Page 1

SERVICE MANUAL

MODEL: P-touch 65

P-touch HOME&HOBBY

P-touch One

Page 2

SERVICE MANUAL

MODEL:P-touch 65

P-touch HOME&HOBBY

P-touch One

Page 3

© Copyright Brother 2000

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Page 4

PREFACE

This publication is a service manual covering the specifications, theory of operation,

disassembly/reassembly procedure, and troubleshooting of the Brother P-touch 65/Ptouch HOME&HOBBY/P-touch One. It is intended for service personnel and other

concerned persons to accurately and quickly provide after-sale service for our P-touch

65/P-touch HOME&HOBBY/P-touch One.

To perform appropriate maintenance so that the machine is always in best condition

for the customer, the service personnel must adequately understand and apply this

manual.

This manual is made up of four chapters and appendices.

CHAPTER I SPECIFICATIONS

CHAPTER II MECHANISMS

CHAPTER III ELECTRONICS

CHAPTER IV TROUBLESHOOTING

APPENDICES CIRCUIT DIAGRAMS

Page 5

Chapter I.

SPECIFICATIONS

Page 6

CONTENTS

CHAPTER I. SPECIFICATIONS

1.1 MECHANICAL SPECIFICATIONS ........................................................................................I-1

1.1.1 External Appearance................................................................................................I-1

1.1.2 Keyboard..................................................................................................................I-1

1.1.3 Display......................................................................................................................I-1

1.1.4 Printing Mechanism..................................................................................................I-2

1.1.5 Tape Cassette..........................................................................................................I-2

1.1.6 Tape Cutter ..............................................................................................................I-2

1.2 ELECTRONICS SPECIFICATIONS ......................................................................................I-4

1.2.1 Character Generator ................................................................................................I-4

1.2.2 Power Supply...........................................................................................................I-4

Page 7

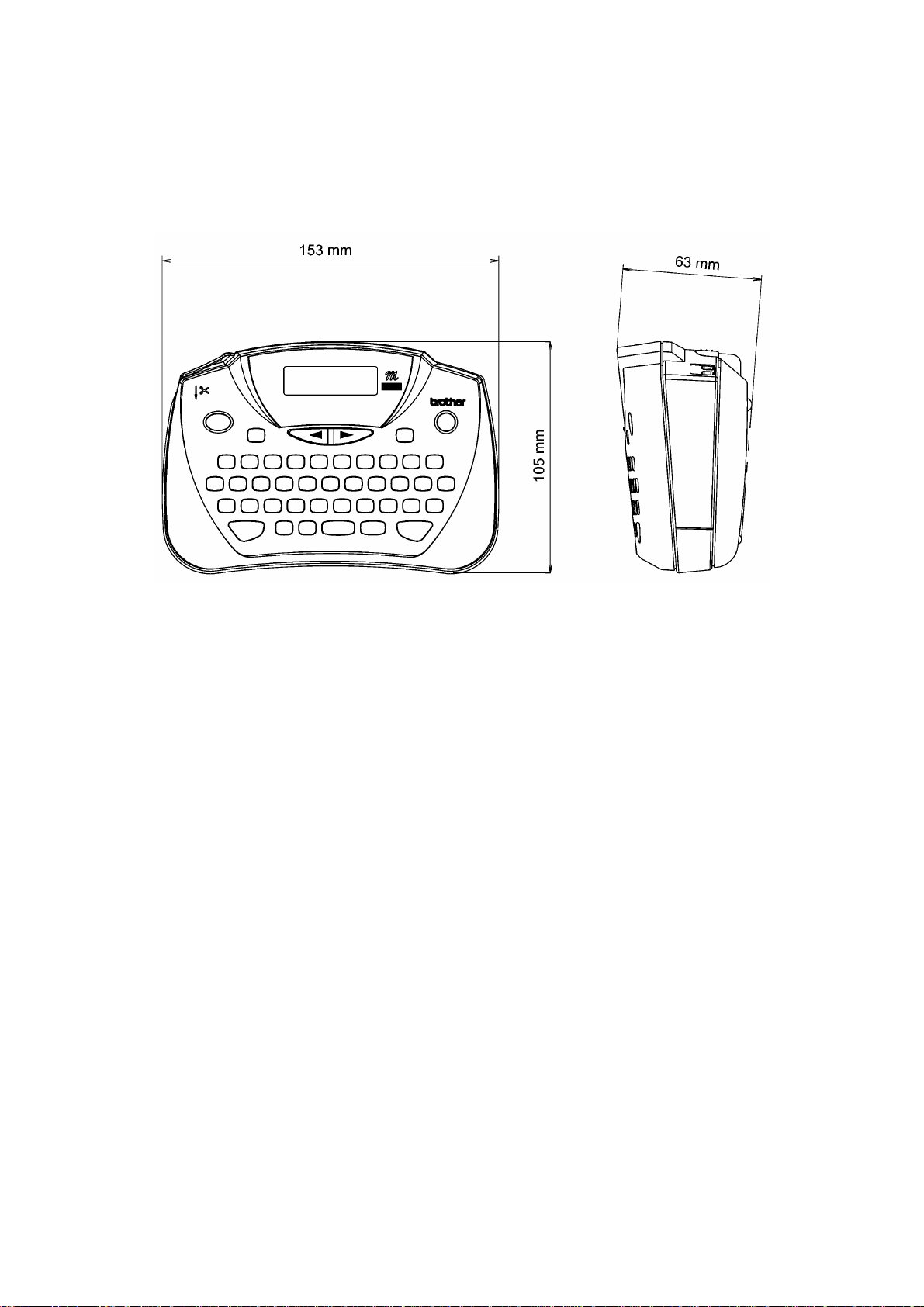

1.1 MECHANICAL SPECIFICATIONS

1.1.1 External Appearance

(1) Dimensions (W x D x H) 153 mm x 105 mm x 63 mm

(2) Weight

Machine proper Approx. 310 g

In package 410 g or less (including dry cells and a tape cassette)

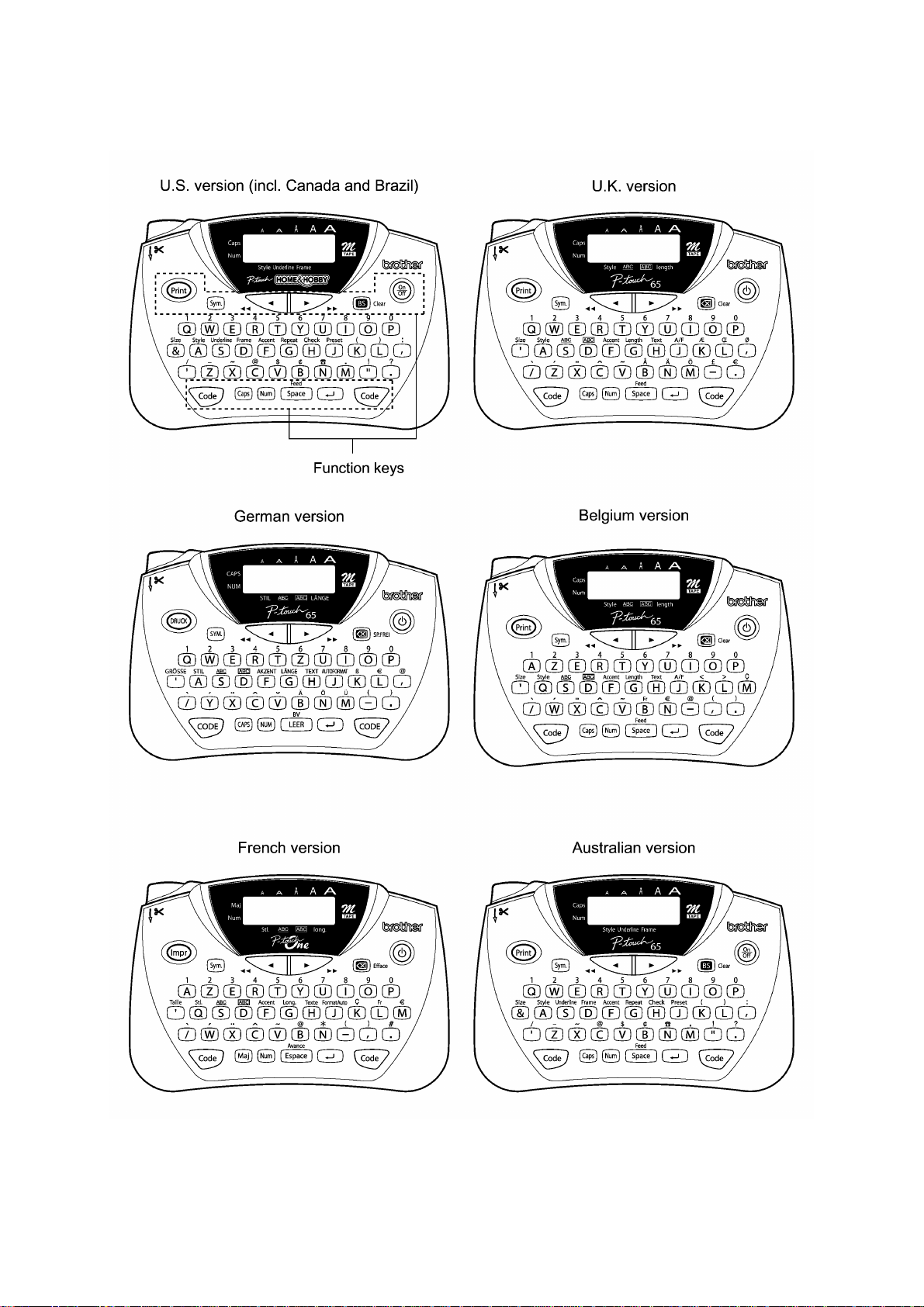

1.1.2 Keyboard

(1) Entry system Rubber key pad

(2) Number of alphanumeric and symbol keys 31

(3) Number of function keys 12 (including On/Off key)

(4) Key arrangement See Figure 1.1-2.

1.1.3 Display

(1) Display type Liquid crystal display (LCD)

(2) Number of columns 8 columns x 1 rows

Figure 1.1-1 External Appearance

(See Figure 1.1-2.)

(3) Number of indicators 11 (See Figure 1.1-2.)

