Page 1

Durability test data

for Brother

laminated

TZe labels

www.brother.eu

Page 2

Page 3

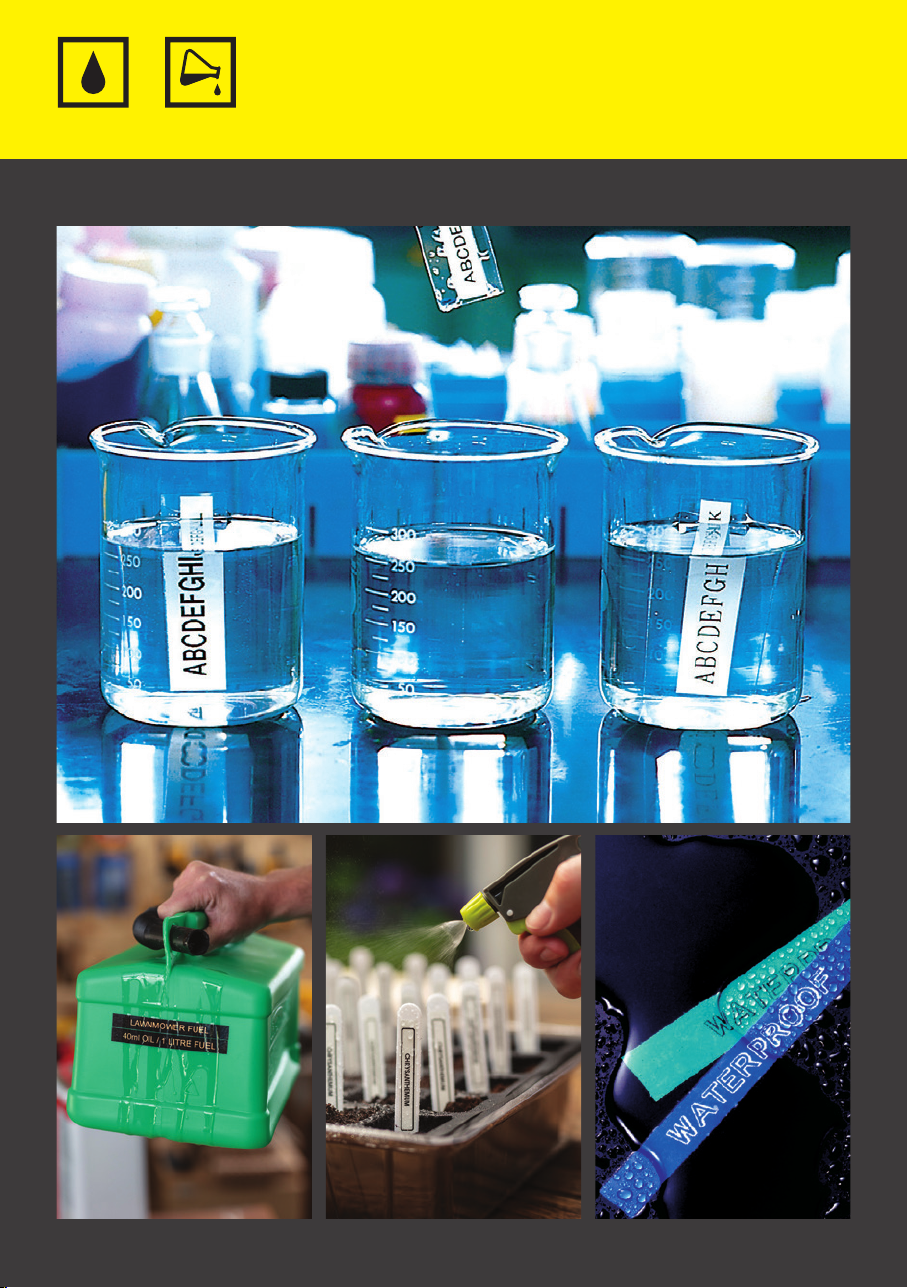

Brother laminated TZe labels

have been designed to last,

wherever you use them

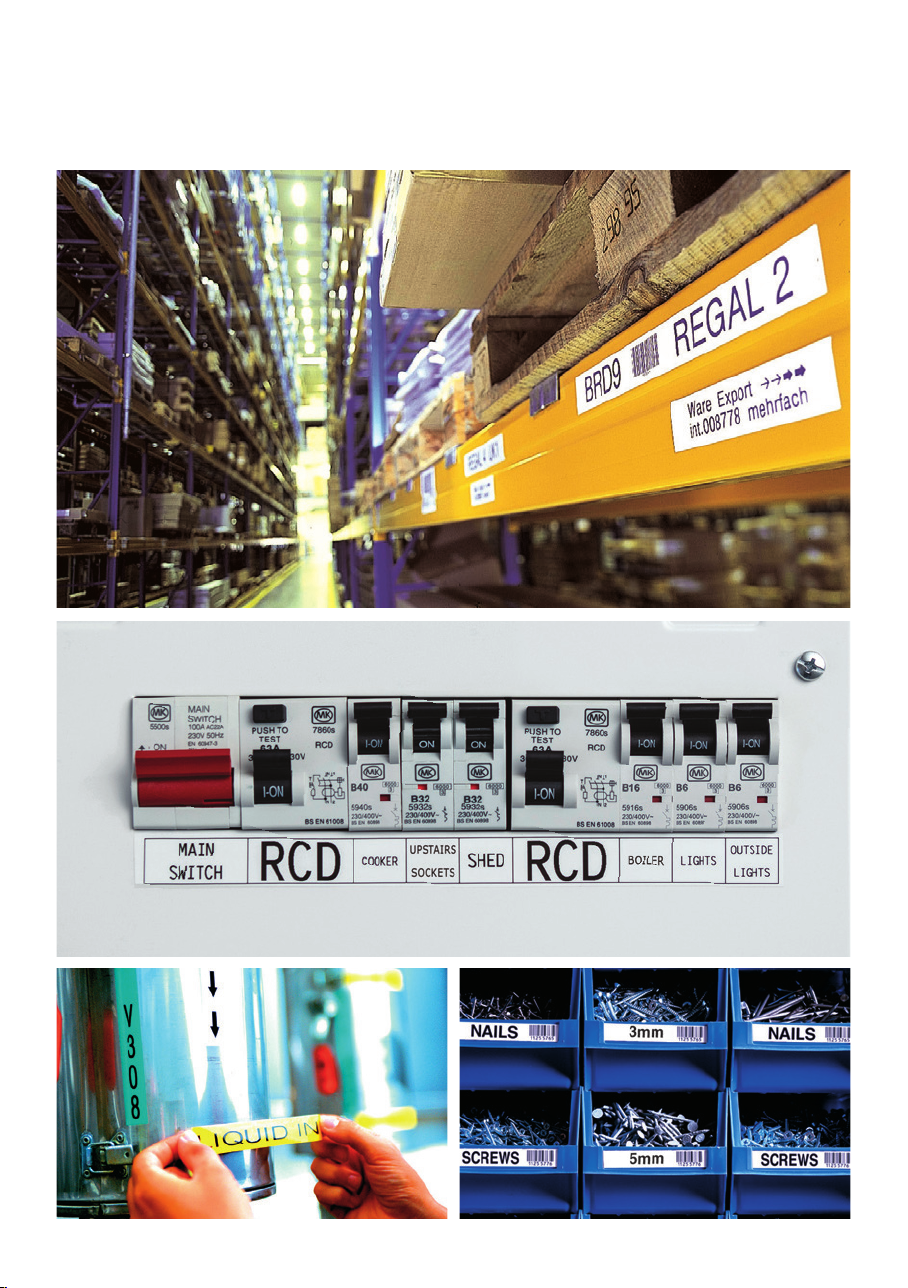

Whether you need a professional labelling solution for the office,

industr

y or home, Brother laminated TZe labels have been designed

with you in mind. We’ve thought about exactly when, where and how

