Page 1

INSTRUCTION MANUAL

BE-1204B-BC

BE-1206B-BC

Stand-Alone type

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

TWELVE NEEDLE FOUR HEAD EMBROIDERY MACHINE

TWELVE NEEDLE SIX HEAD EMBROIDERY MACHINE

Page 2

Page 3

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

jury

please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up lever, and consequently there is always a danger

of injury that can be caused by these parts. Follow the instructions from training personnel and

instructors regarding safe and correct operation before operating the machine so that you will know

how to use it correctly.

SAFETY INSTRUCTIONS

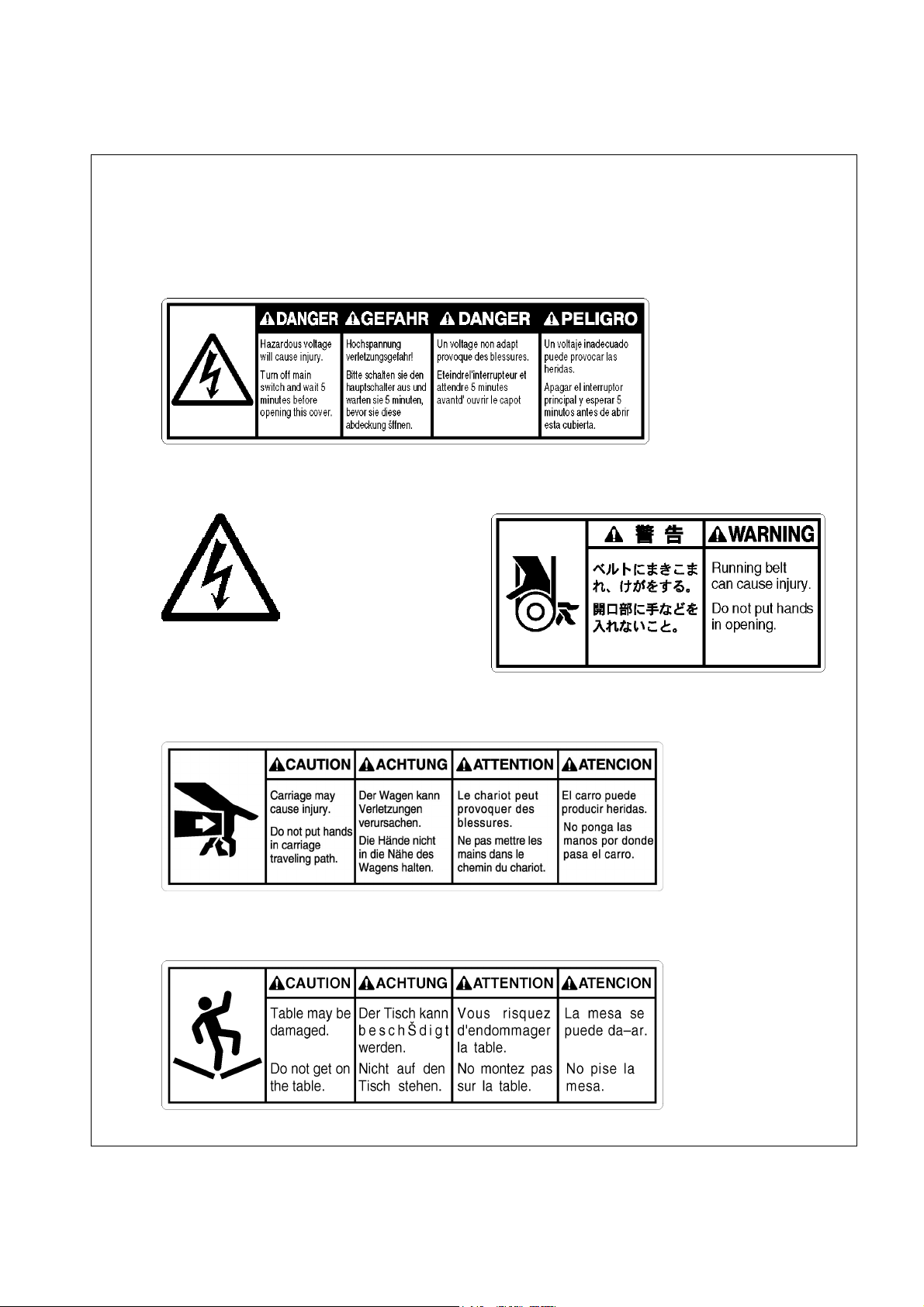

1 Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are

provided in order to ensure safe operation of this machine and to prevent accidents and injury to

yourself or other people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

-------- This symbol (

The picture inside the triangle indicates the nature of the caution that must be taken. (For

example, the symbol at left means "beware of injury".)

--------- This symbol (

--------- This symbol (

The picture inside the circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

The instructions which follow this term indicate situations where failure to

follow the instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to

follow the instructions could cause in

damage to equipment and surroundings.

) indicates something that you should be careful of.

) indicates something that you must not do.

) indicates something that you must do.

when using the machine or physical

BE-1204B-BC • BE-1206B-BC 1

Page 4

2 Notes on safety

p

g

y

g

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall

outlet before o

can result in severe injury.

ening the face plate of the control box. Touching areas where high voltages are present

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is

free from sources of strong electrical noise

such as high-frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within ±10% of the rated volta

the machine.

Voltage fluctuations which are greater than

this may cause problems with correct

operation.

The power supply capacity should be greater

than the requirements for the sewing

machine's electrical consumption.

Insufficient power supply capacity may cause

problems with correct operation.

The air supply should have a capacity greater

than the machine consumption. If air is not

supplied sufficiently, a machine malfunction

may occur.

e for

Installation

Machine installation should only be carried

out by a qualified technician.

Never operate the sewing machine with any

ventilation openings blocked.

Keep the ventilation openings of the sewing

machine free from the accumulation of lint or

dust.

The ambient temperature should be within the

range of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidit

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems

with correct operation.

In the event of an electrical storm, turn off the

power and disconnect the power cord from the

wall outlet.

Lightning may cause problems with correct

operation.

Do not use this machine outdoors.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

should be within the range of

Contact your Brother dealer or a qualified

electrician for any electrical work that may

need to be done.

The sewing machine weights more than 700

Kg (600 Kg in four head models).

The installation should be carried out by four

or more people.

Do not connect the power cord until

installation is complete, otherwise the

machine may operate if the start switch is

pressed by mistake, which could result in

injury.

2 BE-1204B-BC • BE-1206B-BC

Be sure to wear protective goggles and gloves

when handlin

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Secure the machine with the adjustment bolts on

the sound floor so that it will not move.

the lubricating oil or grease, so that

Page 5

Avoid setting up the sewing machine near

p

g

sources of strong electrical noise such as

high-frequency welding equipment.

If this precaution is not taken, incorrect

machine operation may result.

Installation

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary

training in safe use beforehand.

Keep children away from the sewing machine.

The sewing machine should not be used for

any applications other than sewing.

Be sure to wear protective goggles when

using the machine.

If goggles are not worn, there is the danger

that if a needle breaks, parts of the broken

needle may enter your eyes and injury may

result.

Always use the proper needle plate. Any

wrong plate can cause needles to break.

Do not use a bent needle.

Turn off the power switch at the following

times, otherwise the machine may operate if

the start switch is pressed by mistake, which

could result in injury.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when

leaving the machine unattended

• When cleaning the machine.

Do not get on the table.

Table may be damaged.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any moving parts, press any objects

against the machine, or pull/push the cloth during

sewing. Doing so may result in personal injury,

machine damage, or needle breakage.

Do not touch the

bed section during operation or for 30 minutes

after operation. Otherwise burns may result.

Never drop or insert foreign objects or a

screwdriver into the ventilation openings or the

machine inside.

Touching any high-voltage area may result in an

electric shock.

Never damage, alter, heat, or put a strain on the

power cable as well as other cables. Doing so

may result in a fire or an electric shock.

If the controller is exposed to water or a chemical

agent or if its entry is found inside the controller,

turn off the power switch immediately.

Continuing to use the machine under such a

condition may result in a fire or an electric shock.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed,

immediately turn off the power switch. Then

contact your nearest Brother dealer or a qualified

technician.

ulse motor and sewing machine

Do not operate this machine where aerosol

(spray) products are being used or where

oxygen is being administered.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Cleaning

Turn off the power switch before starting any

cleaning work, otherwise the machine may

operate if the start switch is pressed by

mistake, which could result in injury.

BE-1204B-BC • BE-1206B-BC 3

Be sure to wear protective goggles and gloves

when handlin

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

the lubricating oil or grease, so that

Page 6

Maintenance and inspection

p

ying

Maintenance and inspection of the sewing

machine should only be carried out by a

qualified technician.

Ask your Brother dealer or a qualified

electrician to carry out any maintenance and

inspection of the electrical system.

Turn off the power switch and disconnect the

power cable (do not pull on the cable itself)

from the wall outlet before attempting to

erform the following operations. Otherwise,

the machine is started if the start switch is

pressed by mistake. Injury may occur in

such a case.

• When carr

or maintenance

• When replacing consumable parts such

as a rotary hook, a knife, or a fluorescent

lamp

out inspection, adjustment,

If the power switch needs to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

Use only the proper replacement parts as

specified by Brother.

When replacing a fluorescent lamp, use the

same-type lamp having a rating of 40 watts.

Wait until the fluorescent lamp cools off before

replacement. Failure to do so can result in

burns.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine

will not be covered by the warranty.

4 BE-1204B-BC • BE-1206B-BC

Page 7

3 Warning labels

* The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels

have been removed or are difficult to read, please contact your nearest Brother dealer.

1 Electric shock danger display

W1408Q

2 Electric shock danger display 3 Injury warning display

Hazardous voltage will

cause injury.

4 Injury caution display

5 Injury caution display

W1410Q

W1200Q

W1202Q

BE-1204B-BC • BE-1206B-BC 5

Page 8

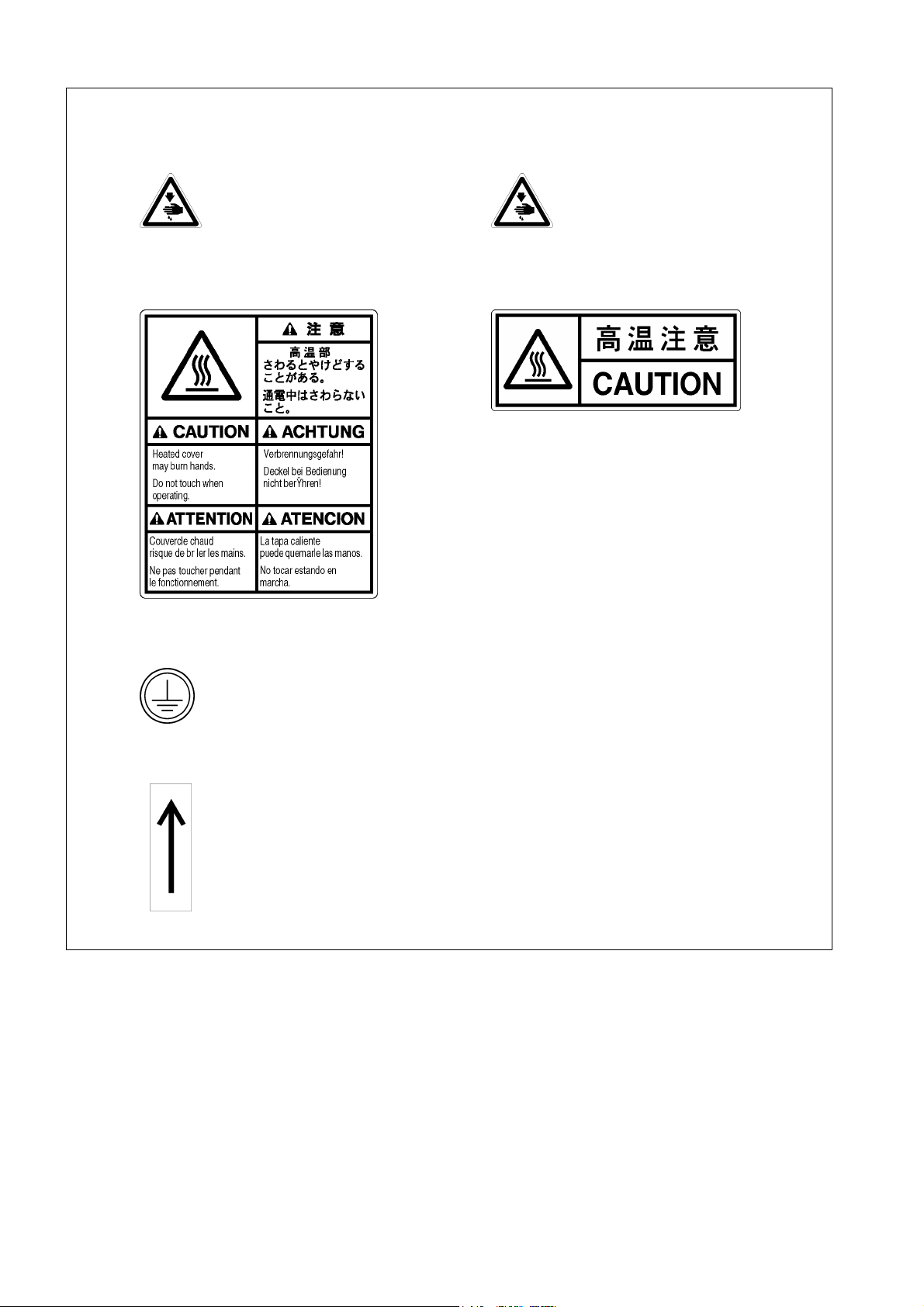

6 Injury caution display

7 Injury caution display

Never touch or push the

thread take up during

operation as it may result in

injuries machine.

Never touch or push the needle

bar during operation as it may

result in injuries or damage to

the sewing machine.

8 High temperature caution display 9 High temperature caution display

W1206Q

Do not touch this part during activitation

or for 30 minutes after shut-off. Otherwise

burns may result.

W1201Q

10 Ground mark

Be sure to connect the ground. If the ground connection is not secure, you run

a high risk of receiving a serious electric shock, and problems with correct

operation may also occur.

