Broan 332H, Elite 331H, Elite 332H Installation Manual

MODELS331H & 332H

BReAN

FOR USE WiTH RANGEIVlASTER HOODS AND ECLIPSE DOWNDRAFT VENTILATORS

WARNING CAUTION

EXTERIOR MOUNTEDBLOWER

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufac-

turer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as atag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhaust-

ing of gases through the flue (chimney) of fuel burning

equipment to prevent backdrafting. Follow the heating equip-

ment manufacturer's guideline and safety standards such as

those published by the National Fire Protection Association

(NFPA), and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and the local

code authorities.

5. When cutting or drilling into wall, or ceiling, do not damage

electrical wiring or other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce risk of fire, use only metal ductwork.

8. This unit must be grounded.

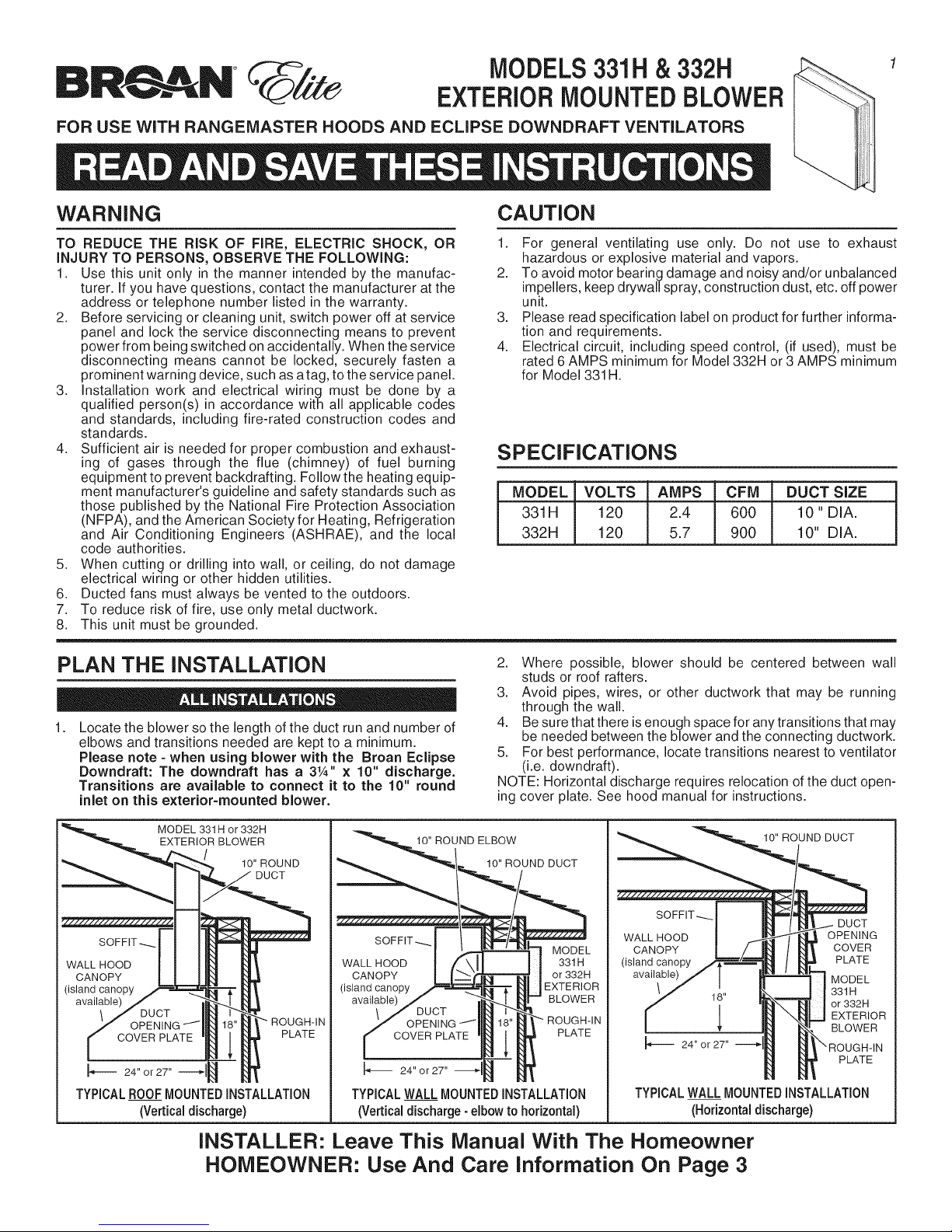

PLAN THE INSTALLATION

1.

