Brother BES-960BC, BES-1260BC Service Manual

SERVICE MANUAL

BES-960BC

BES-1260BC

BROTHER

EMBROIDERY

SYSTEM

Please read this manual before making any adjustments.

NINE NEEDLE SIX HEAD ELECTRONIC EMBROIDERY MACHINE

TWELVE NEEDLE SIX HEAD ELECTRONIC EMBROIDERY MACHINE

This service manual is intended for BES-960BC, 1260BC; be sure to read the BES-960BC, 1260BC

instruction manual before this manual.

Carefully read the “SAFETY INSTRUCTIONS” below and the whole of this manual to understand

this product before you start maintenance.

As a result of research and improvements regarding this product, some details of this manual may

not be the same as those for the product you purchased.

If you have any questions regarding this product, please contact a Brother dealer.

SAFETY INSTRUCTIONS

1 Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided

in order to ensure safe operation of this machine and to prevent accidents and injury to yourself or other

people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

.................This symbol ( ) indicates something that you should be careful of.

.................This symbol ( ) indicates something that you must not do.

The instructions which follow this term indicate situations where failure

to follow the instructions will almost certainly result in death or severe

injury.

The instructions which follow this term indicate situations where failure

to follow the instructions could cause injury when using the machine

or physical damage to equipment and surroundings.

The picture inside the triangle indicates the nature of the caution that must be

taken. (For example, the symbol at left means "beware of injury".)

.................Thi s s ymbol (

The picture inside the circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

) indicates something that you must do.

BES-960BC.1260BC

i

2 Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall

outlet before opening the face plate of the control box. Touching areas where high voltages are present can

result in severe injury.

DANGER

CAUTION

Installation

Machine installation should only be carried out

by a qualified technician.

Contact your Brother dealer or a qualified electrician for any electrical work that may need to

be done.

The sewing machine weighs more than 720 kg.

The installation should be carried out by four or

more people.

Do not connect the power cord until installation

is complete, otherwise the machine may operate

if the start switch is pressed by mistake, which

could result in injury.

Be sure to connect the ground. If the ground connection is not secure, you run the risk of receiving a serious electric shock.

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

Be sure to wear protective goggles and gloves

when handling the lubricating oil or grease, so that

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting and

diarrhoea.

Keep the oil out of the reach of children.

Avoid setting up the sewing machine near sources

of strong electrical noise such as high-frequency

welding equipment.

If this precaution is not taken, incorrect machine

operation may result.

The casters should be secured in such a way so

that they cannot move.

Sewing

This sewing machine should only be used by operators who have received the necessary training in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Turn off the power switch at the following times,

otherwise the machine may operate if the start

switch is pressed by mistake, which could result

in injury.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when leaving the machine unattended

Do not get on the table.

ii

BES-960BC.1260BC

Table may be damaged.

Attach all safety devices before using the sewing

machine. If the machine is used without these devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the machine.

Do not touch the pulse motor and sewing machine

bed section during operation or for 30 minutes after

operation. Otherwise burns may result.

If an error occurs in machine operation, or if abnormal noises or smells are noticed, immediately turn

off the power switch. Then contact your nearest

Brother dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

CAUTION

Cleaning

Turn off the power switch before starting any

cleaning work, otherwise the machine may operate if the start switch is pressed by mistake, which

could result in injury.

Maintenance and inspection

Maintenance and inspection of the sewing machine should only be carried out by a qualified

technician.

Ask your Brother dealer or a qualified electrician

to carry out any maintenance and inspection of

the electrical system.

Turn off the power switch and disconnect the

power cord from the wall outlet at the following

times, otherwise the machine may operate if the

treadle is depressed by mistake, which could result in injury.

• When carrying out inspection, adjustment

and maintenance

• When replacing consumable parts such as

the rotary hook and knife.

Be sure to wear protective goggles and gloves

when handling the lubricating oil or grease, so that

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting and

diarrhoea.

Keep the oil out of the reach of children.

If the power switch needs to be left on when carrying out some adjustment, be extremely careful to

observe all safety precautions.

Use only the proper replacement parts as specified by Brother.

If any safety devices have been removed, be absolutely sure to re-install them to their original positions and check that they operate correctly before

using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine

will not be covered by the warranty.

BES-960BC.1260BC

iii

This service manual gives explanations for the following two models:

• BES-960BC (9 needle)

• BES-1260BC (12 needle)

Description limited to either model is given with the appropriate model name.

Before reading this manual, check your machine's model name.

CONTENTS

Chapter 1 Mechanical Descriptions .................................................................................. 1

1. Feed guide mechanism ............................................................................................................ 1

2. Crank shaft mechanism ........................................................................................................... 2

3. Lower shaft and rotary hook mechanisms ........................................................................... 3

4. Thread trimmer mechanism ................................................................................................... 4

5. Thread take-up mechanism .................................................................................................... 5

6. Needle bar mechanism ............................................................................................................ 6

7. Needle bar flip-up mechanism ............................................................................................... 7

8. Presser foot lifter mechanism ................................................................................................ 8

9. Thread wiper mechanism........................................................................................................ 9

10. Cap frame device ...................................................................................................................... 10

Chapter 2 Parts Replacement and Adjustment.............................................................. 11

1. Replacing and adjusting the machine heads ........................................................................ 11

2. Removing the needle bar case ............................................................................................... 18

3. Replacing and adjusting the thread take-up lever ............................................................... 19

4. Replacing the needle bar ........................................................................................................ 20

5. Replacing the jump bracket .................................................................................................... 21

6. Replacing and adjusting the jump solenoid ......................................................................... 22

7. Replacing the rotary encoder and the sensor PCB.............................................................. 23

8. Replacing timing belt X ........................................................................................................... 24

9. Replacing timing belt Y ........................................................................................................... 25

10. Replacing the driving wire ...................................................................................................... 27

11. Replacing and adjusting the presser lifter parts.................................................................. 28

11-1. Presser foot ..................................................................................................................... 28

11-2. Presser foot shaft ........................................................................................................... 28

11-3. Replacing and adjusting the W retracting lever and the RET motor lever .............. 30

11-4. Replacing and adjusting the pulse motor ................................................................... 31

BES-960BC.1260BC

12. Replacing and adjusting the gears related to the needle bar flip-up mechanism ........... 32

13. Replacing and adjusting the potentiometer ......................................................................... 34

14. Replacing and adjusting the movable and fixed knives ..................................................... 37

15. Replacing and adjusting the lower shaft module ................................................................ 38

16. Replacing the presser foot switch ......................................................................................... 41

17. Replacing and adjusting the solenoid that controls pulley ................................................ 42

Chapter 3 Standard Adjustment ...................................................................................... 43

1. Adjusting Needle Bar Height .................................................................................................. 43

When using the bottom dead center gauge ......................................................................... 45

2. Adjustment of Clearance Between Needle and Rotary Hook ............................................ 47

3. Adjustment of Timing Between Needle and Rotary Hook.................................................. 48

4. Adjusting the clearance between the rotary hook and the inner rotary .......................... 50

5. Adjustment of Presser Foot Height ....................................................................................... 51

Adjusting the position of the presser shaft ........................................................................... 51

6. Adjustment of Thread Trimmer .............................................................................................. 52

6-1. Attaching the Fixed Knife .............................................................................................. 52

6-2. Checking the Movable Knife Position .......................................................................... 52

7. Adjusting the thread wiper ..................................................................................................... 55

8. Adjusting the jump solenoid .................................................................................................. 56

9. Adjusting the switch................................................................................................................ 57

10. Adjusting the timing belt tension .......................................................................................... 61

10-1. Timing belt X .................................................................................................................. 61

10-2. Timi ng b elt Y .................................................................................................................. 62

11. Adjusting the driving wire ...................................................................................................... 65

12. Adjusting the Y carriage ......................................................................................................... 66

12-1. When the sliding resistance of the Y-carriage is below the standard value........... 67

12-2. When the sliding resistance of the Y-carriage is over the standard value .............. 68

12-3. When the sliding resistance of the Y-carriage is over the standard value

even after adjustment 2 ................................................................................................ 69

12-4. When linear guide 505L, which is attached to machine head No.3,

is not parallel to the top surface of the bed ............................................................... 69

13. Adjusting the rotary encoder and sensor PCB..................................................................... 70

13-1. Adjusting the machine stop position signal ............................................................... 70

13-2. Adjusting the synchronizing signal .............................................................................. 71

14. Adjusting the bobbin winder .................................................................................................. 72

14-1. Positioning the bobbin winder claw ............................................................................ 72

14-2. Positioning the bobbin presser .................................................................................... 72

15. Adjusting the wire of the cap frame attachment ................................................................ 73

15-1. Adjusting the wire tension ............................................................................................ 73

15-2. Adjusting the feed roller ............................................................................................... 74

BES-960BC.1260BC

15-3. Adjusting cap support plates L and R ......................................................................... 74

15-4. Adjusting the presser foot height ................................................................................ 75

Chapter 4 Test mode.......................................................................................................... 76

[Test mode on the operation panel] ................................................................................................... 76

1. Starting test mode ................................................................................................................... 76

2. Selecting test mode menu ...................................................................................................... 76

3. Test mode functions ................................................................................................................ 77

3-1. Thread trimmer adjustment .......................................................................................... 77

3-2. Needle bar case test ...................................................................................................... 77

3-3. Home position searching test ....................................................................................... 78

3-4. Encoder signal test ......................................................................................................... 78

3-5. Switch and LED test on operation panel and head ................................................... 79

3-6. Presser foot test ............................................................................................................. 80

3-7. Solenoid test ................................................................................................................... 80

3-8. Driving shaft rotation test ............................................................................................. 81

3-9. Stitch compensation ...................................................................................................... 81

3-10. Adjusting the timing between the needle and the rotary hook ................................ 83

3-11. Program version indication on the operation panel and head display ................... 83

3-12. Pow er voltage and frequency indication ..................................................................... 84

3-13. Port check........................................................................................................................ 85

3-14. 7 segment LED indication test ...................................................................................... 86

3-15. Machine head communication test .............................................................................. 86

3-16. Er ror sound switching ................................................................................................... 86

3-17. Automatic start at the end of mending ....................................................................... 86

[Test mode and each function on the PC] .......................................................................................... 87

1. PC test mode ............................................................................................................................ 87

2. Confirming the program version ............................................................................................ 88

3. Confirming and deleting the BC error ................................................................................... 92

4. BC sensor test .......................................................................................................................... 94

5. Lower shaft module test (BC auto test) ................................................................................ 97

6. Power supply voltage adjustment ......................................................................................... 99

Chapter 5 Upgrading version of machine program ....................................................... 101

Chapter 6 Maintenance ...................................................................................................... 104

1. Cleaning Rotary Hook .............................................................................................................. 104

2. Oiling ......................................................................................................................................... 105

2-1. Head ................................................................................................................................. 105

BES-960BC.1260BC

3. Greasing .................................................................................................................................... 107

3-1. Head................................................................................................................................. 107

3-2. Feed Guide Section........................................................................................................ 111

Chapter 7 Electric Components........................................................................................ 112

1. PCBs locations .......................................................................................................................... 112

2. Replacing the PCBs in the control box .................................................................................. 114

2-1. Removing and reattaching the control box ................................................................ 114

2-2. Removing and reattaching the control box cover ...................................................... 114

2-3. Replacing the main PCB ................................................................................................ 115

2-4. Replacing the power supply PCB ................................................................................. 116

3. Replacing power supply PCB B in the power supply base ................................................. 117

3-1. Removing and attaching the leg cover and the power supply base cover ............. 117

3-2. Replacing power supply PCB B in the power supply base ....................................... 118

4. Replacing the head switch PCB on the adjustment base ................................................... 119

4-1. Removing and reattaching the adjustment base cover ............................................. 119

4-2. Replacing the head switch PCB .................................................................................... 121

4-3. Removing the TR breakage sensor PCB ...................................................................... 122

5. Replacing the head PCB .......................................................................................................... 124

6. Replacing the BC PCB.............................................................................................................. 125

7. Replacing the BC sensor PCB ................................................................................................. 126

8. Replacing the panel PCB ......................................................................................................... 127

9. Replacing the Y-feed sensor PCB ........................................................................................... 128

10. Replacing the X-feed sensor PCB........................................................................................... 129

11. Replacing the retracting bed sensor PCB ............................................................................. 130

12. Replacing the thread trimming sensor PCB ......................................................................... 131

13. Replacing the cooling fans ...................................................................................................... 132

13-1. Replacing the control box fan ...................................................................................... 132

13-2. Replacing the main PCB fan ......................................................................................... 133

13-3. Replacing the power supply PCB fan .......................................................................... 133

14. Fuses .......................................................................................................................................... 134

14-1. Fuse positions ................................................................................................................. 134

14-2. Fuse type and capacity.................................................................................................. 135

14-3. Replacing the fuses ........................................................................................................ 137

15. Handling the circuit protector of the bobbin winder (optional) ........................................ 138

16. P-ROM position ........................................................................................................................ 139

17. Connectors ................................................................................................................................ 140

17-1. Main PCB connectors ..................................................................................................... 140

17-2. Connectors in power supply PCB in the control box ................................................. 151

17-3. Connectors in power supply PCB B in power supply base ....................................... 158

BES-960BC.1260BC

17-4. Connector in panel PCB ................................................................................................ 159

