Page 1

SERVICE MANUAL

BE-1204B-BC

BE-1204C-BC

BE-1206B-BC

Please read this manual before making any adjustments

TWELVE NEEDLE FOUR HEAD EMBROIDERY MACHINE

TWELVE NEEDLE FOUR HEAD EMBROIDERY MACHINE<WIDE AREA>

TWELVE NEEDLE SIX HEAD EMBROIDERY MACHINE

Page 2

Page 3

This service manual is intended for BE-1204B, 1204C, 1206B; be sure to read the BE-1204B, 1204C,

1206B instruction manual before this manual.

Carefully read the “SAFETY INSTRUCTIONS” below and the whole of this manual to understand this

product before you start maintenance.

As a result of research and improvements regarding this product, some details of this manual may not

be the same as those for the product you purchased.

If you have any questions regarding this product, please contact a Brother dealer.

SAFETY INSTRUCTIONS

1 Safety indications and their meanings

This service manual and the indications and symbols that are used on the machine itself are provided

in order to ensure safe operation of this machine and to prevent accidents and injury to yourself or

other people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

-------- This symbol (

The picture inside the triangle indicates the nature of the caution that must be taken. (For

example, the symbol at left means "beware of injury".)

--------- This symbol (

--------- This symbol (

The picture inside the circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to

equipment and surroundings.

) indicates something that you should be careful of.

) indicates something that you must not do.

) indicates something that you must do.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1

Page 4

2 Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall

outlet before opening the face plate of the control box. Touching areas where high voltages are present

can result in severe injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is

free from sources of strong electrical noise

such as high-frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within ±10% of the rated voltage for

the machine.

Voltage fluctuations which are greater than

this may cause problems with correct

operation.

The power supply capacity should be greater

than the requirements for the sewing

machine's electrical consumption.

Insufficient power supply capacity may cause

problems with correct operation.

The air supply should have a capacity greater

than the machine consumption. If air is not

supplied sufficiently, a machine malfunction

may occur.

Installation

Machine installation should only be carried

out by a qualified technician.

Never operate the sewing machine with any

ventilation openings blocked.

Keep the ventilation openings of the sewing

machine free from the accumulation of lint or

dust.

Contact your Brother dealer or a qualified

electrician for any electrical work that may

need to be done.

The sewing machine weighs approximately

700 kg.

The installation should be carried out by four

or more people.

Do not connect the power cord until

installation is complete, otherwise the

machine may operate if the start switch is

pressed by mistake, which could result in

injury.

The ambient temperature should be within the

range of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems

with correct operation.

In the event of an electrical storm, turn off the

power and disconnect the power cord from the

wall outlet.

Lightning may cause problems with correct

operation.

Do not use this machine outdoors.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

Be sure to wear protective goggles and gloves

when handling the lubricating oil or grease, so that

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Secure the machine with the adjustment bolts on

the sound floor so that it will not move.

2 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 5

Avoid setting up the sewing machine near

sources of strong electrical noise such as

high-frequency welding uipment.

If this precaution is not taken, incorrect

machine operation may result.

Installation

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary

training in safe use beforehand.

Keep children away from the sewing machine.

The sewing machine should not be used for

any applications other than sewing.

Be sure to wear protective goggles when

using the machine.

If goggles are not worn, there is the danger

that if a needle breaks, parts of the broken

needle may enter your eyes and injury may

result.

Always use the proper needle plate. Any

wrong plate can cause needles to break.

Do not use a bent needle.

Turn off the power switch at the following

times, otherwise the machine may operate if

the start switch is pressed by mistake, which

could result in injury.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when

leaving the machine unattended

• When cleaning the machine.

Do not get on the table.

Table may be damaged.

Do not operate this machine where aerosol

(spray) products are being used or where

oxygen is being administered.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any moving parts, press any objects

against the machine, or pull/push the cloth during

sewing. Doing so may result in personal injury,

machine damage, or needle breakage.

Do not touch the pulse motor and sewing machine

bed section during operation or for 30 minutes

after operation. Otherwise burns may result.

Never drop or insert foreign objects or a

screwdriver into the ventilation openings or the

machine inside.

Touching any high-voltage area may result in an

electric shock.

Never damage, alter, heat, or put a strain on the

power cable as well as other cables. Doing so

may result in a fire or an electric shock.

If the controller is exposed to water or a chemical

agent or if its entry is found inside the controller,

turn off the power switch immediately.

Continuing to use the machine under such a

condition may result in a fire or an electric shock.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed,

immediately turn off the power switch. Then

contact your nearest Brother dealer or a qualified

technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Cleaning

Turn off the power switch before starting any

cleaning work, otherwise the machine may

operate if the start switch is pressed by

mistake, which could result in injury.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3

Be sure to wear protective goggles and gloves

when handling the lubricating oil or grease, so that

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Page 6

Maintenance and inspection

Disassembly, assembly, maintenance and

inspection of the sewing machine should only

be carried out by a qualified technician.

Ask your Brother dealer or a qualified

electrician to carry out any maintenance and

inspection of the electrical system.

Turn off the power switch and disconnect the

power cable (do not pull on the cable itself)

from the wall outlet before attempting to

perform the following operations. Otherwise,

the machine is started if the start switch is

pressed by mistake. Injury may occur in

such a case.

• When carrying out inspection, adjustment,

or maintenance

• When replacing consumable parts such as

a rotary hook, a knife, or a fluorescent lamp

If the power switch needs to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

Use only the proper replacement parts as

specified by Brother.

When replacing a fluorescent lamp, use the

same-type lamp having a rating of 40 watts.

Wait until the fluorescent lamp cools off before

replacement. Failure to do so can result in

burns.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine

will not be covered by the warranty.

4 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 7

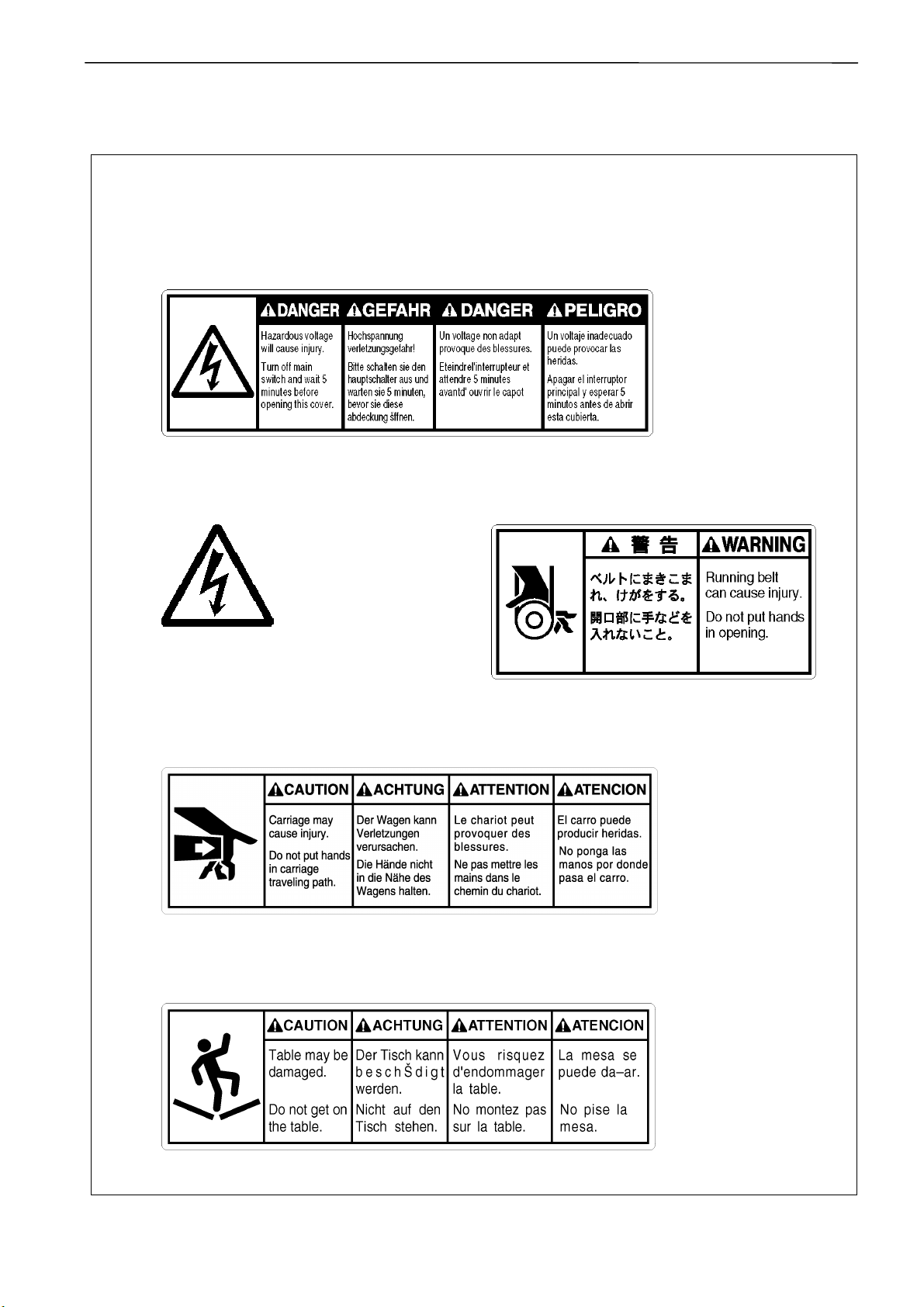

3 Warning labels

* The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels

have been removed or are difficult to read, please contact your nearest Brother dealer.

1 Electric shock danger display

W1408Q

2 Electric shock danger display 3 Injury warning display

Hazardous voltage will

cause injury.

4 Injury caution display

5 Injury caution display

W1410Q

W1200Q

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 5

W1202Q

Page 8

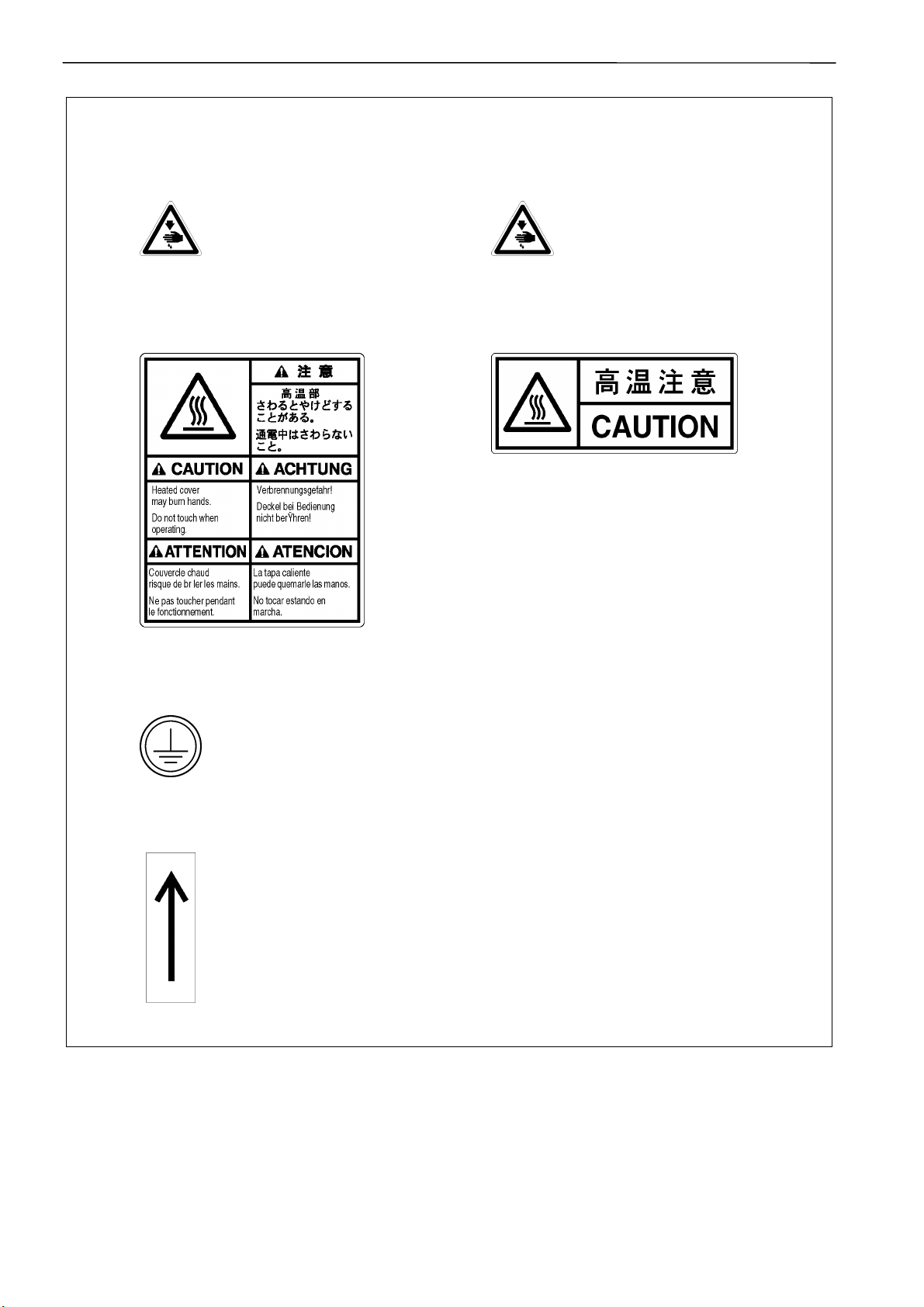

6 Injury caution display

7 Injury caution display

Never touch or push the

thread take up during

operation as it may result in

injuries machine.

Never touch or push the needle

bar during operation as it may

result in injuries or damage to

the sewing machine.

8 High temperature caution display 9 High temperature caution display

W1206Q

Do not touch this part during activitation

or for 30 minutes after shut-off. Otherwise

burns may result.

W1201Q

10 Ground mark

Be sure to connect the ground. If the ground connection is not secure, you run

a high risk of receiving a serious electric shock, and problems with correct

operation may also occur.

