Brother 1034DX, 3534DT, SB3734T, ST4031HD Operation Manual

Operation Manual

Compact Overlock Machine

Product Code: 884-B02 / B03

Manual de instrucciones

Máquina Compacta Overlock

Código de producto: 884-B02 / B03

English

Español

Be sure to read this document before using the machine.

We recommend that you keep this document nearby for future reference.

Lea este documento antes de utilizar la máquina.

Recomendamos que tenga este documento a mano por si necesita consultarlo más adelante.

IMPORTANT SAFETY INSTRUCTIONS

When using the sewing machine, basic safety precautions should always be followed, including the following.

Read all instructions before using.

18. Young children should be supervised to ensure that

they do not play with this sewing machine.

DANGER

To reduce the risk of electric shock.

The sewing machine should never be left unattended

when plugged in. Always unplug this sewing machine

from the electrical outlet immediately after using and

before cleaning.

WARNING

To reduce the risk of burns, fi re, electric shock,

or injury to persons.

1. Do not allow to be used as a toy. Close attention is

necessary when the sewing machine is used by or

near children.

2. Use this sewing machine only for its intended use

as described in this manual. Use only accessories

recommended by the manufacturer as contained in

this manual.

3. Never operate this sewing machine if it has a

damaged cord or plug, if it is not working properly,

if it has been dropped or damaged, or dropped into

water. Return the sewing machine to the nearest

authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the sewing machine with any air

openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the

accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are

being used or where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol

"O" position which represents off, then remove plug

from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp

the plug, not the cord.

10. Keep fi ngers away from all moving parts. Special

care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong

plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may

defl ect the needle causing it to break.

14. Switch the sewing machine to the symbol "O"

position when making any adjustments in the needle

area, such as threading needle, changing needle, or

changing presser foot, etc.

15. Always unplug the sewing machine from the

electrical outlet when removing covers, lubricating,

or when making any other user servicing

adjustments mentioned in the instruction manual.

16. Electrical Hazards:

- This machine should be connected to an AC

power source within the range indicated on the

rating label. Do not connect it to a DC power

source or inverter. If you are not sure what kind

of power source you have, contact a qualifi ed

electrician.

- This machine is approved for use in the country of

purchase only.

17. This sewing machine is not intended for use

by young children or infi rm persons without

supervision.

19. Do not disassenble the machine.

20. If the LED light unit (light-emitting diode) is

damaged, it must be replaced by authorized dealer.

CAUTION

To use the machine safely

1. (For U.S.A. only)

This appliance has a polarized plug (one blade wider

than the other) to reduce the risk of electric shock,

this plug is intended to fi t in a polarized outlet only

one way.

If the plug does not fi t fully in the outlet, reverse

the plug. If it still does not fi t, contact a qualifi ed

electrician to install the proper outlet.

Do not modify the plug in any way.

2. Make sure you watch the needles carefully while you

are sewing. Do not touch the hand wheel, needles,

knives, or other moving parts.

3. Turn off the main power and unplug the cord in the

following circumstances:

- When you have stopped using the machine

- When you are replacing or removing the needle or

any other part

- If there is a power failure while you are using the

machine

- If you are checking or cleaning the machine

- Leaving the machine unattended

4. Do not store anything on the foot controller.

5. Fully plug the machine directly into the wall. Do not

use extension cords.

6. If water is dropped on the machine, unplug the

machine immediately, and contact your local

authorized dealer.

7. Do not put furniture on the cord.

8. Do not bend the cord, or pull on the cord to unplug.

9. Do not touch the cord with wet hands.

10. Place the machine near to the wall outlet.

11. Do not place the machine on an unstable surface.

12. Do not put on the soft cover.

13. If you notice any abnormal sound or condition,

consult your local authorized dealer.

To give your machine a longer life

1. Do not store this machine in direct sunlight or in

high humidity conditions. Do not use or store the

machine near a heater, iron, halogen lamp or other

hot object.

2. Use only mild soaps or detergents to clean the

case. Benzene, thinner, and scouring powders can

damage the case and machine, and should never

be used.

3. Do not drop or hit the machine.

4. Always consult this manual before you replace or fi t

the presser foot, needle, or any other parts to make

sure you fi t them correctly.

To repair or adjust the machine

If the machine breaks down or needs adjustment,

fi rst follow the troubleshooting table to inspect and

adjust the machine yourself. If the problem persists,

consult your local authorized dealer.

SAVE THESE INSTRUCTIONS

This machine is intended for household use.

FOR USERS IN COUNTRIES EXCEPT EUROPEAN COUNTRIES

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

FOR USERS IN EUROPEAN COUNTRIES

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

CAUTION

When leaving this sewing machine unattended, the main power and light switch of the machine must be

switched off or the plug must be removed from the socket-outlet.

When servicing the sewing machine, or when removing covers, the machine or the electrical set must be

disconnected from the supply by removing the plug from the socket-outlet.

English

FOR USERS IN THE UK, EIRE,

MALTA AND CYPRUS ONLY

IMPORTANT

- In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the mark,

rating as marked on plug.

- Always replace the fuse cover. Never use plugs with the fuse cover omitted.

- If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact your

authorized dealer to obtain the correct lead.

1

CONGRATULATIONS ON CHOOSING THIS COMPACT

AVERTISSEMENT:

PARTIES EN MOUVEMENT. POUR

ÉVITER TOUTE BLESSURE:

FERMER LE CAPOT AVANT DE

COUDRE.

DÉBRANCHER AVANT ENTRETIEN.

OVERLOCK MACHINE

Your machine is a high quality, easy-to-use product. To fully enjoy all the features, we suggest that you study

this booklet.

If you need more information regarding the use of your machine, your nearest authorized dealer is always

happy to be of service.

Enjoy yourself!

CAUTION

When threading or replacing needle, the main power and light switch of the machine must be switched off or

the plug must be removed from the socket-outlet.

When the machine is not in use, it is recommended that the electric supply plug is disconnected from the wall

socket to avoid any possible hazards.

Notes on the motor

- The maximum operating speed of this sewing machine is 1,300 stitches per minute, which is quite fast compared

to the normal operating speed of 300 to 800 stitches per minute for the ordinary sewing machine.

- The bearings in the motor are made of a special sintered, oil-impregnated alloy mounted in oilsoaked felt to

withstand long hours of continuous operation.

- Continuous operation of the sewing machine can cause heat to build in the motor area, but not enough to

adversely affect its performance.

It is important to keep fabric and paper away from the air openings on the back and sides of the machine so air

can get to these openings.

- When the motor is running, sparks can be seen through the air openings in the motor bracket on the side opposite

the hand wheel. These sparks are produced by the carbon brushes and the commutator, and are part of the

machines normal operation.

WARNING LABELS

The following warning labels are on the machine.

Be sure to observe the precautions described in the labels.

Caution (U.S.A. and CANADA only)

1

2

Face plate sticker (U.S.A. and CANADA only)

3

2

(for complying with UL and CSA requirements)

Label locations

[Product code: 884-B02] [Product code: 884-B03]

Contents

Chapter 1: Names of parts and their functions ................................................................... 4

Accessories ........................................................................................................................5

Powering the machine ........................................................................................................6

Turning direction of hand wheel .........................................................................................6

Opening/ Closing front cover ..............................................................................................6

Attaching/ Removing presser foot ......................................................................................6

Trim trap .............................................................................................................................7

Free-arm sewing (removing bed extension) .......................................................................7

Retracting knife ..................................................................................................................8

Stitch length........................................................................................................................8

Stitch width .........................................................................................................................8

Differential feed ..................................................................................................................9

Adjusting the presser foot pressure ....................................................................................9

Tension adjustment dial ......................................................................................................10

Chart of thread tension adjustment, Two needle (Four thread) ..........................................11

Chart of thread tension adjustment, One needle (Three thread) .......................................12

Needle ................................................................................................................................13

Removing/ Installing the needle .........................................................................................13

Chapter 2 : Preparation before threading ............................................................................. 14

Thread tree .........................................................................................................................14

How to use the thread spool cap ........................................................................................14

How to use the thread net ..................................................................................................14

Before threading .................................................................................................................14

Chapter 3: Threading .............................................................................................................. 15

Threading the lower looper .................................................................................................15

Threading the upper looper ................................................................................................17

Threading the right needle .................................................................................................18

Threading the left needle....................................................................................................18

Chapter 4: Sewing materials, threads and needles comparison chart .............................. 19

Chapter 5: Sewing .................................................................................................................. 20

Stitch selection ...................................................................................................................20

Test sewing .........................................................................................................................20

Chaining-off ........................................................................................................................21

To start sewing ...................................................................................................................21

To remove work ..................................................................................................................21

To secure chain ..................................................................................................................22

If threads break during sewing ...........................................................................................23

To sew fi ne materials ..........................................................................................................23

Narrow overlock/ Rolled hemming stitch ............................................................................23

Chart of narrow overlock/ rolled hemming stitch ................................................................25

Chapter 6: Troubleshooting ................................................................................................... 26

Chapter 7: Maintenance .........................................................................................................27

Cleaning .............................................................................................................................27

Oiling .................................................................................................................................27

Chapter 8: Introduction of optional feet ............................................................................... 28

Blind stitch foot ...................................................................................................................28

Taping foot ..........................................................................................................................30

Pearl sequence foot ............................................................................................................31

Piping foot ..........................................................................................................................32

Gatheing foot ......................................................................................................................33

Specifi cations ......................................................................................................................... 34

Setting record ........................................................................................................................ 71

