Page 1

WWW.BROAN.CA WWW.NUTONE.CA

RANGE HOOD

Series: BKDJ1, BKDN1 and NKDN1

INSTALLATION, USE

AND CARE MANUAL

Serial number:

99045655-003A

Page 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Cleaning and Maintenance . . . . . . . . . . . . . . . . . .7

Motors

Grease Filters

Non-Ducted Recirculation Filters

Fan Wheels

Stainless Steel Cleaning

Painted Finish Cleaning

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Recommended Tools

and Accessories for Installation . . . . . . . . . . . . 8

Install Ductwork (Ducted Installations Only) . . . 8

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prepare the Hood . . . . . . . . . . . . . . . . . . . . . . . 10-12

Prepare the Hood Location . . . . . . . . . . . . . . . . 13

EZ1 Person Installation . . . . . . . . . . . . . . . . . 13-15

Install the Hood (EZ1 Bracket) . . . . . . . . . . . . 16-17

Standard Installation . . . . . . . . . . . . . . . . . . . 18

Install the Hood (Standard Installation) . . . . . 19

Connect the Wiring . . . . . . . . . . . . . . . . . . . . . . 20

Install the Filters . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .21

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

INSTALLATION MANUAL

TABLE OF CONTENTS

2

Page 3

READ AND SAVE THESE INSTRUCTIONS

!

Intended for domestic cooking only

!

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

For Broan range hoods, register your range hood online at www.broan.ca

For NuTone range hoods, register your range hood online at www.nutone.ca

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

• Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer at the address or telephone number

listed in the warranty.

• Before servicing or cleaning unit, switch power off at service panel and

lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

• Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards, including

fire-rated construction.

• Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guidelines and

safety standards such as those published by the National Fire Protection

Association (NFPA) and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and the local code authorities.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

• Ducted fans must always be vented to the outdoors.

• Do not use this unit with any additional solid-state speed control device.

• To reduce the risk of fire, use only metal ductwork.

• This unit must be grounded.

• As an alternative, this product may be installed with the UL-approved cord

kit designated for the product, following instructions packed with the cord

kit.

• When applicable local regulations comprise more restrictive installation

and/or certification requirements, the aforementioned requirements prevail

on those of this document and the installer agrees to conform to these at

his own expense.

INSTALLATION MANUAL

SAFETY

3

Page 4

!

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or when flambeing food

(i.e.: Crêpes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fan frequently. Grease should not be allowed to

accumulate on fan, filters or in exhaust ducts.

d) Use proper pan size. Always use cookware appropriate for the size of

the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. IF THE

FLAMES DO NOT GO OUT IMMEDIATELY, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels — This could

cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

INSTALLATION MANUAL

SAFETY

4

!

CAUTION

• For indoor use only.

• For general ventilating use only. Do not use to exhaust hazardous or explosive materials

and vapors.

• To avoid motor bearing damage and noisy and/or unbalanced fan blade, keep drywall

spray, construction dust, etc. off range hood.

• Your hood motor has a thermal overload which will automatically shut off the motor if it

becomes overheated. The motor will restart when it cools down. If the motor continues to

shut off and restart, have the hood serviced.

• For best capture of cooking fumes, the bottom of the hood MUST NOT BE LESS than 18”

and at a maximum of 24” above the cooking surface.

• Always follows the cooking equipment manufacturer’s requirements regarding the

ventilation needs.

• To reduce the risk of fire and to properly exhaust air, be sure to duct air outside — Do not

exhaust air into spaces within walls or ceiling or into attics, crawl space or garage.

• When installing, servicing or cleaning the unit, it is recommended to wear safety glasses

and gloves.

• Please read specification label on product for further information and requirements.

Page 5

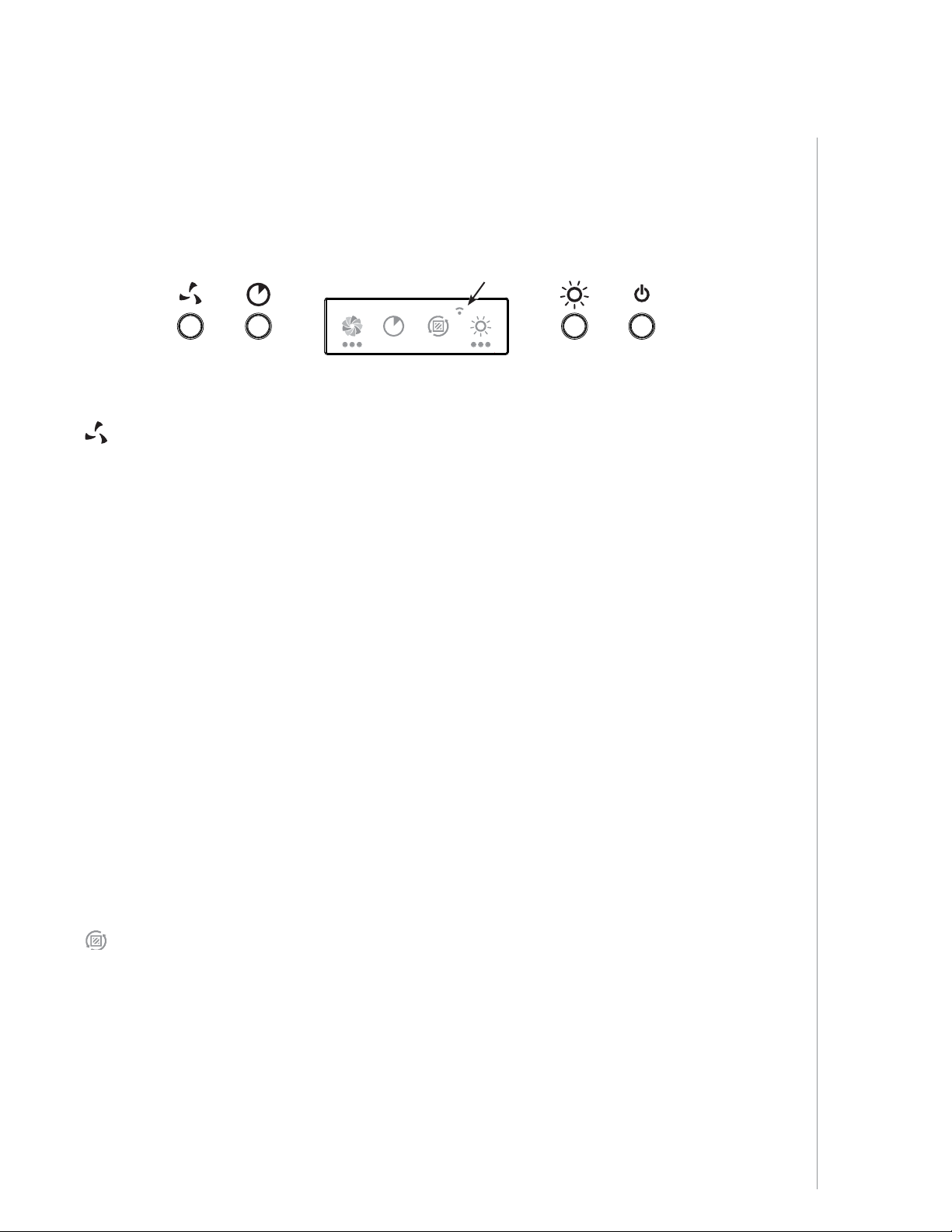

Operation

Always turn your hood on before you begin cooking to establish an air flow in the kitchen.

