Page 1

-p

042

OA

INSTRUCTION

MANUAL

T-8720A

TWIN

Please

Please

DOS

Por

Per

NEEDLE

read

this manual before using

keep

this manual within

AGUJAS

favor

lea

favor

guarde

este

manual

este

LOCK

easy

CON

antesdeusarlamaquina.

manualalalcancedela

STITCHER

the

machine.

reach

for quick reference.

CAMILLA

mano

ik<SLX<tm\

para

una

MANUAL

rapida

referenda.

DE

INSTRUCCIONES

brother.

Page 2

T-8420A

T-8720A

2

Page 3

:f^-^f-xmit.

A^&gg^s-e.

C<DJft«A<l^oST•^l^§A^JS:Jfe•e^»^J:5. rs^acDgBfl

s^(ciB®Lfcti-^<

yj$s*t

Ltzmmisii^^ib.

«&««

L•ce^^tl(0«l31lci|#glJ<D:^®^^^fcf£#S•r

il

X<tztl\

"

tLX9mLx<tzii\

•ssm^m^mnmtt^tzHi.

J: 5 fe6il,^l^fc

iHiiiR®#i=®a

LS-r.

attii=sas}T%«)

itffifisattt.

-®ssa©ffl«isa»t«fcfti=itn5!&isa-e-r.

ya,s®

s

l-ci^s-r.

Page 4

c©fctftt:?7-s'-x®ffls-»$j3i±ifufcfc*i?SLr.

:rfi6ffl©«rl=.

fc»l=]feJ:tf«^lRl^®KW^J:

scti=fcyA<i:5:r^?i.^s-r.

<

S3iS^<

fcSl^.

1.

7I\

0iH*§-

A

$^ICfcfi6t\tVfcf£<

^ fe(D t (7)-el-o

t

X'ir^

fcftic

0

O

r

(D|E-^(D

(&(Dm-t.

4" HI t T V^

T-^mm^'r^:it)

-fo

T-8420A,

8720A

Page 5

2.

a

«3i^a^tt

ai+'S:t^sa-effifflL-c<fcSi,\. " ^,^«a•cffifflL•c<fiSl,^.

Siu«a/-i'Xii5-»®aaf^®iiHi:!!c

45%a^&

sa®ss(i5-»®Bai^®ii

85%-e,

aai=®SL.!S:

Oaams®aaii>£«ms®±io%ein®a

a-eaffl

x#!S:aii®Baii

Lr <

fc*sl,^.

5 •>

v®»af^®®H

a

V tx.

t

Os^$attsa®«Baafi<ty^«®i6'& a

aaafi®

ysi".

Oansaaid:

<<•=51^.

•f.

0

5-»®gA#ittt>»iasai+fcfta#<i<fTaa-K®s$tta<®aA^&

ftor<fc*SLv

Oaasistt.

naffi#i=ttsaLr<f:$iv

0 5

e/Vtti®

•eaji«itSlTfto-c<f=st-v

^aii

s

•»®^af^®

bs

t

ft

35%®®a-?a®LT

a s •>

43kg

:/®Maf^®

«i*®®asg®sfci4aa®B

®«gA<fcy

® B

^1".

ft

y $

^ X # 1+

V

O "

-AI2l±

A f

^ x5.-^0^L,T<fc$l^,

BitB%®3tc&«;i^sia-c;afflL.r<f=$

aitajfetts

•»®aaft®HHi:'S:

y

tt,

SA<a£LTo«£:#ij:ma$ay.aa:^7

stts'»®Maft®®

Sfc®aicfliffcy,

h tfty

25mm

s-r.

ia±«L

xt-X;u

®®®®®

tJa-jsT.

aA^ftL^J:O4r-V

^

aA«itA<0T-r.5«t?.asx7i?$ajSL

^

ft:L^-^?<fc•^l,^.

MoTaasafct.

®Ht fty

St.

5-»A<<^aLTi+A<®

A

^

®r-xaasur<«^i,^. Q

r-xaaA<^0^ft«^.

as^saf^®®

s^v^fflufcy,

SLfcy-r^t^ii. h#

^tiftor<fc$l,V

14

s t ftt

i+s<®®

Ht fty

St.

f22^2*«5fS?ff>-

•^O

^•To

^^(D^0@35>J5:L^<b

C <

f£$

l^o

T-8420A,

8720A

Page 6

(S)

\itzXa)M<^m

c0

5i/>(±,

o

fflL^^L^"^<f£$l^o

X<tztsi\

^SrMzm^BizX

^(Dii^lclimssx

A

frf£

Lmsix>r

(^b<a)fel^f£1I1t•r?Illy^Sl(t^•ro

ro^^c±^or/)^^).

L^o

ust^py^-To

•

^®L

LX<tzt^l\

LX(Dmm\>j,mz^

y y

>r ^ o r <t£$

^o

fc^t

f^^^fr'&ror

^ L

^-To

<f£$

LNo

#€«

A

A

<tz^l\

tiSi^J^to

i!i<gPp°«(w5xtLfcy.

tdil'^X<tz^l\

5i/>^f9Lfcy>

•efr^cor

(i

t?>5:ifIt

4" ^ f=

-r

L^o

^LT.

<f£$i^o

A<a)lisi:/cfy

lima'S:

ci^S3Sx>r

tsm^i^o^mjsi^tzimm^^

^-r

W-\;>

-v^^^^ior

^xi^Ltz^)

o

ICfcl^^ ^

u

<

f£$

O+A'X^—SlIA^^^:L^J:5+•V

fc ^ ^ ^

f^ll0fr(::m35X>(

Lmux^ofc^t

fztz

[iP><(DfeL>t£ii14-eiHiy«|lt^-ro

L>o

I^Si:«:y^-ro

A5i/>$®Ltcy.

•Cft^^:or<f£$L^o

(i

$ t;j&:if(tX)<a)lgS

v^-^^-dX

5i/>A<f^illL-C(t;()^0

<tztsi\

A<

SiJb*

MLfcy-r^ir^fi.

i:

y

^-r

o

Iifin^^sittcfi[{^#(c:r5i$&<

0

L

lcLr<f£$l>o

to

stc;li7l;'^^^y-x^0:^t£y^^fcy

^|:l^r'<f£$l^o

tto

=f-^(D^(Dmi3^ti:i\t

l^o

ife^^ec-rj^SirJEfy^

T^-fc5i!fr5Ci:;&<fey

Z^izm^X

t£$l^o

<

t£$

LT<fztS

l

l^o

T-8420A,

8720A

Page 7

3.

^W^=7<)\^(D^^mm.

^fzs

1

A ^

!S6<ffl«-T'(t3!»<St--5<,

^^mmm-Difx.

it^Zto

Moving

Operate with safety devices.

Turn

threading, changing bobbin

and

®3S$«Io•CA^c>,

A

CAUTION

parts may

off

main

switch

needle, cleaning etc.

(A)

(B)

(C)

cause

^o

asf^s

injury.

before

r

f^H

^tr^S:

o r <tzts

^^J(sLi^tJi<tJ:'Dtz^^its

l\

tsm^ii)<ommj^\z;rmm<tztsi\

T-xl^jSl^Lr<f£$l^o

0

2955M

m

jfflSIt

2954M

IV

T-8420A,

8720A

2956M

Page 8

1.

2.

3.

f—^lcoL^r

6.

1

2

3

mm

6-1.

mU(D:^^

6-2.

3Ib^V^<79;^^fe

6-3.

19

19

19

20

4.

4-2.

4-3.

^^yy^-V(Dmuij\^(Dmm

4-4.

T7

—Ax-r

(-tr^

5.

mmmomm

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

aK

±^OjiL;^

i^v>

t9

\fy<D^19^

@ ^ <DmW<D:}7m 18

^•^l^4'{COV^T

t;^

19

11

i3

13

m

14

14

15

16

17

18

4

5

7-1.

7-2.

7-3.

xuAy^mcomw

8.

8-1.

^0(79jo^Atl

8-2.

8-3.

jvt!(Q^MU)

(-Ir^

9.

10.

z^3S:i:#lc(i

21

21

22

23

24

24

25

26

29

30

T-8420A,

8720A

Page 9

1.

1.

(1)

(3)

#X.JS

(5)3^«9

(7)

(2)W^±ifx:i

(4)

t>^^T

(6) —

(8)

(10)

0

2957M

(11)

(13)

(12)

T-8420A,

8720A

Page 10

2.

2.

BROTHER

T-8n20A-0

T-8420A

^ ^ ^ $

^ 1^ ^

ill

^ m

«9

INDUSTRIES,

•

H ^

;t

t>

#

a-

CD

( D p X 5 )

±

^

1^ $

LTD.

(f

Ji

m

T r

~

tf

-OOF

4,000rpm

#9'-#14

F 3 5

0 3

4 7

-03F

3,000rpm

4mm

-003

4,000rpm

7mm

13mm

1mm

-033 -005

3,000rpm

#11~#16

mmm

:k^

3,000rpm

5mm

#14~#22

T-8720A

^ H

^ ^ §

^

iH

^

"9

tf

if

t>

<?:>

;t±{f

^ _h

t^

$

#

( D P X 5 )

ii

5:

T r

1^ $

-003 -005

^

^

Jf

#11~#16

T-8420A,

8720A

3,000rpm

7mm

7mm

13mm

1mm

#14~#22

Page 11

3.

3.

'r—-^}lt=E—^\zr>[,\x

A.

x-3f;uj!inxg|

•7^—:7VK7)jf:^fi40mm-t:\

11(^0:

9t-/t$){t^PX^LT<

/c^v\

t:

520.5

T—7.mmn—

2-«3.5

•m\^

bT<

^c:$V\

20

RIO

19.5

19.5

I

B.

=E—9

3—25mm

Q

tz^l\

;k|g-®Sa)I^S<!:35:y^fo

0

<^—^:^-y

50Hz±ll2^<}r

t

v^;u

h>

60Hz«ir-r:1i.

4,000rpin

3,500rpin

3,000rpm

i2l±filLr<f£^L^o

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

•

V-</V

^7"—y

HIi

Wi)

y

y

y

lOOV

200V

100

85

90

70

75

65

2g58M

7.^—'^)\^XWX-t^fS:l^X<

pp^

2®•400W^—

2^•400W^—^

;^c$V\

V

-</I^

h

46

45

45

44

44

43

T-8420A,

8720A

Page 12

4.

0

nEor<fc*si,%

iiui$si+fcaffi#A<iT

OSSieaiis

0

5->:/ttl|!l43kg®*fiA<fcy«f.

•es

jtWI+^ffiEs^T

0S^#lt3!i<^T-r.5«-C.

!ai,>-e<fc*$u.

e^rSiffiSKfei:.

5

•

5;v':/(irAT\

<

fiS

U.

aS:^5<^SS«SL

5-»A<f^aiiLri+A<ffl

-Am±

A5-»SfflLfcy. i

•efT'S:o7:<f=Sl.\

I4S

fc«i:ifltA<©HHift

A

7-xa®^L.r<fc•SL^

Htftys-r.

y

S-f.

2959M

Si/XDfflLS

T-A^flcSrifLT,

5

">>01)4,ifLS

2.

:fe#T-BSa»^»«FLifc;4Se),

VfflaSrtt'ttl-o

5->i-a®^0LT<ffS^\

2871M

9

5->

2872M

T-8420A

8720A

Page 13

4-1.

i.jisit

(1)

«M=fAte)[2«]

(2)

aa5®:=iAte)[2fi]

(3)

iftSit

(4) jKI) 7 —

2874M

2.ii®t>i?sit=rA

(1)

wait

(2) <

Vv=SW=fA[2®]

#'[4

*]

3.U^?±(fffL#

0

2875M

(3)

O-S'ilfffL#

4.

$i/:

(1)

(2)

(3) ^ < lb

^

2960M

T-8420A,

8720A

T't

o 0

fi*•b5A^r'

<

fc

Page 14

5.

(1)

t>^^T

(2) h

\—r

2962M

2881M

I^Str

2961M

<t>i?±if®iiSiJ>

1.

^-USriaL,

2.

ff;t±lfrr(4)-Cff^JE(5)SrTlfS-r.

3.

-t-y

K6)%i^5«f)i-t'o

4.

t>S'aT(l)4r¥T-e<i¥Lfcti:,

{him

lHlL-Cli»Li-r„

5.

P»«,

6.

•:^•y

K9)^i^-5«)t-r„

7.

SSlaC(10);!iS!>S'±lf(7)J;

'is

4:51-,

8.

Si

9

ISmmWrtW-tfelCiSJ:

SrlElt-CH»Li-fo

9.«»a,

;ii5^2imii(::;fe.5J;5t;:.

K6)SrLo)i>?)«i5»t-ro

SSlaC(lO)SrlHlt^-f„

•4-5'K9)%LoA>i9«i5fcS-f-.

<

/c:^V\

Ufci#,

0-S"±lf(7)i»ti

iBlali(8)Sr

5mm

o-+fe(c

if;iS(5)i4S#t

5IC,

»fcC(io)

U

13mm

IsiW

2963M

T-8420A,

8720A

Page 15

4.

6.7-

(1)

T-Tsi

(2)

mi3.

i:

(tr.

(2) ^

3®^^

— ^

2S64M

7.

v\

(1)

(2)

7-

tT<

If^^C

T-X-7—<7

m

m

\ %

10-14mm

m

2965M

2966M

8.VK;uh

(1)

V-</l-h

10~14mm

h(2)[2

9.

^;u

^0

LTM

h^/^—h

L

•:^5/

^-fo

(1) h y ^ y h

(2) |fi5:j3iC[2;2^]

1^7

(2)—^

V

T-8420A,

8720A

2967M

Page 16

4.

3^-'J0TlcA

tL^o

2968M

1

0.

^;uh:b/<—u

(1) U

(2)

l^laC[4:^]

5

V>

T-8420A,

8720A

2g69M

2970M

1

1.

(1) D

(2)

:^UC[2^]

(3)

mM2m]

D

Page 17

2971M

1

2.^;Uh^/^-D^Sxfc

(1) h D

^fz

0mm

2972M

2973M

h;^7/<-D(2)^^B^^^C§|V^T.

h

:fy

U(3)

t h

;^7

t^-to

D

/

2974M

T-8420A,

8720A

Page 18

2975M

13.

tt—Ax-fx::#'U'r

(•bs

(1)

r?—

(2)

«iftoc[2*]

(3)

l^t3iC[4;2^:

(4)

h''y-<9^:f)

^-f]

•To

(DP«q{iij(c^-c^-ro

2976M

T 7 — A

^ <CN1>{C =I (4)

^7C<7)J; 0

^•to

X-r

^ 1/--r (1)

CO

(-l?if:JaC(3)T'®l«9#(t

(7)

T-8420A,

8720A

2878M

1

4.

(1)

^aE-^

[:r?^iS]

=f'A(2)[2{@] • ^

{31,

•:h>;/

^

Lo;6^«9

V\

J: 5

h(4)

<

fz^

10

Page 19

4.

4-2.

0

M o

xassat?

t,

s •>>A<<wii L r

M.

ItA<o5iis

t ift y

s-r.

0

fcSlV

«fca5»a-¥>yy-x$fi)!A,fc*y6'«t:y

WJ?)T5iK.-fffia

Mfiait.

*

jftSSiEc-rBHi:«:yS-r.

i c ?>

:^7it*-JB^t--l'/K

#»;i-'l'/i-it-C<3;i'yv^-f/i-3;y7'y^;«.SM10;VG10>«frtt)ii<fc'St\

tai^r

05HSV—(

< t= $

L!!i:tNx<t=si.^

i,\.

ION;

1. 5:

2.

3. V

[:r?^3i]

»?a?rSII(4)J:

S<b/ce«9^-t-o

4.

5.

^L^-fo

T«•fedtt-rsctA^&ys-r.

VG10>^ffiffl

tT<

t^1-o

y^(2)X\

f9

±{c?^AL;:^V^T'<

LT<

tcSVo

(3)

v\

2977M

2978M

1.

2.

#M(D7Ky

Sll(4)^-e?i

fz^l\

;^-r

A t ^ -fo

y-{2)x\

^im^ft^^*f^^.(3)(D±

11

T-8420A,

8720A

Page 20

Page 21

4-3.

A

^

5b>:^—'J®lHlfe^l^®fiil[

M<SS»l=.5»*i.fcy.

«<.

$fctt5-»<D5Si«®®Hi:iS:y*-ro

A

jJj

i|SlT?ff

2980M

u

ji*r,

cm

Lfcy

L.<i:l.^t?</£Sl.A

1.

S:Aix4-f«

2.

Lr<fc'$v\

i->yy'-l):ii^W(l)<0

iE|ie;^iS)5riEL<K

4-4.

T7—Ax-f

X-^b'f

lcoL^•C

2981M

(-bs

K^'T^'T:^

(1)POWER7>:^(J!ife)

POWER

(2)

if—;{)5b|o^c^,

(P.26^m)

7 ^

GREASE

7

power

POWERyyX'(lWM'):J

/c:U«(C

GREASE7yX{2WMl

—x^MIpLT<

L.

t

X

13

T-8420A,

8720A

Page 22

5.

iHMfrcDiiii

5.

A

«

tf&<®fcufiiitt-ciHiy«ii+s-r.

. 5 LTita<®igH^:iSy

5-2.7l?e>(D®y^1>Lj^

«

j)?e>sffiy#i--ri:#ij:,

aSX-f>y^S«or<fc$Uo

=E-aiib<^^i=±sora^&.

an©

9

2894M

A

asx-i'-v5^s«o-c<fi^Uo

fcfc*L®iX-l'

^-r.

t^1-o

3.

fl-(2)(D:g:ft^i^jliJ{::[^{t.

fcttuasx-l'•vf'^«Iofcat^-^'A<

C^V^o

2g82M

® -3r

^L^t-0

ass

^i:.

5 •>>A<ftML-T lti6<©]SBai:jSy

(2)

3001M

3.

T-8420A,

8720A

14

Page 23

5.

A

A

2897M

.V

il<Si&K&ht:y,

l+A<.

Sfctt5-»®«a®liHt'S:yS-f.

t|-C»Lfcy

L«:t,\T?<

1.

5.

^i"„

-To

tztSl\

$ V

"*o

^¥;x±(fTr-e±(rt1-,

(6)

^^i()

2123M

15

80%

2124M

T-8420A,

$V

[:r?^ift]

8720A

> 1-„

:^A80%^-Ci;iLT<fc:$V\

Page 24

5-4.

5.

A

A

♦x

A<LI^6<©fcl.^/^tttt•elsl^JmS•r.

Ko

TSiffiSSSt?

i.

ssx-f'y^s«ooT<esLv

5 •>

»!i<(^ll

(3)

L X

c:^

2898M

2983M

tztzLmm^-c

ft#SlT'S:or<f£$lV

1. 9

2.

/5^^cOo^;^(3)^#JL^1-o

75^^(2)^0

4.

5.

6.

50mm

ir^^U^mci^iro

L^-To

{J#

ttl

{-LT.

l^^{f:fe(4)(DT^<

L^"f"o

Ch

2902M

50

mm

50

mm

2900M

1. 9

7'(2){CAtt^1"o

2.

^^^fi(3)(ciib.

3.

^^;^A(5)(;iiit.

4.

=^^5/9^(2)^;0^^(cAtl^-fo

6.

|)^i^{t*;Ja(4)(^T^<

50mm{5^^^l#l±lL^-r„

f-tr.

5/

2999M

T-8420A,

8720A

16

Page 25

s.gim(o«(e

5-5.±^i(DiiL:^

A

if?><fl5fcufc*«ttT5iay«si+«-r.

SoTSs^aiitt,

<:77>x—a

eSX-C-y^$«lor<fc*Sl,^

^-^^6<^±l=±^orA^6..

s

•»A<4^a

LT

i+A<©®Ht

fefe'LaSX-C'V^SaofeSt^-^A^L

f^asiT!S:o-c<fc*$u.

ftys-r.

2984M

5^0J:5 (c ^

^±(fr c r

ii^JI110FBllz?ii||(c^

i, i,i:^

T'tt

L

^-r

(2)

^

50mm

17

50mm

T-8420A,

8720A

Page 26

5-6.

5.

fflfgiitfrtnanis

5-7.

u^aT<7)fi6L^:^

2985M

1.