11 Direction of operation

W1205Q

6 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 9

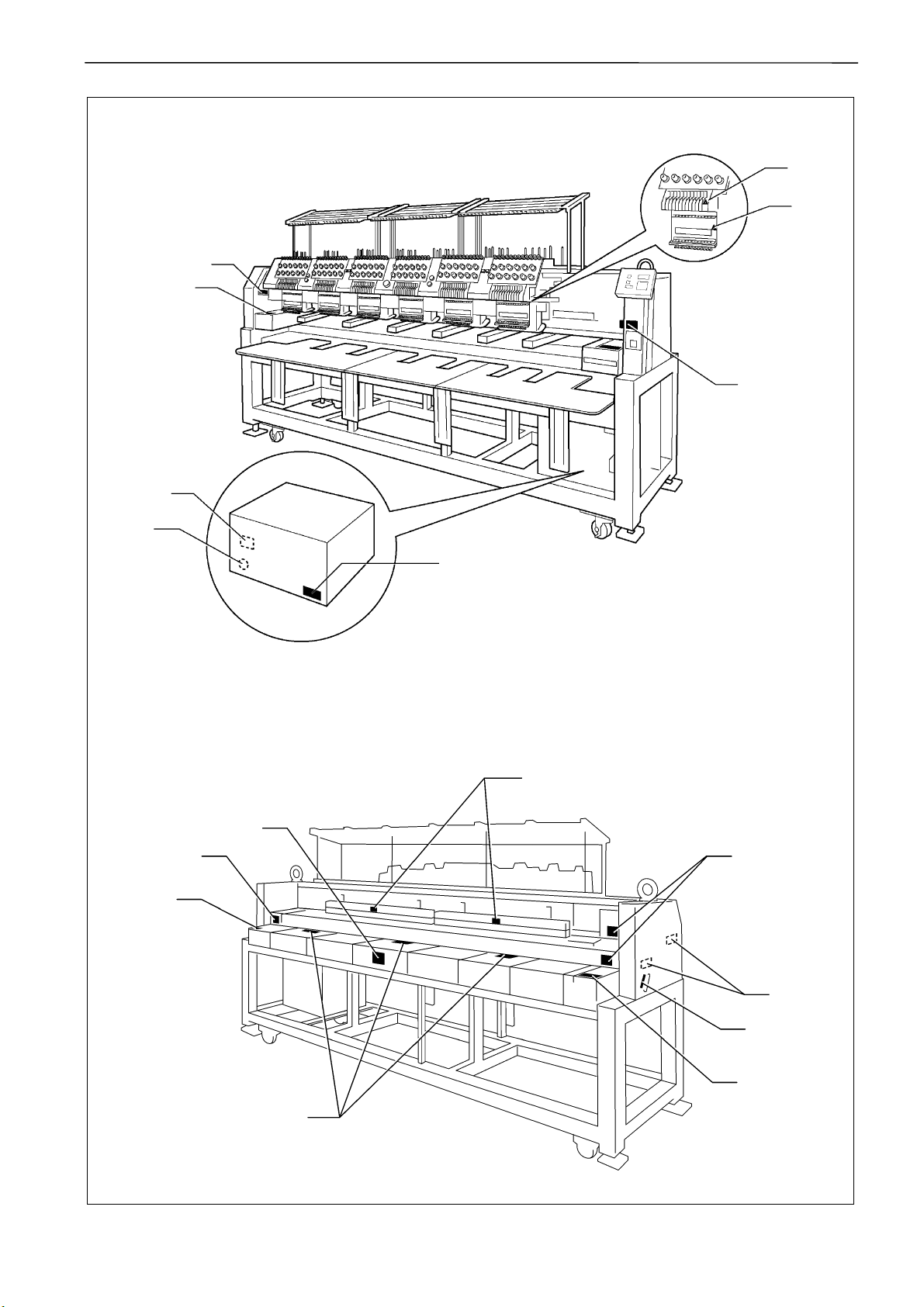

10

6

7

5

4

5

2

1

W1400Q

9

8

8

8

4

3

11

4

4

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 7

W1208Q

Page 10

Contents

Contents

Chapter 1 Mechanical Descriptions

1. Feed guide mechanism............................................................................................................................................ 1-1

2. Crank shaft mechanism ........................................................................................................................................... 1-2

3. Presser foot mechanism.......................................................................................................................................... 1-3

4. Thread take-up mechanism .....................................................................................................................................1-4

5. Needle bar mechanism ........................................................................................................................................... 1-5

6. Lower shaft and rotary hook mechanisms............................................................................................................. 1-6

7. Thread trimmer mechanism.....................................................................................................................................1-7

8. Thread wiper mechanism ........................................................................................................................................1-8

9. Picker mechanism.................................................................................................................................................... 1-9

10. Needle bar flip-up mechanism.............................................................................................................................1-10

11. Cap frame device.................................................................................................................................................. 1-11

Chapter 2 Parts replacement and adjustment

1. Replacement and adjustment of jump driving assy, cloth presser cam, thread take-up driving cam, needle bar

driving cam, driving belt and upper shaft sensor.................................................................................................. 2-1

2. Replacement and adjustment of thread take-up lever......................................................................................... 2-11

3. Replacement and adjustment of work clamp....................................................................................................... 2-12

4. Replacement and adjustment of stepping motor for thread sweeping and wiper sensor ............................... 2-13

5. Replacement and adjustment of picker solenoid ................................................................................................ 2-16

6. Replacement and adjustment of movable knife and fixed knife.........................................................................2-19

7. Replacement and adjustment of Timing belt, X ...................................................................................................2-21

8. Replacement and adjustment of Timing belt, Y ...................................................................................................2-23

9. Adjusting Needle Bar Height ................................................................................................................................. 2-26

10. Attachment and Adjustment of Rotary Hook......................................................................................................2-30

Chapter 3 Electrical components

1. Location of the PCB .................................................................................................................................................3-1

2. Replacement of PCB inside the control box ..........................................................................................................3-3

2-1. How to detach and attach the control box ........................................................................................................3-3

2-2. Replacement of the main PCB ......................................................................................................................... 3-5

2-3. Replacement of the power supply PCB ............................................................................................................ 3-7

2-4. Replacement of the drive PCB ...................................................................................................................... 3-10

2-5. Replacement of the SBUS PCB (For PC-type model).................................................................................... 3-12

2-6. Replacement of the relay PCB ....................................................................................................................... 3-14

2-7. Replacing the panel PCB (For PC-type model) .............................................................................................. 3-15

2-8. Replacement of the control panel PCB (For SA-type model) ......................................................................... 3-16

3. Replacement of head switch PCB of thread tension base and tension base PCB ........................................... 3-18

4. Replacement of I/O PCB (1, 2) and step back/forward switch PCB....................................................................3-21

5. Replacement of head PCB..................................................................................................................................... 3-23

6. Replacement of I/O PCB.........................................................................................................................................3-25

7. Replacement of picker PCB...................................................................................................................................3-26

8. Fuses ....................................................................................................................................................................... 3-27

8-1. Types and capacity of fuses ........................................................................................................................... 3-28

8-2. Replacement of fuses..................................................................................................................................... 3-28

9. Description of P-ROM ............................................................................................................................................ 3-29

10. Replacement of change color motor, collar, w/dog and change color sensor PCB ....................................... 3-30

11. Replacement and adjustment of index sensor................................................................................................... 3-32

8 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 11

12. Description of connectors....................................................................................................................................3-35

12-1. Main PCB......................................................................................................................................................3-35

12-2. Drive PCB .....................................................................................................................................................3-42

12-3. Power supply PCB........................................................................................................................................3-47

12-4. IO PCB..........................................................................................................................................................3-53

12-5. Picker PCB....................................................................................................................................................3-57

12-6. Head switch PCB..........................................................................................................................................3-58

12-7. Tension base PCB ........................................................................................................................................3-59

12-8. Step switch PCB ...........................................................................................................................................3-60

12-9. Head PCB.....................................................................................................................................................3-61

12-10. Relay PCB ..................................................................................................................................................3-64

12-11. SBUS PCB ..................................................................................................................................................3-66

Chapter 4 Test Mode (For Stand – Alone type)

1. Entering into the test mode......................................................................................................................................4-1

2. Selecting the test mode menu .................................................................................................................................4-1

3. Function of the test mode ........................................................................................................................................4-3

3-1. Thread trimmer adjustment...............................................................................................................................4-3

3-2. Needle bar moving test ....................................................................................................................................4-3

3-3. Carriage sensor test (Fine adjustment of the carriage origin point) ..................................................................4-5

3-4. Encoder signal test ...........................................................................................................................................4-6

3-5. LED SW test .....................................................................................................................................................4-7

3-6. Port/voltage check ............................................................................................................................................4-8

3-7. Solenoid test .....................................................................................................................................................4-9

3-8. Main shaft motor rotation test..........................................................................................................................4-10

3-9. Detailed version of CPU in the machine .........................................................................................................4-11

3-10. Power supply voltage adjustment .................................................................................................................4-12

3-11. Modifications of X-direction slowing area of a cap frame and its reduction ratio ...........................................4-14

3-12. Modification of the stitch compensation value on the sewing machine .........................................................4-15

Contents

Chapter 5 Test mode (For PC Control type)

1.Test mode on the operation panel ............................................................................................................................5-1

1-1. Starting test mode.............................................................................................................................................5-1

1-2. Selecting test mode menu ................................................................................................................................5-1

1-3. Test mode functions..........................................................................................................................................5-2

2. Test mode and each function on the PC.................................................................................................................5-9

2-1. PC test mode ....................................................................................................................................................5-9

2-2. Confirming the program version......................................................................................................................5-10

2-3. Power supply voltage adjustment ...................................................................................................................5-14

2-4. Modifications of X-direction slowing area of a cap frame and its reduction ratio.............................................5-16

2-5. Modification of the stitch compensation value on the sewing machine ...........................................................5-18

Chapter 6 6. Upgrading version of machine program ...............................................................6-1

Chapter 7 Maintenance

1. Cleaning.....................................................................................................................................................................7-1

1-1. Cleaning and Lubrication of Rotary Hook .........................................................................................................7-1

1-2. Cleaning of Needle Plate ..................................................................................................................................7-2

2. Oiling..........................................................................................................................................................................7-3

2-1. Head .................................................................................................................................................................7-3

2-2. Lower shaft .......................................................................................................................................................7-5

3. Greasing ....................................................................................................................................................................7-6

3-1. Cam grooves.....................................................................................................................................................7-6

3-2. Lower gear........................................................................................................................................................7-8

3-3. Driving shaft......................................................................................................................................................7-8

3-4. The needle bar change mechanism and the case guide rail UL .......................................................................7-9

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 9

Page 12

Contents

Chapter 8 Troubleshooting

1. Mechanical Section .................................................................................................................................................. 8-1

2. Electrical Section......................................................................................................................................................8-2

Chapter 9 Error code list (For Stand Alone)............................................................................... 9-1

Chapter 10 Error code list (For PC Control type) .................................................................... 10-1

Chapter 11 Block Figure............................................................................................................ 11-1

10 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 13

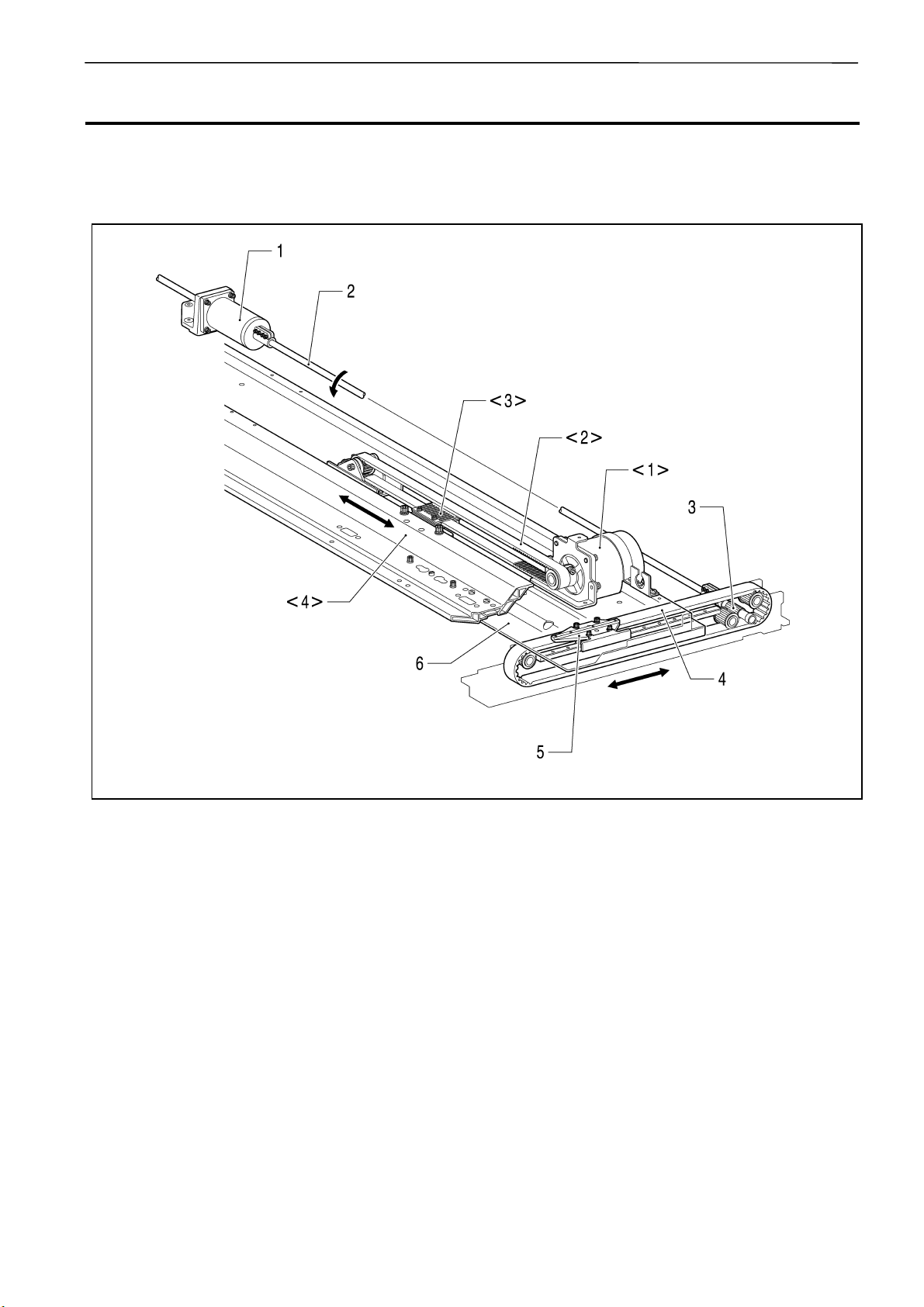

Chapter 1 Mechanical Descriptions

Chapter 1 Mechanical Descriptions

The mechanisms operate in the order of the numbers given in the illustrations.

