Page 1

INSTRUCTION MANUAL

BE-1204B-BC

BE-1204C-BC

BE-1206B-BC

PC Control type

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

TWELVE NEEDLE FOUR HEAD EMBROIDERY MACHINE

TWELVE NEEDLE FOUR HEAD EMBROIDERY MACHINE<WIDE AREA>

TWELVE NEEDLE SIX HEAD EMBROIDERY MACHINE

Page 2

Page 3

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

jury

please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up lever, and consequently there is always a danger

of injury that can be caused by these parts. Follow the instructions from training personnel and

instructors regarding safe and correct operation before operating the machine so that you will know

how to use it correctly.

SAFETY INSTRUCTIONS

1 Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are

provided in order to ensure safe operation of this machine and to prevent accidents and injury to

yourself or other people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

-------- This symbol (

The picture inside the triangle indicates the nature of the caution that must be taken. (For

example, the symbol at left means "beware of injury".)

--------- This symbol (

--------- This symbol (

The picture inside the circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

The instructions which follow this term indicate situations where failure to

follow the instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to

follow the instructions could cause in

damage to equipment and surroundings.

) indicates something that you should be careful of.

) indicates something that you must not do.

) indicates something that you must do.

when using the machine or physical

BE-1204B-BC • BE-1206B-BC 1

Page 4

2 Notes on safety

p

g

y

g

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall

outlet before o

can result in severe injury.

ening the face plate of the control box. Touching areas where high voltages are present

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is

free from sources of strong electrical noise

such as high-frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within ±10% of the rated volta

the machine.

Voltage fluctuations which are greater than

this may cause problems with correct

operation.

The power supply capacity should be greater

than the requirements for the sewing

machine's electrical consumption.

Insufficient power supply capacity may cause

problems with correct operation.

The air supply should have a capacity greater

than the machine consumption. If air is not

supplied sufficiently, a machine malfunction

may occur.

e for

Installation

Machine installation should only be carried

out by a qualified technician.

Never operate the sewing machine with any

ventilation openings blocked.

Keep the ventilation openings of the sewing

machine free from the accumulation of lint or

dust.

The ambient temperature should be within the

range of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidit

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems

with correct operation.

In the event of an electrical storm, turn off the

power and disconnect the power cord from the

wall outlet.

Lightning may cause problems with correct

operation.

Do not use this machine outdoors.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

should be within the range of

Contact your Brother dealer or a qualified

electrician for any electrical work that may

need to be done.

The sewing machine weighs approximately

700 kg.

The installation should be carried out by four

or more people.

Do not connect the power cord until

installation is complete, otherwise the

machine may operate if the start switch is

pressed by mistake, which could result in

injury.

2 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Be sure to wear protective goggles and gloves

when handlin

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Secure the machine with the adjustment bolts on

the sound floor so that it will not move.

the lubricating oil or grease, so that

Page 5

Avoid setting up the sewing machine near

p

g

sources of strong electrical noise such as

high-frequency welding equipment.

If this precaution is not taken, incorrect

machine operation may result.

Installation

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary

training in safe use beforehand.

Keep children away from the sewing machine.

The sewing machine should not be used for

any applications other than sewing.

Be sure to wear protective goggles when

using the machine.

If goggles are not worn, there is the danger

that if a needle breaks, parts of the broken

needle may enter your eyes and injury may

result.

Always use the proper needle plate. Any

wrong plate can cause needles to break.

Do not use a bent needle.

Turn off the power switch at the following

times, otherwise the machine may operate if

the start switch is pressed by mistake, which

could result in injury.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when

leaving the machine unattended

• When cleaning the machine.

Do not get on the table.

Table may be damaged.

Do not operate this machine where aerosol

(spray) products are being used or where

oxygen is being administered.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any moving parts, press any objects

against the machine, or pull/push the cloth during

sewing. Doing so may result in personal injury,

machine damage, or needle breakage.

Do not touch the

bed section during operation or for 30 minutes

after operation. Otherwise burns may result.

Never drop or insert foreign objects or a

screwdriver into the ventilation openings or the

machine inside.

Touching any high-voltage area may result in an

electric shock.

Never damage, alter, heat, or put a strain on the

power cable as well as other cables. Doing so

may result in a fire or an electric shock.

If the controller is exposed to water or a chemical

agent or if its entry is found inside the controller,

turn off the power switch immediately.

Continuing to use the machine under such a

condition may result in a fire or an electric shock.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed,

immediately turn off the power switch. Then

contact your nearest Brother dealer or a qualified

technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

ulse motor and sewing machine

Cleaning

Turn off the power switch before starting any

cleaning work, otherwise the machine may

operate if the start switch is pressed by

mistake, which could result in injury.

BE-1204B-BC • BE-1206B-BC 3

Be sure to wear protective goggles and gloves

when handlin

no oil or grease gets into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or grease under

any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

the lubricating oil or grease, so that

Page 6

Maintenance and inspection

p

ying

Maintenance and inspection of the sewing

machine should only be carried out by a

qualified technician.

Ask your Brother dealer or a qualified

electrician to carry out any maintenance and

inspection of the electrical system.

Turn off the power switch and disconnect the

power cable (do not pull on the cable itself)

from the wall outlet before attempting to

erform the following operations. Otherwise,

the machine is started if the start switch is

pressed by mistake. Injury may occur in

such a case.

• When carr

or maintenance

• When replacing consumable parts such

as a rotary hook, a knife, or a fluorescent

lamp

out inspection, adjustment,

If the power switch needs to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

Use only the proper replacement parts as

specified by Brother.

When replacing a fluorescent lamp, use the

same-type lamp having a rating of 40 watts.

Wait until the fluorescent lamp cools off before

replacement. Failure to do so can result in

burns.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine

will not be covered by the warranty.

4 BE-1204B-BC • BE-1206B-BC

Page 7

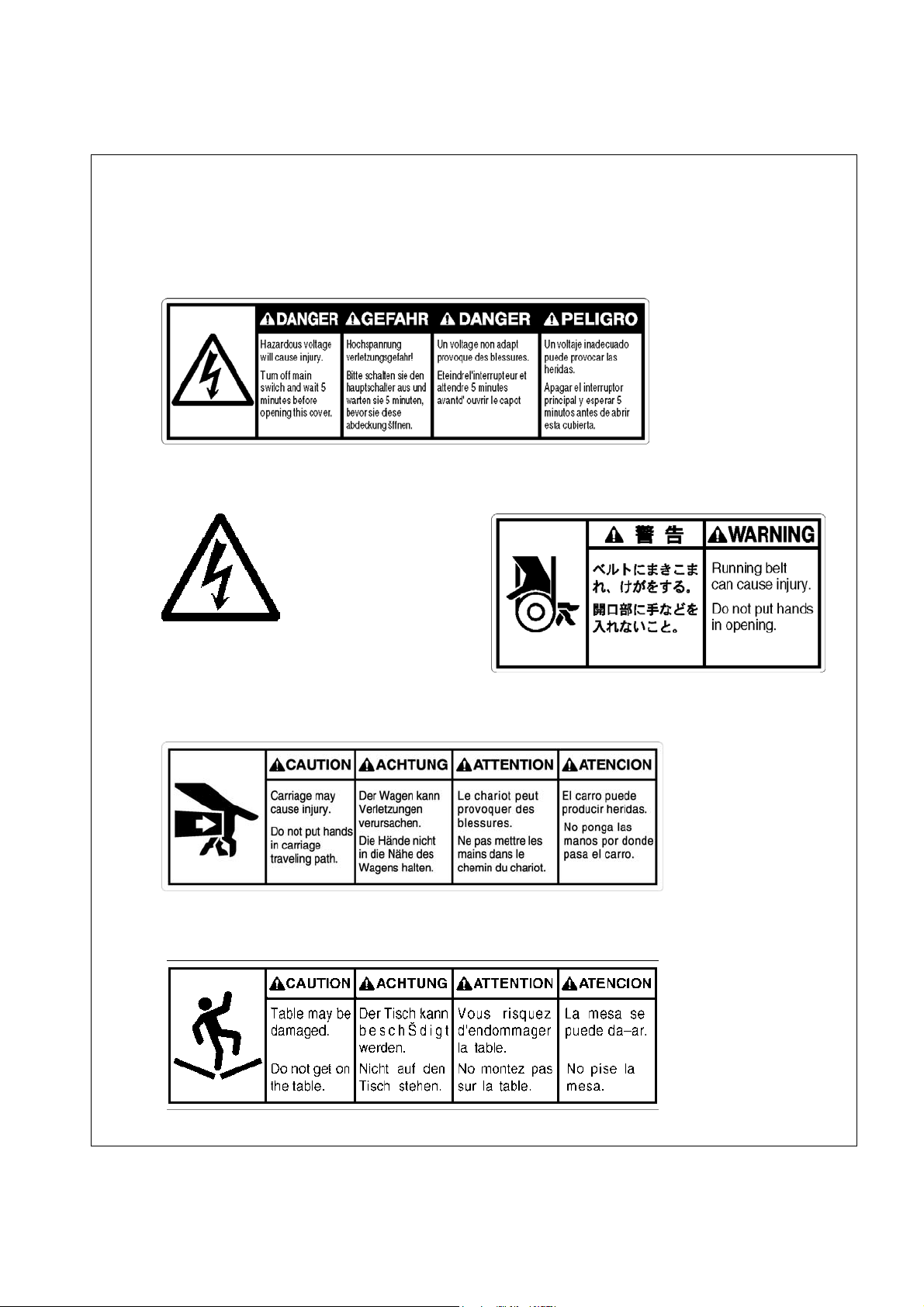

3 Warning labels

* The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels

have been removed or are difficult to read, please contact your nearest Brother dealer.

1 Electric shock danger display

W1408Q

2 Electric shock danger display 3 Injury warning display

Hazardous voltage will

cause injury.

