador con diferencial en menos de 1, los alimentadores

delanteros van a moverse más despacio que los

traseros, estirando el tejido a medida que se cuese.

Esta operación resulta muy eficiente al coser materiales finos que pueden arrugarse.

Cuando el alimentador con diferencial esté ajustado

en un valor superior a 1, los alimentadores delanteros van a moverse más rápido que los alimentadores

traseros, juntando el tejido al coserlo. Esta función

permite quitar las arrugas al coser tejidos que se

estiran.

•

Para ajustar el alimentador diferencial.

(1)Busque la palanca de ajuste del alimentador

diferencial en al lado izquierdo de la máquina.

(2)El ajuste normal es de 1,0 en la palanca de ajuste

del alimentador diferencial.

(3) Para ajustar menos de 1,0, mueva la palanca

hacia atrás.

(4)Para ajustar más de 1,0, mueva la palanca hacia

adelante.

1

2

3

4

5

6

7

8

9

10

11

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

11

1.0

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 19

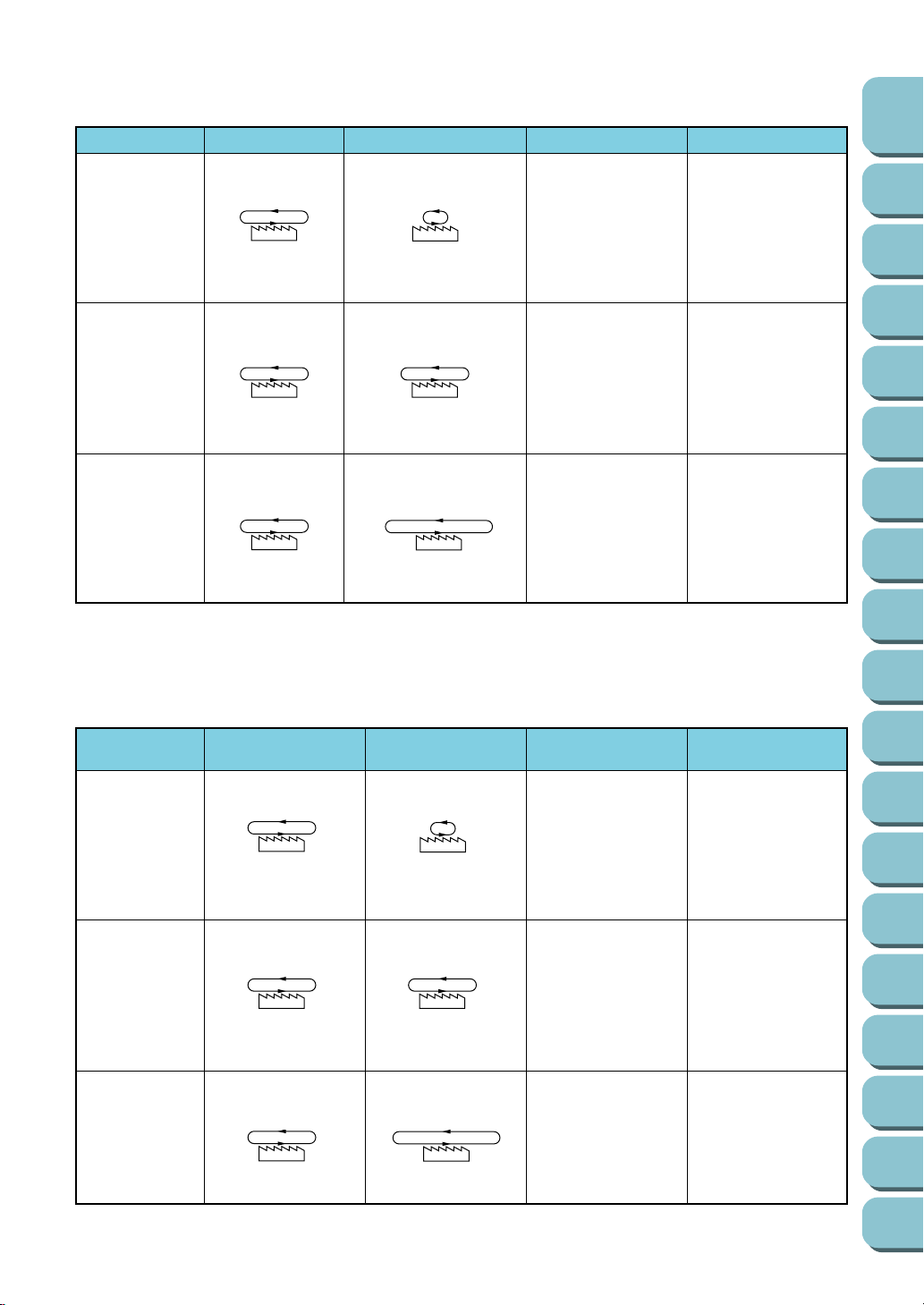

Feed ratio Main feed (rear) Differential feed (front) Effect Application

CONTENTS

TABLE OF

Chapter

1

0.7 – 1.0

1.0

1.0 – 2.0

Velocidad de

alimentación

Alimentador

principal (detrás).