(4) Character size 5 dots wide by 7 dots high

(5) Field-of-view angle adjustment Fixed by a resistor

I - 1

Page 8

1.1.4 Printing Mechanism

(1) Print system Direct thermal printing

(2) Print speed 7.5 mm/second (Typical)

(3) Print head

Type Thermal print head

Heat generator Consists of 64 heating elements vertically

Size of heating element 0.136 mm wide by 0.106 mm high

(4) Character size (dots) Height x Width

Standard (Small) size (1) 32 x 20

Double width (W2) 32 x 40

Double height (H2) 64 x 20

Large size (4) 64 x 40

(Fixed print head and tape feeding

mechanism)

aligned

1.1.5 Tape Cassette

(1) Cassette Cartridge type

(2) Tape type Direct thermal print tape (Metal deposit layer

(3) Tape size Width: 9, 12 mm

(4) Tape cassette packed with the Character color: Black

machine Tape color: White

1.1.6 Tape Cutter

(1) Tape cutting Manual cutting with the cutter lever

(2) Cutter unit User-replaceable

on substrate)

Length: 8 m

Tape width: 12 mm or 9 mm (EU)

Tape length: 4 m

I - 2

Page 9

Figure 1.1-2 Key Arrangement

I - 3

Page 10

1.2 ELECTRONICS SPECIFICATIONS

1.2.1 Character Generator

(1) Internal characters U.K./French/Belgium 180

German 188

U.S./Canada 178

(2) Internal fonts HELSINKI

(3) Print buffer capacity 55 characters

(4) Phrase memory capacity None

1.2.2 Power Supply

(1) Power supply Driven by 6 dry cells

Optional AC line adapter (7 VDC, 1.2A)

available (Europe only)

(2) Battery type Alkaline dry cells (AM3/LR6)

(3) Service life of batteries Will last through one tape cassette, and then

some (at room temperature and normal

humidity).

(4) Automatic powering-off Yes (If the machine remains unused for

approx. 5 minutes, it automatically powers itself

off.)

(5) Low battery indication

1) If the voltage level drops below approx. 5.7V, the CPU displays the

"BATTERY" message to warn you of low battery after completion of printing.

2) If it drops further below approx. 5.2V, the CPU immediately shuts down the

power.

3) Adapters with an output of 10.8 V or greater are designated as "high-voltage"

adapters and cannot be used for this machine. If this machine detects any

high-voltage adapter plugged in, it will power itself off.

I - 4

Page 11

Chapter II.

MECHANISMS

Page 12

CONTENTS

CHAPTER II. MECHANISMS

2.1 THEORY OF OPERATION ..................................................................................................II-1

2.1.1 Print Mechanism......................................................................................................II-1

2.1.2 Platen Setting & Retracting Mechanism..................................................................II-2

2.1.3 Tape Feed Mechanism............................................................................................II-3

2.1.4 Tape Cutter Mechanism..........................................................................................II-4

2.1.5 Cutter Safety Lock Mechanism................................................................................II-5

2.2 DISASSEMBLY & REASSEMBLY........................................................................................II-6

2.2.1 Disassembly Procedure...........................................................................................II-7

[ 1 ] Removing the Cassette Cover, Dry Cells, Tape Cassette, and Cutter Unit.............II-7

[ 2 ] Removing the Chassis ASSY..................................................................................II-8

[ 3 ] Removing the Sub PCB*, Main PCB, and Rubber Key Pad .................................II-11

[ 4 ] Taking out the - and + Terminal ASSYs 65, +/- Terminals P1 and P3,

and Battery Terminals P2 .....................................................................................II-12

[ 5 ] Unsoldering the + and - Terminal ASSYs 65 and Sub PCB Leads*

from the Main PCB................................................................................................II-14

2.2.2 Reassembly Procedure.........................................................................................II-15

[ 1 ] Soldering the Sub PCB Leads* and + and - Terminal ASSYs 65

onto the Main PCB................................................................................................II-15

[ 2 ] Setting the Battery Terminals P2, +/- Terminals P3 and P1,

and + and - Terminal ASSYs 65 ..........................................................................II-16

[ 3 ] Installing the Rubber Key Pad, Main PCB, and Sub PCB* ...................................II-17

[ 4 ] Installing the Chassis ASSY..................................................................................II-18

[ 5 ] Setting the Cutter Unit, Tape Cassette, Dry Cells, and Cassette Cover ...............II-21

[ 6 ] Demonstration Print and Final Check ...................................................................II-22

Page 13

2.1 THEORY OF OPERATION

0.106 mm

6.784 mm

0.136 mm

2.1.1 Print Mechanism

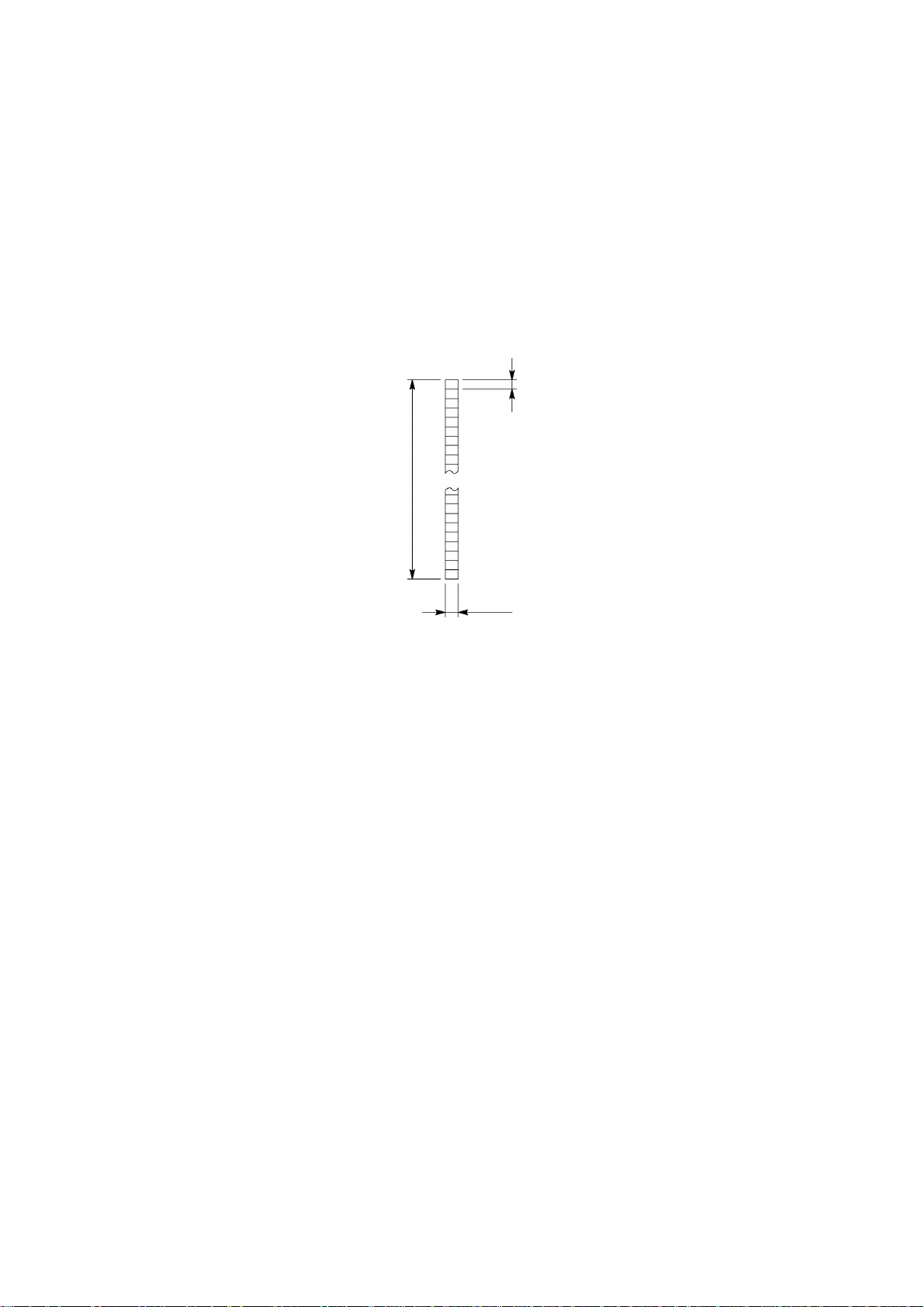

n Structure of Thermal Head

This machine uses direct thermal printing. The thermal print head has a heat generator

consisting of 64 heating elements which are vertically aligned as shown in Figure 2.1-1.

Each heating element is 0.136 mm wide by 0.106 mm high.

Figure 2.1-1 Heat Generator of Thermal Head

n Printing Process

When the cylindrical rubber platen is pressed against the thermal print head with the

thermal tape sandwiched inbetween, the CPU applies electric power to the selected ones

of those 64 heating elements.

The selected heating element(s) generates heat that dissolves the metal deposit layer of

the thermal tape so as to reveal the substrate layer, producing a dot on the tape. The

tape is advanced and the next heating cycle is repeated, thus forming a character on the

tape.

n Character Formation

While the drive motor (DC motor) feeds the tape by 0.106 mm for 13.8 ms, the thermal

head generates heat once. The feed amount of 0.106 mm is smaller than the width

(0.136 mm) of the heating elements so that the heat generated at one heating cycle will

overlap with the next heating cycle. This forms a character having no gap between

adjacent printed dots.