English

3

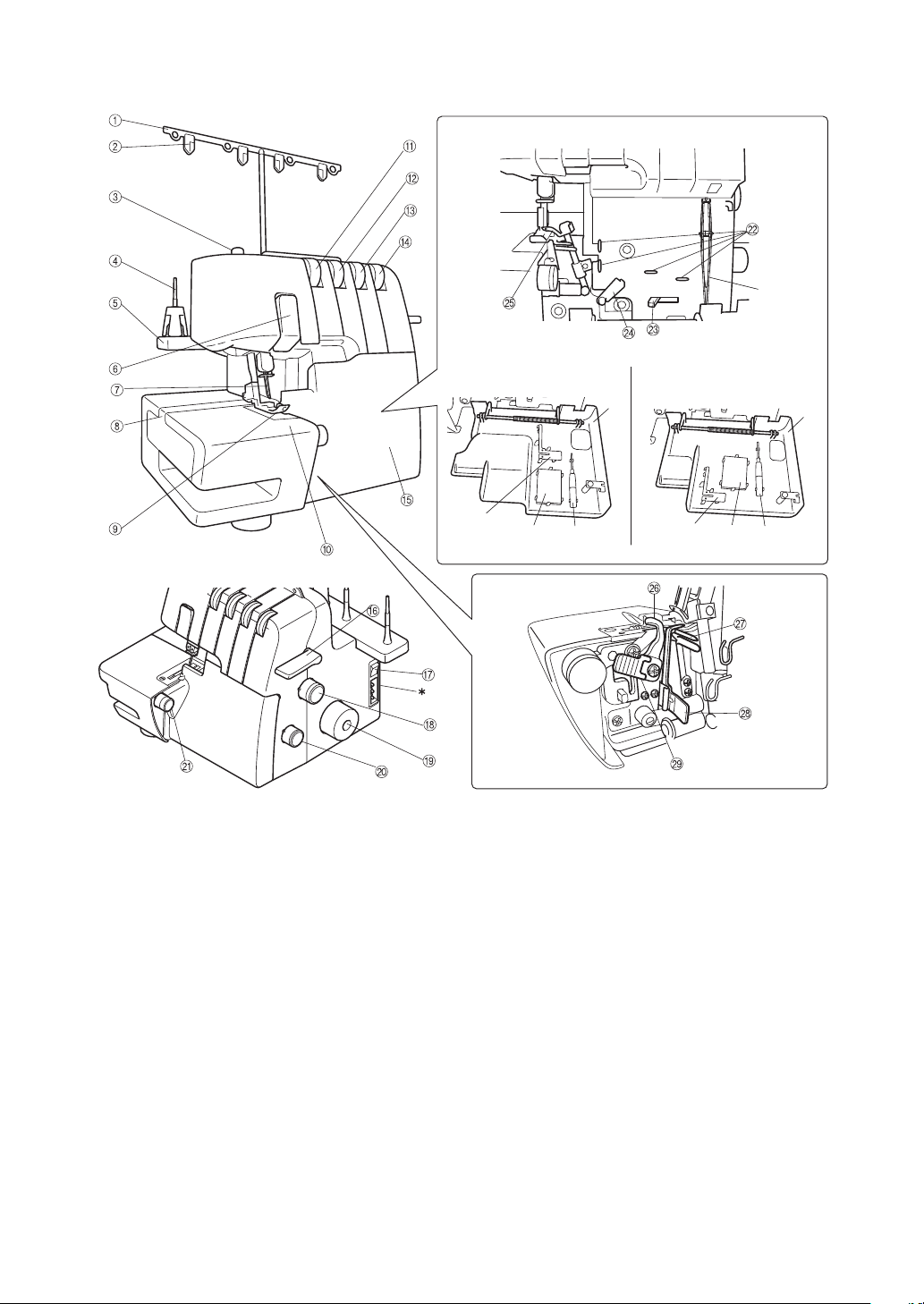

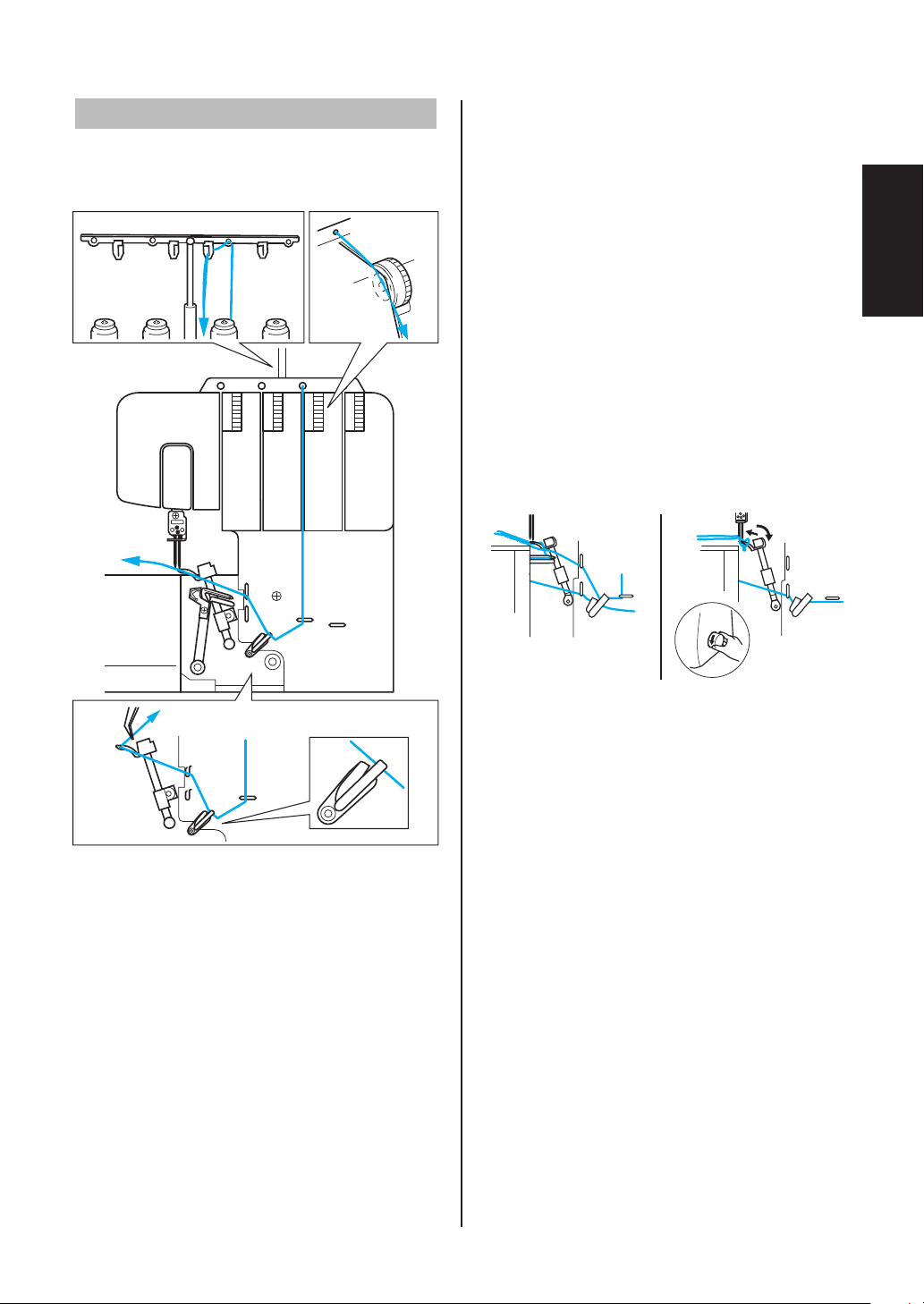

CHAPTER 1

NAMES OF PARTS AND THEIR FUNCTIONS

Inside of the front cover

[Product code: 884-B02] [Product code: 884-B03]

t

<C>

t

Thread tree

1

Thread plate

2

Presser foot pressure adjustment screw

3

Spool pin

4

Spool support

5

Thread take-up cover

6

Needles

7

Bed extension

8

Presser foot

9

Material plate cover

0

Left needle thread tension dial

A

Right needle thread tension dial

B

Upper looper thread tension dial

C

Lower looper thread tension dial

D

Front cover

E

Presser foot lifting lever

F

Main power and light switch

G

Stitch length adjustment dial

H

4

<B>

<A>

<D>

* The product code is shown on the machine rating plate.

Hand wheel

I

Differential feed ratio adjustment dial

J

Stitch width dial

K

Inside of the front cover

Thread guide

L

Lower looper threading lever

M

Thread take up for loopers

N

Upper looper

O

Upper knife

P

Lower looper

Q

Stitch fi nger

R

Knife lever

S

Front cover compartment

t

You can hold the included accessories and the

removed stitch fi nger in this front cover compartment.

<A>: Needle set, <B>: Stitch fi nger (when removed,

see CHAPTER 5 "Narrow overlock/ Rolled hemming

stitch"), <C>: Tweezers, <D>: Hexagonal driver

* Air openings (on the side and back)

<B>

<A>

<D>

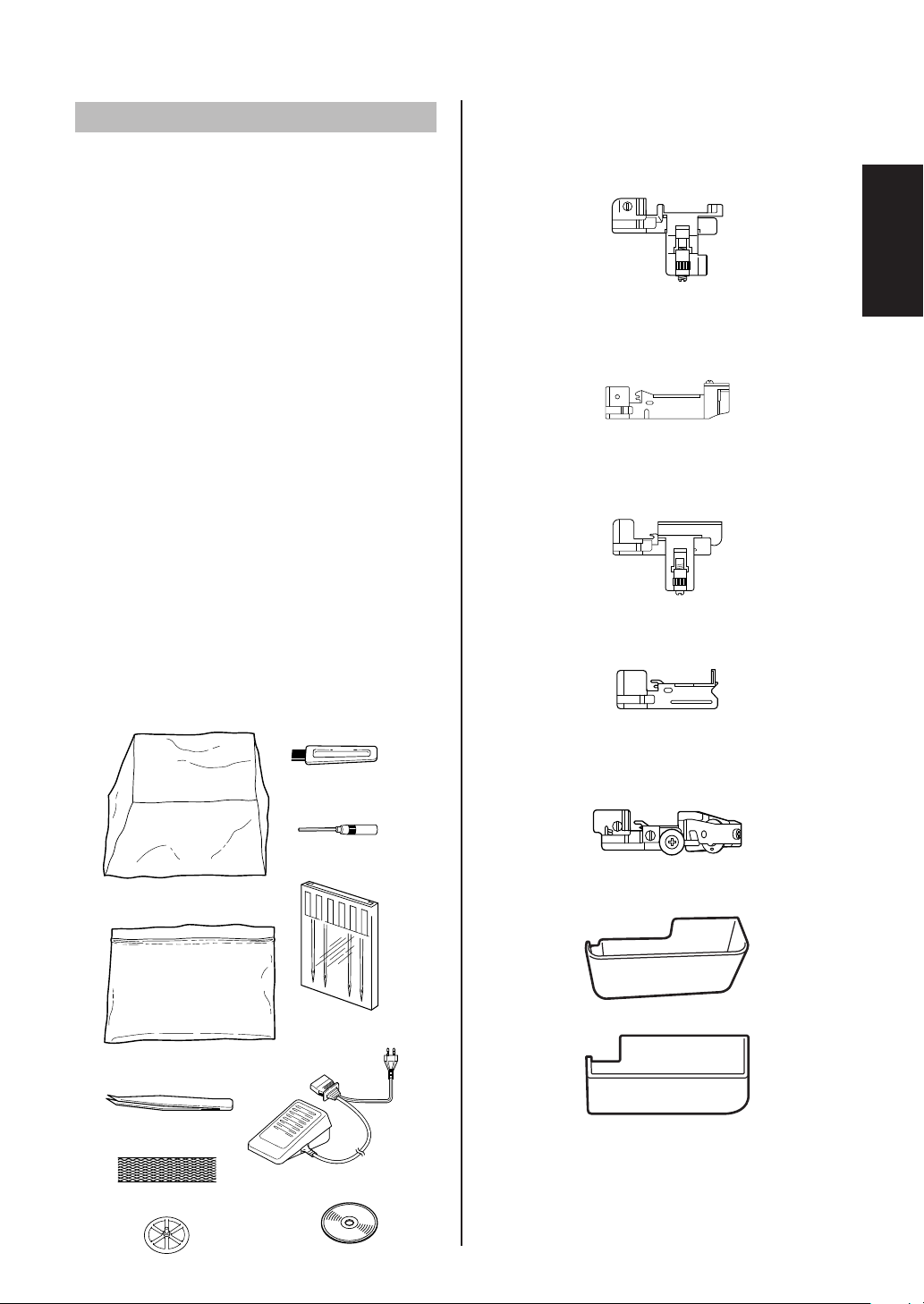

Accessories

LG

LS

LP

1

2

4

5

7

3

8

0

9

6

Included accessory

Soft cover: X77871000

1

Accessory bag: 122991052

2

Tweezers: XB1618001

3

Thread net (4): X75904000

4

Thread spool cap (4): X77260000

5

Cleaning brush: X75906001

6

Hexagonal driver: XB0393001

7

Needle set (130/705H): XB2772001

8

#80: 2 pcs., #90: 2 pcs.

Foot controller:

9

XC7359021 (120V Area)

XC7438421 (230V Area)

XC7456521 (U.K.)

XD0112121 (Argentina)

XD0852121 (Korea)

XD0105021 (China)

XE0629001 (Australia, New Zealand)

XF2826001 (Brazil 127V)

XE4302201 (Brazil 220V)

Instruction DVD: XB2791001 (NTSC)

0

XB2776001 (PAL)

Optional accessory

For further information about the following items,

see CHAPTER 8.

Blind stitch foot: X76590002

A

Gathering foot:

B

SA213 (U.S.A., CANADA)

X77459001 (OTHERS)

Pearl sequence foot:

C

SA211 (U.S.A., CANADA)

X76670002 (OTHERS)

Piping foot:

D

SA210 (U.S.A., CANADA)

XB0241101 (OTHERS)

English

Taping (Elastic) foot:

E

SA212 (U.S.A., CANADA)

X76663001 (OTHERS)

Trim trap: XB1530002 for product code 884-B02

F

Trim trap: XB2793001 for product code 884-B03

* The product code is shown on the machine rating

plate.

