Page 1

.!

BUTI'ON

SEW

THROUGH

THE

B448/BA15

FITI'ING

ADJUSTING

OPERATING

BtJri'ON

HOLE

Page 2

B448/BA15

BUTTON

INSTRUCTIONS

FITTING

1)

Remove

the

No.S07111-001

2)

3)

4)

5)

Change

the

Remove

Button

and

Fit

part

Drill

the

raised

the

clamp

bracket

the

for

and

807080-001

6)

unit

Assemble

clamp

for

{photo.B).

bracket/opener

credit.

SEW

'loose

{fig.1).

needle

hole.

existing

holder

153835-006

modified

credit.

tap

the

(ref.drawing

the

button

(photo.A).

THROUGH

button

hole

plate

{fig.2).

button

assembly

(fig.3).

bracket

(fig.3).

end

of

448/03000/35)

clamp

803464-101

THE

BUTTON

wire'

clamp

{button

for

a

bracket

807080-001,

153835-006

the

button

parts

to

and

HOLE

flat

and

clamp

and

the

return

float

bar)

type,

803464-101,

return

holder

fit

modified

the

i.e.

the

the

button

old

part

without

old

cylinder

bracket

7)

Fit

the

modified

{fig.4)

8)

Fit

the

modified

9)

Fit

the

main

10)

11)

12)

13)

11)

12)

assembly

Fit

the

Fit

the

suitable

the

head

Fit

the

Fit

the

Connect

diagram

Connect

(photo.C).

start

main

hole

mounted

3

position

foot

the

{ref.

the

YELLOW/GREEN = EARTH

BLUE

BROWN

presser

button

clamp

cylinder

control

in

the

air

switch

air

tubes

drawing

electrical

c

NEUTRAL

= LIVE

lift

catch

lowering

to

unit

table

cylinders.

switch

unit

{photo.F).

and

438/3000/39)

supply.

220

(SELECT

cylinder

the

under

top

unit

head

- 240

roller

plate

start

for

the

{fig.5)

solenoid

table

the

{photo.E).

reset

VAC

CONTROL

arm

shaft

and

head

air

switch

OR

110-120

BOX

(photo.D)

top

tubes

wire

LINK)

807072-001

reset

and

drill

to

as

switch

reach

per

VAC

a

Page 3

B448/BA15

BUTTON

SEW

THROUGH

THE

BUTTON

HOLE

ADJUSTMENTS & OPERATING

1)

Adjust

of

the

underside

2)

Adjust

movement arm

3)

Turn

is

correct

cylinder

switch

switch

the

time.

The

button

set

the

sewing

switch

Adjust

the

button

the

button

cylinder

4)

OPENING

The

for

length

optimum

thickness

However,

button

longer

must

be

the

pins

in

of

the

the

machine

and

and

on

the

must

be

clamp

step

clamp

ONCE

the

to

height

hole

hole.

(photo.B).

FINGER

of

results.

of

if

these

stand

than

the

filed

button

the

the

button

button

loading

button

clamp

S07075-001.

by

the

unit

there

button

is

and

pressed

is

lowered

switch

with

lower

the

of

to

button

the

the

opening

This

is

LENGTH.

the

button

They

the

button

off.

are

The

left

best

thickness

to

the

correct

INSTRUCTIONS

arm

catch

latch

plate

plate

height

hand

press

each

position

to

no

fowling

loading

the

time

in

make

parts.

two

3.

hole

clamp

clamp

fingers

done

hole

must

hole

to

too

to

assembly

are

by

opening

be

maintain

long

length

of

the

buttonholed

length

S07075-001

are

S09582-001.

to

line

sure

the

between

reset

the

switch,

unit

steps,

Place

the

central.

position

so

approximately

the

screw

fingers

long

enough

a

this

is

and

will

approximately

re-polished.

so

that

just

up

clear

with

the

button

the

finger

the

is

switched~n

to

adjust

garment

Press

the

1.

that

the

1mm

in

the

end

must

to

penetrate

positive

create

fabric.

the

tips

of

the

button

alignment

opening

reset

step

under

start

tips

of

above

of

the

be

adjusted

action.

excessive

0.5mm

These

for

1,

the

the

3 POSITION

POSITION

POSITION

First

position

Second

This

1.

2.

press

and

press

facility

experienced

POSITION

First

first

button

Second

second

Third

After

allow

allow

3.

press

position

hole.

press

position

press

sewing

the

the

SWITCH.

Is

for

Gives

of

the

opens

of

is

operators.

Gives

of

the

to

of

of

the

is

button

next

button

standard

2

step

start

the

button

the

start

used

3

for

step

start

allow

the

start

and

open

start

complete,

to

be

released

to

action.

switch

switch

easy

action.

switch

the

switch

the

switch

pull

be

sewing.

lowers

hole.

starts

to

will

fingers

will

button

will

the

easily

loaded.

handle

lower

to

lower

hole.

start

garment

the

clamp

the

garments

the

be

aligned

the

away

from

to

machine.

and

clamp

with

the

clamp

machine.

