Page 1

\.

T-8421B,

84228

MANUAL

INSTRUCTION

DE

INSTRUCCIONES

MANUAL

T-8722B

T-8452B,

2 h 5

TWIN

Please

Please

DOS

Por

For

NEEDLE

read

this manual before using

keep

this manual within

AGUJAS

favor

lea

favor

guarde

este

manual

este

manual al

8752B

DIRECT

the

machine.

easy

reach

for quick reference.

CON

antesdeusarlamaquina.

MOTOR

alcancedela

V>

DRIVE

INCORPORADO

mano

para

LOCK

una

rapida

STITCHER

referenda.

brother.

Page 2

T-8421B

T-8422B

2

3^n-M^Vb^hK7'r3Jfgib^t:)]y5v>

T-8452B

T-8722B

T-8752B

2

Page 3

^^lciEJiLfctl':J< yj$S;$:i: ttzmmiSi[^^lsb. ifeJitt

TL^tfc^,^i:go-C^,^^•r„

ScticfeyA^tdcr^LNS-ro

Lr^^tl(D^^lSlC^SlJ(Dc:i2ii$L^fcy•£#S•rd:-5

iSlpLNtNfc

LS1"o

4j ^ffl(~'EEofciis#ii, wti^fRsysSJi'fbf l|j|xis#(z®is

X<fztSl\

tLx^mtx<tz^iK

MSBo-jiii:, ^<i>ms>0mmimwt&tzibiz!mtma,vt.

Page 4

•rsftKA'fey

1.

$-r<,

ye^f^s®fc«)row<tsf^OTfi#^S(+s

fcibic

jEu<

feffiLK

fc*$

i.\

in^TntrnMii^^iDtii')

7I\

Q

Q

"Ci"„

0HS-^(i

rLriilMfECt^Zirj

T-8421B,

8422B,

8452B, 8722B,

8752B

Page 5

2.

A

o

o

®ay

y^-To

mv^mLx<fz^i\

^dry^-To

-(•

o

y

^-To

5

0

^CoT<t£$L^o

o

P^S^&#(cMLr<f£^L^o

5i>>ld:^^50kg<7)MSA^fcySt'o

o

0

^cj:L^"e<

x®»ff

-r

f£^l^o

XIJ

S •> s t

11113

L-r

~AJil±

iSfili:

o

>&:

<tzii.\

ffig-v>saii

•f".

45%;!)''&

Htifey^f.

SA<*tL-CU.5i$MS^«y,

o

S(i5

X.#lt

->>®^«lf^®®S<!:

Op-K^gi^-r-sir^ii.

tzf-J.

^

^!a-®m®BH<t'S:y^-r.

0

4r-v;^^i-#®x—X;Ui.

xa!-^sguT<fSLv

xx—^^i:L^-e<f£^l^o

A5-»^ffi]Lfcy,

r*fT'SoT<fc*$i,*o

^i^'CtT^Cd

i:

(tA<0JgS

5°C!!)^6

5 V

35°c®saT-ffifflLT

V®Sllf^®lgH

85%r%

)&ySt".

=i-h'^mmiz

«)!!l>JEft,^J:5+-V

SLfcy-r.5i:#i4,

<i:5v>0S^-e^A^^y

t tj: y o

i:

Sac^SEL'S

asx^

y s

a#

s

0

<

f£$L^o

zi>

hP—;U7H»:/^7X0ite|^a)JIia<!:^i:y

to

7-X^^^Lr

<f£$L^o

^

o

liI2:^j:yS-ro

T-8421B,

8422B,

8452B,

(cLr<f£^L^o

to

ttzmmi^'p^*j-7.^^/vfz^)'k-<fz^)

^fL>tr<fc'$lNo

^to

8722B,

8752B

T#i-

fcaRt-r-S-itA^fcy

Z^izmi^X

<

^

L

fz^l\

Page 6

0

(+fc

LT

s^rofctoweasss®

<

A

y

#itTffiffl

lt

0

fflL->S:l.^-e<fc'Sl.\

O

SftifcWJl'i

A

KoTMSSgt-i:,

HHt^cy^-r.

• L

• Tt^lf

O

X^-^ll^LT<f£^L^o

l::AyltA<®)SSttty^"T.

5-»A<f^aLri+A<®

O

O

^ ^

t'sysf,

iaffl4'.

(+A<,

5-»^«Lfcy,

T??T'aor<f£$i.\

li$t'lSi:(+A<®)iH

Cfca^,

i.^,,

i+fca«#i;

5->»!)«itteLfcli^,

»<®p°plwi^^lfcy,

Sfctt5-»®iiSa®®Si:'S:yS1-,

5i:S

-»OT«$•?#*</«#

-fCCSSX-f

-j-LT,

fci#«>®iS5Sis$fcttiiiass

-a«s<t£ii\

ti-effufcy

MLfcy-r^stttt,

t ^ y ^ f o

fclS?ft®I5§S)£«fc

l

y,

„

<^S®Biri:S®:^'i'-y^S«oT<fc*^L^c

^ a-or!gffiS!gt?i:, 5-»)b<t^ttLrit)!i<®

5-»^«Lfcy,

mttc'-Jtiiztit.

A

)T-¥-C-fT'S-5i5->:/®B$-C¥A<jSy.

14S

t?!St*(t

A<®

EH

i:

y $ f o

0

o

(cLr<f£^L>o

to

<f£^LV

LT<t£^

L^o

T-8421B,

8422B,

8452B,

8722B,

8752B

III

Page 7

3.

^fcs

7^J^A<(iA^:f^•CL^fcy.

1 <

1

A

A\

1A

DANGER

Hazardous voltage

will

cause

off

wait

injury.

main

Sminutes

Turn

and

before opening this

cover.

S®ESiJ^^lc,5x^ir.

ZLtii<&^o

AGEFAHR

Hochspannung

vertetzungsgefahr!

Bitte

switch

hauptschalter

warten

bevor

abdeckung offnen.

schalten

sie

sie

7-X^i^^Lr

m^^^tj:<,tj:-otz

A ^ P

®3S$«iy,

sie

den

aus

und

5 minuten,

dtese

<f£$L^<

"n

lin

i A )g ^ 1

:*:lt;b<$-r5

ADANGER

Un voltage non

provoque

Eteindre i'interrupteur et

attendre5minutes

d'ouvrir le capot.

isfs?ay£E%Si5^.##a§^.

APELIGRO

adapte

des

blessures.

Un voltaje

puede

heridas.Apagar el

avant

interruptor principal y

esperar5minutes

de

abrir

provocar

esta

inadecuado

las

antes

cublerta.

A^m

m<&^vi-fii<^t?>o

$±ffiSgS$oitr.

Moving

Operate with safety devices.

Turn

threading, changing bobbin

and

(A)

®ag$«)orA^p),

A

CAUTION

parts maycause

off

main

switch

before

needie, cleaning etc.

y-CyiS—ii—

injury.

K

2867M

2083M

IV

T-8421B,

8422B,

8452B,

8722B,

8752B

2868M

Page 8

1.

5 1

2.

nn 3

3.

3-1.X—y/WjpXlD

3-2.

3-4.

3-5.

3-4-1.

3-4-2.

s^iSife

Y(D^W.

:n >1>p—/i^yj<5/^

=^'-\<'(Dmjt

X.OO

4.

4-1.

4-2.

4-3.

T^cd##;^

4-4.

4-5.

4-6.

4-7.

4-8.

4-9. (T-8452B,

\fy(D^

^@;S:$

19

#{t:^

(Dm%(Olj'i^

8752B)

11

11

11

15

16

16

17

18

19

21

23

23

23

24

7.

mu

7-1.

7-2.

jgLllV^co;^&

4

5

5

9

7-3.

8.

i|£t^ilS'?'0ilRlS!i

8-1.

^m'f-(Dmw

8-2.W^}±:h(DmW

8-3.

8-4.

9.

9-1.

9-3.

19

(^^<9

##(79^)

SS^Atl

^ 0 (7):}Q-XAtL

^Tf^^tifziD

10.

^$n/A

11.

11-1.

»®M«

11-2.

3^7—^—

y)

m(DmMi

-

GREASEUP;^'^

(ir^

KyXttli)

iJ^

32

32

33

34

35

35

36

36

37

38

38

39

40

.43

44

44

49

5.

5-l.^W^tntih

5-2.

S^J•^^±46l|V^(7);^^';fe

5-3.

5-4.

6-2.

6-3.

LOCK

6-4.

^

{Co^^T

(#^li)

T8421B,

...25

25

27

28

29

...30

30

31

31

31

8422B,

8452B.

8722B,

8752B

Page 9

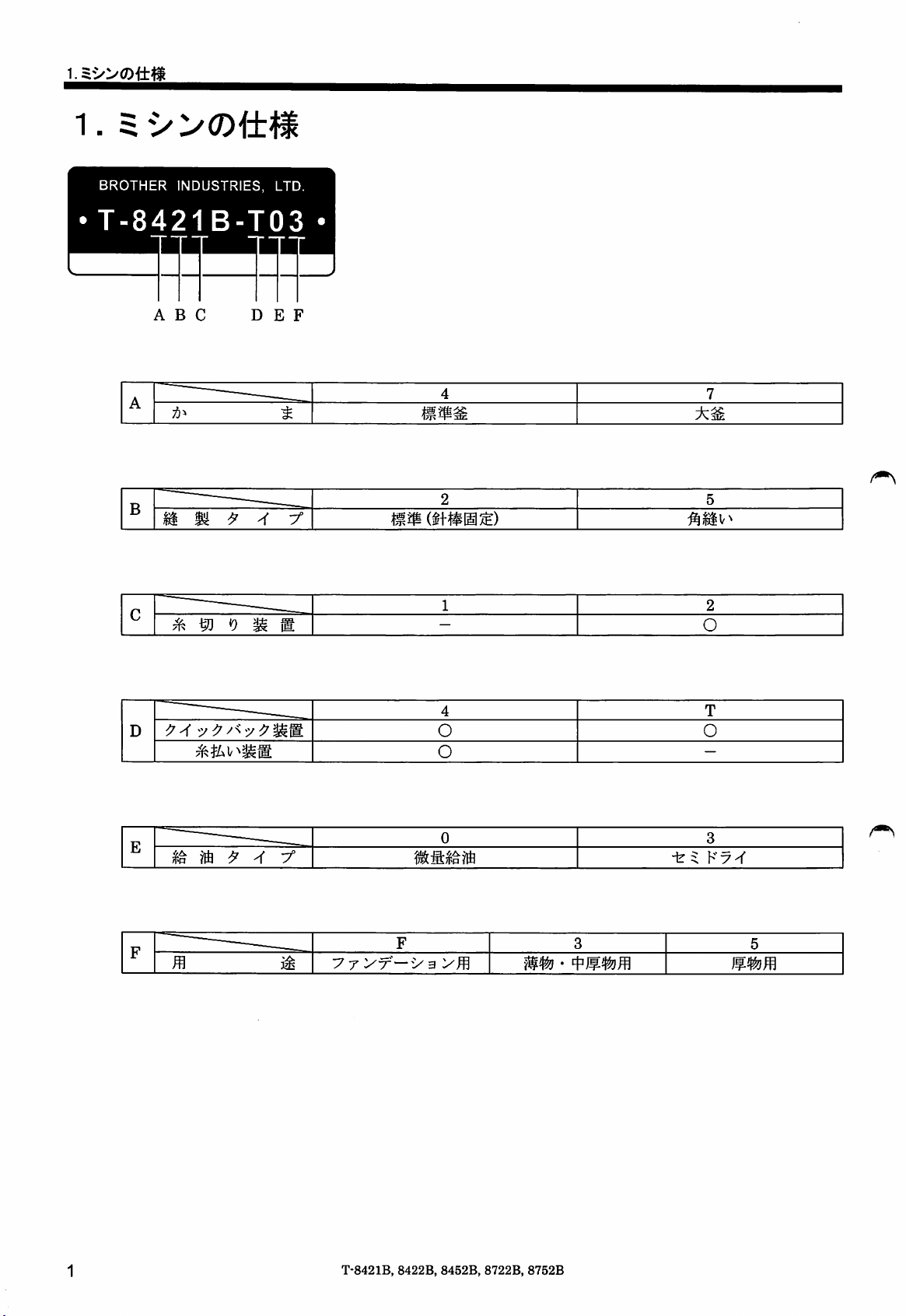

1• 5

1.

5

BROTHER

INDUSTRIES, LTD.

T-8421B-T03

ABC

A

7j^ ^

B

m m ^ 4 y

C

-—.

DBF

•

4

2 5

mm

_

1 2

—

7

O

___

D

E

F

^ ^

•—

7°

y 7

^7—-7

4

O O

O

0

F 3

3

T

—

3

-i? ^ K 7 ^

5

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 10

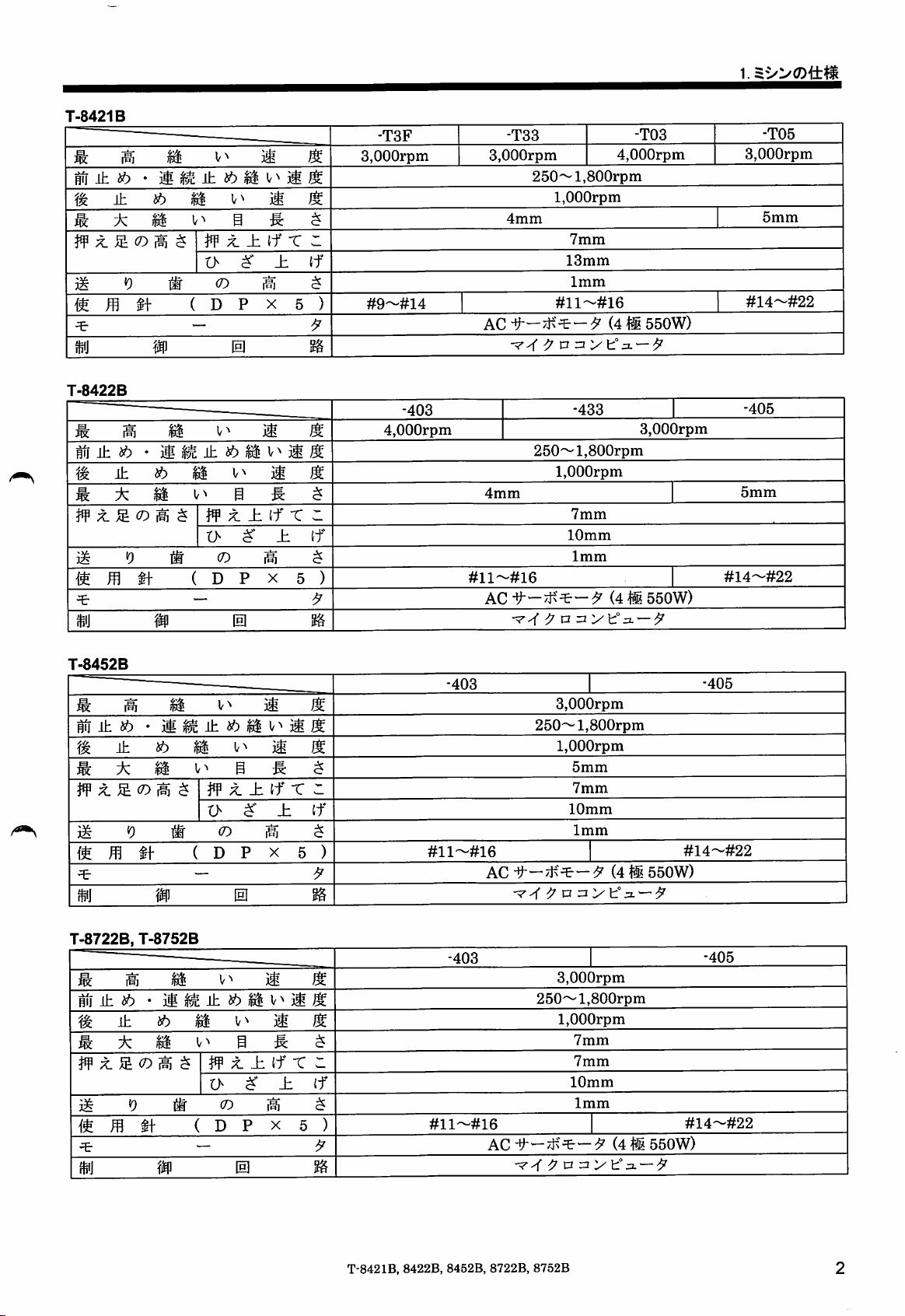

T-8421B

III ®

m ±

isb

•

m ± ^

H

^ ^ ^ (O ^ $

3^

f9

it

V^

ig

V"*

§ $

^ X Z

t>

(7)

±

it; $

( D P X 5 )

m ^ ^

T-8422B

H 3^ &

HUlhi'')

•

3g|^lhJ6l|V^3git

± a6 ^ v^ 3g ®

^ H V^ g .& $

±

{f

^ ^ O 1^ ^

3^

"9

t>

it

(7)

r r

±

if

m m m ( D P X 5 )

X — ^

m n ^ ^

-T3F

3,000rpm

-T33

3,000rpm

-T03

4,000rpm

-T05

3,000rpm

250~l,800rpm

it

4mm

tf

#9~#14

AC

-403

4,000rpm

l,000rpm

7mm

13mm

1mm

#11~#16

f—(4550W)

-r-Y^ti

:ny\::°

-433

5mm

#14^#22

:x — ^

-405

3,000rpm

250~l,800rpm

l,000rpm

4mm

7mm

If

$

#11~#16

AC

1i—(4^1550W)

-xrX

10mm

1mm

—^

5mm

#14-'#22

T-8452B

if

m ± '

3igcih^i^v^3i^

3g

± 46 ^ 3g

m m n ^ ^

#

;i

±

tf

^ X ^ (O ^ $

311

f9

it

t>

(79

T r

±

if

^ ( D P X 5 )

$|J lip 0 Sg

T-8722B,

Hijih46

^ Jh

S ^

W X

T-8752B

if

H V^ 3$

*

3g^ll:46I^V^3gi^

46

^(D

^ ^

V>

V^

3i

g ^

;t

JiIfT

1> ±

^

<0

M (D M ^

m ^ n ( D P X 5 )

X: — ^

glj 0

-403

•405

3,000rpm

250~l,800rpm

It

If

$

#11~#16

AC (4 m

-403

l,000rpm

5mm

7mm

10mm

1mm

#14~#22

550W)

-rX^i:i:=iy\l°=L—^

-405

3,000rpm

250~l,800rpm

it

::

If

#11~#16

l,000rpm

7

mm

7mm

10mm

1mm

#14~#22

AC-f-(4^®550W)

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 11

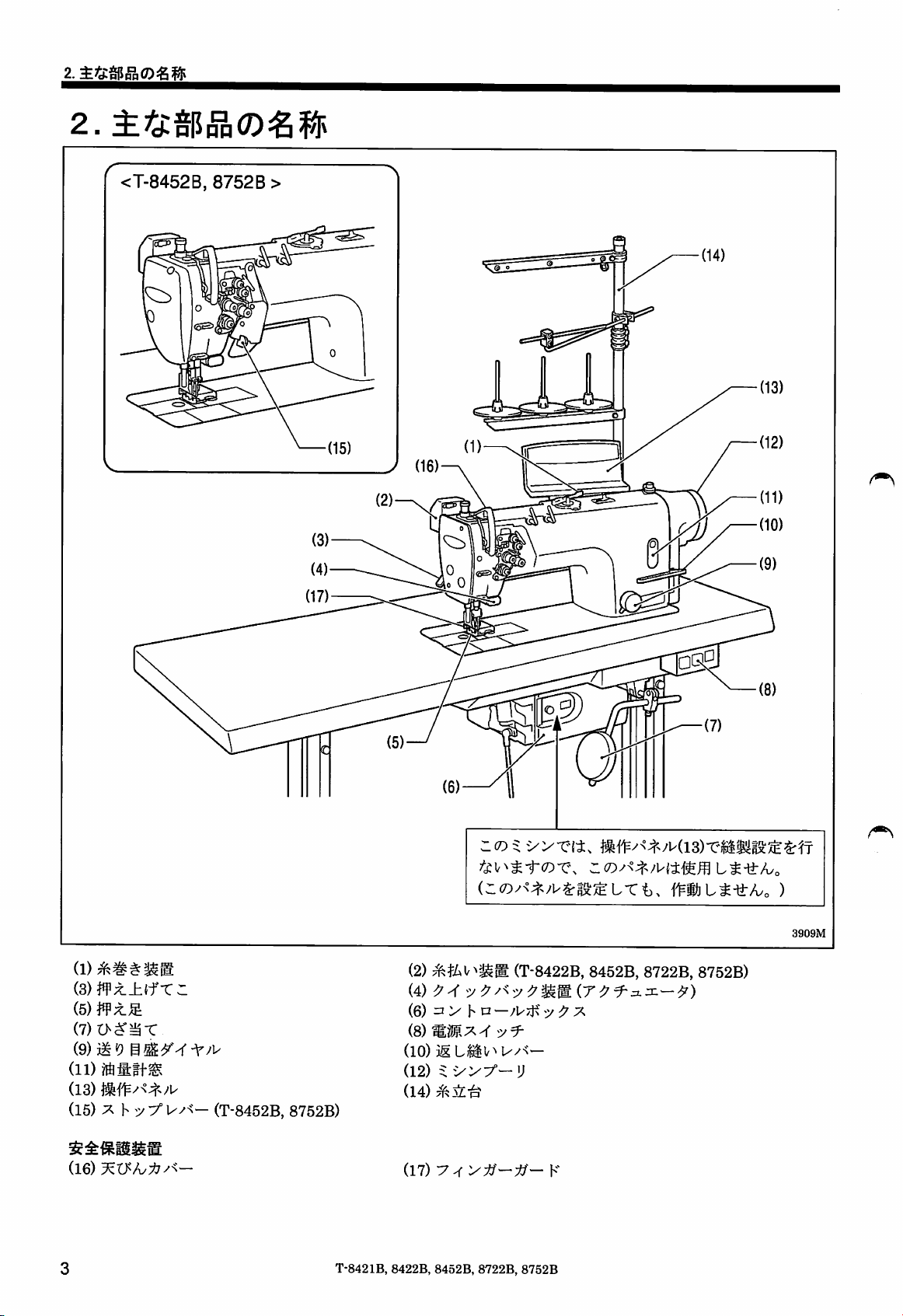

2.

