Page 1

Operation Manual

Sewing Machine

Product Code: 885-X06/X08/X09/X16/X18/X19/X26/X28/X29

888-X06/X08/X09/X16/X18/X19/X26/X28/X29

Manual de instrucciones

Máquina de coser

Código de producto: 885-X06/X08/X09/X16/X18/X19/X26/X28/X29

888-X06/X08/X09/X16/X18/X19/X26/X28/X29

ENGLISH

ESPAÑOL

Please visit us at http://solutions.brother.com where you can get product

support and answers to frequently asked questions (FAQs).

Visítenos en http://solutions.brother.com donde hallará consejos para la solución

de problemas así como la lista de preguntas y respuestas más frecuentes.

Page 2

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

IMPORTANT SAFETY

INSTRUCTIONS

Please read these safety instructions

before attempting to use the machine.

DANGER - To

reduce the risk of electric shock:

1 Always unplug the machine from

the electrical outlet immediately after

using, when cleaning, when making

any user servicing adjustments

mentioned in this manual, or if you are

leaving the machine unattended.

WARNING - To

reduce the risk of burns, fire, electric

shock, or injury to persons.

2 Always unplug the machine from

the electrical outlet when making any

adjustments mentioned in the

instruction manual:

• To unplug the machine, switch the

machine to the symbol “O” position

to turn it off, then grasp the plug and

pull it out of the electrical outlet. Do

not pull on the cord.

• Plug the machine directly into the

electrical outlet. Do not use an

extension cord.

• Always unplug your machine if the

power is cut.

3 Never operate this machine if it has

a damaged cord or plug, if it is not

working properly, if it has been

dropped or damaged, or water is spilled

on the unit. Return the machine to the

nearest authorized dealer or service

center for examination, repair,

electrical or mechanical adjustment.

•

While the machine is stored or in use if

you notice anything unusual, such as an

odor, heat, discoloration or deformation,

stop using the machine and immediately

unplug the power cord.

• When transporting the machine, be

sure to carry it by its handle. Lifting

the machine by any other part may

damage the machine or result in the

machine falling, which could cause

injuries.

• When lifting the machine, be careful

not to make any sudden or careless

movements, otherwise you may

injure your back or knees.

4 Always keep your work area clear:

• Never operate the machine with any

air openings blocked. Keep

ventilation openings of the machine

and foot control free from the build

up of lint, dust, and loose cloth.

• Do not store objects on the foot

controller.

• Do not use extension cords. Plug the

machine directly into the electrical

outlet.

• Never drop or insert any object into

any opening.

• Do not operate where aerosol (spray)

products are being used or where

oxygen is being administered.

• Do not use the machine near a heat

source, such as a stove or iron;

otherwise, the machine, power cord

or garment being sewn may ignite,

resulting in fire or an electric shock.

• Do not place this machine on an

unstable surface, such as an unsteady

or slanted table, otherwise the

machine may fall, resulting in

injuries.

5

Special care is required when sewing:

• Always pay close attention to the

needle. Do not use bent or damaged

needles.

• Keep fingers away from all moving

parts. Special care is required around

the machine needle.

1

Page 3

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

• Do not turn on the machine while

pressing down the foot controller.

The machine may start unexpectedly

and cause personal injury or damage

to the machine.

•

Switch the machine to the symbol “O”

position to turn it off when making any

adjustments in the needle area.

• Do not use a damaged or incorrect

needle plate, as it could cause the

needle to break.

• Do not push or pull the fabric when

sewing, and follow careful instruction

when freehand stitching so that you

do not deflect the needle and cause it

to break.

6 This machine is not a toy:

Your close attention is necessary when

•

the machine is used by or near children.

• The plastic bag that this machine was

supplied in should be kept out of the

reach of children or disposed of.

Never allow children to play with the

bag due to the danger of suffocation.

• Do not use outdoors.

7 For a longer service life:

• When storing this machine, avoid

direct sunlight and high humidity

locations. Do not use or store the

machine near a space heater, iron,

halogen lamp, or other hot objects.

• Use only neutral soaps or detergents

to clean the case. Benzene, thinner,

and scouring powders can damage

the case and machine, and should

never be used.

•

Always consult the operation manual

when replacing or installing any

assemblies, the presser feet, needle, or

other parts to assure correct installation.

8 For repair or adjustment:

• If the Light unit (light-emitting diode)

is damaged, it must be replaced by

authorized dealer.

• In the event a malfunction occurs or

adjustment is required, first follow the

troubleshooting table in the back of

the operation manual to inspect and

adjust the machine yourself. If the

problem persists, please consult your

local authorized Brother dealer.

Use this machine only for its intended

use as described in this manual.

Use accessories recommended by the

manufacturer as contained in this manual.

The contents of this manual and

specifications of this product are

subject to change without notice.

For additional product information,

visit our web site at www.brother.com

SAVE THESE

INSTRUCTIONS

This machine is intended

for household use.

This appliance is not intended for use by

persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning

use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure

that they do not play with the appliance.

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of

experience and knowledge if

they have been given

supervision or instruction

concerning use of the appliance

in a safe way and understand

the hazards involved. Children

shall not play with the

appliance. Cleaning and user

maintenance shall not be made

by children without supervision.

2

Page 4

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

FOR USERS IN THE UK, EIRE,

MALTA AND CYPRUS ONLY

IMPORTANT

• In the event of replacing the plug fuse, use a fuse

approved by ASTA to BS 1362, i.e. carrying the

mark, rating as marked on plug.

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...........1

1. KNOWING YOUR SEWING

MACHINE .................................. 4

ACCESSORIES .................................................4

Optional accessories .......................................... 4

THE MAIN PARTS ...........................................5

Flat bed attachment ............................................ 5

USING YOUR SEWING MACHINE ................ 6

Connecting plugs ............................................... 6

Main power and sewing light switch .................. 7

Foot controller .................................................... 7

Checking the needle ........................................... 7

Replacing the needle .......................................... 7

Changing the presser foot ................................... 8

THE CONTROLS .............................................9

Pattern selection dial .......................................... 9

Stretch stitching .................................................. 9

Patterns and stitch names ................................. 10

Stitch length dial .............................................. 14

Stitch width dial ............................................... 14

Reverse sewing lever ........................................ 14

THREADING THE MACHINE .......................15

Winding the bobbin ......................................... 15

Lower threading ............................................... 17

Lower threading (for models equipped with a

quick-set bobbin) ............................................. 18

Upper threading ............................................... 19

Using the needle threader (for models equipped

with a needle threader) ..................................... 21

Drawing up the lower thread ............................ 22

FABRIC, THREAD, AND NEEDLE

COMBINATIONS .........................................24

2. SEWING BASICS ......................25

Please read before sewing ................................ 25

Starting sewing ................................................. 25

Trial sewing ...................................................... 26

Changing the sewing direction ......................... 26

Sewing thick fabrics ......................................... 26

Sewing thin fabrics ........................................... 27

Sewing stretch fabrics ....................................... 27

Stitching cylindrical pieces ............................... 27

Sewing with a twin needle (Option) ................. 27

Thread tension ................................................. 29

• Always replace the fuse cover. Never use plugs with

the fuse cover omitted.

• If the available electrical outlet is not suitable for the

plug supplied with this equipment, you should

contact your authorized dealer to obtain the correct

lead.

3. BUILT-IN STITCHES ................. 30

Straight stitching ............................................... 30

Zigzag stitching ................................................. 30

Blind hem stitching ........................................... 30

Shell tuck stitching ............................................ 32

Elastic stitching .................................................32

Double action stitching ..................................... 33

Fagoting ............................................................33

Overedge stitching ............................................ 34

Feather stitching ................................................34

Triple zigzag stretch stitching ............................ 35

Decorative stitching .......................................... 35

4. SEWING BUTTONHOLES AND

BUTTONS ............................... 36

Making a buttonhole

(1-step automatic buttonhole) ...........................36

Adjusting buttonholes ....................................... 38

Sewing buttons .................................................39

5. USING ATTACHMENTS AND

APPLICATIONS ....................... 40

Zipper insertion ................................................ 40

Gathering ..........................................................41

Darning ............................................................41

Appliqués .........................................................41

OPTIONAL ACCESSORIES ........................... 42

Using the walking foot ...................................... 42

Using the quilting guide .................................... 43

Using the quilting foot ...................................... 43

Using the 1/4-inch quilting foot ........................ 44

Using the narrow hemmer foot ......................... 44

Using the blind stitch foot .................................46

6. APPENDIX ................................ 47

MAINTENANCE ........................................... 47

Restrictions on oiling ........................................ 47

Precautions on storing the machine .................. 47

Cleaning ...........................................................47

TROUBLESHOOTING .................................. 49

INDEX .......................................................... 52

3

Page 5

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Note

1 KNOWING YOUR SEWING MACHINE

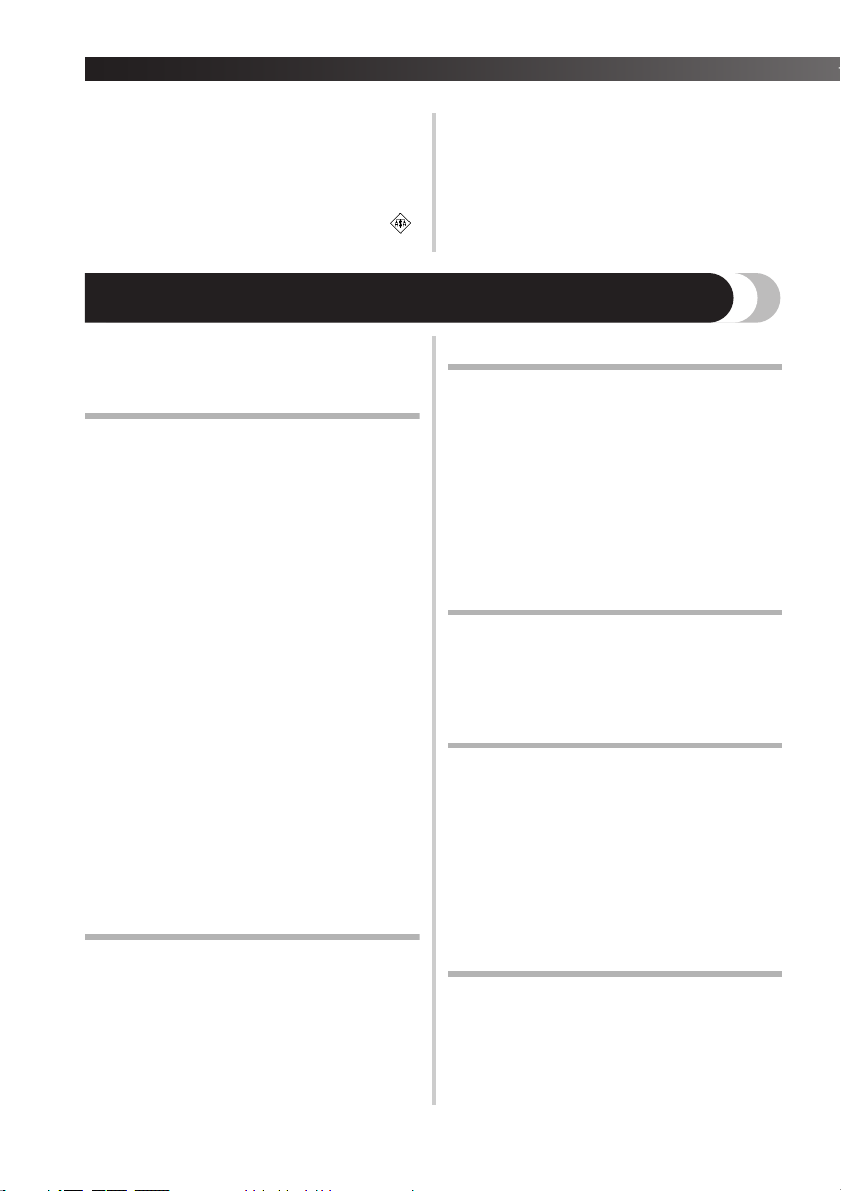

ACCESSORIES

We have designed these accessories to help you easily perform most sewing tasks.

1. 2. 3. 4. 5.

6. 7. 8. 9.

1

No. Part Name

Zigzag foot “J”

1

(on machine)

2 Buttonhole foot “A” XD1792-031

3 Zipper foot “I” XE9369-001

4 Darning Plate XC6063-021

5 Button sewing foot “M” XE2137-001

● The included accessories vary depending on the machine model.

Part Code

Americas Others

XC4901-121

No. Part Name

Bobbin

6

(One is on machine)

Needle set

7

(90/14 needle)

8 Oval screwdriver XE5241-001

9 Foot controller See page 5

Part Code

Americas Others

3-piece set: XE5328-001

2-piece set: XE7064-001

SA156

SFB:

XA5539-151

Optional accessories

The following are available as optional accessories to be purchased separately. Depending on the model you

purchased, the following accessory may be included with your machine.

1. 2. 3. 4. 5.

6. 7. 8.