QUICKLY

the

clamp

the

to

first

more

the

the

to

the

to

and

to

Page 4

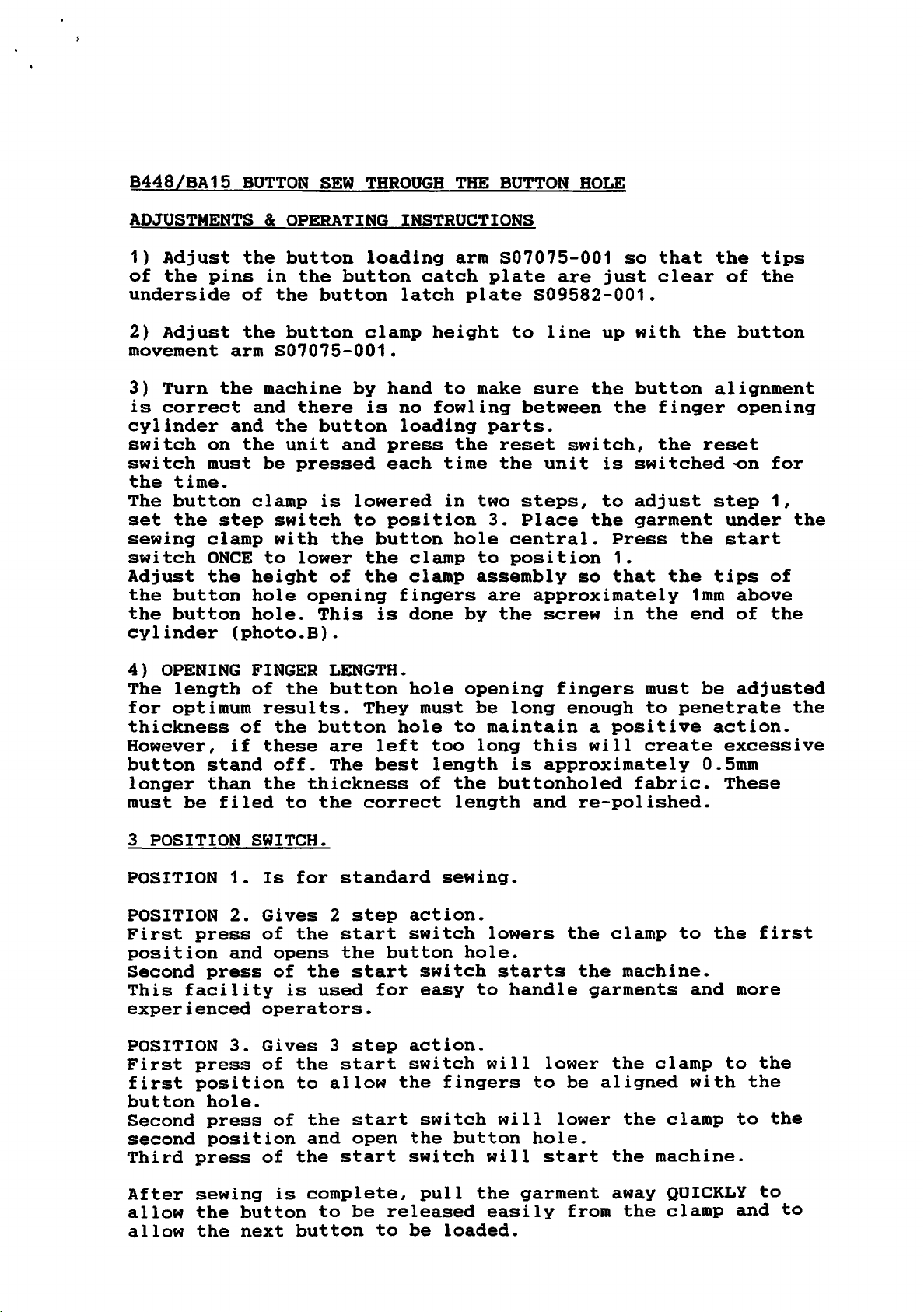

BUTTON

CLAMP

HOLDER

PART

NUMBER

S07081-001

~

0

3

HOLES

D& T M5

---i

~I

::

-

~

I

I

I

I

ncsr·DJPTI/\1\}

UL

vi

'\1

lVI'

MODIFIC/\TION

TO

ARM

SCALE

DRN

BY

'1:1

-

J.D.C

~H-I-

:

vI

~MATERIAL

TITLE

448/8/SEW

IREATMENT

i

~0

()")

(J1

I

_j_

/THRU

I

BROTHlR

I

IORAvVII'IG

DATE

No

448/03000/35

21/10/92

Page 5

R .

-}(;.

_.L

/l.

/ j

Mecani sme de re i ache-

)hlf,f:

I Tension Release m

tension

I M

ecanismo

ec

hani

w-

sm /

Span

de liberad

--

4

nungsvc

or

de tensi6n

rm111d

crun g

S.

*'--1"1.1/~

M

eca

Jfif-/Trea

nisme

de

tir

e-fil I M

d

wi

per

mec

eca

nismo de

han

ism I

Fad

enwisc hvorric hrung

limpiad

or de

hil

os

;l-!!!HPt &

Ref No

)

1

--

•

I

I

J

1-

I

1--

,

ID

11

11

1)

r--

11

II

II

r-;a

~

10

-

11

-

l1

l...,<-77-7·:~

1

-f ~ ot+t

:r:?

Sf:,..-~::;,_]1

I

9/

.:J-

::;,_

) ]

-f~~J1.F7-f"1'?