2.

pPpp(7)^

<T-8452B,

8752B

>

(2) (T-8422B, 8452B, 8722B, 8752B)

{S)W^±.ifXZ

(5)|f;tJ£

(7)

(9)m'o

(11)

yftftM,

(13)

(15) ^

(16)^V^A,;fjy<-

hyX

yy<— (T-8452B, 8752B)

T-8421B, 8422B, 8452B, 8722B,

(4)

(6) =i > h n —yP:!^-y^

(8)

(lO)

jS

(12) ^

(14)

^IL-^

(17) y 4

y^

!//•<—

yyX-v

yi^—IS—

8752B

K

3909M

Page 12

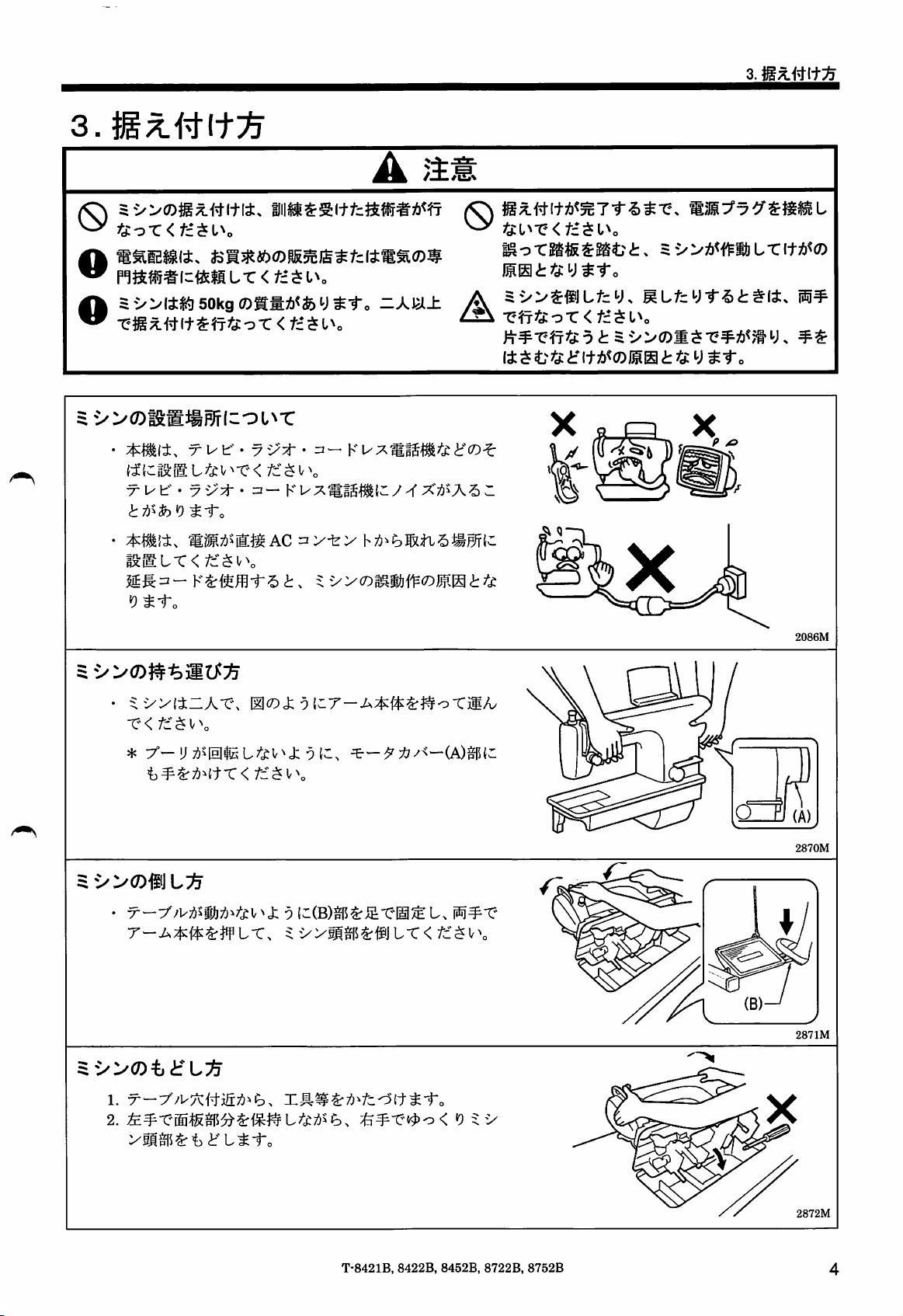

3.

td:z>X<tz^l^o ^ tjil^X<fz^l^o

3.

?^^mm\:i^mLX

O5v>(i^50kga)MMA<fcy^-ro

5

v>^DiSMliPJT^col^r

•

•ri/f"'

ix®L-C<

$£S=3-^i^y(DmW}i7<DWMt^£

<0

5

i/>(Dj$*>)lu:s

•

^iyyii^AX\

X<ti^l\

^-To

-ri/fc'*

L^c^v^-C<

y-yif'

^

^i~o

<tz^l\

yiy^'

fc:$V\

:=i—7

m(DX

-x\>^±

3"

BHir'Sy^-ro

svvsfflufcy,

A ^

(i^t;

^j:

<1:ItA<0jia

it

jS»:y^-r

ii¥

o

2086M

5

v>0®jL:^

7"—9

5'>>(0tt'L:^

1.

7-—7'/l':^Hi&ii^h.

2.

;fe#T-B1gSii»^(ftttL/£/4s^.

VBlSliSrfcifLt-fo

LT.

{c:(B)fP^^'C|§^L.

^i/>'Sj§[5^^Jt-C<fc:$v^o

rft^^7)>fc-:3lti'fo

T-8421B,

8422B,

i^^T'

t)

8452B,

?•>

8722B,

2870M

2871M

2872M

8752B

Page 13

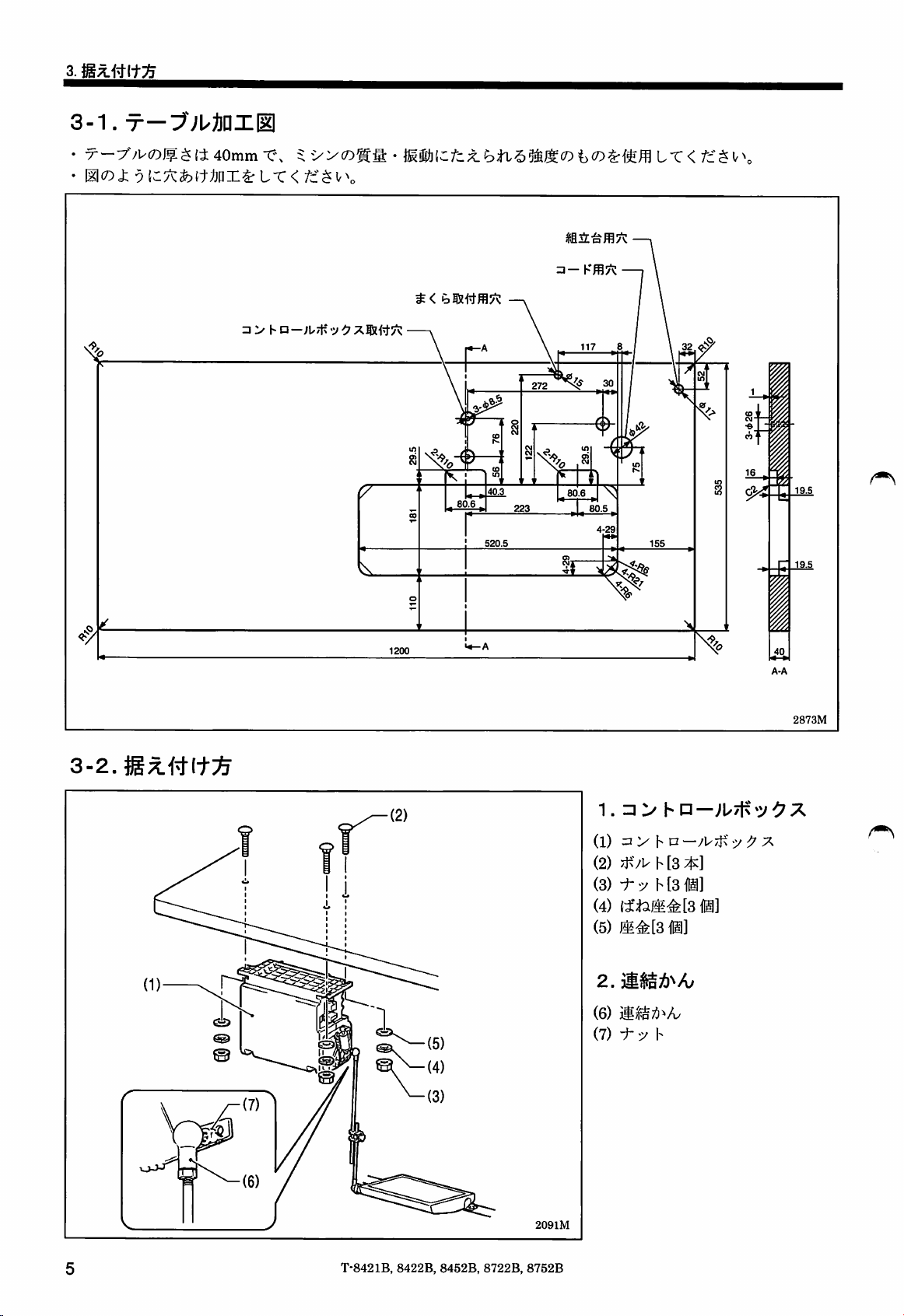

3.

3-1.

' lll(7)J; 9

L-c<

fc$v\

• > h p —;u7t? ^

p—

hfflT^

lt<

/-f

$v\

I

I

16

19.5

3-2.

(L.

520.5

m:

1.

(1) =I>' h n

(2)

(3)

(4)

(5)

2.3I^gA^^

155

Z1>

hP—

-Ty

h[3f|i|]

(i*^ll^[3fi]

M^[3®]

—/1/a}^'

19.5

i

2873M

y ^ ^

(6)

(7)

i-y

2091M

T-8421B,

8422B,

8452B,

8722B,

8752B

h

Page 14

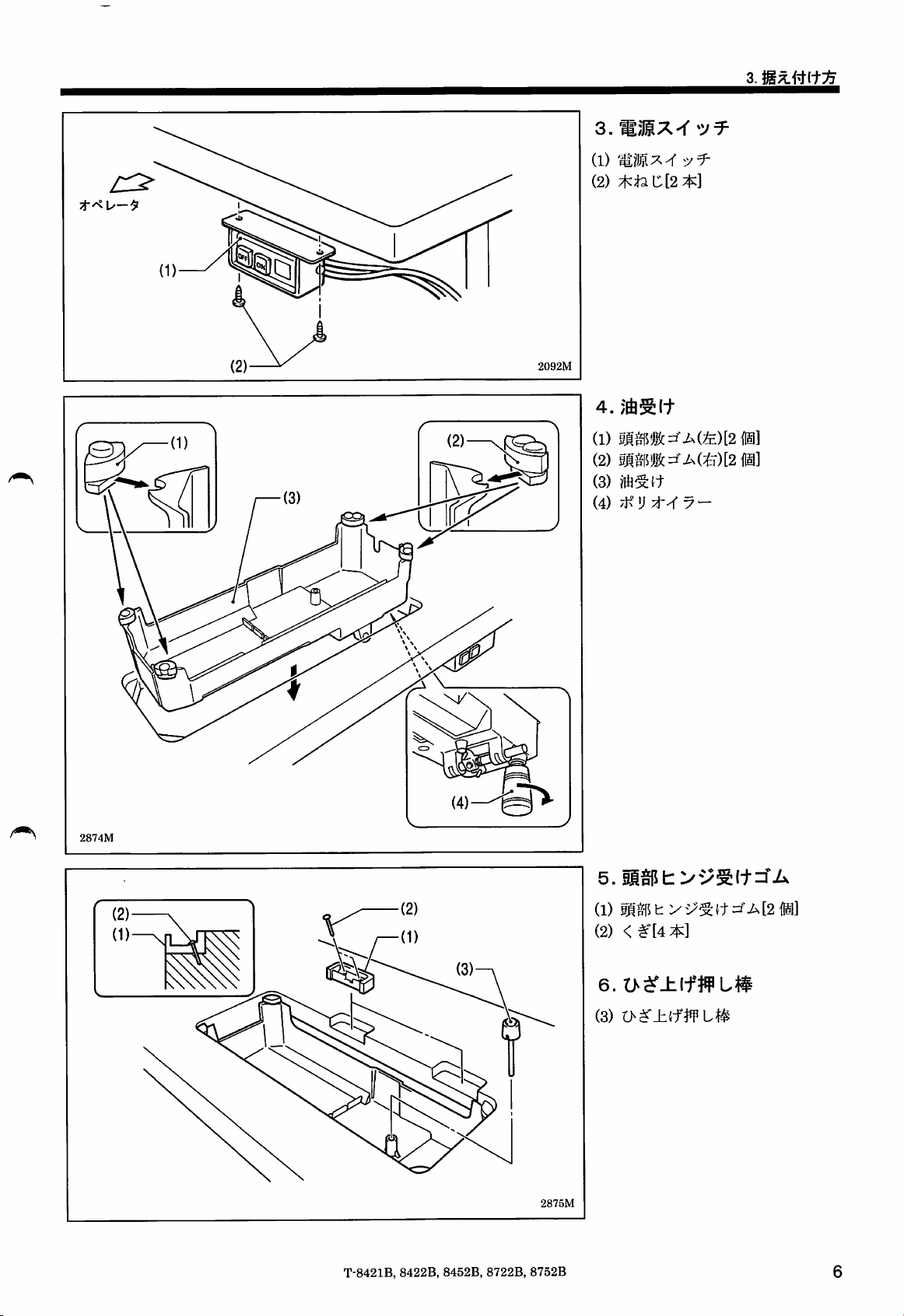

(1)

A i

3.

Silxi'

(1)

(2)

:^t3.Z[2^]

3.

(2)^^

2092M

4.

;4^(t

(1) 9j^i{c=^'A(:fe)[2flS]

(2) 9j§[5f:=^'A(;fe-)[2flil]

(3)

(4)7Ky

:t4'

y —

2874M

T-8421B,

8422B,

8452B,

0

8722B,

2875M

8752B

5.aia5tVvg:(t=fA

(1) t >'

(2)

<^'[4:^]

6.

X>^±\iWLm

(3)

(t

^ [2

fi]

Page 15

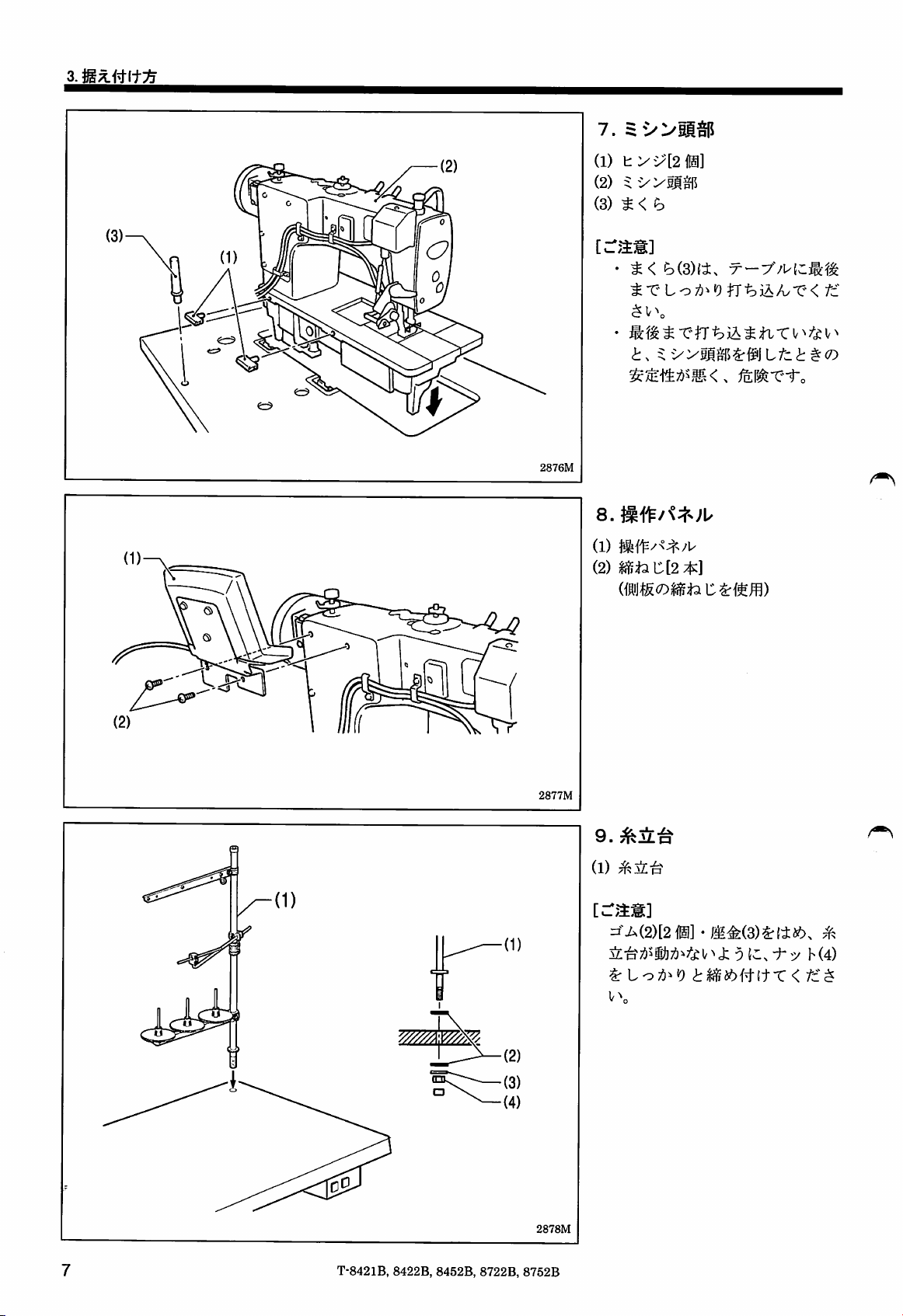

3.

7.5v>sISP

(1)

hyiy[2m]

(2)

^->^11^

(3) ^ ^

$ V

'^O

2876M

2877M

t s ^

8.

(1)

(2)

I^^I:[2

mm(Dmt3^L^im)

Ltit^(D

7^]

T-8421B,

8422B,

8452B,

8722B,

9.