Alimentador con

diferencial (delante).

Material is pulled

tight.

Without differential

feed.

Material is gathered or pushed

together.

Efecto.

Prevents thin materials from puckering

Normal sewing

Prevents stretch materials from stretching or puckering

Uso.

2

3

4

5

6

7

8

9

10

11

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

0,7 – 1,0

1,0

1,0 – 2,0

El tejido se estira

Sin alimentación con

diferencial.

El tejido se contrae

o se junta.

Impide que los tejidos finos frunzan.

Costura normal.

Impide que los tejidos extensibles se

estiren o frunzan.

12

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 20

CONTENTS

TABLE OF

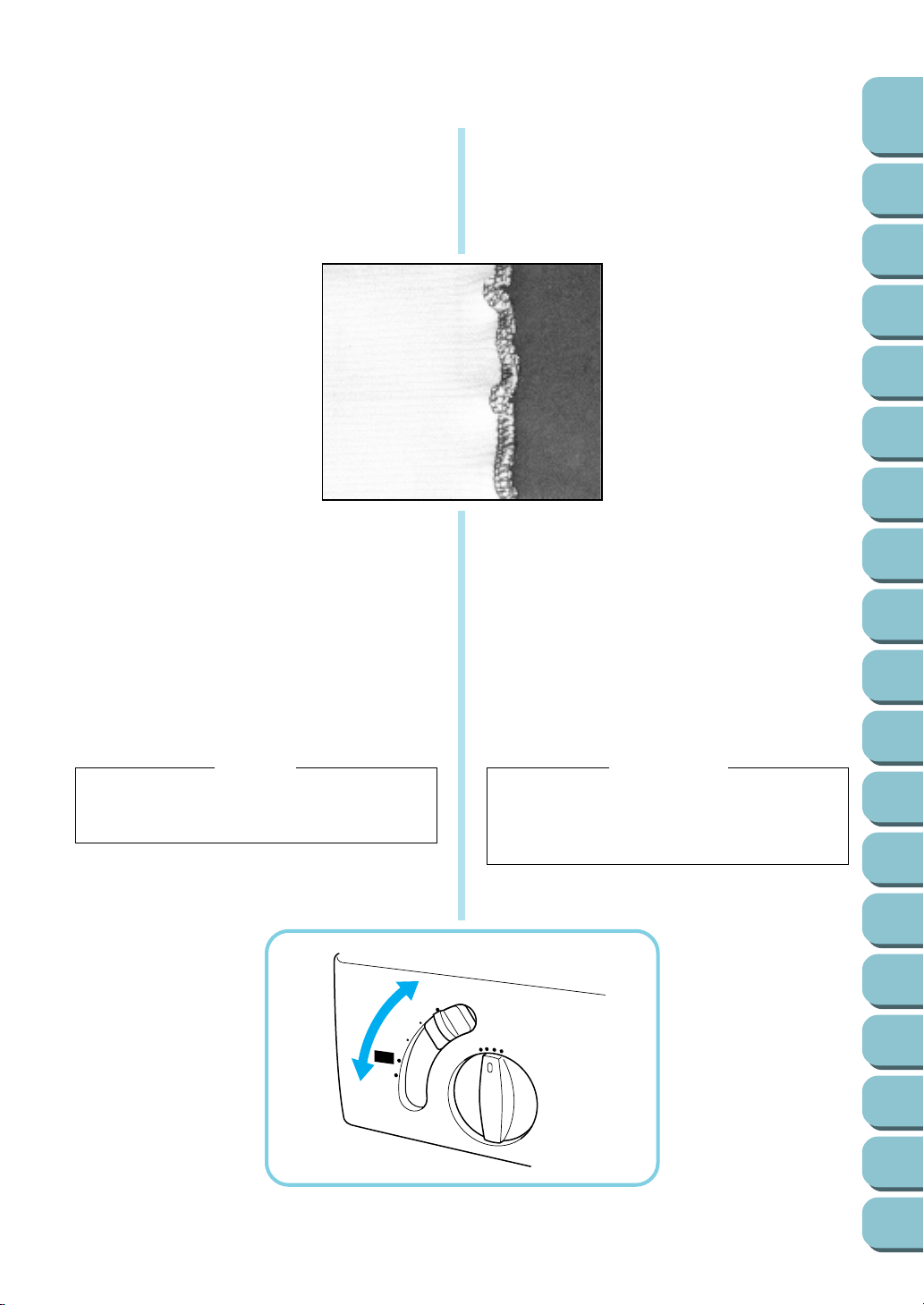

• An example where adjustment is required

When stretch material is sewn without using the

differential feed, the edge will be wavy.

To make the edge more smooth, adjust the feed ratio

from 1.0 toward 2.0.

(The feed ratio required depends on the elasticity of

the material.)