5

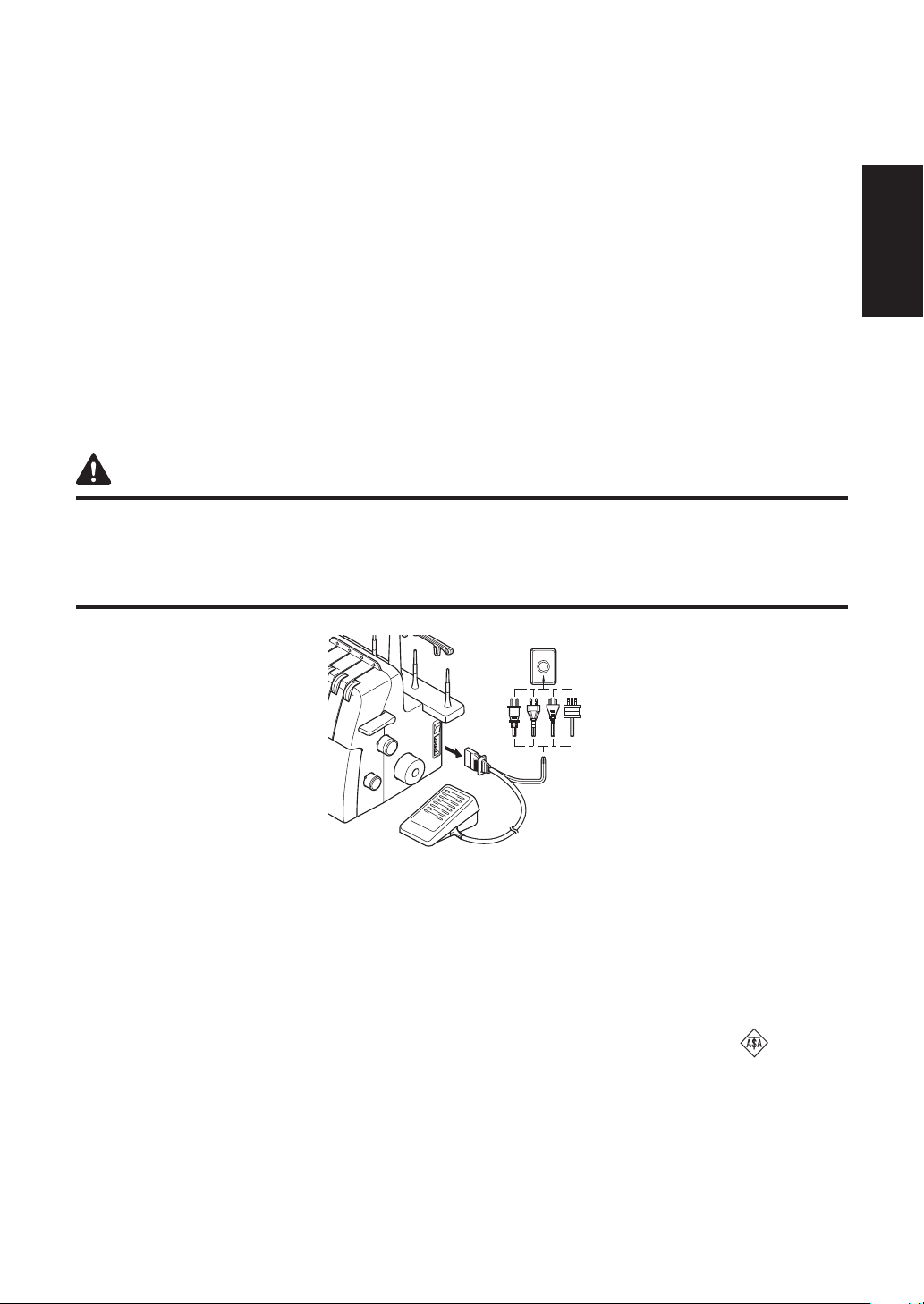

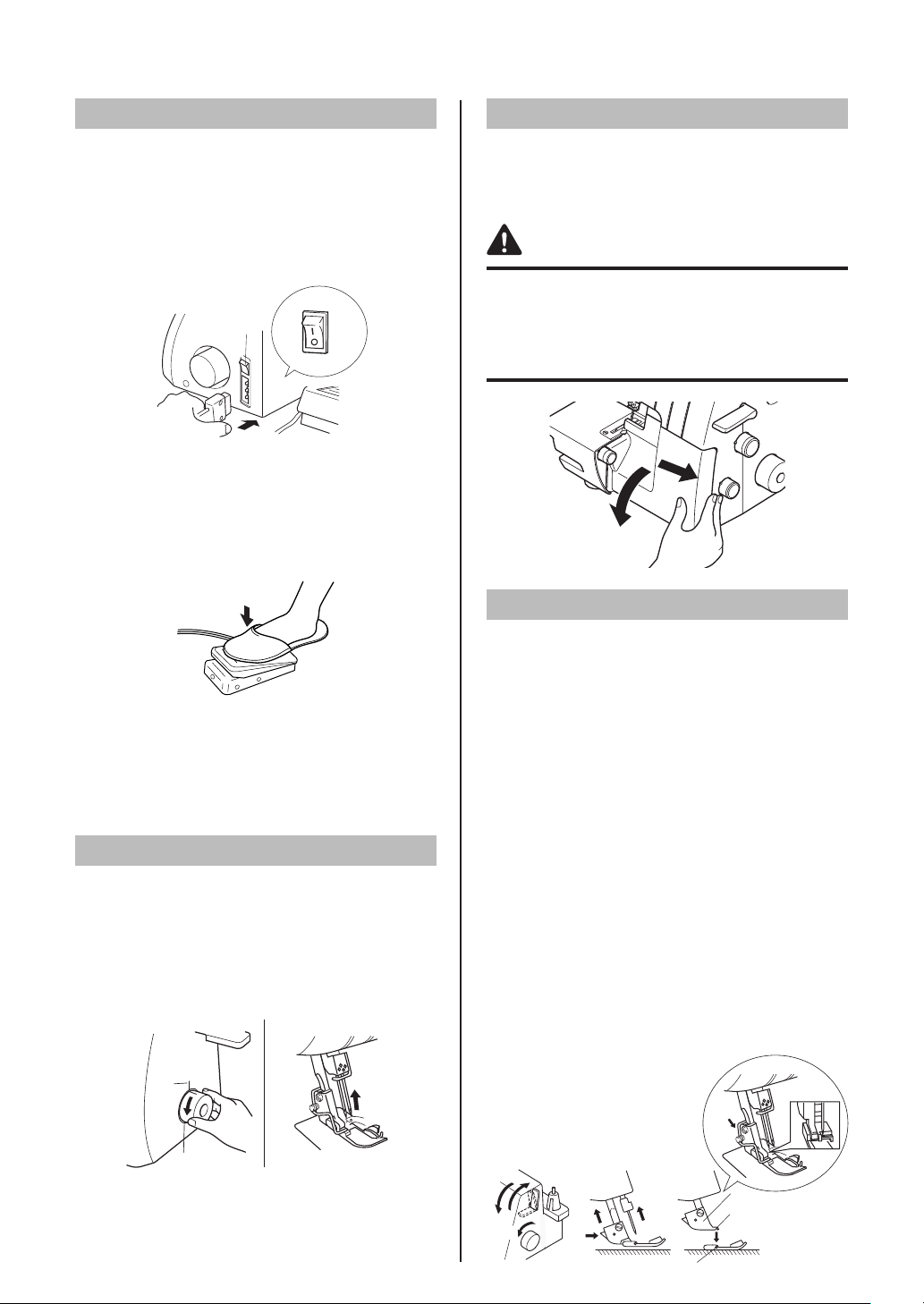

Powering the machine

Turning on the machine

1. Insert the three-pin plug into the socket on the

bottom right side of the machine. Insert the

power supply plug into a power outlet.

2. Turn the main power and light switch <A> to "I"

mark (to "O" mark to turn off).

<A>

Opening/ Closing front cover

It is necessary to open the front cover when

threading this machine. Slide it to the right 1 and

open 2, or close it and slide it to the left.

CAUTION

For your safety, make sure that the front cover is

closed when operating the machine.

Always turn off the machine before opening the

front cover.

Operation

When the foot controller is pressed lightly, the

machine runs at a low speed. As the foot controller

is pressed further, the machine will increase

speed. When the foot controller is released, the

machine stops.

NOTE (For U.S.A. only):

Foot controller: Model KD-1902

This foot controller can be used on the machine

with product code 884-B02 and 884-B03.

* The product code is shown on the machine rating

plate.

Turning direction of hand wheel

The hand wheel <A> turns in a counterclockwise

direction (direction of arrow). This is the same

direction as an ordinary home sewing machine.

The needles move to their highest positions by

turning the hand wheel so that the mark <B>

on the hand wheel is aligned to the line on the

machine.

1

2

Attaching/ Removing presser foot

1. Turn off the main power and light switch or

disconnect the electric supply plug.

2. Raise the presser foot lever.

3. Turn the hand wheel 2 so that the mark on

the hand wheel is aligned to the line on the

machine. (See CHAPTER1 "Turning direction

of hand wheel".)

4.

Push the button on the presser foot holder and

the standard presser foot will be released.

5. Raise the presser foot farther by pushing the

presser foot lever upward. Then remove the

presser foot and store it in a safe location.

6. Again, raise the presser foot farther by pushing

the presser foot lever upward. Then place the

presser foot just under the presser foot holder

<A> so that the groove in the bottom of the

presser foot holder <B> is aligned and catches

the bar on the top of the foot <C>. Then lower

the presser foot lever to attatch the foot,

pushing the button on the presser foot.

1

3 4

<B>

<A>

6

4

1

2

1

3

2

<A>

<B>

4

<C>

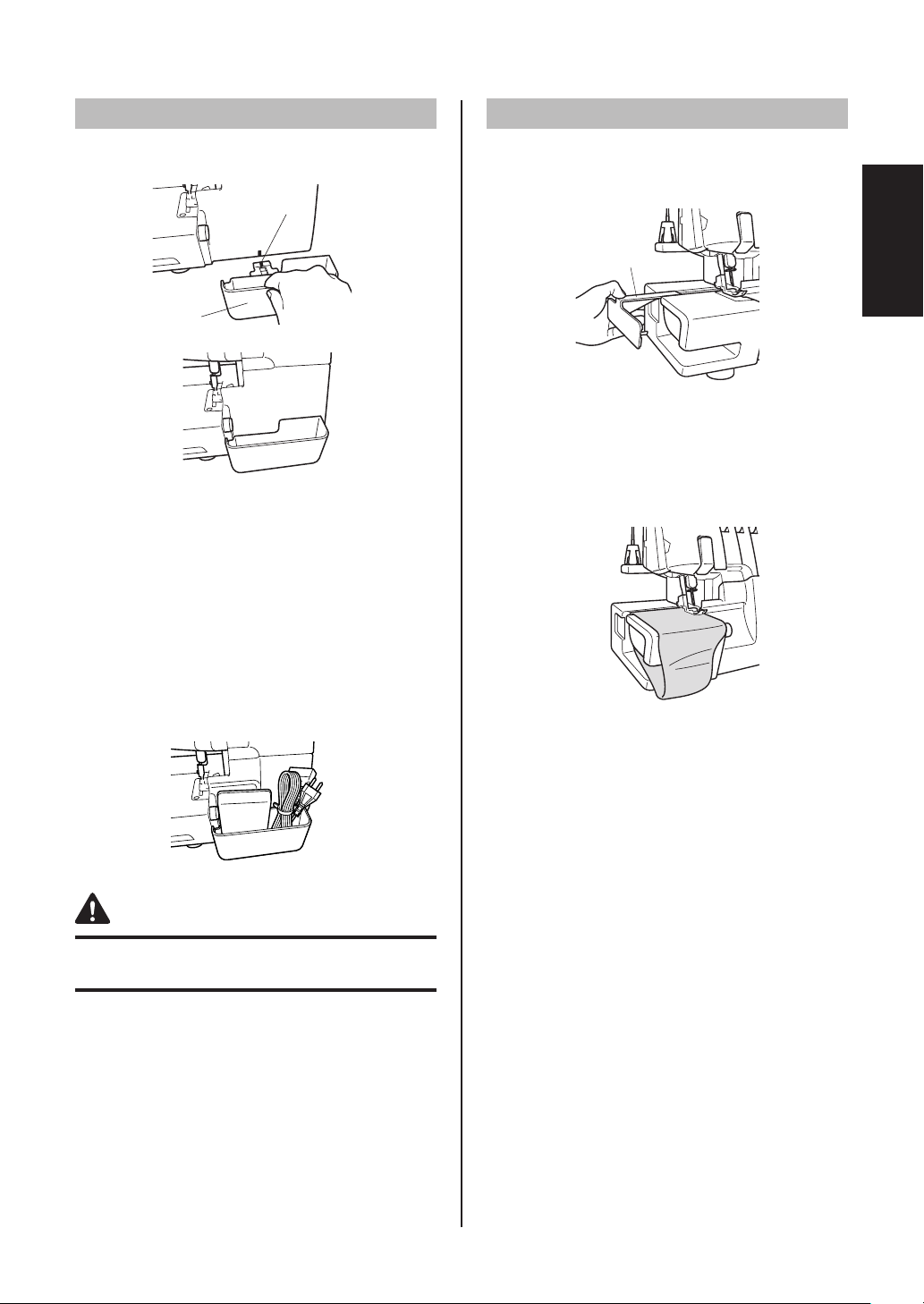

Trim trap

The optional trim trap <A> holds the trimmed fabric

and thread produced when sewing.

<B>

Free-arm sewing (removing bed extension)

Free-arm sewing enables tubular pieces to be

sewn more easily.

1. Remove the bed extension <A>.

<A>

To install:

Insert the trim trap <A> until it contacts the front

cover.

NOTE:

Be sure to position the positioning guide <B> to

the one on the machine.

To remove:

Slowly pull out the trim trap.

NOTE:

The optional trim trap can also be used as the foot

controller holder.

<A>

NOTE:

Be careful not to lose the removed bed

extension.

2. Position the fabric, and start sewing. (See

CHAPTER 5.)

English

CAUTION

Always remove the foot controller from the trim

trap when carrying the machine.