4 Injury caution display

5 Injury caution display

W1410Q

W1200Q

W1202Q

BE-1204B-BC • BE-1206B-BC 5

Page 8

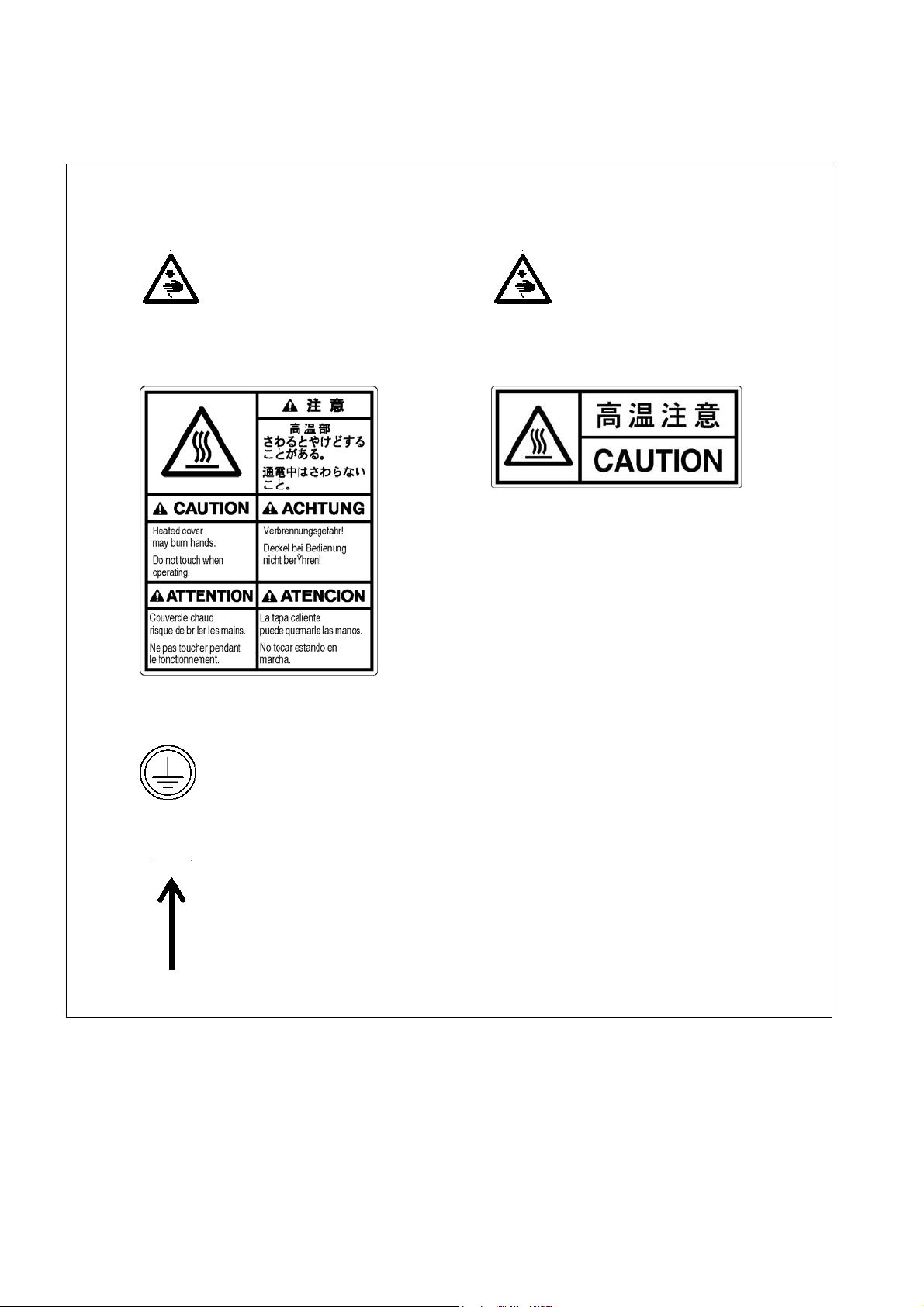

6 Injury caution display

7 Injury caution display

Never touch or push the

thread take up during

operation as it may result in

injuries machine.

Never touch or push the needle

bar during operation as it may

result in injuries or damage to

the sewing machine.

8 High temperature caution display 9 High temperature caution display

W1206Q

Do not touch this part during activitation

or for 30 minutes after shut-off. Otherwise

burns may result.

W1201Q

10 Ground mark

Be sure to connect the ground. If the ground connection is not secure, you run

a high risk of receiving a serious electric shock, and problems with correct

operation may also occur.

11 Direction of operation

W1205Q

6 BE-1204B-BC • BE-1206B-BC

Page 9

10

6

7

5

4

5

2

1

W1400Q

9

8

8

8

4

3

11

4

4

W1208Q

BE-1204B-BC • BE-1206B-BC 7

Page 10

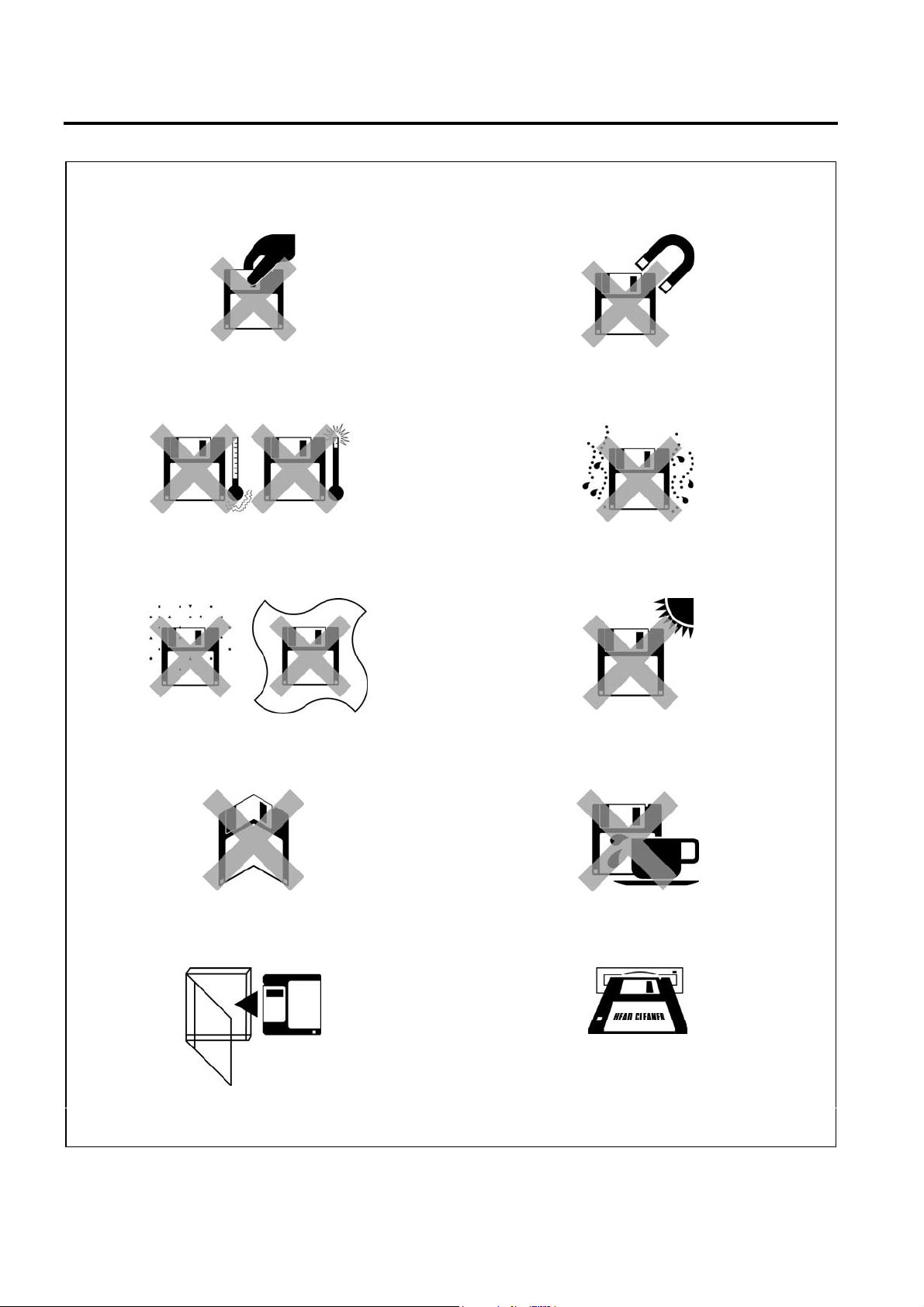

Before Starting Operation

Q

Do not force open the shutter for direct contact

with the magnetic area.

W1209

Do not store floppy disks in an extremely high or

low ambient temperature.

W1211Q

Do not use or store floppy disks in a dusty place.

Do not place it on cloth.

Do not bring disks near magnetic matters such as

magnetic screwdriver or the back side of the

programmer.

W1210Q

Do not use floppy disks under high humidity.

W1212Q

Do not store floppy disks under direct sunlight.

W1213Q

Do not bend the disk. Do not put things on the

Avoid contact with solvent or drink.

disk.

W1215Q

Store it in the case immediately after using it to

protect it from dust and damage.

W1217Q

Use a commercially available cleaning disk to clean

the head of the floppy disk drive periodically.

Do not remove the disk out of the drive during the access lamp is lit.

