Page 1

Brother 681B-UG

Page 2

R

WHEN CHANGING NEEDLE, BOBBIN OR LIGHT BULB, O

WHEN SEWING MACHINE IS NOT IN USE, IT IS

RECOMMENDED THAT ELECTRICAL SUPPLY IS

DISCONNECTED TO AVOID ELECTRICAL HAZARDS.

CAUTION

Page 3

CONTENTS

1. Knowing Your Sewing

Machine

PRINCIPAL PARTS . . . . . . . . . . . . . . . . . . 2

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . 4

OPERATING YOUR SEWING

MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connecting plug. . . . . . . . . . . . . . . . . 5

Controlling sewing speed. . . . . . . . . . 5

UPPER (NEEDLE) THREAD. . . . . . . . . . . . 6

LOWER (BOBBIN) THREAD. . . . . . . . . . . 7

How to wind bobbin. . . . . . . . . . . . . 7

How to remove bobbin case . . . . . . . 8

How to thread and insert

bobbin case . . . . . . . . . . . . . . . . . . . . 8

How to pull up lower thread . . . . . . . 9

NEEDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How to change the needle . . . . . . . . . 9

How to check the needle . . . . . . . . . . 9

RELATIVE CHART OF SEWING

MATERIAL, NEEDLE AND THREAD. . . .10

EXTENSION TABLE . . . . . . . . . . . . . . . . . .10

SEW-LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . 11

PRESSER FOOT . . . . . . . . . . . . . . . . . . . . . 11

VARIOUS CONTROLS . . . . . . . . . . . . . . . . 12

Stitch length . . . . . . . . . . . . . . . . . . . .12

Zigzag width . . . . . . . . . . . . . . . . . . . 12

Pressure adjuster . . . . . . . . . . . . . . . . 13

Feed dog . . . . . . . . . . . . . . . . . . . . . . 14

Reverse stitch . . . . . . . . . . . . . . . . . . 14

THREAD TENSIONS . . . . . . . . . . . . . . . . . 15

Upper thread tension. . . . . . . . . . . . . 15

Lower thread tension. . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . .2

2. Straight Stitching . . . . . . . . . . . . . . 17

How to start sewing. . . . . . . . . . . . . . . . . 17

How to change sewing direction. . . . . . . 17

How to finish your sewing

project . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How to remove final sewing

from machine . . . . . . . . . . . . . . . . . . . . . 18

How to guide and support material. . . . . 18

3. Zigzag Stitching . . . . . . . . . . . . . . . 19

Simple zigzag stitch . . . . . . . . . . . . . . . . .19

Satin stitch . . . . . . . . . . . . . . . . . . . . . . . . 19

Decorative stitches . . . . . . . . . . . . . . . . . 20

4. Using Built-in Patterns . . . . . . . . 21

Triple stretch stitch . . . . . . . . . . . . . . . . . 21

Blind stitch . . . . . . . . . . . . . . . . . . . . . . . 22

Shell stitch . . . . . . . . . . . . . . . . . . . . . . . 22

5. Various Other Stitches. . . . . . . . . 23

Buttonholes . . . . . . . . . . . . . . . . . . . . . . . 23

Mending . . . . . . . . . . . . . . . . . . . . . . . . . 24

Attaching lace . . . . . . . . . . . . . . . . . . . . . 24

Appliquéing . . . . . . . . . . . . . . . . . . . . . . .25

Cording. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Monogramming . . . . . . . . . . . . . . . . . . . . 26

Embroidering . . . . . . . . . . . . . . . . . . . . . 27

Button sewing . . . . . . . . . . . . . . . . . . . . . 28

Darning . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cloth guide . . . . . . . . . . . . . . . . . . . . . . . 29

Narrow Hemming . . . . . . . . . . . . . . . . . . 30

Zipper insertion . . . . . . . . . . . . . . . . . . . 31

6. Maintenance and Care of

Your Machine

CLEANING . . . . . . . . . . . . . . . . . . . . . . 32

Removing shuttle hook . . . . . . . . . . . 32

Cleaning shuttle race . . . . . . . . . . . . . 33

Cleaning feed dog . . . . . . . . . . . . . . . 33

OILING . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CHECK LIST FOR BETTER SEWING . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

-1-

. . . . . . . . . . . . . . . . . 32

Page 4

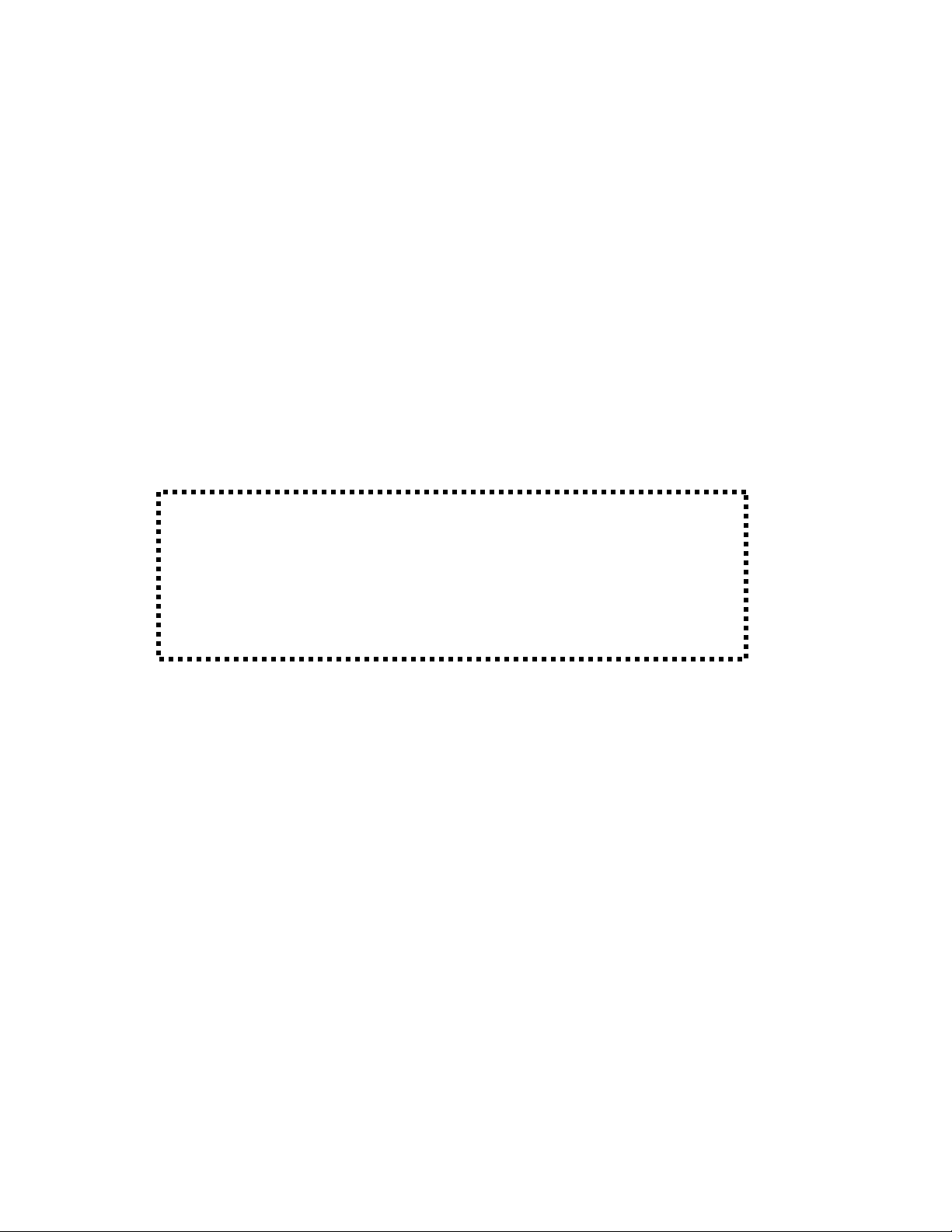

1. Knowing Your Sewing Machine

Principal Parts

1. Top Cover

2. Zigzag Width Lever

(See page 12)

3. Upper Thread Guide and Bobbin Winder

Tension Disc

4. Front Thread Guide

5. Pressure Adjuster (See page 13)

6. Face Plate

7. Thread Tension Dial (See page 15)

8. Thread Cutter

9. Presser Foot Screw

10. Presser Foot (Zigzag)

11. Feed Dog (See page 14)

12. Needle Plate

13. Needle Clamp Screw

14. Shuttle Race cover

15. Drop Feed Knob (See page 14)

16. Reverse Sewing Button (See page 14)

17. Stitch Length Dial

By turning this dial, you can control the

length of the stitch.