No. Part Name

1 Extra spool pin XE2241-001

Twin needle

2

(2.0/75 needle)

3 Walking Foot SA107

4 Quilting Foot SA129

Part Code

Americas Others

X57521-021

F034N:

XC2165-002

F005N:

XC1948-052

No. Part Name

5 1/4-inch Quilting Foot SA125

6 Narrow Hemmer Foot SA127

7 Blind Stitch Foot SA134

8 Quilting guide SA132

Part Code

Americas Others

F001N:

XC1944-052

F003N:

XC1945-052

F018N:

XC1976-052

F016N:

XC2215-052

4

Page 6

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

1

3

2

4

5

6

7

8

9

0

A

B

C

D

G

F

H

I

K

E

J

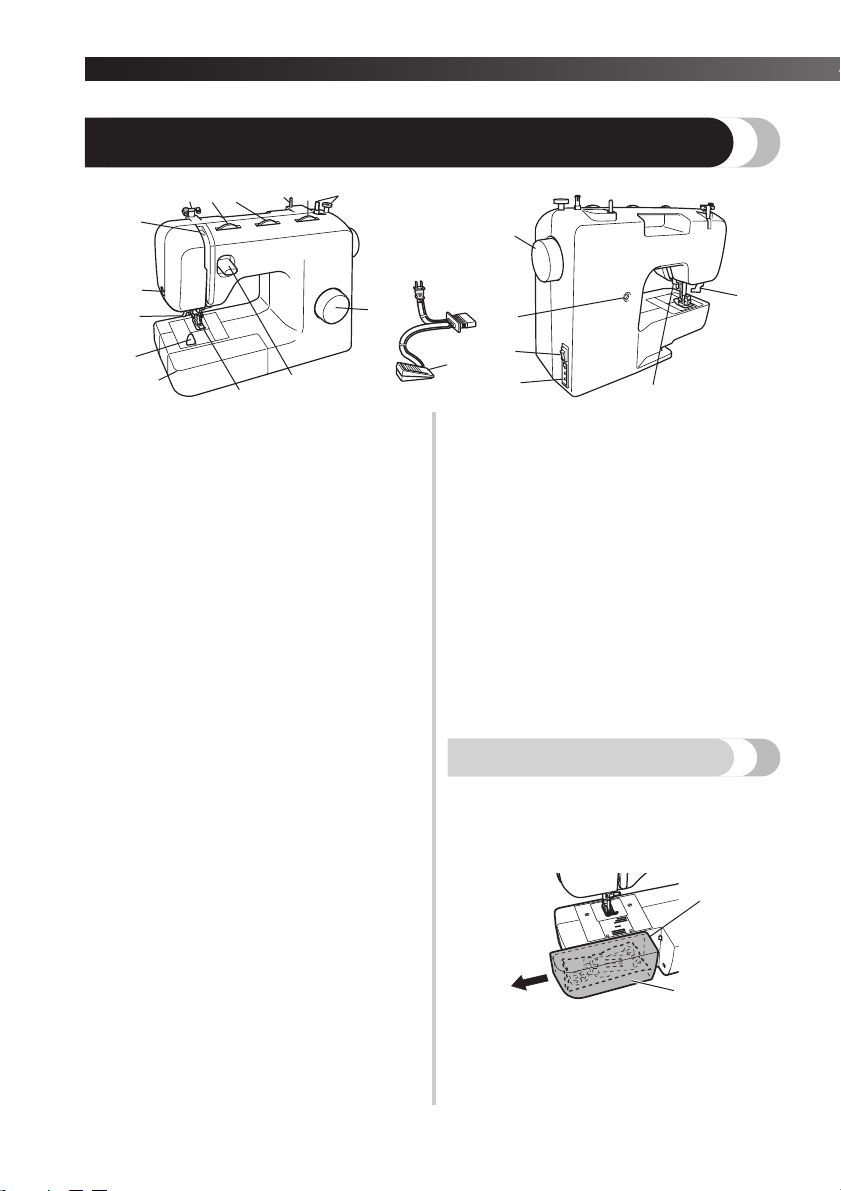

THE MAIN PARTS

1 Bobbin winder (Page 15)

This winds the thread onto the bobbin for use as the

lower thread.

2 Stitch length dial (Page 14)

Rotate the dial to control the stitch length.

3 Spool pin (Page 15, 19)

This holds the spool of thread.

4 Stitch width dial (Page 14)

Rotate the dial to control the stitch width.

5 Upper tension-control dial (Page 29)

This controls the tension of the upper thread.

6 Thread guide (Page 15, 19)

This is used when winding the thread onto the

bobbin and then threading the machine.

7 Thread take-up lever (Page 20)

8 Thread cutter (Page 26)

Pass the threads through the thread cutter to cut

them.

9 Needle threader (Page 21)

(This is only available on certain models.)

0 Quick-set bobbin (Page 18)

(This is only available on certain models.)

A Flat bed attachment with accessory compartment

(Page 5)

B Presser foot (Page 8)

C Reverse sewing lever (Page 14)

Push this lever to stitch in the reverse direction.

D Pattern selection dial (Page 9)

Rotate the dial in either direction to choose the

stitch you want.

E Handwheel

Used to manually raise and lower the needle.

F Buttonhole fine-adjustment screw (Page 38)

G Main power and sewing light switch (Page 7)

You can turn the main power and sewing light

switch on and off.

5

H Foot controller jack / socket (Page 6)

Plug in the foot controller plug and connect the

machine to the power supply.

I Presser foot lever (Page 19)

Used to raise and lower the presser foot.

J

Buttonhole lever (1-Step automatic buttonhole)

Page 36

)

(

Lower the buttonhole lever when sewing

buttonholes.

K Foot controller (Page 7)

You can use this to control the sewing speed, and to

start and stop sewing.

Foot Controller:

Model KD-1902 for 110-120V area

KD-1902 for 110-127V area (Brazil only)

Model KD-2902 for 220-240V area

The foot controller part code differs depending on the

country or region. Contact your dealer or the nearest

authorized service center.

Flat bed attachment

The accessories can be stored in a compartment inside

the flat bed attachment.

Slide the flat bed attachment to the left to

1

open it.

2

1 Flat bed attachment

2 Storage compartment

1

Page 7

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Note

a

b

USING YOUR SEWING MACHINE

WARNING

● Use only regular household electricity for the power source. Using other power sources may

result in fire, electric shock, or damage to the machine.

● Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and

the power supply jack on the machine.

● Do not insert the plug on the power cord into an electrical outlet that is in poor condition.

● Turn off the main power and remove the plug in the following circumstances:

• When you are away from the machine

• After using the machine

• When the power fails during use

• When the machine does not operate correctly due to a bad connection or a disconnection

• During electrical storms

CAUTION

● Use only the power cord included with this machine.

● Do not use extension cords or multi-plug adapters with many other appliances plugged in to

them. Fire or electric shock may result.

● Do not touch the plug with wet hands. Electric shock may result.

● When unplugging the machine, always turn off the main power first. Always grasp the plug to

remove it from the outlet. Pulling on the cord may damage the cord, or lead to fire or electric

shock.

● Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted,

or bundled. Do not place heavy objects on the cord. Do not subject the cord to heat. These

things may damage the cord and cause fire or electric shock. If the cord or plug is damaged,

take the machine to your authorized dealer for repairs before continuing use.

● Unplug the power cord if the machine is not to be used for a long period of time. Otherwise

a fire may result.

1

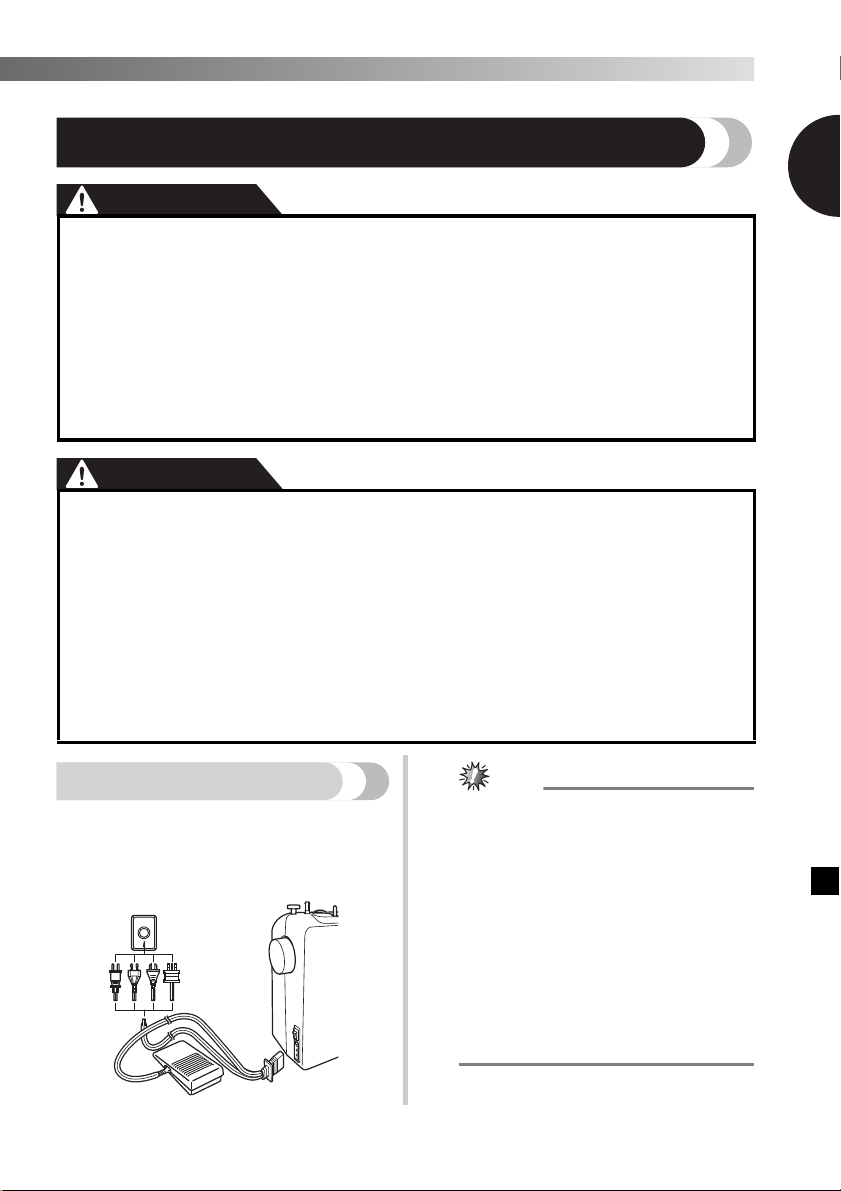

Connecting plugs

Connect the foot controller plug to the

1

machine.

Connect the power supply plug to a wall

2

outlet.

● If a power outage occurs while the sewing

machine is being operated, turn off the main

power and unplug the power supply cord.

When restarting the sewing machine, follow

the necessary procedure to correctly operate

the machine.

(For U.S.A. only)

● This appliance has a polarized plug (one

blade wider than the other). To reduce the

risk of electric shock, this plug is intended to

fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse

the plug.

If it still does not fit, contact a qualified

electrician to install the proper outlet. Do

not modify the plug in any way.

6

Page 8

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

CAUTION

Note

CAUTION

2

1

1

2

1

2

1

Main power and sewing

light switch

This switch turns the main power and sewing light on or off.

1 Turn on (toward the ‘I’ mark)

2 Turn off (toward the ‘O’ mark)

CAUTION

●

Do not turn on the machine while pressing

down the foot controller. The machine

may start unexpectedly and cause

personal injury or damage to the machine.

Foot controller

When you press the foot controller down lightly, the

machine will run at a low speed. When you press harder,

the machine’s speed will increase. When you take your

foot off the foot controller, the machine will stop.

1 Slower

2 Faster

You should make sure that nothing is placed on the foot

controller when the machine is not in use.

● Do not allow pieces of cloth and dust to

build up on the foot controller. Doing so

could cause a fire or an electric shock.

(For U.S.A. only)

●

Foot Controller: Model KD-1902

This foot controller can be used on the machine

with product code 885-X06, 885-X08, 885-X09,

885-X26, 885-X28, 888-X06, 888-X08, 888-X09,

888-X16, 888-X18, 888-X26 and 888-X28.

The product code is mentioned on the machine

rating plate.