W1214Q

W1216Q

W1218Q

8 BE-1204B-BC • BE-1206B-BC

Page 11

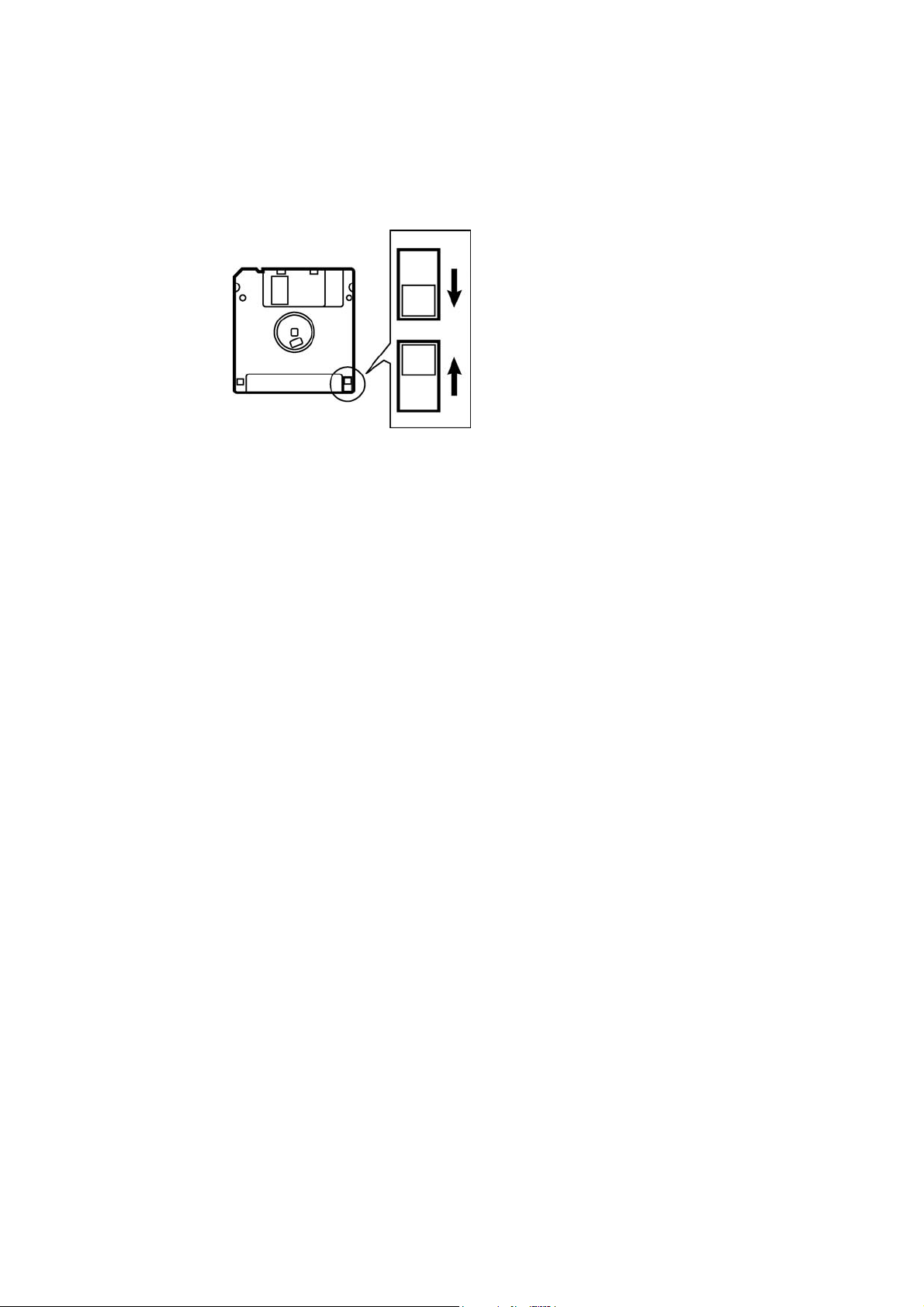

Protecting data in floppy disks

Write-protection is available for a floppy disk to prevent undesired data deletion.

A write-protected disk is read-only. It is recommended to provide write-protection for disks which

contain important data.

To do so, slide the write-protect notch to open the slot as shown below.

Slide the notch in this direction to

prevent data loss or overwriting.

Slide the notch in this direction to

write data.

W1219Q

BE-1204B-BC • BE-1206B-BC 9

Page 12

Procedure of Reading This Manual

Explanation of models

This manual explains three models:

- BE-1204B-BC

- BE-1204C-BC

- BE-1206B-BC

Explanation for individual model is provided by identifying the model name. Check the model before

using the machine. The display is BE-1206B-BC.

Configuration of this manual

This manual consists of the following chapters:

Chapter 1 An Introduction of Embroidery Machine

Provides information on the specifications of the embroidery machine, software installation

environment, and basic software operations.

Chapter 2 Preparation of Embroidery Machine

Describes machine installation and preparation to be conducted before starting embroidering

operation.

Chapter 3 Embroidering Procedures

Provides explanations on the operation panel and briefly reviews the flow of embroidering

processes.

Chapter 4 Selecting and Transferring Embroidery Data

Explains how to use the Embroidery Data Explorer.

Chapter 5 Editing Embroidery Data

Explains how to use the Embroidery Data Editor.

Chapter 6 Embroidering

Explains how to use the Machine Controller.

Chapter 7 Operation of Machine

Provides information on machine operation during embroidering.

Chapter 8 Creating Production Report

Explains how to use the production report program.

Chapter 9 Maintenance

Describes appropriate maintenance of the machine.

Chapter 10 Adjustment

Explains how to adjust the needles.

Chapter 11 List of Error Codes

Provides information on error codes and action to be taken.

Chapter 12 Troubleshooting

Provides troubleshooting for the machine.

Chapter 13 Connection and Installation of Optional Equipment

Describes connections between the machine/computer and optional equipment available.

10 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 13

Contents

SAFETY INSTRUCTIONS.................................................................................................................................................1

Before Starting Operation ...............................................................................................................................................8

Procedure of Reading This Manual..............................................................................................................................10

Chapter 1 Preparation of Embroidery Machine

1. Specifications............................................................................................................................................................1-2

Accessories..............................................................................................................................................................1-3

2. Software.....................................................................................................................................................................1-4

2-1 Necessary Systems ...........................................................................................................................................1-4

2-2 Configuration of Software...................................................................................................................................1-4

2-3 Notes on use......................................................................................................................................................1-5

2-4 Help ...................................................................................................................................................................1-5

2-5 Basic Operation of Software ..............................................................................................................................1-6

Chapter 2 Preparation of Embroidery Machine

1. Names of Machine Components..............................................................................................................................2-2

2. Installation.................................................................................................................................................................2-3

2-1 Transportation of Machine..................................................................................................................................2-3

2-2 Installation of Machine .......................................................................................................................................2-5

2-3 Preparation of Needle Bar Case ........................................................................................................................2-6

2-4 Mounting of Table...............................................................................................................................................2-7

2-5 Mounting of Cotton Stand ................................................................................................................................2-10

2-6 Lubrication to Needle Bar Case .......................................................................................................................2-11

2-7 Connection of Personal Computer to Machines (for connecting 4 sets) ..........................................................2-12

2-8 Connection of Power Supply............................................................................................................................2-14

2-9 Grounding ........................................................................................................................................................2-15

2-10 Installation of Software...................................................................................................................................2-16

3. Preparation for Embroidering................................................................................................................................2-17

3-1 Upper Threading..............................................................................................................................................2-17

3-2 Replacement of Bobbin....................................................................................................................................2-19

3-3 Replacing and Selecting Needle......................................................................................................................2-21

3-4 Attachment of Embroidery Hoop and Frame....................................................................................................2-22

3-5 Adjustment of Thread Tension..........................................................................................................................2-26

Contents

Chapter 3 Embroidering Procedures

Functions of Operation Panel......................................................................................................................................3-2

Operation Panel .......................................................................................................................................................3-2

Switches at Machine Heads.....................................................................................................................................3-4

Lamps and switches on the thread tension stand ....................................................................................................3-5

Flowchart of Preparation for Embroidering................................................................................................................3-6

Run the Software .....................................................................................................................................................3-7

Turn on the Machine Power .....................................................................................................................................3-7

Register the Machine Name.....................................................................................................................................3-8

Retrieve the Embroidery Data..................................................................................................................................3-8

Start Embroidering ...................................................................................................................................................3-9

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 11

Page 14

Contents

Chapter 4 Selecting and Transferring Embroidery Data

Functions (Command Reference) ............................................................................................................................... 4-2

Description of Screen ..................................................................................................................................................4-3

Creating a Directory .....................................................................................................................................................4-4

Transferring data ..........................................................................................................................................................4-5

Copy ..............................................................................................................................................................................4-7

Select from Menu.....................................................................................................................................................4-7

Drag Data ................................................................................................................................................................4-7

Moving Data .................................................................................................................................................................. 4-8

Select from Menu.....................................................................................................................................................4-8

Drag Data ................................................................................................................................................................4-8

Deleting Data.................................................................................................................................................................4-9

Recreate an icon......................................................................................................................................................... 4-10

Select All ..................................................................................................................................................................... 4-11

Renaming Data ...........................................................................................................................................................4-12

Finding Data................................................................................................................................................................ 4-13

Adjusting Screen Display ..........................................................................................................................................4-15

Reading Data in Floppy Disk ..................................................................................................................................... 4-16

Reading DOS Format Data....................................................................................................................................4-16

Converting the Non DOS format data .................................................................................................................... 4-18

Reading Data in Paper Tape ...................................................................................................................................... 4-22

Settings for Data Reading.......................................................................................................................................... 4-24

Writing Data in DST Format.......................................................................................................................................4-25

Viewing Pattern Information...................................................................................................................................... 4-26

Chapter 5 Editing Embroidery Data

Functions (Command Reference) ............................................................................................................................... 5-2

Description of Screen ..................................................................................................................................................5-4

Opening Embroidery Data ...........................................................................................................................................5-5

Setting Display..............................................................................................................................................................5-6

Centering ................................................................................................................................................................. 5-6

Zoom .......................................................................................................................................................................5-6

Needle Penetration.................................................................................................................................................. 5-8

Embroidering Start/End............................................................................................................................................5-8

Trim and pause........................................................................................................................................................5-8

Microstitch ............................................................................................................................................................... 5-9

Needle Bar and Speed Range................................................................................................................................. 5-9

Thread Color..........................................................................................................................................................5-13

Tool bar..................................................................................................................................................................5-14

Status Bar.............................................................................................................................................................. 5-14

Back to Previous Status.............................................................................................................................................5-15

Undo ...................................................................................................................................................................... 5-15

Redo ...................................................................................................................................................................... 5-15

Editing .......................................................................................................................................................................5-16

Rotate .................................................................................................................................................................... 5-16

Horizontal Flip........................................................................................................................................................5-17

Vertical Flip ............................................................................................................................................................ 5-17

Point Symmetry .....................................................................................................................................................5-17

Repeat................................................................................................................................................................... 5-17

Resize....................................................................................................................................................................5-20

Delete Stitch ..........................................................................................................................................................5-20

Insert or Delete Code.............................................................................................................................................5-21

Insert Lock Stitch ...................................................................................................................................................5-22

12 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 15

Changing Data.............................................................................................................................................................5-23

Changing Start .......................................................................................................................................................5-23

Changing End ........................................................................................................................................................5-24

Mask ......................................................................................................................................................................5-25

Group ...........................................................................................................................................................................5-26

Setting Group for Repetition...................................................................................................................................5-27

Selecting from Menu ..............................................................................................................................................5-27

Merge ...........................................................................................................................................................................5-28

Saving Data .................................................................................................................................................................5-30

Save.......................................................................................................................................................................5-30

Save As..................................................................................................................................................................5-31

Viewing Pattern Information ......................................................................................................................................5-32