The higher the number, the longer

the stitch (See page 12)

18. Blind Stitch & Stretch Stitch Lever

19. Spool Pins

20. Bobbin Winder Device

21. Balance Wheel

22. Stop Motion Knob

-2-

Page 5

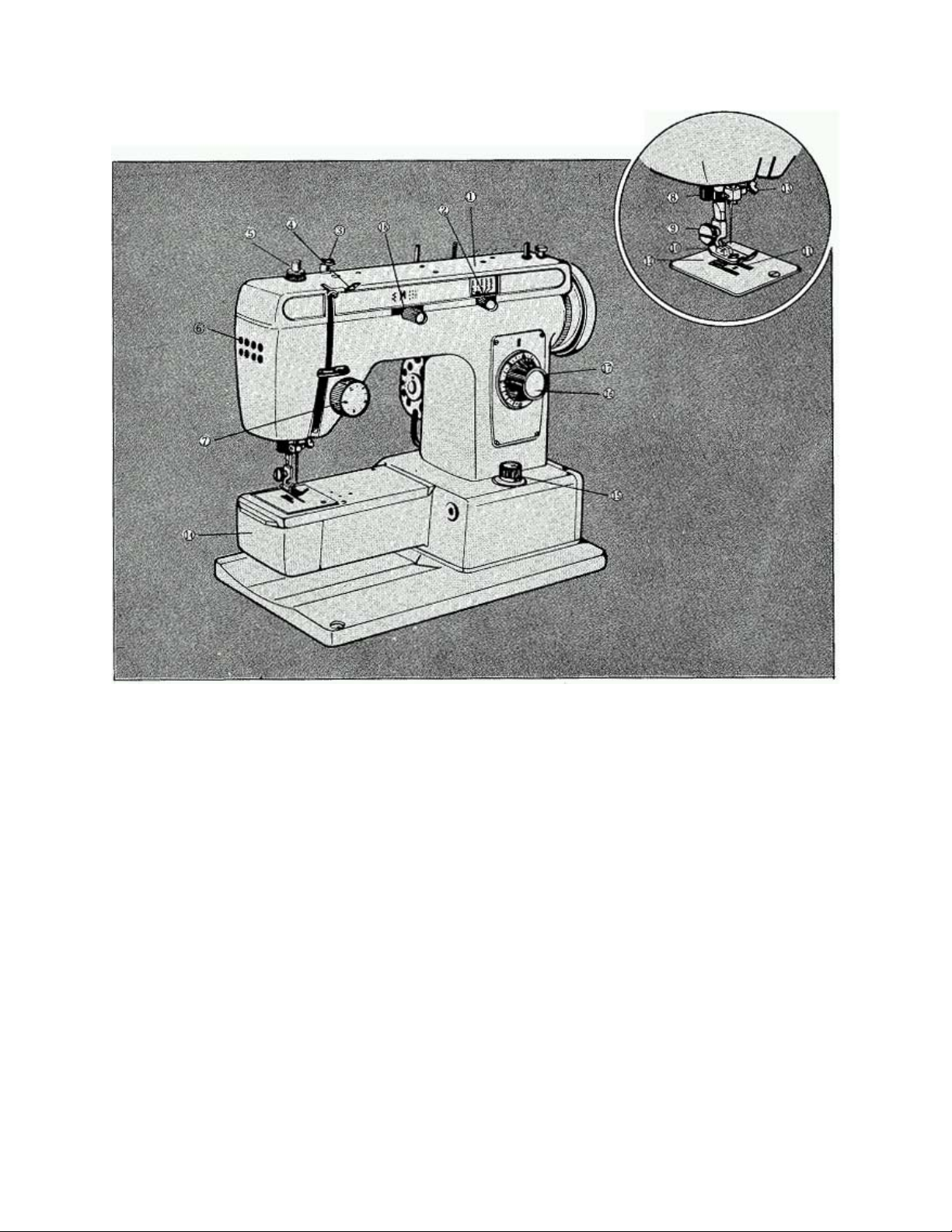

23. Motor Belt

24. Motor

25. 3-pin Socket

26. Extension table

27. Presser Foot Lifter

When the presser foot is at the highest

position, the tension on the upper thread

is released.

28. Sew-light Switch

Turn this knob in any direction to switch

light on and off.

-3-

Page 6

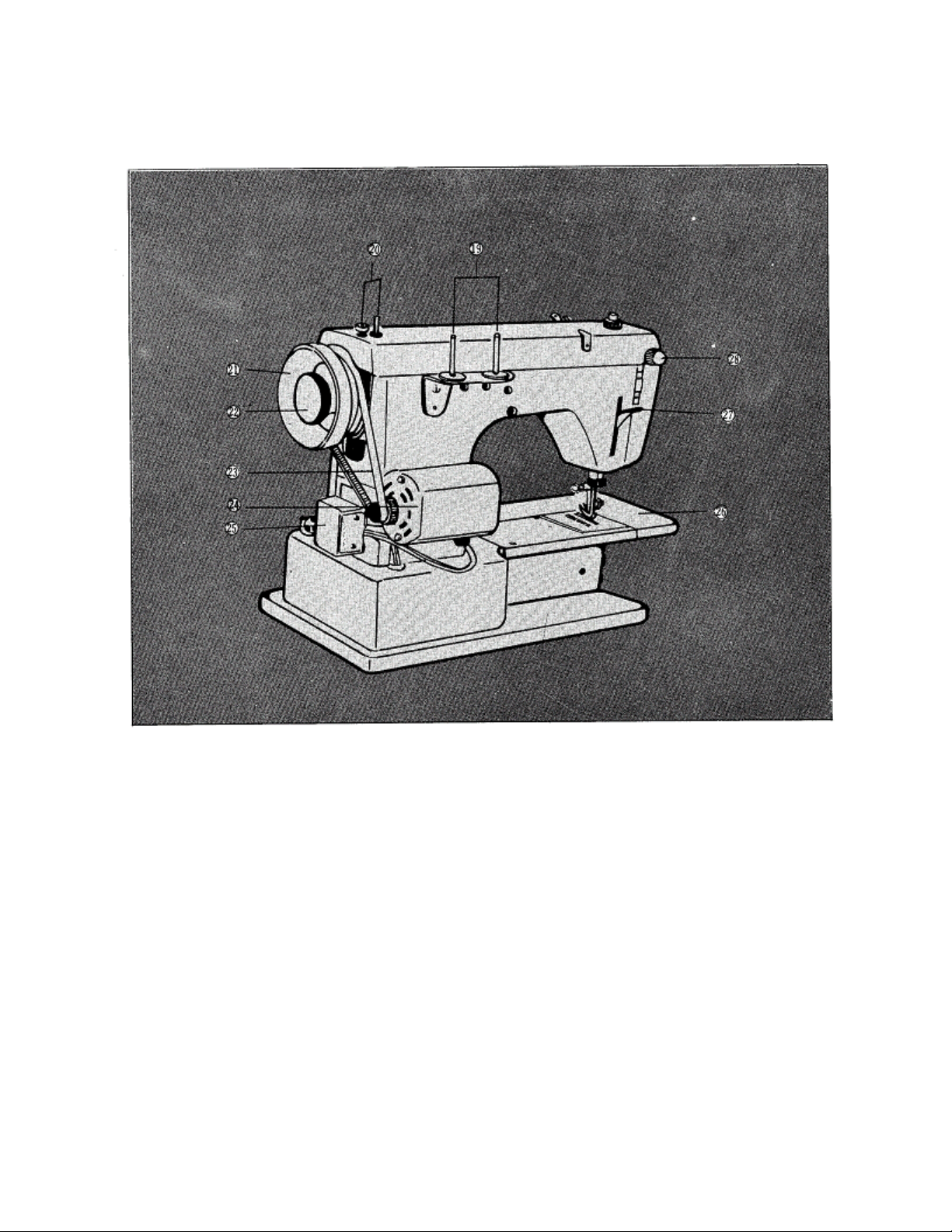

Accessories

1. Needles

Single Needle No.14 (3 pcs.)