7

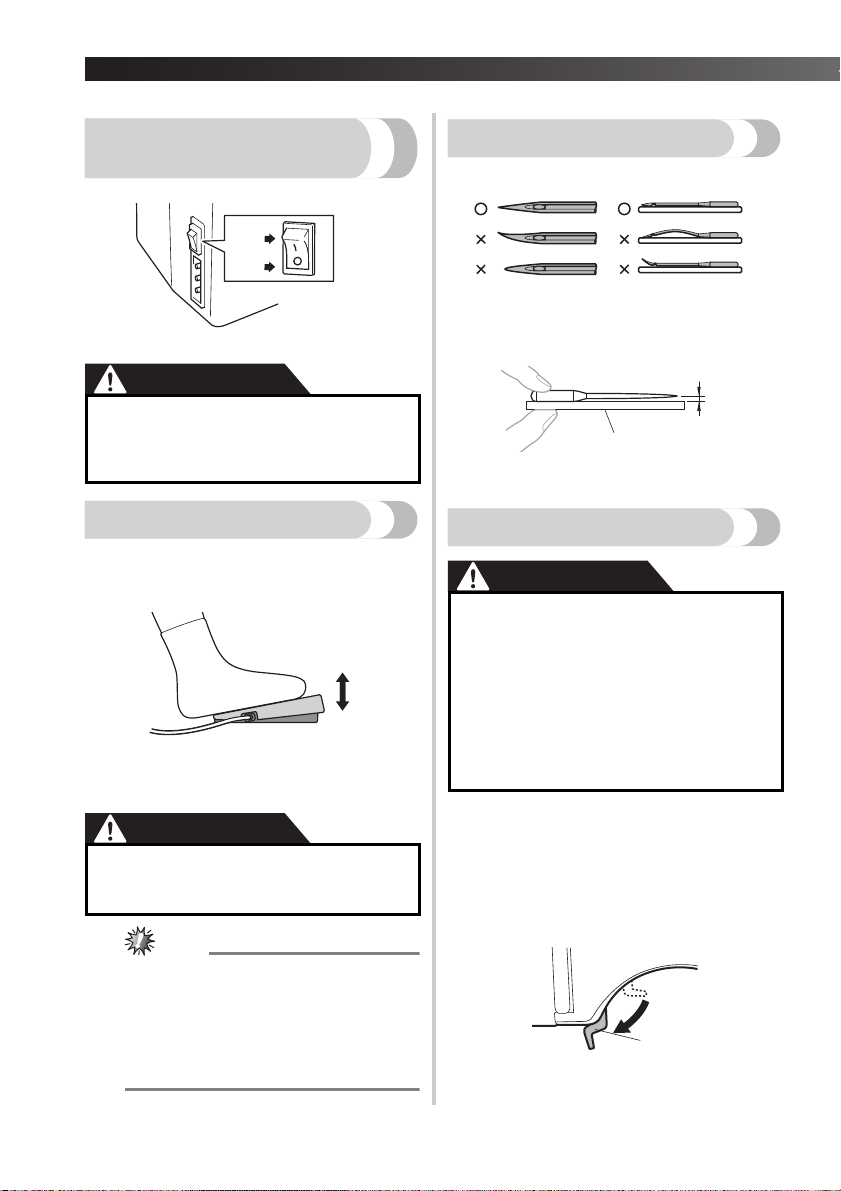

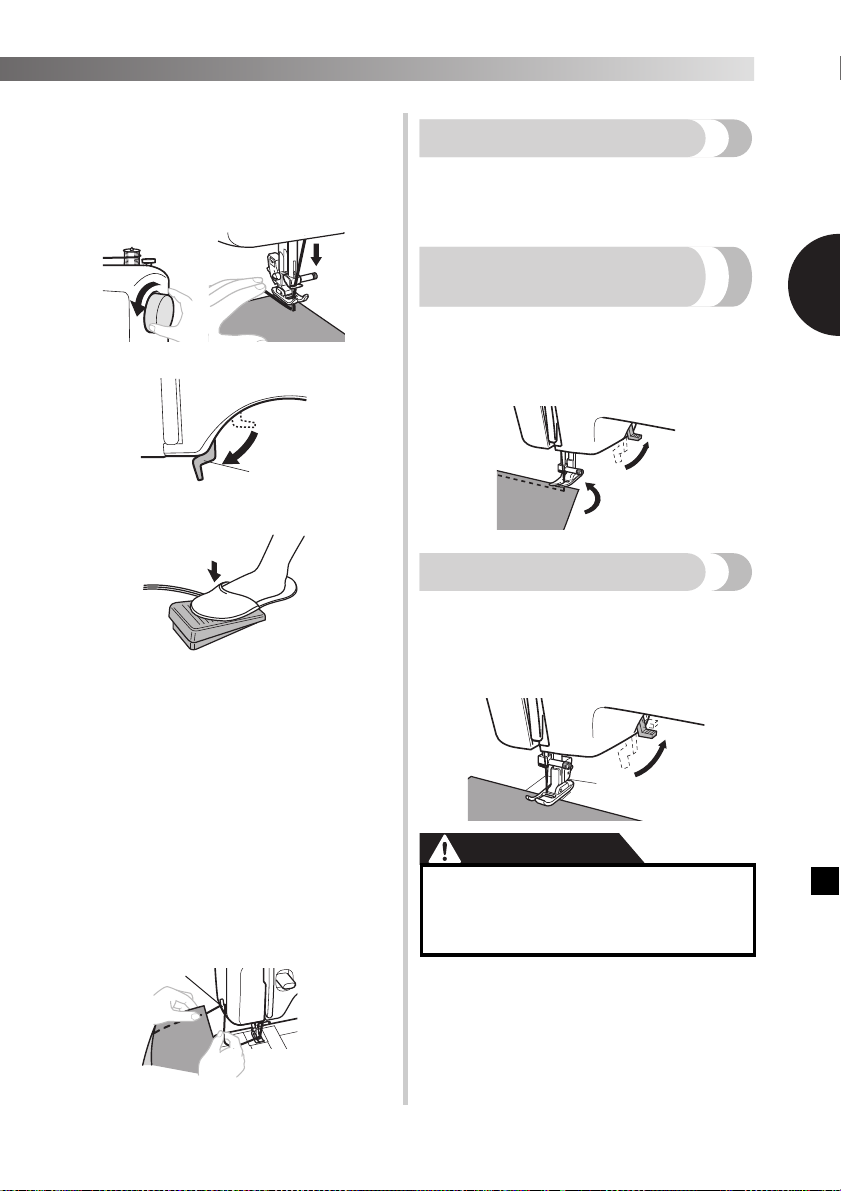

Checking the needle

The sewing needle must always be straight and sharp

for smooth sewing.

■ Checking the needle correctly

Put the flat side of the needle on a flat surface.

Check the needle from the top and the sides.

Dispose of any bent needles safely.

1 Parallel space

2 Level surface (bobbin cover, glass, etc.)

Replacing the needle

● Always turn off the machine before you

change the needle. Otherwise, injuries

may occur if the foot controller is

accidentally pressed and the machine

starts sewing.

● Only use sewing machine needles for

home use. Other needles may bend or

break and cause injury.

● Never sew with a bent needle. A bent

needle will easily break and cause injury.

Turn off the machine.

1

Raise the needle by turning the

2

handwheel toward you

(counterclockwise) so that the mark on

the wheel points up.

Lower the presser foot lever.

3

1 Presser foot lever

Page 9

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

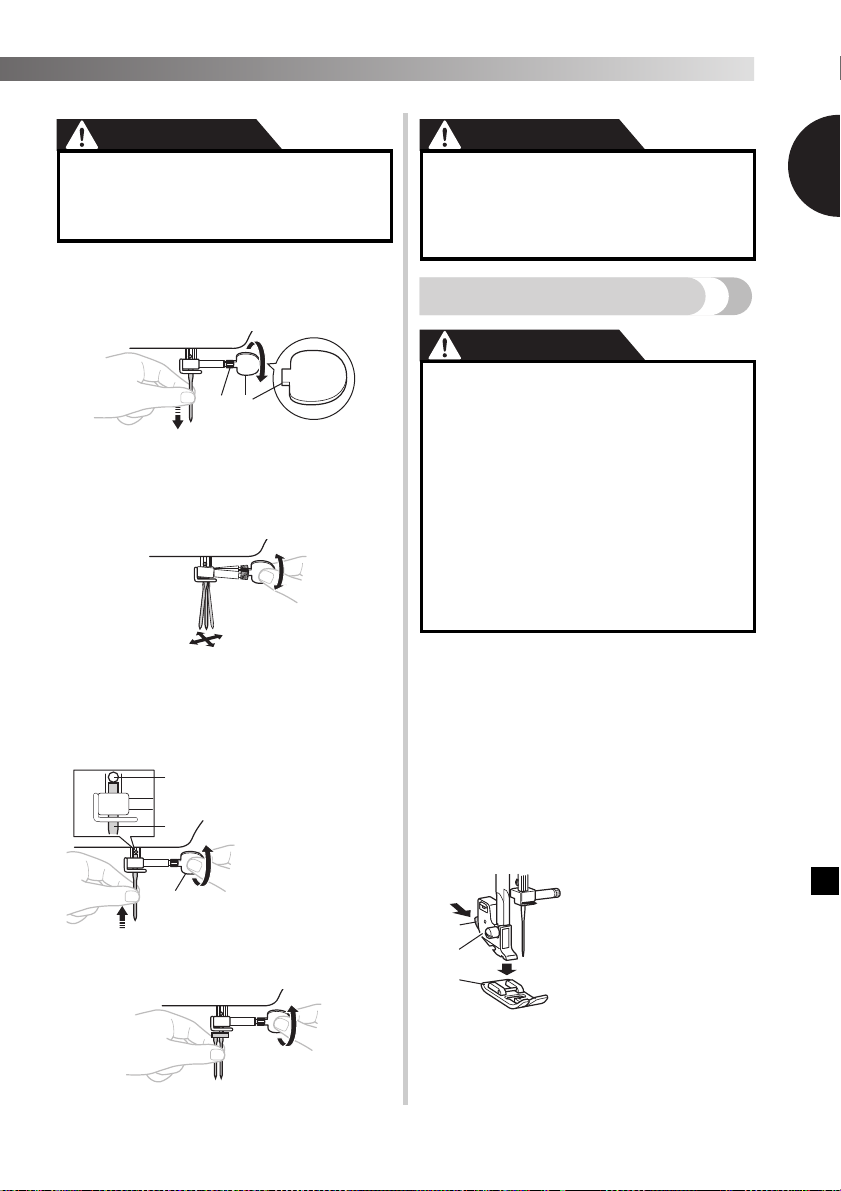

CAUTION

21

2

3

1

CAUTION

● Before replacing the needle, place fabric

or paper under the presser foot to

prevent the needle from falling into the

hole in the needle plate.

Hold the needle with your left hand, and

4

then use an oval screwdriver to turn the

needle clamp screw counterclockwise to

remove the needle.

1 Use an oval screwdriver

2 Needle clamp screw

• Do not use excessive force when loosening

or tightening the needle clamp screw,

otherwise certain parts of the sewing

machine may be damaged.

With the flat side of the needle toward the

5

back of the machine, insert the needle

until it touches the needle stopper. Next,

tighten the needle clamp using an oval

screwdriver.

CAUTION

● Make sure you insert the needle until it

touches the stopper, and securely tighten

the needle clamp screw with an oval

screwdriver, otherwise the needle may

break or the machine may be damaged.