Printing Data................................................................................................................................................................5-33

Chapter 6 Embroidering

Functions (Command Reference)................................................................................................................................6-2

When the Power to the Machine is Off.....................................................................................................................6-2

When the Power to the Machine is On.....................................................................................................................6-2

Description of Screen...................................................................................................................................................6-5

Settings before Turning On the Machine....................................................................................................................6-6

Displaying the Tool Bar ............................................................................................................................................6-6

Displaying the Status Bar.........................................................................................................................................6-7

Upgrading the Version of Interface Board ................................................................................................................6-7

Reset Interface Board ..............................................................................................................................................6-7

Communication Port.................................................................................................................................................6-7

Language .................................................................................................................................................................6-8

Settings after Turning Power On .................................................................................................................................6-9

Tool Bar ....................................................................................................................................................................6-9

Status Bar ................................................................................................................................................................6-9

Zoom In....................................................................................................................................................................6-9

Zoom Out .................................................................................................................................................................6-9

Zoom In Specified Range.......................................................................................................................................6-10

Fit to Window .........................................................................................................................................................6-10

Whole Pattern ........................................................................................................................................................6-10

Grid ........................................................................................................................................................................6-11

Hoop ......................................................................................................................................................................6-11

Hoop position fine adjustment................................................................................................................................6-11

Needle Penetration ................................................................................................................................................6-12

Thread Color ..........................................................................................................................................................6-13

Needle Bar and Speed Range ...............................................................................................................................6-13

Setting Needle Bar.................................................................................................................................................6-13

Setting Ranges ......................................................................................................................................................6-17

Grid Setting ............................................................................................................................................................6-18

Background color ...................................................................................................................................................6-18

Renaming Machine ................................................................................................................................................6-19

Viewing Machine Information .................................................................................................................................6-20

Design Information.................................................................................................................................................6-20

Setting Window Display .........................................................................................................................................6-20

Minimizing and Aligning Windows ..........................................................................................................................6-21

Language ...............................................................................................................................................................6-23

Copying Data to Other Machines ...........................................................................................................................6-23

Configuration..........................................................................................................................................................6-24

Upgrading the Machine Program ...........................................................................................................................6-24

Contents

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 13

Page 16

Contents

Setting the Machine....................................................................................................................................................6-25

Needle Bar.............................................................................................................................................................6-25

Same Speed Range ..............................................................................................................................................6-26

Pause ....................................................................................................................................................................6-26

Speed Range.........................................................................................................................................................6-27

Head Operation Suspend ...................................................................................................................................... 6-27

Hoop Feed Position ............................................................................................................................................... 6-28

Embroidery Area....................................................................................................................................................6-29

Embroidery Hoop...................................................................................................................................................6-29

Thread Trimming ...................................................................................................................................................6-31

Thread Breakage Sensor.......................................................................................................................................6-32

Automatic Step Back .............................................................................................................................................6-33

Automatic Hoop Feed............................................................................................................................................6-33

End of embroidery .................................................................................................................................................6-34

Mending................................................................................................................................................................. 6-35

Adjust.....................................................................................................................................................................6-36

Driving shaft...........................................................................................................................................................6-37

Activate escape with pause ................................................................................................................................... 6-37

Short stitch speed reduction .................................................................................................................................. 6-38

Thin / Thick Material ..............................................................................................................................................6-39

Area Trace.............................................................................................................................................................6-40

Trace with needle No.1..........................................................................................................................................6-40

Default Settings .....................................................................................................................................................6-41

Show Setting ......................................................................................................................................................... 6-42

Load Setting .......................................................................................................................................................... 6-44

Save Setting ..........................................................................................................................................................6-45

Load Hoop ............................................................................................................................................................. 6-46

Embroidering ..............................................................................................................................................................6-50

Starting Embroidering ............................................................................................................................................ 6-50

Moving the Home Position ........................................................................................................................................6-52

Step-forward/Step-back .............................................................................................................................................6-53

Entering in the Step-forward/Step-back Mode ....................................................................................................... 6-53

Setting Step-forward/Back Distance or Timing....................................................................................................... 6-54

Stepping Forward/Back..........................................................................................................................................6-55

Resuming Embroidering ........................................................................................................................................ 6-56

Moving Embroidery Position..................................................................................................................................... 6-57

Centering Pattern ....................................................................................................................................................... 6-58

Saving Data.................................................................................................................................................................6-59

Save ......................................................................................................................................................................6-59

Save As... ..............................................................................................................................................................6-59

Test .............................................................................................................................................................................. 6-60

Running Other Programs........................................................................................................................................... 6-61

14 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 17

Chapter 7 Operation of Machine

1. Operating Procedures ..............................................................................................................................................7-2

1-1 Power Source ....................................................................................................................................................7-2

1-2 Preparation for Embroidering.............................................................................................................................7-2

2. Machine Stop.............................................................................................................................................................7-3

2-1 Stopping the Machine ........................................................................................................................................7-3

2-2 Emergency Stop of the Machine........................................................................................................................7-3

2-3 Resetting Emergency Stop ................................................................................................................................7-3

3. Permission for Hoop Movement..............................................................................................................................7-4

4. Measures against Thread Breakage........................................................................................................................7-5

4-1 Remedies...........................................................................................................................................................7-5

4-2 Mending .............................................................................................................................................................7-6

5. Jog Embroidering .....................................................................................................................................................7-8

6. Hoop Feed Position ..................................................................................................................................................7-9

7. Area Check ..............................................................................................................................................................7-10

7-1 External Tracing...............................................................................................................................................7-10

7-2 Automatic Hoop Movement in Area..................................................................................................................7-10

8. Jog Switches...........................................................................................................................................................7-11

8-1 Hoop Movement to Start Position.....................................................................................................................7-11

8-2 Inching Mode during Embroidering (Forcible Hoop Movement).......................................................................7-12

Contents

Chapter 8 Creating Production Report

Functions (Command Reference)................................................................................................................................8-2

Description of Screen...................................................................................................................................................8-3

Displaying Report .........................................................................................................................................................8-4

Display Example of Details ......................................................................................................................................8-5

Display Example of Thread Breakage Information on Needle Bar ...........................................................................8-6

Display Example of Thread breakage Information in Pattern ...................................................................................8-7

Display Example of Output Information....................................................................................................................8-8

Display Example of Total Output Information .........................................................................................................8-10

Setting Display Items..................................................................................................................................................8-12

General ..................................................................................................................................................................8-12

Details ....................................................................................................................................................................8-13

Thread Breakage Information on Needle Bar.........................................................................................................8-14

Thread Breakage Information in Pattern ................................................................................................................8-14

Output Information .................................................................................................................................................8-15

Total Output Information.........................................................................................................................................8-16

Recess Time Setting..............................................................................................................................................8-17

Save As CSV... .............................................................................................................................................................8-18

Printing Production Report........................................................................................................................................8-19

Page Setup ............................................................................................................................................................8-19

Print........................................................................................................................................................................8-19

Copying Report Data ..................................................................................................................................................8-20

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 15

Page 18

Contents

Chapter 9 Maintenance

1. Cleaning .................................................................................................................................................................... 9-2

1-1 Cleaning and Lubrication of Rotary Hook.......................................................................................................... 9-2

1-2 Cleaning of Needle Plate................................................................................................................................... 9-3

2. Oiling .........................................................................................................................................................................9-4

2-1 Head.................................................................................................................................................................. 9-4

2-2 Lower shaft........................................................................................................................................................ 9-5

3. Greasing....................................................................................................................................................................9-6

3-1 Cam grooves ..................................................................................................................................................... 9-6

3-2 Lower gear ........................................................................................................................................................9-8

3-3 Driving shaft.......................................................................................................................................................9-8

3-4 Needle bar flip-up mechanism...........................................................................................................................9-9

3-5 Feed Guide Section.........................................................................................................................................9-10

Chapter 10 Adjustment

1. Adjusting Needle Bar Height ................................................................................................................................. 10-2

2. Attachment and Adjustment of Rotary Hook........................................................................................................ 10-6

3. Adjustment of Presser Foot Height.......................................................................................................................10-8

4. Thread Wiper Adjustment ...................................................................................................................................... 10-9

Chapter 11 Error code list

Chapter 12 Troubleshooting

Mechanical Section .................................................................................................................................................... 12-2

Electrical Section........................................................................................................................................................12-4

Personal Computer Section ......................................................................................................................................12-8

Chapter 13 Connection and Installation of Optional Equipment

1. Attaching Bobbin Winder....................................................................................................................................... 13-2