2. Straight Stitch Foot

3. Narrow Hemmer foot

4. Zipper Foot

5. Buttonhole Foot

6. Button Sewing Foot

7. Seam Ripper

8. Bobbin (3 pcs.)

9. Cloth Guide with Screw

10. Screw Drivers (Large & Small)

11. Oiler

-4-

Page 7

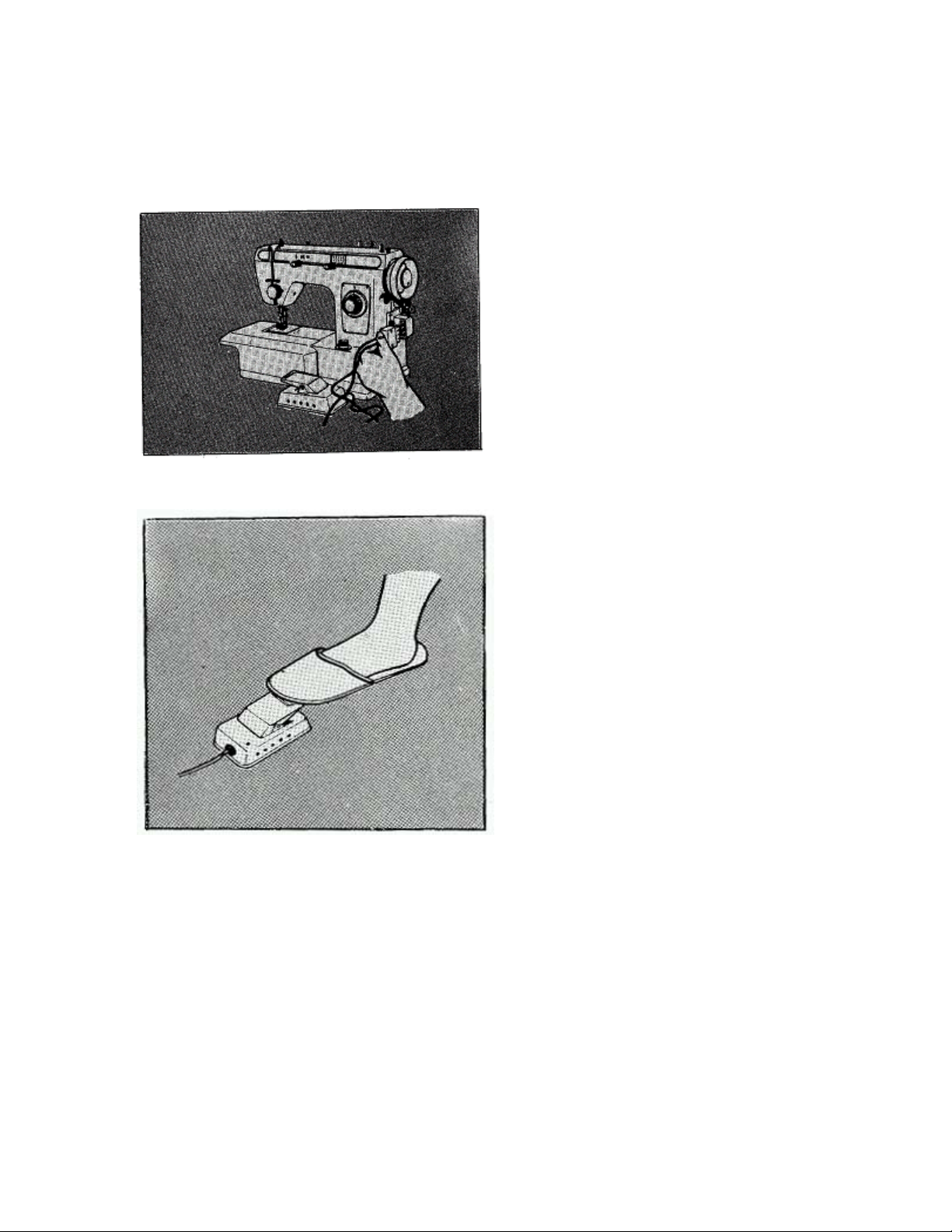

Operating Your Sewing Machine

CONNECTING PLUGS

1. First connect three-prong plug in socket.

2. Then connect electric supply plug into wall.

CAUTION

When changing needle, bobbin or light bulb,

or when sewing machine is not use, it is

recommended that electrical supply plug

is disconnected to avoid electrical hazards.

Place foot on control pedal as shown in

illustration at left.

When foot controller is pushed down lightly,

machine will run at a low speed.

When pressure on foot is increased, sewing

machine will pick up speed.

When foot controller is released the sewing

machine will stop.

NOTE: Care should be taken that nothing is

placed on foot controller when

sewing machine is not in use.