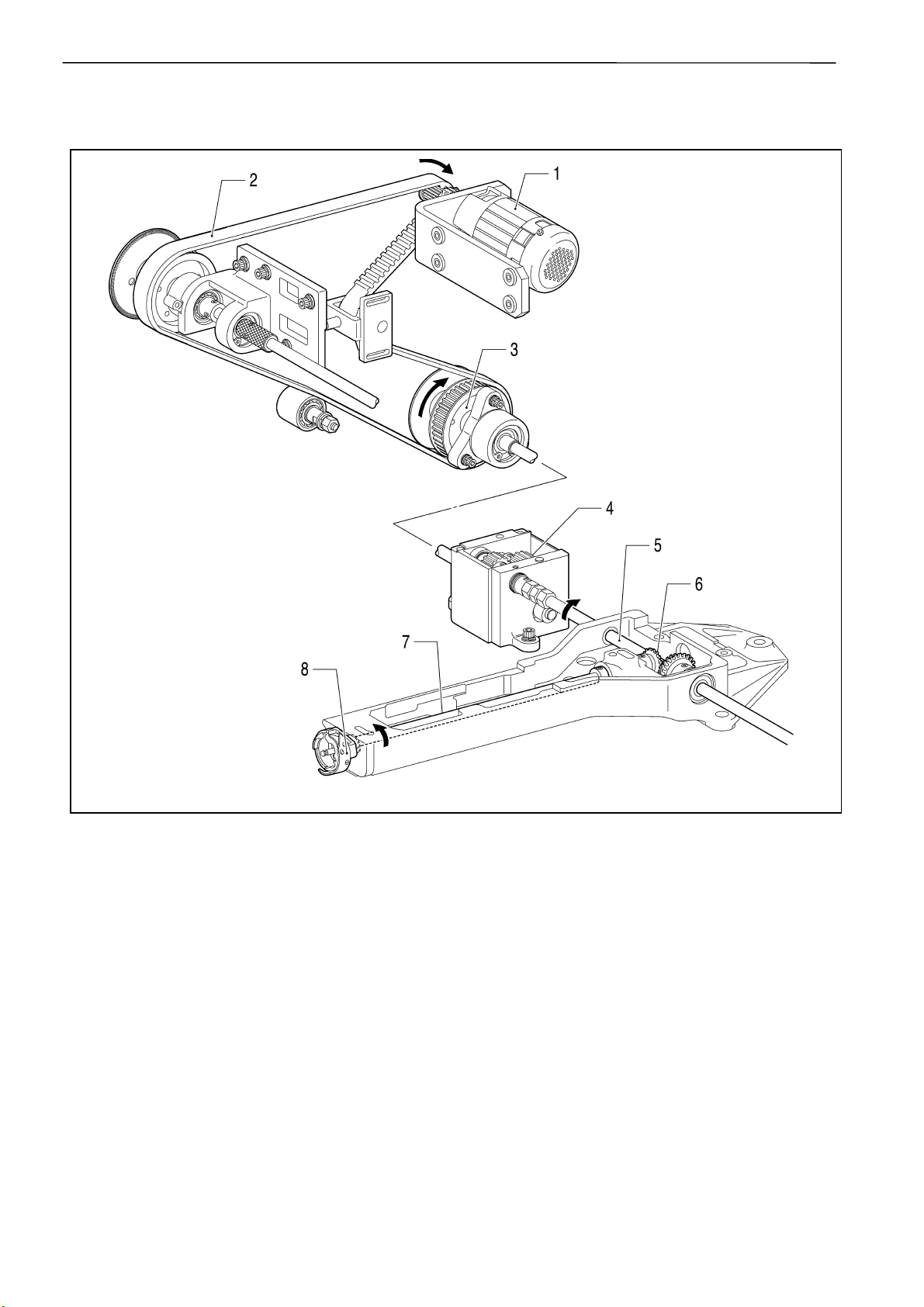

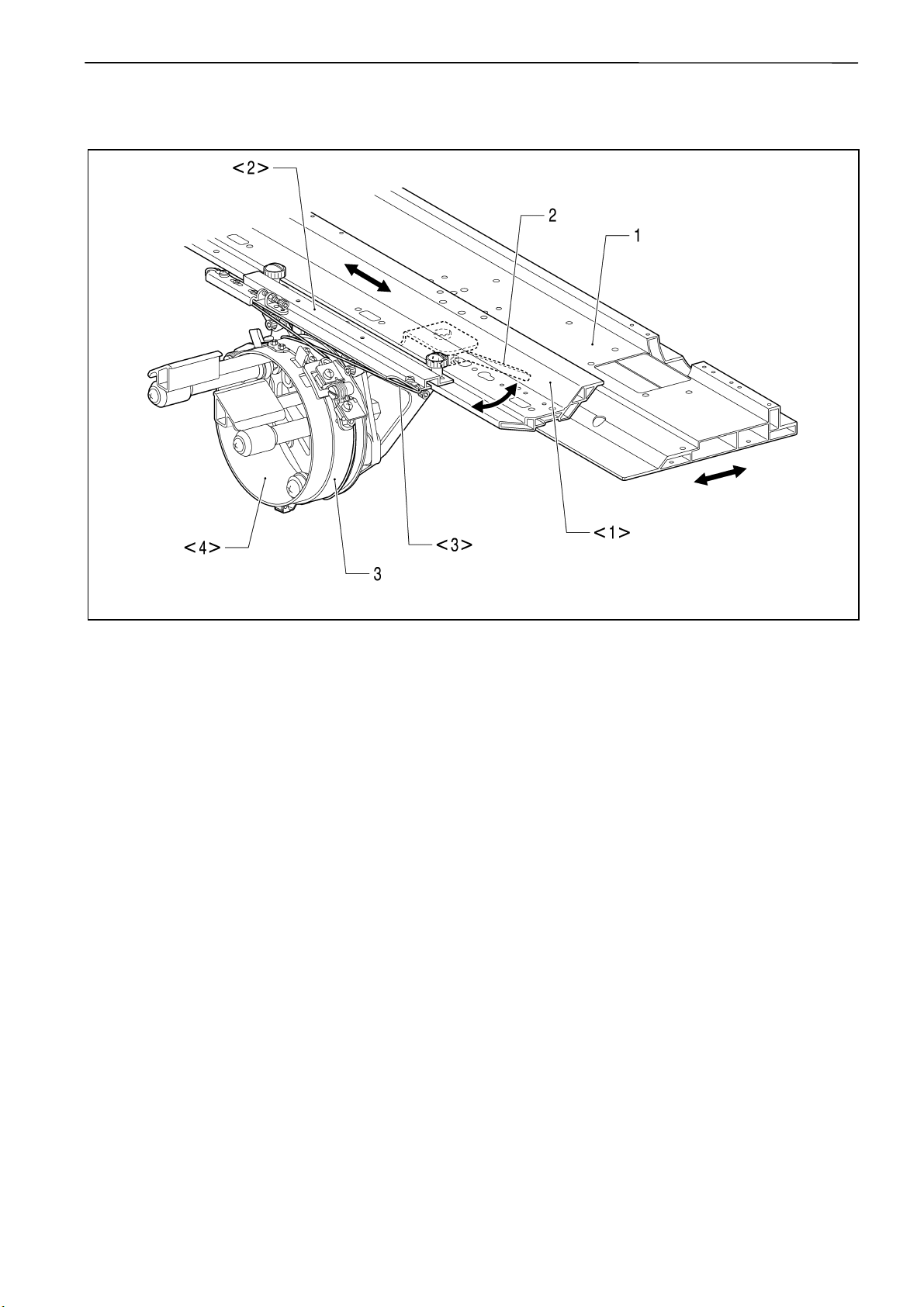

1. Feed guide mechanism

[X direction]

<1>.X-pulse motor

<2>.Timing belt

<3>.X-driving carriage

<4>.X-feed frame

[Y direction]