17-5. Connectors in BC PCB ................................................................................................... 160

17-6. Connectors in head PCB ................................................................................................ 163

17-7. Connectors on the rear of the control box ................................................................. 167

Chapter 8 Finding Cause of Problem ............................................................................... 170

1. Mechanical problems ............................................................................................................... 170

2. Electrical parts.......................................................................................................................... 171

Chapter 9 Error code list ................................................................................................... 180

Test mode menu list ........................................................................................ 184

Control Block Diagram (BES-960BC, 1260BC) ............................................... 185

Control box (BES-960BC, 1260BC) .................................................................. 186

Heads (1-6) (BES-960BC).................................................................................. 187

Heads (1-6) (BES-1260BC)................................................................................ 188

BES-960BC.1260BC

Chapter 1 Mechanical Descriptions

Chapter 1 Mechanical Descriptions

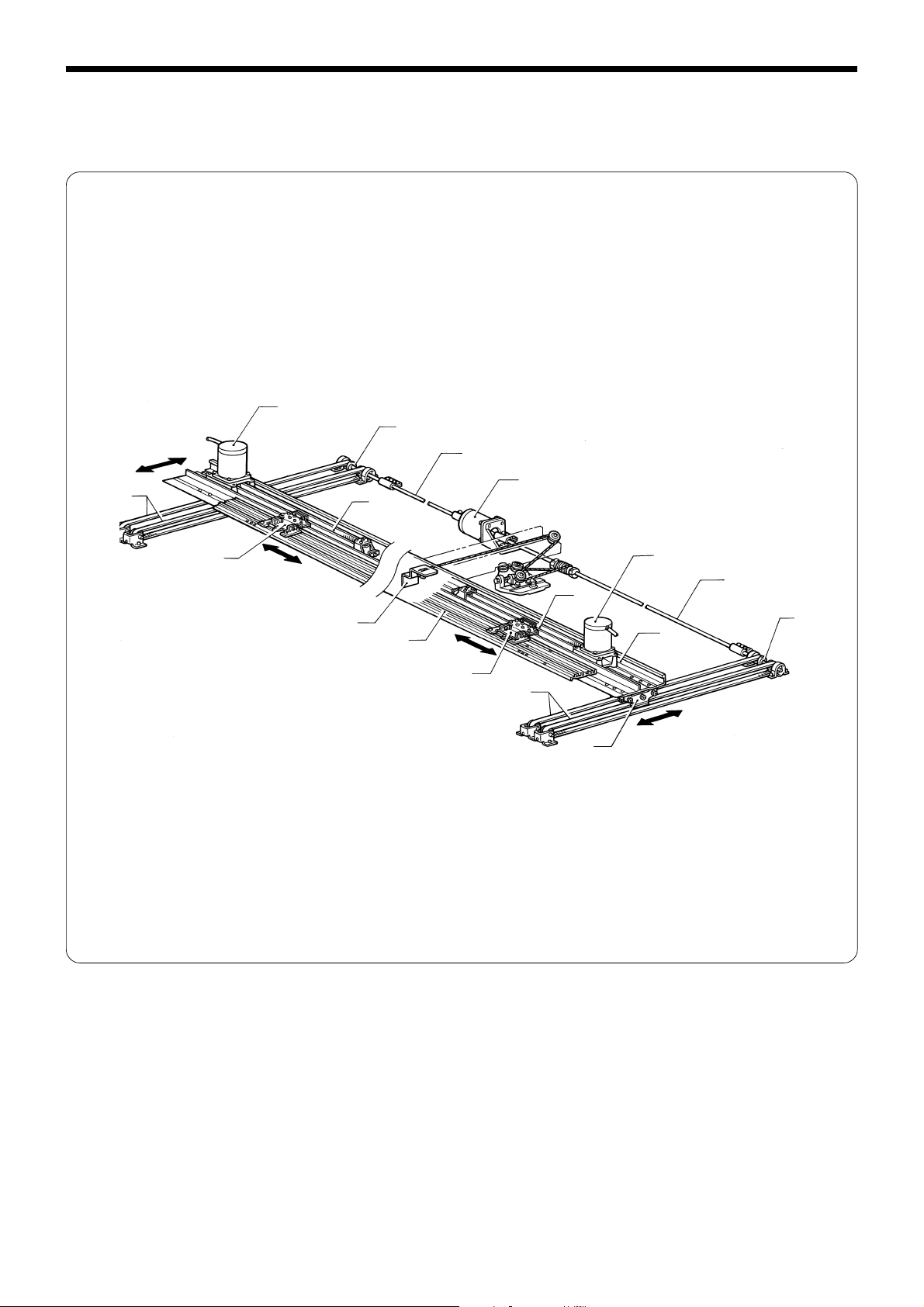

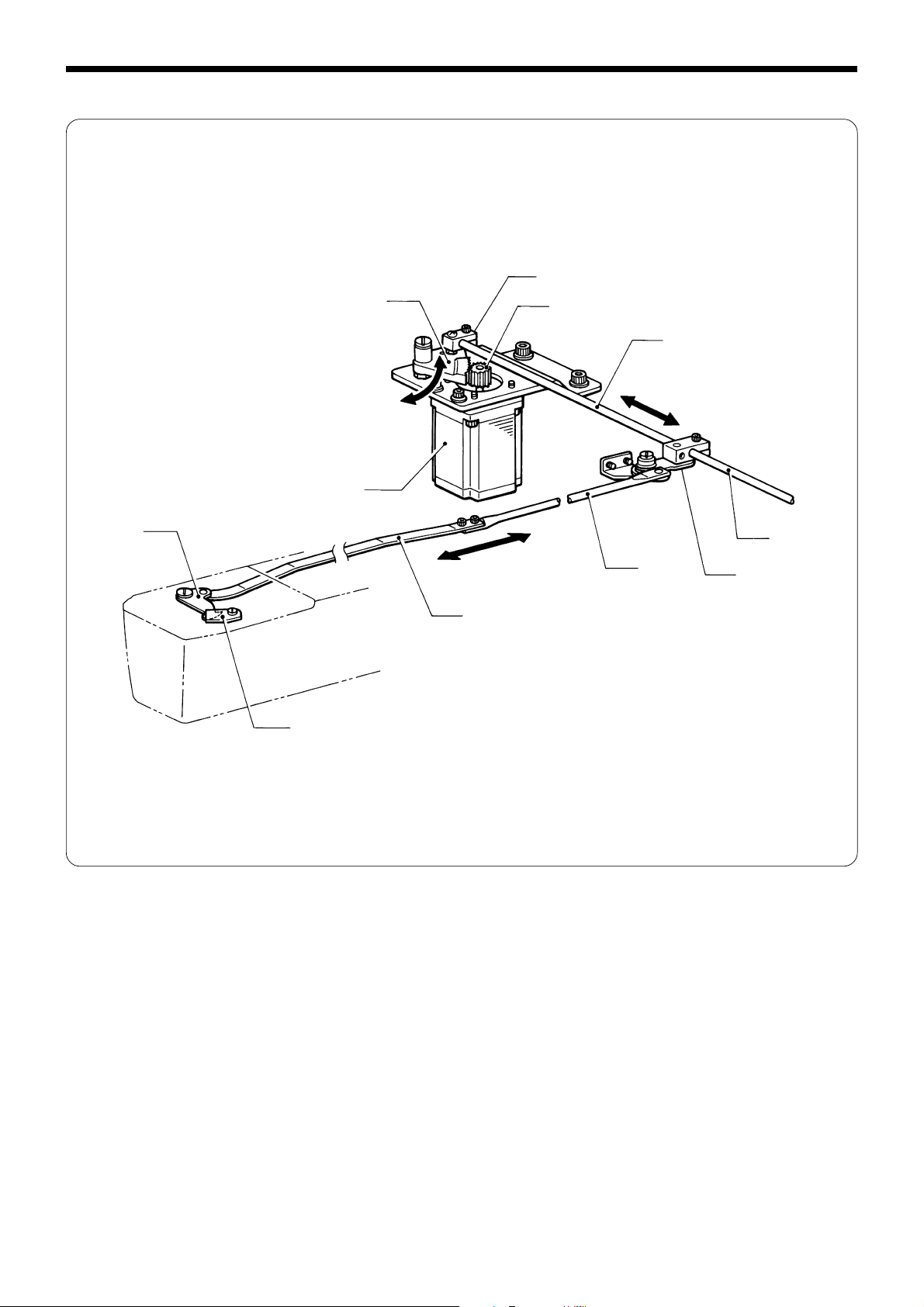

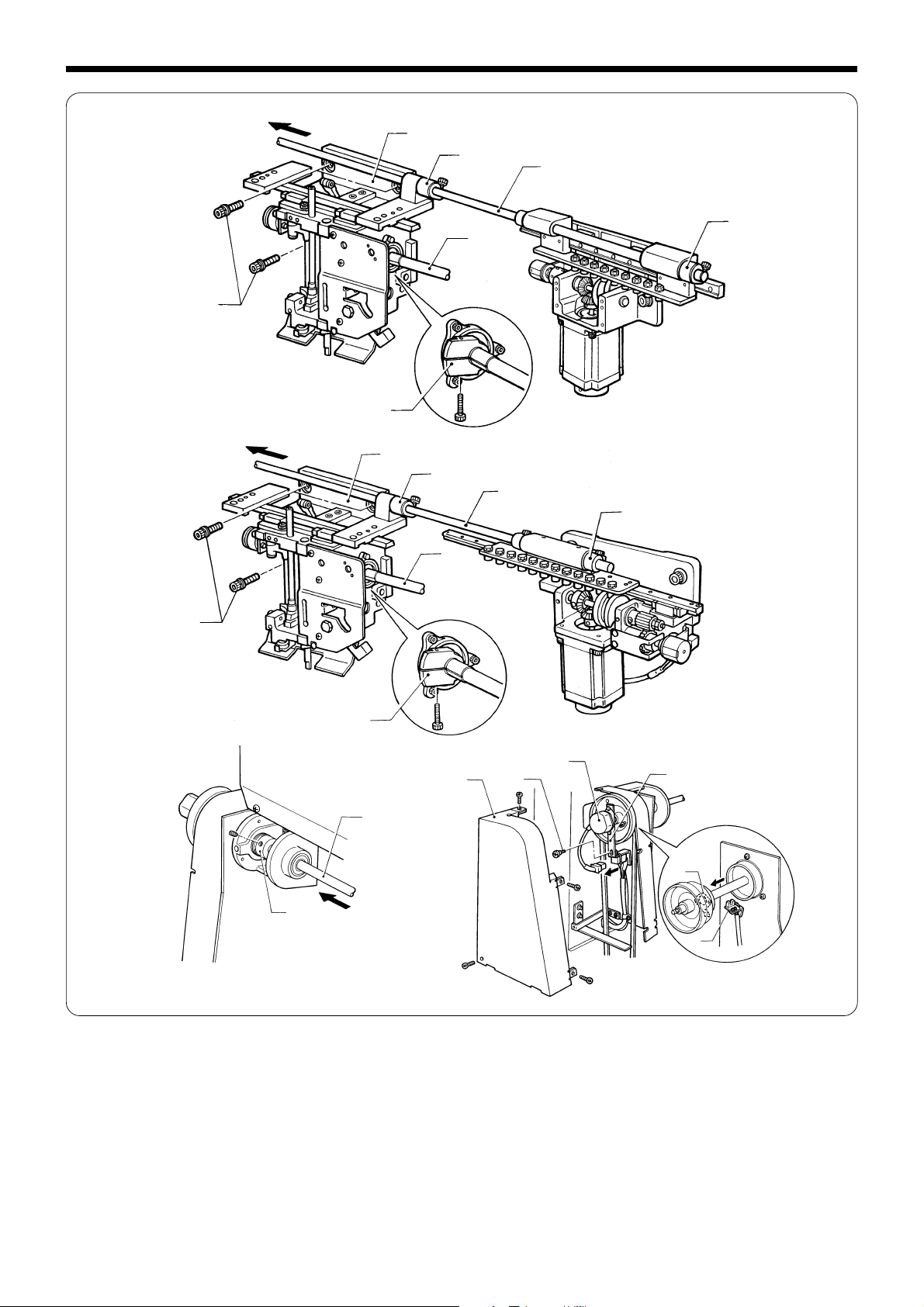

1. Feed guide mechanism

o

r

e

q

u

!0

!1

!0

y

!2

!1

u

i

o

w

r

t

[Y direction]

When the Y-pulse motor qstarts, its motion is transmitted to connecting shafts A w and B e, and the Y driving shaft r. The rail

connecting plate y secured to the Y-feed frame t moves the wire, and the Y carriage i attached to the Y timing belts u moves

the Y-feed frame

t in the Y direction.

[X direction]

When the X pulse motor o starts, its motion is transmitted to the X timing belt !0, and the X-feed bracket !1, resulting in causing

the X-feed frame

!2 to move in the X direction.

BES-960BC.1260BC

1

Chapter 1 Mechanical Descriptions

2. Crank shaft mechanism

w

e

q

r

t

e

y

When the motor q starts, pulley B w is rotated via the V-belt, resulting in causing the driving shaft e to rotate the thread

take-up cam r, the needle bar driving cam t, and the work clamp cam y.

