Page 1

HUMIDITY SENSING RECESSED

FLUORESCENT FAN / LIGHT

READ AND SAVE THESE INSTRUCTIONS

MODEL 744SFL

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch

power off at service panel and lock the service

disconnecting means to prevent power from

being switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag,

to the service panel.

3. Installation work and electrical wiring must be

done by a qualified person(s) in accordance with

all applicable codes and standards, including

fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards

such as those published by the National Fire

Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local

code authorities.

5. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to

the outdoors.

7. Never place a switch where it can be reached

from a tub or shower.

8. Do not use a dimmer switch to operate the light

in this unit.

9. Install this unit in a flat ceiling only.

10. For use in non fire rated installations only.

11. Not for use in environmental air handling spaces.

12. If this unit is to be installed over a tub or shower, it

must be marked as appropriate for the application

and be connected to a GFCI (Ground Fault Circuit

Interrupter) - protected branch circuit.

13. Do not install in a ceiling thermally insulated to a

value greater than R40.

14. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

2. To avoid motor bearing damage and noisy and/

or unbalanced impellers, use the cardboard

protector (provided) to keep drywall spray,

construction dust, etc. off power unit.

3. The fluorescent bulb used with this product

inserts straight into the bulb socket. Do not

attempt to insert or remove bulb by twisting it.

4. Please read specification label on product for

further information and requirements.

!

OPERATION

The light, fan and humidity control can be operated

together or independently using multi-function switch

wall controls.

• Use a 3-function control to independently operate

light, fan and humidity control.

• Use a 2-function control to independently operate

light and humidity control. For fan operation see

MANUAL ON WITH TIMED OFF section below.

• Use a 2-function control to independently operate

light and fan. Wire humidity control direct to insure

humidity control is always on.

See “Connect Wiring” section for various wiring options.

Do not use a dimmer switch control to operate

light, fan or humidity control.

SENSOR OPERATION

This humidity-sensing

moderate humidity increases and (b) humidity above

a 50%-100% relative humidity set-point. (a) and (b)

are set with “SENSITIVITY” adjustment. Fan may

occasionally turn on when environmental conditions

change. If the fan continuously responds to changing

environmental conditions, “SENSITIVITY” adjustment

may be required (see section below).

STATUS INDICATOR

This indicator can only be seen by looking directly at it.

Normal mode is 5-seconds on and off. If it blinks rapidly

for 5-seconds and then off, check sensor connections

on trim ring/baffle and fan housing.

MANUAL ON WITH TIMED OFF

For odor or vapor control, the fan can be energized

by cycling its wall-mounted switch if one is installed.

Once the fan has been turned on in this manner, it will

remain on for the set “TIMER” period.

To manually energize the fan:

1. Go to Step 2 if switch is already on; otherwise,

turn switch on for more than 1 second.

2. Switch off for less than 1 second.

3. Switch back on and fan will turn on.

SENSITIVITY ADJUSTMENT

“SENSITIVITY” has been factory set for most

shower applications. If the fan is in a tub area or is

used for dampness control, the “SENSITIVITY” may

need to be increased toward maximum (“MAX.”).

If the control is responding too often to changing

environmental conditions, adjustment toward less

(“MIN.”) “SENSITIVITY” may be required. To adjust

the “SENSITIVITY”:

1. Turn power off at electrical service panel.

2. Remove bulb.

3. Through trim ring/baffle, locate the “SENSITIVITY”

screwdriver slot.

4. Using a small, flat-blade screwdriver, carefully

rotate “SENSITIVITY” adjustment clockwise

toward “MAX.” or counterclockwise toward “MIN.”

5. Re-install bulb.

6. Turn power on and check operation by turning

on shower or other humidity source until fan

turns on.

7. Repeat above steps if necessary.

fan responds to: (a) rapid to

TIMER ADJUSTMENT

This humidity-sensing fan has a “TIMER”. It is useradjustable from 5 to 60 minutes and is factory-set

at 20 minutes. The “TIMER” controls how long the

fan remains on (a) after rise in humidity and (b)

humidity level are both below the user-adjustable

“SENSITIVITY” setting or after being energized by

cycling power switch.

To adjust the “TIMER”:

1. Disconnect power at electrical service panel.

2. Remove bulb.

3. Through the trim ring/baffle, locate the

“TIMER” screwdriver slot.

4. Using a small, flat-blade screwdriver, carefully

rotate “TIMER” adjustment clockwise

to increase time or counterclockwise to

decrease time.

5. Re-install bulb.

6. Turn power on and check operation by cycling

power switch as instructed under “MANUAL

ON WITH TIMED OFF” or by turning on a

humidity source until fan turns on.

7. Check “TIMER” setting with watch or clock

after turning humidity source off if it was

turned on it Step 6.

8. Repeat above steps if necessary.

CLEANING &

MAINTENANCE

To clean trim ring / baffle: Vacuum with a

soft brush attachment or remove trim ring /

baffle and clean with a soft cloth.

SENSOR CLEANING

The humidity sensor is mounted in the trim

ring/baffle. The sensor will operate most

reliably when cleaned occasionally as follows:

1. Disconnect power at service entrance.

2. Remove the trim ring/baffle. Use a dry

dustcloth, clean toothbrush, or lightly

vacuum to clean sensor and grille.

DO NOT USE ABRASIVE CLOTH,

STEEL WOOL PADS, OR SCOURING

POWDERS.

3. DO NOT USE cleaning sprays, solvents,

or water on or near the sensor!

To clean inside of housing: Remove trim

ring / baffle and vacuum inside of housing

with a soft brush attachment.

Motor is permanently lubricated. Do not oil or

disassemble motor.

See “Service Parts” section for a list and

illustrations of service parts.

Installer: Leave this manual

with the homeowner.

Page 2

PLAN THE INSTALLATION

POWER

MODEL 744SFL

Page 2

INSTALLATION

CABLE

CEILING

JOIST

FINISHED CEILING

4" ROUND

DAMPER/DUCT

CONNECTOR &

4” ROUND

DUCTWORK

TRIM RING / BAFFLE

HOUSING

MOUNTING

BRACKET

Typical Installation

The unit can be installed anywhere between ceiling joists using

mounting brackets provided. Install in a flat ceiling only.

INSULATION

(Can be placed around and

over fan housing.)

ROOF

CAP

*

CARDBOARD PROTECTOR

1. Install mounting brackets.

Slide the adjustable mounting brackets into the bracket channels

on the housing.

Bend the tabs on the cardboard protector and insert protector

into opening in housing.

NOTE: The cardboard protector shields the inside of the housing

from drywall spray and construction dust. Do not remove it until

after construction is completed.

FAN

HOUSING

Purchase

*

separately

4-IN.

ROUND

DUCT

*

4-IN. ROUND

ELBOW(S)

*

WALL

CAP

*

Two of the most common ways to

connect ductwork to the unit.

The unit will operate most quietly and efficiently when located

where the shortest possible duct run and minimum number of

elbows will be needed.

Use a roof cap or wall cap that has a built-in damper to reduce

backdrafts.

Plan to supply the unit with proper line voltage and appropriate

power cable.

COOKING AREA

Do not install above or

inside this area.

NOT FOR USE IN

A COOKING AREA.

45

o

Cooking

Equipment

o

45

Floor

Do not install in a cooking area.

The unit must not be installed above or inside the cooking area shown.