1.Y-pulse motor

2.Y-driving connecting shaft

3.Y-driving pulley

4.Y-driving belt

5.X-carriage

6.Y-feed frame

2549M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-1

Page 14

Chapter 1 Mechanical Descriptions

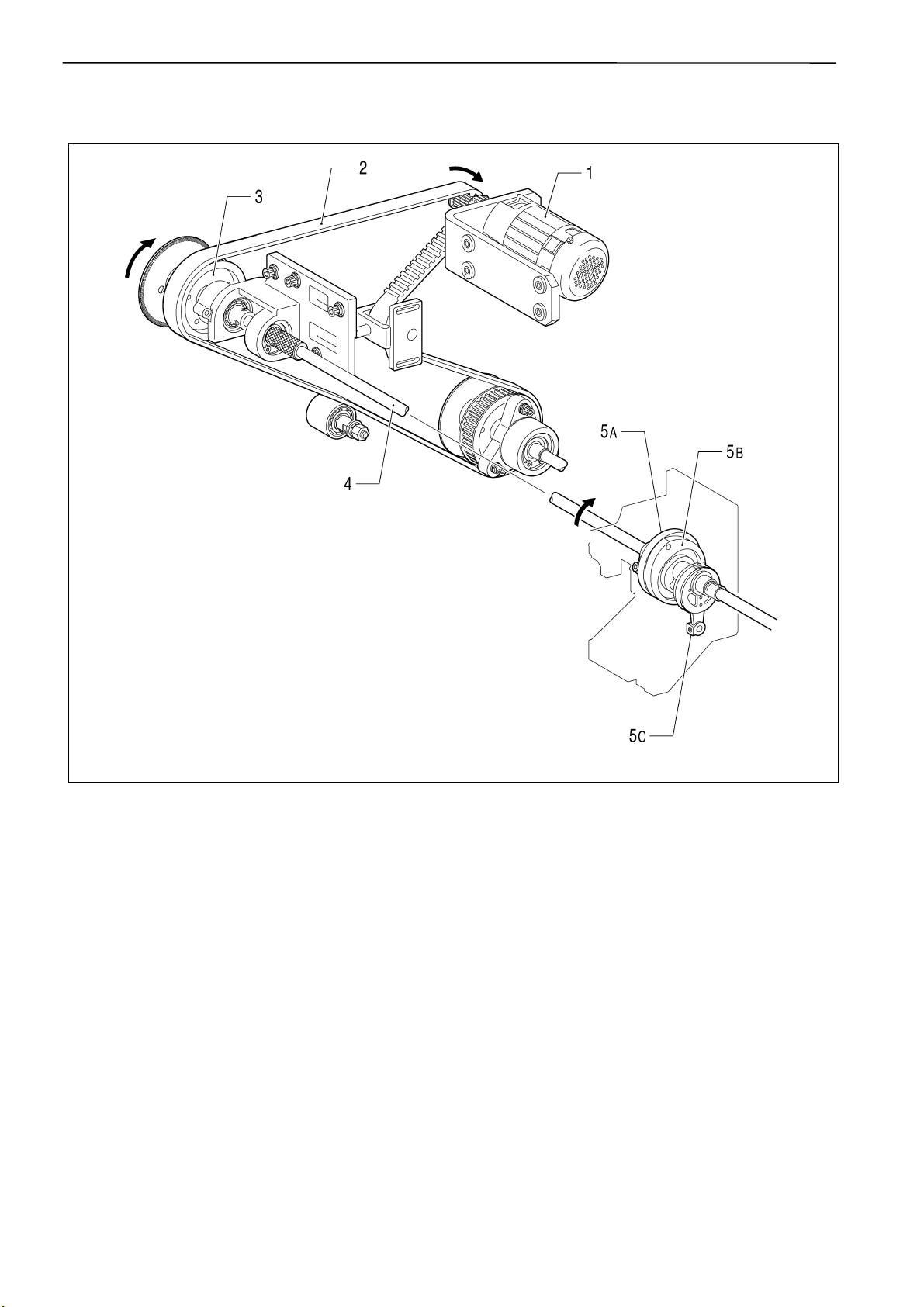

2. Crank shaft mechanism

1.Motor

2.Timing belt

3.Driving pulley

4.Connecting shaft upper

5A.Cloth presser cam

5B.Thread take-up driving cam

5C.Needle bar driving cam

2550M

1-2 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 15

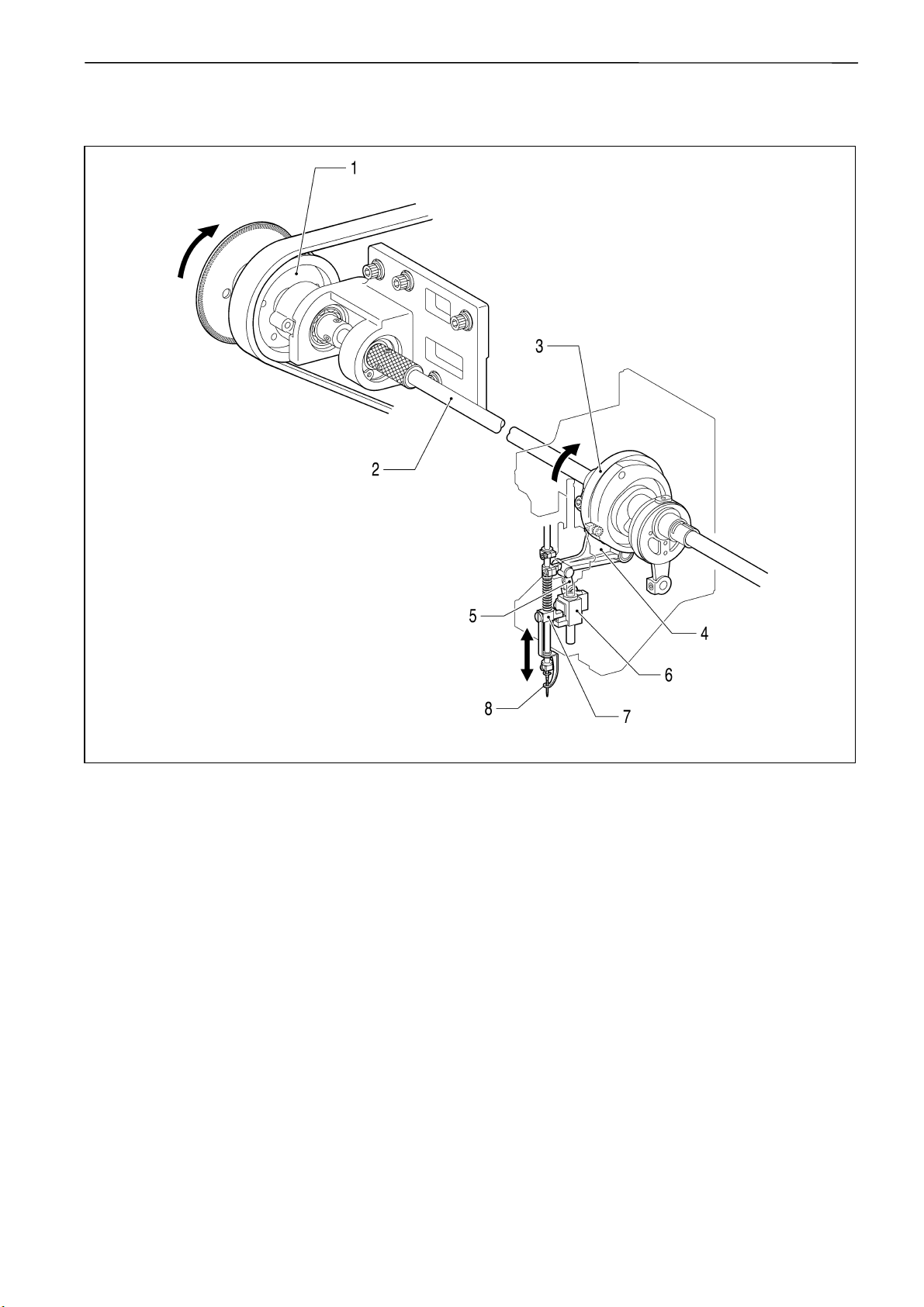

3.Presser foot mechanism

Chapter 1 Mechanical Descriptions

1.Driving pulley

2.Connecting shaft upper

3.Presser foot cam

4.Work clamp driving lever assy

5.Driving connector

6.W-clamp lifting parts

7.Work clamp bracket

8.Presser foot

2551M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-3

Page 16

Chapter 1 Mechanical Descriptions

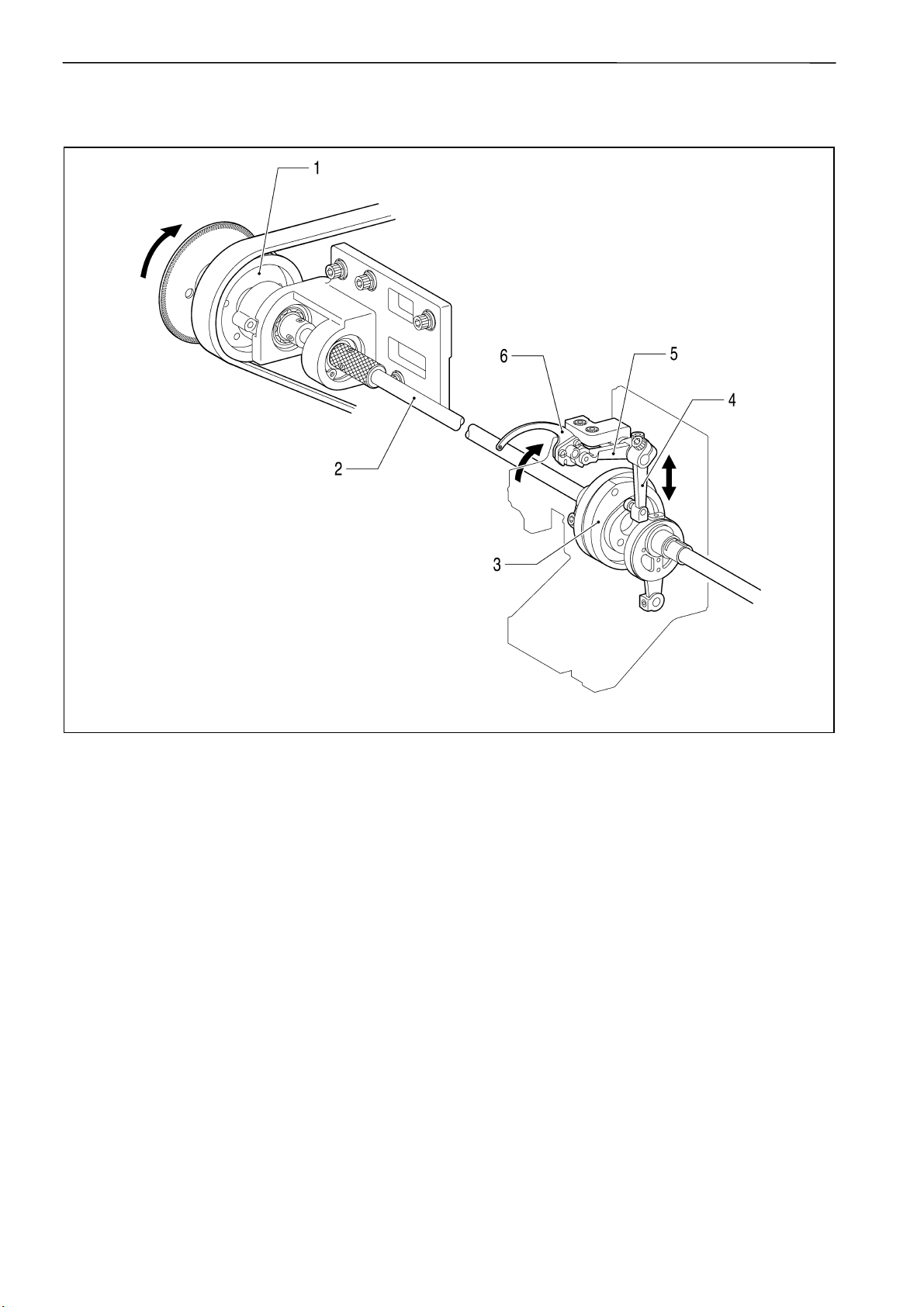

4.Thread take-up mechanism

1.Driving pulley

2.Connecting shaft upper

3.Thread take-up driving cam

4.Thread take-up driving lever

5.Lever

6.Thread take-up lever

2552M

1-4 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 17

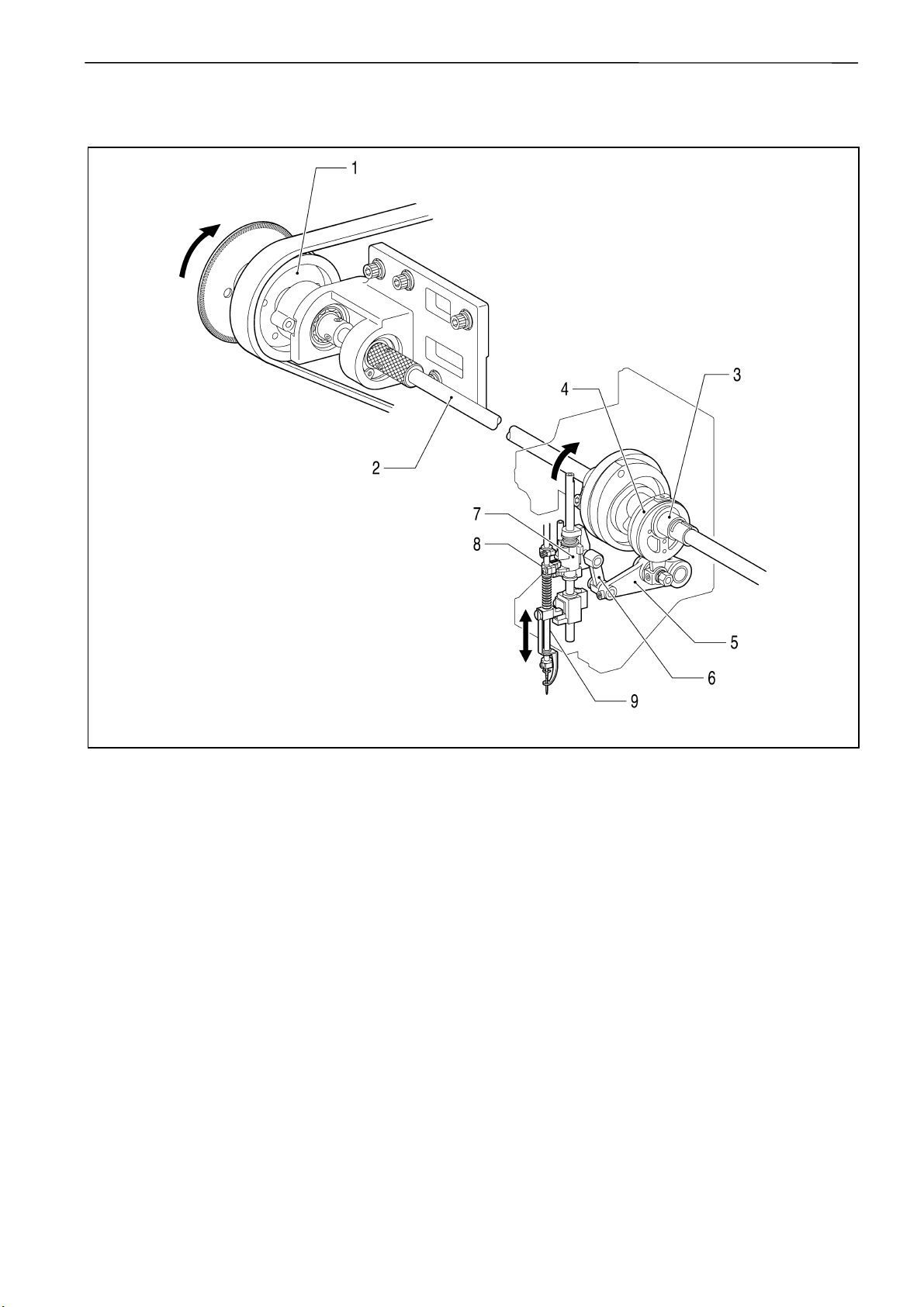

5. Needle bar mechanism

Chapter 1 Mechanical Descriptions

1.Driving pulley

2.Connecting shaft upper

3.Needle bar driving cam

4.Connecting rod

5.Needle bar driving lever

6.Driving connector

7.Needle bar lifting parts

8.Needle bar clamp

9.Needle bar

2553M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-5

Page 18

Chapter 1 Mechanical Descriptions

6.Lower shaft and rotary hook mechanisms

1.Motor

2.Timing belt

3.Driving pulley

4.Gear

5.Driving shaft lower

6.Lower shaft gear

7.Lower shaft

8.Rotary hook

2554M

1-6 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 19

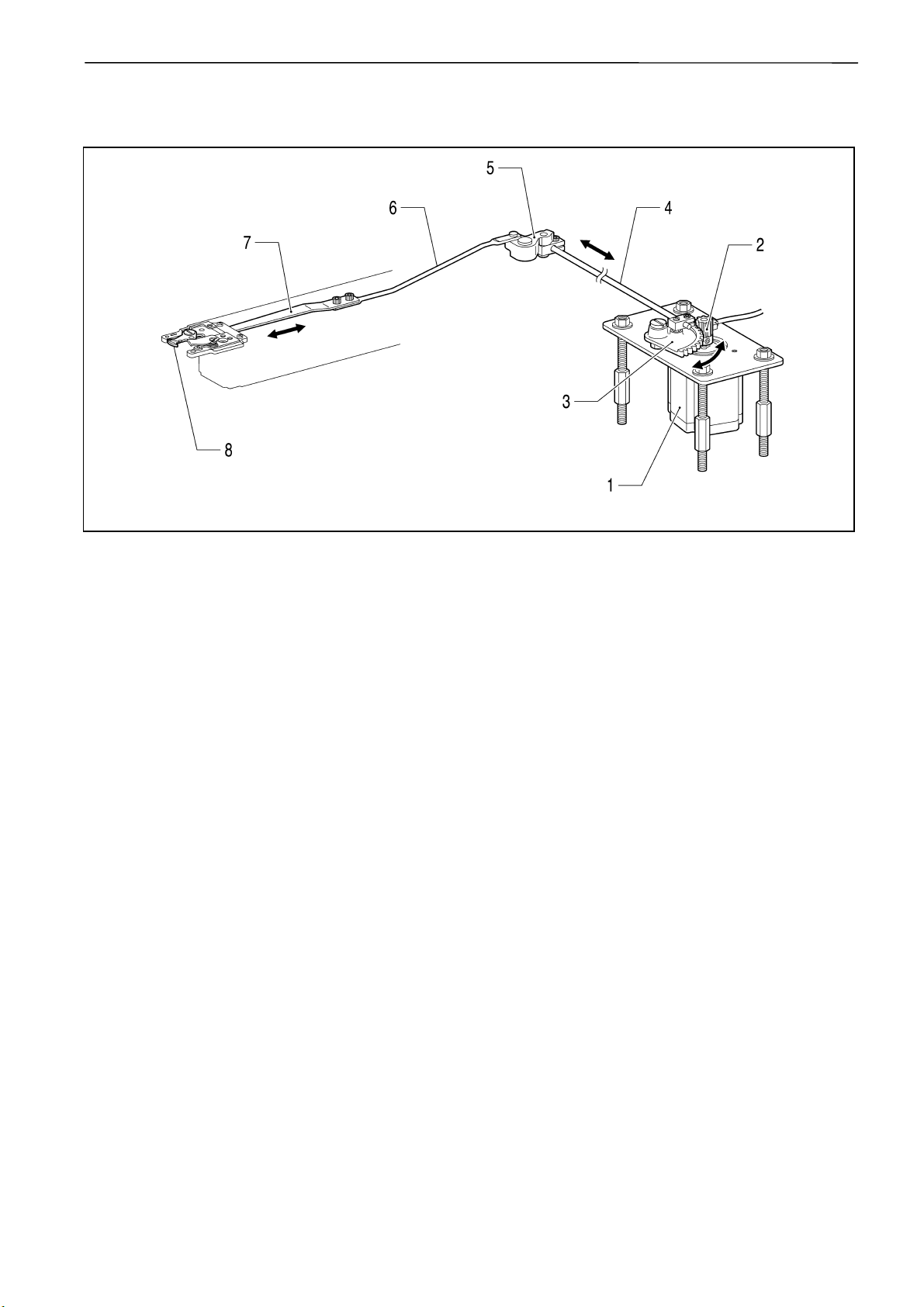

7.Thread trimmer mechanism

Chapter 1 Mechanical Descriptions

1.Thread trimmer motor

2.Thread trimmer gear

3.Driving lever

4.Connedtion shaft

5.T-trimmer connecting rod lever

6.T-trimmer connecting rod, B

7.T-trimmer con. rod assy, A

8.Movable knife

2555M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-7

Page 20

Chapter 1 Mechanical Descriptions

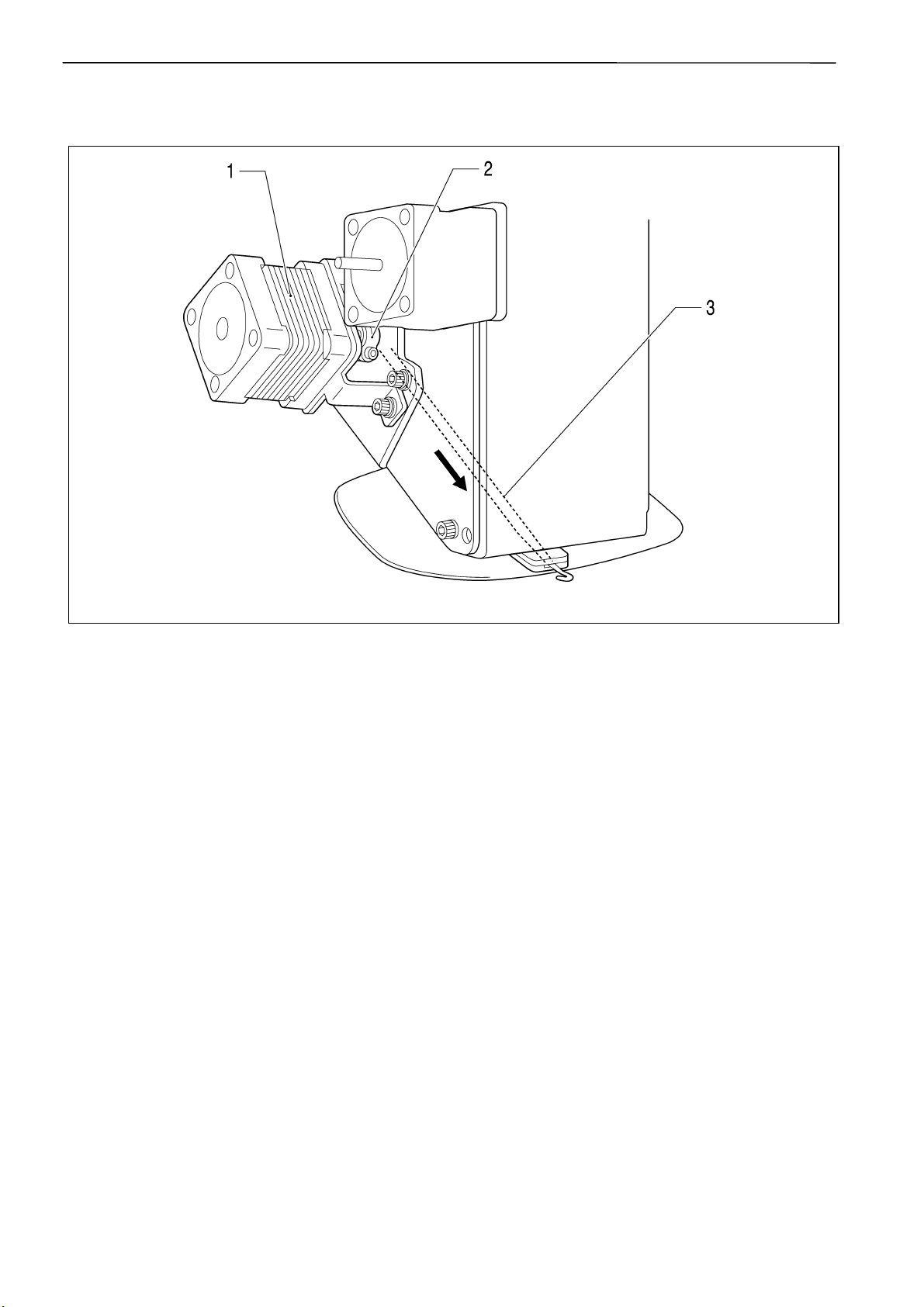

8.Thread wiper mechanism

1.Wiper motor bracket

2.Wiper lever

3.Upper thread hook

2556M

1-8 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 21

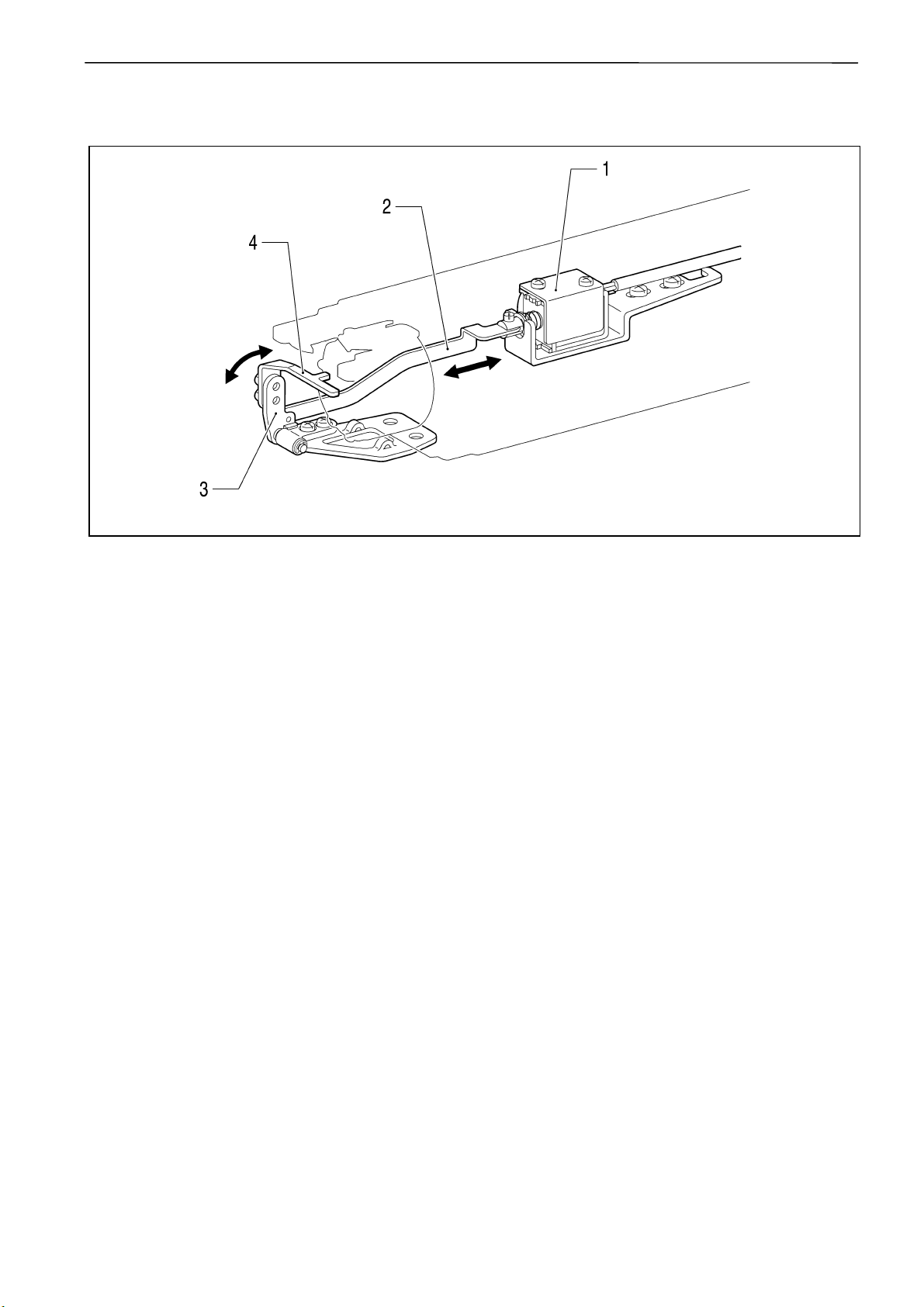

9.Picker mechanism

Chapter 1 Mechanical Descriptions

1.Picker solenoid

2.Picker lever

3.Picker base

4.Picker

2557M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-9

Page 22

Chapter 1 Mechanical Descriptions

10.Needle bar flip-up mechanism

1.Change color motor

2.Change color gear

3.Shaft

4.Change cam

5.Change roller base

6.Needle bar case

7.Change bracket collar

8.Connection shaft

*A Change color sensor

*B Dog

2558M

1-10 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 23

11.Cap frame device

Chapter 1 Mechanical Descriptions

[X direction]

<1>.X-feed frame

<2>.Cap frame

<3>.Wire

<4>.Driving ring

[Y direction]

1.Y-feed frame

2.Fixing lever

3.Driving ring

2559M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-11

Page 24

Chapter 2 Parts replacement and adjustment

Chapter 2 Parts replacement and adjustment

1. Replacement and adjustment of jump driving assy, cloth presser cam,

thread take-up driving cam, needle bar driving cam, driving belt and

upper shaft sensor

[Removing procedure]

2560M

1. Unscrew the screws of cover lower and

upper (1) and cover R (2) to remove them.