7-f"l'+t+t

:X:

7 -f"l'ot+t:x:

1-71"'l'J•

·

-~ T·:~J-2-;...~

t-

-

: T

;

! A 9 1

I

'

~t.JIXI

:

T"':HH-•OX6

t:+::J:.

,..,,_

5(:.--+'/~JJ

?:.--~-:..:

·

37

t

?'f

ti:?-'1-:>?<

4.JJ

.

d~·tJ-7

-r....:.::J

lll-.COX'

17.7-f

S'-A

~

'1'9:.-?1JY'I'70

.....;.

:nJS-

56

~7-{

:9'-,(.;?-

f"

1-'

S'-f

X 6

t-

?v,<-

<

JJ

I I

--

N

ame

of

~<l1>1

l

Sc.re

!

i

S~l.d

l

SludSc.r~

I W

~

Nvt ' )1

1

Sonne

f

Ser

!

Sl<le< ·•)

S..:tton

i

"Sc,

! Soong

-----

,

s~\}(]

-

'

&

Pan

s

lrver

Br

.teket

Tlr

t'~

Pr~~

C,.~

St>ASu

...

<

St

T ~ Rettase W

w

Yl

DuG

l1

Ld

Su

...

<

l1

~e

Suooorti'\C

~ePresse-r

- CJI>.'

Lneor

Sc.re

..

a

JJ

(

lJ

asher

c l_l

--

Hool

f'

..

&

)IX

'

Flo.!Jt

Bat 0 I

e::-m;;-

rre

Srac.kt'l

.

L~

Assenbly

11:1

S&.=>

O'ty

P"rts

1

5 0709 3- 00 I

1

507092-

1

144

526-

l 148417-

I

5 07981 -

1

507086- 0

1

153941 - 0

1

80

0186

l

062680-611

1

5 0708 2- 00 I

I

144

526- 00 I

1 5070831 025680 - 232

1

021

680-202

1 5 0709 71 062680- 611

1

5 0708 7- 0

1 5 0 7

1 0626

I

5 0

I

150721 -

111-001

30-61

7091

I

I

- r

No.

001

001

001

- 522

00

001

- 0

001

001

01

01

I

01

)

1

01

O'.l!il&ft

Ref

No

I

?

-(~\-o

?-f,\

-o

7T

I-,j

~

J

7E

-1ftj

.,;?.

i

7-f,<-;>?

_

t?-tfn-1-7.:~.?'

~

J

7E

71"

fF'I-;>t

?

-ft\

-?r?;

~

J

7E

,.-!

J&,-f.

~

F;?-;>I.ll

---

?-(,\

- A

:1--<:J

J5l-<OXI

t5•t1f~~

12

I

"

-

14

~

10

13

~~

2

t-

-

-

-

-

--

--

-

1

--

J

•

I

6

-

1

-

I

!

10

11

11

1)

11

15

11

'l

f

Y?

.,

F?

t

.l-9.tl17-r.;

i

<

Jl?'l'<

l

1)1!.

/"

?'l'

<

a?

& ~

N~

~

-

-

-

H

-..

-

---

fli5&.:J

tl:!

p,_,,..ts No

of

p.,_,u,

':"trMdW~RodShaft

; lnread W

oet

Rod

Au<"r.

bfy

I Sere•

~

11

Xl

Stoo

R.n'

[5

4

j W

asher

l

Trw-cad

W

¢t't

Sh.,tt

-

I

1'1

ashet '

J~

tO(l

R~t~

e--

t

--

ew

UJ

""""'

ll

()e(

c

El

JS

XS

-

Xl

l.tnl<

~setrelt

j StooRV'I( E'

fSc.r~t

ilvcad W

t-----

S

Q.IC.O

Sc.r

-

Scr

w

o·t,

I

15

1 152816- 00 1

I 014680- 621

048060-

I

1 1166 29-00 I

1 I 52821- 00 1

1

025770- 131

I

048040- 342

1

014680 621

I

152823- 0

I 048030

1

152827- 00 I

1

013710-712

I 1562

I

062670- 512

1

02535

t

2815-001

34

01

-341

06-001

0-132

2

Page 6

Q.

1

)

.J{;

VJ

lxlfff;

nisme

Meca

61,'

~

1

16

~',

/

Thr

ead

de coupe-fil

trimmer mechanism / Fad c

l Mecanismo de r

cco

rta

nabschn

dora de

eidevorric

orillos

::::=;

18-2--o

htun

g

~

@--

24

23

31

~

9

~

~

10

~

~

so

~L

~

54

-@

53

-®

52~

st

~

~1>1

&-'l-

1

Rt!f.No. Na

I ! 1

-

l 71">!!1" H .31X 10

I

---

;

5-1

l- 1

1

----r:;-;:--

!

i

J

)(

· 1

-I

· ]

_,

-s

-6

1

t-

4

V

:..-?"-

'/ C

-

~

}

I-~1J?TA7 ~

f

~

'1'11

?7'8

f .1'7ES

j

"'lfS'C

t-

1- -

'!'

'I

?

T"C

Y

.1~

::.;

ff'I''IJ.../tl/7'

1

f?"7'

Y

.l

* Y4.

:J7'i "

:,_,,1

;t-

::;1

-tt?