(31(11

-V/WP

LT^

p

{nmtB^X\

mnivx<tc^\^\

l^i"i:#fi.31

Ui'^X^t.iTo

3. 5/i^

L^i"o

tc^\^\

^v^±;^)S!9

19

^-To

)

L^V^

w<-(i)^toj?)^i9

0^v^g;S$(«(D

19

(3)^4':^c»fig^X

XM2)^^'r

i::fc(::lH]LT.

t

M<

2907M

x^t.i-o

2S08M

T-8420A,

8720A

18

Page 27

6.mm

A

A

lx<kh-k

33s:0ii^(c(im3SX-f

A

A

W£©tt-eiHiy|^(t^-ro

•

i6<SP^(c.Sxtitcy.

(t35<.

^f=ii5i/>a)5SMa)iis.tJ&:y^-ro

5i/>$tJLfcy.

A

G-i.m.m<oi5^

.

5LTrtA<a)iisi:jS:y^-To

HLfcy-r-Sir^tt.

y.

2914M

fcfcL®3SX>r'Ve><Ofe

f^ll$ft35:o-C<f£^LNo

LJ5:L^T?<f£$l^o

(l^'e1T^^-^•C<f£$l^o

1.

±M2^]^tSX-^-lof£i'^b,

2.

T*^#Bf|ii§lV^T,

5r

tiJrii|gLi-to

3.

MU^'f

4.

-yi-^Atit-Xo

tuy^to

T;^^^!XA-X|C<

5

i/VT"—y

f#

l9mSi^

6-2.

19

JIL^L^0:&^£

J

2915M

T-8420A,

f

8720A

Page 28

6.

6-3.

=1

i

o o

jI

! >

(1)

«iL^:^ISl

=l>x>7.i||L\

2987M

2g88M

1.

yVir/l^n

4. |f|f:^C(4)^|?if2se)-C.

1~o

ifb^-fo

•fo

3.

4. (1)

ts(6)

5/^:7

W^—(2)^^f(ClHlLT.

^ ^ ±jf^-ro

2g89M

T-8420A,

}:i, h

fz

h V^'^4®^

8720A

^y/^°(5)^3SL^V^

r-Ttf

T

<tz^^

\

20

Page 29

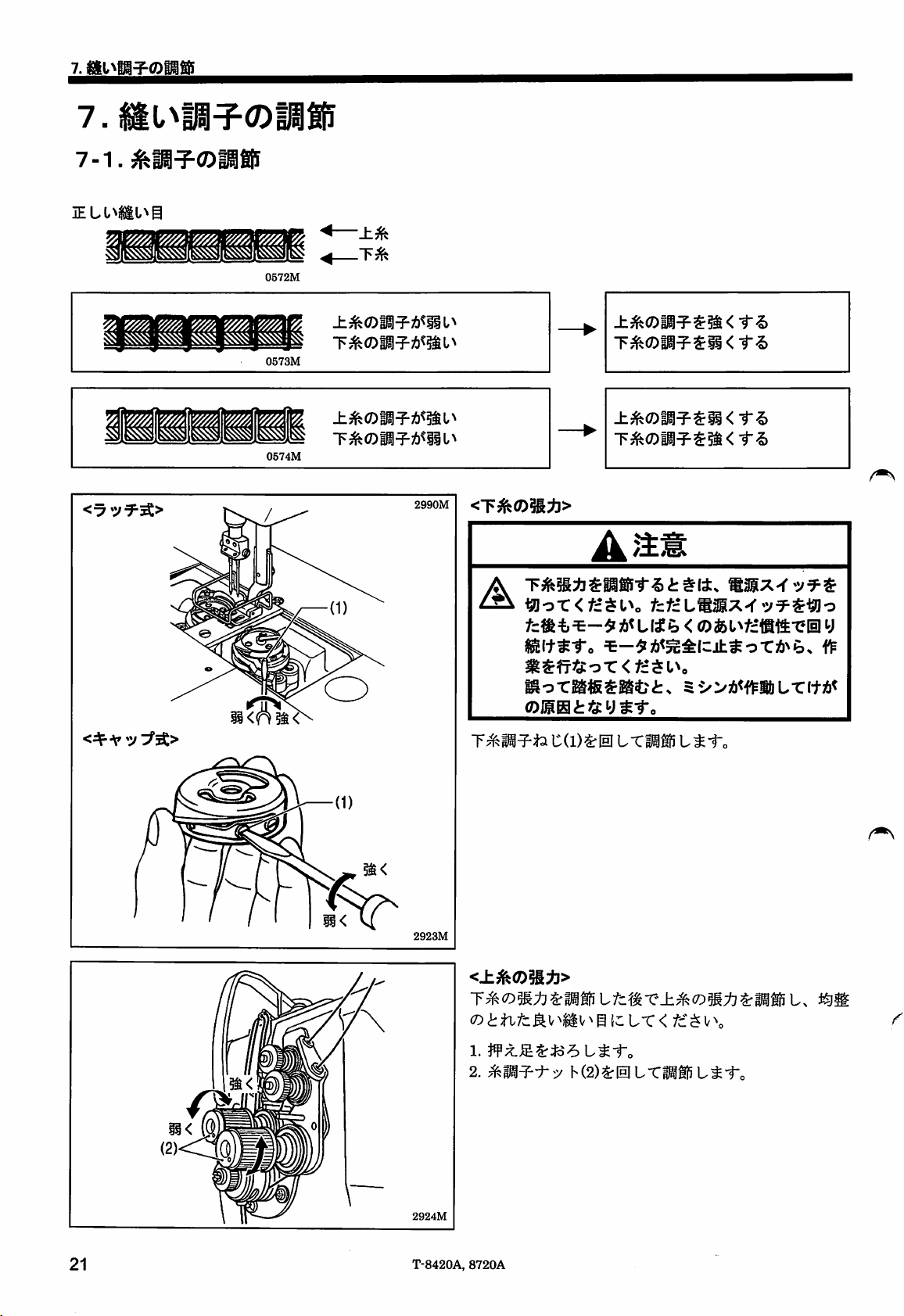

7.

lELtmNg

_ _

11

——<#

ii

11'

0572M

ii

* *

0573M

0574M

&

±^®ia^-)!i'ai.^

T^<®ffl^-)!i<^l.^

-S)

2990M

2923M

<Tj^a)3i^>

A

«or<fc*SlV

jSl+Sf.

ie^ffftor<KSL\

iSoTKffigKiJi:.

®li0i:iS:y^-r.

C(l)%|g

/±.m

fefcU^SX-f-y^SWo

A<Ltf

& < ®&l^fc*1Itt^?lHl y

$A<^^(=JtSorib\6.

5-»i6<f^»L-CltA<

LTMffi

LS-r.

<±^a)3i^>

21

2924M

T-8420A,

1.

2.

8720A

L^-fo

h(2)^|HlL-C»L^-tc

Page 30

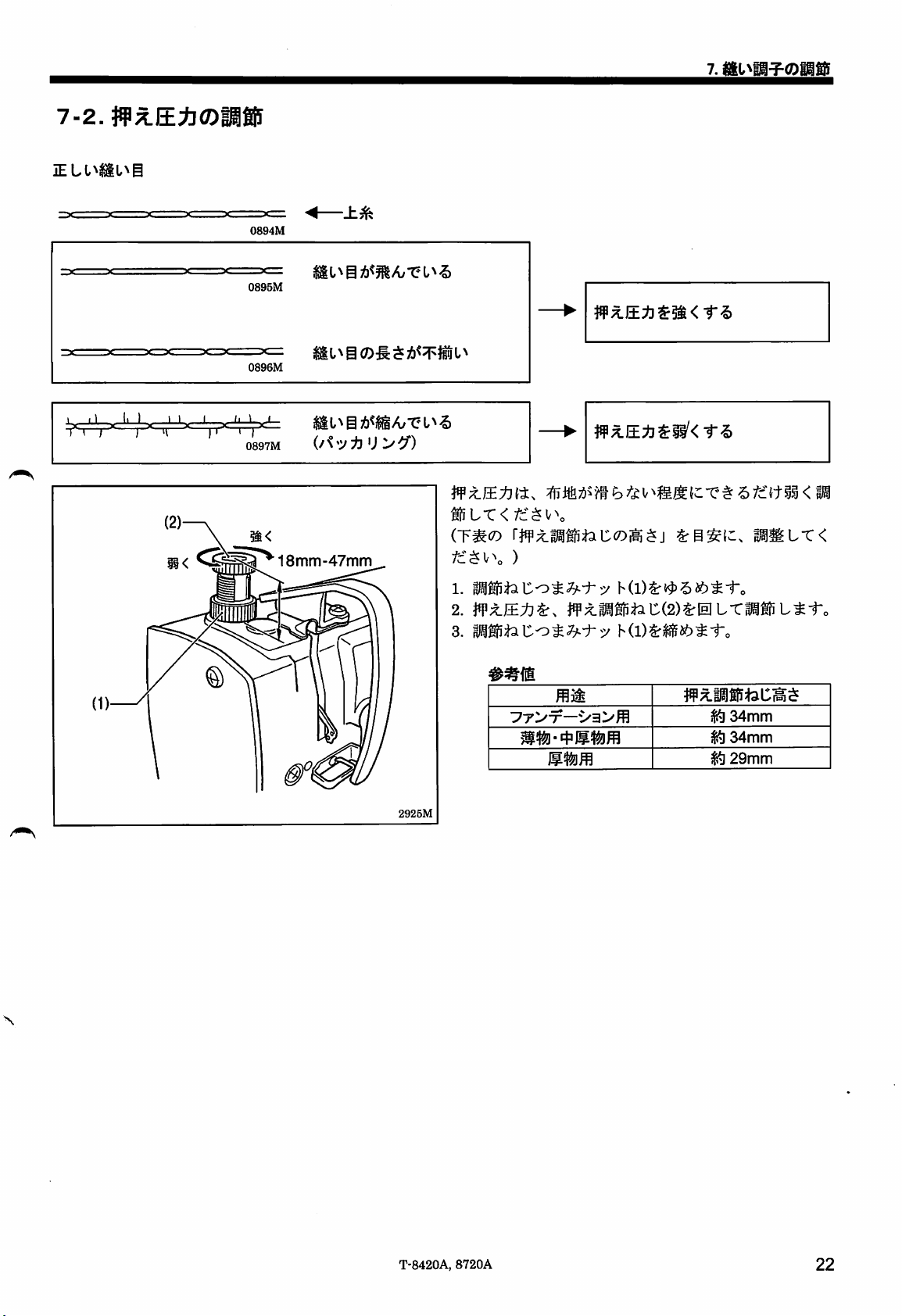

7-2.

7.

0894M

0895M

0896M

^

P

ir^

0897M

[I ^@ L^

iL^iA<IS^-ca^'S

(/ ^'V^ U >

>^)

t-C<

18mm-47mm

(rm(D

fc$v\

1.

2.

W^}±tl^.

3.

)

h(l)^t4>^ib^iro

Jfx.i^gH:fei:(2)^0L-CML^1-o

h(l)5rlfi5a6^-ro

iiML-c<

mm

34mm

^

34mm

^

w-^m

29mm

2925M

N

T-8420A,

8720A

22

Page 31

7.

2928M

1"o

<;^li0^fi:illS(1)(D^^l^:^>

y r

>-T—i/

5/

<^^;^^fi<7)iisf^>

a

<:77>X—

2g29M

g{^-fe

•:77'i/3

5/ h -f-^

. X h n ^'/ce<!f.

•

m\r^n^^^2mm^rx-mo

(51\

{p'fj: <

<9

^ 1*0

23

T-8420A,

8720A

/"

Page 32

00

00

4H

>-

•

4H

MT

^ntb

i+i^

I"

w

m

g>

0

9»f

4J

IiP III

S

(tt

0

^

ru*

^ft-

V"

4H

dSS^

iP

^

° i3f

sm

d V

1^11^

d f 1

SI

SM)eeN5;

>4

w-

cf

rt-

niHU

1

i^-^p^^=

r

ft-

vE

/«

rv

Of

Pi*n

^ 1

V

vS

Wf-^

III ^

'

^ Of

pjir 1

nr >J ^4 8?

5BI1

V

S r

v" " s*

^ H rv

v>*

msrt

Pi}

rf*

V

n Or nfr

vi:

FM-

0

^

1 jS

N^i-

^1&

9;

r

;!F

g^d

5&

9H-

^'

^

)3i^

c-

d

PSrft9?-9+

r^

«3;fv

d ^

Mtt

^

04-

M- n

a*

® & d H>rft

sE

ntrt

fM-

^ H

ar

r

!:

rt

0

s w

Si

if

•*

<-

«•

"

w- d

P?HH

nt

r

rt-»

0 d

4H

m

f5

/V.

OUffi

N

Pi*-v2

1^14*

0 2$

»5-Pit

rt

d 0

>N

rt*

d»-

S

rft ^

fM-

r

tu*

H

S

\i|-

C

/s

8}

" 1

®

r

4

m

«•»

e-

it

Ol-

0

lU

rr» d

£». T&

M- ^

^ 0

3S

•tI

S m-

•

H"

mi

Of

fV

n

if

m

53}

p?

d<

9H-

4

<-

«•

n

Or

9;

0

8^

n

d

/\

9t

vE

r

Of

n

0

)

I

v=

{O J-»

CO

^ ^

n; rx ): K'

ffl-

V V

vs

a F^ ^ H

3V

r:

2

2 /\

h 4 r n 1]

3 ^ ^

o ^ S r

o

v

r

'S

or

rt

(Vc A

^

)

y

A

<r

ft

r\

0^

^•c|<

O

✓

%

^

fx-

to

^ vs W

'h-.

<-

00

/\

S c W- 0

T1 W

® ^ »

vS

✓

O -"r-

i/

<r-

0

r

?4t-

0

ii-

o<

a

(^

r

?4f

it

n

r\

ho

Page 33

8.

8-2.

{6

3002M

1.

2.

jKy^r-f-y-w^iftSittcfccii^y-i-ro

*BSiaiife^(cffiv\

<4z5

{-/iMLT

7-(i)ic)Si#iiS;6Sfcs-oTv^fcib,

igjE(ci®aL-C<fc"Si<'

< $

V\

ION;

VGlO>^^ffiLT<;^c$v\

*

1.

X y y X

^

SMIO;

(P.iiM)

3.

5:

VGIO>

$r <

L^-fo

L'C<:j^:}'y

fc'^

I \

f/p

niy

y

25

T-8420A,

8720A

Page 34

8.

8-3.

•i/--GREASE

K«Sr®i9-iAtffcOTc

<nm>

o @

POWER

ffit>pioAditr.

Whenthe lamp When the temp Bumtnstes and the alarm sounds, the ipoofiod

Buminatosdu^

the opacBllon(**/. an

:*^Aa.

Cusnjobilfflparaie Cuando la tempara sa

endodeioladmle

•Itrtbrunrieiej. un aoddonta. (Consulta d Manualdo Instruodonos.)

7("feS

GREASE 7

9>?a«flffur9-Ai'iaofc6.

-eoxsEaeuaitstanogEB^Gyxf.

mustberoptenlshod.tfoporatianisoontlnuod

acddant

might be

i!ir(Kfla«aBttnM.fli-£s«r»«SMjn)»a.

tasKamaatnnadai^atsmnannsia.

lubricanto especlficado. Si se ccntlnria usando sin lubricar,tepcdtia

V^(1)AS^«"L,

o-»*

GREASE

fi*fflsy'j-xsai4LT<fc*si«.

caused.

(See

ins'juction manual.)

endendeysuena

la atarma, se

(naHnssts)

wttlwut

grease

<•«««)«««)

debe

ropteRlshlng,

asregar

grease

el

causar

-;^SrW;^•r•5ll#«^ftfe^S^rv^

2994M

2995M

GREASE

2.

*

^U

'j

10<9^1-0

5

t.5i/>0St®<OllS

)

"tomtit.

t tj: U

^"To

T-8420A,

8720A

26

Page 35

8.

GREASE

(SA2694-001)

mM

•

^ 1

"

1

30

1.

j-D.—y(o^i\y5

® ^

2.

<riJ-X05fflje^ra

TIEro;&?4-c\

BZL-301

broBaef •

m

^3

mm

7

o ©

»:-<—:^ro^5fn(DS0fc^y-;^SrttlSLS-r.

(2)

2934M

•

(SA2694-001)W(7)^3.—:/>

•

•

<GREASE

it.

-7.lt

r<

GREASE

<GREASE

BZL-301

r^fg-X3|i§(SA2693-001)J

©

GREASE

BZL-300(SA2355-001)

fc:$V\

(SA2694-OOl)#0^rL-:f

BZL-301

•V.

LT

< fc ^ V\

^fcll^^a6

(2)

BZL-301

>

2935M

2936M

yX;u(i)(D5fe^.5^0a0SP

1.

2.

^;fei:(2)^^L^i-o

3.

5/^"^

OFF

Xy-7;^/>Lfe^tt^ait{c:aAt^-r„

L^-to

y 3

(1)

icaA-r^o

5.

lfif^i:(2)(7)j^iS(cfe^ti/cXy

ti-o

^rmx.

•

xy-xfi,

He

)

—

^'e^#5i«9

^i~o

A

2937M

27

•r<DX\ )

T-8420A

8720A

Page 36

8.

29g6M

*

mmz.

(2)

O©

POWER

9>^aKV>

f»Bipe«^dff.

??sgf

t>()\^i3^^-\zmmf6i^^ii^Lx<tz^i\

(3)

{•4«liK««)

«oraoir

brother

*1

O ®

POWER

9:/?«(AOL79-^099fS^,

««««xiitiirr«£Kn»tafeovfrr.

KMSIIStKtltatlUISailllttltllSB.

Cuanda

la Mmpars M

•btjati

ium«rt»«iptdlcMa.AttcenMiuBtndoainiuBnetr.a*pednacM

«ndwi0«

C8RBABBUPALARM

o^%

QREASe

Arit>{f9-RHUSLT<I2«1«,

(BSttiivcm

VtMA* It •Mmw. M «*b«

(1)

(p.h^m)

1.

L^-fo

*

2.

n^V-ty

-to

5 'J ^ 0

^^WiizL^to

ZtX'7^^-{2)\Z

)

V-^y

L.

\^^'</<-<D

5~10mm

5-10mm

^C^(3)0±T2E^

a)4A^Rlr

VTLi^i-o

y^(D^m5WnWLmni^i-o

2 ^ y

V±y

rmmt^Tx

2939M

h:^4

<^ur^7a)5iii^^>

2997M

[:^^m]

•

-hLV^y

•

v±y

h^4

h:^-(

y^ilM.

y'^(l)^WLXh.

GREASE

7

T-8420A,

/c$v\

8720A

POWER

y>':f(2)(D^

—

0-

28

Page 37

9.

9.

}±.m.

\zLX<tzt^l\

\fii<<Ommti^^)^to

/}

[9-14mm

2942M

1. 5:

2.

t^1-o

<$&»>a><i@>

1.

WM^'f

2.

3.

t\-t^\^'yi:JS.'OS^L^'i',

4.

ff;i±lf-CrT-}f^SSr±lfS1-„

5.

6. 5 5

s'^SrW?

S-fo

i^Sr^il-LS-f-o

-yym^».X'm

te[iiSife»fsa^5]4^T^fcv^^-r,

7. iS

i:5tK-ffltt(2)

^VAtixmh,

T\

swAi-^v^ateLj-ro

^

*lSic®®^fT''£5

9~

14mm

i

»Pfl<DSil

l±(c

=;->v|Hie»

(ttfiii»ffltt(2)(i

1^1

^

29

wiivwiwitPwi;?

3000M

T-8420A,

<mfAm(om^>

^

t.i-o

^1*0

3.

JilB

-to

4. m 2 mrn^<Dmm'ik.

8720A

«9agLT</f$V\

Page 38

5

6

y<^y:fy V

<0

i-^i

2948M

• ii^'9

•

V^/i^

3^i9itcOi^

h(D^f9

V h

<

fd^^\

^

^mxW^.

UT<y^c$V\

lO'-Hmm

LT<yf$v\

10.