2

BES-960BC.1260BC

Chapter 1 Mechanical Descriptions

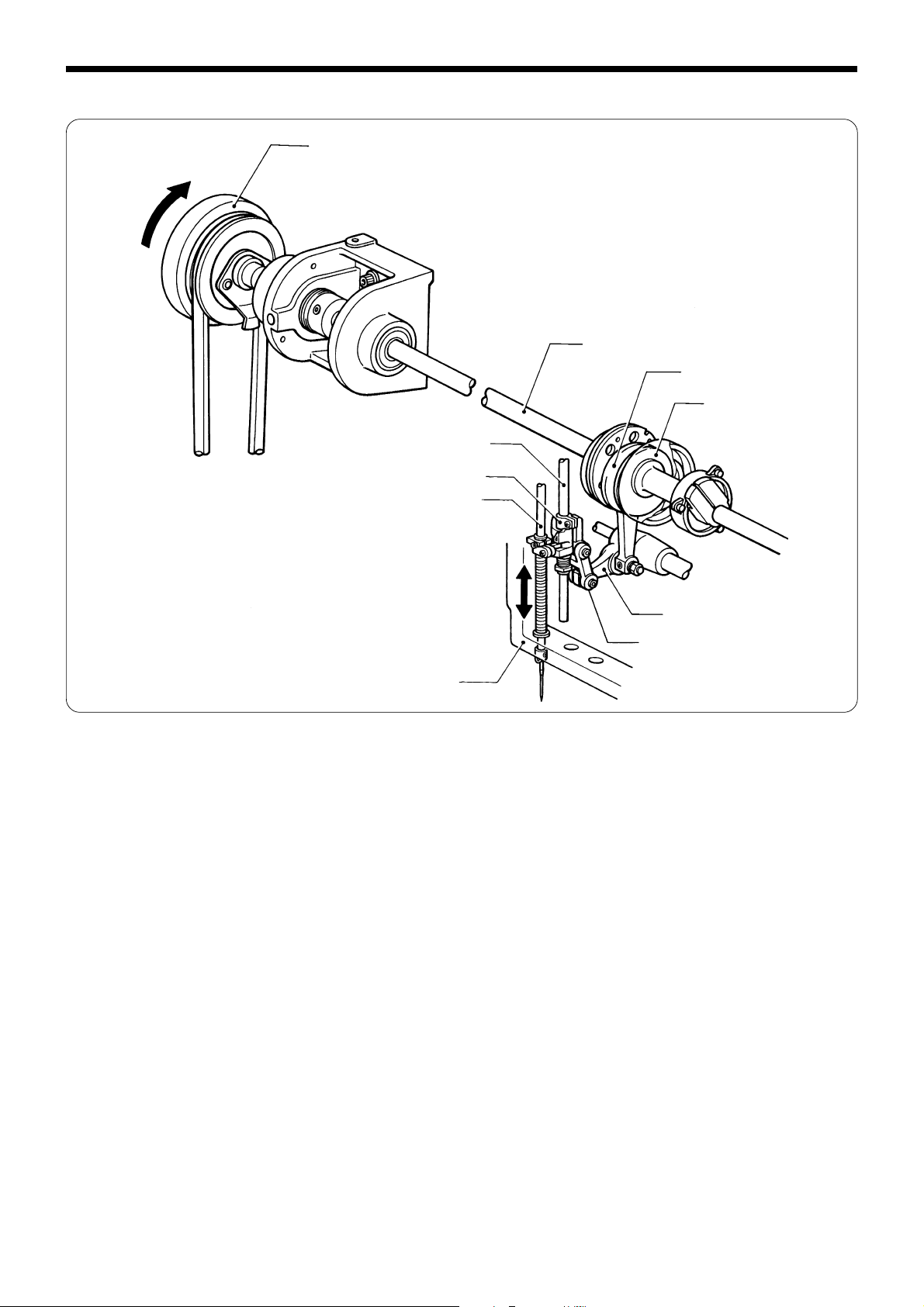

3. Lower shaft and rotary hook mechanisms

q

w

e

r

t

When pulley B and the crank shaft rotate, the pulse motor q of the lower shaft module is synchronized with the upper

shaft by the coupling hub assembly R w, and rotates the coupling hub e, the lower shaft r, and the rotary hook t.

BES-960BC.1260BC

3

Chapter 1 Mechanical Descriptions

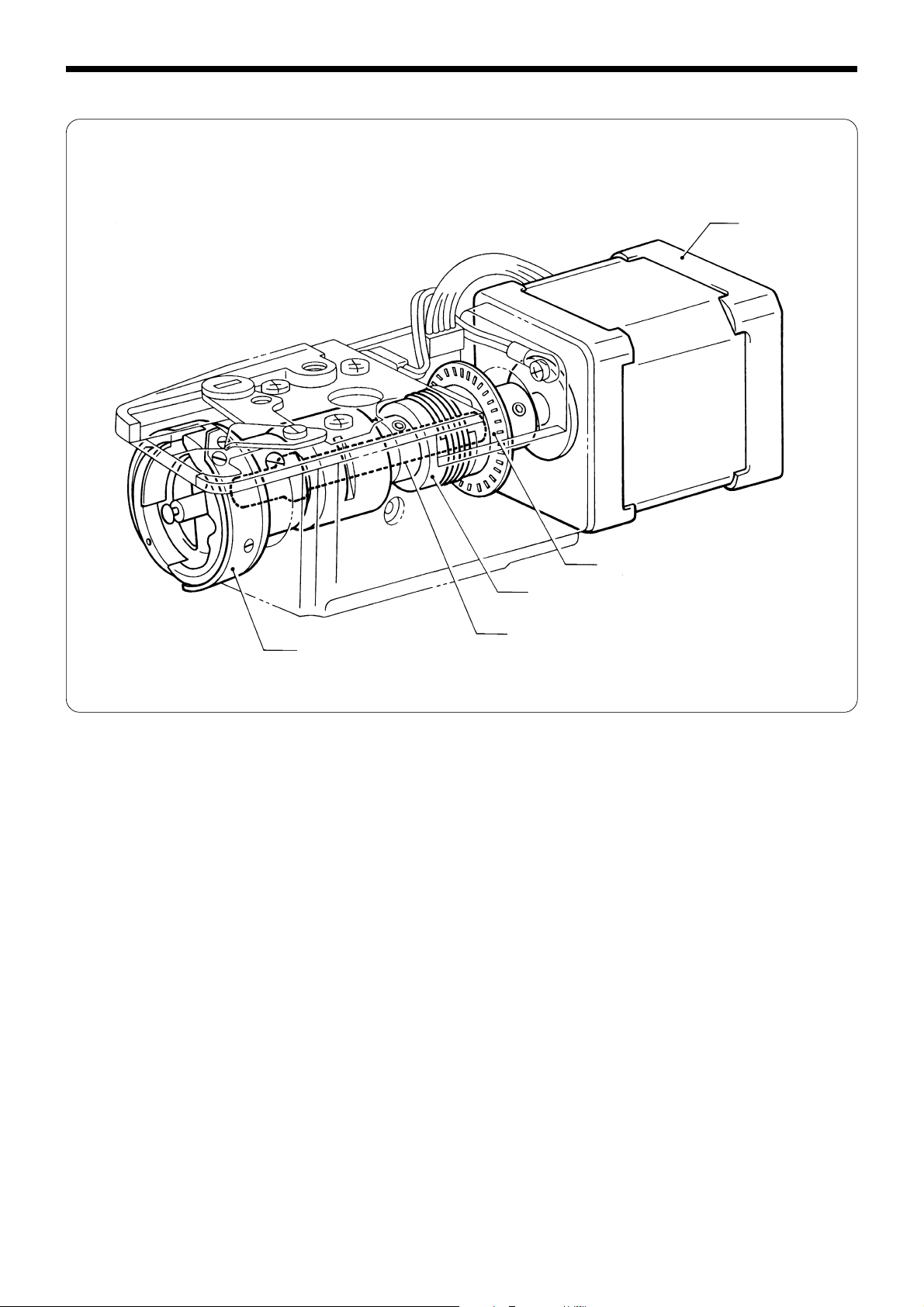

4. Thread trimmer mechanism

e

q

r

w

t

o

i

t

y

u

!0

• When the pulse motor q receives the signal for the final stitch, TR gear C w rotates, and gear A TR e rocks.

• The motion of TR gear A e is transmitted to connecting block TR r, resulting in causing the two TR connecting rods t to move

to the right and left.

• The motion of TR connecting rods

B u and C i to move back and forth.

• When TR connecting rod assys B

other to trim the thread.

t is transmitted to the thread trimmer lever y, resulting in causing TR connecting rod assys

u and C i move back and forth, the movable knife o and the fixed knife !0 engage with each

4

BES-960BC.1260BC

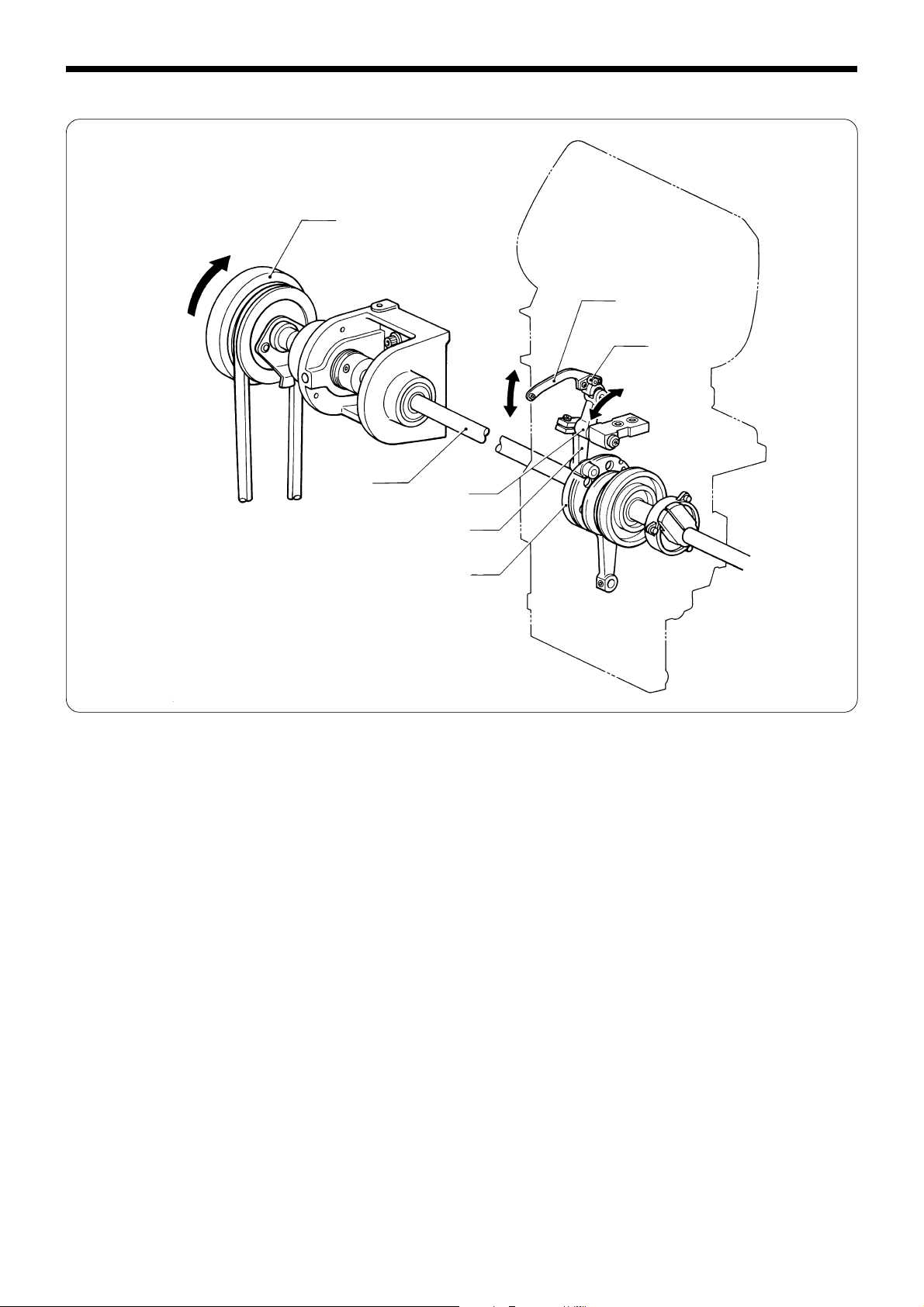

5. Thread take-up mechanism

q

Chapter 1 Mechanical Descriptions

u

y

w

t

r

e

• When pulley B q rotates in the direction of the arrow, the motion is transmitted to the crank shaft w, and the thread take-up

driving cam e rotates.

• The thread take-up driving cam

• The lever

t moves the thread take-up lever u via the thread take-up boss y.

e rocks the lever t via the roller of the TR take-up driving lever assembly r.

BES-960BC.1260BC

5

Chapter 1 Mechanical Descriptions

6. Needle bar mechanism

q

w

r

e

i

u

o

t

y

!0

• When the pulley B q rotates in the direction of the arrow, the driving shaft w rotates the needle bar driving cam e.

• The connecting rod r is connected to the needle bar driving cam e.