1/8" GAP

2. Mark mounting location.

Position unit between joists and extend mounting brackets.

IMPORTANT: Position brackets so there will be an 1/8” gap

between bottom of housing and ceiling material. Mark the top

of keyhole slot on all four mounting brackets.

3. Pound in nails.

Remove unit temporarily, and pound nails partially into joists at

all four marked locations.

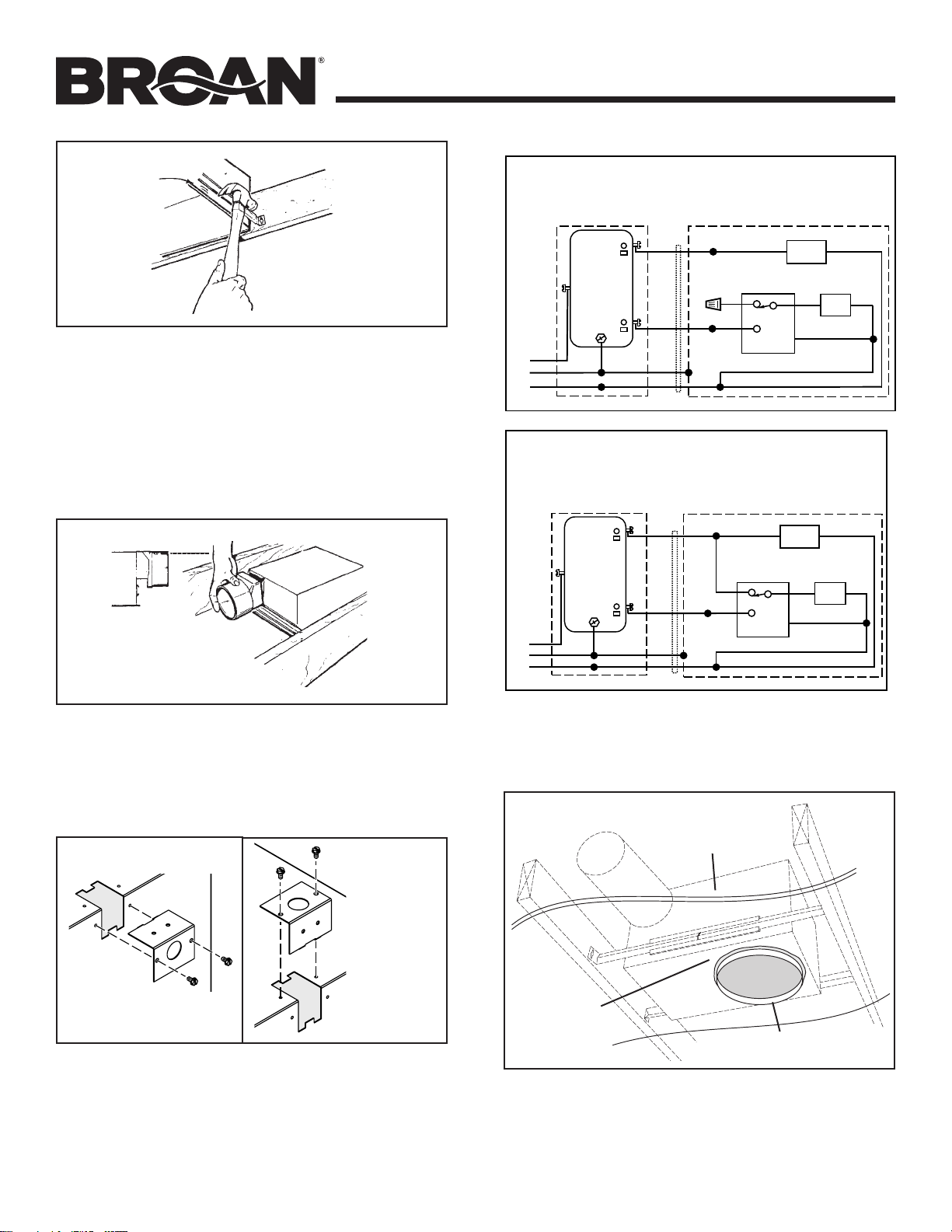

Page 3

MODEL 744SFL

BLK

HUMIDITY

CONTROL

LIGHT

BRN

BLK

BLU

BLK

WHT

WHT

GRD

SWITCH

UNIT

LIGHT

120

IN

COM

WIRIN

G OP

TION #1

MODEL 68W

(PURCHASE SEPARATELY)

WHT

GRD

BLK

HUMIDITY

LIGHT

FAN

ORG

RED

BLU

BLK

WHT

WHT

GRD

WHT

SWITCH

UNIT

LIGHT

&

IN

COM

GRD

Page 3

4. Hang and secure housing.

Hang unit from nails. Check to make sure that there will be a 1/8”

gap between bottom of housing and ceiling material. Pound nails

tight. For wide joist centers: A #8 x 3/8 self-tapping screw can be

used to join extended brackets together and create a rigid mount.

To ensure a noise-free mount, crimp the bracket channels tightly

around mounting brackets.

FLUSH

manual mode (for odor control) by cycling ON/OFF switch.

– Allows fan to operate in automatic mode or

2-FUNCTION CONTROL

(ON/OFF)

FAN

(AUTO/OFF)

VAC

LINE

RED

GRD

ORG

FAN

WHTWHT

WIRING OPTION #2 – Allows fan to operate in automatic mode

or manual mode (for odor control) by cycling ON/OFF switch.

Fan always on with light.

MODEL 68W

2-FUNCTION CONTROL

(PURCHASE SEPARATELY)

FAN

(ON/OFF)

FAN

(AUTO/OFF)

120

VAC

LINE

GRD

WHT

BRNBLK

CONTROL

5. Attach damper/duct connector.

Snap the damper/duct connector onto housing. Make sure that

tabs on the connector lock in housing slots. (Top of damper/duct

connector will be flush with top of housing.) Install ductwork.

VERTICAL

POWER CABLE

CONNECTION

HORIZONTAL POWER CABLE

CONNECTION

6. Choose power cable direction.

Remove wiring plate. When re-attached, the wiring plate allows

the power cable to enter unit horizontally or vertically.

7. Connect wiring.

Unit can be wired from outside of housing as shown. Use UL

approved connectors to wire per local codes.

FINISHED

CEILING

MATERIAL

CLEARANCE

HOLE

HOUSING

COLLAR

8. Finish ceiling.

Cut an opening in finished ceiling material for housing collar.

Page 4

SERVICE PARTS

1

2

4

3

9

MODEL 744SFL

Page 4

Humidity Control Assembly

must be removed to

service these parts.

5

6

9. Plug in wiring.

Plug wiring into the proper receptacles.

TRIM RING / BAFFLE

LAMP

BRACKET

SPRINGS

10. Attach trim ring / baffle to housing.

Remove the cardboard protector from inside the housing collar.

Use a pencil to insert one end of each spring into the holes on the

lamp bracket. Center trim ring / baffle in ceiling opening.

11. Install bulb.

CAUTION - RISK OF FIRE: Use only R30-shaped,

14W compact fluorescent lamp with GX24Q-1 base

(supplied). Replacement bulbs can be ordered from

Broan if not available locally (see service parts list).

CAUTION: Push bulb straight into bulb socket.

!

Do not twist bulb to install or remove.