#BS^—i/

22

*

LT

7

21

7

Hv^-fti

8

^ -5

^W"90#(7)7K

X^^ti^X^^tz\m<

19

{i*:fe;^ h

$ V

"*0

LT</c$V\

r'#6/f(ti^<

LX<fz

if;tj^;^^MLT<fc:$V\

LT<ff^v\

2949M

2950M

>-(7)015;^

If

v\

tr

<

21

*

*

22

23

22

16

2951M

T:^##fi:{t

{ctT<

•

#tr^^(7)'?ti9;JiS|i<

«9

80%^T'

fc$V\

h'V

T-8420A,

^^9

8720A

«9

# ^ T

</f

f9#;t"t

^ V\

c^S.

<

fc$V\

15

16

2124M

32

Page 39

10.

-C<

^c:^V\

14

10

niffti

0471M

t.-h^>:k.X\^^fztt\-t.

^&$m(Drmm^xmmm^^rr^^x\^^fzh.

T<fc^V\

±^tr^(Dmti

Ay-^\

^;{iSoV

^fcft.

tfcft.

^

^-CV

^6 i: #

ft.

'®;^|Sov^-CV^'5§|5p"p^®l^9#;iT<

^;65oV^TV^'5lfPp"p^®i^9#;tT<fc:$V^o

ftftii^

T-t

;0^o

X-aAy^m^mWLX<tz^\^\

11^4"^

«9

tf-^^f9#;tr

19

(c5lv^;fci9^f

<

/f$V\

iEL<^^aiLT<

Lx<fz^^\

L/c«9

^T<iTc

;rc:$v\

15-17

11

21

24

$ V\

*

*

23

14

11

12

oT

(O

GREASE

:I:TL.

Lt

V

\

s»

)S0^Lrv^-5

LT<

i+^^^^^^LT<

/

ff

^c:^V\

t^ft.

iii9lt<^$f:A:4^/il4cff;5S^

*

ff1$^0LTiELV44gfC

*

1®j4^JtLr<f£$LNo

^fz^hho^^mmizmtms

0469M

9

ii#.

X y

7

^

^?SIS

t r <

;^c:

LX<fz^\^\

$ V

pl

ti"o

)

26

33

T-8420A,

8720A

Page 40

T-8420A

TWIN

TWIN

NEEDLE

NEEDLE

LOCK

STITCHER

T-8720A

LOCK

STITCHER

WITH

LARGE

HOOK

Page 41

Thank

you

very

much

for

buyingaBROTHER

instructions below and the explanations given in the Instruction manual.

With

industrial sewing machines, it is

needle and thread take-up, and consequently there is always a danger of

the instructions fromtraining personnel and Instructors regarding safe and correct operation before operating the machine so

that you

will

know how to

use

Itcorrectly.

normal

sewing

machine.

to carryout work

while

Before

positioned

using

your

new

machine,

directlyinfrontofmoving

injury

that can be caused bythese parts.

please read the

parts such as the

safety

Follow

SAFETY

1.

Safety

This instruction manual

safe

indications

indications

operation of this machine and to prevent accidents and Injuryto yourself or other people.

and

and

the indications

their

meanings

and

The

Instructions

instructions could

equipment and surroundings.

INSTRUCTIONS

symbols that

which

cause

are

usedonthe

follow

this

injury when using

term

machine itself

indicate

Symbols

A

symbol ( ) Indicates

indicates

(For example,

This

the

natureofthe

the

symbolatleft

symbol((S))Indicates

something

caution

means

something

that

you

that

mustbetaken.

"beware of injury".)

that

vou

shouldbecareful of.

must

not

This

G

This

Q

symbol

natureofthe

(For example, the symbolatleft

( ^ )

thing

Indicates

that

mustbedone.

something

means

"you must

that

you

must

do.

make

the ground connection".)

are

situations

the

machine or physical

do.

The

picture

provided in order to

where

failuretofollow

The

picture Inside

Inside

the

circle

ensure

damage

the

triangle

indicates

the

to

the

T-8420A,

8720A

Page 42

2.

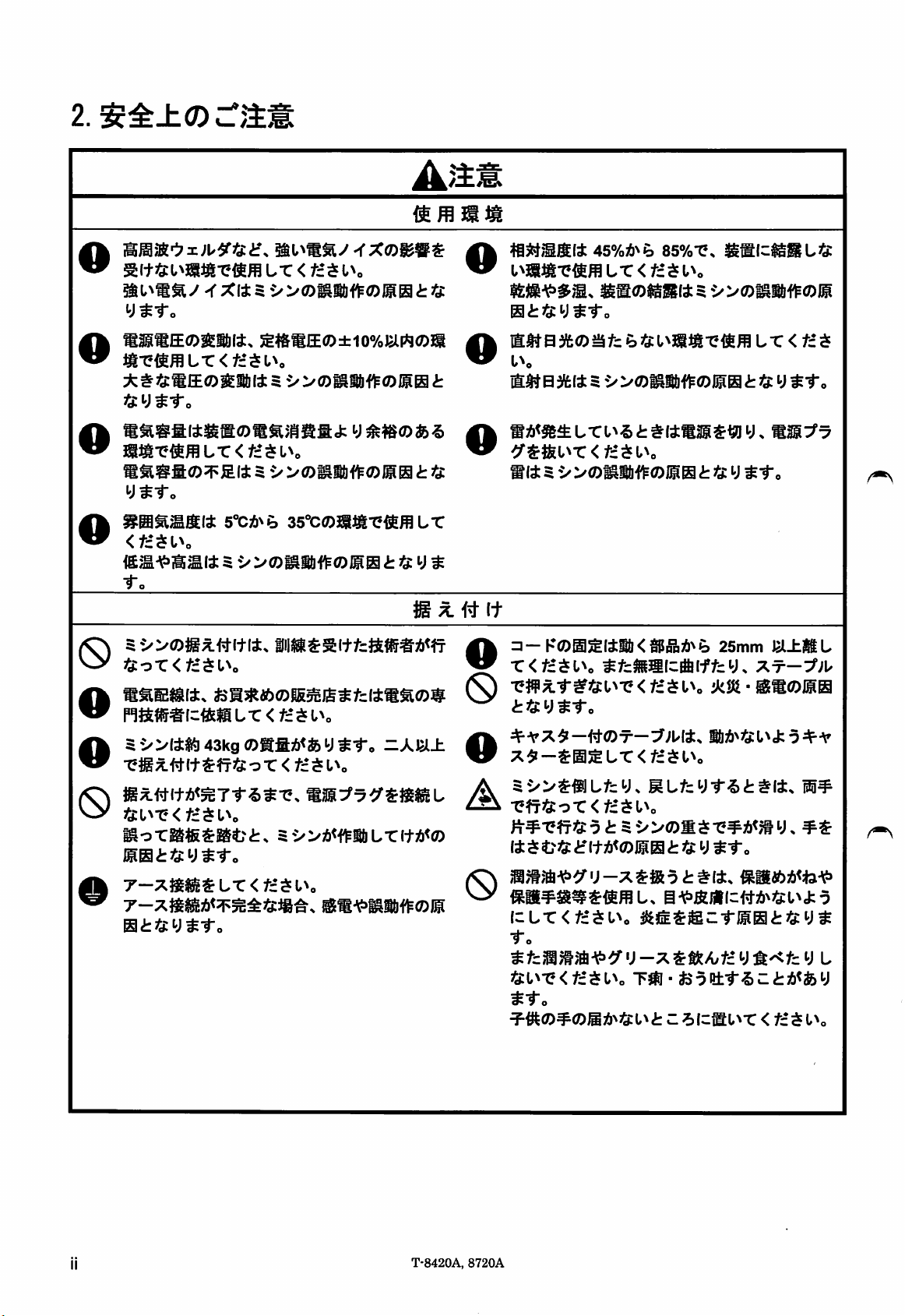

Notes

on

safety

Use

the

sewing

from

sources

high-frequency welders.

Sources

problems

Any fluctuations in

should be within ±10% of

o

o

machine.

Voltage fluctuations which

may

The

the

electrical

Insufficient power supply capacity may

problems

The

rangeof5°Cto35°C

Temperatures

may

of

with

cause

power supply capacity should be

requirements for

consumption.

with

ambient

cause

A

Environmental

machineinan

of

strong

strong

problems

problems with correctoperation.

electrical

correct

operation.

the

with

correct

operation.

temperature

during

which

are

area

which is

electrical

power

the

correct

the

lower or higher than this

noise

noise

may

supply

rated voltage for the

are

greater

operation.

sewing machine's

should

use.

than this

greater

be within

CAUTION

requirements

free

such

as

o

cause

voltage

o

than

cause

Installation

Q

the

The

relative humidity should be within

45%to85%

should

occurinany

Excessively dryorhumid

formation may

operation.

Avoid

exposure

Exposure

with

correct

the

eventofan

In

and

disconnect

Lightning

operation.

during

to direct sunlight

operation.

may

use,

devices.

cause

to direct sunlight during

electrical storm, turn off

the

power

cord

cause

the

range

and

no

dew

formation

environments

problems with correct

may

from

problems with correct

cause

the

and

dew

use.

problems

the

power

wall outlet.

of

Machine installation should only be carried out by

a qualified

Q

Contact your Brother dealer or a qualified

electrician for any electrical work that may

be

done.

technician.

The sewing machine weighs approximately 43 kg.

The installation should be carried out by two or

more

people.

0

Do not

complete.

is

injury.

connent

The

depressed

the

power

cord until installation is

machine

by mistake, which could result in

may

operateifthe

Be sure to connect the ground. If the ground

connection is not

O

secure,

you run a high risk of

receiving a serious electric shock, and problems

with correct operation may

also

occur.

need

treadle

All

cords should be

from

any

moving parts. Furthermore, do not

excessively

firmly

0

to

that

fireorelectric

If using a work table which

should be

o

cannot

Use

both

tilting it back or returning it to its original position. If

A

one

only

head may

may

get

Be

sure

when handling the lubricatingoiland grease, so that

0

bend

with staples, otherwise there is the

secured

move.

hands

hand is used, the weight of the machine

cause

caught.

to wear protective goggles and gloves

they do not get into your

otherwise

inflammation

Furthermore, do not drink the oil or

under

any

circumstances,

vomiting

Keep

the

and

oil

outofthe

diarrhea.

secured

the

shocks

in such a way so that they

to

hold

at least 25 mm away

cords

or

secure

could

occur.

has

casters,

the

machine

the

head

them

danger

casters

too

when

your hand to slip, and your hand

eyes

or onto your skin,

can

result.

eat

the

grease

as

they

can

cause

reach

of children.

T-8420A,

8720A

Page 43

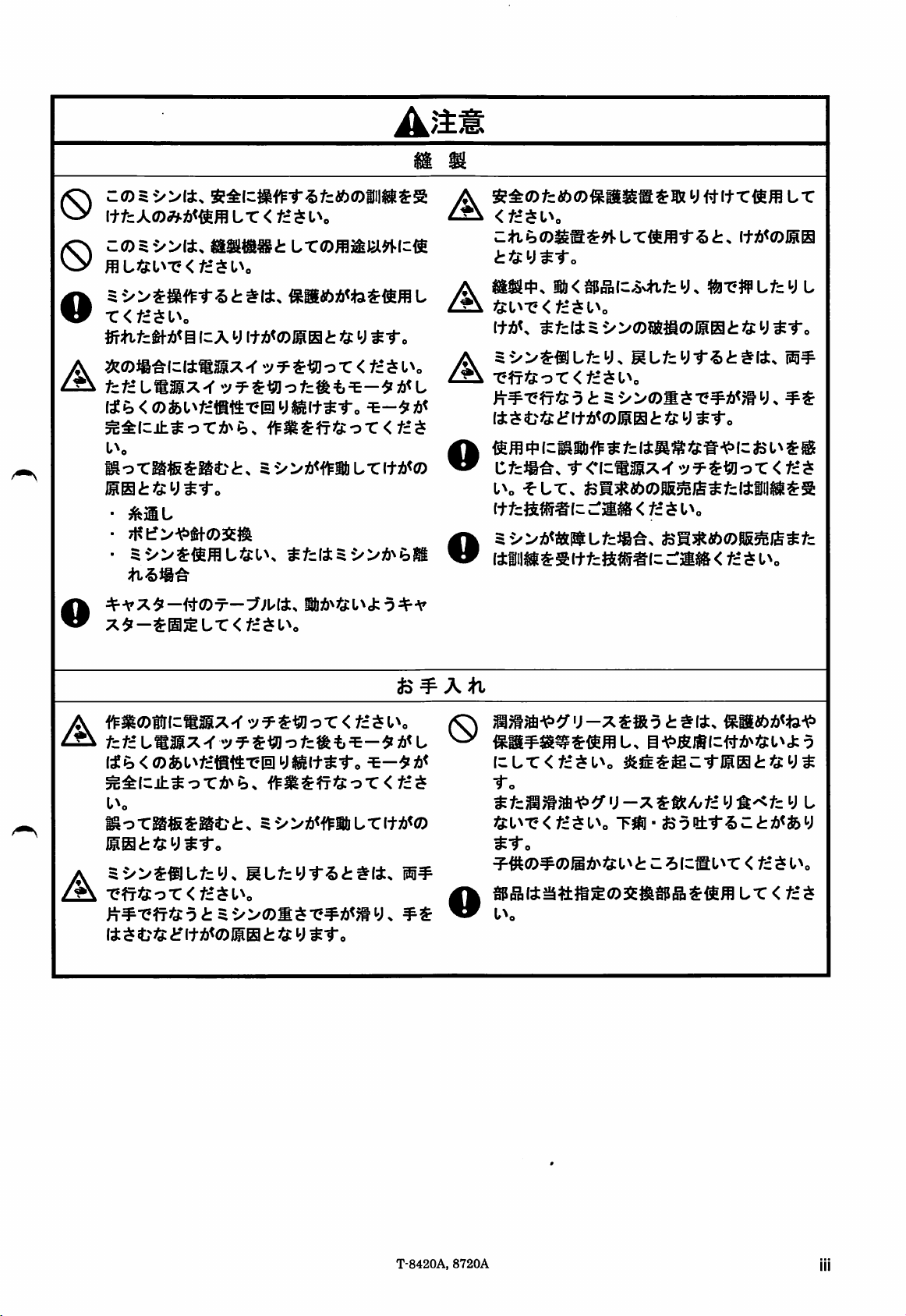

This sewing machine should only be

operators who

0

in

safe

use

The

sewing machine should not be

applications

0

Be

suretowear

machine.

O

If

goggles

needle

enter

your

Turn off

The

A

O

motor will

switched

until

the

machine

mistake, which could result in injury.

•

When

•

When

•

When

the

machine

If using a work

should be

cannot

move.

have

beforehand.

other

than sewing.

protective

are

not worn,

breaks,

the

offasa

motor

may

threading

replacing

partsofthe

eyes

and

power

switchatthe

keep

resultofthe

stops

operateifthe

the

not

using

unattended

table

securedinsuch

received

injury

tuning

fully

the

needle

bobbin

the

which

thereisthe

machine

A

the

necessary

used

goggles

may

even

before

treadleisdepressed

has

when

danger

broken

result.

following times.

motor's

and

a way

needle

after

the

inertia.

starting work.

needle

and

when

casters,

the

so

CAUTION

Sewing

used

by

training

for

using

that ifa

power

Wait

leaving

casters

that

any

the

may

The

by

they

A

is

O

Attach all safety devices before using

machine.

devices

Do not touch

objects

may

machine.

Use

tilting it back or returning it to its original position. If

only

head

may

Ifanerror

or

power

dealerora qualified

If

the

nearest

If

the

attached,

anyofthe

against

resultinpersonal

both

one

may

get

caught.

smells

switch.

machine

Brother

the

hands

to

handisused,

cause

your

occursinmachine,orif

are

noticed, immediately turn off

Then

develops

dealer

machine

injury

machine

technician.

is

used

may

result.

moving parts or

while sewing,asthis

injuryordamage

hold

the

machine

the

weightofthe

hand

to slip,

contact

your

a problem,

or a qualified technician.

the

without

head

and

your

abnormal

nearest

contact

sewing

these

press

to

when

machine

noises

Brother

any

the

hand

the

your

Tum

off

the

A

cleaning.

The

motor will

switched

untii

the

machine

mistake,

Use

both

power

keep

offasa

motor

stops

may

operateifthe

which could result in injury.

hands

switch

turning

resultofthe

fully before starting work.

to

hold

before

even

after

motor's

treadleisdepressed

the

machine

tilting it back or retuming it to its original position. If

only

one

head

may

may

get

hand is

caught.

used,

the

weight of the machine

cause

your hand to slip, and your hand

Cleaning

carrying

the

inertia.

head

out

power

Wait

The

when

by

Be

0

is

suretowear

when handling

they do not

otherwise

Furthermore, do

under

vomiting

Keep

Use

by Brother.

inflammation

any

and

the

oil

only the proper replacement partsasspecified

protective

the

iubricating oil

get

into your

can

not

drink

circumstances,

diarrhea.

outofthe

reach

goggles

and

grease,sothat

eyes

or onto your skin,

result.

the

oil or

eat

as

they

of children.

and

the

can

gloves

grease

cause

T-8420A,

8720A

Page 44

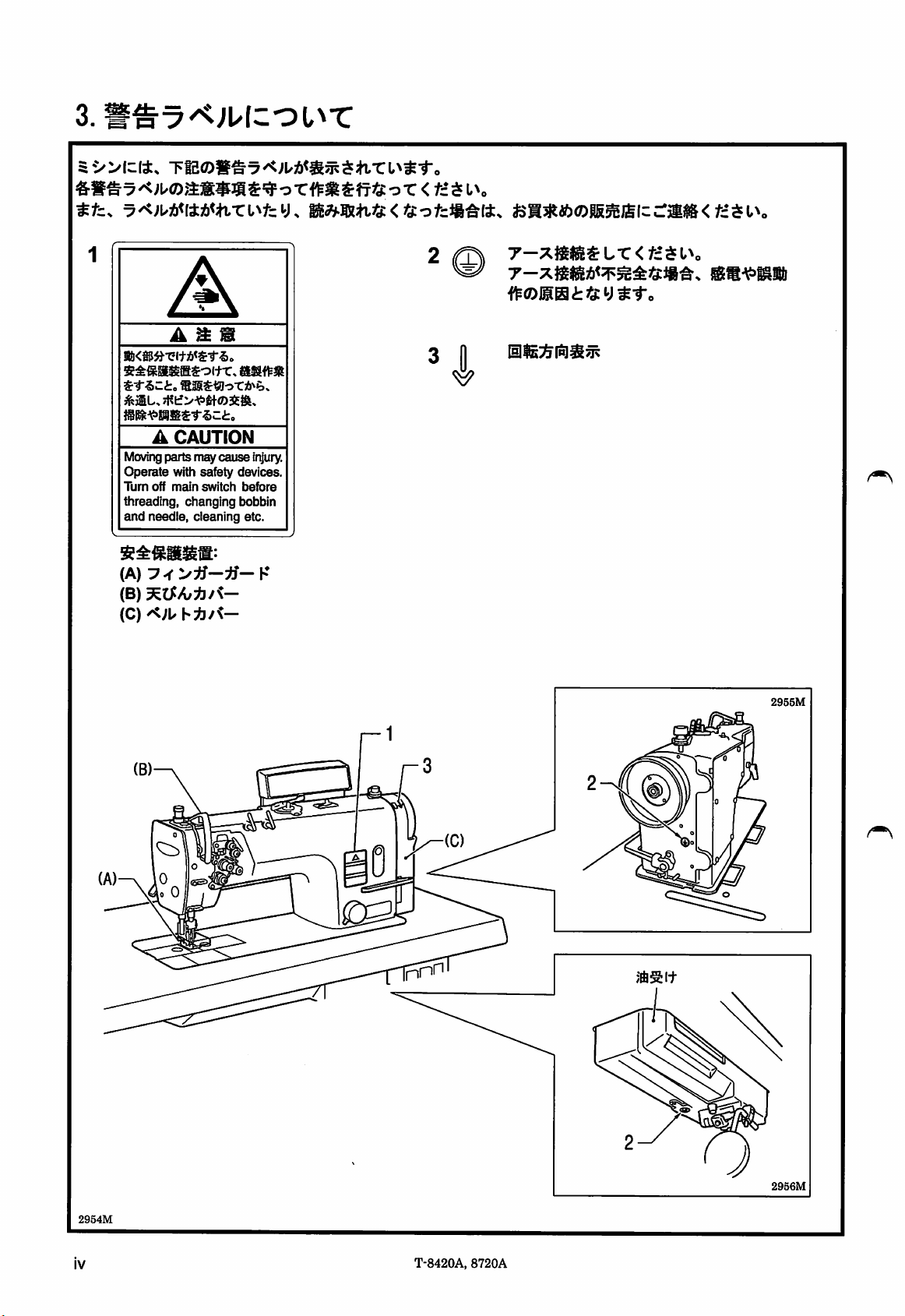

3.Waming

The

following warning labels

Please

labels

follow

difficultto read,

1

the

instructions on

please

appearonthe

the

contact your

sewing machine.

labelsatall

nearest

Brother dealer.

times

when

using

the

machine.Ifthe

Be

sure

connection is not

receiving a

with

correct

to

connect

serious

operation

labels

the

secure,

electric

may

have

been

removedorare

ground. If

the

ground

you run a high risk of

shock,

also

occur.

and

problems

A ^ S

A

CAUTION

Moving

parts may

Operate

Turn

threading, changing bobbin

and

Safety

(A)

with safety devices.

off

main

needle, cleaning etc.

devices:

Finger

(B) Thread take-up cover

(C) Belt

cover

guard

cause

switch

before

injury.

