Page 1

INST

.RUCTION

FOR

MANUAL

BROTHER

LH4-B814-2,

-3, -5

BROTHER

NAGOYA,

INDUSTRIES,

JAPAN

LTD.

Page 2

~

FEATURES

~

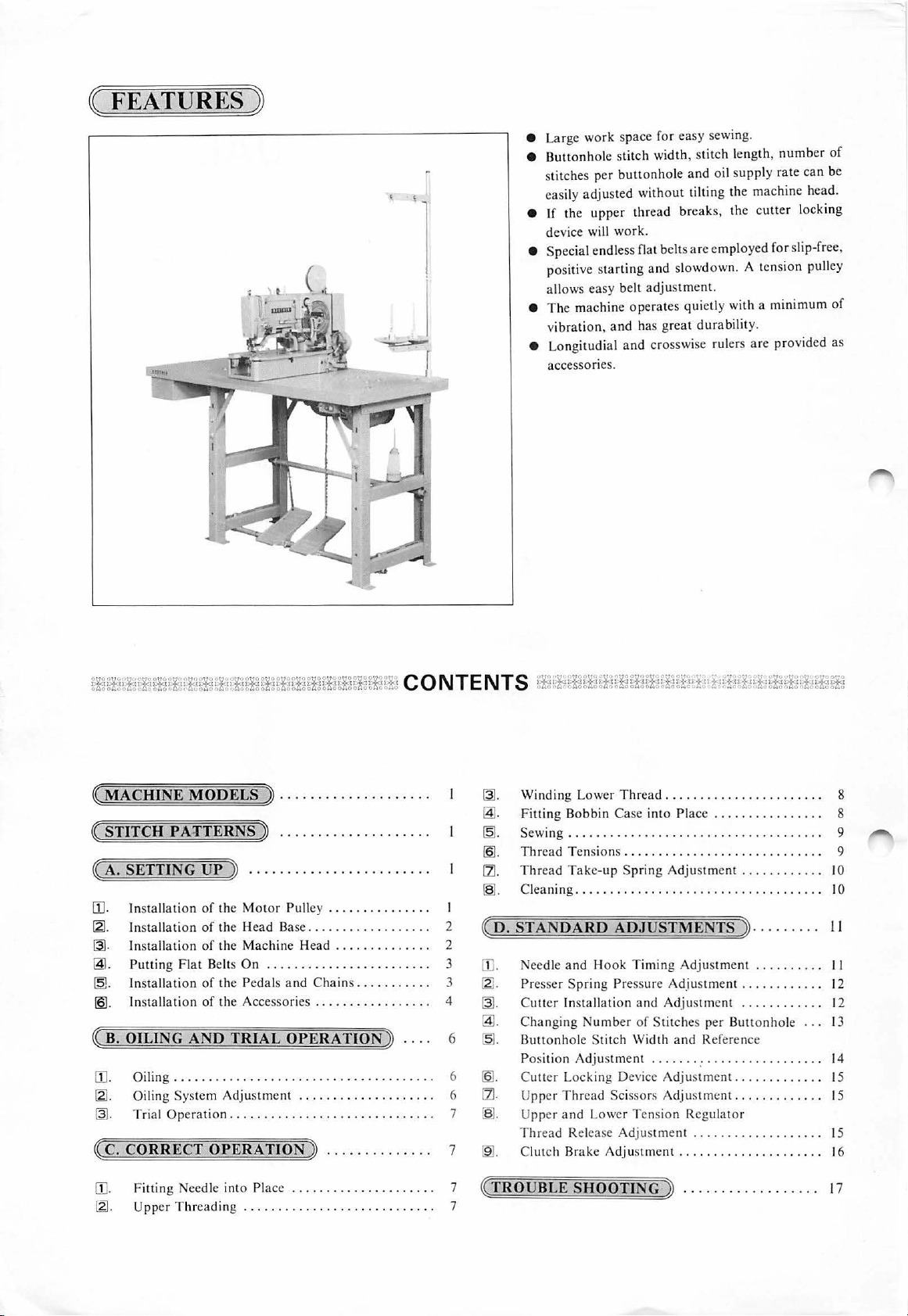

• Large

e

Buttonhole

s

titches per

easily

e If the

device will

•

Special

positive s

allows

e

The

vi

bration,

e

Longitudial

accessories.

work

adjusted

upper

work.

endless flat

tarting

easy

machine

and has

space

for

stitch

width, stitch

butt

onho

without

thread

belts

and

belt

adjus

opera

tes

great

and

crosswise rulers

easy

sewing.

length,

numb

er

of

le

and

oil s

upply rate can

tilting

the

machine

break

s,

the

cutter

are

employed

slowdown. A tension pulley

tment.

quietly

durability.

with a

are

for

minimum

provided

be

head

loc

king

slip-free,

of

as

.

~

MACHINE

~

STITCH PA:rTERNS » ............

« A. SETTING

[I]. In

~-

!3].

@.

~-

[2]

~ B

[1].

~C.

[I].

st

In

sta

I

nstallation

Putting

In

stallation

. Ins

.

OILING

Oiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

~-

Oiling

~-

Trial

CORRECT

Fitting

[2]

.

Upper

MODELS ~ ...............

UP

» .......................

allation

tallation

of the

Motor

llation

of the

Head

of

the

Mach

Flat

Belts

On

of the

Pedals

of

the Accessories . . . . . . . . . . . . . . . . . 4

AND

TRIAL

System

Operation................

Adjustment

OPERATION

eedle

int o Pla

Threading

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pulley . . . . . . . . . . . . . . . I

Base................

ine

Head

. . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . 3

and Chains...

OPERATION

. . . . . . . . . . . . . . . . . . . . 6

.

.......

~

. . . . . . . . . . . . . . 7

ce

. . . . . . . . . . . . . . . . . . . . . 7

...

. .

......

. .

.

..

. . . . . . . . 3

~

..

. . 6

......

~-

~-

~-

!21.

rll.

~-

2

~

D.

STANDARD

[1]

.

~-

~

-

~-

~-

!21.

[ZI.

7

~-

~-

~

TROUBLE

Winding Lower

Fitting

Bobbin

Sewing... ..

Thr

ead Tensions.

Thread

Cleaning.

Case

.....................