15

8

11

13

12

KEY NO. PART NO. DESCRIPTION

1 97014185 Damper / Duct Connector

2 97016382 Housing Assembly

3 98003036 Mounting Bracket (4 req.)

4 98005512 Wiring Adaptor Plate

5 99524804 Blower Wheel *

6 99524805 Motor Bracket / Venturi *

7 99080557 Motor *

97016454 Motor / Motor Bracket Assembly

(includes Key Nos. 6 & 7) *

8 99770141 Lamp Wire Harness

9 99770143 Main Wire Harness

10 97018168 Humidity Control Assy.

(includes Lamp Bracket)

11 99271401 Ballast / Lampholder

12 97018169 Trim Ring / Baffle with Springs

& Humidity Sensor

13 99525160 Baffle Springs (2 req.)

14 97016848 Fluorescent Lamp

15 98010628 Electrical Box Cover

Order replacement parts by PART NO. - not by KEY NO.

* Humidity Control Assembly must be removed to service these parts.

10

14

WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that

such products will be free from defects in materials or workmanship for a period of

one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without

charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND

TUBES. This warranty does not cover (a) normal maintenance and service or (b) any

products or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation

contrary to recommended installation instructions.

The duration of an implied warranty is limited to the one-year period as specified for

the express warranty. Some states do not allow limitation on how long an implied

warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S

OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER

THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or

telephone number stated below, (b) give the model number and part identification and

(c) describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

Broan-NuTone LLC Hartford, Wisconsin www.broan.com 800-558-1711

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

99044499B

7

Page 5

LAMPE FLUORESCENTE / VENTILATEUR

ENCASTRÉ À DÉTECTEUR D’HUMIDITÉ

LIRE CES DIRECTIVES ET LES CONSERVER

MODÈLE 744SFL

Page 5

AVERTISSEMENT

OBSERVEZ LES DIRECTIVES CI-DESSOUS AFIN

DE RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURES CORPORELLES :

1. N’utilisez cet appareil que de la manière prévue par le

fabricant. si vous avez des questions, communiquez

avec le fabricant à l’adresse ou au numéro de

téléphone indiqués dans la garantie.

2. Avant de procéder à l’entretien ou au nettoyage de

l’appareil, coupez l’alimentation du panneau électrique

et verrouillez l’interrupteur principal afin d’empêcher

que le courant ne soit accidentellement rétabli. S’il est

impossible de verrouiller l’interrupteur principal, fixez

solidement un message d’avertissement, par exemple

une étiquette, sur le panneau électrique.

3. La pose de l’appareil et les travaux d’électricité

doivent être effectués par des personnes qualifiées

conformément à la réglementation en vigueur,

notamment les normes de la construction ayant trait

à la protection contre les incendies.

4. Pour éviter les refoulements, l’apport d’air doit être

suffisant pour brûler les gaz produits par les appareils

à combustion et les évacuer dans le conduit de fumée

(cheminée). Respectez les directives du fabricant de

l’appareil de chauffage et les normes de sécurité,

notamment celles publiées par la National Fire

Protection Association (NFPA), l’American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) et les codes des autorités locales.

5. Veillez à ne pas endommager le câblage électrique

ou d’autres équipements non apparents lors de la

découpe ou du perçage du mur ou du plafond.

6. Les ventilateurs canalisés doivent toujours rejeter l’air

à l’extérieur.

7. Ne jamais placer un interrupteur de sorte que l’on

puisse l’atteindre d’une baignoire ou d’une douche.

8. N’utilisez pas un gradateur pour commander la lumière

de cet appareil.

9. N’installez cet appareil que dans un plafond plat.

10. À utiliser uniquement dans des installations non

classées résistantes au feu.

11. Ne pas utiliser dans un endroit équipé d’un système

de traitement de l’air ambiant.

12. Si cet appareil doit être installé au-dessus d’une

enceinte de baignoire ou de douche, il doit comporter

les mentions appropriées pour ces utilisations et doit

être branché sur un circuit de dérivation protégé par

un disjoncteur de mise à la terre.

13. Ne pas installer dans un plafond isolé thermiquement

d’une valeur supérieure à R40.

14. Cet appareil doit être relié à une mise à la terre.

ATTENTION

1. Pour ventilation générale uniquement. Ne pas utiliser

cet appareil pour évacuer des matières ou des vapeurs

dangereuses ou explosives.

2. Pour ne pas endommager les roulements du

moteur, déséquilibrer les pales ou les rendre

bruyantes, utilisez le protecteur en carton afin de

protéger l’appareil de la poussière de plâtre, de

construction, etc.

3. L’ampoule fluorescente utilisée dans ce produit

s’insère en ligne droite dans le socle de la lumière.

N’essayez pas d’insérer ou d’enlever l’ampoule en

la tournant.

4. Veuillez lire l’étiquette de spécifications du produit

pour obtenir plus de renseignements, notamment sur

les exigences.

!

FONCTIONNEMENT

La lumière, le ventilateur et le contrôle d’humidité peuvent

être commandés ensemble ou séparément à l’aide de

commutateurs muraux multifonction.

• Utilisez un commutateur à 3 fonctions pour commander

séparément la lumière, le ventilateur et le contrôle

d’humidité.

• Utilisez un commutateur à 2 fonctions pour commander

séparément la lumière et le contrôle d’humidité.

Pour le fonctionnement du ventilateur consultez

la section MISE EN MARCHE MANUELLE AVEC

ARRÊT DIFFÉRÉ ci-dessous.

• Utilisez un commutateur à 2 fonctions pour commander

séparément la lumière et le ventilateur. Branchez

directement le contrôle d’humidité pour qu’il soit

toujours activé.

Voir la section « Câblage » pour les différentes options

de connexion.

Ne pas utiliser un gradateur pour commander la

lumière, le ventilateur ou le contrôle d’humidité.

FONCTIONNEMENT DU DÉTECTEUR

Ce ventilateur à détecteur d’humidité réagit à : (a) une

hausse rapide à modérée de l’humidité et (b) à un taux

d’humidité relative supérieur à un point de consigne fixé

entre 50 % et 100 %. Les variables (a) et (b) sont fixées

avec le réglage de « SENSIBILITÉ ». Le ventilateur

peut à l’occasion se mettre en marche lorsque les

conditions ambiantes changent. Si le ventilateur réagit

continuellement aux variations des conditions ambiantes,

il peut être nécessaire de modifier le réglage de

« SENSIBILITÉ » (voir la section ci-dessous).

INDICATEUR D’ÉTAT

Cet indicateur doit être observé directement En mode

normal, il clignote à toutes les 5 secondes. S’il clignote

rapidement pendant 5 secondes puis s’éteint, vérifiez

les connexions du détecteur sur l’anneau de garniture /

déflecteur et le boîtier du ventilateur.

MISE EN MARCHE MANUELLE AVEC ARRÊT

DIFFÉRÉ

Pour le contrôle des odeurs ou de la vapeur, le ventilateur

peut être activé en tournant le commutateur mural, s’il y en

un d’installé. Lorsque le ventilateur est mis en marche de

cette façon, la MINUTERIE le laisse fonctionner pendant

la période réglée.

Pour actionner manuellement le ventilateur :

1. Passez à l’étape 2 si le commutateur est déjà sur

MARCHE; sinon, mettez-le sur MARCHE pour au

moins 1 seconde.

2. Placez le commutateur sur ARRÊT pour moins

d’une seconde.