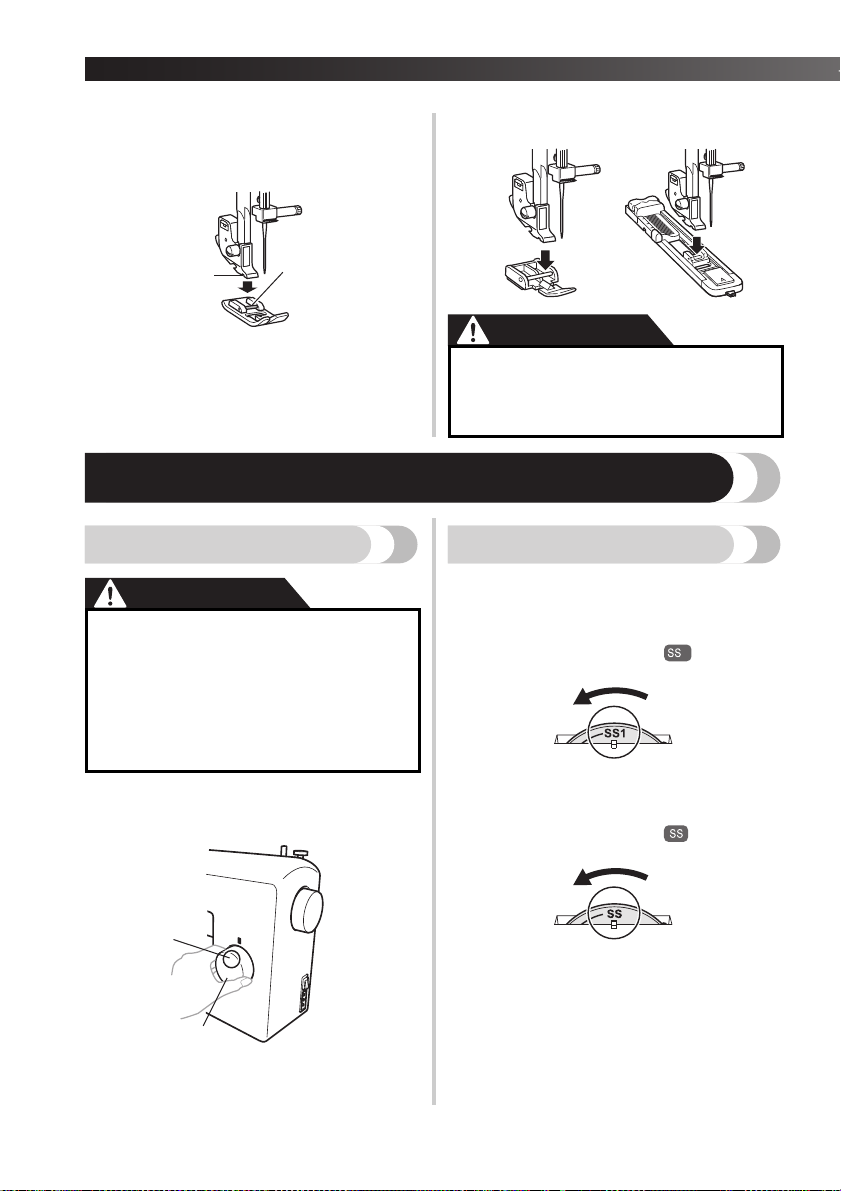

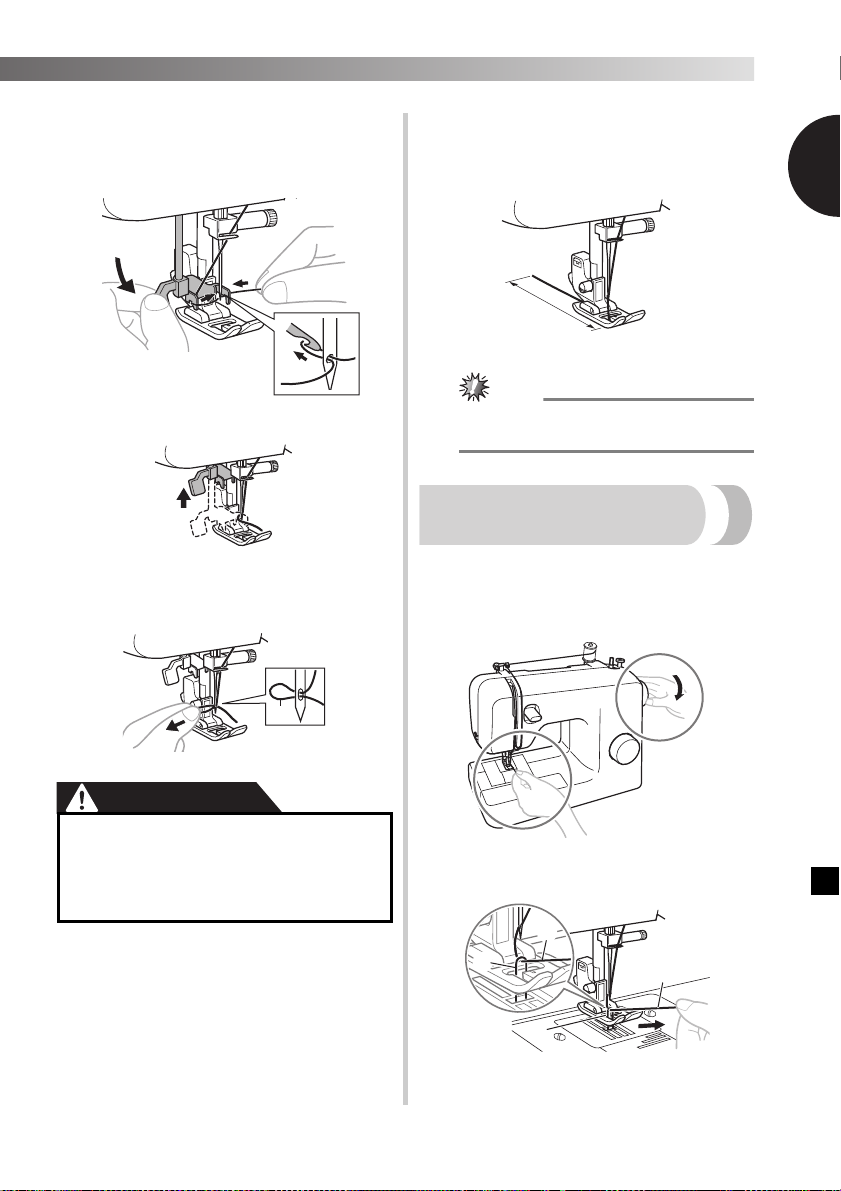

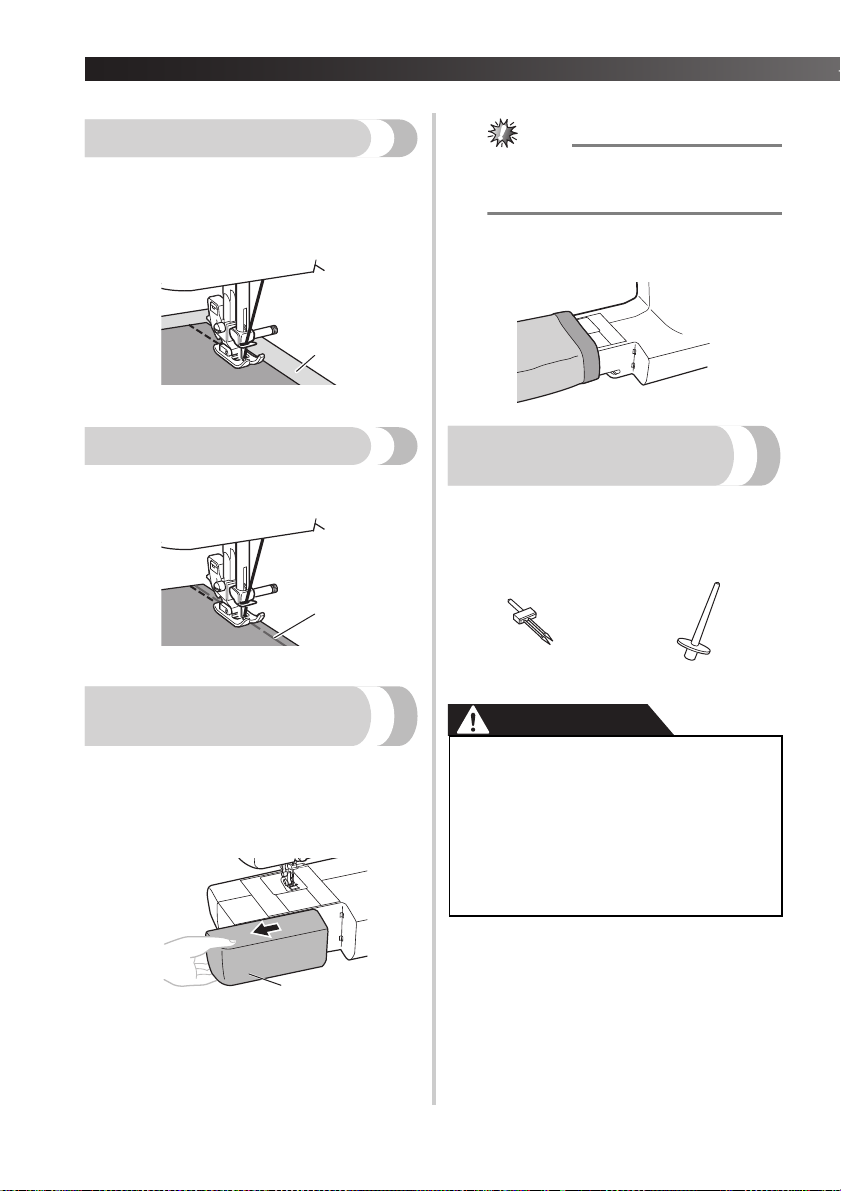

Changing the presser foot

● Always turn off the machine before you

change the presser foot. If you leave the

power on and step on the controller, the

machine will start and you may be

injured.

● Always use the correct presser foot for

the stitch pattern you have chosen. If

you use the wrong presser foot, the

needle may strike the presser foot and

bend or break, and may cause injury.

● Only use presser feet that have been

designed to be used with this machine.

Using any other presser foot may cause

accident or injury.

You will have to change the presser foot depending on

what you want to sew and how.

Turn off the machine.

1

Raise the presser foot lever.

Raise the needle by turning the

2

handwheel toward you

(counterclockwise) so that the mark on

the wheel points up.

Press the black button at the back of the

3

presser foot holder to release the presser

foot.

1

Install the twin needle in the same way.

1 Use an oval

screwdriver

2 Needle stopper

3 Needle

1

2

3

Put a different presser foot on the needle

4

plate so that the bar on the presser foot is

in line with the slot on the shank.

1 Black button

2 Presser foot holder

3 Presser foot

8

Page 10

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

CAUTION

Lower the presser foot lever and fix the

5

presser foot onto the shank. If the presser

foot is in the correct place, the bar should

snap in.

2

1 Shank

2 Bar

1

THE CONTROLS

Pattern selection dial

CAUTION

● When you use the pattern selection dial

to choose a pattern, raise the needle by

turning the handwheel toward you

(counterclockwise) so that the mark on

the wheel points up. If the needle is in

the down position when you turn the

pattern selection dial, the needle, presser

foot or fabric may be damaged.

To choose a stitch, simply turn the pattern selection dial

in either direction. The next section shows

recommended stitch lengths and widths.

■ Presser foot installation orientation

● If the presser foot is not installed with

the correct orientation, the needle may

strike the presser foot, which may bend

or break the needle and cause injury.

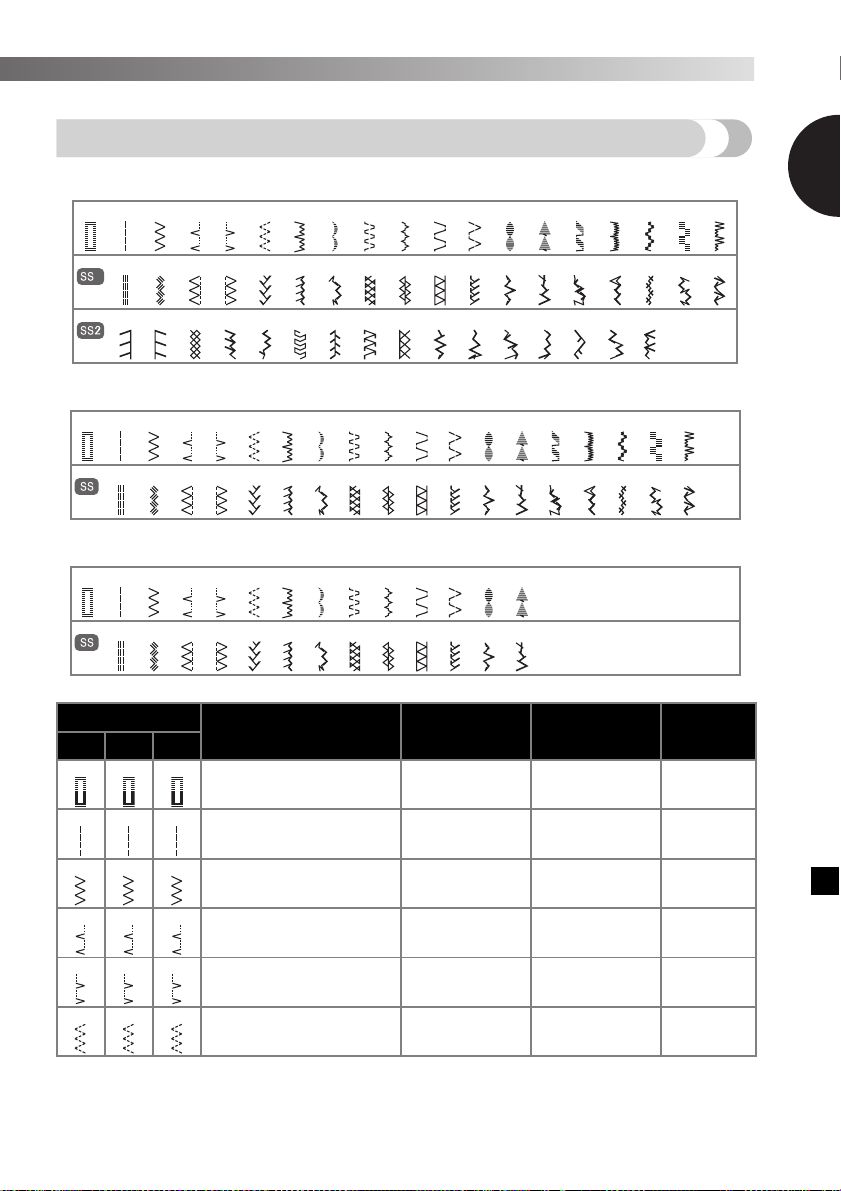

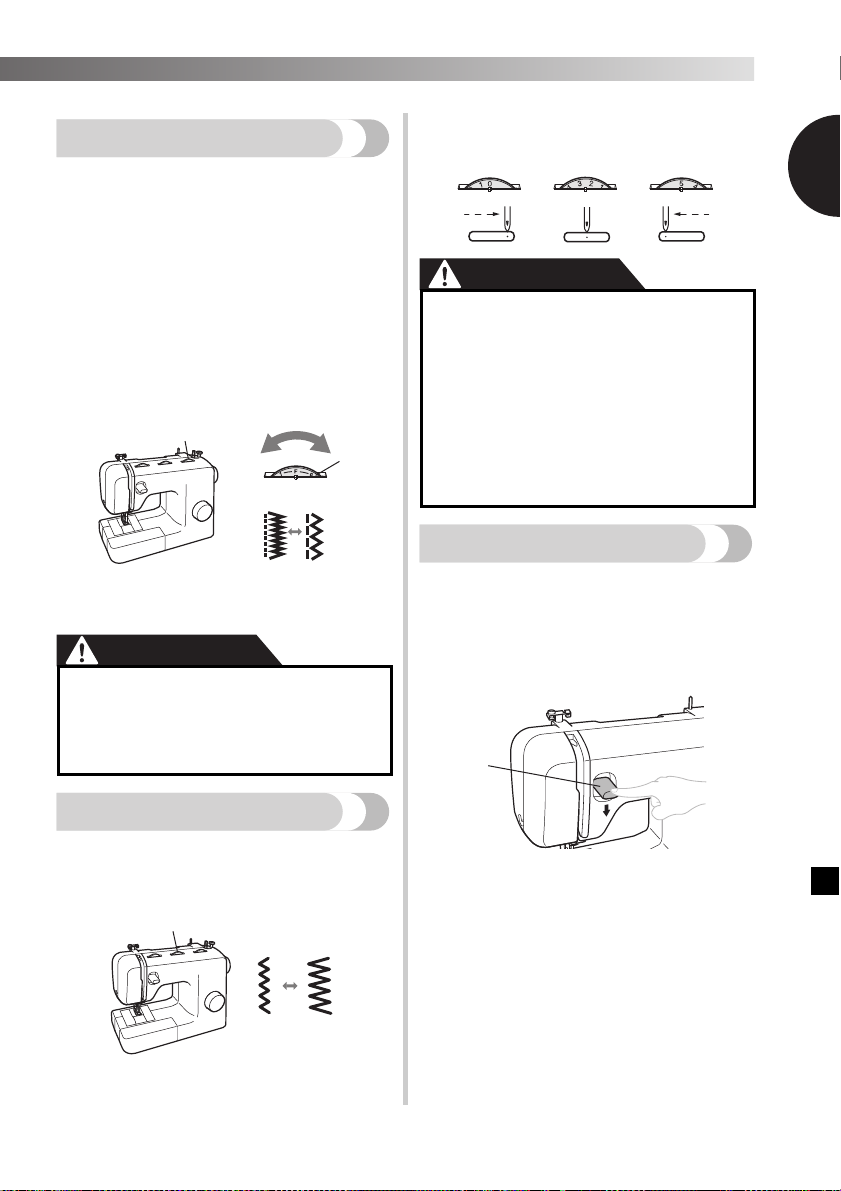

Stretch stitching

Raise the needle by turning the handwheel toward you

(counterclockwise) so that the mark on the wheel points

up.

■ 53 Stitches

Setting the stitch length dial to “ ” changes the

selected pattern to a stretch stitch.

* To set the dial to “SS2”, set it to “SS1”, and then turn the

dial further to the left (direction of the arrow).

■ 27/37 Stitches

Setting the stitch length dial to “ ” changes the

selected pattern to a stretch stitch.

1

9

2

1

1 Pattern selection dial

2 Chosen pattern number

Page 11

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

3

1

20

38

123

123

111

222

333

444

555

666

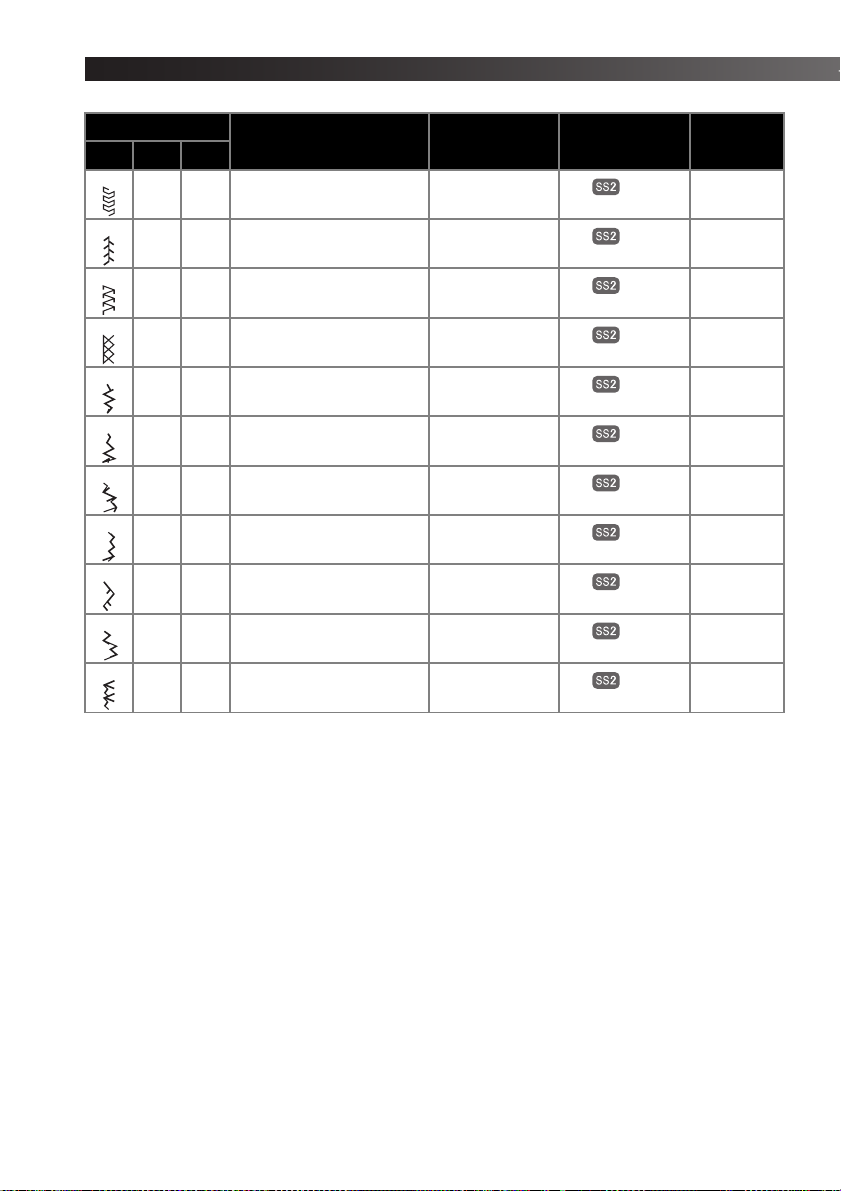

Patterns and stitch names

■ 53 Stitches (only available on certain models)