II - 1

Page 14

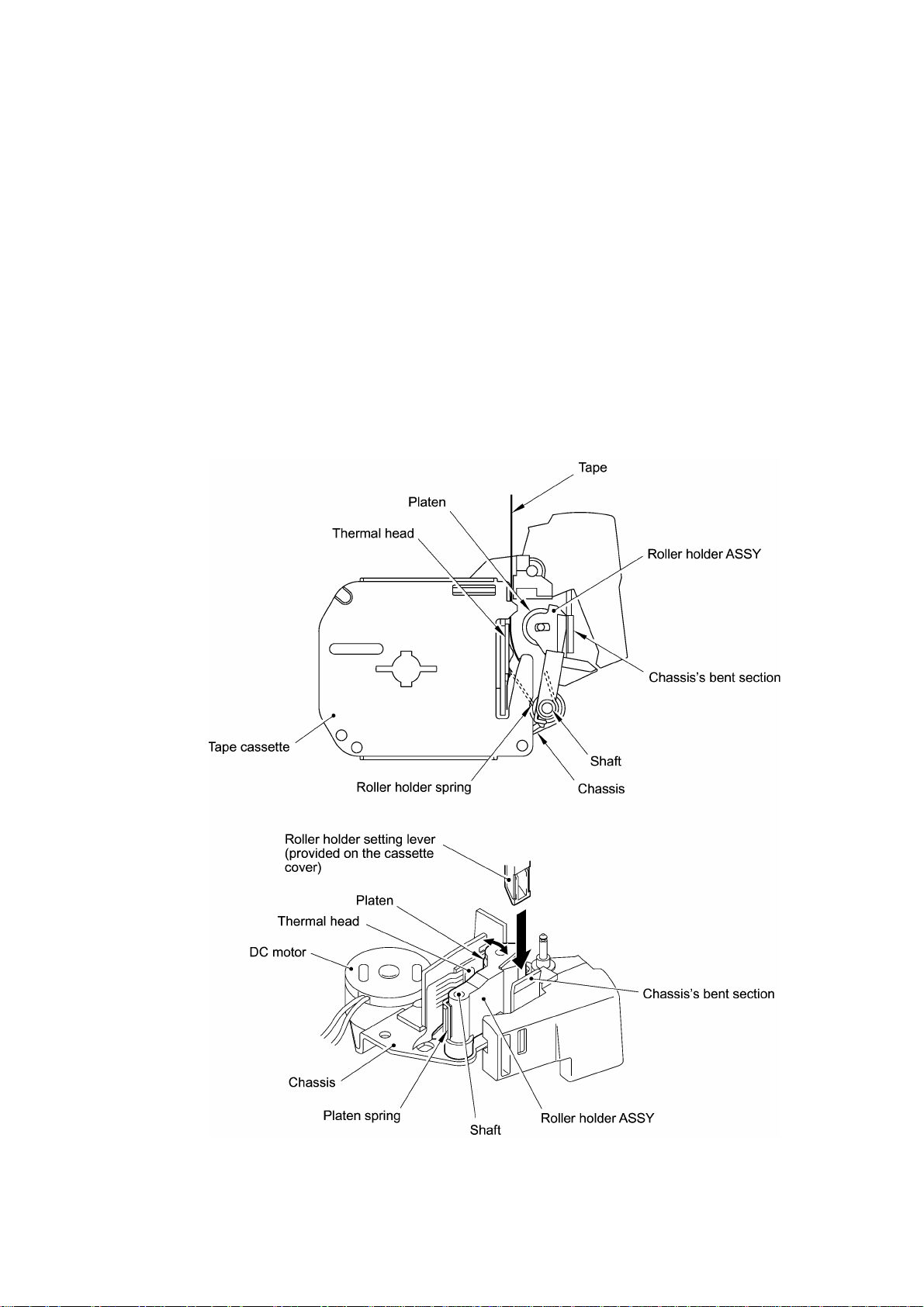

2.1.2 Platen Setting & Retracting Mechanism

This mechanism consists of the roller holder ASSY and the roller holder setting lever

(wedged lever) provided on the inside of the cassette cover.

The roller holder ASSY supports the platen so that the platen can move perpendicularly

to the thermal head and rotate freely.

Closing the cassette cover fits its roller holder setting lever into the slot between the roller

holder ASSY and the chassis's bent section. This pivots the roller holder ASSY around

the shaft provided on the chassis so as to press the roller holder ASSY against the

thermal head.

The platen is pressed perpendicularly against the thermal head with the tape sandwiched

inbetween under a uniform load by the platen spring. At the same time, the platen gear

becomes engaged with the drive gear of the gear train on the chassis (see Figure 2.1-3).

Opening the cassette cover pulls out its roller holder setting lever so that the roller holder

spring retracts the roller holder ASSY from the thermal head, providing you with enough

space to replace the tape cassette.

Figure 2.1-2 Platen Setting & Retracting Mechanism

II - 2

Page 15

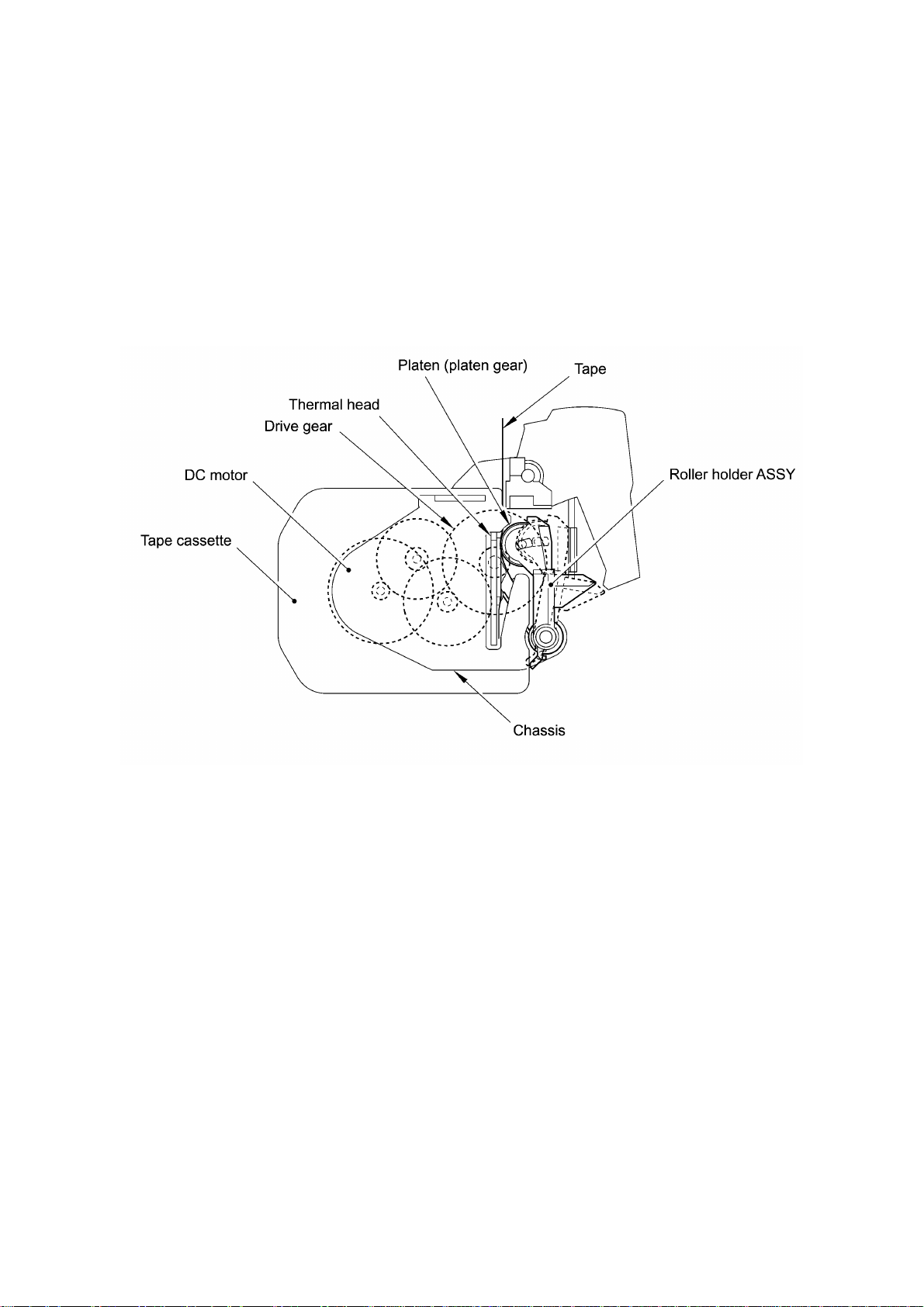

2.1.3 Tape Feed Mechanism

This mechanism consists of a DC motor, gear train and roller holder ASSY.

When you load a tape cassette and close the cassette cover, the platen and the thermal

head sandwich the tape inbetween and the platen gear becomes engaged with the gear

train, as described in Subsection 2.1.2.

As the DC motor rotates, the rotation is transmitted via the gear train to the platen gear.

Accordingly, the sandwiched tape will be advanced.

Figure 2.1-3 Tape Feed Mechanism

II - 3

Page 16

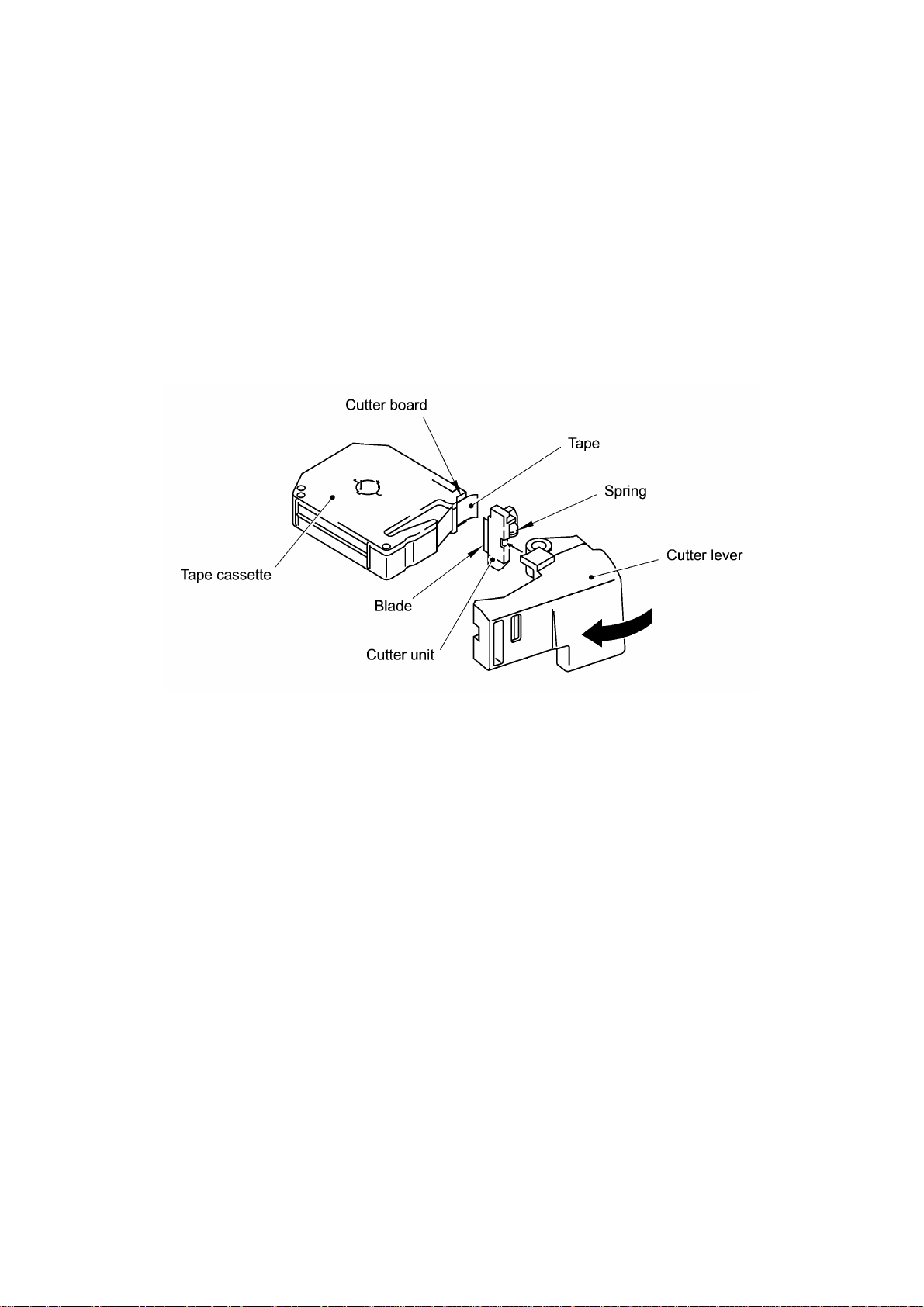

2.1.4 Tape Cutter Mechanism

The cutter mechanism consists of a cutter lever and a cutter unit in which a blade is

retracted by a spring.