Let the blower run for a few minutes to clear the air after you turn off the range. This will help

keep the whole kitchen cleaner and fresher.

Operate the hood as follows:

1

NOTE: At range hood start-up or after a power failure, a small icon (1) appears shortly

(for ± 2 seconds) on LCD screen; this is normal.

BLOWER ACTIVATION/SPEED LEVEL CHANGE/FILTER INDICATOR RESET

When blowers are OFF, press on this push button to turn ON the blowers at the last saved speed.

If there was no speed saved, the blowers will be set on LOW speed.

NOTE: When LOW speed is activated from OFF, the blowers start on MEDIUM speed for a very

short lapse of time, and then resume to LOW speed.

To change the blower speed, press this button again until the desired speed is reached (from LOW

to MEDIUM to HIGH speed to OFF). Each time a blower speed is activated, a rotating blower

icon appears on left side of LCD screen, with dot(s) under it (slow for LOW with one dot, faster for

MEDIUM with 2 dots and fastest for HIGH with 3 dots).

When blowers are on (no matter the speed level), press and hold this button until the blower icon

disappears from the LCD screen; this will turn off the blowers and save the blower speed chosen.

Heat Sentry™

This hood is equipped with a protective device that activates the blowers when an abnormally high

heat level is detected while the blowers are activated. During the Heat Sentry activation, this device

takes control of the blowers and sets them on MEDIUM speed while all dots under the blower icon

blink. However, the lights can be still controlled. The blowers will remain on MEDIUM speed until

the heat is back to normal, they then return to the speed previously selected.

NOTE: When excessive heat is detected, Heat Sentry will shut off both blowers and lights while all

dots under the blower icon will blink faster. Both blowers and lights will remain off until the

ambient temperature cools down; the blowers will then start on MEDIUM speed (the lights

can be controlled again). The blowers will remain on MEDIUM speed until the heat is back

to normal, they then return to the speed previously selected.

FILTER CLEANING REMINDER

This icon appears on LCD screen 30 seconds after turning OFF the blowers when it is time to

clean hood and filters (refer to Cleaning and Maintenance on page 7). This happens every time

the blowers are turned OFF until the filter cleaning reminder has been reset. Once the cleaning is

done, reset the filter cleaning reminder by pressing on blower activation push button for 3 seconds

while the icon appears on LCD screen for 30 seconds.

OPERATION

INSTALLATION MANUAL

5

Page 6

DELAY OFF

When the blowers are on, press this button to activate the delay function. This icon appears on LCD

screen beside the blower icon to indicate the function is on. The blowers will continue to operate for

10 minutes and then, will shut off automatically (both blower and delay icons will disappear from

LCD screen). When Delay off is activated, it is possible to change the blower speed by pressing on

blower push button without affecting the remaining time of the delay.

To cancel the delay off function before the end of the 10-minute cycle, press this button again.

ON LIGHTING/LIGHT INTENSITY CHANGE

Press this button to turn on the lights at the last saved intensity; the light icon appears on right side

of LCD screen and the number of dots below it shows which light intensity is on (one dot for LOW,

two dots for MEDIUM and three dots for HIGH).

To change the light intensity, press button until the desired level is reached (from HIGH intensity,

pressing again will shut off the lights).

When lights are on (no matter the light intensity), press and hold this button until the light icon

disappears from the LCD screen; this will shut off the lights and save the chosen light intensity.

MASTER ON/OFF

Press this button to turn on the ligths and the blowers at the last saved intensity. When either lights

or blowers are ON, pressing this button will memorize the current blower speed and lighting level

prior to shut them OFF.

INSTALLATION MANUAL

OPERATION

6

Page 7

Cleaning and Maintenance

Proper maintenance of the Range Hood will assure proper performance of the unit.

MOTORS

The motors are permanently lubricated and never need oiling. If the motor bearings make

excessive or unusual noise, replace the motor with the exact service motor. The fan wheel should

also be replaced.

GREASE FILTERS

The grease filters should be cleaned frequently. Use a warm dishwashing detergent solution.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the

filters may occur if using phosphate detergents, or as a result of local water conditions - but this

will not affect filter performance. This discoloration is not covered by the warranty. To minimize or

prevent discoloration, hand wash filters using a mild detergent.

NON-DUCTED RECIRCULATION FILTERS

The non-ducted recirculation filters should be changed every 3 to 6 months. Replace more often

if your cooking style generates extra grease, such as frying and wok cooking. Refer to installation

instructions included with non-ducted recirculation filters.

FAN WHEELS

The center of the fan wheels should be cleaned frequently. Use a clean cloth soaked with warm

detergent solution.

CLEANING AND MAINTENANCE

STAINLESS STEEL CLEANING

Do:

• Regularly wash with clean cloth or rag soaked with warm water and mild soap or liquid dish

detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning. Wipe dry completely.

• You may also use a specialized household stainless steel cleaner.

Don’t:

• Use any steel or stainless steel wool or any other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the hood. During construction/

renovation, cover the range hood to make sure no dust sticks to the stainless steel surface.

Avoid when choosing a detergent:

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing: chloride, fl uoride, iodide, bromide will deteriorate surfaces

rapidly.

• Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc.,

are highly explosive and should never be used close to a range.

PAINTED FINISH CLEANING:

Clean with warm water and mild detergent only. If discoloration occurs, use a finish polish such

as automotive polish. (DO NOT use rough abrasive cleaner or porcelain cleaner.)

INSTALLATION MANUAL

7

Page 8

For ADA compliance installation guidelines, please visit www.broan-nutone.com

Recommended Tools and Accessories

for Installation

• Measuring tape

• Phillips screwdriver no. 2

• Nutdriver or socket 11/32”

• Flat blade screwdriver (to open knockout holes)

• Drill, 1/8” drill bit and 1½” hole saw (to mark holes for ducting and cut electrical access hole)

• 7/64” drill bit (to drill holes for EZ1 brackets mounting screws)

• Wood shims (2) and wood screws (4) (required for standard installation to framed cabinet)

• Saw (to cut holes for ducted application)

• Sheet metal shears (ducted installation only, for duct adjustment)

• Pliers (ducted installation only, for duct adjustment)

• Metal foil duct tape (for ducted applications)

• Scissors (to cut metal foil duct tape)

• Pencil

• Wire stripper

• Strain relief, 1/2” diameter (to secure house wiring cable to the hood)