Unscrew the screws of side cover L (3) to

remove it.

Also remove the other covers.

2561M

2. Detach the connector of tension base

harness (5) from I/O PCB (4).

Unscrew the screws of base (6) to remove it.

2562M

2-1 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 25

2563M

Chapter 2 Parts replacement and adjustment

3. Take off 4 bolts of thread take-up cover (7) to

remove it.

4. Take off 4 bolts of needle bar case (8) to

remove it.

2564M

5. Loosen 2 bolts of bearing collar pulley (9),

and also loosen 1 bolt of needle bar cam

collar (10) of each head.

2565M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-2

Page 26

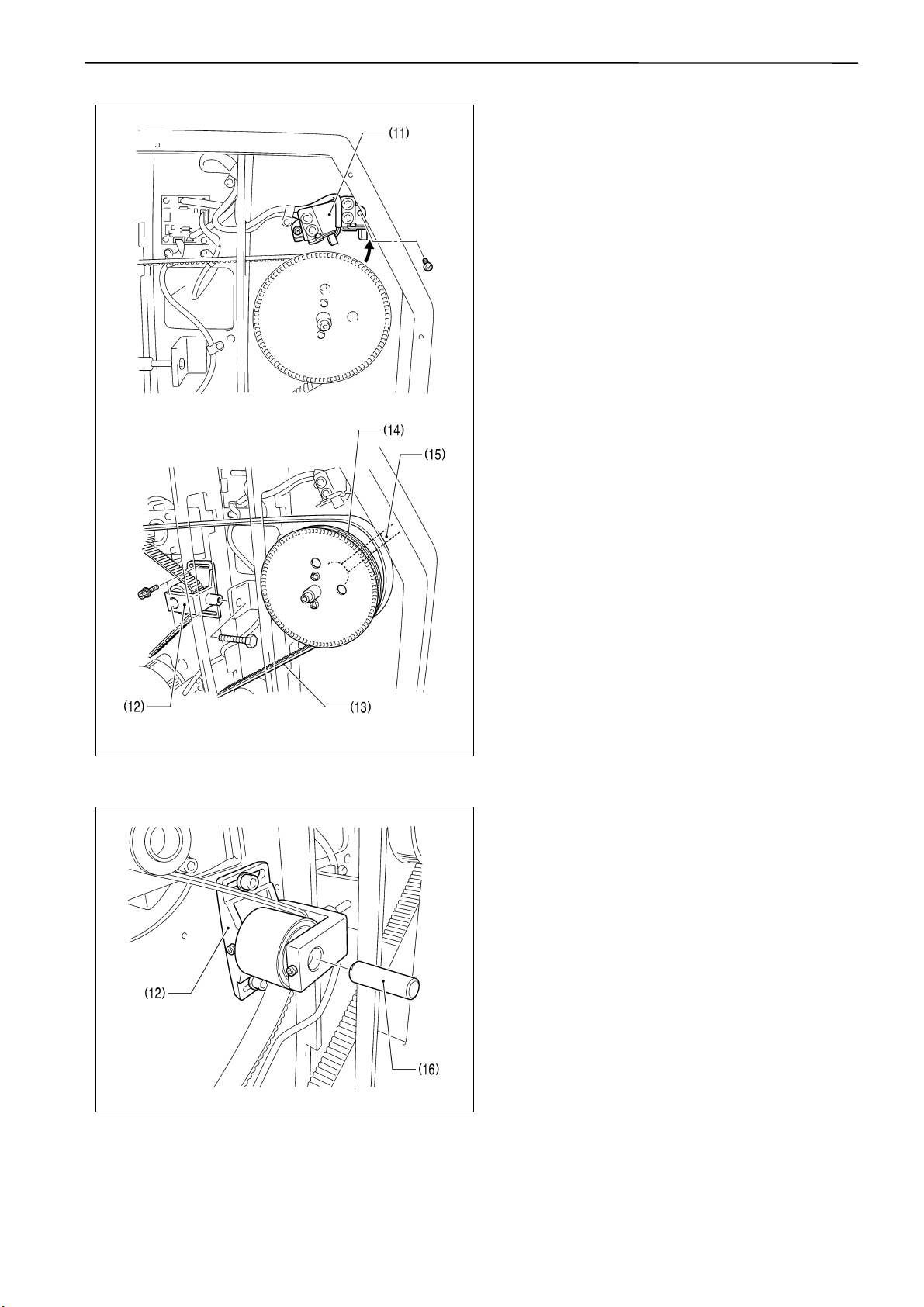

Chapter 2 Parts replacement and adjustment

2566M

6. Unscrew 1of 2 screws of upper shaft sensor

base plate (11), and then loosen the other

one to fasten upper shaft sensor base plate

(11) upward temporary.

Take off 3 bolts of tensor pulley holder (12)

to remove it.

Detach driving belt (13) from driving pulley

(14).

Extract driving shaft upper (15) together with

driving pulley (14).

2567M

2568M

7. To replace driving belt, loosen 2 set screws

of tension pulley holder (12) to extract

tension shaft (16), and then detach driving

belt (13).

2-3 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 27

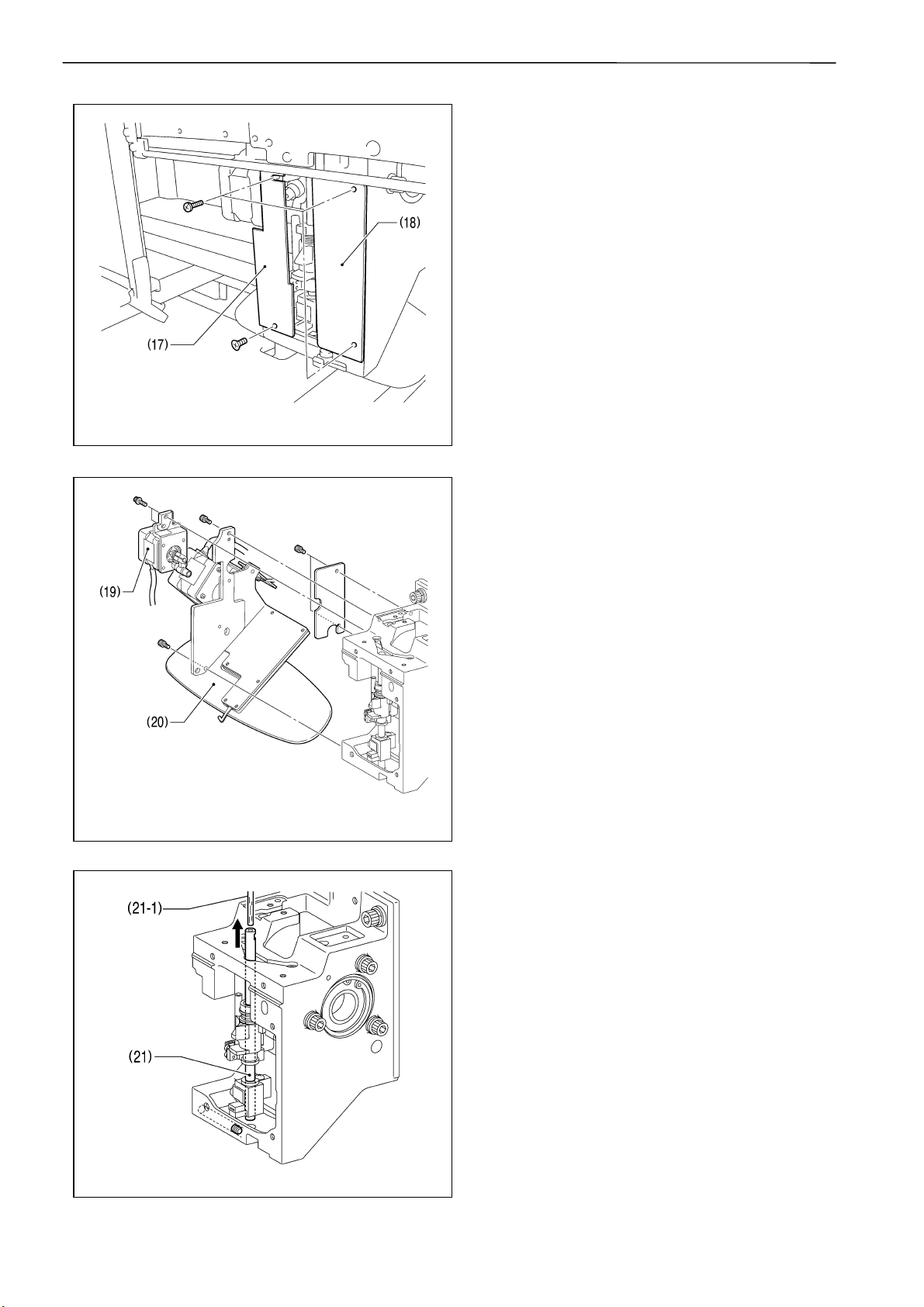

2569M

Chapter 2 Parts replacement and adjustment

8. Unscrew 2 screws each of front cover R (17)

and front cover L (18) to remove both of

them.

9. Take off 2 bolts of jump driving assy (19) to

remove it.

Take off 2 bolts of wiper driving assy (20) to

remove it.

2570M

10. Remove the base needle bar felt (21-1) and

loosen a set screw, socket to pull out the

base needle bar (21).

2571M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-4

Page 28

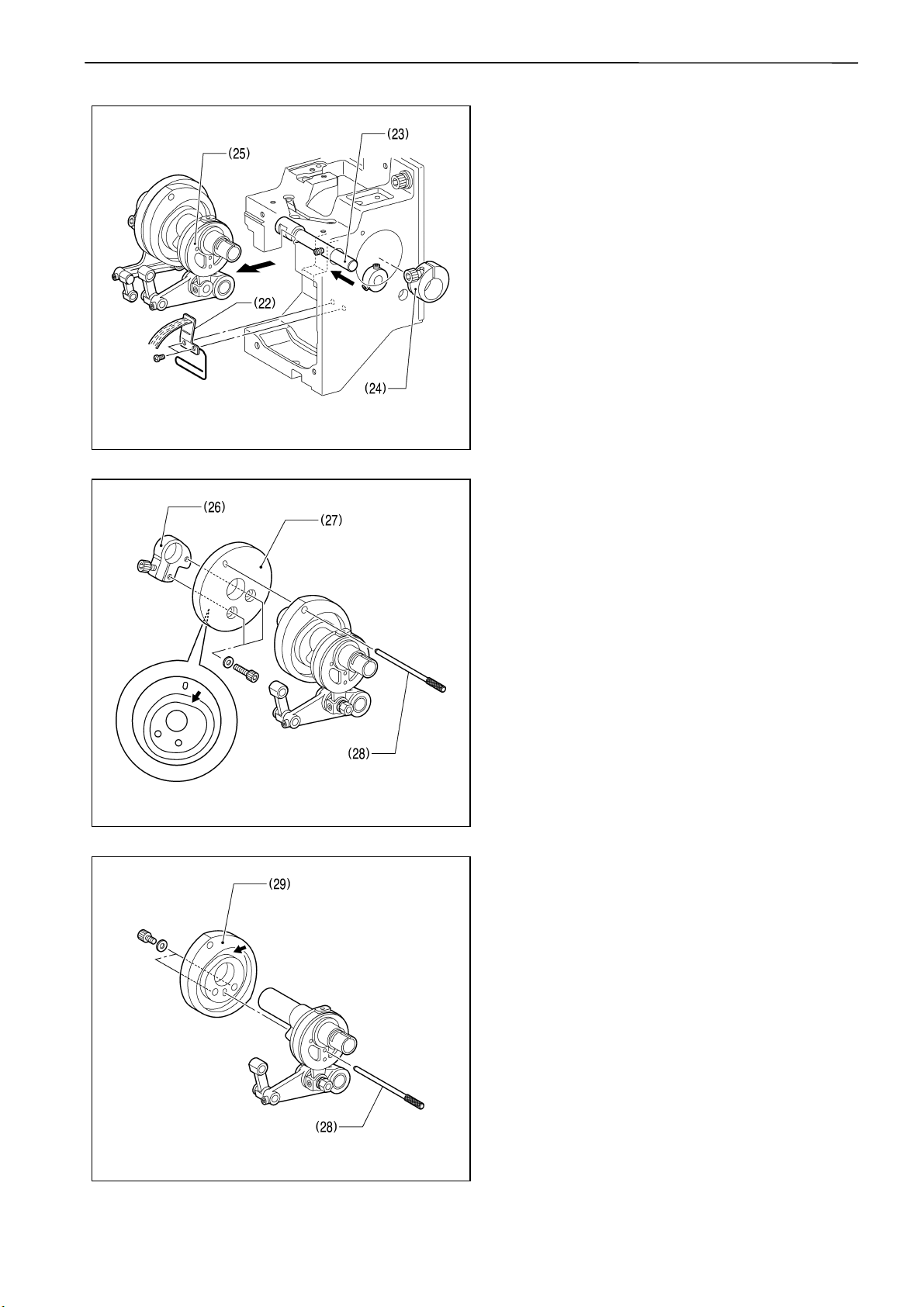

Chapter 2 Parts replacement and adjustment

11. Unscrew 2 screws of oil support A (22) to

remove it.

Loosen 3 set screws of driving lever shaft

(23) to extract it.

Loosen 1 bolt of needle bar cam collar (24)

to remove it.

Now needle bar cam (25) can be detached.

2572M

12. Loosen 1 bolt of cloth presser cam collar

(26) to remove it.

Loosen 2 bolts of cloth presser cam (27) to

remove it.

To mount cloth presser cam collar (26),

insert positioning gauge pin (28) into the

positioning hole on the cam and fasten 1

bolt.

Grease the groove of cloth presser cam (27)

indicated by the arrow in the drawing.

2573M

CAUTION

Use the positioning gauge pin included in

the attachment of the sawing machine.

Use the attached grease tank EM-30L for

the greasing.

13. Take off 2 bolts of thread take-up driving cam

(29) to remove it.

To mount thread take-up driving cam (29),

insert positioning gauge pin (28) into the

positioning hole on the cam and fasten 2

bolts.

Grease the groove of thread take-up driving

cam (29) indicated by the arrow in the

drawing.

CAUTION

Use the positioning gauge pin included in

the attachment of the sawing machine.

Use the attached grease tank EM-30L for

the greasing.