Direction of

operation

2g55M

0

Oil pan

2954M

IV

T-8420A,

8720A

2956M

Page 45

CONTENTS

1.

NAMES

2.

MACHINE

3.

TABLE

4.

INSTALLATION

4-1.

Installation

4-2.

Lubrication

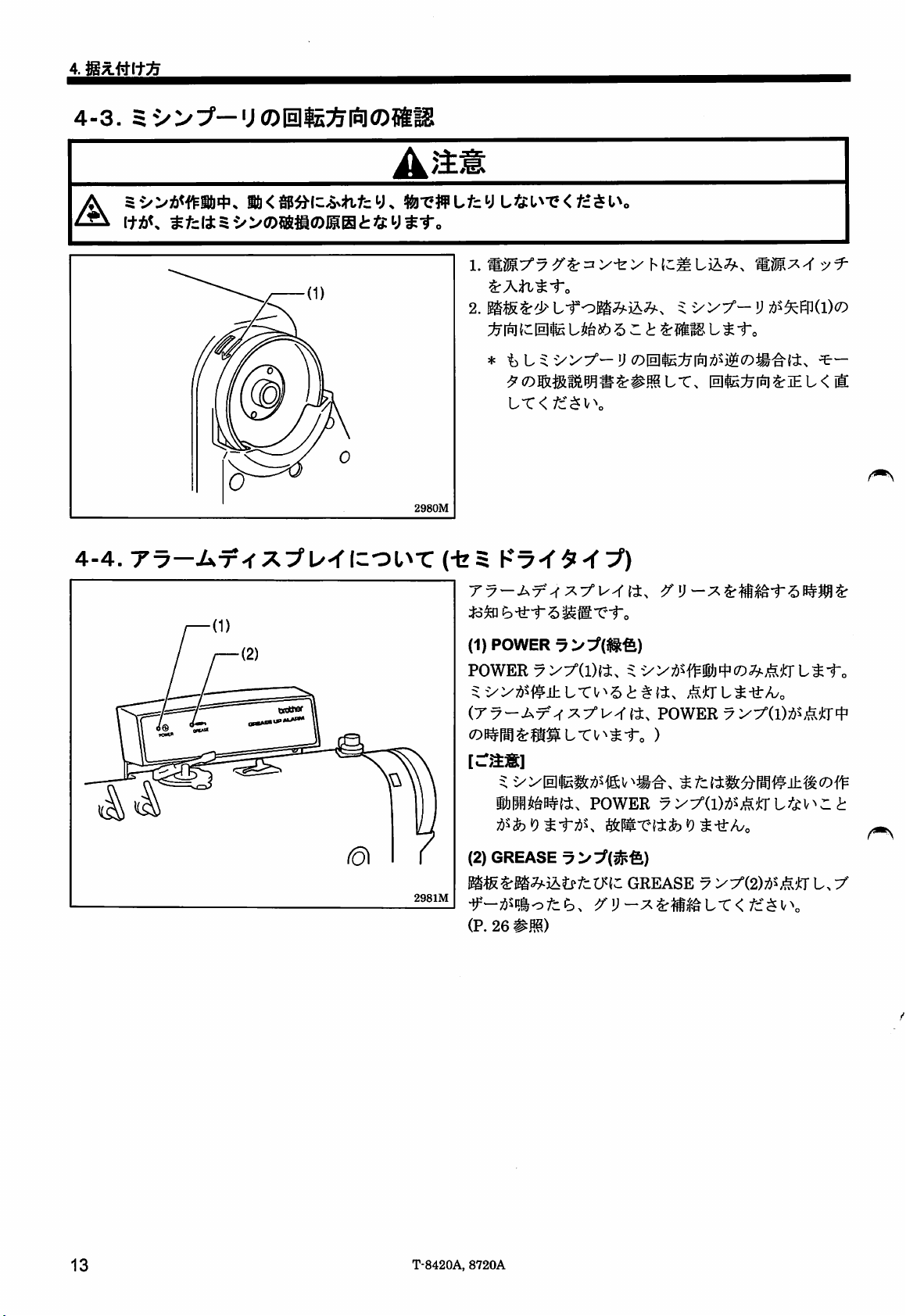

4-3. Checking the machine pulleyrotatingdirection.... 13

4-4. Alarm display (Semi dry

5.

PREPARATION

5-1. Installing

5-2. Removing

5-3. Winding

5-4. Installing

5-5. Threading

5-6. Adjusting

5-7. Using

OF

MAJOR

SPECIFICATIONS

AND

the

MOTOR

the

needle

the

bobbin 14

the

lower

the

bobbin 16

the

upper

the

stitch length 18

knee

lifter 18

PARTS

type)

BEFORE

thread

thread

SEWING

....14

11

13

14

15

17

1

2

3

4

5

6.

SEWING

6-1.

Sewing

6-2. Backtacking 19

6-3.

Sewing

7.

THREAD

7-1. Adjusting

7-2. Adjusting

7-3. Adjusting

8.

CLEANING

8-1. Daily cleaning

8-2. Lubricating via

(every 6

8-3. Applying

condensed

TENSION

the

the

the

stitches

thread

presser

thread

procedures

the

oil

months)

grease-When

tension

foot

take-up

cover

the

pressure

amount

GREASE

19

19

20

21

21

22

23

24

24

25

indicator illuminates (Semi dry type) 26

9.

ADJUSTING

LUBRICATION

10.

TROUBLESHOOTING

THE

AMOUNT

ROTARY

HOOK

29

30

T-8420A,

8720A

Page 46

1.

NAMES

1.

NAMES

OF

MAJOR

PARTS

OF

MAJOR

PARTS

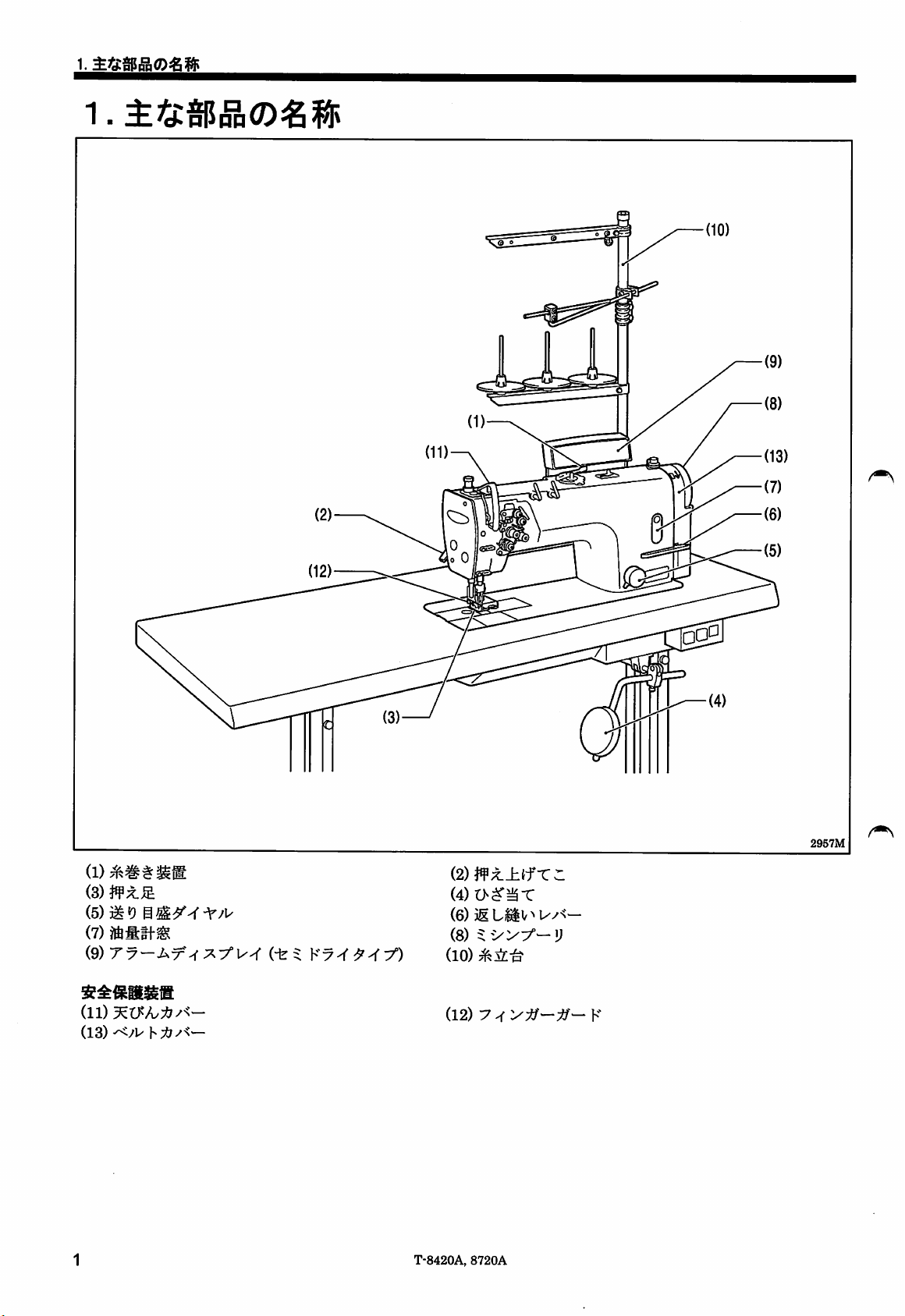

(1) Bobbin winder

(3)

Presser

(5) Stitch length dial

(7) Oil

(9)

Alarm

Safety

devices

(11) Thread take-up cover

(13) Belt

foot

gauge

window

display (semi dry type)

cover

(2)

(4)

(6)

(8)

(10)

(12)

Lifting

lever

Knee lifter

Reverse

Machine pulley

Cotton

Finger guard

assembly

lever

stand

0

2957M

T-8420A,

8720A

Page 47

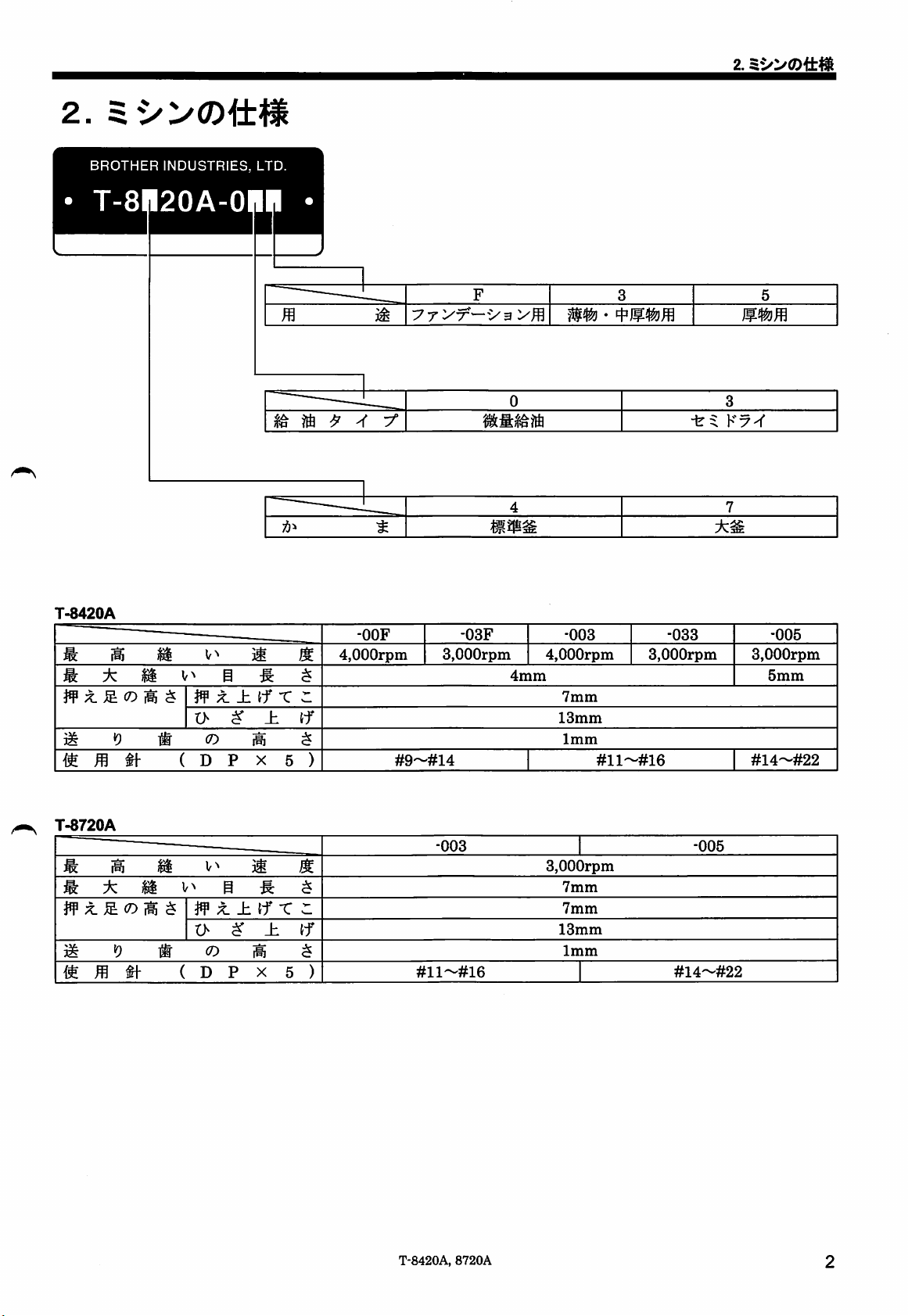

2.

MACHINE

SPECIFICATIONS

2.

MACHINE

SPECIFICATIONS

BROTHER

INDUSTRIES,

T-8n20A-0

LTD.

Rotary

Use

Lubrication

hook

type

For

Minimum

F

foundation

Standard

3 5

For

light-weight

medium-

materials

0 3

lubrication

4

hook

weight

and

For

Semi

Large

heavy-weight

materials

dry

7

hook

T-8420A

Max.

Max.

Presser

height

Feed

Needle

T-8720A

Max.

Max.

Presser

height

Feed

Needle

sewing

stitch

foot

dog

(DPx5)

sewing

stitch

foot

dog

(DPx5)

speed

length

height

speed

length

height

Lifting

Knee

Lifting

Knee

lever

lifter

lever

lifter

-OOF

4,000

rpm

-03F

3,000

rpm

#9-#14

•"UUO 1

#11-#16

-003

4,000

rpm

4

mm

7

mm

13

mm

1

mm

#11-#16

3,000

rpm

7

mm

7

mm

13

mm

1

mm

-033

3,000

rpm

uuo

#14-#22

-005

3,000

5

#14-#22

rpm

mm

T-8420A,

8720A

Page 48

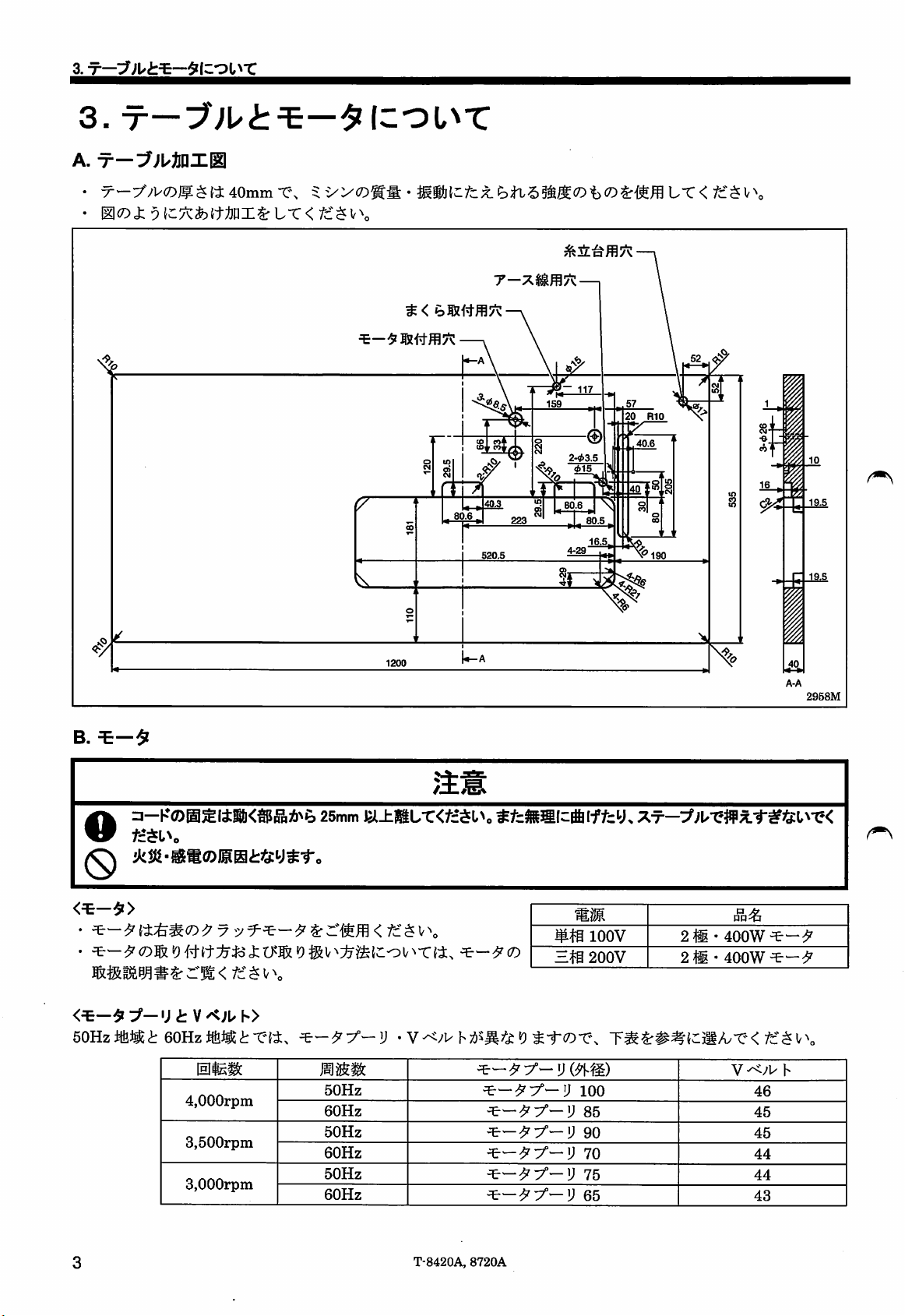

3.

3.

A.

•

TABLE

The

AND

TABLE

Table

processing

top of

vibration of

• Drill

holesasindicatedinthe

MOTOR

the

the

AND

table

sewing

diagram

shouldbe40

machine.

illustration

MOTOR

mm In

thickness

below.

and

shouldbestrong

Ground

Head

rest

hole

Cotton

wire

enough

stand

hole

—

to hold

hole

the

weight

and

with-stand

the

B.

Motor

Motor mounting

holes

520.5

2-«3.5

20

RIO

A-A

2958M

A

CAUTION

All

cords should be secured at least 25 mm away from any movingparts. Furthermore, do not excessively bend

the cords or secure them too

occur.

firmly

with staples, otherwise there is the danger that fire or electric shocks could

0

<Motor>

• Use one ofthe clutch motors given in the table at rightasthe motor.

