Page 1

Page 2

CONTENTS

~MECHANISM~

OJ

Upper shaft and needle

................................ .

bar

mechanism

[I] Lower shaft and rotary hook

mechanism ..........................................

[I]

Feed mechanism ( 8714/ 8716/ 8747) .... 2

[I]

Feed mechanism (8706/ 8707) .............. 3

..

0 Lubrication mechanism ........................ 4

[I]

Thread

[]]

Thread tension release lever

(8707/8716/8747)................................ 9

[I]

Thread wiper mechanism ..................... 9

[!]

Quick-back mechanism ........................ 9

[]]

Automatic presser lifter mechanism ..... 9

trimmer

mechanism ................. 6

~ASSEMBLY~

OJ

Needle

[I]

Feed mechanism (8706/ 8707) ..............

I1J

Feed mechanism

[I]

Thread

0

Rotary

bar

trimmer

hook.........................................

......................................

............................................

(8714/

....................................

8716/ 8747) ....

[I] Presser mechanism ...............................

[]]

Cover....................................................

~ADJUSTMENTS~

OJ

Needle

adjustments ..........................................

I1J

Feed

and

rotary hook timing

dog

height adjustment .................

............................. 20

14

14

15

16

17

18

19

19

20

21

~DISASSEMBLY~

OJ

Cover....................................................

I1J

Presser..................................................

[I]

Rotary hook ......................................... II

0 Thread

[I]

Feed. mechanism

[I]

Feedmechanism(8714/B716j8747)

[]]

Needle

trimmer

bar

mechanism .........................

..............................

.................................... II

(8706/

8707) ..............

....

10

10

10

12

13

13

[I]

Feed timing adjustment ........................

0 Presser height adjustment .....................

[I]

Synchronizer adjustment ......................

[]]

Thread trimmer

[I]

Tension release lever adjustment ..........

[!]

Thread wiper adjustment......................

[]]

Automatic presser foot lifter

(

-900;

electromagnetic type) ...............

~TROUBLESHOOTING

~djustment

..................

adjustment

GUIDE~...

21

21

22

23

24

24

24

25

Page 3

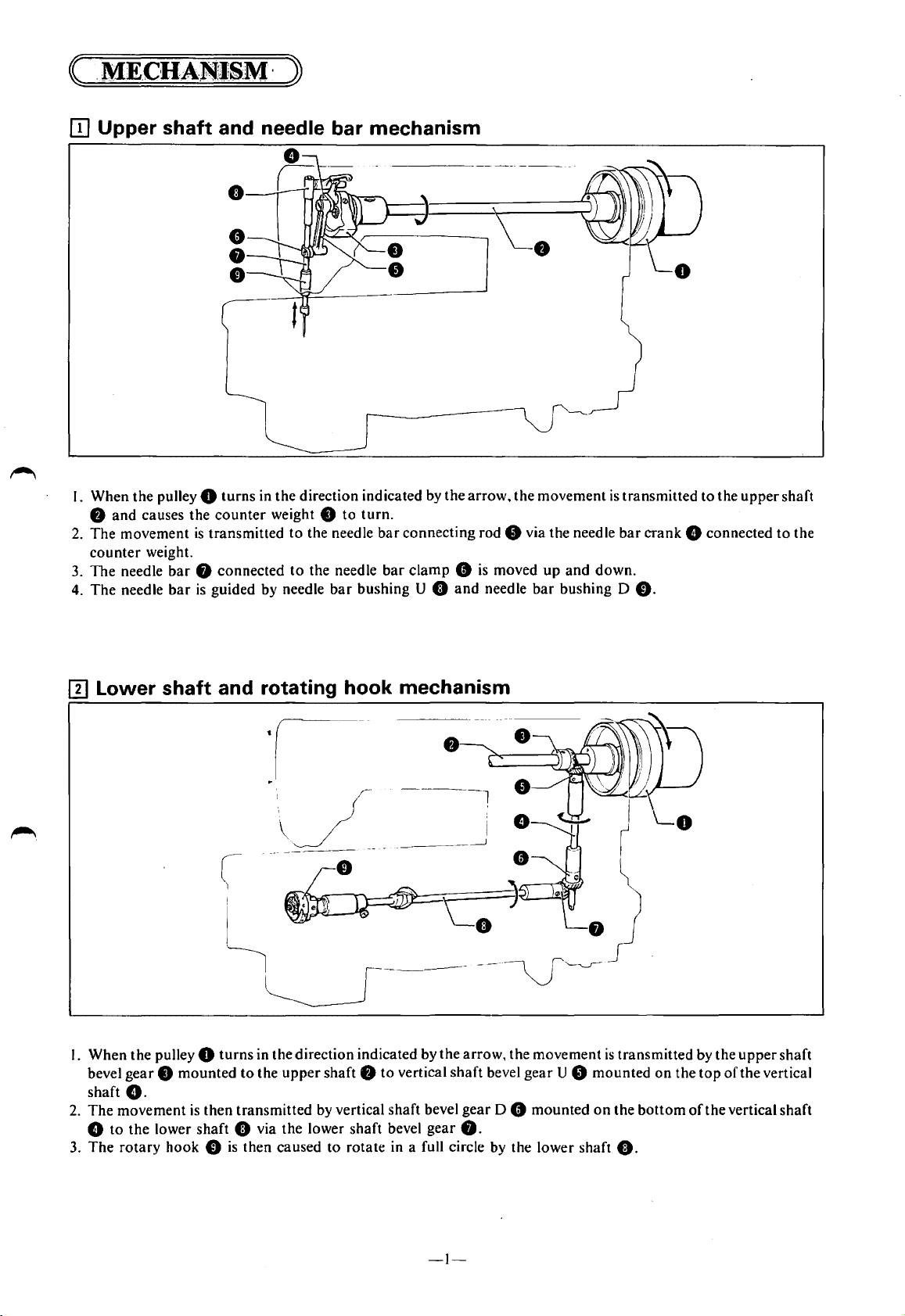

[I] Upper shaft and needle bar mechanism

I. When the pulley 0

8

and

causes the

2.

The

movement

counter

3.

The

The

4.

weight.

needle

needle

bar

bar

turns

in the direction indicated by

counter

is

transmitted

weight 8

8 connected

is

guided by needle

to

the needle

to

the needle

to

turn.

bar

bar

bushing U 0

the

arrow,

connecting rod 8 via the needle

bar

clamp 8 is

and

moved

needle

[I] Lower shaft and rotating hook mechanism

the

movement

up

bar

is

bar

and

down.

bushing D

transmitted

crank

8 connected

0.

to

the

upper

shaft

to

the

I. When the pulley 0

gear 8 mounted

bevel

G.

shaft

2.

The

movement

8

to

the

lower

3.

The

rotary

hook 0

turns

in the direction indicated by

to

the

upper

shaft 8

is

then

transmitted by vertical shaft bevel

shaft

0 via the lower shaft bevel

is

then caused

to

rotate in a full circle by the lower shaft

to

vertical

the

arrow, the movement

shaft

bevel

gear

D 8 mounted

gear

8.

-I-

gear

U 8

is

transmitted by the

mounted

on

the

on

the

bottom

0.

upper

top

of

the vertical

of

the vertical shaft

shaft

Page 4

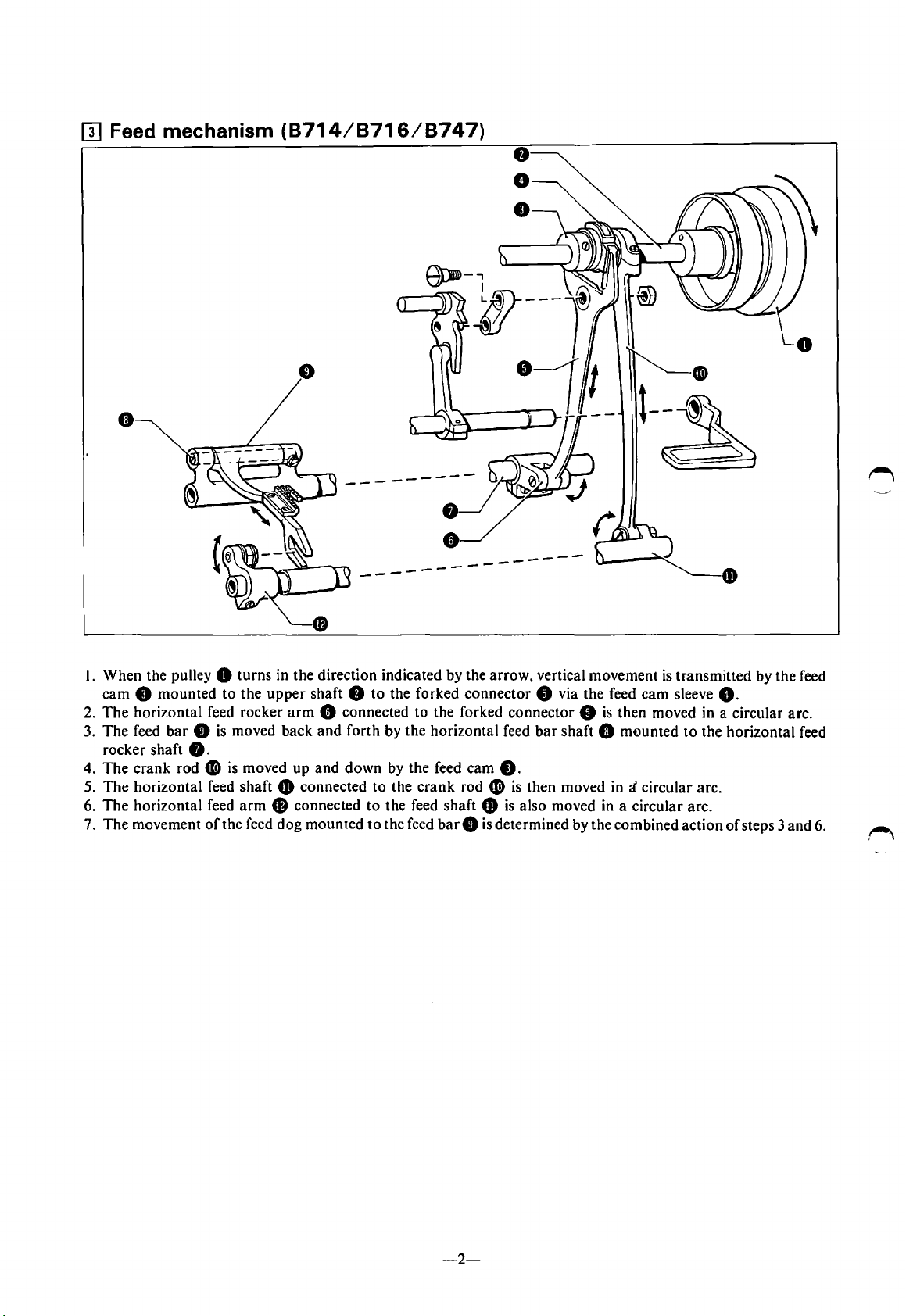

[I] Feed mechanism

•

(8714/8716/8747)

----

---

I. When the pulley 0 turns in the direction indicated by the arrow, vertical movement

cam

8 mounted

2.