The more elastic the material, the further toward 2.0

the differential feed ratio should be set. Test sew with

a scrap of the fabric to find the correct adjustment.

•

Ejemplo en que se requiere ajuste

Al coser tejidos extensibles sin utilizar una alimentación con diferencial, su borde va a ser oleado.

Para remediar al problema y mejorar la apariencia

del borde, ajuste la velocidad de alimentación de 1,0

hacia 2,0. (El ajuste de la velocidad de alimentación

depende de la elasticidad del material).

Cuanto más elástico el tejido, más hacia 2 se debe

poner el ajuste de la velocidad de alimentación con

diferencial. Haga una prueba con un poco de tejido

para encontrar el ajuste correcto.

1

2

3

4

5

6

7

8

9

10

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

CAUTION

When sewing thick non-stretchable material

such as denim, do not use the differential

feed as it may damage the fabric.

13

1.0

PRECAUCION

Si debe coser tejidos gruesos que no son

elásticos, tales como el tejano, no trabaje

con el alimentador diferencial, para no deteriorar el material.

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 21

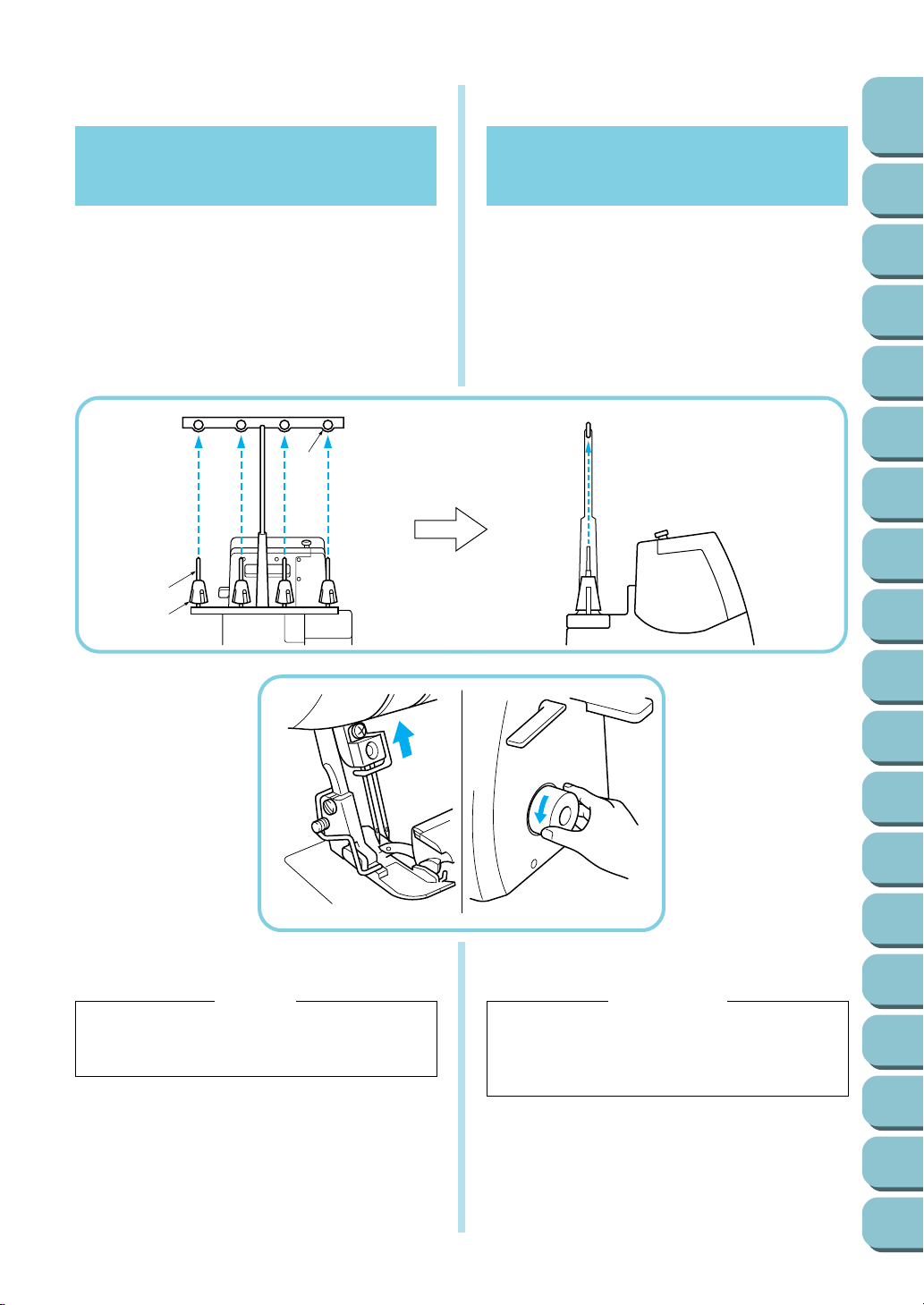

Before Threading

Antes del enhebrado