INSTALLATION MANUAL

INSTALLATION

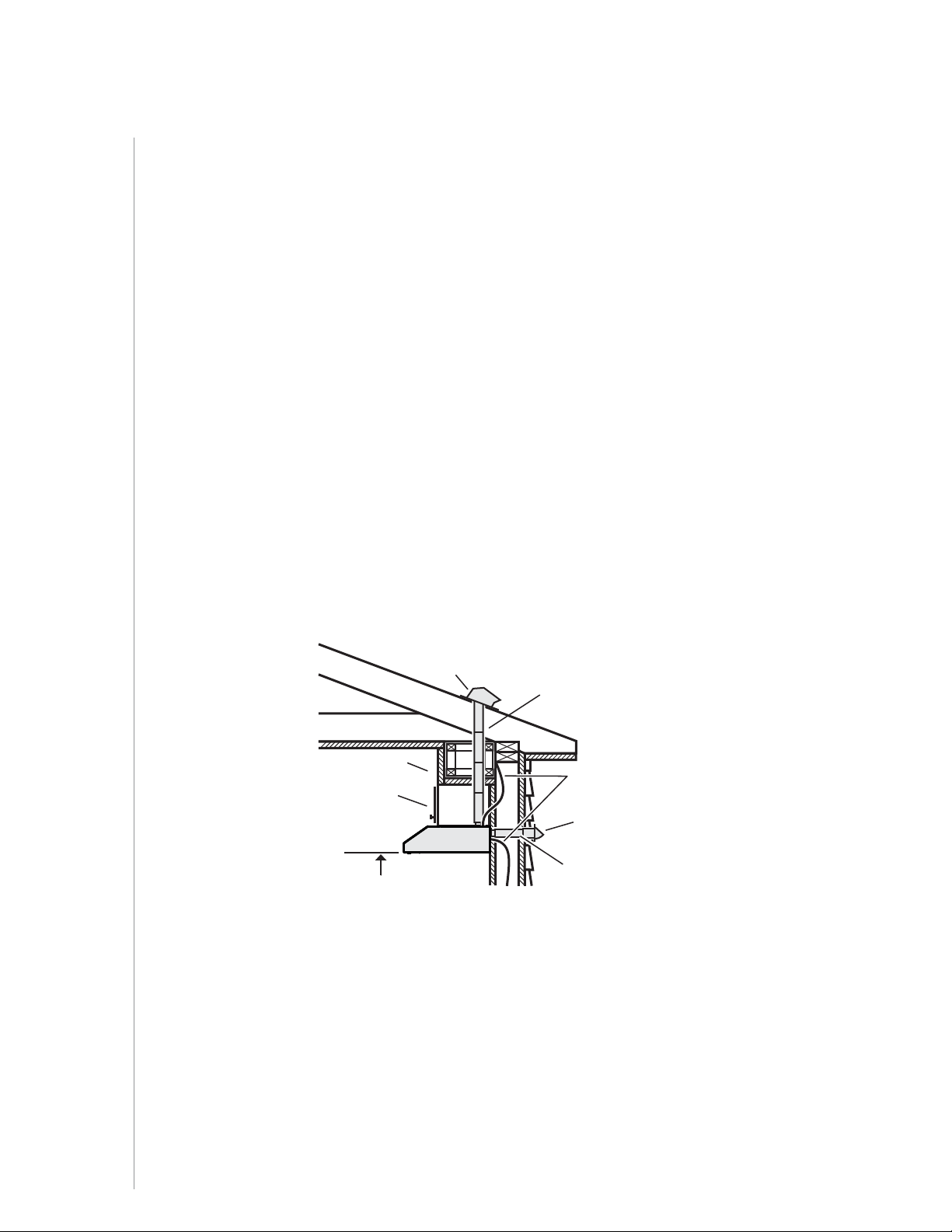

Install Ductwork (Ducted Installations Only)

ROOF CAP

SOFFIT

CABINET

HOOD

18" MIN - 24" MAX

ABOVE

COOKING SURFACE

NOTE: Distances over 24” are at the installer and user discretion.

1 ] Determine whether hood will discharge vertically (3¼” x 10” or 7” round),

or horizontally (3¼” x 10” only).

2 ] Decide where the ductwork will run between the hood and the outdoors.

3 ] Choose a straight, short duct run to allow the hood to perform most efficiently. Long duct

runs, elbows and transitions will reduce the performance of the hood. Use as few of them as

possible. When possible, use at least 2 foot straight runs before any turns. Larger ductwork

may be required for best performance with longer duct runs.

4 ] Install wall cap or roof cap (sold separately); ensure there is no leak in house insulation.

Connect metal ductwork to cap and work back towards the hood location. Use 2” metal foil

duct tape to seal the joints between ductwork sections.

3¼" X 10" OR

7" ROUND DUCT

(FOR VERTICAL

DISCHARGE

HOUSE WIRING

(TOP OR BACK OF HOOD)

3¼" X 10" DUCT

(FOR HORIZONTAL DISCHARGE)

)

WALL CAP

8

Page 9

Contents

VERTICAL EXHAUST

VERTICAL EXHAUST

Before proceeding to the installation, check the contents of the box. If items are missing or

damaged, contact the manufacturer.

Make sure that the following items are included:

BKDJ1 Series BKDN1 and NKDN1 Series

(2) GREASE FILTERS

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

L

7½”

10½”

14½”

C

Appuyer ce bord au mur arrière

** FIND EZ1 BRACKETS ATTACHED INSIDE OF HOOD

(1) PARTS BAG*** CONTAINING:

(6) N

O. 8 X 5/8”

RD. HD.

W

OOD SCREWS

*** FIND PAR T S BAG INSIDE OF HOOD

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BE TRANSLATED IN SPANISH

Apoyar este borde contra la pared de atrásPlace this edge against back wall

DE

7 PULG.

EZ1 C

RECTANGULAR DUCTING7” ROUND DUCTING

OR

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

4¼”

* FIND INSIDE

HOOD

OF

(1) 3¼” X 10”

AMPER ASSEMBLY*

D

OMPONENTS

= 3¼” x 10”

= 3¼” x 14”

= 3¼ po x 10 po

= 3¼ po x 14 po

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

(1) TEMPLATE FOR DUCTING

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

(PRINTED BOTH SIDES)

(2) INSTALLATION BRACKETS**

FOR FRAMED CABINET

(2) INSTALLATION BRACKETS**

FOR FRAMELESS CABINET

(4) NO. 8-18 X 1/2”

M

(1) 7” R

DUCT CONNECTOR

ETAL SCREWS WITH

(4) WASHERS

(6) NO. 8 X 1/2”

C

OUNTERSUNK

WOOD SCREWS

OUND

(2) GREASE FILTERS

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

L

7½”

10½”

14½”

C

Appuyer ce bord au mur arrière

** FIND EZ1 BRACKETS ATTACHED INSIDE OF HOOD

(1) PARTS BAG*** CONTAINING:

(6) N

O. 8 X 5/8”

RD. HD.

W

OOD SCREWS

*** FIND PAR T S BAG INSIDE OF HOOD

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BE TRANSLATED IN SPANISH

Apoyar este borde contra la pared de atrásPlace this edge against back wall

DE

7 PULG.

D

EZ1 C

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

4¼”

AB

* FIND INSIDE

HOOD

OF

(1) 3¼” X 10”

AMPER ASSEMBLY*

OMPONENTS

(1) TEMPLATE FOR DUCTING

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

C

(PRINTED BOTH SIDES)

(2) INSTALLATION BRACKETS**

FOR FRAMED CABINET

(2) INSTALLATION BRACKETS**

FOR FRAMELESS CABINET

(4) NO. 8-18 X 1/2”

ETAL SCREWS WITH

M

(4) WASHERS

OUND

(1) 7” R

DUCT CONNECTOR

(6) NO. 8 X 1/2”