(1)

[CTj-iS]

=f'A(2)[2fli] • ^

h(4)

2878M

8752B

Page 16

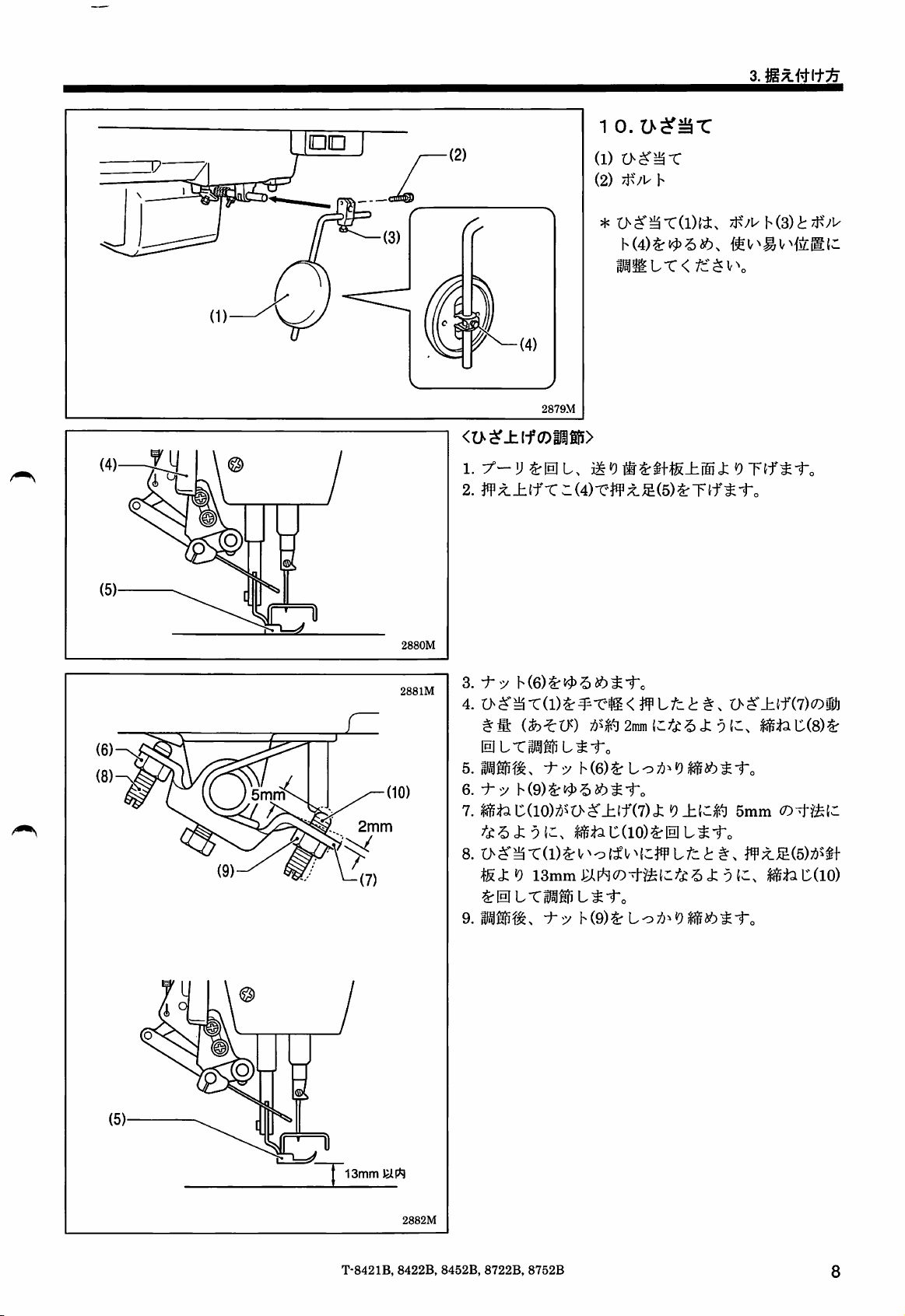

1

0.

(1)

(2) h

3.

2880M

2881M

flSLT<

2879M

<u^±\i<Dm^>

1.

2.

#;i±lfT::(4)T-^tP;t^(5)^Tff^1-o

;e$v\

13mm

JilH

ihxrf)

LXM^Lt.Xo

mmk.

Xy

Xy

h{6)^L->:f)-<0^ib-^Xo

h(9)^^^l^^Xo

l^jfeC(lO);6^t>^"±{f(7)ct

|^:taC(10)^0L^-to

^0LTML^-to

9.

Xy

hi9)^L^f}-^mib1^Xo

5mm

muc(s)^

(D-Xm^

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 17

(S)

iSoTSgtS^Sit-t,

5->>!!iM'^|jlUTI+A<®llHi:'SyS-ro

iHTiaAS'^'J-X^iaaiStt.

(S)

tziiK

Sfca»i4-¥>y•)-7.yy

a»iii3(4,

*

A^09iB4aS<,

ffi?S>|•-|•/^i

0

L-C<3;^'

5H#y—ion;

yy^-KVu/T'yyx

t^co^-e<tz$i\

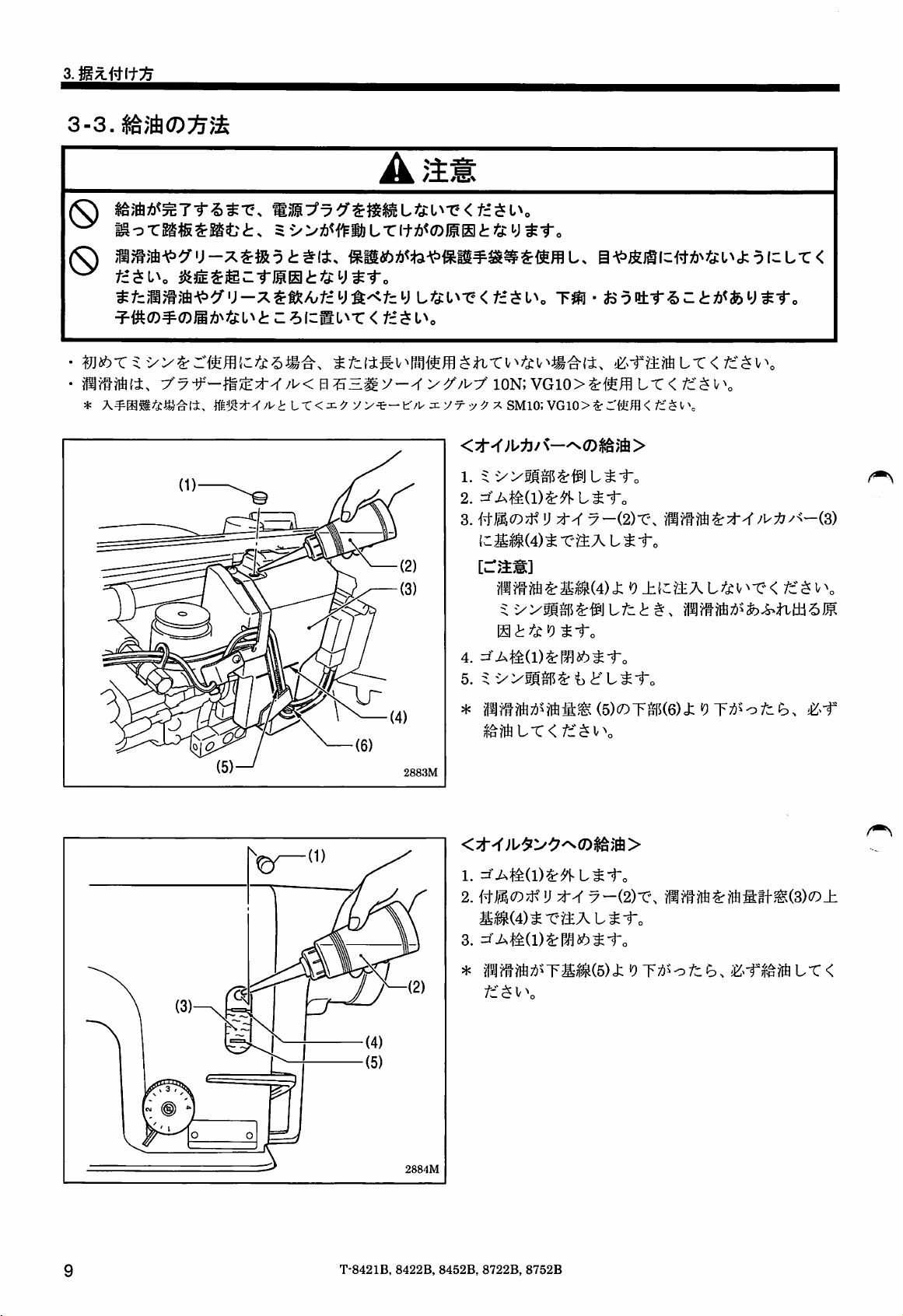

1. 5:

3. V

[rjiS]

yiW^^li(4)J:

la^/c^

5. ^

VGio^ttffl

SMIO;

a•V'i£lSI=#)b^^fl-^J:•5(::LT<

t^o•fc5tt-r.5cty

lt<

VG10>S-rffiifi<

t^-fo

7—(2)'C\

19

±^c^^AL7:^V^-e<

>9^1-0

t^-fo

fc'Sir-,

/c:$v\

2883M

2884M

1.

2.

S,^(4)^-X;r3lAL^i-o

3.

^•"i^+^(l)^r^i6^-ro

*

PM;0^^T»(5)J:'9T/0^o/cf5.

fz $ V\

7-(2)-C\

P^t?[l3^yti3ftth^^(3)0±

T-8421B,

8422B, 8452B, 8722B,

8752B

Page 18

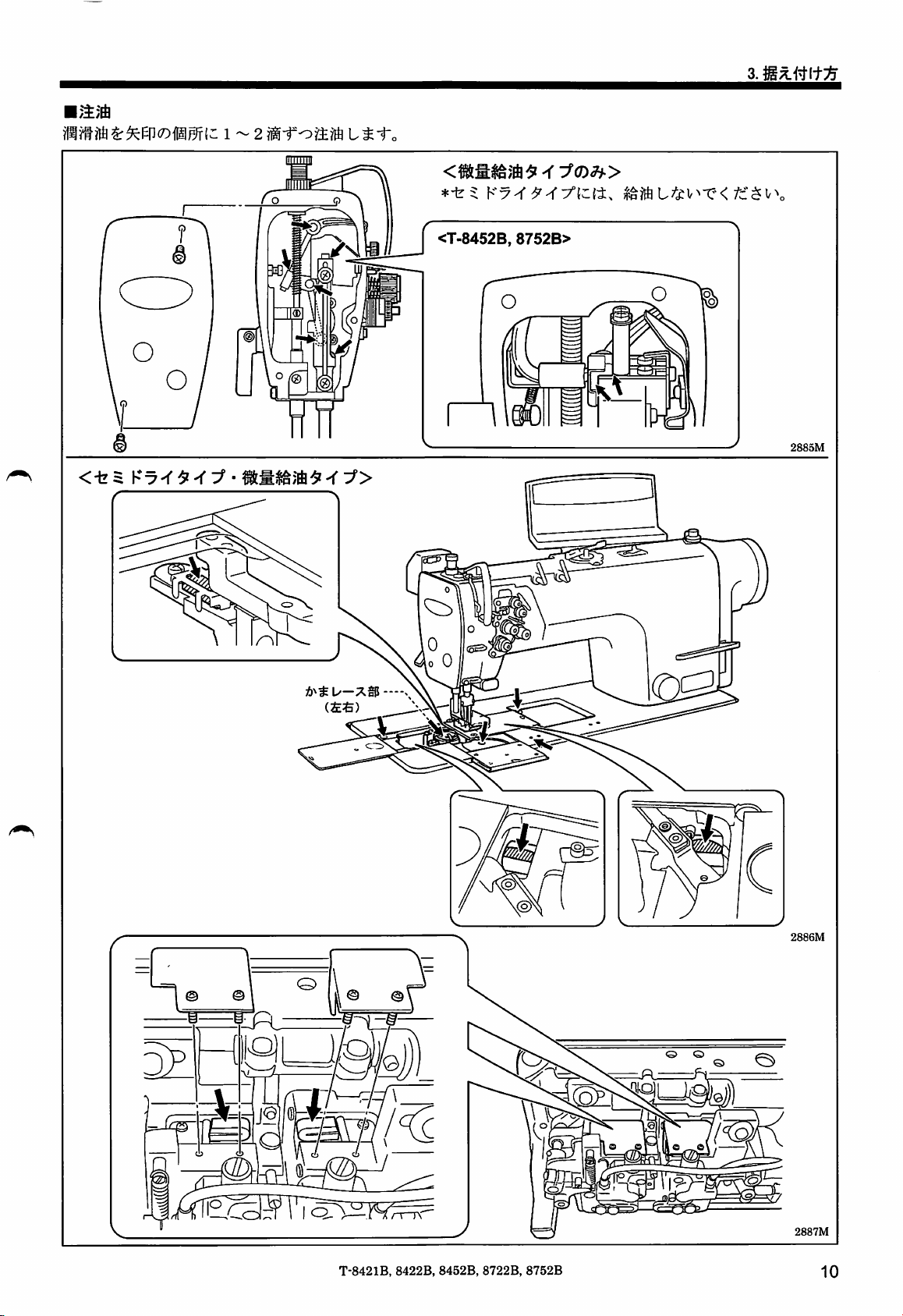

1 2

oiirft

Lt.i~c

*-fe;

h'y'f

-r

:^(D^>

l&ifi

L'fcV'T*<

S;Sv\

<-b5

r

o

\~=7>('3i>(Zf

r^

<T-8452B,

8752B>

o

2885M

y

v.

© ©

©

©

©'

II

3

mE

I/a

T-8421B,

8422B,

8452B,

8722B,

ra

8752B

La—

<i) c!)

(Ml

J0

a

2886M

2887M

10

Page 19

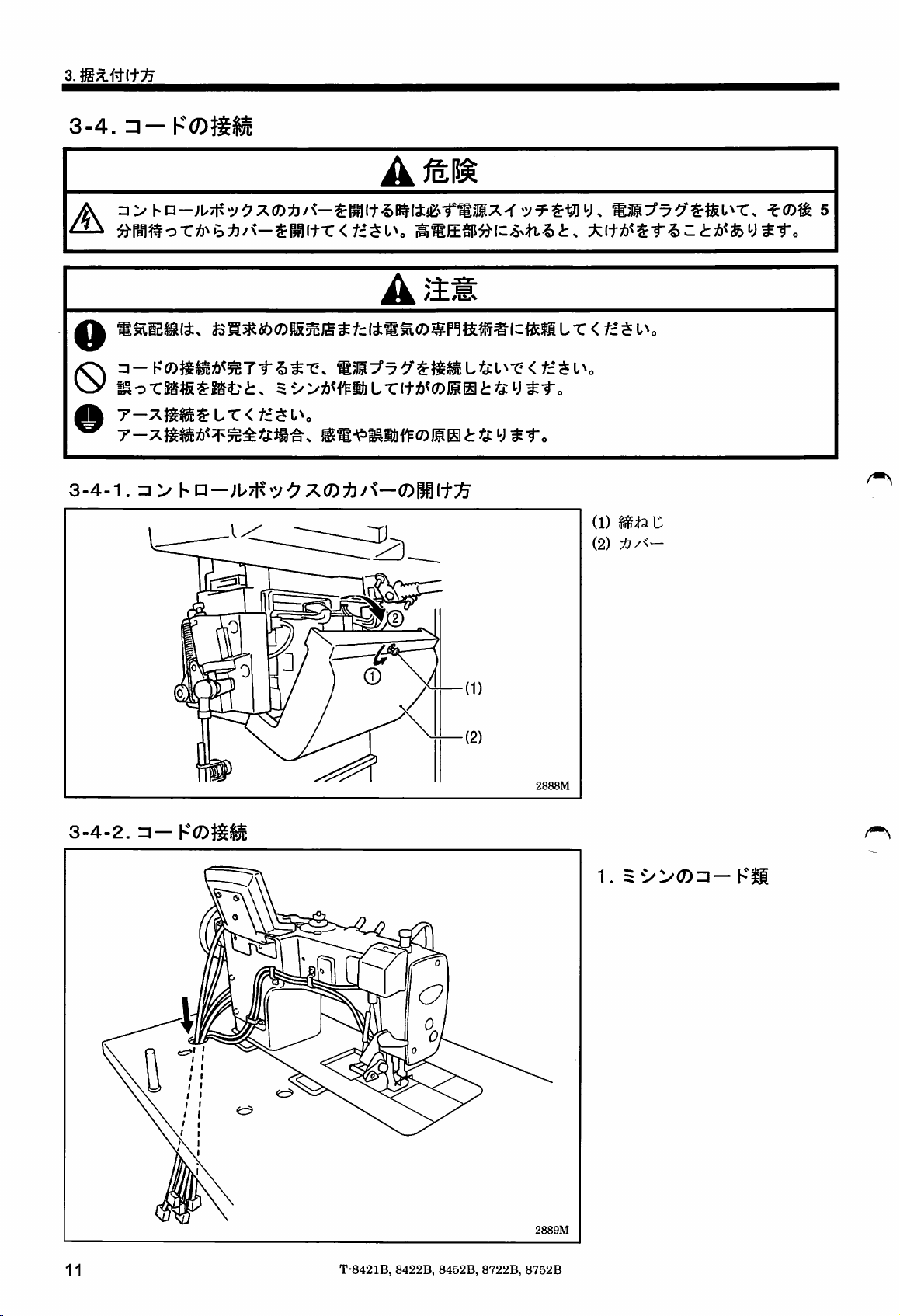

3-4.

A

zi-

O

0

o

3-4-1.

fcist«)®aj5g)ssfciia«®iip^s«#i:«ffi

p-K®SS)!)«^7-r.5$r-,

m o

=i>

hP—;i/7K>v<7X(Dt]/^—

t.

5 •>

>A<t^l!i

S«*>IS«f^®EH

UrItA<®

)SS

i tj: y

t y

Sf

$-To

o

lt

<

f£$

iv

(1)

iStlC

(2)

i}^<—

3-4-2.

11

3—

1.5vV0=i—

K

I

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 20

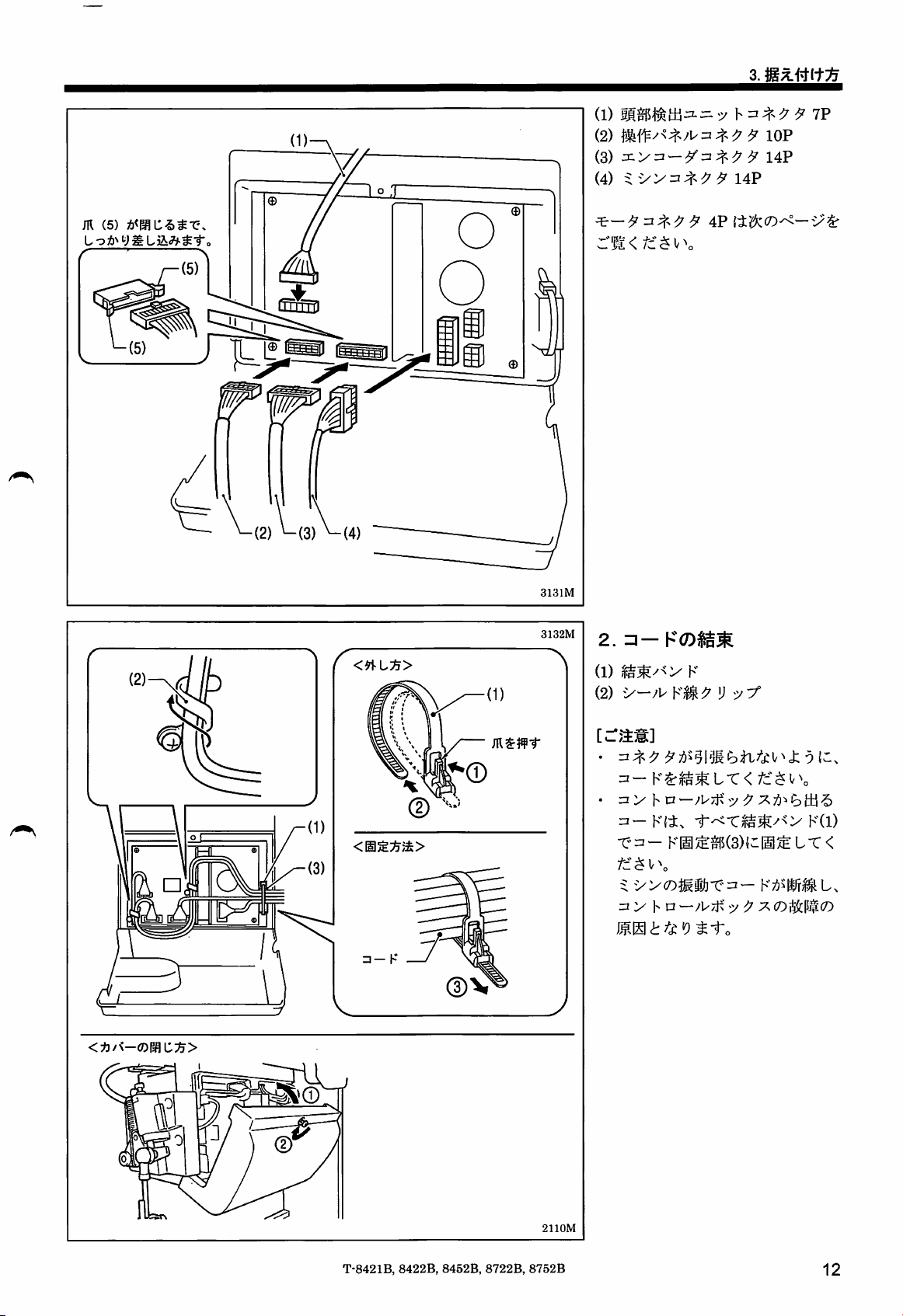

3.

mxmi5

m

(5)

LoA^yllL3i^^^•rc

(1)

(2) ^

(3) n

(4)

2

^3

—^

5:

^

lOP

14P

14P

7P

1

<9\-Ll5>

<il^:^;4>

3—

K

®v

3131M

3132M

2.

=]-

K<7)fgS

(1) K

(2)

v—/!^

Kl

[rjiS]

:=!-

K^IS^LT<

• =I

>-h

D—^

=''-K{i^

-C=i—

fz ^ V

Klil^^(3){^@:SLT

^o

^

3:/h p —/W;jf y ^

K(l)

<

K/iWrHL.