Locate the blower so the length of the duct run and number of

elbows and transitions needed are kept to a minimum.

Please note = when using blower with the Broan Eclipse

Downdraft: The downdraft has a 31A'' x 10" discharge.

Transitions are available to connect it to the 10" round

inlet on this exterior=mounted blower.

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive material and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

3. Please read specification label on product for further informa-

tion and requirements.

4. Electrical circuit, including speed control, (if used), must be

rated 6 AMPS minimum for Model 332H or 3 AMPS minimum

for Model 331H.

SPECiFiCATiONS

MODEL VOLTS AMPS

331H 120 2.4

332H 120 5.7

2. Where possible, blower should be centered between wall

studs or roof rafters.

3. Avoid pipes, wires, or other ductwork that may be running

through the wall.

4. Be sure that there is enough space for any transitions that may

be needed between the blower and the connecting ductwork.

5. For best performance, locate transitions nearest to ventilator

(i.e. downdraft).

NOTE: Horizontal discharge requires relocation of the duct open-

ing cover plate. See hood manual for instructions.

CFM DUCT SIZE

600 10 " DIA.

900 10" DIA.

MODEL 331H or 332H

EXTERIOR BLOWER

10" ROUND

DUCT

PLATE

TYPICALROOFMOUNTEDINSTALLATION

(Verticaldischarge)

INSTALLER: Leave This Manual With The Homeowner

HOMEOWNER: Use And Care Information On Page 3

IO"ROUNDELBOW

lO"ROUND DUCT

WALL HOOD 331H

CANOPY or 332H

(island canopy EXTERIOR

available) BLOWER

TYPICALWALL MOUNTEDINSTALLATION

(Verticaldischarge- elbow to horizontal)

DUCT

MODEL

ROUGH-IN

PLATE

10"ROUND DUCT

WALL HOOD OPENING

CANOPY COVER

(island canopy PLATE

available) MODEL

18"

24" or 27"

TYPICALWALL MOUNTEDINSTALLATION

(Horizontaldischarge)