11 Direction of operation

W1205Q

6 BE-1204B-BC • BE-1206B-BC

Page 9

10

6

7

5

4

5

2

1

W1207Q

9

8

8

8

4

3

11

4

4

W1208Q

BE-1204B-BC • BE-1206B-BC 7

Page 10

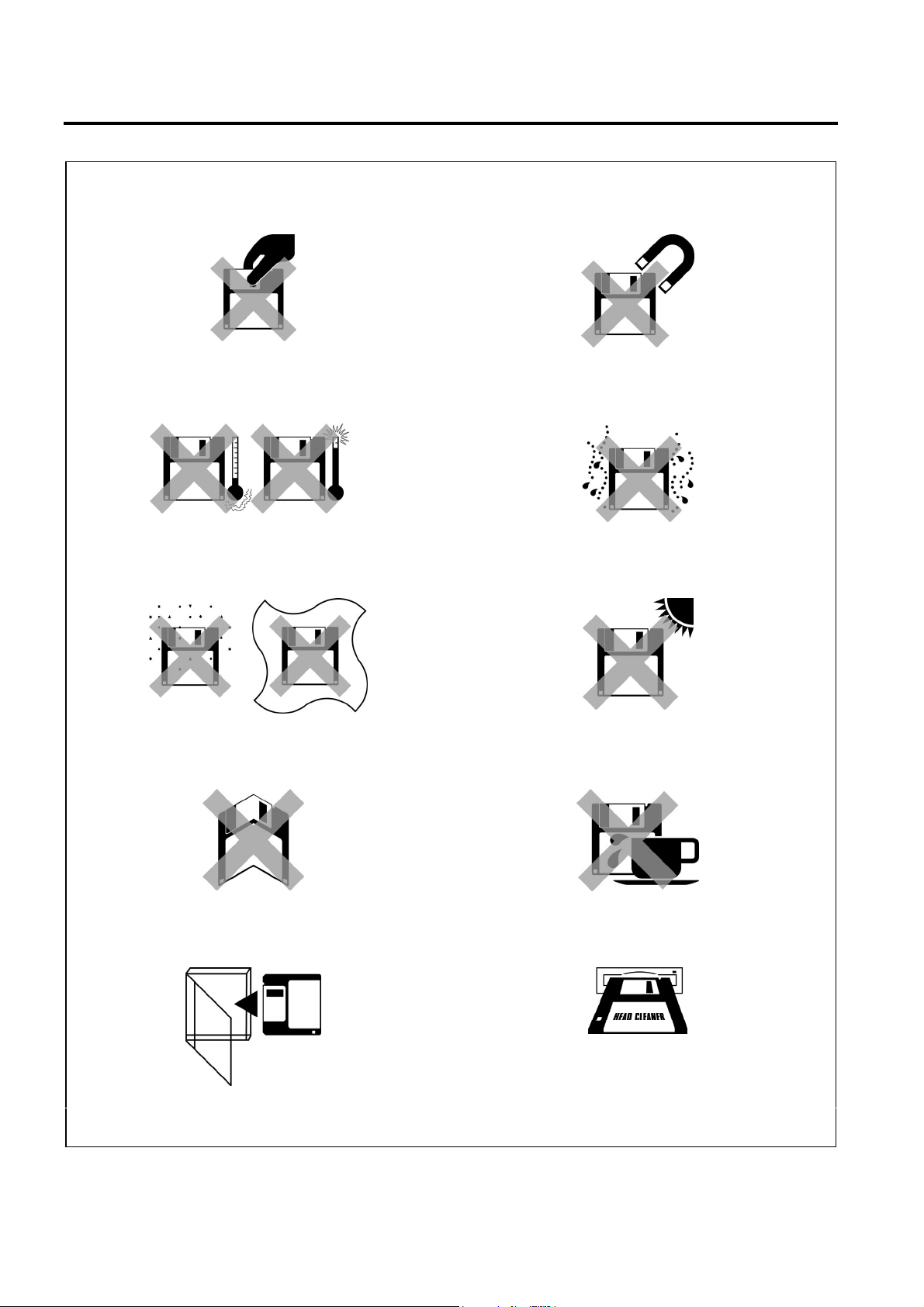

Before Starting Operation

Do not force open the shutter for direct contact

with the magnetic area.

W1209Q

Do not store floppy disks in an extremely high or

low ambient temperature.

W1211Q

Do not use or store floppy disks in a dusty place.

Do not place it on cloth.

Do not bring disks near magnetic matters such as

magnetic screwdriver or the back side of the

programmer.

W1210Q

Do not use floppy disks under high humidity.

W1212Q

Do not store floppy disks under direct sunlight.

W1213Q

Do not bend the disk. Do not put things on the

Avoid contact with solvent or drink.

disk.

W1215Q

Store it in the case immediately after using it to

protect it from dust and damage.

W1217Q

Use a commercially available cleaning disk to clean

the head of the floppy disk drive periodically.

Do not remove the disk out of the drive during the access lamp is lit.

W1214Q

W1216Q

W1218Q

8 BE-1204B-BC • BE-1206B-BC

Page 11

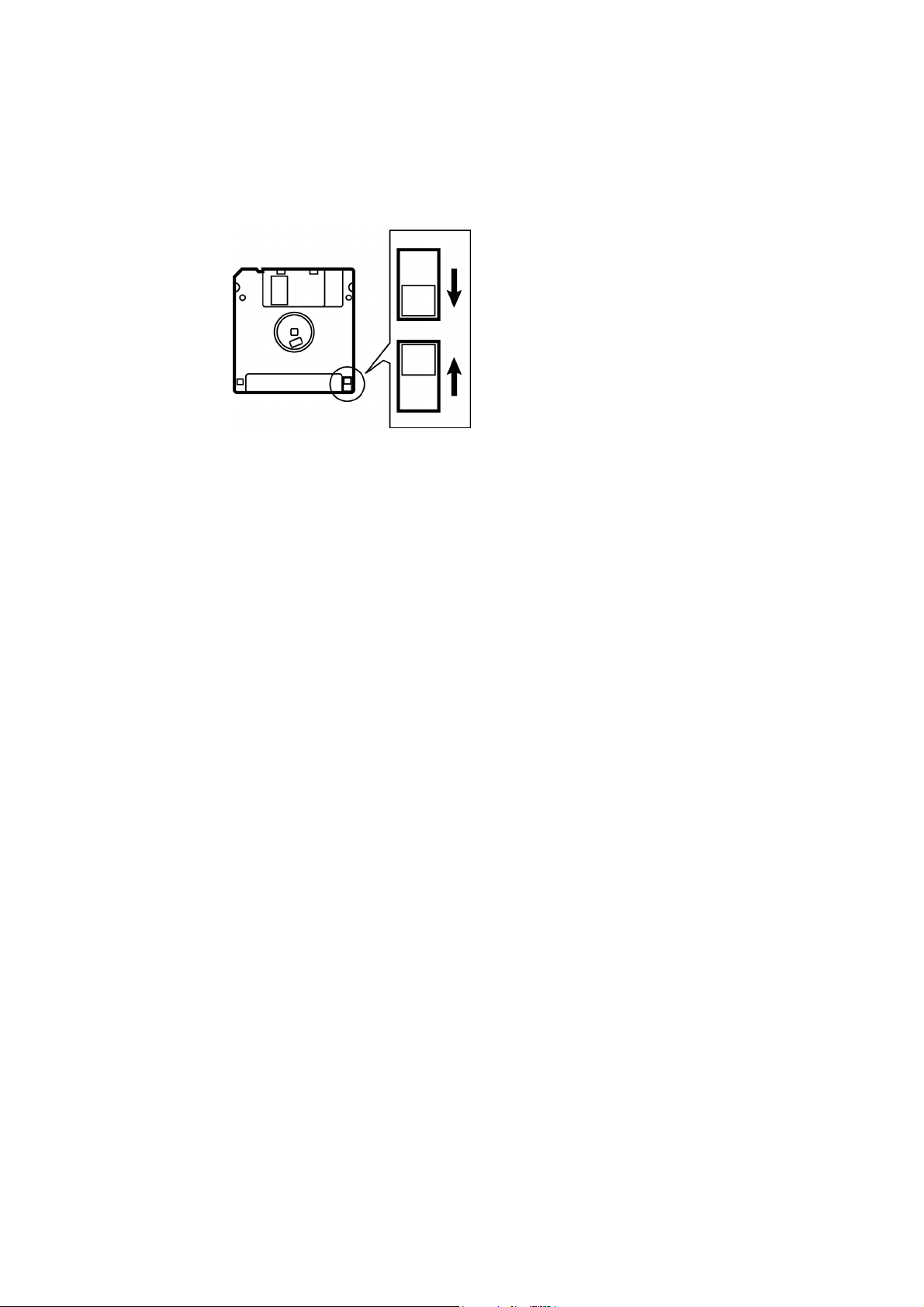

Protecting data in floppy disks

Write-protection is available for a floppy disk to prevent undesired data deletion.

A write-protected disk is read-only. It is recommended to provide write-protection for disks which

contain important data.

To do so, slide the write-protect notch to open the slot as shown below.

Slide the notch in this direction to

prevent data loss or overwriting.

Slide the notch in this direction to

write data.

W1219Q

BE-1204B-BC • BE-1206B-BC 9

Page 12

Procedure of Reading This Manual

Explanation of models

This manual explains two models:

- BE-1204B-BC

- BE-1206B-BC

Explanation for individual model is provided by identifying the model name. Check the model before

using the machine. The display is BE-1206B-BC.

Configuration of this manual

This manual consists of the following chapters:

Chapter 1 Preparation of Embroidery Machine

This Chapter describes the specifications, installation and preparatory procedures of starting up

the machine.

Chapter 2 Embroidering Procedures

Provides explanations on the operation panel and briefly reviews the flow of embroidering

processes.

Chapter 3 Selection of Data and Embroidering

This Chapter describes procedures of reading sewing data and sewing.

Chapter 4 Editing of Embroidering Data

Explains how to edit the embroidery data.

Chapter 5 Setting

This Chapter describes procedures of setting the machine and working environment.

Chapter 6 Operation of Machine

Provides information on machine operation during embroidering.

Chapter 7 Maintenance

Describes appropriate maintenance of the machine.

Chapter 8 Adjustment

Explains how to adjust the needles.

Chapter 9 List of Error Messages

Provides information on error codes and action to be taken.

Chapter 10 Troubleshooting

Provides troubleshooting for the machine.

Chapter 11 Connection and Installation of Optional Equipment

Describes connections between the machine/computer and optional equipment available.

10 BE-1204B-BC • BE-1206B-BC

Page 13

BE-1204B-BC • BE-1206B-BC 11

Page 14

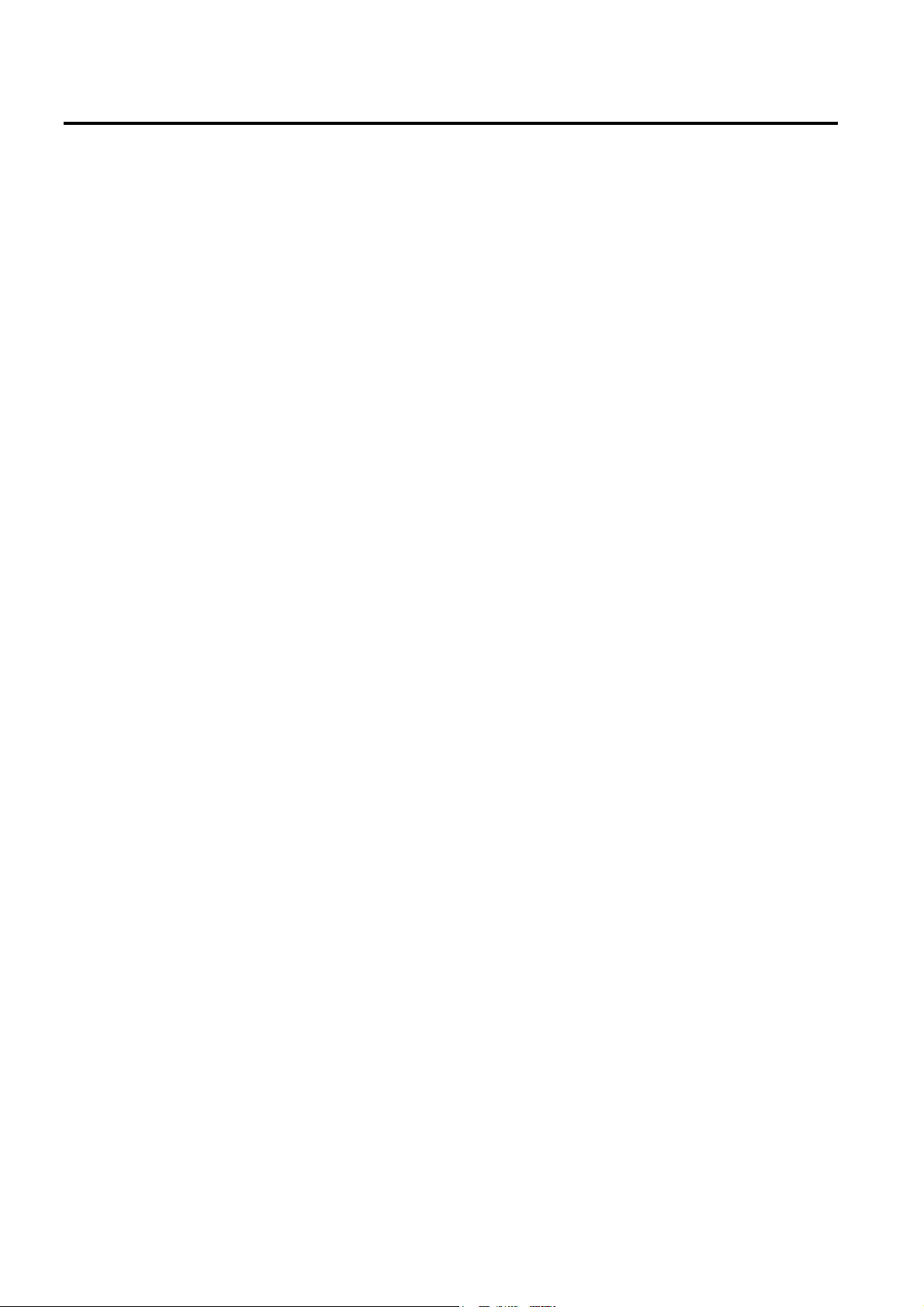

Screen Composition

A

Initial Screen

W0406Q

Starting Sewing

Operation (→ page 3-17)