Pressing the cutter lever pushes out the blade from the cutter unit to press the printed

tape against the cutter board of the tape cassette, cutting the printed tape coming

through the cutter unit and the cutter board.

When the cassette cover is opened and no tape cassette is loaded, the cutter safety

mechanism works to lock the cutter lever as described in Subsection 2.1.5.

Figure 2.1-4 Tape Cutter Mechanism

II - 4

Page 17

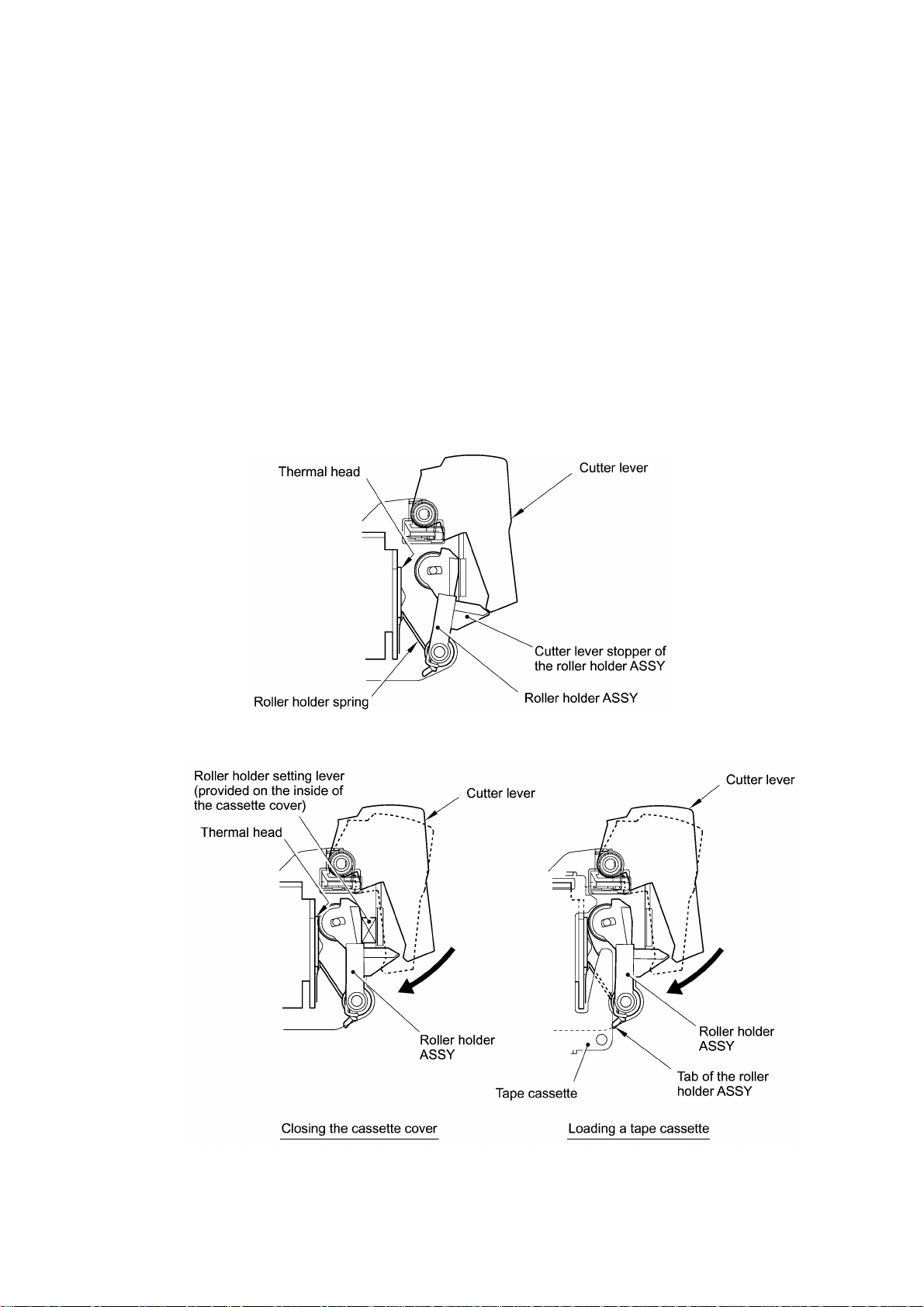

2.1.5 Cutter Safety Lock Mechanism

When the cassette cover is opened and no tape cassette is loaded, the roller holder

ASSY is retracted from the thermal head with the roller holder spring (as described in

Subsection 2.1.2). In this retracted position, the cutter lever stopper of the roller holder

ASSY blocks the end of the cutter lever, preventing the cutter blade from coming out of

the cutter unit for safety, as shown below.

Closing the cassette cover or loading a tape cassette releases the cutter safety lock

mechanism as follows.

Closing the cassette cover pivots the roller holder ASSY towards the thermal head so

that the cutter lever stopper does not interfere with the cutter lever.

When a tape cassette is loaded, its outer edge pushes the tab of the roller holder ASSY

to pivot the roller holder ASSY towards the thermal head so that the cutter lever stopper

does not interfere with the cutter lever.

Figure 2.1-5 Cutter Safety Lock Mechanism

Figure 2.1-6 Releasing the Cutter Safety Lock Mechanism

II - 5

Page 18

2.2 DISASSEMBLY & REASSEMBLY

nn Safety Precautions

(1) You should carry out disassembly & reassembly jobs on an anti-static sheet

grounded correctly. Otherwise, the LSI and other electronic devices will be

damaged due to the electricity charged in your body.

(2) When transporting PCBs, be sure to wrap them in conductive sheets such as

aluminum foil.

(3) When using soldering irons and other heat-generating tools, take care not to

damage the resin parts such as wires, PCBs, and covers.

(4) Be careful not to lose screws, washers, or other parts removed for parts

replacement.

(5) Tighten screws to the torque values listed below.

nn Tightening Torque List

Location Screw type Q'ty Tightening torque

Bottom cover Taptite, bind B M2.6 x 8 4 0.39 ±0.10 N•m (4 ±1 kgf•cm)

Chassis ASSY Taptite, bind B M2.6 x 4 3 0.196 ±0.049 N•m (2 ±0.5 kgf•cm)

Chassis ASSY (for motor) Screw, pan M1.7 x 2.5 2 0.10 to 0.196 N•m (1 to 2 kgf•cm)

Thermal head ASSY Screw, cup M2.6 x 4 1 0.49 ±0.196 N•m (5 ±2 kgf•cm)

Sub PCB* Taptite, bind B M2.6 x 4 2 0.196 ±0.049 N•m (2 ±0.5 kgf•cm )

Main PCB Taptite, bind B M2.6 x 4 2 0.196 ±0.049 N•m (2 ±0.5 kgf•cm )

*Provided on the European version

II - 6

Page 19

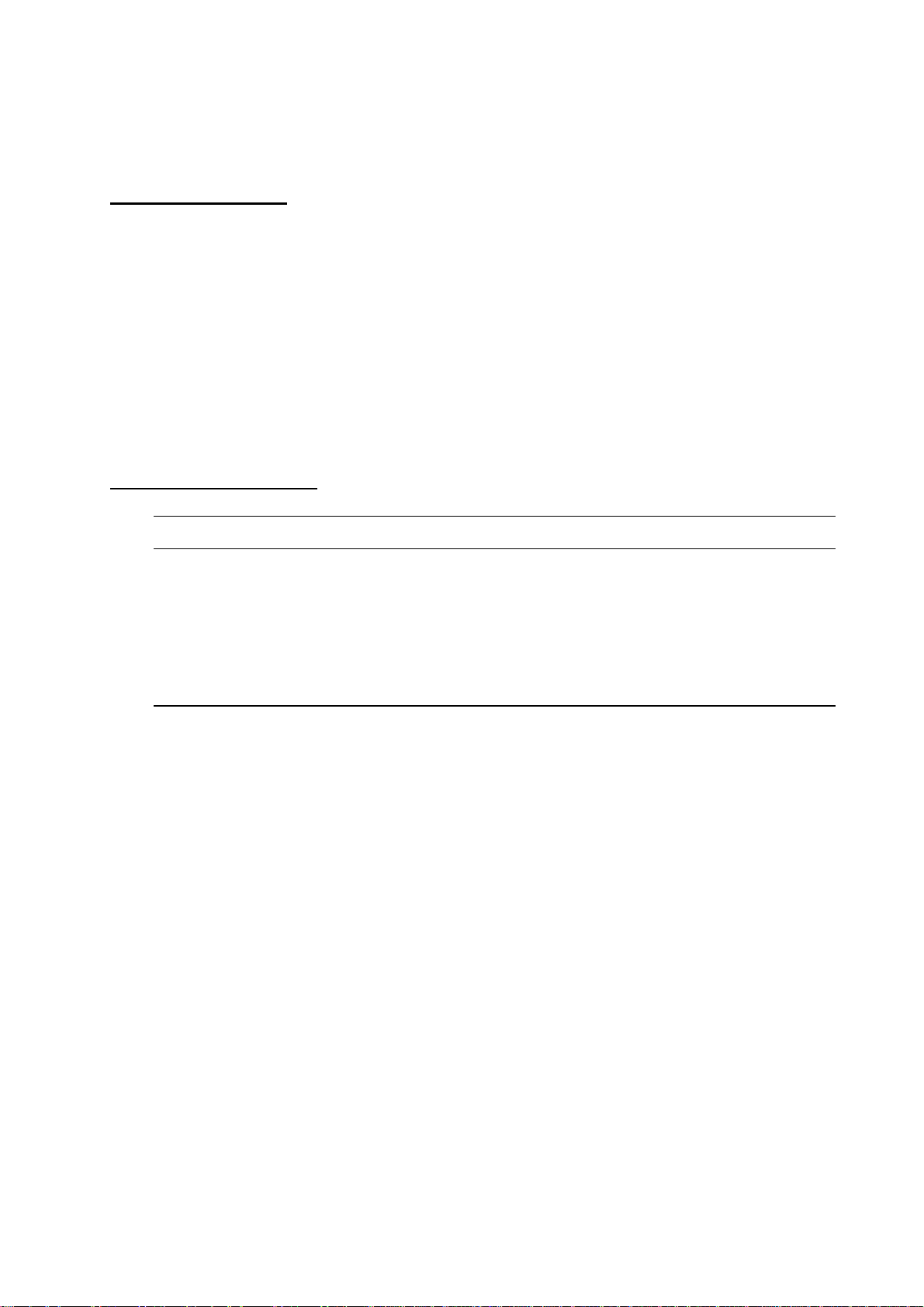

2.2.1 Disassembly Procedure

[ 1 ] Removing the Cassette Cover, Dry Cells, Tape Cassette, and Cutter Unit

(1) Turn the machine upside down.