Take-up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I 0

ADJUSTME

eed

le

and

Hook

Pre

sser

Spring Pressure

Cutter Installat

Ch

anging

Buttonhole Stitch

Positi

on

C

utt

er Locki

Upper

Thread Scissors

Upper

and

Thr

ead

Clut ch Br

ion

Number

Adjustment

ng Device

Lower Tens

Release

ake

Adjust

SHOOT

Thr

ead..

..........

into Place

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Spring Adjustment

.

..........

. . . . . . . . . . . . . . . . 8

...........

. . . . . . . . . . . . I 0

NTS] .........

Timing

Width

Adjustment

ING

Adjus

tment

..........

Adjustment

and

Adjustme

of

Stitches

and

. . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjustment........

Adjustment.

ion Regu

...................

ment

...............

~

. . . . . . . . . . . . . . . . . . 17

.........

nt . . . . . . . . . . . . 12

per Buttonhole

Reference

..... 15

. . . . . . . . . . . .

lator

......

. . .

. . .

8

9

II

II

12

13

15

15

16

Page 3

~

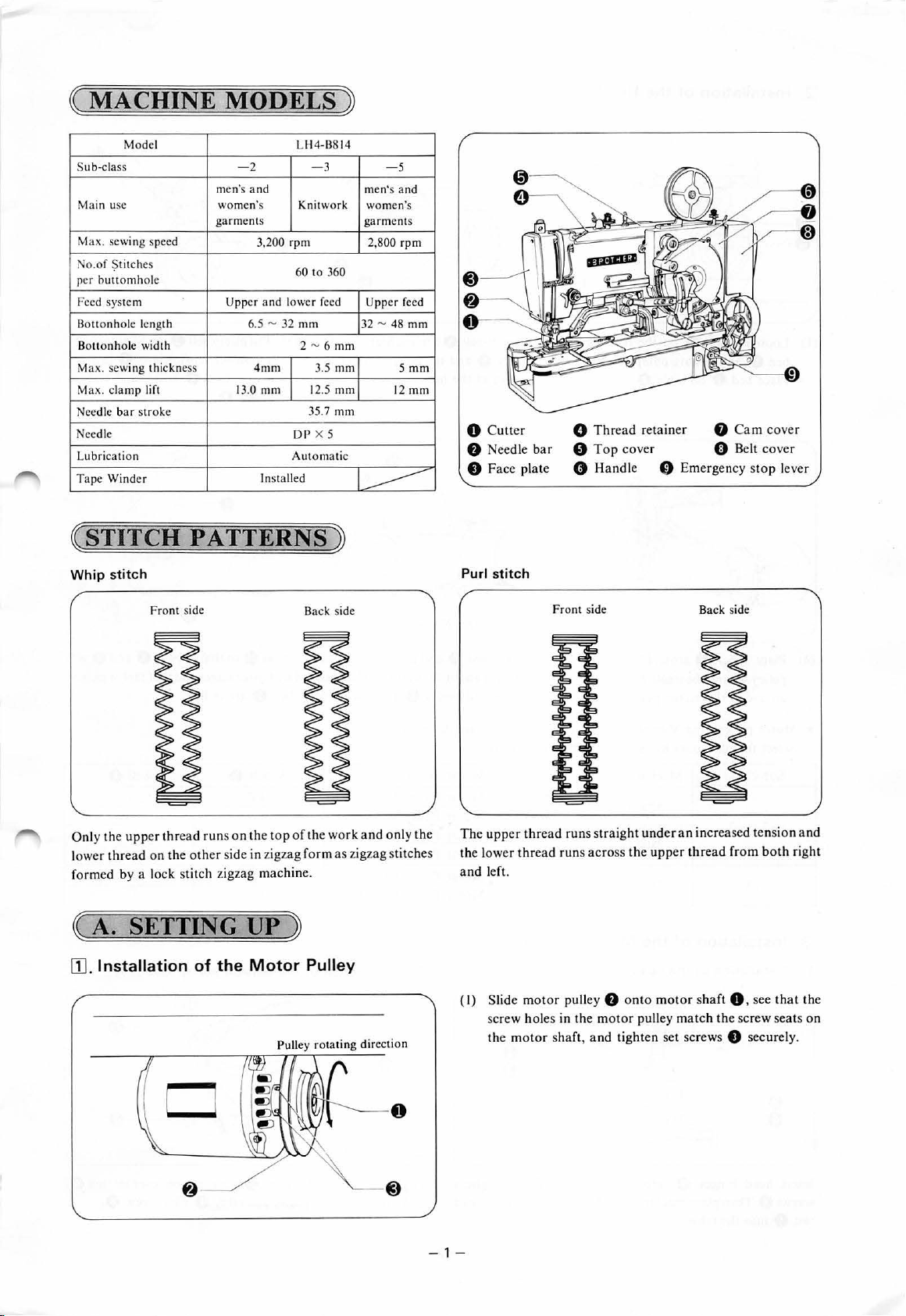

MACHINE

Model LH4-B814

Su

b-class - 2

Main usc

Ma

x. sewing speed

N

o.of

~titches

p

er

buttomhole

Feed system Upper

Botto nhole length 6.5 - 32

Bot

tonhole

wid

th

Max. sewing thic

Max.

clamp lift

Needle

bar str

Needle

Lubr

icati

Tape

Win

kness

oke

on

der

MODELS

men's

and

women's

gar

ments

3.200 rpm 2,800 rpm

and

4mm

13.0

mm

Installed

-3

Kn

itwork

60 to 360

lower feed

mm

2-6

3.5

12.5

35.7

DP

X 5

Automatic

~

- 5

men's and

women's

garments

Upper

32-48

mm

mm

mm

mm

5mm

12

-----

feed

mm

mm

0 C

utter

f)

Needle

bar

8 Face plate

0

0 T

0

Thread

retain

er

op

cover 0 Belt

Handle

f)

Emergency s

8 Ca m cover

cover

top

lever

( STITCH

Whip

stitch

Fro

nt side

Only the

lower thread on the ot

formed

~

[]]

upp

er

thr

ead runs on the

by

a lock stitch zigzag machine.

A.

SETTING UP

. Installation

PATTERNS

top

her

side in zigzag form

Back side

of

the work

~

and only

as

zigzag stitches

~

of

the

Motor

Pulley

the

Purl stitch

The

upper

the l

ower

and left.