2574M

2-5 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 29

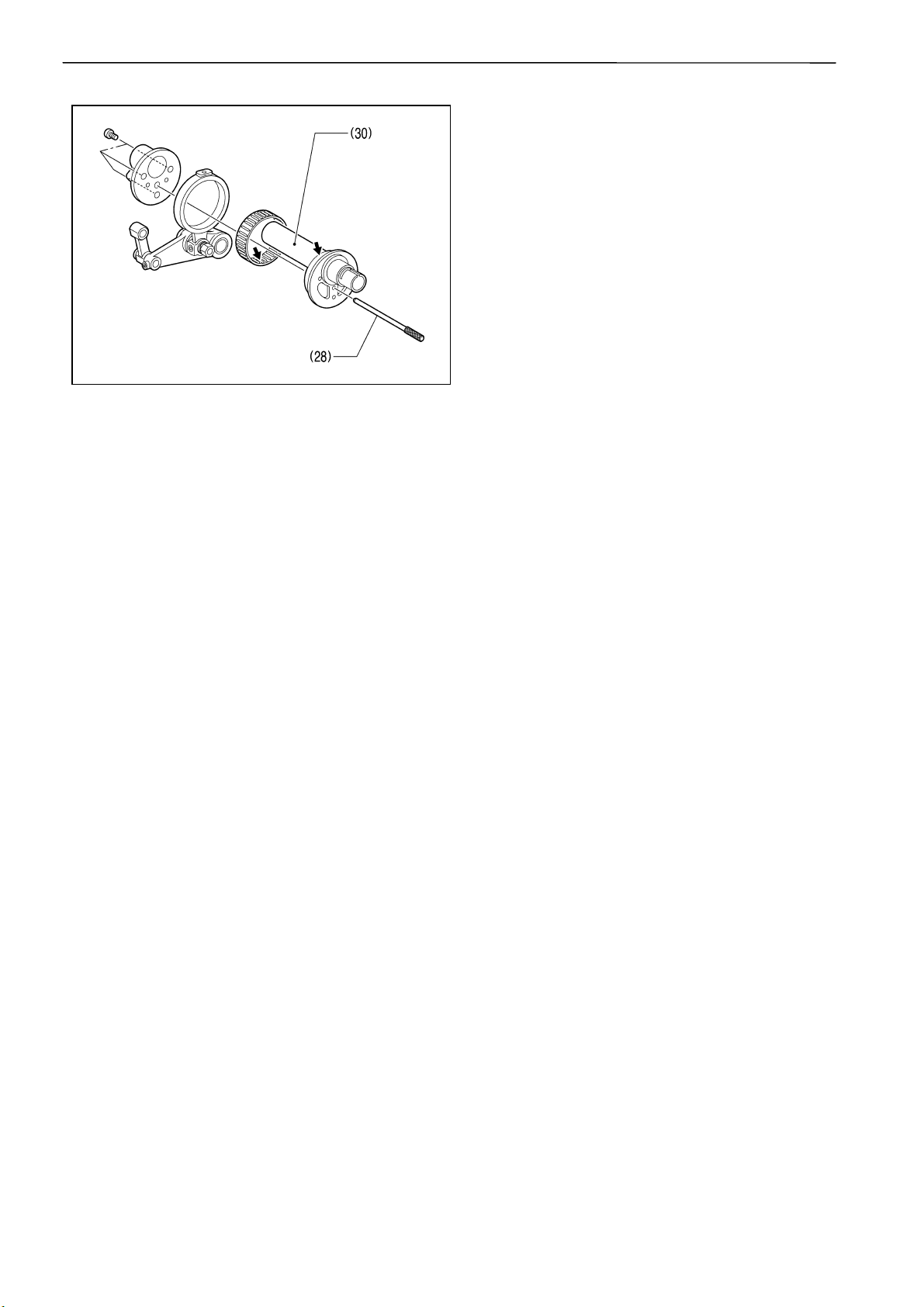

2575M

Chapter 2 Parts replacement and adjustment

14. Unscrew 2 screws of needle bar driving cam

(30) to remove it.

Grease needle bar driving cam (30) at the

position indicated by the arrow in the

drawing.

To mount needle bar driving cam (30), insert

positioning gauge pin (28) into the

positioning hole on the cam and fasten 2

screws.

CAUTION

Use the positioning gauge pin included in

the attachment of the sawing machine.

Use the attached grease tank EM-30L for

the greasing.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-6

Page 30

Chapter 2 Parts replacement and adjustment

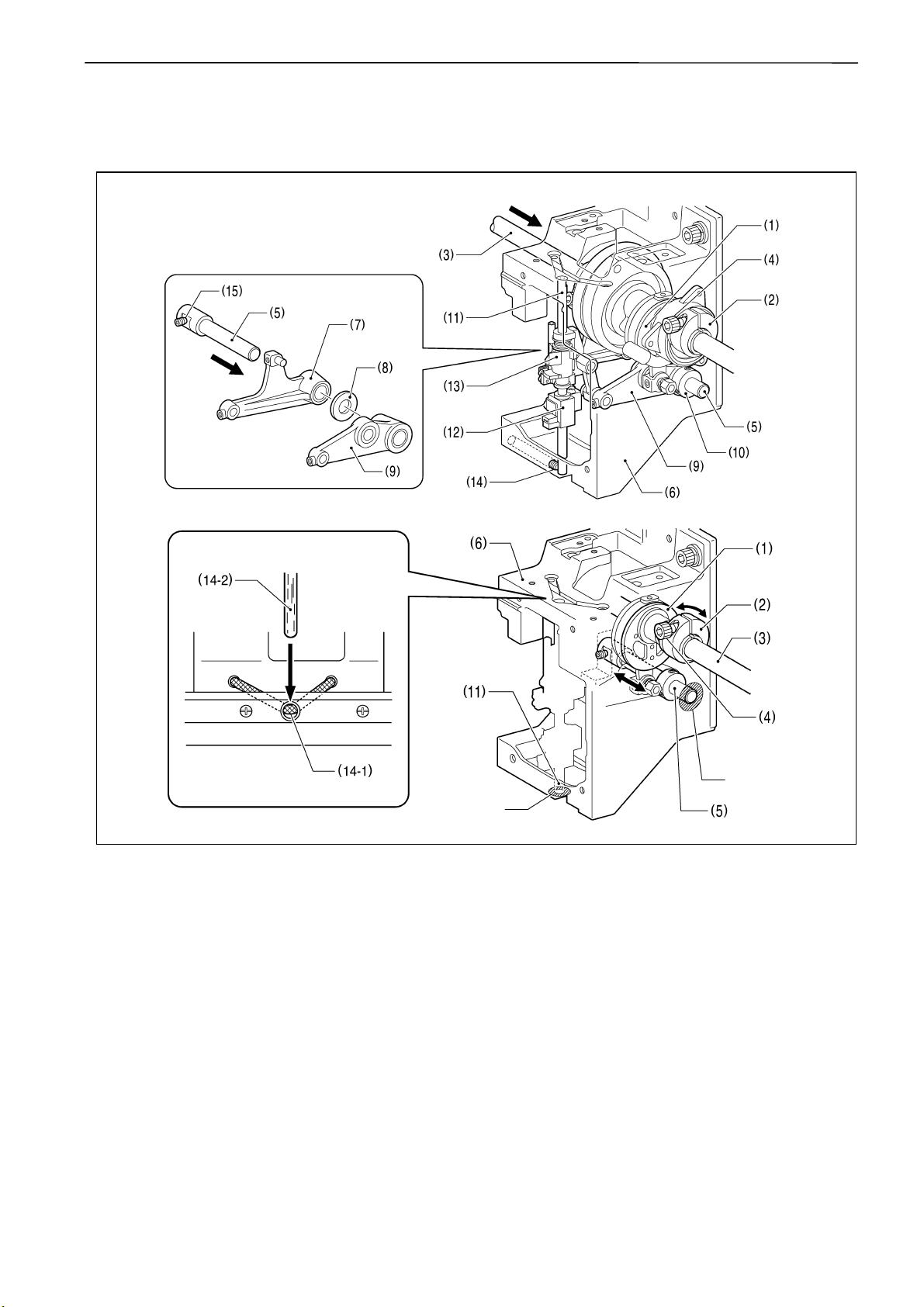

[Mounting procedure]

To mount pieces, follow the reverse procedure to the disassembly. The followings are the key points in

the mounting.

2576M

LIQUID GASKET

LIQUID GASKET

2577M

1. Grease the connecting shaft upper on spots that touches bearings of the driving pulley, driving

shaft support or each head.

2. Attach needle bar cam collar (2) to needle bar driving cam (1), insert driving shaft upper (3) and

fasten the bolt (4) temporary so that needle bar driving cam (1) rotates easily.

3. Insert driving lever shaft (5) into head (6), work clamp driving lever (7), spacer (8), needle bar

driving lever (9) and set screw collar (10), then fasten 3 set screws.

4. Spread a sealing agent on the left side of head (6) and lever shaft (5) to prevent oil leak.

5. Insert base needle bar (11) into head (6), work clamp lifting parts (12), and needle bar lifting parts

(13), and fasten 1 set screw (14).

6. Reset the wick (14-1) so that it touches the base needle bar felt (14-2).

7. Spread a sealing agent on the bottom faces of head (6) and base needle bar (11) to prevent oil

leak.

CAUTION

Rotate needle bar cam collar (2) and see if needle bar driving cam (1) rotates easily. If not, loosen

1 set screw (15) of driving lever shaft (5) to shift it toward the thrust for adjustment.

2-7 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 31

CAUTION

Use three bond 1215 commercially available for the sealing.

Use the attached grease tank EM-30L for the greasing.

Chapter 2 Parts replacement and adjustment

2579M

9. Align driving pulley (16) and the positioning hole on pulley case upper (17), then insert positioning

bar (18) therein.

CAUTION

Use the positioning bar (18) included in the attachment of the sawing machine.

10. Repeat the following procedure for each

head in order: Align the hole on the right side

of the head and the positioning hole of

thread take-up driving cam (19) (needle bar

bottom dead center), then insert positioning

gauge pin (20) therein. Also align slit of

needle bar driving cam (1) and needle bar

cam collar (2), and fasten bolt (4) to fix them.

CAUTION

Use the positioning gauge pin included in

the attachment of the sawing machine.

11. Adjust arrow plate (21) and scale plate (22)

to make 180 degrees angle each other, then

attach driving belt (23) on them.

2578M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-8

Page 32

Chapter 2 Parts replacement and adjustment

15N

8mm

12. Temporarily fasten 2 bolts (25) which are

fixing tension pulley holder (24).

13. Turn tension adjusting bolt (26) for the

adjustment.

Clockwise turn: Increases the tension

Anticlockwise turn:Decreases the tension

14. Fasten 2 bolts (25) of tension pulley holder

(24), then adjust the holder so that the

bending should be about 8 mm when

pushed with the force of 15 N at the center of

the belt.

Measuring with the sonic tension meter

by Gates Unitta Asia Company,

Unit weight :4.0g/mm

Width :20mm

Span :310mm

Adjust the tension to be 130 N ± 10 N

when (A) is twanged. Be sure to clear

around the belt so that nothing touches it

when twanged.

2580M

2580M

15. Fasten 2 screws (28) of upper shaft sensor

base plate (27) temporarily.

Put sensor position plate (29) as shown in

the illustration, adjusting its position so as to

touch both phase-A sensor (30) and phaseB sensor (39) lightly, and then fasten the 2

screws (28) of upper shaft sensor base plate

(27) firmly.

CAUTION

Use the sensor positioning plate (29)

included in the attachment of the sewing

machine.

2581M

2-9 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 33

2582M

Chapter 2 Parts replacement and adjustment

16. Insert bed frame side packing (32) between

heads (33), then attach wiper driving assy

(31) with 2 bolts.

No need to adjust any parts in this case.

If troubled, follow the description on Page

2-13. “Replacement and adjustment of

stepping motor for thread sweeping and

wiper sensor”.

2583M

17. Fasten 2 bolts to fix jump driving assy (34) at

the position where jump lever (35) and jump

base (36) make no spaces between them.

18. Spread a sealing agent around the contact

points between the head and the bottom

faces of front cover R (30) and front cover L

(31) to prevent oil leak, then attach those

covers with 2 screws each.

CAUTION

Use three bond 1215 commercially

available for the sealing.

LIQID

GASKET

2584M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-10

Page 34

Chapter 2 Parts replacement and adjustment

2. Replacement and adjustment of thread take-up lever

2620M

1. Detach needle bar case (1).

Refer to “1. Replacement and adjustment

of jump driving assy, cloth presser cam,

thread take-up driving cam, needle bar

driving cam, driving belt and upper shaft

sensor” for information on how to detach

needle bar case (1).

2. Loosen the right and left set screws, (2) to

pull out thread take-up shaft (3), then detach

thread take-up lever (4).

To mount pieces after the replacement,

follow the reverse procedure to the above.

(Instructions for the mounting)

1. Put the slit of thread take-up position bush

(5) upward and make the faces of needle bar

case stick together on visor before fastening

set screws.

2. Put the slit of thread take-up adjusting bush

(6) upward as well and keep the clearance

between thread take-up adjusting bush (6)

and thread take-up lever (4) to be within 0.3

to 0.5 mm before fixing them.

Slit

2621M

Turn driving pulley and follow the procedure below to adjust the heights of the other thread take-up

lever (4) and lever (7) to be even when driving pulley is angled at 100 degrees (stop position).

Loosen bolt, socket (8) which is fixing lever (7) to

adjust the height of thread take-up lever (4) when

driving pulley is angled at 100 degrees (stop

position).

CAUTION

Adjust the position not to make a noise

“Click” when changing the color.

2622M

2-11 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 35

3. Replacement and adjustment of work clamp

1. Unscrew 2 screws of lower cover (1) to

detach it.

2. Unscrew 2 screws of lower thread eyelet (2)

to detach it.

2623M

Chapter 2 Parts replacement and adjustment

2624M

3. Unscrew needle clamp screw (3) to detach

needle (4), needle bar thread guide (5) and

work clamp cushion (6).

4. Unscrew screw, M3 (7) to detach work clamp

(8).

To mount pieces after the replacement,

follow the reverse procedure to the above.

How to adjust the height of work clamp (8)

1. Loosen screw, M3 (7) to adjust the height of

work clamp (8) so that the bottom face of

cloth presser and the upper surface of the

cloth touch each other at the alignment point

of the N.H mark (200 degrees) and the arrow

plate (contact point between the needle and

rotary hook).

Cloth

2625M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-12

Page 36

Chapter 2 Parts replacement and adjustment

4.Replacement and adjustment of stepping motor for thread sweeping and

wiper sensor

Turn off the power of the sewing machine.

[How to detach]

2626M

1. Detach bolt (1) and then detach cord holder

washer (2).

2. Detach wiper sensor connector P2 or P3 (4)

from head PCB (3).

3. Unscrew 1 screw (6) of wiper sensor bracket

(5) and replace sensor PCB (7).

4. Detach wiper stepping motor connector P8

or P9 (8) from head PCB (3)

2627M

5. Detach the nut of shoulder screw (11) to

detach upper thread hook (10) from wiper

lever (9).

6. Detach 2 bolts (14) to detach wiper motor

bracket (13) from wiper assy reference base

(12), then replace stepping motor (15).

2628M

2-13 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 37

Chapter 2 Parts replacement and adjustment

[How to mount]

To mount pieces, follow the reverse procedure to the disassembly.Key points in the mounting and the

adjustment afterward are described below.

2629M

1. Mount wiper lever (9) and upper thread hook

(10), and then move them with fingers in the

direction of arrow to see if they can be

moved easily. If not, loosen 4 set screws

(16) of thread nipper (15) to adjust the height

until they become lighter. Then check needle

bar No. 1 and No. 12.

2630M

2. Put wiper sensor bracket (5) according to the

arrow direction, adjusting the gap between

the emboss (6) to be 1 mm as shown in the

illustration, and then secure the bracket with

1 screw (6).

2631M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-14

Page 38

Chapter 2 Parts replacement and adjustment

5. Replacement and adjustment of picker solenoid

[How to detach]

2636M

2637M

2632M

2639M2638M

1. Unscrew screws of table cover (1) and bed cover B (2), and then remove each cover.

2. Disconnect the connector of picker solenoid (3).

3. Unscrew picker shoulder screw (4).

4. Unscrew 2 screws (5) to detach picker setting plate (6), and then replace picker solenoid (7).

2-15 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 39

Chapter 2 Parts replacement and adjustment

[How to mount]

To mount pieces, follow the reverse procedure to the disassembly. Key points in the mounting and the

adjustment afterward are described below.

2640M

1. Adjust the position of picker setting plate (6)

by moving it back and forth so that the tip of

picker (8) keeps 14.0-14.5 mm distance from

bobbin (9) when picker solenoid (3) is turned

off, and then fasten 2 screws (5) there.

(Cautions in the mounting)

1. Confirm that picker lever (10) does not touch

bed (11).

2641M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-16

Page 40

Chapter 2 Parts replacement and adjustment

2642M

2. Check if the distance between the tip of

picker (8) and bobbin (9) is whithin 0.5 to 1.0

mm when picker solenoid (3) is turned on. If

it is less, repeat the adjustment of 1. again.

3. Check if the distance between the upper

surface of the tip of picker (8) and the bottom

face of rotary hook sttopper is within 3.5 to

4.5 mm. If the distance is out of range,

loosen 2 screws (12) to adjust the height of

picker (8).

2643M

2-17 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 41

Chapter 2 Parts replacement and adjustment

6. Replacement and adjustment of movable knife and fixed knife

[How to detach]

2644M

1. Unscrew screws of needle plate (1) and bed

cover B (2), and then remove both.