The

horizontal feed rocker

3. The feed

rocker shaft

4.

The

5.

The horizontal feed shaft & connected

6.

The

7.

The movement

bar 8 is

crank rod fi)

horizontal feed

to

the

upper

shaft 8

arm

8 connected

moved back and forth by the horizontal feed

to

the forked connector 8 via the feed cam sleeve

to

8.

is

moved up and

arm

Cl

connected

of

the feed dog mounted

down

by

to

the

to

the feed shaft &

to

the feed

the feed cam

crank

----

the forked connector 8

rod ~ is

bar 8 is

_...---

is

then moved in a circular arc.

bar

shaft 0 mounted

8.

then moved

is

also moved in a circular arc.

determined by the combined action

in

i circular arc.

is

transmitted by the feed

G.

to

the horizontal feed

of

steps 3 and 6.

-2-

Page 5

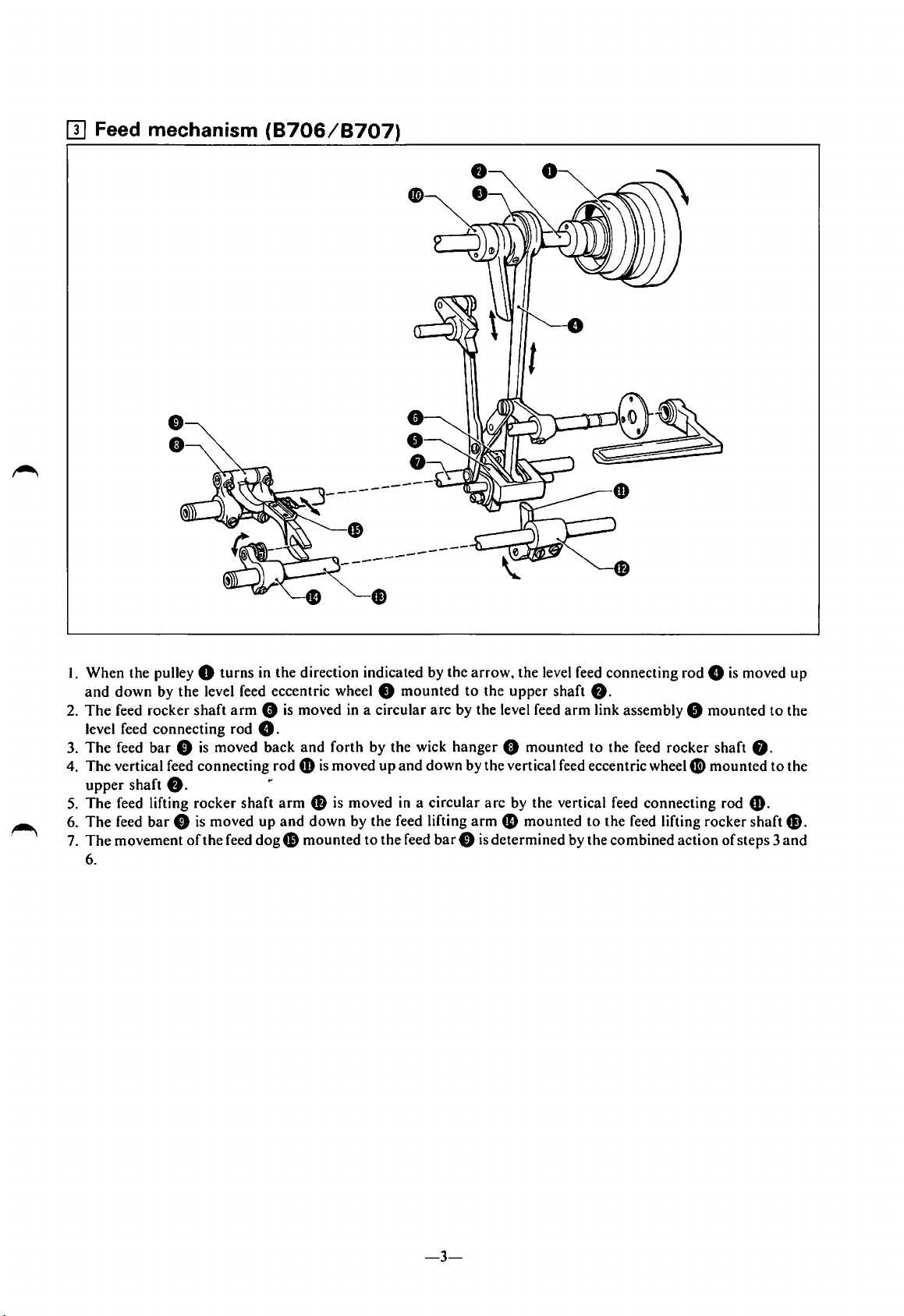

(}] Feed mechanism

(8706/8707)

.

~

I. When the pulley 0 turns in

and

down

by

the

level feed eccentric wheel 8

2.

The

feed rocker

level feed connecting rod

3.

The

feed

4.

The

vertical feed connecting

upper

shaft

5.

The

feed lifting

6.

The

feed

7.

The

movement

6.

shaft

bar 0 is

f).

rocker

bar 0 is

oft

arm

moved back

shaft

moved up

he feed

dog

the

direction indicated by the

mounted

0 is moved in a circular

8.

and

forth by the wick hanger 0 mounted

rod

6)

is

moved up

arm

• is moved in a circular

and

down

by the feed lifting

G)

mounted

to

the feed

and

arrow,

to

arc

by the level feed

down

by the vertical feed eccentric wheel

arm

bar 0 is

the level feed connecting rod 8

the

upper

shaft

f).

arm

link assembly 0 mounted

to

arc

by the vertical feed connecting rod 6).

4D

mounted

determined by the combined action

to

the feed

the

rocker

shaft

Gi)

mounted

feed lifting rocker shaft

of

is

moved up

to

f).

steps 3

to

the

the

G)

and

.

-3-

Page 6

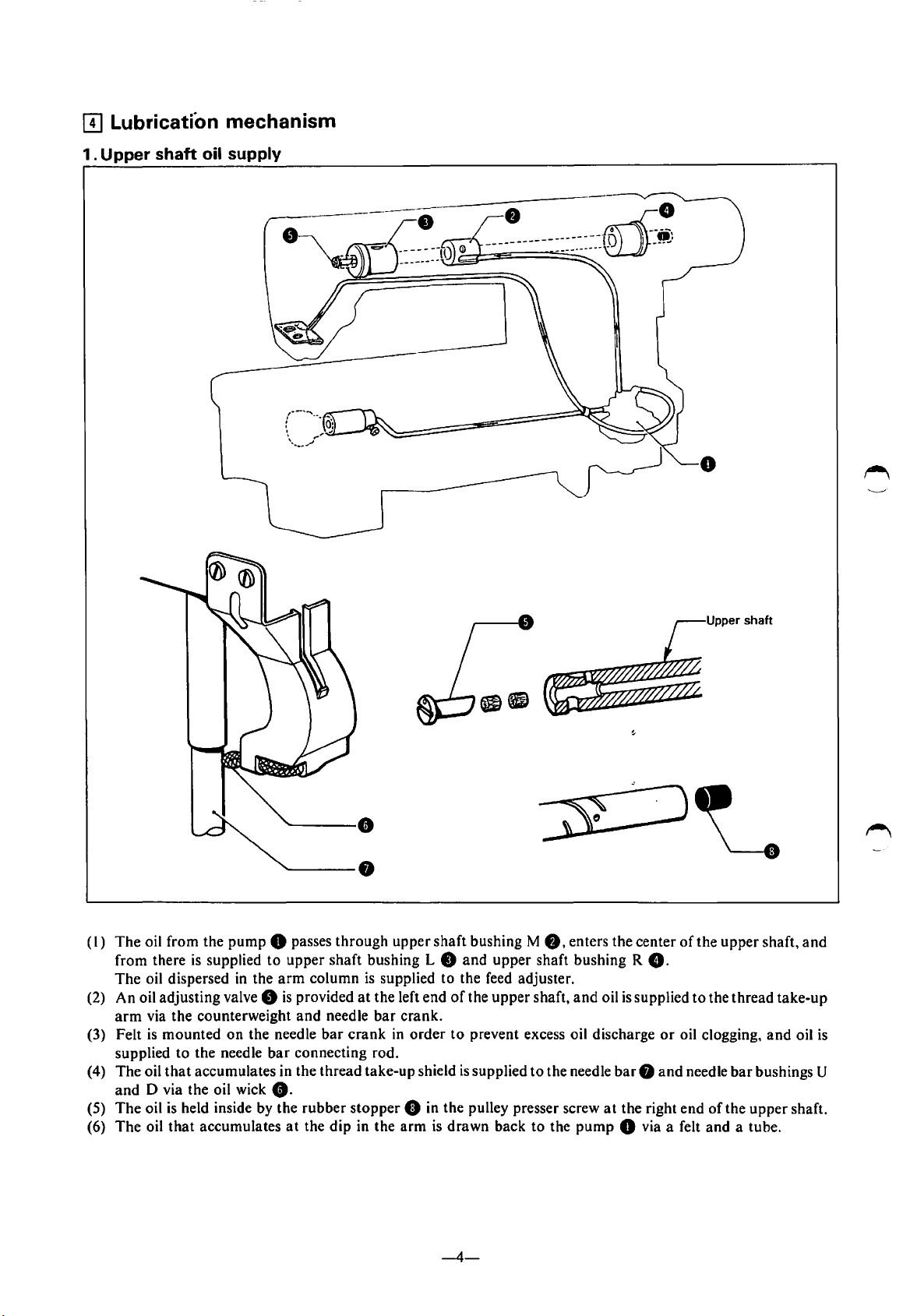

[!] Lubrication mechanism

1.