C

OUNTERSUNK

WOOD SCREWS

INSTALLATION

INSTALLATION MANUAL

9

Page 10

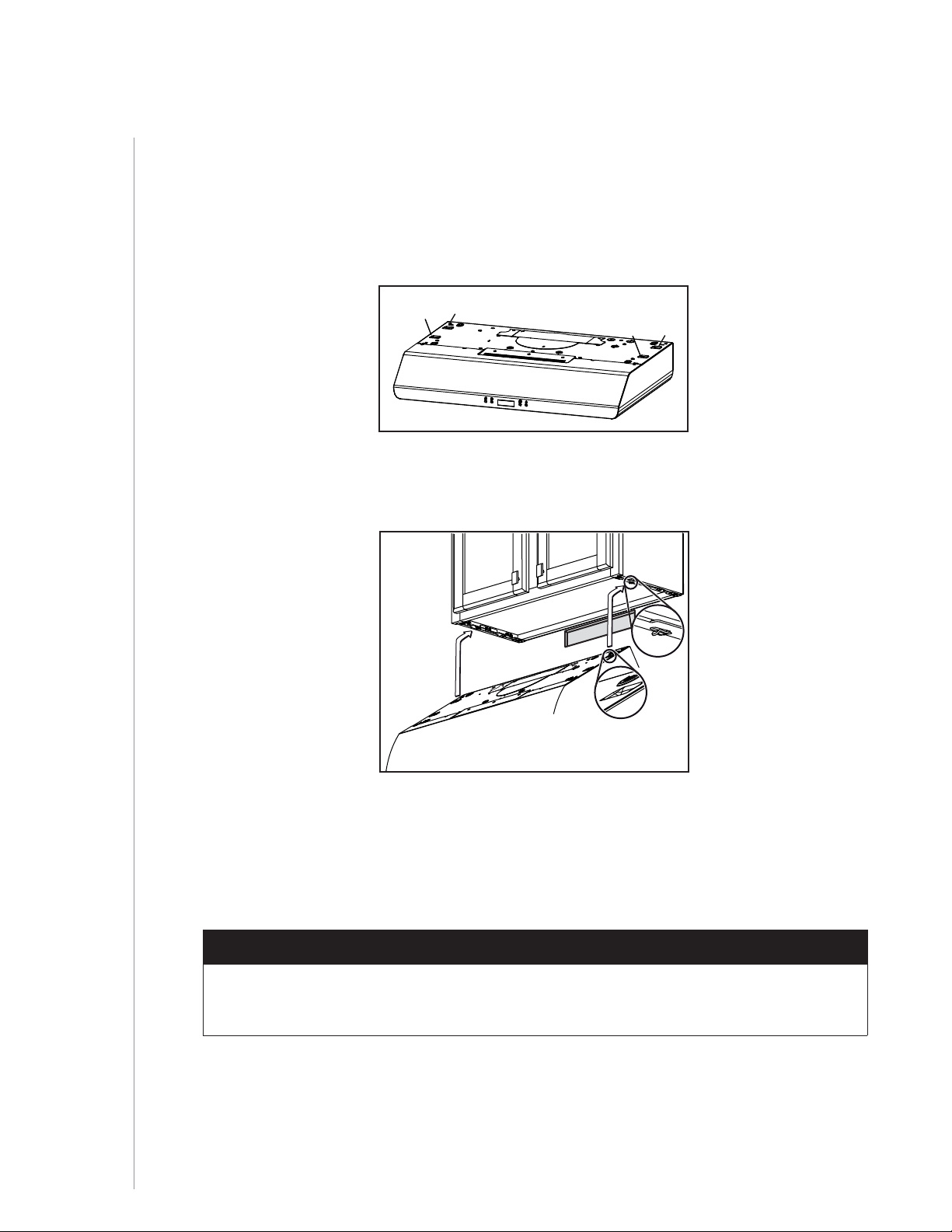

Prepare the Hood

1 ] If present, remove all protective polyfilm from the hood and/or parts.

2 ] Remove 7” Round Duct Plate from top/back of hood (see illustration below). Keep the screws

for further use.

7” ROUND

DUCT

PLATE

2 SCREWS

3 ] Using the finger cup, remove the grease filters from the hood by pushing down and tilting

filters out .

B

C

4 ] Using a 11/32” nutdriver or socket, remove the lock nut retaining the flange of the right cover

plate (shaded part on illustration below) to the inner back of hood (see inset). Remove the

right cover plate retaining screws (7 screws), then set the blower cover along with its screws

and nut aside.

6

7

BACK OF HOOD

B

C

45

3

2

1

INSTALLATION MANUAL

10

LOCK NUT

INSTALLATION

Page 11

5 ] Remove the damper assembly, taped over the EZ1 brackets, and the parts bag, taped on the

inner back of hood, near the left corner.

PARTS BAG LOCATION

NOTE: The damper assembly has to be slightly bent to fit inside the range hood. Once removed,

bend it back to ensure its opening is rectangular (4 corners at 90°).

6 ] Remove the EZ1 brackets from inside the hood by cutting off the tie wrap. Discard the tie

wrap.

7 ] Remove Electrical Power Cable Knockout from top (vertical exhaust) or back (horizontal

exhaust) of hood. For knockout removed from back of hood, install an appropriate strain

relief, 1/2” diameter (not included). For knockout removed from top of hood, the strain relief

will be installed later.

DAMPER ASSEMBLY

EZ1

BRACKETS

ELECTRICAL

POWER CABLE

KNOCKOUT

NON-DUCTED INSTALLATION ONLY

8 ] Remove 3 screws retaining the recirculation cover plate to the hood. Discard this plate with

its screws.

9 ] Peel off and discard the membrane covering the recirculation grille, ensuring the openings

are totally cleared.

RECIRCULATION

COVER PLATE

SCREWS

INSTALLATION

INSTALLATION MANUAL

11

Page 12

DUCTED INSTALLATION ONLY

8 ] Remove 3¼” x 10” vertical, 3¼” x 10” horizontal (both are the rectangular central

knockout plates, see hatched areas) or 7-inch round knockout plate as appropriate for

your ducting method (see FIGURES 1 A and 1 B).

FIGURE 1 A

7” ROUND KNOCKOUT

PLATE (ALSO REMOVE

3¼” X 10” VERTICAL

KNOCKOUT PLATE)

3¼” X 10”

VERTICAL

KNOCKOUT

PLATE

3¼” X 10”

HORIZONTAL

KNOCKOUT

PLATE

9 ] Attach 3¼” x 10” Damper Assembly on top OR back of hood (if using 3¼” x 10” duct; shaded

part in FIGURE 2 A below) or 7” Round Duct Plate (if using 7-inch round duct, FIGURE 3) over

the knockout opening. When installed, the 3¼” x 10” damper assembly must open as shown

in FIGURE 2 B.

FIGURE 2 A FIGURE 2 B

3¼” X 10”

DAMPER

ASSEMBLY

SCREWS

FIGURE 1 B

TOP/BACK

EDGE OF

HOOD

DAMPER

FLAP

PIVOT

INSTALLATION MANUAL

INSTALLATION

SCREWS

3¼” X 10”

DAMPER

ASSEMBLY

FIGURE 3

SCREWS

BACK OF

HOOD

DAMPER

FLAP

PIVOT

7” ROUND

DUCT

PLATE

NOTE: To accommodate off-center ductwork, the 7” round duct plate can be installed up

to 1/2” on either side of the hood center.

TIP: Insert a small length of duct over the 3¼” x 10” damper assembly (for rectangular ducting) or

7” round (for round ducting) and seal the joint using aluminum foil duct tape to ease connection

with the house ductwork.

12

Page 13

Prepare the Hood Location

VERTICAL EXHAUST

VERTICAL EXHAUST

This manual covers 2 kinds of installation: the standard (without EZ1 brackets) and the

EZ1one-person installation system (using included template and brackets).

For the standard installation, go to page 18.

EZ1 one-person installation system

EZ1 installation is designed for use with kitchen cabinets that have the same width designation as

the range hood width. If the cabinet is greater than 1/2” wider than the range hood width, please

use the standard installation method.