-5-

Page 8

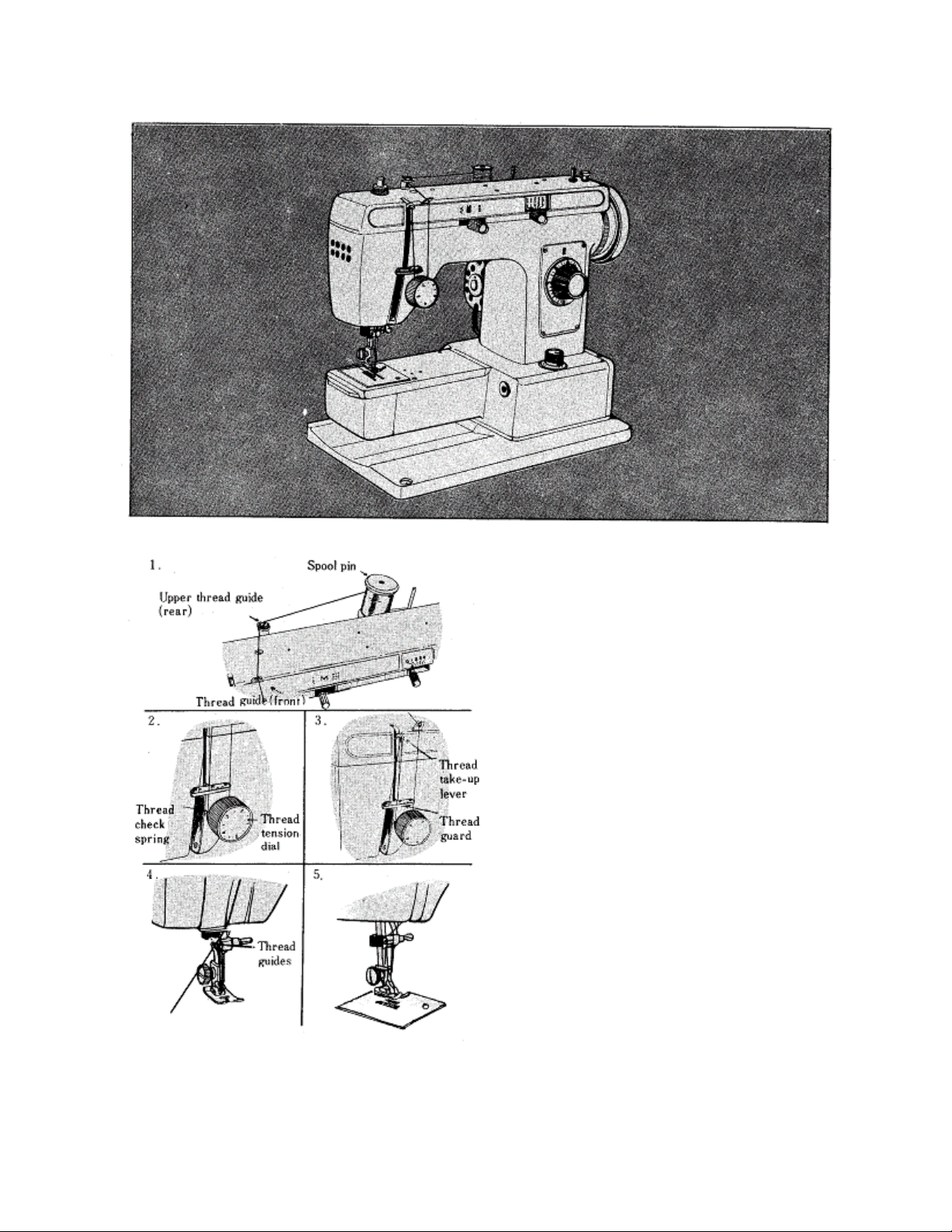

Upper (Needle) Thread

Before threading, make sure to raise presser

foot and take-up lever to the highest position.

Then place spool of thread on the spool.

1. Pass thread through the upper thread

guide, (rear) and thread guide (front).

2. Now bring thread down and up through

thread tension dial from right to left so

that thread picks up thread check spring.

3. Pass thread into the eyelet of the thread

take-up

lever from right to left. And

bring down again and pass through

the thread guard.

4. Bring down and pass through the thread

guides.

5. Thread needle from left to right and

draw the thread out about 15 cm (6

inches).

NOTE: If the threading order is not correct,

thread breakage, stitch skipping,

wrinkling of fabric will occur.

-6-

Page 9

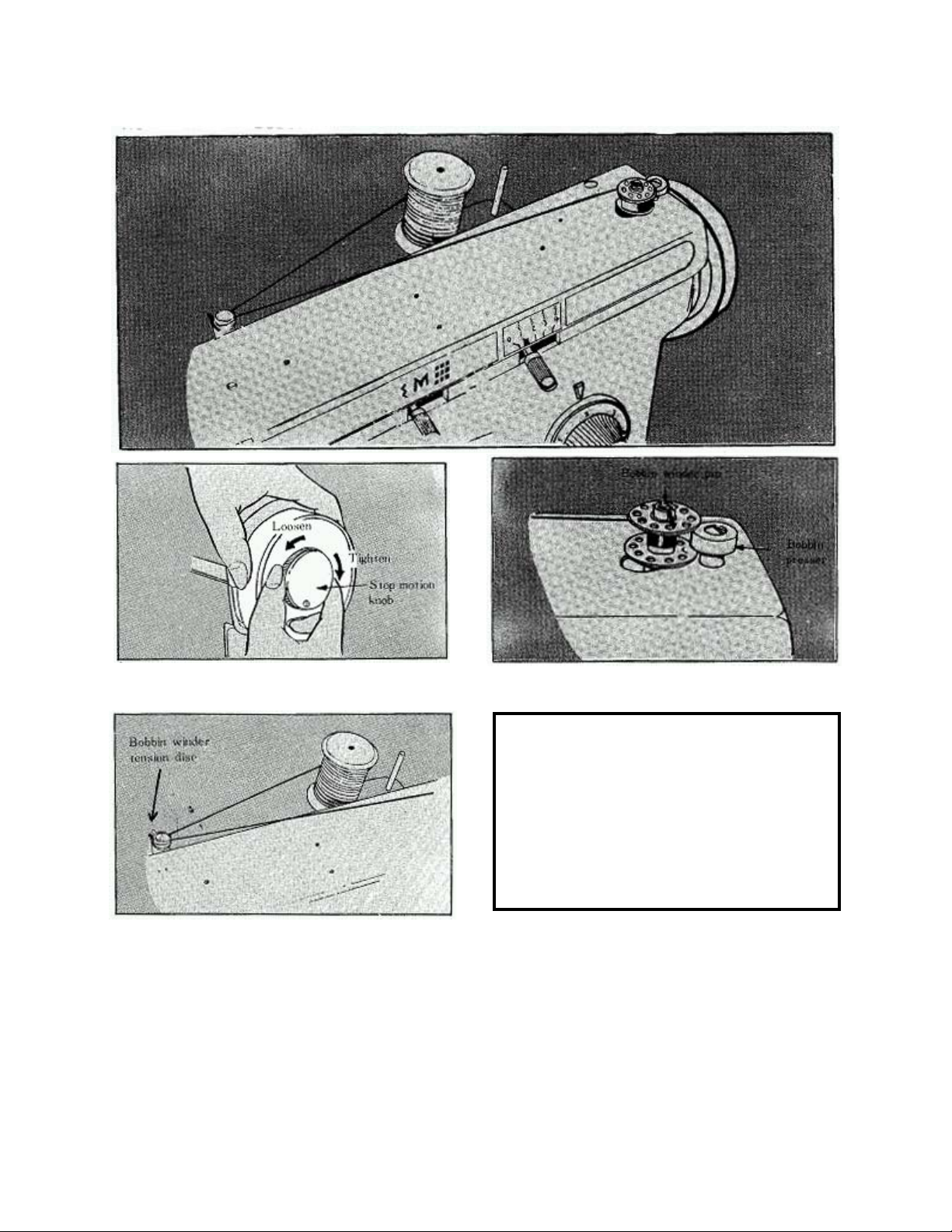

Lower (Bobbin) Thread

HOW TO WIND BOBBIN

1. Loosen stop motion knob by turning it

toward you.

3. Place thread spool on the spool pin and take

thread through bobbin winder tension disc.

2. Place an empty bobbin on the bobbin

winder pin.

4. Wind the thread a few times around the

bobbin clockwise and push the bobbin

toward bobbin presser. Start the machine

gently.

5. Bobbin stops winding when full.

6. Push the bobbin to the left and remove it.

Tighten stop motion knob securely.