2

1

5

4

7

6

8 9 10

12

11

13

15

14

16

17

19

18

1

21 22 23 24

40

39

37 Stitches (only available on certain models)

■

20

21 22 23 24

41

42

5

4

6

25

43

7

25

26

44

8 9 10

26

■ 27 Stitches

7

6

20

8 9 10

21

Stitch Name

1-STEP AUTOMATIC

BUTTONHOLE

STRAIGHT STITCH

ZIGZAG STITCH

15

16 17 18 19

Pattern

53 37 27

5

4

32

50

15

14

32

33

14

27

Recommended

33

34

51

52

16

17

34

35

Length

(mm (inch))

F-1.5

(1/64-1/16)

1-4

(1/16-3/16)

F-4

(1/64-3/16)

35

36

53

19

18

37

36

Reference

30, 40, 41,

42, 43, 44, 46

30, 39, 41,

42, 46

37

Page

36

30

48

12

30

12

25

Width

31

49

13

31

13

26

27

45

27

22

29

28

46

47

11

29

28

11

24

23

Recommended

(mm (inch))

3-5

(1/8 – 3/16)

0-5 (0-3/16)

(Changes needle

position)

0-5

(0-3/16)

BLIND HEM STITCH

SHELL TUCK STITCH

ELASTIC STITCH

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

F-2

(1/64-1/16)

F-3

(1/64-1/8)

F-2.5

(1/64-3/32)

30, 46

32

32

10

Page 12

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

777

9

9

101010

11

11

12

12

131313

14

15

15

16

16

17

17

18

18

19

19

20

20

1

212116

22

22

23

23

1

242419

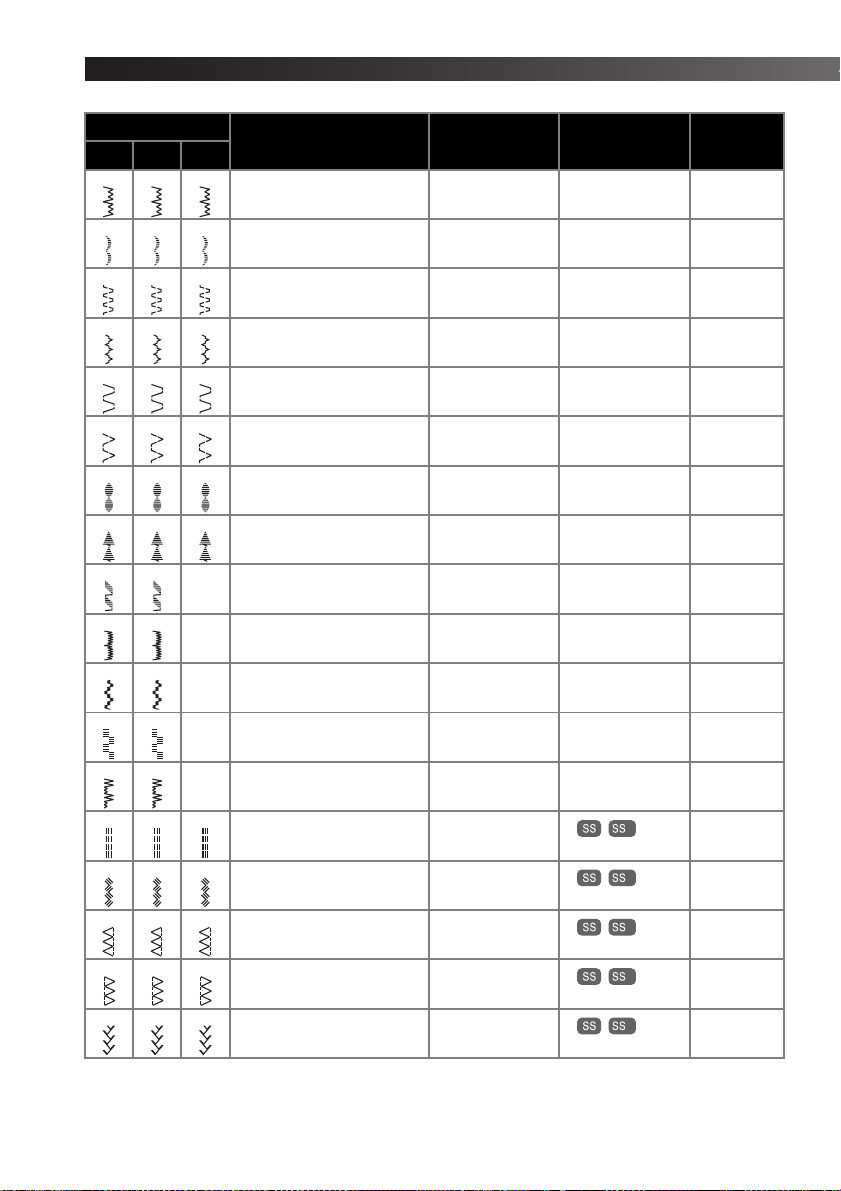

Pattern

53 37 27

8 8 8

14

14

Stitch Name

STRETCH BLIND HEM STITCH

SCALLOP STITCH

9

DOUBLE ACTION STITCH

BRIDGING STITCH

11

12

RAMPART STITCH

ELASTIC SHELL TUCK STITCH

BEAD STITCH

ARROWHEAD STITCH

— PARALLELOGRAM STITCH

— SCALLOP STITCH

— LIGHTNING STITCH

Recommended

Width

(mm (inch))

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

5

(3/16)

Recommended

Length

(mm (inch))

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

F-3

(1/64-1/8)

F-3

(1/64-1/8)

F-3

(1/64-1/8)

F-3

(1/64-1/8)

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

Reference

Page

30

35

33

33

33

34

35

35

35

35

35

—SQUARE STITCH

— DECORATIVE STITCH

15

TRIPLE STRETCH STITCH

TRIPLE ZIGZAG STRETCH

STITCH

17

ELASTIC OVERLOCK STITCH

18

ELASTIC OVERLOCK STITCH

FEATHER STITCH

11

5

(3/16)

5

(3/16)

0-5 (0-3/16)

(Changes needle

position)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

F-1.5

(1/64-1/16)

F-1.5

(1/64-1/16)

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

/ Fixed

(3/32)

2.5

1

/ Fixed

2.5 (3/32)

35

35

30

35

34

34

34

Page 13

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

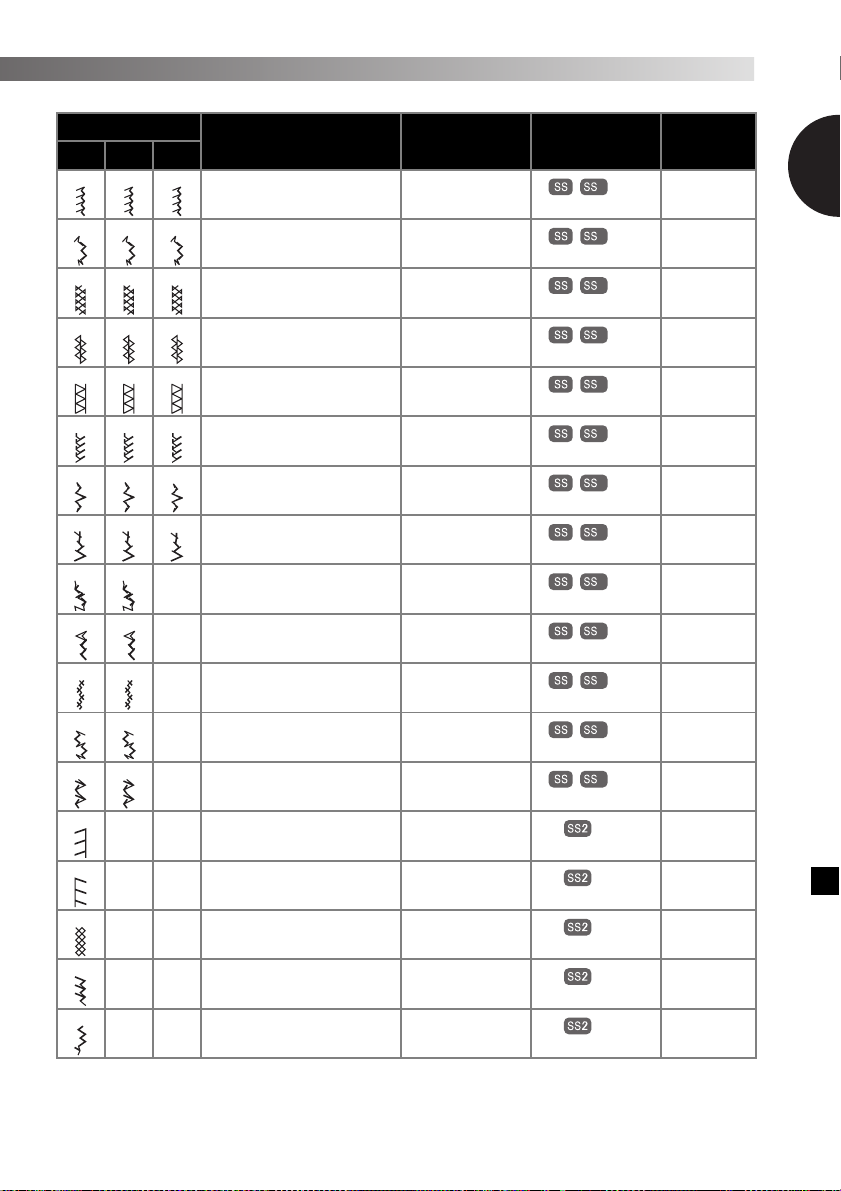

252520

26

21

1

27

22

28

28

23

29

24

1

30

25

31

31

26

32

27

1

33

33

34

35

1

36

36

37

39

42

Pattern

53 37 27

Stitch Name

COMB STITCH

26

27

DECORATIVE STITCH

FAGOTING STITCH

DECORATIVE STITCH

29

30

DECORATIVE HEM STITCH

DECORATIVE STITCH

DECORATIVE STITCH

32

DECORATIVE STITCH

— DECORATIVE STITCH

34

35

— DECORATIVE STITCH

— LINK STITCH

— DECORATIVE STITCH

37

38

— DECORATIVE STITCH

— — STRETCH OVERLOCK STITCH

— — STRETCH OVERLOCK STITCH

40

— — SMOCKING STITCH

41

— — DECORATIVE STITCH

— DECORATIVE STITCH

—

Recommended

Width

(mm (inch))

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

3-5

(1/8-3/16)

5

(3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

5

(3/16)

5

(3/16)

Recommended

Length

(mm (inch))

1

/ Fixed

2.5 (3/32)

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

1

/ Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Reference

Page

1

34

35

33

33

33

35

35

35

35

35

35

35

35

35

35

35

35

35

12

Page 14

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

43

44

45

46

47

48

49

50

51

52

53

Pattern

53 37 27

— — LEAF STITCH

— — TREE STITCH

— — LEGS STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

— — DECORATIVE STITCH

Stitch Name

Recommended

Width

(mm (inch))

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3-5

(1/8-3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

Recommended

Length

(mm (inch))

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Reference

Page

35

35

35

35

35

35

35

35

35

35

35

13

Page 15

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

CAUTION

1

2

3

1

1

When the Straight or Triple Stretch Stitch is selected, the

Stitch length dial

Depending on the selected stitch, you may need to

adjust the stitch length for best results.

The numbers marked on the stitch length dial represent

the stitch length in millimeters (mm) (1/25 inch).

THE HIGHER THE NUMBER, THE LONGER THE

STITCH. With the “0” setting, material is not fed. This is

used when sewing a button.

The “F”-“1” range is for making a satin stitch (closed

zigzag stitch), which is used for making buttonholes

and decorative stitches. The position needed for making

the satin stitch varies according to the material and

thread being used. To determine the exact dial position,

first test the stitch and length settings on a scrap piece of

fabric to observe the feeding of the material.

needle position can be changed from left to right by

adjusting the stitch width dial.

● After adjusting the stitch width, slowly

turn the handwheel toward you

(counterclockwise) and check that the

needle does not touch the presser foot. If

the needle hits the presser foot, the

needle may bend or break.

● If the stitches are bunched together,

increase the stitch length. Continuing to

sew with the stitches bunched together

may result in the needle bending or

breaking.

Reverse sewing lever

1 Stitch length dial

2 Shorter

3 Longer

CAUTION

● If the stitches are bunched together,

lengthen the stitch length and continue

sewing. Do not continue sewing without

lengthening the stitch length, otherwise

the needle may break and cause injury.

You can use reverse sewing for back tacking and

reinforcing seams.

To sew in reverse, push the reverse sewing lever in as

far as possible and hold it in that position while you

lightly push the foot controller. To sew forward, release

the reverse sewing lever. The machine will then sew

forward.

1

1

Stitch width dial

Raise the needle by turning the handwheel toward you

(counterclockwise) so that the mark on the wheel points

up. The numbers marked on the dial represent the stitch

width.

1 Stitch width dial

1 Reverse sewing lever

14

Page 16

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

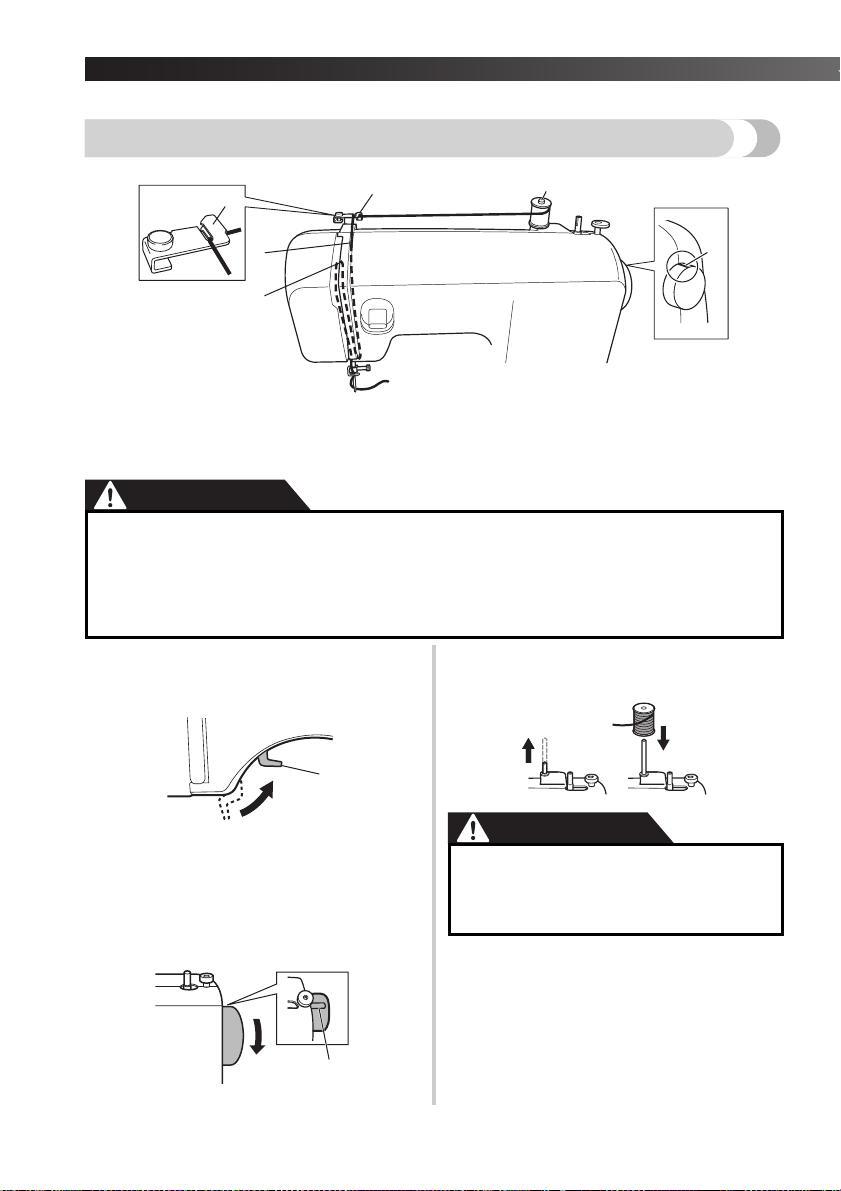

1

3

2

1 Pull the thread

in completely.