Canceling of Sewing

Thread trimming

Hoop Retract

Selection of Embroidery data

(→ page 3-3)

W0397Q

Setting of Needle Bars

(→ page 5-4)

W0481Q

rea Check

Editing of Embroidery data

(→ page 4-1)

W0451Q

W0465Q

W0601Q

12 BE-1204B-BC • BE-1206B-BC

Page 15

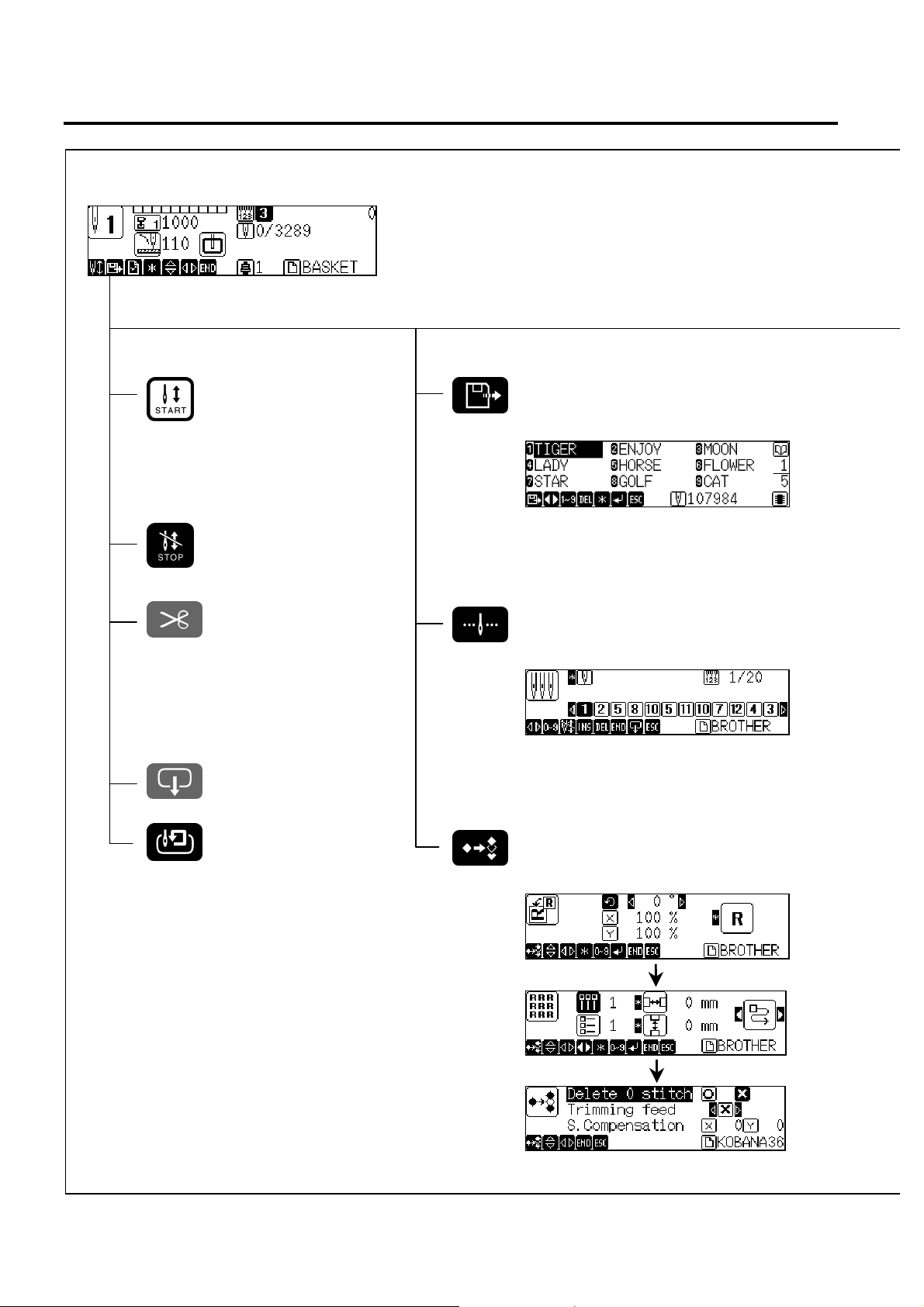

Setting of thread breakage sensor (→ page 5-6)

W0488Q

W0490Q

W0494Q

Setting of Machine (→ page 5-9)

W0609Q

W0620Q

W0621Q

BE-1204B-BC • BE-1206B-BC 13

Page 16

Contents

Contents

SAFETY INSTRUCTIONS................................................................................................................................................. 1

Before Starting Operation ............................................................................................................................................... 8

Procedure of Reading This Manual..............................................................................................................................10

Screen Composition...................................................................................................................................................... 12

Chapter 1 Preparation of Embroidery Machine

1. Specifications ........................................................................................................................................................... 1-2

2. Names of Machine Components ............................................................................................................................. 1-4

3. Installation.................................................................................................................................................................1-5

3-1 Transportation of Machine................................................................................................................................. 1-5

3-2 Installation of Machine.......................................................................................................................................1-7

3-3 Preparation of Needle Bar Case........................................................................................................................1-8

3-4 Mounting of Table .............................................................................................................................................. 1-9

3-5 Mounting of Cotton Stand................................................................................................................................ 1-12

3-6 Lubrication to Needle Bar Case.......................................................................................................................1-13

3-7 Grounding........................................................................................................................................................1-14

4. Preparation for Embroidering................................................................................................................................1-15

4-1 Upper Threading..............................................................................................................................................1-15

4-2 Replacement of Bobbin ................................................................................................................................... 1-17

4-3 Replacing and Selecting Needle......................................................................................................................1-19

4-4 Attachment of Embroidery Hoop and Frame ................................................................................................... 1-20

4-5 Adjustment of Thread Tension ......................................................................................................................... 1-24

Chapter 2 Embroidering Procedures

Functions of Operation Panel......................................................................................................................................2-2

Operation Panel.......................................................................................................................................................2-2

Switches at Machine Heads ....................................................................................................................................2-5

Lamps and switches on the thread tension stand .................................................................................................... 2-6

Flowchart of Preparation for Embroidering ...............................................................................................................2-7

Turn on the Machine Power..................................................................................................................................... 2-8

Retrieve the Embroidery Data ................................................................................................................................. 2-9

Start Embroidering................................................................................................................................................... 2-9

Chapter 3 Selection of Data and Embroidering

What Can the Machine Do? .........................................................................................................................................3-2

Selection of Embroidery Data....................................................................................................................... 3-2

Embroidering Operation...........................................................................................................................................3-2

Selection of Data .......................................................................................................................................................... 3-3

Registration of Embroidery Data from Floppy Disk..................................................................................................3-3

Reading from Memory ............................................................................................................................................. 3-7

Registration of Embroidery Data from BES-100E.................................................................................................... 3-8

Deletion of Embroidery Data from Machine Memory ............................................................................................... 3-9

Tape Reader Input Setting ......................................................................................................................................... 3-11

Modification of Embroidery Data Name....................................................................................................................3-13

Sewing Operation....................................................................................................................................................... 3-17

Before Starting Sewing ..........................................................................................................................................3-17

Starting Sewing Operation..................................................................................................................................... 3-17

Feedhold and Cancellation of Sewing ................................................................................................................... 3-18

Step Forward and Step-Back.....................................................................................................................................3-19

Step Forward/Step-Back Mode.............................................................................................................................. 3-19

Setting Amount or Timing of Step Forward/Step-Back........................................................................................... 3-19

14 BE-1204B-BC • BE-1206B-BC

Page 17

For Step Forward (Back) ........................................................................................................................................3-20

Resuming Sewing ..................................................................................................................................................3-20

Writing the embroidering data ...................................................................................................................................3-21

Chapter 4 Editing of Embroidering Data

What Can the Machine Do?..........................................................................................................................................4-2

Editing.............................................................................................................................................................4-2

Rotation .........................................................................................................................................................................4-3

Enlargement and Reduction ........................................................................................................................................4-4

Mirror .............................................................................................................................................................................4-6

Repetition ......................................................................................................................................................................4-8

Other Editing ...............................................................................................................................................................4-10

Chapter 5 Setting

What Can the Machine Do?..........................................................................................................................................5-2

Setting of Needle Bars..................................................................................................................................5-2

Setting of Thread Breakage Sensor .............................................................................................................5-2

Setting of Machine........................................................................................................................................5-2

Setting of Environment .................................................................................................................................5-2

Setting of Lock Stitch ......................................................................................................................................5-3

Setting of speed limit in a small pitch..............................................................................................................5-3

Display of Information...................................................................................................................................5-3

Hoop Retract Point .......................................................................................................................................5-3

Hoop Movement.......................................................................................................................................................5-3

Setting of Needle Bars..................................................................................................................................................5-4

Thread Breakage Sensor..............................................................................................................................................5-6

Setting of sensor validity/invalidity............................................................................................................................5-6

Thread Breakage Sensitivity ....................................................................................................................................5-6

Automatic Step-Back................................................................................................................................................5-7

Setting of Lower Thread Counter/Stitch Counter......................................................................................................5-8

Setting of Machine........................................................................................................................................................5-9

Embroidery Hoop .....................................................................................................................................................5-9

Speed Range .........................................................................................................................................................5-10

Speed of Each Speed Range................................................................................................................................. 5-11

Setting of Mending .................................................................................................................................................5-12

Thread Trimming Length ........................................................................................................................................5-14

Thread Withdrawal Feed Length ............................................................................................................................5-15

Inching ...................................................................................................................................................................5-16

Sewing Area...........................................................................................................................................................5-17

Registration of Sewing Start Position .....................................................................................................................5-18

Hoop Retract Point.................................................................................................................................................5-18

Hoop Automatic Retract .........................................................................................................................................5-19

Movement to Registered Sewing Start Point..........................................................................................................5-19

Setting of Environment ..............................................................................................................................................5-20

Return to Start Point...............................................................................................................................................5-20

Speed Range .........................................................................................................................................................5-21

Checking the Embroidery Area ..............................................................................................................................5-21

Slow sewing needle number at start-up .................................................................................................................5-22

Setting of RS-232C Communication Speed ...........................................................................................................5-23

Display Language ..................................................................................................................................................5-24

Alarm Sound ..........................................................................................................................................................5-25

Motive Speed .........................................................................................................................................................5-26

Small-Pitch Deletion...............................................................................................................................................5-27

Automatic pause insertion......................................................................................................................................5-28

Contents

BE-1204B-BC • BE-1206B-BC 15

Page 18

Contents

Lock Stitch ............................................................................................................................................................. 5-29

Speed Limit in a Short Pitch...................................................................................................................................5-32

Feed Timing...........................................................................................................................................................5-33

Automatic Input Setting..........................................................................................................................................5-34

Display of Information................................................................................................................................................5-37

Pattern Information ................................................................................................................................................ 5-37

Features of Machine.............................................................................................................................................. 5-38

Information about Versions .................................................................................................................................... 5-39

Chapter 6 Operation of Machine

1. Operating Procedures.............................................................................................................................................. 6-2

1-1 Power Source....................................................................................................................................................6-2

1-2 Preparation for Embroidering............................................................................................................................. 6-2

2. Machine Stop ............................................................................................................................................................ 6-3

2-1 Stopping the Machine........................................................................................................................................ 6-3

2-2 Emergency Stop of the Machine........................................................................................................................6-3

2-3 Resetting Emergency Stop ................................................................................................................................ 6-3

3. Measures against Thread Breakage .......................................................................................................................6-4

3-1 Remedies ..........................................................................................................................................................6-4

3-2 Mending.............................................................................................................................................................6-5

4. Jog Embroidering..................................................................................................................................................... 6-7

5. Hoop Feed Position.................................................................................................................................................. 6-8

6. Area Check................................................................................................................................................................ 6-9

6-1 External Tracing.................................................................................................................................................6-9

6-2 Automatic Hoop Movement in Area ................................................................................................................... 6-9

7. Jog Switches...........................................................................................................................................................6-10

7-1 Hoop Movement to Start Position .................................................................................................................... 6-10

7-2 Inching Mode during Embroidering (Forcible Hoop Movement) ...................................................................... 6-11

8. Detection of Home position................................................................................................................................... 6-12

Chapter 7 Maintenance

1. Cleaning .................................................................................................................................................................... 7-2

1-1 Cleaning and Lubrication of Rotary Hook .......................................................................................................... 7-2

1-2 Cleaning of Needle Plate................................................................................................................................... 7-3

2. Oiling .........................................................................................................................................................................7-4

2-1 Head.................................................................................................................................................................. 7-4

2-2 Lower shaft........................................................................................................................................................ 7-5

3. Greasing....................................................................................................................................................................7-6

3-1 Cam grooves ..................................................................................................................................................... 7-6

3-2 Lower gear ........................................................................................................................................................7-8

3-3 Diving shaft........................................................................................................................................................7-8

3-4 Needle bar flip-up mechanism........................................................................................................................... 7-9

3-5 Feed Guide Section.........................................................................................................................................7-10

16 BE-1204B-BC • BE-1206B-BC

Page 19

Chapter 8 Adjustment

1. Adjusting Needle Bar Height....................................................................................................................................8-2

2. Attachment and Adjustment of Rotary Hook ..........................................................................................................8-6

3. Adjustment of Presser Foot Height .........................................................................................................................8-8

4. Adjustment of Thread Trimmer ................................................................................................................................8-9

4-1 Attaching the Fixed Knife ...................................................................................................................................8-9

4-2 Checking the Movable Knife Position.................................................................................................................8-9