:f-

;>1.31

~''}

7-t-i

-( ~ _.,IJ

::JD:/?

f

.I

'7E

:l[]

''"'

tl'T

1f'\'1IC·>f~/

1 f

'\'111JJ.<--;<-·y_,..

1"""-

::>

I!S· II X H Scr

t71fti

-(

..

""

'}1'J

'!ti'l-

~

.1'7;>73?Cll

-

4

31

l1

ll

S'B

'?JJ,.Lo<-

< StOCtRngEI I

:f-Y3?&

J.,.V

,i-::,;~

; .

~

~

~

~13

®--..._

45

,~

18-s--fj

7

~

~~

4 :

41

8

~~

r-

---

I

~

I

L_J

~

3 I

~

~

I

5

.::,

me

of

J

Thread

Tlreod

Bol

Tlreod Trfl-mni

St

---

N«d<

Kntte

Scr

KMe

Mo.

Scr

F"ue<ll<rofe

Scr

Scr

N«d<Hoi<PiateiSI

TlrNd T nnnng

Roller

Rollo<

Scri1c

p.,

Tlreod

W-1

Tlread

w

""""

Stoo

t.

Parts

TrW'!Ynln&

~:.,g

fntl't?W1ll

Arm(o.)~y

t I l1Xll

km

oo

R.nc

El

Plot<

(S)

~>rm(CI

...

u l

Comoct

"'i

Rod

obleKrwfe~

...

l.l

l

ew

I

31

...

l

31

c.m

Stud

Hool<

T-

C

I!I X

R""

T-

Cll

«n

II

C.... t...... Sh.llt

...

Rod

(8)

---

Au<nt>1y

)('

u..< J

u..<

0,..

----

C8.1l.:l

S'Jtt

Q'ty

--

- 152892- 001 I , -'(

1 IS

I

-

1

I

1

-

1

I

1-

1

1- 1

;-

I

J

I

I

I

1

1

0

1

1

J

1

152915

1

06276

1

0250 60- 132

I

1529 16- 001

-

1

1

J

048120-14

r

PC;'Ir

t s N o. Ref.No. Na

1

52896

- 001

018681 - 022

152893-

101

04805 0- 342

5

01887

- 001

I

529

95- 00 1

152981- 001

53222

- 001

1

152897- 201

1

5290

1- 001

1

5290

4- 001

1

529

05- 001

111140-

002

I

00360

- 003

156150- 001

1529 12- 001

152913- 001

48040

- 342

152914- 001

15

4789

- 001

152919- 001

- 001

1- 412

529

17- 001

2

1J

I!!I

&<t

li

11

'---·

II

IS

ll

31

ll

33

34

lS 1 f

36

ll

31

l!

16

"

<I

0 -+t?

"

<I

<S

..

10

11

II

ll

I< '111'1-

----·

"

32

~

~

48

18

·,--tJ

,..---

I

I

~

26

---'

~~

r---------

fiMteffl

for Exp

-'(

,.

::t-

7

-t-~.l;t.:;S

•ttf'l-

~.I

'7E

f f

'\'

71"

f

f

f'\'11

so·:.-"" :;s.

-r., H

f f

'l'-11

'l''l'tf-J.n<-:.

..,tf'l-

f

.I

'7ES

1 f *

;;t. 1

"-1 :t

f.I'7

:;7

:t11".177t:.-

71'

f

,..

1

-t-

::;431

:,..

.;J

;r.

::.;

-<

f 411 ? T'C:n ? -

I -f

f-·?·"

...

<:t-:tJT

;,.

s-1

:,..

~

;r.

::;

011

/~P

:,..

5'-(

----------

6-1

ort

~

•J

1

J}...

t,...,<-,

957>1!

< Stoo

'I 11

:.-

7 7 3 ? t ·

.I

;t.:;S.!S7>!!'

1

1:.-7

ss

!S

-ttf

- L

n<-

•1..,.

r-

"''-:;7

1

7

1 7 7 '-' 7 'I

3?C

""

:;s

ss

c

l1

117

-

f

..,.,,'~'A

c

l7

J

,.

..

j"

,(~1J?

me

~~

'

y:;

7

c

;,

?'

11

7

>r.

'

-

----------------~

t.

of

P8rt..s Q

KMe

c.m ~ ...

Scr

ew

w

.-

Stud I

Scr

ew

Tlreod T rvrmng !-"'< 1

St

ud

Nut I !I

Tlreod T

Roll<f

w

w....

Stoo Rng El J

~Sh,ft

Hu=nt.ol

Stoo

C"'F

Screw

Screw '

Sct-

e--r(

I<Me

--

Scn'i

Tlre<ld

Screw .

PacJ<rc P I J

Tlre<ld

Wo>J>c<

Sonng

S.!SX5 1

Rtng

El 1

I.!

IXI

Scrc>o

1.!

I I

rvrmng

~

Feed

Crri

Cll

ICI

Rtng

Co/'.,y

Rng

crOil Wet

I !

lXI

ll

11

km

Kr<I•Col¥

Hool<

R.u.ner

(A)

ll

Reu.ner

eon...