you might need to use our labels and put them through a series of

tests which demonstrate how our laminated labels withstand heavy

abrasion, heat, cold, sunshine, water and chemicals.

Page 4

Brother laminated TZe labels

Page 5

Why Brother laminated

TZe labels withstand

the test of time

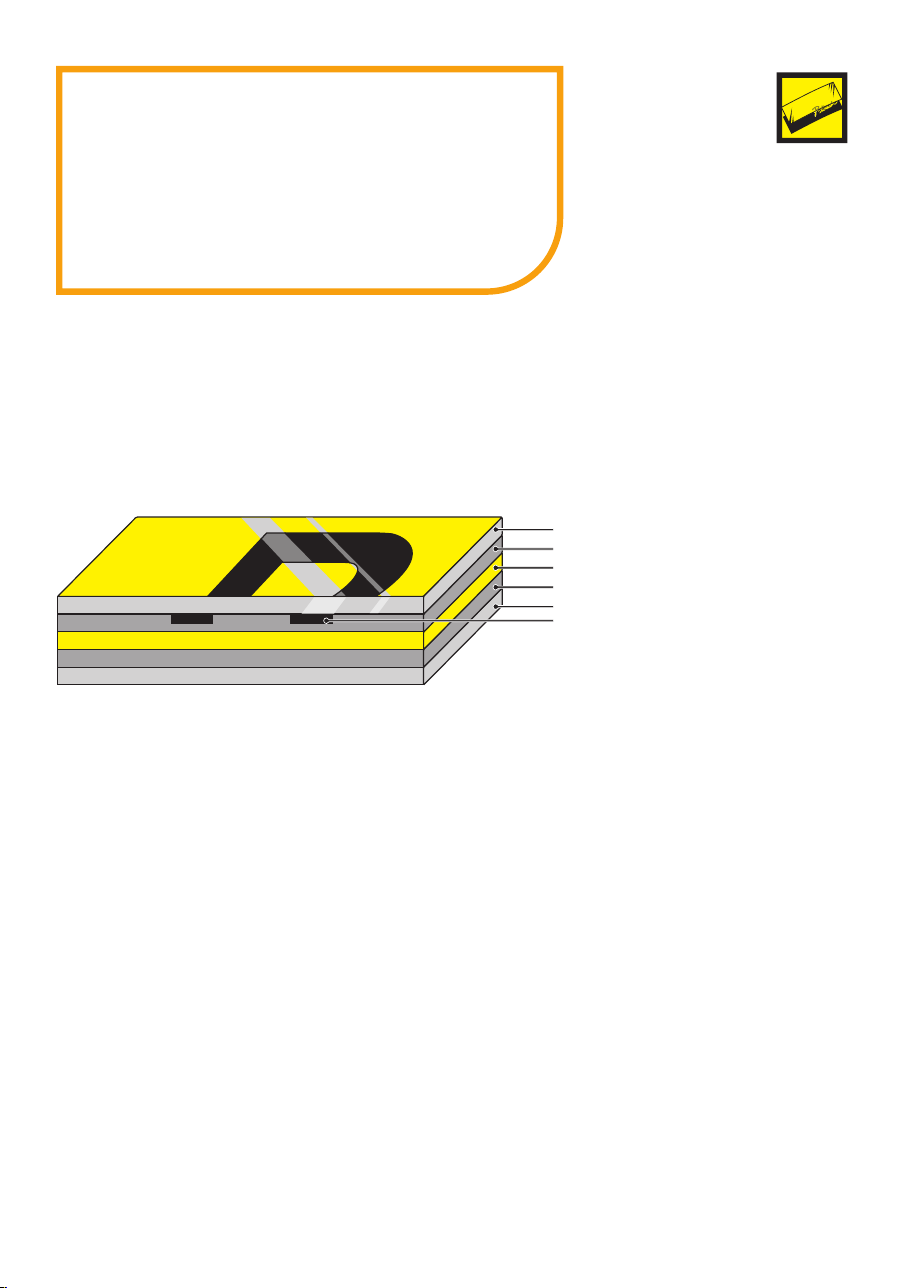

Unlike non-laminated labels, our laminated TZe tape technology applies a layer of

super-clear polyethylene laminate to protect your text.