Fron

t side B

thread

runs

thre

ad runs across the

straight

under

upper

an

increased

thread

ack side

fro m

ten

sion and

both

right

(

I)

Slide

motor pull

screw holes in the

the

motor shaf

- 1-

t,

ey

motor

and

f)

onto

motor sh

pulley

tig

ht

en set screws e sec

matc

aft

0,

h the scr

see that

ew

seats on

ur

ely.

the

Page 4

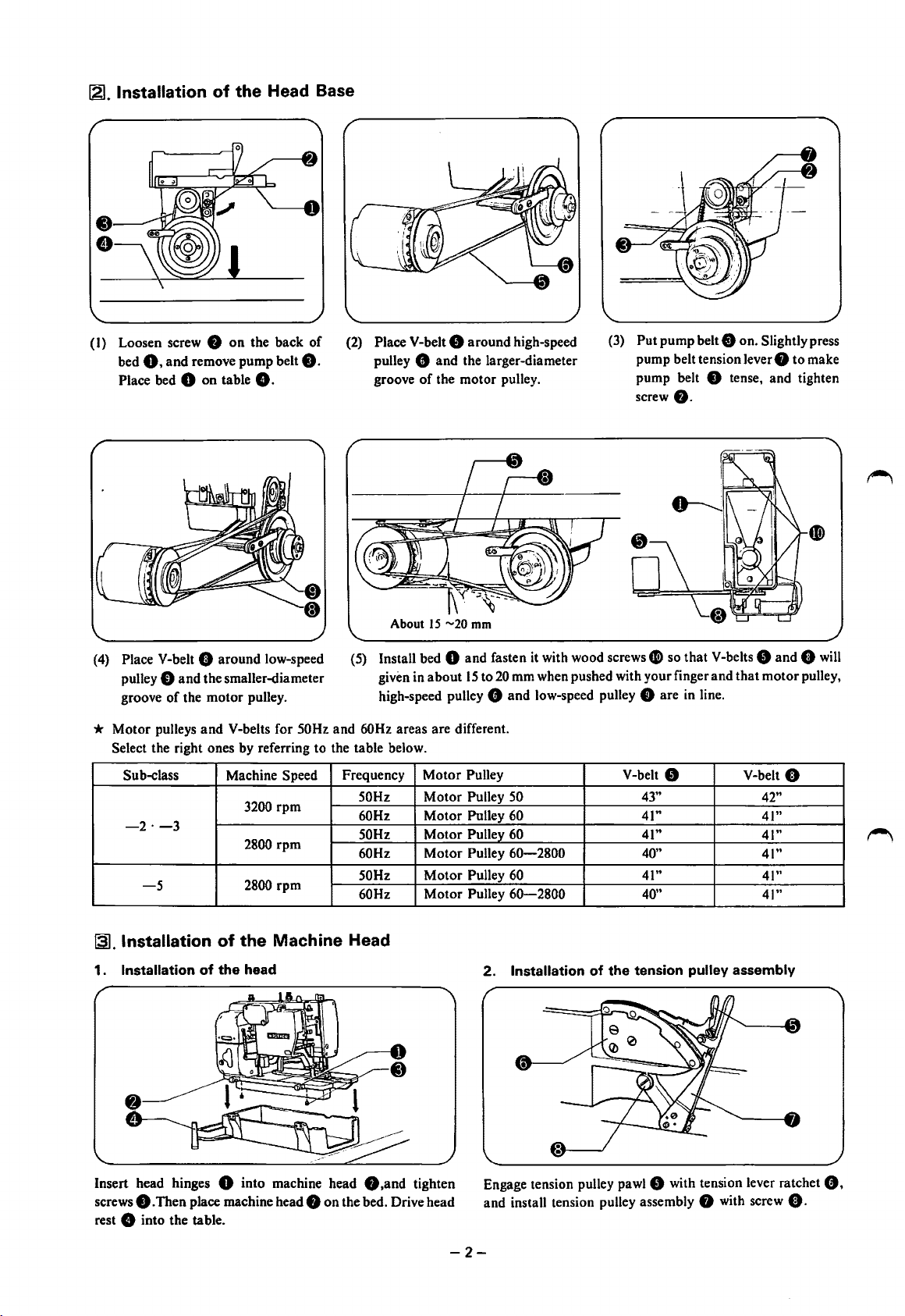

121.

Installation

(I) Loosen screw 8

0.

bed

Place bed 0 on table

and remove pump belt

of

the

on

Head Base

the back of

8.

8.

(2)

Place V-belt 8 around high-speed

8 and the larger-diameter

pulley

of

groove

the motor pulley.

(3)

Put pump belt 8 on. Slightly press

pump belt tension lever

pump belt

screw

8 tense, and tighten

8.

0 to make

About

15

-20

mm

(4)

Place V-belt 0 around low-speed

pulley

0 and the smaller-diameter

groove of the motor pulley.

(5) Install bed

given in about

high-speed pulley 8 and low-speed pulley 0 are

0 and fasten

15

to

20

* Motor pulleys and V-belts for 50Hz and 60Hz areas are different.

Select the right ones by referring to the table below.

Motor

Sub-class Machine Speed

3200 rpm

-2·-3

2800

rpm

2800

the

head

rpm

Machine

-5

~.Installation

1.

Installation

of

of

the

Frequency

50Hz Motor Pulley

60Hz

50Hz

60Hz

50Hz

60Hz

Head

Pulley

Motor Pulley 60

Motor Pulley

Motor Pulley

Motor Pulley

Motor Pulley

2.

it

with wood screws

mm when pushed with your finger and that motor pulley,

50

60

60-2800

60

60-2800

Installation

of

V-belt 8

the

tension

fli)

so that V-belts 8 and 0

in

line.

V-belt 0

43"

41"

41"

40"

41"

40"

pulley

assembly

will

42"

41"

41"

41"

41"

41"

Insert head hinges 0 into machine head 8 ,and tighten

screws

8.

Then place machine head 8 on the bed. Drive head

8 into the table.

rest

Engage tension pulley

and install tension pulley assembly 0 with screw

-2-

pawl8

with tension lever ratchet

0.

0.