7

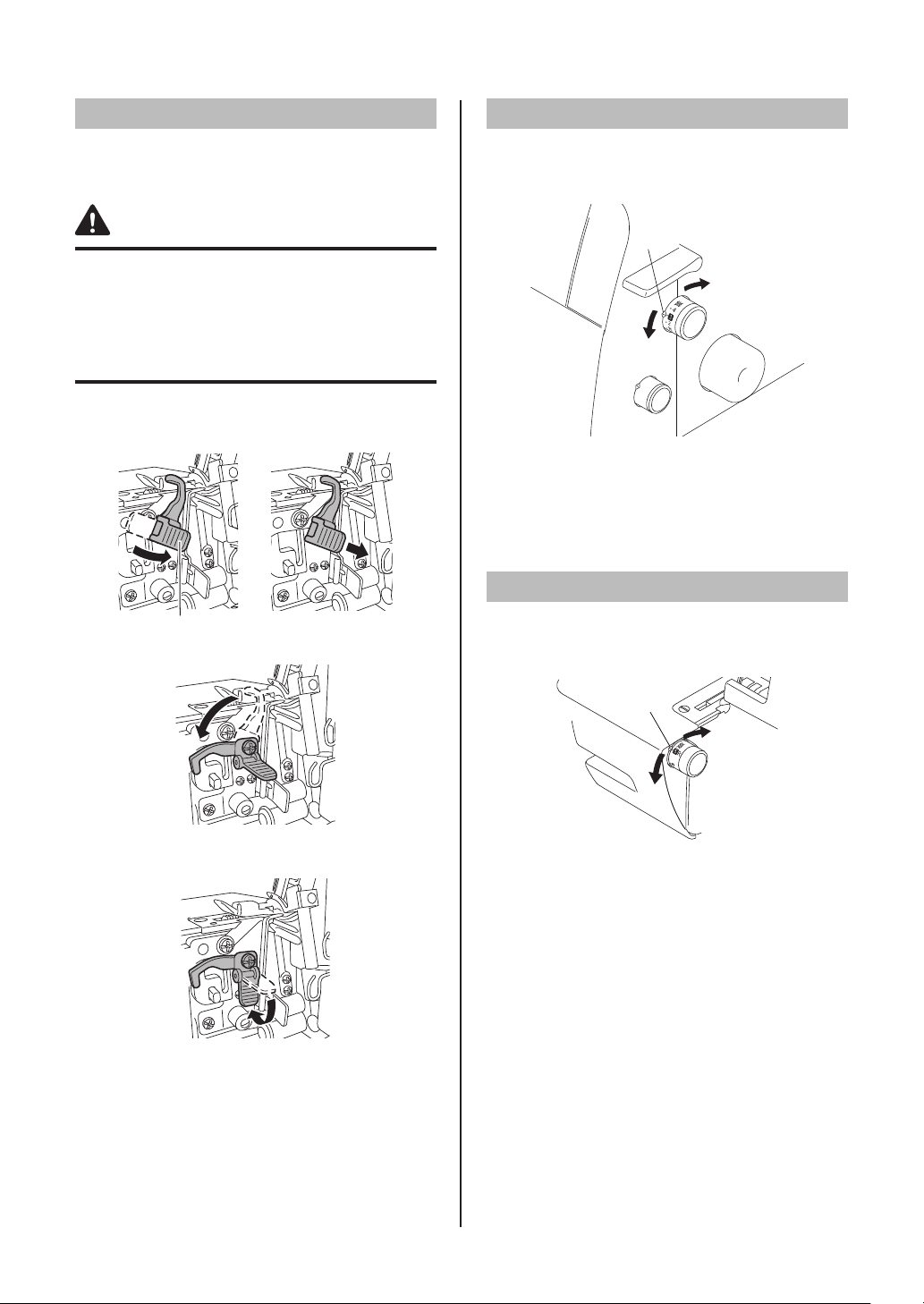

Retracting knife

1

2

<A>

1

2

<A>

To sew without cutting the fabric edge, you need to

retract the knife as follows.

CAUTION

Do not touch the knife.

Move the knife lever only while the needle is at its

lowest point.

Be sure to unplug the power supply cord from the

wall outlet before retracting the knife.

1. Pull up the knife lever <A>, then pull it to the

right.

<A>

2. Bring down the knife.

Stitch length

The normal stitch length setting is 3 mm. To

change the stitch length, turn the stitch length

adjustment dial on the right side of the body.

Shorten the stitch length to a minimum of 2 mm

1

(5/64 inch).

Lengthen the stitch to a maximum of 4 mm (5/32

2

inch).

<A> Selection mark

Stitch width

The normal stitch width setting for regular overlock

stitch is 5mm (13/64 inch). To change the stitch

width, turn the stitch width adjustment dial.

3. Retract the knife completely, then take your

hand off from the lever.

8

Increase the width to a maximum of 7 mm (9/32

1

inch).

Reduce the stitch width to a minimum of 5 mm

2

(3/16 inch).

<A> Selection mark

Differential feed

1

2

<A>

1

2

<A>

This serger is equipped with two sets of feed dogs

under the presser foot to move the fabric through

the machine. The differential feed controls the

movement of both the front and the rear feed dogs.

When set at 1, the feed dogs are moving at the

same speed (ratio of 1). When the differential feed

ratio is set at less than 1, the front feed dogs move

slower than the rear feed dogs, stretching the

fabric as it is sewn. This is effective on lightweight

fabric that may pucker. When the differential feed

ratio is set at greater than 1, the front feed dogs

move faster than the rear feed dogs, gathering

the fabric as it is sewn. This function assists in

removing the rippling when serging stretch fabrics.

Differential feed adjustment

Feed

ratio

0.7 - 1.0

1.0 - 2.0

The normal setting is 1.0 on the differential feed

adjustment dial.

To adjust the diffrerential feed, turn the dial on the

right bottom of the body.

1.0

Main

feed

(rear)

Differential

feed (front)

Effect

Material is

pulled tight.

Without

differential

feed.

Material is

gathered

or pushed

together.

Application

Prevents thin

materials

from

puckering

Normal

sewing

Prevents

stretch

materials

from

stretching or

puckering

An example

When stretch material is sewn without using the

differential feed, the edge will be wavy.

English

To get smooth fi nish, adjust the feed ratio from 1.0

toward 2.0.

(The feed ratio required depends on the elasticity

of the material.)

The more elastic the material, the further toward

2.0 the differential feed ratio should be set. Test

sew with a scrap of the fabric to fi nd the correct

adjustment.

CAUTION

When sewing thick non-stretchable material such

as denim, do not use the differential feed as it may

damage the fabric.

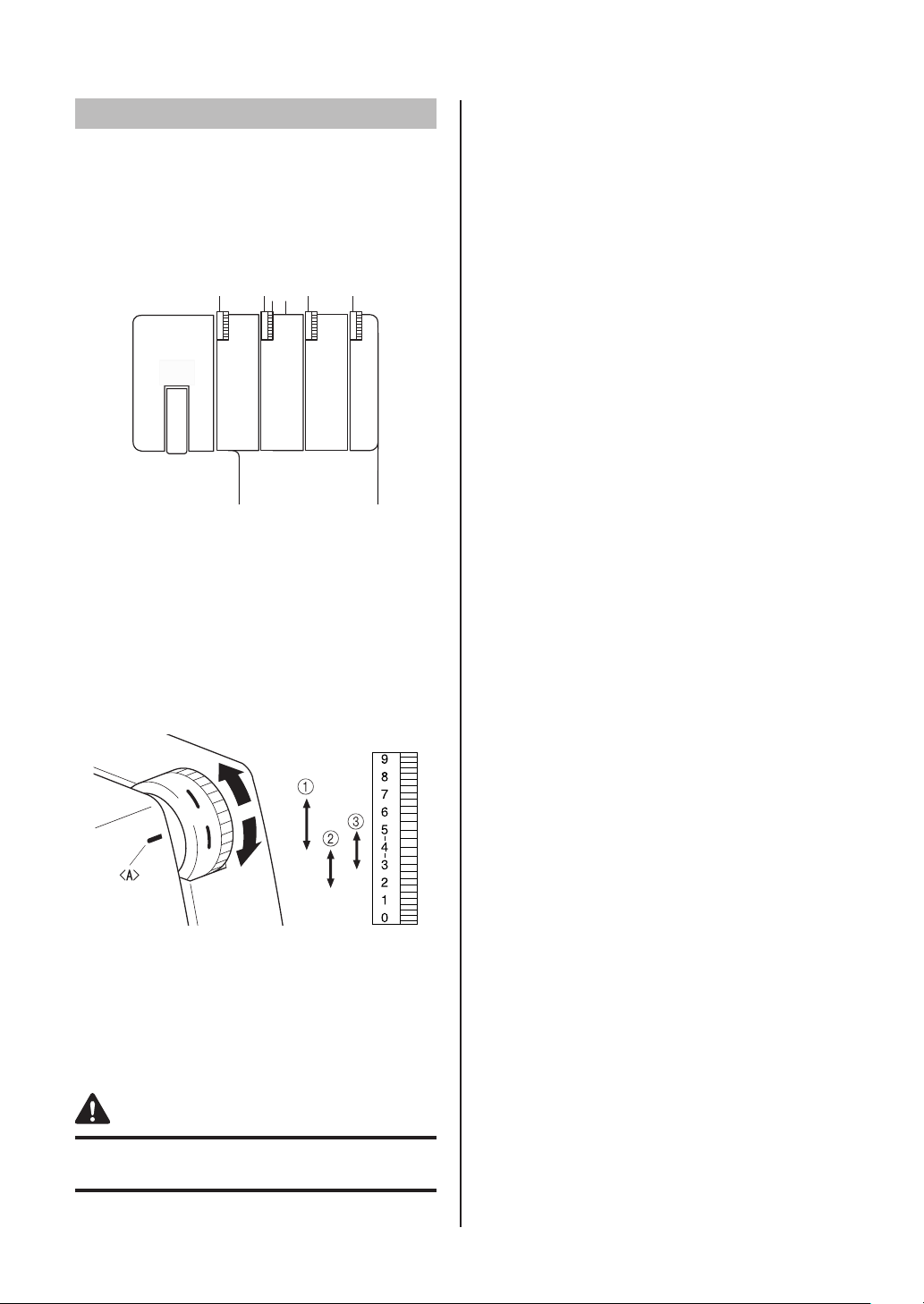

Adjusting the presser foot pressure

Turn the pressure adjustment screw on the top

left of the machine. You can adjust by referring the

value on the screw.

The normal setting is "2".

Less than 1.0 2 Greater than 1.0 <A> Selection mark

1

Less pressure

1

More pressure

2

<A> Selection mark

9

Tension adjustment dial

1234

!

There is a thread tension dial for each needle

thread, the lower looper thread and the upper

looper thread. The correct thread tension may

vary according to the type and thickness of the

fabric and the type of thread used. Thread tension

adjustments may be necessary for any change in

sewing materials.

Yellow marked tension disc is for left needle.

1

Pink marked tension disc is for right needle.

2

Green marked tension disc is for upper looper.

3

Blue marked tension disc is for lower looper.

4

Tension control

Sewing is possible at position "4" for most

circumstances. (Standard: SPAN 60/3Z)

If the stitch quality is insuffi cient, select a different

tension setting.

5

4

3

For heavy tension: 4 to 7

1

For light tension: 4 to 2

2

For medium tension: 5 to 3

3

If you cannot fi nd the correct tension, refer to the

charts on following pages.

<A> Tension selection mark

CAUTION

Make sure that the thread is properly seated in the

tension discs.