Brother laminated TZe labels consist of six layers of materials, resulting

in a thin, extremely strong label. Characters are formed with a thermal

transfer ink and sandwiched between two protective layers of PET

(polyethylene film). The result is a virtually indestructible label that can

withstand harsh conditions.

In fact, we are sure about the durability of our laminated labels

because we’ve had them tested to the extreme. The results prove that

Brother laminated TZe labels stay legible and attached, so you can be

confident of a professional quality label that has been designed to last.

The following pages will show you exactly how our labels were tested

to the extreme.

Lamination

pr

ovides an extra

protective overcoat

Protective coating (PET)

Adhesive (acrylic)

Coloured base film (PET)

Adhesive (acrylic)

Backing paper

Lettering

Page 6

Strong Adhesion Tests

Strong

Adhesion

Page 7

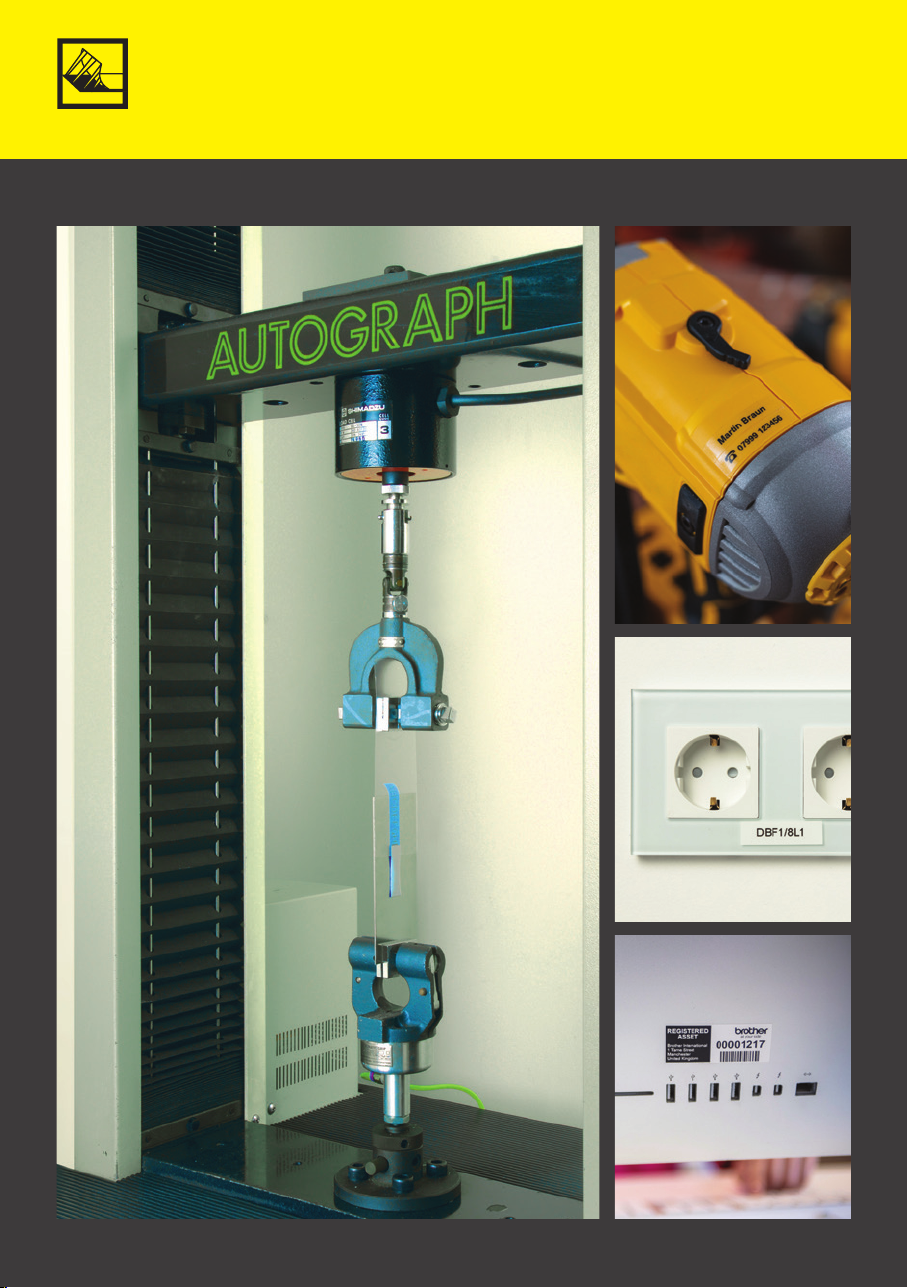

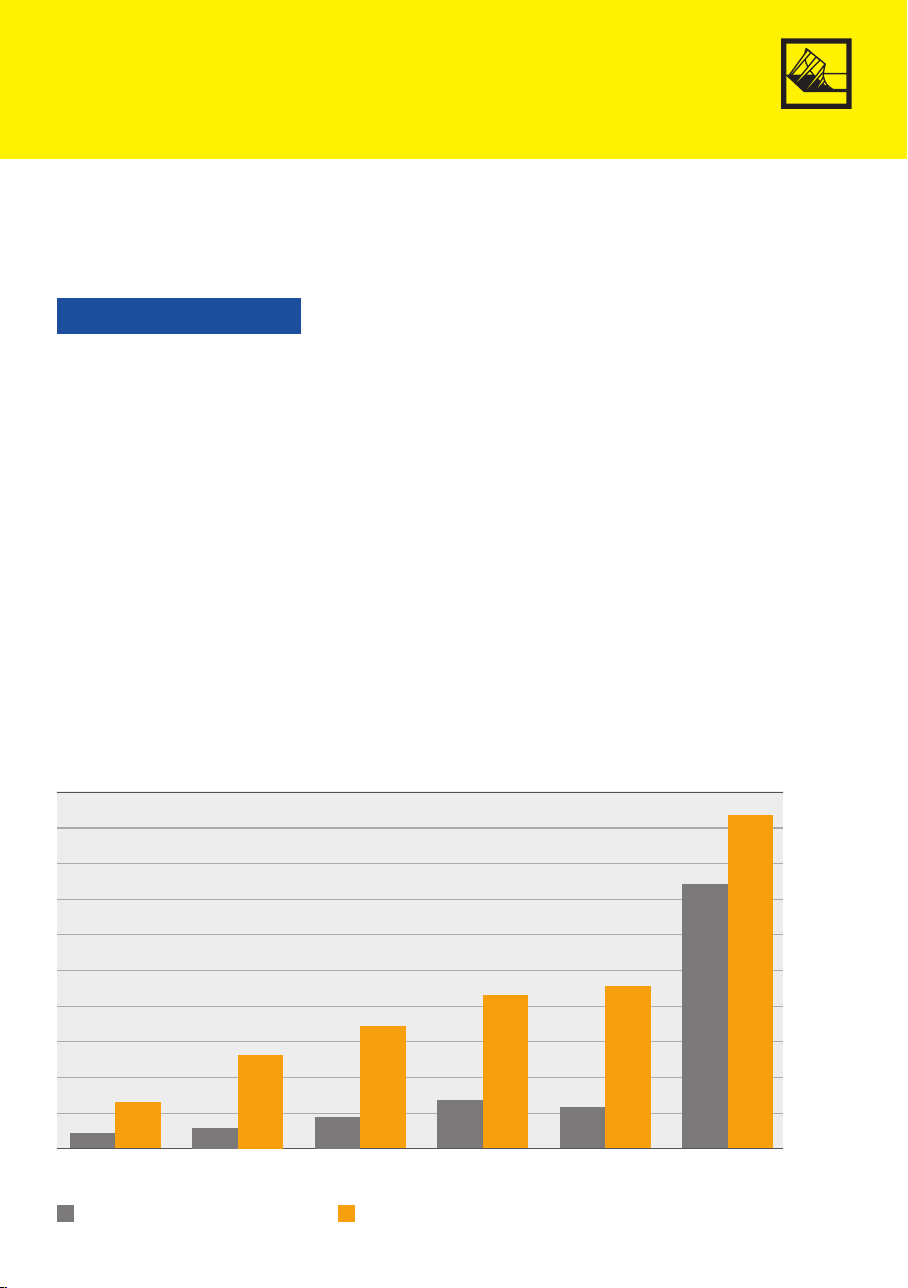

The chart below details the amount of force needed (measured in Newtons) to remove Brother standard

adhesive labels and Brother strong adhesive labels from the various materials. The higher the value, the

stronger the tape was affixed to the material. As this test shows, when used on textured surfaces

Brother strong adhesive labels maintained three times the adhesive strength of Brother standard

adhesive labels on average. Brother strong adhesive labels have been specially developed to adhere to

both smooth and textured surfaces, and on more demanding materials.

Strong Adhesion Tests

Strong

Adhesion

Results in Newtons for 12mm width tape

Polyethylene (PE)Polypropylene (PP)Acrylic (AC)Polyethylene

Terephthalate (PET)

Polyamide (PA)Stainless

Steel (SUS 304)

Standard adhesive TZe tapeStrong adhesive TZe tape

Strong adhesion tests were conducted in two stages:

Stage 1:Adhesion to smooth and textured surfaces test

Stage 2: Adhesion to various diameter curved surfaces test

STAGE 1

Adhesion to smooth and textured surfaces test procedure

To test the adhesive strength of Brother laminated T

Ze labels, Brother standard adhesive and strong

adhesive laminated TZe labels were affixed to a variety of materials at room temperature and left for 30

days. After this period, adhesive strength was tested by measuring the force needed to remove the

labels at an angle of 180 degrees.

The testing method complies with Japanese Standard JIS Z 0237 (2009) testing.