Upper shaft oil supply

(I)

The

oil from the

from there

The

oil dispersed

(2) An oil adjusting valve

arm

via the counterweight

(3) Felt

(4) The oil

(5)

(6)

is

mounted

supplied

and

The

The

to

that

D via the oil wick

oil

is

oil

that

pump

is

supplied

in

on

the needle

the needle

accumulates in the thread take-up shield

held inside by the

accumulates

8 passes

to

upper

the

arm

8

is

provided

and

bar

connecting rod.

8.

rubber

at

the dip in the

through

shaft bushing L 8

column

needle

bar

is

supplied

at

the left end

bar

crank

stopper

upper

crank.

in

8 in the pulley presser screw

arm

shaft bushing M

and

to

the feed adjuster.

of

the

order

to

prevent excess oil discharge

is

supplied

is

drawn

8,

upper

shaft bushing R

upper

shaft,

to

the needle

back

to

enters the center

and

oil

is

barO

at

the right end

the

pump

8 via a felt

of

8.

supplied

or

oil clogging,

and

Upper shaft

the upper shaft,

to

the

thread

and

needle

bar

bushings U

of

the

upper

and

a tube.

and

take-up

oil

is

shaft.

-4-

Page 7

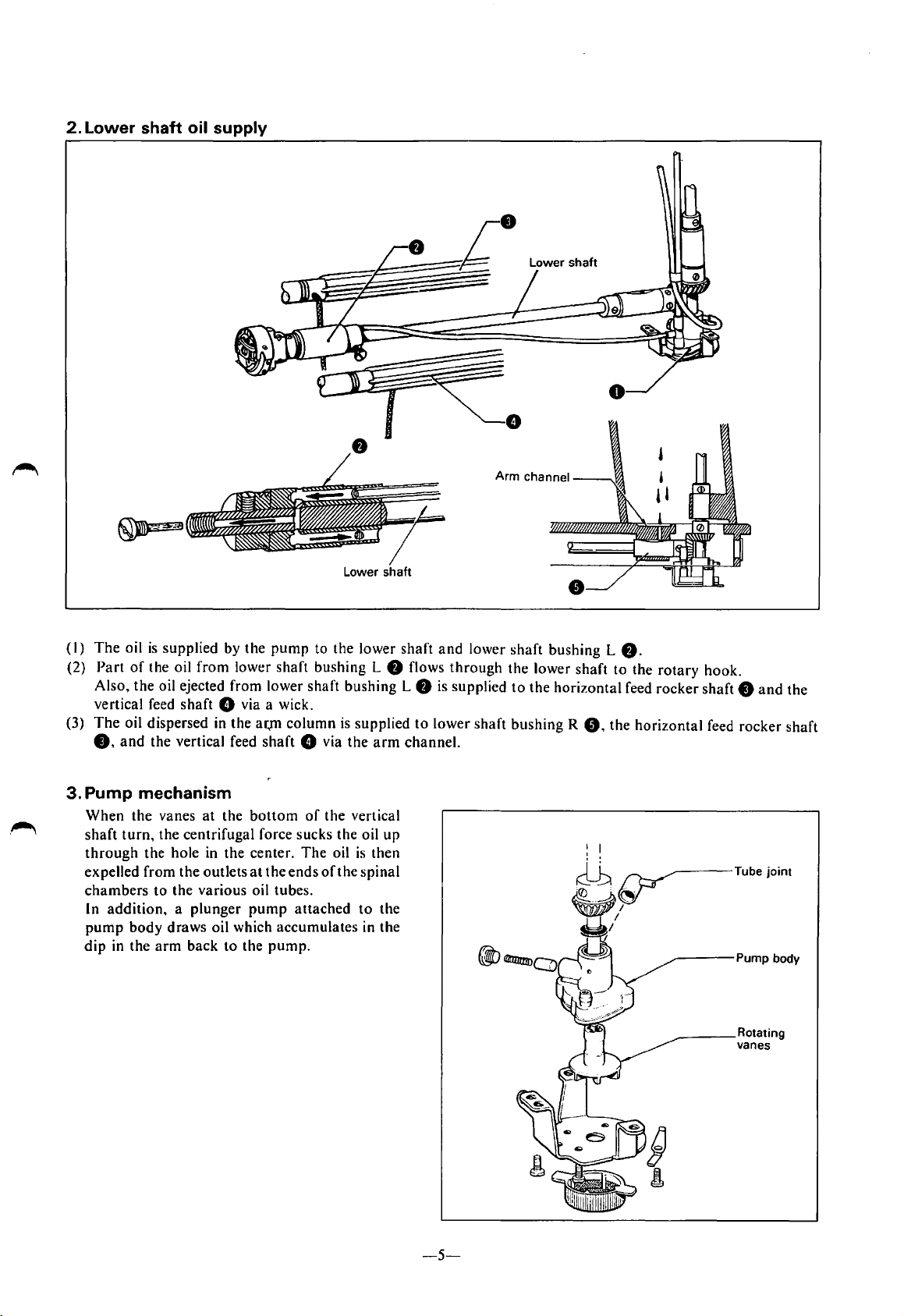

2.

Lower shaft oil supply

Lower shaft

(I)

The

oil

is

supplied

(2)

Part

of

the oil

from

Also,

the

oil ejected

vertical feed

The

(3)

0,

oil dispersed in

and

shaft

the

vertical feed

8 via a wick.

3. Pump mechanism

When

the

vanes

at

the

shaft

turn,

the

centrifugal

through

expelled

chambers

In

pump

dip

the

hole

in the center.

from

the

outlets

to

the

various

addition, a plunger

body

draws

oil which

in

the

arm

back

by

lower

from

the

to

the

the

pump

shaft

lower

ar.,m

column

shaft

bottom

force

sucks

at

the

ends

oil tubes.

pump

attached

accumulates

pump.

to

bushing

shaft

8 via

of

the

The

oil

of

the

lower

bushing

is

supplied

the

vertical

the

oil

is

the

spinal

to

in

L

f)

arm

up

then

the

the

shaft

and

flows

L

f)

is supplied

to

lower

channel.

lower

through

shaft

shaft

the

lower

to

the

bushing

bushing

shaft

horizontal

R

0,

L

f).

to

the

feed

the

horizontal

rotary

rocker

----Pump

____

hook.

shaft 0 and

feed

rocker

body

Rotating

vanes

the

shaft

-5-

Page 8

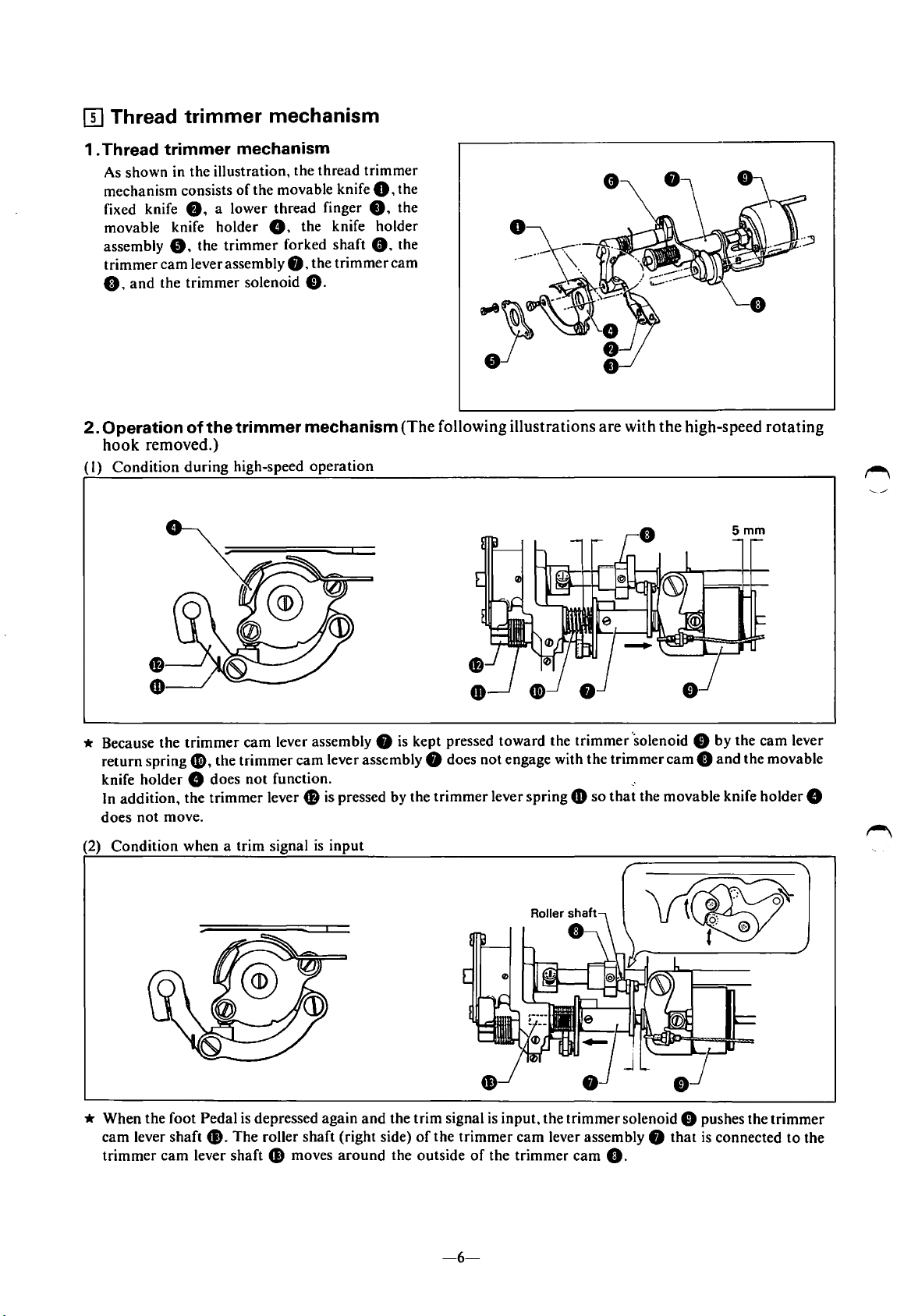

(}] Thread trimmer mechanism

1 . Thread trimmer mechanism

As shown

mechanism consists

fixed knife

movable knife holder

assembly

trimmer cam lever assembly

0,

2.