(D'^f$(D

<id^<-(DmciD>

©

2110M

T-8421B,

8422B,

8452B,

8722B,

8752B

12

Page 21

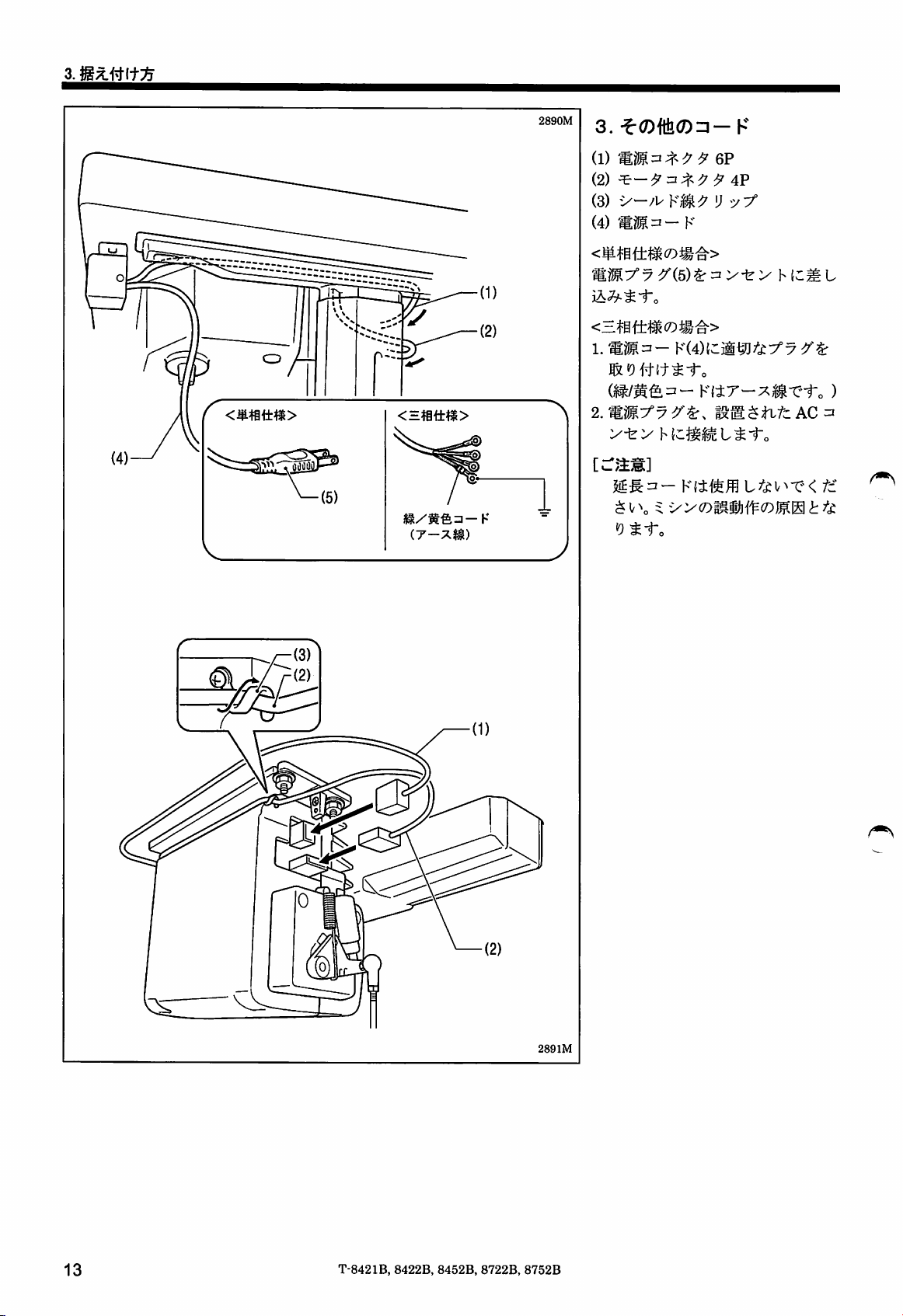

3.

(7-XI^)

2890M

3.-€-a)ftfe0=i-K

(1)

(2) ^

(3) V

(4) K

<mmm(DiM^>

(5)^=1

K{tT-x^x:^-r„)

5S5:

=i — K L

'Oi^-to

6P

4P

yZf

h(c^L

T'ceV^-e</c

2891M

13

T-8421B,

8422B, 8452B, 8722B,

8752B

Page 22

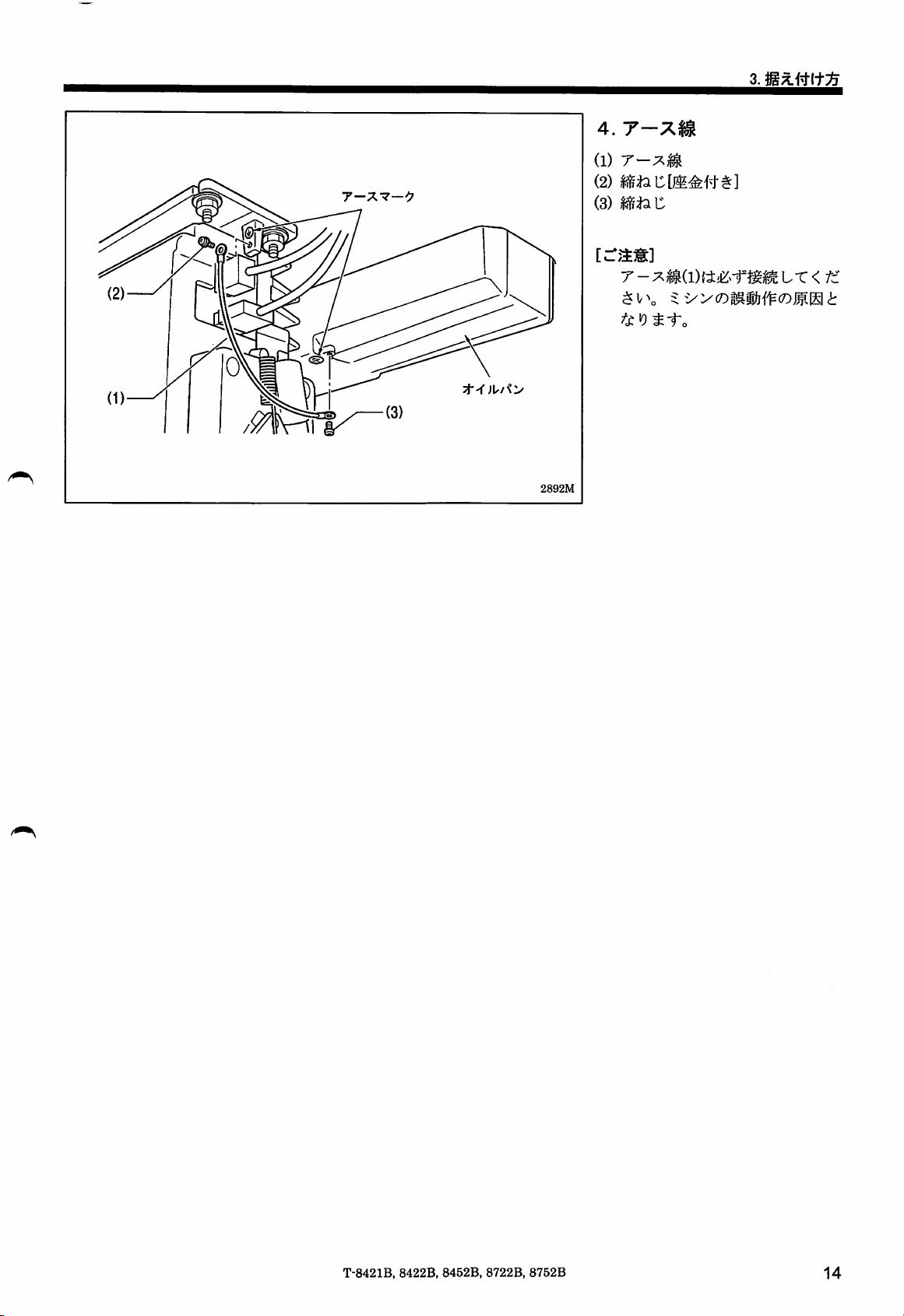

4.

(1)

(2)

(3) lfi5:Jai:

[cram]

3.

^iv-1

T-f

JU/

$^/^o

^i^y(Dmmi¥<DWMt

T-8421B,

8422B,

8452B,

8722B,

8752B

14

Page 23

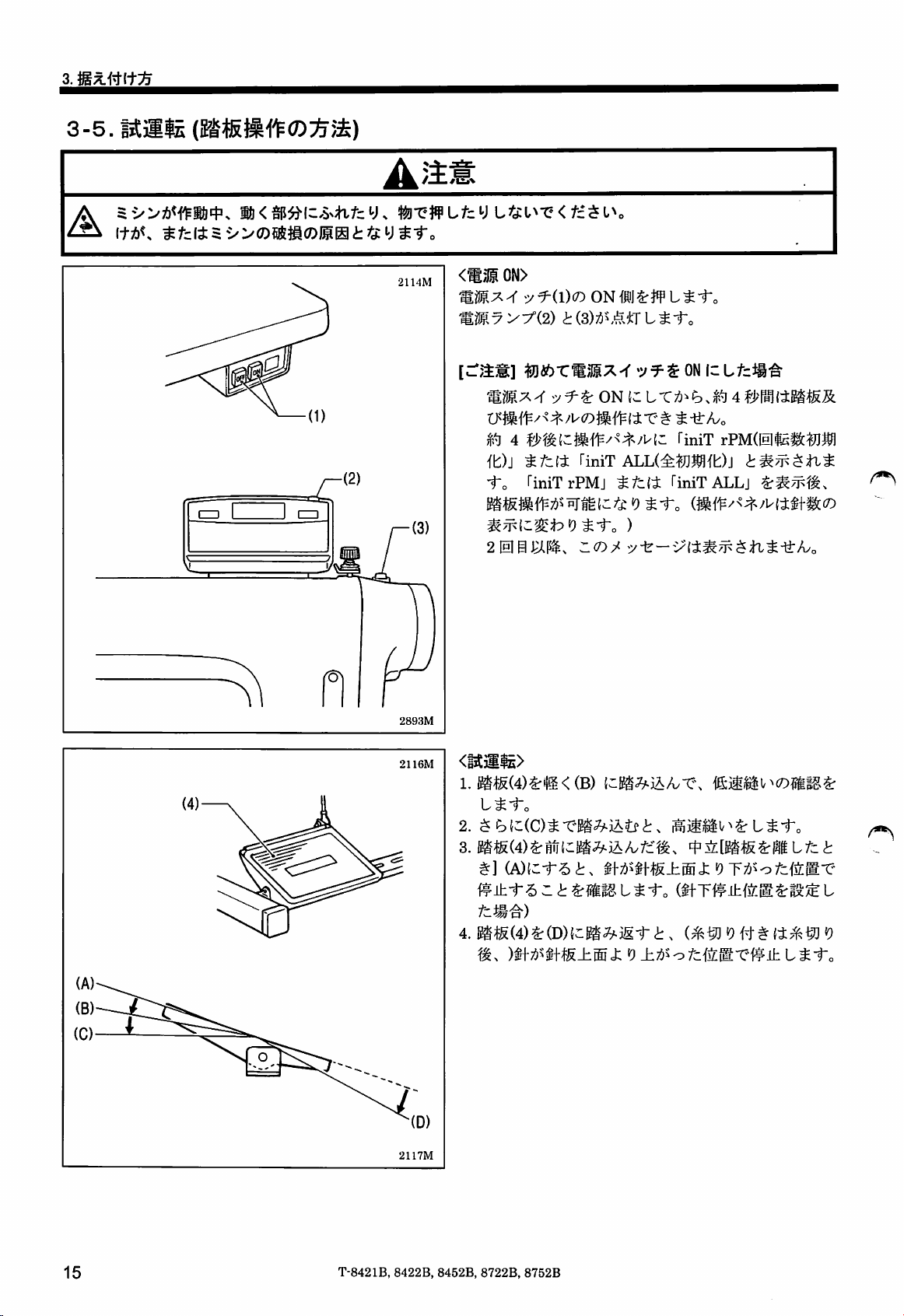

3.

3-5.

A'±^

A

^X'WLfz^)

2114M

<mm

mm^-c

"MMy y

[:^^M]

Ltd:l^V<fz^l\

oN>

y'^(i)(D

^(2)

oNM^WL^-to

t (3)

'):T

L ^ i~o

DDiftrSjlX'f'v5=-$0NlzLfcli^

m 4

it)}

-To

riniTrPMj

2llIgJ[^[5$,

TiniT ALL(^^ZI»]{l:)j

tfzit

r:y-tr—

rimT

TiniTALLj

2893M

2116M

2117M

<ijC3i^>

L^-to

^]

(A)(c-t6

4.

K^t^(4)^(D){df^^ig-f

t.

J:>9T;6>o/-d4^-e

0^^19{^#{1:^^19

15

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 24

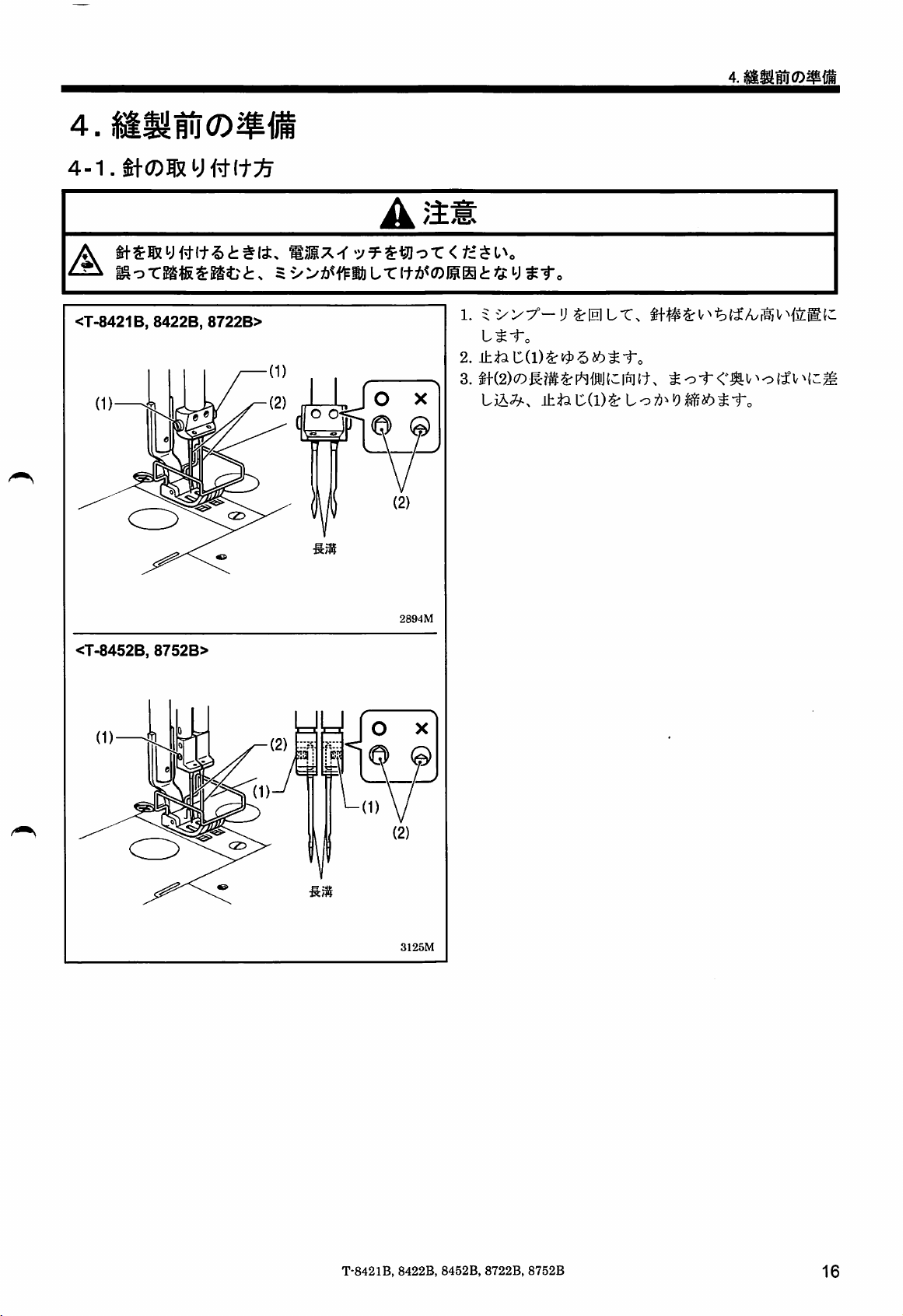

^.mmrncDmrn

4J

A/5S

A

<T-8421B,

<T-8452B,

8422B,

8752B>

8722B>

5v>Mf^«iLT(+A<rolSHi:'S:yS-r,

1.

Lt-iTo

2.

±^C(l)^^6i6^i"o

O O

O X

9

X

(2)

o

2894M

D

jisfi

ffe

iS f

(1)

(2)

3125M

T-8421B,

8422B,

8452B,

8722B,

8752B

16

Page 25

4.

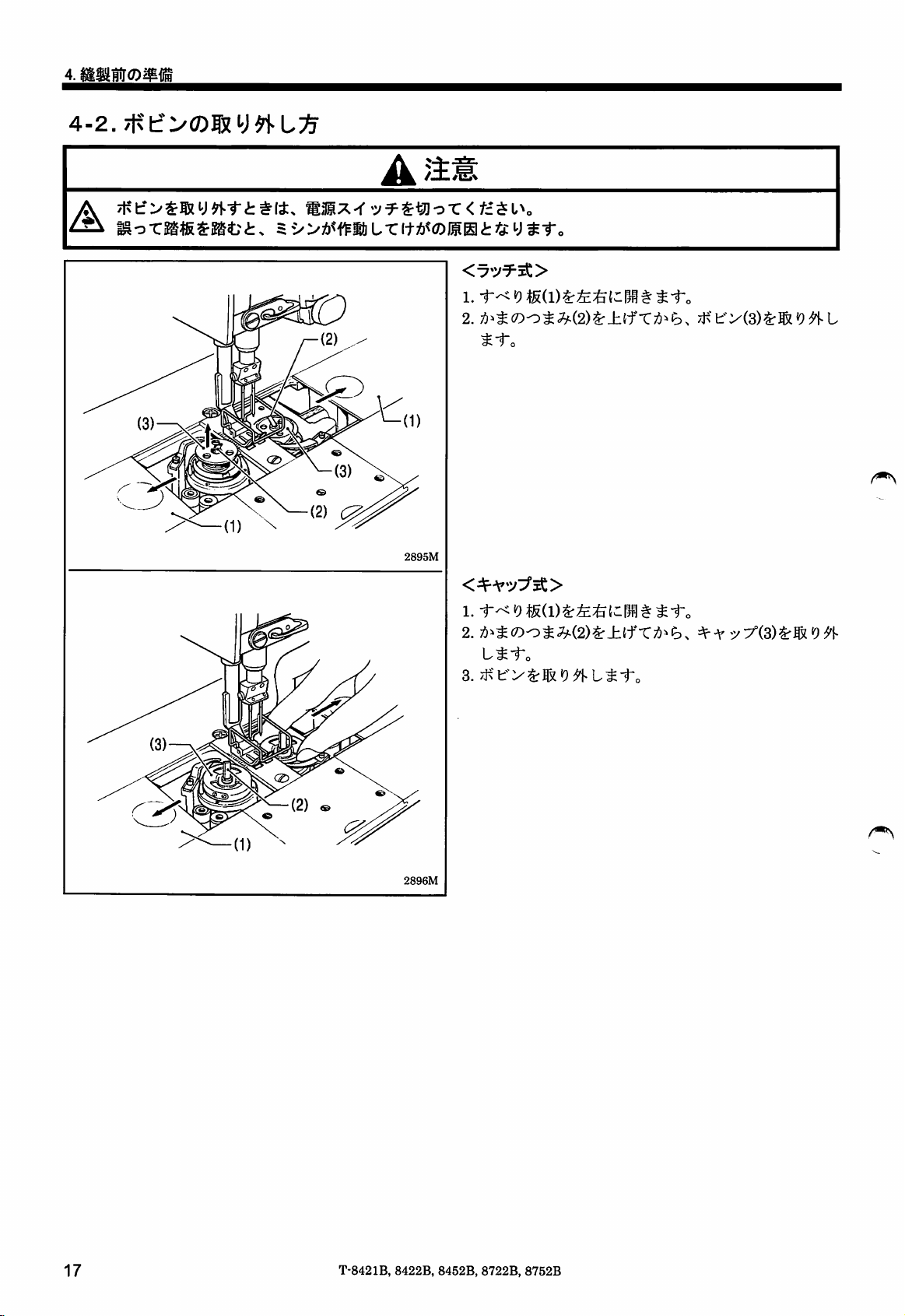

4-2.

A

A

♦x

®3ix-r</£^L^o

5i/>A^f^SlLT(tA<0JIS(hJ5:y^-r<

^1"o

2895M

2.

;0^:S(7)o^;9-(2)^±{f-C}6^^,

L^-fo

3.