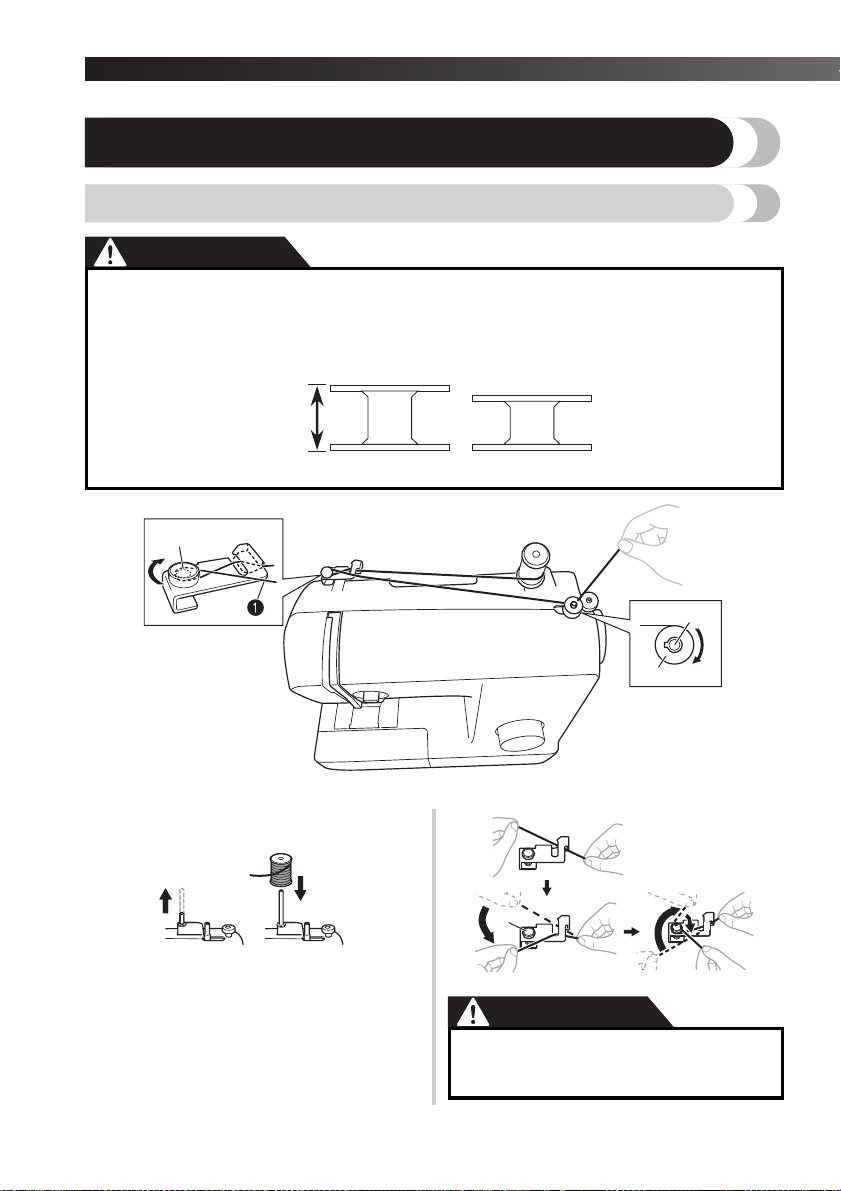

THREADING THE MACHINE

Winding the bobbin

CAUTION

● We designed the bobbin that comes with this machine. If you use bobbins from other models,

the machine will not work properly. Only use the bobbin that comes with this machine or

bobbins of the same type (part code: SA156, SFB: XA5539-151). Using other bobbins may

cause damage to the machine.

11.5 mm

(7/16 inch)

This model Other models

Actual size

1 Pre-tension disk 2 Bobbin winder shaft 3 Bobbin

Pull up the spool pin and put a spool of

1

thread on this pin.

While holding the thread from the spool

2

with your right hand, pass the thread

toward you, in the groove on the thread

guide. Then, pass the thread around the

pre-tension disk and pull the thread in

completely.

15

1

1 Pre-tension disk

CAUTION

● If the spool of thread is in the wrong

place, or is set incorrectly, the thread

may tangle on the spool pin.

Page 17

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

CAUTION

Note

3

1

2

1

Pass the end of the thread through the

3

hole on the bobbin from the inside of the

bobbin.

Put the bobbin onto the bobbin winder

4

shaft and slide the bobbin winder shaft to

the right. Turn the bobbin clockwise, by

hand, until the spring on the shaft slides

into the notch of the bobbin.

• Make sure to pull out 7 to 10 cm (3-4 inches)

of thread from the hole on the bobbin.

1 Spring on the shaft

2 Notch

3 7-10 cm (3-4 inches)

● Pull the thread taut and hold the end of

the thread straight up. If the thread is too

short, not pulled taut or held at an angle,

injuries may occur when the thread is

wound around the bobbin.

While holding the end of the thread,

6

gently press the foot controller to wind

the thread around the bobbin a few times.

Then stop the machine.

Trim the excess thread above the bobbin.

7

1 1 cm (1/2 inch)

CAUTION

● Make sure you follow the instructions

carefully. If you do not cut the excess

thread completely before winding the

bobbin, when the thread runs low it may

tangle around the bobbin and cause the

needle to break.

Press the foot controller to start.

8

1

Turn on the machine.

5

CAUTION

● Do not turn on the machine while

pressing down the foot controller. The

machine may start unexpectedly and

cause personal injury or damage to the

machine.

When the bobbin seems full and begins

9

spinning slowly, take your foot off the foot

controller.

Cut the thread, slide the bobbin winder

0

shaft to the left and remove the bobbin.

● When the sewing machine is started or the

handwheel is turned after winding the thread

around the bobbin, the machine will make a

clicking sound; this is not a malfunction.

● The needle bar does not move when you slide

the bobbin winder shaft to the right.

16

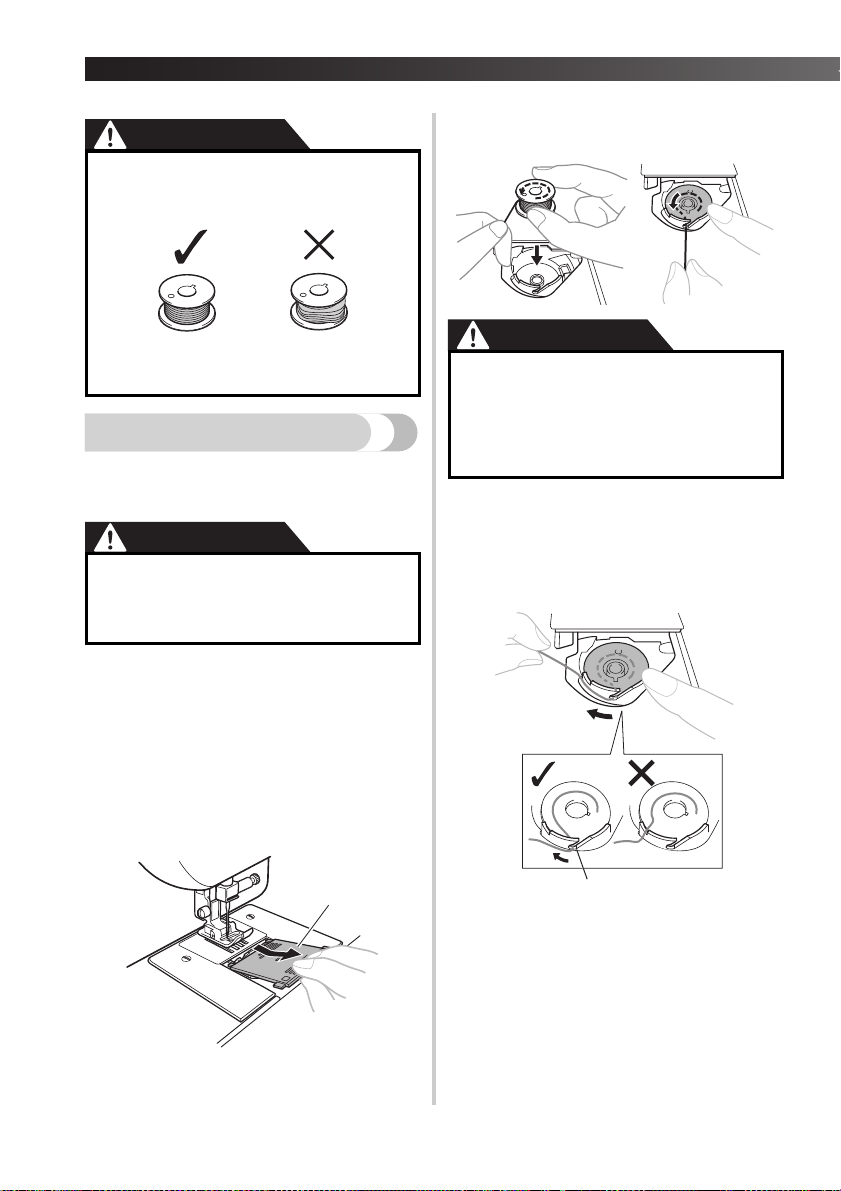

Page 18

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

1

1

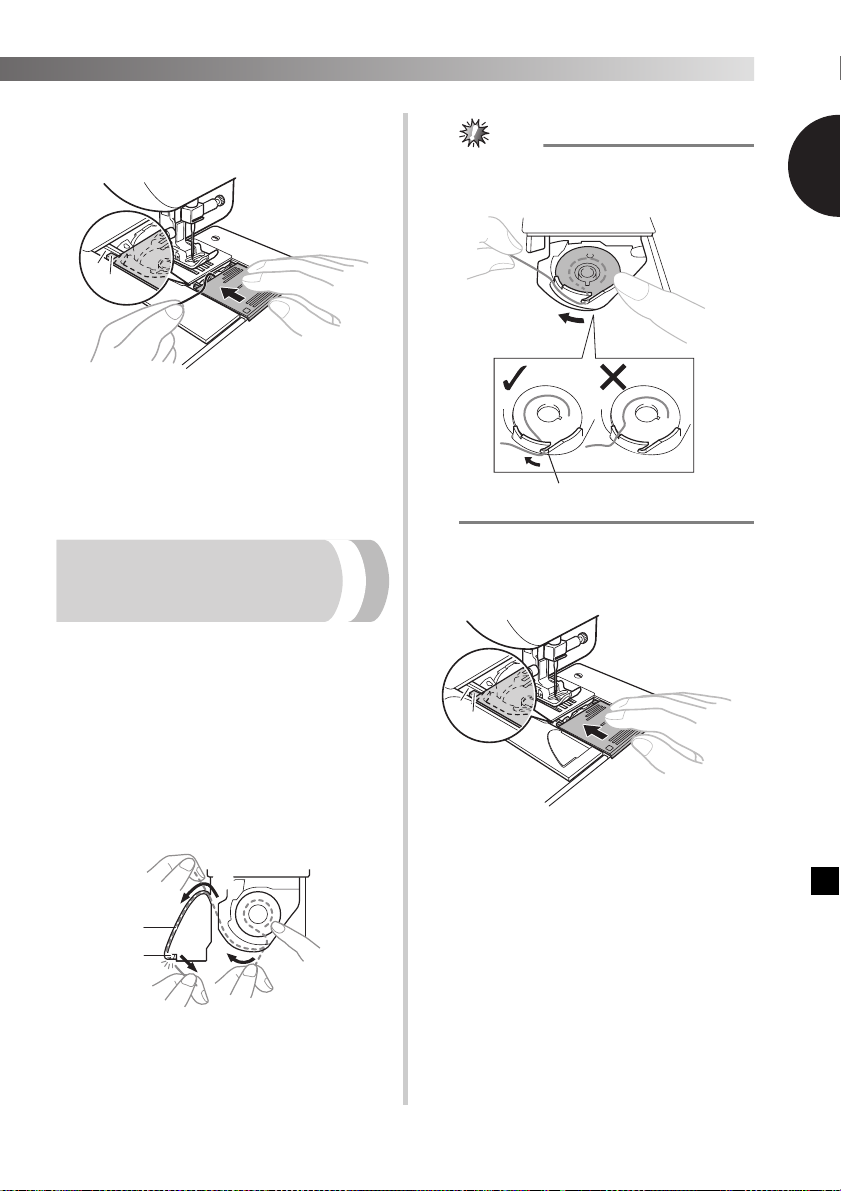

Put the bobbin in so the thread comes out

4

CAUTION

● Not winding the bobbin properly may

in the direction shown by the arrow.

cause the thread tension to loosen, and

may break the needle.

1 Wound evenly

2 Wound poorly

Lower threading

2

Install the bobbin wound with thread.

• For more details on using the quick-set

bobbin, see page 18.

CAUTION

● Make sure you turn off the machine

while threading. If you accidentally step

on the foot controller and the machine

starts to sew, you could be injured.

Prepare the bobbin wound properly

1

before threading the lower thread.

• See page 15 for the details about bobbin

winding.

Raise the needle by turning the

2

handwheel toward you

(counterclockwise) and raise the presser

foot lever.