Page 5

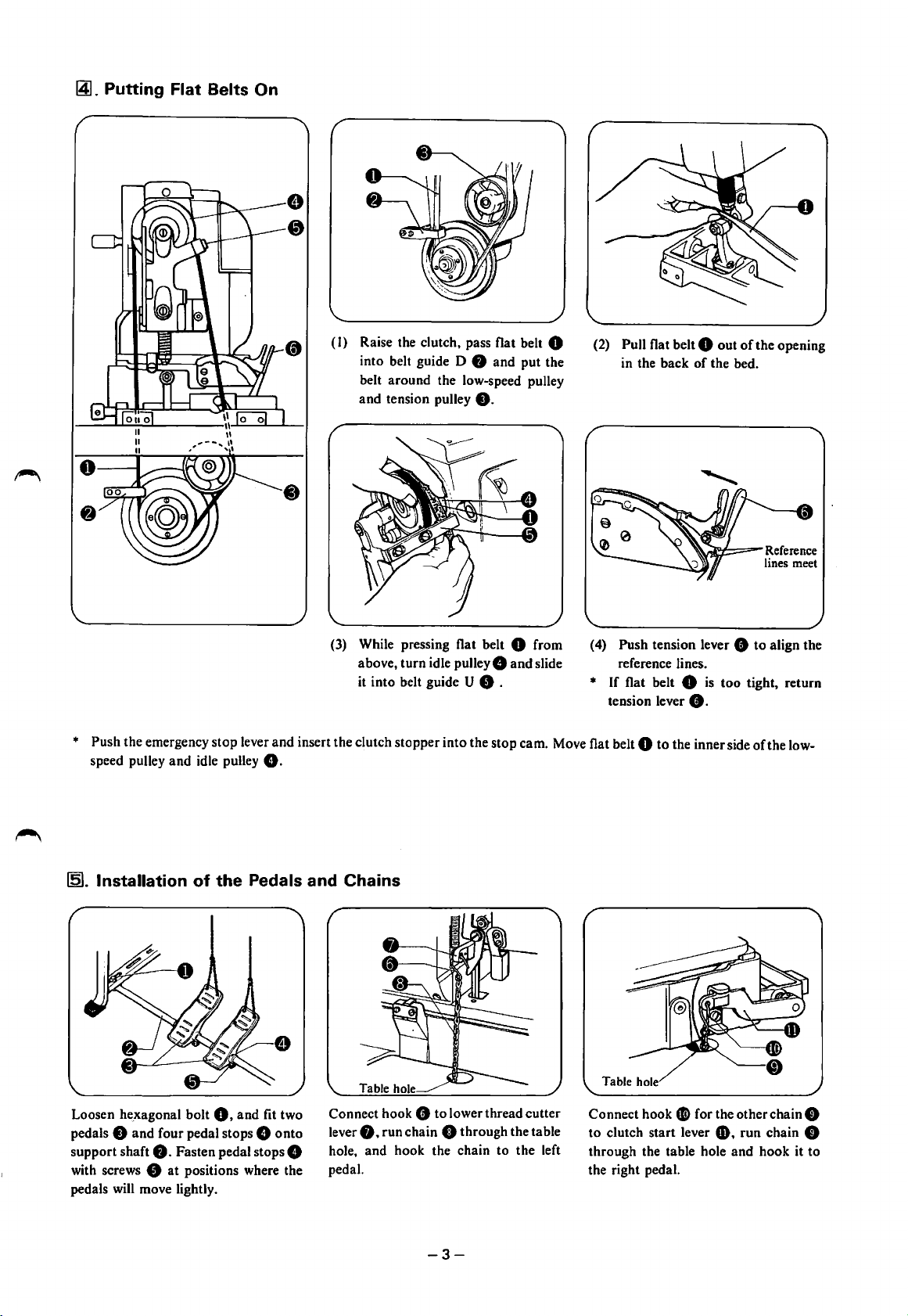

~.

Putting Flat Belts On

(I)

Raise the clutch, pass flat belt 0

into belt guide D 8 and put the

belt around the low-speed pulley

and tension pulley

8.

(2)

Pull flat belt 0 out

in the back of the bed.

of

the opening

~~=~Reference

(3)

While pressing flat belt 0 from

above, turn idle

it into belt guide

pulley&

and slide

U 8 .

(

4)

Push tension lever 8 to align the

reference lines.

* If flat belt 0

tension lever

is

too tight, return

8.

* Push the emergency stop lever and insert the clutch stopper into the stop cam. Move flat belt 0 to the inner side

speed pulley and idle pulley

151.

Installation

of

the Pedals and Chains

8.

lines meet

of

the low-

Loosen

pedals

support shaft

with screws 8 at positions where the

pedals will move lightly.

he_xagonal

bolt

0.

and fit two

8 and four pedal stops 8 onto

8.

Fasten pedal stops 8

Connect hook

0.

lever

hole, and hook the chain to the left

pedal.

8 to lower thread cutter

run chain 8 through the table

-3-

Connect hook

to clutch start lever

through the table hole and hook it to

the right pedal.

Gi>

for the other chain 8

G).