1 ] Use the proper template for vertical OR horizontal discharge (included) for the placement of

ductwork and electrical cutouts in cabinet or wall. For a non-ducted installation, DO NOT cut a

duct access hole, only cut the hole for electrical wiring. If replacing a hood and plan to use

the existing duct and electrical, steps 2 to 5 may not be necessary. If so, skip to step 6.

2 ] Measure and mark the hood center line on cabinet bottom.

3 ] Align the center line on template with the hood center line marked on the bottom of the

cabinet, placing the edge (where indicated) of the template against the back wall. When

using with framed cabinet for vertical exhaust installation, fold over rear edge of template

equal to the depth of the cabinet frame at the wall (use graduations on template, C locations

on template). Tape the template in place.

NOTE: When facing the installation, A and B (on template) must be at right.

CABINET FRONT

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

14½”

C

C

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

7 PULG.

C

L

7½”

10½”

Appuyer ce bord au mur arrière

DE

= 3¼ pulg. x 14 pulg.

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

4¼”

A = single blower hood

B = double blower hood

AB

Apoyar este borde contra la pared de atrásPlace this edge against back wall

C

BEND TEMPLATE ALONG GRADUATED

WHEN INSTALLING TO FRAMED

SCALE

P

CABINET

.

CENTER LINE

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Place this edge against

cabinet bottom.

Appuyer ce bord contre le bas

de l’armoire.

Apoyar este borde contra

la base del armario.

CABINET FRONT

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

conséquence.

To be translated in Spanish.

C

CENTER LINE

HORIZONTAL EXHAUST

DUCTING

AB

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRE

= 3¼ po x 10 po

= 3¼ po x 14 po

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

ELECTRICAL

ACCESS HOLE

LOCATION (B)

C

L

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING

= 3¼” x 10”

= 3¼” x 14”

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULAR

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

8”

ess hole center

wer hood

wer hood

(

IN WALL )

C

L

7½”

10½”

14½”

ELECTRICAL

ACCESS HOLE

LOCATION (B)

IN CABINET BOTTOM)

(

B

VERTICAL EXHAUST

DUCTING

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

7 PULG.

DE

= 3¼ pulg. x 14 pulg.

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

4¼”

A = single blower hood

B = double blower hood

AB

C

B

INSTALLATION

INSTALLATION MANUAL

4 ] Drill a 1/8” dia. pilot hole for house wiring, at B location on template. Use a sharp pencil or 1/8”

drill bit to mark the locations for the appropriate duct access holes (16 locations for 7” round

duct, or 4 corner locations for rectangular duct). Remove the template.

5 ] Draw the border for the exhaust ducting by linking its marks (16 for round duct and 4 for

rectangular duct), then cut the opening in the cabinet bottom (vertical exhaust) or in the wall

(horizontal exhaust). Drill the house wiring hole by using a 1½” hole saw centered with the

pilot hole previously made in 4.

13

Page 14

6 ] Install the proper installation brackets according to the type of cabinet (framed or frameless).

See below.

FRAMED CABINET

Refer to the marking on brackets to determine the correct installation side and orientation.

INSTALLATION MANUAL

INSTALLATION

7/64”

Mate the corresponding bracket to the cabinet side frame, while placing rear end

of bracket against the wall. Use a pencil to mark 3 holes (there are 6 holes but only

3 are necessary).

Remove the bracket. Using a 7/64” drill bit, drill 3 holes where marked.

Assemble the bracket to the side frame using a Phillips screwdriver and 3 provided

no. 8 x 5/8” wood screws. Repeat for the other side frame.

14

Page 15

FRAMELESS CABINET

Refer to the marking on brackets to determine the correct installation side and orientation.

3 X

7/64”

Align the corresponding bracket to the cabinet side, while placing rear end of bracket

against the wall. Draw a line on the outer edge of the bracket (as shown).

Slide the bracket towards the center of cabinet and align side edge to marked line,

keeping the rear end edge leaning on the wall.

Use a pencil to mark 3 holes.

INSTALLATION

INSTALLATION MANUAL

Remove the bracket. Using a 7/64” drill bit, drill 3 holes where marked.

Assemble the bracket to the cabinet bottom using a Phillips screwdriver and 3 provided

countersunk wood screws. Repeat for the other cabinet side.

15

Page 16

Install the Hood (EZ1 Bracket)

OTE: N The following procedure applies to both framed or frameless cabinet installations.

1 ] Run the house power cable between service panel and hood location.

2 ] There are 2 pairs of recessed holes on each side of the top of the hood (on rear: A and B,

on front C and D on illustration below); these holes allow the range hood to hang on the

brackets (previously installed).

A

C

HORIZONTAL EXHAUST INSTALLATION

3 ] Temporarily hang the hood on the brackets using its 2 recessed REAR HOLES (A and B).

While holding the hood, run the house power cable into the hood through the strain relief

previously installed in step7 on page11.

B

D

INSTALLATION MANUAL

INSTALLATION

A

4 ] Unhook the rear holes from the brackets and hang the hood using its 2 recessed FRONT

HOLES (C and D). Attach power cable to the hood using the strain relief.

VERTICAL EXHAUST INSTALLATION

5 ] Hang the hood on the brackets using the 2 recessed FRONT HOLES (C and D). Tighten an

appropriate strain relief, 1/2” diameter (not included) to the power cable, then insert the strain

relief in the knockout hole and secure power cable to the hood.

B

DUCTED INSTALLATION ONLY

6 ] Connect ductwork to the hood and use metal foil duct tape to make joints secure and

airtight. Make sure the damper assembly (or round duct plate) enters the ductwork and

that the damper opens and closes freely.

16

Page 17

7 ] For framed cabinet, secure the hood to the EZ1 brackets using 4 no. 8-18 x 1/2” metal screws

with washers. For frameless cabinet, secure the hood to the cabinet using 4no.8x5/8” round

head wood screws (screws and washers included in parts bag). Insert2 screws and washers

per side in the slots (as shown in insets on illustration below).

FRAMED

CABINET

FRAMELESS

CABINET

INSTALLATION

INSTALLATION MANUAL

17

Page 18

Standard Installation (without EZ1 brackets)

VERTICAL DUCT

ACCESS HOLE

5¼"

5¼"

CENTER LINE

ELECTRICAL ACCESS

HOLE (

IN CABINET BOTTOM)

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

CABINET FRONT

3/4"

1⅜"

1½"

9¾"

47/16"

CABINET

BOTTOM

REAR HOOD MOUNTING SCREWS (2)

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

CABINET

BOTTOM

CABINET FRONT

HORIZONTAL DUCT

ACCESS HOLE

REAR HOOD

MOUNTING

SCREWS (2)

ELECTRICAL

ACCESS HOLE

(

IN WALL)

3⅞"

CENTER

LINE

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

13/16"

3/16"

5¼"

5¼"

9¾"

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

7-IN. ROUND

DUCT

ACCESS

HOLE

1 ] Use the proper diagram below for placement of ductwork and electrical cutout in cabinet

or wall. For a non-ducted installation, DO NOT cut a duct access hole, only cut the hole for

electrical wiring.

3¼" X 10"

VERTICAL DUCTING

3¼" X 10"

HORIZONTAL DUCTING

INSTALLATION MANUAL

18

INSTALLATION

2 ] Install part-way 2 ROUND HEAD no. 8 x 5/8” mounting screws into shims/cabinet, according

7-IN. ROUND

VERTICAL DUCTING

1⅜"

1½"

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

4¹¹/16"

CENTER LINE

7-IN. ROUND

7-IN. ROUND

DUCT

DUCT

ACCESS

ACCESS

HOLE

HOLE

9¾"

8" DIA.