5. Thread Wiper Adjustment ......................................................................................................................................8-12

Chapter 9 Error code list

Chapter 10 Troubleshooting

Mechanical Section.....................................................................................................................................................10-2

Electrical Section........................................................................................................................................................10-4

Chapter 11 Connection and Installation of Optional Equipment

1. Attaching Bobbin Winder .......................................................................................................................................11-2

Contents

BE-1204B-BC • BE-1206B-BC 17

Page 20

Contents

18 BE-1204B-BC • BE-1206B-BC

Page 21

Chapter 1

Preparation of Embroidery Machine

Page 22

Chapter 1 Preparations of operation

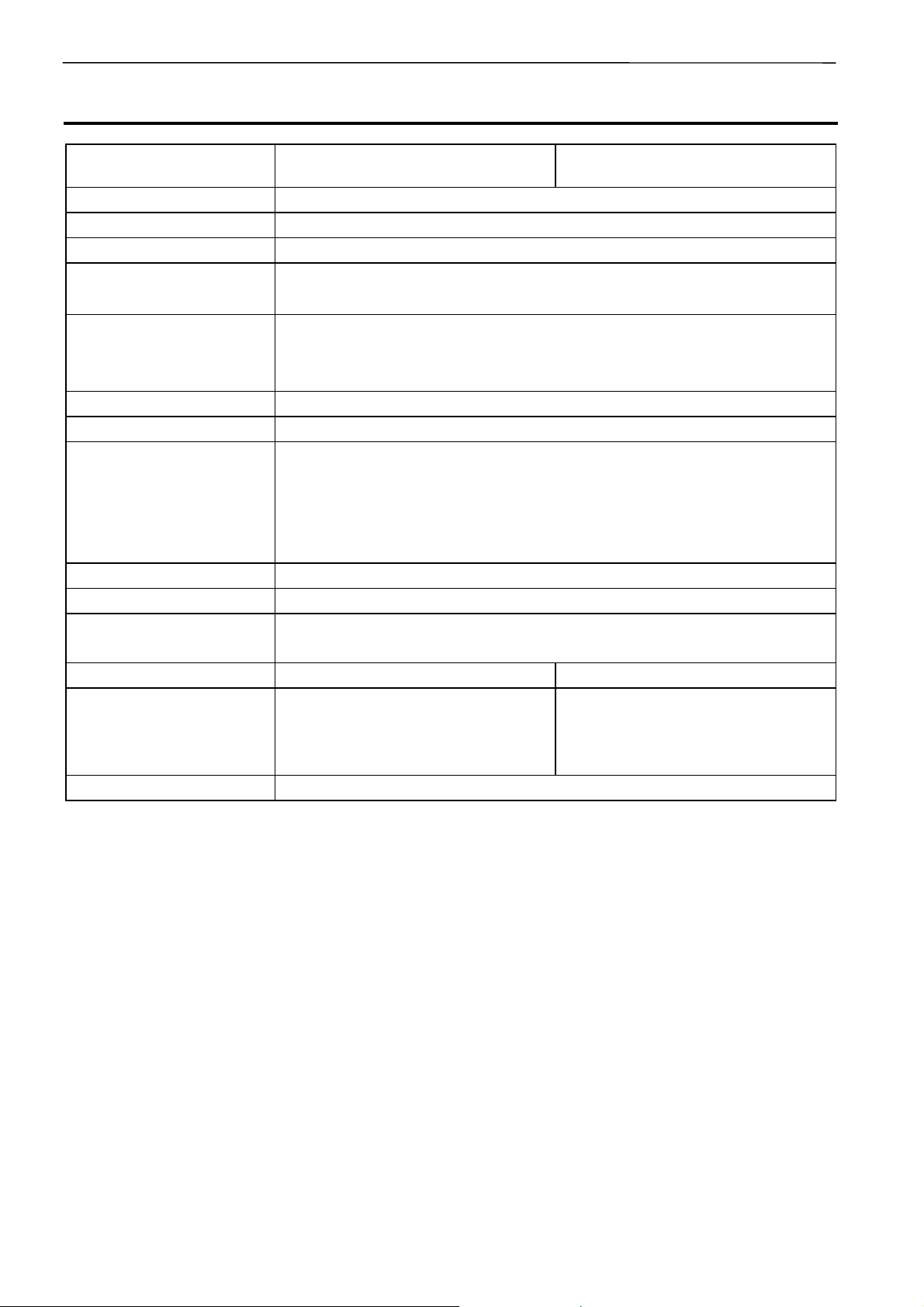

1. Specifications

Embroidery machine used

Application Pattern embroidery

Sewing speed Maximum 1000 rpm

Distance between heads 360 mm

Maximum feed range

Sewing area

Feed system By timing belt and stepping motor drive

Stitch length 0.1 ~ 12.7 mm (minimum pitch: 0.1 mm)

Storage medium

Thread trimming Automatic thread trimmer

Thread breakage detect Upper and lower thread breakage detector

Power supply

Weight 700 kg 600kg

Dimensions

Options Embroidery hoops in different sizes, Bobbin winder

12 needle six-head embroidery

machine

450 (V) × 360 (H) mm

95 (V) × 360 (H) mm (With cap frame)

450 (V) × 360 (H) mm (With sash frame)

430 (V) × 300 (H) mm (With maximum-size tubular square hoop/flat hoop)

85 (V) × 360 (H) mm (With cap frame)

3.5 2DD floppy disk (Tajima format)

3.5 2HD floppy disk (the equivalent to Tajima format)

3.5 2DD floppy disk (Barudan FDR/FMC format)

3.5 2DD floppy disk (ZSK format)

3.5 floppy disk (brother ECS format)

Single phase 200 V, 220 V, 230 V, 240 V,1.7 kVA

Flourescent lamp: 92VA 49W (Maximum)

(Before assembly)

3036 (W) × 800 (L) × 1405 (H) mm

(After setup)

3112 (W) × 1345 (L) × 1750 (H) mm

12 needle four-head embroidery

machine

(Before assembly)

2320 (W) × 800 (L) × 1405 (H) mm

(After setup)

2396 (W) × 1345 (L) × 1750 (H) mm

1-2 BE-1204B-BC • BE-1206B-BC

Page 23

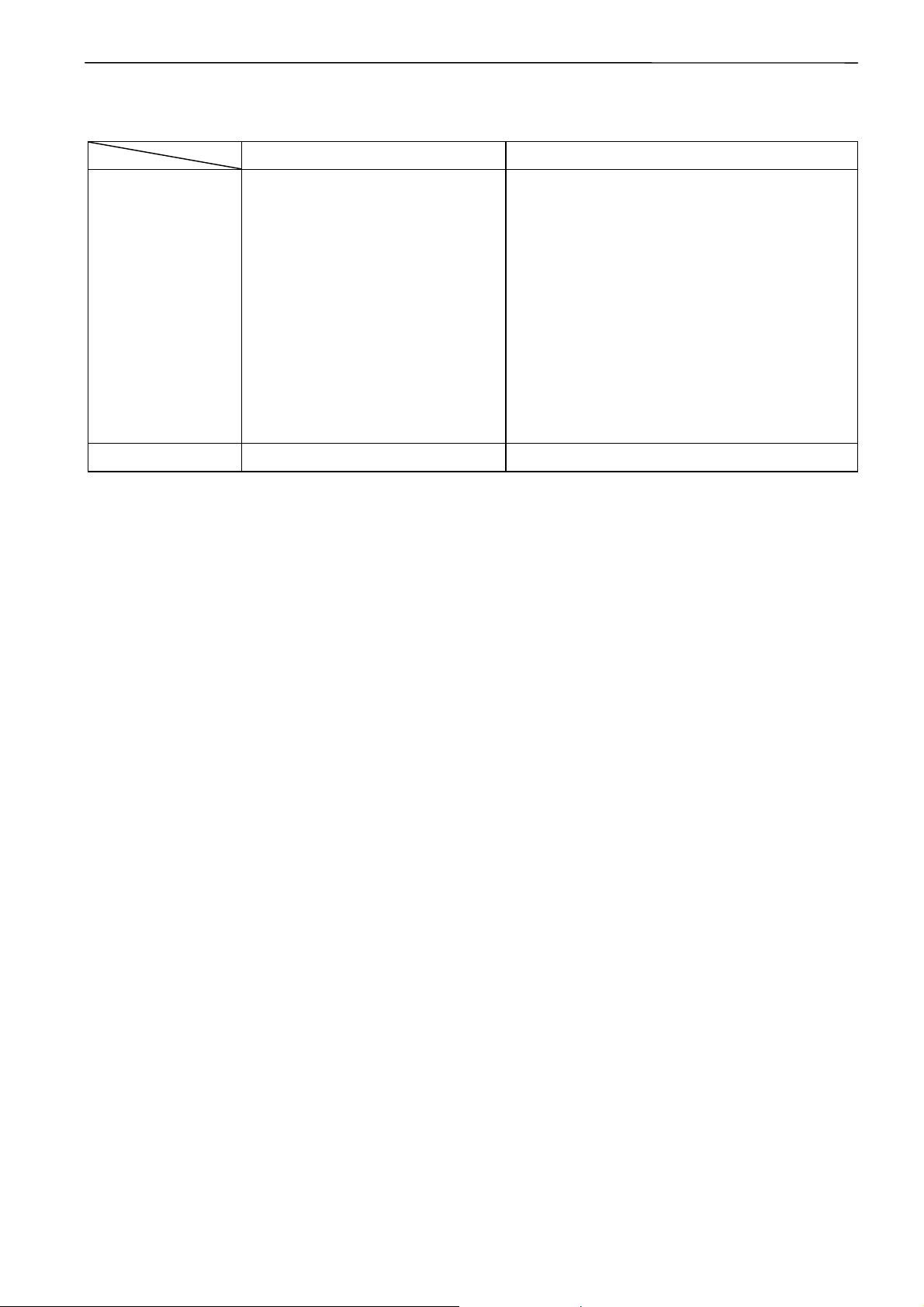

Accessories

Chapter 1 Preparations of operation

Standard Accessories Optional Accessories

Embroidery hoop

• Tubular square hoop 26 × 43

(6 head: 6, 4 head: 4)

• Tubular round arm set

• Holder base 30 × 43

(6 head: 6, 4 head: 4)

Other embroidery hoops in different sizes

(6 head: 7, 4 head: 5)

• Sash frame assembly

* Other Tajima embroidery hoops that can

be used with BAS-412A and BES-916AC

• Cap frame (6 head: 6, 4 head: 4)

Cap frame drive assembly

(6 head: 6, 4 head: 4)

Base frame set

(6 head: 12, 4 head: 8)

Set frame base set (1)