run chain 0

Page 6

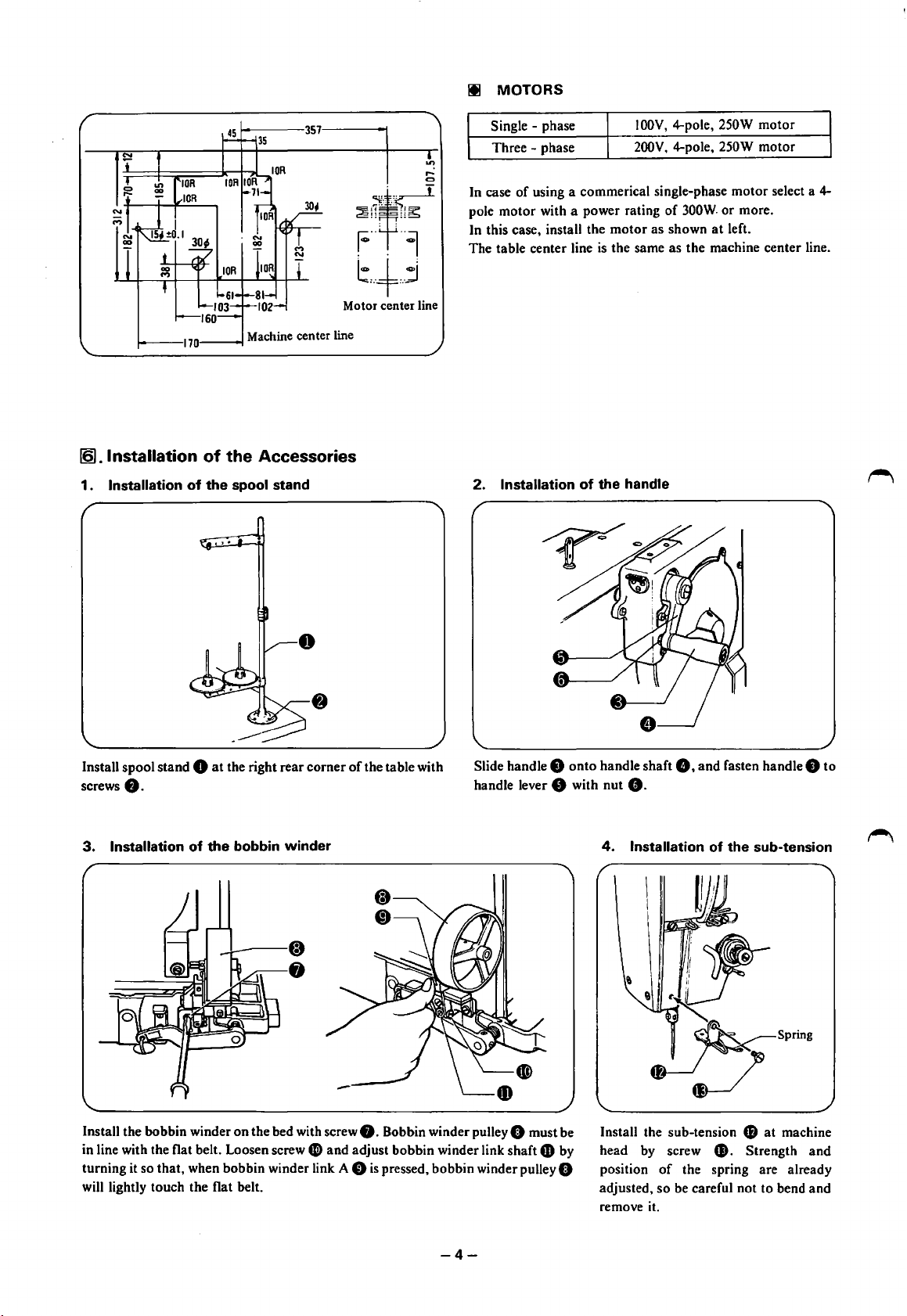

12)

.Installation

of

the

Accessories

Ill MOTORS

Single - phase

Three-

~

,...

C)

In case

pole motor with a power rating

~i~~

In this case, install the motor as shown

The table center line

phase

of

using a commerical single-phase motor select a 4-

is

the same as the machine center line.

t,+j

Motor center line

IOOV,

4-pole, 250W motor

200V,

4-pole, 250W motor

of

300W.

or more.

at

left.

1 . Installation

Install spool stand 0

screws

0.

3.

Installation

of

of

the

spool stand

at

the right rear corner

the

bobbin

winder

of

the table with

2. Installation

Slide handle 8 onto handle shaft

handle lever

of

the

8 with nut

4.

handle

8.

Installation

8.

and fasten handle 8 to

of

the

sub-tension

Install the bobbin winder on the bed with screw

in line with the flat belt. Loosen screw

turning it so that, when bobbin winder link A

will lightly touch the flat belt.

0 and adjust bobbin winder link shaft 0 by

0.

Bobbin winder pulley 0 must be

0

is

pressed, bobbin winder pulley 0

-4-

fB

at

Install the sub-tension

head

by

screw

position

adjusted, so be careful not to bend and

remove it.

of

$.

the spring are already

machine

Strength and

Page 7

5.

Installation

of

the

crosswise

ruler

and

longitudinal

ruler

(I) Fasten crosswise ruler • to length

(2)

Fasten longitudinal ruler 8 to bed cover

* In case of sub-class

6.

Installation

When elastic materials such

be

material to

sewn altogether.

of

-5,

fix ruler directly on the bed.

the

tape

winder

as

knitted materials

·----

•

(I) Install tape winder

e.

fl

on top cam cover

feed

and

plate

41

with bolts

41)

with

bolts.

tape

guide

(in case

is

used, a strong buttonhole can

I)

with screws

and washers

(2)

(3)

CD

and washers

41.

fD.

of

sub-class

Fasten tape guide rear

length feed plate

Fasten tape guard front 8 in case

fasten tape guard front

screws G).

-2

and

-3)

be

made with a tape at the backside

fa

41

by screws

fJ) in case

and tape guide front

•.

of

sub-class

of

sub-class

of

-2

-3

the

fD

to

and

by

7.

Installation

(4) Pass a tape through as per the picture at the above.

Fasten belt cover G to the back

G and screws G).

hinge

-5-

of

the

belt

cover

of

the bed with belt cover

Page 8

~B.

(]].Oiling

(I)

(2) Connect vinyl tube joint (black) 0 with joint nut (black)

OILING

Remove belt

AND

and

tilt the machine.

TRIAL

OiPE.R~Aflt(Q)~-~

f).

(3) Connect vinyl tube joint (white) 8 with

joint

nut (white)

••

© Oiling

'-------·

(4)

Gently pour oil into oil tank 0 under the table through

filter 8 until the tank

••

If oil level falls below reference line 8 .

is

filled up to upper reference line

* Remove the face plate, side cover and belt cover, and oil all working parts.

* Pour a drop

~.

Oiling

or

two of oil to the arrow-indicated points daily. *Note: Use white spindle oil.

System

Adjustment

8-~~=

======~~~=====

_/

Base

A

few

minutes after the power

of

the base by turning it until oil level can be seen in gauge pipe

• Oil level falls during sewing.

is

switched on, adjust oil flow regulator 8

~Moreoil

Less oil

on

the right

0.

-6-

©

Hook

oil

flow

adjustment

Adjust oil flow to the hook by turning

oil regulator shaft 8 on the front

bed.

of

the

Page 9

~.Trial

Operation

At stop

(I)

Before star

clut

(2)

Switch

(3) The ma

~

C.

CORR

ting

ch stopper

the ma

chine will s

the

f)

is in stop c

chine

on.

tart

ECT

machine,

whe n the rig

be

am

OPERATION

!]] . Fitting Needle into Place

I

sure

to confirm

asse mbly O.

ht

peda l is stepped

that

on.

~

(4) Release the peda l

pedal

is kept

stepped

(5)

After

a fixed

num

sto

ps.