10

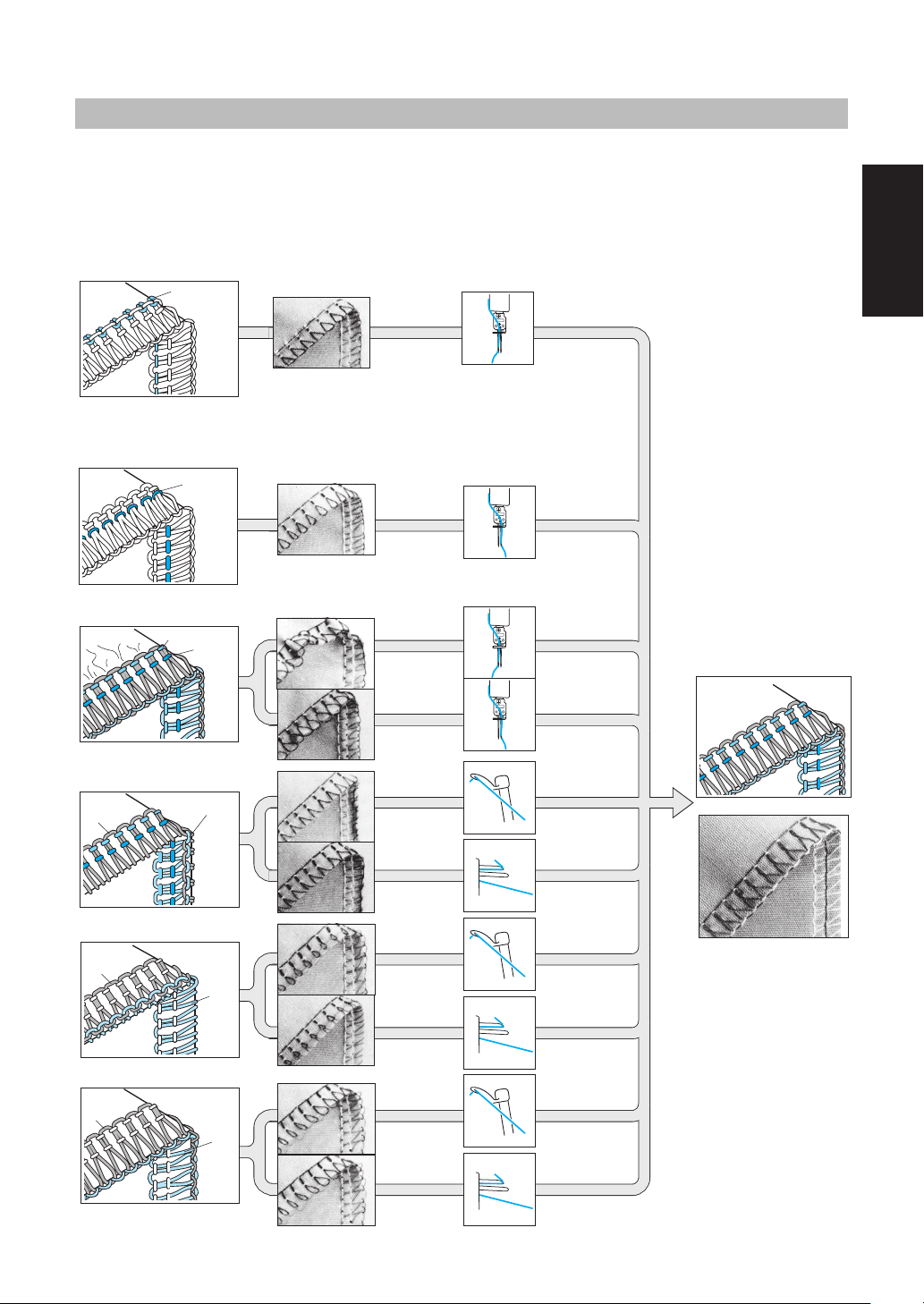

Chart of thread tension adjustment, Two needle (Four thread)

A: Reverse

B: Surface

C: Left needle thread

D: Right needle thread

E: Upper looper thread

F: Lower looper thread

A

C

English

Left needle

thread is

B

A

B

A

B

A

F

D

C

D

E

loose.

Right needle

thread is

loose.

Left needle

thread is tight.

Right needle

thread is tight.

Upper looper

thread is tight.

Tighten left

needle thread.

(yellow)

Tighten right

needle thread.

(pink)

Loosen left

needle thread.

(yellow)

Loosen right

needle thread

(pink)

Loosen upper

looper thread

(green)

B

A

F

E

Lower looper

thread is

loose.

Upper looper

thread is

loose.

Tighten lower

looper thread

(blue)

Tighten upper

looper thread

(green)

When you adjust the

thread tension, do it in

the following order:

B

A

F

E

B

Lower looper

thread is tight.

Upper looper

thread is

loose.

Lower looper

thread is

loose.

Loosen lower

looper thread

(blue)

Tighten upper

looper thread

(green)

Tighten lower

looper thread

(blue)

(1) Left needle thread

(2) Right needle thread

(3) Upper looper thread

(4) Lower looper thread

This is the easiest way

to obtain the correct

thread tension.

11

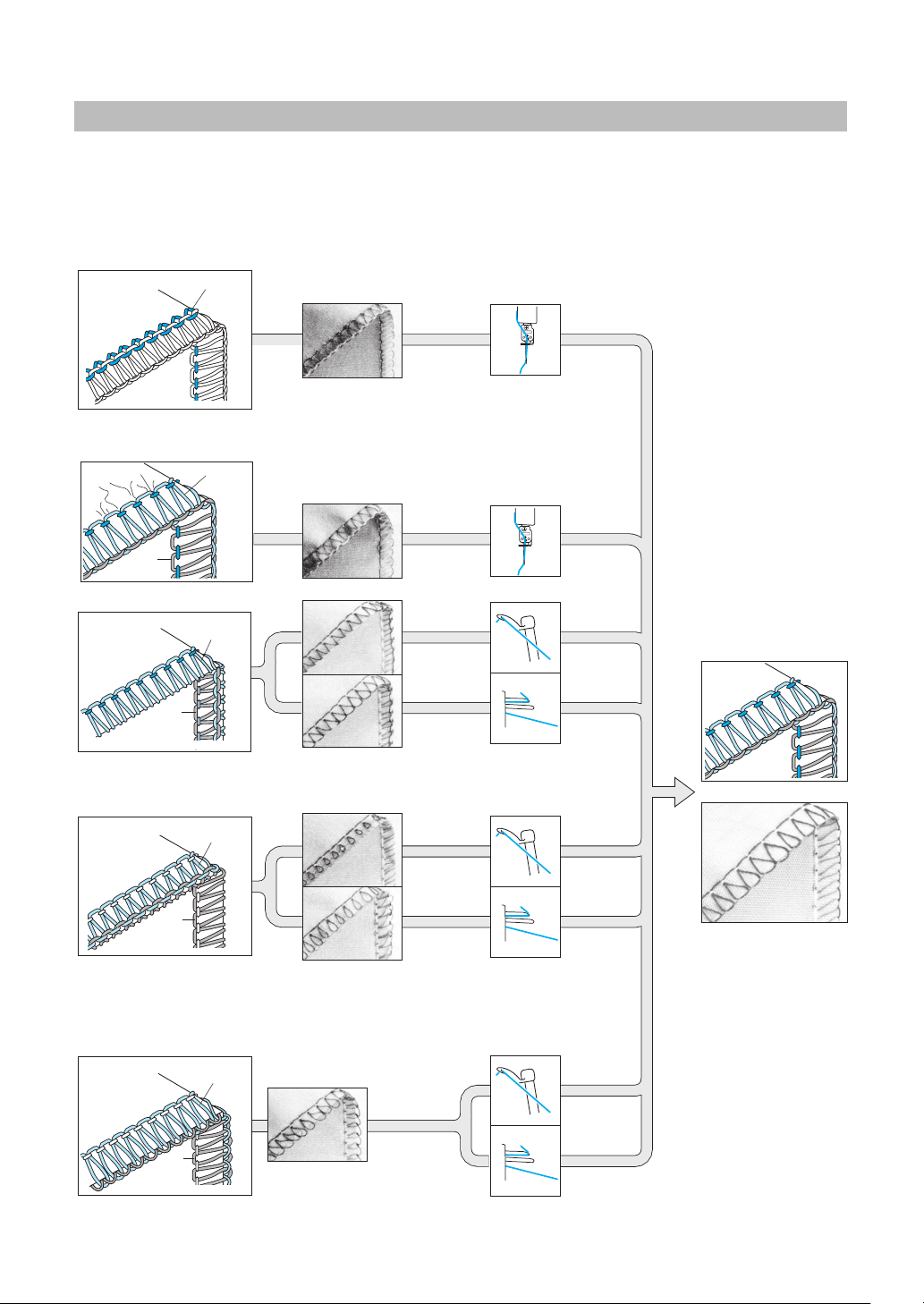

Chart of thread tension adjustment, One needle (Three thread)

A: Reverse

B: Surface

C: Needle thread

D: Upper looper thread

E: Lower looper thread

C

A

Needle thread

B

C

A

D

A

B

A

B

E

B

E

D

E

D

is loose.

Needle thread

is tight.

Upper looper

thread is tight.

Lower looper

thread is

loose.

Upper looper

thread is

loose.

Lower looper

thread is tight.

Tighten

needle

thread.

(yellow or

pink)

Loosen

needle thread.

(yellow or

pink)

Loosen

upper looper

thread

(green)

Tighten

lower looper

thread (blue)

Tighten

upper looper

thread

(green)

Loosen

lower looper

thread (blue)

When you adjust the

thread tension, do it in

the following order:

(1) Needle thread

E

A

D

B

Upper looper

thread is loose.

Lower looper

thread is loose.

Tighten

upper looper

thread

(green)

Tighten

lower looper

thread (blue)

(2) Upper looper thread

(3) Lower looper thread

This is the easiest way

to obtain the correct

thread tension.

12

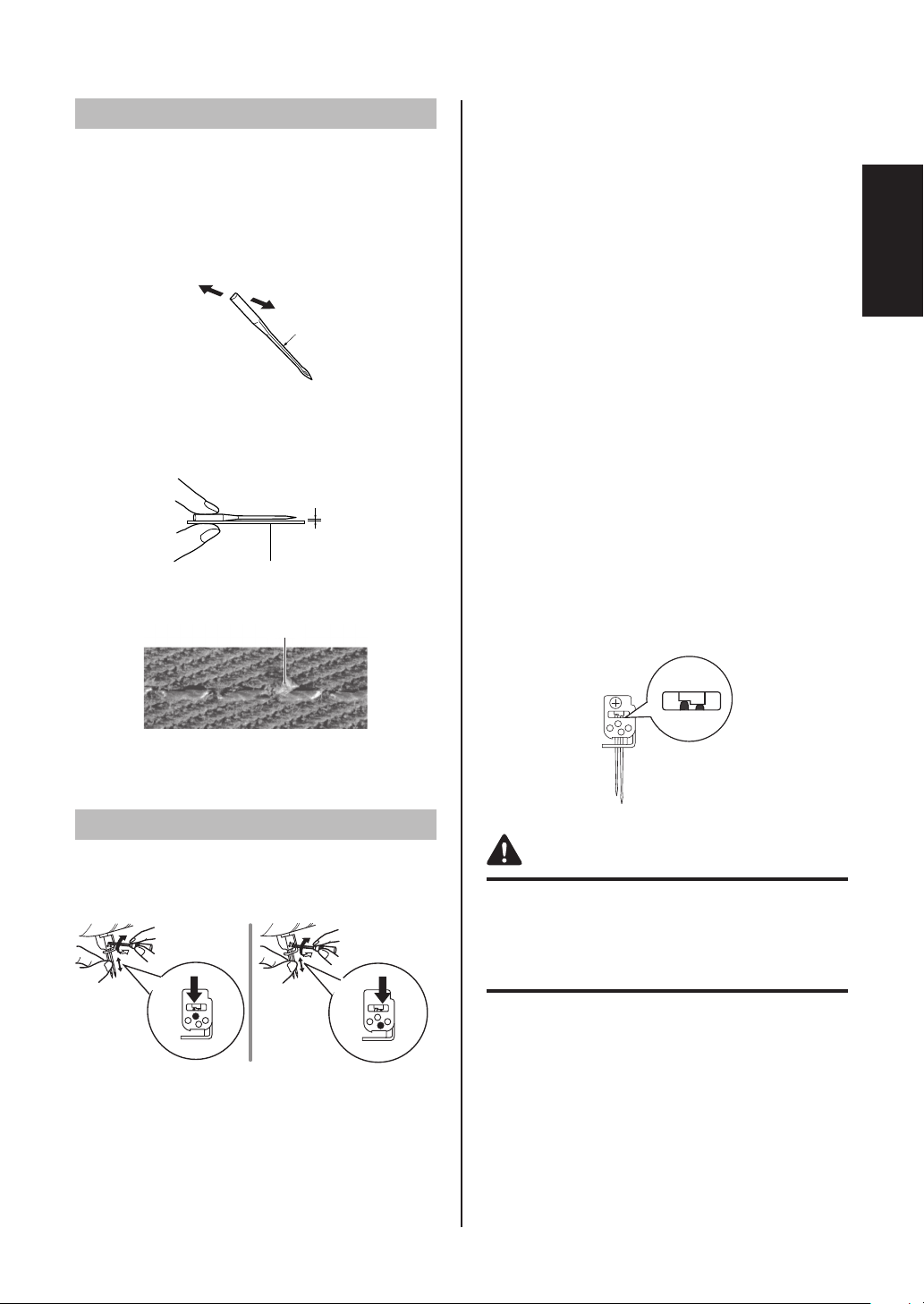

Needle

1

2

3

4

5

<A>

This machine uses a standard home sewing

machine needle.