CONTENTS

TABLE OF

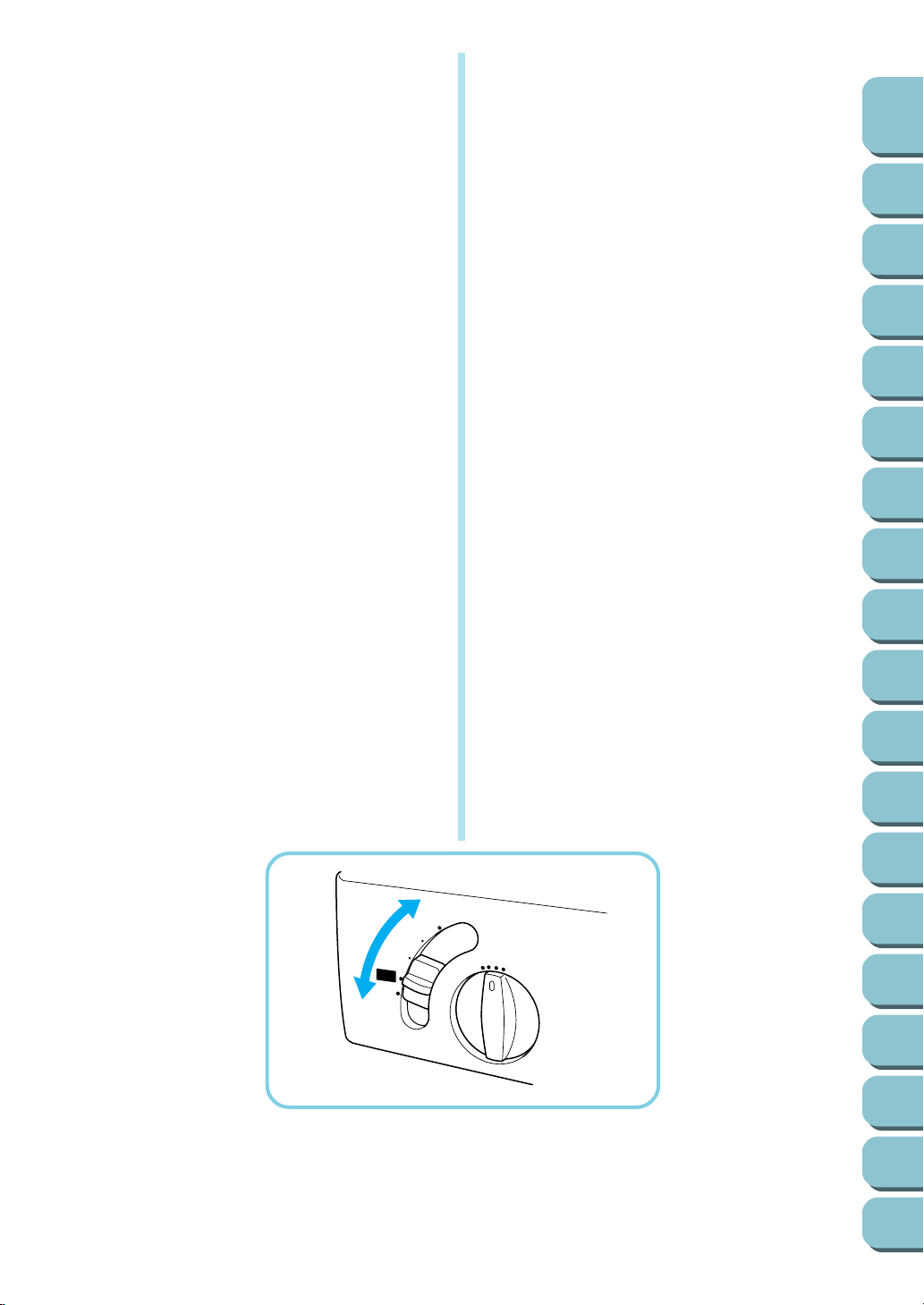

Preparation before

threading

Raise the telescoping thread tree to its highest

position. Make sure that the thread holders are in

alignment above the spool pins as illustrated below.

1 Thread holder on thread tree

2 Spool pin

3 On Two-needle models

4 Correct position

1

2

3

Preparación antes del

enhebrado

Levante el árbol telescópico del hilo hasta su posición más alta. Compruebe que los corchetes de hilos

quedan alineados sobre los portabobinas como se

ilustra a continuación.

1

Portahilos en el árbol del hilo

2

Portabobina

3

En los modelos de dos agujas

4

Posición correcta

4

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

CAUTION

When threading, always thread in this order:

upperlooper, lowerlooper, right needle and

then the left needle.

PRECAUCION

Cuando haga el enhebrado, enhebre siempre en este orden: áncora superior, áncora

inferior, aguja derecha y luego aguja izquierda.

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

14

Page 22

CONTENTS

5

6

4

3

TABLE OF

How to use the thread

spool cap

When using sewing thread spools, the thread spool

cap should be used as illustrated below.