• Refer to the instruction manual for the motor for details on installing

and

using

the

motor.

<Motor

Select the correctmotor

pulley

and

Sewing

V-belt>

4,000

3,500

3,000

pulley

speed

rpm

rpm

rpm

and

V-beltbyreferring

Freguency

50

60

50

60

50

60

Hz

Hz

Hz

Hz

Hz

Hz

to the tablebelowto suitthe powerfrequencyofyourarea.

Motor

pulley

Motor

Motor

Motor

Motor

Motor

Motor

Power

Single-phase

Three-phase

(Outer

pulley

pulley

pulley

pulley

pulley

pulley

diameter)

100

85

90

70

75

65

2-pole.

2-pole,

Motor

400Wmotor

400Wmotor

V-belt

46

45

45

44

44

43

T-8420A,

8720A

Page 49

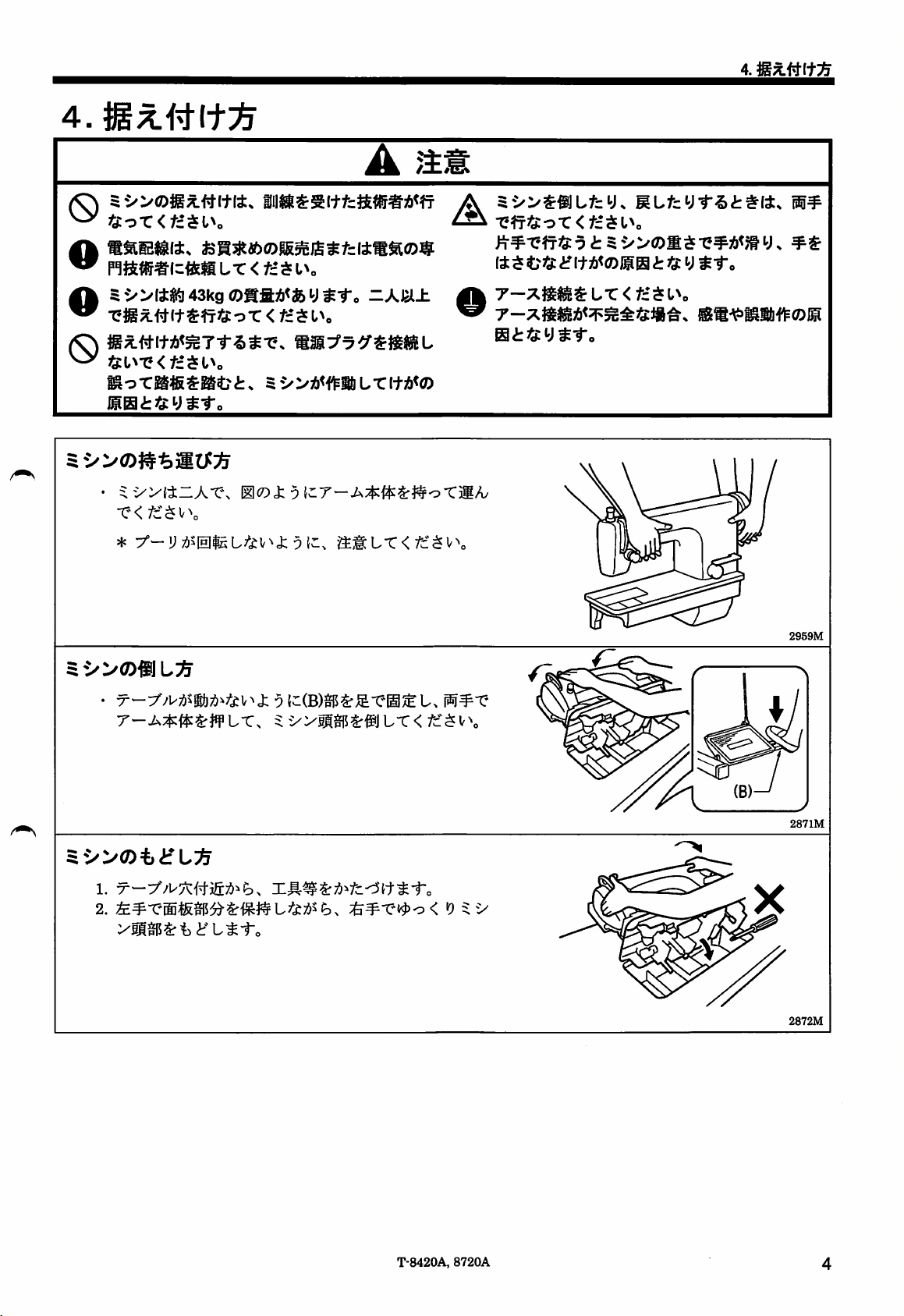

4.

INSTALLATION

A

CAUTION

4.

INSTALLATION

Machine installation should only be carried out by a

0

qualified

Contact

O

for

The

O

The

people.

Do not

0

compiete.

depressed

Carrying

•

The

machine

showninthe

* Make

Tilting

• Hold section (B) with your footsothat

and

then

head.

technician.

your

any

electricai work

sewing

installation

connect

the

illustration.

sure

that

back

the

push

Brother

machine

The

by mistake, which could result in injury.

dealer

or a qualified electrician

that

may

weighs

shouldbecarried

the

power

cord

machine

may

operateifthe

needtobe

approximately 43 kg.

out

until installation is

machine

shouldbecarried by

the

machine

machine

the

arm

with both

pulley

head

the

does

the

hands

by two or

arm

by two

not turn.

table

to tilt

done.

treadle

does

back

more

is

peopie

not move,

the

machine

Use

tilting it

only

head

may

Be

o

connectionisnot

receiving a

correct

as

both

back

one

handisused,

may

get

caught.

sure

to

operation

hands

to

hoid

the

machine

or retuming it to its original position. If

the

weightofthe

cause

your

hand

to slip,

connect

serious

secure,

electric

may

the

ground.Ifthe

you run a high risk of

shock,

also

occur.

and

head

and

your

problems

machine

when

hand

ground

with

2969M

Returning

1.

Clear

2. While holding the face plate with your left hand, gently return

machine

the

away

any

headtothe

machine

tools, etc. which may be

headtothe

upright position with your right hand.

upright

near

the

table holes.

position

2871M

the

2872M

T-8420A,

8720A

Page 50

4.

INSTALLATION

4-1.

Installation

2874M

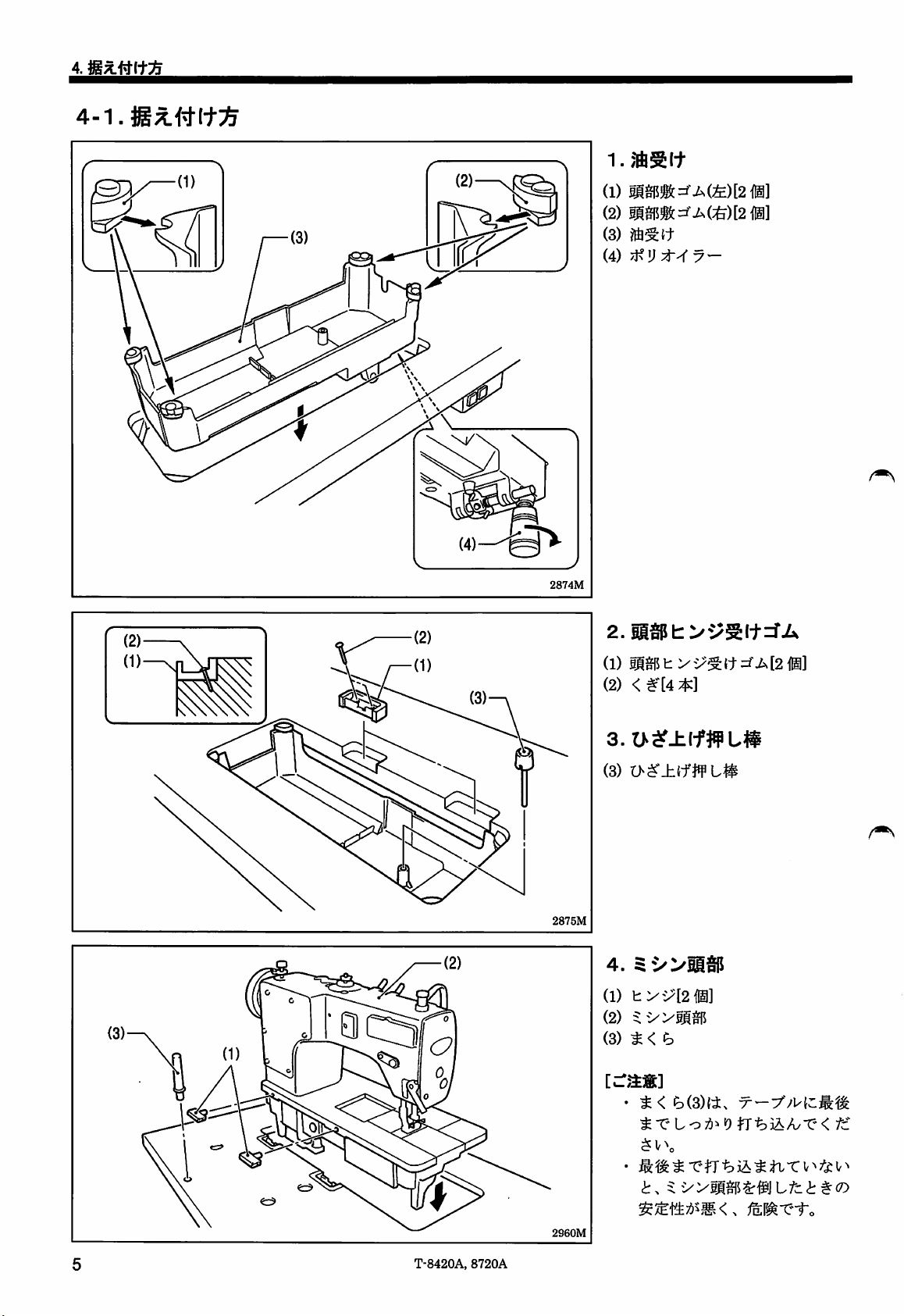

1. Oil

(1)

Head

(2)

Head

(3) Oil

(4) Oiler

pan

cushions

cushions

pan

(left) [2 pcs]

(right) [2 pcs]

2875M

2

Rubber

(1)

Rubber

(2) Nails [4 pcs]

3.

Knee

(3)

Knee

4

Machine

(1)

Hinges

(2) Machine

(3)

Head

NOTE:

Tap

the

not

machine

stable

cushions

lifter

lifter complying

[2 pcs]

head

rest

the

head

table

hole. If

pushedinas

head

whenitis

cushions

[2 pcs]

compiying

bar

head

rest

(3)

securely

the

head

rest

farasit will go,

will notbesufficiently

tilted

back.

bar

into

(3) is

the

2960M

T-8420A,

8720A

Page 51

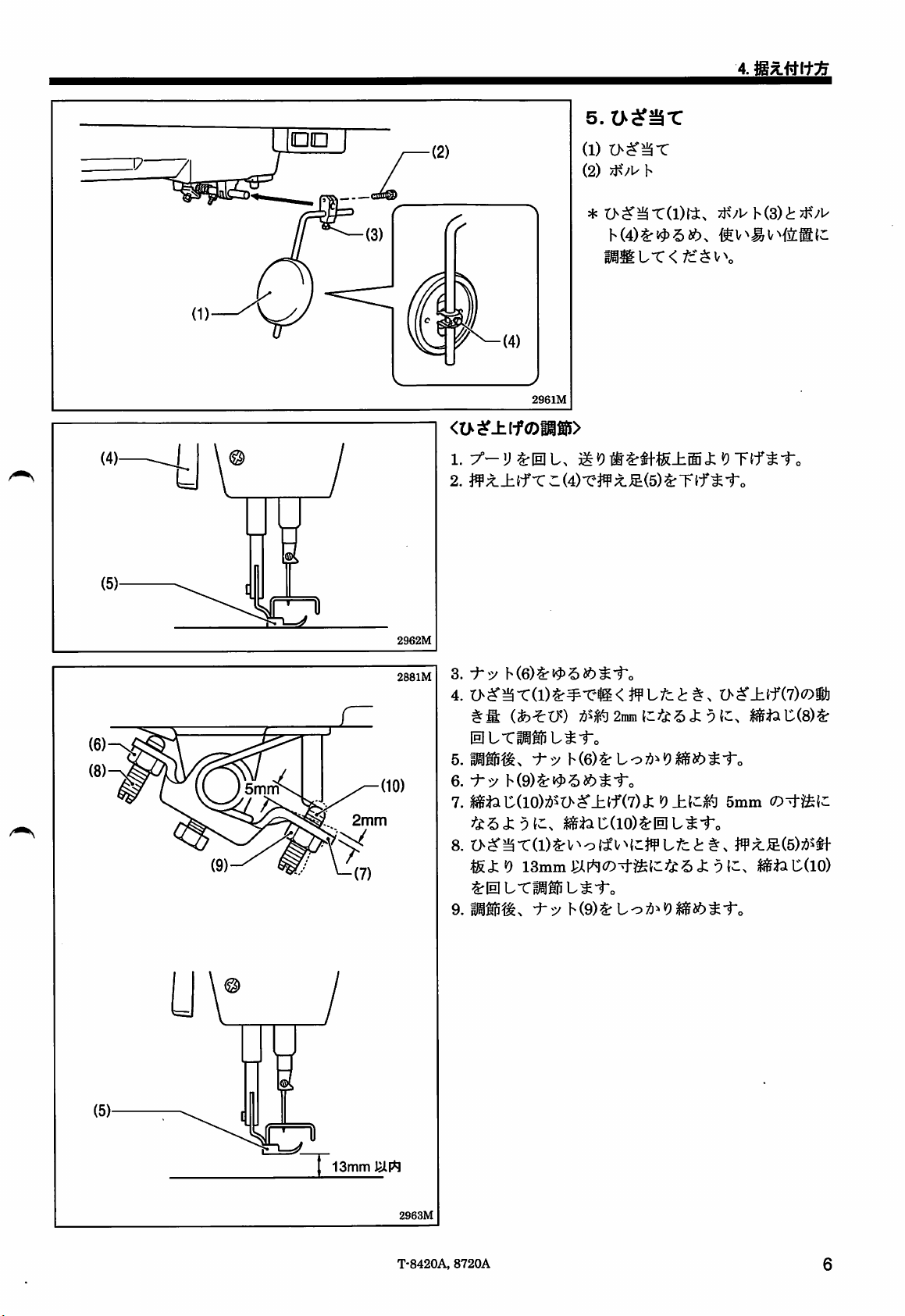

5.

Knee

(1)

Knee

(2) Bolt

lifter

lifter

plate

4.

INSTALLATION

plate

<Knee

1. Turn

topofthe

2. Lower

lifter

the

the

machine

* Loosen

2961M

adjustment>

pulleysothat

needle

plate.

presser

foot (5) by using

and

move

a position

the

where

bolt (3)

the

the

the

and

knee

lifter plate (1) to

it is

easytouse.

feed

dog

lifting

the bolt (4),

is below

lever (4).

the

U

2S62M

2881M

3.

Loosen

4. Turn

the

lifter plate (1) is gently

5.

Securely

6.

Loosen

7. Turn the screw (10) until the distance between

the

nut

(6).

the

screw

(8) to adjustsothat

knee

lifter (7) is approximately 2 mm when

pressed.

tighten

the

nut (6).

the

nut (9).

the

amount of play in

the

the

knee

end of

the screw (10) and the knee lifter (7) is approximately 5

mm.

8. Turn

the

adjusting screw (10) to adjustsothat

foot (5) is at the desired position

mm of

fully

the

needle plate when the knee liter plate (1) is

pressed.

within

a distance of 13

the

presser

9. After adjustment is completed, securely tighten the nut

(9).

Within13mm

2963M

T-8420A,

8720A

Page 52

4.

INSTALLATION

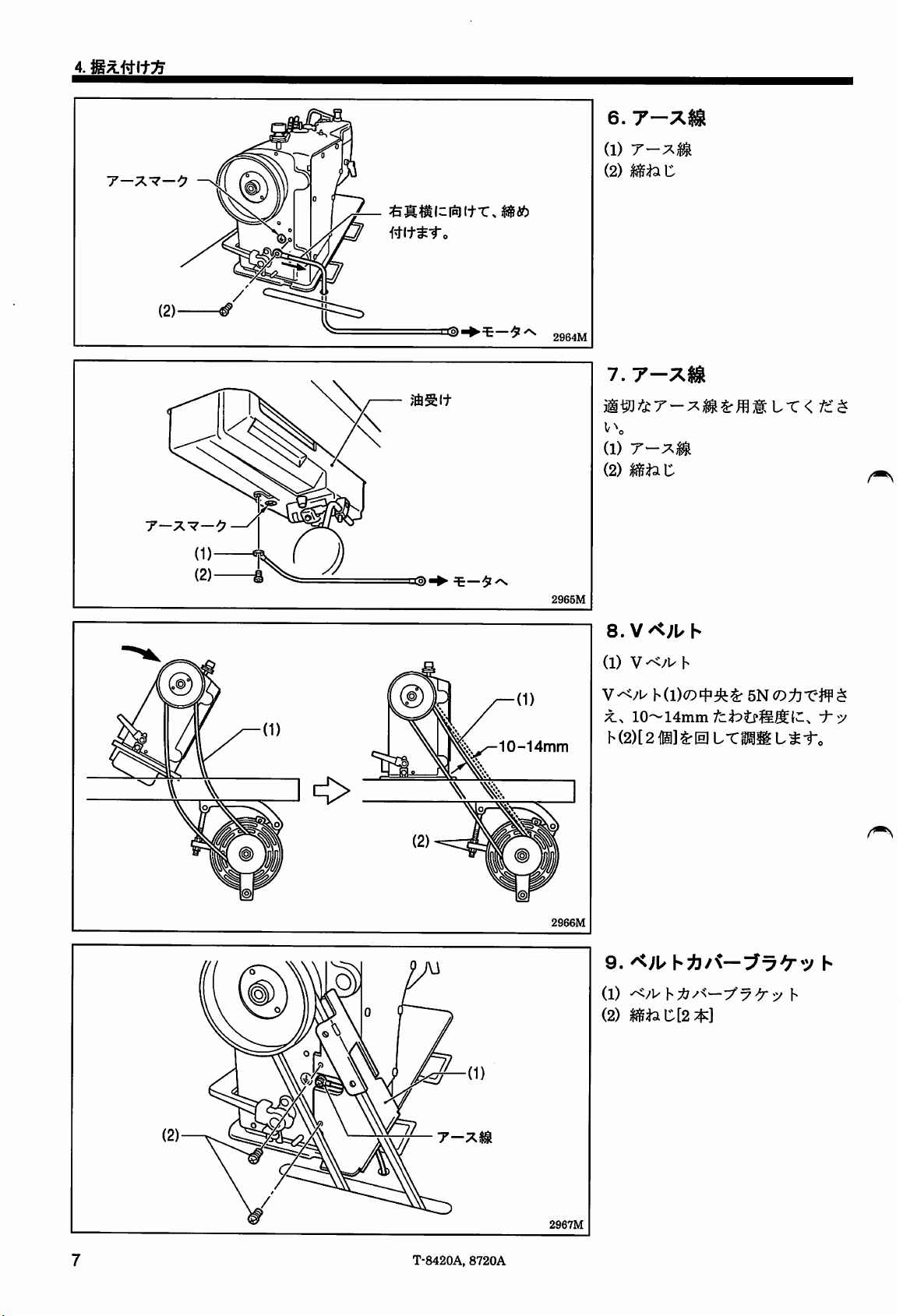

Ground

symbol

^ L

6.

Ground

(1) Ground wire

(2)

Screw

wire

(2) ^

Ground

symbol

— Align horizontally to

right

and

—

Oil

=0^

then

uS>

pan

tighten.

Motor

Motor

the

i!y64M

2965M

7.

Ground

Useasuitable

(1)

Ground

(2)

Screw

8.

V-belt

(1) V-belt

wire

wire

ground

wire.

m

m

O

\

Ground

(1)

wire

0-14mm

2966M

Turn

the

two nuts (2) to adjustsothat

thereis10-14

V-belt (1) when it is

midway point with a force of 5 N.