• The connecting rod

needle bar

• The motion of the needle bar o depends on the needle bar case !0.

o move up and down via the driving connector y.

r moves the needle bar driving lever t, and the base needle bar i attached to the jump bracket u and the

6

BES-960BC.1260BC

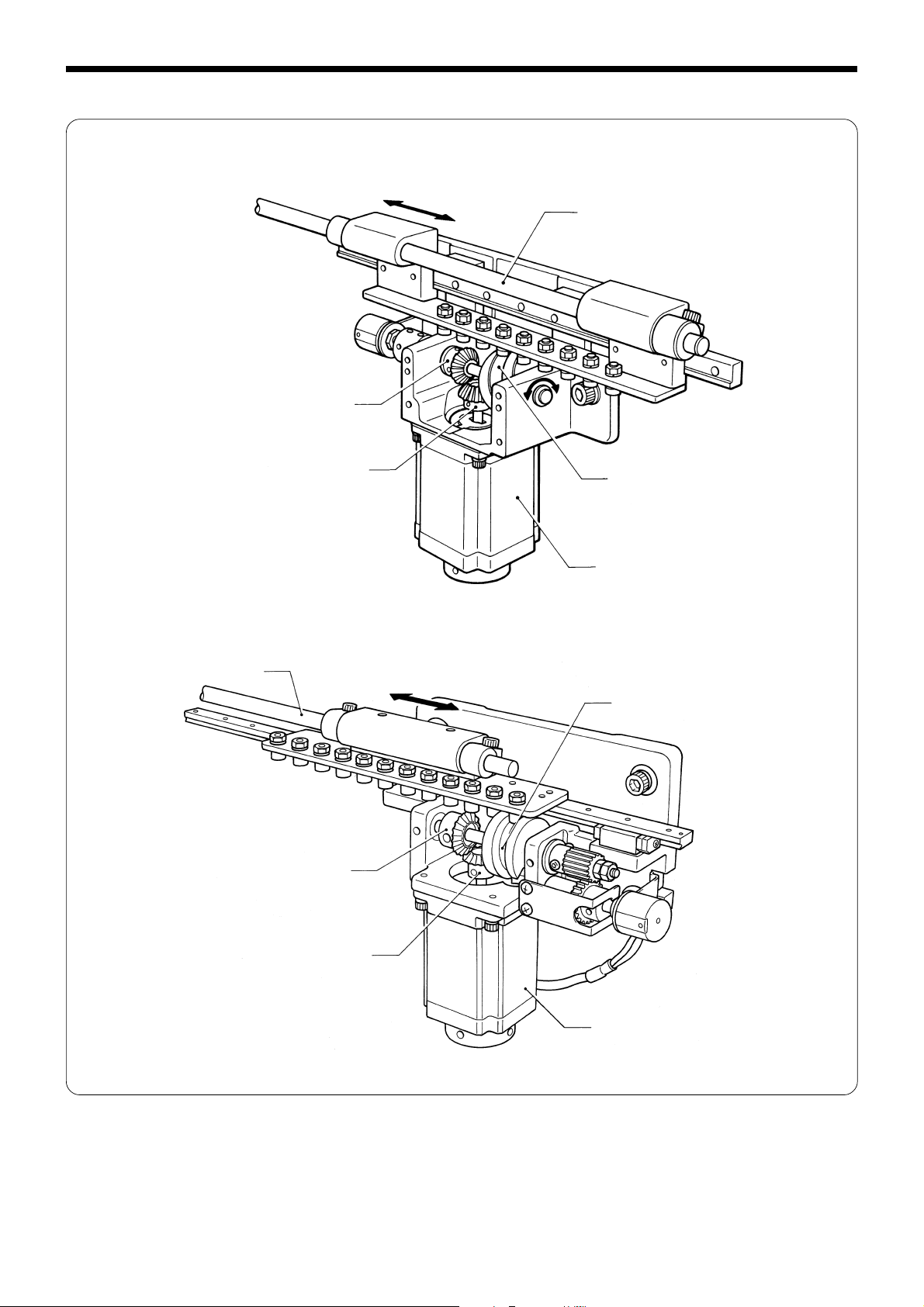

7. Needle bar flip-up mechanism

■ BES-960BC

e

Chapter 1 Mechanical Descriptions

t

■ BES-1260BC

t

e

w

r

q

r

w

q

• The needle bar flip-up signal is transmitted to the pulse motor q to activate bevel gears A w and B e.

• The change cam r switches needle bars.

• The needle bar flip-up is sent to all six machine heads via the connecting shaft

BES-960BC.1260BC

t.

7

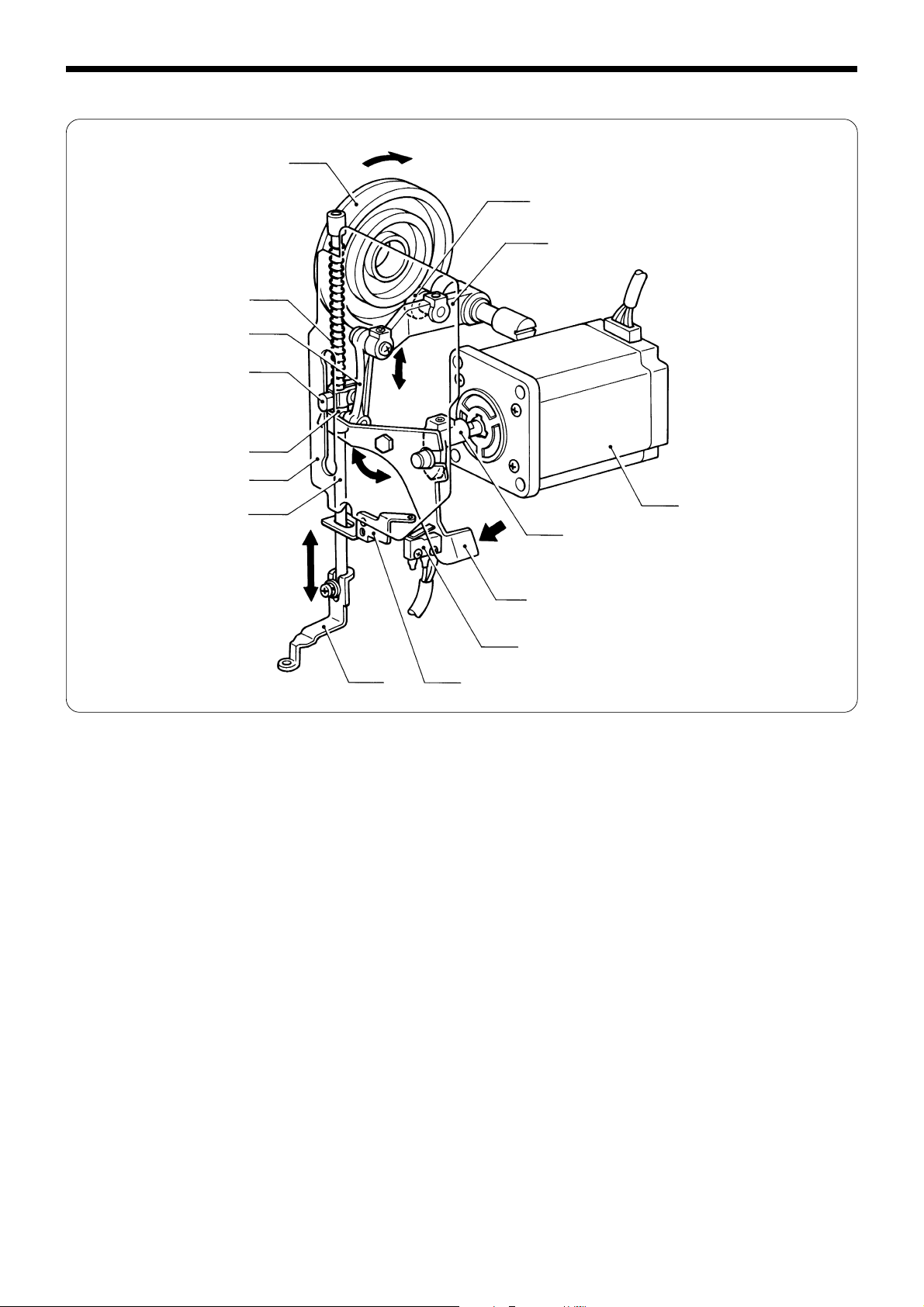

Chapter 1 Mechanical Descriptions

8. Presser foot lifter mechanism

!1

i

!2

r

!3

!5

!4

!0

o

q

w

e

u

t

• When the power is turned on, the pulse motor q receives a signal, the RET motor lever w works, the W retracting lever e raises

the presser foot shaft clamp r and the presser foot t to a position decided by W motor sensor plate y and the W switch assy

u.

• When sewing starts, the pulse motor

• The roller !0, which is attached to the presser foot driving lever o and inserted into the groove of the work clamp cam !1,

transmits the motion to the link

• The presser foot operating base !3 set in the link !2 and the presser foot shaft clamp r secured to the presser foot shaft !4 are

connected by the retracting spring i. They move the presser foot t up and down along the groove of the presser guide plate

!5.

• When sewing is completed, the pulse motor

sensor plate y and the W switch assy u.

• While the power is turned off, the presser foot

q is off, and the presser foot t is lowered by the retracting spring i.

!2

q receives a signal, and raises the presser foot t to a position decided by W motor

t can be raised manually by pressing the W retracting lever e.

y

8

BES-960BC.1260BC

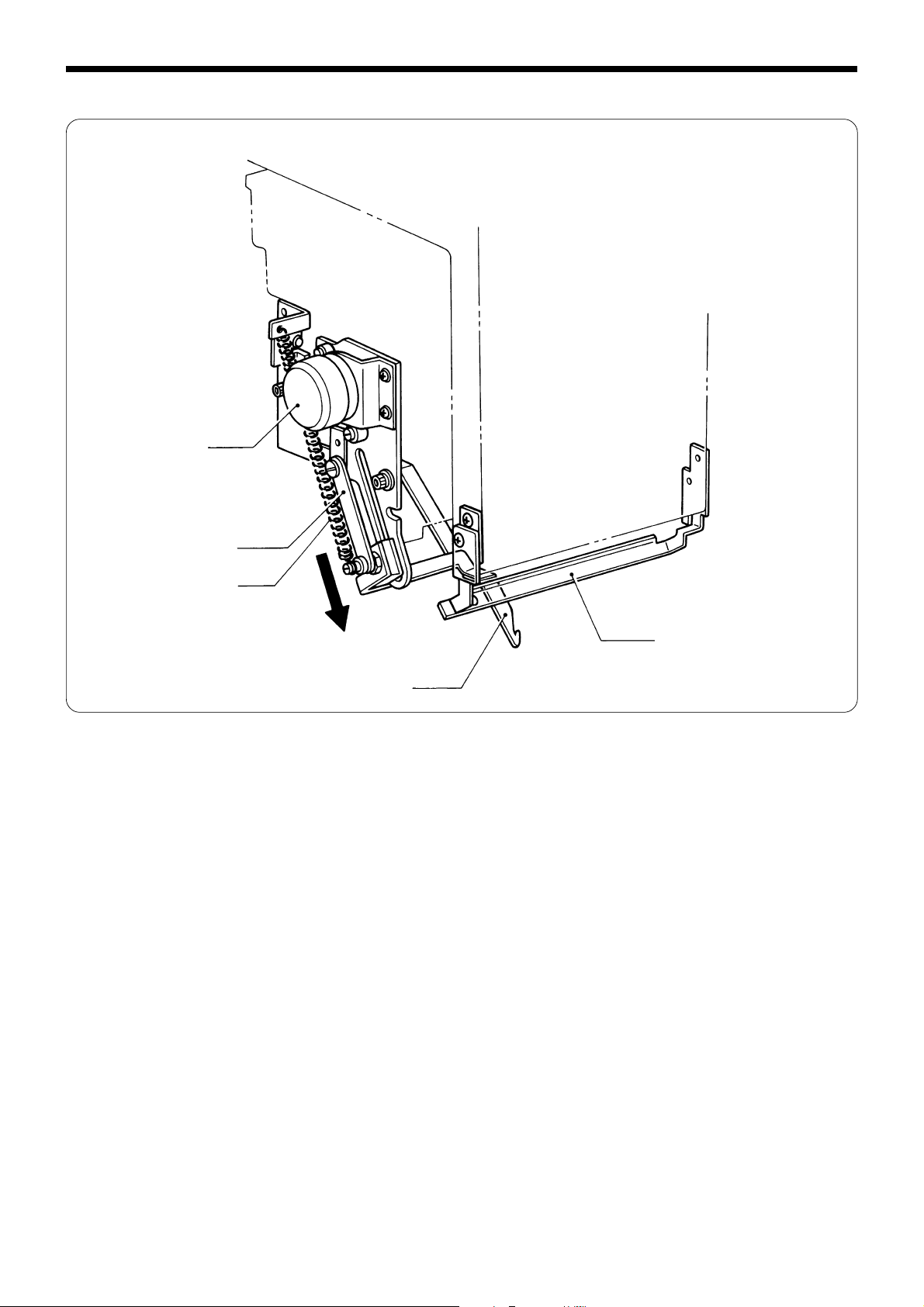

9. Thread wiper mechanism

q

Chapter 1 Mechanical Descriptions

w

r

t

e

• After sewing is finished, the wiper solenoid q moves the plate w in the direction of the arrow.