DUCT

331H

or 332H

EXTERIOR

BLOWER

PLATE

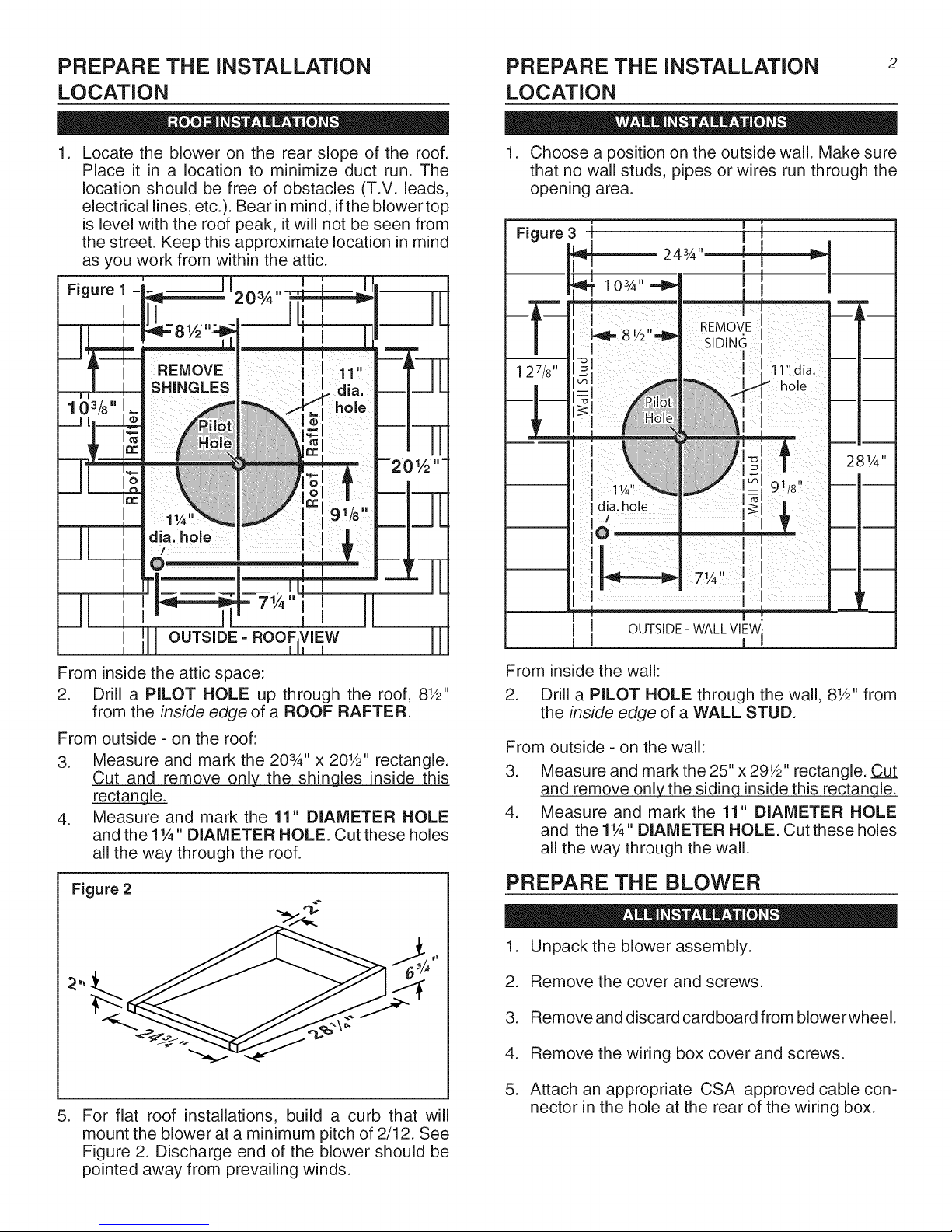

PREPARE THE INSTALLATION

LOCATION

.

Locate the blower on the rear slope of the roof.

Place it in a location to minimize duct run. The

location should be free of obstacles (T.V. leads,

electrical lines, etc.). Bear in mind, if the blower top

is level with the roof peak, it will not be seen from

the street. Keep this approximate location in mind

as you work from within the attic.

PREPARE THE INSTALLATION 2

LOCATION

1. Choose a position on the outside wall. Make sure

that no wall studs, pipes or wires run through the

opening area.

Figure 3 4 =f=-i

,, [ [

103A "€_ .[ I

127/8"

r

i 281/4"

243_,,

I

I

i

I rI----'-- Ili_

I ! _

I

II

From inside the attic space:

2. Drill a PILOT HOLE up through the roof, 81/2"

from the inside edge of a ROOF RAFTER.

From outside - on the roof:

3. Measure and mark the 203A" x 201/2" rectangle.

Cut and remove only the shingles inside this

rectangle.

4. Measure and mark the 11" DIAMETER HOLE

and the 11A" DIAMETER HOLE. Cut these holes

all the way through the roof.

Figure 2

ez _ ,

71/4,,

'i i[ OUTSIDE- WALLVl Wl

I

From inside the wall:

2. Drill a PILOT HOLE through the wall, 81/2" from

the inside edge of a WALL STUD.

From outside - on the wall:

3. Measure and mark the 25" x 291/2" rectangle. Cut

and remove only the siding inside this rectangle.

4. Measure and mark the 11" DIAMETER HOLE

and the 11A'' DIAMETER HOLE. Cut these holes

all the way through the wall.

PREPARE THE BLOWER

1. Unpack the blower assembly.

2. Remove the cover and screws.

. For flat roof installations, build a curb that will

mount the blower at a minimum pitch of 2/12. See

Figure 2. Discharge end of the blower should be

pointed away from prevailing winds.

3. Remove and discard cardboard from blowerwheel.

4. Remove the wiring box cover and screws.

5. Attach an appropriate CSA approved cable con-

nector in the hole at the rear of the wiring box.