9.

Belt

(1) Belt

(2)

Screws

mmofdeflection

cover

cover

bracket

[2 pcs]

pressedatthe

bracket

in

the

2967M

T-8420A,

8720A

Page 53

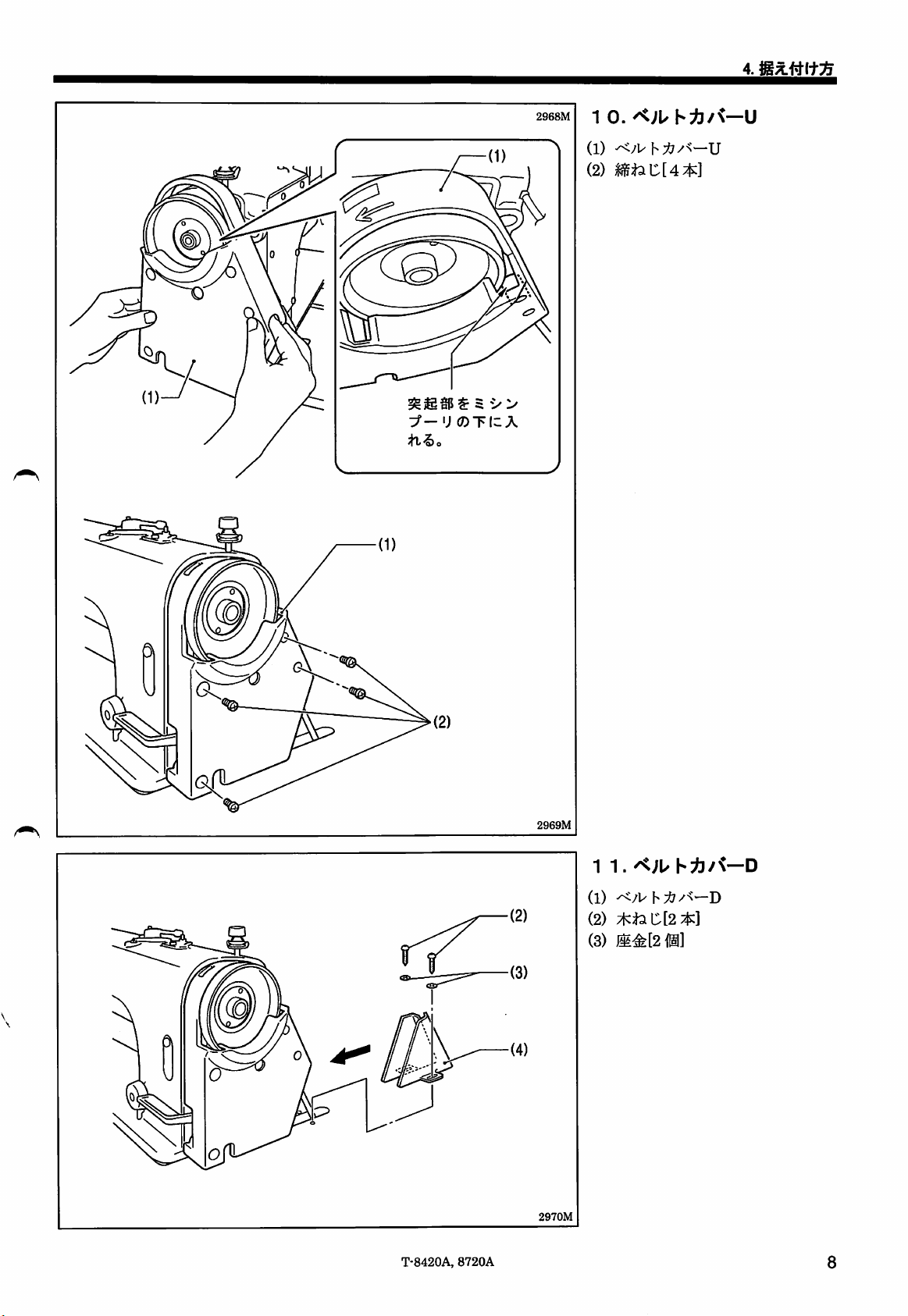

Insert

part

underneath

machine

the

pulley.

projecting

the

2968M

10.

Belt

(1) Belt

(2)

Screws

cover

cover

U

[4 pcs]

4.

INSTALLATION

U

T-8420A,

8720A

2969M

2970M

11.

Belt

(1) Belt

(2)

Wood

(3)

Washers

cover

cover

screws

D

D

[2 pcs]

[2 pcs]

Page 54

4.

INSTALLATION

2971M

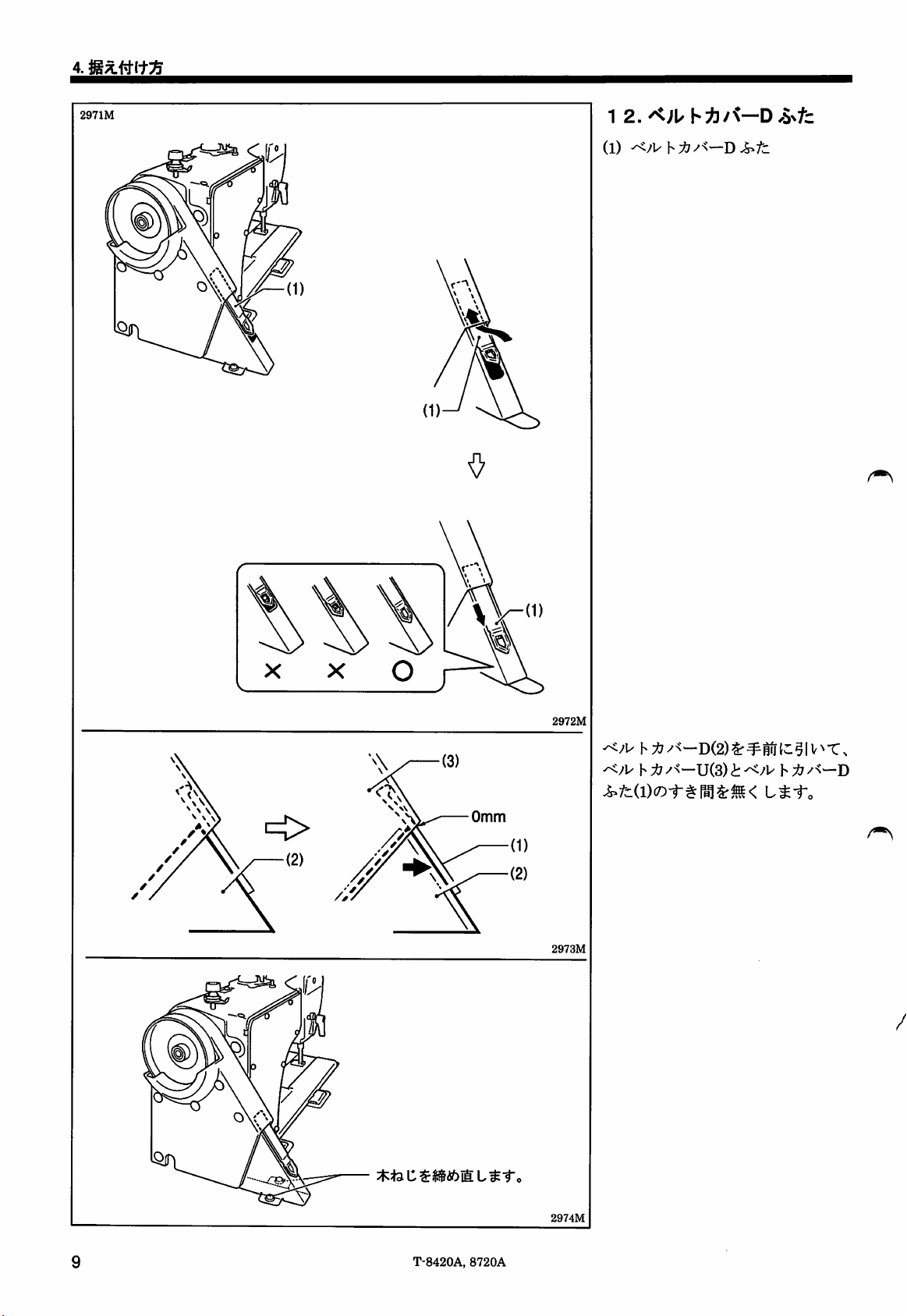

0

12

Belt

(1) Belt

cover

cover

D lid

D

lid

X X O

2972M

2973M

Pull belt

so

that

cover

there

U (3)

cover

D (2) forward to

Is no

and

the

belt

gap

between

cover

adjust

belt

D lid (1).

Re-tighten

the

T-8420A,

wood

8720A

screws.

2974M

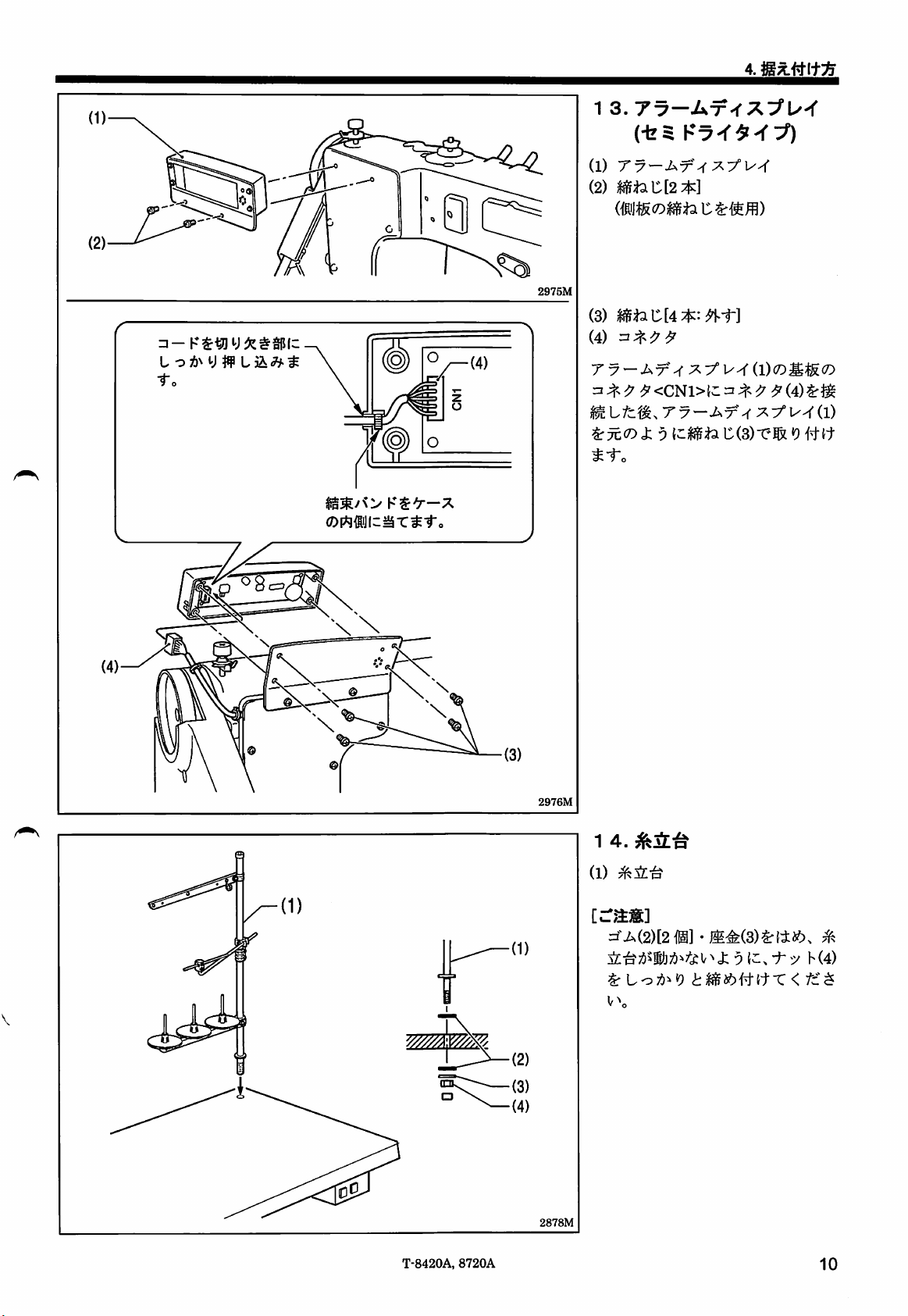

Page 55

2975M

13.

Alarm

(semi

display

dry

(1) Alarm display

(2)

Screws

[2 pcs]

(Use for tightening

(3)

(4)

Screws

Connector

[4 pcs: removed]

4.

INSTALLATION

type)

rear

cover)

Place the cord securely

Into

the

notch.

Place

against

the

box.

the

the

cable

Inside of

After connecting

connector

alarm display (1), return

display (1) to its original position

then

tighten

tie

<CN1>

the

the

on

screws

connector

the

P.C.B.ofthe

the

(3).

(4) to

alarm

and

2976M

2878M

14

Cotton

(1) Cotton

NOTE:

Securely

the

two

washer

so

that

move.

stand

tighten

rubber

(3)

are

the

stand

securely

cotton

the

nut (4)sothat

cushions

stand

{2}

and

clamped

(1)

does

the

and

not

T-8420A,

8720A

10

Page 56

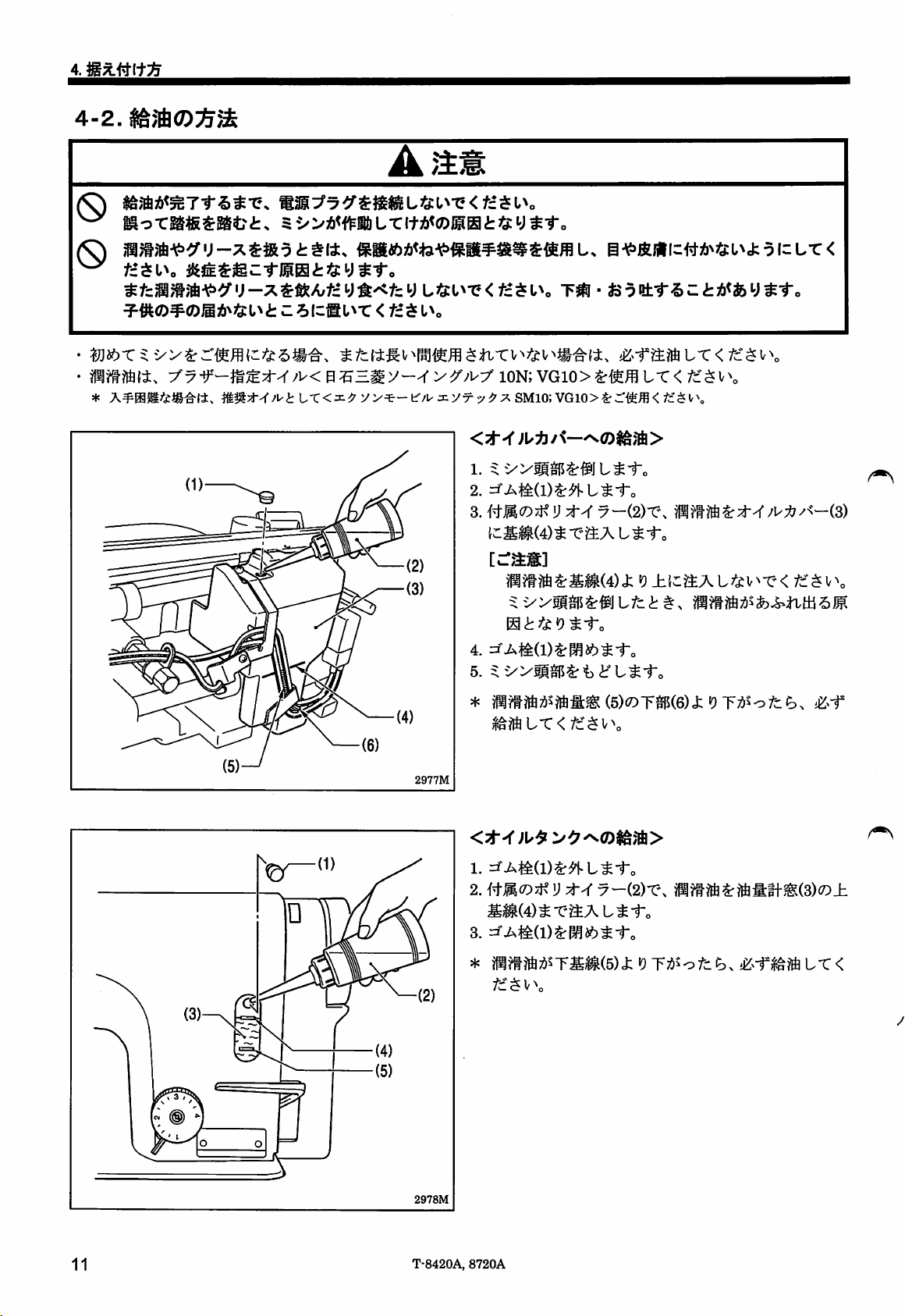

4.

INSTALLATION

4-2.

Lubrication

A

CAUTION

0

Do not connect the power cord until lubrication

treadle is

depressed

by mistake, which could result in injury.

has

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not

0

into your

Furthermore, do not drink the oil or

diarrhea.

Keep

The sewing machine should always be lubricated

after

long

Use

only

* Ifthis type of lubricating oil Is difficult to obtain, the recommended oilto

eyes

or onto your skin, otherwise inflammation

eat

the

grease

the

oil

outofthe

periodsofnon-use.

the

lubricating oil (Nissekl Mitsubishi Sewing Lube ION; VG10) specified by Brother.

reach

of children.

and

the

oil supply replenished before itis

been completed, othenwise the machine may operate if the

get

can

result.

under any circumstances,asthey can

used

use

Is <Exxon

<Lubrlcatlng

1.

Tilt

back

2.

Remove

3.

Use

the

oil

cover

(4).

NOTE:

Do not

If you

when

4.

Replace

5. Return

* If

the

lubricating oil level drops below the bottom (6) of

oil

gauge

Mobil

Essotex SM10; VG10>.

via

the

oil

cover>

the

machine

the

rubber

accessory

(3) until

fill

with lubricating oil

pourintoo

the

machine

the

rubber

the

machine

window (5),besuretoadd

head.

cap

(1).

oiler (2) to

the

oil level

much

headistilted

cap

(1).

head

lubricating oil, it

to its original position.

cause

vomiting and

for the first time, and

pour

lubricating oil into

reaches

past

the

back.

more

the

reference line

reference

may

oil.

also

line (4).

spill

the

out

the

2977M

<Lubricating

1. Remove

Use

2.

the

gauge

3.