3. Remettez le commutateur sur MARCHE et le

ventilateur se mettra en marche.

SRÉGLAGE DE LA SENSIBILITÉ

La « SENSIBILITÉ » est réglée à l’usine pour convenir à

la plupart des douches. Si le ventilateur est installé pour

une baignoire ou pour contrôler l’humidité, il se peut que

la « SENSIBILITÉ » ait besoin d’être augmentée vers le

maximum (« MAX. »). Si la commande réagit trop souvent

aux changements des conditions ambiantes, diminuez le

réglage de « SENSIBILITÉ » (vers « MIN. »). Pour régler

la « SENSIBILITÉ » :

1. Coupez le courant sur le panneau d’alimentation

électrique.

2. Enlevez l’ampoule.

3. À l’intérieur de l’anneau de garniture / déflecteur,

repérez la vis de réglage de la « SENSIBILITÉ ».

4. À l’aide d’un petit tournevis à lame plate, tournez

délicatement le réglage de « SENSIBILITÉ » dans

le sens horaire vers l’indication « MAX. » ou dans le

sens antihoraire vers « MIN. ».

5. Remettez l’ampoule.

6. Rétablissez le courant et vérifiez le fonctionnement

de l’appareil en faisant couler la douche ou

une autre source d’humidité jusqu’à ce que le

ventilateur démarre.

7. Répétez les étapes ci-dessus au besoin.

RÉGLAGE DE LA MINUTERIE

Ce ventilateur à détecteur d’humidité comporte une

« MINUTERIE ». L’utilisateur peut la régler pour une

durée de 5 à 60 minutes, mais elle est réglée à l’usine à

20 minutes. La « MINUTERIE » détermine combien de

temps le ventilateur reste en marche (a) après une hausse

de l’humidité (b) après que le taux d’humidité soit inférieur

au degré de « SENSIBILITÉ » réglé par l’utilisateur ou

après qu’il ait tourné le commutateur mural.

Pour régler la « MINUTERIE » :

1. Coupez le courant sur le panneau d’alimentation

électrique.

2. Enlevez l’ampoule.

3. À l’intérieur de l’anneau de garniture / déflecteur,

repérez la vis de réglage de la « MINUTERIE ».

4. À l’aide d’un petit tournevis à lame plate, tournez

délicatement le réglage de la « MINUTERIE » dans le

sens horaire pour accroître la durée ou dans le sens

antihoraire pour la diminuer.

5. Remettez l’ampoule.

6. Rétablissez le courant et vérifiez le fonctionnement

de l’appareil en tournant le commutateur mural,

tel qu’indiqué sous « MISE EN MARCHE

MANUELLE AVEC ARRÊT DIFFÉRÉ », ou en faisant

couler une source d’humidité jusqu’à ce que le

ventilateur démarre.

7. Vérifiez le réglage de la « MINUTERIE » avec une

montre ou une horloge après avoir fermé la source

d’humidité ouverte à l’étape 6.

8. Répétez les étapes ci-dessus au besoin.

NETTOYAGE ET ENTRETIEN

Pour nettoyer l’anneau de garniture / déflecteur :

Utilisez un aspirateur avec une brosse souple ou enlevez

l’anneau de garniture / déflecteur et nettoyez-le avec un

chiffon doux.

NETTOYAGE DU DÉTECTEUR

Le détecteur d’humidité est installé dans l’anneau de

garniture / déflecteur. Le détecteur sera plus fiable s’il est

nettoyé comme suit de temps à autre :

1. Coupez le courant au panneau électrique.

2. Enlevez l’anneau de garniture / déflecteur. À l’aide d’un

chiffon à épousseter, d’une brosse à dents propre ou

d’un aspirateur, nettoyez délicatement le détecteur et

la grille. N’UTILISEZ PAS DE CHIFFONS ABRASIFS,

DE LAINE D’ACIER NI DE POUDRE À RÉCURER.

3. N’UTILISEZ PAS de nettoyant en vaporisateur, ni de

solvant ni eau sur le détecteur ou à proximité!

Pour nettoyer l’intérieur du boîtier : Enlevez l’anneau

de garniture / déflecteur et nettoyez l’intérieur avec un

aspirateur muni d’une brosse souple.

Le moteur est lubrifié en permanence. Il ne doit pas être

huilé ni démonté.

Consultez la section « Pièces de rechange » pour la liste

et les illustrations des pièces.

Installateur : Veuillez remettre

ce manuel au propriétaire.

Page 6

PLANIFICATION DE L’INSTALLATION

MODÈLE 744SFL

Page 6

INSTALLATION

CLAPET / RACCORD

FIL D'ALIMENTATION

SOLIVE DU

PLAFOND

PLAFOND FINI

DE CONDUIT ROND DE

10,2 CM (4 PO) ET

CONDUIT ROND DE

10,2 CM (4 PO)

ANNEAU DE GARNITURE / DÉFLECTEUR

BOÎTIER

BRIDE DE

MONTAGE

Installation type

L’appareil peut être installé partout entre les solives du plafond à l’aide

des brides de montage incluses. Ne l’installez que dans un plafond plat.

ISOLANT

(Peut être placé sur le

boîtier de ventilateur

et autour.)

CAPUCHON

DE TOIT *

PROTECTEUR EN CARTON

1. Installez les brides de montage.

Glissez les brides de montage réglables dans les rainures

du boîtier.

Courbez les onglets du protecteur en carton et insérez-le dans

l’ouverture du boîtier.

REMARQUE : Le protecteur en carton protège l’intérieur du boîtier

de la poussière de plâtre et de construction. Ne l’enlevez pas tant

que la construction n’est pas terminée.

BOÎTIER DE

VENTILATEUR

Vendu

*

séparément

CONDUIT

ROND DE

10,2 CM (4 PO)

ROND(S) DE

10,2 CM (4 PO)

CAPUCHON

MURAL *

COUDE(S)

Deux des façons les plus courantes de raccorder les

conduits à l’appareil.

L’appareil sera plus silencieux et efficace si le conduit est le plus court

possible et comporte le minimum de coudes.

Utilisez un capuchon de toit ou un capuchon mural muni d’un clapet

intégré afin de réduire les refoulements d’air.

Prévoyez l’alimentation de l’appareil avec la tension adéquate et le

câble approprié.

ZONE DE CUISSON

Ne pas installer au-dessus

ou à l'intérieur

de cette zone

NE PAS INSTALLER

DANS UNE ZONE

DE CUISSON.

45

o

Appareil

de cuisson

45

o

Plancher

Ne pas installer dans une zone de cuisson.

Cet appareil ne doit pas être installé au-dessus ou à l’intérieur de la

zone de cuisson illustrée.

2. Marquez la position de montage.

Placez l’unité entre les solives et allongez les brides de montage.

IMPORTANT : Placez les brides de manière à avoir un jeu de

3 mm (1/8 po) entre le bas du boîtier et le matériau du plafond.

Marquez la partie supérieure du trou de serrure de chaque bride.

3. Plantez les clous.

Enlevez temporairement l’unité et enfoncez partiellement un clou sur

chacune des quatre marques tracées.

Page 7

MODÈLE 744SFL

(VENDUE SƒPARƒMENT)

Page 7

OPTION DE CåBLAGE N¡ 1 Ð Permet au ventilateur de fonctionner en mode automatique

ou manuel (pour le contrôle des odeurs) en tournant le commutateur MARCHE / ARRÊT.