Operation of the trimmer mechanism(The following illustrations are with the high-speed rotating

hook

(I)

Condition during high-speed operation

in

the illustration, the thread trimmer

0.

a lower thread finger

8.

the trimmer forked shaft

and

the trimmer solenoid

removed.)

of

the movable knife

G. the knife holder

8,

the trimmer

8.

0,

8.

8.

the

the

the

cam

* Because the trimmer cam lever assembly 8

f),

return spring

knife holder

In addition, the trimmer lever 8

does not move.

(2) Condition when a trim signal

* When the foot Pedal

cam lever shaft

trimmer

cam

the trimmer cam lever assembly 8 does not engage with the trimmer

8 does

lever shaft

not

function.

is

pressed by the trimmer lever spring

is

input

is

depressed again

G).

The roller shaft (right side)

G)

moves

around

and

is

kept pressed toward the trimmer 'solenoid 8 by the cam lever

the trim signal

of

the trimmer

the outside

of

cam 0 and

,.

CD

so

that

the movable knife holder 8

is

input, the trimmer solenoid 8 pushes the trimmer

cam

lever assembly 8

the trimmer

cam

0.

that

the movable

is

connected

to

the

-6-

Page 9

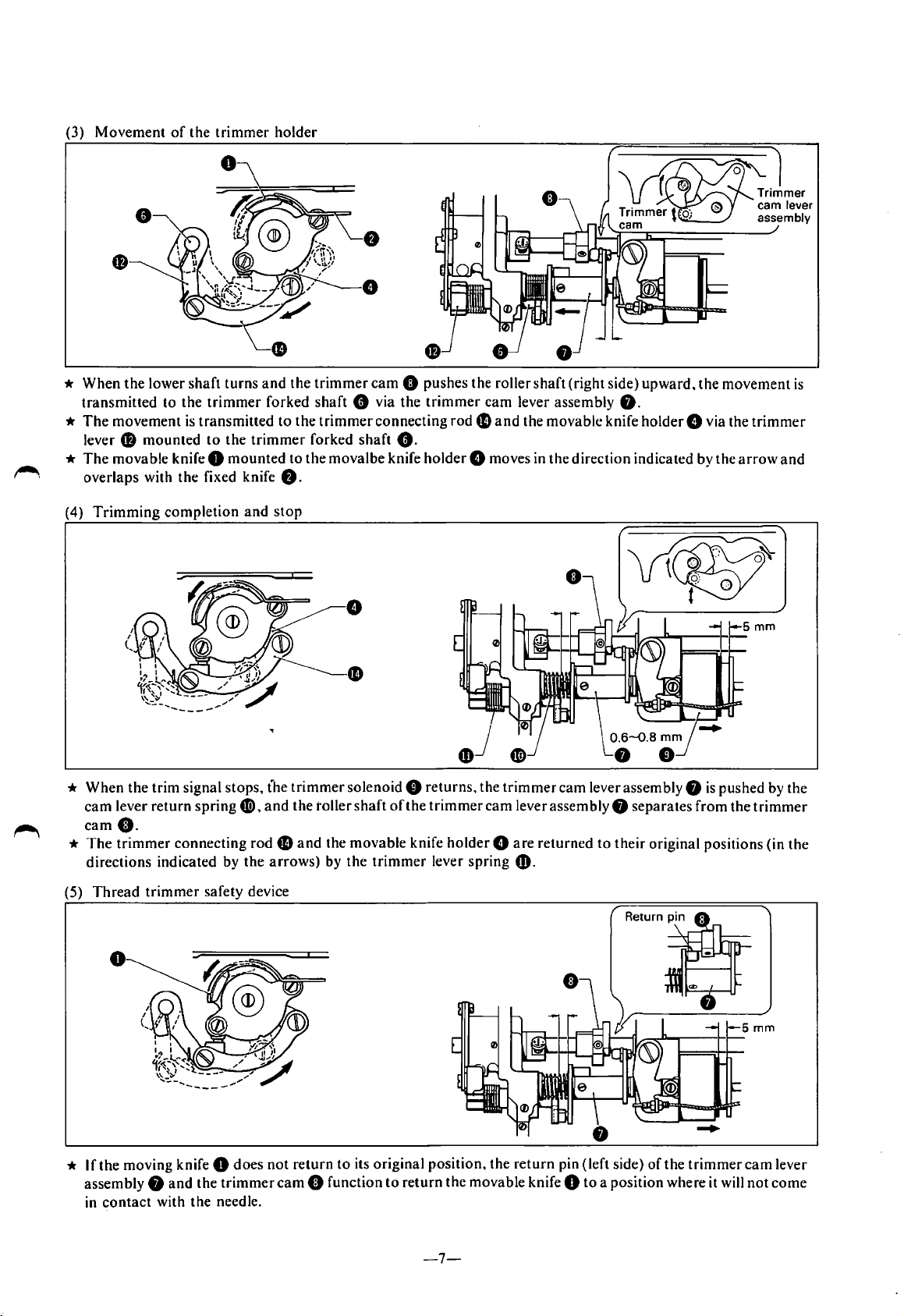

(3) Movement

*

When

transmitted

*

The

movement

lever 0

*

The

movable knife 0

overlaps with the fixed knife

(4)

Trimming

the

lower shaft

to

mounted

completion

of

the

the

trimmer

is

transmitted

to

trimmer

turns

the

mounted

holder

and

the

trimmer

forked

trimmer

shaft

to

the

trimmer

forked

to the movalbe knife

8.

and

stop

cam

0 pushes the roller

8 via the

connecting

shaft

8.

shaft

(right side)

trimmer

holder

cam

rode

lever assembly

and

the movable knife

8.

8 moves in the direction indicated by the

upward,

holder

the

movement

8 via the

arrow

is

trimmer

and

* When

*

(5)

the

trim signal stops, t'he

cam

lever

return

spring

G),

came.

The

trimmer

directions indicated by the

Thread

connecting rod

trimmer

safety device

0

* If the moving knife 0 does

8

and

the

the

trimmer

needle.

assembly

in

contact

with

trimmer

and

the toller

fD

and

arrows)

not

return

cam

solenoid 8 returns, the

shaft

oft

he

the movable knife

by

the

trimmer

to

its original position, the

8 function

to

return

trimmer

lever

cam

holder 8 are

spring

the

movable knife 0

trimmer

cam

lever assembly 8

lever assembly 8 separates

returned

to

their original positions (in

CD.

return

pin (left side)

to

a position where it will

of

the

is

pushed by the

from

the

trimmer

trimmer

cam

lever

not

come

the

-7-

Page 10

---

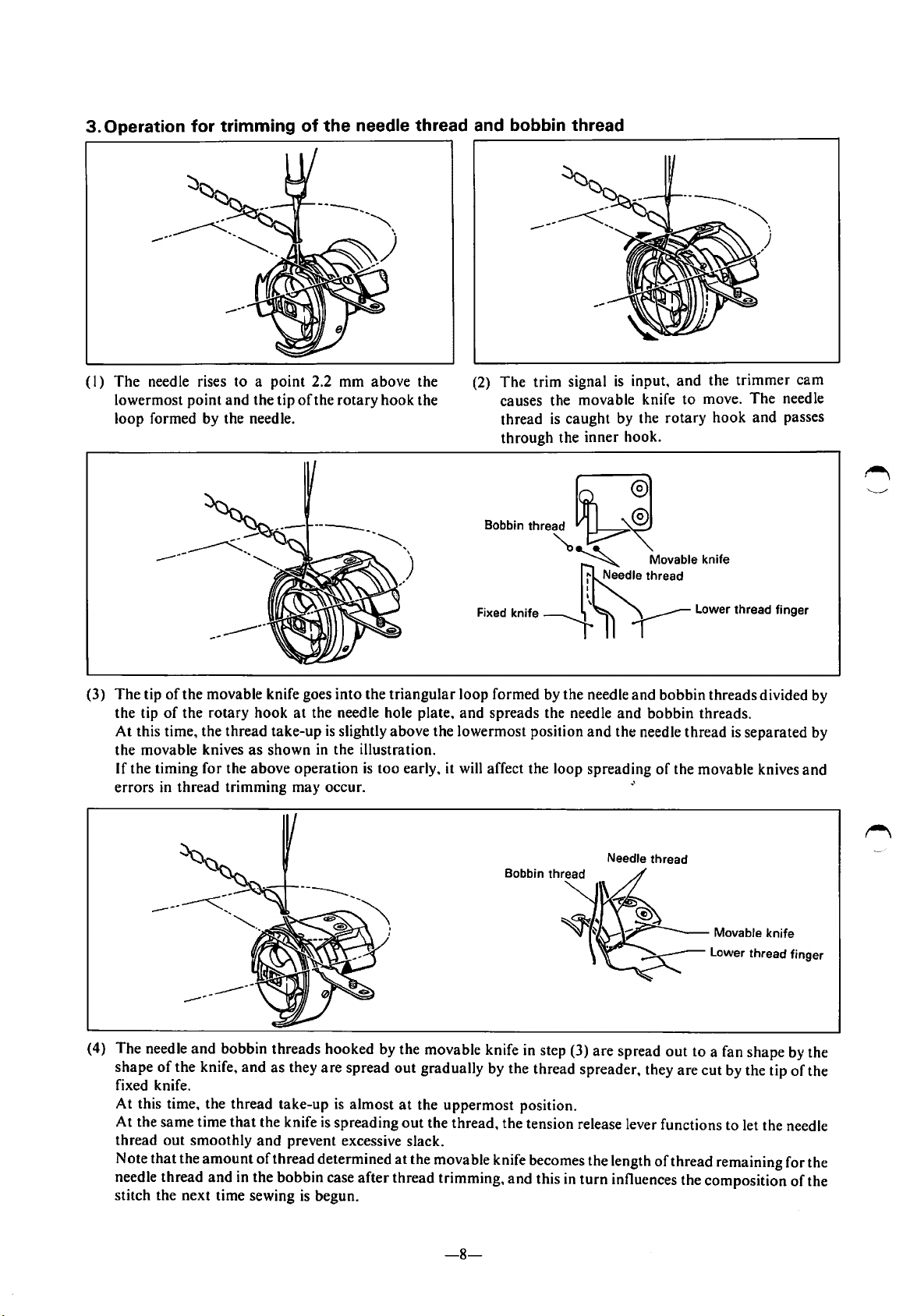

(I)

The

needle rises to a point 2.2 mm above the

lowermost point and the tip

loop formed by the needle.