2. Unscrew screw (4) of fixed knife (3) and

screw (6) of movable knife (5), and then

detach both knives.

2645M

[How to mount]

To mount pieces, follow the reverse procedure to the disassembly. Key points in the mounting and the

adjustment afterward are described below.

1. Attach movable knife (5).

2. Detach 2 bolts (7) of T-trimmer con. rod assy,

A (6).

3. Slide the tip of fixed knife (3) to the left and

fasten 1 screw (4) temporarily.

4. Fasten screw (4) of fixed knife (3) gradually

with shifting movable knife (5).

CAUTION

A quick fastening of screw (4) of fixed knife

(3) might destroy both knives when

operating.

2646M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-18

Page 42

Chapter 2 Parts replacement and adjustment

5. Put a thread between movable knife (5) and

fixed knife (3) to cut it for testing.

Thread

2647M

2648M

6. If it does not cut well, insert movable knife

spacer (8) in the attachment beneath

movable knife (5) to increase the pressure of

the knife.

7. Fasten 2 bolts (7) of T-trimmer con. rod assy,

A (6) temporarily.

8. Shift to the test mode.

For Stand Alone type : Refer to Chapter 4

For PC Control type : Refer to Chapter 5

9. Pushing step back switch (9) will operate

movable knife (5) indicated by the arrow.

Loosen 2 bolts (7) of T-trimmer con. rod assy,

A (6) for the adjustment so that the tip of

movable knife (5) sticks out by 1 mm from

fixed knife (3) when it is in the side A.

2649M

2-19 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 43

7. Replacement and adjustment of Timing belt, X

[How to detach]

Chapter 2 Parts replacement and adjustment

2650M

2651M

2652M

1. Turn off the power.

2. Unscrew screws of X-feed cover L, R and C (1) to detach them from Y-frame (2).

3. Loosen 2 bolts (4) fixing X-pulley bracket (3) to loosen bolt, socket (5) to the limit which is for the

belt tension adjusment.

4. Detach 4 bolts of belt stopper plate, 20 (7) attached to X-driving carriage (6), and then detach

timing belt (8) and belt stopper plate, 20 (7) from X-driving carriage (6).

5. Loosen bolts (10), extract pulley shaft (11), and remove timing belt (8).

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-20

Page 44

Chapter 2 Parts replacement and adjustment

[How to mount]

To mount pieces, follow the reverse procedure to the disassembly. Key points in the mounting and the

adjustment afterward are described below.

2654M

1. Slide X-feed frame (10) to the limit to the X

pulse motor side.

2. Loosen 2 bolts (4) fixing X-pulley bracket (3)

and turn bolt (5) to adjust the belt tension.

• Right turn : Increases the tension.

• Left turn : Decreases the tension.

3. Fasten 2 bolts fixing X-pulley bracket (3),

and adjust the deflection under the force of

15 N pressing down at the belt center to be 9

mm.

Measuring with the sonic tension meter

by Gates Unitta Asia Company,

Unit weight : 4.0 g/mm

Width : 20 mm

Span : 653 mm

Adjust the tension to be 200 N ± 10 N

when twanged at the point indicated by

the arrow. Be sure to clear around the belt

so that nothing touches it when twanged.

2655M

4. Follow the procedures below to adjust

sewing machines with double X-pulse

motors.

Loosen 2 bolts (12) of X-feed frames (11)

attached to the right and left X-driving

carriages.

Turn on the power to keep X-pulse motor

excited, and then fasten 4 bolts (12) on X-

feed frame (11) in total on the right and left

sides, adjusting each position to have even

clearances on the both sides of the bolt in

the hole.

CAUTION

If this adjustment has been done improperly,

X feeding might be failed during the sewing.

X feeding failures might be caused also by

2656M

2-21 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

the improper frame settings for the sewing

machine.

Page 45

8. Replacement and adjustment of Timing belt, Y

[How to detach]

Chapter 2 Parts replacement and adjustment

2650M

1. Turn off the power.

2. Unscrew screws of X-feed cover L, R, C (1)

and X-motor cover to detach them all from

Y-frame (2) .

3. Unscrew screws of Y-feed cover front and

rear (2) to detach them from Y-cover

support.

2657M

2659M

4. Detach 6 bolts (4) in total on the both sides

of Y-feed frame (3) to detach it from Ycarriage (5) on the both sides.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-22

Page 46

Chapter 2 Parts replacement and adjustment

2658M

2660M

2661M

5. Loosen 2 bolts (5) fixing pulley bracket YF (6) and then loosen bolt (7) to the limit for the belt

tension adjustment.

6. Unscrew 1 bolt, socket (9) and 1 screw, flat (10), and then detach Y-frame support plate (8).

7. Unscrew 4 bolts (12) to detach Y-carriage (11).

8. Detach Y-driving belt (13) from Y pulley A (14) and Y-driving pulley (15) etc.

2-23 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 47

Chapter 2 Parts replacement and adjustment

[How to mount]

To mount pieces, follow the reverse procedure to the disassembly. Key points in the mounting and the

adjustment afterward are described below.

2662M

1. Slide Y-feed frame (1) to the back from the

front face of the sewing machine to the limit.

2. Loosen 2 bolts (3) fixing pulley bracket, YF

(2) and loosen bolt, socket (4) to the limit for

the belt tension adjustment.

•Right turn : Increases the tension.

•Left turn : Decreases the tension.

3. Fasten 2 bolts (3) fixing pulley bracket, YF

(2), and adjust the deflection under the force

of 15 N pressing down on the belt at the

point of 250 mm from the front timing pulley

to be about 3 mm.

Measuring with the sonic tension meter

by Gates Unitta Asia Company,

Unit weight : 4.0 g/mm

Width : 35 mm

Span : 590 mm

Adjust the tension to be 370 N ±10 N

when twanged at the point indicated by

the arrow. Be sure to clear around the belt

so that nothing touches it when twanged.

2663M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-24

Page 48

Chapter 2 Parts replacement and adjustment

9. Adjusting Needle Bar Height

W1304Q

(1)

(5)

(4)

(6)

(2)

(3)

11.3 mm

W1306Q

1. Put the attached T-shaped hexagonal

wrench (4 mm) into the hole (1) on the left

side of the machine body, and adjust the

arrow plate to align with 180° (N.D mark) to

move the needle bar to the lowest point.

2. Loosen Needle bar guide bracket set screw

(6) and the bolt (3) of the top dead center

stopper (4) when the needle tip is positioned

11.3 mm above the center of the rotary hook

shaft. Adjust the position of the needle bar

thread guide so that the set screw (2) on it is

turned to the right by 25 - 30°. Tighten

Needle bar guide bracket set screw (6)

securely.

When tightening the needle bar clamp set

screw (6), the hole in the needle bar guide

should face the front.

W1305Q

2-25 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 49

(5)

Chapter 2 Parts replacement and adjustment

Tighten the

bolt (6) so

that the

clearance

can be even.

(7)

(4)

(6)

W1296Q

Do not hit

this section.

(7)

W1307Q

3. Set the needle bar at the highest position (where the arrow plate and the “N.U.” mark are aligned).

Lightly press the top dead center stopper (4) toward the cushion rubber (5), and tighten Socket

head bolt for top dead center stopper (6) while pressing down the needle bar clamp so that it faces

the front. (Tightening torque: 0.78 N • m)

• Make sure that the top dead center stopper does not hit the needle bar guide rail (7) at

this time.

• When tightening the upper dead point stopper bolt (6), insert the longer side of the

attached wrench into the bolt and tighten it by using the shorter side.

Excessive tightening may make the needle bar movement sluggish.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-26

Page 50

Chapter 2 Parts replacement and adjustment

■When using the bottom dead center gauge

CAUTION

Use the gauge (S58553001 Bottom dead center gauge) included in the accessories of the sewing

machine for this operation.

1. Put the attached T-shaped hexagonal

wrench (4 mm) into the hole (1) on the left

side of the machine body, and adjust the

arrow plate to align with 180 degrees (N.D

mark) to move the needle bar to the lowest

point.

(1)

W1304Q

Cut

(2)

(3)

W1306Q

Cut

(4)

(7)

(5)

(6)

(8)

(2)

11.3 mm

W1308Q

2. Insert the bottom dead center gauge (2) into the rotary hook (3).

3. Loosen the screw (5) of the needle bar clamp (4) and Socket head bolt for top dead center stopper

(8), then move the needle bar up and down until the needle tip touches the gauge (2) lightly.

• The needle point should touch the gauge at a place other than the cutting section.

• The bottom dead center gauge should be set in or removed from the rotary hook with its

cutting section facing upward.

4. Tighten the screw (5) of the needle bar clamp (4) securely.

2-27 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 51

(7)

Chapter 2 Parts replacement and adjustment

Tighten the

bolt (8) so

that the

clearance

can be even.

(9)

(6)

(8)

W1296Q

Do not hit

this

section.

(9)

W1307Q

5. Set the needle bar at the highest position (where the arrow plate and the "N.U.”mark are aligned).

Lightly press the top dead center stopper (6) toward the cushion rubber (7), and tighten Socket

head bolt for top dead center stopper (8) while pressing down the needle bar clamp so that it faces

the front. (Tightening torque: 0.78 N • m)

• Make sure that the top dead center stopper (6) does not hit the needle bar guide rail (9) at

this time.

• When tightening the upper dead point stopper bolt (8), insert the longer side of the

attached wrench into the bolt and tighten it by using the shorter side.

Excessive tightening may make the needle bar movement sluggish.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-28

Page 52

Chapter 2 Parts replacement and adjustment

10. Attachment and Adjustment of Rotary Hook

(3)

(2)

(1)

W1309Q

W1310Q

1. Turn the power switch off.

2. Select the needle bar No. 1 (1).

3. Remove two flat screws (2) and dismount

the needle plate (3).

4. Adjust so that the needle (4) and the point of

rotary hook (5) should meet at the position

(where the arrow plate aligns with N.H mark

(200 û)) higher by 1.7 mm than the needle bar

lowest point (180 û ).

Perform this after the height adjustment

of the needle bar.

W1314Q

0.1 - 0.3 mm

Lower

2845M

2846M

5. Turn the rotary hook manually until the point

of rotary hook (5) turns up.

6. Adjust the clearance between the needle

and the rotary hook to be within 0.1 to 0.3

mm.

Confirm that the height of the needle bar

is 1.8 mm then.

7. Temporarily fasten either one of screws (6).

8. Check with needle bars of No. 2 to No. 12 if

the clearance between each needle and the

rotary hook is within 0.1 to 0.3 mm.

If there are any needles with clearances

out of the range above, adjust them again

to get proper clearances.

W1313Q

9. Fully tighten the screw (6).

2-29 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 53

Chapter 3 Electrical components

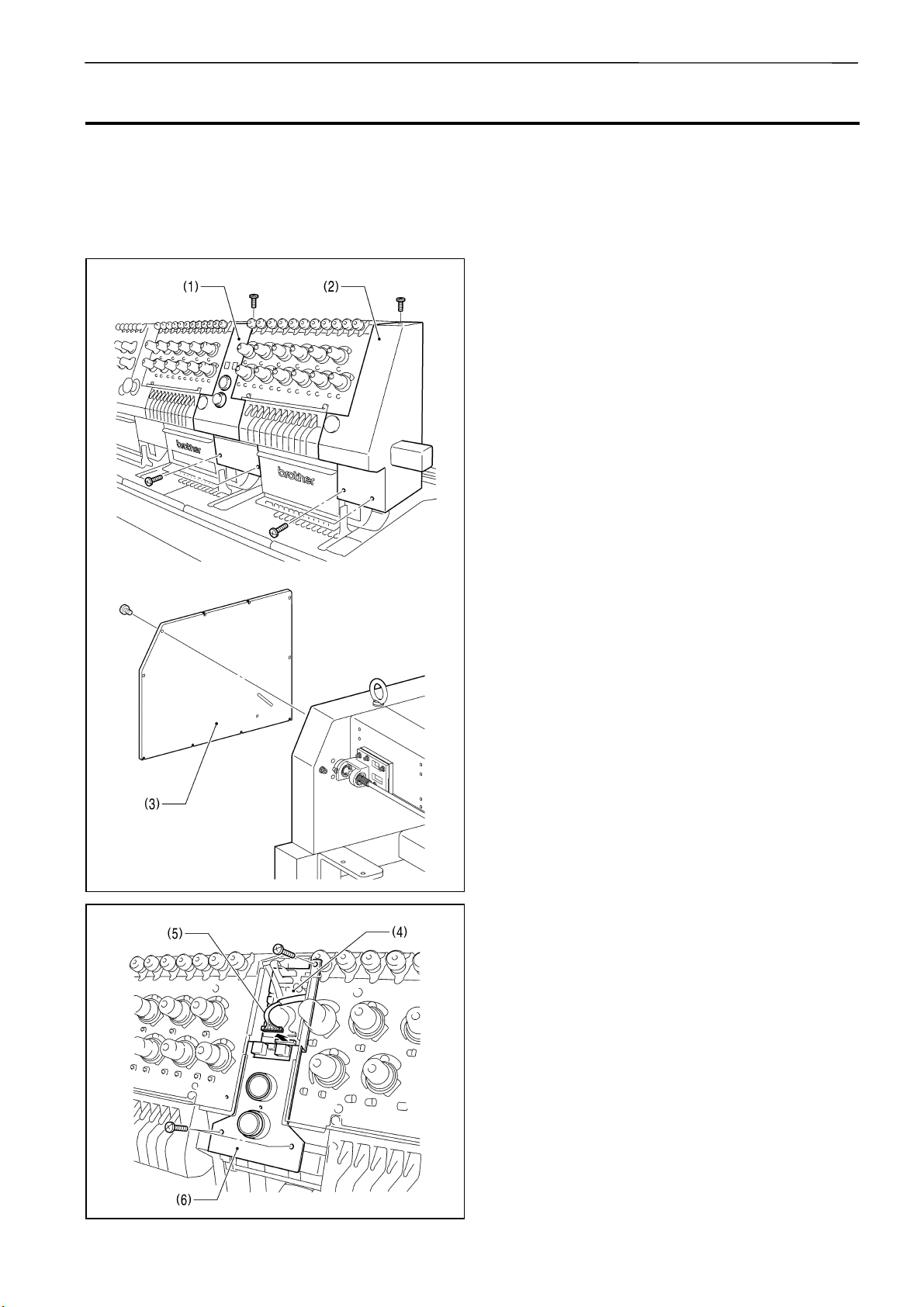

1. Location of the PCB

Chapter 3 Electrical components

PC-type model

(1) Main PCB

(2) D-drive PCB

(3) Power supply PCB

(4) Panel PCB

(5) I/O PCB

(6) Picker PCB

(7) Head switch PCB

(8) Tension base PCB

(9) Thread breakage sensor PCB

(10)Head-head I/O PCB

(11)Step switch PCB

(12)Wiper sensor PCB

(13)Index sensor A, B, C, D

(14)Index sensor PCB

(15)SBUS PCB (PC –type model)

2585M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-1

Page 54

Chapter 3 Electrical components

(16)Head PCB

(17)Y-feed sensor

(18)X-feed sensor

(19)Thread breakage sensor PCB

(20)Encoder sensor A, B

(21)Needle stop position sensor

2586M

3-2 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 55

Chapter 3 Electrical components

DANGER

Before opening the cover of control box, be sure to turn off the main power switch, pull out the plug and wait for

5 minutes at least.

Touching the high voltage parts might cause serious injuries.