MODéLE 68W

COMMANDE Ë 2 FONCTIONS

4. Suspendez et fixez le boîtier.

Suspendez l’unité aux clous. Vérifiez qu’il y a bien un jeu de

3 mm (1/8 po) entre le bas du boîtier et le matériau du plafond.

Finissez d’enfoncer les clous. Si les solives sont très espacées :

utilisez une vis à tôle n° 8 x 3/8 pour réunir les brides allongées

et solidifier le montage. Pour éviter les bruits de vibration, pincez

les brides de montage dans les rainures où elles sont insérées.

DE NIVEAU

ƒCLAIRAGE

(MARCHE /

ARRæT)

VENTILATEUR

(AUTO / ARRæT)

NOIR

ALI-

MENTA-

TERRE

TION

120

BLANC

VCA

COM

TERRE

COMMUTATEUR

ROUGE

NOIR

ORG

BLANC

ORG

BRUN

BLEU

CONTRïLE

DÕHUMIDITƒ

APPAREIL

ƒCLAIRAGE

NOIR

VENTI-

LATEUR

BLANC

BLANC

BLANC

BLANC

OPTION DE CåBLAGE N¡ 2 Ð Permet au ventilateur de fonctionner en mode

automatique ou manuel (pour le contrôle des odeurs) en tournant le commutateur

MARCHE / ARRÊT. Ventilateur toujours en marche avec l’éclairage.

MODéLE 68W

COMMANDE Ë 2 FONCTIONS

(VENDUE SƒPARƒMENT)

ƒCLAIRAGE

ET VENTILA-

TEUR

(MARCHE /

ARRæT)

VENTILATEUR

(AUTO /

ARRæT)

NOIR

ALI-

MENTA-

TERRE

TION

BLANC

120

VCA

COM

TERRE

COMMUTATEUR

ROUGE

NOIR

ORG

BLANC

ORG

BRUN

BLEU

CONTRïLE

DÕHUMIDITƒ

APPAREIL

ƒCLAIRAGE

NOIR

VENTI-

LATEUR

BLANC

BLANC

BLANC

BLANC

5. Fixez le clapet / raccord de conduit.

Enclenchez le clapet / raccord de conduit sur le boîtier. Assurezvous que les ergots du raccord sont correctement bloqués dans

les fentes du boîtier. (Le dessus du clapet / raccord doit être de

niveau avec le dessus du boîtier.) Installez les conduits.

CONNEXION

VERTICALE DU FIL

D’ALIMENTATION

CONNEXION HORIZONTALE

DU FIL D’ALIMENTATION

6. Choisissez la direction du fil d’alimentation électrique.

Retirez la plaque de câblage. Une fois reposée, la plaque de

câblage permet au fil d’alimentation d’entrer horizontalement ou

verticalement dans l’unité.

7. Branchez les fils.

Le câblage peut être effectué à l’extérieur du boîtier, tel qu’illustré.

Utilisez des connecteurs homologués UL pour effectuer le câblage

conformément aux codes locaux.

MATÉRIAU DU

PLAFOND FINI

TROU

DE PASSAGE

COLLET

DU BOÎTIER

8. Finissez la surface du plafond.

Découpez une ouverture dans le plafond fini pour le collet

du boîtier.

Page 8

MODÈLE 744SFL

PIÈCES DE RECHANGE

1

2

4

3

9

L’ensemble du contrôle

d’humidité doit être enlevé pour

accéder à ces pièces.

Page 8

5

6

9. Branchez les fils.

Branchez les fils dans les prises appropriées.

ANNEAU DE GARNITURE /

DÉFLECTEUR

SUPPORT

D’ÉCLAIRAGE

RESSORTS

10. Fixez l’anneau de garniture / déflecteur au boîtier.

Enlevez le protecteur en carton à l’intérieur du collet du boîtier.

À l’aide d’un crayon, insérez une extrémité de chaque ressort dans

les trous du support d’éclairage. Centrez l’anneau de garniture /

déflecteur dans l’ouverture du plafond.

11. Installez l’ampoule.

ATTENTION - RISQUE D’INCENDIE : N’utilisez qu’une

ampoule fluorescente compacte 14W de forme

R30 avec culot GX24Q-1 (fournie). Vous pouvez

commander des ampoules chez Broan si elles ne

sont pas vendues localement (voir la liste des pièces

de rechange).

ATTENTION : Poussez l’ampoule en ligne droite

dans le socle. Ne tournez pas l’ampoule pour

!

l’installer ou l’enlever.

15

8

11

13

12

REPÈRE N° DE PIÈCE DESCRIPTION

1 97014185 Clapet / raccord de conduit

2 97016382 Ensemble de boîtier

3 98003036 Bride de montage (4 req.)

4 98005512 Plaque d’adaptateur de câblage

5 99524804 Roue à ailettes*

6 99524805 Support de moteur / venturi *

7 99080557 Moteur *

97016454 Ensemble moteur / support de moteur

(comprend repères n° 6 et 7) *

8 99770141 Connecteur d’éclairage

9 99770143 Connecteur principal

10 97018168 Ensemble de contrôle d’humidité

(comprend le support d’éclairage)

11 99271401 Ballast / douille de lampe

12 97018169 Anneau de garniture / déflecteur avec ressorts

et détecteur d’humidité

13 99525160 Ressorts de clapet (2 req.)

14 97016848 Ampoule fluorescente

15 98010628 Couvercle du boîtier électrique

Veuillez commander les pièces par N° PIÈCE - et non par N° REPÈRE.

* L’ensemble du contrôle d’humidité doit être enlevé pour accéder à ces pièces.

10

14

7

GARANTIE

Broan-NuTone garantit à l’acheteur original que les produits vendus en vertu de la présente sont libres

de tout vice de matériau ou de fabrication pour une période d’un an à compter de la date d’achat

originale. CETTE GARANTIE NE COMPORTE AUCUNE AUTRE GARANTIE, EXPRESSE OU TACITE,

Y COMPRIS, MAIS SANS S’Y LIMITER, LES GARANTIES TACITES DE VALEUR MARCHANDE OU

D’ADAPTATION À UN USAGE PARTICULIER.

Durant cette période d’un an, Broan-NuTone réparera ou remplacera gratuitement, à sa discrétion,

tout produit ou toute pièce jugés défectueux dans des conditions normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS.

Cette garantie ne couvre pas (a) les frais d’entretien ou de service normaux ni (b) tout produit ou

toute pièce soumis à un abus, une négligence, un accident, un entretien ou une réparation inadéquats

(autres que ceux effectués par Broan-NuTone), une mauvaise installation ou une installation contraire

aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d’un an stipulée pour la garantie expresse.

Certains territoires ou provinces interdisant de limiter la durée d’une garantie tacite, la limitation

ci-dessus peut ne pas s’appliquer à votre situation.

L’OBLIGATION POUR BROAN-NUTONE DE RÉPARER OU DE REMPLACER LE PRODUIT, À SA

DISCRÉTION, CONSTITUE LE SEUL RECOURS DE L’ACHETEUR EN VERTU DE CETTE GARANTIE.