(2) Press section "A" of the cassette cover to release the latch, and then remove the

cassette cover.

Figure 2.2-1 Removing the Cassette Cover

(3) Remove the six dry cells, tape cassette, and cutter unit. For easier removal of the

tap cassette, lift up the front edge and then take it out.

Figure 2.2-2 Removing the Dry Cells, Tape Cassette and Cutter Unit

II - 7

Page 20

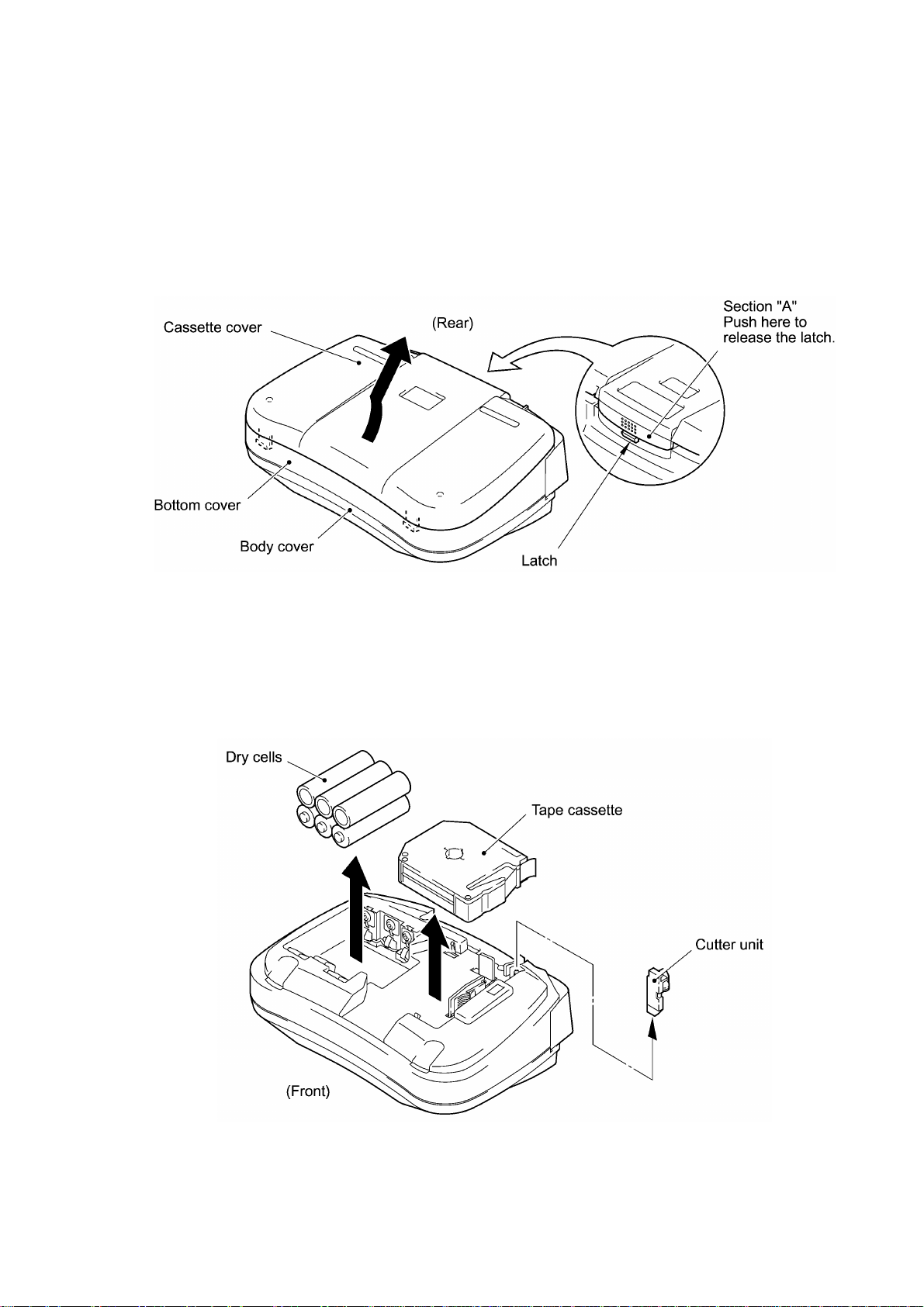

[ 2 ] Removing the Chassis ASSY

(1) Remove the four screws from the bottom cover.

Figure 2.2-3 Unscrewing the Bottom Cover

(2) Slightly open the bottom cover and disconnect the head flat cable from the main

PCB.

Figure 2.2-4 Disconnecting the Head Flat Cable

II - 8

Page 21

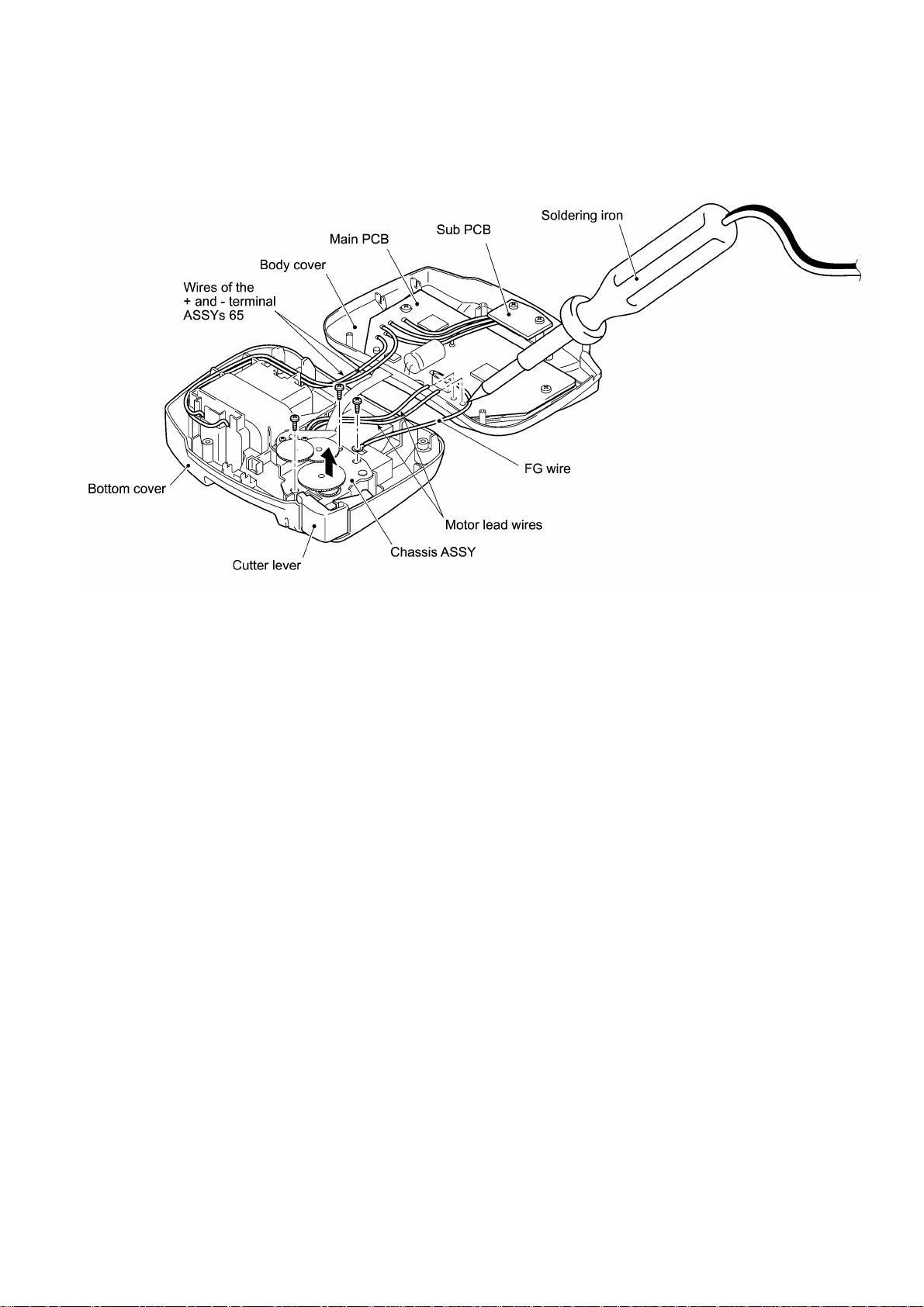

(3) Remove the three screws from the chassis ASSY. The FG wire also comes off.

(4) Unsolder the motor lead wires from the main PCB.

Figure 2.2-5 Unsoldering the Motor Lead Wires and Removing the Chassis ASSY

(5) Lift the chassis ASSY up and out of the bottom cover. The cutter lever also comes

off.

II - 9

Page 22

nn Disassembling the Chassis ASSY

When handling the thermal head ASSY, do not touch the thermal head by hand.

Otherwise, it may be damaged due to the electricity charged in your body.

(1) Remove the screw from the thermal head ASSY and take off the ASSY.

(2) Remove the retaining ring from the shaft of the chassis ASSY.

(3) Pull up the roller holder ASSY together with the spring.

(4) Remove the two screws from the chassis ASSY and take off the DC motor ASSY.

Figure 2.2-6 Disassembling the Chassis ASSY

II - 10

Page 23

[ 3 ] Removing the Sub PCB*, Main PCB, and Rubber Key Pad

*Provided on the European version.