16 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 19

Chapter 1

An Introduction of

Embroidery Machine

Page 20

Chapter 1 An Introduction of Embroidery Machine

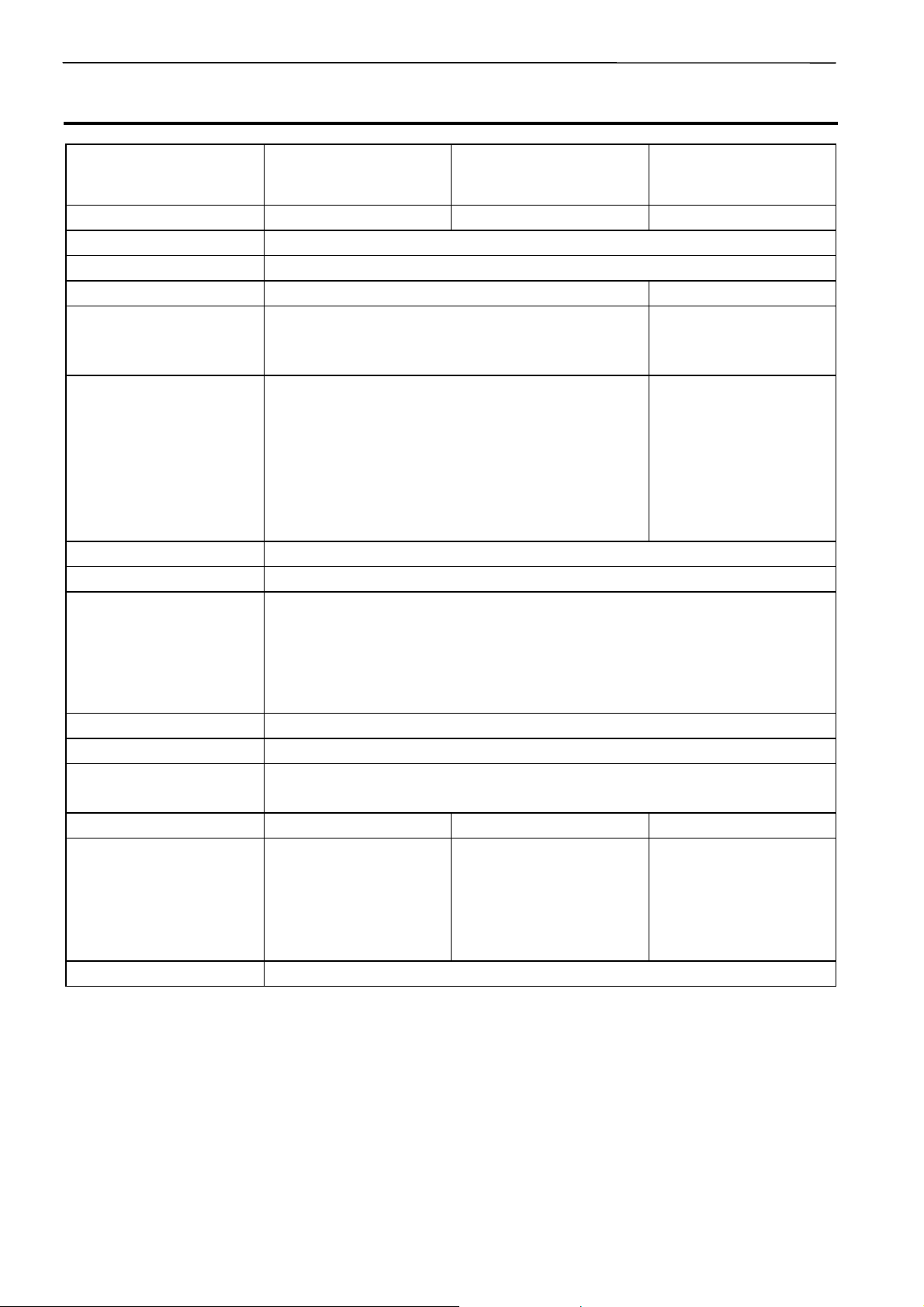

1. Specifications

Embroidery machine used

Application Pattern embroidery

Sewing speed Maximum 1000 rpm

Distance between heads 360 mm 500 mm

Maximum feed range

Sewing area

Feed system By timing belt and stepping motor drive

Stitch length 0.1 ~ 12.7 mm (minimum pitch: 0.1 mm)

Storage medium

Thread trimming Automatic thread trimmer

Thread breakage detect Upper and lower thread breakage detector

Power supply

Weight 700 kg 600kg 670kg

Dimensions

Options Embroidery hoops in different sizes, Bobbin winder

12 needle six-head

embroidery machine

BE-1206B BE-1204B BE-1204C

450 (V) × 360 (H) mm

95 (V) × 360 (H) mm (With cap frame)

450 (V) × 360 (H) mm (With sash frame)

430 (V) × 300 (H) mm (With maximum-size tubular

square hoop/flat hoop)

85 (V) × 360 (H) mm (With cap frame)

3.5 2DD floppy disk (Tajima format)

3.5 2HD floppy disk (the equivalent to Tajima format)

3.5 2DD floppy disk (Barudan FDR/FMC format)

3.5 2DD floppy disk (ZSK format)

3.5 floppy disk (brother ECS format)

Single phase 200 V, 220 V, 230 V, 240 V,1.1 kVA

Flourescent lamp: 92VA 49W (Maximum)

(Before assembly)

3040 (W) × 810 (L) ×

1400 (H) mm

(After setup)

3040 (W) × 1360 (L) ×

1750 (H) mm

12 needle four-head

embroidery machine

(Before assembly)

2320 (W) × 810 (L) ×

1400 (H) mm

(After setup)

2320 (W) × 1360 (L) ×

1750 (H) mm

12 needle four-head

embroidery

machine<wide area>

450 (V) × 500 (H) mm

95 (V) × 360 (H) mm

(With cap frame)

450 (V) × 500 (H) mm

(With sash frame)

440 (V) × 400 (H) mm

(With maximum-size

tubular square hoop/flat

hoop)

85 (V) × 360 (H) mm

(With cap frame)

(Before assembly)

3040 (W) × 810 (L) ×

1400 (H) mm

(After setup)

3040 (W) × 1360 (L) ×

1750 (H) mm

1-2 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 21

Chapter 1 An Introduction of Embroidery Machine

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 1-3

Page 22

Chapter 1 An Introduction of Embroidery Machine

2. Software

2-1 Necessary Systems

The following systems are needed for installing the software.

• Personal computer with a CPU of Intel Pentium 166 MHz or above

(Even if the software is operable under the environment less than the required specification, such a

case is out of the scope of warranty.)

• Memory of 32 MB or above (Even if the software is operable under the environment less than the

required specification, such a case is out of the scope of warranty.)

• Free space of 100 MB or above in the hard disk

• 3.5 floppy disk drive

• CD-ROM drive

• Video card of 1024 × 768 resolution in 256 colors

(1280 × 1024 in 65000 colors is recommended.)

• Serial port (RS-232C) × 1

• PCI slot × 1

(Use full-size type PCI slot. Low profile type and half pitch type cannot be used.)

• Windows 95/98/2000/NT4.0/XP (Some functions are not available with Windows NT. Refer to page

4-18.)

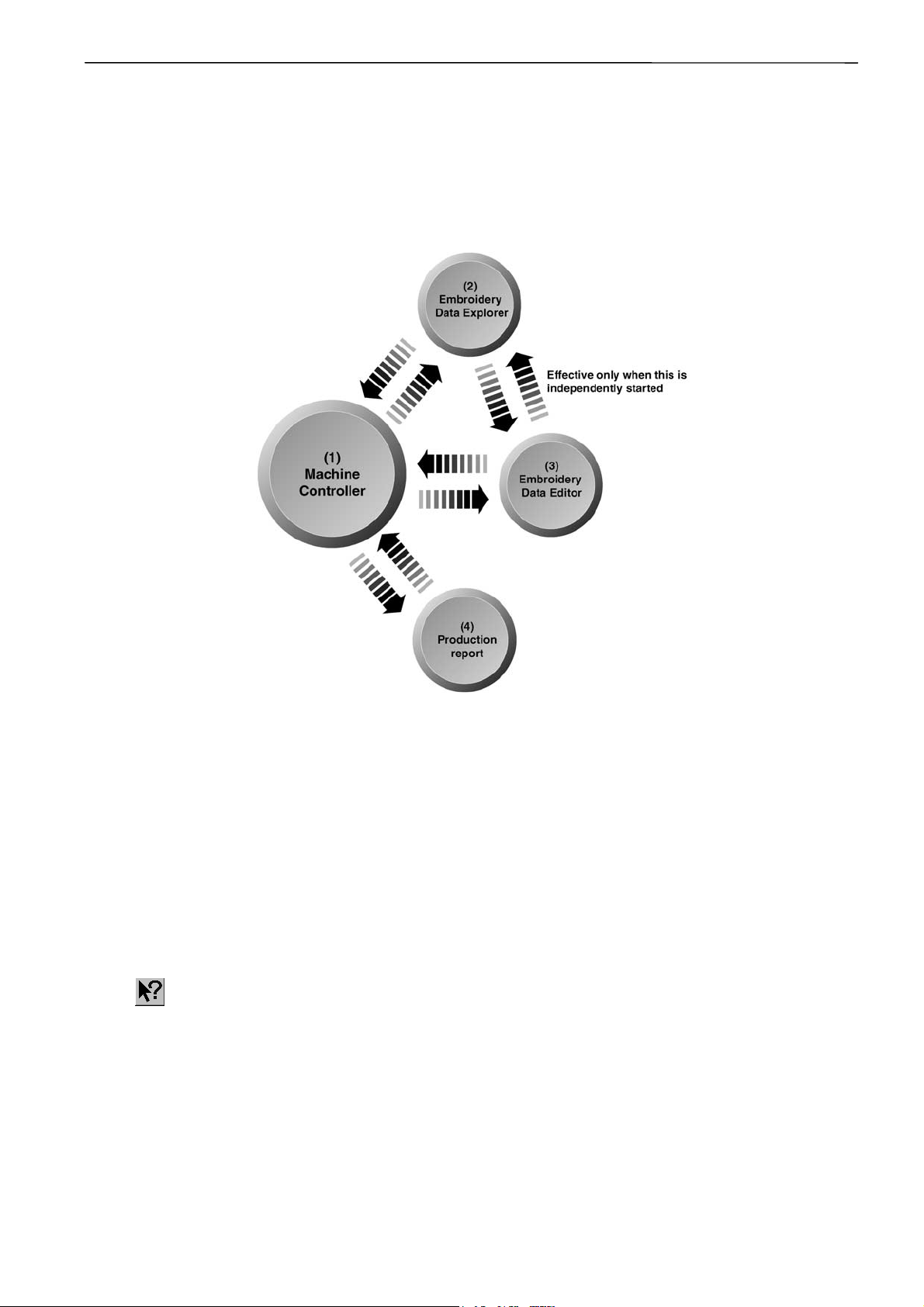

2-2 Configuration of Software

This software is mainly composed of the following four programs. The software is provided on CD-R.