The recommended needle is 130/705H (#80 or

#90).

Needle description

Back (fl at side) 2 Front 3 Groove

1

How to check the needle

Flat surface

4

Place the needle on its fl at side and check to see if the

5

space is parallel.

NOTE:

Countermeasures for material breakage <A>.

To remove:

1. Turn the main power and light switch to the OFF

position.

2. Turn the hand wheel so that the mark on

the hand wheel is aligned to the line on the

machine. (See CHAPTER 1 "Turning direction

of hand wheel".)

3. Loosen the corresponding needle set screw

with turning the included hexagonal driver

toward 2 in the fi gure, and remove the needle.

To install:

1. Turn the main power and light switch to the OFF

position.

2. Turn the hand wheel so that the line on the

hand wheel is aligned to the line on the

machine.

3. Hold the needle with its fl at side away from you

and insert it up as far as it will go.

4. Tighten the needle set screw securely with

turning the included hexagonal driver toward

in the fi gure.

1

NOTE:

Make sure to insert the needles all the way.

If the needles have been inserted correctly, the

right needle should be set slightly lower than the

left one.

English

It can reduce the occurrence of material breakage

by using 130/705H SUK (#90) BALL POINT.

Removing/ Installing the needle

<A> Removing/ installing the left needle

<B> Removing/ installing the right needle

<A> <B>

1

2

Tighten 2 Loosen

1

1

2

CAUTION

Always be sure to turn off the power before

removing/ inserting the needle.

Do not drop the needle and needle set screw in

the machine, otherwise it may be damaged.

13

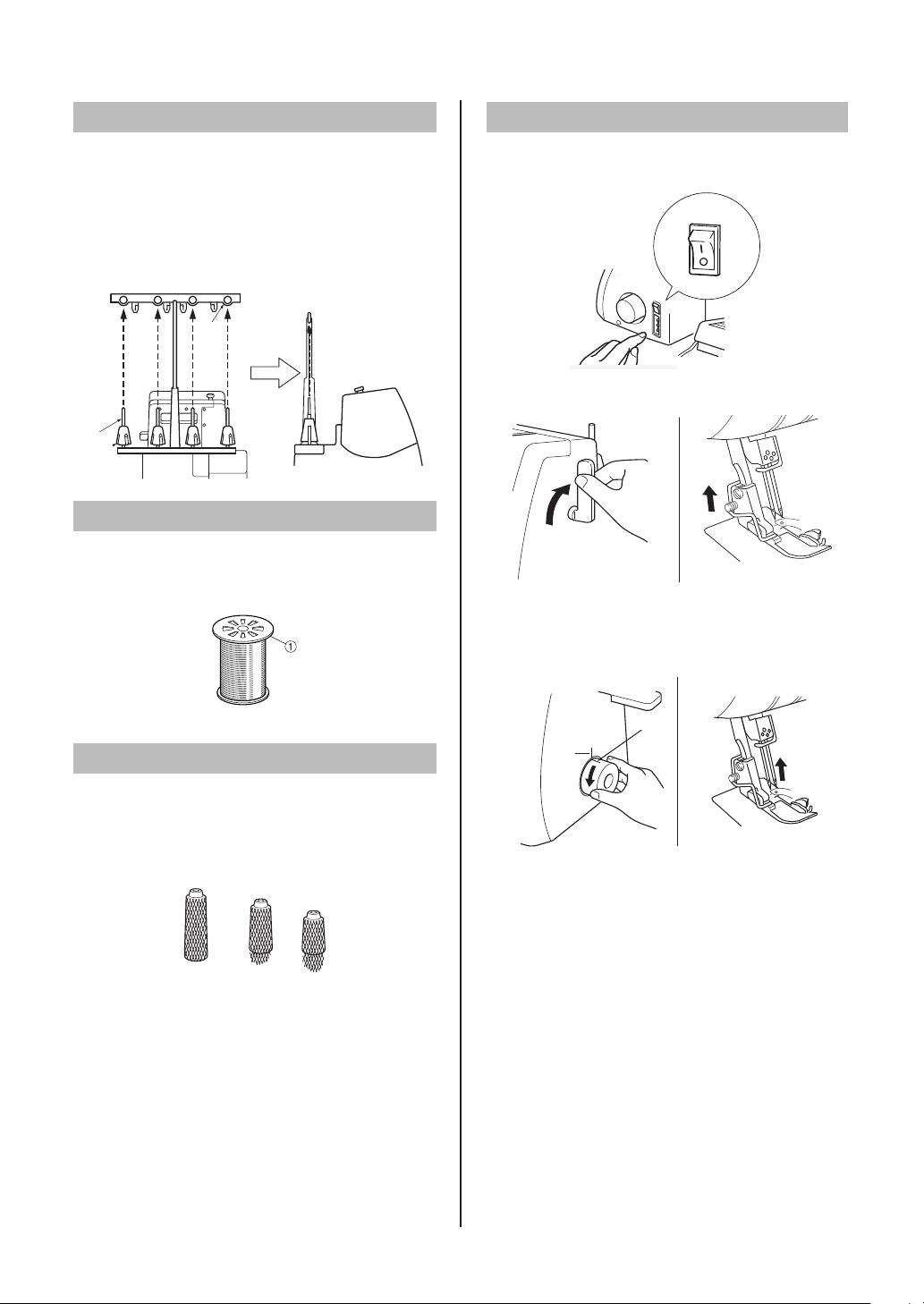

CHAPTER 2

PREPARATION BEFORE THREADING

Thread tree

Raise the telescoping thread tree to its highest

position. Make sure that the thread holders are

in alignment above the spool pins as illustrated

below.

Thread holder on thread tree

1

Spool pin

2

Correct position

3

3

1

2

How to use the thread spool cap

When using sewing thread spools, the thread spool

cap should be used as illustrated below. Make sure

that the spool notch is on the bottom.

Before threading

1. Turn off the main power and light switch for

safety.

2. Raise the presser foot using presser foot lever.

3. Turn the hand wheel so that the mark on the

hand wheel <A> is aligned to the line <B>

on the machine. (See CHAPTER 1 "Turning

direction of hand wheel".)

Thread spool cap

1

How to use the thread net

If you are sewing with loosely spun nylon thread,

we recommend that you cover the spool with the

net supplied to prevent the thread from slipping off

the spool.

Adapt the net to the shape of the spool.

<A>

<B>

14

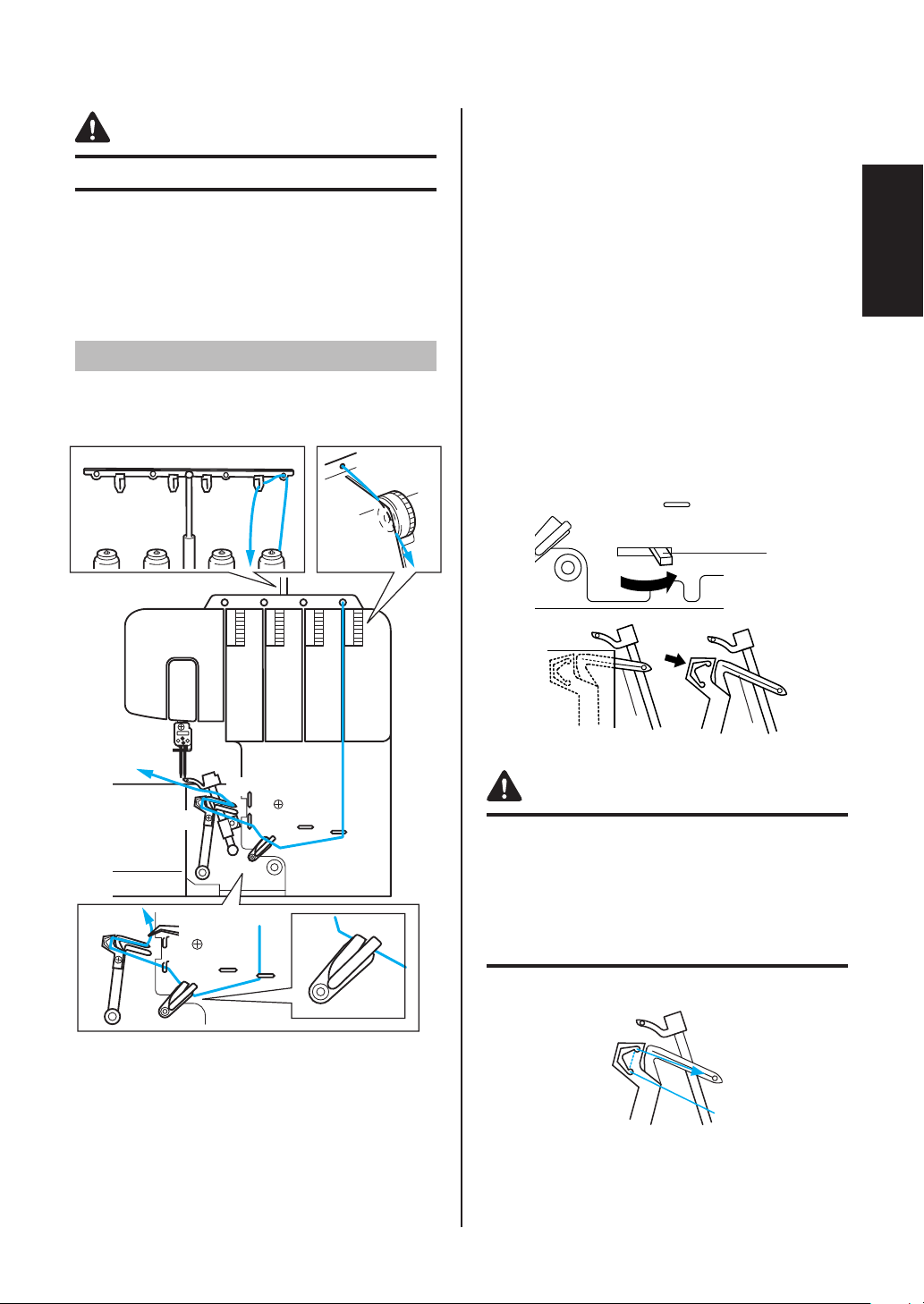

CHAPTER 3

<A>

<B>

<B>

THREADING

CAUTION

Turn off the machine before threading for safety.

Threading has to be done in the following order.

1. Lower looper

2. Upper looper

3. Right needle

4. Left needle

4. Pass the thread through the tension disc 4

which is in the channel next to the blue tension

adjustment dial.

5. Guide the thread down the channel and

pass the thread through the threading points

5678

the numerical order in the accompanying

illustration.

NOTE:

Make sure to thread both of the thread take ups 7.