.It

1

J

J

I

1

J

I

I

I

I

J

J

1

J

J

1

't

y

1

154788- 001

014760- 622

1

14

04

152920- 00 1

I

014760-622

152921 - 001

15 I 907-

I

150553-

I

152922- 001

I

152923- 0

112468- 001

048050-342

153482-0

14

04811 0- 142

111865014760

100032-004

I 53208- 002

15

15321914 13

152906-101

153598- 00 I

081008- 070

153597- 001

153596-

Al!.!l.:l-f

Part.s No .

02

08-

001

8040- 342

001

001

2628-

001

001

-622

3220-

001

001

34- 00 I

001

01

01

Page 7

H . .

r-;

1 / ·;--<'

Mecanisme

~ f1~

~)JIX.Jf;Y:

du

pincc-bowtons I Mccanismo

/ Button clamp mech<1ni

sm I Knopfh alt.:vornc

de

Ia mensula de rcsor

te

htun

g

5

-

6~

5-s

~

5

- 4

~

5-J

~

5-1~

5

- 7

~

5"2

d

- f

<'

~..1

12

II

I

fl71

0

I

I

L

----,

I

I

I

I

~l

fj>

J;i!·~

Ref.N

1-1

)(

1-2

1· 3

1-<

2

3

•

(· 1

X

<- 2

<· 2- 1 or.?

~

<·2· 2

<- 2- 3

(-2-C

<·2-1

<· 2·6

<-2~

<-2-~

<- 2-!

<-

2·10

4-

2-11

<-

2- 12

<- 2<- 2<· 2· 15

<- J

·-·

<-1

<-6

'-Y?

~

.,

,

''

* Button

?

I<~

o{

t::.-

AW2

I

~8

91JJ.

F·

;.,<

;t.

oil.

~

!

o. Narne o f P

L.-1<

- ;t-JL-?

'-

.rt:?

/':1"1):.

7-TL.-,(-

;f.?'".r:J

1'J

:

~-'

'!-

;;.;

?"f

ti

'1-'f' :1.

~mn,.Sf-?

~*'~Sf-

~?~UI

:.0

';11>' 9 of

:.0"/

1J

'R

?':111

~

:.O':t'JJ! 7 :.O'f'

......::Hl1-40XS

:.O?"t:

)6

:.o·:t

1J

' M?

:.0';11>'

HJ1

-40XI

$::f.

::/4.

17

·

t-

.c

7

/'Y

tJ

~

~

4 .1SX 14

'1-

:.0t:7+

"''

S !S ?or.

R1"

:.o

-f

11

...:

-tt-tt.I:

7'f'

Yt'or.J1-.~6X20

t

or.?:.-·:t:n

,r,j>;..•;t1J

,r,j>;..·;t1J

,r,j>;.o·;~'Jl~L

or.?:.-·;~ 1J~Lof9

or.?

;f!?

;f.j>

)

j-

;...-;I•}

?

'/"~:/ 4

or.?

;f.j>

1".....:.:

.Y

ll

1<

7IL-T

;t!?

:f.

I'-'

"1''11

'l'of;('f-•?t•;~of?::>

;f.9

&

ar

t s

Brxk

et

Button

Cton-o

Lrlt"'

Button

SGr

ewl

Bolt

l X

W,W..,. I

Button

Clon'o

ButtonCion'c>Haldo<

Button

Clon'o

Button

Clon'o

Button

Clon'o

Clon'o

Button

Clon'o

Button

Clon'o

SGt

...

SctP UIXS 2

Son\&

p.,

Stud

Su

Button

Clon'o

Button Cl.orro

SGt...

CU

x.-

...

.

Nut

c.u I

Button C

Boh.

C UXU

w

......-

S.L<

A41-s"" PlAte

But ton

Ooene<-

L.,,

Clon'o

Lev..-

Shaft

!I I

II

Held«~

AsS«Tb'y

Brlld<et

(L)

(L)

Plot<

(R) I

(R)

Plote

AWl I

.,. 4 II

(M)

A»

Platt

XI 2

ll

lon'o

So-"'

-

As"""''

s...x>o<t

111

~

So-re

ec.t:l) (

)(

')(

X

-

0)

l!.!l.:>-r

11111

O'ty

PMt.s No.

I

153835-006

I

153836-101

1

153838- 001

014 760- 622

2

018062-

2

025060-232 -

I

507080-001

I

507081-001

I

5

10779-001

I

503464

I

505679-101

I

05680-10

5

5

05678

I 505681

2

11

062680

2

047250-642

2

115158-001

-

I

5 05687- 001

I

505905-

062680

I

503468-001

03657-001

5

I

03610-001

5

2

017711-412

2

1463

I

5

03600-00

I

507079

5156-

54-

022-'

- 10 I

- 1

01

-10

001

- 512

001

- 812

001

- 00 1

4+

15

Q

~--~

4·

14

4-

13

#l!ll.

-'}

Rel.No

. N

( · )

;,

;t-l-~6

H

<· I

'f'

7

~I

<

·!

(· 10

( - 11

<· 12

(·

13

<-

14

<·

IS

<·

16

HI

C-

11

I

I

1· 1

1

5 ~ 2

S· l

I· <

5·

1

S·6

5· 1

5 ~ 1

'

l

I

!

10

II

I

12

35

S':..--1-:/( .

31

A ..

':t"

'-:t-

;f!?/t:?~

'''f.1l?-

t?~L,<-

::,..

T 7

t?"f'ti'l-7'

or.?:.ot?'f-'I''I'I

Si

~'1'~7-'im,•?'-::>

~"'ti7"i'I'J~$f

~"'ti7"i7

*?