Test Results

4.31

3.46

2.69

1.29

0.30

0.60

0.92

1.23

9.30

7.48

4.62

1.16

Page 8

Strong Adhesion Tests

Strong

Adhesion

Adhesion to various diameter curved surfaces test procedure

Standard TZe tape

Strong adhesive TZe tape

Flexible ID TZe tape

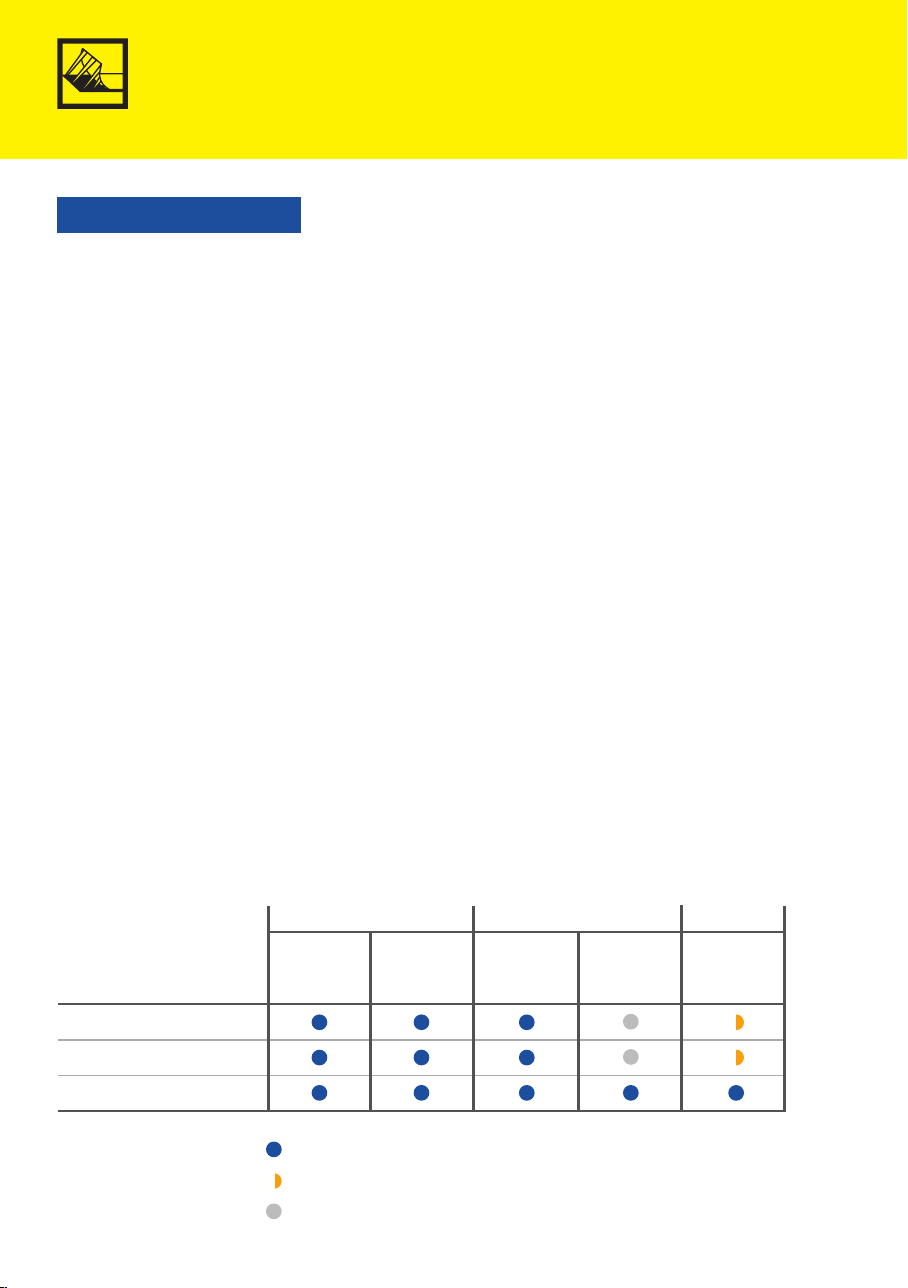

CURVED SURFACEWRAPPEDFLAGGED

Ø50mm

glass beaker

Ø25mm

glass beaker

Ø6mm

PVC cable

Ø3mm

Polypropylene

tube

Ø3mm

Polypropylene

tube

No peeling of label observed

Some peeling of label observed

Label peeled off completely

STAGE 2

To test the adhesive strength of Brother laminated T

Ze labels, Brother standard adhesive, strong

adhesive and flexible ID laminated TZe labels were affixed to a variety of materials at room temperature

and left for 14 days. After this period, the labels were visually inspected to note any peeling from the

materials they were attached to.

Test Results

The table below explains that Brother standard adhesive, strong adhesive and flexible ID laminated TZe

labels showed no signs of peeling from the materials of 6mm or higher diameter. However, when the

labels were wrapped or applied as a flag to the 3mm diameter material, the standard adhesive and

strong adhesive laminated labels either showed signs of peeling or fell off completely. Only the Brother

flexible ID labels showed no peeling.

Brother flexible ID labels have been developed for flagging and wrapping around wires, cables, pipes

and tubes with a minimum diameter of 3mm, and should be used to ensure your labels stay affixed.

Brother self-laminating labels have the exact same properties as Brother flexible ID labels and can

therefore also be safely used for wrapping around cables. Brother strong adhesive labels should be

used for applying to the surfaces of larger diameter curved surfaces.

Page 9

Strong

Adhesion

Strong Adhesion Tests

Page 10

Water and Chemical

Resistance Tests

Water

Resistant

Chemical

Resistant

Page 11

Water and chemical resistance tests were conducted in three stages:

Stage 1: Water and chemical submersion test

Stage 2: Water and chemical abrasion test

Stage 3: Pure water and 5% sodium chloride (salt) solution immersion test

Label: Brother strong adhesive laminated TZe label

Chemical: Acetone

Standard TZe tape

Strong adhesive TZe tape

Flexible ID TZe tape

Toluene

No print discolouration

Hexane

Ethanol

Ethyl Acetate

Acetone

Mineral Spirit

Pure Water

0.1N

Hydrochloric Acid

0.1N Sodium

Hydroxide

Water and Chemical

Resistance Tests

Water

Resistant

Chemical

Resistant

To test Brother laminated labels against the effects of water and chemicals, Brother standard adhesive,

strong adhesive and flexible ID laminated TZe labels were firstly attached to glass slides and immersed

in a variety of liquids for 2 hours at room temperature.

STAGE 1

Water and chemical submersion test procedure

Label after testing:

Test Results

Although some labels soaked in certain chemicals showed slight separation of the laminate, the table

below explains no change in the print quality occurred and the labels remained affixed to the slides. So

even if any of the chemicals tested are spilled on your Brother TZe laminated labels, a quick wipe should

be enough to prevent any damage.

Page 12

STAGE 2

Water and Chemical

Resistance Tests

Water

Resistant

Chemical

Resistant

Label: Brother strong adhesive laminated TZe label

Chemical: 0.1N Hydr

ochloric Acid

Standard TZe tape

Strong adhesive TZe tape

Flexible ID TZe tape

Toluene

No print discolouration

Hexane

Ethanol

Ethyl Acetate

Acetone

Mineral Spirit

Pure Water

0.1N

Hydrochloric Acid

0.1N Sodium

Hydroxide

Label: Brother strong adhesive laminated TZe label

As the table below demonstrates, the print quality of Brother TZe laminated labels was unaffected by

being rubbed with various chemicals.

Water and chemical abrasion test procedure

Next, Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels were subjected to

a 200gf weight with a chemical and solvent infused cloth, which was passed over each label for 100

round trips. The labels were then visually inspected to note if any print quality problems were observed.

Test Results

Label before testing:

Label after testing:

Page 13

Water and Chemical

Resistance Tests

Water

Resistant

Chemical

Resistant

Standard TZe tape

Strong adhesive TZe tape

Flexible ID TZe tape

4 DAYS10 DAYS30 DAYS

PeelingFading

No peeling of tape or fading of text observed

PeelingFadingPeelingFading

STAGE 3

Label after testing:

The final test involved Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels

being affixed to stainless steel plates which were then immersed in the two solutions. They were placed

in a thermostatic chamber set at 40°C and removed after the predetermined periods shown in the table

below. After that, the appearance of the labels was visually checked.