• The upper thread guide hook e attached to the plate w trims the upper thread. The trimmed thread is raised by the spring r,

and maintained in a position on the thread presser base

t.

BES-960BC.1260BC

9

Chapter 1 Mechanical Descriptions

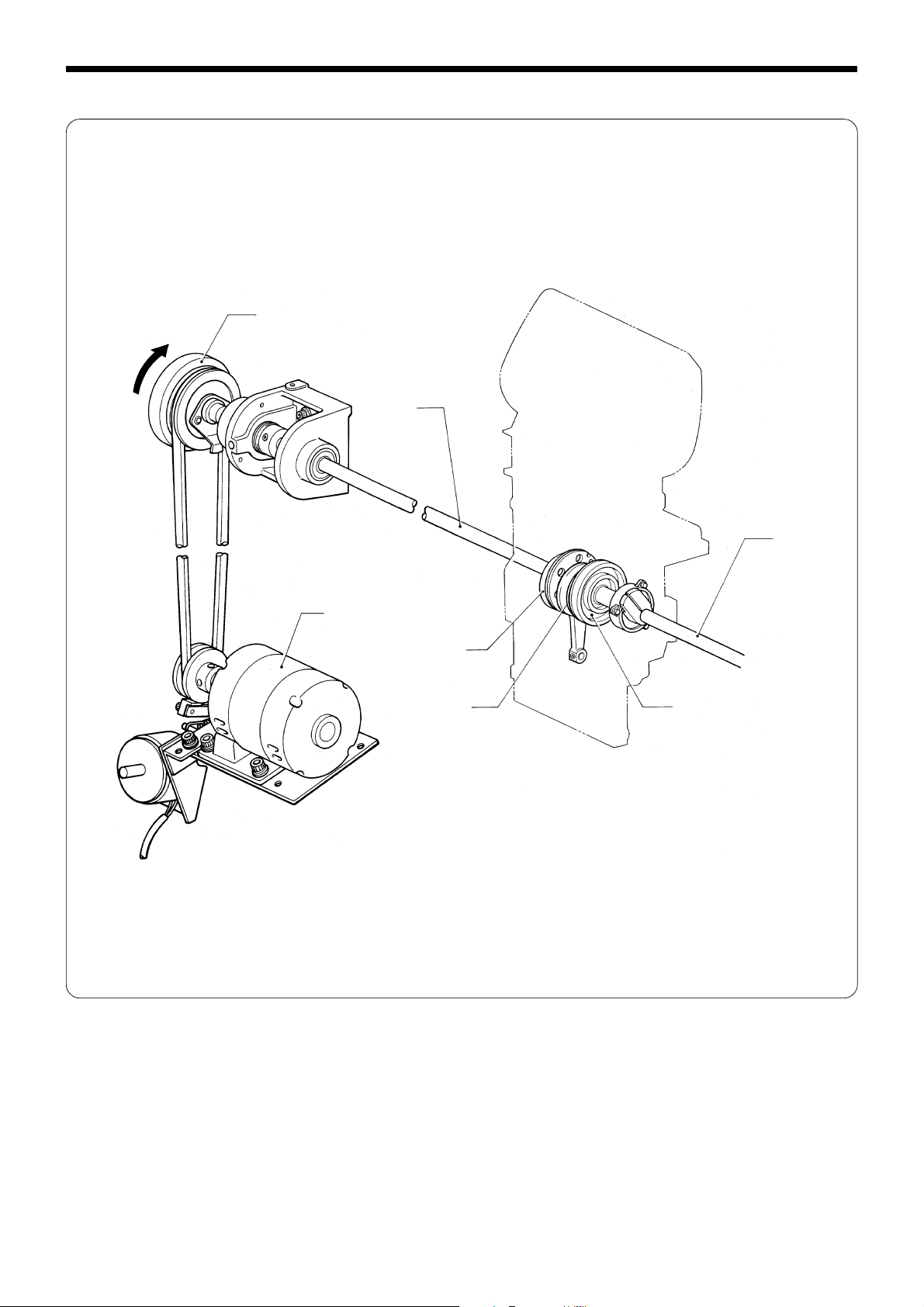

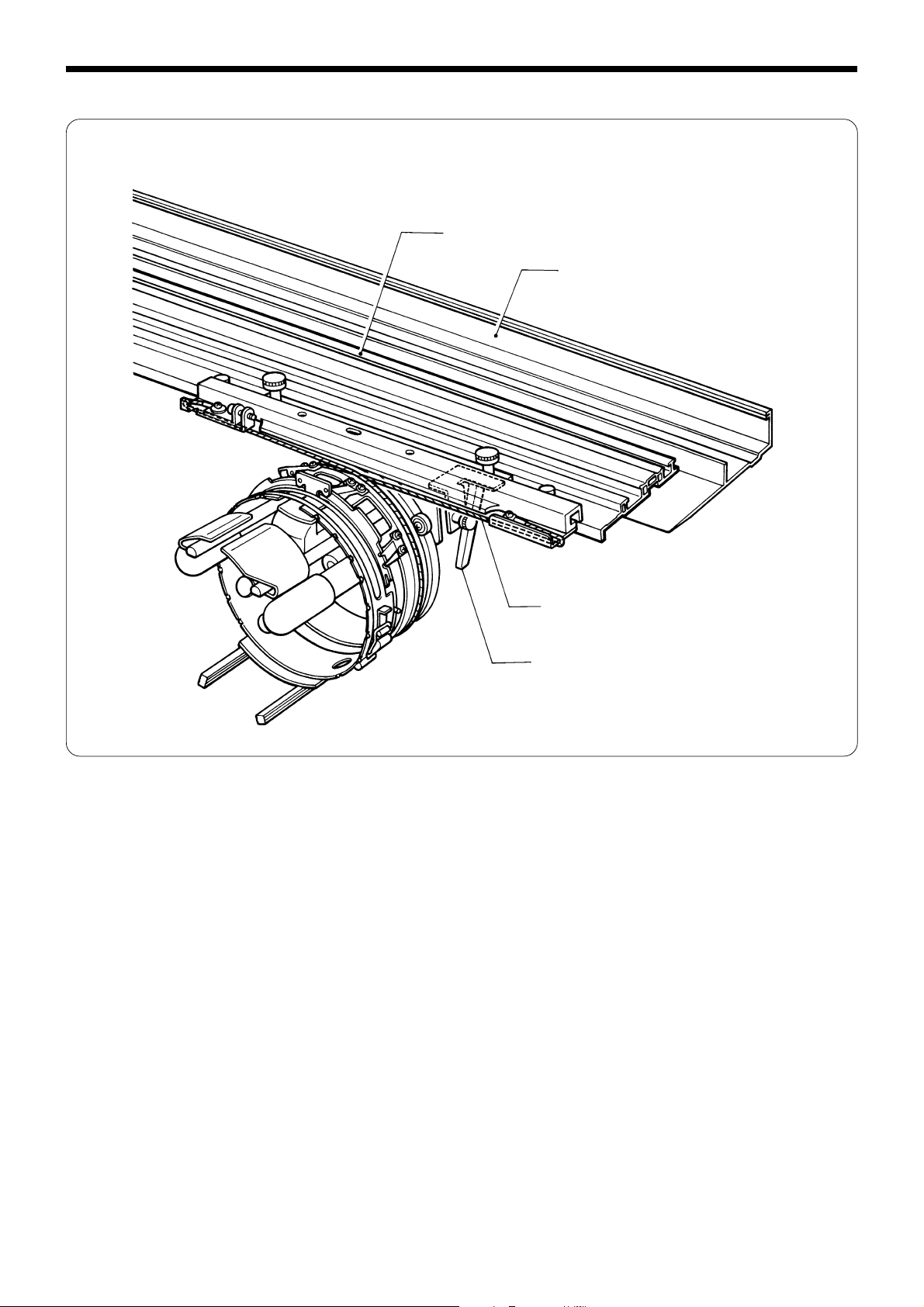

10. Cap frame device

q

e

w

r

• When the X-feed frame q moves in the direction of X, the cap frame device is rotated by the wire w.

• When the Y-feed frame

e moves in the direction of Y, the motion is transmitted to the cap frame device via the fixed lever r.

10

BES-960BC.1260BC

Chapter 2 Parts Replacement and Adjustment

Chapter 2 Parts Replacement and Adjustment

CAUTION

Turn off the power switch before starting any

cleaning work, otherwise the machine may

operate if the start switch is pressed by mistake,

which could result in injury.

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the treadle

is depressed by mistake, which could result in

injury.

• When carrying out inspection, adjustment and

maintenance

If the power switch needs to be left on when carrying

out some adjustment, be extremely careful to

observe all safety precautions.

Use only the proper replacement parts as specified

by Brother.

If any safety devices have been removed, be

absolutely sure to re-install them to their

original positions and check that they operate

correctly before using the machine.

Any problems in machine operation which

result from unauthorized modifications to the

machine will not be covered by the warranty.