When

(6)

Repeat

DP

Use a

Lo

ose

n set screw

facing in

th

your

e needl e hole.

the left p

X 5 needle

abov

dire

e s

edal

tep

f)

ctio

At s

tart

once

the machine s

on,

the mac

ber

of s

titch

es

is

stepped

s (3), (4)

and

on,

(5) a few

0.

.

ho

ld the needle with its

n. a nd insert

the

tarts runnin

hine will n

are

made, the

the work

nee

dle

all the way

clamp

tim

groo

g. (If

ot

sto p.)

machine

es.

ved si

rise

the

s.

de

into

[21

.

Upper

Threading

I I

*When

threading

other side to this side

the needle. pass from the

Pass a

Thr

thread

Pass a

and

ead han

onl

<

Synthetic fith

thread

sprin

g.

<

Co

tton thr

ger

y

throug

~

thread han

th rough thread

er

ead

thread

I I

'

'

hang

ger

>

>

er

Spr

ing

.

- 7-

Page 10

~-

Winding

Lower

Thread

(I)

Check the power switch that it

(2)

Slide bobbin 0 onto bobbin winder spindle

(3)

Pass the thread in the order

wind a

few

turns

of

the thread around bobbin 0 in the

arrow direction.

(4) Push bobbin winder link A

will wind on the bobbin.

(5)

After the bobbin finishes winding the thread, bobbin

winder link A

(6)

Remove the bobbin 0 and cut the thread with the thread

cutter

*

Turn

screw 0 to adjust the bobbin to the correct thread

winding volume.

8 automatic return to its original position.

8.

is

on.

of

the numbers shown, and

8 and release it. The thread

f).

• If the thread winds unevenly on the bobbin

screw

G. and move bobbin winder tension guide

left

or

right as necessary.

right

Uneven with

more thread

wound on left

bobbin

case

Uneven with

more thread

wound

on

© Threading

After winding the thread on the bobbin, pass the thread in the order shown below.

0,

f)

loosen

to the

~-

Insert the bobbin into the bobbin case.

~.

~itting

Bobbin

Case

into

Pass the thread through a slit in the

bobbin case and under the tension

spring.

Place

Hold the bobbin case by latch

Let

the thread end fall in front

-8-

Pass the thread through another slit

and pull it out of the thread hole.

0.

and insert it into the hook.

of

the bobbin case.

Page 11

~-Sewing

©

How

to

use

the

emergency

stop

lever

-8

(I) Make sure that the clutch stopper

then switch the power on.

(2)

Depress the left pedal to raise work clamp

work under it, and release the left pedal.

(3)

Depress the right pedal to start the machine.

When the machine starts running,

(4)

The machine

stop.

(5)

Depress the left pedal and take out the work.

©

How

to

use

will

sew a fixed number

the

cutter

locking

device

is

in

the stop cam, and

0,

place your

release the right pedal.

of

stitches and then

Push emergency stop lever 8 down and immediately release

it. The machine will stop.

©

How

to

use

the

handle

Keep cutter lock lever 8 lightly depressed with your finger

until the machine stops. The cutter

Turn handle 8 after confirming that the needle is not in the

work.

will

I§). Thread Tension

* Thread tensions vary with sewing conditions. Refer to the following when selecting suitable tensions.

1.

Lower

thread

tension

ttfoake

Spring

Turn adjusting screw 0 to such an extent that you will

little resistance when pulling the thread out

Standard

tensions

not drop.

ofthe

feel

bobbin case.

a

~

0

Brake spring

s

-2

-3

-5

in

the bobbin case reduces bobbin racing.

-9-

About.

About.

About.

Purl

15

15

15

"'

"'

"'

20g

20g

20g

Whip

About. 30g

About. 30g

About. 30g

Page 12

2.

Upper

Whip stitch

thread

___

tension

~

(~}

Purl

stitch

--r--~

(B)

Upper

~--1--~

~---1~(~)

(A):

Bar

tacking

(B): Zigzag stitches

IZ]. Thread

(1) Thread

Take-up

take-up

Spring

spring

height

ment

Turn tension regulator nut 8 to adjust

thread tension for

Adjustment

tension

regulator

bar

tacking (A).

(2) Thread

adjust-

Less tension

Lower

ment

Turn

thread tension for zigzag stitches

(Decrease tension for whip stitches; and

Increase tension for purl stitches.)

take-up

tension

tension regulator nut 0 to adjust

spring

tension

regulator

About

20

Less tension

adjust-

"'

30g

(B).

Adjust the working scope

loosening set screw

regulator .itself. (Standard range

IBI.

Cleaning

Remove lint and dust from thread

passages.

of

thread take-up spring 0 by

0 and turning the upper thread tension

is

about 8 mm)

Adjust the thread take-up spring tension

0.

stud

Remove lint and dust from around the

work clamp.

(Standar~

by

turning tension

ten~ion

is

about 20 to 30g.)

Remove the bobbin case, and remove

lint and dust from around the shuttle.

And wipe the bobbin to remove oil.

-10-

Page 13

(

D.

STANDARD

[].

Needle and

*

The

correct

from

*

When

s

ure

that the needle

1.

Needle

timing

the lowest

adjusting

bar

Hook

position

the n

upward stroke

Timing

of

the needle

eedle

bar upward stroke,

is

at

the

ADJUSTMENTS

~

Adjustment

and

the

hook

center

of

the n

is necessary

needle

eed

le hole plate.

bar

for

the

height

hook

point to

and the clea

scoop an

ran

ce

upper

between

the

thre

needle

ad

loop

and

as

hook

the needle rises

point

make

Loosen screws 0

Mo

de l 8814-2 · -5)

2.

Needle bar

Loosen

screw 0 an

top

end

of

the needle eye when

and

height

d raise

turn

or

shuttle 0

3.5

mm

or lower

hook

I

I I

I I

I I

\.1

,,

unti

(for

-----

needle

point

l h

ook

Model

0

bar

f)

0

point

8814- 3)

f)

until there

meet

f)

the

meets

from

is a

center

the

center

the

lowest position.

clearance

line

of

needle

c

line

of

the needle wh

of a

bout

1.5

to

0.

en need

*N

eve r loosen scr

2

mm

between

e

~

0

le 0

ri

ews

the hook

ses

0 in

by

2.5

mm

any case

point and

(fo r

.

the

3.