9\-

17

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 26

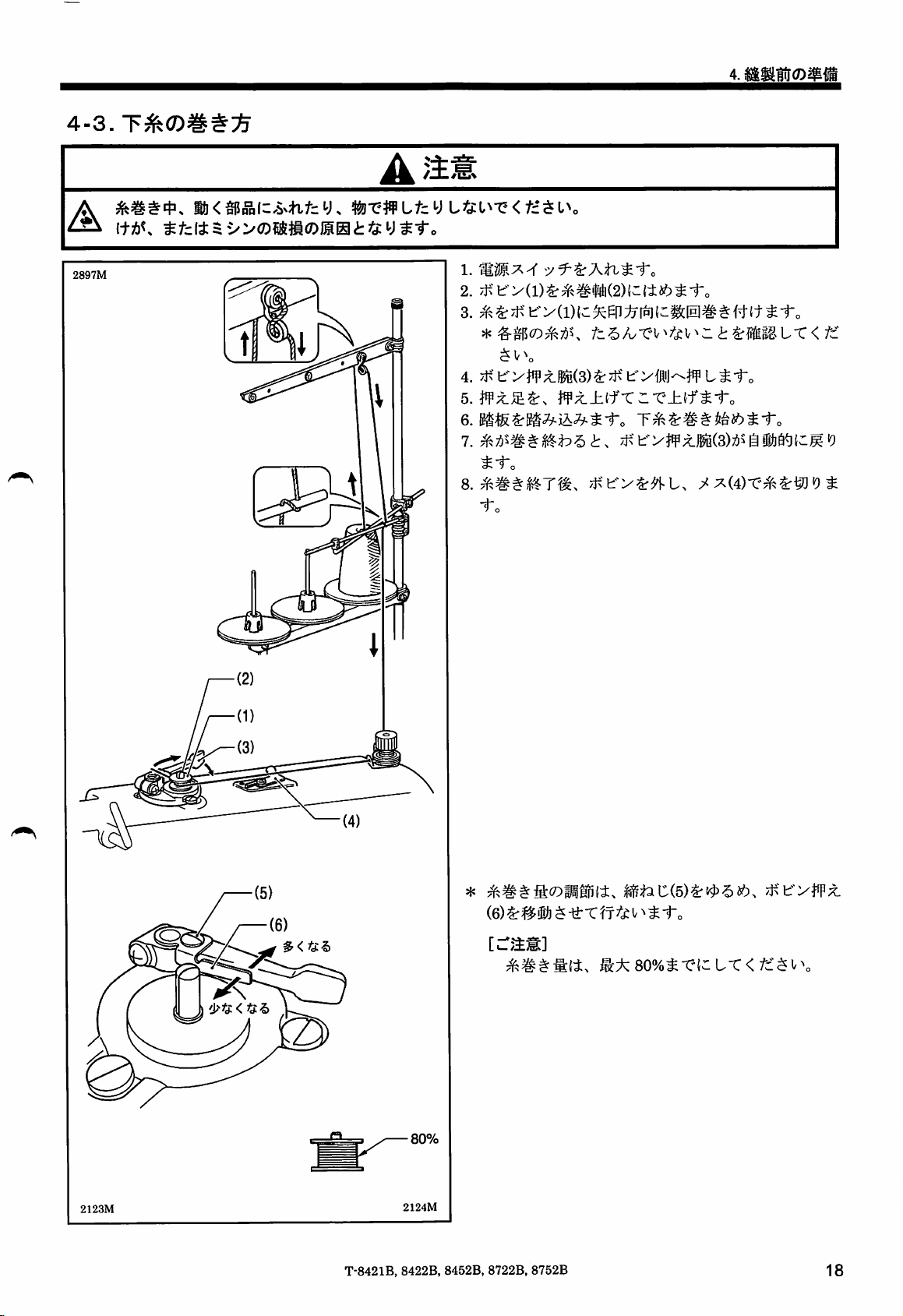

4.

A

2897M

♦X

i!I<gPp°n(c.S^tLfry.

^VWLtz^) Ltsil^X^<t£t^l\

1.

3. ^ ^

5.

/1^"f'^(1)(cAfflAl^

*

^ V

'^o

#;i±{fTri:"±{f^-ro

t-to

-to

fc6^-C'V^/^V^r

ift-to

/c

(6) ^

#i!j

^-It

T tT V^

:^A80%^7:"{CL-C</c:$V\

2123M

T-8421B, 8422B, 8452B, 8722B, 8752B

2124M

^-fo

18

Page 27

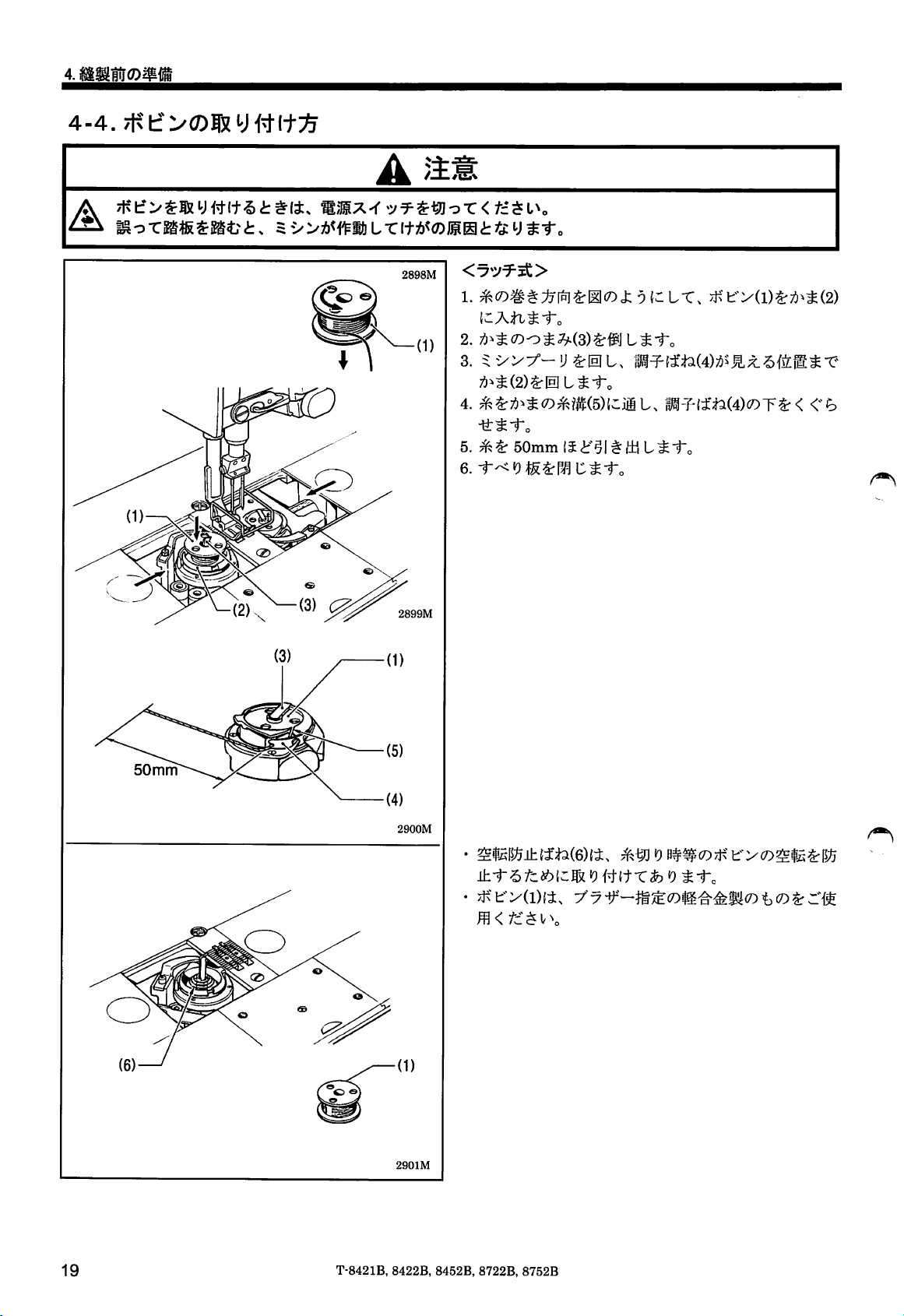

4-4.

A

A

.X

Sao

TSIS^Sft

t.

5

->LTItA^CDIlS

mmx'f

•y'}'imr3x<t:^i\

t !S y

2898M

2.

75)^^(2)^111

4.

^^75)^:S(7)^?||(5){c:iiL.

6.

-r^<o

^"T,

L^-fo

ff-T-(f:ta(4)(DT^<

m^mc^-To

50mm

2900M

2901M

ihi-'5fca6{::|x'9

#

t'Xl){i.

fy-ftrfe19t.i'c

^'7

if—t

(7)^r-f^

19

T-8421B,

8422B, 8452B, 8722B,

8752B

Page 28

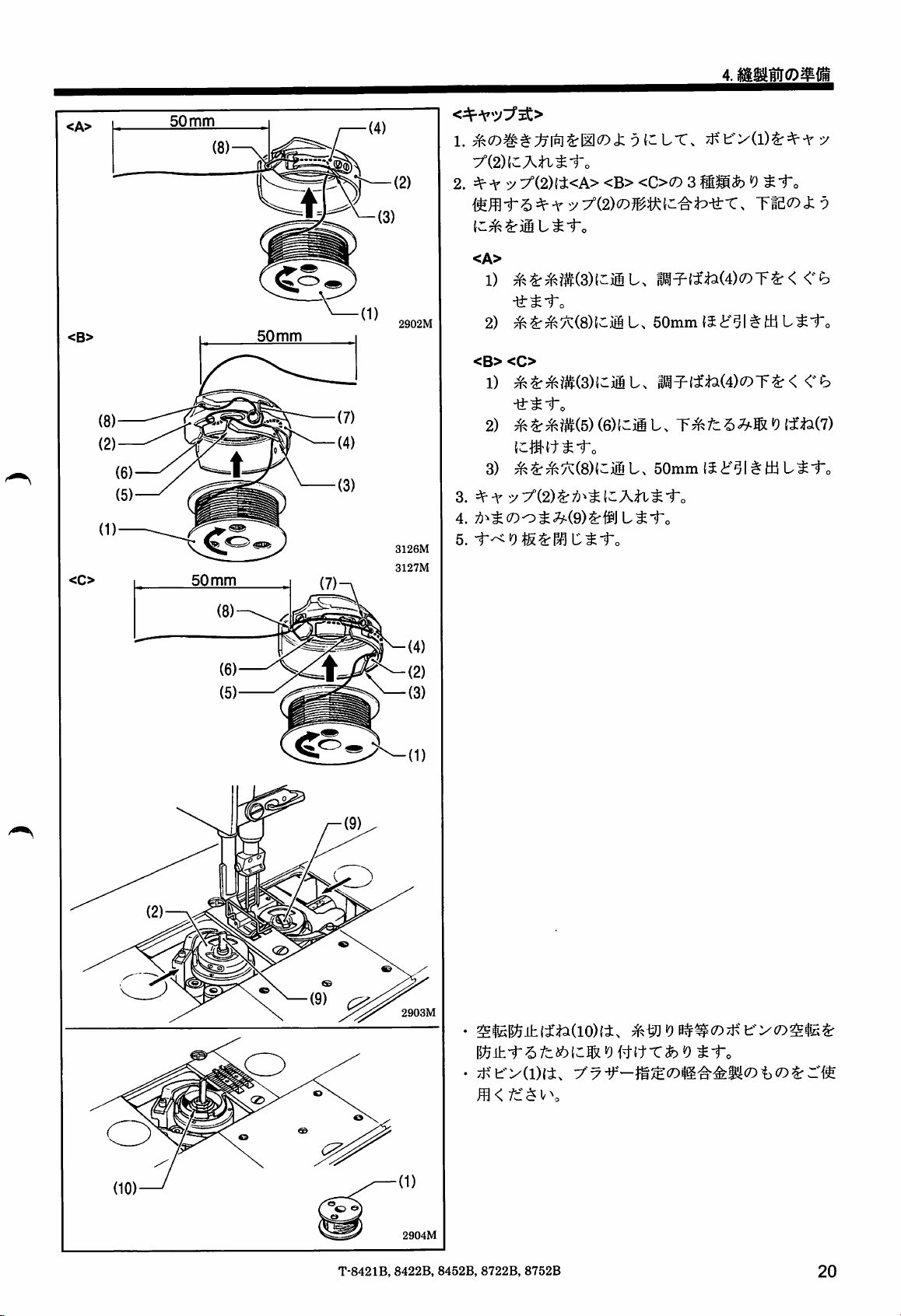

50

mm

50

mm

50

mm

2902M

3126M

3127M

2.

:/i2)n<A>

<B>

<C>(D 3

UMh

L'^"^o

<A>

1) <

2) A(8)('i:iS

<B>

<C>

2) (6){^ii

3)

4.

;^^^c79o^A(9)^'fiJ

5.

-t"^'9tg^r^C^i~o

50mm

t.

L,

50mm(J<!f^1

L^-fo

(5.^:51#tUL^i"o

<9^1-0

<9

(t*:fe(7)

# tU

L^i~o

Cb

2903M

T-8421B,

2904M

8422B,

8452B,

P^ih-t6

8722B,

8752B

19

Hnxh

19

^-To

20

Page 29

4-5.±^(DmLl5

SoTSgffiSKt?.!:,

fe<BlrojftA>e,5felciiLT</-c'Sw

5->>A'#liUTIti(p<<DaEt!S:yS-r<

21

T-8421B, 8422B, 8452B, 8722B, 8752B

Page 30

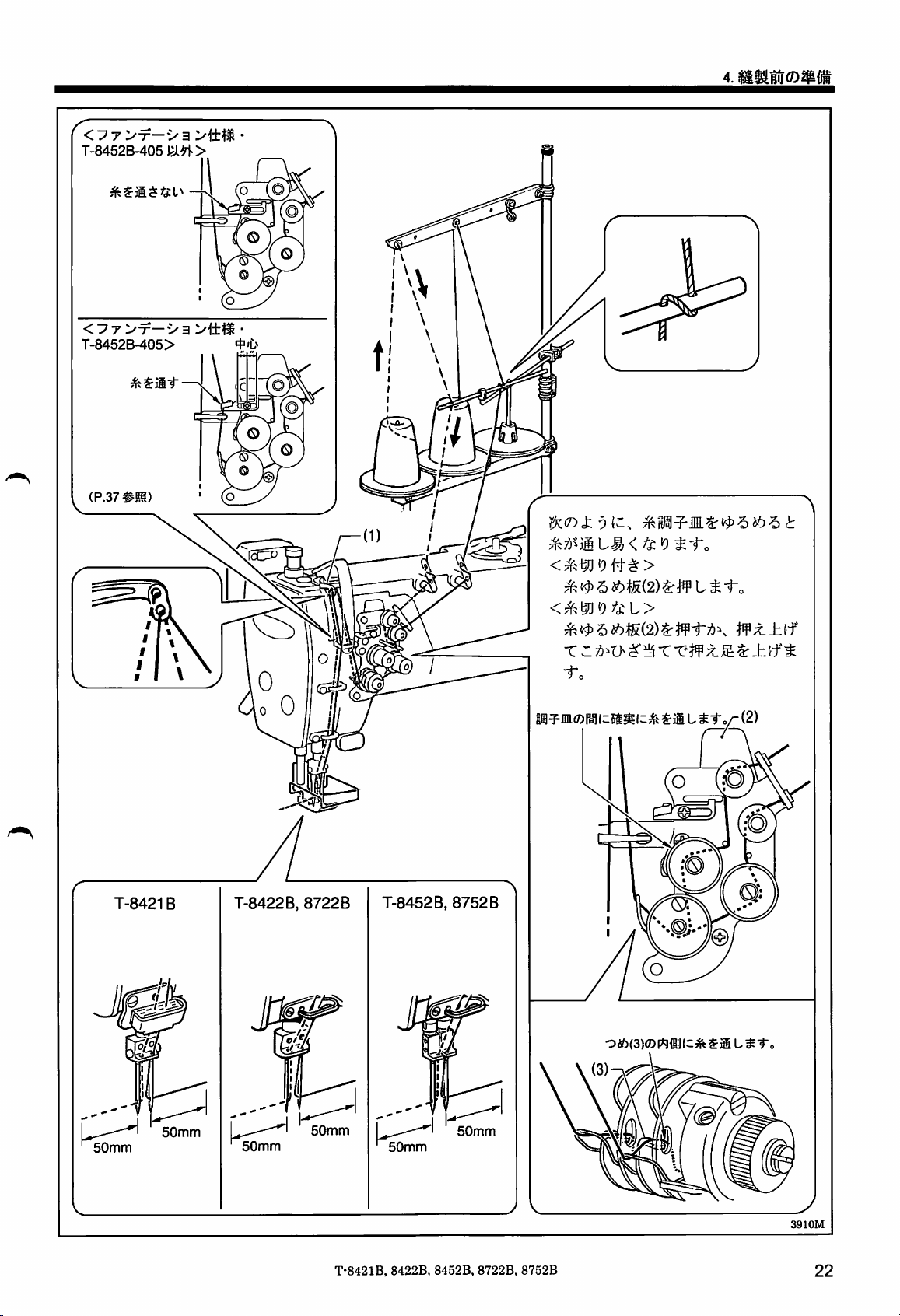

T-8452B-405

T-8452B-405>

(P.37#SB)

4.

T-8421B

T-8422B,

8722B

T-8452B,

8752

"C::/?)^t> ^

T;t

s ^

±(f

^

•t

iiM0PBiiz5tii(z^*a

L^-ro/-(2)

B

oft(3)0rt®llc^^jlL^T

50mm

50mm

50mm

50mm

T-8421B,

^Omm

8422B,

50mm

8452B, 8722B,

8752B

3910M

22

Page 31

4-6.

ii

(/J2

1.

(CHILT.

2.3^i9

n

^m'^}i\z.^t>

4-7.

u^^r0^L^:^

2906M

f^gnt-C</c$V^

• i^«9

Hl-f

3.

n -y ^

* i^«9

fc

^ V

^ -T:-^;b«9^"To

)

•YM2)(Dm^^k:^^h4^(Dk\^{^

^ t

(±.

LHv^

y^

U/-^—(l)^

Lo75^'9

t^-fo

g^y^-\'/K2)75)>lHl^4n^::

^V

N±<9^1.lb.

(3)^

<b:fe{-lHlLT.

t^5S|gUT<

2907M

2910M

2908M

^tAV^(2)•rv^^^l#±{«fc

2209M

®

I

23

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 32

4-9.

(T-8452B,

8752B)

Z(7)5

4-9-1.

v>^

1

nmc&.•^)<D^±1jii

mn±

L^-e <

f£$

L^o5v>0M0JSia<i:

-Jit

I

3128M

O

CO

'Lk-

ttf?±

y; h

yy'Uy<—(D^^i^lX

If-Lh

LT^fl^

V

y-f

X h

5/-7°Iy/^—(1)^,

^cC

L T <

oq

CO

LTl

y

y^c

$ V\

.

Lj4E{-t^i"o

RjiL®{-L^i"c

CO

o

o

Lr

^ofdiit'C

l,000rpm

JL^X

4-9-2.

L^^®40

3131M

3129M

<2

-fy^y=^

hy^

(2)^ff

ly/-<—(l)a,

t^1-o

g h t

coiilMi^

ht'Ot

-to

3130M

140°

40° 50° 60° 70° 80°

2

4.4

3.5

2.9

2.5

2.2

4.6

3.4

2.7

2.3

2.0

1.7

3

4

5

6

7

8

4.8

4.0

3.7

3.0

3.5

2.8

2.2

1.9

1.6

4.6

3.0

2.3

1.8

1.5

2.5

1.9 1.6

1.5

1.3

3.2

2.1

1.3

100°

2.7 2.2

1.8 1.5

1.3

110°

120°

1.8

1.2

130°

1.5

1.1

mm

1/4

om-^y

•y]

2.9mm

T-8421B,

8422B, 8452B, 8722B,

8752B

24

Page 33

5.

5.

5-1.

^n^tltfzh^

(-

=^-60jitR.

(16) (15) (4) (3)

UUUfJ

B)

^Xm\m(Dm.'^^mu

O a o

rr\ rr\

y

(:

lr

< fc ^ v\

yO\

rT\

o

LOCK

[4®

(12) 11

^3)

1®

©

1®

my>:f

(10)

(l)

(2)

(3)

(4)

(5)

-Y

y^Tj^

'i-F_?

8888

hx^=^—

^

/T\

1&

(14) (17) (13) (5)

c P D

8S88.:&,

•

•

•

•

A

•

/\A—^Wirt.

V^6

r(7):3r-^#L.

Xo

"^U^mA-m.XrnXhfilXs

{j:

OFF

$nTV^;5ific(0-99)^iiiu±J6^V^L^-to

oc

rfiihi!6i^i/^j

^^^±i6^v^J

^ii^^ihi6)^V^J

r:^vj-^VNj

$1-^(0

1^7^(7)

A • B • C •

- 99) ^ pihi6li

30

(2)

1^/7^(7)

D.

®^-||V^f-l-ic

0~99-^Jf;(jP

V^L

^^il:^s5^v^1ttg(7)

C3 0

(6) (8) (7) (9)

AB

ft.

ABCD^^-^^ikTL. A - B - C - D

t^-fo

^-f

o

LxXo)

-To

yyXX\^X\XX\^^^b^\X.

oo

U.