(1) European version: Remove the two screws from the sub PCB*.

Figure 2.2-7 Taking out the Sub PCB*

(2) Remove the two screws from the main PCB.

(3) Slightly slide the main PCB to the front, press the latches provided on the body

cover outwards, and then take out the LCD by gently pulling out the main PCB and

LCD flat cable.

(4) Take out the rubber key pad.

Figure 2.2-8 Taking out the Main PCB and Rubber Key Pad from the Body Cover

II - 11

Page 24

[ 4 ] Taking out the - and + Terminal ASSYs 65, +/- Terminals P1 and P3, and Battery

Terminals P2

(1) Unlatch the locking pawl of the - terminal ASSY 65 with the tip of the flat screwdriver

and from the bottom push the terminal ASSY up and out of the bottom cover.

(2) In the same manner as in step (1), remove the +/- terminals P1 and P3.

(3) Turn the bottom cover upside down, unlatch the locking pawl of the + terminal ASSY

65 with the flat screwdriver, and push the terminal out of the bottom cover.

Figure 2.2-9 Taking out the - and + Terminal ASSYs 65 and +/- Terminals P1 and P3

II - 12

Page 25

(4) As shown below, press the locking pawl of each battery terminal P2 with a flat

screwdriver and push it out from the bottom cover.

Figure 2.2-10 Taking out the Battery Terminals P2

II - 13

Page 26

[ 5 ] Unsoldering the + and - Terminal ASSYs 65 and Sub PCB Leads* from the Main PCB

*Provided on the European version.

If it is necessary to separate the + and - terminal ASSY 65 or sub PCB* leads from the

main PCB, unsolder them with a soldering iron.

(1) Unsolder the + and - terminal ASSYs 65 from the main PCB.

(2) European version: To remove the sub PCB*, unsolder the four lead wires from the

main PCB.

Figure 2.2-11 Unsoldering the + and - Terminal ASSYs 65 and Sub PCB Leads*

II - 14

Page 27

2.2.2 Reassembly Procedure

[ 1 ] Soldering the Sub PCB Leads* and the + and - Terminal ASSYs 65 onto the Main

PCB

*Provided on the European version.

(1) European version: Solder the four lead wires of the sub PCB* to the main PCB

according to the wire ID colors as shown below.

(2) Solder the + and - terminal ASSYs 65 according to the wire ID colors as shown

below.

European version

US version

Figure 2.2-12 Soldering the Sub PCB Leads* and the + and - Terminal ASSYs 65

II - 15

Page 28

[ 2 ] Setting the Battery Terminals P2, +/- Terminals P3 and P1, and + and - Terminal

ASSYs 65

(1) Place the bottom cover upside down.

(2) Set three battery terminals P2 to the bottom cover until they snap into place, as

shown below.

Figure 2.2-13 Setting the Battery Terminals P2

(3) Turn the bottom cover rightside up.

(4) Snap the + terminal ASSY 65 into the bottom cover.

(5) Snap the +/- terminals P3 and P1 into the bottom cover.

(6) Snap the - terminal ASSY 65 into place.

Figure 2.2-14 Setting the +/- Terminals P3 and P1 and the + and - Terminal ASSYs 65

II - 16

Page 29

[ 3 ] Installing the Rubber Key Pad, Main PCB, and Sub PCB*

*Provided on the European version.

(1) Place the body cover upside down.

(2) Put the rubber key pad in the body cover.

NOTE: Before setting the main PCB, check that there is no foreign material or dust

on the key contacts of the main PCB.

(3) While pressing the latches on the body cover outwards, slide the LCD as illustrated

below. Make sure that the LCD is fully fitted in the body cover.

(4) Secure the main PCB to the body cover with two screws.

Figure 2.2-15 Reinstalling the Rubber Key Pad and Main PCB

(5) European version: Secure the sub PCB* with two screws.

Figure 2.2-16 Securing the Sub PCB*

II - 17

Page 30

[ 4 ] Installing the Chassis ASSY

(1) If the chassis ASSY has been disassembled, assemble the components, referring to

page II-20.

(2) As shown in Figure 2.2-20, fit the cutter lever onto the shaft on the chassis ASSY.

(3) Put the chassis ASSY with the cutter lever back into the bottom cover.

(4) Secure the chassis ASSY with three screws. One of those screws should also

secure the FG wire.

NOTE: Check that the FG wire is secured to the correct position, referring to the

illustration given below.

(5) Solder the motor lead wires to the main PCB as shown below.

NOTE: Check the wire ID colors, then solder the black and red wires to the (+) and (-)

points, respectively.

Figure 2.2-17 Installing the Chassis ASSY and Soldering the Motor Lead Wires

II - 18

Page 31

(6) Route the wires of the + and - terminal ASSYs 65 along the four ribs provided on the

bottom cover as illustrated below.

(7) Connect the head flat cable to the main PCB and close the bottom cover.

Figure 2.2-18 Routing the + and - Terminal ASSYs 65 and Connecting the Head Flat Cable

(8) Secure the bottom cover to the body cover with four screws, taking care not to pinch

the wires between the body cover and bottom cover.

Figure 2.2-19 Securing the Bottom Cover to the Body Cover

II - 19

Page 32

nn Assembling the Components of the Chassis ASSY

(1) Secure the DC motor ASSY to the chassis with two screws so that the motor lead

wires face as shown below.

(2) Set the roller holder spring onto the roller holder ASSY so that its straight end is

fitted into section "A" on the ASSY, then install them to the chassis and secure the

ASSY with the retaining ring.

(3) As shown below, turn the bent end of the roller holder spring with a flat screwdriver

and fit it into an oval hole provided in the chassis. Then secure the thermal head

ASSY with a screw.

Figure 2.2-20 Assembling the Components of the Chassis ASSY

II - 20

Page 33

[ 5 ] Setting the Cutter Unit, Tape Cassette, Dry Cells, and Cassette Cover

(1) Set the cutter unit into place.

(2) Set a tape cassette.

(3) Load dry cells.

(4) Fit hooks "X" of the cassette cover and then snap the cover into place.

Figure 2.2-21 Setting the Cutter Unit, Tape Cassette, Dry Cells, and Cassette Cover

II - 21

Page 34

[ 6 ] Demonstration Print and Final Check

(1) Power on the machine.

(2) While holding down the Code key, press the key (BS key in U.S. and Australian

versions) to cancel data previously entered.

(3) Power off the machine.

(4) While holding down the Code and D keys, press and release the key (On/Off key

in the U.S. and Australian versions), then release the Code and D keys. The

demonstration print will start.

(5) During the demonstration print, check that the machine feeds the tape and prints

data correctly. Then, cut the tape.

(6) Open the cassette cover to check that it retracts the roller holder ASSY from the

thermal head. Close the cassette cover to check that it presses the roller holder

ASSY against the thermal head.

(7) Check that pressing the keys causes correct operation.

(8) Check that the key (On/Off key in the U.S. and Australian versions) operates

correctly.

(9) Replace the dry cells with new ones, and then power on the machine.

(10)Check the tape feeding length according to the steps below.

1) While holding down the Code key, press the Space key to feed tape.

2) Push the cutter lever to cut the tape.

3) Enter arbitrary characters.

4) While holding down the Code key, press the H key. After the print preview, the

tape length will appear. Make a note of the length.

5) Press the Print key to print.

6) After completion of printing, cut the printed tape.

7) Check that the cut tape is the length recorded in step 4) ±5% long.

8) If the cut tape is out of the specified range, insert the tip of a screwdriver

through the hole provided in the bottom cover and rotate the trimmer (VR1) on

the main PCB to adjust the tape feeding length.

Rotating the VR1 clockwise will shorten the tape feeding length; rotating it

counterclockwise will lengthen it.

If any problem is found, go to the troubleshooting in Chapter IV.

Figure 2.2-22 Adjusting the Trimmer (VR1) on the Main PCB

II - 22

Page 35

Chapter III.

ELECTRONICS

Page 36

CONTENTS

CHAPTER III. ELECTRONICS

3.1 OUTLINE OF CONTROL ELECTRONICS..........................................................................III-1

3.2 MAIN PCB...........................................................................................................................III-2

3.2.1 Block Diagram........................................................................................................III-2

3.2.2 CPU........................................................................................................................III-3

3.2.3 LCD Controller........................................................................................................III-3

3.2.4 Key Contacts Matrix ............................................................................................... III-4

[ 1 ] Key contacts matrix................................................................................................III-4

[ 2 ] Solder points..........................................................................................................III-6

3.2.5 Power ON/OFF Key and Reset Circuit...................................................................III-7

[ 1 ] Power ON/OFF circuit............................................................................................III-7

[ 2 ] Automatic powering-off circuit................................................................................III-8

3.2.6 Motor Drive Circuit..................................................................................................III-9

3.2.7 Thermal Head Drive Circuit ..................................................................................III-10

3.2.8 Voltage Detection Circuit......................................................................................III-12

3.2.9 Oscillation Circuit.................................................................................................. III-13

3.2.10 Power Supply Circuit ............................................................................................III-14

3.3 SUB PCB.........................................................................................................................III-15

3.3.1 Sub PCB ..............................................................................................................III-15

Page 37

3.1 OUTLINE OF CONTROL ELECTRONICS

Figure 3.1-1 shows a block diagram of the control electronics of this machine. The

control electronics consists of a main PCB, LCD, motor, thermal print head assembly,

and sub PCB*.

* Provided on the European version.

n Main PCB

This manages all the components including an LCD, motor, key pad, and thermal print

head.

n Motor

The DC motor is a power source to advance tape. It operates on 9V (unstabilized).

n Thermal Print Head

This is a thick-film thermal print head which integrates a heat generator (consisting of 64

heating elements vertically aligned) and driver circuitry. When selectively energized by

9V (unstabilized), those heating elements produce characters.

n LCD

The LCD is 8 characters wide by one row and it has also 11 guidance indicators.

n Sub PCB

This allows you to use an AC adapter.

Figure 3.1-1 Configuration of the Electronic Part

III - 1

Page 38

3.2 MAIN PCB

3.2.1 Block Diagram

Figure 3.2-1 shows a block diagram of the main PCB. The main PCB consists of the

following:

(1) CPU (including a ROM and RAM)

(2) LCD controller

(3) Key contacts matrix and solder points (destination switching circuit)

(4) Power ON/OFF circuit

(5) Motor drive circuit

(6) Thermal head drive circuit

(7) Voltage detection circuit

(8) Oscillation circuit

(9) Power supply circuit

Figure 3.2-1 Main PCB Block Diagram

III - 2

* Provided for the European version.