HOLE

ELECTRICAL ACCESS

IN CABINET BOTTOM)

HOLE (

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

12⅞" (30"

15⅞" (36"

HOOD)

HOOD)

REAR HOOD MOUNTING SCREWS (2)

to the proper diagram above, the other 2 ROUND HEAD no. 8 x 5/8” mounting screws will be

used later. Mounting screws are included in parts bag, but wood shims and shim mounting

screws are not.

Page 19

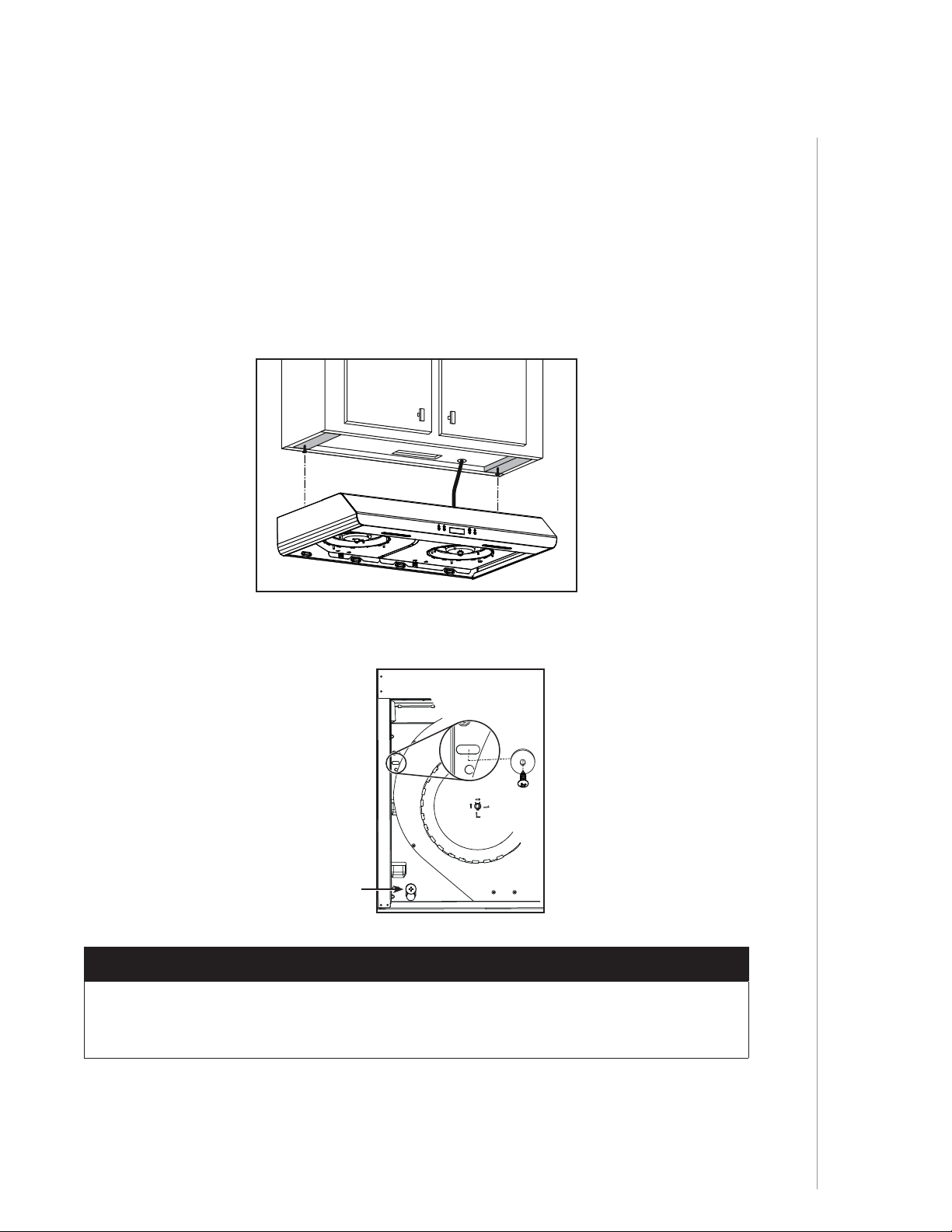

Install the Hood (Standard Installation)

OTE: N Two installers are recommended because of the weight of this hood.

1 ] Run house power cable between service panel and hood location. For hood with power

cable access located on back of hood, run the house power cable into the hood through

the strain relief previously installed in step 7 on page 11. For hood with power cable access

located on top, tighten the strain relief to the power cable before inserting the strain relief in

the knockout hole.

2 ] Hang hood from 2 rear mounting screws previously installed. Slide hood back towards wall

until mounting screw heads are engaged in narrow end of keyhole slots in top of hood.

Tighten screws securely and maintain a hold on the hood until completing step 3.

3 ] Secure the hood to the cabinet using 2 no. 8 x 5/8” round head wood screws and 2 washers

(screws and washers included in parts bag). Insert 1 screw and washer per side, in the slots

(as shown below). Attach power cable to the hood using the strain relief.

Screw previously

tightened in step 2.

BACK OF HOOD

DUCTED INSTALLATION ONLY

4 ] Connect ductwork to hood and use metal foil duct tape to make joints secure and airtight.

Make sure that the damper assembly (or round duct plate) enters the ductwork and that

the damper opens and closes freely.

INSTALLATION

INSTALLATION MANUAL

19

Page 20

Connect the Wiring

!

WARNING

Risk of electric shock. Electrical wiring must be done by qualifi ed

personnel in accordance with all applicable codes and standards.

Before connecting wires, switch power off at service panel and lock

service disconnecting means to prevent power from being switched

on accidentally.

MOTORS

GROUND

WIRE

GROUND

SCREW

HOUSE

POWER CABLE

1 ] Connect House Power Cable to range hood wiring: BLACK to BLACK, WHITE to WHITE and

GREEN or bare wire under GREEN ground screw.

45

3

6

1

7

BACK OF HOOD

1

LOCK NUT

2 ] Reinstall the blower cover plate (shaded part on illustration above) using the lock nut

and7screws previously removed in step 4 on page 10. Pay attention to screw 1 location;

from back of hood point of view, it must be located on left side of the lock nut (see inset).

2

Install the Filters

Ducted Installation Only:

Re-install grease filters removed in step 3 , page 10, under “Prepare the Hood”.

INSTALLATION MANUAL

20

INSTALLATION

Non-ducted Installation Only:

Purchase 2 non-ducted filters from your local distributor or retailer (see product specification label

for filter type). Attach the non-ducted filters following instructions packed with the non-ducted filters.