Pure water and 5% sodium chloride (salt) solution immersion test procedure

Test Results

As the table shows, even after 30 days immersed in pure water or 5% sodium chloride (salt) solution,

Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels stayed perfectly

attached and the print quality was unaffected.

Label: Brother strong adhesive laminated TZe label

Liquid: 5% sodium chloride solution

Page 14

Abrasion Resistance Test

Abrasion

Resistant

Page 15

Abrasion Resistance Test

Abrasion

Resistant

Standard adhesive TZe tape

Strong adhesive TZe tape

Flexible ID TZe tape

PRINT QUALITY

Print quality unaffected

Brother’s tape lamination technology ensures that Brother TZe laminated labels can withstand heavy

abrasion.

Label after testing:

Abrasion test procedure

Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels were firstly attached to

stainless steel plates with a BA (bright annealed surface). A 1kgf sanding device was then passed over

the labels with 50 return passes at a speed of 60 round trips per minute.

Test results

As the table below demonstrates, even after 50 return passes of the heavy sanding device although the

laminated surface showed some sandpaper wear, the characters underneath the Brother laminated TZe

labels were unaffected and the text was completely legible.

Label: Brother flexible ID laminated TZe label

Test: Abrasion with sanding device

Page 16

Temperature Resistance Test

Temperature

Resistant

Page 17

Whether you want to use our labels in freezing conditions or extremely warm environments, our labels

have been designed to last. In fact, results show that Brother laminated TZe labels can withstand

temperatures from -80°C to +150°C.

+50°C at 90% RH

+100°C*

+150°C*

No peeling of tape or fading of text observed

-80°C

-30°C

3 days

30 days

30 days

18 days

2 days

TEMPERATURETIMERESULT

No peeling of tape observed. Text is legible but some tape discolouration observed

* When used under extremely high

temperatures or for long periods of time the

laminate film may be separated, discoloured

or shrink. If in doubt, request a free tape

sample from Brother to perform your own

testing.

Temperature Resistance Test

Temperature

Resistant

Label after testing:

Label: Brother flexible ID laminated TZe label

Temperature: +100C

Time: 18 days

As the table below shows, after 3 days at -80°C no noticeable change in label adhesive or colour had

occurred. After 2 days at +150°C, despite slight discolouration of the label, the text on the label

remained completely intact*. We recommend Brother TZe-M931/951/961 black on matt silver laminated

TZe labels as most resistant to discolouration under high temperatures, and Brother flexible ID laminated

TZe labels as most suitable when used in an autoclave/sterilising unit.

Temperature resistance test procedure

Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels were firstly attached to

stainless steel and placed in a thermo-hygrostat chamber set under the test conditions, taken out after

a predetermined time and returned to room temperature where the appearance of the label was visually

checked.

Test Results

Page 18

Placeholder

Fade Resistance Test

Fade

Resistant

Fade Meter (Time - ∆ E)

TAPE COLOUR118h236h478h*

Transparent

White

Red

Blue

Yellow

Green

Fluorescent Orange

Fluorescent Yellow

Black

Extra Strength Adhesive - White

Flexible ID - White

*478 hours approximates to 1 year in outdoor sunny conditions

9.66

0.83

1.65

1.27

22.59

1.24

46.57

81.02

0.55

0.83

1.49

15.69

1.58

5.95

2.85

55.57

1.62

50.33

85.09

0.18

1.58

2.35

24.69

3.18

54.61

5.71

57.2

3.77

54.43

84.66

1.11

3.18

3.94

9.66

0.83

1.65

1.27

22.59

1.24

46.57

81.02

0.55

0.83

1.49

15.69

1.58

5.95

2.85

55.57

1.62

50.33

85.09

0.18

1.58

2.35

24.69

3.18

54.61

5.71

57.2

3.77

54.43

84.66

1.11

3.18

3.94

Page 19

Fade Resistance Test

Fade

Resistant

*∆ E (Delta E) results showing the amount of fading on

various colours of TZe tape when placed in one year of

simulated sunlight.

Fluorescent Yellow

Hours

0h

118h236h478h*

Wherever you use Brother laminated TZe labels, they

have been designed to keep your text clear and

legible for many years.

Fade resistance test procedure

Brother black on white strong adhesive and flexible ID laminated TZe labels, and various coloured

Brother standard adhesive laminated TZe labels were attached to stainless steel plates and exposed to

simulated outdoor UV radiation of approximately 12 months. After that, the appearance of the labels

was checked, compliant with standard JIS K7350-2/ISO 4892-2.

The printed text on all Brother laminated TZe tapes remained unchanged and was perfectly legible. The

red, yellow and fluorescent tapes showed a larger change to the tape background colour compared

with other tape colours, which showed little or no change. The higher the ΔE (Delta E) value, the larger

the change in visual perception from the original colour.

Test Results

Black

Yellow

Fluorescent Orange

Red

Transparent

Blue

White

Green

Extra Strength Adhesive - White

Flexible ID - White

90

80

70

60

50

40

30

20

10

0

0h 118h 236h 478h*

Page 20

Oil Resistance Tests

Chemical

Resistant

The protective laminate top-coat on Brother laminated TZe labels ensures your text is protected even

when submerged or rubbed with oil. Oil resistance tests were conducted in two stages:

2 hour immersion

100 round trips rubbing

2 hours immersion

100 round trips rubbing

Honilo 981

Variocut B30

CareCut ES1

Hysol X

Alusol B

Syntilo 81E

Syntilo 9954

2 hours immersion

100 round trips rubbing

Standard

TZe tape

Strong

Adhesive

TZe tape

Flexible

ID TZe tape

No change to print quality and label remained affixe

d to the slides

Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels were attached to glass

slides and rubbed with oil-soaked cloths for 100 round trips, using a measuring element of 4.6mm

(16.6mm^2) and a load of 200gf. After this test was completed, the change in appearance of the labels

was checked visually. This test is in accordance with JIS-L-0849. (ISO 105-X12:2001 – Textiles-Tests for

colour fastness-Part X12)

Stage 1: Oil immersion test

Stage 2: Oil rubbing test

STAGE 1

S

TAGE 2

Oil immersion test procedure

Brother standard adhesive, strong adhesive and flexible ID laminated TZe labels were attached to glass

slides and immersed in various oils at room temperature for 2 hours, and the change in appearance was

checked visually after this time.