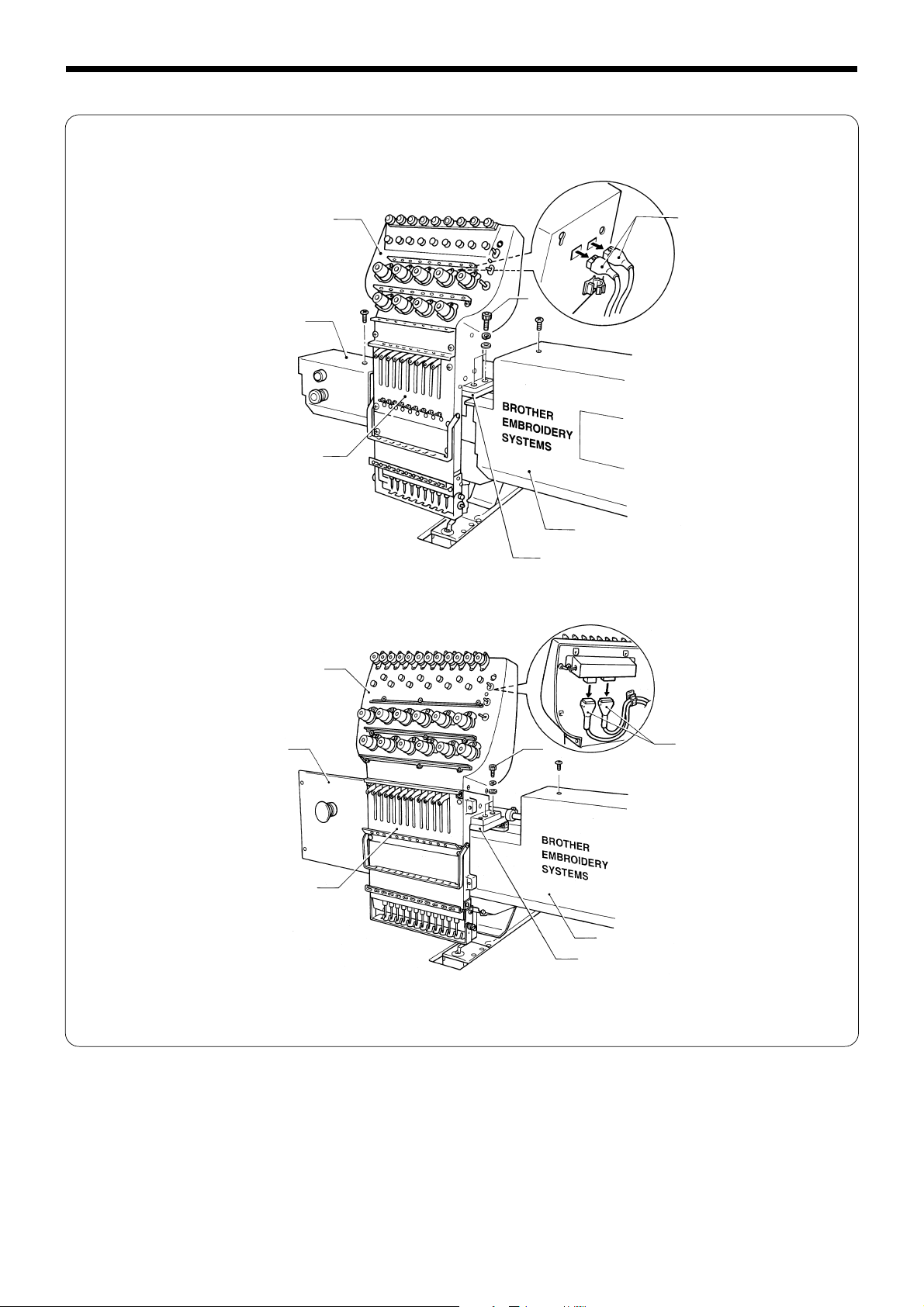

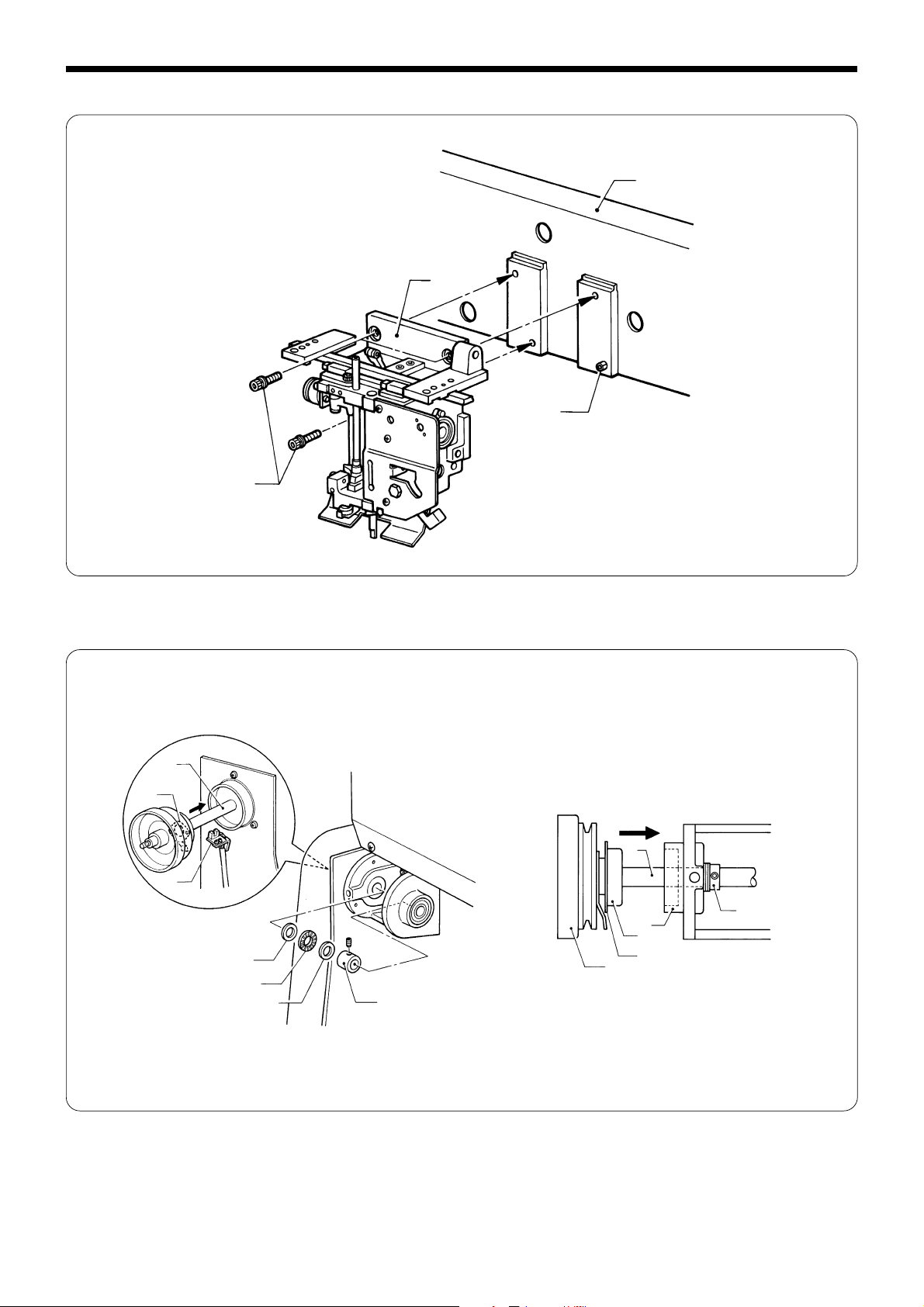

1. Replacing and adjusting the machine heads

Notes:

Be sure to lower table F when it has been used.

Remove all connectors and the like which are attached to the machine heads.

Be sure to replace machine heads one by one. Do not remove two or more heads at once.

Do not remove anything but the feed mechanism.

BES-960BC.1260BC

11

Chapter 2 Parts Replacement and Adjustment

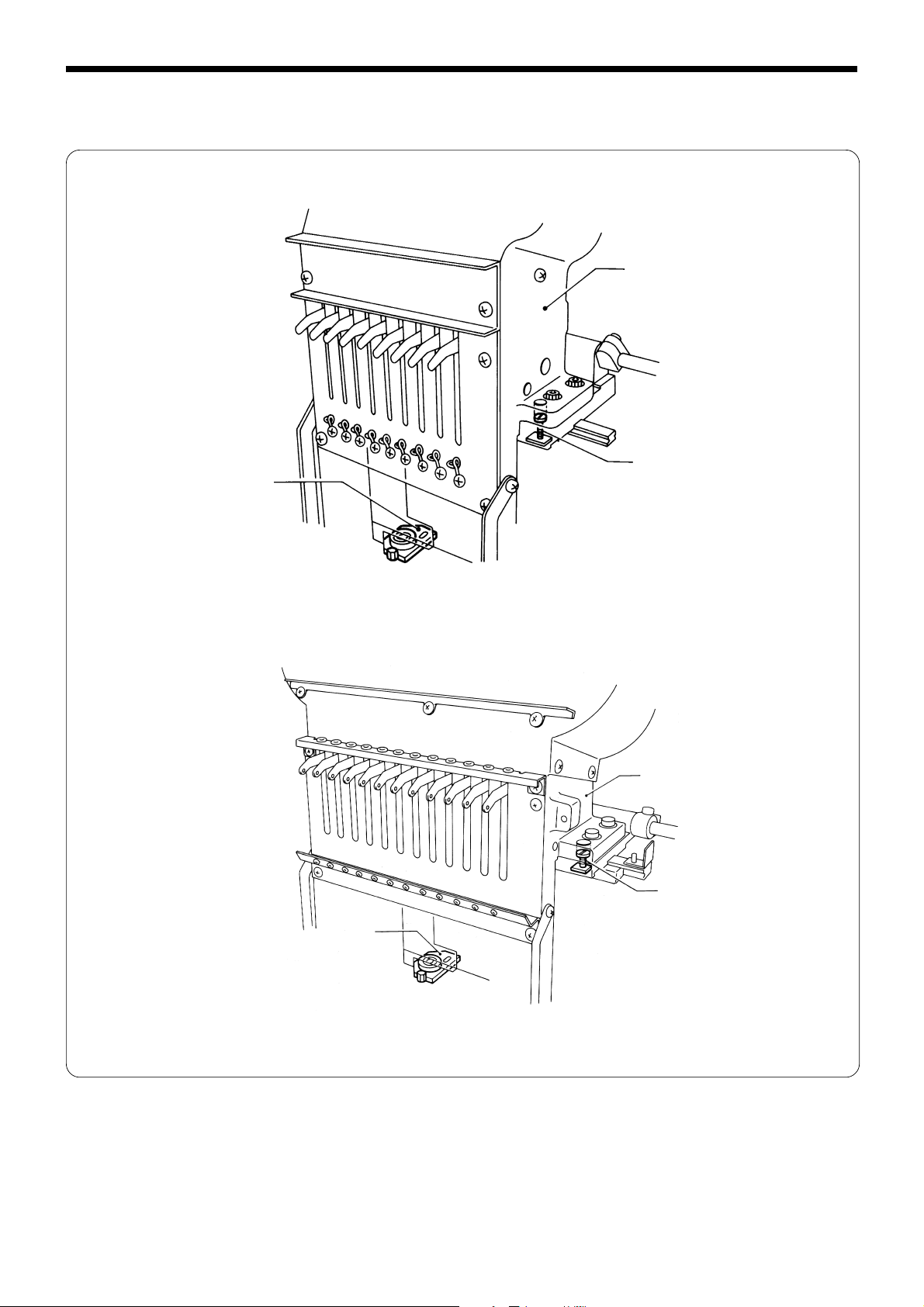

[Removing a machine head]

BES-960BC

BES-1260BC

r

t

q

w

y

e

u

q

r

y

w

t

e

u

1. Remove the two connectors w from the rear of the adjustment base q. (At this time, separate cords from cord clamps.)

2. Remove screws, the cover e, and the switch cover r. (Remove the covers for remaining machine heads u.)

3. Remove the four bolts

Note:

When removing the switch cover

y , and the needle bar case t from the machine head u.

r, remove switch connectors.