Make sure that the spool notch is on the bottom. (See

fig. A)

1 Thread spool cap

How to use the thread net

If you are sewing with loosely spun nylon thread, we

recommend that you cover the spool with the net

supplied to prevent the thread from slipping off the

spool.

Adapt the net to the shape of the spool. (See fig. B)

1 Net

1

Como utilizar el tope del

carrete

Cuando utilice carretes de hilo de coses, el tope del

carrete debe emplearse tal como se ilustra abajo.

Asegúrese de que la muesca del carrete quede

hacia abajo. (Véase fig.

1

Tope del carrete

A

)

Como utilizar la malla

para hilo

Si está cosiendo con un hilo de hilvanar, le recomendamos cubrir el carrete con la malla provista para

que el hilo no se deslice del carrete.

Adapte la malla a la forma del carrete. (Véase fig.

1

Malla

BA

1

B

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

)

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Tension release button

This serger is equipped with a thread tension release

button. When threading, be sure to:

(1)Hold the tension release button directly above the

tension adjustment wheel to the right.

(2)Pass the thread through the tension disc which is

in the channel next to the tension adjustment dial.

(3)Release the button.

1 Thread tension release button

2 Thread tension dial

3 Slide to the right.

1

6

5

4

15

2

Botón de liberación de la

tensión

Esta máquina está equipada con un botón de liberación de la tensión del hilo. Cuando haga en enhebrado, asegúrese de:

(1)Retener el botón liberación de la tensión directa-

mente encima de la rueda de ajuste de la tensión

de la derecha.

(2)Pase el hilo por le disco de tensión, que está en

el canal al lado del disco de ajuste de la tensión.

(3)Libere el botón.

1

Botón de liberación de la tensión del hilo

2

Disco de tensión del hilo

3

Deslícela hacia la derecha.

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 23

CONTENTS

TABLE OF

Before threading

(1)Turn off the main power switch for safety.

(2)Raise the presser foot using presser foot lever.

CAUTION

When threading the needle, always be sure

to lift the presser foot lever, and also take

care to thread in the proper order.

(3)Set the needle bar in its highest position by

turning the handwheel toward you.

Turn the handwheel to find the easiest position for

threading, and then thread the upperlooper thread,

lowerlooper thread, right needle thread and then

the left needle thread. The proper threading order

for this serger is upperlooper, lowerlooper, right

needle, and then the left needle.

1 Slide to the right

2 Thread tension discs

3 Correct

4 Wrong

Antes de enhebrar

(1)Apagar el interruptor principal por seguridad.

(2)Levantar el prensatelas con la palanca.

PRECAUCION

Al enhebrar la aguja, se debe asegurar de

levantar la palanca del prensatelas, y también de enhebrar en el orden correcto.

(3)Colocar la aguja en la posición más alta, girando

la polea hacia afuera.

Girar la perilla hasta encontrar la posición más

fácil para enhebrar, y luego enhebrar el hilo del

áncora superior, él del áncora inferior, él de la

aguja derecha y él de la aguja izquierda o él de la

aguja de puntada de doble cadeneta (sólo en el

modelo de 5 hilos), en ese orden. El orden de

enhebrado correcto de esta máquina es el siguiente: áncora superior, áncora inferior, agujas

derechas y luego aguja izquierda.

1

Deslice hacia la derecha

2

Discos de tensión de hilo

3

Correcto

4

Incorrecto

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

1

Chapter

10

2

Chapter

6

5

4

6

5

4

6

5

4

34

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

16

Page 24

CONTENTS

TABLE OF

Threading the

upperlooper

• Run the thread in the sequence illustrated, follow-

ing the green color and the numbers next to each

threading point.

1 Open the front cover by sliding to the right

and guiding the top toward you.

2 Pull the thread off the spool and directly up

through the thread guide on the thread tree

from back to front.

3 Pull the thread about an extra 15cm (6

inches) through the front of the thread tree.

4 Pass the thread through the proper thread

guide.

5 Slide and hold the thread tension release

button to the right, then pass the thread

through the tension disc which is in the

channel next to the green tension adjustment dial. Release the button.

6 Guide the thread down the channel and

pass the thread through the threading

points next to the green color marks following the numerical order in the accompanying illustration.

Enhebrado del áncora

superior

•

Enhebre el hilo según ilustrado en la secuencia,

siguiendo el color verde y los números inscritos al

lado de cada punto de enhebrado.

1

Abra la tapa delantera deslizándola hacia

la derecha y guiando la parte superior

hacia usted.

2

Saque el hilo del carrete y póngalo directamente por la guía de enhebrado del

árbol de enhebrado desde detrás a delante.

3

Tire del hilo otros 15 cm aproximadamente

por la parte delantera del árbol de enhebrado.

4

Pase el hilo por la guía de hilo correspondiente.

5

Deslice y retenga el botón de liberación de

la tensión del hilo hacia la derecha, y pase

el hilo por el disco de tensión que es el

canal situado al lado del disco de ajuste de

la tensión verde. Suelte el botón.