Oil rubbing test procedure

As the table below shows, at the end of both tests no change to the print quality occurred, and the

labels remained affixed to the slides.

Test Results

Page 21

Autoclave Resistance Test

Temperature

Resistant

Brother flexible ID laminated TZe labels demonstrate excellent adhesion and text legibility, even after several

passes through the harsh environment of an autoclave sterilisation chamber.

*1 Some tape discolouration may be observed

*2 Some separation off the laminate film may be observed

Text blurring

Tape discolouration

Laminate film separation

FLEXIBLE ID TAPES

30

cycles

20

cycles

10

cycles

5

cycles

1

cycles

Tape peeling

*1

*

2

Test Results

The table below shows the high durability of our Brother flexible ID laminated TZe labels during the test.

After several process cycles, some slight label discolouration and separation of lamination film was

observed. Nevertheless, the printed text stayed legible.

Autoclave test machine:

Steam steriliser GETINGE HS22

Test program:

B cycle P11 *EN (European Standard) prEN13060 standard compliant

Pre-vacuum:

4 times

Sterilising temperature:

134°C

Sterilising duration:

5 minutes

Drying duration:

20 minutes

Autoclave resistance test procedure

A Brother flexible ID laminated TZe label was affixed to flat and smooth stainless steel at room temperature.

The condition of the label was observed after it was processed in an autoclave under the following test

conditions:

Page 22

Brother Tape Range

6mm9mm12mm18mm24mm36mm

TZe FLEXIBLE ID LAMINATED - 8 METRES

TZ

e-FX231

Black on white

Black on yellow

TZe-FX241TZe-FX211

TZe-FX221TZe-FX251TZe-FX261

TZe-FX631TZe-FX641TZe-FX611TZe-FX621TZe-FX651TZe-FX661

TZe STRONG ADHESIVE LAMINATED - 8 METRES

Black on white

Black on transpar

ent

Black on yellow

TZe-S231TZe-S241TZe-S211

TZe-S221TZe-S251TZe-S261

TZe-S131TZe-S141TZe-S121TZe-S151

TZe-S631TZe-S641TZe-S621TZe-S651

TZe SECURITY LAMINATED - 8 METRES

TZe-SE4

Black on white

TZe-SE5

TZe SELF-LAMINATING - 8 METRES

Black on whit

e

Black on yellow

TZe-SL251TZe-SL261

TZe-SL651TZe-SL661

FLe FLAG (DIE-CUT) - 72 LABELS

Black on white

Black on green

FLe-2511*

FLe-6511*

FLe-7511*

Black on yellow

STe STENCIL - 3 M

Black on white

STe-161STe-141STe-151

* Labels are: 45mm x 21mm when printed. 45mm x 10.5mm once applied.

Page 23

HSe HEAT SHRINK TUBE - 1.5 METRES

HSe-211

Black on white

HSe-251HSe-221

HSe-231HSe-241

5.8mm8.8mm11.7mm17.7mm23.6mm

STANDARD LAMINATED - 8 METRES

Black on white

TZe-211

Black on transparent

Black on gr

een

Blue on white

Red on white

Red on transparent

Blue on transparent

White on transparentWhite on transparent

White on black

White on blue

White on red

Gold on black

3.5mm6mm9mm12mm18mm24mm36mm

TZ

e-221TZe-231TZe-241TZe-251TZe-261

TZe-111TZe-121TZe-131TZe-141TZe-151TZe-161

Black on red

TZe-421TZe-431TZe-441TZe-451TZe-461

Black on blue

TZe-521TZe-531TZe-541TZe-551TZe-561

Black on yellow

TZe-611TZe-621TZe-631TZe-641TZe-651TZe-661

TZe-721TZe-731TZe-741TZe-751

TZe-223TZe-233TZe-243TZe-253TZe-263

TZe-222TZe-232TZe-242TZe-252TZe-262

TZe-132

TZe-133

TZe-135TZe-145

TZe-315TZe-325TZe-335TZe-345TZe-355TZe-365

TZe-535TZe-555

TZe-435

TZe-334TZe-344TZe-354

Page 24

FLUORESCENT LAMINATED - 5 METRES

TZe-B31

Black on fluorescent orange

Black on fluor

escent yellow

TZe-B51

TZ

e-C31TZe-C51

6mm9mm12mm18mm24mm36mm

MATT LAMINATED - 8 METRES

Black on transparent

TZe-M31

METALLIC LAMINATED - 8 METRES

Black on matt silver

TZe-M931TZe-M921TZe-M951TZe-M961

PREMIUM LAMINATED - 8 METRES

Black on premium glitter gold

White on premium glitter silver

TZe-PR831TZe-PR851

TZe-PR935TZe-PR955

Page 25

Choose the right tape

for the job

Tape

Width

Recommended

cable diameters

HSe-211

HSe-221

HSe-231

HSe-241

HSe-251

5.8mm

8.8mm

11.7mm

17.7mm

23.6mm

Ø1.7mm to 3.2mm

Ø2.6mm to 5.1mm

Ø3.6mm to 7.0mm

Ø5.4mm to 10.6mm

Ø7.3mm to 14.3mm

SURFACE

Flexible ID

Security

Heat Shrink Tube

Self-Laminating

Strong Adhesive

Flag

Stencil

Smooth

surfaces

Textured

surfaces

Cable

wrap

Cable

flag

RecommendedAcceptable

WIRE AND CABLE IDENTIFICATION

GENERAL IDENTIFICATION

HEAT SHRINK TUBE

Page 26

Brother genuine supplies

work in perfect harmony

with Brother printers.