Page 39

3.2.2 CPU

The CPU (#1: MN101C30A) is an 8-bit microprocessor produced by CMOS silicon gate

process, which integrates a 32-kilobyte ROM and a 1.5-kilobyte RAM.

3.2.3 LCD Controller

LCDC (#3: SPLC 780A2) drives the LCD in 1/8 duty and 1/4 bias levels.

Figure 3.2-2 CPU and LCD Controller

III - 3

Page 40

3.2.4 Key Contacts Matrix

[ 1 ] Key contacts matrix

On the main PCB is a key contacts matrix that is a set of carbon-printed 43 key contact

patterns. Each contact pattern has a pair of electrodes.

The rubber key pad is made of high-impedance silicon rubber. As shown in Figure 3.2-3,

each key on the rubber key pad consists of a key top, rubber spring, and conductive

paint which functions as a switching element.

If a particular key is pressed, the conductive paint of the key short-circuits the paired

electrodes carbon-printed on the main PCB.

Figure 3.2-4 shows a key scan timing scheme and scanning pulse outputs. Ports P70

through P75 on the CPU issue a group of key scanning pulses. Every scanning pulse is

Low active for 200 µs and is in high impedance while inactive. Ports P60 through P67

act as input ports which receive key status.

The CPU scans the key contacts matrix every 10 ms. If the CPU reads the same data on

an input port two successive times, it interprets the state as the key being pressed; if the

CPU reads the same data six successive times, it interprets the state as the key being

released. The input mode of this keying system is 2-key roll-over and 3-key lockout.

Figure 3.2-3 Detailed Diagram of Keyboard

III - 4

Page 41

Figure 3.2-4 Key Scan Timing Scheme and Scanning Pulse Outputs

III - 5

Page 42

[ 2 ] Solder points

Figure 3.2-5 shows a circuit diagram relating to the keyboard and solder points. Solder

points 1 through 3 customize the machine for the destination (shipping country) .

20 U.S.A./Canada H H H

10 Germany H H H

02 Belgium H L H

01 France L H H

00 England H H H

Spec.

No.

H: Solder point opened L: Solder point closed

Destination

1 2 3

Solder Points

Solder points A and C are reserved for the future use for the thermal head ranking.

The CPU reads the solder point status once in the powering-on sequence to recognize

the customization.

Figure 3.2-5 Keyboard and Solder Points

III - 6

Page 43

3.2.5 Power ON/OFF Key and Reset Circuit

[ 1 ] Power ON/OFF circuit

Figure 3.2-6 shows a circuit diagram of the power ON/OFF key. The CPU processes the

ON/OFF key state in a sequence quite different from other keys although the ON/OFF

key is on the same key pad.

Figure 3.2-6 ON/OFF Key

•-‚ The ON/OFF key is held down, during which the CPU is inactive.

‚-ƒ Reset operation by the reset circuit

ƒ In the powering-on sequence: The reset signal is canceled and the program

starts.

ƒ In the powering-off sequence: The reset signal is canceled and the program

stops.

Figure 3.2-7 Powering-on/-off sequence

III - 7

Page 44

[ 2 ] Automatic powering-off circuit

If you power off the machine with the ON/OFF key or you make no key entry for approx.

5 minutes, the oscillation stops so that the CPU enters the sleep mode.

To cancel the sleep mode and resume the normal operation mode, press the ON/OFF

key.

III - 8

Page 45

3.2.6 Motor Drive Circuit

Figure 3.2-8 shows the motor drive circuit of the DC motor which feeds tape.

Through P10, the CPU produces a start/stop control signal to the motor drive circuit.

Figure 3.2-9 shows the part of motor waveforms.

#2 (BA6220) is an electronic governor IC and controls to keep the rotation speed of the

motor constant even if the power source voltage (VBT) varies.

Figure 3.2-8 Motor Drive Circuit

Figure 3.2-9 Part of Motor Waveforms

III - 9

Page 46

3.2.7 Thermal Head Drive Circuit

Figure 3.2-10 shows the thermal head drive circuit.

The print head has an integrated heat generator (consisting of 64 heating elements

vertically aligned in 240 dpi) and a built-in driver IC.

Synchronizing with the clock on P02, the CPU outputs print data on P00 in the serial

form. Upon receipt of P01 signal issued by the CPU, the thermal head control circuit

latches the print data and drivers the heating elements of the thermal head according to

the signal issued from P03. Figure 3.2-11 illustrates a timing chart of the thermal head

drive.

Capacitor C10 works as a thermal head overheat protector. It cuts off the P03 signal to

shut down invalid drive current if the signal sticks to the low level due to any malfunctions

of the programs or the CPU.

Since thermal heads are very sensitive to heat and the head drive source is not

stabilized, the CPU determines the ON-time length of the P03 signal while monitoring the

head drive source voltage (refer to Subsection 3.2.8).

Figure 3.2-10 Thermal Head Drive Circuit

III - 10

Page 47

Figure 3.2-11 Timing Chart for Thermal Head Drive

III - 11

Page 48

3.2.8 Voltage Detection Circuit

Figure 3.2-12 shows the voltage detection circuit which is composed of a resistor

network.

Voltage detection circuit

This circuit, which is composed of divider resistors R9 and R10, steps down the power

source VAD fed from dry cells or the AC adapter and feeds the output to the A/D input

port PA1 on the CPU. According to the drive source voltage, the CPU determines the

optimum head drive power.

During non-printing:

If the voltage level of the VAD drops below approx. 6.8V, the CPU immediately shuts

down the power.

Ÿ Adapters with an output of 10.8 V or greater are designated as "high-voltage" adapters

and cannot be used for this machine. If this machine detects any high-voltage adapter

plugged in, it will power itself off.

During printing:

Ÿ If it drops even more below approx. 5.7V, the CPU displays the "BATTERY" message

to warn you of a low battery after completion of printing.

Ÿ If it drops below approx. 5.2V, the CPU immediately shuts down the power.

Figure 3.2-12 Voltage Detection Circuit

III - 12

Page 49

3.2.9 Oscillation Circuit

Figure 3.2-13 shows the oscillation circuit.

This circuit contains an oscillator and generates 8 MHz frequency which acts as the CPU

basic clock. The CPU divides this into half (4 MHz) to synchronize its internal operations.

Figure 3.2-13 Oscillation Circuit

III - 13

Page 50

3.2.10 Power Supply Circuit

Figure 3.2-14 shows the power supply circuit. The 3-terminal regulator RH5RL50A

stabilizes the battery output, producing the +5BV power source (5±0.125V).

Figure 3.2-14 Power Supply Circuit

III - 14

Page 51

3.3 SUB PCB

3.3.1 Sub PCB

The sub PCB is provided for the European version and allows you to connect an AC

adapter.

Figure 3.3-1 Sub PCB Circuit

III - 15

Page 52

Chapter IV.

TROUBLESHOOTING

Page 53

CONTENTS

CHAPTER IV TROUBLESHOOTING

4.1 TROUBLESHOOTING........................................................................................................IV-1

4.1.1 Precautions ............................................................................................................IV-1

4.1.2 After Repairing .......................................................................................................IV-1

4.1.3 Troubleshooting Flows ...........................................................................................IV-2

[ 1 ] Tape feeding failure............................................................................................... IV-2

[ 2 ] Printing failure........................................................................................................IV-5

[ 3 ] Powering failure (Nothing appears on the LCD.) ...................................................IV-8

[ 4 ] No key entry possible...........................................................................................IV-10

[ 5 ] Abnormal LCD indication .....................................................................................IV-11

Page 54

4.1 TROUBLESHOOTING

This section gives the service personnel some of the troubleshooting procedures to be

followed if an error or malfunction occurs with this machine. It is impossible to anticipate

all of the possible troubles which may occur in future and determine the troubleshooting

procedures, so this chapter covers some sample troubles. However, those samples will

help service personnel pinpoint and repair other defective elements if he/she analyzes

and examines them well.

4.1.1 Precautions

Be sure to observe the following precautions to prevent the secondary problems from

happening during troubleshooting:

(1) Get a good idea of what the trouble is. Whenever more than one trouble source is

found, plan the most reasonable repairing procedure after reviewing the relationship

between them.

(2) When supplying power to this machine having problems with either a set of batteries

or the AC line adapter, make sure that its output voltage level is 8 to 10V under no

load.

(3) When using a circuit tester for testing the conductivity, remove all of the batteries

(and disconnect the AC line adapter) from this machine.

(4) To repair an error which occurred in the thermal print head and its related sections,

disconnect the thermal head cable until repairs are finished.

4.1.2 After Repairing

After repairing the defective section, be sure to check again to see if the repaired section

works correctly. Also make a note of the troubleshooting procedure so that it will be

handy should problems occur in the future.

IV - 1

Page 55

4.1.3 Troubleshooting Flows

[ 1 ] Tape feeding failure

IV - 2

Page 56

IV - 3

Page 57

IV - 4

Page 58

[ 2 ] Printing failure

IV - 5

Page 59

IV - 6

Page 60

IV - 7

Page 61

[ 3 ] Powering failure (Nothing appears on the LCD.)

IV - 8

Page 62

IV - 9

Page 63

[ 4 ] No key entry possible

IV - 10

Page 64

[ 5 ] Abnormal LCD indication

IV - 11

Page 65

APPENDICES

Circuit Diagrams

A: Main PCB

B: Sub PCB (for P-touch 65 and P-touch One only)

Page 66

Appendix A. Main PCB

1 2 3 4 5 6 7 8

POWER SUPPLY

US Version

A

B

C

D

P 1 ( M O T O R )

-

E

+

F

+

T E R Y

T

-

A

B

1

V R 1

2 0 0

2

8

2

1

P O W E R

P O W E R

P O W E R

P O W E R

R 2 0

R 2 2

3 9 0

4 5

6

3

+

-

Q 6

B 1 4 2 7

(

R 2 1

* * *

7

+

-

V B T

)

# 2

B A 6 2 2 0

European (UK,FR,GE,BE) Version

+

T

-

A T E R Y

B

B

C

P

B

D A T A

C L O C K

L A T C H

S T R O B E

V A D

R 1 2

1 0 K

R 7

3 . 3 K

D 2

R B 5 2 1 S - 3 0

V B T

U

S

A C

F 1

F G

P 2 ( H E A D )

C O M

1

2

3

4

V D D

5

G N D

6

G N D

7

8

V D D

9

C O M

1 0

Q 4

D T A 1 4 3 Z U A

K I 0

K I 1

K I 2

K I 3

K I 4

K I 5

K I 6

K I 7

4 7 K

P O W E R

A C S E N

V B T

C 8

1 0 V

+ 5 B V

0 V

V B T

(

)

R 2 3

)

(

R 2

4

)

(

R 2 5

0 V

R 1 3

V C C

4 7 0

V B T

4 . 7 K

1

A

2

3

C

K O 6

K O 7

21 3 4 5 6 7 8

2

I N O U T

C 5

1 0 4

C 1 2

1 0 4

Q 5

D T C 1 1 4 Y U A

1 0 K

4 7 K

0 V

A

Z

E

R

T

Y

U

I

+

G N D

1

A C S E N

C 4

1 0 4

R 1 1

1 M

'

Q

S

D

F

G

H

J

K O 0

P O W E R

3

X T 1

C S T 8 . 0 M

V C C

C 1 0

1 0 5

+ 5 B V

4 7 K

4 . 7 K

Q 1 D T A 1 4 3 Z U A

V C C

Cod e

/

Ca

W

um

N

X

S

pace

C

V

Code

B

.