12

BES-960BC.1260BC

Chapter 2 Parts Replacement and Adjustment

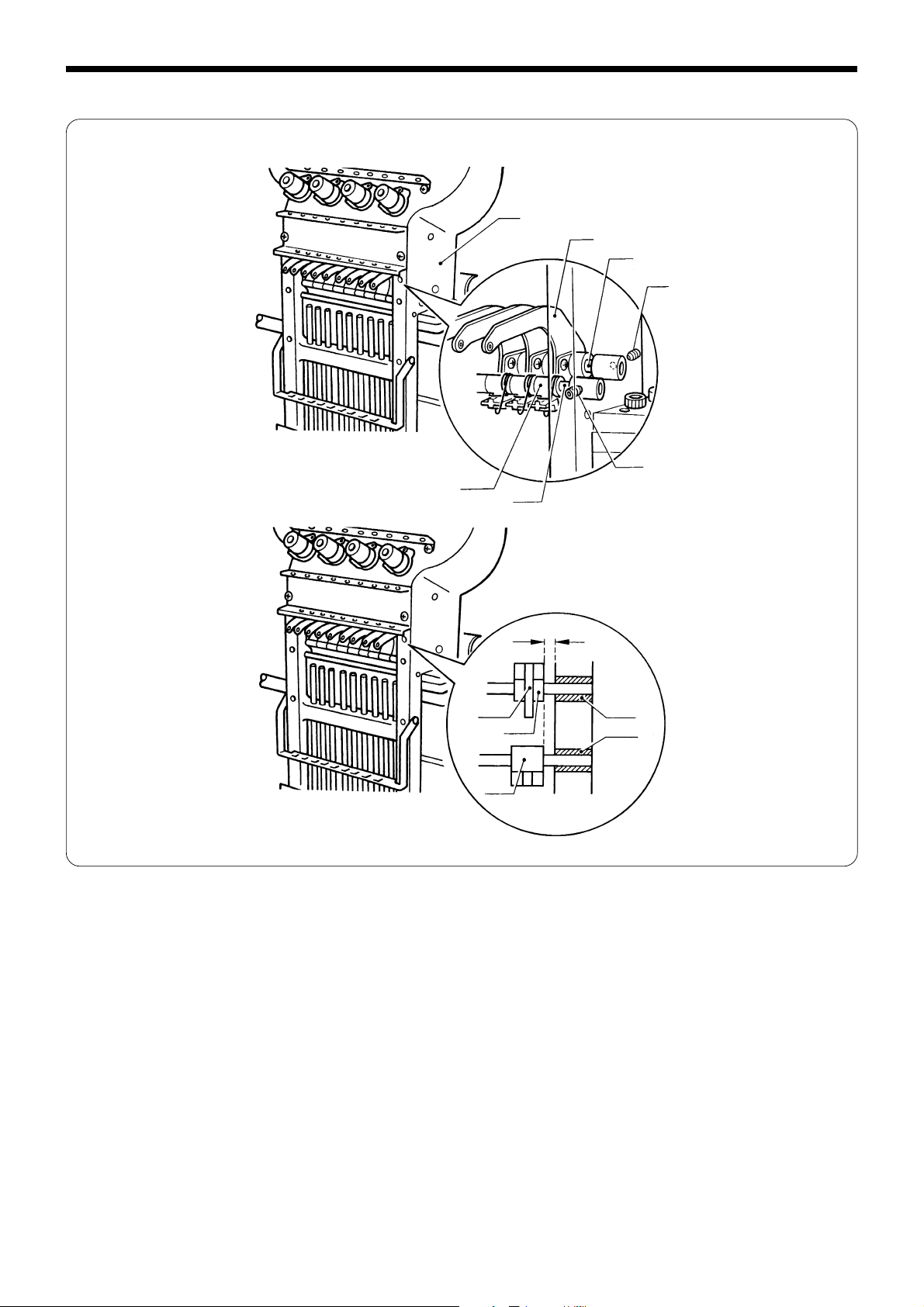

BES-960BC

BES-1260BC

!7

!5

t

t

o

!6

o

i

o

!6

i

o

!7

!5

!1

!0

!3

!2

!6

!8

!4

!9

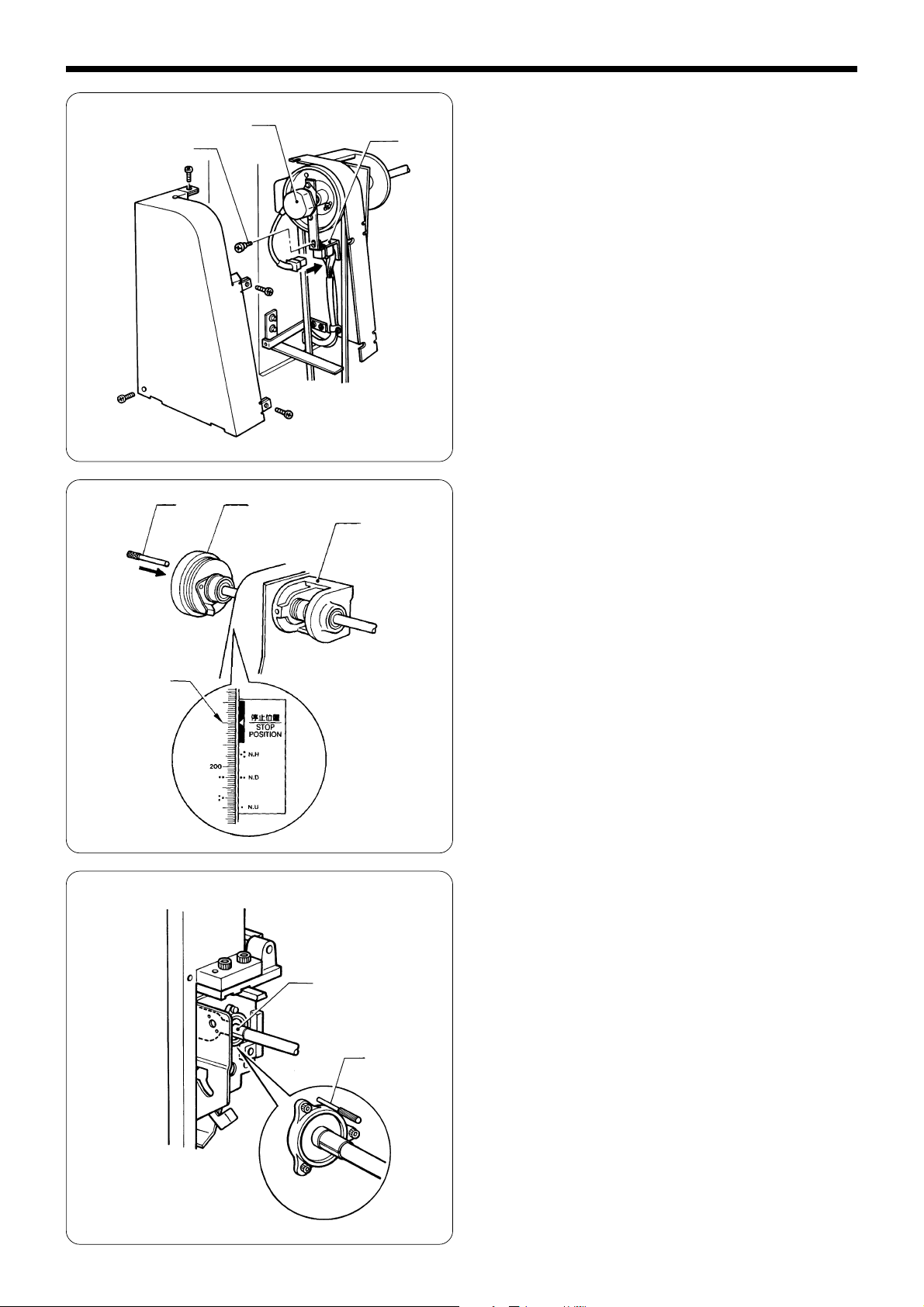

4. Loosen the !4 bolts of the !4 change bracket collars o securing the connecting shaft i, and pull the connecting shaft i.

5. Remove belt cover B

encoder bracket !2.

6. Loosen the two set screws of the inner presser collar

the left.

7. Remove the three bolts

Note:

Pull the driving shaft at the position where the zero bight needle location dog

contact with each other. (They make contact at 80 - 120 degrees.)

!0, and then the connector of the rotary encoder !1. Remove the shoulder screw !3 from the

!4 and the six bolts of the collar !5, and pull the driving shaft !6 to

!7 and the head u.

!8 and the photo-sensor !9 do not make

BES-960BC.1260BC

13

Chapter 2 Parts Replacement and Adjustment

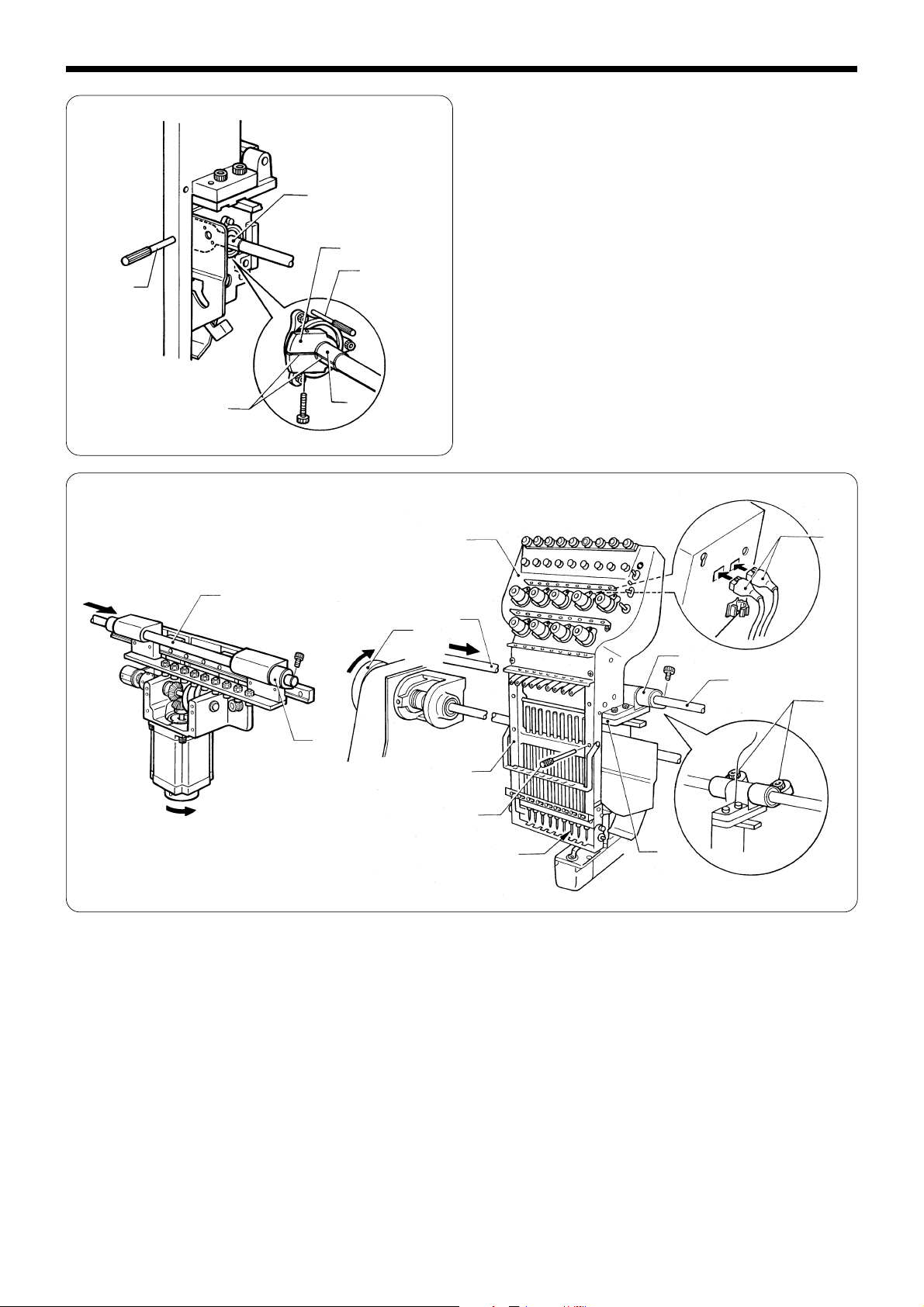

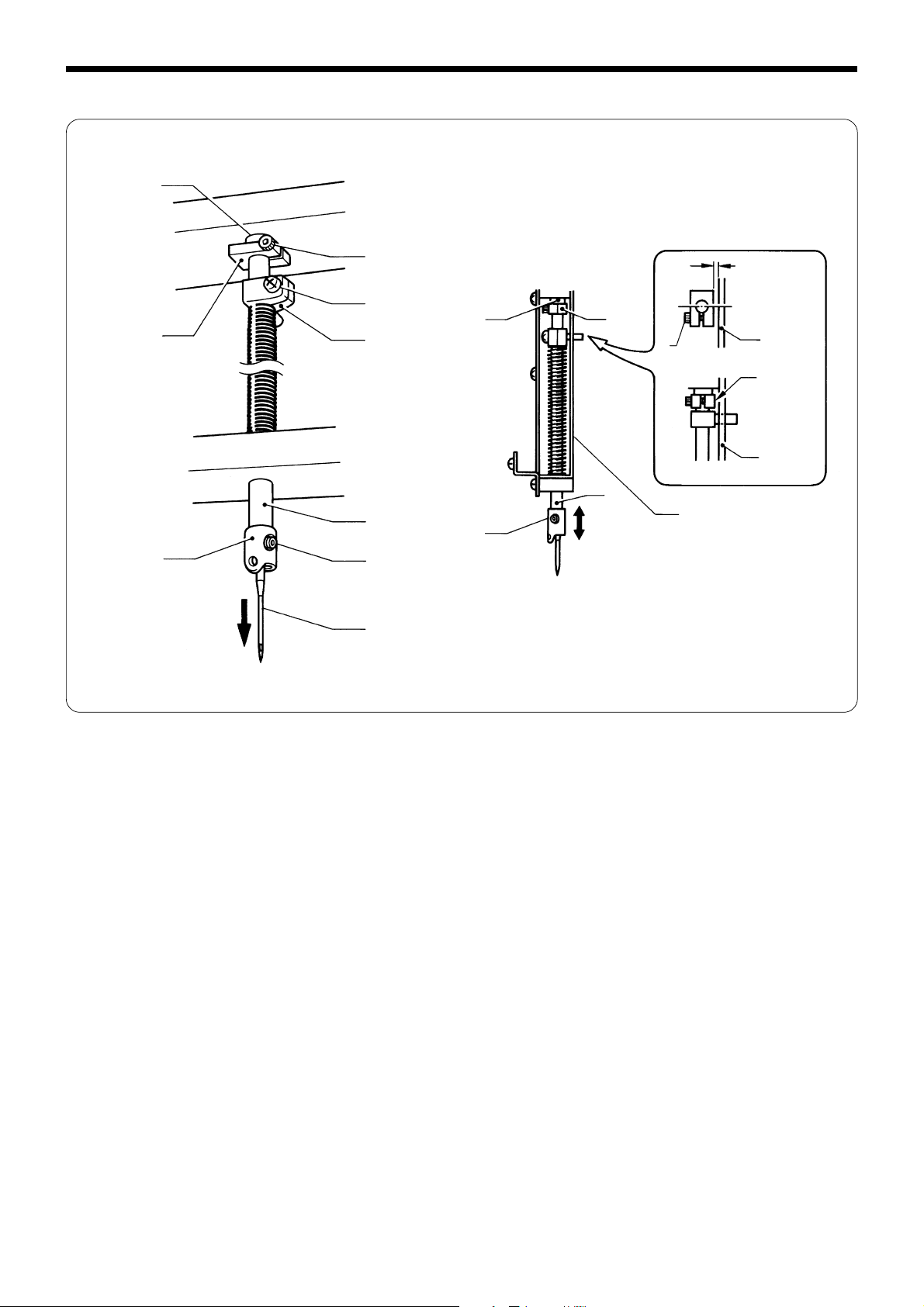

[Reassembling the head]

r

w

q

e

1. Hook the head q on the projections of the bridge w, make contact with the right side of the head to the spring pin e,

and attach the head

q to the bridge w with the three bolts r.

t

y

t

u

!3

i

!2

!0

!1

visor

o

!0

i

2. As shown in the figure, insert the driving shaft t from the left while passing it through the inner presser collar i, the

thrust roller bearing o, and the two thrust washers !0 so that the zero bight needle location dog y and the photo-sensor

u do not make contact with each other.

Insert the driving shaft

bearing !3.

3. Press pulley B

of the inner presser collar

!1 so that it covers the driving shaft bearing !3 with the inner presser collar i, and tighten the set screw

14

t all the way until the visor of the bearing !2 makes contact with the end of the driving shaft

i to eliminate end play.