:>o

"1''11'!-<.16

1-

71"~-''!-;;.;S

*'~5,--"'t'!'.I:

7'f'~-''1-;;.;S

*9

or.?

71-~-'

::t•t::z::

~"'~'"''*7'

:f.?

-;;

';l;ll<;f.

::>

;I

.:f-

:7,;

6.

3S

~

6.

31

:>.

:.-

;f.

;;.;6

.l5 I

·y?A

:.O'f'

Jt,.Sf-7·>7

., H .

Jl

;..•;t

1J

'*'~9-'1'.,

:.O':t

'JJ

'*'~?'-

'!-

;;.;<.

..

<;f-7- 3 ?

.

;_,·~1J ~ :.t'*t

.!l.

~

? <

31

t-,<-

'

-

.

!I::>

*'

;;.;::>

.

!I?*

'

;;.;

?

Jl?or.

'

.Y

::f.

:::;

?t·;t'!-

;;.;

z*~,,

ame

-

:r.

;f.

s

o1

P.vt.~

S:·two i lS

--

N.:: i H

·- -

S:u:Sue--o t

iSc.•f'-

--

! s

or

....

,

-----

;

s:r-n,~

;

~

L~

I

S:.·f'oo~

I N

oJtlll

<

iWa!,~

j &1.t0'1

Ooen«

Sh.<l Suewl

j

P

r~~

Uft

I

Pte-s~ecutt~

! p •

..,,

.,

utw

,

a.,;,;,~

~

~-

---

' N

asf'Ot!r

C "

~~:_,

Jj

I

wr-1

!!

:

Ho:o-<s...x>o<te<S»aft

~

Xr

r--S 1S

i Bun

on

Clamp

i Sunon

Clon'o

1

YJ~

'

Jr

!

x.-

...

ix.-

...

I

5c>-Y>c

--

ll

-

----

~\eTCo

ll

So..ccxYt

ll

--

~ ~$

Hool< (.;)

--

--

Holoe<

Holde<"

-

---

'y

~.,

-

s..-t

Shoft

-~~

-

-

-R

Lever

_j_

-

_

...

_

~-~

-t

-

-

-

-

---

s.co

•

\;1;)

1

Pdrt5

:a ·

tyl

I 5

06

--'

-

I I 50556- 00 I

I

11

5166-

503606- 00 I

j I

I

503607· 001

5 03608- 00 I

J l

5 07098- 001

I '

------

i I 5071

I 50556- 00 I

------

025680- 232

-

--

506992 - 001

~

149127- 0

S 07107-

i-

- S06995 - 00 I

50

6998- 00 I

:

I

506996·

1077H

l

----

+--

153484- 001

I

105134- 00 3

l

l 014160- 622

506

I

--

I 014760- 622

I 5 07084- 00 I

I

153

827- 001

2

014

680- 611

146994- 001

2

I 115148- 101

I

115141- 00 I

:l

- t

No

-

994- 00 I

~

---

00

17

- 001

01

00I

00 I

-001

----

997- 00 I

--

I

-

Page 8

·b • .

-K

5'

/ 7 1 -

Alimentation

5''fMlf*

pour

(2) I

bouto

Button

ns (2) I

feeder mechanism (2) I Knopfzuftihrungvorricht ung (2)

Bot6n de

alimentaci6n

(2)

t'

!!!l~~

I

Ref.No Nbmc o f P

1

-0 0

~

'""+'

1-

011 Jot7

--.--

1-0

16 I 7-r?-r:

1-01!

1-010

1-011

1-0

11

l -

Oll

1-0

1< 1

b . .i;

16

I.7'i1JJ..

---

<lXI

17?

/ ? '.)

-----

nt.7..,o7-

?.19

?;,7

l~ii.7"i7

j~~r.77~?/?

!

l n:.. 7 t 0 7 -

71"1.1

.?-'/S?;f!

5'

;..

7 1 -

Alimenta

.n.

_

1"

:./

?

;.;

?

(

~

P·%

ti

on po ur houtons (3) I Bot6n de alimcntac

t,

.v

ts

iwa.~•

i

11

Pr-ssc

r

L•ft~ng c~

X..e• I XI

I c. ..... Sh,s

lt

s.

Pr~~

Lr

hii"'

1

Pr~~-rt

l.Jft

~nC

l

""'"

Suooort"'

I S....h

Scr

tw S

...

C

Cranlo.

Cr

.. ,

anlo.

Sh.

ft

f:(:l) I Button fee der mecha

G:t

1!11&.::>

- F

~

!\1#

O"ty

Par·

ts

I

I

1

I

I

I

I

I

I

No

15

3484

- 001 1-025

50

5384 - 001

0140

60-632

5

0538

5- 0 00

507073- 00 1

505387

- 001

5

0537

1- 001

5

05388

- 001

014

500

- 5

22

ni

sm (3) I Knopfzuftihrungvorrichtun g (3)

-lt

Ref

No N

)(

-t-ttz7'i=>c77''/

;j"-+f:I:7'f:JC

02

6

1-

1-01) 1"

11- 0

030

1-

l -Ol l

1- 0

1- 0

071

., H l1

71"

15

31

3<

f.l.:f.'/6

t:7=f·'/

3X 11 I

T·:~ 1-l~

:...