Clearance between

Loosen

screws

0 and move h

h

ook

point

f).

4.

Clear

ance

Ab

out 1.0

between

-l.Sm

needle

ook 0 forward

bobbin

m

and

case

hook

holder

point

or

back

and

until

ther

bobbin

e is a cle

arance

case

holder

Loosen scr

case hold

to 1.5 mm.

Mak

e sure that hook

bracke

of

about

0.

03

bracket

ews

f0

and

adj

er 0 and bobbin case h

4D

t e wh

en

it

rotat

es.

to

0.08

ust the

will

mm

older

not

clear

touch

betwecnneed

ance between

bracke

t e to

bobbin

le 0

and

bobbin

abou

t 1.0

case holder

-

11

-

Page 14

12).

1.

Presser

Presser

Spring

spring

Pressure

adjustment

Adjustment

2.

Work

clamp

tilt

adjustment

About

77

mm

Compress presser spring

bottom

8

and retighten screw

131.

of

washer 0 and the top

to

about

77

mm with presser

Cutter

Installation

0.

8.

adjust the distance between the

of

presser bar guide bracket

bar

guide bracket set screw

and

Adjustment

---cl--

Fabric

Loosen screw 8 , and turn work clamp support spring shaft

8 until the bottom of work clamp 8

the work.

0,

Top

of

needle plate

f Parallel

is

parallel to the top

___

)

of

About

0.2

mm

-~n--

(I)

Temporarily fasten cutter 0

8.

screw

(2)

Turn the machine pulley by hand until the needle

nearly

at

the lowest position.

(3)

Loosen screw

back until the clearance between cutter 0 and the needle

bar

is

(6)

Keep cutter lock

the machine pulley with the other hand until cutter

falls to the lowest position.

0.

and move cutter

approximately 0.2 mm.

arm

8 pulled with one hand, and turn

to

cutter holder 8 with

holder8

bar

forward

(4)

Turn the machine pulley by hand until the needle

comes up to nearly the highest position.

is

(5)

Turn the handle until stop cam piece 8 8 rides on the

center of stop cam piece

or

8.

.,.--.--0

~--·

Top

of

needle plate

About 2

(7)

Loosen screw 8 and make an adjustment so that the

0

blade edge

needle plate.

(8) Turn the machine pulley by hand until the clutch

automatically engages.

mm

will

enter about 2 mm deep from the top

of

bar

the

-12-

Page 15

© Feed

adjustment

B

Loosen adjusting nut G and move pointer 0 to the line

directly under the same number as the cutter number

~-

Changing

The number

Any of the numbers

1 . Change

(Example:

L STITCH R L STITCH R

54

52

51

50

48

46

44

42

40

(I) See the above table for

(2)

Loosen thumb screw 0 and raise gear case cover

(3)

Fit change gear

(4)

Fit change gear 42 onto shaft R

(5)

After replacing the gears, be sure to close gear case cover

Number

of

stiches varies with buttonhole size. Select a suitable number.

of

gear

replacement

Selecting

360

319

300

283

252

226

203

182

164

34

of

Stitches

stitches shown in the below table (gear case cover) can be selected by change gear combinations.

119

stitches)

22

38

24

36

34

25

32

26

28

30

28

30

26

32

24

34

22

36

119

stitches, and look

onto shaft L.

147

133

119

107

96

86

77

68

60

in

such away that it will engage the other gear.

A.

per

Buttonhole

at

the

38

40

42

44

46

48

50

52

54

8.

Loosen adjusting nut

under the same number as the cutter number

Land

R columns.

G)

and move token

8.

CD

to the line directly

B.

2.

Stop

cam

replacement

(in case

Stop cam segment

Stop cam segment

of

sub-class

-2

AL

AS

and

-3)

(1) Remove the cam cover.

(2)

Turn the handle until stop cam piece 8 comes to a point

where it can

(3)

Loosen screws 8 and replace stop cam piece

If

the number

If it

is

107

of

stitches

stitches

-13-

be

easily taken off.

is

96

or less, use stop cam piece AL.

or

more, use stop cam piece AS.

8.

Page 16

~.

Buttonhole

1 .

Buttonhole

WI

Reference line A Reference line B

The

machine swings the needle to the left from the right

reference position in sewing forward

2.

Reference

Stitch

stitch

position

Width

width

adjustment

adjustment

and Reference

W2

and

back.

Backward

1

Position

Adjustment

Adjust after raising the small cover

Turning WI adjusting screw

clockwise increases the needle swing motion and turning it

counter-clockwise decrease it.

0.

f)

or

W2 adjusting screw 8

Reference line A

Adjust reference line A by loosening

Reference line B

Adjust reference line 8

adjustment

adjustment

by

e--

nut

0 with a box wrench

loosening nut G with box wrench and turning screw 8 in a similar way.

and

......

turning screw

0.

© Follow the under mentioned procedure when changing the stitch width and stitch reference pasition.

Left

zigzag

stitches

t !

Forward Backward

Wl

Reference line A

(

1)

Adjust reference line A so

stitches will not be cut by a falling

cutter.

(2) Adjust zigzag stitch width WI with

adjusting screw

f).

Wl

that

the

Reference line B

(3) Adjust reference line B so

right zigzag stitches will not be cut

by a falling cutter.

Right

stitches

zigzag

that

the

W2

(4)

Adjust

bar

tacking width

adjusting screw

width varies with manual turning

and high-speed operation due to

different thread tensions. Adjust it

by actually sewing.

Bar

tacking

8.

Bar tacking

W2

with

* The needle swing width

or

if a reference line

sewing forward

After turning the machine pulley by hand, be sure

cam. Then you may start the machine.

or

is

adjustable in excess

is

moved,

turn

back.

of

the work clamp width. If bar tacking width

the machine pulley by hand and make sure

to

use the emergency stop lever

-14-

that

is

adjusted to more

the needle will not touch the work clamp in

to

insert the clutch stopper into the

than

4 mm,

stop

Page 17

1§1.

Cutter

locking

Device

-

Adjustment

About 7--10 mm

.

~

Loosen screw 8

part

of

the upeer thread which

between cutter lock

!ZI.