Page 21

BK

BK

BK

BK

PINK

PURPLE

RED

WHITE

YELLOW

PNPPRWY

COLOR CODE

BLACK

BLUE

BROWN

BROWN/STRIPE

GREEN/YELLOW

BKBLBN

BN/S

G/Y

LED

W

ORANGE

O

LED

O 120

BK

BL 88

PP 60

12345

12345

Y 10

PN 45

BN

W

O

R

BK

G/Y

FAN MOTOR

12345

6

PP

W

W

W

W

BN/S

G/Y

BK

PP

BN

FAN MOTOR

BN/S

W

O

R

BK

G/Y

12345

6

G/Y

W

W

R

R

BK

R

5

4

3

2

1

12

34 5

J6

6

Override

J8

1

2

J4

LED

3

4

BL

BL

12345

Transformer

J1

LCD INTERFACE

PP

R (Low)

O (Medium)

12345

J2

BK (High)

W

6

7

Power, Motor

Fuse 5 A

G/Y

BK

BK

WIRING DIAGRAM

W

Control Board

BK

Line

Neutral

Ground

120 V AC

INSTALLATION MANUAL

21

Page 22

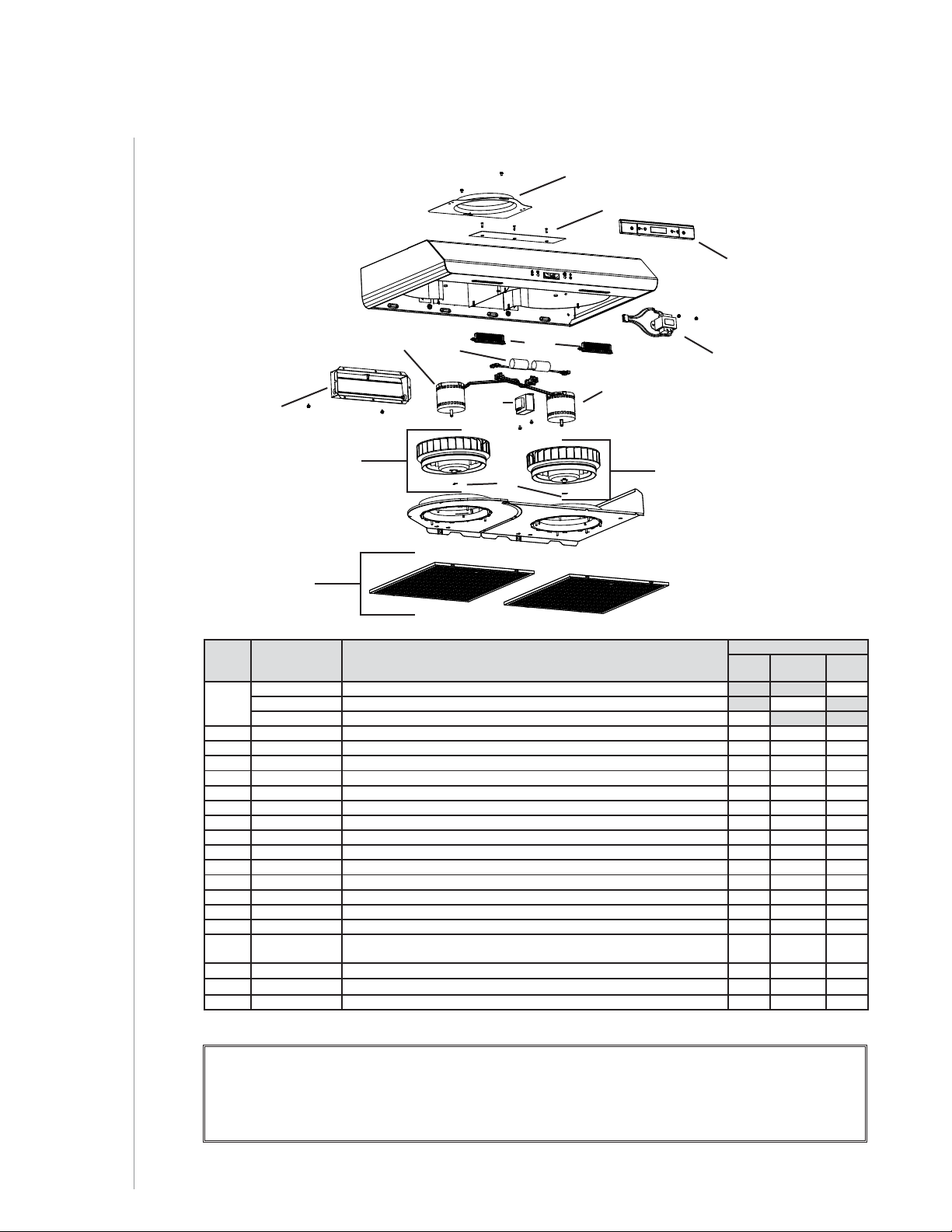

BKDJ1 SERIES

O

M

L

KEY NO.PART NO.DESCRIPTION

S97020030 R

S97020031 R

1

S97020029 R

2 S97018567 7'' R

3 S97020534 3¼”

4 S97020412 C

5 S97020410 B

6 S97020411 B

7 SR99420635 C

8 S99010431-002 G

9 S97020414 B

10 S97020413 B

11 S97020797 A

12 S97020444 LED

13 S97020445 T

14 S97020453 LCD C

* S97020796 W

* S97020360

* S97020466 N

* S99527587 N

* S97020470 E

* ITEM NOT SHOWN.

ECIRCULATION COVER PLATE, WHITE (INCLUDING SCREWS)1

ECIRCULATION COVER PLATE, STAINLESS STEEL (INCLUDING SCREWS)1

ECIRCULATION COVER PLATE, BLACK (INCLUDING SCREWS)1

OUND DUCT PLATE (INCLUDING SCREWS) 111

X 10” DAMPER ASSEMBLY (INCLUDING SCREWS) 111

APACITOR (INCLUDING TIE WRAP) 222

LOWER MOTOR CW (INCLUDING HARDWARE) 111

LOWER WHEEL CW (INCLUDING ITEM 7) 1 1 1

LIP FOR FANPELLER 222

REASE FILTER - MICRO MESH-OBLONG -TYPE C3 (SET OF 2) 1 1 1

LOWER WHEEL CCW (INCLUDING ITEM 7) 111

LOWER MOTOR CCW (INCLUDING HARWARE) 111

UTOTRANSFORMER (WITH SCREWS) 111

MODULES (PAIR) 111

RANSFORMER 24 V 18 VA (WITH SCREWS) 111

ONTROL 111

IRE HARNESS WITH AUTOTRANSFORMER AND FUSE 111

P

ARTS BAG INCLUDING: 4 METAL SCREWS NO. 8-18 X 1/2”, 4 WASHERS, 6 ROUND

HEAD NO. 8 X 5/8” WOOD SCREWS, 6 NO. 8 X 1/2” COUNTERSUNK WOOD SCREWS

ON-DUCTED FILTER - TYPE XC (SET OF 2) (NON-DUCTED INSTALLATION ONLY) 111

ON-DUCTED FILTER CLIP KIT (INCLUDES 4 CLIPS) 111

ASY INSTALL KIT (INCLUDING HARDWARE) 111

N

QUANTITY

B

30"

LACK

30"

S

TAINLESS

111

W

30"

HITE

INSTALLATION MANUAL

22

SERVICE PARTS

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Broan-NuTone Canada ULC genuine replacement parts

only. Broan-NuTone Canada ULC genuine replacement parts are specially designed for each unit and are manufactured to comply with

all the applicable certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious

damage and drastically reduce the performance level of your unit, which will result in premature failing. Broan-NuTone Canada ULC

recommends to contact a certified service depot for all replacement parts and repairs.

Page 23

BKDN1 AND NKDN1 SERIES

O

M

L

KEY NO.PART NO.DESCRIPTION

S97020030 R

1

S97020031 R

2 S97018567 7'' R

3 S97020534 3¼”

4 S97020412 C

5 S97020410 B

6 S97020411 B

7 SR99420635 C

S97020204-002 G

8

S97020204-003 G

9 S97020414 B

10 S97020413 B

11 S97020797 A

12 S97020444 LED

13 S97020445 T

14 S97020453 LCD C

* S97020796 W

* S97020360

* S97020466

* S99527587 N

* S97020470 E

* ITEM NOT SHOWN.