BES-960BC.1260BC

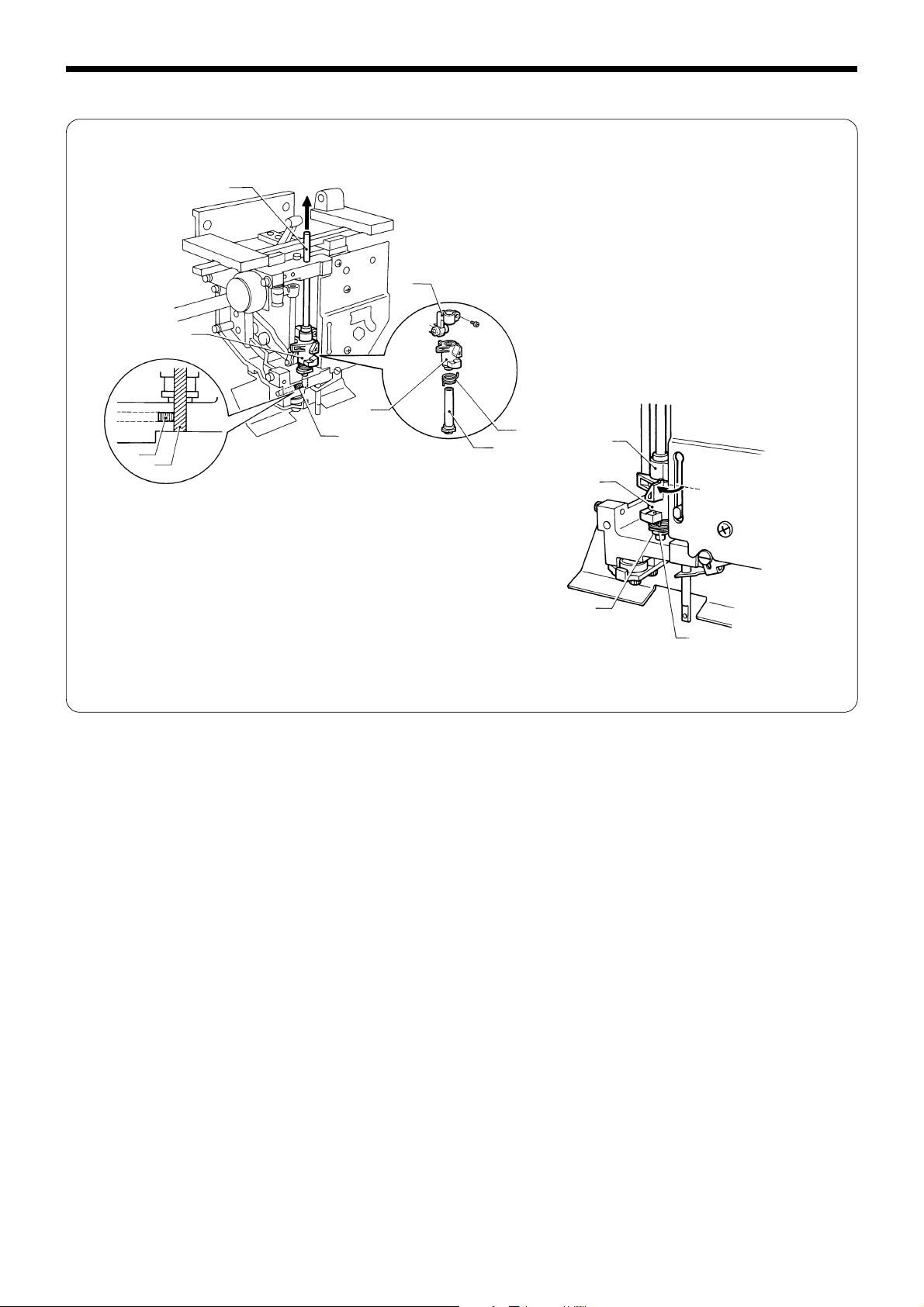

!4

!6

!7 !1

!3

!5

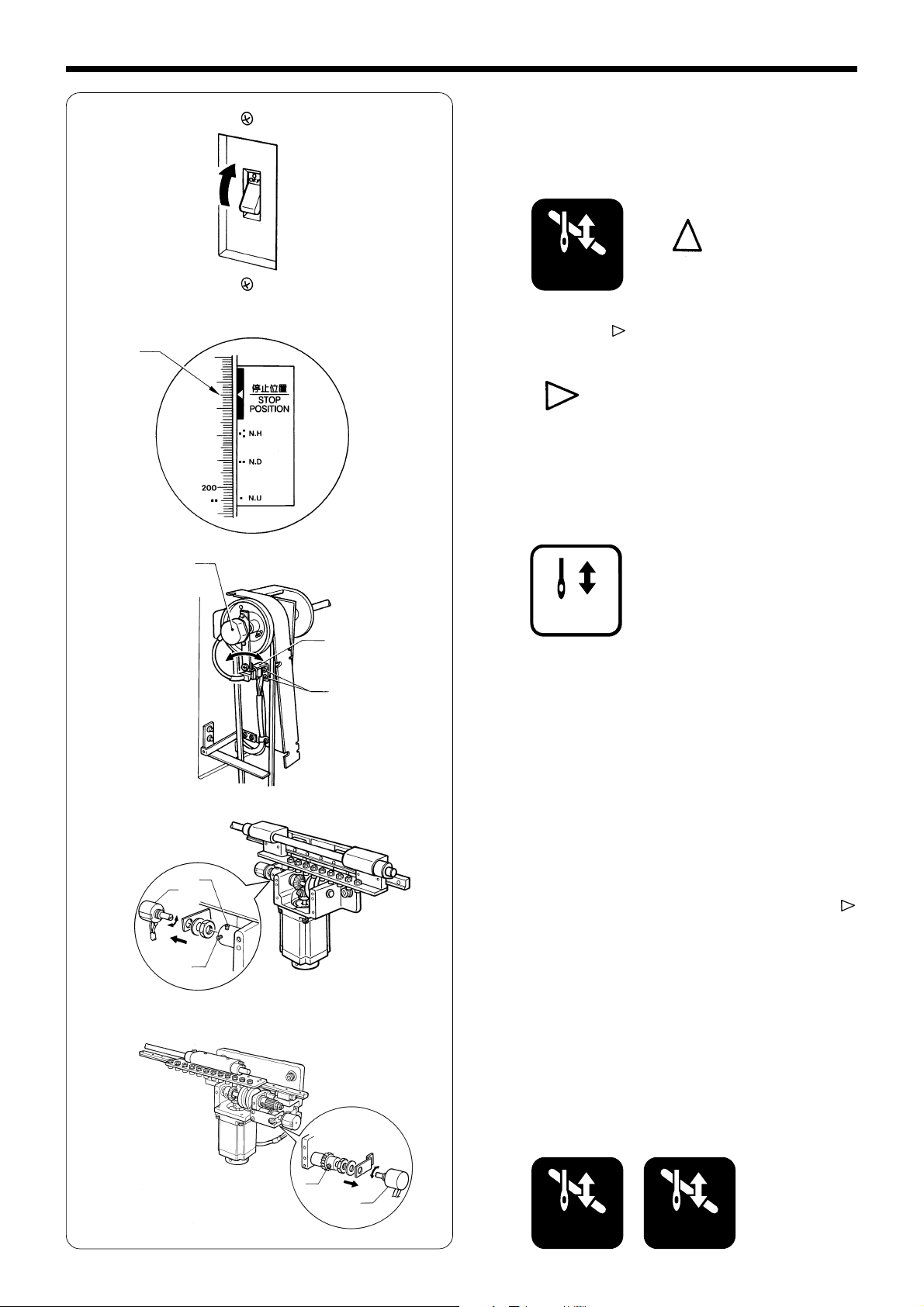

Chapter 2 Parts Replacement and Adjustment

4. Attach the connector of the rotary encoder !4 to the encoder bracket !5 using the shoulder screw !6.

5. Insert the positioning bar !7 into the holes of pulley B !1

and the driving shaft bearing !3 (when the pulley indicator is aligned with 180 degree mark) to secure the driving shaft

t.

180°

6. Align the hole on the right side of the head with that of

the needle bar driving cam !8, and insert the gauge pin !9

into them.

Note:

Use optional gauge pins.

!8

!9

BES-960BC.1260BC

15

Chapter 2 Parts Replacement and Adjustment

!7

BES-960BC

Slits

!8

@0

!8

!9

7. Align the slit of the needle bar cam !8 with that of the

@0, and secure the latter.

collar

Repeat this step for all of the six heads. After this step

is completed for all heads, remove the gauge pin

and the positioning bar !7.

@4

!9

@5

@2

@2

!1

@3

@2

@3

@1

!7

Needle ber

No.3

8. Install the needle bar case

change bracket collar

9. At needle bar No.3, insert the positioning bar

secure the needle bar case @1. Insert another positioning bar !7 into needle bar case of the next head, secure two

change bracket collars

bed.

Notes:

Two positioning bars

determined; the other is inserted into the head whose needle penetration position will be determined. (If both bars are

used for heads whose needle penetration position is not yet determined, you will not be able to find the correct needle

penetration position.)

Turn pulley B

!1 on each head to make sure that the needle will fall into the hole on the needle plate.

@1 on the head q, and insert the connecting shaft @2. Do not forget to pass it through the

@3.

!7 from the front of the needle bar case @1 into the hole of the head q to

@3 while checking that the needle definitely falls into the hole on the needle plate attached to the

!7 are required. One is inserted into the head whose needle penetration position has been

q

Bolt

10.Attach covers, and insert two connectors @5 into the rear of the adjustment base @4.

At this time, be sure to attach the harnesses to the cord holder, providing an allowance for the harnesses tension

between the adjustment base set and the bridge. (If there is no allowance, the pattern to be sewn may be distorted

during color change.)

16

BES-960BC.1260BC

STOP

START

STOP

165°

Chapter 2 Parts Replacement and Adjustment

11.Turn on the power of the machine.

12.Press the stop switch and the jog switch (∆) simultaneously to enter into the test mode.

13.Use the jog switch ( ) to display "Ecd."

14.Press the start switch, and turn the pulley to make sure

the buzzer will start to sound at 165 degrees.

BES-960BC

BES-1260BC

Encoder

@8

@7

@7

!5

@6

15.If it does not start to sound at 165 degrees, loosen the

two screws

!5.

16.Press the stop switch once. Keep pressing the jog switch ( )

until "CASE" appears, and press the start switch. Select

needle bar no.1 to make sure "19-1" will appear with buzzer

sounding.

If the buzzer does not sound, loosen the set screws

remove the potentiometer

justment.

• Refer to page 34 when replacing and adjusting the potentiometer.

@6, and adjust the angle of the encoder bracket

@7,

@8, and turn the shaft for ad-

@8

@9

17.Press the stop switch twice to finish the test mode, and

turn off the power of the machine.

BES-960BC.1260BC

STOP

17

Chapter 2 Parts Replacement and Adjustment

2. Removing the needle bar case

Refer to page 11, "1. Replacing and adjusting the machine head."

BES-960BC

q

e

w

BES-1260BC

q

w

e

[Notes on assembly]

• The needle bar case q should move to the right and left easily, and a needle should be aligned with the hole in the needle plate.

• Loosen the two positioning bars

e for adjusting the inclination.

• Do not loosen the positioning bars

18

w for adjusting the needle bar case q or needle penetration point; adjust the positioning plate

w unnecessarily.

BES-960BC.1260BC

Chapter 2 Parts Replacement and Adjustment

3. Replacing and adjusting the thread take-up lever

q

y

r

e

w

u

t

Fig. A

0.5 mm

y

!0

i

o

u

1. Loosen the set screws w on the right and left of the needle bar case q when viewed from the front, and the set screws e on

both sides of the rear of the needle bar case

2. Move the thread take-up shaft r and thread take-up holding shaft t, and remove one or two thread take-up holding(s) u.

• After replacing the thread take-up lever, reverse the above procedure for re-assembly.

q.

[Notes on re-assembly]

• When attaching the thread take-up lever y and the thread take-up holding u, provide a 0.5 mm clearance from the end of the

thread take-up holding

thread take-up lever y and the thread take-up holding u should be as shown in figure A; the thread take-up holding u should

be inserted into the thread take-up boss

• When the pulley is at 100 degrees (stop position), the thread take-up lever

u to both the thread take-up shaft bush i and the thread take-up holding bush o. The positions of the

!0 without touching the thread take-up lever y.

y should be the same height as the others.

BES-960BC.1260BC

19

Chapter 2 Parts Replacement and Adjustment

4. Replacing the needle bar

o

t

e

y

i

u

r

q

w

o

e

t

r

y

!0

Tighten the bolt

6 so that

clearance is the

same at all

points.

!0

This part

should not

make

contact with

anything

nearby.

!0

1. Remove the set screw q and the needle w.

2. Remove the needle bar thread guide e from the needle bar r.

3. Loosen the bolt

4. Remove the needle bar

clamp, and the spring will come off.)

• After replacing the needle bar, reverse the above procedure for re-assembly.

y of the top dead center stopper t and the screw i of the needle bar clamp u.

r by pulling it downward. (The cushion rubber, the top dead center stopper, the needle bar

[Notes on re-assembly]

• Attach the needle bar thread guide e with its hole facing the front.

• Adjust bottom dead center using the bottom dead center gauge.

• Adjust the top dead center stopper by pressing it against the cushion rubber

the needle bar clamp are securely fixed in position (when the "❚" mark on the pulley is aligned with the one on the belt cover),

and pressing the needle bar clamp downward.

Make sure that the top dead center stopper does not make contact with the needle bar guide rail

• When tightening the bolt

the bolt head, and tighten it (Tightening torque: 8 kg•cm).

Note:

• If the bolt is tightened too much, the needle bar may be sluggish.

• After re-assembly, make sure that the needle bar can be retracted to the top dead center when it is pressed down

and released.

y of the top dead center stopper, use the accessory wrench, insert the longer side of the wrench into

o at top dead center when the jump bracket and

!0.

20

BES-960BC.1260BC

5. Replacing the jump bracket

w

r

e

y

q

q

w

Chapter 2 Parts Replacement and Adjustment

u

t

y

r

70°

t

i

1. Loosen the screw q on the left of the head.

2. Remove the base needle bar w by pulling it from above. (The needle bar vertical set e will come off.)

3. Loosen the screw of the jump clamp

bar bush

• After replacing the jump bracket, reverse the above procedure for re-assembly.

t. (The jump spring u will come off.)

r, and remove the jump clamp r and the jump bracket y from the base needle

[Notes on re-assembly]

• When loosening the screw of the jump bracket q, pay attention to the position of the base needle bar bush t (the spring

strength). Turn the jump bracket

faces the front). Tighten the screw so that the jump bracket y can be moved easily but have no looseness vertically (it can be

moved vertically only 0.03 - 0.05 mm).

• When attaching the base needle bar, align it with the bottom of the head.

y 70 degrees from the natural state (where the flat surface i of the base needle bar bush t

BES-960BC.1260BC

21

Loading...

Loading...