A • B

C - D

E • F i

/xym^

ON

:^^ymXA'B'C'B{zmX^

^ A • B • C • D

LxXo

C'B

2137M

L^-To

2138M

{cm^^nx

(7)

2135M

2136M

2139M

2140M

Xfz

2141M

1-D'T'

,,,,,,

2142M

25

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 34

(6)

(7)

(8)

(9)

Oa

Oa

^-1-^(1

-1999)

V^'5i+ic(l-1999)-C\

E

{d^;^$tl-CV^^im(l

-1999)^

jg

5.

V^L

^-To

2143M

2144M

2145M

(10)

(11)

(12)

(13)

AUTO(;^-

Oa

Wk

iiiiiiiiiiii

I • I i I • I • I

h)^-

v\

(5).

gilj^{:i^^«9

^Tt*lll/^^>-(6).

/<^-;^5i-^-cm:l:TL-CV^S<^:#{j;,

•

x(D^-^nL.

•

AUTO

=^-(10)0

yyXX\^xrLx\^^^t^it.

t|±lfjJl

t^-fo

7

L^i-o

(7)if^ffl

|g:3i(220rpm)^^t>tXV^^-ro

>9^1-0

2149M

2150M 2151M

2146M

LT

2147M

^hsm

(14)

^i~o

(15)

(16)

10000

QQUU

11^75^

^

10rij

^ ^ ^ t # t

11-To

x-^U'PLt-Xo

S-To

(P. 25

w(f~^

(17)

RESET(y

ir-y

^):^-

T.^

+•

;7 ^

25

T-8421B,

8422B,

8452B,

8722B,

^tz{tm^mi'p^nm-t^t^(ci^iiu^

8752B

2152M

2153M

2154M

^Wd

2155M

26

Page 35

5-2.

iI±tf)aua)K$

1

M

||D

29nM

ON

i;

^ O

A(0-99)

B(0-99)

2157M

W±

ON

k

L^-to

L^1"o

C(0-99)

D{0-99)

D^12

2158M

2159M

216OM

27

T-8421B,

8422B,

8452B, 8722B,

8752B

Page 36

5-3.

1

10

5.

2912M

2161M

ON

i:

c>

(1-19) \

(0-99)

1®

ti'/f

<011•^Ill^^>^iL^(c•^^^r>

•

Biill:a6^V^=5r-.

t.-to

Eti'^»»(S:-+av>)f^,

t^-To

ii±T*-(p.

26#!S)T-®«Lfc«H!i;Br*ffit

2159M

216OM

^

OFF

{CLX:^^h^^LX

T-8421B,

8422B,

8452B,

^

8722B,

CD

8752B

19

.

28

Page 37

5-4.

•

T^-ti''p-y?^{im-tizkX\

L,

r-5j

KTic'feofct#(c9'&«ifl5^tf'iv>S1-„

<®!)W(I®iS$>

1

"(•4)

iiX^(DT^B.fit^?>xti''X-it.ir,

ft2»-cy-r-7)Sn,!l»),

(^D^)

(2

»a±ff-f)

lOStSlz

Mj

icmWJPL^-to

|»|(V

A)

RESETS-

(2)

2167M

2166M

2168M 2169M

1. 9

(

^OJ

2.

r-5j

iTx

10 Mj

3.

<9

RESET=3f—(2)^ffp-f-<i:, X

RESET^-i2)=t

29

2my^±.wLmii61.

ift;^-999

>9

fjmfj:fDtim±W±

y(lWrMJ

T-8421B,

\_/oN 2

(2)

V K

L^i~o

5 #fHiyif-Ci:^^)/j=5p|-19

^-Ct

L^ir,

L.

J:

<0^-to

8422B, 8452B,

8722B,

8752B

RESET

8>ja±if-r

LTV^^^-fo

)

^i9

(2)

^9

^

21

TOM

^"^0

/i/cU

Page 38

6.

6.

6-1.

iSKrxtttfcb#

n(W~£)

(23) (21) (19)

^.0

EE0S1

(24) (18) (20) (22)

O00

000

0 0 0

uuOu.n!?,

0^

brother

^

^ m

(8)

(18) P

(20)

(22)

^f±T=^-

—h^—

2ii^

\:tim^vmmL^iro

T-f

p>(l9);^»^^.;^:TtTV^6^#^c,

ri):TL^-ro

fj:o

?

L-CV^6

(250rpm)'C|IM

lOOrpm-VMML^-to

^fHiEllv^T-r

<!:

#.

L ^ "I'd

[crjiE]

r-1'p>(2l);^)\'^?.'J:TLrv^6^#(c,

f^'lT t ^ "To

^fL^^t•o

LT

=I>'(2l);6\'^.;J:Tt-CV^a^#{i,

r ^ ^

=L=c^^

< l^o

t.

r^p:/(l9)^>

1.

r4^y(2iW

2171M

21/2M

2173M

'

if±T-rp>-

•

ilTT-r

T-8421B,

1

=1^/ -J-

(23)/i^'^^'j:TtTV^6,^:t{±,

(24);^\'^.'j:TLTV^^

8422B,

8452B, 8722B,

<b

8752B

i9

±-ef?±

J:«9T-Cf^ih

2207M

2208M

t

^-To

U^-fo

2174M

30

Page 39

6.

6-2.

8888

«(•

® ©

A)

m

(1) (3) (4)

H <

(-10-20)

(^~De

2210M

t^-fo

2.

^-Y

(xx

•

•

4.

ENTER

^-(4)^

N:/if—;i>P|i9. -r

Fioj

-t"o

Fn. 0

^^fit~20

—10

2

>'^^(2)(±tl-ic^^^—

{i,

±!|ill)(7)[I||5^i^?ii^ 10°

xxj

^mmt

L^-To

FOJ

tr-to)

il±

n

K

6-3.

LOCK

O O Q Q 1

UO

A

4^—(ZOLNT

ODDO.:^.

/T\

A A

(2)

(23)®

(3) (4) (5) (

brother

2913M

2212M

ON

ON

c7);licB{-4^

•to

)

^ti{::=):i9.

FUNC(7TV^

TB

i/3

ENTER(^^t-)=3r-(4)

MAX(-^

/c

^ V

;^)dr-(5)

{zLtztt.

S

t # u

LOCK(d>y^)=3r-(l)

(T4

3 ^(2);ii\'^,:l:T

(3)

t-to

#

icim

t

t-to

^

2138M

Lt-to

2139M

LTV

6-4.

RESET

ENTER

tnmiti'^?S.Ti-it

31

^mit<Dijm

finiTALLj

15

ON(cLi-T,

^

tlil".

i: fc

4-f„

T-8421B,

8422B,

8462B,

8722B,

8752B

i'D

Page 40

7 jK#

/ •

nu£

A

A

^ y

a-^t-

MoTi®«sat;i:,

* u

•

7|tt*>-¥'tt®3EM

MSt,

«<ffli»l-.5>tvfcy,

'j^ivi-ox

5

-»Lrlt!f)<®®Httc

^fcii5i/>®®a®)gHt!tcys-r.

5v>^ffllUfcy,

RUfcy-r-St^li,

t 5

Lx<

tzti\

<

fc'^Lv

mxWLtz^)Ltti^X<f£H.\

iS¥-CtT«i:or<f£$LV

y,

*$tt$b'S:fl+A<ro)iBi:'a

2914M

1.

^diRiL.

•5ci<}r

y

$1".

y

SI",

r^^m'oWKD^mc^i^i^Lt-to

^

2915M

2114M

2893M

3.

5.

mUy

1"o

:y^(l)c7)0NiRiJ^if

XX(2)^(3);6\^,^T

L^-To

t^1-0

T-8421B,

8422B,

8452B,

8722B,

8752B

32

Page 41

7.

2916M

l^-to

2917M

2918M

Ti^^:xni—[2|c7)J:

<

/c$v\

9(;:9

0°

::

.ir

33

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 42

7-3.

7.

TE(7:'J;9^-='VxV^llv^^o^v^g:5

2919M

P-:/7

2920M

1.

(3)^^(;:|hILT>

L^1-o

2.

3^19

3.

1/^^-15(7)1-

4.

^ fc ^ ^ ^ -To

=i>'xV;^IIV^cD|iV^@:S

/^v

K/v:^hi//>(6)^)ix

/N^

K/^/^H5//-?(6)^[SI^L^

1"o

<iiii^}£>

t^-fo

2.

^Vir/l^D-y

^^7

(3)^;fe(;i[Hj

tr.

-fo

3.

4.

^

fcfiil

t^V^l//-^—(2)^Jf

L^1-o

(^fLTV^;5r01> )

LllV^

^(1)

T-8421B,

2921M

8422B,

8452B,

fi,

8722B,

K/^;^h5//N(6)^igL^V^U/<-|g(7)(v:^

vnfx

8752B

< ^ V\

34

Page 43

8.

8-1.

<-7'>5=-5C>

^UrI-T-CDI®®!

0572M

0573M

0574M

-±^

-T^

±^(»liWilLN

2922M

A

t:oor<f£^LNo

iRori®l5^sgt;<t.

0I1S

i:'Ji: y

^1*0

5

v>7b<f^ii]Lr(t7!)<

2923M

5t<

< ^

'5t<

/^/•^

A

<±^<D^ti>

1.

2.

i:(l)^0

LTP®

h(2)^lHlLTf«1iit^i-o

t

^-tc

2924M

8422B, 8452B,

8722B,

8752B

35

\

T-8421B,

Page 44

8-2.

lELUSSUS

•^r—'-'

*-

IT—r

. 1

) '1

8.

=y

X—:

A

±.^

0894M

0895M

0896M

11

I ^ ll

l.^J-

M > I

0897M

o^vti

u

y^)

8-3.

y

W:(D±^m

18mm-47mm

y

s0iiii5

2925M

33-37mm

(r^(D

/c:$V\

rjfp;tiitp:JgLCcDi^^j

)

3.

mm

y

•

•

•fuv->'y3>(i)(Dmt]^m<i-^t.

±^^•9

<9

ttfi

aS-aTmm

h(l)^l^i6^-ro

<9.IKi::S:<

^

*LT<

34mm

34mm

29mm

4k^'0\k(r>

^9

^i"o

±^m

2927M

T-8421B,

8422B,

8452B, 8722B,

8752B

36

Page 45

m

u

G

5 o

H<

4=^

if

m ^

V Pv

A

Pv

A

N

vie vie ^

iW

dM

fK

5!>

H<4^

m

A AJ

vie

-H

^ I

km

® i

A

'Jh

ii

441

Ih

A

m ^ S 1

I

1^ ^ ^

V

G

m

%

IK

A

K

1

vie

4$i

^

vie

^

A

vi^

t!

s

ff-M

fK

4^

m

fiiiS

a?

^ s

G H

^ S

•i^

_) ^

ii

^

(ii

<»

«

I—

-w

4-4^

® -H

—^

n n

^5

if

u

/\

m

i]^

m w

niiS

t~4 ^

—

%

ti

Q

A

^

CM

S o ^ P

tK

•1^

m

^ w

lit

iO

Q

?

o-^

T ^ V

A

o

S

;5

o

4^^

N/

vie

A

m

Q

to

45

S o

•§^

^

j<?

vie

-W

4-

Ji!

—i

s>

^C]

•ie V

,• w

r2i

Q

4^

u

m

4^

rH

<n

m

4^

.0

P

->

f

if

-fP

Din

iK

li

4^

^

->

_>

_>

tliin

~v

•vo

uiK

4^

nn

4\ti

AJ

^ Aj ^ 4^ ^

<

jL

A ^

n •& nn tni

4^

4rtJ

uiK

nJ

tni Q

A

4<

•ttJ

^

4^

4\U

•{on

^ AJ

•r\

g

s ^

-f^

)f

\/

0

4\0

AJ

K?

*/'

10

liSi

£5!?

-R

w

•fov

f p

K^ •

vie

<n

f

4^

.CV

JJ

4^

<F

S

4i:J

H<

»CA

vie

5

M ^ AJ

f5

4\0

[m ^

P

.'

k)

•

CO

rv.

Page 46

9.

9.

A

KoT^ffiSSft-i.

0

fcsi.^

iSffi^fic-risst^fys-To

^fca5t;•i•¥>•9•|J-x^tt^fc•y;t'<fcyt#i•

^tt®¥(DaA^';j:l>i:

5-»^ffiufcy.

A

4-

-51S•»©«$

9-1.SS(Dfc^A^X

Z(D

i^v^r^r

5->>A<#«lLTI+A<®®S<t!Sy^-r<,

«a«);!i<fe-¥>«a¥a9$ttfflU,

C^ilcBL^T

TJ^Tb'Ji

TlS<7)^o^Ati^tT/c^oT;6^?5

X X V

<

y,

^

SliS

2930M

t?4

fl+A'roliS

^

<Ji^>

1.

^yyx-v§f^m±imi^L^-ro

2.

3.

5.

19

@-¥>S)SI:'(«^4-1-^J:5IcLT<

•5c<t)!i«fcy*-ro

i:

4 y

^-To

LX<

/c^v^

t^-fo

—ryyv^y

ION;

VG10>^{5^fflL-C</!:^V\

*

X -y y X

1.

flvt^/9^^liiiitfl^^(l)(7)TSi^(2)J:

I

/n\

5

293IM

SMIO;

VG10>^r-Siffl<yd"

LTci^^

^ V\

y

>'^—fvi'

f9

T;6^oTV^/d

<5iis>

^•9

2.

±^;6^IEL<iio-Cl^6^^^flS|gL^i-o

(P.22

#,WS)

3.

^LliV^^

2932M

T-8421B,

8422B,

8452B,

8722B,

8752B

38

Page 47

9.

2.

Tjfy

3002M

9-2.

;i-'i';u*/<—(6

2933M

6

^j^^;l-itC^v^(DfI]'g^-C\

^Wi^LX

ION;

VG10>^{£fflL-C<ff$i/\

*

1. ^

2.

3.

A -yy X

(P.9

^

SMio;

vGio

^>:x9j§[5^#JL^i-o

/^;^/<-(l){;i®i^(2)^-e?^AL^fc

#BS)

fair#

</c^ V\

Lrci^^'y>^-tvu

> ^ </f$ v \

39

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 48

9-3.

^^U-Xa)1t$&"-GREASEUPA<S^^tlfcb

("b^K^-Tttlt)

y^^O'^\:i\^fzt^.

(2)-

iuCtuu

?^^ym^(l)l^

roREASEUPj

r . c O C CftOC

U f c

ft

JC

U f r

LOCK

y"-f-:/)'^^Motih.

1®

W

1.

RESET

2. ^ ^

mmy

[ca/

rOREASEUPj

•

tgreaseupj

^

A—(2)^^f

yy(3)(t.m'WJz/£

TErrlOOj ^ ^J; 9 Cl

commit,

^to

L^-To

^^'y—^

HHS^

Fiz^t><0.mM^^^i2<ii^imm'(:-^^J:oizfj:^frc

^ )

'€11^.7

^'v~^(Dm^(^

V

Ti§if^^7^£oX<f:z^\y\

(5) (4) (6)

^9

^"to

i@fc

L^-to

lOb

2191M

T-8421B,

8422B,

8452B,

8722B,

8752B

40

Page 49

9.

y

-(i.

y y

•f-^'^(D

<

GREASE

(SA7300-001) >

LT</c^1/

\

<f*)-X{t

2.

<7''J—

r^'J-A3^

©

(SA7300-001)

(SA8122-001)J <

SA2695-001)

•(2)

(1)

f£^l^<

(1)

1

S\3

3 ^

3908M

-(2)

H

1.

y^^OFF

2y^f3.C(2)^^L^ir^

4.

lf(J:tai:(2)^l^466^cb{::=l:

(lU^-To

{y

<9,

y'')

2937M

ISIt(C;SA-r^c

i^Xo

7.X(Dm.

[:r^m]

^rmx.

•

yv-yit.

•

(m$mo)yv

^ycDX'.

7";:^V\ )

y

VTm¥^n^j:^^^Xo

-e#^fcl-j•-P•<^^v^•^o-c<fc:$v^o

yV

)

2936M

—y^^x

41

T-8421B,

8422B, 8452B,

8722B,

8752B

Page 50

(l{cL^-fo

9.

2938M

* I^B#IZ.

:t->l';uyD/\'-(Cjl,^;ft^MS^Lr<f£^CNo

g7:^?s>

z0rER5EUPc

(P. 9

#M)

1.

rOREASEUPj

2.

RESET

.^X7-r

^fe^cCif"!:•>

V

y r

:yON(>1

A—(2)^^f

i i

L^-fo

^•"—(2){>l

y y ^

L/c:fi-c\

L^i'o

L^-To

60

5-lOmm

5-10mm

^^Z^(3)a)±T2E^

0 4

2939M

y-

^-to

^ -T

8888

"(Q)

(2)

(6) (5) (7) (3)

T-8421B,

8422B,

2940M

LOCK

3.

r-f

4.

FUNG

(Pxxx

(1.

5. V=3r-(6)^i<P

6.

ENTER(piy^-)A—(7)^

l^^^<Oti-o

8.

m:^4':y^?rOFF{cL^-ro

•efo

8452B, 8722B,

=^-(3)^

:=f

y(4);0^?i^'j:TL. p y

2

(y'T^^'^aV)

i7-

y -

CD

^^"if—<9

s

)

8752B

#^±#

rn.l34Pxxxj

rf^|r§/i^ ^ 3^ L ^ -To

lOO%m;|^Lyc<!:V^5E^^X:-to

Lt-To

^4'

L^-to

'itMf>t^^tit.-to

=^-(5)^if

rpxxxj

2|^^iyii:#t^-ro

t^-to

f^J

X. PlOO

^-T

Tp

2139M

)

Oj

K

42

Page 51

10.

10.

lztx<tztl,\

.5 k

tit.

ItA'roSHir'SyS-r.

li^S-V'iS y <

SSp°»l:JHf>»aiil®ffl«)!)<.ix*i,4%^J:5

«v

10-15

2941M

mm

2942M

@

1. ^ y

2.

yf^U

L ^

"to

2.^Xfh-h^h^\'^X^(D^

3. ft" V

4.

JfPx.±{fT::TjfF;tJS^±{f^-ro

5.

6.

ifg

[ii;^

/j: ^ tT

7.

msrtMil

>9

L ^

9 ^ 1

1^(2)(Di^m{-:^mco^tj){-

mLAtix^h.

h^.^9VLt.-to

i"o

T'cf

V^^ -fo

10~15mm

^yym^m

di

8.

ffllft{::fl^t5:tfc:?iiifi^?^|g:L^i-o

5y(^TTitijyi;v«>;r

V

1.

2.

XX/ymnitxc(i)^\^Lx.

•9

XXo

•

XX

xmWt3i

i:(i)^;fe-^[Eli-1

/c^^9t.Xo

3.

±E

Xo

*

miEmm{z.f^^xx\

'ic^'S\R(DmUX<<9iltr

2943M

43

T-8421B,

8422B,

8452B,

8722B,

8752B

<

xx/^mniuc{i)(Dm^t

</c$ V\

Page 52

11.

1

1.

A

11-1.

1

mmmu

ig.^

—

-yf-^aoT.

/±s

sv^b^tFaiiUTWwisair'sysi-.

^iiL ^

±^smX}

^-fb^;tT V^

^•ibA^;tTV^Ac<J:#{i,

•

^-ti:

initt^aitfcM^ifciiiDHv^-hifwRg^g

< fc $ V\

Ay/O

^?

IE t <

LT<

Ac$i/\

#ns^—

18~22

35

0573M

0574M

^©19

#7f±^t(=0 ^

ct '9

^^>9

Acf9

7}f

\Z^y(D'^^19A\W;<

(7)^l^'b<^A^^)'9

tz

^ V\

T^^011aiL T

{ftax

hLT</c$v\

25XJF

^9

^itAy/j^

(7)Al

LT<fz$i

{-1?

\

D

/cCI^t.

*

m

2944M

7K

0977M

^t>X:^a^ML-C<

T-8421B,

8422B,

8452B,

8722B,

Ai$V\

8752B

37

44

Page 53

11.

2945M

T<

ff

ffcD©

<9

^iiL ^ ^ ^ ;9^;tr V^ -y:

^it^^>o

if;ti±;^^»L-C</-c$V\

1

yyi!^Xi!b<Dm^WL'OW^X<fz^\^\

:?^5:®^

3^

t>X^

19

ft

#ii

^

t-^^^;9>o

iEL

^/9

UT</c

<

>9

{^(tT<

16

^

18-22

36

*

$ V^

Hi

37

*

9^5:^

19^.

(i®t«9#;tT<

;^p

tf

{1^MLT<

h

ti-9^;9^ib(D±^^'9ft;6^^<

^c^V^-el~79^o

/c^V^

—h=^—^jML-C<

±#lhfM

(79^fTo

M3D(2)(D®ftf5;

fc^v\

LT<fc$V\

;^c:^V\

T <ff^ V\

*

36

*

30

31

*

2947M

ft(79fc§O

S

ft(79/^^^i^i9lt^^;^

r?c=5?|

=Sr

itUT

(79V

^^l!^X.ft

V ^;9^o

L-c

LT<

fc^V\

SXHr

< ^ V\

I

2946M

45

T-8421B,

8422B, 8452B,

8722B,

8752B

D

2944M

Page 54

11.