Upper

Thin reference line

Thread Scissors

and

adjust the clearance between cutter lock

is

at

the tip

of

thread break sensor 8

arm

0 and cutter lock lever 8

Adjustment

to

about

arm 0 and

0.5 mm when

(I)

cutter lock lever 8 to

is

taut. Also, loosen screw 0

cutter

lever 8 shifts onto

Loosen screw

with one

0,

and

align upper thread cutter level S 8

of

the reference lines

L8.

Sub-class

-2

-3

-5

Loosen screw

clamp as possible. (If the scissors

thread end remains

* If the thread end

scissors open either

and move scissors guide 0 forward

sooner,

* In case

Thickness

Less

3 mm to 4 mm

Less

3 mm

Less

3 mm to 5 mm

than

than

to

than

of

3 mm

3 mm

3.5 mm

3 mm

8 and install scissors D 8

on

the work after the thread is cut.)

is

not sewn into stitches, it

too

or

backward

of

sub-class

to

-5,

about 7 to

of

cloth

are

soon

or

open the scissors later.

no

return spring 0

10

mm when that

and

adjust the clearance

cutter

clutch

upper thread cutter level

Reference line

Thin reference line

Thick reference line

Thin

reference line

Thick reference line

Thin reference line

Thick reference line

as

close

positioned

is

too

late. Loosen screw 8

to

open the scissors

bar

8 .

to

the work

too

high, the

because the

is

available.

IBJ.

Upper

1.

Upper tension regulator

Upper tension discs 0 tighten

Loosen screws

and

Lower

Tension

adjustment

at

Regulator

high speed sewing, and rise as the machine stops.

8 and move upper tension releaser 8 up

Thread Release

At

high speed

or

down,

to

the right

Adjustment

or

-15-

At

low speed

left to adjust the discs.

At

stop

Page 18

2.

Lower

tension regulator

adjustment

11:

iiL---~-------~

b·:.-:::-~:::::::::

Loosen screws 8 at. the machine stop position, and make

release cam piece

' Loosen screw 0 and move thread release bar 0 to the right

191.

Clutch

Unless the clutch brake

operation, and machine durability may be adversely affected

1.

Clutch

Loosen screw 8 and move spring

adjuster

spring

possible

stop the clutch stopper positively.

8

0 to as weak a tension as

which, however, is sufficient to

0.

Brake

return

to

Adjustment

is

properly adjusted, the machine will stop half way

spring

adjust clutch return

tension

2.

Clutch

Loosen nut 0 and turn bolt 8

adjust the clearance between clutch

lever pin 8 and bolt 0

1.0

mm

at

an

start

the machine stop position.

adjustment so thread release lever 8 will

or

left so that discs 8 will rise about 0.5 mm

or

fail to start; and extra power may be required for

lever clearance

3.

•

f3

Stop

spring A

·----~:::---

Turn

nuts

to

about

to

0.5 to

of stop spring shaft

mm

out

f)

of

the bottom

be

on top

of

thread

at

this time.

tension

and 8 until the lower end

0

is

about 4.5 to 5

of

nut

0.

4.

Clutch

Clutch

Loosen bolt

stopper

Clutch

Loosen bolt 8 and move clutch pawl 8

mm deep when the tip of stop cam segment 8

pawl

A and B

pawl A adjustment

CD

and move clutch pawl A

G)

will be about 3

pawl B adjustment

adjustments

mm

when the tip stop cam segment 8

49

to the right

CD

up or down so that clutch paw 8

CD

comes to

or

left so that the shortest distance between stop cam

part®

CD

comes to

CD

of

stop cam segment A

-16-

part®

will engage clutch pawl A

of

stop cam segment A

41).

49

CD

and clutch

about

G!).

I to

1.5

Page 19

~

TROUBLESHOOTING

.__

__ T_ro

_u_h_le

__

___.ll

._ ___

-

Needle bent or blunt.

~

c_au_s_e _ _ _

___JII .__

__

~

Needle.

c_h_e_c_k _P_o_in_t _

____JII._

___

Replace needle.

1--

R_e_m_e_d_v

__

__J_IP_a_g

7

-

__Ji

thr

start

ead breaks.

of

sewing.

Upper

Lower thread breaks.

Thread end remains·

at

I--

Needle installed

-

improperly.

Wrong threading.

-

Upper thread tensi

-

too strong.

Needle and shuttle

-

timing wrong.

Lower th read tension

r-

too strong.

1--

Oil

'-

r-

and lint around Remove lint and wipe

bobbin case.

Upper thread scissors

too

high.

Needle bent or blunt.

on

~

Needle direction.

Threading.

-

Upper and lower

tens1on regulat

-

tensions.

Needle and shuttle.

-

Tension

thread tension adjusting

1--

screw.

1--

Bobbin case.

Height of scissors

r-

r-

Needle -

of

or

lower

D.

In

sta

ll

1---

1---

-

-

r-

r-

t---

needle in the

right direction.

Refer

to

fo

r upper

Adjust to correct

tension.

Refer to instructio ns

for needle and s

timing.

Adjust lower thread

tension correctly.

off

oil.

Refer to instructions

fo_r

upper

S

CISSO

rS a

Replace needle.

instruction

th_rea

ding.

hut

~hread

djUStment.

tle

7

7 -

10

II

9 .

10

15

7

Stitches skip.

Thread loose.

Needle break

-

s.

-

1--

'----

r-

r-

L-

improperly.

Wr

ong upper threading.

we

r thre

Lo

too strong.

Bar

tack stitches loose.

Zi

gzag stitches loose.

Needle install

r-

improperly.

Ne

1---

'--

edle and shuttle

timing wrong.

Stitch width wrong.

ad

tension

ed

Needle installed

r-

Needle direction,

r-

heig

ht.

Upper threading.

1--

t---

Lower thread te

Upper tension dis

-

tension.

Lower tension di

t-

tension.

Needle direction

1---

height.

1---

Nee

dle a

Needle swin

t---

nd

nsi

cs

scs

shuttle.

g.

on.

Put needle in the

- correct direction a

height

Pas

r-

-

-

t---

-

r-

-

s upper thread

correctly.

Adjust lower

thread tensi

Ad

just upper

tension regulator.

Adjust lower

tension regulator.

Put needle in the

correct direction and

height.

Adjust timing of

needle and rotary hook.

Adj

ust stitch width

an stitch

position.

on.

refereu

ce

nd

7

7

9

10

9

7

II

14

-17

-

/

Page 20

__,.....

118-814-2,-3,-5

192814-3-02

Printed

in

Japan

Loading...

Loading...