'i'"

11X

77?7/7

,(

~1J

7

7

1"?'!'

( 6

i6n (3)

X6?;r<<

l

X6

? I

~

d

;?.

~

&,

ame

t,

of P A

ra

;lr

~

U

ft"C ROI!tf

Nm

Sha

lt

t'S

Sef

Uftlt\(..!:_~

! Nv': l

)1

t t •

'X

· )

XI

-

J

NOOL

::-ix1

--

'

!

I

S<:

5<-t

1•

..-:

Sor-r.t

~ ~V'(

~.

){

--

--

-

"

:!!

O'ty

I

5 07072- 001

I

50

7 105234

I

014060

I

00i301- 2 12

1

021300- 103

~

50

I

i

I

1~1

1

01~

t5£:J-...

Pa

rts

No.

7071- 00 1

-00

- 6

5391-001

334-00

060-632

3

22

1

t'!!!l#

~

Ref

No

1-

006

00

1

11-

001

1-018

1-

037

1-

031

1-

039

1-040

~ -

"f"

7

7-J",r, J• H XIO

l(;f.

1>

1..

n

J..-";;?~

1J

L.

?:.r-J,..;t.-(

--

9

f ')

"/

'T-19

;f!11-

H X I8

"tf

'fi~·l-t

-";)

? C

9J

"F

::;J ? ;I

?

JLofl

- J

L.

&,

N

ome

-

f,

of P o

,.l

s

Mot

or

Settlf'I

C

P\.:!.

Bol

t ( X II 4

Bolt.

' XItl

Sor

""

«n

Sh,

CNn

Cam

Shah

W

onn

tt

W

astw

H

ft I

S....ft

IJW'"'C

(F) I

IJU'.hon&

(R) I

Wheel I

«:t

O'

t y

I

4

•

BS&.:>

F

P a

rts

No

5 0 7 110- 00 I

018401-02

018401-022

028040-24

5

07070

- 001

5

05329-000

05330-000

5

5 05331 -

000

II'

!!!I

# ~

Rcf.No.

1-041

71"?-t<

7•-J..

7

1"

f

.I.?-'/~?*

1JL:.;?A-1

7-J"?:t<

.:<

?

.:<

~

"'f

"'f

"tf:t-

<Gx >

(

·7 + 1': ·7 ? C

( 6X6

"tf:t

·

042

1-

2

1-

043

1-o

•c

2

045

11-

050

1- 051

dl,

N4

.£.

mt'

of

PA

rts

lx-

..

1x1

~

f::~

----=--

¥'1

51-..t

lt s

..

tCh

Ooc.

5!

Sc.t

t-

i X'

w.,..,

w

....,.

11!1&.=>

P.lrts N

014060 - 632

50

5332- 000

014500- 522

014060-632

5 060 24-

001

001

5 06029-

f

o.

l'l:!

O't y

-

7

I

!

1 5 05333 - 001

1

I

I

Page 9

b

.-r

; 9 > J 1 -

Alimentation pour

1

-12

~

,_

.,

f{j

)'

IX'Jf;'~(5)

I

boutons (5)

I 1 1 g

~

i

·~

Button

I Bot

i"

J"

feeder mccharusm (5) I Knopfzuf

6n

de a

lim

entaci6n (5)

uhrungvorrrchtu ng (5)

1-12~

.

~'~1-1

~

G?

:··::a

"j

I

4D

1-128~-

1-12~

~

~!!'!~

~

Ref

No N ame o f

I·

OSS

'f!~

;..-

'f-1-11-71/..

1-100

7

1-101

1-101

- ,

..

-,-03--,f-

1-10<

_•_·

•_o_s

1-106

HOI

__

•·_1

1-1

111 "t"·>H!I

1·

---l----

1-11

H"

·-·--_".;.s_+t::.7

116

t-

H I)

----

Hl

"t" 7 '1!

1>/..7.

7-J..B37

..,-.,-~

--------

~.17E6

- -1-7_

"1"

....:...7.;.'1<_

1>/..7~07

?":.-~;>M

.:_08=---t--'

7·

:..

'-'_"_"t"

11

3

l

__;_·

~7·;t-1'

9'/~ y

/y;~.

"f"•'H

.:....:

1f

...:.

ti

.:....:

-'~<fti~l·•

~7"/"i''T?

~----------1-~~~----~4-~~:.:--j

~7

·;t

"i'

c

~

6 X 6 S«ew I X' l 0 I 4 0 6 0- 6 3 2

078377-/..

;.-r:-t::-

·

-

~

_6 x_6

-----+

-

<

'

..c.

~-'

-----+N:..v:.:.

7-

?

i R

----l-----

~

..c.

""-"

.:....:

"-'----l-w..:

i L .bntAue:rbly(U I 148589-

79':.-~;>

....

___

26

&,

Butt

c.m5uooort"'S(8)

+.,-m-,B-1-Fu~<N>o_...:_""'

\'/

..,.... I 110367-

-

StooRont£1

~

_

..

'C

amSuooorton

S

tud

Baii

Nutl.

StudS«

'*'

.....,.

So<ncW..,_

StudS«e- I

. l

~

,

.....