(1) Embroidery Machine Controller

(2) Embroidery Data Explorer

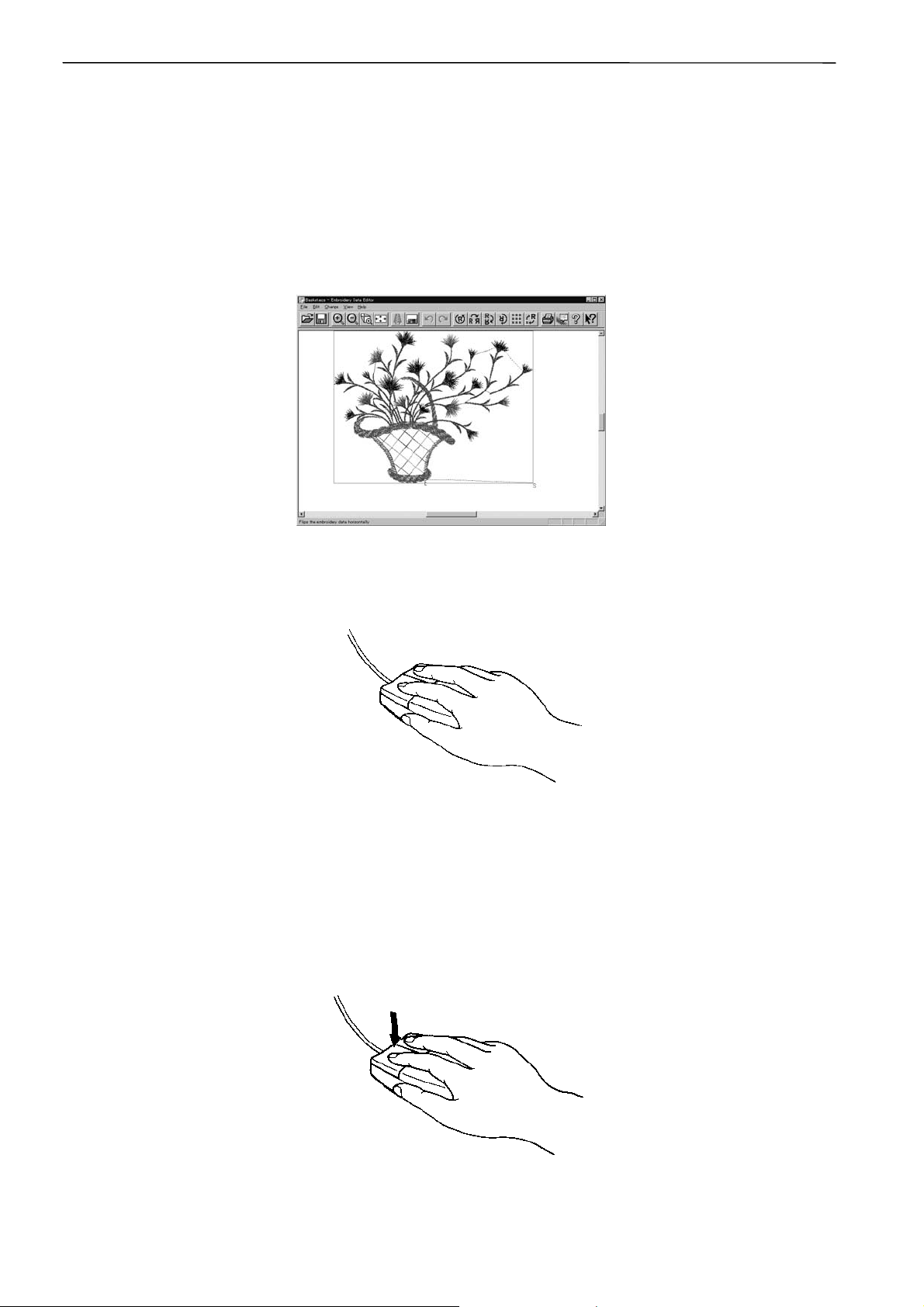

(3) Embroidery Data Editor

(4) Production Report

Program Functions

(1) Machine Controller

This program controls embroidering operation of the machine.

A embroidering status can be displayed on the screen in real time, and data for operating the

machine can be set.

(2) Embroidery Data Explorer

This program handles files of embroidery data on patterns.

Transmission of embroidery data to the machine, as well as copy, move and retrieval of a file are

available by means of this program. Embroidery data can be converted from the paper tape or

floppy disk.

(3) Embroidery Data Editor

This program allows editing of data on embroidering operation including scaling, rotation, color

change, etc.

(4) Production Report

This program is for collecting data on actual embroidering operation and calculating output, etc.

1-4 BE-1204B-BC • BE-1206B-BC

Page 23

Chapter 1 An Introduction of Embroidery Machine

Relationship among Programs

When the software is started, the program (1) for actuating the machine starts first.

Next, embroidery data is called by the program (2). Use the program (3), when required, for editing

and embroidering. The embroidery data is totaled by the program (4).

The programs (2), (3), and (4) can be started from the menu of the program (1). Each program can

also be started independently.

W1357Q

2-3 Notes on use

• Do not start other application software while the machine controller is used.

• Do not set the screen saver.

To cancel setting, select the "Screen saver" on the "Control panel" screen and set "Not used".

• Set the computer not to use the system agent included in the Windows 95 PLUS.

2-4 Help

The software is equipped with an on-line help function as an accessory.

Click

usage of the item. Pressing the [F1] key brings up the help screen of the application for your

reference.

, then the icon of the desired item. A message is displayed to explain the meaning and

BE-1204B-BC • BE-1206B-BC 1-5

Page 24

Chapter 1 An Introduction of Embroidery Machine

2-5 Basic Operation of Software

This section explains the basics of using the software. It covers only the operating procedures that

are commonly used for the software. If there are any special operating procedures inherent to a

program, they are explained in each section.

How to Use the Mouse

When selecting an icon or a menu displayed on the screen, move the white arrow pointer on the

screen to the required position, then press the button on the mouse.

W1358Q

Place the mouse on a flat, smooth surface and move it by sliding on it. The white arrow pointer

moves along the mouse motion.

W1359Q

The mouse has two buttons. The left one is used in general. There are three ways of operating the

mouse button as described below:

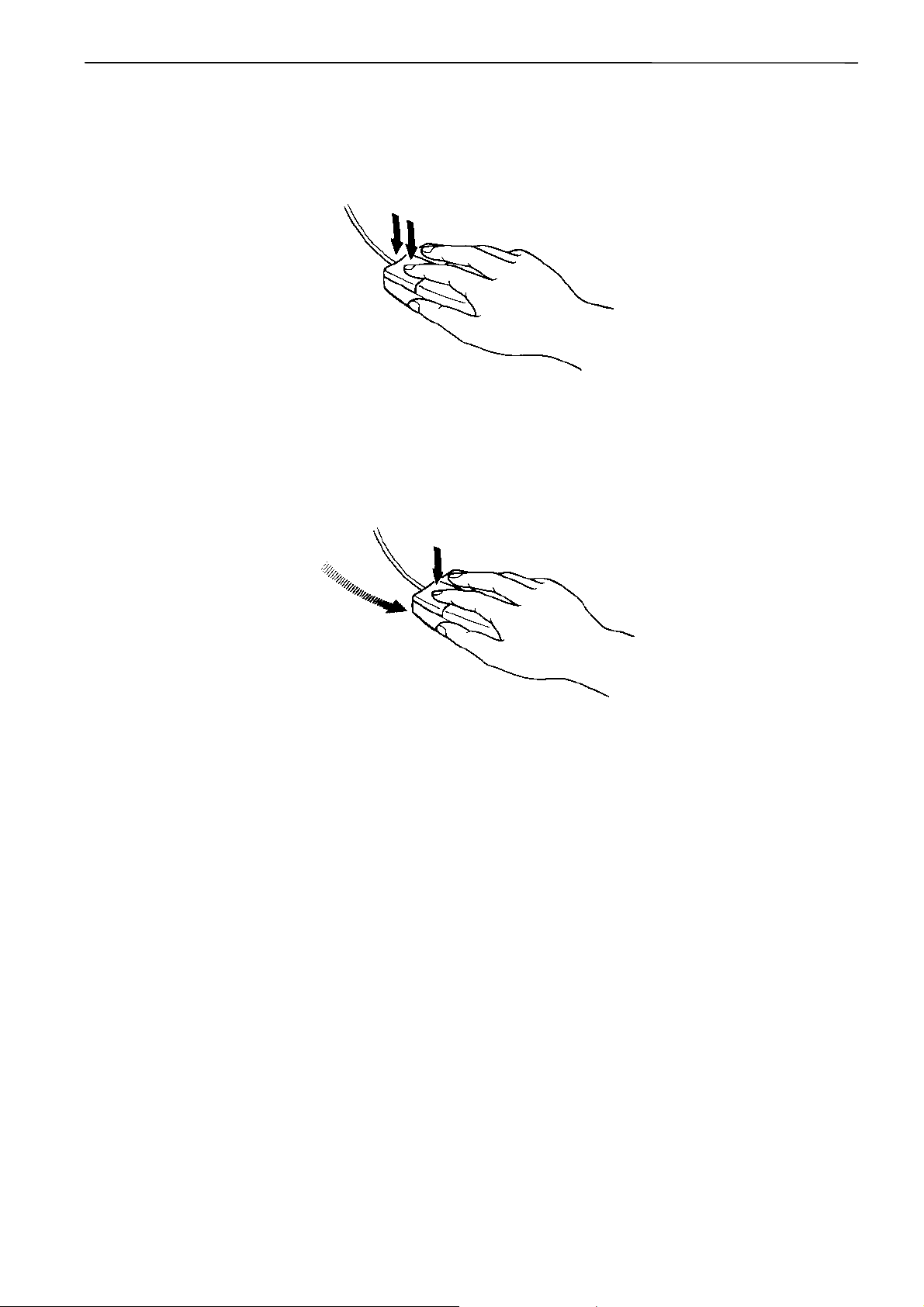

!!!! Click

Press the left button of the mouse once.

"Click [xx]" means moving the white arrow pointer to "xx" and pressing the left button once.

1-6 BE-1204B-BC • BE-1206B-BC

W1360Q

Page 25

Chapter 1 An Introduction of Embroidery Machine

!!!! Double-click

Press the left mouse button twice continuously. Do not leave a long pause in between.

"Double-click [xx]" means moving the white arrow pointer to "xx" and pressing the left button twice

continuously.

W1361Q

!!!! Drag

Move the mouse while holding down the left button.

Dragging is used for defining an area.

W1362Q

BE-1204B-BC • BE-1206B-BC 1-7

Page 26

Chapter 1 An Introduction of Embroidery Machine

Names of Screen Components

Names of major components on the screen of the machine controller are described below:

Menu

Tool bar

Dimmed icons

cannot be used

unless an

appropriate item

is selected.

Leftward movement

Status bar

Upward

movement

Scroll bar

Downward

movement

Rightward movement

W1363Q

!!!! Menu

Processing of software is carried out by giving relative commands.

Commands are divided in groups and stored in each menu. The menu displayed on the screen

changes depending on the program which is currently active.

!!!! Tool bar

A command is executed by clicking a relative icon (illustrated button) on the screen. If it is hard to

recognize icons from illustrations, move the white arrow pointer to the icon. The name of the icon

is displayed.

!!!! Scroll bar, scroll box, and scroll arrow

Some patterns may not be displayed entirely on the screen. Use the scroll bar to see hidden parts

of the pattern into view.