Remove the bobbin cover by sliding it and

3

lift toward you.

1

CAUTION

● Make sure you set the bobbin so the

thread unrolls in the right direction. If

the thread unrolls in the wrong

direction, it may cause the thread

tension to be incorrect or break the

needle.

Hold the end of the thread, push the

5

bobbin down with your finger, and then

pass the thread through the slit, as shown.

• If the thread is not correctly inserted through

the tension-adjusting spring of the bobbin

case, it may cause incorrect thread tension.

1 Tension-adjusting spring

17

1 Bobbin cover

Page 19

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Note

1

2

1

2

2

3

1

1

1

2

Replace the bobbin cover. Put the

6

projection into the race retainer groove

and push closed.

1 Groove

2 Projection

• Make sure that the end of the thread comes

out from the cover toward the rear of the

machine (as shown in the illustration).

• Draw up the lower thread before starting

sewing. Refer to “Drawing up the lower

thread” on page 22 after threading the upper

thread.

● If the thread is not correctly inserted through

the tension-adjusting spring of the bobbin

case, it may cause incorrect thread tension.

1 Tension-adjusting spring

1

Lower threading (for

models equipped with a

quick-set bobbin)

Install the bobbin wound with thread.

This feature is only available on certain models.

Follow steps 1 to 4 from “Lower

1

threading” on page 17.

While lightly holding down the bobbin

2

with your right hand as shown, guide the

thread through the slit (

pull the thread toward you to cut it with

the cutter (

• At this time, check that the bobbin easily

1 Slit

2 Cutter (Cut the thread with the cutter.)

3).

rotates counterclockwise.

1 and 2). Then,

Replace the bobbin cover. Put the

3

projection into the race retainer groove

and push closed.

1 Groove

2 Projection

• Start sewing after threading the lower and

upper thread. When sewing gathers or darts,

you can draw up the lower thread by hand so

that some thread will be left over. Refer to the

steps in “Drawing up the lower thread”

(page 22).

18

Page 20

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

CAUTION

4

3

2

2

1

5

1

1

Upper threading

1 Spool pin

2 Thread guide (back)

3 Thread guide (front)

4 Thread take-up lever

5 Mark on the handwheel

CAUTION

● When threading the upper thread, carefully follow the instructions. If the upper threading is

not correct, the thread may become tangled or the needle may bend or break.

● Never use a thread weight of 20 or lower.

● Use the needle and the thread in the correct combination. For details on the correct

combination of needles and threads, refer to “FABRIC, THREAD, AND NEEDLE

COMBINATIONS” on page 24.

1

2

3

19

Turn off the machine.

Raise the presser foot lever.

1 Presser foot lever

Raise the needle by turning the handwheel

toward you (counterclockwise) so that the

mark on the wheel points up.

• If the needle is not correctly raised, the

sewing machine can not be threaded.

1 Mark on the wheel

Pull up the spool pin and put a spool of

4

thread on this pin.

● If the spool of thread is in the wrong

place, or is set incorrectly, the thread

may tangle on the spool pin and cause

the needle to break.

Page 21

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Memo

Note

1

1

1

While holding the thread from the spool

5

with your right hand, pass the thread

toward you, in the groove on the thread

guide.

• Make sure that the spring in the groove

catches the thread.

1 Spring

Feed the upper thread as shown in the

6

following illustration.

Make sure you guide the thread through

7

the thread take-up lever from right to left

as shown in the following illustration.

Put the thread behind the guide above the

8

needle.

• The thread can easily be passed behind the

needle bar thread guide by holding the

thread in your left hand, then feeding the

thread with your right hand.

1

1 Needle bar thread guide

Thread the needle from front to back

9

leaving a thread tail of about 5 cm

(2 inches).

• If your sewing machine is equipped with a

needle threader, use the needle threader to

thread the needle (see next section).

1

1 Thread take-up lever

● If the thread take-up lever is lowered, the

upper thread can not be wrapped around

the thread take-up lever. Make sure you

raise the needle by turning the handwheel

toward you (counterclockwise) so that the

mark on the wheel points up.

1

1 5 cm (2 inches)

● Make sure you raise the presser foot lever

and the thread take-up lever before you feed

the upper thread.

● If you incorrectly feed the thread you may

cause sewing problems.

20

Page 22

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

CAUTION

1

1

2

3

While lowering the needle threader lever,

Using the needle threader

4

hook the thread onto the guide.

(for models equipped with

a needle threader)

This feature is only available on certain models.

1

The needle threader can be used with a

●

75/11 through 100/16 home sewing

machine needle. However, the needle

threader cannot be used with a 65/9

home sewing machine needle. When

using special thread such as transparent

nylon thread or metallic thread, the

needle threader cannot be used.

● Thread with a thickness of 130/120 or

thicker cannot be used with the needle

threader.

● The needle threader cannot be used with

the wing needle or the twin needle.

● If the needle threader cannot be used,

refer to “Upper threading” on page 19.

Follow steps 1 to 8 from “Upper

1

threading” on page 19 before using the

needle threader.

Lower the presser foot lever.

2

Make sure that the mark on the wheel

3

points up as shown in the following

illustration.

2

1 Needle holder

2 Needle threader lever

1 Needle holder

2 Needle threader lever

3 Guide

Pull down the needle threader lever as

5

much as possible, and then turn the lever

toward the back of the machine (away

from you). Make sure that the hook passes

through the eye of the needle and grabs

the thread.

21

1 Mark on the wheel

1 21

1 Hook

2 Thread

• Hold the thread in front of the needle to

make sure that the hook grabs it.

Page 23

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

CAUTION

Note

1

While lightly holding the thread, turn the

6

needle threader lever toward the front of

the machine (toward you). The hook will

pull the thread through the needle.

Raise the needle threader lever.

7

Pull the loop of the thread passed through

8

the eye of the needle toward the rear of

the machine.

Pass the end of the thread through the

0

presser foot, and then pull out about 5 cm

(2 inches) of thread toward the rear of the

machine.

1

1 5 cm (2 inches)

● If you incorrectly feed the thread you may

cause sewing problems.

Drawing up the lower

thread

While lightly holding the end of the upper

1

thread, slowly turn the handwheel toward

you (counterclockwise) by hand to lower

and then raise the needle.

1

1 Loop of thread

● Be careful not to pull on the thread with

force or it may bend the needle.

● If the thread does not pass through the

eye of the needle, start from step

again.

Raise the presser foot lever.

9

3

Pull on the upper thread to draw up the

2

lower thread.

1

2

2

1 Upper thread

2 Lower thread

1

22

Page 24

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

Pull out about 10 cm (4 inch) of both

3

threads and put them toward the back of

the machine under the presser foot.

1

2

1 Upper thread

2 Lower thread

■ For models equipped with a quick-set

bobbin

You can begin sewing immediately without drawing

up the bobbin thread.

When sewing gathers or darts, you can draw up the

lower thread by hand so that some thread will be

left over. Before you draw up the lower thread, put

the bobbin back in.

Remove the bobbin cover, and then

1

reinstall the bobbin.

Pass the thread along the slit in the

2

direction of the arrow, and leave it there

without cutting it.

• The bobbin cover should still be removed.

Draw up the lower thread as described in

3

the previous steps

Replace the bobbin cover.

4

1 to 3.

23

Page 25

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Note

Memo

CAUTION

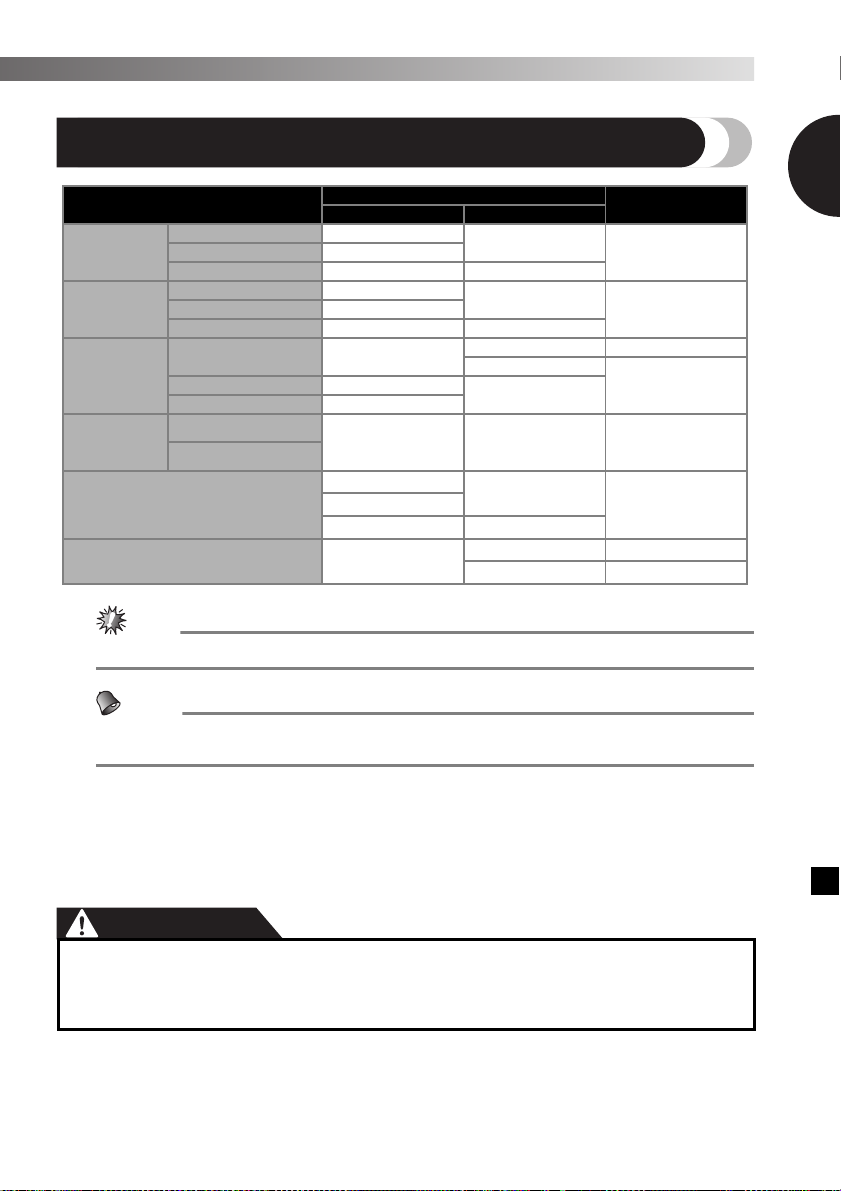

FABRIC, THREAD, AND NEEDLE COMBINATIONS

Fabric Type/Application

Medium weight

fabrics

Thin fabrics

Thick fabrics

Stretch fabrics

Easily frayed fabrics

For top-stitching

Broadcloth Cotton thread

Taffeta Synthetic thread

Flannel, Gabardine Silk thread 50

Lawn Cotton thread

Georgette Synthetic thread

Challis, Satin Silk thread 50

Denim Cotton thread

Corduroy Synthetic thread

Tweed Silk thread

Jersey

Tricot

Type Size

Thread for knits 50–60

Cotton thread

Silk thread 50

Synthetic thread

Silk thread

Thread

Size of Needle

60–90

60–90

30 100/16

50

50–60

50–90

30 100/16

50–60 75/11–90/14

75/11–90/14

65/9–75/11

90/14–100/16

Ball point needle

75/11–90/14

(gold colored)

65/9–90/14Synthetic thread

1

● Never use a thread of weight 20 or lower. It may cause machine malfunction.

● The lower the thread number, the thicker the thread; and the larger the needle number, the thicker the

needle.

■ Ball point needle

Use the ball point needle when sewing on stretch fabrics or fabrics where skipped stitches easily occur.

The factory recommended needle is “HG-4BR” (Organ). Schmetz needles “JERSEY BALL POINT” 130/705H SUK

90/14 may be used as a substitute.

■ Transparent nylon thread

Use a 90/14 to 100/16 needle, regardless of the fabric or thread.

Make sure you follow the needle, thread, and fabric combinations listed in the table.

●

Using the wrong combination, such as heavyweight fabric like denim with a small needle

(65/9-75/11), may bend or break the needle. The wrong combination may also cause the seam

to be uneven, the fabric to pucker, or the machine to skip stitches.

24

Page 26

SEWING BASICS ——————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

CAUTION

1

2 SEWING BASICS

Please read before sewing

CAUTION

● To avoid being injured, watch the needle carefully while you are using the machine. Keep

your hands away from moving parts.

● Do not stretch or pull the fabric during sewing, otherwise the needle may be damaged and

you may be injured.

● Do not use bent or broken needles, otherwise you may be injured.

● Take care that the needle does not hit basting pins or other objects during sewing. The needle

may break and you may be injured.

● Always use the correct presser foot. If you use the wrong presser foot, the needle may hit the

presser foot and bend or break and you may be injured.

● When you turn the handwheel by hand, always turn it toward you (counterclockwise).

Turning it the other way may cause the thread to tangle and damage the needle or fabric, and

you may be injured.

● Do not start sewing without placing the fabric under the presser foot, otherwise the presser

foot may be damaged.

Raise the presser foot lever.

Starting sewing

Turn on the machine.

1

5

1

2

3

4

25

● Do not turn on the machine while

pressing down the foot controller. The

machine may start unexpectedly and

cause personal injury or damage to the

machine.

Raise the needle by turning the

handwheel toward you

(counterclockwise) so that the mark on

the wheel points up.

Turn the pattern selection dial to select a

stitch (see page 9 - 13).

Change the presser foot (see page 8).

1 Presser foot lever

Place the fabric under the presser foot,

6

pass the thread under the presser foot,

and then pull out about 5 cm (2 inches) of

thread toward the rear of the machine.

1 5 cm (2 inches)

Page 27

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

CAUTION

1

1

1

2

While holding the end of the thread and

7

the fabric with your left hand, turn the

handwheel toward you

(counterclockwise) with your right hand

to lower the needle to the starting point of

the stitching.

Trial sewing

A trial piece of fabric should be sewn. Use a piece of

fabric and thread that are the same as those used for

your project, and check the thread tension and stitch

length and width.

Changing the sewing

direction

Stop the machine with the needle in the fabric at the

point where you want to change the sewing direction,

Lower the presser foot lever.

8

1 Presser foot lever

Slowly press down on the foot controller.

9

and then raise the presser foot lever. Using the needle

as a pivot, turn the fabric, lower the presser foot lever,

and then continue sewing.

Sewing thick fabrics

■ If the fabric does not fit under the presser

foot

X The machine starts sewing.

Take your foot off the foot controller.

0

X The machine stops sewing.