----~~

of

the

rotary

hook

the

(2)

The

trim signal

causes the movable knife

is

thread

through

Bobbin

caught

the inner hook.

thre~~

is

input.

by the

and

to

rotary

the

move.

hook

trimmer

The

and

cam

needle

passes

(3)

The

tip

of

the movable knife goes

of

the tip

At

the movable knives

If

the timing for the above operation

errors in

the rotary hook

this time, the thread take-up

as

thread

trimming may occur.

into

at

the needle hole plate,

is

slightly above the lowermost position

shown

in

the illustration.

~

~

Needle thread

I

I

Fixed knife r

the

triangular

is

too early. it will affect the loop spreading

loop formed by the needle and

and

spreads the needle

'

and

Needle thread

Movable knife

bobbin

and

bobbin threads.

the needle thread

of

·'

threads divided by

the movable knives

is

separated by

and

(4)

The

needle

and

bobbin threads hooked by the movable knife in step (3)

shape

of

the knife.

fixed knife.

At this time, the thread take-up

At the same time

thread

Note

needle thread

stitch the next time sewing

out

that

smoothly

the

and

as

that

the knife

and

amount

and

of

thread

in the bobbin case

they

are

spread

is

is

spreading

prevent excessive slack.

determined

is

begun.

out

almost

at

out

at

after

thread trimming,

gradually by the thread spreader, they

the uppermost position.

the thread, the tension release lever functions to let the needle

the movable knife becomes the length

and

this in

-8-

are

spread

turn

influences the composition

out

of

thread

to

a fan shape by the

are

cut by the tip

of

the

remaining for the

of

the

Page 11

11]

Thread tension release lever

mechanism

*

When

trim

signal

functions. the tension release plate 8 pushes the

tension release

8

and

the tension release wire 0

tension disc.

When

the

needle

no

longer flows

the

tension disc closes.

(8707

is

input. the

bar

8 via the tension release lever

upper

to

the

/8716/8747)

trimmer

stop

signal

thread

trimmer

solenoid 0

and

is

input,

solenoid,

opens

current

the

and

[I] Thread wiper mechanism

(8707

* When

a delay

functions.

thread

neelde

thread

When

thread

spring.

/8716/8747)

the

needle

upper

of

85

ms,

the

thread

wiper 8 via

thread

trimming.

the

wiper

is

current

is

returned

wiped

stops

stop

signal

is

input,

and

then

the

wiper lever 8 moves

the

grooved link

on

top

of

the

material

flowing

to

to

the

solenoid,

its original position by a

there

solenoid 0

the

0.

and

the

after

the

is

·

[!]

Quick-back mechanism

•

•

*

When

the

quick-back switch

solenoid

pulled via the solenoid lever 8

link

downward.

While

machine does reverse stitching. When

released, it

return

stitching.

0 functions. the solenoid lever plate 8

0.

and

the reverse lever 8

the

quick-back switch remains pressed, the

is

returned

spring

and

the

is

to

its original position

machine resumes

0

pressed, the reverse

is

and

the connecting

is

pulled

the

switch

is

by

a

forward

[!]

Automatic presser lifter mechanism

* When the

lifter solenoid

presser

lifter link

*

When

lightly,

the presser lifter link 8 returns,

drops

power

switch

0 functions

bar 8 is

pressed

is

turned

(ON)

upward

and

8.

the

upper

part

of

the foot

the

presser lifter solenoid 0 becomes

back

down.

pedal

on,

the

via

and

the

the

is

the

presser

knee lifter

presser

depressed

OFF,

presser

-9-

Page 12

CDISASSEMBLY

I.

Loosen the set screw 8

2.

Remove the three screws

3. Remove the five screws 0

4. Remove the two screws

5.

Remove the oil

6. Loosen the set screw

7. Remove the slide plate

8. Remove the two screws 6'.

cap

Gi)

CB

and

0.

and

0.

and

and

the oil cap

and

e.

and

-~

remove the needle G. (Loosen the set

and

then remove the face plate 8

then remove the side cover

then remove the oil stopper plate

CD.

remove the tension regulator assembly

then remove the needle plate

and

0.

48.

and

remove the thread wiper.)

the packing

0.

0.

•.

II)

Presser

I. Loosen the two set screws 8 and remove the feed

assembly.)

2. Loosen the set screws

holder.)

3. Remove the screw

4. Loosen the set screw 0

5. Remove the presser

8.

bar

0

and

remove the presser foot

and

then remove the presser spring

and

remove the presser

CD

by extracting it from the

dog

G. (Use the presser lifter lever

8.

(Remove the screw,

bar

bar

clamp fl).

top

of

O.

the presser spring

the

arm.

to

raise the presser

and

then remove the thread wiper

8.

and

the washer

0.

-10-

Page 13

[I) Rotary hook

l. Tilt the machine.

2.

Remove the bobbin case

3. Remove the screw

4. Loosen the three set screws

f).

and

0.