BROAN-NUTONE NE PEUT ÊTRE TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU

CONSÉCUTIFS NI DES DOMMAGES-INTÉRÊTS PARTICULIERS DÉCOULANT DE L’UTILISATION

OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces interdisent l’exclusion ou la

restriction des dommages indirects ou consécutifs. La restriction susmentionnée peut donc ne pas

s’appliquer dans votre cas. La présente garantie vous confère des droits spécifiques reconnus par

la loi. D’autres droits pourraient également vous être accordés selon la législation locale en vigueur.

La présente garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou au

numéro de téléphone indiqués ci-dessous, (b) donner le numéro de modèle du produit et le numéro

d’identification de la pièce et (c) décrire la nature de la défectuosité du produit ou de la pièce.

Lors de votre demande de garantie, vous devez présenter une preuve de la date d’achat originale.

Broan-NuTone LLC Hartford, Wisconsin www.broan.com 800-558-1711

GARANTIE LIMITÉE D’UN AN BROAN-NUTONE

99044499B

Page 9

MODELO 744SFL

VENTILADOR EMPOTRADO CON SENSOR

DE HUMEDAD Y LÁMPARA FLUORESCENTE

LEA Y CONSERVE ESTAS INSTRUCCIONES

Página 9

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS,

DESCARGAS ELÉCTRICAS O LESIONES PERSONALES,

OBSERVE LAS SIGUIENTES PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el

fabricante. Si tiene preguntas, comuníquese con el

fabricante a la dirección o al número telefónico que se

incluye en la garantía.

2. Antes de dar servicio a la unidad o de limpiarla,

interrumpa el suministro eléctrico en el panel de servicio

y bloquee los medios de desconexión del servicio para

evitar que la electricidad se reanude accidentalmente.

Cuando no sea posible bloquear los medios de

desconexión del servicio, fije firmemente una señal de

advertencia (como una etiqueta) en un lugar visible del

panel de servicio.

3. Una o más personas calificadas deben realizar el trabajo

de instalación y el cableado eléctrico, de acuerdo con

todos los códigos y normas correspondientes, incluidos

los códigos y normas de construcción específicos de

protección contra incendios.

4. Se necesita suficiente aire para que se lleve a cabo

una combustión y una extracción adecuadas de los

gases a través del tubo de humos (chimenea) del

equipo quemador de combustible, con el fin de evitar el

contratiro. Siga las directrices y las normas de seguridad

del fabricante del equipo de calentamiento, como las

publicadas por la Asociación Nacional de Protección

contra Incendios (National Fire Protection Association,

NFPA), la Sociedad Americana de Ingenieros de

Calefacción, Refrigeración y Aire Acondicionado

(American Society for Heating, Refrigeration and Air

Conditioning Engineers, ASHRAE) y las autoridades

normativas locales.

5. Al cortar o perforar a través de la pared o del techo,

tenga cuidado de no dañar el cableado eléctrico ni otros

servicios ocultos.

6. Los ventiladores en conductos siempre deben ventearse

hacia el exterior.

7. Nunca coloque el interruptor en un lugar en donde se

pueda alcanzar desde la bañera o ducha.

8. No utilice un reductor de intensidad para hacer funcionar

la luz en esta unidad.

9. Instale esta unidad únicamente en un cielo raso plano.

10. Para usarse únicamente en instalaciones sin

clasificación contra incendios.

11. No se debe usar en espacios que manejen aire

ambiental.

12. Si se va a instalar esta unidad sobre una tina o

ducha, debe estar 3marcada como apropiada para

esta aplicación y conectarse a un GFCI (interruptor

accionado por pérdida de conexión a tierra) en un

circuito de derivación protegido.

13. No instale en un techo aislado termalmente a un valor

mayor que R40.

14. Esta unidad debe estar conectada a tierra.

PRECAUCIÓN

1. Sólo para usarse como medio de ventilación general. No

debe usarse para la extracción de materiales ni vapores

peligrosos o explosivos.

2. Para evitar daños a los cojinetes del motor y rotores ruidosos

y/o no equilibrados, use el protector de cartón (incluido) para

mantener alejados de la unidad de accionamiento el rocío

de yeso, polvo de la construcción, etc.

3. La bombilla fluorescente que se utiliza con este producto

debe insertarse rectamente en el receptáculo de la bombilla.

No gire la bombilla para introducirla ni para sacarla.

4. Lea la etiqueta de especificaciones que tiene el producto

para ver información y requisitos adicionales.

!

FUNCIONAMIENTO

La lámpara, el ventilador y el control de humedad deben

funcionar en conjunto o individualmente, usando controles

de pared en un interruptor de funciones múltiples.

• Use un control de 3 funciones para activar la lámpara,

el ventilador y el control de humedad de manera

independiente.

• Use un control de 2 funciones para activar la lámpara

y el control de humedad de manera independiente.

Si desea ver el funcionamiento del ventilador, consulte

la sección ENCENDIDO MANUAL CON TIEMPO DE

APAGADO, más adelante.

• Use un control de 2 funciones para activar la lámpara y

el ventilador de manera independiente. Cablee directo

el control de humedad para garantizar que el control

de humedad siempre esté encendido.

En la sección “Conexión eléctrica” se describen varias

opciones de cableado.

No utilice un control reductor de intensidad para

hacer funcionar el ventilador, el control de humedad

o la lámpara.

OPERACIÓN DEL SENSOR

Este ventilador con sensor de humedad responde ante:

(a) incrementos de humedad rápidos a moderados, y

(b) humedad por arriba de un punto de referencia de

humedad relativa de 50 a 100%. (a) y (b) se configuran con

el ajuste “SENSIBILIDAD”. El ventilador podría encenderse

en ciertas ocasiones cuando cambien las condiciones

ambientales. Si el ventilador responde continuamente a

condiciones ambientales cambiantes, es posible que se

requiera el ajuste de la “SENSIBILIDAD” (vea la sección

más adelante).

INDICADOR DE ESTADO

Este indicador sólo se puede ver mirándolo directamente.

El modo normal es de 5 segundos encendido y apagado.

Si destella rápidamente durante 5 segundos y luego se

apaga, revise las conexiones del sensor en el anillo/

deflector y en la cubierta del ventilador.

MANUAL CON TIEMPO DE APAGADO

Para control de olores o vapores, el ventilador puede

activarse ciclando el interruptor montado en la pared, si se

tiene instalado. Una vez que se enciende el ventilador de

esta manera, se mantendrá encendido durante el tiempo

establecido del “TEMPORIZADOR”.

Para energizar manualmente el ventilador:

1. Vaya al Paso 2 si el interruptor ya está activado; de otra

manera, active el interruptor por más de 1 segundo.

2. Apague por menos de 1 segundo.

3. Vuelva a activar y el ventilador se encenderá.

AJUSTE DE LA SENSIBILIDAD

La “SENSIBILIDAD” es ajustada en fábrica para la

mayoría de las aplicaciones de regadera. Si el ventilador

se encuentra en el área de la tina o se está usando para

el control de la humedad, es posible que se necesite

aumentar la “SENSIBILIDAD” hasta el máximo (“MAX.”).

Si el control está respondiendo con demasiada frecuencia

a condiciones ambientales cambiantes, quizás sea

necesario ajustarlo a una “SENSIBILIDAD” menor (“MIN.”).

Para ajustar la “SENSIBILIDAD”:

1. Apague la energía eléctrica en el panel de servicio

eléctrico.

2. Quite la bombilla.

3. A través del anillo/deflector, encuentre la ranura para

el destornillador de la “SENSIBILIDAD”.