• You can use reverse sewing for back tacking

and reinforcing seams by pressing the reverse

sewing lever. Refer to “Reverse sewing lever”

on page 14 for the details.

Raise the needle by turning the

a

handwheel toward you

(counterclockwise).

Raise the presser foot lever.

b

Pull the fabric to the left side of the

c

machine, and then pass the threads

through the thread cutter to cut them.

.

If the fabric does not fit easily under the presser foot,

raise the presser foot lever even higher to bring the

presser foot to its highest position.

● If fabric more than 6 mm (15/64 inch)

thick is sewn or if the fabric is pushed

with too much force, the needle may

bend or break.

2

1 Thread cutter

26

Page 28

SEWING BASICS ——————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

Note

1

1

1

Sewing thin fabrics

When sewing thin fabrics, the stitching may become

misaligned or the fabric may not feed correctly. If this

occurs, place thin paper or stabilizer material under the

fabric and sew it together with the fabric. When you

have finished sewing, tear off any excess paper.

1 Stabilizer material or paper

● When you are finished with free-arm

sewing, install the flat bed attachment back

in its original position.

Slide the part that you wish to sew onto

2

the arm, and then sew from the top.

Sewing stretch fabrics

First, baste the pieces of fabric together, and then sew

without stretching the fabric.

1 Basting

Stitching cylindrical

pieces

Removing the flat bed attachment makes it easier to sew

cylindrical pieces such as cuffs and pant legs, or hardto-reach areas.

Slide the flat bed attachment to the left to

1

release it.

1 Flat bed attachment

X With the flat bed attachment removed,

free-arm sewing is possible.

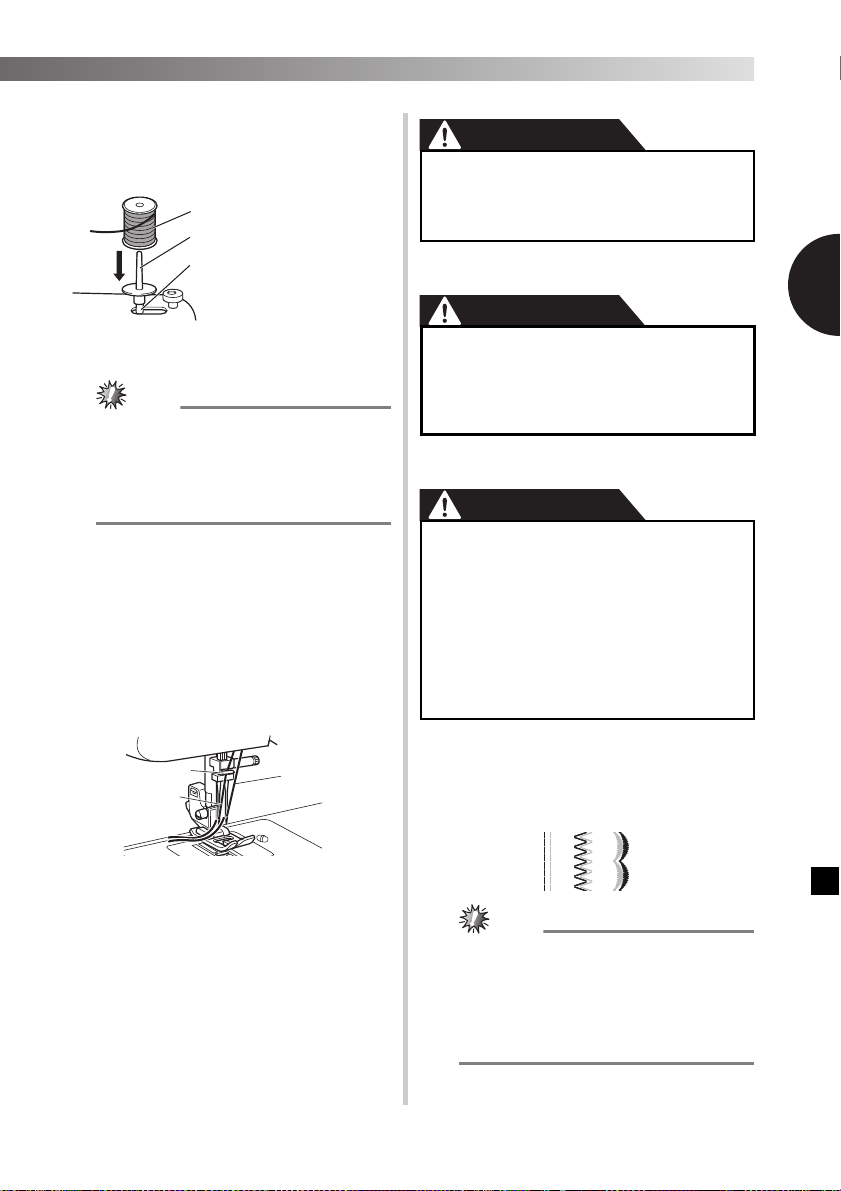

Sewing with a twin needle

(Option)

We have designed your machine so you can sew with

this needle and two top threads. You can use the same

color or two different colors of thread for making

decorative stitches.

1 Twin needle 2 Extra spool pin

CAUTION

● Use only twin needles that have been

made for this machine (part code:

X57521-021:2.0/75 with a 2 mm width).

Other needles could break and damage

the machine.

● Make sure that the needle does not strike

the presser foot.

● Do not sew with bent needles. The

needle could break and injure you.

■ Attaching the twin needle

Attach the twin needle in the same way as a single

needle (see page 7–8). The flat side of the needle

should face toward the back and the rounded side

should face toward you.

27

Page 29

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Note

CAUTION

Note

■ Attaching the extra spool pin

Insert the extra spool pin onto the end of the bobbin

winder shaft. Install the second thread spool onto

the extra spool pin.

1 Bobbin winder shaft

2 Extra spool pin

3

3 Thread spool

2

1

■ Twin needle threading

You should thread each needle separately.

Models equipped with a needle threader

● You cannot use the needle threader to

thread the twin needle. Instead, thread the

twin needle by hand, from front to back.

Using the needle threader may damage the

machine.

Thread the left needle.

1

Follow the same instructions for threading a

single needle (see page 19).

Thread the right needle.

2

Thread the right needle in the same way that

you threaded the left needle using the thread

from the spool on the extra spool pin, but do not

pass the thread through the guide above the

needle before you pass it through the eye of the

right needle.

3

2

1

CAUTION

● When using the twin needle, be sure to

attach zigzag foot “J”, otherwise the

needle may break or the machine may be

damaged.

Turn on the machine.

4

● Do not turn on the machine while

pressing down the foot controller. The

machine may start unexpectedly and

cause personal injury or damage to the

machine.

Select a stitch.

5

CAUTION

● After adjusting the stitch width, slowly

turn the handwheel toward you

(counterclockwise) and check that the

needle does not touch the presser foot. If

the needle hits the presser foot, the

needle may bend or break.

● When using the twin needle, make sure

the stitch width is not set above “2.5”

since this may cause the needle to hit the

needle plate and break.

Start sewing.

6

For details on starting to sew, refer to “Starting

sewing” on page 25.

X Two lines of stitching are sewn parallel to

each other.

2

1 Left needle thread passes through the needle

bar thread guide

2 Right needle thread passes in front of the needle

bar thread guide

3 Needle bar thread guide

Attach zigzag foot “J”.

3

For details on changing the presser foot, refer

to “Changing the presser foot” on page 8.

● When using the twin needle, the stitches

may become bunched together, depending

on the types of thread and fabric that are

used. If this occurs, increase the stitch

length. For details on adjusting the stitch

length, refer to “Stitch length dial” on

page 14.

28

Page 30

SEWING BASICS ——————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

Memo

Note

Note

1

2

3

4

CAUTION

When changing the sewing direction, be

●

sure to raise the needle from the fabric,

and then raise the presser foot lever and

turn the fabric. Otherwise the needle may

break or the machine may be damaged.

Thread tension

The tension of the thread will affect the quality of your

stitches. You may need to adjust it when you change

fabric or thread.

● We recommend that you do a test sample

on scrap of a fabric before you start to sew.

■ Correct tension

Correct tension is important as too much or too little

tension will weaken your seams or cause puckers

on your fabric.

1 Surface of fabric

2 Back of fabric

3 Upper thread

4 Lower thread

■ Upper tension is too tight

Loops will appear on the surface of the fabric.

■ Upper tension is too loose

Loops appear on the back of the fabric.

● If the upper thread was incorrectly threaded,

the upper thread may be too loose. In this

case, refer to “Upper threading” on page 19

and rethread the upper thread.

5

2

1

3

4

Solution

Increase the tension by turning the upper tension

control dial to a higher number.

1 Surface of fabric

2 Back of fabric

3 Upper thread

4 Lower thread

5 Loops appear on back

of fabric

● If the bobbin thread was incorrectly

threaded, the upper thread may be too tight.

In this case, refer to “Lower threading” on

page 17 and rethread the bobbin thread.

2

1

3

5

4

Solution

Reduce the tension by turning the upper tension

control dial to a lower number.

29

1 Surface of fabric

2 Back of fabric

3 Upper thread

4 Lower thread

5 Loops appear on

surface of fabric

Page 31

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

Memo

2

20

3 BUILT-IN STITCHES

We recommend that you sew using the Straight

Straight stitching

Straight stitches are used for sewing plain seams.

Stitch

Name

Pattern Stitch

53 37 27

[mm (inch)]

Length

Stitch

Width

[mm (inch)]

Stitch at the beginning and end of zigzag stitches.

(This acts as a reinforcement stitch.)

Straight

Stitch

Triple

Stretch

Stitch

* Turn the stitch width dial to adjust the needle position.

Setting the dial to “5” selects the left needle position;

setting the dial to “0” selects the right needle position.

Refer to “Stitch width dial” on page 14.

15

1-4

(1/16-3/16)

/

Fixed 2.5

(3/32)

0-5*

(0-3/16)

1

■ Top stitching and stretch materials

You can use a straight stitch for top stitching and

sewing lightweight fabrics.

You can use a triple stretch stitch for sewing stretch

fabrics.

Zigzag stitching

Stitch

3

Length

[mm (inch)]

F-4

(1/64-3/16)

Stitch Name Pattern

Zigzag Stitch

■ Zigzag stitch

Turn the pattern selection dial to the Zigzag Stitch,

and then start sewing.

Stitch

Width

[mm (inch)]

0-5

(0-3/16)

■ Satin stitch

Setting the Zigzag Stitch length in the “F”-“1” range

produces a satin stitch (close zigzag stitch). The

Satin Stitch can be used for making buttonholes and

decorative stitches. Set the pattern selection dial to

the Zigzag Stitch, set the stitch length in the “F”-“1”

range, and set the stitch width dial between “0” and

“5”.

Blind hem stitching

4

7

Stitch

Length

[mm (inch)]

F-2

(1/64-1/16)

F-1.5

(1/64-1/16)

Stitch Name Pattern

Blind Hem

Stitch

Stretch Blind

Hem Stitch

You can use the Blind Hem Stitch to finish the edge of a

project, like the hem of a pair of trousers, without the

stitch showing. Blind Hem Stitch: sewing on non-stretch

fabrics. Stretch Blind Hem Stitch: for stretch fabrics.

● When the size of cylindrical pieces is too

small to slide onto the arm or the length is

too short, the fabric will not feed and

desired results may not be achieved.

Stitch

Width

[mm (inch)]

3-5

(1/8-3/16)

3-5

(1/8-3/16)

3

Reverse the skirt or pants.

1

2

1

3

4

1 Wrong side of fabric

2 Right side of fabric

3 Bottom side

4 Edge of fabric

30

Page 32

BUILT-IN STITCHES ———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

—————

1

2

1

2

1

3

3

4

2

1

2

1

2

3

5

6

4

1

2

1

2

3

4

1

1

6

7

5

1

3

Fold the fabric along the desired edge of

2

the hem, and press.

1 Wrong side of

fabric

2 Right side of

fabric

3 Edge of fabric

4 Desired edge of

hem

<Thick fabric>

<Normal fabric>

<Seen from the side>

Use a chalk to mark on the fabric about 5

3

mm (3/16 inch) from the edge of the

fabric, and then baste it.

1 Wrong side of

fabric

2 Right side of

fabric

3 Edge of fabric

4 Basting stitching

5 5 mm (3/16 inch)

6 Desired edge of

hem

<Thick fabric>

<Normal fabric>

<Seen from the side>

Fold back the fabric inside along the

4

basting.

1 Wrong side of

fabric

2 Edge of fabric

3 Basting

4 5 mm (3/16 inch)

5 Desired edge of

hem

6 Right side of

fabric

7 Basting point

<Thick fabric>

<Normal fabric>

<Seen from the side>

Unfold the edge of fabric, and position the

5

fabric with the wrong side facing up.

1 Wrong side of

fabric

5

3

1

1

1

1

1

<Seen from the side>

Remove the flat bed attachment and make

6

free-arm sewing possible.

• For details on free-arm sewing, refer to

“Stitching cylindrical pieces” (Page 27).

Slide the part that you wish to sew onto

7

the arm, make sure that the fabric feeds

2 Right side of

4

3 Basting

4 Edge of fabric

5 Desired edge of

6 Basting point

<Thick fabric>

6

2

<Normal fabric>

fabric

hem

correctly, and then start sewing.

1 Arm

After selecting a stitch, slowly turn the

8

handwheel toward you

(counterclockwise) until the needle has

moved from the right side to the left.

Position the fabric under the presser foot,

9

and then adjust the stitch width until the

needle slightly catches the fold of the

hem.

1 Wrong side of fabric

2 Fold of hem

3 Needle drop point

31

1

2

1

2

3

1 Needle

2 Needle drop point

3 Fold of hem

Page 33

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

1

2

6

Stitch width

Lower the presser foot lever.

0

• For details on changing the stitch width, refer

to “Stitch width dial” on page 14.

Sew at a slow speed holding the fabric

a

with your hands, so that the needle

slightly catches the fold of the hem.

Remove the basting stitching and turn the

b

fabric right side up.

1 Wrong side of fabric 2 Right side of fabric

Shell tuck stitching

5

Stitch

Length

[mm (inch)]

F-3

(1/64-1/8)

[mm (inch)]

(1/8-3/16)

Stitch Name Pattern

Shell Tuck

Stitch

Stitch

Width

3-5

Sew at a slow speed.

3

2

1 Straight stitches

2 Zigzag stitches

1

Elastic stitching

Stitch Name Pattern

Elastic Stitch

You can use the Elastic Stitch for mending, sewing

elastic or joining fabric. Each is explained below.

Stitch

Length

[mm (inch)]

F-2.5

(1/64-3/32)

■ Mending

Place the reinforcement fabric under the

1

area you want to mend.