then remove the rotary

G

and

remove the

f)

~~~"L,..~~-·

r---"\:'~·

hook

position bracket.

rotary

hook

0.

!"'.,

[I] Thread

trimmer

0

f)

Remove the screw

I.

Push

the

2.

screws

Remove the screws

3.

Remove the screw

4.

Remove the screw 0

5.

Remove the bolt

6.

trimmer

Remove the

7.

Remove the screw e.

8.

Remove the screw

9.

Move

10.

thread

G where they

connecting rod

trimmer

the

trimmer

41.

Loosen

II.

solenoid side).

Remove the collar

12.

the cushion

Remove the screw

13

.

the

set screw G),

fJ.

0.

and

then remove the fixed knife

trimmer

41).

connecting rod 0 in the direction indicated by the

can

be seen.

0.

and

then remove the movable knife

8.

and

then remove the lower

on

the thread

and

then remove the knife holder assembly

0.

lever spring G).

and

then remove the thread tension lever fl.

~.

and

then

cam

lever assembly

and

fi,

the

cam

f),

and then remove the

trimmer

remove the

Gil

then remove

lever

return

f).

arrow,

0.

thread

lever 0 side.

trimmer

in the direction indicated by the arrow,

the

trimmer

spring

fJ,

trimmer

lever

finger

solenoid

cam

lever

the

trimmer

0.

CD.

the

0.

0.

the movable knife holder fl,

shaft

f)

toward

cam

lever assembly e. the washer

trimmer

leverspringfl),

and

then position the two

and

then remove the

the right side (the

and

and

stop

trimmer

f),

the forked

the

ring

and

shaft

••

-11-

Page 14

[I] Feed mechanism

(8706/8707)

I.

Remove the wick

2.

Loosen the two set screws 0

3. Loosen the two set screws 8

arm

8.

4.

Tap

wedges

feed lifting rock shaft

5.

Loosen the two set screws

6. Remove the wick

7.

Loosen the set screw e

8.

Tap

wedges into the notches in the feed rock

rocker shaft j toward the left. (The oil rejector

into

the notches

0.

8

toward

fD

from the feed

on

on

the right side

on

the feed lifting rock shaft

oft

he feed lifting rock shaft

the left side.

CD

on the right side

bar

the feed rock shaft

arm

of

the feed lifting rock shaft

arm 8 and

arm 8 and

(The

oil rejector 8 and the feed lifting

of

the feed rock shaft

G).

arm • and

shaft

arm

fD

and

the two set screWS·"·

Cl

and

the feed

the three set screws 0

the feed lifting

G),

the feed

bar

arm

8,

and then remove the collar

arm

8,

and

arm

8 will also come off.)

and

then remove the collar

on

the feed

bar

arm

G),

and

then remove the feed

G) will also come off.)

on

the feed lifting

then remove the

•.

bar

arm

G).

8.

-12-

Page 15

[II Feed mechanism

(8714/8716/8747)

I. Loosen the

2.

Remove the two set screws

3. Loosen the set screw

4. Loosen the set screw

5. Remove the two set screws

6. Loosen the set screw

and

feed

[!]

Needle bar mechanism

Needle bar

bushing U

bar

nut

8.

0.

and remove the screw

8,

rotate the

8.

8.

disconnect the

8.

and

taper

and

remove the feed

G),

and

•

•

•

•

8.

remove the oil

pin

8.

and

arm

remove the oil

taper

pin

fD,

stopper

remove the feed lifting rock shaft 8

pin

stopper

and

G.

and

GD.

48.

remove the feed rock shaft fl, feed rock shaft

feed lifting

arm

arm

0.

tD.

I. Tilt the machine.

2. Remove the needle

3. Remove the wick 8 from the

4. Loosen the set screw

5. Remove the oil cap

6. Remove the oil

crank

G),

needle

bar

8.

8.

cap

and

bar

connecting rod

thread guide

and

remove the needle

loosen the set screw 8

loosen the two set screws

top

G.

of

the needle

CJ,

and

wahser

bar

bushing

bar

8.

and

remove the thread take-up

8.

Now remove the thread take-up rocking

and

U.

needle

bar

e.

-13-

clamp

8.

(Remove the slide block.)

support

pin

arm

0.

GD.

needle

bar

Page 16

~

ASSEMBLY )

[I] Needle bar

Screw flat

Reference

lines

••

J~t

~~

/·-=

Line

I.

Install the thread take-up

washer 8 with the set screw

arm

assembly

8.

0.

the needle

* Refer to the above illustration for the position

Thread

2.

3. Fit the thread take-up lever

with the set screw

4. Fit the block 0 into the groove,

and

(Fit

5. Fit the needle

••

6.

Pass the wick

7.

Turn

8. Align the second reference line from the

the wick through the

thread

support

take-up lever

shaft 8

8.

and

then fit the needle

the block

the block into the groove with the chamfered side toward the inside.)

the pulley

0.

bar

0 into needle

through

and

set the needle

bar

from needle

bushing U

bar

bushing U

bar

to the lowermost position.

bottom

oe.

@Threading the wicks

bar

of

the needle

support

through

fD

from the

the

fD.

on the needle

crank

thread

bar

clamp 8

(Refer

f),

the needle

bar

crank

shaft

8.

take-up

through

top.

and

then pass

to

the illustration.)

bar

fD

with the

f)

(Refer

arm

B706 DA x 1

B707 DA X 1

B714

B716 DA

B747

bar

connecting rod

screw flat.

to

the illustration.)

assembly

the neelde

it

through the needle

bottom

end

0.

bar

of

DB

X 1

DB

DA

DB

X 1

X 1

X 1

DB

DB

X 1

X 1

X 1

----

0.

and

and

then secure it

connecting rod 0

bar

needle

bar

bushing

the

clamp

~

'-___/

(

l)

Thread the wick

assembly

(2)

Thread

the thread take-up

(3) Insert a length

pull

(4) Align the end

thread take-up

of

8.

the wick into the machine while installing

out

the wick as shown

the wick into the oil hole.

through

of

piano wire into the oil hole

of

the wick with the edge

arm

the thread take-up

arm

assembly

in

assembly 8

8.

the illustration.

and

insert the rest

of

arm

and

the

(I)

Thread

needle

(2) Manually

up

(3) As shown in the illustration, insert the wick until

contacts the

assembly

(4) Insert the end

-14-

the wick through the

bar

to

the

bushing.

turn

the pulley

uppermost

top

0.

of

the wick into the oil hole.

Piano

wire

Wick

upper

and

set the thread take-

position.

of

the thread take-up

end

of

the

it

arm

Page 17

II]

Feed mechanism

(8706/8707)

•

~

I

I

I

I•

Feed dog

I. Install the needle plate 0 with the screws

2.

Tilt the machine.

3.

Mount

lifting rock shaft

4.

Mount

easily with no play.

Connect

5.

6.

Fit the forked

7.

Mount

rock shaft

8.

Fit

play.

* Secure the feed rock shaft·arm

easily.

* Secure the feed lifting

divides the groove in the needle plate 0

the feed

9.

Connect

* Secure the feed lifting rock shaft

fJ)

the feed lifting rock shaft 8

arm

8.

the set

collar 0 onto

the wick 8 to feed lifting rock shaft

part

of

the feed

the feed rock shaft e (from the left side), the feed

arm

41.

the feed rock shaft

dog

G)

the wick 8 to the feed lifting rock shaft

moves easily.

4D

into

arm 8 and

projects I mm

(from

the feed lifting rock shaft

bar

f1

onto

the set collar

4D

with the screw

the feed

front

out

of

the needle plate

arm

8 with the screws

8.

the left side), the feed lifting

8.

and

then secure it with the screw 8 so

8.

the roller

0.

and

bar

arm

to

(Refer

then secure it with the screw 8 so

41

in a position where the level feed

back

to the illustration below.)

on

the end

bar

$ with the screws

and

left

of

arm$.

to

right. In addition, tighten the screw

0.

8.

(Refer

to

the diagram below.)

G)

in

a position where the vertical feed connecting rod

arm

8.

the oil rejector

the feed lifting

the oil rejector

fD

in a position where the feed

arm

G),

and

that

it moves easily with no

arm

•

•

•

8.

and

the feed

that

it moves

8.

the horizontal feed

link assembly moves

dog

G)

CD

so

that

Ql)--

-15-

Page 18

II]

Feed mechanism

(8714/8716/8747)

~

1

I

I

I•

•

Feed dog

I.

Install the needle plate 0 with the screws

2.

Tilt the mac}line.

3.

Mount

4.

Mount

5.

Secure the feed rock shaft

move easily with no play

the

6.

Fit the forked shaft 0 into the forked

arm

7.

Mount

8.

Mount

9.

Mount

with not play

10.

Fit

slides easily.

II.

Fit the screw

12.

Install the oil

13.

Turn

needle plate.

14.

Set

15.

Loosen the screw

plate in

the

taper

pin 8

the feed

throat

pin

4D

the oil

the

the feed lifting rock shaft 8

the side block

the pulley

the length control dial

half

dog 8 onto

plate into left

with the set screw

stopper

taper

pin $

on

the

G)

fJ)

into the crank rod

stopper

and

front to back.

onto

on

and

fl

onto

taper

of

the feed lifting

fl

loosen the screw

fa

and

adjust the feed rock shaft 8 so

the

the feed

8.

the feed rock shaft

the

taper

right.)

Q).

with the screws

the

pin

$.

with the screws fl.

to

the highest setting

arm

pin

arm

and

fD

fa

bed.

bar

8.

part

bed.

arm

and

to

8.

8 with the screws

arm

O.

(At

this time, adjust the feed

of

the feed rock shaft

CJ).

the feed lifting

C1

into the forked

the feed lifting rock shaft fl,

adjust the feed

and

turn

and

the feed

arm

Cl

part

dog

the pulley.

that

the feed

8.

arm

with the set screw

of

8 so

1/

bar

8.

dog

0.

and

the feed

and

that

it extends I mm

dog

8 divides the groove in the needle

1/

with the set screw

8 so

that

it

then secure the feed rock shaft

G)

so

bar

8.

and

then secure it with the

f)

divides the groove in

that

they move easily

then confirm

out

of

so

the

that

top

that

nut

ofthe

•

•

G

they

it

8.

-16-

Page 19

fl]

Thread trimmer

I. Fit the forked shaft 0 into the

2.

Mount

cushion 8 onto

the

3. Fit the

4.

Tighten

5.

Mount

Mount

trimmer

6.

Mount

releasing lever.)

7.

Mount

trimmer

8.

Mount

screw

9.

Mount

10.

Mount

II.

Mount

12.

Mount

13.

Hook

14.

Confirm

the collar

trimmer

stop

the set screw

the

the solenoid so

solenoid

the tension releasing lever

the movable knife

connecting rod 8> with the bolt

the

8.

the

cam

the

arm

bed,

cam

lever assembly 8 into the fork

ring 0

thread

trimmer

onto

~.

trimmer

that

CD

is

as

lever

the

solenoid

the gap between the

small as possible.

holder

spring~

fl.

the

thread

the lower thread finger

the fixed knife

the movable knife

the

trimmer

that

the

trimmer

f)

lever

position

connecting

to

f1

spring~

of

* Move the lower thread finger

rotary

hook.

arm

bed.

lever return spring

and

then

mount

trimmer

cam

4D

to

CD

with the screw

4D

onto

the

the

lever

the

arm

8.

trimmer

shaft

arm

trimmer

bed,

Cl).

and

the

trimmer

rod 8 to

fJ

to

the

arm

the

arm

bed with the screws fi.

to

the movable knife holder

onto

the

the

fJ

towards

trimmer

cam

the movable knife in

the

bed with the screw fi.

trimmer

is

correct.

the

trimmer

of

the forked

cam

cam

lever shaft 8

shaft

8.

bed with the screw

cam

lever shaft 8

48.

(Refer

to

p.23 for instructions

and

then

mount

lever

fJ

onto

the forked

thread

lever fl.

trimmer

4D

with the screws