4. Usando un destornillador pequeño de punta plana,

gire cuidadosamente el ajuste de “SENSIBILIDAD”

hacia la posición máxima (“MAX.”) a la derecha, o

mínima (“MIN.”) a la izquierda.

5. Reinstale la bombilla.

6. Suministre energía y revise el funcionamiento

abriendo la regadera u otra fuente de humedad hasta

que el ventilador se encienda.

7. Repita los pasos anteriores si es necesario.

AJUSTE DEL TEMPORIZADOR

Este ventilador con sensor de humedad tiene un

“TEMPORIZADOR”. El usuario lo puede ajustar de

5 a 60 minutos, y está ajustado en fábrica a 20 minutos.

El “TEMPORIZADOR” controla el tiempo que se mantiene

encendido (a) después del aumento en humedad y (b)

si el nivel de humedad está debajo del ajuste realizado

por el usuario de ”SENSIBILIDAD” o después de que se

activó al ciclar el interruptor de encendido.

Para ajustar el “TEMPORIZADOR”:

1. Desconecte la energía en el panel de servicio eléctrico.

2. Quite la bombilla.

3. A través del anillo/deflector, encuentre la ranura para

el destornillador del “TEMPORIZADOR”.

4. Usando un destornillador pequeño de punta plana,

gire cuidadosamente el ajuste de “TEMPORIZADOR”

hacia la derecha para aumentar el tiempo, o a la

izquierda para reducir el tiempo.

5. Reinstale la bombilla.

6. Suministre energía y revise la operación ciclando

el interruptor de alimentación de acuerdo con las

instrucciones contenidas en la sección “MANUAL

CON TIEMPO DE APAGADO” o encendiendo una

fuente de humedad hasta que el ventilador se

encienda.

7. Revise el ajuste del “TEMPORIZADOR” con un

reloj después de apagar la fuente de humedad, si la

encendió en el Paso 6.

8. Repita los pasos anteriores si es necesario.

LIMPIEZA Y MANTENIMIENTO

Para limpiar el anillo/deflector: Límpielo con una

aspiradora que tenga un cepillo suave como accesorio.

También puede sacar el anillo/deflector y limpiarlo con

un trapo suave.

LIMPIEZA DEL SENSOR

El sensor de humedad está montado en anillo/deflector.

El funcionamiento del sensor será más confiable si se

limpia ocasionalmente. Para ello, haga lo siguiente:

1. Desconecte la energía en la entrada de servicio.

2. Quite el anillo/deflector. Limpie el sensor y la rejilla

con un paño sacudidor seco o un cepillo de dientes

limpio, o aspírelos ligeramente. NO USE PAÑOS

ABRASIVOS, ALMOHADILLAS DE LANA DE ACERO

NI POLVOS ABRASIVOS.

3. ¡NO USE sprays limpiadores, solventes ni agua en el

sensor o cerca del mismo!

Para limpiar el interior de la cubierta: Saque el anillo/

deflector y aspire el interior de la cubierta con una

aspiradora que tenga un cepillo suave como accesorio.

El motor está permanentemente lubricado. No lubrique

ni desarme el motor.

En la sección “Piezas de repuesto” se encuentra una lista

con ilustraciones de tales piezas.

Aviso al instalador: Deje este

manual con el dueño de la casa.

Page 10

ANILLO/DEFLECTOR

CONECTOR DEL REGULADOR

PLANEACIÓN DE LA INSTALACIÓN

MODELO 744SFL

Página 10

INSTALACIÓN

CABLE

ELÉCTRICO

VIGUETA

DE TECHO

CIELO RASO ACABADO

DE TIRO/CONDUCTO REDONDO

DE 4 PULG. Y CONDUCTO

REDONDO DE 4 PULG.

CUBIERTA

SOPORTE

DE MONTAJE

Instalación típica

Esta unidad se puede instalar en cualquier lugar entre las vigas del

cielo raso usando los soportes de montaje que se proporcionan. Instale

únicamente en un cielo raso plano.

AISLAMIENTO

(puede ponerse alrededor

y sobre la cubierta del

ventilador)

TAPA DE

TECHO *

PROTECTOR DE CARTÓN

1. Instale los soportes de montaje.

Deslice los soportes de montaje ajustables en los canales del soporte

de la cubierta.

Doble las lengüetas en el protector de cartón e inserte el protector en

la abertura de la cubierta.

NOTA: El protector de cartón protege el interior de la cubierta contra el

rocío de yeso y el polvo de la construcción. No lo quite sino hasta que

la construcción esté completa.

CUBIERTA DEL

VENTILADOR

Se compra

*

por separado

CONDUCTO

DE 4 PULG. *

REDONDO

CODOS REDONDOS

DE 4 PULG.

TAPA DE

PARED *

Dos de las maneras más comunes de conectar

conductos a la unidad.

El ventilador funcionará con más eficiencia y menos ruido si se ubica en

un sitio donde requiera el tramo de conductos más corto posible y una

cantidad mínima de codos.

Instale una tapa de techo o de pared que tenga un regulador de tiro

integrado, a fin de reducir los contratiros.

Alimente la unidad con el voltaje de línea y el cable alimentador apropiados.

ÁREA DE COCINA

No instale el equipo sobre

o dentro de esta área.

o

NO LA USE EN UN

45

Equipo

de cocina

o

45

Piso

No instale el equipo en un área donde cocine.

No se debe instalar la unidad sobre el área donde cocine mostrada ni dentro

de ella.

2. Marque el sitio de montaje.

Coloque la unidad entre las vigas y extienda los soportes de montaje.

IMPORTANTE: Coloque los soportes de tal manera que exista una

separación de 1/8 pulg. (0.3 cm) entre la parte inferior de la cubierta

y el material del cielo raso. Marque la parte superior de la ranura tipo

bocallave en los cuatro soportes de montaje.

3. Martille los clavos.

Quite temporalmente la unidad y clave parcialmente los clavos en las

vigas en los cuatro lugares marcados.

Page 11

MODELO 744SFL

Página 11

OPCIîN DE CONEXIîN N.¼ 1: Permite que el ventilador funcione en modo automático o en

modo manual (para el control del olor) al ciclar el interruptor de ENCENDIDO/APAGADO.

MODELO 68W

CONTROL DE 2 FUNCIONES

(SE COMPRA POR SEPARADO)

LçMPARA

(ENCENDIDO/

APAGADO)

ROJO

AZUL

LUZ

4. Cuelgue la unidad y asegúrela.

Cuelgue la unidad de los clavos. Revise para asegurarse de que

exista una separación de 1/8 pulg. (0.3 cm) entre la parte inferior

de la cubierta y el material del cielo raso. Clave los clavos de

manera que queden bien ajustados. Para centros de vigas anchas:

se puede usar un tornillo autorroscante #8 x 3/8 para unir entre sí

los soportes extendidos y crear un montaje rígido. Para lograr un

montaje silencioso, doble los canales del soporte ajustadamente

alrededor de los soportes de montaje.

AL RAS

5. Acople el conectador del regulador de tiro/conducto.

Conecte a presión el conector del regulador de tiro/conducto en

la cubierta. Asegúrese de que las lengüetas del conector queden

fijas en las ranuras de la cubierta. (La parte superior del conector

del regulador de tiro/conducto quedará al ras con la parte superior

de la cubierta.) Instale los conductos.