6

Guíe el hilo por el canal y pase el hilo por

los puntos de enhebrado al lado de las

marcas de color verde siguiendo el orden

numérico de la ilustración.

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

Chapter

1

8

7

2

3

4

6

5

2

2

6

5

4

3

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

17

Page 25

CONTENTS

TABLE OF

8

7

6

5

NOTE:

If the upperlooper thread breaks during sewing

This may be caused by the lowerlooper thread

getting caught on the upperlooper. If this happens,

lower the upperlooper by turning the hand wheel,

remove the lowerlooper thread from the upperlooper,

and re-thread the upperlooper from at least the

tension disc.

8

7

NOTA:

Si el hilo del áncora superior se rompe al coser.

El hilo del áncora inferior se engancha a veces con

el hilo del áncora superior. En este caso, baje el

áncora superior girando la ruedecilla, saque el hilo

del áncora inferior y vuelva a enhebrar el áncora

superior por lo menos hasta el disco de tensión.

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

18

Page 26

CONTENTS

TABLE OF

Threading the

lowerlooper

• Run the thread in the sequence illustrated, follow-

ing the blue color and the numbers next to each

threading point.

1

3

4

Enhebrado del áncora

inferior

•

Enhebre el hilo según lo ilustrado en la secuencia, observando el color azul y los números

inscritos al lado de cada punto de enhebrado.

2

2

2

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

9

0

A

1 Open the front cover by sliding to the right

and guiding the top toward you.

2 Pull the thread off the spool and directly up

through the thread guide on the thread tree

from back to front.

3 Pull the thread about an extra 15cm (6

inches) through the front of the thread tree.

4 Pass the thread through the proper thread

guide.

B

7

8

6

5

6

5

4

3

1

Abra la tapa delantera deslizándola hacia

la derecha y guiando la parte superior

hacia usted.

2

Saque el hilo del carrete y póngalo directamente por la guía de enhebrado del

árbol de enhebrado desde detrás a delante.

3

Tire del hilo otros 15 cm aproximadamente

por la parte delantera del árbol de enhebrado.

4

Pase el hilo por la guía de hilo correspondiente.

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

19

Page 27

CONTENTS

TABLE OF

5 Slide and hold the thread tension release

button to the right, then pass the thread

through the tension disc which is in the

channel next to the blue tension adjustment dial. Release the button.

6 Guide the thread down the channel and

pass the thread through the threading

points next to the blue color marks following the numerical order in the accompanying illustration up to the lowerlooper threading lever.

NOTE:

If the lowerlooper thread breaks during sewing,

cut and remove thread from both of the needles.

Before re-threading the lowerlooper, make sure

that the lowerlooper re-threading is done exactly

as diagrammed above. The machine will not oper-

ate properly if the threading is not done in the proper

sequence.

Lowerlooper Easy Threading Operation

(Illustrated on page 21)

(1)Slide the lowerlooper threading lever to the right.

(2)Position the thread under the hook (left end) of the

threading lever.

(3)Place the thread through the eye of the

lowerlooper.

(4)Holding the end of the thread, slide the lowerlooper

threading lever to the left which returns it to its

standard position.

(5)Make sure that the pink triangular marks line up.

CAUTION

When sliding the lowerlooper threading lever to the left, always make sure that the two

pink triangular marks line up as illustrated.

1 Lowerlooper

2 Lowerlooper threading lever

CAUTION

Thread the needles after the lowerlooper

and upperlooper have been threaded.

CAUTION

Slide the threading lever only in the directions shown by the arrow. Forcefully moving

the threading lever in any other direction

may damage it.

5

Deslice y retenga el botón de liberación de

la tensión del hilo hacia la derecha, y pase

el hilo por el disco de tensión que es el

canal situado al lado del disco de ajuste de

la tensión azul. Suelte el botón.

6

Guíe el hilo por el canal y pase el hilo por

los puntos de enhebrado al lado de las

marcas de color verde siguiendo el orden

numérico de la ilustración hasta la palanca

de enhebrado del áncora inferior.

NOTA:

Si el hilo del áncora inferior se rompe al coser

Antes de volver a enhebrar el áncora inferior,

asegúrese de que el enhebrado se haya realizado tal como se enseñó en el diagrama arriba. La

máquina no funcionará correctamente si no está

enhebrada en el orden apropiado.

Proceso simple de enhebrado del áncora inferior

(Se ilustra en la página 21)

(1)Deslice la palanca de enhebrado del áncora

inferior hacia la derecha.

(2)Coloque el hilo debajo del corchete (extremo

izquierdo) de la palanca de enhebrado.

(3)Pase el hilo por el ojo del áncora inferior.

(4) Mientras sujete el extremo del hilo, deslice la

palanca de enhebrado del áncora inferior hacia la

izquierda para que vuelva a su posición normal.

(5)Asegúrese de que las marcas en forma de trián-

gulo rosadas queden bien alineadas.