ECIRCULATION COVER PLATE, WHITE (INCLUDING SCREWS)11

ECIRCULATION COVER PLATE, STAINLESS STEEL (INCLUDING SCREWS)1 1

OUND DUCT PLATE (INCLUDING SCREWS)1111

X 10” DAMPER ASSEMBLY (INCLUDING SCREWS)1111

APACITOR (INCLUDING TIE WRAP)2222

LOWER MOTOR CW (INCLUDING HARDWARE)1111

LOWER WHEEL CW (INCLUDING ITEM 7) 1 1 1 1

LIP FOR FANPELLER 2222

REASE FILTER - HYBRID -TYPE C5 (SET OF 2) 1 1

REASE FILTER - HYBRID -TYPE C5 (SET OF 2) 1 1

LOWER WHEEL CCW (INCLUDING ITEM 7) 1111

LOWER MOTOR CCW (INCLUDING HARWARE)1111

UTOTRANSFORMER (WITH SCREWS)1111

MODULES (PAIR)1111

RANSFORMER 24 V 18 VA (WITH SCREWS)1111

ONTROL 1111

IRE HARNESS WITH AUTOTRANSFORMER AND FUSE 1111

ARTS BAG INCLUDING: 4 METAL SCREWS NO. 8-18 X 1/2”,

P

4W

ASHERS, 6 ROUND HEAD NO. 8 X 5/8” WOOD SCREWS,

NO. 8 X 1/2” COUNTERSUNK WOOD SCREWS

6

ON-DUCTED FILTER - TYPE XC (SET OF 2)

N

NON-DUCTED INSTALLATION ONLY)

(

ON-DUCTED FILTER CLIP KIT (INCLUDES 4 CLIPS)1111

ASY INSTALL KIT (INCLUDING HARDWARE)1111

N

30"

S

TAINLESS

1111

1111

QUANTITY

36"

S

TAINLESS

W

30"

HITE

W

36"

HITE

SERVICE PARTS

INSTALLATION MANUAL

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Broan-NuTone Canada ULC genuine replacement parts

only. Broan-NuTone Canada ULC genuine replacement parts are specially designed for each unit and are manufactured to comply with

all the applicable certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious

damage and drastically reduce the performance level of your unit, which will result in premature failing. Broan-NuTone Canada ULC

recommends to contact a certified service depot for all replacement parts and repairs.

23

Page 24

INSTALLATION MANUAL

24

Warranty Period and Exclusions: Broan-NuTone Canada ULC (the “Company”) warrants to the original consumer

purchaser of its product (“you”) that the product (the “Product”) will be free from material defects in the Product or its

workmanship for a period of one (1) year from the date of original purchase (or such longer period as may be required by

applicable law). For Range Hood Product that includes built-in LED modules, the Company warrants the LED modules and

driver to be free from material defects for a period of three (3) years from the date of purchase. The limited warranty period

for any replacement parts provided by the Company and for any Products repaired or replaced under this limited warranty

shall be the remainder of the original warranty period (or such longer period as may be required by applicable law).

This warranty does not cover fluorescent lamp starters, tubes, halogen and incandescent bulbs, fuses, filters, ducts, roof

caps, wall caps and other accessories for ducting that may be purchased separately and installed with the Product. This

warranty also does not cover (a) normal maintenance and service, (b) normal wear and tear, (c) any Products or parts

which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper or insufficient maintenance,

storage or repair (other than repair by the Company), (d) damage caused by faulty installation, or installation or use contrary

to recommendations or instructions, (e) any Product that has been moved from its original point of installation, (f) damage

caused by environmental or natural elements, (g) damage in transit, (h) natural wear of finish, (i) Products in commercial or

nonresidential use, or (j) damage caused by fire, flood or other act of God or (k) Products with altered, defaced or removed

serial numbers. This warranty covers only Products sold to original consumers in Canada by the Company or its Canadian

distributors authorized by the Company.

This warranty supersedes all prior warranties and, subject to applicable law, is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective

products. The foregoing warranties are exclusive and in lieu of any other warranties and conditions, express or implied. THE

COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES AND CONDITIONS, AND DISCLAIMS

AND EXCLUDES ALL WARRANTIES AND CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent that applicable law

prohibits the exclusion of implied warranties or conditions, the duration of any applicable implied warranty or condition is

limited to the period specified for the express warranty above. Some jurisdictions do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you. Any oral or written description of the Product is for the

sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid

under applicable law, but if any provision is held to be prohibited or invalid, such provision shall be ineffective only to the

extent of such prohibition or invalidity, without invalidating the remainder of such provision or the other remaining provisions

of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or

repair or replace, without charge, any Product or part thereof, to the extent the Company finds it to be covered by and in

breach of this limited warranty under normal use and service. The Company will ship the repaired or replaced Product or

replacement parts to you at no charge. You are responsible for all costs for removal, reinstallation and shipping, insurance or

other freight charges incurred in the shipment of the Product or part to the Company. If you must send the Product or part to

the Company, as instructed by the Company, you must properly pack the Product or part—the Company is not responsible

for damage in transit. The Company reserves the right to utilize reconditioned, refurbished, repaired or remanufactured

Products or parts in the warranty repair or replacement process. Such Products and parts will be comparable in function

and performance to an original Product or part and warranted for the remainder of the original warranty period (or such

longer period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually paid by you for the Product in lieu of repair or

replacement. If the Product or component is no longer available, replacement may be made with a similar product of equal

or greater value, at Company’s sole discretion. This is your sole and exclusive remedy for breach of this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR,

REPLACE OR REFUND, AT THE COMPANY’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER

THIS LIMITED WARRANTY AND THE COMPANY’S SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL

NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN

CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE. Incidental damages include but are not limited to

such damages as loss of time and loss of use. Consequential damages include but are not limited to the cost of repairing

or replacing other property which was damaged if the Product does not work properly.

THE COMPANY SHALL NOT BE LIABLE TO YOU, OR TO ANYONE CLAIMING UNDER YOU, FOR ANY OTHER

OBLIGATIONS OR LIABILITIES, INCLUDING, BUT NOT LIMITED TO, OBLIGATIONS OR LIABILITIES ARISING

OUT OF BREACH OF CONTRACT OR WARRANTY, NEGLIGENCE OR OTHER TORT OR ANY THEORY OF STRICT

LIABILITY, WITH RESPECT TO THE PRODUCT OR THE COMPANY’S ACTS OR OMISSIONS OR OTHERWISE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which

vary from jurisdiction to jurisdiction. The disclaimers, exclusions, and limitations of liability under this warranty will not apply

to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and

does not include the cost of field service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty

will not constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product,

except for those incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or

WARRANTY

telephone number stated below within seven (7) days of discovering the covered defect, (b) give the model number and

part identification and (c) describe the nature of any defect in the Product or part. At the time of requesting warranty

service, you must present evidence of the original purchase date. If you cannot provide a copy of the original written limited

warranty, then the terms of the Company’s most current written limited warranty for your particular product will control.

The most current limited written warranties for the Company’s products can be found at www.broan.ca or www.nutone.ca.

Broan-NuTone Canada ULC, 1140 Tristar Drive, Mississauga, Ontario, Canada L5T 1H9

www.broan.ca www.nutone.ca 1-877-896-1119

Limited Warranty

Loading...

Loading...