-7-

Page 10

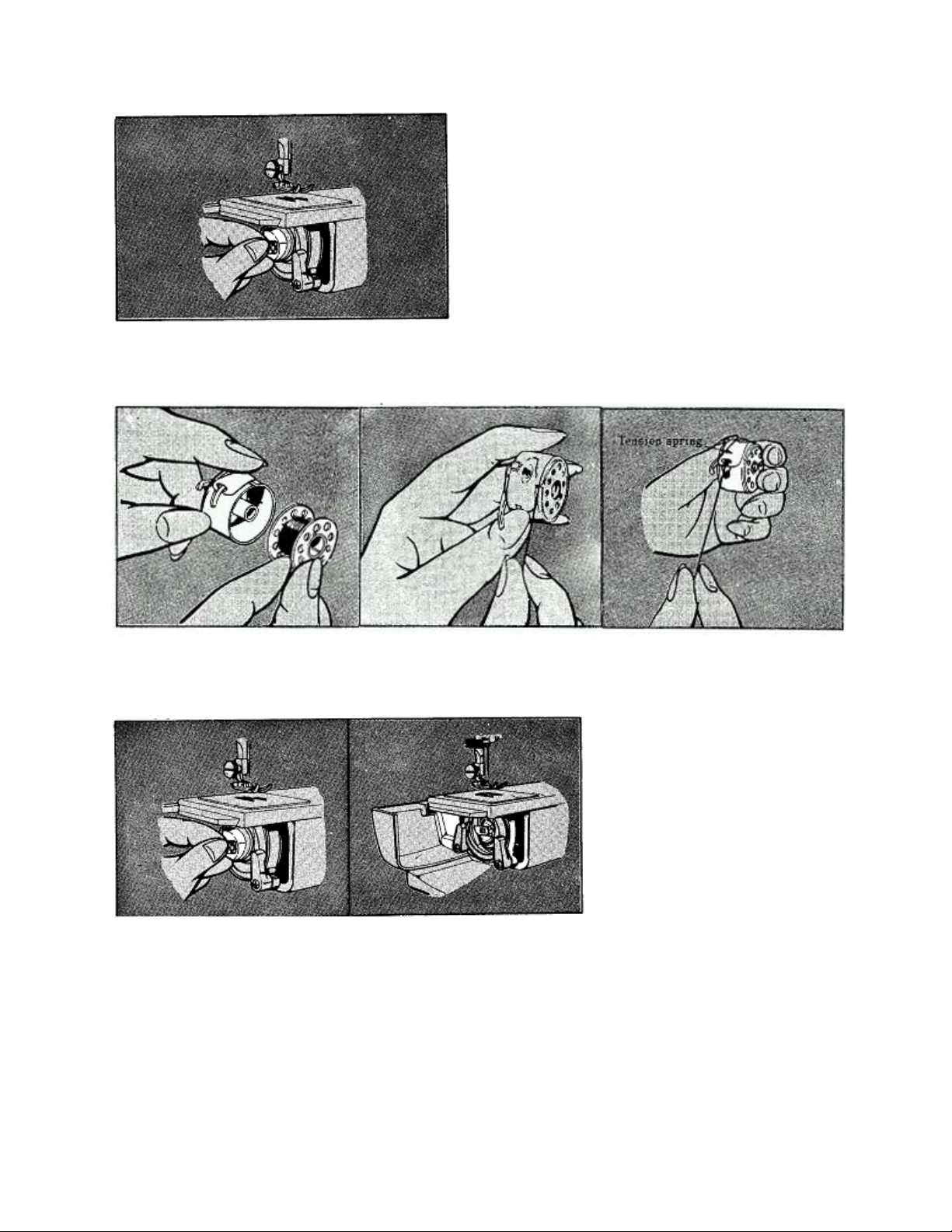

HOW TO REMOVE BOBBIN CASE

1. Raise needle to its highest position.

2. Open the shuttle cover.

3. Pull and open the latch of bobbin case.

4. Pull out bobbin case from the shuttle.

HOW TO THREAD AND INSERT BOBBIN CASE

1. Unwind about 8 cm

(3- inches) of thread

from the bobbin. Insert

wound bobbin into

4. Holding case latch

with the metal finger

of case pointing up, fit

it into the notch at the

top of the shuttle race.

2. Pull trailing thread into the slot

case.

5. Release latch and push case to

the right making sure the case

is in the proper position. Close

the Shuttle Cover.

-8-

3. Pull thread to the left

under the tension

spring until thread

enters into delivery

eye.

NOTE: The thread drawn

out of the case is to be

left hanging below the

race. Leave about 15

cm ( 6

inches )

hanging.

Page 11

HOW TO PULL UP LOWER THREAD

1. Raise needle and presser

foot to the highest point.

With left hand, hold the end

of upper thread and with

right hand, turn balance

wheel toward you until the

needle moves down and up

again to its highest position.

2. Now upper thread catches

the lower thread in a loop.

Pull upper thread toward

you so that lower thread will

come up in a large loop

from the presser foot.

3. Pull both threads under the

toes of presser foot and

place them to the rear

leaving about 10 cm ( 4inches).

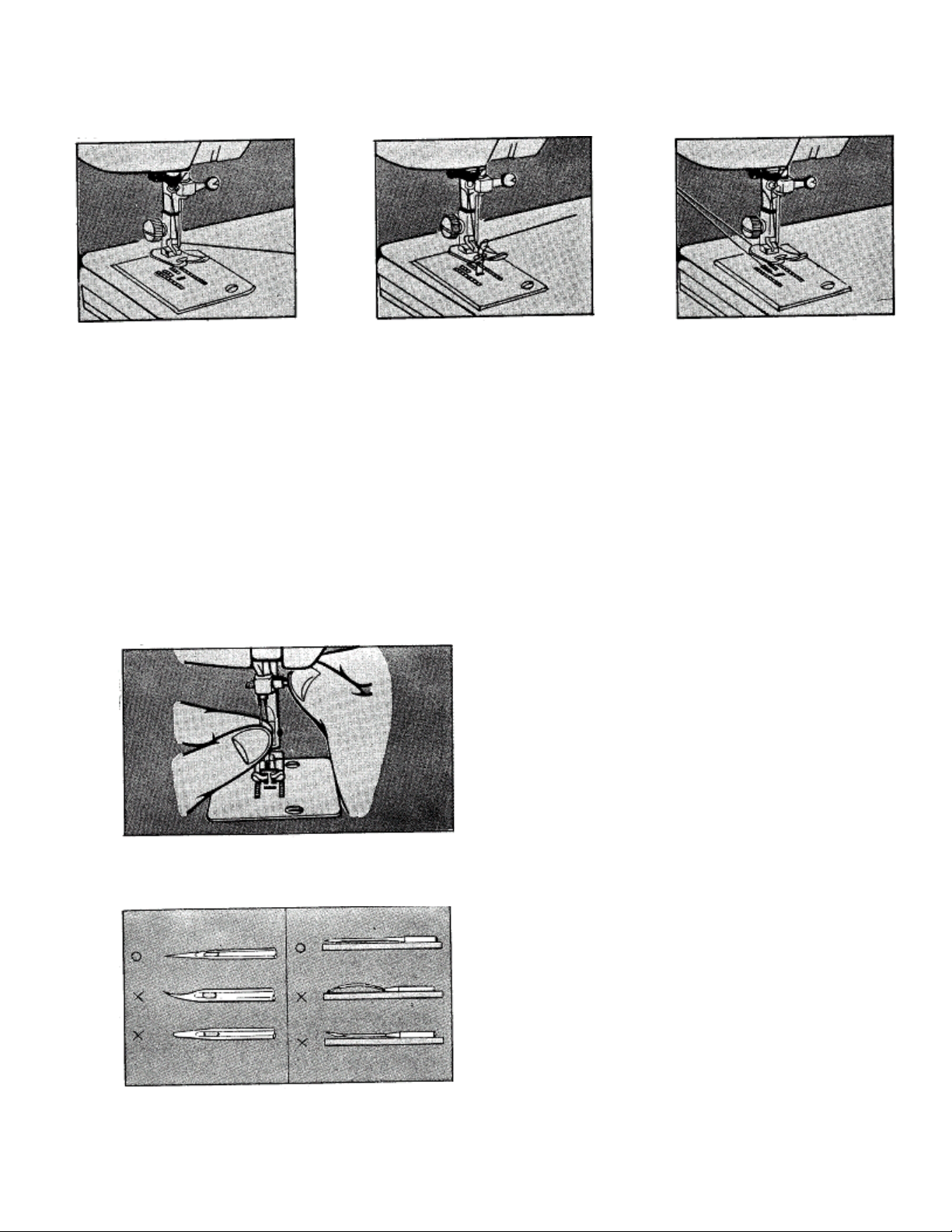

Needle

HOW TO CHANGE THE NEEDLE

1. Raise needle to its highest position.

2. Loosen needle clamp screw and remove

3. Insert new needle up into needle clamp hole

4. Tighten needle clamp screw securely.

HOW TO CHECK THE NEEDLE

For smooth sewing, needle must be straight and

sharp.

To check if the needle is bent, place the flat side

of the needle down on slide plate as shown in

illustration.

-9-

old needle.

as far as it will go against the needle stop.

Make sure the flat side of needle faces

toward the right side and the long groove

toward left.