PRECAUCIONES

Al deslizar la palanca del áncora inferior

hacia la izquierda, asegúrese siempre que

las dos marcas triangulares rosadas coincidan como se ilustra.

1

Ancora inferior

2

Palanca del áncora inferior

PRECAUCION

Enhebre siempre las agujas después de

haber enhebrado las áncoras superior e inferior.

PRECAUCION

Deslice la palanca de enhebrado sólo en las

direcciones mostradas por la flecha. Si mueve a la fuerza la palanca de enhebrado en

cualquier otra dirección, podría dañarla.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

20

17

18

Chapter

Chapter

Page 28

(1)

1

(2) (3)

CONTENTS

TABLE OF

Chapter

1

7

8

Chapter

2

2

(4)

Threading the right

needle (on Two-needle

models)

• Run the thread in the sequence illustrated on

page 22, following the pink color and the numbers

next to each threading point.

1 Pull the thread off the spool and directly up

through the thread guide on the thread tree

from back to front.

2 Pull the thread about an extra 15cm (6

inches) through the front of the thread tree.

3 Pass the thread through the proper thread

guide.

4 Slide and hold the thread tension release

button to the right, then pass the thread

through the tension disc which is in the

channel next to the pink tension adjustment dial. Release the button.

5 Guide the thread down the channel and

across through the threading points next to

the pink color marks following the numerical order in the accompanying illustration.

6 Bring the thread down through the guide 7

above the needle and through the right

needle from front to back.

(5)

Enhebrado de la aguja

derecha (los modelos de

dos agujas)

•

Enhebre la aguja tal como está ilustrado en la

secuencia (en la página 22), respetando el color

rosa y los números inscritos al lado de cada punto

de enhebrado.

1

Saque el hilo del carrete y póngalo directamente por la guía de enhebrado del

árbol de enhebrado desde detrás a delante.

2

Tire del hilo otros 15 cm aproximadamente

por la parte delantera del árbol de enhebrado.

3

Pase el hilo por la guía de hilo correspondiente.

4

Deslice y retenga el botón de liberación de

la tensión del hilo hacia la derecha, y pase

el hilo por el disco de tensión que es el

canal situado al lado del disco de ajuste de

la tensión rosado. Suelte el botón.

5

Guíe el hilo por el canal y pase el hilo a

través de los puntos de enhebrado al lado

de las marcas de color rosa siguiendo el

orden numérico de la ilustración.

6

Baje el hilo por la guía 7 por encima de la

aguja y por la aguja derecha desde delante a atrás.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

21

Page 29

CONTENTS

TABLE OF

1

2

Chapter

1

Chapter

2

Chapter

3

2

3

Chapter

4

Chapter

5

5

4

6

7

6

7

2

6

5

4

3

Chapter

6

Chapter

7

Chapter

8

Chapter

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

22

Page 30

CONTENTS

TABLE OF

Threading the left needle

• Run the thread in the sequence illustrated, follow-

ing the yellow color and the numbers next to each

threading point.

1 Pull the thread off the spool and directly up

through the thread guide on the thread tree

from back to front.

2 Pull the thread about an extra 15cm (6

inches) through the front of the thread tree.

3 Pass the thread through the proper thread

guide.

4 Slide and hold the thread tension release

button to the right, then pass the thread

through the tension disc which is in the

channel next to the yellow tension adjustment dial. Release the button.

5 Guide the thread down the channel and

across through the threading points next to

the yellow color marks following the numerical order in the accompanying illustration.

6 Bring the thread down through the guide 7

above the needle and through the left

needle from front to back.

Enhebrado de la aguja

izquierda

•

Enhebre la aguja tal como ilustrado en la secuencia, respetando el color amarillo y los números

inscritos al lado de cada punto de enhebrado.

1

Saque el hilo del carrete y póngalo directamente por la guía de enhebrado del

árbol de enhebrado desde detrás a delante.

2

Tire del hilo otros 15 cm aproximadamente

por la parte delantera del árbol de enhebrado.

3

Pase el hilo por la guía de hilo correspondiente.

4

Deslice y retenga el botón de liberación de

la tensión del hilo hacia la derecha, y pase

el hilo por el disco de tensión que es el

canal situado al lado del disco de ajuste de

la tensión amarillo. Suelte el botón.

5

Guíe el hilo por el canal y pase el hilo a

través de los puntos de enhebrado al lado

de las marcas de color amarillo siguiendo

el orden numérico de la ilustración.

6

Baje el hilo por la guía 7 por encima de la

aguja y por la aguja izquierda desde delante a atrás.