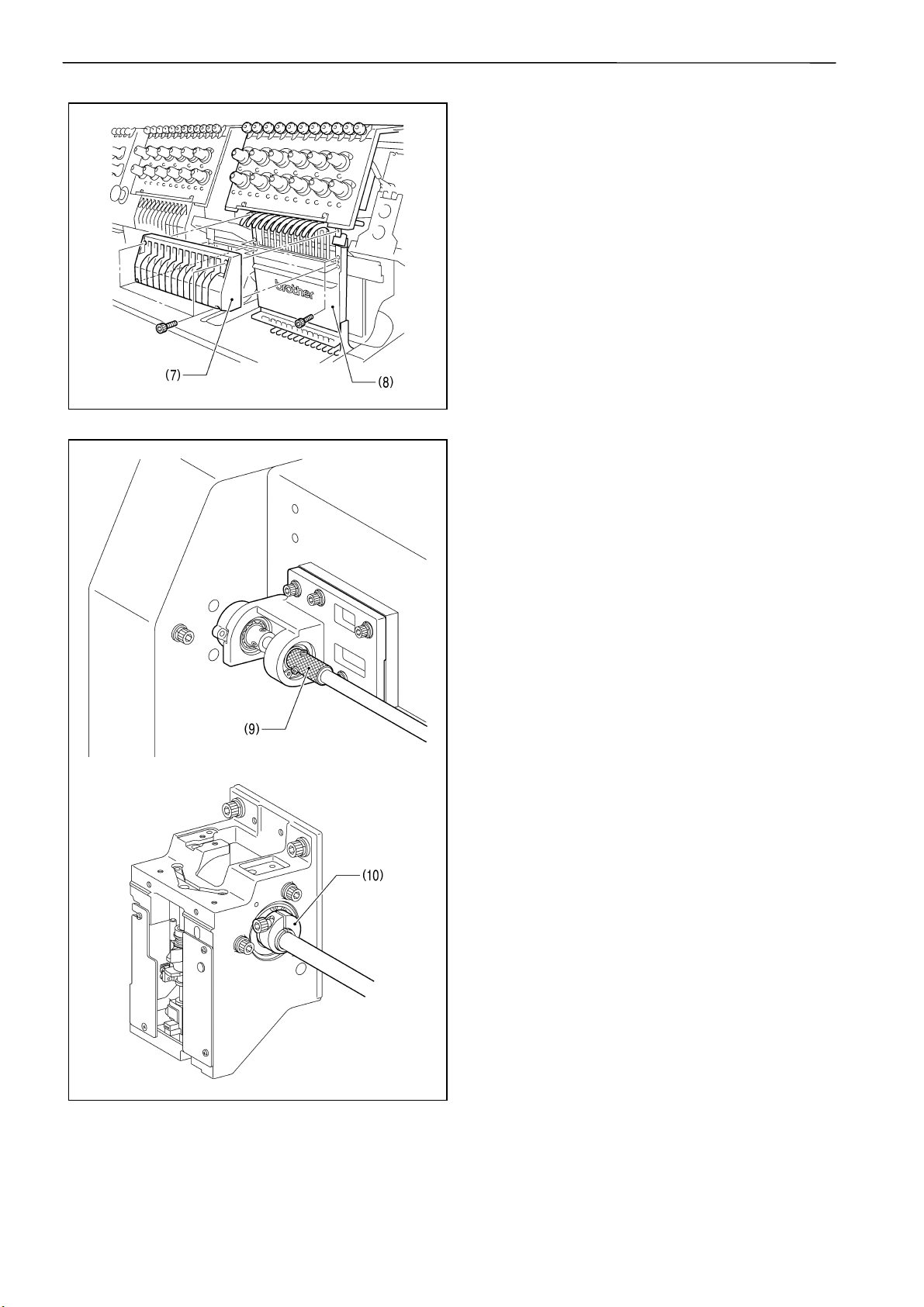

2.Replacement of PCB inside the control box

2-1.How to detach and attach the control box

1. Loosen 5 screws and unscrew remaining 5

screws on the right side cover of the sewing

machine, and then remove the side cover

(1).

2587M

2588M

2. Pull out all connectors on the right side of

control box.

3. Unscrew 4 screws fixing inner cover, A (2)

and control box.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-3

Page 56

Chapter 3 Electrical components

4. Unscrew 6 bolts (3 in front, 3 on back) fixing

2589M

* To mount it, follow the reverse procedure to the above.

control box (3) and the sewing machine main

body, and then detach control box.

3-4 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 57

2-2. Replacement of the main PCB

Chapter 3 Electrical components

2683M

1. Unscrew 2 screws and loosen remaining 7 screws on the box cover F (1) to remove it.

2. Unscrew 6 screws and loosen remaining 5 screws on the box cover R (2) to remove it.

3. Remove 4 (3 for SA-type model) connectors

(4) connected to the main PCB (3).

4. Unscrew 2 screws (5) on the main PCB (3).

2684M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-5

Page 58

Chapter 3 Electrical components

5. Fold down 4 tabs of the PCB support (6) to

detach it from the main PCB (3).

2685M

6. Pull up the main PCB (3) aslant to remove it

from the connector (8) of the drive PCB (7).

2686M

7. Pull the main PCB (3) to slide it out.

8. Detach the P-ROM (9) from the main PCB

(3).

2687M

* To mount it, follow the reverse procedure to the above.

3-6 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 59

2-3. Replacement of the power supply PCB

Chapter 3 Electrical components

2683M

1. Unscrew 2 screws and loosen remaining 7 screws on the box cover F (1) to remove it.

2. Unscrew 6 screws and loosen remaining 5 screws on the box cover R (2) to remove it.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-7

Page 60

Chapter 3 Electrical components

3. Remove all 15 connectors connected to the

power supply PCB (3).

2688M

2689M

4. Unscrew 4 screws (5) on the right and left

side of the heatsink stay B (4) to detach it.

5. Unscrew 1 screw (6) on the cooling fan (7)

mounted on the power supply PCB (3) and

detach the fan.

3-8 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 61

2690M

Chapter 3 Electrical components

6. Unscrew 5 screws (8) on the power supply

PCB (3).

7. Fold down 6 tabs (except for the 1 in the

PCB center) of the PCB support (9) to

detach it from the power supply PCB (3).

8. Fold down 1 tab of the PCB support (10) in

the center of the PCB to detach the support

from the PCB setting plate (11).

2691M

9. Pull up the power supply PCB (3) to detach

10. Fold down 1 tab of the PCB support (10) in

2692M

* To mount it, follow the reverse procedure to the above.

it.

the center of the PCB to detach the support

from the power supply PCB (3).

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-9

Page 62

Chapter 3 Electrical components

2-4. Replacement of the drive PCB

1. Unscrew 2 screws and loosen remaining 7 screws on the box cover F (1) to remove it.

2683M

2. Unscrew 6 screws and loosen remaining 5 screws on the box cover R (2) to remove it.

3. Remove all connectors connected to the

right side of the box and unscrew 10 screws

on the same side.

4. Detach the main PCB (3) according to the

procedure described in “2-2. Replacement of

the main PCB“ in the Chapter 3.

2693M

5. Unscrew 2 screws (6) on the PCB setting

plate (5) to shift it toward the center of the

box.

2694M

3-10 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 63

2695M

Chapter 3 Electrical components

6. Remove all connectors connected to the

drive PCB (4).

7. Unscrew 2 screws (7) to detach the cooling

fan (8) mounted on the drive PCB (4).

8. Detach the heat sink stay (9) on the other

side.

9. Unscrew 2 screws (10) on the drive PCB.

2696M

10. Fold down 6 tabs (other than 2 in the PCB

center) of the PCB support (11) to detach it

from the drive PCB (4).

11. Fold down lower 2 tabs of the PCB support

(12) in the PCB center to detach it from the

PCB setting plate (5).

2697M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-11

Page 64

Chapter 3 Electrical components

12. Pull up the drive PCB (4) to detach it.

13. For models without the beam sensor,

remove sensorless harness (5) from the 2P

connectors.

2698M

* To mount it, follow the reverse procedure to the above.

* When attaching connectors to the right side of the box, be sure to connect corresponding

connectors with the same marking shown on the right side of the box.

2-5. Replacement of the SBUS PCB (For PC-type model)

1. Unscrew 2 and loosen remaining 7 screws on the box cover F (1) to remove it.

2. Unscrew 6 and loosen remaining 5 screws on the box cover R (2) to remove it.

2683M

3-12 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 65

2699M

Chapter 3 Electrical components

3. Disconnect all 3 connectors on the right side

of the box which are connected to the SBUS

PCB (3).

4. Disconnect all 2 connectors connected to

the SBUS PCB (3).

2700M

5. Unscrew 4 screws (4) on the SBUS PCB (3).

6. The SBUS PCB (3) can be detached now.

2701M

* To mount it, follow the reverse procedure to the above.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-13

Page 66

Chapter 3 Electrical components

2-6. Replacement of the relay PCB

1. Unscrew 7 and loosen remaining 3 screws

on the side cover L (1) to remove it.

2713M

2. Remove all connectors connected to the

relay PCB (2).

2714M

3. Unscrew 4 screws fixing the relay PCB (2) to

2715M

* To mount it, follow the reverse procedure to the above.

detach it.

Be careful not to lose 4 PCB spacers (3).

3-14 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 67

2-7. Replacing the panel PCB (For PC-type model)

Chapter 3 Electrical components

2716M

1. Loosen the four screws (1) securing the operation panel at the top and bottom, and remove the

panel cap (2) by lifting it.

2. Separate the sheet holder plate (3) slowly, and remove the connector (4) from the rear of the panel

PCB.

3. Remove the five screws (5) from the rear of the PCB, and replace the panel PCB (6) with a new

one.

After replacing the panel PCB, reverse the above procedure for re-assembly.

CAUTION

• After replacing the panel PCB, be sure to attach the ground wire and connector.

• When removing and reattaching connectors, do not pull on the cables; hold the connectors.

• Do not lose the collar (7) which is to be placed between the shaft holder plate (3) and the

panel PCB (5).

• Attach the ground wire (8) to the panel PCB (6) using the screw (5) and the plain washer (9).

As to the remaining three holes, insert screws with two plain washers on each. Pay attention

to the number of plain washers as they influence the position of the holes.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-15

Page 68

Chapter 3 Electrical components

2-8. Replacement of the control panel PCB (For SA-type model)

1. Loosen 4 screws in total on the upper and

lower side of the control panel main body

and lift up the panel cover (1). Put the panel

cover aside with care not to bring any

tension to the harness (2) of the cap switch.

2717M

2. Unscrew 2 screws (4) fixing the sheet key

support (3) and lift up the sheet key support

(3) slightly to detach the LCD harness (5)

and the sheet key harness (6) from the

control panel PCB (7).

2718M

3. Lift up the sheet key support (3) to

disconnect the inverter harness (8) from the

inverter PCB (9) and separate them

completely from the panel body.

2719M

3-16 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 69

2720M

Chapter 3 Electrical components

4. Disconnect all connectors attached to the

control panel PCB (7).

When handling the FDD harness, unlock

the connector first.

5. Unscrew 5 screws (10) fixing the control

panel PCB (7).

6. The control panel PCB (7) can be detached

now.

2721M

* To mount pieces, follow the reverse procedure to the disassembly above.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-17

Page 70

Chapter 3 Electrical components

3. Replacement of head switch PCB of thread tension base and tension

base PCB

1. Loosen upper 2 screws and unscrew

remaining 4 screws fixing cover (2) between

the both sides of tension base (1), and then

remove cover (2).

2. Unscrew 4 bolts, socket fixing tension base

(1).

3. Lift tension base (1) slightly on the front side.

Be careful about fixed ground wire (3)

connected to tension base (1).

4. Unscrew bolt, socket (4) of the ground

terminal to disconnect it.

2591M

3-18 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 71

2592M

Chapter 3 Electrical components

5. Disconnect head-head tension base harness

connector (5).

6. Disconnect tension base harness connector

(6) connecting tension base PCB and head

switch PCB (7).

2593M

7. Unscrew 2 screws fixing head switch PCB to

detach it.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-19

Page 72

Chapter 3 Electrical components

8. Disconnect tension base harness connector

(6) connecting tension base PCB (8) and

head switch PCB (7).

9. Detach 12 thread breakage sensor

harnesses (9) of P1 to P12 from the

connector connecting tension base PCB (8).

10. Unscrew 4 screws fixing tension base PCB

(8) and tension base PCB sheet (10) and

then detach tension base PCB (8).

The blue

colored

surface of

the tape is

to be near

side.

2594M

* To mount it, follow the reverse procedure to the above.

3-20 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 73

Chapter 3 Electrical components

4. Replacement of I/O PCB (1, 2) and step back/forward switch PCB

1. Loosen upper 1 screw and unscrew

remaining 3 screws fixing cover (1) between

the head No. 3 and No. 4, and then remove

cover (1).

2595M

2596M

2. Take out all connectors connected to I/O

PCB (1, 2) (2).

3. Unscrew 2 screws under cover base (3) and

upper 1 screw on I/O PCB (2), and then take

out I/O PCB (1, 2) (2) and step back/foward

switch together with cover base (3).

4. Disconnect terminal connector (4) from P6

connector (6) on I/O PCB (1, 2) (2).

Be sure not to lose I/O terminal connector

(4) (connector with 3 blue lines) detached

here.

PCB support

CAUTION

In four head embroidery machine, this

DIP switch

terminal connector (4) is connected to I/O

PCB (1, 2) (2) between the head No. 3 and

No. 4.

In six head embroidery machine, this is

connected to I/O PCB (1, 2) (2) between the

head No. 5 and No. 6.

CAUTION

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-21

2597M

Page 74

Chapter 3 Electrical components

Follow the DIP switch settings below when replaced I/O PCB (1, 2).

For four head embroidery machine

SW1 SW2 SW3 SW4

No. 1 and No. 2

head PCB

No. 3 and No. 4

head PCB

ON

OFF

OFF OFF OFF

ON

OFF OFF

For six head embroidery machine

SW1 SW2 SW3 SW4

No. 1 and No. 2

head PCB

No. 3 and No. 4

head PCB

No. 5 and No. 6

head PCB

ON

OFF

OFF OFF OFF

ON

ON ON

OFF OFF

OFF OFF

5. Unscrew 2 screws connecting I/O PCB (1, 2)

(2) and step back/forward switch PCB (5).

2601M

* To mount it, follow the reverse procedure to the above.

3-22 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 75

5. Replacement of head PCB

Chapter 3 Electrical components

1. Unscrew upper 1 bolt, socket and loosen

lower 2 bolts, socket on bridge cover (1) and

pull down bridge cover (1).

2602M

5 blue lines

PCB support

2. Disconnect the connector on head PCB (2).

3. Detach terminal connector (3) from P5

connector.

Be sure not to lose terminal connector (3)

(connector with 5 blue lines).

CAUTION

In four head embroidery machine, this

terminal connector (3) is connected to head

PCB (2) between the head No. 3 and No. 4.

In six head embroidery machine, this is

connected to head PCB (2) between the

head No. 5 and No. 6.

DIP switch

2603M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-23

Page 76

Chapter 3 Electrical components

CAUTION

Follow the DIP switch settings below when replaced head PCB.

For four head embroidery machine

SW1 SW2 SW3 SW4

No. 1 and No. 2

head PCB

No. 3 and No. 4

head PCB

For six head embroidery machine

No. 1 and No. 2

head PCB

No. 3 and No. 4

head PCB

No. 5 and No. 6

head PCB

ON

OFF

SW1 SW2 SW3 SW4

ON

OFF

ON ON

OFF OFF OFF

ON

OFF OFF OFF

ON

OFF OFF

OFF OFF

OFF OFF

* To mount it, follow the reverse procedure to the above.

3-24 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 77

6. Replacement of I/O PCB

Chapter 3 Electrical components

1. Loosen lower 3 screws and unscrew

remaining 6 screws on side cover(1) of the

sewing machine, and then remove the side

cover.

2598M

DIP switch

2. Disconnect the connector on I/O PCB (2).

3. Unscrew 4 screws fixing I/O PCB (2) to

detach it.

Be sure not to lose 4 spacers (3).

CAUTION

DIP switch settings on I/O PCB

SW1 SW2 SW3 SW 4

OFF OFF OFF OFF

All set to OFF.

2599M

* To mount it, follow the reverse procedure to the above.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-25

Page 78

Chapter 3 Electrical components

7. Replacement of picker PCB

1. Loosen lower 3 screws and unscrew

remaining 6 screws on side cover (1) of the

sewing machine, and then remove side

cover (1).

2598M

2604M

2. Disconnect the connector on picker PCB (2).

3. Unscrew 4 screws fixing picker PCB (2) to

detach it.

Be sure not to lose 4 spacers (3).

* To mount it, follow the reverse procedure to the above.

3-26 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 79

8. Fuses

Chapter 3 Electrical components

1. Remove the cover of control box.

2. 5 fuses are attached on the power supply PCB in the upper part inside the control box.

Another fuse holder is attached on the right side of the control box.

CAUTION

Before the replacement, be sure to turn off the power.

2606M

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 3-27

Page 80

Chapter 3 Electrical components

8-1. Types and capacity of fuses

No. Fuse type and capacity Article number Product name

F1, F2 8A-250V (Semi time-lag fuse) S56790000 GFUSE8A-250V