Replace

* if the lubricating oil level

(6),besuretoadd

the

the

accessory

oil level

window (3).

the

via

rubber

reaches

ruliber

the

oil

tank>

cap

(1).

oiler (2) to pour in lubricating oil until

the

top reference line (4) of

cap

(1).

drops

below

the

more

oil.

bottom reference line

the

oil

7

2978M

11

T-8420A,

8720A

Page 57

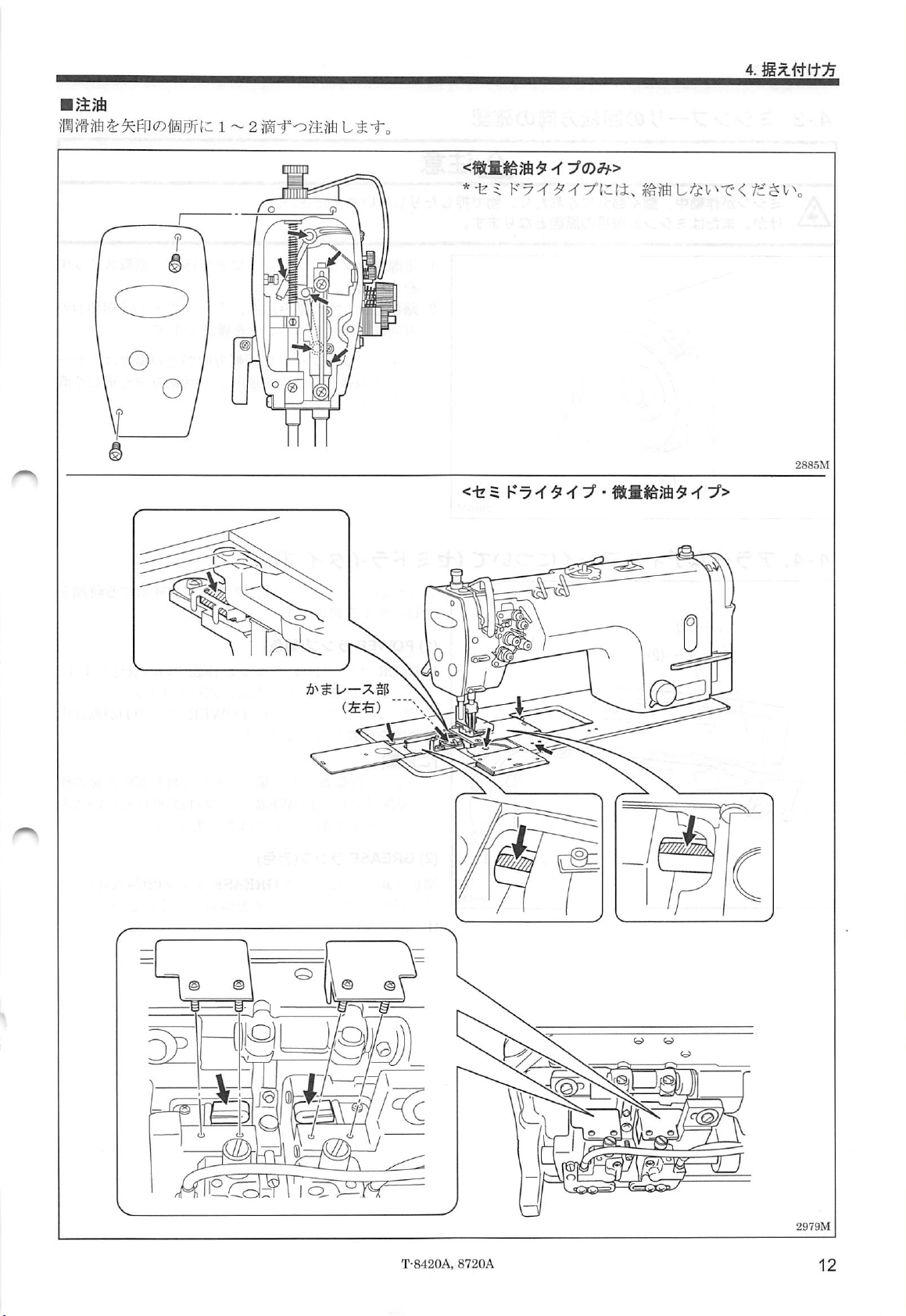

•

Lubrication

Apply 1 - 2 drops of oil to the places indicated by the arrows.

<Minimum

* Do not apply oil for semi dry types.

lubrication

type

only>

4.

INSTALLATION

I

m

T-8420A,

8720A

Page 58

4.

INSTALLATION

4-3.

Checking

Do not touch any of the moving parts or press any objects against the machine while sewing,asthis may result in

personai injury or

A

the

machine

damagetothe

puiiey

machine.

rotating

A

CAUTION

direction

4-4.

Alarm

display

(Semi

dry

type)

2980M

1. Insert

2.

The alarm display is a device that

next

(1)

The

machine is operating. It

machineisstopped.

(The alarm display

indicator (1) is lit.)

NOTE:

the

power cord plug into

turn on

the

power

Depress

pulley

* If

greasing

POWER

The

such

speed,orwhen

stopped

the

the

starts

the

direction

referring to

indicator

POWER

POWER

asifthe

for

sign

of a malfunction.

to turn in

direction of rotation is

of

is required.

indicator (1) only illuminates while

several

switch.

treadle slightly

the

direction of

rotation

the

instruction

makes

indicator (1)

sewing

operation

to

(green)

does

a total of

machine

minutes,

and

the

manual

not illuminate while

may

starts

but

the

wall outlet,

check

that

the

arrow (1).

reversed,

correct

for

the

shows

the

the

time

not illuminate at

is operating at a slow

again

after

this is

normal

the

direction

motor.

time until

that

and

machine

change

the

sewing

the

sewing

the

POWER

having

andisnot

then

the

while

the

times

been

13

2981M

T-8420A,

(2)

GREASE

If

the

sounds

grease.

(See

8720A

P. 26.)

indicator

GREASE indicator (2) illuminates

each

time

the

(red)

treadle is

depressed,

and

the

buzzer

it is time to apply

Page 59

5.

PREPARATION

5-1.

Installing

^

Turn

off

the

power

A

as

a result of the motor's inertia. Wait until the motor

The machine may operate ifthe treadle is depressed by mistake, which could result in

the

needle

switch

before

BEFORE

A

installing

the

needle.

SEWING

CAUTION

The

motor

will

stops

fullybefore starting work.

keep

5.

turning

PREPARATION

even

after

the

injury.

BEFORE

SEWING

powerisswitched

off

5-2.

A

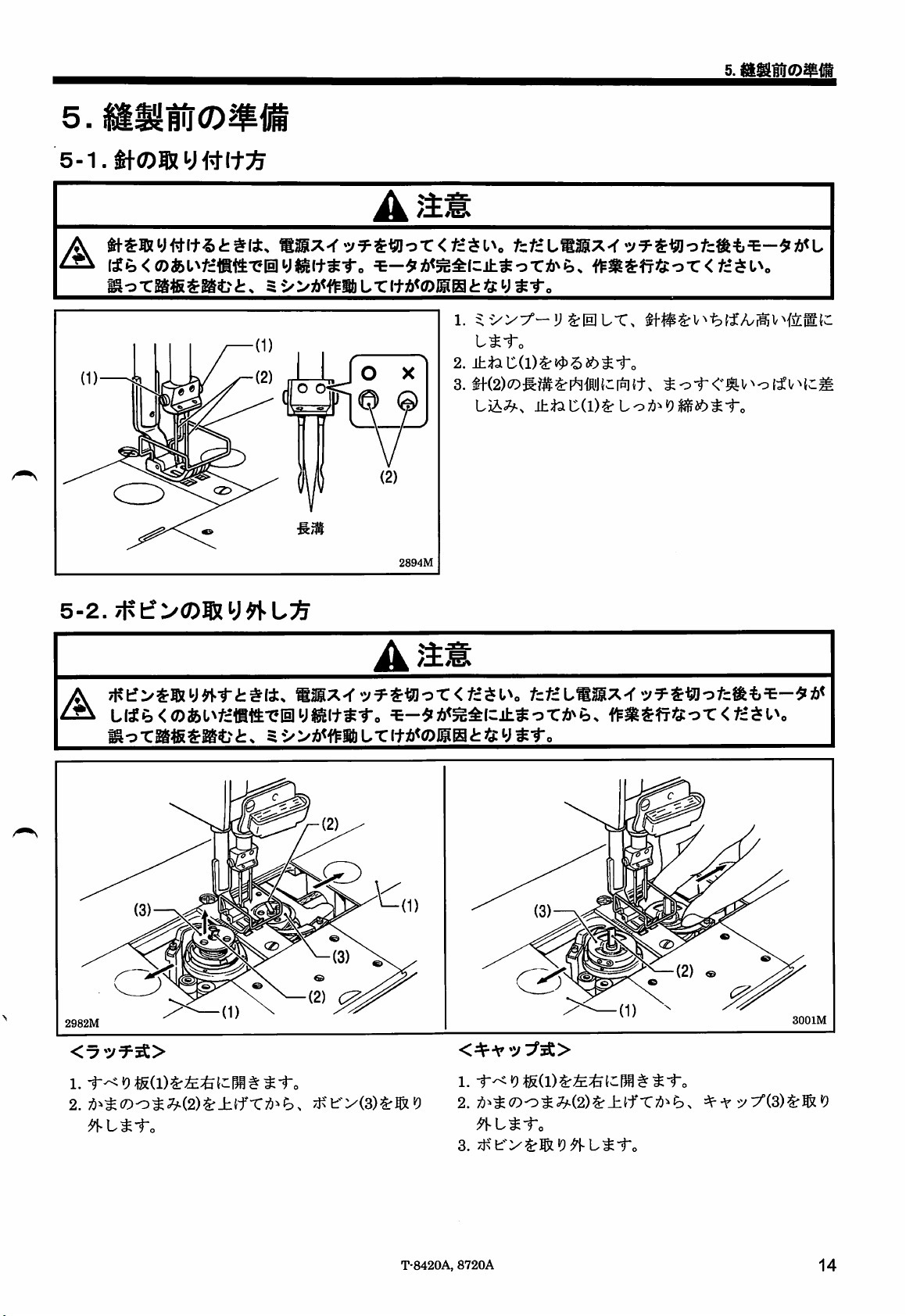

1. Turn the machine pulley to move the needle

highest position.

2. Loosen

3. Insert

long

screws

2

Long

groove

2894M

Removing

Turn offthe power switch before removing the bobbin. The motor

as

a resultof

The machine may operate if

the

the

motor's

bobbin

inertia. Wait until

the

treadle is

A

CAUTION

the

motor

stops

depressed

by mistake, which could result in injury.

fully

the

screws

the

needle

groove

(1).

will

keep turningeven after the power is switched off

before

starting work.

(1).

(2) straight inasfarasitwillgosothat

is facing inward,

and

then

securely

bar

tighten

to its

the

the

(2)

c:^

2g82M

<Latch

1.

Open

and

2. Pull

remove

type>

the

left.

the

rotary hook

the

slide

bobbins

plates

(1) by moving them to

latches

(3).

(2) upward,

and

the

right

them

T-8420A,

<Bobbin

1. Open the slide plates (1) by moving them to the right and

2.

3.

8720A

case

left.

Liftupthe

bobbin

case

Remove

type>

latch (2) of

(3).

the

bobbin.

the

rotary hook,

and

then remove the

3001M

14

Page 60

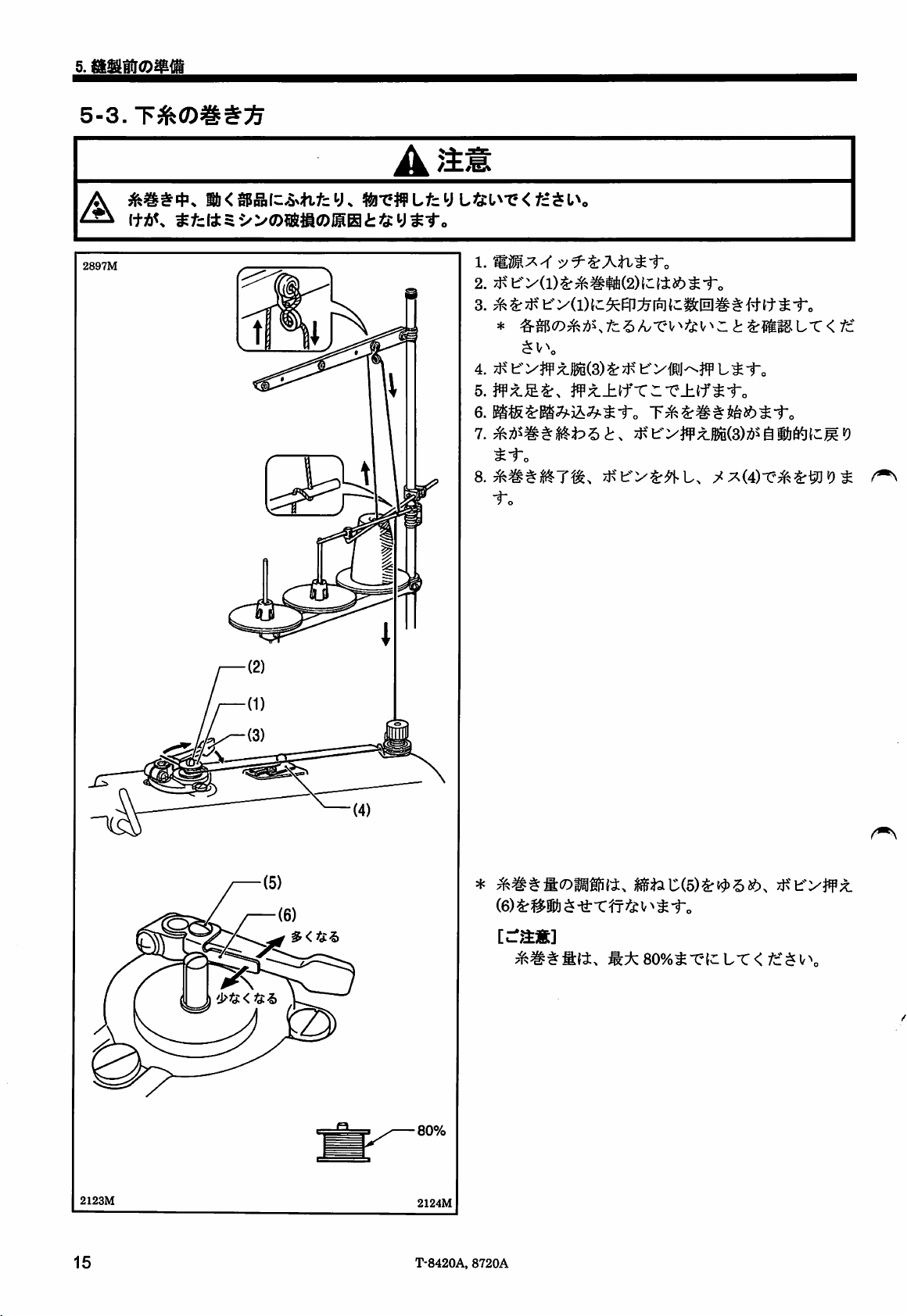

5.

PREPARATION

5-3.

Winding

BEFORE

the

SEWING

iower

thread

A

CAUTION

Do not touch any ofthe moving parts or

may result in personal injuryor

A

2897M

press

damagetothe

any

objects againstthe machine while winding

machine.

1. Turn on

2.

Place

3. Wind

direction indicated by

* Check that

4.

Push

5.

Raise

6.

Depress

7.

Once

presser

8.

After

and

the

power

switch.

the

bobbin (1)

the

thread several times around the bobbin (1) in

thread

path.

the

bobbin

the

presser

the

treadle. Lower

winding of

arm

(3) willreturn automatically.

the

thread

cut

the

thread

onto

the

the

thread is not loose anywhere along

presser

foot with

the

lower

has

been

with

the

lower thread,asthis

the

bobbin winder

arrow.

arm (3) toward

the

lifting lever.

thread

winding will

threadiscompleted,

the

wound

knife (4).

on,

the

remove

shaft

(2).

bobbin(1).

then

start.

the

bobbin

the

bobbin

the

the

Loosen the screw (5) and move the bobbin presser (6) to

adjust

the

amountofthread

More

thread

NOTE:

The

amountofthread

wound

a maximum of80 % ofthe bobbin capacity.

Less

thread

80%

2123M

15

2124M

T-8420A,

8720A

wound

onto

onto

the

the

bobbin

bobbin.

should

be

Page 61

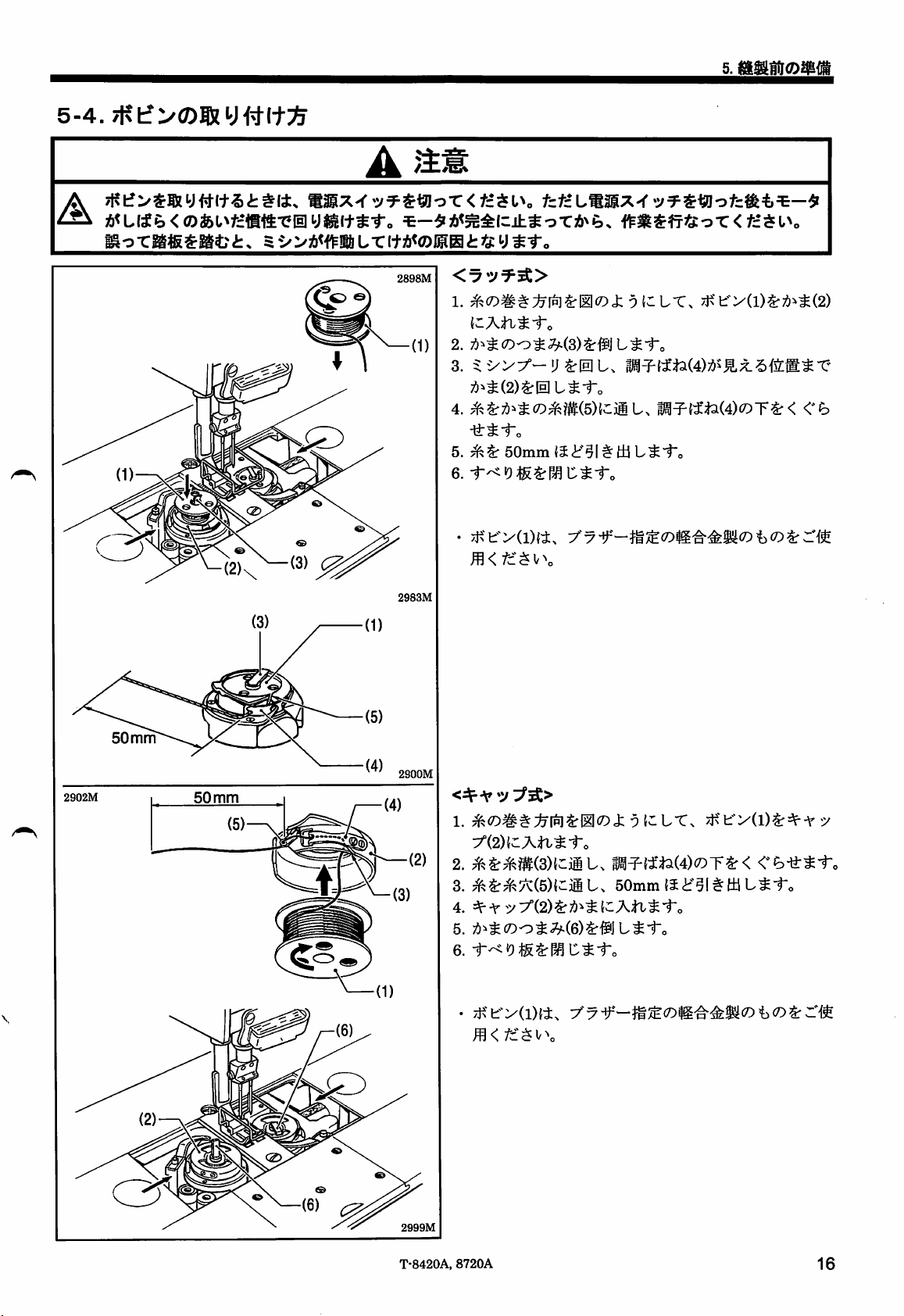

5-4.

Installing

the

bobbin

CAUTION

A

5.

PREPARATION

BEFORE

SEWING

Turn offthe power switch before Installing the bobbin. The motor

as

A

a result of the motor's Inertia. Walt untilthe motor stops

The machine may operate Ifthe treadle is

depressed

2898M

2983M

will

keep turning even after the power Is switched off

fully

before starting work.

by mistake, which could result In

<Latch

1. Insert

2. Return

3. Turn

4.

5. Pull

6.

type>

the

bobbin (1) into the rotary hook (2)sothat

winding direction Isasshowninthe

the

rotary hook latch (3) to Its original position.

the

machine pulley to rotate

the

tension

Pass

passItunder

Close

Use

BROTHER.

spring (4) Is visible.

the

thread

the

out

the

thread

the

slide plates.

bobbins (1)

through slit (5) In

thread

tension

to a length of approximately 50 mm.

made

Injury.

Illustration.

the

the

rotary hook

spring.

of light alloy

the

rotary hook (2) until

and

then

as

specified by

50

mm

50

mm

2900M

<Bobbin

1. Insert

2.

3.

4. Insert

5.

6.

• Use bobbins (1)

case

type>

the

bobbin (1) Into

winding direction IsasshownInthe

Pass

the

thread

spring (4).

Pass

the thread through

about

50

mm.

the

bobbin

Push

latch (6) of

Close

the

slide

BROTHER.

through slot (3)

case

the

plates.

the

the

(2) Into

rotary hook flat.

made

of light alloy

bobbin

thread hole (5)

the

case

Illustration.

and

under

rotary hook.

as

(2)sothat

the

tension

and

pull out

specified by

the

(6)

^

2999M

T-8420A,

8720A

16

Page 62

5.