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

Chapter

7

Chapter

8

Chapter

9

10

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

23

Page 31

CONTENTS

TABLE OF

1

2

Chapter

1

Chapter

2

Chapter

3

2

6

5

4

3

2

3

5

4

Chapter

4

Chapter

5

Chapter

6

Chapter

7

43

6

7

Chapter

8

6

7

6

7

9

10

11

12

13

14

15

16

17

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

24

18

Chapter

Page 32

Comparison Chart of Sewing Materials,

Threads and Needles

CONTENTS

TABLE OF

Material Stitch

Crepe de chine

Light

materials

Light Georgette

materials Lawn

Medium Seersucker

materials Gabardine

Heavy Tweed

materials Denim

Georgette

Lawn

Organdy

Tricot

Crepe de chine

Organdy

Poplin

Gingham

Serge

Knitted

Cashmere

Jersey

Overlock stitch

Narrow/rolled

Hem stitch

Overlock stitch

Overlock stitch

Stitch Length

(mm)

2.0-3.0

Smaller than 2.0

2.5-3.5

3.0-4.0

Thread

Spun : #80

Cotton : #80·100

Silk : #80·100

Needle thread

Polyester: #80

Nylon : #80

Looper thread

Polyester: #80

Nylon : #80

Woolly nylon thread

Spun : #60·80

Cotton : #60·80

Silk : #50·80

Nylon : #50·80

Polyester: #50·80

Cotton : #40·60

Silk : #40·60

Polyester: #30·60

Nylon : #30·60

Needle

SCHMETZ

130/705H

#70

#80

SCHMETZ

130/705H

#70

#80

SCHMETZ

130/705H

#80

#90

SCHMETZ

130/705H

#90

1

2

3

4

5

6

7

8

9

10

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

NOTE:

Decorative thread will work best in the upperlooper for fashion sewing.

25

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 33

Tabla de relación entre los distintos tejidos,

hilos y agujas

CONTENTS

TABLE OF

Tejido Puntada

Crepe de China

Tejidos

finos

Tejidos Georgette

finos Lino

Tejidos

medios Gabardina

Tejidos Tweed

gruesos Tejano

Georgette

Lino

Organdí

Tricot

Crepe de China

Organdí

Popelina

Guinga

Crespón de algodón

Sarga

Prendas de punto

Cachemir

Jersey

Puntadas

Overlock

Estrechas/

Puntadas de

dobladillo

enrollado

Puntadas

Overlock

Puntada

Overlock

Largo de

puntada (mm)

2,0 - 3,0

Inferior a 2,0

2,5 - 3,5

3,0 - 4,0

Hilo

Hilo de

hilvanar : n°80

°

Algodón : n

Seda : n

Hilo de las agujas

Poliester: n° 80

Nilón : n

Hilo del áncora

Poliester: n

Nilón : n

Hilo de nilón tipo lana

Hilo de

hilvanar : n

Algodón : n

Seda : n

Nilón : n

Poliester: n

Algodón : n

Seda : n

Poliester: n

Nilón : n

80 - 100

°

80 - 100

°

80

°

80

°

80

°

60 - 80

°

60 - 80

°

50 - 80

°

50 - 80

°

50 - 80

°

40 - 60

°

40 - 60

°

30 - 60

°

30 - 60

Aguja

SCHMETZ

130/705H

n

°

70

°

80

n

SCHMETZ

130/705H

°

70

n

°

80

n

SCHMETZ

130/705H

n°80

°

90

n

SCHMETZ

130/705H

n°90

1

2

3

4

5

6

7

8

9

10

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

NOTA:

Un hilo decorativo dará mejores resultados en el áncora superior para la costura de prendas de moda.

26

11

12

13

14

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Page 34

Thread Tension

Thread tension dial

From the left to right:

1 Yellow marked tension disc is for left nee-

dle.

2 Pink marked tension disc is for right nee-

dle.

3 Green marked tension disc is for

upperlooper.

4 Blue marked tension disc is for lowerlooper.

5 Tension selection mark.

6 Dial up to decrease tension.

7 Dial down to increase tension.

1 2 3 4

Tensión del hilo

Disco de tensión del hilo

Desde la izquierda a la derecha:

1

El disco de tensión con marca amarilla es

para la aguja izquierda.

2

El disco de tensión con marca rosada es

para la aguja derecha.

3

El disco de tensión con marca verde es

para el áncora superior.

4

El disco de tensión con marca azul es para

el áncora inferior.

5

Marca de selección de tención.

6

Disco hacia arriba para reducir la tensión.

7

Disco hacia abajo para aumentar la tensión.

CONTENTS

TABLE OF

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

CAUTION

Make sure that the thread is properly seated

in the tension discs by holding the tension

release button to the right while passing the

thread through the tension discs.

6

6

5

5

4

7

PRECAUCION

Asegúrese de que el hilo esté bien colocado en los discos de tensión reteniendo el

botón de liberación de la tensión a la

derecha mientras pasa el hilo por los

discos de tensión.

6

7

8

9

10

11

12

13

14

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

Chapter

27

15

16

17

18

Chapter

Chapter

Chapter

Chapter

Page 35

CONTENTS

TABLE OF

Tension control

Sewing is possible at position “4” for most circumstances. If improper stitching occurs, adjust the

tension according to the drawing below.

(Standard: SPAN 60/3Z)