Page 12

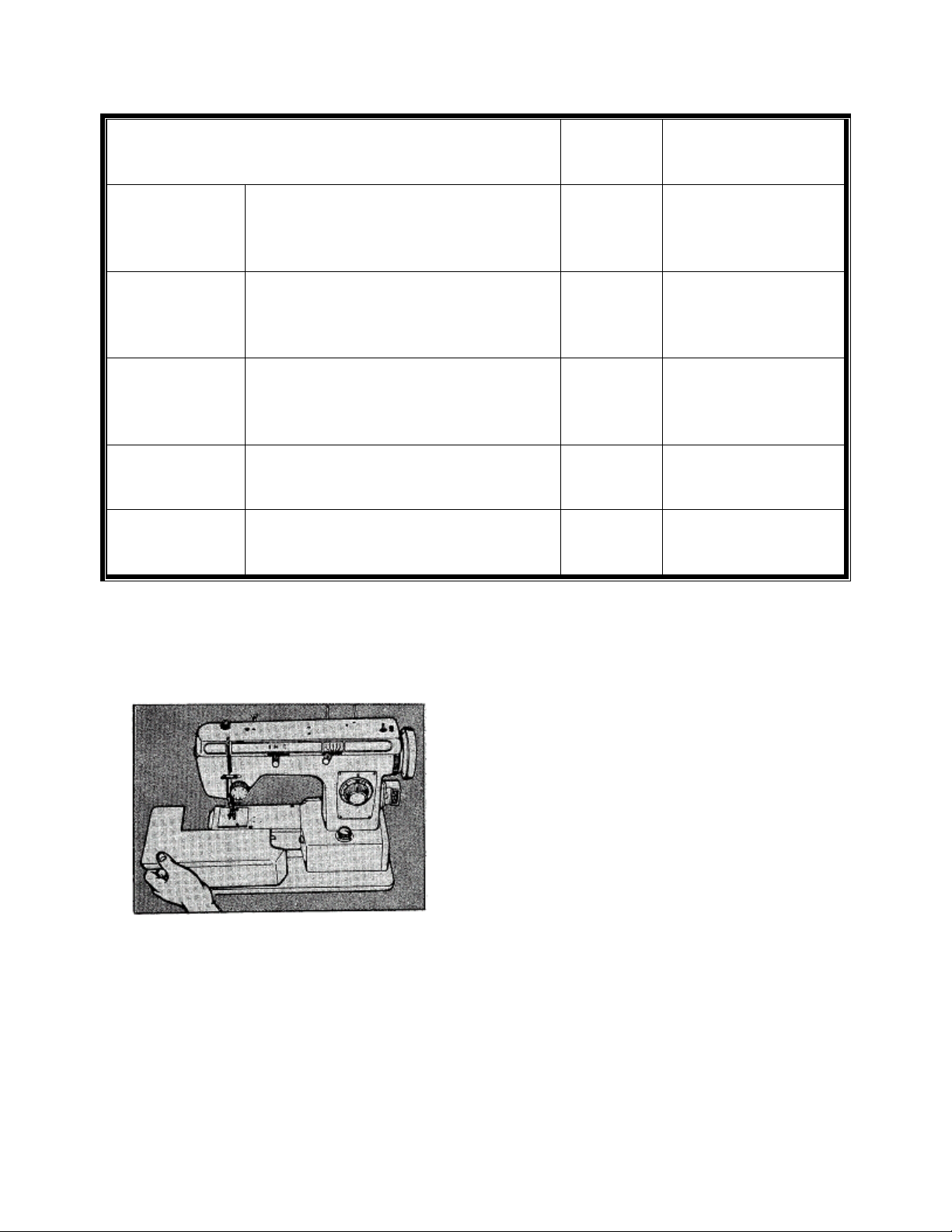

Relative Chart of Sewing Material, Needle and Thread

SEWING MATERIAL

VERY THIN

LIGHT

WEIGHT

MEDIUM

HEAVY Denim, Gabardine, Tweed, Corduroy 16

VERY HEAVY Canvas, Overcoatings, Upholstery 18

Fine tricot, Fine Lace, Thin linen, Silk,

Tulle, Chiffon

Organdy, Jersey, Voile, Taffeta,

Synthetics, Silk

Batiste

Cotton, Gingham, Poplin, Percale,

Pique, Satin,

Velvet, Lightweight wool, Fine

corduroy, Suitings.

NEEDLES

SIZES

9

11

14

THREAD SIZES

Cotton: 80~120

Synthetic

Fine Mercerized

Cotton

Cotton: 60~80

Silk: “A”

Synthetic

Mercerized 50

Cotton: 50~60

Silk: “A”

Synthetic

Mercerized 50~60

Cotton: 40~50

Mercerized Heavy

Duty

Cotton: 30~40

Mercerized Heavy

Duty

NOTE: The same size thread should be

used for upper and lower threads.

Extension Table

This sewing machine has an extension table which

converts it into a flat-bed machine.

To insert the extension table:

1. Slide the extension to the right as shown in

2. To remove extension table, just pull it to the

illustration.

left.

-10-

Page 13

Sew-Light

To change the bulb:

1. Swing open face plate.

2. Remove bulb by turning counterclockwise.

3. After replacement, close the face plate.

NOTE:

1. Make sure new bulb is the same

specification as old one.

2. Make sure to switch off the light and

pull out supply plug when you replace

the bulb in order to avoid electric

hazards.

Presser Foot

To remove the presser foot;

1. Raise needle to its highest position.

2. Raise presser foot.

3. Loosen presser foot thumb screw and remove presser

foot.

4. To attach the presser foot, place grooved side of the

foot against the flat of the presser bar.

5. Tighten thumb screw.

-11-

Page 14

STITCH LENGTH

The stitch length is regulated by turning the

stitch length dial.

Numerals on the dial represent the stitch

length.

THE HIGHER THE NUMBER, THE

LONGER THE STITCH.

To increase the stitch length, turn stitch

length dial counter-clockwise to larger

number on the dial.

To decrease the stitch length, turn dial

clockwise to smaller on the dial.

NOTE:

1. The “0” on the dial means that the

material is not being fed.

2. Always set at 4 when you sew triple

stretch stitch (See page21).

ZIGZAG WIDTH

The zigzag width is regulated by operating

the zigzag width lever.

Numerals above the lever represent the

width of stitch.

THE HIGHER THE NUMBER, THE

WIDER THE STITCH.

The “0” means straight stitch only.

NOTE: Do not move the lever while

the needle is in the material.

-12-

Page 15

PRESSURE ADJUSTER

Correct pressure on presser foot is important

to obtain the smooth sewing.

Regulate presser according to type and

thickness of the materials to be sewn.

1. To regulate the pressure, lower presser

foot.

2. Push outer ring of pressure adjuster

down, and inner pin will spring up to its

highest position. In this position,

pressure is completely released from the

presser foot.

3. To increase pressure, push inner pin

down with your finger.

NOTE: You will be able to select the

correct combination by

referring to the table below.

-13-

Page 16

FEED DOG

REVERSE STITCH

Proper use of Feed Dog is necessary for

correct sewing.

1. “DOWN” is used for special sewing

such as

darning, embroidery, etc.

2. “UP” is used for general sewing.

Push the Reverse Sewing Button in as far as

it will go to sew in reverse position.

Release Reverse Sewing Button and you are

back to sewing in a forward position.

Reverse sewing is used for tacking and

reinforcement.

-14-

Page 17

THREAD TENSIONS

It is important that tension of upper and lower threads be equal to prevent puckering of

material or other problems.

It is recommended that a test sample be made before starting to sew.

UPPER THREAD TENSION

To regulate upper thread tension, merely

turn thread tension dial with your thumb

after lowering the presser foot.

THE HIGHER THE NUMBER, THE

TIGHTER THE TENSION.

To increase tension: Turn dial to right to

larger number.

To decrease tension: Turn dial to left to

smaller number.

NOTE: The zigzag stitch requires less upper

tension than the straight stitch.