Others Table assembly • Bobbin winder

BE-1204B-BC • BE-1206B-BC 1-3

Page 24

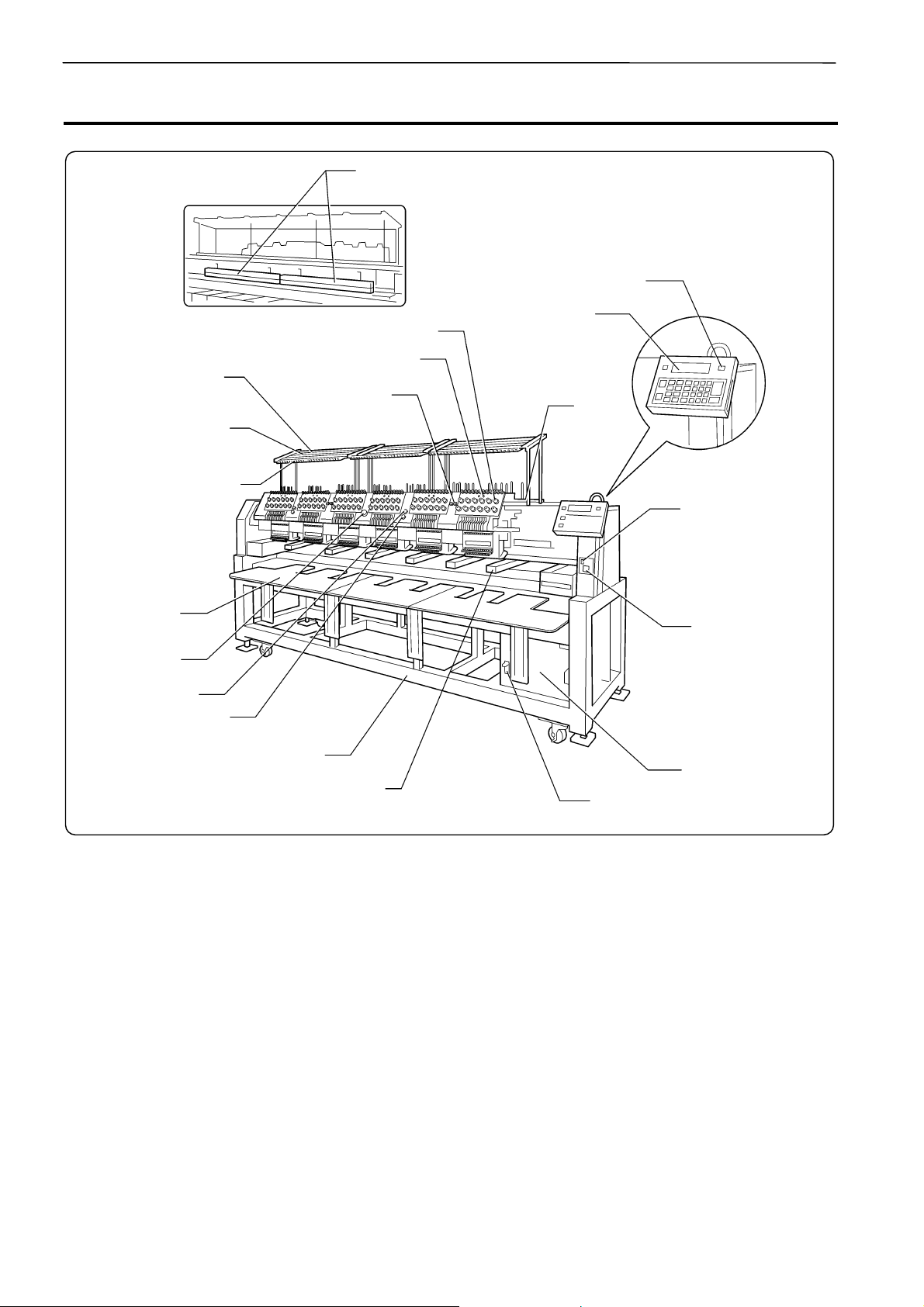

Chapter 1 Preparations of operation

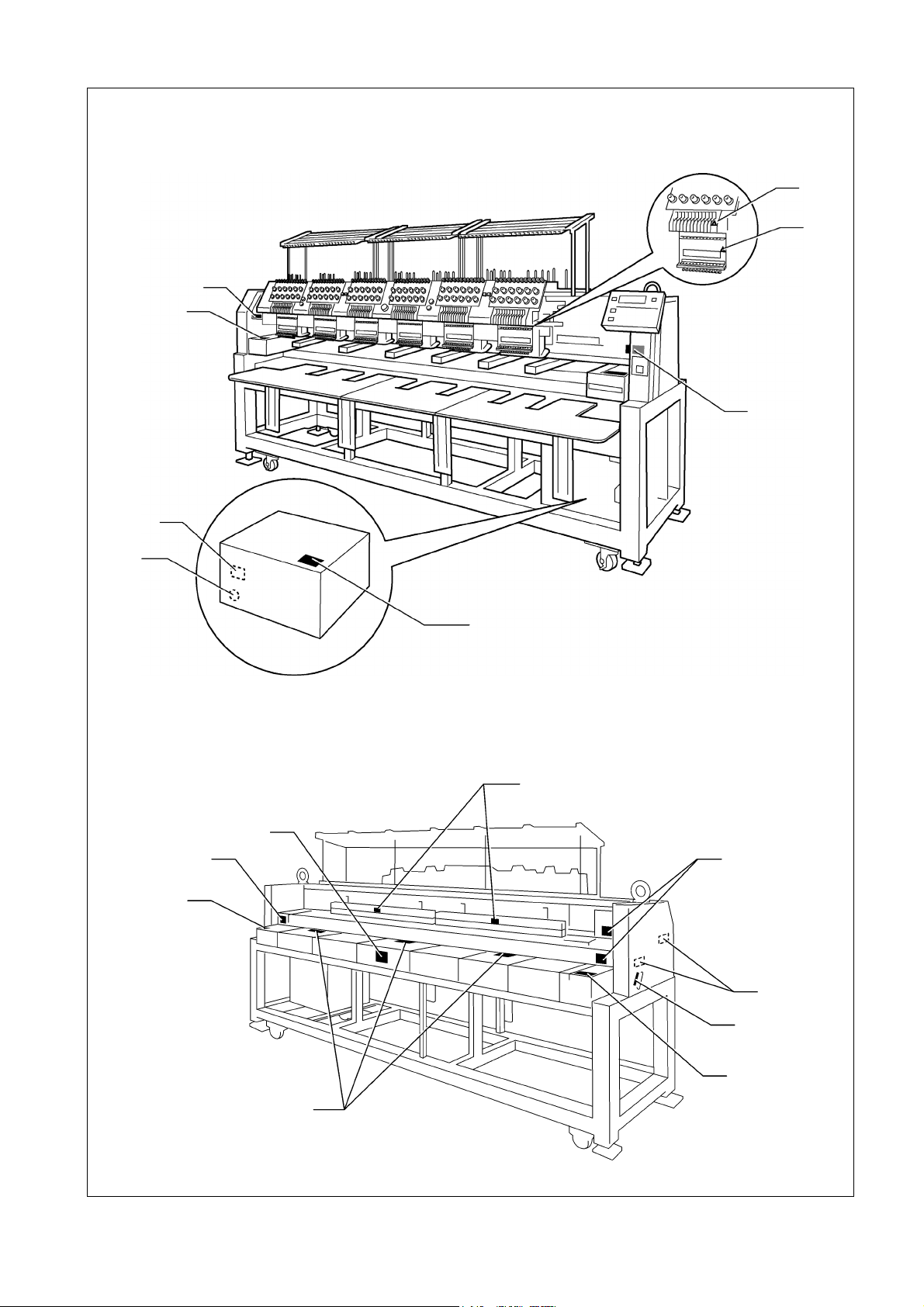

2. Names of Machine Components

Fluorescent lamp switch

Flat / Cap hoop select switch

Operation panel

Thread tension dial

Thread tension base switch

Thread guide C

STEP BACK /

FWD switch

Thread guide B

Thread guide A

Cotton

stand

Fluorescent lamp

switch

Table

Emergency stop

switch

Start switch

Stop switch

Leg

Rotary hook cover (Safety device)

Main power switch

Power switch

Control box

The machine heads are numbered 1 to 6 (1 to 4 in four head models) from the right front.

W1220Q

1-4 BE-1204B-BC • BE-1206B-BC

Page 25

3. Installation

y

q

Chapter 1 Preparations of operation

DANGER

Embroidery machines should be installed onl

by trained engineers.

Electric wiring should be laid by your

distributor or electric experts.

The sewing machine weights more than

700 Kg (600 Kg in four head models).

The installation should be carried out by four

or more people.

Do not connect the power source until

installation is completed. Doing so may start

the machine unintentionally through an

accidental activation of the START switch,

resulting in bodily injuries.

Install a machine in a place away from a highfre

uency welding machine or other machines that

may generate a strong electric noise. Failure to

do so may cause the embroidery machine to

malfunction.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Secure the machine with the adjustment bolts on

the sound floor so that it will not move.

After installation is completed, get the power supply from a dedicated outlet.

When connecting multiple machines, exercise care not to exceed the capacity of the outlet.

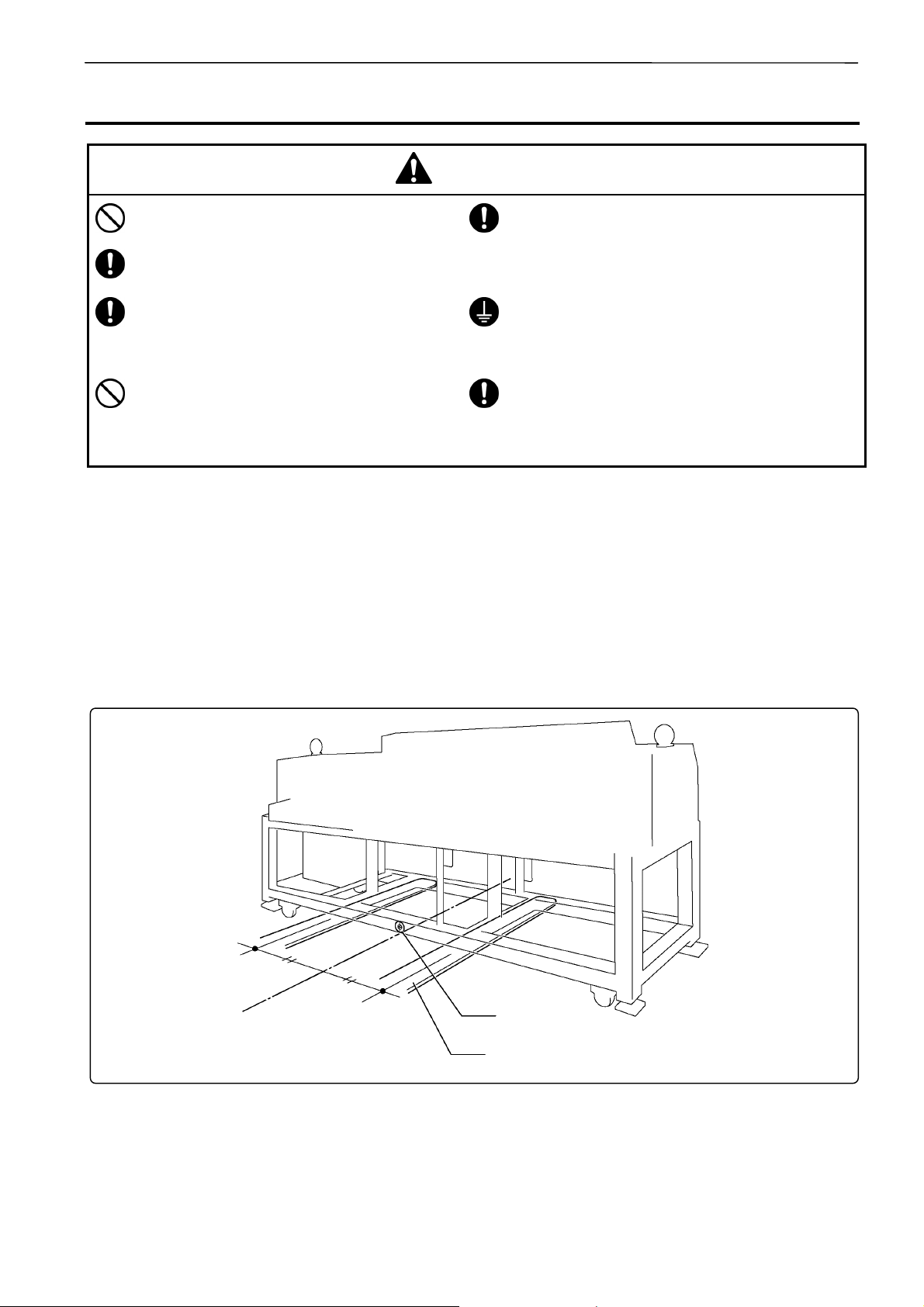

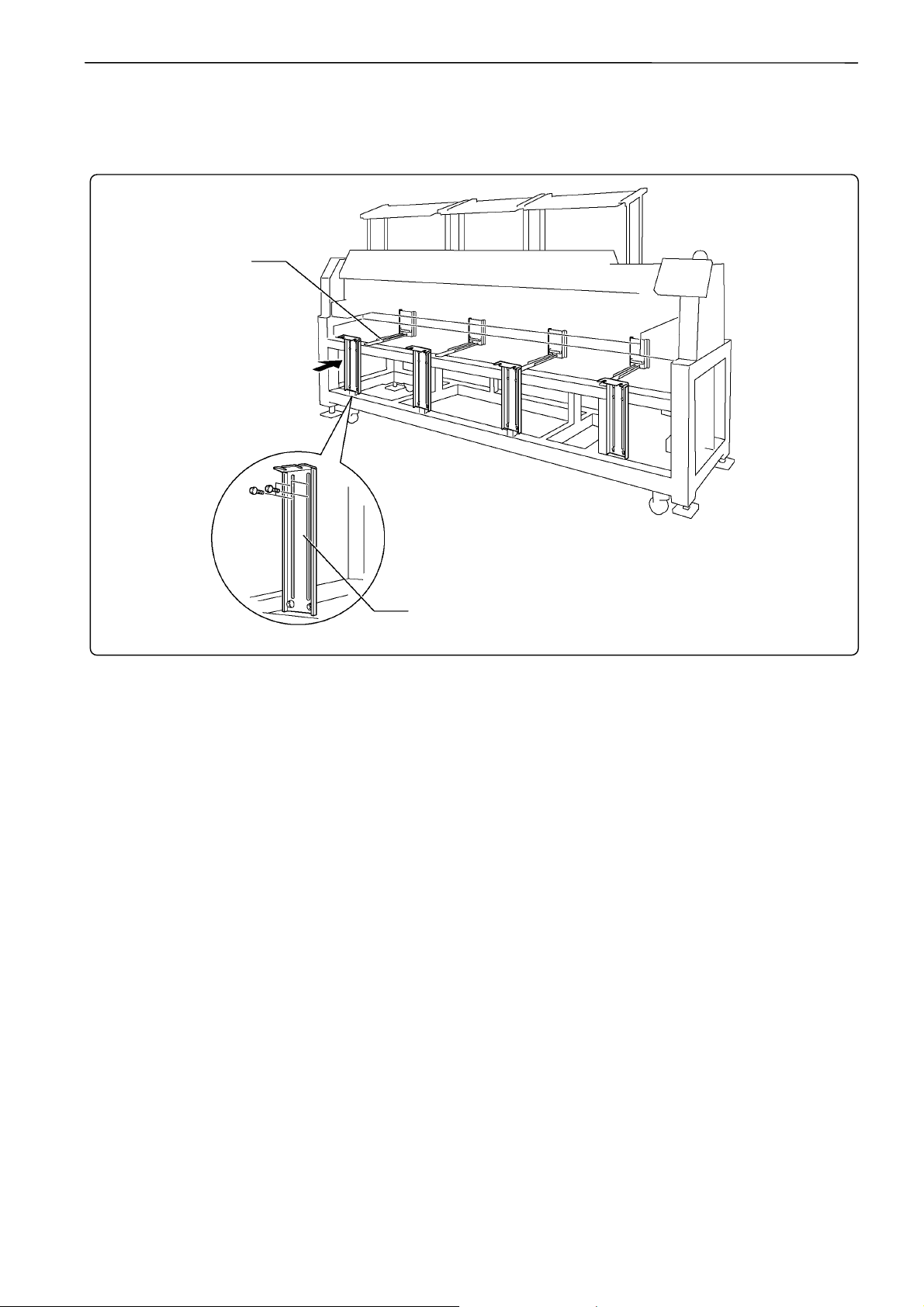

3-1 Transportation of Machine

When relocating the machine, push the steel frame. Never push the cover or carriage.

!!!! When using a fork lift

The central seal

Lift forks

W1222Q

1. Viewing the machine from the back, position their center at the central seal, insert the forks under

the legs and lift the machine.