When displaying the right part, for example, click the scroll arrow at the right end. The box in the

scroll bar moves to the right. By dragging the scroll box to the right, the screen can scroll quickly.

The vertical scroll bar can be used in the same way.

!!!! Status bar

This bar is for displaying a brief description of the selected command.

1-8 BE-1204B-BC • BE-1206B-BC

Page 27

Chapter 1 An Introduction of Embroidery Machine

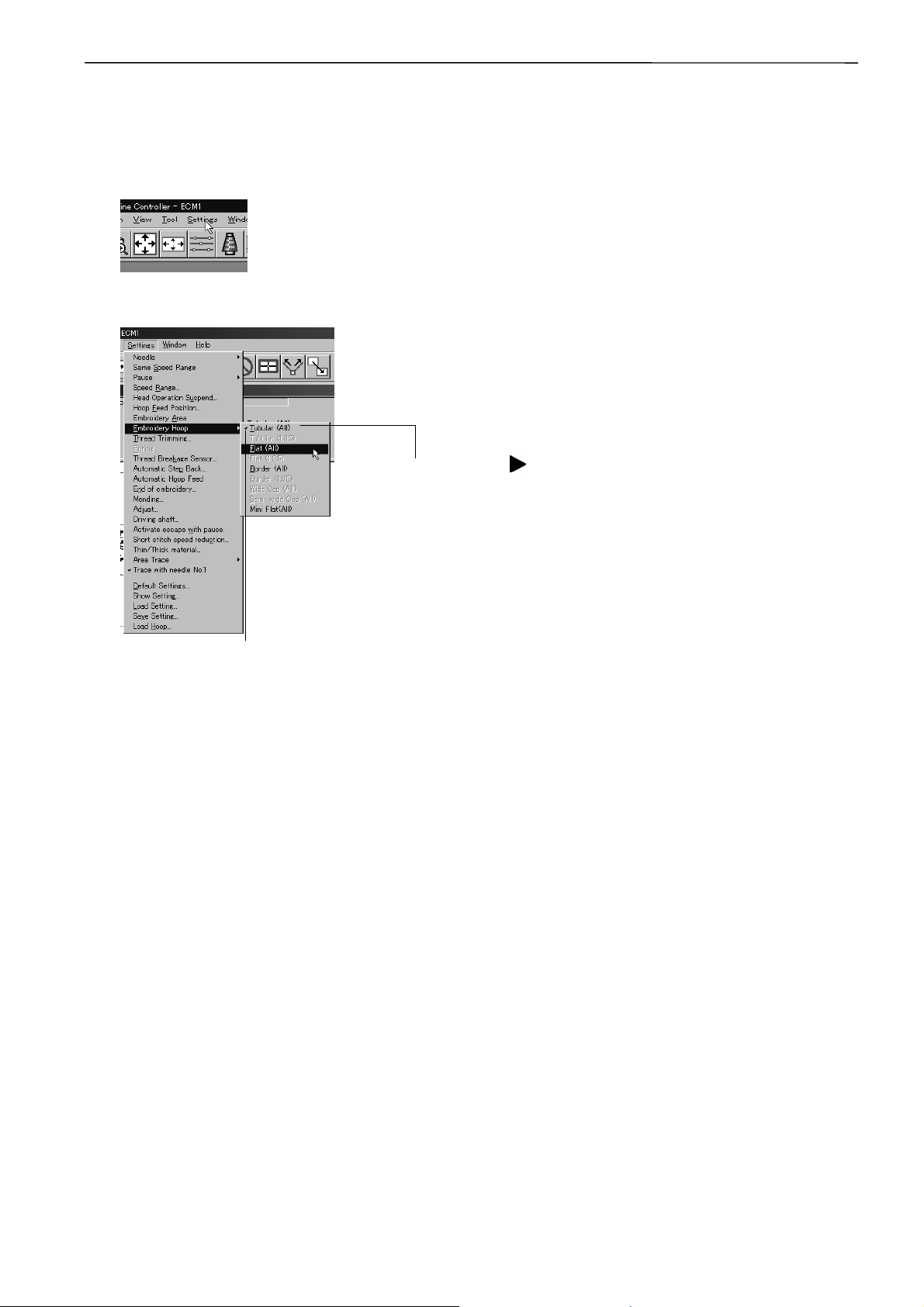

Selection of Menu

Processing of software is carried out by giving a command. A command can be given by the mouse

as described below:

1. Move the arrow pointer to a menu name and click there.

W1364Q

2. A list of commands is displayed. Click the required command.

Dimmed commands cannot

be used unless an

appropriate item is selected.

Commands with a

mark have sub menus.

The check mark (√) indicates

that the command is selected.

W111 7Q

When the arrow pointer is moved to another menu while a list of commands is displayed, those of the

latter menu are displayed.