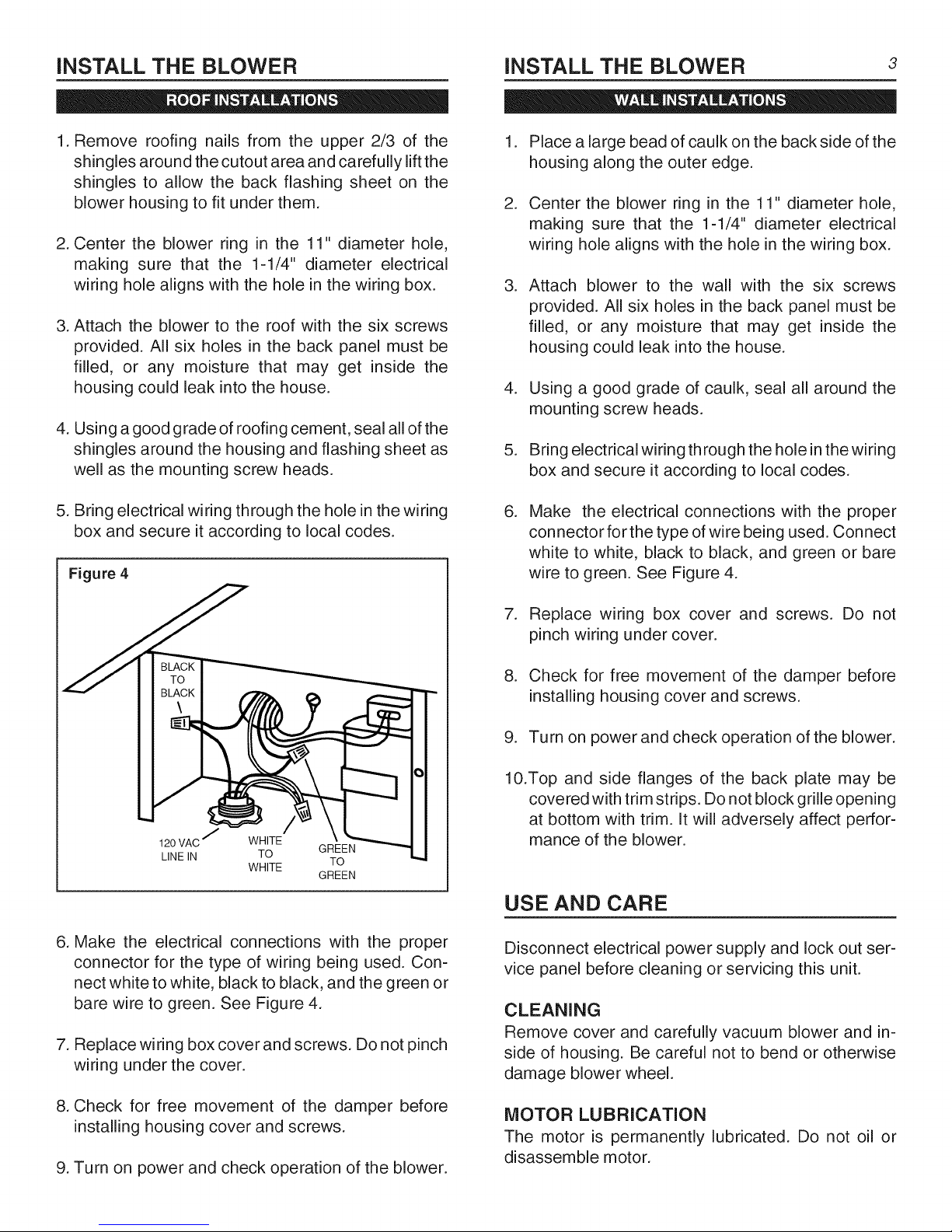

iNSTALL THE BLOWER

INSTALL THE BLOWER 3

1. Remove roofing nails from the upper 2/3 of the

shingles around the cutout area and carefully lift the

shingles to allow the back flashing sheet on the

blower housing to fit under them.

2. Center the blower ring in the 11" diameter hole,

making sure that the 1-1/4" diameter electrical

wiring hole aligns with the hole in the wiring box.

3. Attach the blower to the roof with the six screws

provided. All six holes in the back panel must be

filled, or any moisture that may get inside the

housing could leak into the house.