LOWER THREAD TENSION

Although lower thread tension has already

been adjusted at the factory, when sewing

very thin or heavy materials it may have to

be readjusted.

To regulate the lower thread tension, turn

small screw on the tension, spring of the

bobbin case with the small screw driver.

To increase tension: Turn the small screw

clockwise very

slightly.

To decrease tension: Turn the screw

counterclockwise

very slightly.

-15-

Page 18

PERFECT STITCHING

INCORRECT STITCH (A)

Tension of upper and lower threads should

be equal, just sufficiently strong to lock

both threads in material.

Perfect stitching appears flat with no

puckering of material.

When the upper thread lies on the surface

of the material by pulling the lower thread

up as shown.

This is caused by tight tension on the upper

thread or loose tension on the lower thread.

To correct this, turn the upper thread tension

dial to a lower number.

If perfect stitching cannot be obtained by

adjusting upper thread tension, adjust bobbin

tension.

INCORRECT STITCH (B)

When the lower thread lies on the under

surface of the material by pulling upper

thread down as shown.

This is caused by loose tension on the upper

thread or tight tension on the lower thread.

To correct this, turn the upper thread tension

dial to a higher number.

If perfect stitching cannot be obtained by

adjusting upper thread tension, adjust bobbin

tension.

NOTE: It is recommended that a test sample

is made before starting to sew.

-16-

Page 19

2. Straight Stitching

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

HOW TO START SEWING

1. Raise needle to its highest position and

lift presser foot.

2. Place material under presser foot and

position needle about one half inch

(10mm) from material edge.

3. Lower presser foot.

4. For reverse sewing push Reverse Sewing

button sewing is used wherever

reinforcement is needed.

5. Release Reverse Sewing Button and start

sewing in forward position.

NOTE: Do not pull the material. Let the

machine do the work. Merely guide

the material with your fingers. If

you pull the material, your needle

might either bend or break.

HOW TO CHANGE THE SEWING

DIRECTION

1. Stop machine at the turning point while

the needle is in the material.

2. Raise the presser foot and turn the

material to the new direction while the

needle acts as the axis.

3. Lower presser foot and sew in new

direction.

-17-

Page 20

HOW TO FINISH YOUR SEWING PROJECT

(REVERSE STITCHING)

Reverse stitching is used to reinforce stitches near

the edge of material or wherever reinforcement is

needed.

1. That is done by stitching to the material edge…

then stopping.

2. Push Reverse Sewing Button and stitch

backwards for ½ inch (10mm) from material

edge.

HOW TO REMOVE FINAL SEWING FROM

MACHINE

1. Stop the machine.

2. Raise needle to its highest position and make

sure that the thread take-up lever is in the

highest position also.

3. Lift presser foot and pull out the material gently

to the left side diagonally.

4. Cut both threads on the thread cutter.

5. Leave 4 inches (10cm) of thread between the

presser foot loose while the thread take-up lever

is at highest position. You are ready to sew.

HOW TO GUIDE AND SUPPORT MATERIAL

Generally it is enough to guide the material in front

of the presser foot as shown in the upper

illustration.

However, in case of special materials such as tricot,

crepes, knits, etc., we recommend you to support

the material both in front and back of the presser

foot with gentle tension as shown in the lower

illustration.

-18-

Page 21

3. Zigzag Stitching

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

SIMPLE ZIGZAG STITCH

Set the Stitch zigzag, sew about 1-4 to

obtain simple zigzag stitch.

1. Before stitching zigzag, sew about 5-6

Straight stitches with stitch length

between for reinforcement.

2. Set zigzag width lever to your desired

width and commence to sew.

3. Before removing work from machine,

reset the zigzag lever to “O” and sew 5-6

stitches for reinforcement.

NOTE: Generally, zigzag stitch requires less

upper thread tension than the straight

stitches.

SATIN STITCH

When the Stitch Length Dial is set to

between the “SATIN STITCH” is produced.

This is used to make buttonholes and

various decorative stitches.

NOTE: It is recommend that a test sample

is made before starting to sew.

-19-

Page 22

DECORATIVE STITCHES

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

Using the “SATIN STITCH” various

decorative stitches are produced by using

the zigzag width lever as follows:

-20-

Page 23

4. Using Built-in Patterns

TRIPLE STRETCH STITCH

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

Set Blind Stitch and Stretch Stitch Lever at

as shown in illustration at left.

The “Triple Stretch Stitch” is used for any

stretch material such as knitted fabric,

tricot, etc. This stitch is three times the

strength of a regular stitch and gives

elasticity to seams which prevents breakage

of thread.

NOTE: With zigzag width lever set at 4, a

triple zigzag stitch is produced which

can be used as a decorative stitch.

-21-

Page 24

BLIND STITCH

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

SET BLIND STITCH AND STRETCH

STITCH LEVER AT

1. Fold material to size of hem desired and

then fold back as shown in Figure A,

leaving ¼ inch (6mm) overlap at edge.

2. Sew on fold as in Figure B.

3. When material is unfolded you will have

a blind stitched hem as in Figure C.

NOTE: Thread used should be the same

color as material used.

SHELL STITCH

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

This can be used for sewing a picoted

edge on a light material.

1. Set the machine as for blind stitch.

2. Sew material on bias, placing material

under the presser foot so that straight

stitches are sewn on seam line and

zigzag stitches are sewn slightly over

seam edge.

3. The “SHELL STITCH” requires a little

tighter upper thread tension than

normal.

4. Sew at slow speed.

5. Edge of material becomes picoted.

-22-

Page 25

5. Various Other Stitches

BUTTONHOLE

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

Step A:

1. Set zigzag width lever to 2.

2. Set drop feed to Up.

3. Lower presser foot and commence to sew

predetermined length.

4. Stop machine when the needle is in the

material at the right side of row.

Step B:

1. Lift the presser foot and run material 180 degree

while the needle acts as the axis.

2. Lower the presser foot and raise the needle from

material by turning balance wheel toward you.

3. Set zigzag width lever to 4 and drop feed

knob to Down.

4. Commence to sew 5 to 6 stitches and stop

the machine when the needle is in the material

at the left side of the row.

Step C:

1. Lift the presser foot slightly and set the feed

dog knob to Up.

2. Raise the needle and set the zigzag width

lever to 2.

3. Sew row to predetermined length.

4. Stop the machine when the needle is in the

material at the left side of row.

Step D:

1. Raise the needle and set the feed dog knob to

Down.

2. Set the zigzag width lever to 4.

3. Sew 5-6 stitches across to finish buttonhole, then

turn material 90 degrees clockwise and sew 5-6

straight stitches to secure stitching.

4. Lift presser foot and remove work from

NOTE:

1. It is recommended that a sample buttonhole

be made starting to sew.

2. Use tailor’s chalk to mark length of buttonhole.

-23-

Page 26

MENDING

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Place reinforcement material under

material to be repaired.

2. Sew both edges of tear together.

3. Use satin stitch to strengthen and secure

ends of tear as in illustrations.

ATTACHING LACE

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Place lace under material edge letting it

overlap ¼ inch (6 mm).

2. Place under presser foot and sew.

-24-

Page 27

APPLIQUÉING

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Baste cut design to the material.

2. Following the design, commence to sew

carefully.

3. Cut away the surplus material close to the

design.

4. Remove basting.

CORDING

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. In accordance with thickness of cord being

used, set zigzag width lever.

2. Place cord on fabric to be sewn.

3. Lower presser foot and sew using zigzag

stitch. Guide cord by hand to where you

desire it.

-25-

Page 28

MONOGRAMMING, USING EMBROIDERY HOOP

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Remove presser foot.

2. Draw lettering on the right side of the

material.

3. Stretch work between embroidery hoops

as firmly as possible.

4. Place the work under the needle and

lower presser bar.

5. Pull lower thread up through the material

at starting position by turning balance

wheel and holding both threads.

6. Hold the hoop with thumb and forefinger

of both hands while pressing the material

with middle and third fingers and

supporting the outside of hoop with

smaller finger.