N

-

,

K O 1

K O 2

C 7

4 7

6 . 3 V

ps

.

K 0 3

A

-

V A D

R 1 0

5 . 6 K ( 1 % )

R 9

4 . 3 K ( 1 % )

+ 5 B V

0 V

)

(

C 1 1

* * *

0 V

V C C

G N D

C

(

)

* * *

0 V

P

ri nt

K I 0

Sym.

K I 1

K I 2

M

P

O

L

K

K I 3

K I 4

K I 5

K I 6

K I 7

K O 4

K O 5

C 9

1 0 2

N C

0 V

1

N C

2

3

N C

4

N C

5

N C

6

7

8

9

1 0

1 1

1 2

N C

1 3

1 4

1 5

1 6

N C

6 4

6 3

6 2

6 1

P A 2

V R E F -

P A 1 / A N 1

P A 3

P A 4

P A 5

P A 6

P A 7

V R E F +

V D D

O S C 2

O S C 1

V S S

X I

X O

M M O D

P 0 0

P 0 1

P 0 2

P A 0 / A N 0

# 1

M N 1 0 1 C 3 0 A

P 0 5

P 0 4

P 0 3

2 0

1 9

1 8

1 7

L C D R W

L C D R S

Q

A1

P 0 6

L C D E

W

E

C23

R

T

Z

U

I

K O 6

K O 7

K O 0

D B 4

D B 5

D B 6

D B 7

K O 5

K O 6

K O 7

K O 4

N C

N C

N C

N C

7

6 0

5 9

5 8

5

5 6

5 5

P 8 2

P 8 1

P 8 0

P 8 4

P 8 3

P 1 2

P 1 1

P 1 3

P 1 0

- R S T

2 6

2 5

2 4

2 3

2 2

2 1

N C

N C

CODE

/

'

CAPS

Y

A

NUM.

X

S

LEER

C

D

V

F

CODE

B

G

.

N

H

M

-

J

K O 1

K O 2

K 0 3

5 0

4 9

5 2

5 4

5 3

5 1

P 7 5

P 7 4

P 7 6

P 7 7

P 8 7

P 8 6

P 8 5

4 8

P 7 3

P 7 2

P 7 1

P 7 0

P 6 7

P 6 6

P 6 5

P 6 4

P 6 3

P 6 2

P 6 1

P 6 0

P 5 4

P 5 3

P 5 2

P 5 1

P 5 0

P 2 4

P 2 3

P 2 2

P 2 1

P 2 0 / I R Q 0

P 1 4

3 2

3 1

3 0

2 9

2 8

2 7

N C

N C

N C

N C

N C

N C

K O 3

4 7

K O 2

4 6

K O 1

4 5

K O 0

4 4

K I 7

4 3

K I 6

4 2

K I 5

4 1

K I 4

4 0

K I 3

3 9

K I 2

3 8

K I 1

3 7

K I 0

3 6

N C

3 5

N C

3 4

N C

3 3

N C

+ 5 B V

2 2 0 K

K S 2

O N / O F F

Keyboard

0 V

DRUCK

K I 0

K I 1

M

SY

K I 2

,

P

O

L

K

K O 4

K I 3

K I 4

K I 5

K I 6

K I 7

K O 5

K O 6

A

A1

C23

K O 7

'

Z

Q

E

S

R

D

T

F

G

Y

U

H

I

J

K O 0

K O 1

C

/

Ma

W

N

X

Espace

C

V

CODE

B

.

N

-

,

K O 2

D B 4

D B 5

D B 6

D B 7

For Destination

K I 0

K I 1

K I 2

K I 3

K I 4

K I 5

K I 6

K I 7

ode

Im

j

Sy

un.

M

P

O

L

K

K 0 3

K O 4

C O M 1

C O M 2

C O M 3

C O M 4

C O M 5

C O M 6

C O M 7

C O M 8

pr

m.

K O 5

0 V

2 6

V 1

V 1

2 7

V 2

V 2

2 8

V 3

V 3

2 9

V 4

V 4

3 0

V 5

V 5

3 1

C L 1

N C

3 2

C L 2

N C

3 4

M

N C

3 5

D

N C

3 9

N C

D B 0

4 0

N C

D B 1

4 1

N C

D B 2

4 2

N C

D B 3

4 3

D B 4

4 4

D B 5

4 5

D B 6

4 6

D B 7

2 4

O S C 1

2 5

O S C 2

4 7

C O M 1

4 8

C O M 2

4 9

C O M 3

5 0

C O M 4

5 1

C O M 5

5 2

C O M 6

5 3

C O M 7

5 4

C O M 8

5 5

C O M 9

5 6

C O M 1 0

5 7

C O M 1 1

5 8

C O M 1 2

5 9

C O M 1 3

6 0

C O M 1 4

6 1

C O M 1 5

6 2

C O M 1 6

For Head Ranking

A1

32C

K O 7

K O 6

C 1 3

1 0 4

2 3

V C C

3 7

3 8

3 3

V C C

G N D

R / W

E

S E G 1

S E G 2

S E G 3

S E G 4

S E G 5

S E G 6

S E G 7

S E G 8

# 3

S E G 9

S E G 1 0

S E G 1 1

L C D C S P L C 7 8 0 A 2

S E G 1 2

S E G 1 3

S E G 1 4

S E G 1 5

S E G 1 6

S E G 1 7

S E G 1 8

S E G 1 9

S E G 2 0

S E G 2 1

S E G 2 2

S E G 2 3

S E G 2 4

S E G 2 5

S E G 2 6

S E G 2 7

S E G 2 8

S E G 2 9

S E G 3 0

S E G 3 1

S E G 3 2

S E G 3 3

S E G 3 4

S E G 3 5

S E G 3 6

S E G 3 7

S E G 3 8

S E G 3 9

S E G 4 0

U

Keyboard

Q

&

W

A

E

S

R

D

T

F

G

Y

U

H

I

J

K O 1

K O 0

L C D E

L C D R W

L C D R S

3 6

R S

2 2

S E G 1

2 1

S E G 2

2 0

S E G 3

1 9

S E G 4

1 8

S E G 5

1 7

S E G 6

1 6

S E G 7

1 5

S E G 8

1 4

S E G 9

1 3

S E G 1 0

1 2

S E G 1 1

1 1

S E G 1 2

1 0

S E G 1 3

9

S E G 1 4

8

S E G 1 5

7

S E G 1 6

6

S E G 1 7

5

S E G 1 8

4

S E G 1 9

3

S E G 2 0

2

S E G 2 1

1

S E G 2 2

8 0

S E G 2 3

7 9

S E G 2 4

7 8

S E G 2 5

7 7

S E G 2 6

7 6

S E G 2 7

7 5

S E G 2 8

7 4

S E G 2 9

7 3

S E G 3 0

7 2

S E G 3 1

7 1

S E G 3 2

7 0

S E G 3 3

6 9

S E G 3 4

6 8

S E G 3 5

6 7

S E G 3 6

6 6

S E G 3 7

6 5

S E G 3 8

6 4

S E G 3 9

6 3

S E G 4 0

S E G 4 0

S E G 3 9

S E G 3 8

S E G 3 7

S E G 3 6

S E G 3 5

S E G 3 4

S E G 3 3

S E G 3 2

S E G 3 1

S E G 3 0

S E G 2 9

S E G 2 8

S E G 2 7

S E G 2 6

S E G 2 5

S E G 2 4

S E G 2 3

S E G 2 2

S E G 2 1

S E G 2 0

S E G 1 9

S E G 1 8

S E G 1 7

S E G 1 6

S E G 1 5

S E G 1 4

S E G 1 3

S E G 1 2

S E G 1 1

S E G 1 0

S E G 9

S E G 8

S E G 7

S E G 6

S E G 5

S E G 4

S E G 3

S E G 2

S E G 1

L C D U T S - G 5 3 5 A Y

1

2

3

4

5

6

7

8

9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

2 4

2 5

2 6

2 7

2 8

2 9

3 0

3 1

3 2

3 3

3 4

3 5

3 6

3 7

3 8

3 9

4 0

B

C

D

C O M 8

S

C o d e

'

Z

X

C

V

B

N

M

P r i n t

C a p s

S y m .

N u m.

BS

S p a c e

,

P

C o d e

O

.

L

"

K I 1

K

K I 2

K I 3

K I 4

K I 5

K I 0

K O 2

K O 5

K I 6

K O 4

K 0 3

K I 7

1

2

3

C O M 7

C O M 6

C O M 5

C O M 4

C O M 3

C O M 2

C O M 1

Q

A

W

E

C

R

T

Y

U

I

K O 6

K O 7

K O 0

4 1

4 2

4 3

4 4

4 5

4 6

4 7

4 8

V 2

V 3

e

od

C

/

'

Cap

s

Z

A

um.

N

X

S

pace

S

C

D

V

F

G

H

J

P

ode

C

B

O

.

N

L

M

-

K

K O 1

K O 2

K 0 3

V 5

Prin

t

y

m.

S

,

K O 4

K O 5

NAME

CODE

R A 1

Y A 1 0 4 4 0 5 0

V c c

V 1

V 4

MAIN PCB CIRCUIT

DIAGRAM PT65

LA3765000

E

F

Page 67

Appendix B. Sub PCB

3

R 0 A

3 R

0 R

+

T

V B

C

8

H E

1

C

4

0

1

V

C

D

K

A C

J

0

6 3

0 1 -

-

1

7

4

0

C

B 8

R

E

R

4

0 0

3 -

1

1 3 3

S

S

1

0

-

S

E N

S

C

A

NAME

CODE

SUB PCB CIRCUIT

DIAGRAM PT65

LA3766000

Page 68

May, 2000

8V2008BE0

Printed in Japan

Loading...

Loading...