BE-1204B-BC • BE-1206B-BC 1-9

Page 28

Chapter 1 An Introduction of Embroidery Machine

1-10 BE-1204B-BC • BE-1206B-BC

Page 29

Chapter 2

Preparation of Embroidery Machine

Page 30

Chapter 2 Preparation of Embroidery Machine

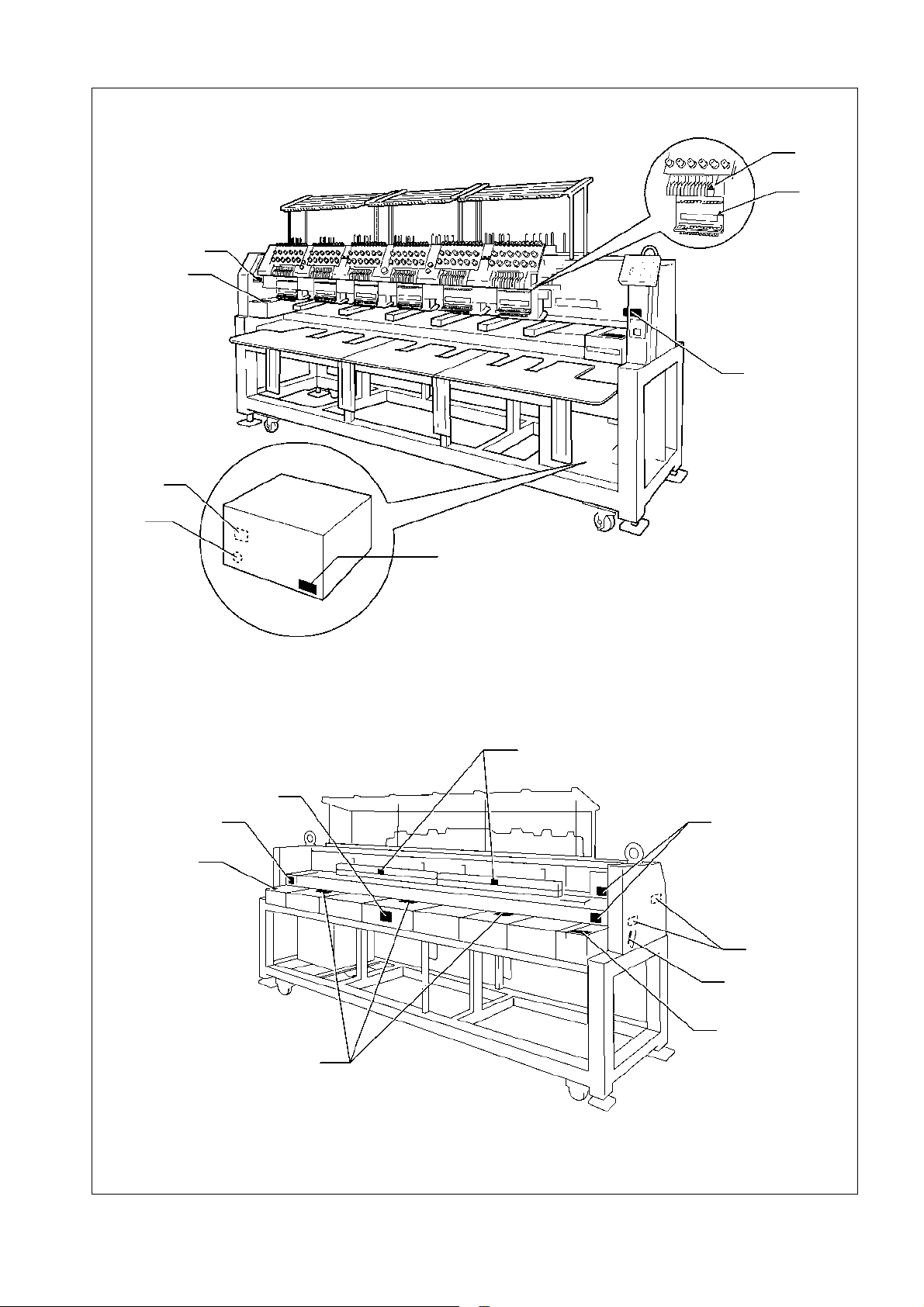

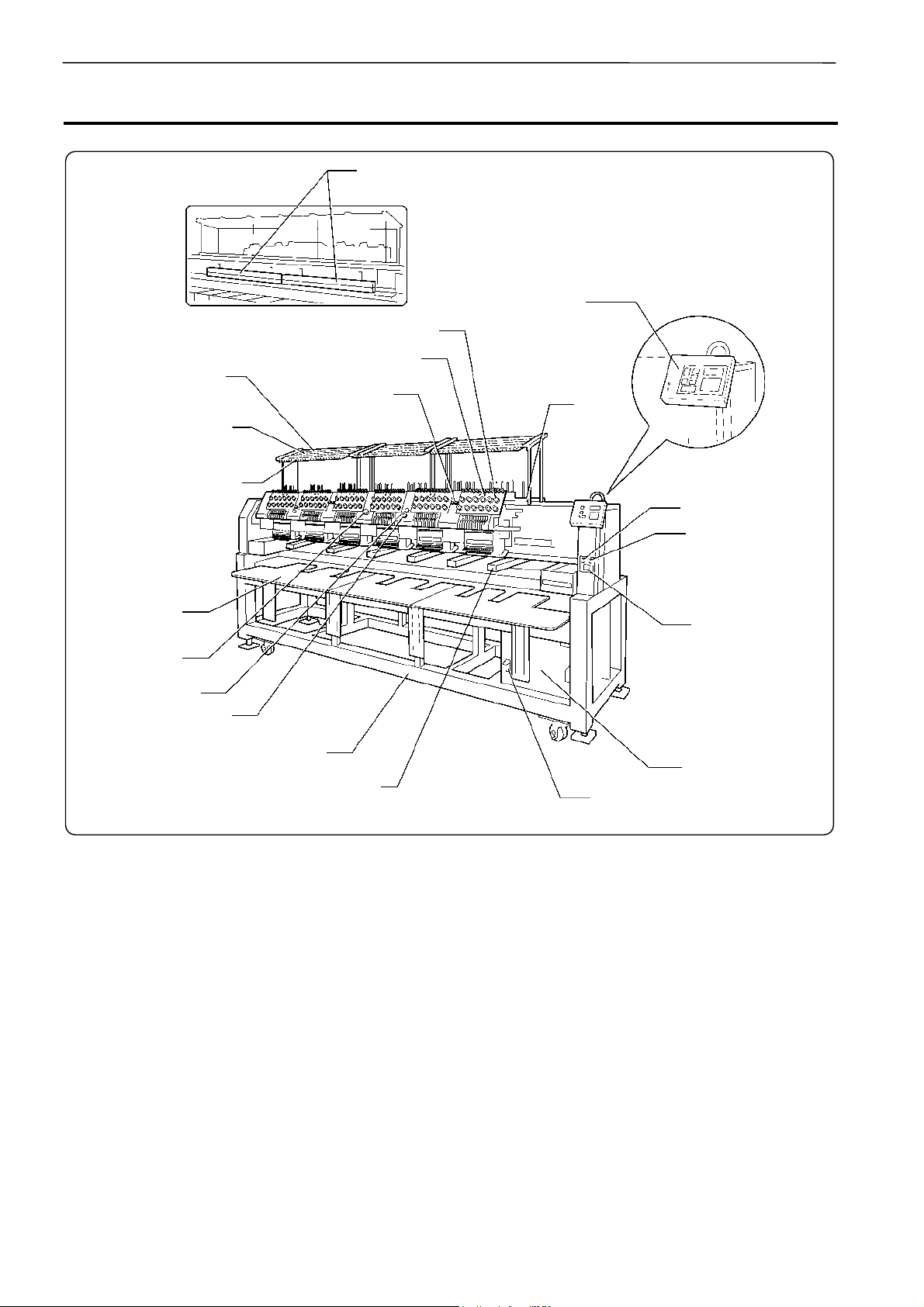

1. Names of Machine Components

Fluorescent lamp switch

Operation panel

Thread tension dial

Thread tension base switch

Thread guide C

STEP BACK /

FWD switch

Thread guide B

Thread guide A

Cotton

stand

Fluorescent lamp

switch

Flat / Cap hoop

select switch

Table

Emergency

stop switch

Start switch

Stop switch

Rotary hook cover (Safety device)

Leg

Main power switch

Power switch

Control box

The machine heads are numbered 1 to 6 (1 to 4 in four head models) from the right front.

W1401Q

2-2 BE-1204B-BC • BE-1206B-BC

Page 31

2. Installation

y

q

Chapter 2 Preparation of Embroidery Machine

DANGER

Embroidery machines should be installed onl

by trained engineers.

Electric wiring should be laid by your

distributor or electric experts.

The sewing machine weighs approximately

700 kg.

The installation should be carried out by four

or more people.

Do not connect the power source until

installation is completed. Doing so may start

the machine unintentionally through an

accidental activation of the START switch,

resulting in bodily injuries.

Install a machine in a place away from a highfre

uency welding machine or other machines that

may generate a strong electric noise. Failure to

do so may cause the embroidery machine to

malfunction.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Secure the machine with the adjustment bolts on

the sound floor so that it will not move.

After installation is completed, get the power supply from a dedicated outlet.

When connecting multiple machines, exercise care not to exceed the capacity of the outlet.

2-1 Transportation of Machine

When relocating the machine, push the steel frame. Never push the cover or carriage.

!!!! When using a fork lift

The central seal

Lift forks

W1222Q

1. Viewing the machine from the back, position their center at the central seal, insert the forks under

the legs and lift the machine.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-3

Page 32

Chapter 2 Preparation of Embroidery Machine

!!!! When using a crane

Belt

More than

45°

More than

45°

W1223Q

2. Hook on the eyebolts with each belt to lift up the machine.

When lifting the machine, make sure that the belts do not contact the machine table or the tension

plate.

2-4 BE-1204B-BC • BE-1206B-BC

Page 33

2-2 Installation of Machine

[5]

Chapter 2 Preparation of Embroidery Machine

[1]

[4]

[3]

[2]

W1224Q

1. Place Footboard [4], a rubber cushion 10 [3] (provided with the machine), and PE sheet [2] under

each of four adjustment bolts M20 [1]. The Footboard must be on the rubber cushion.

2. Fit four adjustment bolts M20 [1] into the hole of Footboard [4], and adjust the embroidery machine

in height.

The adjustment must be made in such a manner that the four bolts are under an equal load when

the machine is placed down. (To lower adjustment bolt M20 [1], turn it in the direction of the arrow.)

Also, the casters should be raised.

3. After adjusting four adjustment bolts M20 [1], turn nuts M20 [5] in the direction of the arrow to

fasten them.

If the floor is not strong enough, the embroidery machine may be rocked during operation. In such a

case, it is recommended that a secure base of concrete be placed below the embroidery machine.

BE-1204B-BC • BE-1206B-BC 2-5

Page 34

Chapter 2 Preparation of Embroidery Machine

2-3 Preparation of Needle Bar Case

[1]

[2]

Repeat the procedures below for all the heads:

1. Unscrew the screw [1], then detach the bracket [3] and pin [2].

[3]

W1225Q

2-6 BE-1204B-BC • BE-1206B-BC

Page 35

2-4 Mounting of Table

!!!! Preparation for mounting the table

Table guide bridge

Chapter 2 Preparation of Embroidery Machine

[1]

W1226Q

• This operation is required only when the table set is purchased separately from the machine.

• The table is a standard attachment.

1. Tentatively mount 4 (3 in BE-1204B) table supports Front [1] on the leg front using 4 bolts each.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-7

Page 36

Chapter 2 Preparation of Embroidery Machine

!!!! For embroidering with tubular square hoop or cap frame (lower position)

[8]

[3]

[7]

[6]

[4]

[6]

[5]

[2]

[1]

[5]

W1227Q

1. Attach four hexagon socket head cap screws to each of table parts R [1], M [2](BE-1206B and

BE-1204C only), and L [3] from the back.

2. Put the table backing plate [4] of each table on to the table guide bridge [5], and slide to the other

side. Insert the table backing plate [4] into the table backing rubber on the table support Rear [6].

3. Adjust table supports front [7] in height so as to make the table parallel with the floor.

4. Tighten all hexagon socket head cap screws [8] firmly.

2-8 BE-1204B-BC • BE-1204C-BC • BE-1206B-BC

Page 37

!!!! For embroidering with flat hoop/sash frame (upper position)

[5]

[4]

[2]

[3]

Chapter 2 Preparation of Embroidery Machine

[1]

[7]

[6]

W1228Q

1. Attach four hexagon socket head cap screws to each of table parts R [1], M [2](BE-1206B and

BE-1204C only), and L [3] from the back.

2. Insert the table backing plate [4] of each table into the table backing rubber on the table support

Middle [5].

3. Adjust the height of the table support Front [6] to be even with the upper surface of the bed.

4. Tighten all hexagon socket head cap screws firmly.

5. Attach four (three in BE-1204B) thumb bolts to the lower front steel pipe of the leg section.

Fasten the table and the leg section using table stays (4 pcs(3 pcs in BE-1204B)) [7].

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-9

Page 38

Chapter 2 Preparation of Embroidery Machine

2-5 Mounting of Cotton Stand

Thread guide A

Thread guide B

Thread guide C

[5]

Front

[1]

[2]

[4]

[3]

[6]

W1229Q

1. Attach the cotton stand bars [2] to the cotton stand [1].

2. Attach six thread guide support bars [3] to the cotton stand [1], while fitting into the six holes.

3. Mount the thread guide assembly [4] on the thread guide support bars [3] using the six screws [5].

• When mounting, use one flat washer [6] below the thread guide support bar [3].

• Pay careful attention to the front and back directions of the thread guides (A, B, C).

2-10 BE-1204B-BC • BE-1206B-BC

Page 39

Chapter 2 Preparation of Embroidery Machine

2-6 Lubrication to Needle Bar Case

Proper lubrication is necessary for keeping the machine head in good condition.

CAUTION

Turn off the power switch before starting any cleaning work, otherwise the machine may operate if the

start switch is pressed by mistake, which could result in injury.

W1221Q

Before operating the machine for the first time after unpacking or after leaving the machine without

operation for a long period of time, supply one or two drops of oil to each needle bar from the oil supply

holes of the lower cover.

• Use the Brother’s specified oil (Nippon Oil, Embroidery Lube 10N; VG10) for this.

* If this type of lubricating oil is difficult to obtain, the recommended oil to use is <Exxon Mobil Essotex SM10;

VG10>.

• Supplying an excessive amount of oil will cause dripping onto the material.

BE-1204B-BC • BE-1204C-BC • BE-1206B-BC 2-11

Page 40

Chapter 2 Preparation of Embroidery Machine

2-7 Connection of Personal Computer to Machines (for connecting 4 sets)

Be sure to ground the personal computer.

Interface board

Control box

CAUTION

Before inserting or removing IF cables or RS

cables, turn off the power switches of the

machine, the computer, and peripheral

equipment.

(1st machine)

RC

cable

IF cable

(2nd machine)

(3rd machine)

IF cable

(4th machine)

Term in at or

(Be sure to attach

a terminator.)

W1352Q

1. Turn off the power of the personal computer and the machine.

2. Open the cover of the personal computer and insert an interface board into the slot for the PCI

bus.

3. Connect the interface board male connector and the personal computer RS-232C connector

(COM1 or RS-232C-1) using the attached short RS cable.

4. Remove the side cover of the control box.

2-12 BE-1204B-BC • BE-1206B-BC

Page 41

Chapter 2 Preparation of Embroidery Machine

5. Pass the IF cable from the crevice between the frame of leg and the control box.

W1354Q

6. Connect the interface board female connector and the control box connector SBUS1 of the first

machine using an IF cable.

(Terminator)

W1353Q

7. Connect the control box connector SBUS2 of the first machine and the control box connector

SBUS1 of the second machine using an IF cable.

8. Attach the side cover of the control box.

9. Connect the control box connector SBUS2 of the second machine and the control box connector