7. Start sewing, moving hoop lightly along

the lettering with even rate of speed

while controlling zigzag width lever

with your right hand.

-26-

Page 29

EMBROIDERING, USING EMBROIDERY HOOP

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Remove presser foot.

2. Draw design on the material.

3. Use embroidery hoop as you would for

monogramming.

4. Position the hoop under the needle and

lower presser bar.

5. Pull lower thread up through material.

6. Stitch outline of design by removing

embroidery hoop accordingly.

7. To fill in design stitch from outline of

design to inside and from inside to edge

of outline alternately until design is

completely filled in. Keep stitching close

together.

NOTE: A long stitch is made by removing

embroidery hoop rapidly and a short

stitch is made by moving it slowly.

-27-

Page 30

BUTTON SEWING

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Put button in place on material to be

sewn.

Place under presser foot.

2. Set zigzag width control to regulate

distance of stitch between the holes in

the button.

3. Lower presser foot and check to see that

needle enters holes in button properly.

4. Slowly sew approximately 10 stitches.

5. Stop machine and raise needle from the

Material.

6. Turn zigzag width lever to 0.

7. Sew approximately three stitches in one

of the holes in the button to secure it.

8. Remove work and cut threads.

BUTTON SEWING WITH THREAD SHANK

For heavier material use the following

method to sew on buttons:

1. Place a needle on the button as shown in

illustration and then sew on button as

you would regularly. (see above)

2. When removing work from machine

leave a long upper thread to be used to

form a thread shank.

3. Pull the upper thread through the hole of

button between button and material to

form thread shank.

4. With normal sewing needle sew in

thread ends.

-28-

Page 31

DARNING

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Place portion to be darned under the

presser foot.

2. Lower presser foot.

3. Sew alternately drawing the work gently

away from you and pulling it toward

you.

4. Repeat this motion until the portion to be

darned is filled with parallel lines of

stitching.

CLOTH GUIDE

The cloth guide helps to make straight and

parallel stitches follow the edge of the

material.

To attach the cloth guide, place it over two

holes to the right of the needle plate in the

sewing machine bed.

Place thumb screw through the guide slot,

adjusting the guide for the desired distance

and fasten it securely.

-29-

Page 32

NARROW HEMMING

By using narrow hemmer foot a neat scroll type hem

is made.

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Cut top corner of the material about

0.3cm (1/8”).

2. Place material wrong side up and insert

cut off angel into foot opening.

3. Pull material by hand from the back of

the presser foot.

Make sure the needle is positioned over

material.

Lower presser foot.

4. Make sure upper and lower threads are

placed behind presser foot.

5. Sew at medium speed. Guide the

material by hand through the presser foot

opening.

NOTE: With zigzag width lever set a 3,

zigzag narrow hemming can be done

following the above procedure.

-30-

Page 33

ZIPPER INSERTION

Zipper foot is used to sew various types of

zippers and can easily be positioned to right

or left side of needle.

When zipper is being sewn at left side of

needle, position zipper foot by loosening

thumb screw and sliding zipper foot to right.

When zipper is being sewn at right side of

needle, position zipper foot by loosening

thumb screw and sliding zipper foot to left.

SET YOUR SEWING MACHINE AS PER FOLLOWING TABLE.

1. Lower needle into side notch located on

presser foot. (right or left)

2. Tighten thumb screw to lock presser foot

into position.

3. Fold edge of material ¾ inch (2cm) and

place zipper under folded portion.

4. By guiding zipper foot along the zipper

teeth you will stitch close to edge of

zipper in correct position.

5. To sew opposite side of zipper, loosen

thumb screw and position zipper foot.

(right or left)

-31-

Page 34

6. Maintenance and Care of Your Machine

Cleaning

The sliding parts of the shuttle race body and the hook must be cleaned regularly so that lint does

not accumulate.

REMOVING SHUTTLE HOOK

1. Raise needle to its highest position.

2. Open the shuttle race cover.

3. Take out bobbin case.

4. Push latch levers down and remove

retaining ring.

5. Remove hook by grasping center post of

hook.

NOTE: When needle is lowered,

hook cannot be removed.

CLEANING SHUTTLE RACE

1. Remove accumulated lint and thread

from the retaining ring, hook, driver and

race body with brush.

2. A cloth dampened with machine oil

should be used to wipe shuttle race

clean.

3. Clean shuttle hook in the same manner

as above.

4. Reassemble.

CLEANING FEED DOG

1. Take out free arm upper plate by

loosening the screw on it.

2. Clean upper part of feed dog and shuttle

race body with brush.

-32-

Page 35

Oiling

For smooth and silent operation the moving parts of the machine should be oiled

periodically. (see diagram below)

OIL ONCE A WEEK IF MACHINE IS USED MORE THAN ONE HOUR.

PER DAY. IF MACHINE IS USED MORE OFTEN OIL EVERY DAY.

NOTE: If machine has not been used for along period of time, oil tends to coagulate and

operation of machine will not be smooth. To ensure best operation in such a case,

apply a small amount of benzine to oiling points as noted in diagram. For motor; One

or two drops of oil twice a year is recommended.

-33-

Page 36

Check List for Better Sewing

Check this list if you are having the following problems:

IF MATERIAL IS NOT FED

1. Feed dog is down .

2. Stop motion knob is loose.

3. Stitch length regulator is at 0.

IF NEEDLE BREAKS

1. Needle is inserted incorrectly.

2. Needle clamp screw is loose.

3. Bent needle is used.

4. Upper threading is not correct.

5. Upper thread tension is too tight.

6. Wrong needle and thread for cloth being

sewn are used.

7. Material pulled excessively.

IF LOOPS FORM ON FABRIC

1. Tension of upper or lower thread is

wrong.

IF MATERIAL SHOULD PUCKER

1. Thread tension is too tight.

2. Threading is not correct.

3. Thread is caught by something.

4. Lower thread is unevenly wound on

bobbin.

IF UPPER THREAD BREAKS

1. Upper threading is not correct.

2. Upper thread is too large for needle eye.

3. Upper thread tension is too tight.

4. Needle is inserted incorrectly.

IF LOWER THREADS BREAKS

1. Lower thread is entangled in shuttle.

2. Lower thread tension is too tight.

3. Lower threading is not correct.

IF MACHINE SKIPS STITCHES

1. Needle is not sharp and straight.

2. Needle is inserted incorrectly.

3. Wrong needle and thread for cloth being

4. Upper threading is not correct.

5. Lint is clinging to under-side of needle

plate.

-34-

sewn are used.

Page 37

M E M O

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page 38

M E M O

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page 39

Replacement Sewing Manuals

From

http://www.mastersewusa.com

Thank you for your purchase.

We try to scan original manuals at the highest DPI settings without

compromising the readability of the manual. We also have a technical

team that has been working over a year retyping hard to find and in

poor shape manuals from many different manufacturers. During he

retype operation the technicians try their best to maintain the wording

and page set up as of the original manual.

If you are satisfied with this product please tell others about us. Many

of our sales are made to people who heard of us by referrals of

customers like you. Many homes have sewing machines but their

manuals became lost or damaged.

We are here 24/7 on the Internet at:

http://www.mastersewusa.com

We have Instructional manuals, service manuals, parts lists, and

instructional videos for many industrial and consumer sewing

machines.

We assist owners of older Singer sewing machines by using their

machines serial number and converting it to their sewing machines

model number. Contact us at:

Mastersewusa is committed to adding manuals to our library to

consistently improve our service in the sewing community.

BERNINA * BROTHER * CONSEW * FEIYUE-YAMATA * ELNA

* GN * PFAFF * JUKI * MORSE * NECCHI * NEW HOME *

SEARS KENMORE * SIMPLICITY * SINGER * WHITE

For Reprints Visit on the web.

sales@mastersewusa.com

Our manuals are:

http://www.mastersewusa.com May 2006

Loading...

Loading...