order

lever assembly G. the

(after

fitting

washer8

the

slide block 8

0).

$.

and

the solenoid lever

on

adjusting the tension

the knife holder assembly

shaft 0 and

lever

fJ

with

1).

to

maintain the space between it

secure them with the

the

screw tl.

41

and

G)

on

(and

and

the

of

the

then

the

-17-

Page 20

~

Thread trimmer timing adjustment

I.

Thread

*

Turn

above

solenoid

the roller shaft contacts the

trimmer

roller shaft

lever assembly returns.

2.

Fixed knife

*

The

knife

roller shaft

moves

the movable knife holder

mating

If

thread

end

e agree with the position

moves

[!]

Bottom of the needle bar bushing

trimmer

the pulley,

the lowermost position, press the thread

CD

cam

end

of

cam

position

and

then when the needle

and

adjust the thread

G)

and

the end

is

0.6

to

0.8

mm

and

moving knife position

the fixed knife e

adjustment

trimmer

cut

out

of

the

when the thread

and

the blade

e must be in the position shown in Fig. A when

of

up

the

mark

the

positions

trimmer

of

the fixed knife e

up

the thread

Rotary

the thread

thread

on

the kpife

do

not agree with those in Fig. A. move the

lever

hook

trimmer

trimmer

fD

holder

fJ)

and

and

trimmer

cam

G).

must be in alignment with the

assembly

tighten the screw

the blade

in

Fig. A when the roller shaft

cam

41

•

em]

Reference

lines

~

""

-

-

-

-

-.....

-

-:

-

bar

cam

part

of

cam

and

the end

trimmer

adjustments

of

the movable

cam

lever assembly 0

(The

mating

$).

f)

of

the movable knife

G).

rises 5 mm

trimmer

G)

so

that

the

thread

of

the

cam

the

mark

on

so

that

the

~j

~·[;

Lower shaft

fJ

1-1.5

mm

•

B706 DA X 1

B707

B714 DA X 1

B716

B747

I.

Mount

2.

Mount

3.

Mount

4.

Mount

5.

Turn

with the

6. Align the

At this time,

is 0 to

7.

Mount

Mount

8.

9. Adjust the feed timing.

Turn

plate when the feed

surface

*

Confirm

thread

DA X 1

DA

X 1

DB

X 1

~

the needle plate.

the

rotary

hook 0

the

rotary

hook

the needle

the pulley so

bottom

rotary

0.5

mm

the needle plate.

the slide plate C).

the pulley forward

of

the needle plate. (Refer

that

being used

of

hook

adjust

and

the

gap

bar

that

the needle

so

the distance between the needle 8

dog

between the rotary

to

pass

DB

~~;~re

X 1

DB

X 1

DB

x 1

DB

X 1

onto

the lower shaft 0

position bracket 0 with the screws

thread guard 8

the needle

bar

point with the center

that

the distance between the

and

adjust so

finishes the feed

through

onto

the needle bar,

bar

rises from the lowermost position

bushing as

of

that

the tip

and

begins

to

the timing

hook

easily.

and

shown

the needle

rotary

of

the needle

to

retract

adjustment

position bracket 0

-18-

·,~>'o

~

•

secure it with the screw

8.

and

then

secure the needle 8 with the set screw

and

in the illustration.

8.

hook

point

and

the

and

the

and

on

rotary

is

the tip

p.21.)

hook

aligned with

of

the feed

and

the

rotary

•

8.

align the needle

upper

edge

of

the

tip

is

0.05

to

the

upper

surface

dog

is

aligned with the

hook

0 is

bar

reference line

eye

of

0.1

mm.

of

the needle

just

enough for the

8.

the needle

upper

Page 21

[I]

Presser

mech~r:'_ism

•

I.

Insert the presser

2.

Mount

presser

3.

Mount

foot adjustment screw

(Mount

4.

Mount

5.

Adjust the height

the presser

bar

guide bracket

the washer

the thread wiper holder onto the presser

the presser foot 8

bar

0 from the

bar

guide bracket 8

G.

8,

the presser bar spring

8.

onto

the presser

of

the presser foot 8

--

top

of

the arm.

onto

the groove in the

8,

and

the presser

bar

0 and secure it with the screw.)

bar

8 with the screw

to

approximately 6 mm.

arm,

and

bar

spring guide

then pass the presser

8,

and then tighten the presser

8.

Approx. 6

bar

0 through the

mm

f

.~

[]]Cover

Screw_./

l'l~

Thread

I.

Mount

(The thread take-up spring operating range

2.

Mount

3.

Mount

4.

Mount

5.

Mount

(Mount

the tension regulator assembly 0 with the screw

the oil

the oil cap 8 and the oil cap

the rear cover 8

the face plate

stopper

the thread wiper with the screw.)

plate 8 with the screws

and

the packing 8 with the screws C).

f)

and

the packing

·

wi~er

is

8 mm

. _

8.

8.

CD

with the screws

G.

and

the tension

CB.

is

20 to

30

kg.)

-19-

Page 22

[I] Needle and rotary hook timing adjustments

In

order

for the tip

point. the needle

1 . Needle bar height

of

the rotary hook

and

rotary hook must be correct.

to

catch the loop

in

the needle thread when the needle rises from the lowest

•

Reference line

*

Turn

the pulley slowly.

bottom

• Loosen set screw 8 and align this second reference line with the bottom

reference line on the needle

adjusting. firmly tighten set screw

and

lower the needle bar 8

bar 8 is

8.

to

the needle

aligned with the bottom

down

position. Confirm

of

the needle

of

the needle

bar

that

the second from

bushing.

bar

bushing

8.

After

2.

Rotary hook position

0

Reference line

*

Turn

the pulley slowly.

bushing

center

• Loosen set screw 8 and

to

8.

With the needle

0 and

rotary

hook

that

and

align the

bar

the needle 0 to rotary hook point 8 gap

after

point 8 gap to between 0.05 -

bottom

in this position. check that the rotary hook

aligning the rotary

reference line on the needle

hook

point 8 with the needle center

0.1

mm. Firmly tighten set screw

bar

is

between 0.05 -

8 with the

pointe

0.1

bottom

is

of

the needle

aligned with the needle

mm.

0.

adjust the needle 0

8.

* Always perform the steps for rotary hook lubrication adjustment after replacing the rotary hook.

bar

-20-

Page 23

II]

Feed dog height adjustment

••

Feed dog height

I.

The standard height

thick materials

2.

Adjust the feed

needle plate surface, and move the feed lifting

Feed dog angle

I.

The

standard angle

is

position)

• In

• In

2.

In

order

directions indicated by the arrows.

obtained by matching the

order

to prevent packering. raise the feed

order

to prevent the material from slipping. slant the feed

to adjust the feed

* When the feed

of

the feed

1.2

mm (when the stitch length

dog

height by loosening the screw 8 when the feed dog 8

of

the feed

dog

angle has been adjusted, check

dog

for sewing thin materials

dog

8 (horizontal

"0"

dog

angle, loosen the screws 8 and then

mark

A

.

~

j B

••

~

A

===::l

,---

~

__..,

F1

B

~

is

0.8 mm. for medium materials

is

set

to

the maximum).

arm

0 up and down.

to

the

needle plate surface when the feed

of

the feed plate shaft 8 with the notch

dog

8 in the forward direction.

dog

to

confirm

that

r-_

==:::::1

~

_./

is

at

8 in the forward direction.

turn

the feed plate shaft 8 90° in the

its height has not changed.

Rises

in

the forward direction

t=:=

Descends in the forward direction

c::::::::=

1.0

mm,

and

for

its height position from the

dog

is

at

its highest

on

the

feed

bar

arm

8.

I~

[I) Feed timing adjustment

Feed

dog~

~

I.

Turn

the pulley manually; the area

alignment with the

tip

of

the feed

2.

If

the

feed timing

If

the feed

turns; if the feed

machine turns.

3.

After adjusting the timing, tighten the screw securely.

dog

top

surface

dog

is level with the

is

not correct, loosen the set screw 8

retracts

dog

too

early, turn the feed cam slightly in the opposite direction from which the machine

retracts

[I] Presser height adjustment

*

The

amount

when the presser foot

bar

lifter lever

Turn

the presser

Remove the cap 8 from the front cover. loosen

the screw

down

of

presser foot rise should be 6 mm

8 is raised by the presser

8.

the presser regulating screw 0

bar

8.

to

adjust it.

lifter lever

and

move the presser

8.

of

the needle between the tip

of

the needle plate when the feed

top

surface

too

late,

turn

the feed

and

lower

bar

8 up and

of

the needle plate.

of

the feed cam 8

cam

slightly in the same direction as

and

the lower edge

dog

completes the feed and retracts so

and

of

the eye should be

adjust.

that

in which the

that

in

the

-21-

6mm

Page 24

IT]

Synchronizer

1 .

Position

adjustment

adjustment

of

the

thread

trimmer

Synchronizer Adjustment (8707 /8716)

1.

Turn

off the power

(If

the hole IC's are to be adjusted.

2.

Remove the synchronizer cover.

3. Rotate the pulley towards you

must be aligned

· If the lower end

loosening the screw

4.

Turn

on

the power

22 mm above the surface

If the needle

hole IC

5.

Stop

the machine

for thin

If

the point

up

hole IC

* The needle

rise when they are moved in the opposite direction.

bar

8.

and

medium thickness materials. and

of

f).

bar

of

the machine.

it

is

important

and

stop

the needle 5 mm above its lowest point.

at

this time with the upper edge

of

the magnet 0

8

and

and

stop

does not

at

the needle-up position.

the needle does not

will lower when hole IC 8 and hole IC 8 are moved

and

the upper edge

moving the

the machine

of

the needle plate.

stop

at

this position, adjust by loosening the screw 8

stop

at

thread-trimmer

at

the needle-down positidh. At this time the needle

this position, adjust by loosening the screw 8

The

signal

18-22

that

the power first be turned off.)

of

the thread-trimmer hole IC

oft

he thread-trimmer

hole IC.

point

of

the needle must stop 9

10

-

12

mm

above

the needle plate for thick materials.

mm

hole·IC8

in

the direction

The

lower end

oft

he magnet 0

8.

are

not aligned, adjust by

bar

must

and

moving the needle-down

-II

mm above the needle plate

and

moving the needle-

of

machine rotation.

stop

18-

and

Synchronizer Adjustment (8747)

I.

Turn

off the power

(If

the hole IC's are to be adjusted, it

2. Remove the synchronizer cover.

3. Rotate the pulley towards you

must be aligned

If

the lower end

loosening the screw

Turn

on

the

4.

22 mm above the surface

If the needle

hole IC

5.

Stop

the machine

for thin

If the point

up

hole IC

* The needle

rise when they are moved in the opposite direction.

power

bar

0.

and

medium thickness materials, and

of

f).

bar

of

the machine.

is

important

and

stop

the needle 7 mm above its lowest point.

at

this time with the

of

the magnet 0

8

and

moving the

and

stop

the machine

of

the needle plate.

does not

at

the needle does not

will lower when hole IC 8 and hole IC 8 are moved

stop

at

the needle-up position.

upper

and

the upper edge

thread-trimmer

at

the needle-down position. At this time the needle