next to the blue color marks following

English

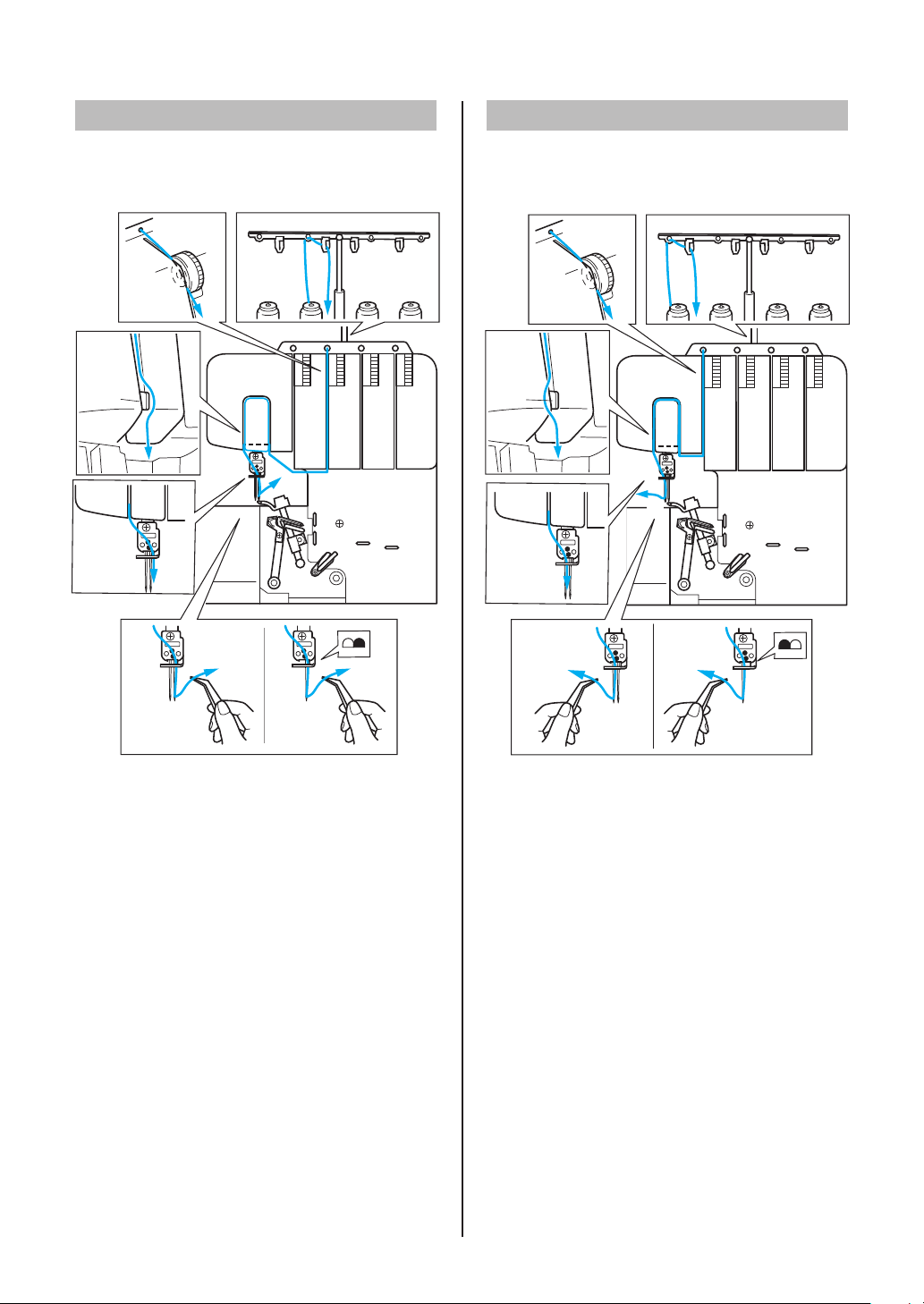

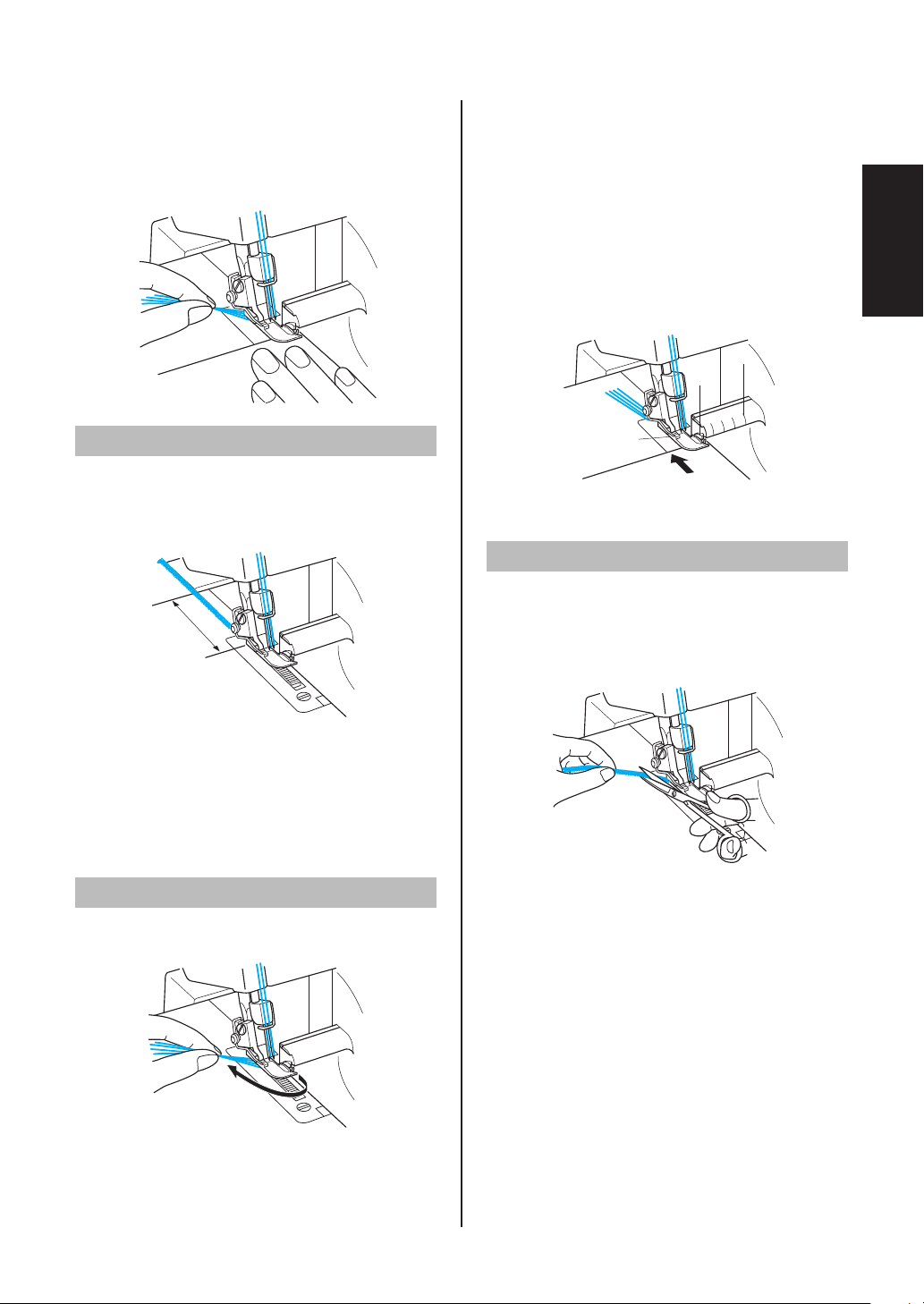

Threading the lower looper

Run the thread in the sequence illustrated,

following the blue color and the numbers next to

each threading point.

9

0

8

1

2

7

3

4

3

4

5

6

Continue on "Lower looper easy threading

operation".

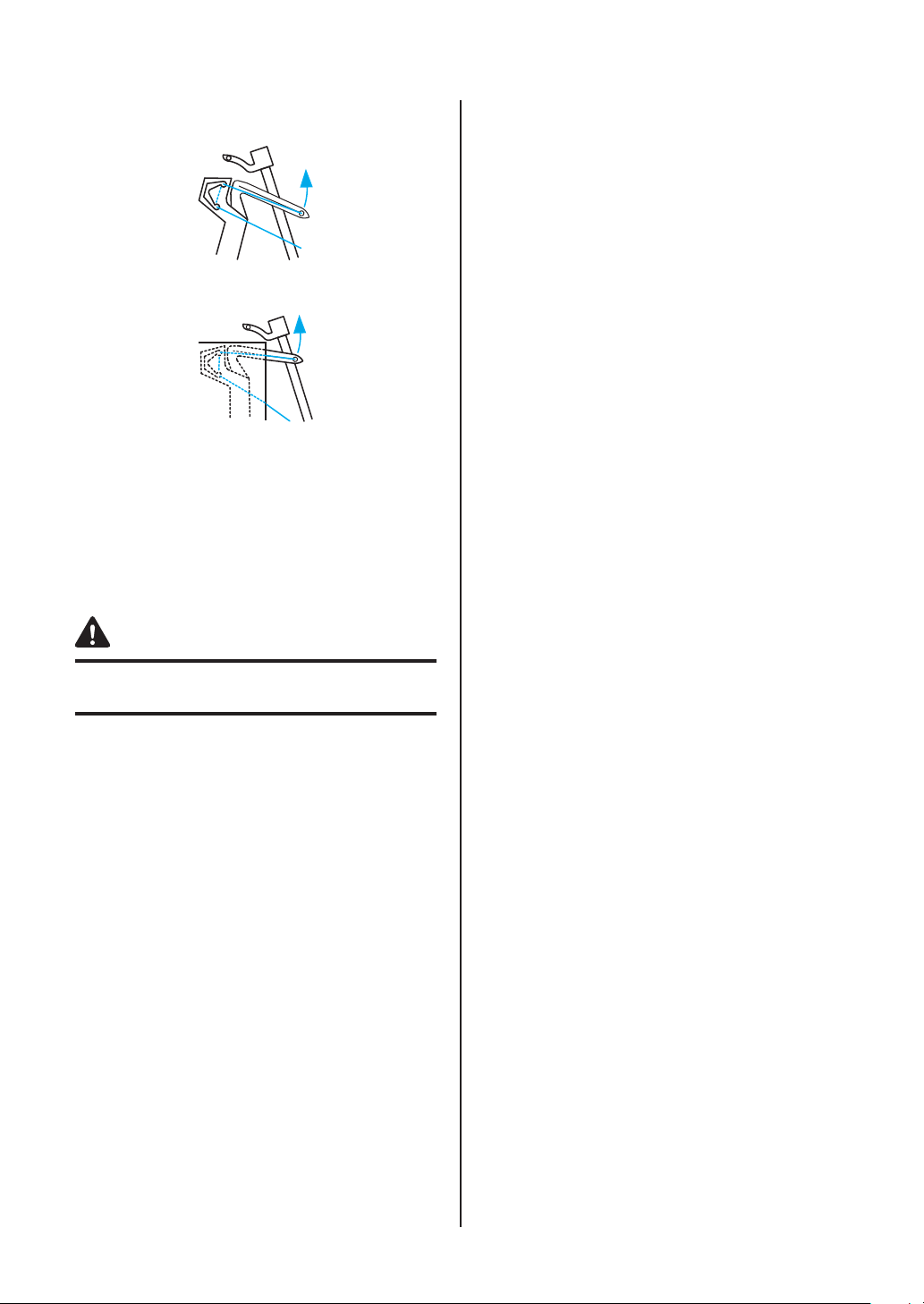

Lower looper easy threading operation

1. Slide the lower looper threading lever <A> to

the right.

The lower looper <B> moves to the position

illustrated as below.

CAUTION

Slide the threading lever only in the directions

shown by the arrow. Forcefully moving the

threading lever in any other direction may damage

it.

0

9

1. Open the front cover by sliding to the right and

guiding the top toward you.

2. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

plate 2 on the thread tree from back to front.

3. Pass the thread thourgh the hole 3 on the top

of machine.

8

7

6

Before sliding the lower looper threading lever,

make sure the needle is at its highest position.

2. Pass the thread as illustrated.

15

3. Pass the thread through the eye of the lower

looper.

4. Slowly turn the hand wheel, and make sure the

returns to the original position.

NOTE:

If the lower looper thread breaks during sewing,

cut and remove thread from both of the needles.

Before re-threading the lower looper, make sure

that the lower looper re-threading is done exactly

as diagrammed. The machine will not operate

properly if the threading is not done in the proper

sequence.

CAUTION

Thread the needles after the lower looper and

upper looper have been threaded.

16

Threading the upper looper

Run the thread in the sequence illustrated,

following the green color and the numbers next to

each threading point.

1

2

3

4

9

8

7

3

4

5

6

5. Guide the thread down the channel and

pass the thread through the threading

points

5678

marks following the numerical order in the

accompanying illustration.

NOTE:

Make sure to thread only through the upper

thread take up 7.

6. Pass the thread through the eye of the upper

looper 9.

NOTE:

If the upper looper thread breaks during sewing:

This may be caused by the lower looper thread

getting caught on the upper looper. If this happens,

lower the upperlooper by turning the hand wheel,

remove the lower looper thread from the upper

looper, and re-thread the upper looper from at

least the tension disc.

next to the green color

English

9

1. Open the front cover by sliding to the right and

guiding the top toward you.

2. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

plate 2 on the thread tree from back to front.

3. Pass the thread thourgh the hole 3 on the top

of machine.

4. Pass the thread through the tension disc 4

which is in the channel next to the green

tension adjustment dial.