^

5

36

6

7

^—V_

liv^-ftl

2948M

V-

2949M

•

19

it(^i«

^ t T </c$ VX

^i;^l^ov^TV^^(^#fi.

^"9

r^mxi^x^^fzim<

^®'9{^;^3i(D?^$^-et6/::'ltil<

^®i'9

:^®lf9{ft3ix

$ V

"*0

h y^<<Di\LW:^.

)MiM^<-^-x\

i^t}±:fj^m^LX<

fiIELT</f$Vx

#;tr

<

/^c

^ VX

t-c<fc$v\

•C#'5/ctti^<

;^v^3iit^'>t-roii<

fz^l\

LT<yc^Vx

t-c<^c$v\

H<

35

35

*

LT</c

*

36

26

37

36

(-'

CD

2950M

8

-5

19

}^'y(D'^

$s

T

jk

•

T^^§lv^fc:<!r

7j<

t^->'(7)lHl^;^l^(79[H]|a;^[^

VX

• « qqo/

#(79^'t'^^(7)IE]^:^[B]{l'^o-CV^^•i-;^)X

i:LT

80%^-e

c^S,

< iTc$

(::t-C<ff$vx

19

T </c$ VX

• ;j^'l::^':/cort»9/J)^®<

^>9

Tjf

295IM

t'^19

fc'9

#;1T

#x.T<fc^vx

< /J: $ VX

2124M

19

18

19~20

to

0

T-8421B,

8422B, 8452B,

8722B,

8752B

46

Page 55

11.

±^•r^yf^wti6

./

iiH-^56'^ft;6-^orv^/c'9.

T <

yd'^1/

\

t^:^>;tXh'fzt^(i.

:^iil

y3y^;^'CV

t-ib^'<;tXl'fztt(t.

-DStiXl'fzh.

jEL<tf-^®«9j^{t-C<

IEL<^^iSLT</d'$V\

/d'$l\

16

18~22

xmmm^r^'^^x\^'fzh.

X<fz^\^\

t

r^^(Dmx]

^mm

Lx<fz^\^\

y^^^»LT<yd'$V\

hii\

Htr

^/d{i.

fi;^i^'oi

^ycfi.

^

0471M

10

^mj\^m:i&hr>fz^.

t/^

fiy'>ov>TV^^§Ro"p^I&'9#;iT<

^TV^6E#{i.

^i/i»^ov^TV^^gl5p"p^^lxt9#;tT<yd$V\

a ^

ti

L X < yd$ V

^o

^^i^y•^oXl^^•ti:^y^

<

yd'^V^

^mji^mm^x<fz^\\

11

mfxfi

y[T?ri?'9{C^K^yc:^9^f

Lycf9

m\it

/d'^Vv

/d$v\

9

35

38

*

*

37

*

^f^fey^o^tiTv^yc:0.

<0

LTl/^^iy^y^o

'9#;tT<

yd$V\

16

47

12

Mz^x

Lxms.^m^ihA.x

t ^

V

\

/

im-h^mmLx<fz^i\

§f[Hi

*LX<yd'$V^o

^

XiiS

it'9lt^a{tELr

i|£ L X V^6 i: #

$^0m^<m7Lvt^^x\

^tz^hhCDif^smizmtWs

0469M

ON

Lyei/^

\z

n > I- n

ii

/v/j\

—/P;Jf

=1

^ ^

r^^{c^tiA^x<

T-8421B,

y ^ z^

y^^Ktix

8422B, 8452B,

I ^t -ty

(DM

yd

8722B,

it0

<

{t.

^

iHl

i&Pi^^Lx<tz^i\

PL

8752B

yd$V\

t X IE t VM4SE(-

)iMmtLxii

*

*

13

2952M

Page 56

rWI3i'C^l$g'T:•i:/c^V^

13

14

oT

11.

i:

r 6

26

^

'M'i:j±^^ig:<

LT.

yyX^

OF¥{cLX<fz^\^\

26

V

tr

< ^ V

N,

*

15

16

mn^X

Ltzb^.

-ra

•

/P

{C.

y'f-^

rOREASEUPj

fpj ^

ON

7f^

{:

n p —yl/jjf>7^ (7)'®

-^ Uii/v

p

\>

a -y Af^](D

"C^ fz

Xl^t.-\tAy^\

5ii^{^^tjAAy-e<

$

"*0

fz

y —X t r < ;^f$ V

^o

2952M

13

12*

3154M

40*

T-8421B,

8422B,

8452B,

8722B,

8752B

48

Page 57

11.

1

1-2.

X-7—KS/F

rn

-7 — n — K

Err

(ia«)i)

i::i6

L.^

11=1

2198M

X7—=1—

ti^i'o

i^-<Tv^fc/l<

1

®'/PR(^'f®li (bX ^ V h n —/UaK 7 ^

ot:V^

i~/j

^

CO

i[^{iML-C</-f^V\

i^5^IE^^t'C<

zi h

P—/W/jf

7 ^

7.\c%%iy-h

"9

^

*

i~o

Err

Err

(rc>zi

y~)

Err

(^

3

—^"zc

4

^ p 7

/i'

^ V

^o

P h p —/PaK 7 ^ l^lCOll^p^p

p > h

ph

p—;U7jf

7 ^

^ ^ T V^

M

LiA^T-<

p—/i^aK7

it^;0

/f$1/\

X(0^—^

\

p^^

—y

* *

2199M

*

3155M

=3

12*

3156M

^

13

>'>;6'^P

49

7 ^

LTV^^^i•^7'J^

7^^

r

i:^#:|gL-C</c$V\

T-8421B, 8422B, 8452B, 8722B,

OFF

{::

LX^i^>X—U^^xm

8752B

L.

xste-c-ta

2202M

Page 58

11.

z^tJit^\z\t

ZC7 — =3— K

Err

4

Err

(mj±i5$r)

Err

y—)

:-CV^/c/c<

ZI

^ h

5

7.

p—>y

:^LiA^X:•<;rd•$V^o

5;

X —

y^

X<fz^^\

6

nM(Dmj±

^

;KD

7

p y }.

C P U i:(Diiit

p—yl^/K

m.%\z^^WxhhX<

^

7\^(D

ht'LX<fz^\^\

^

7-^

:y L

nW^7X

fC.

d^v^-C•i-75^

^mm

-/ y

Lx<fz^^\

^

nM.7-i

0#{d o/c1-{C^

fz^\^\

i::i6

on

(-L^^i:^-t:•t/d7!)^

ON

KLX<tz^\^\

12*

3157M

*

^

1~c

*

Err

ix-^<-yx

A)

Err

(x-y^'^m

B)

Err

(y

y y X

Err

yX—W^)

10

11

> h p—/i/7j<5/

=iy

hP-zU-^jf^y

8

ii^3

5j'l^±il^Lfc<!r

M7X

yX^AtiW.LX.

#.

CKD

7\z^.^ii^h

J: 9

3I^ili|£LX</c^l\

'0

^"Xc

<

fd^V^o

3154M

* *

9

Kii

jaj^/?)^T75^o/ct^.

tz

^ V

x—y{z^'^^^^h^-^Xo

x—y^^^LX<fz^\^\

yyyx

W.Mzm-^^z^x^til^Xo

X—

^yyyX

p>-

h p

y I^gp(7)

Y(Dm}i{$.^^M%\^x<fz^\\

W^t-h^t,Xo

CN5

(D=iXyy

:^LJA^'t:•<fc^V^o

yy

y^^^YX<fz^\\

yX^

ON

(dLT.

^^P;^±{f)cDv^-ft^7^)^

ii'ft'illGUT<

* *

* *

* *

*

T-8421B, 8422B, 8452B, 8722B, 8752B

3116M

50

Page 59

11.

ZAjtjittlzlt

my

Err

(y

uy

U=^y—)

—3—

^

12

K

K®

yu-y-r

Kffl(7)t

t ^

—X^^4^tT<

^-XF2(5A);6^^nT

/c$V\

*

Err

5/ )

Err

hzny—)

Err

(^-y

Is)

13

14

15

3 V|>n —/i^tK>y y

3:/hp—y

3 > Hn —/W/K«yy

3-:3.;/

1.3zf.y

tlTl>-5;0^^^filSgLT<

Bi§|5^a}3.->y

V\

•^—y^xi^L-c</::$v\

3 > h n —/P/if y

XLT

xi^(7)gg;^jA^3^>

y!.

I^T(0sJ§f5l^,'±l

h^^mLX<tz^

19^1-0

XLT

<ff^

V\

3702M

3158M

3703M

* *

* *

*

* *

* *

* *

Err

Err

(EEROM

-)

Err

( 3

:/

-t-

Err

®-T-

51

19yuy

). P _

y

x;y—/<

h)

16

18

19

20

^_)

*

«9V

LT

< V\

* *

y

3 V h p—/W7|f :y

y;A^^^tT<

* *

(3.11rWjffitt'tll'A)^)

?^iny

Mx

j;^iA;^3.3-/

T y

i^^iA^x

T-8421B, 8422B,

hp

r y

—y

LT

<9

^i~o

8452B, 8722B,

LT<fc:^l/\

< fc ^ I \

8752B

/c$v\

* *

* *

*

* *

Page 60

11.

7 — ^ — K

Err

(f—5:

7—)

Err

21

100

(GrEASEUP)

Err

(diP

101

SW

4)

1-

TGrEASEUPj

y

—7

=3

V h

n—/l^/if

ON

xV

77^7^

tz$1/

m^x\^^fzfz<

LyhhX<

2/ ^

(ci7^oTl''''^'1i"A/7!)^o

\

fz ^ V\

t.

7y"4^0FF{-LT<

CN16

y

rr

tzs

(7)3^-

*

3159M

40*

<ff^ v^

7:^7.^

*

3160M

=1—fcl±(fC0i5

T-8421B, 8422B,

8452B,

8722B,

8752B

52

Page 61

T-8421B

TWIN

TWIN

TWIN

NEEDLE

NEEDLE

NEEDLE

LOCK

DIRECT

DRIVE

T-8422B

WITH

DIRECT

THREAD

DRIVE

T-8452B

DIRECT

STITCHER

DRIVE

WITH

T-8722B

LOCK

LOCK

TRIMMER

SPLIT

THREAD

STITCHER

STITCHER

NEEDLE

TRIMMER

BAR

TWIN

WITH

TWIN

NEEDLE

LARGE

NEEDLE

LOCK

DIRECT

HOOK

DRIVE

AND

THREAD

T-8752B

DIRECT

STITCHER

AND

THREAD

DRIVE

WITH

TRIMMER

LARGE

LOCK

SPLIT

STITCHER

TRIMMER

NEEDLE

HOOK

BAR

Page 62

Thank

you

very

much

for

buyingaBROTHER

instructions below and the explanations given inthe instruction manual.

With

industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts suchasthe

needle and thread take-up, and consequently there is always a danger of injurythat can be caused by

the instructions from training personnel and instructors regarding safe and correct operation before operating the machine

that you

will

know how to

use

it correctly.

sewing

machine.

Before

using

your new

machine,

please read the safety

these

parts. Follow

so

1.

Safety

This instruction manual

safe

Indications

A

indications

operation

of this

DANGER

CAUTION

Symbols

A

(S)

SAFETY

and

their

meanings

and

the

indications

machine

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates

(For example, the symbol at left

This

andtoprevent

The

instructions

The

instructions

equipment and surroundings^

the

symbol

( (J) )

and

accidents

instructions

instructions

natureofthe

indicates

INSTRUCTIONS

symbols

may

could

caution

that

are

and

injury to yourself or

which

follow

result in

which

deathorserious

follow

cause

that

mustbetaken.

means

"beware of injury".)

something

usedonthe

injury

that

this

this

term

term

when

you

must

machine

other

indicate

injury.

indicate

using

not

itself

are

people.

situations

situations

the

where

where

machineorphysical

do.

provided in

failuretofollow

failuretofollow

ordertoensure

damage

the

the

to

o

This

symbol

natureofthe

(For example, the symbol at left means "youmust make the ground connection".)

( ^ )

thing that

indicates

must

something

be done.

that

you

must

do.

The

picture

inside

the

circle

indicates

the

T-8421B,

8422B,

8452B, 8722B,

8752B

Page 63

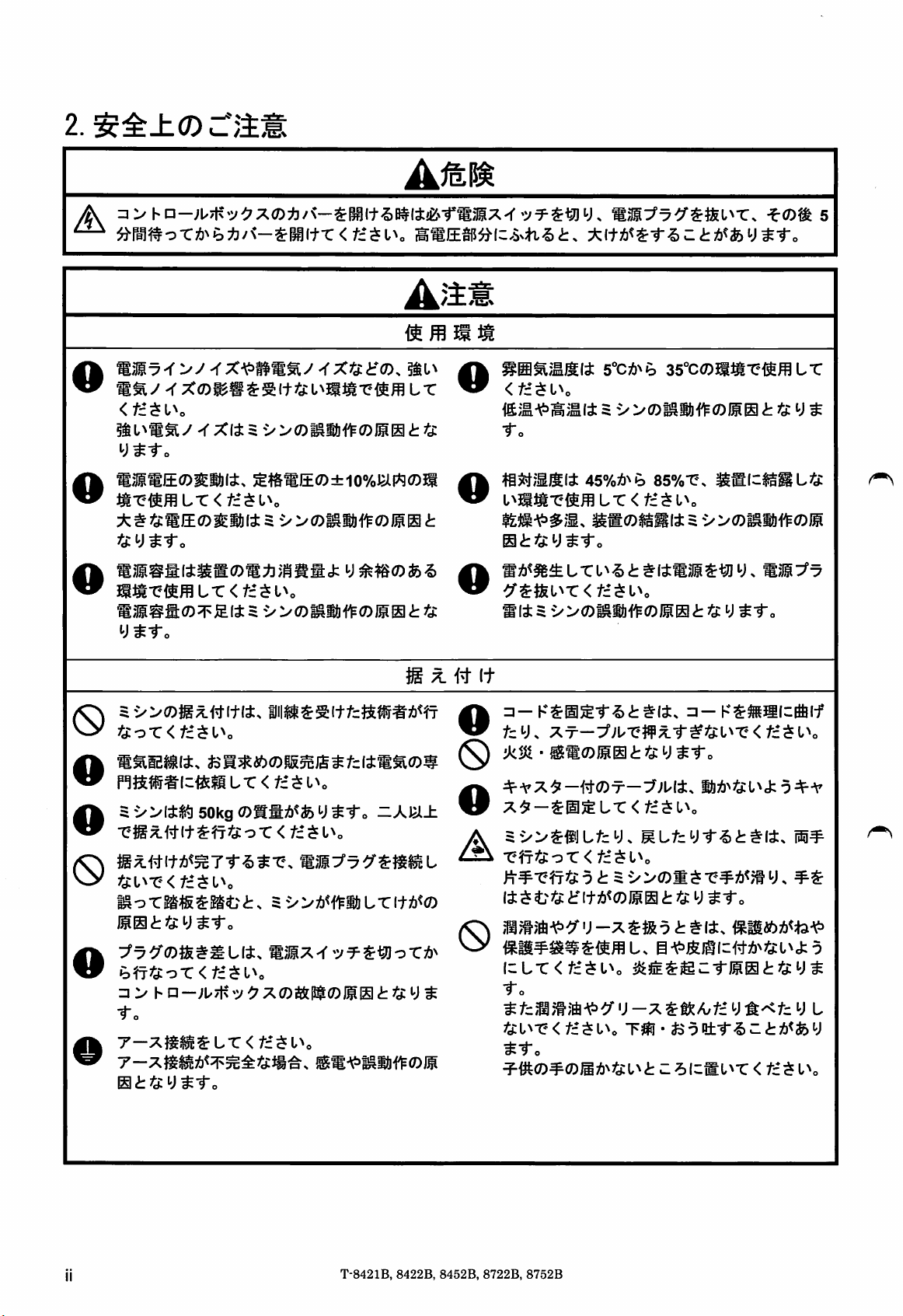

2.

Notes

on

safety

A

Wait at least 5 minutes after turning off the power switch

before opening

A

severe

injury.

Use

the

from

o

o

sources

electrical

Sources

problems

Any fluctuations in the power supply voltage

should be within ±10% of

machine.

Voltage fluctuations which

may

cause

The power supply capacity should be greater than

the

requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may

problems with correct operation.

the

face

plate of

the

control box. Touching

Environmental

sewing

machineinan

of strong electrical noise

line

noiseorstatic

of strong electrical noise may

with

correct

operation.

problems

with

area

electric

the

are

correct

noise.

rated voltage for

greater

operation.

which is

A

than this

DANGER

CAUTION

requirements

free

such

as

o

cause

the

cause

o

o

and

disconnecting the power cord from the wall outlet

areas

where

high voltages

The

ambient

range

of 5°C to

Temperatures

may

cause

The

relative humidity should be within

45%to85%

should

Excessively dry or humid

formation may

operation.

In

the

event

and

disconnect

Lightning

operation.

temperature

35°C

which

problems

during

occurinany

cause

of an electrical storm, turn off

the

may

cause

are

present

should

during

use.

are

lower or

with

correct

use,

devices.

problems with correct

power

cord

problems with correct

higher

operation.

and

no

environments

from

can

be within the

the

dew

the

wall outlet.

result in

than

this

range

formation

and

dew

the

power

of

Machine installation should only be carried out by

a qualified

0

Contact your Brother dealer or a qualified

electrician for any electrical work that may need to

O

be

done.

The sewing machine weighs approximately 50 kg.

The installation should be carried out by two or

O

more

Do not

complete.

0

is

depressed

injury.

people.

connent

The

technician.

the

power

cord until installation is

machine may

by mistake, which could result in

operate

Turn off the power switch before inserting or

Q

removing the plug, otherwise

control

box

could

result.

damage

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

Q

receiving a serious electric shock, and problems

with correct operation may

also

occur.

Installation

ifthe treadle

to the

When

securing

excessively or fasten them too hard with staples,

o

otherwise there is the

shocks

0

should be secured in such a way so that they

cannot

tilting

A

only

head may

may

Be sure to wear protective goggles and gloves

when handling the lubricatingoiland grease, so that

0

they do not get into your

otherwise

Furthermore, do not drink the oil or

under

vomiting

Keep

could

If using a work

move.

Use

both

it back or returning it to its original position. If

one

get

caught.

any

and

the

the

cords,

do not

danger

occur.

table

which

hands

to

hold

hand is used, the weight of the machine

cause

your hand to slip, and your hand

inflammation

circumstances,

diarrhea.

oil

outofthe

can

reach

that fire or electric

has

casters,

the

machine

eyes

or onto your skin,

result.

as

they

of children.

bend

head

eat

can

the

cords

the

casters

when

the grease

cause

T-8421B,

8422B,

84o2B,

8722B,

8752B

Page 64

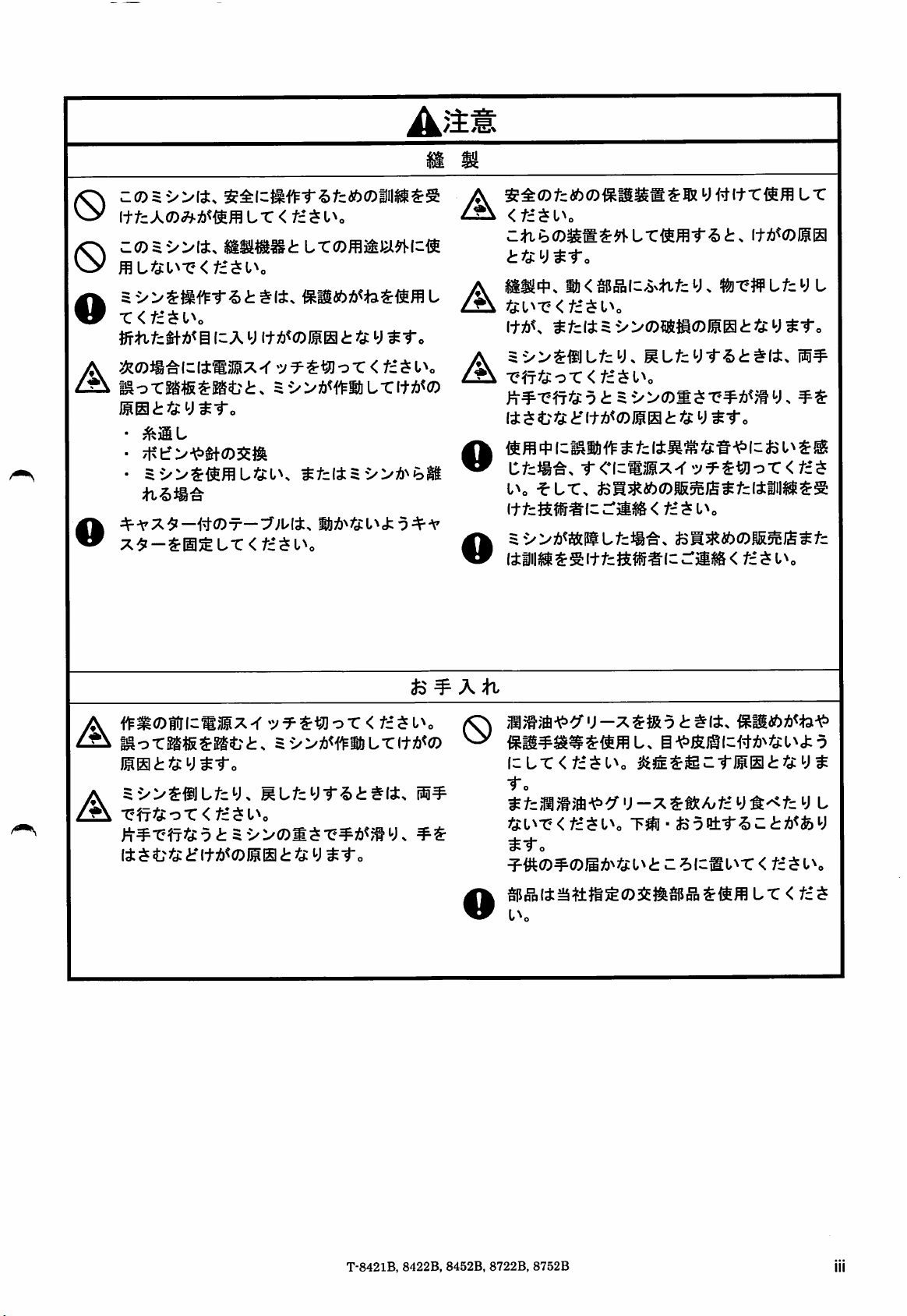

This sewing machine should only be used by

(S)

(S)

o

operators

in

safe

The

applications

Be

machine.