this position. adjust by loosening the screw 8

The

stop

at

this position, adjust by loosening the screw 8

edge

point

10--

that

the power first

of

the thread-trimmer hole IC

ofthe

thread-trimmer

hole IC.

of

the needle must stop 9

12

mm above the needle plate for thick materials.

be

turned off.)

hole

in

the direction

The

lower end

8.

IC8

are

not aligned. adjust by

and

moving the needle-down

-II

mm above the needle plate

and

of

machine rotation,

of

the magnet 0

bar

must

stop

18-

moving the needle-

and

-22-

Page 25

11]

Thread trimmer adjustment

1 . Replacement of the fixed knife and movable knife

*

Turn

off

the power.

ilstone

Removal

(I)

(2.)

(3) Remove the screw 8

@ If the thread

Removal

(I)

(2) Remove the screw

(3)

(4)

(5) Remove the screw

of

the fixed knife

Tip the machine

Remove the screw 0

of

the movable knife

Use the presser foot lifter lever

Turn

the pulley until the needle

Press the thread trimmer connecting

screw

8 can be seen.

of

its side.

trimmer

8

and

the rotary

and

the fixed knife

should need sharpening, sharpen the fixed knife 8 as shown in Fig. A.

to

lift the presser foot.

and

the needle plate

bar

8 and the movable knife

hook

position bracket

8.

8.

is

at

its highest position.

bar

8 in the direction

8.

8.

of

the arrow

and

stop

in

at

the point where the

* Remove the needle plate 8 and the movable knife 8 only after the needle has been removed.

* Assemble in the reverse

2.

Adjustment

of

order

of

disassembly.

the fixed knife, movable knife, and lower thread finger

1-1.5

mm

Fig.

8

~

~~

•

(I)

After attaching the movable knife 8 and the fixed knife

match up the marking

At this time the relationship between the end

be as shown in Fig.

If

it

is

not, loosen the screw 8 and adjust the thread trimmer lever G).

* If the above adjustment

* In

order

to

maintain the distance between the lower thread finger

finger towards the movable knife

on

the movable knife holder

B.

cannot

be performed, refer

8.

of

the fixed knife 8 and the blade

8,

depress the thread trimmer connecting rod

Cl)

with the marking on the knife holder assembly

to

thread

trimmer

and

the rotary hook, move the lower thread

-23-

of

the movable knife 0 must

timing adjustment

on

p.l6.

8,

and

CD.

Page 26

(I] Tension release lever adjustment

* Adjust the

solenoid

(tension release lever does

moving for the next 2

Confirm

at

this time.

Also, when the solenoid

that

the disc

nut

f)

so

that

the

thread

trimmer

0 moves easily for the first 0 - 2 mm

not

- 5 mm.

that

the tension disc 8 opens

is

not

is

firmly closed.

operate)

operating, confirm

and

0.5-

resists

I mm

[!]Thread

I.

Attach

presser foot

come in contact with the presser bar.

2.

Loosen the thread wiper lever screw

the thread wiper lever

grooved link

3.

Attach the thread wiper 8 so

not

come

presser foot

wiper

the thread wiper bearing 0 so

is

8

in

contact

is

adjustment

lifted with the knee lifter, it does not

f)

so

that

is

vertical

raised.

to

with the presser foot when the

that

when the

and

position

the groove

the bed surface.

that

the end

of

of

the

it does

[!] Automatic presser foot lifter adjustment (

=?:mmm

,..,~

..

~

_£dog

~Knee

o.a--O.s

I. Adjustment

Adjust so

Turn

2.

Damper

Adjust so

Se the feed

Loosen the screw

to

3.

Damper

Adjust the speed the presser foot comes down with the

adjustment screw

* When the adjustment screw 8

material).

If

damaging the material being sewn.

*

The

changes in presser foot pressure

mm

\~complying

Presser foot

of

the solenoid

that

the noise (impact noise) made by the presser foot when it

the adjustment nut 0 so

support

joint

that

the noise (impact noise) made by the presser foot when it comes

dog

in

8.

0.3-

0.5 mm, match up the

adjustment

8

this screw

above procedure

is

too loose, the presser foot will come down

lifter

bar

f)

lifter

link

and

plunger

that

the space between the solenoid

adjustment

its lowest position.

and

after

adjusting the space between the knee lifter push

damper

to

approximately 30° from the fully tightened position.

is

(I

--

3)

is

the

and

support

to

tight. the presser foot will not come down (will

standard

power supply voltage.

joint

adjustment; however, there may be subsequent variations due

•

8 with the

adjustment

too

-900;

fast, thus making

electromagnetic type)

is

lifted

and

the plunger

bar

rubber

cushion

screw 8

oo

Tighten

is

small.

f)

is

down

is

and

the presser foot lifter link

fully

Adjustable

0.6 - 0.8 mm.

small.

8.

of

the

damper

an

impact noise

8.

not

press against the

and

range

Adjust the

possibly

to

-24-

Page 27

~==T=R=O=U=B=L=E=SH====O=O=TI=N=G=G=U=I=D=E=.

:::::::::~

[I] Machine head

I Trouble I L...-..-.-1

r--

Improper needle installation

Bent needle, blunt

-

tip, blocked needle hole

Improper feed timing

-

Needle breaks

r-

Improper needle

....._

hook timing

_cause

-------~~

needle

to rotary

1~...-----c_heck

1--

Needle bias. height

1--

Needle

Is

material

1--

is

in material?

Needle

-

r-r-

'---

bar

Needle

bar

Needle to rotary hook gap

_I

fed

when needle

lift stroke

height

IL--_Solution_____._____....l

-

Reinstall properly

......____

Replace needle

f---

Adjust timing

Refer to

..

-

Hook Timing Adjustment"

Refer to

r--

Hook Timing Adjustment"

Refer to

r--

Hook Timing

Needle and Rotary

..

Needle and Rotary

..

Needle and Rotary

Adjustment"

Page I

/

/

21

20

20

20

Thread breaks

Thread frays

.---

Improper threading

Bent needle, blunt needle

-

tip, blocked needle hole

-

Improper needle installation

i-

Exc~ssive

-

tens10n

Excessive lower thread

r-

tension

....._

Loose upper thread

.---

Burr in thread path

r-

....._

Blunt needle tip

upper thread

f--

Threading

f--

Needle

1--

Needle bias, height

f--

Upper thread tension

1--

Lower thread tension

Thread take-up spring

r--

stroke

1-

Rethread properly

f---

Replace needle

r--

Reinstall properly

-

Adjust tension

- Adjust tension

Adjust take-up spring

-

Remove with sandpaper

Replace needle

/

/

/

/

/

/

/

/

-25-

Page 28

..._____T_rouble-------,J.II

L....---

_cause

-------~~~

L....---

_Check

-------~~

IL..,_____Solutio_n

....~....----..1

Page I

Skipped

stitches

-

-

-

I-I-

-

Improper

Bent needle

tip

Improper

Improper

hook

Upper thread left

short

material

needle installation

or

blunt needle

threading

to

at

needle

rotary

is

too

needle

timing Hook Timing·

and

doesn't remain

Needle bias. height

-

Needle bias, height

-

Threading

-

r--

Needle

Needle lift length

f-f--

....__

Needle

in

bar

to

lift

rotary

stroke

hook

gap

Reinstall properly

-

Replace needle

-

,....--

Rethread properly

Refer to "Needle and

1-

Hook

1--

f----

Adjust pretension

Timing

Refer to

..

Needle

Referto

"Needle and Rot'ary

Hook

Timing

Rotary

Adjustment"

and

Rotary

Adjustment"

Adjustment"

/

v

/

20

20

20

/

Upper

tighten

Lower

tighten

thred

thread

does

does

not

not

Bobbin idles and bobbin thread

is

too

-

'--

-

-

-

r--

t-

'--

short to rise

trimming

Thread

weak to lift bobbin thread

Upper

weak

Exc~ssive

tensiOn tension

Excessive upper thread

tension

Lower

weak

during

take-up spring

tension

thread

upper

thread

tension

thread

thread

is

too

too

too

Bobbin case idler prevention

-

screw

Thread

-

take-up

tension

spring

Replace idler

1--

spring

Adjust thread take-up

-

spring

Increase

tension

Decrease bobbin thread

Decrease

tension

Increase

tension

upper

upper

bobbin

prevention

/

/

thread

/

/

thread

/

thread

1/

-26-

Page 29

..__T_rouble______.l~

~_cause

______.II'----

_check

______,II~

_solution~~

Page I

Thread trimmer misses

neither upper

a.

er

thread

upper

b.

cut

lower

c.

cut

is

thread

thread

cut

or

is

is

low-

not

not

Movable

r--

do not meet

Movable

r--

are burred

Movable

-

does not move

Improper needle installation

-

Stitch skips at last stitch

upper thread trimmer does not

r--

catch upper thread

Movable

r--

do

Poor cutting

r--

and fixed knives

not

and

and

fixed knife blades

or

abraded

and

and

meet

.....

Movable

'--

do not meet

and

knives

fixed

knife

fixed

and

fixed knives

movable

by

knives

fixed

Check alignment

1--

holder and thread trimmer holder

presser i ndcx marks

Movable

t---

blades

Is

t---

f---

f---

t---

-

-

thread trimmer

output?

Needle bias

Thread take-up spring Adjust thread take-up

stroke

Check alignment

holder and thread trimmer holder

presser index marks

Movable

blades

Check alignment

holder and thread trimmer holder

presser index marks

of

thread trimmer

and fixed knife

signal

of

thread trimmer

knife

fixed

and

of

thread trimmer

Align movable

-

knives

Replace movable and fixed

-

knives ·

Check electrical circuitry

f---

Reinstall properly

-

-

spring

movable

.Align

-

knives

Replace movable

-

knives

movable

Align

r--

knives

and fixed

and fixed

and

fixed

fixed

and

23

23

v

/

v

23

23

23

thread

Upper

sewing start

casts

off

at

Insufficient tension disc

-

opening

-r--

~xcessive

Thread too thick for needle

i--

hole

Needle upper

'--

high

take-up

pretension

stop

and

thread left by thread

position

Tension disc ,opening

-

f---

Adjust tension release lever

Adjust pulley tension

24

/

Needle size

/

is

too

Thread take-up height when

machine

is

f---

position

in needle upper

-27-

stop

Delay needle up stop

-

22

Page 30

.._T_rouble______.JI

cutter does not

Thread

move

L..----1

Thread

-

output

r--

Upper thread

_cause

trimmer signal not

too

_____,II

long

L..---

_check

______,II

L.---

_solution------'--------1

Check circuits

and

Check

Page I

v

adjust pretension

v

Thread wiper does not

pull upper thread

from material

Thread wiper strikes

and

needle

return

does

up

not

Excessive material

1--

presser foot resistance with rear

I-

Early

1--

'---

....--

1-

.__

timing~

before tension disc closes

Thread wiper

too

short

Thread

wiper

too

long

Automatic

too

4uickly

and

pulls

off

operating

operating

presser foot rises

time

time

Replace with presser foot

Adjust

Adjust

Adjust

Adjust

presser foot

gap

operating

operating

operating

operating time

time

time

time

v

v

[7

[7

of

v

-28-

Page 31

BROTHER

HEAD

OFFICE:

HORITA-DORI, MIZUHO-KU, NAGOYA, JAPAN

CABLE:

TELEX:

INDUSTRIES,

No. 35, 9-CHOME,

BROTHER

BROTHER

NAGOYA,

4473696J & J59743

13090153B Printed in Japan

LTD.

467

Loading...

Loading...