~

Part~

onC

.vry

C.vn

Ann

_____

_w_l_x_t

---

-

---+

t 1 5 05371 -

S«e

wMI

t_•

________

Bearon

gAs,..,.,.,(R) I 148587-

!l

---+-1-=c:.......:..::-=----JI

•·

''

:..:._

•

__

___

_

H 1 028040-142 1·1

«:t

a·ty

I

I

-t-

,

+--'s-o

I 048060- 342 1_ 11_<

-' -r-..:0.;.1.;.40:.6:.:0

I

-l

,- '

+..:

I 100022- 005

I 5 05373I 021400- 202

__

+-'+-0

SS

&l.::>-

~

Pnrt

s No

505368-10

505369-001

505341-001

0.:.2

:::2:.:5.:.0.;.4.:.0-...:.

505336-001

1 1·

~-·---'7_o

.:..s.:..37.:..

o'"--'-oo l

~

001

:..-..:

6.:.3:.2 -l--•-·•_1_1

001

..:..1..:..

4 0:.:0

:..-.:.

2.:.0:..2

-h·-'

001

---+------

001

~~

2

:.:3:.:2-li-'---'J...:.

001

N-5

1-131

!:.'!!HPt

Re

f No N

115

"t"7H51

_+-.,_L_7.;.~_o_7_B_3_7_•_"l_

1·

111

-'

~1l

'r

:r.?:-.f

f"

7 3

77-LB

1·

113 7:1"7ot'"x!

--

-!---

_+-"'-·?_:-_7_:.-_

·-l-

1-111

1·

111

-·-11_&_

1·115

1-130

s

_f-C-7-'

3!

~

---------

•_'

_"_

;.._·?

t

-'

-,

-'~-"....:...7_-

-t-~.I~YI

f"

7377

__

XI?-t-i

____

7

'1!?:-.f

+-7_r_?_ot<_~_,_x_6

't7~Yl.I1X<

'I'Jt.HXll

~~

--.:.-;.:-t·:.-

'-' :.-'r ·;<:.-?

'1<1/7

6

r-'-~ _;_c;....;.:.-_s:...;.l

l_~?-·1':..

'r9'-f7i{l- lmm)

J>

ame

of

1<-

Jt l _!l

·A

__

+-

c..-~_s..oocr.

~Hoc>

eua

S«ewlxi - ! I j O

____

__ _ _ +s.:_:_:_'

-LA

-·-~

&r.t

Sc<e

Button"""""""t """'(>! _ l

-t_

Sc<_

Sc<

BoltiXII I •

:..:.__.:_

Nvt i

Pn 5 06119-

·

_,

--+-'

Scn-

-'-_

C<Yne<tO'Y.or.

But

<,

Pan

.$ 0

_--:.,.,...-,-

_:..:._

on....,_

onT

•.-=-rtSo.llt I I I

Col.;..;...,

:____

• iXi ! I I

•_· _•_x_i

ewl

ll>• !1 i 5 06044-001

--:

">

..::..;_(ll.;.)

So<-<>(....:.....

~··1

.,....,..,_,e

l ! ' j SOSJ76-

--

-----

_____

s_!_;

___

1

'1:1

t,

.

- ' ' i

,--

1~6592-00

I I I s 0 5

I r

1~1334-001

507~_8-_0_0_

J 1 1 SO

Oltu60-622

~-,--solO~

1 I j

01

II

:' l

017

021060-

0 1 0 6 0- 622

-

I' 5 07016-

lMC...

~?~t

e'->

.....,.1

11~1

I 5 06686- 004

-r-~

I

il"""

~

P.'lrt~

No

31

s- o 0 1

001

I!06ii=6J2

712

9-0~1

t 0 6 0- 63 2

062- 503

106

001

001

1

1

)(

Page 10

BU£

110

SUPPLY

\

VOLT

~-

_/

TRAHSFORivF~·.

I

(')

')

~

"ED.AL

~

X2

><3

X4

X5

X6

X7

PLC

FXo

,--~

Y1

COM2

Y2 Y3 Y4 Y5

~)

0

?

L

YELLOW

------

BLACK

·-

D

>

v

('J

f--

:J

0

>

0

E

c

z

u

<(

~

u

<(

F

L__

;::r-

~~

~~

>-

~

(.)

..__

3

POSITIOI'-1

CONNECTIONS

l~t~

C'fLI\DER

SWITCH

J

1

A

YELLOW,!::-

BLACK

krt«R

Ylta.R

6

!:>

J

>=

~

BLUE

\'7.-

1

$d

6'

ooo

0®

0

RED

o(O

000

S>

~

(.)

~

!;;)

~0

Oo

L

~

«<

<

C:}

v

0

.f>.

C4

~~

-

l'fD

Wfl£

FROIA

J

POSITON

SWTOi

---·-----------------

~o~tfoo

__________

Dote

11 1 93

__

-=j:~

---

·:·-

__::tment

=t·

--DrgBy

J.j~dBy

~A

[i

[i_

DESCRPTION

WIRING

v

~

~

~

I~

8~

DIAGR.A~M

I]

Title

Drawing

BROTHER

438/448

No

438/3000/39

BSTBH

Page 11

(A)

(B)

Page 12

(C)

(D)

Page 13

'

(E)

- -

·-

i..-;

',

....

011

~

.

•• -OR' . .

:.

( i

:)

Loading...

Loading...