BE-1204B-BC • BE-1206B-BC 1-5

Page 26

Chapter 1 Preparations of operation

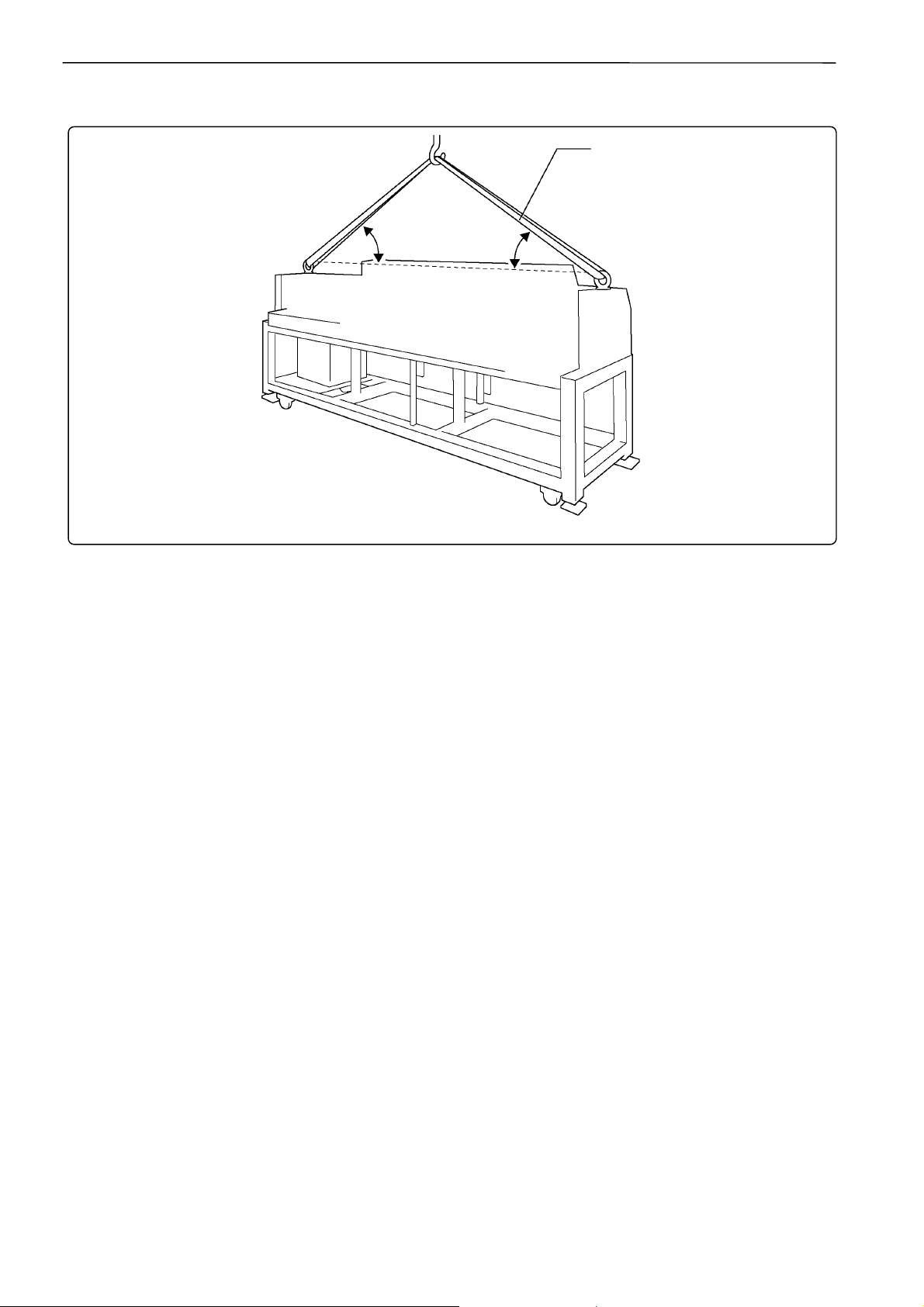

!!!! When using a crane

Belt

More than

45°

More than

45°

W1223Q

2. Hook on the eyebolts with each belt to lift up the machine.

When lifting the machine, make sure that the belts do not contact the machine table or the tension

plate.

1-6 BE-1204B-BC • BE-1206B-BC

Page 27

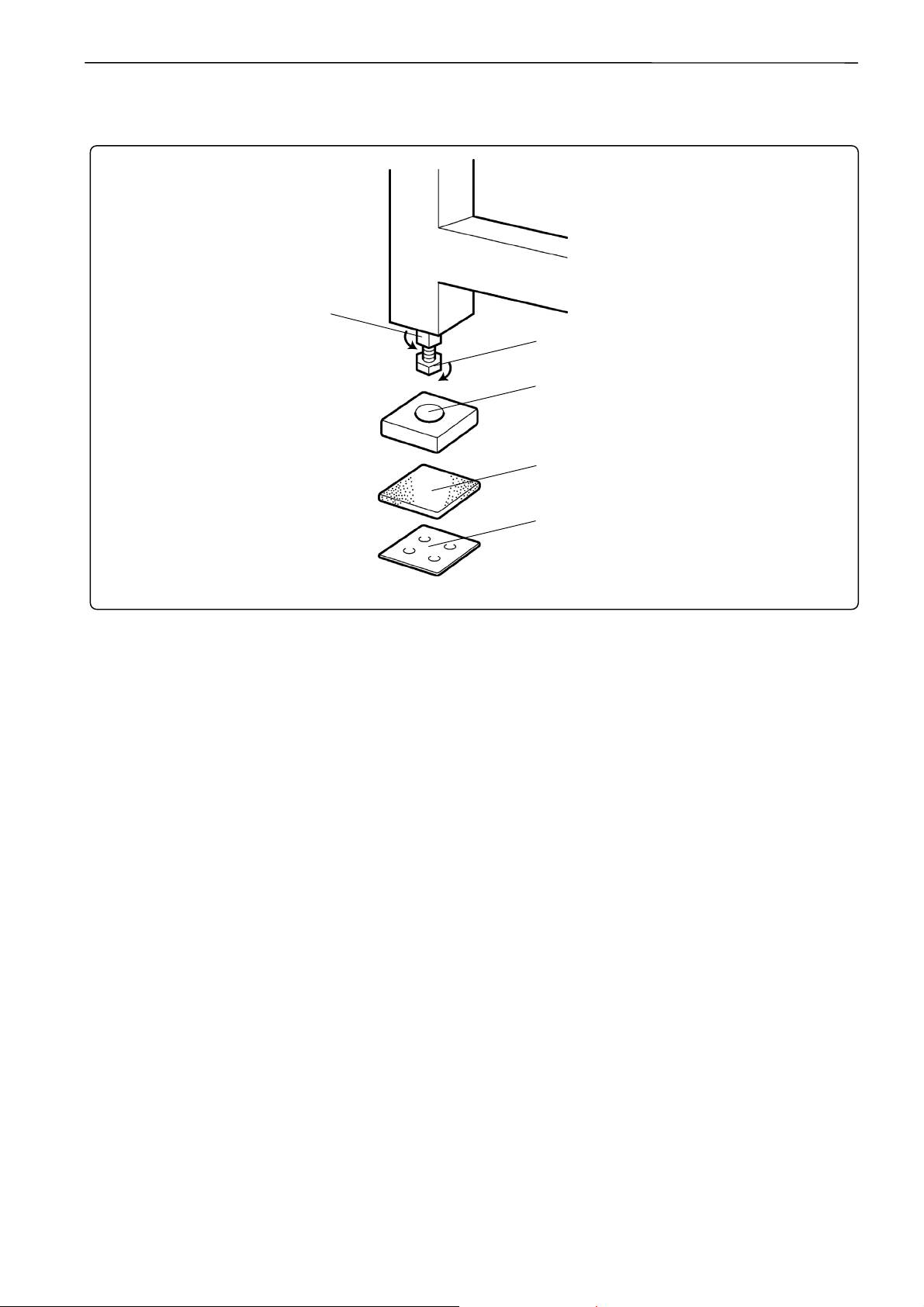

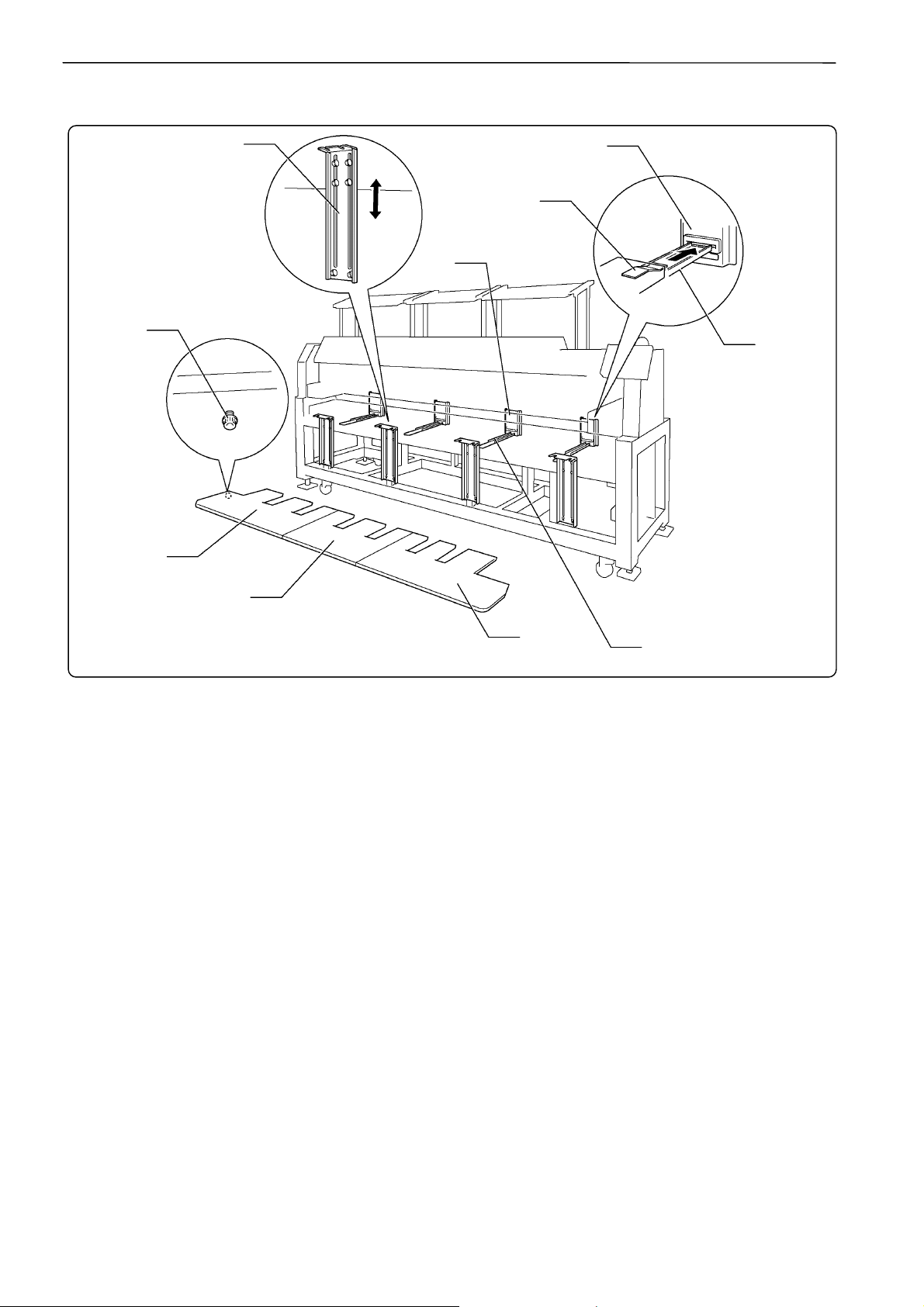

3-2 Installation of Machine

[5]

Chapter 1 Preparations of operation

[1]

[4]

[3]

[2]

W1224Q

1. Place Footboard [4], a rubber cushion 10 [3] (provided with the machine), and PE sheet [2] under

each of four adjustment bolts M20 [1]. The Footboard must be on the rubber cushion.

2. Fit four adjustment bolts M20 [1] into the hole of Footboard [4], and adjust the embroidery machine

in height.

The adjustment must be made in such a manner that the four bolts are under an equal load when

the machine is placed down. (To lower adjustment bolt M20 [1], turn it in the direction of the arrow.)

Also, the casters should be raised.

3. After adjusting four adjustment bolts M20 [1], turn nuts M20 [5] in the direction of the arrow to

fasten them.

If the floor is not strong enough, the embroidery machine may be rocked during operation. In such a

case, it is recommended that a secure base of concrete be placed below the embroidery machine.

BE-1204B-BC • BE-1206B-BC 1-7

Page 28

Chapter 1 Preparations of operation

3-3 Preparation of Needle Bar Case

[1]

[2]

Repeat the procedures below for all the heads:

1. Unscrew the screw [1], then detach the bracket [3] and pin [2].

[3]

W1225Q

1-8 BE-1204B-BC • BE-1206B-BC

Page 29

3-4 Mounting of Table

!!!! Preparation for mounting the table

Table guide bridge

Chapter 1 Preparations of operation

[1]

W1226Q

• This operation is required only when the table set is purchased separately from the machine.

• The table is a standard attachment.

1. Tentatively mount 4 (3 in four-head models) table supports Front [1] on the leg front using 4 bolts

each.

BE-1204B-BC • BE-1206B-BC 1-9

Page 30

Chapter 1 Preparations of operation

!!!! For embroidering with tubular square hoop or cap frame (lower position)

[8]

[3]

[7]

[6]

[4]

[6]

[5]

[2]

[1]

[5]

W1227Q

1. Attach four hexagon socket head cap screws to each of table parts R [1], M [2](six head models

only), and L [3] from the back.

2. Put the table backing plate [4] of each table on to the table guide bridge [5], and slide to the other

side. Insert the table backing plate [4] into the table backing rubber on the table support Rear [6].

3. Adjust table supports front [7] in height so as to make the table parallel with the floor.

4. Tighten all hexagon socket head cap screws [8] firmly.

1-10 BE-1204B-BC • BE-1206B-BC

Page 31

!!!! For embroidering with flat hoop/sash frame (upper position)

[5]

[4]

[2]

[3]

Chapter 1 Preparations of operation

[1]

[7]

[6]

W1228Q

1. Attach four hexagon socket head cap screws to each of table parts R [1], M [2](six head models

only), and L [3] from the back.

2. Insert the table backing plate [4] of each table into the table backing rubber on the table support

Middle [5].