4. Using a good grade of roofing cement, seal all of the

shingles around the housing and flashing sheet as

well as the mounting screw heads.

5. Bring electrical wiring through the hole in the wiring

box and secure it according to local codes.

Figure 4

1. Place a large bead of caulk on the back side of the

housing along the outer edge.

2. Center the blower ring in the 11" diameter hole,

making sure that the 1-1/4" diameter electrical

wiring hole aligns with the hole in the wiring box.

. Attach blower to the wall with the six screws

provided. All six holes in the back panel must be

filled, or any moisture that may get inside the

housing could leak into the house.

4. Using a good grade of caulk, seal all around the

mounting screw heads.

5. Bring electrical wiring th rough the hole in the wiring

box and secure it according to local codes.

.

Make the electrical connections with the proper

connector for the type of wire being used. Connect

white to white, black to black, and green or bare

wire to green. See Figure 4.

120VAC j WHITE

LINEIN TO GREEN

WHITE TO

GREEN

6. Make the electrical connections with the proper

connector for the type of wiring being used. Con-

nect white to white, black to black, and the green or

bare wire to green. See Figure 4.

7. Replace wiring box cover and screws. Do not pinch

wiring under the cover.

7. Replace wiring box cover and screws. Do not

pinch wiring under cover.

8. Check for free movement of the damper before

installing housing cover and screws.

9. Turn on power and check operation of the blower.

10.Top and side flanges of the back plate may be

covered with trim strips. Do not block grille opening

at bottom with trim. it will adversely affect perfor-

mance of the blower.

USE AND CARE

Disconnect electrical power supply and lock out ser-

vice panel before cleaning or servicing this unit.

CLEANING

Remove cover and carefully vacuum blower and in-

side of housing. Be careful not to bend or otherwise

damage blower wheel.

8. Check for free movement of the damper before

installing housing cover and screws.

9. Turn on power and check operation of the blower.

MOTOR LUBRICATION

The motor is permanently lubricated. Do not oil or

disassemble motor.