PREPARATION

5-5.

Threading

BEFORE

the

SEWING

upper

thread

A

CAUTION

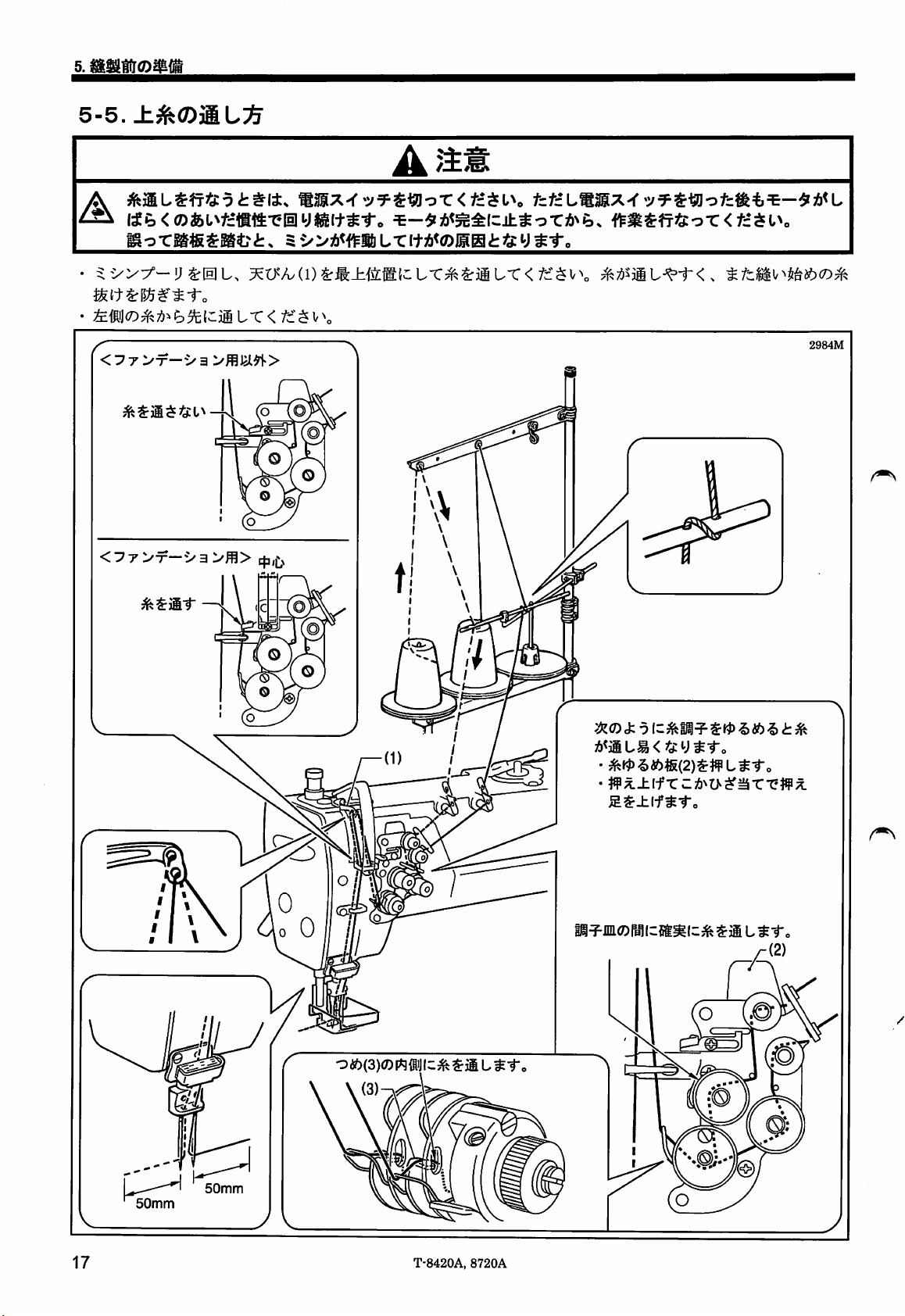

Turn offthe powerswitch before threading the upperthread.

switched offasa result of

A

The

machine

may

operateifthe

Turn the machine pulley

This will

Thread

<For non-foundation specifications> ^

Do

not

thread

make

the

pass

through.

threading

left-side

the

thread

the

motor's inertia. Wait until

treadleisdepressed

and

raise the thread take-up (1) before threading the

easier

anditwill

first.

prevent the thread from coming out at

N

<Forfoundation specifications>

Center

Pass

the

through.

thread

The

motor

will

keep

tuming

the

motor

stops

fully before starting work.

by mistake, which could result in injury.

upper

thread.

the

sewing start.

even

after

the

power is

2984M

(Refer

to p.33)

Pass

the

thread on the inside of the tab (3)

If

the

tension

follows,

to

thread.

•

Press

•

Operate

the

thread

the tension

the

lifterto raise

The thread can be

the

tension

discs.

discs

are

will

become

release

lifting

lever or the

the

presser

passed

securely in between

opened

plate (2).

foot.

^ (2)

as

easier

knee

50mm

17

50mm

T-8420A,

8720A

Page 63

5-6.

Adjusting

the

stitch

1d~1

length

5.

PREPARATION

BEFORE

SEWING

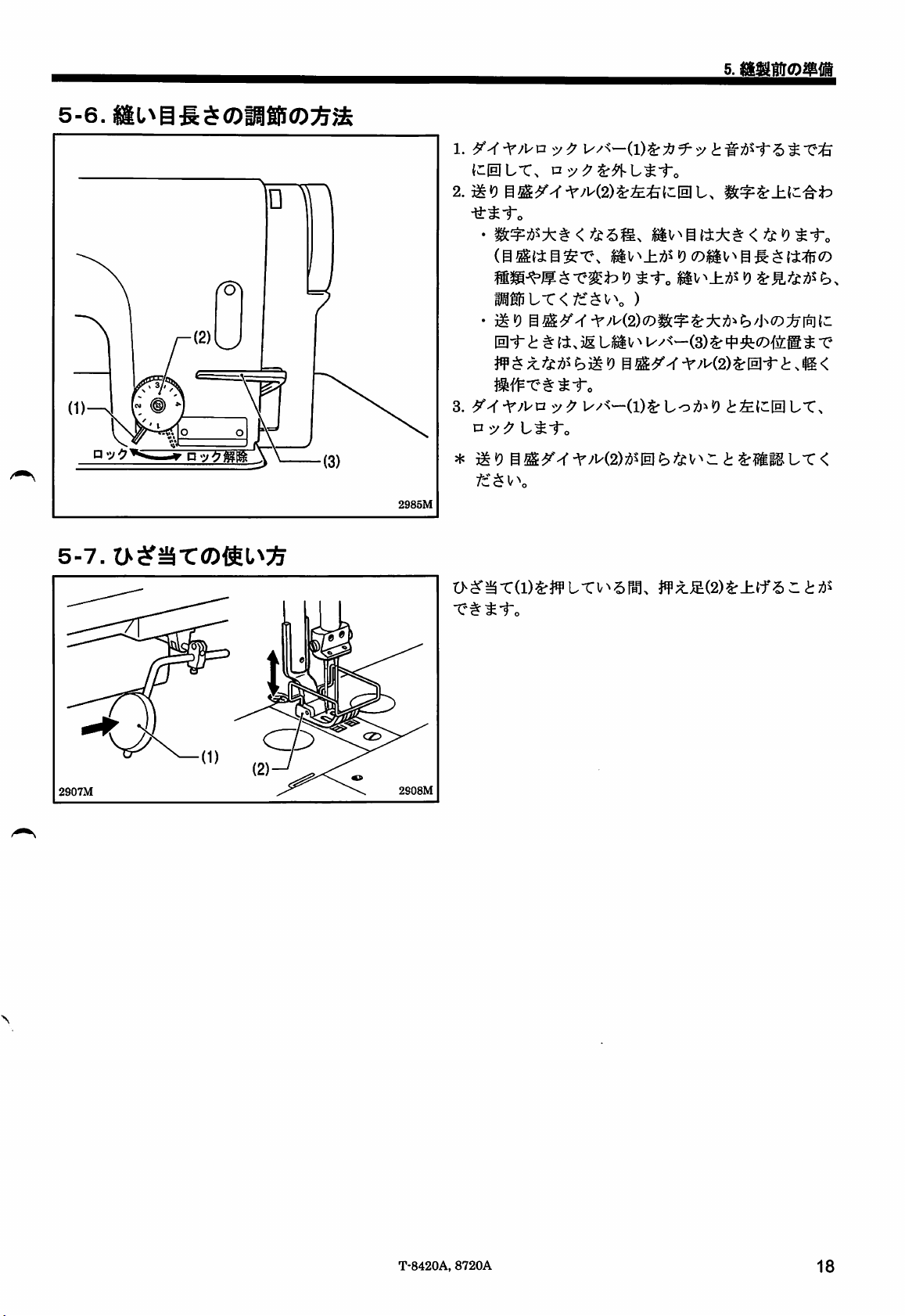

1. Unlockthe stitch length dial (2) by turning the dial lock lever

(1) to

the

right untila click is heard.

2. Turn the stitch length dial(2) clockwise or counterclockwise

so that

the

desired stitch length Isat

on

the

dial.

•

The

largerthe number, the longer

(The numbers on

length of

type

lookingatthe

• When tuming the stitch length dial (2) from a larger

setting to a smallersetting, itwillbe

if

position.

3. Turn

length dial (2).

*

Check

the

and

thickness of material being sewn. Adjust while

the

reverse lever (3) is

the

dial lock lever (1) firmlyto the left to lock

that

the

the

dial

finished stitches may vary depending on

finished

stitch length dial (2)

stitches.)

are

for

pushed

the

uppermost position

the

stitch length

useasa guide.

easiertotum

to the halfwaydown

the

does

not rotate.

will

the

be.

The

the

dial

stitch

5-7.

2907M

Locked

Using

the

Unlocked

knee

lifter

2g85M

2g08M

The

plate

presser

(1).

foot (2)

canberaised by pressing

the

knee

lifter

T-8420A,

8720A

18

Page 64

6.

SEWING

6.

SEWING

Attach

Turnoffthe powerswitchat the

A

The machine may operate ifthe treadle is

A

A

6-1.

Sewing

A

CAUTION

all safety devices before using the sewing machine. Ifthe machine is used

injury

may

result.

a result of

•

When

• When replacing

• When not using

the

motor's inertia. Wait until

threading

the

the

the

needle

bobbin

machine

following

and

and

times. The motor

the

motor

depressed

needle

when leaving

will

keep

stops

fully before starting work.

by mistake, which could result in injury.

the

machine unattended

turning

without

these devices attached,

even after the poweris switchedoffas

Do not touch any of the moving parts or press any objects against the machine while sewing,asthis may result in

personal

Use both

is

used,

injury or

hands

the

weight of

damagetothe

to hold

the

the

machine

machine.

machine

head

head

when tilting it back or returning it to its original position. Ifonly

may

cause

2914M

your hand to slip,

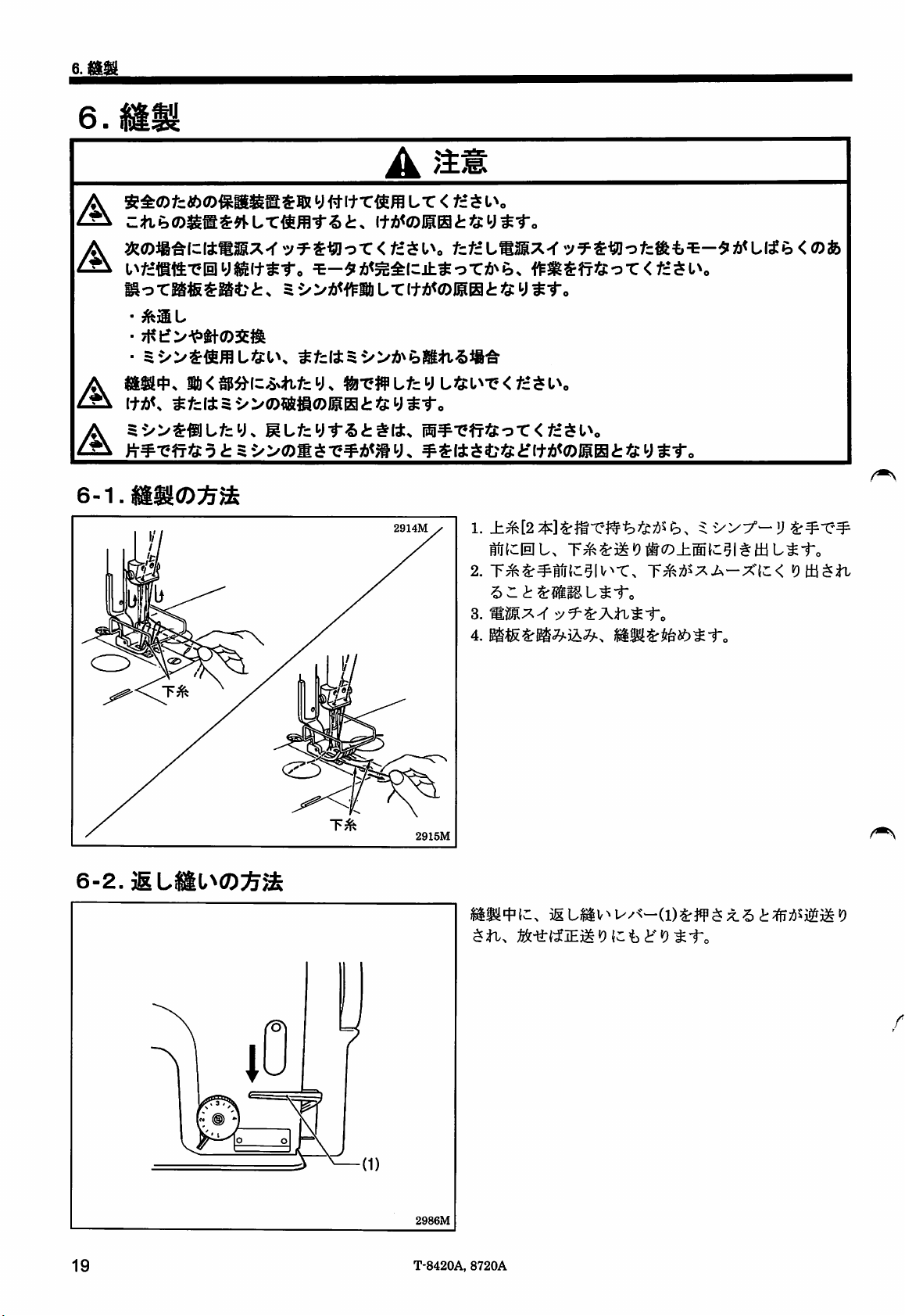

1. While holding

the

threads

2. Pull

out

3. Turn on

4.

Depress

and

machine

come

the

lower

smoothly.

the

the

your hand may

the

two

upper

pulley by

out

onto

the

threads

power

treadletostart

toward you

switch.

get

threads

hand

toward you until

feed

dog.

sewing.

caught.

with

and

check

your

that

one

hand

fingers, turn

the

lower

they pull

6-2.

Backtacking

Lower

thread

Lower

thread

2915M

When

the

reverse lever (1) is

feed

direction willbereversed.

direction

will

returntonormal.

pressed

When

during sewing,

it is

released,

the

the

feed

2986M

19

T-8420A,

8720A

Page 65

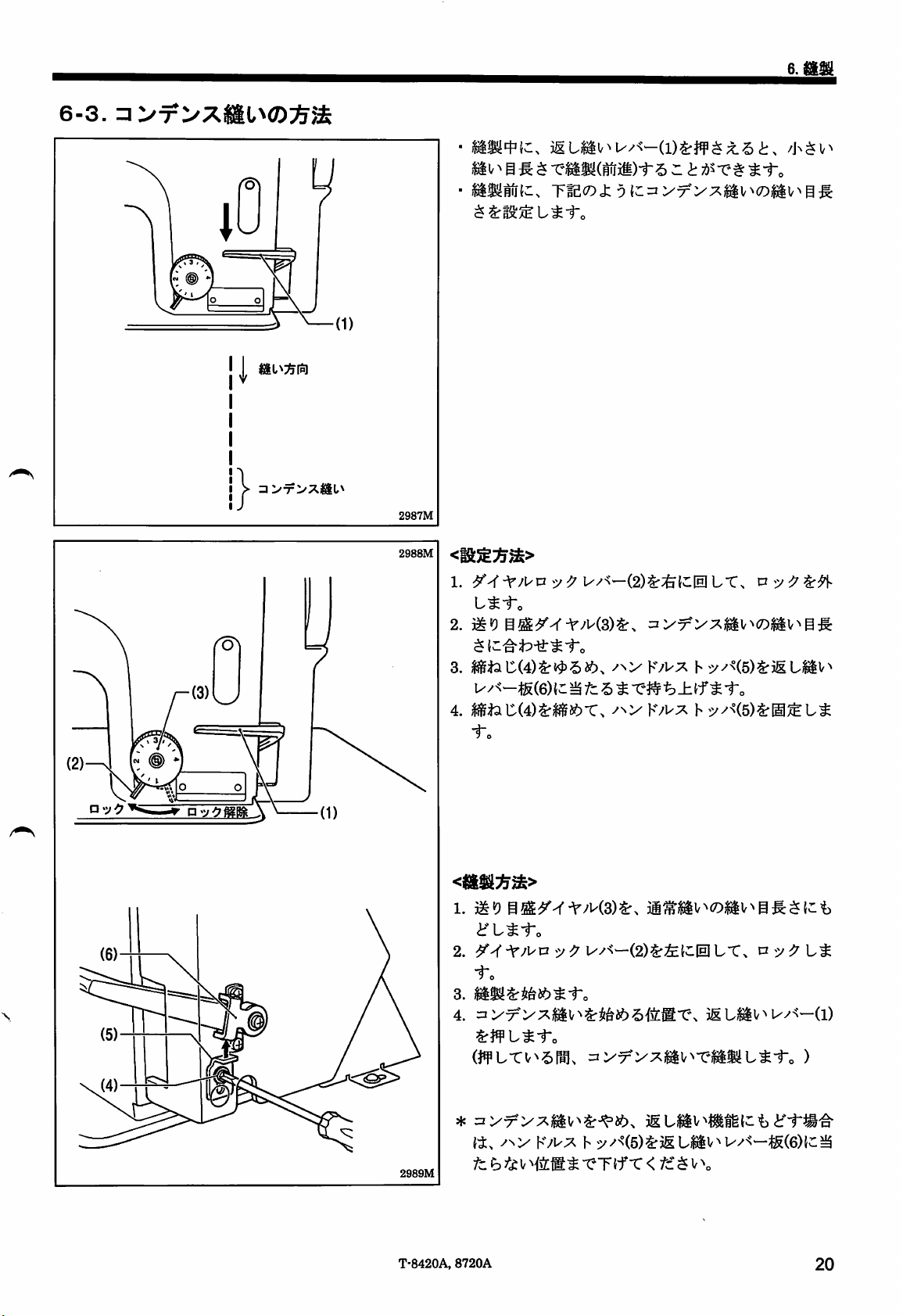

6-3.

Sewing

condensed

I

Sewing

stitches

direction

6.

SEWING

If you press the reverse lever (1) while sewing is In

progress, you

small stitch lengths.

Before carrying out sewing,

condensed

can

sew

stitches (forward direction) with

stitchesasfollows.

set

the stitch length for

Locked

Unlocked

Condensed

I

stitches

2987M

2988M

<Settlng>

1. Unlock

lever (2) to

2. Turn

used

3.

Loosen

touches

4. Tighten

<Sewlng>

1. Return

normal

2. Turn

stitch length dial (3).

3.

Start

4. At

condensed

the

stitch length dial (3) by turning

the

right.

the

stitch length dial (3) to

for

condensed

the

screw

the

reverse

the

screw

the

stitch length dial (3) to

sewing.

the

dial lock

sewing.

the

position

stitches,

(Condensed stitches

is being

To

stop

pressed.)

sewing

backtack function, lower

touch

the

reverse

the

stitches.

(4)

and

lift up

the

stitching

(4) to

lever

where

press

are

condense

stitching lever plate (6).

lever

plate

secure

the

(2) firmly to

you would like to

the

reverse