3. Adjust the height of the table support Front [6] to be even with the upper surface of the bed.

4. Tighten all hexagon socket head cap screws firmly.

5. Attach four(three in four head models) thumb bolts to the lower front steel pipe of the leg section.

Fasten the table and the leg section using table stays (4 pcs(3pcs in four head models)) [7].

BE-1204B-BC • BE-1206B-BC 1-11

Page 32

Chapter 1 Preparations of operation

3-5 Mounting of Cotton Stand

Thread guide A

Thread guide B

Thread guide C

[5]

Front

[1]

[2]

[4]

[3]

[6]

W1229Q

1. Attach the cotton stand bars[2] to the cotton stand assembly[1].

2. Attach four thread guide support bars [3] to the cotton stand assembly [1], while fitting into the four

holes.

3. Mount the thread guide assembly [4] on the thread guide support bars [3] using the four screws

[5].

•When mounting, use one flat washer [6] below the thread guide support bar [3].

•Pay careful attention to the front and back directions of the thread guides (A, B, C).

1-12 BE-1204B-BC • BE-1206B-BC

Page 33

Chapter 1 Preparations of operation

3-6 Lubrication to Needle Bar Case

Proper lubrication is necessary for keeping the machine head in good condition.

CAUTION

Turn off the power switch before starting any cleaning work, otherwise the machine may operate if the

start switch is pressed by mistake, which could result in injury.

W1221Q

Before operating the machine for the first time after unpacking or after leaving the machine without

operation for a long period of time, supply one or two drops of oil to each needle bar from the oil supply

holes of the lower cover.

• Use the Brother’s specified oil (Nippon Oil, Embroidery Lube 10N; VG10) for this.

• Supplying an excessive amount of oil will cause dripping onto the material.

BE-1204B-BC • BE-1206B-BC 1-13

Page 34

Chapter 1 Preparations of operation

3-7 Grounding

Perform a grounding cable connection. Failure to do so may result in electric shock or machine

malfunction.

CAUTION

Grounding cable

W1231Q

When connecting the power supply, make sure to connect it to the grounding cable (with green and yellow

stripes). When plugging in the outlet, use a plug suited to the outlet.

1-14 BE-1204B-BC • BE-1206B-BC

Page 35

4. Preparation for Embroidering

CAUTION

Turn off the power switch before starting preparation.

Failure to do so may start the machine unintentionally through an accidental activation of the START

switch, resulting in bodily injuries.

4-1 Upper Threading

Chapter 1 Preparations of operation

[3]

Ten si on

stand inner

thread guide

[1]

[2]

Thread Guide

tension disc

Rotary

disc

[4]

Tension stand lower

thread guide

Inner thread guide

[5]

Lower thread

guide

Needle bar

No.3, 6, 9, 12

No.2, 5, 8, 11

No.1, 4, 7, 10

Spring

[6]

Needle bar

thread guide

Pressure foot

W1232Q W1233Q

BE-1204B-BC • BE-1206B-BC 1-15

Page 36

Chapter 1 Preparations of operation

1. Pass an upper thread from the cotton stand through the hole of the thread guide right above each

cotton stand bar. Pass the thread from the back to the front hole.

The cotton stand (top view)

Pass a thread in the order

indicated in the figure.

Front

W1234Q

2. Pass the thread through the upper hole of the pretension[1]. Push up the thread guide tension

disc with your finger, and pass it from the left to the lower hole.

3. Pass the thread through the upper hole of the 2nd pretension. Push up the thread guide tension

disc[2] with your finger, and pass it from the left to the lower hole.

4. Wind the thread clockwise once around the rotary disc and place it on the spring.

5. Pass the thread through the hole of tension stand inner thread guide [3].

6. After passing the thread through the hole of tension stand lower thread guide [4], insert the thread

into the right side of the inner thread guide and pass it through the hole of the thread take-up.

7. Bring the thread back to the inner thread guide. Insert the thread into the hole from the upper

section.

8. Pass the thread through the hole of the wire of the needle bar thread guide [6] and pass it through

the needle eye. Pass it through the presser foot. Pass it to presser spring at the front of lower

thread guide [5].

1-16 BE-1204B-BC • BE-1206B-BC

Page 37

4-2 Replacement of Bobbin

Remove dust, lint and oil from the bobbin case before replacement.

!!!! Removing bobbin case

[2]

[1]

[3]

Chapter 1 Preparations of operation

W1235Q

1. Open the rotary hook cover [1].

2. Hold the knob [2] and take out the bobbin case.

3. Close the knob and take out the bobbin [3].

!!!! Replacing bobbin

Pull out by

about 50 mm

[4]

[5]

[5]

W1238Q W1239Q W1240Q

1. Put a new bobbin in the bobbin case.

Check the winding direction.

Check that the bobbin is pushed out of the bobbin case by about 0.5 mm. If not, the slip prevention

spring of the bobbin case does not work. Adjust the height of the spring or replace it with a new one.

[6]

Bobbin

0.5mm

W1237Q

BE-1204B-BC • BE-1206B-BC 1-17

Page 38

Chapter 1 Preparations of operation

2. Slide the thread under the tension spring [5] through the notch [4].

3. Pull out the thread from the hole of the tension spring [5].

4. Pull out the thread by about 50 mm.

5. Pass the thread through the thread guide [6].

!!!! Attaching bobbin case

[2]

[1]

1. Hold the knob [2] and attach the bobbin case securely.

2. Close the rotary hook cover [1].

W1241Q

1-18 BE-1204B-BC • BE-1206B-BC

Page 39

4-3 Replacing and Selecting Needle

* Relationship between materials and needles

Material Needle Needle thickness

Chapter 1 Preparations of operation

Denim

Leather

Handkerchief #9, #10

Shirt

Towe l

DB × K5

#14,

#16, #18

#11,

#12, #13

!!!! Selecting needle

• When using special threads such as gold, silver, and rame yarn, use a heavy-duty needle (#11~

#16). For better finish, paste the waxed paper on the back of the material.

• In general, use DB×K5 #11 ~ #18 according to the material thickness. For knitted materials, use

DB×K23 #11 because its rounded point prevents the knit thread from breaking.

[1]

[2]

W1242Q

!!!! Removing needle

Loosen the set screw [1] and remove the needle [2].

!!!! Attaching needle

With the flat side facing the front, insert the needle all the way until it meets the end of the needle bar.

Tighten the set screw [1] firmly.

• Set the needle so that the notched part will come on the rotary hook side.

• The needle should not be angled to the left (when viewed from the front).

BE-1204B-BC • BE-1206B-BC 1-19

Page 40

Chapter 1 Preparations of operation

4-4 Attachment of Embroidery Hoop and Frame

!!!! Tubular square hoop

[4]

[3]

[1]

[2]

[5]

W1243Q

1. Loosen the thumb bolt M6 [1] to draw it to the center.

2. Align the positioning hole on the tubular round arm frame [4] with the positioning pin [3] (S58665)

on the X-feed sash [5] (S58650), and fit the tubular round arm fixing nut [2] on the back side of the

thumb bolt M6 [1] into the hole on the X-feed sash.

3. While keeping the nut in the hole, slide the thumb bolt M6 toward the edge and tighten it firmly at

the outermost point.

1-20 BE-1204B-BC • BE-1206B-BC

Page 41

!!!! Holder base (optional)

Y

Chapter 1 Preparations of operation

[8]

[1]

[10]

[5]

[9]

[12]

[7]

Table

Felt

[9]

[11]

[1] [3]

-axis cover

1mm 1mm

[2]

[4]

[6]

[3]

W1244Q

Attaching the holder base frame

1. Set the table. (Refer to “Mounting of Table” on page 1-9.)

2. Insert the frame connecting plate F [4] into the holder base frame L [1], flat frame C6-360 [2] and

holder base frame R [3], using bolts and washers.

3. Attach the flat frame S connecting plates L [5] and R [6] to the holder base frames L [1] and R [3].

4. Attach the flat frame S6-360 set [7] to the flat frame S connecting plates L [5] and R [6], using bolts

of 4×12 and washers of middle 4.

5. Remove 4 bolts [9] from the front of X-feed sash [8].

6. Put the frame connecting plates L [10] and R [11] on the X-feed sash [8]. Fix them with bolts and

washers.

7. Check that the clearance between the mounted flat frame C6-360 [2] and the table is even when

viewed from the machine front.

If adjustments are needed, loosen bolts of the F table support Front [12] and move it in the

direction of the arrow.

8. Tighten each bolt securely after the adjustment is completed.

BE-1204B-BC • BE-1206B-BC 1-21

Page 42

Chapter 1 Preparations of operation

Attaching the holder base

1. Mount the holder base vertically to the X-axis feed sash [1] and flat frame C6-360 [2] using the

thumb bolts [3].

[3]

[1]

[3]

[2]

W1246Q

1-22 BE-1204B-BC • BE-1206B-BC

Page 43

!!!! Sash frame (optional)

[4]

[1]

Chapter 1 Preparations of operation

[2]

[1]

[3]

[5]

[6]

[3]

[4]

[5]

[6]

[3]

[3]

W1247Q

Attaching the sash frame

1. Set the table. (Refer to "3-4 Mounting of Table" (Page 1-9) for details.)

2. Mount two vertical sash frames [1] on the holder base frames L and R, and two horizontal sash

frames [2] on the X-axis feed sash [3] and the holder base frame C6-360 [4], using the screws.

3. Set the material. Then set sash clips 290 [5] horizontally and set sash clips 220 [6] vertically.

Six head models: Sash clips 290 12 units, sash clips 220 10 units

Four head models: Sash clips 290 10 units, sash clips 220 6 units

BE-1204B-BC • BE-1206B-BC 1-23

Page 44

Chapter 1 Preparations of operation

4-5 Adjustment of Thread Tension

!!!! Adjustment of upper thread

0.8~1.4N

Upper stitch width

Upper

thread

Lower

W1248Q W1249Q

Lower stitch width

Adjust upper thread tension to 0.8~1.4N when the thread is pulled at the needle bar thread guide.

* Correct adjustment

thread

Turn the upper thread tension dial so that the needle thread can be pulled to the back of the material

and that the lower stitch width will be about 1/3 of the upper stitch width.

!!!! Adjustment of tension spring

[1]

6~8mm

14mm

[2]

0.2~0.3N

[3]

W1250Q

1. The standard height of the tension spring is the point from where the upper thread comes down by

about 14 mm when it is pulled with certain tension which does not pull out the thread.

2. The standard force of the tension spring is 0.2 to 0.3 N at the start of the motion when it is pulled in

the direction illustrated.

Adjust it so that the tension spring does not move when the upper thread is pulled out slowly from

the presser foot.

1-24 BE-1204B-BC • BE-1206B-BC

Page 45

Chapter 1 Preparations of operation

3. For adjusting the height, loosen the screw [1] and turn the tension spring bracket [2].

4. For adjusting the tension spring force, insert a driver tip in the groove of the thread tension bar [3]

and turn it.

!!!! Lower thread tension

To tighten

To loosen

W1251Q W1252Q

The standard tension of the lower thread is 0.15 ~ 0.3N.

This tension may vary depending on the used thread. In general, press the bobbin case to a smooth

vertical surface and hang the designated number of coins. Turn the thread tension screw so that the

lower thread will come out smoothly.

Check that the bobbin is pushed out of the bobbin case by about 0.5 mm. If not, the slip prevention spring

of the bobbin case does not work. Adjust the spring in height or replace it with a new one. (Refer to

“Replacing Bobbin” on page 1-17.)

We recommend the use of the optional gauge set TM-3 (S59956-001).

BE-1204B-BC • BE-1206B-BC 1-25

W1396Q

Page 46

Chapter 1 Preparations of operation

1-26 BE-1204B-BC • BE-1206B-BC

Page 47

Chapter 2

Embroidering Procedures

After installation of machine start embroidering.

This chapter explains about the operation panel

on the machine as well as precautions for the

actual embroidering process.

Page 48

Chapter 2 Embroidering Procedures

Functions of Operation Panel

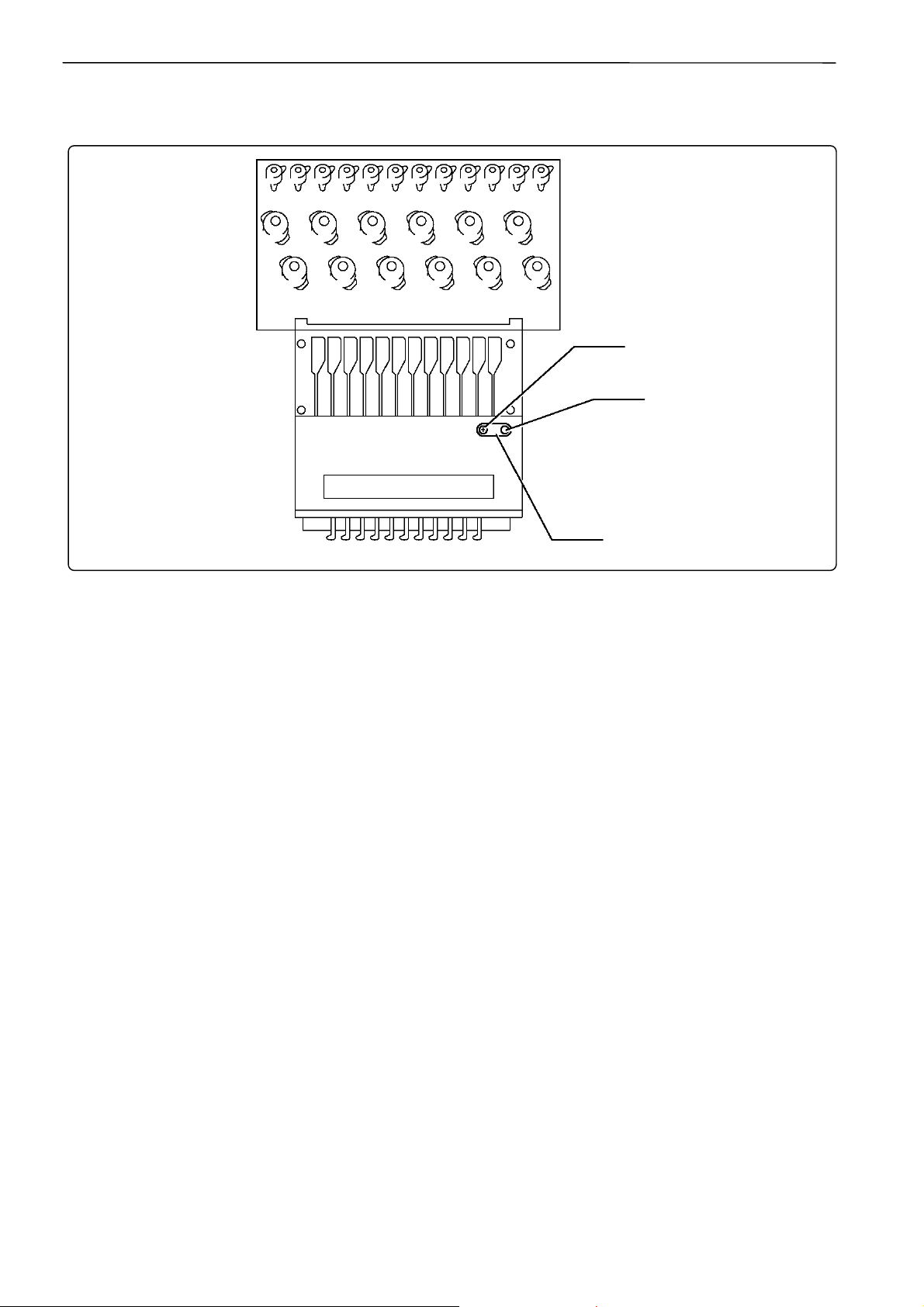

Operation Panel

W1253Q

Starts embroidering.