Ifgoggles

needle

enter

Turn off

The

depressed

•

•

•

If using a work

should

cannot

who

use

beforehand.

sewing

suretowear

are

breaks, parts of

your

eyes

the

power

machine

by mistake, which could result in injury.

When

threading

When

replacing

When'not

the

machine

be

secured

move.

have

received

machine

other

should not be

than

sewing.

protective

goggles

not worn, there is the

the

and

injury

may

switch at

may

using

unattended

table

the

the

the

the

operate

needle

bobbin

machine

which

has

in

suchaway

the

necessary

broken

result.

following times.

if

and

needle

and

casters,

A

training

used

for

when using

danger

the

needle

treadle

when

the

so

that

that if a

casters

CAUTION

Sewing

Attach all

machine.

devices

any

the

may

is

leaving

they

Do not touch

objects

A

may

machine.

Use

tilting it

only

head

may

Ifanerror

or

o

power

dealerora qualified

If

nearest

o

both

one

get

smells

the

safety

devices

If

the

machine

attached,

against

result in

back

handisused,

may

caught.

switch.

machine

Brother

injury may result.

any

of the moving parts or

the

machine

personal

hands

to

hold

or returning it to its original position. If

cause

your

occursinmachine,orif

are

noticed, immediately turn off

Then

contact

technician.

develops

dealer

or a qualified

before

using

is

used

while sewing,asthis

injury or

the

the

hand

a problem,

damage

machine

weightofthe

to slip,

abnormal

your

nearest

the

sewing

without

press

head

machine

and

your

Brother

contact

technician.

these

any

to

when

hand

noises

the

your

the

Tum

off

the

power

cleaning.

A

depressedbymistake,

Use

tilting it back or retuming it to its original position. If

A

only

head

may

The

both

hands

one

hand is used,

may

cause

get

caught.

machine

switch

may

which could result in injury.

to

hold

before

operateifthe

the

machine

the

weight of

your hand to slip,

Cleaning

carrying

treadle

head

the

machine

and

your hand

out

when

Be

0

is

suretowear

when

handling

they do not

otherwise

Furthermore,donot

under

vomiting

Keep

inflammation

any

and

the

oil out of

protective

the

lubricating oil

get

into your

can

drink

circumstances,

diarrhea.

the

reach

goggles

and

eyes

or onto your skin,

result.

the

oiloreat

as

they

of children.

and

gloves

grease,sothat

the

grease

can

cause

Use only the proper replacement partsasspecified

by Brother.

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 65

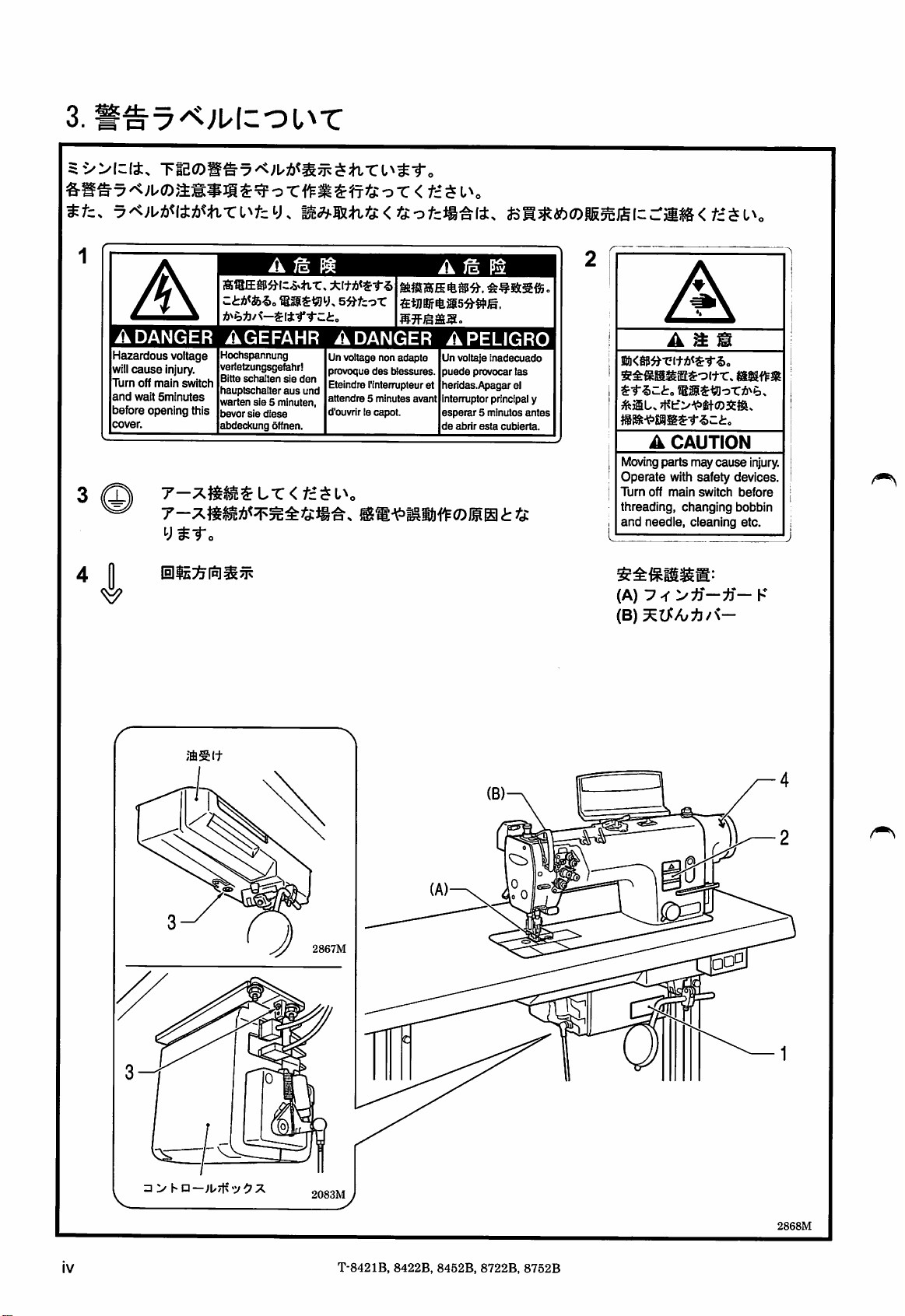

3.Warning

The

following warning

Please

difficult to

follow

labels

read,

the

instructions on

please

labels

contact

appearonthe

the

labels at all

your

nearest

sewing

Brother

machine.

times

dealer.

when

using

the

machine.Ifthe

labels

have

been

removedorare

1

ADANGER

Hazardous voltage

will

Turn

and

before opening this

cover.

A

AGEFAHR

Hochspannung

cause

off

wait

injury.

main

Sminutes

Be

secure,

verletzungsgefahr!

Bitte

switcfi

sure

schalten

hauptschalter

warten

s!e 5

t)evor

atxleckung fiffnen.

minuten,

sle

diese

to connect the ground. Ifthe ground connection is not

you run a high risk of receiving a

and problems with correct operation may

Direction of operation

sle

aus

den

und

attendre5minutes

d'ouvrir la capoL

ADANGER

Un voltage non

provoque

Etelndre rinterrupteur et

des

adapte

IXessures.

avant

A € ^

APELIGRO

Un voltaje

inadecuado

puede

provocarlas

t]eridas.Apagar el

interruptor principal y

esperar

5 minutes

de

abrir

esta

cublerta.

serious

also

electric

occur.

antes

shock,

A ^

A

CAUTION

Movingpartsmay

Operate

Turn

off

with

main

threading, changing bobbin

and

needle, cleaning etc.

Safety

devices:

(A)

Finger

(B)

Thread

guard

take-up

cause

safety

switch

devices.

cover

injury.

before

Oil

Control

pan

box

2867M

2083M

IV

T-8421B,

8422B,

8452B,

8722B,

8752B

2868M

Page 66

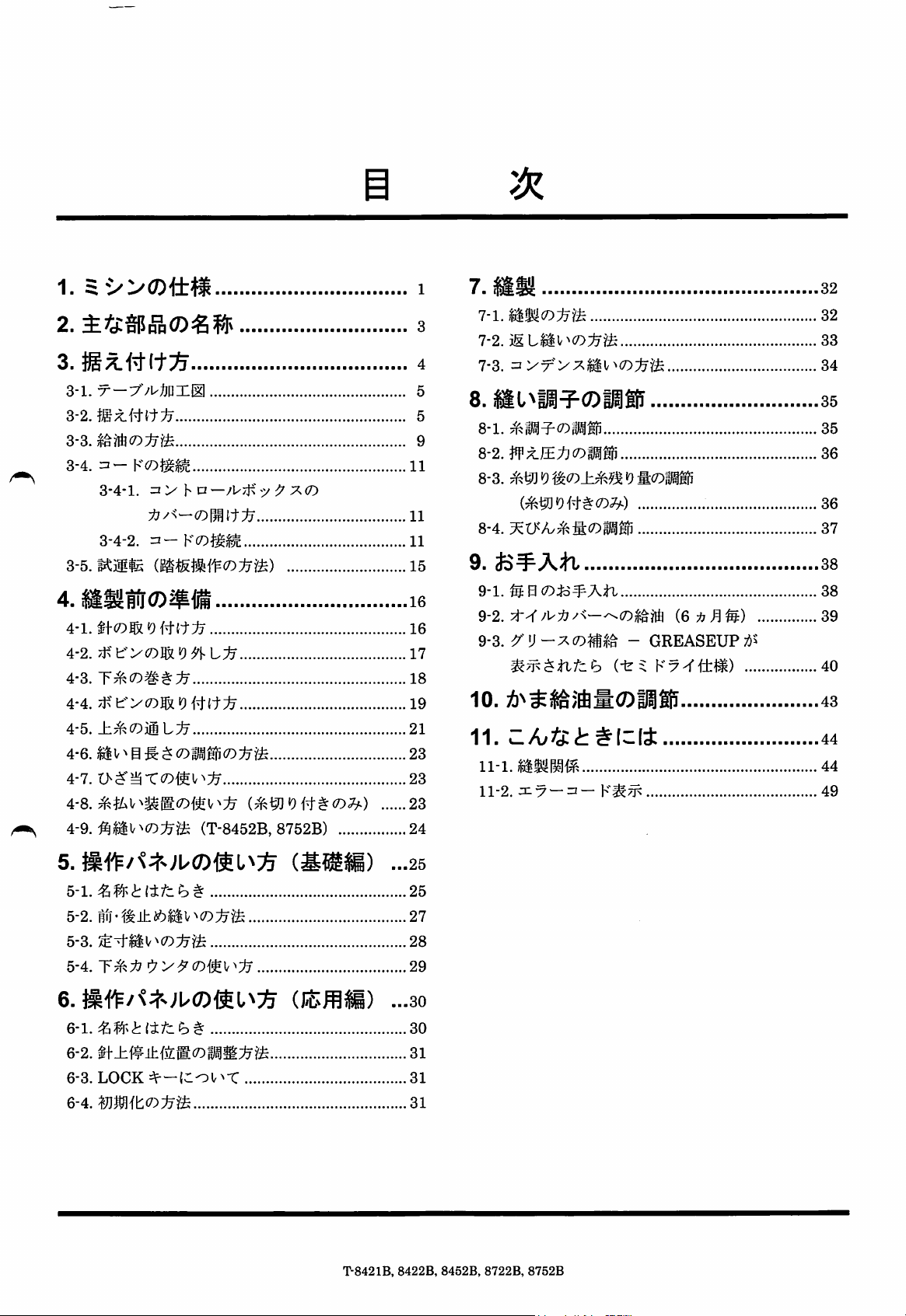

CONTENTS

1.

MACHINE

2.

NAMES

3.

INSTALLATION

3-1.

Table

3-2.

installation

3-3.

Lubrication

3-4.

Connecting

3-4-1.

3-4-2.

3-5.

Test

4.

PREPARATION

SPECIFICATIONS

OF

MAJOR

processing

the

Opening

Connecting

cords

the

PARTS

diagram

control

the

cords

operation (Operating

BEFORE

box

cover

the

treadle) 15

SEWING

4-1. Installing the needle 16

4-2. Removing

4-3. Winding

4-4. Installing

4-5.

Threading

4-6. Adjusting

4-7. Using the

4-8. Using

the

the

bobbin 17

the

lower

thread

the

bobbin 19

the

upper

thread

the

stitch length 23

knee

lifter 23

thread

wiper

(Models with thread trimmer only) 23

4-9. Corner sewing method (T-8452B, 8752B) 24

5.

USING

THE

OPERATION

PANEL

11

11

11

16

18

21

1

3

4

5

5

9

7.

SEWING

7-1.

Sewing

7-2. Backtacking

7-3.

Sewing

8.

THREAD

8-1. Adjusting

8-2. Adjusting

8-3. Adjusting

condensed

TENSION

the

the

the

trimming (Models with

8-4. Adjusting

9.

CLEANING

the

9-1. Daily cleaning

9-2. Lubricating via

stitches

thread

presser

tension 35

foot

pressure

trailing length after

thread

thread

take-up

trimmer only)....36

amount

procedures

the

oil

cover

32

32

33

34

35

36

thread

37

38

38

(every 6 months) 39

9-3. Applying

appears

10.

ADJUSTING

LUBRICATION

11.

TROUBLESHOOTING

grease

- When "GREASEUP"

(Semi dry specifications) 40

THE

ROTARY

AMOUNT

HOOK

43

44

11-1. Sewing 44

11-2. Error

code

displays 49

(BASIC OPERATIONS) 25

5-1.

Names

5-2. Sewing start and

and

functions

end

backtack stitches 27

5-3. Sewing fixed stitches 28

5-4. Using the lower thread counter 29

6.

USING

THE

OPERATION

PANEL

(ADVANCED OPERATIONS) 30

6-1.

Names

6-2. Adjusting the needle up stop position 31

6-3. LOCKkey 31

6-4. Resetting all settings to their defaults 31

and

functions

25

30

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 67

1.

MACHINE

1.

MACHINE

SPECIFICATIONS

SPECIFICATIONS

BROTHER

INDUSTRIES,

•T-8421B-T03

ABC

A

B

Rotatv

Stitch

Thread

hook

function

trimmer

______

LTD.

555

DBF

•

Standard

Fixed

4

2

needle

1

-

hook

bar

Large

Split

7

hook

5

needle

2

O

bar

D

E

F

"

Quick

Thread

Lubrication

reverse

Use

wiper

—

type

For

Minimum

F

foundation

4

O

O

0

lubrication

For light-weight

medium-

weight

3

and

materials

T

O

-

3

Semi

dry

For

heavy-weight

5

materials

T-8421B, 8422B,

8452B,

8722B,

8752B

Page 68

T-8421B

Max.

sewing

Start

backtacking

End

backtacking

Max.

stitch

Presser

height

Feed

dog

Needle

Motor

Control

T-8422B

Max.

sewing

Start

backtacking

End

backtacking

Max.

stitch

Presser

height

Feed

dog

Needle

Motor

Control

speed

backtacking

speed

speed

length

foot

height

(DPx5)

circuit

speed

backtacking

speed

speed

length

foot

height

(DPx5)

circuit

Lifting

Knee

Lifting

Knee

and

lifter

and

lifter

lever

lever

continuous

continuous

-T3F

3,000

#9-#14

rpm

-huo

4,000

rpm

1.

-133

3,000

rpm

250-1,800

1,000

rpm

rpm

-T03

4,000

MACHINE

rpm

SPECIFICATIONS

3,000

4 mm 1 5 mm

7

mm

13

mm

1

mm

#14-#22

AC

servo

#11-#16

motor

(4-pole,

550W)

Microprocessor

-4oo

250-1,800

1,000

rpm

rpm

3,000

rpm

-huo

4 mm 1 5 mm

7

mm

10

mm

1

mm

#11-#16

AC

servo

motor

(4-pole,

Microprocessor

550W)

-105

rpm

#14-#22

T-8452B

Max.

sewing

Start

backtacking

End

backtacking

speed

backtacking

Max. stitch length

Presser

foot

height

Feed

dog

height

Needle

Motor

Control

T-8722B,

Max.

Start

backtacking

End

Max.

Presser

(DPx5)

circuit

8752B

sewing

backtacking

speed

backtacking

stitch

length

foot

height

Feed

dog

height

Needle

Motor

Control

(DPx5)

circuit

speed

speed

speed

Lifting

Knee

speed

Lifting

Knee

and

lever

lifter

and

lever

lifter

continuous

continuous

-403 1 -405

3,000

rpm

#11-#16

#11-#16

AC

AC

250-1,800

1,000

servo

motor

Microprocessor

3,00(

250-1,800

1,000

servo

motor

Microprocessor

5

7

10

1

7

7

10

1

rpm

mm

mm

mm

mm

(4-pole,

rpm

rpm

mm

mm

mm

mm

(4-pole,

rpm

#14-#22

550W)

rpm

#14-#22

550W)

T-8421B,

8422B, 8452B, 8722B,

8752B

Page 69

2.

NAMES

2.

NAMES

OF

MAJOR

PARTS

OF

MAJOR

PARTS

<T-8452B,

8752B

>

0

Bobbin

(1

Lifting lever

(3

Presser

(5

Knee

(7

Stitch length dial

(9

(11

Oil

Operation panel

(13

(15

Stop

Safety

devices

winder

foot

lifter

assembly

gauge

window

lever (T-8452B, 8752B )

(16) Thread take-up cover

T-8421B,

8422B,

The

settings

using

used.

(Settings

machine

Thread wiper (T-8422B, 8452B, 8722B, 8752B)

(2

Quick

(4

(6

(8

(10

(12

(14

(17) Finger

8452B,

reverse

Control

Power

switch

Reverse

Machine pulley

Cotton

guard

8722B,

the

operation

made

operation.)

box

lever

stand

8752B

for this sewing

panel

using this panel

(Actuator)

machine

(13),

are

andsothis

will

not affect sewing

carried out

panel

is not

3909M

Page 70

3.

INSTALLATION

A

CAUTION

3.

INSTALLATION

Machine installation

0

qualified

Contact

for

The

The

O

people.

About

• Do not

televisions, radios or

equipment may be affected by electronic interference from the

sewing

• The sewing machine should be plugged directly into an AC wall

outlet. Operation problems may result if extension cords are

used.

Carrying

•

The

machine

showninthe

* Hold the motor cover (A) by hand alsosothat

not

technician.

your

any

electrical work

sewing

Installation

the

machine

set

up this sewing

machine.

the

illustration.

rotate.

machine

should be carried by

should

Brother

machine

dealer

that

weighs approximately 50 kg.

shouldbecarried

set-up

machine

cordless

only be carried

or a qualified electrician

may

need

outbytwoormore

to be

out

done.

location

near

other

equipment

telephones,

the

arm

otherwise

by two

the

by a

pulley

0

such

people

A

as

such

does

Do not

complete.

depressed

Use

tilting it back or returning it to its original position. If

only

head

may

as

both

one

may

get

connect

caught.

the

power

cord until installation is

The

machine

by mistake, which could result in injury.

hands

handisused,

cause

may

operateifthe

to

hold

the

machine

the

weight of

your hand to slip,

head

the

and

treadle is

your hand

when

machine

2086M

Tilting

• Hold section (8) with your footsothat the table

Returning

1. Clear away any tools, etc. which may be

2. While holding

back

the

machine

and then push the arm with both hands to tilt back the machine

head.

the

machine

the

face plate with your left hand, gently return

machine

head

to the upright position with your right hand.

head

headtothe

upright

near

the table holes.

does

not move,

position

the

Q rl

(A)

2870M

2871M

2872M

T-8421B,

8422B,

8452B,

8722B,

8752B

Page 71

3.

INSTALLATION

3-1.

Table

processing

diagram

• The top of the table should be 40 mm In thickness

vibration of

• Drill

the

sewing

holesasindicatedinthe

machine.

illustration

below.

Control box mounting hole

and