8

6

7

17

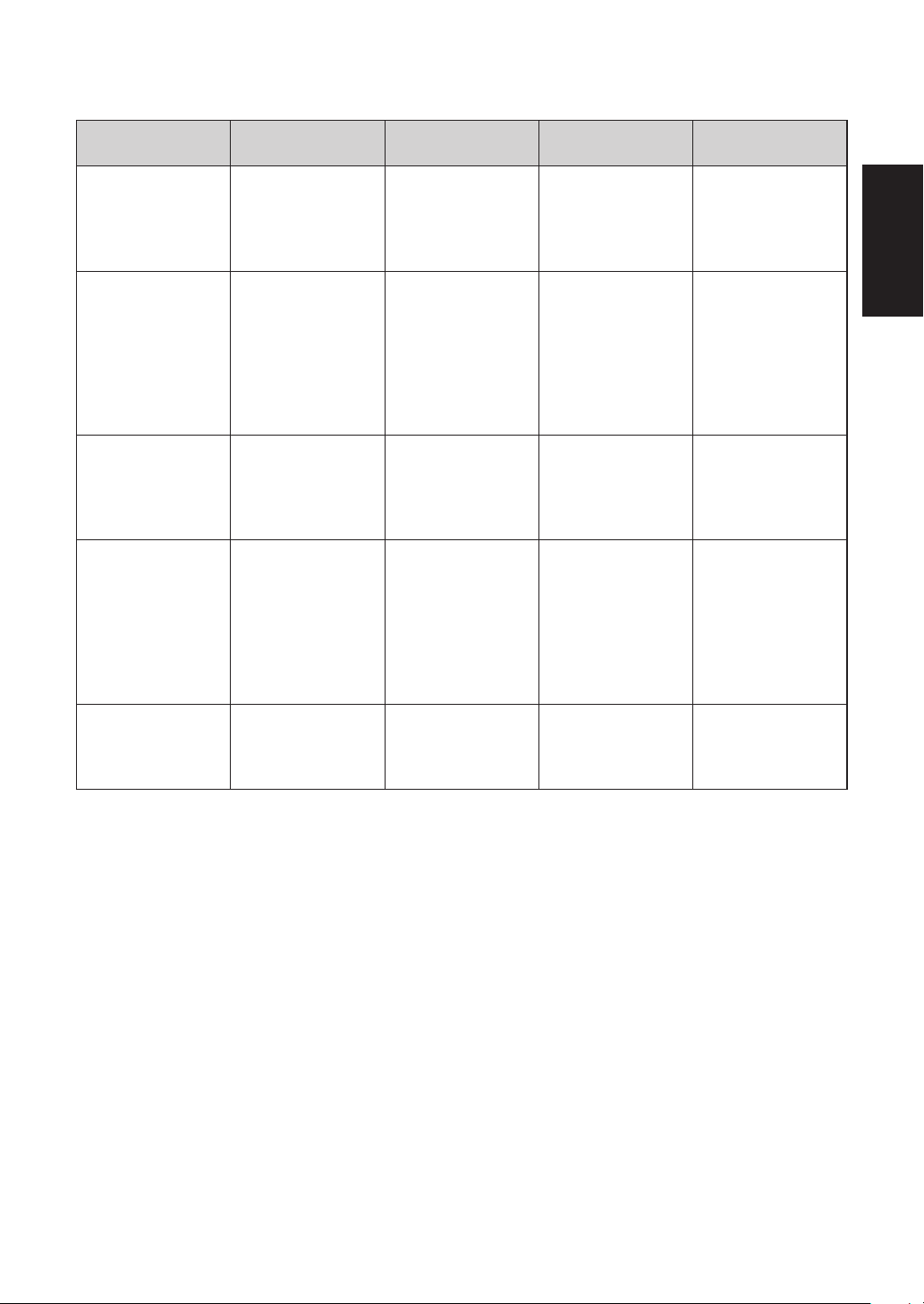

Threading the right needle

Run the thread in the sequence illustrated below,

following the pink color and the numbers next to

each threading point.

Threading the left needle

Run the thread in the sequence illustrated,

following the yellow color and the numbers next to

each threading point.

3

4

<A>

7

88

<B> <C>

7

6

8

1

2

3

4

5

<A>

<B>

7

3

4

8

7

1

2

3

4

6

5

8

<C>

8

1. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

plate 2 on the thread tree from back to front.

2. Pass the thread thourgh the hole 3 on the top

of machine.

3. Pass the thread through the tension disc 4

which is in the channel next to the pink tension

adjustment dial.

4. Guide the thread down the channel and across

through the threading points 5 6 7 next to

the pink color marks following the numerical

order in the accompanying illustration.

NOTE:

Make sure the thread is through the right of the

separater <A>.

5. Bring the thread down through the needle bar

thread guide and through the right needle 8

from front to back.

(<B>: two needles/ <C>: one needle)

18

1. Pull the thread off the spool and directly up

through the thread holder 1 and the thread

plate 2 on the thread tree from back to front.

2. Pass the thread thourgh the hole 3 on the top

of machine.

3. Pass the thread through the tension disc 4

which is in the channel next to the yellow

tension adjustment dial.

4. Guide the thread down the channel and across

through the threading points 5 6 7 next to

the yellow color marks following the numerical

order in the accompanying illustration.

NOTE:

Make sure the thread is through the left of the

separater <A>.

5. Bring the thread down through the needle bar

thread guide and through the left needle 8

from front to back.

(<B>: two needles/ <C>: one needle)

CHAPTER 4

SEWING MATERIALS, THREADS AND NEEDLES COMPARISON CHART

Material Stitch

Fine materials:

Georgette

Lawn

Organdy

Tricot

Fine materials:

Georgette

Lawn

Organdy

Tricot

Medium materials:

Gabardine

Serge

Medium materials:

Heavy materials:

Tweed

Denim

Knits

Broad cloth

Broad cloth

Stitch Length

(mm)

Overlock stitch 2.0-3.0 Spun #80-90

Narrow over lock/

Rolled hemming

stitch

Overlock stitch 2.5-3.5 Spun #60-80

Narrow over lock/

Rolled hemming

stitch

Overlock stitch 3.0-4.0 Cotton #50-60

R-2.0 Needle thread :

R-2.0 Needle thread :

Thread Needle

Cotton #100

Tetron #80-100

Spun #80-90

Tetron #80-100

Looper thread :

Woolly nylon thread

Spun #80-90

Tetron #80-100

Cotton #60-80

Tetron #60-80

Spun #60-80

Tetron #60-80

Looper thread :

Woolly nylon thread

Spun #60-80

Tetron #60-80

Spun #60

Tetron #50-60

130/705H

#80

130/705H

#80

130/705H

#80

#90

130/705H

#80

#90

130/705H

#90

English

NOTE:

Decorative thread will work best in the upper looper for fashion sewing.

19

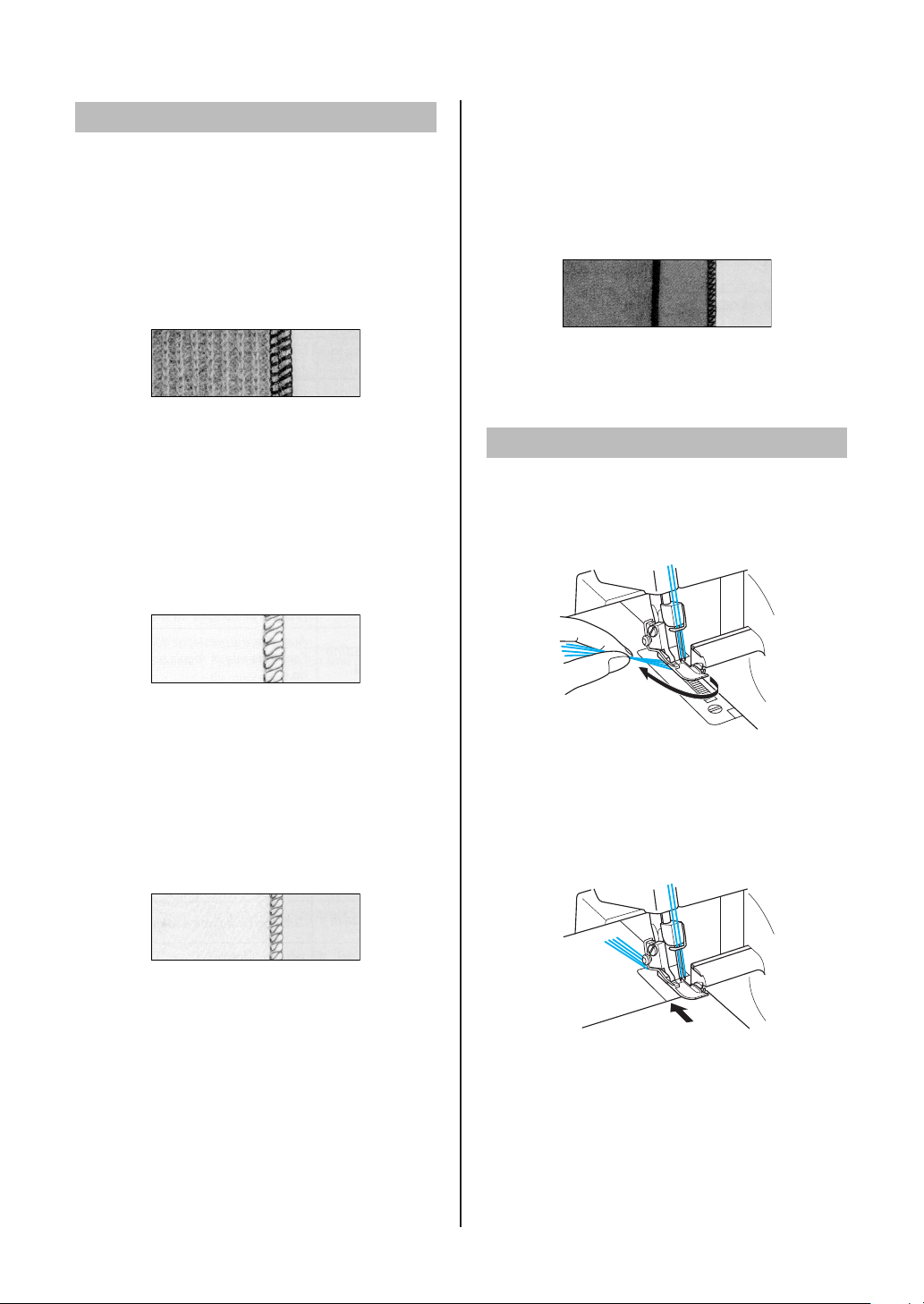

CHAPTER 5

SEWING

Stitch selection

Select the stitch pattern before you start sewing.

This sewing machine can sew fi ve different stitches

by following the simple steps below:

Four-thread overlock stitch

Use all four threads and two needles for producing

four-thread overlock stitches.

Use: Produces strong seam. Ideal for sewing knits

and wovens.

Three-thread overlock stitch

5 mm (3/16 inch)

Use three threads and the left needle, producing 5

mm (3/16 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for medium to heavy materials.

NOTE:

Remove the right needle when sewing this

overlock stitch.

Narrow overlock stitch 2.0mm (5/64

inch) and

Rolled hemming stitch 2.0mm (5/64

inch)

Use as decorative or fi nishing stitch. See "Narrow

overlock/ Rolled hemming stitch" in this chapter for

details.

NOTE:

You can use the optional accessory foot for even

more varieties of stitches. See CHAPTER 8 for

details.

Test sewing

Test-sew before you start sewing.

1. Set all the thread tension to "4".

2. Thread the machine and pull all threads out

about 15 cm (6 inches) behind the presser foot.

Three-thread overlock stitch 2.8 mm

(7/64 inch)

Use three threads and the right needle, producing

2.8 mm (7/64 inch) seams.

Use: For overlock stitching on suits, blouses,

slacks, etc. Ideal for fi ne to medium materials.

NOTE:

Remove the left needle when sewing this overlock

stitch.

3. Place a piece of scrap material under the

presser foot for test sewing.

NOTE:

Always lift the presser foot before placing the

fabric under it. You cannot start sewing by just

running the fabric under the foot without lifting

the presser foot.

20

4. Holding all threads with your left hand, turn the

hand wheel slowly a few times toward you,

and check to see that the threads entwine

themselves before using the foot controller to

sew.

3. The fabric will be fed automatically. You need

only guide it in the required direction.

4. Check the stitch formation (stitch chain) to

see if it is uniform. If the stitch is not uniform,

re-check that the threading has been done

properly and in sequence.

5. Follow the Seam Allowance Guide for

consistent cutting of the fabric seams. The

scale of Seam Allowance Guide shows 9.5,

12.7, 15.9, and 25.4 mm (3/8, 1/2, 5/8, and 1

inches) when the stitch width dial is set to "5".

3

2

English

Chaining-off

After test-sewing, continue to depress the foot

controller slightly and chain off 10 cm (4 inches).

The threads will entwine themselves into a chain

automatically.

NOTE:

If the thread tension is not correctly balanced, the

chaining-off result will be uneven. If this happens,

pull the threads slightly. Check the threading order

and adjust the thread tension to create an even

chain. (See CHAPTER 1 "Tension adjustment

dial".)

To start sewing

1. Thread the machine and pull all threads out

about 15 cm (6 inches) behind the presser foot.

1

Presser foot 2 Upper knife 3 Seam Allowance Guide

1

To remove work

When the seam is fi nished, keep the machine

running at a low speed to obtain chaining-off. Then

cut the stitches 5 cm (2 inches) from the work.

If feeding for chaining-off is not enough, pull the

thread gently.

2. Lift the presser foot and place the material well

underneath the presser foot before starting to

sew. Slowly sew a few stitches by turning the

hand wheel.

21

Loading...

Loading...