Consommables originaux Brother

Brother

Genuine

Supplies

Designed, manufactured and tested in controlled environments by the

same team of engineers as Brother hardware. Providing you with the

best possible results for your business and protection of your print

investment.

Page 27

Page 28

Frequently asked questions

How accurate are the tests in simulating real-world examples?

Every effort was made to ensure the tests accurately simulate real-world examples. However when

printed labels are used in the real-world, many factors could change the results of these tests,

such as surface material, heat, moisture, pressure, chemicals etc. If in doubt, always test Brother

P-touch laminated labels in your own environment to ensure they meet your requirements.

Which tape is recommended for rough or textured surfaces?

Brother strong adhesive TZe tape has been specially developed for more demanding surfaces

such as rough or textured surfaces.

Which tape is recommended for cable labelling?

Use Brother self-laminating TZe tape or flexible ID TZe tape for cable wrap labelling, For cable flag

labelling use Brother flexible ID TZe tape, or non-laminated flag labels.

Brother HSe heat shrink tube is also available for wire and cable identification.

Which tape is recommended for high temperatures?

We recommend TZe-M931/951/961 black on matt silver TZe tape as most resistant to high

temperatures in terms of discolouration.

How thick are laminated TZe labels?

Laminated TZe labels are around 160 micro metres in thickness, but this varies slightly by

tape type.

Page 29

Frequently asked questions

Do TZe tapes contain silicone?

Since the tape liner itself is silicone coated on both sides, there is a chance that small amounts of

silicone may remain on the adhesive layer underneath the label even after the liner is peeled off.

Do TZe tapes contain latex?

TZe tape uses acryl based adhesive materials and do not include latex.

Do TZe tapes contain lead?

There is no lead in the TZe cassette case, tape or ink.

Do TZe tapes contain chloride?

Except for clear (transparent) and silver TZe tapes, chloride materials are used in the coloured

base film layer of other TZe tapes.

Do TZe tapes contain polyvinyl chloride (PVC) or halogen?

There is no PVC in the TZe cassette case, tape or ink. The coloured layer of the base film includes

some chlorine compound which means TZe tapes cannot be categorised as halogen-free.

Do TZe tapes contain REACH SVHC?

Please see www.brother.eu/reach for the latest information.

Do TZe cassettes contain recycled material?

TZe cassettes contain at least 5% of recycled material.

Do TZe labels create any outgassing?

The following gases may be produced when labels are stored or applied in a hot environment:

Toluene, n-butanol, 2-ethylhexyl alcohol, butyl carbinol acetate. These levels are however very low.

Do TZe labels leave any adhesive residue when removed?

Labels can be removed from most materials with relative ease leaving little or no adhesive on the

material. Extreme heat, humidity and certain chemicals may result in some residual adhesive being

left but this can be removed in most cases with Ethanol.

Page 30

Frequently asked questions

Can TZe labels be used on circuit boards?

We do not recommend that TZe labels are used on circuit boards due to the sensitivity of circuit

boards to dust, static electricity and acid (although these are at very low levels).

Can TZe labels be used to label food?

TZe labels can be used safely on food packaging but should not be in contact with the food itself.

Can TZe labels be used on copper?

As adhesive materials used in our labels are acrylic and therefore weakly acid we do not

recommend that TZe labels are used on copper.

Can TZe labels be used for the marking of electrical and electronic

equipment (EEE) that is covered by the RoHS Directive?

TZe labels are in conformity with the requirements of the RoHS Directive, and do not contain

restricted substances (Cadmium (Cd), Lead (Pb), Mercury (Hg), Hexavalent Chromium (Cr VI),

Polybrominated Biphenyls (PBB), Polybrominated Diphenyl Ethers (PBDE), Bis(2-Ethylhexyl)

phthalate (DEHP), Benzyl butyl phthalate (BBP), Dibutyl phthalate (DBP), Diisobutyl phthalate

(DIBP) ) above the allowed limit values. TZe tape cassettes themselves do not fall under the

definition of EEE.

Can TZe labels be submerged in alcohol?

Submersion of TZe labels in alcohol is not recommended for extended periods due to the possible

deterioration of the tape adhesive.

Are Brother TZe tapes or HSe Tubes UL certified?

Most of our strong adhesive, flexible ID and security TZe tapes have been recognised by

Underwriters Laboratories, and which are listed under the UL file number PGJI2.MH21016.

How long should a security TZe label be attached before peeling off?

We recommend that security TZe labels are affixed for at least 24 hours in order to work

effectively.

Page 31

Notes

Allion Japan Inc (April 2020):

Strong adhesive | Water and chemical resistance | Abrasion resistance

Temperature resistance (all temperatures except -80°C) | Oil resistance

Brother Industries Ltd Japan (December 2012):

F

ade resistance | Temperature resistance (-80°C)

Autoclave resistance

Test data sources:

1. A random sample of Brother laminated TZe tapes were selected and used to perform

these tests.

2. All test results were acquired under specific conditions configured by Brother and/or Allion

(as detailed below), with the sole aim of providing information contained within this booklet.

3. Since TZe tape adherence performance is affected by many variable factors, including the

material the tape is attached to, the material’s surface condition, whether it is greasy, dusty,

rough or curved, and environmental conditions, customers should confirm adherence

performance under the actual usage conditions. Products are used at the customers own risk

and the findings presented in this document should not be taken as a guarantee of TZe tape

performance in each customers’ specific circumstances.

4. Brother accepts no responsibility for losses incurred as a result of reliance on information

contained in this document.

Page 32

Brother House, 1 Tame Street,

Audenshaw, Manchester M34 5JE

Tel: +44(0)161 330 6531

Fax: +44(0)161 330 5520

Brother International Europe Ltd

www.brother.eu

All specifications correct at the time of printing and are subject to change. Brother is a registered trademark of Brother Industries Ltd.

Brand product names are registered trademarks or trademarks of their respective companies.

Contact:

07/2020

Loading...

Loading...