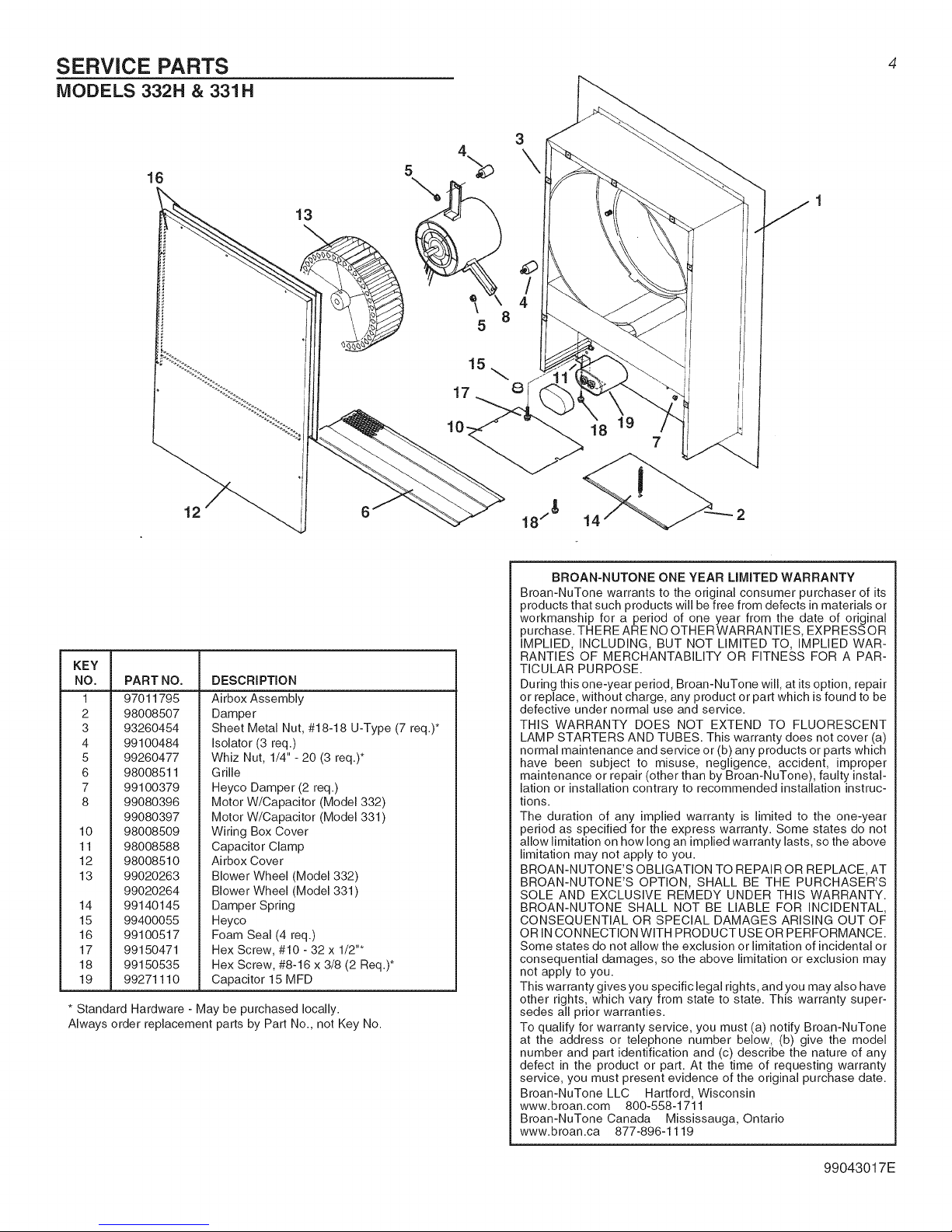

SERVICE PARTS

MODELS 332H & 331H

16

12

3

\

13

\

5

KEY

NO. PART NO.

1 97011795

2 98008507

3 93260454

4 99100484

5 99260477

6 98008511

7 99100379

8 99080396

99080397

10 98008509

11 98008588

12 98008510

13 99020263

99020264

14 99140145

15 99400055

16 99100517

17 99150471

18 99150535

19 99271110

* Standard Hardware - May be purchased locally.

Always order replacement parts by Part No., not Key No.

DESCRiPTiON

Airbox Assembly

Damper

Sheet Metal Nut, #18-18 U-Type (7 req.)*

Isolator (3 req.)

Whiz Nut, 1/4" - 20 (3 req.)*

Grille

Heyco Damper (2 req.)

Motor W/Capacitor (Mode[ 332)

Motor W/Capacitor (Model 331 )

Wiring Box Cover

Capacitor Clamp

Airbox Cove r

Blower Wheel (Model 332)

Blower Wheel (Model 331 )

Damper Spring

Heyco

Foam Seal (4 req.)

Hex Screw, #10 - 32 x 1/2"*

Hex Screw, #8-16 x 3/8 (2 Req.)*

Capacitor 15 MFD

BROAN-NUTONE ONE YEAR LiMiTED WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its

products that such products will be free from defects in materials or

workmanship for a period of one year from the date of original

purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WAR-

RANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR-

TICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair

or replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT

LAMP STARTERS AND TUBES. This warranty does not cover (a)

normal maintenance and service or (b) any products or parts which

have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty instal-

lation or installation contrary to recommended installation instruc-

tions.

The duration of any implied warranty is limited to the one-year

period as specified for the express warranty. Some states do not

allow limitation on how long an implied warranty lasts, so the above

limitation may not apply to you.

BROAN-NUTONE'S OBLIGATION TO REPAIR OR REPLACE, AT

BROAN-NUTONE'S OPTION, SHALL BE THE PURCHASER'S

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY.

BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF

OR INCONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may

not apply to you.

This warranty gives you specific legal rights, and you may also have

other rights, which vary from state to state. This warranty super-

sedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone

at the address or telephone number below, (b) give the model

number and part identification and (c) describe the nature of any

defect in the product or part. At the time of requesting warranty

service, you must present evidence of the original purchase date.

Broan-NuTone LLC Hartford, Wisconsin

www.broan.com 800-558-1711

Broan-NuTone Canada Mississauga, Ontario

www.broan.ca 877-896-1119

99043017E

Loading...

Loading...