VENTILADOR

(AUTO/

APAGADO)

NEGRO

LêNEA

DE EN-

TIERRA

TRADA

DE 120

BLANCO

VCA

COM

TERRE

INTERRUPTOR

BLEU

TIERRA

BLANCO

NARANJA

CAFƒ

CONTROL

DE HUMEDAD

UNIDAD

NEGRO

VENTI-

LADOR

BLANCO

BLANCO

BLANCO

BLANCO

OPCIîN DE CONEXIîN N.¼ 2: Permite que el ventilador funcione en modo

automático o en modo manual (para el control del olor) al ciclar el interruptor de

ENCENDIDO/APAGADO. Ventilador siempre encendido con la luz.

MODELO 68W

CONTROL DE 2 FUNCIONES

(SE COMPRA POR SEPARADO)

LUZ Y

VENTILADOR

(ENCENDIDO/

APAGADO)

VENTILADOR

(AUTO/

APAGADO)

LêNEA

DE ENTRADA

DE 120

BLANCO

VCA

NEGRO

TIERRA

COM

TERRE

INTERRUPTOR

ROJO

NEGRO

TIERRA

BLANCO

NARANJA

CAFƒ

UNIDAD

AZUL

CONTROL

DE HUMEDAD

LUZ

NEGRO

DOR

BLANCO

BLANCO

BLANCO

BLANCOVENTILA-

7. Conecte el cableado.

El cableado de la unidad puede hacerse desde afuera de la

cubierta, tal como se muestra. Realice el cableado con conectores

aprobados por UL y en cumplimiento de los códigos locales.

MATERIAL

ACABADO

DE TECHO

CONEXIÓN DEL

CABLE ELÉCTRICO

VERTICAL

CONEXIÓN DEL CABLE

ELÉCTRICO HORIZONTAL

6. Elija la dirección del cable eléctrico.

Quite la placa de cableado. Una vez reinstalada, la placa de

cableado permite al cable eléctrico entrar a la unidad en sentido

horizontal o vertical.

ORIFICIO

DE HOLGURA

COLLARÍN DE

LA CUBIERTA

8. Termine el techo.

Corte una abertura en el cielo raso terminado para el collarín

de la cubierta.

Page 12

PIEZAS DE SERVICIO

1

2

4

3

9

MODELO 744SFL

Página 12

Debe quitar el conjunto de

control de humedad para dar

servicio a estas piezas.

5

6

9. Conecte el cableado.

Enchufe las conexiones en los receptáculos adecuados.

ANILLO/DEFLECTOR

SOPORTE

DE LA LÁMPARA

RESORTES

10. Acople el anillo/deflector a la cubierta.

Quite el protector de cartón del interior del collar de la cubierta.

Utilice un lápiz para insertar un extremo de cada resorte en los

agujeros que están en el soporte de la lámpara. Centre el anillo/

deflector en la abertura del cielo raso.

15

8

11

13

12

CLAVE N.º PIEZA N.º DESCRIPCIÓN

1 97014185 Conector del regulador de tiro/conducto

2 97016382 Conjunto de la cubierta

3 98003036 Soporte de montaje (se requieren 4)

4 98005512 Placa del adaptador de cableado

5 99524804 Rueda del soplador*

6 99524805 Venturi/Soporte del motor *

7 99080557 Motor *

97016454 Motor/Conjunto de soporte del motor

(incluye las claves nº. 6 y 7) *

8 99770141 Arnés para el cable de la lámpara

9 99770143 Arnés del cable principal

10 97018168 Conjunto de control de humedad

(Incluye soporte para lámpara)

11 99271401 Balasta/Soporte de la lámpara

12 97018169 Anillo/Deflector con resortes

y sensor de humedad

13 99525160 Resorte del deflector (se req. 2)

14 97016848 Lámpara fluorescente

15 98010628 Cubierta de la caja de controles

Al pedir piezas de repuesto, indique el No. DE PIEZA, no el No. DE CLAVE

* Debe quitar el conjunto de control de humedad para dar servicio a estas piezas.

10

14

GARANTÍA

7

11. Instale la bombilla.

PRECAUCIÓN: RIESGO DE INCENDIO. Utilice

únicamente una lámpara fluorescente de 14 W y forma

R30 con base GX24Q-1 (suministrada). Las bombillas

de repuesto pueden obtenerse a través de Broan, en

caso de que no puedan conseguirse en un comercio

de la localidad (vea la lista de piezas de servicio).

PRECAUCIÓN: Empuje la bombilla en dirección

!

recta en su receptáculo. No gire la bombilla para

instalarla ni para sacarla.

Broan-NuTone garantiza al consumidor comprador original de sus productos que dichos

productos estarán libres de defectos en materiales o mano de obra durante un período de un

año a partir de la fecha de compra original. NO EXISTEN OTRAS GARANTÍAS, EXPRESAS NI

IMPLÍCITAS, INCLUIDAS, ENTRE OTRAS, GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN

O IDONEIDAD PARA UN PROPÓSITO PARTICULAR.

Durante este período de un año, Broan-NuTone, a su criterio, reparará o reemplazará sin cargo

alguno cualquier pieza o producto que se encuentre defectuoso bajo condiciones normales de

uso y servicio. ESTA GARANTÍA NO SE APLICA A TUBOS Y ARRANCADORES DE LÁMPARAS

FLUORESCENTES. Esta garantía no cubre (a) mantenimiento y servicio normales, ni (b)

ningún producto o piezas que se hayan sometido a uso inadecuado, negligencia, accidente,

mantenimiento o reparación inadecuada (no hecha por Broan-NuTone), instalación incorrecta

o instalación en contra de las instrucciones de instalación recomendadas.

La duración de una garantía implícita se limita al período de un año como se especifica para la

garantía explícita. Algunos estados no permiten limitaciones en cuanto al tiempo de vencimiento

de una garantía implícita, por lo que la limitación antes mencionada podría no aplicarse a usted.

LA OBLIGACIÓN DE BROAN-NUTONE DE REPARAR O REEMPLAZAR, A CRITERIO DE BROANNUTONE, SERÁ EL ÚNICO Y EXCLUSIVO RECURSO DEL COMPRADOR BAJO ESTA GARANTÍA.

BROAN-NUTONE NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES, RESULTANTES O

ESPECIALES QUE SURJAN DEL USO O DESEMPEÑO DEL PRODUCTO O EN RELACIÓN CON

EL MISMO. Algunos estados no permiten la exclusión o la limitación de daños incidentales o

resultantes, de manera que es posible que la limitación antedicha no se aplique en su caso.

Esta garantía le otorga derechos legales específicos, y usted podría tener otros derechos que

varían entre estados. Esta garantía sustituye todas las garantías anteriores.

Para tener derecho al servicio de la garantía, usted debe (a) notificar a Broan NuTone a la

dirección y número de teléfono que aparecen abajo, (b) proporcionar el número de modelo

y la identificación de la pieza y (c) describir la naturaleza de cualquier defecto en el producto

o pieza. En el momento de solicitar servicio cubierto por la garantía, debe de presentar un

comprobante de la fecha original de compra.

Broan-NuTone LLC Hartford, Wisconsin www.broan.com 800-558-1711

GARANTÍA LIMITADA DE UN AÑO DE BROAN-NUTONE

99044499B

Loading...

Loading...