Restarts after moving the carriage to embroidering start position by using the jog switch.

Restarts embroidering after a suspension.

Cancels errors during embroidering.

Suspends embroidering.

Sewing without home position detection (i.e. the frame does not move) is available when turning on the power

with this key pressed.

Selects sewing data. (→ "Chapter 3 Selection of Data and Embroidering" page 3-1)

Specifies a sequence of colors (sequence of needle changes) in sewing data.

(→ "Setting of Needle Bars" page 5-4)

2-2 BE-1204B-BC • BE-1206B-BC

Page 49

Edits sewing data. (→ "Chapter 4 Editing of Embroidering Data" page 4-1)

Sets the upper thread breakage sensor. (→ "Thread Breakage Sensor" page 5-6)

Machine motions can be set. (→ "Chapter 5 Setting" page 5-1)

Trims thread during suspension.

Chapter 2 Embroidering Procedures

Moves the hoop to a preset hoop retract position. When this switch is pressed again, the hoop returns to the

previous position.

Checks the embroidering area.

Moves the hoop automatically into the embroidering area when the embroidery position is out of the area.

W1254Q

Used for selecting data and setting functions.

Turning on the power with key pressed will display the memory clear selection screen.

Selects the flat or cap hoop. This selection should be done before turning the power ON to the machine.

The setting will not be changed if the selection is done after turning the power OFF.

BE-1204B-BC • BE-1206B-BC 2-3

Page 50

Chapter 2 Embroidering Procedures

A

Moves the hoop.

Step-back or forward is available during suspension. (Use

switches only.)

Changes the speed range during embroidering (Use switches only).

Carries out inching of the hoop when the switch is pressed in the inching mode.

Move the cursor for selecting sewing data and an icon.

Turning on the power with key pressed will display the test mode screen.

Moves the needle bar. The needle moves by the diameter every time this switch is pressed.

Change to the screen for selecting sewing data.

Operation panel

Contrast volume

djusts the screen contrast.

W1256Q

SBUS interface connector

Not used (Do not connects anything.)

RS-232C interface connector

Connect personal computer with BE-100 installed, etc.

2-4 BE-1204B-BC • BE-1206B-BC

Page 51

Switches at Machine Heads

Chapter 2 Embroidering Procedures

Step forward switchStep back switch

Start switch

Stop switch

W1257Q

! Stop switch

Stops embroidering operation. "Release stop SW to operate!" is displayed on the screen as

soon as the machine stops.

Refer to "Stopping the machine" ( page 6-3) to stop flashing.

In BE-1206B-BC models, this switch is located between the head 2 and 3, and also between the

head 5 and 6.

In BE-1204B-BC models, this switch is located between the head 1 and 2, and also between the

head 3 and 4.

! Start switch

Starts embroidering. Holding down this switch executes embroidering at a low speed.

When resuming embroidering after a stop, release stop before pressing this switch. Refer to

"Stopping the machine" ( page 6-3) for details.

In BE-1206B-BC models, this switch is located between the head 2 and 3, and also between the

head 5 and 6.

In BE-1204B-BC models, this switch is located between the head 1 and 2, and also between the

head 3 and 4.

! STEP BACK/FWD switch

When BACK switch is pressed, the machine steps back. When FWD switch is pressed, the

machine steps forward. If you keep the switch pressed for a while, the machine will continue

stepping even after you let the switch alone.

If any error occurs, it can be reset.

When the sewing is suspended during the area checking, pushing this switch can move the head to

the previous or the next vertex of the outlined rectangle pattern.

In BE-1206B-BC models, switches are located between the head 1 and 2, and also between the

head 5 and 6.

In BE-1204B-BC models, switches are located between the head 1 and 2, and also between the

head 3 and 4.

BE-1204B-BC • BE-1206B-BC 2-5

Page 52

Chapter 2 Embroidering Procedures

Lamps and switches on the thread tension stand

The thread tension stand has lamps and switches mounted on it.

Switches can set movements of the heads such as to drive, to suspend or mending, and those

statuses can be checked by lamps.

Thread tension stand lamp Thread tension stand switch

W1258Q

! Thread tension stand lamp

Shows statuses of each head of the machine.

Lamp illumination Machine head status

Off

Illuminates green The head is ready to drive.

Blinks green The head has an error. Blinking will change into illuminating when the error is cleared.

Blinks red

The head is suspended

The head is not suspended but its mending is set to OFF.

Some other head has an error.

The head has a thread breakage error. Blinking will change into illuminating when the

error is cleared.

! Thread tension stand switch

Sets drive/suspend of each head and ON/OFF of the mending.

Mending is a function to drive or suspend the head for the specified time period when the machine

steps back during embroidering.

• Switching of drive/suspend should be done when the machine is stopped.

• Switching of the mending should be done when the machine is suspended during embroidering.

Flip the switch up to

suspend the head.

Flip up the switch further to

switch ON/OFF the mending.

Flip the switch down

to suspend the head.

2-6 BE-1204B-BC • BE-1206B-BC

W1259Q

Page 53

Flowchart of Preparation for Embroidering

Turn on the machine power. (→ page 2-8).

Retrieve the embroidery data (→ page 2-9).

"Chapter 3 Selection of Data and Embroidering" (→ page 3-1)

Edit the retrieved embroidery data.

"Chapter 4 Editing of Embroidering Data" (→ page 4-1)

Press on the operation panel.

Chapter 2 Embroidering Procedures

Press on the operation panel.

BE-1204B-BC • BE-1206B-BC 2-7

Page 54

Chapter 2 Embroidering Procedures

A

A

A

A

A

A

A

Turn on the Machine Power

Main power switch

Emergency stop switch

W1262Q W1265Q W1404Q W1266Q

Flat / Cap hoop select switch

Power switch

1. Turn on the main power switch.

2. Reset the emergency stop switch.

3. Change the Flat / Cap hoop select switch on the operation panel according to the hoop to be used.

4. Press the power switch.

5. A message is displayed on the LCD as soon as the power is turned ON.

BE-1204B-BC

BE-1206B-BC

W1263Q

W1264Q

6. The alarm sounds three times. The hoop moves back to the zero point and the sewing screen is

displayed.

The speed range and actual speed is displayed.

sequence of changing colors is displayed.

sequence of colors is displayed.

total number of stitches is displayed.

data name is displayed.

number of colors registered in data is displayed.

kind of hoop is displayed.

Operational icons are basically displayed; however, some icons,

such as

n angle at which the hoop feeding finishes is displayed.

, may not be on the screen.

W0406Q

2-8 BE-1204B-BC • BE-1206B-BC

Page 55

Chapter 2 Embroidering Procedures

Retrieve the Embroidery Data

The description in this section is based on the method of reading data which is registered in the

memory unit of the machine.

Refer to "Selection of Data" (→ Page 3-3) for details.

1. Press

Data saved in the machine is displayed.

2. Select a screen by pressing

switch.

keys, and select required data by pressing ten keys or

.

When using ten keys for data selection, input a numerical figure (1 ~ 9) which indicates each data

name. Required embroidery data is selected and read.

W0397Q

3. Press key.

Required embroidery data is selected and read.

W0405Q

Selected embroidery data is read.

W0406Q

Start Embroidering

1. Press to check the embroidering area.

2. Press

Sewing is started and the next screen is displayed.

to start embroidering.

W0406Q

W0439Q

BE-1204B-BC • BE-1206B-BC 2-9

Page 56

Chapter 2 Embroidering Procedures

2-10 BE-1204B-BC • BE-1206B-BC

Page 57

Chapter 3

Selection of Data and Embroidering

This Chapter describes how to select embroidery data in order to start embroidering.

Page 58

Chapter 3 Selection of Data and Embroidering

What Can the Machine Do?

Selection of Embroidery Data

Registration of data from the floppy disk (→ Page 3-3)

Reading of data from the memory (→ Page 3-7)

Registration of data created by BE-100 (→ Page 3-8)

(These icons are displayed in the lower right of the screen.)

Modification of data name (→ Page 3-13)

Deletion of embroidery data (→ Page 3-9)

Embroidering Operation

Embroidering start (→ Page 3-17)

Embroidering feedhold (→ Page 3-18)

Embroidering cancel (→ Page 3-18)

Step forward/step back (→ Page 3-19)

Step forward (back) stitch by stitch

Step forward (back) by every 10 stitches

Step forward (back) by every 100 stitches

Step forward (back) until a next color change

Step forward (back) to the embroidering start point of a next pattern

Step forward (back) by a specified number of stitches

(→ Page 3-19)

3-2 BE-1204B-BC • BE-1206B-BC

Page 59

Chapter 3 Selection of Data and Embroidering

Selection of Data

Select data in order to start sewing.

! Data to use for actual embroidering is selected from data registered in the machine memory. A

maximum of 45 kinds or 480,000 stitches of embroidery data can be registered in the machine

memory; however, depending on the combination of embroidery data, the number of pieces or total

stitches available may become less.

! When using data in a floppy disk or in BES-100E, register it in the machine memory once before

selection.

If there is no space in the machine memory, delete unnecessary data to make a space.

Registration

Data in a floppy disk

Data created by BES-100E

Reading

Sewing

W0394Q

Registration of Embroidery Data from Floppy Disk

Register embroidery data from a floppy disk into the machine memory.

! Types of data to be registered are as shown below.

• DOS-formatted data

Data format Extension Icon

ECS Data with a name of [xxxx.ECS]

Tajima Data with a name of [xxxx.DST]

Barudan Data with a name of [xxxx.DSB]

Zanks (ZSK) Data with a name of [xxxx.DSZ]

Data received from BE-100 Data with a name of [xxxx.STH]

(These icons are displayed in the lower right of the screen.)

Machine memory

• Other data

Barudan FDR

Barudan FMC

Zanks ZSK

Data format Icon

(These icons are displayed in the lower right of the screen.)

BE-1204B-BC • BE-1206B-BC 3-3

Page 60

Chapter 3 Selection of Data and Embroidering

A

Loading and Loading of Floppy Disk

1. When loading a floppy disk, set it straight with the labeled surface facing this side.

W0395Q

2. When unloading a floppy disk, press the eject switch.

3. When it comes out, pull it straight.

When the access lamp if ON, never press the eject switch. Otherwise, embroidery data in the floppy

disk may be destroyed.

Registration of Sewing Data into Machine Memory

1. Load a floppy disk with sewing data.

Eject switch

ccess lamp

W0396Q

W0395Q

3-4 BE-1204B-BC • BE-1206B-BC

Page 61

2. Press .

Chapter 3 Selection of Data and Embroidering

3. Select a screen for data registration by pressing

Currently displayed screen

No. of screens to be selected

Data in machine memory

Currently selected

embroidery data

When there is no data

Number of stitches in selected

embroidery data

W0398Q

4. Select an area for registration, using ten keys or

W0399Q

A space available is automatically selected.

Pressing

automatically locates the first space in the memory.

.

W0397Q

, then press .

5. Data in the floppy disk is displayed. Press

Icon indicating a kind of selected data

Pressing displays a pattern name.

Name of a selected embroidery pattern

(It may be the same as a file name.)

to select a screen.

Currently displayed screen

No. of screens to be selected

Data in floppy disk

W0401Q

W0400Q

BE-1204B-BC • BE-1206B-BC 3-5

Page 62

Chapter 3 Selection of Data and Embroidering

6. Select data to register by pressing ten keys or

then press .

Data is newly registered in the machine memory.

W0402Q

Select embroidery data and press . The selected data is automatically registered in the memory

and the machine enters a standby status.

If registration is done without loading a floppy disk, the following screen is displayed after the step 4 is

finished.

Load a floppy disk for data registration.

W0588Q

3-6 BE-1204B-BC • BE-1206B-BC

Page 63

Chapter 3 Selection of Data and Embroidering

Reading from Memory

Data to use for sewing can be selected from the machine memory.

! A maximum 45 kinds or 480,000 stitches of embroidery data can be registered in the memory.

1. Press

Embroidery data registered in the memory is displayed.

2. Select a screen by pressing

.

.

Currently displayed screen

No. of screens to be selected

W0397Q

3. Select embroidery data to read by pressing ten keys or

W0404Q

4. Press .

Embroidery data is selected and read.

.

W0405Q

When a free space is specified in the memory, a screen for reading data from the floppy disk is

displayed.

Refer to "Registration of Sewing Data into Machine Memory" (steps 5 and afterward on Page 3-5).

5. The initial screen is displayed.

W0406Q

BE-1204B-BC • BE-1206B-BC 3-7

Page 64